Patents

Literature

152results about How to "Smooth penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

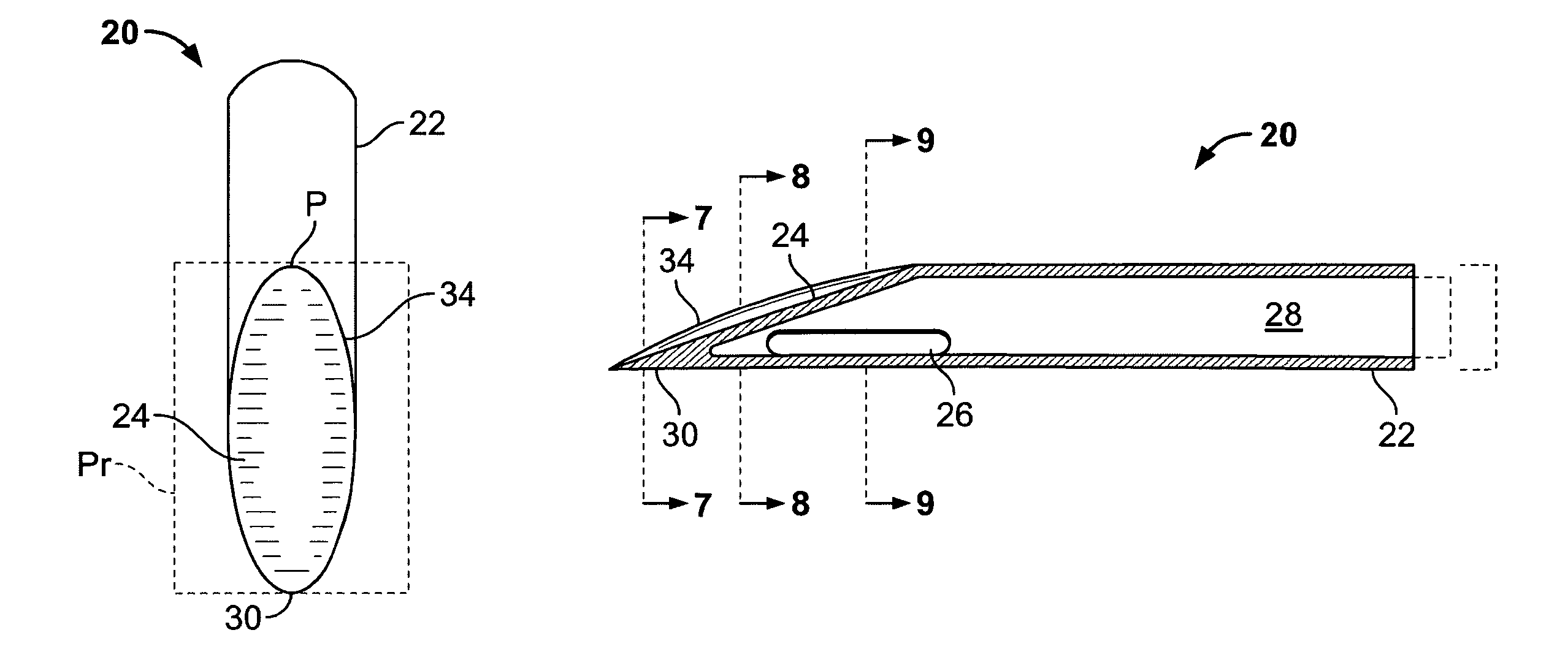

Fluid sampling, analysis and delivery system

InactiveUS20050228313A1Small volumeMinimal amountMedical devicesPressure infusionMedication monitoringPancreatic hormone

