Heat energy recovery system of slag of magnesium reducing furnace

A heat recovery and reduction furnace technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of discontinuous heat supply, intermittent supply of slag supply, waste of heat energy, etc., and achieve the effect of continuous supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with accompanying drawing:

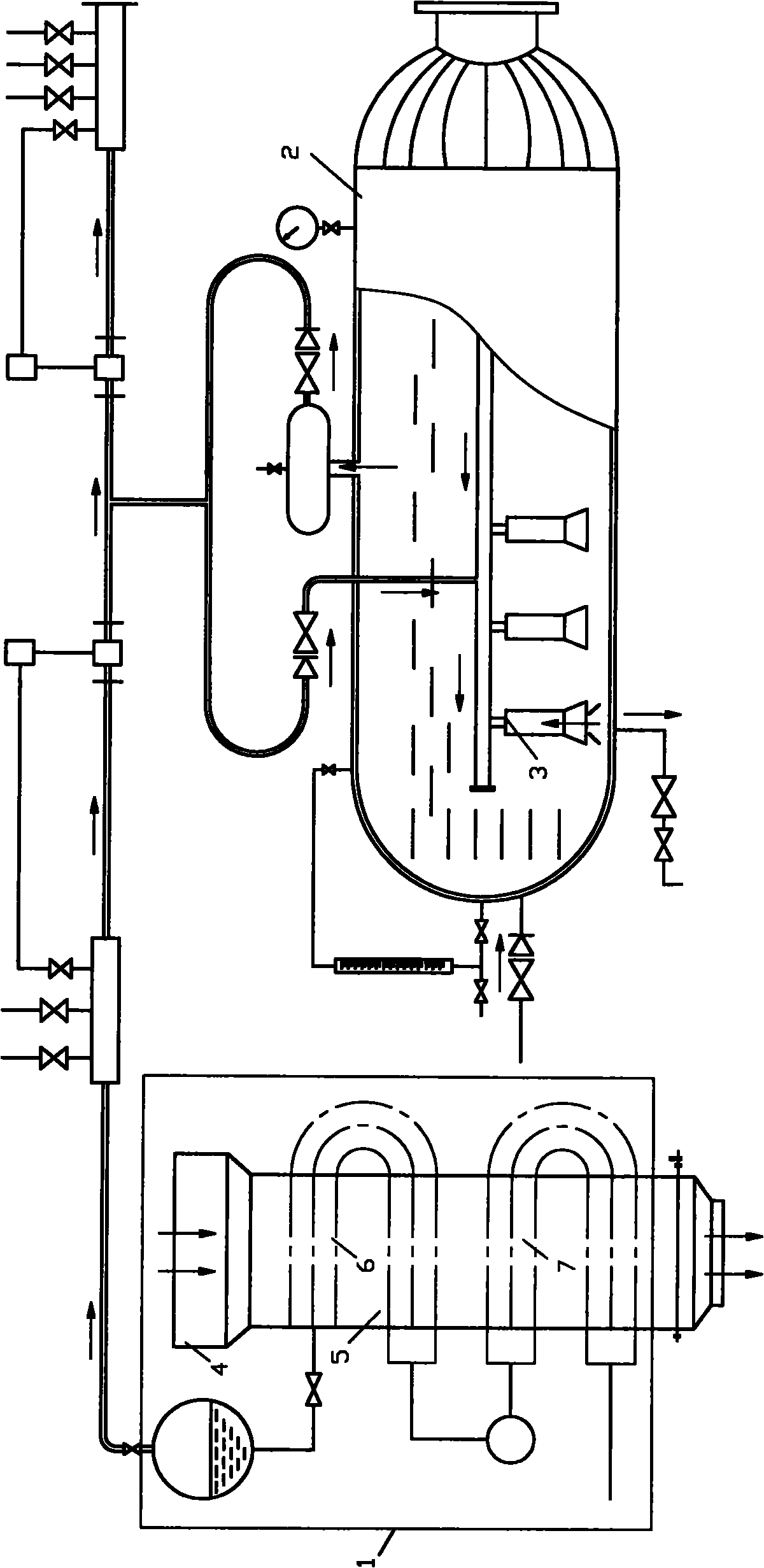

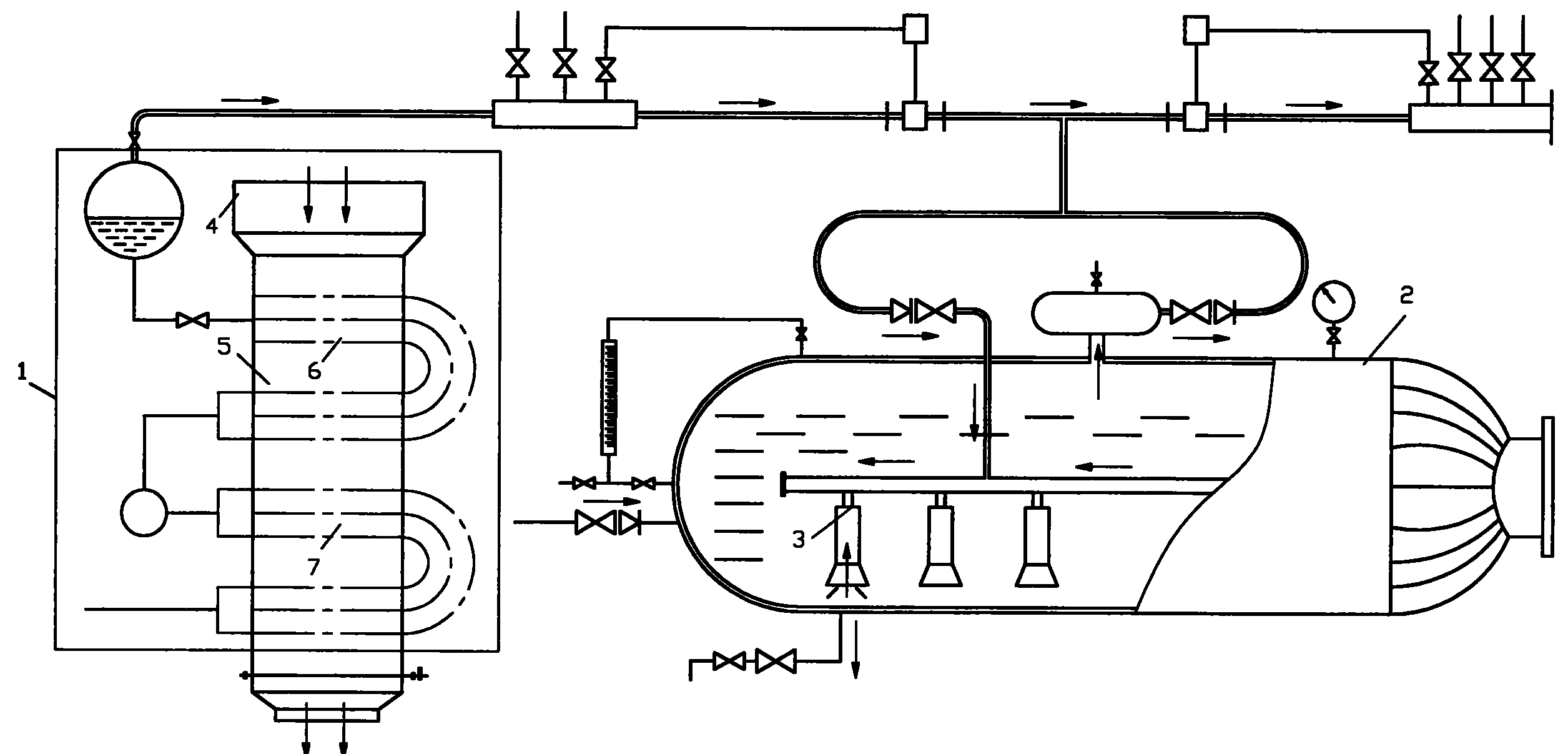

[0010] Such as figure 1 As shown, the system mainly consists of 2 parts of steam heat accumulator and 1 part of waste heat boiler 1, 2 parts of steam heat accumulator

[0011] 1. Working principle

[0012] The working principle of the steam accumulator 2 is to store water in a pressure vessel, pass steam into the water to heat the water, that is, transfer heat energy and water, increase the temperature and pressure of the water in the vessel, and form saturated water with a certain pressure; Then under the condition that the pressure of the container drops, the saturated water becomes superheated water, which immediately boils and self-evaporates to produce steam. Use water as a carrier to store steam indirectly. The water in the container is not only the heat transfer medium for heat exchange between steam and water, but also the heat carrier for storing heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com