Device for assembling handle skeleton and balance weight block of vehicular door automatically

A door handle and automatic assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as easy hand pinching and scratches, low qualified rate of finished products, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

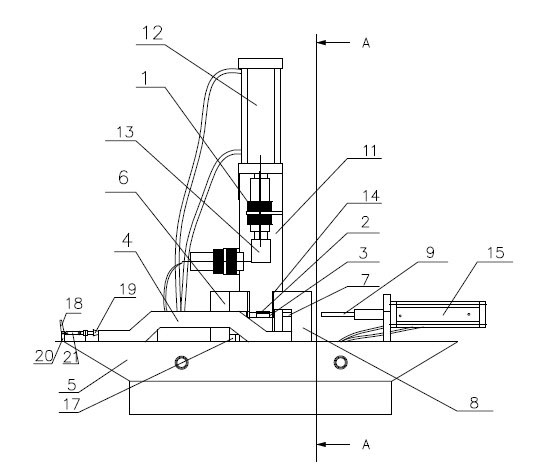

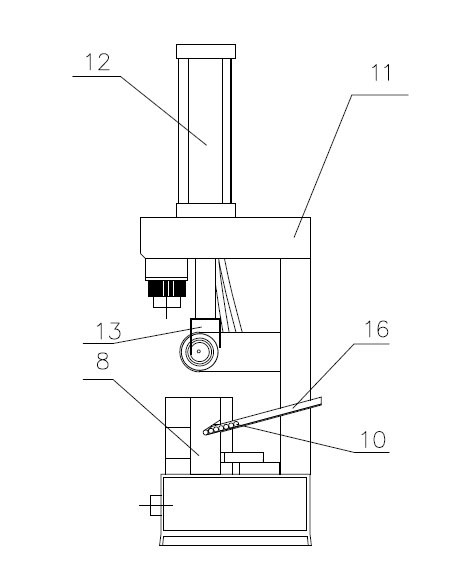

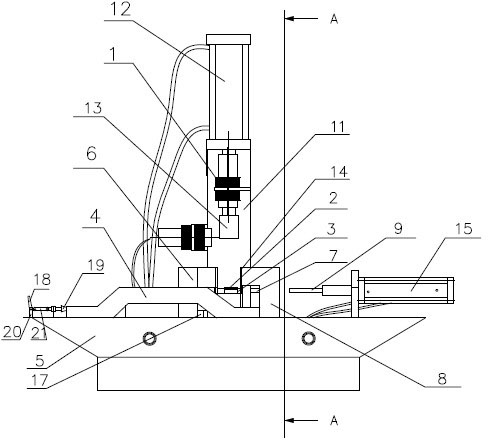

[0016] The main function of the automatic assembly device for the frame counterweight of the car door handle related to the present invention is to pass the pin 10 through the pin hole 3 of the counterweight 2 and the mounting hole of the handle frame 4. In terms of structure, it is as follows: figure 1 , figure 2 As shown, it includes a workbench 5 and a positioning block 6 placed on the workbench 5 to fix the handle frame 4. The positioning block 6 mainly realizes positioning and pressing of the handle frame 4 opposite to the workbench 5 along the vertical direction. tight.

[0017] The left end of the workbench is provided with a tightening device for horizontally tightening the handle frame 4. The tightening device includes an operating handle 18 and a pushing head 19. The operating handle 18 is hinged on the support plate 20 fixed on the workbench 5. Through the rotation operation of the operating handle 18, the operating handle 18 pushes the push arm 21 hinged therewit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com