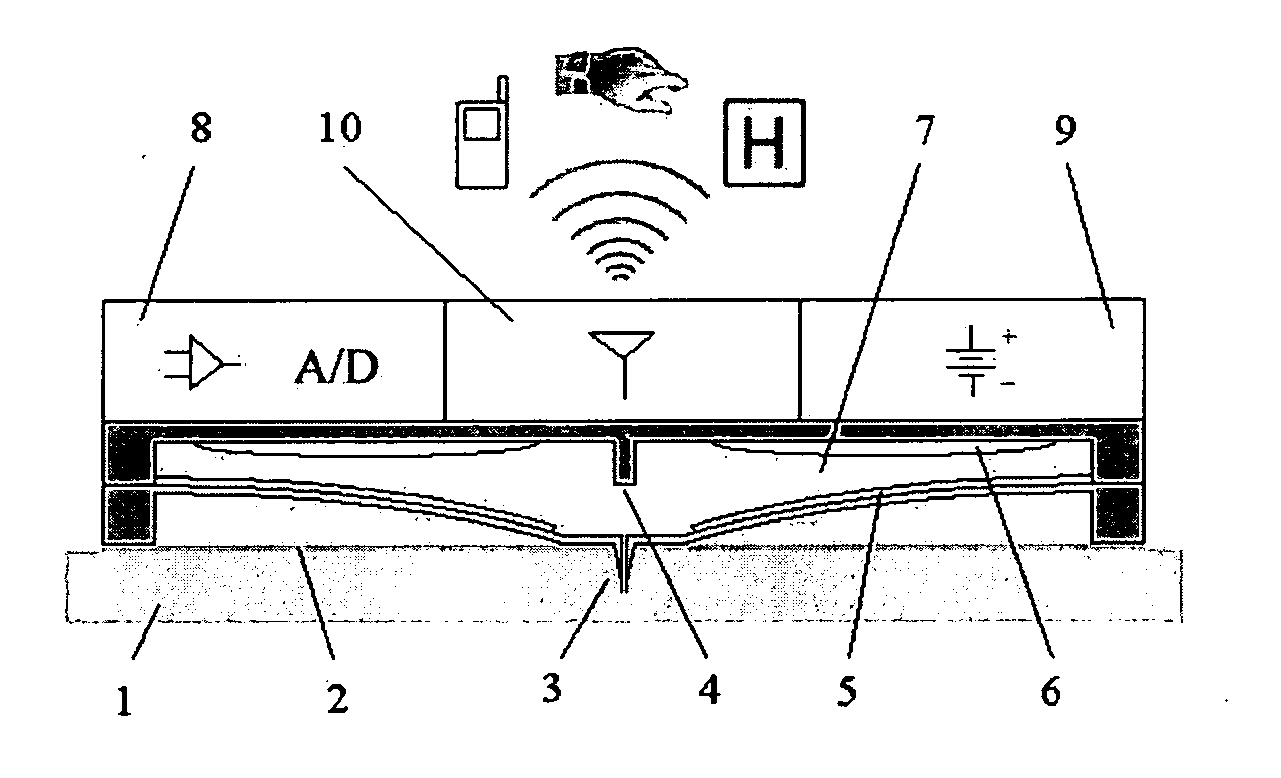

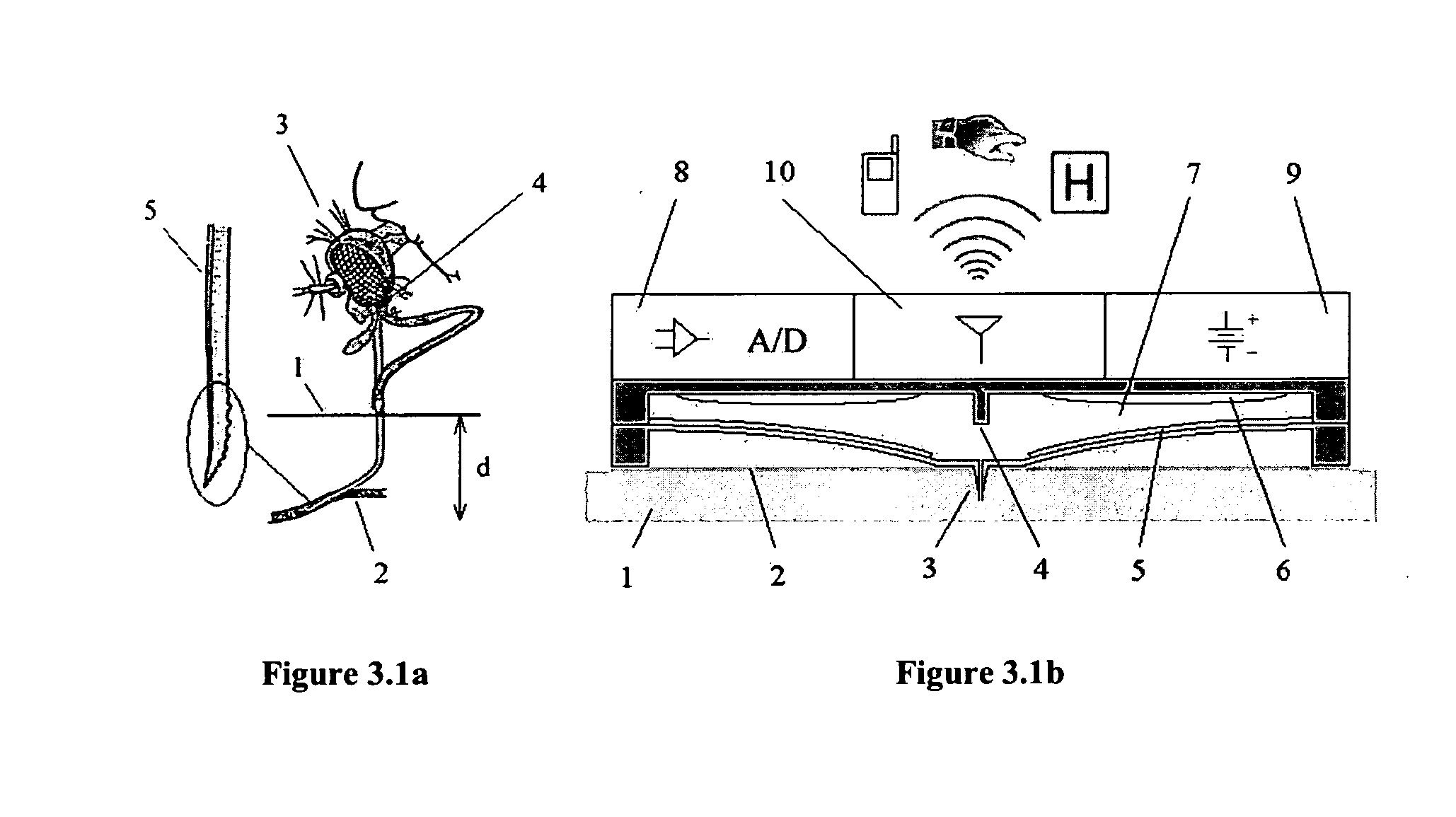

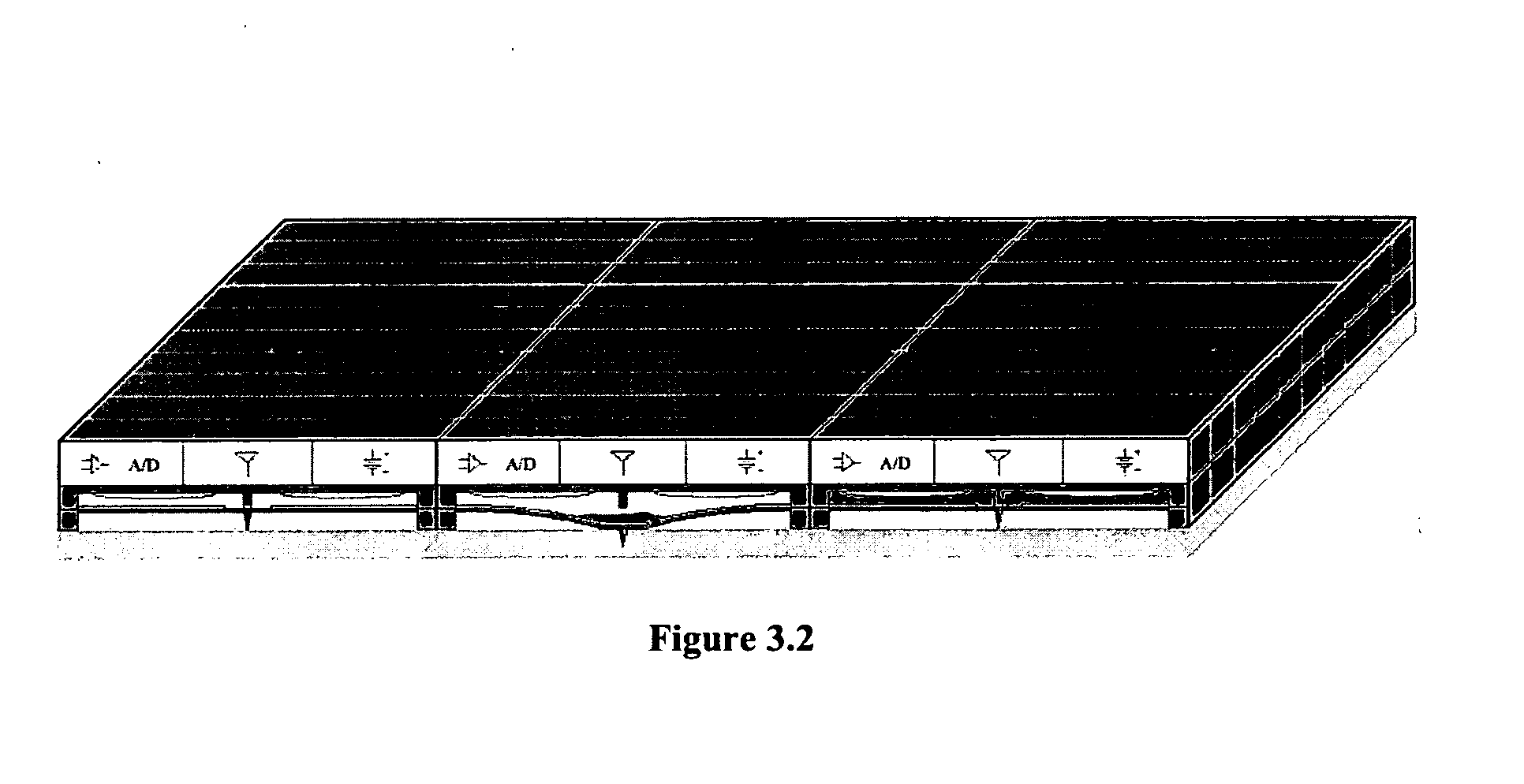

The lack of safe, reliable, automated and clinically acceptable blood sampling has been the main problem precluding the development of real-time systems for blood analysis and subsequent closed-loop physiological function control. While the analysis of a static blood sample in laboratory conditions has been rapidly advancing in reliability and blood volume reduction, non-invasive real-time blood analysis performed in vivo (while the blood is circulating in the body) has been elusive and unreliable. In this study we propose an innovative idea for semi-invasive blood sampling and analysis, which resembles the operation of a mosquito. At a miniature scale the proposed system does penetrate the skin to extract a static blood sample for further analysis, but the extent of this penetration, and the fact that it can be made painless, is particularly attractive for such applications as automated glucose analysis for closed-loop control of insulin infusion (artificial pancreas), continuous drug monitoring, or even periodic DNA analysis for security and identification purposes. These design aspects are described, and a specific implementation, applying MEMS (Micro Electro Mechanical Systems) technology, is suggested. The proposed microsystem is a matrix of individually controllable e-Mosquito™ cells, packaged in a disposable patch and attached to the skin, could be an avenue for real-time semi-invasive blood analysis and diagnostics.

