Full-automatic metal double-buckle pipe assembling device

A fully automatic, metal technology, applied in the direction of feeding devices, metal processing, positioning devices, etc., can solve the problems of unable to meet the feeding requirements of high-capacity intelligent production lines simultaneously, unable to achieve fully automatic feeding and grasping, and low efficiency of manual assembly and installation , to achieve the effect of changing flatness, reducing work intensity and improving penetration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

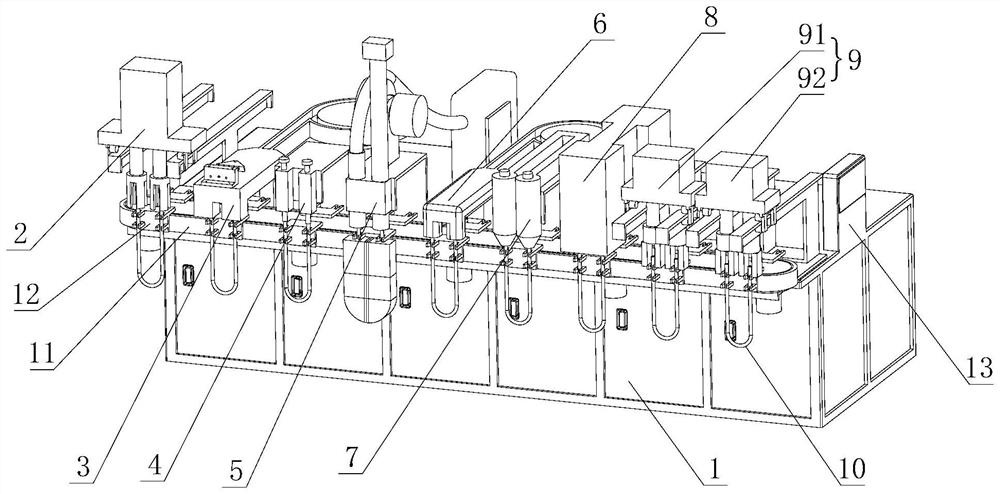

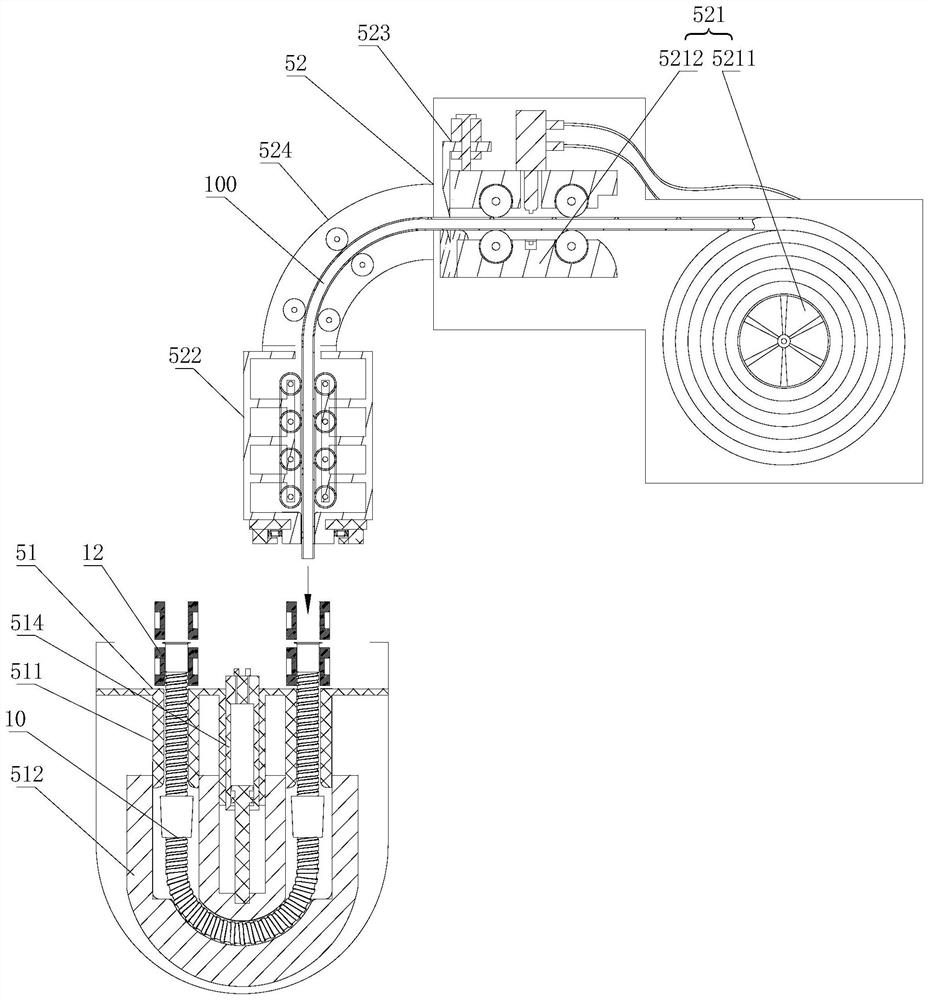

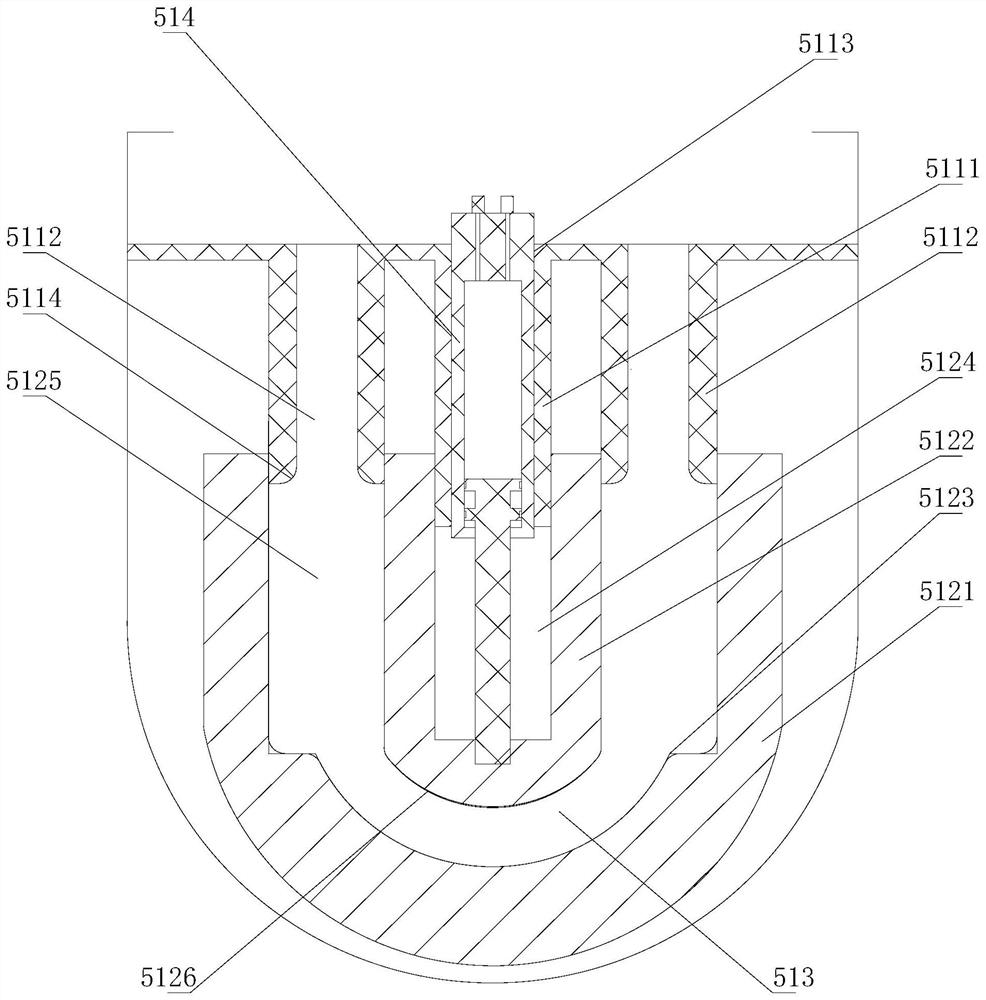

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a fully automatic metal double-button tube assembly device includes a frame 1 and a conveyor belt 11 arranged on the frame 1. The conveyor belt 11 is provided with a clamping and fixing mechanism 12 for fixing the outer tube 10. 11 Feeding direction The frame 1 is provided with a feeding module 2 for automatically assembling the nut on the outer tube 10, a steel sleeve installation module 3 for simultaneously installing the steel sleeve on both ends of the outer tube 10, and a steel expansion module. The inner expansion steel sleeve module 4 of the sleeve, the inner tube module 5 for shrinking the outer tube and the inner tube 100 penetrating the outer tube 10, the core installation module 6 for inserting the core into the inner tube 100, The crimping module 7 that crimps the core in place, the detection module 8 that scans and detects the crimped outer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com