Full-automatic proportioning device and method of lubricating agent for thread throwing of ceramic fibers

A technology of ceramic fibers and lubricants, which is applied in the directions of lubricating compositions, chemical instruments and methods, mixers with rotary stirring devices, etc. Save operation steps and increase the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

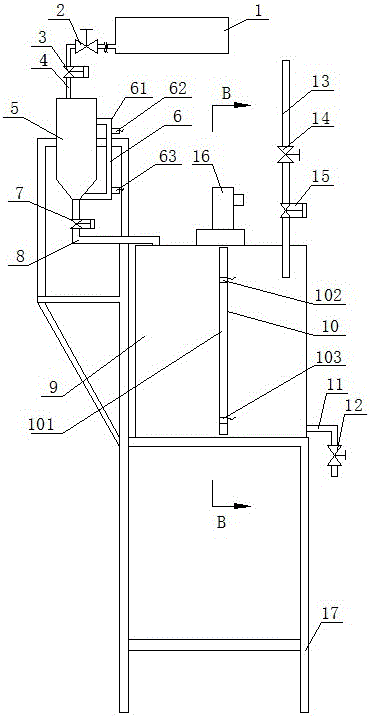

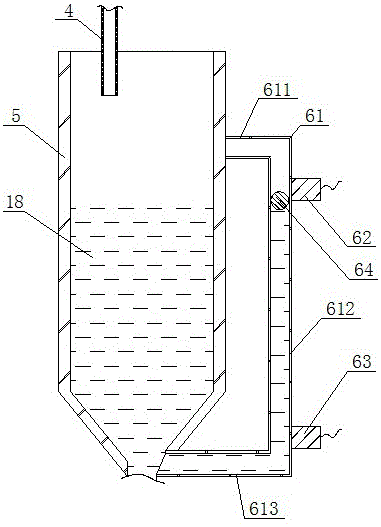

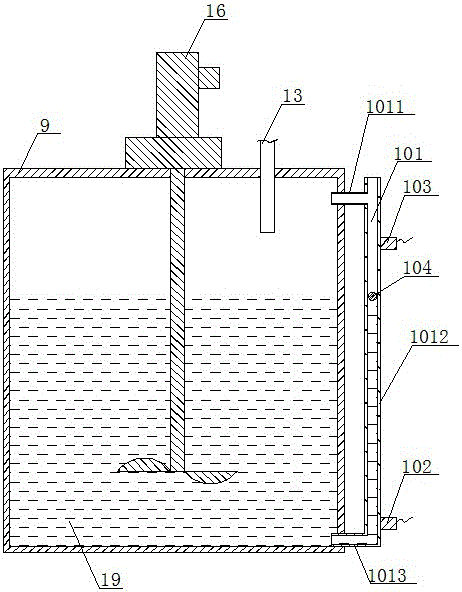

[0063] as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, a fully automatic proportioning device for lubricant for ceramic fiber spinning of the present invention includes a support 17, a liquid level detection device, a stirring device 16, a controller 20, a water pipe 13, a liquid outlet pipe 11, and a top-to-bottom The lubricant container 1, the lubricant metering cup 5 and the upper container 9 arranged in sequence on the bracket 17, the lubricant metering cup 5 and the upper container 9 are provided with upper and lower ports arranged up and down, the lubricant container 1 and the lubricant The upper port of the lubricant metering cup 5 is connected up and down through the upper infusion tube 4, the lower port of the lubricant metering cup 5 and the upper port of the upper container 9 are connected up and down through the lower infusion tube 8, and the lower port of the upper container 9 is connected with the liquid outlet pip...

Embodiment 2

[0083] as attached Figure 5 , attached Image 6 And attached Figure 7 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is: the upper container 9 is provided with a temperature detector I22 heating device I21, a temperature detector I22 heating device I21 Both are connected with the controller 20.

[0084] The temperature detector I22 is used to detect the temperature of the lubricant 18 and water in the upper container 9; the heating device I21 is an electric heating tube, which is used to heat the lubricant 18 and water in the upper container 9. When the temperature of the lubricant 18 and water in the upper container 9 is lower than the preset value, the lubricant 18 and water are heated by the heating device I21 to facilitate the complete dissolution of the lubricant 18 in the water.

[0085] Simultaneously, a nozzle 23 is communicated with the liquid outlet pipe 11, and when the lu...

Embodiment 3

[0095] as attached Figure 8 , attached Figure 9 And attached Figure 10 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is that it also includes a lower container 26 and a liquid level detection device corresponding to the lower container 26, and the lower container 26 is arranged on On the bracket 17 and below the upper container 9, the lower container 26 is provided with an upper port and a lower port arranged up and down, and the upper port of the lower container 26 and the lower port of the upper container 9 communicate through the mixed liquid infusion tube 24, and the lower container 26 The lower port of the lower port is connected with the liquid outlet pipe 11, and the mixed liquid infusion pipe 24 is provided with an electric valve IV 25, and the liquid level detection device and the electric valve IV 25 are connected with the controller 20.

[0096] Wherein, the liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com