Owner:UNIV TECH INT

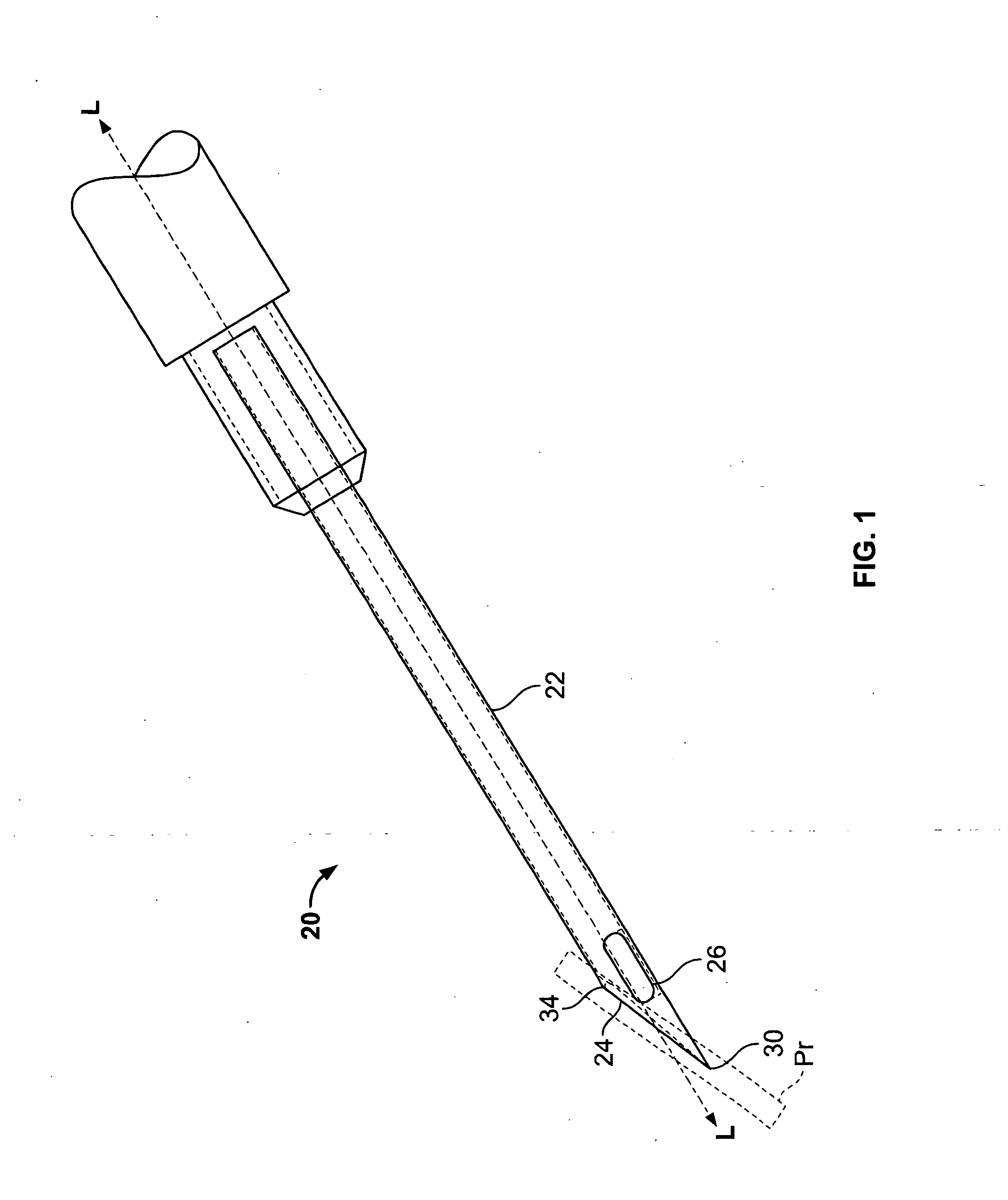

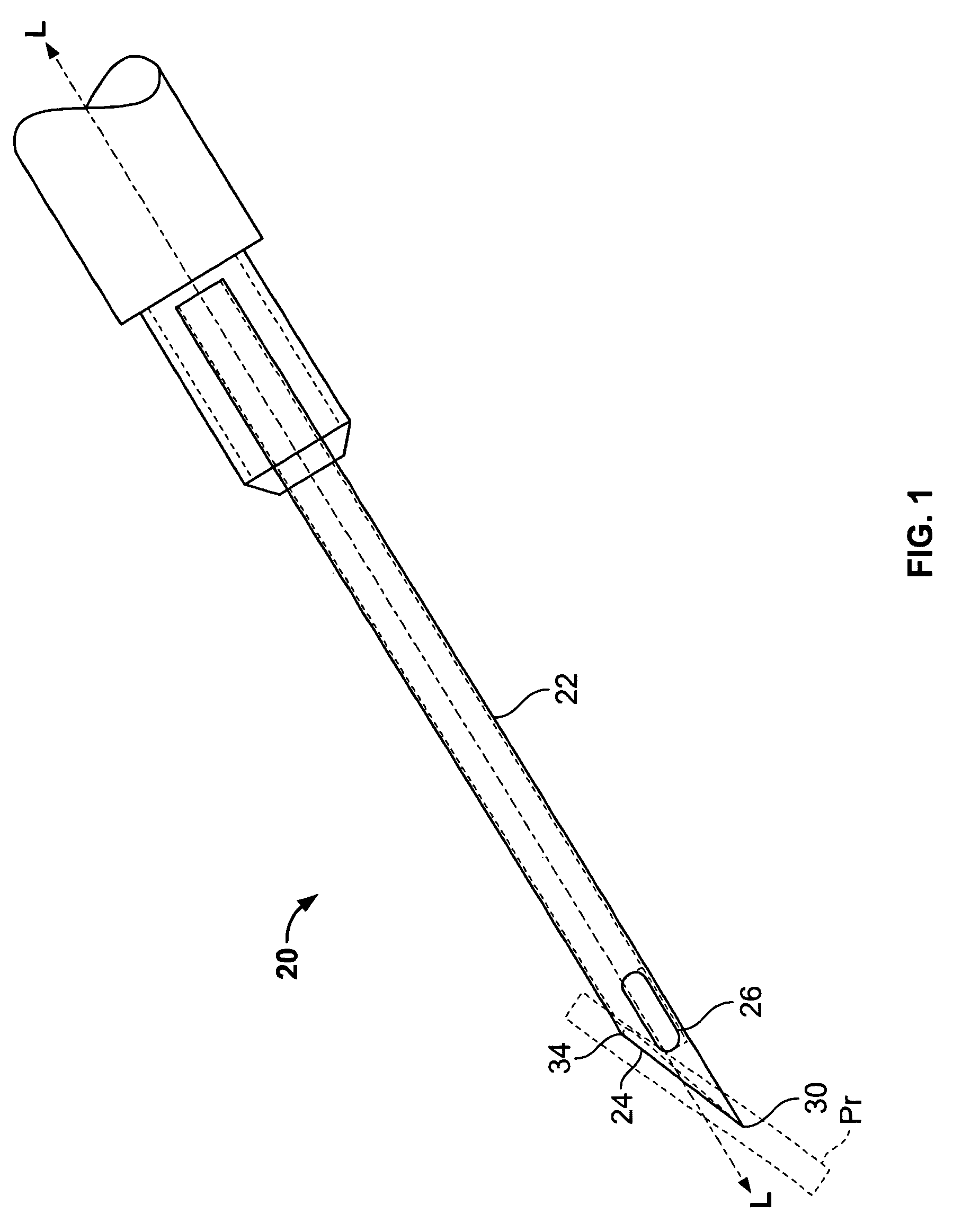

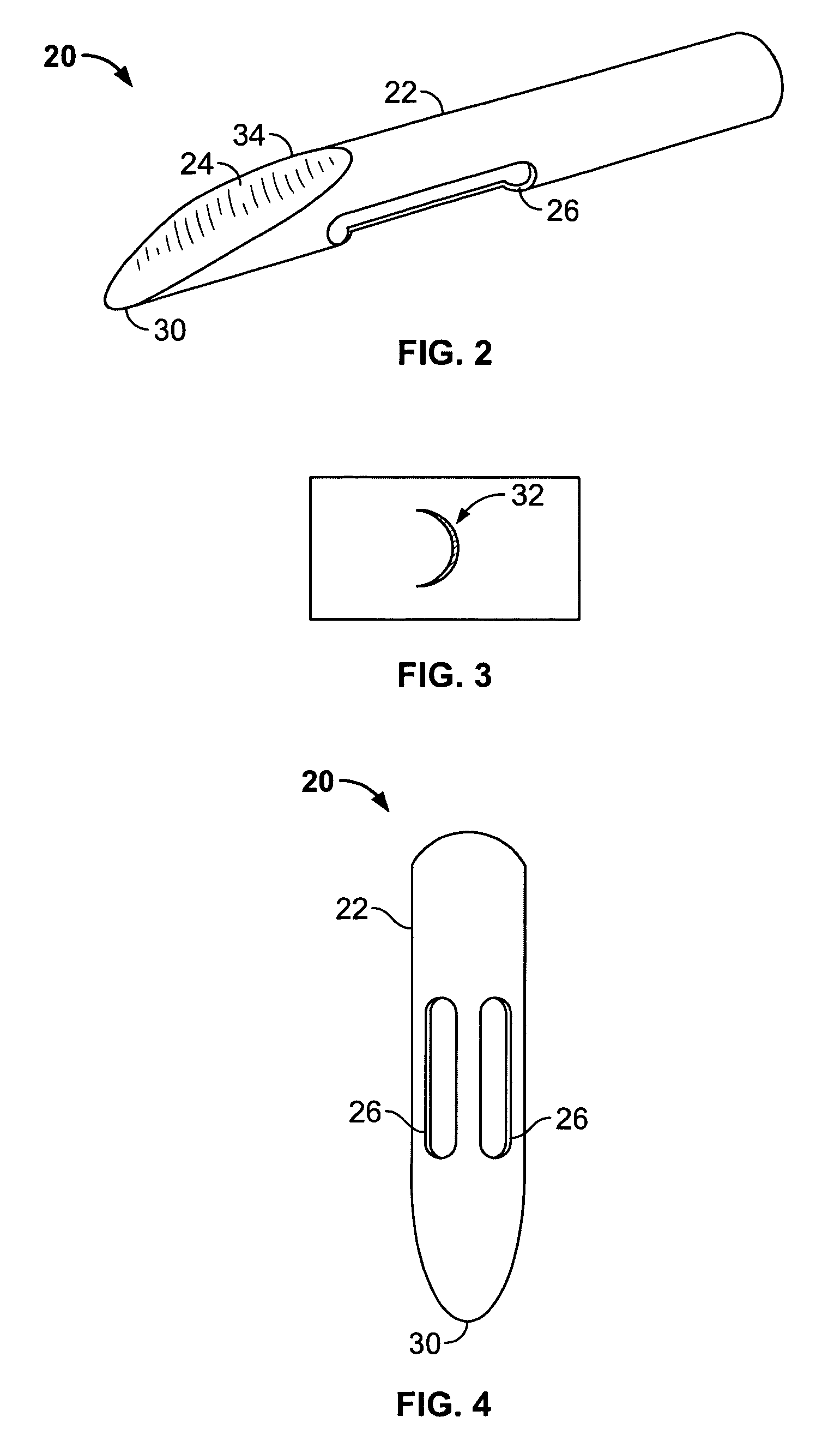

Medical needle having a closed tip

Owner:ATIL PLARIDEL CERNA

Container flooring material and method of manufacture

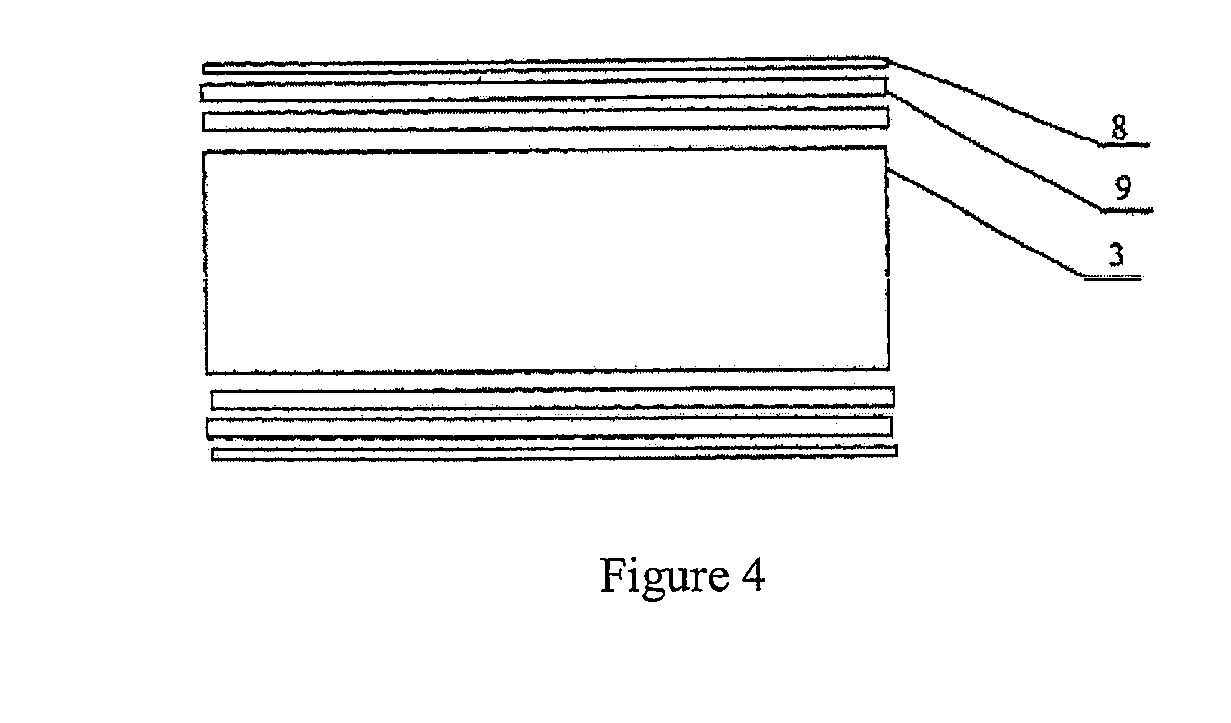

InactiveUS20100015389A1Efficient use ofOvercome shortageLamination ancillary operationsLayered product treatmentSoutheast asiaResin coating

The present invention relates to a composite container floorboard having a structural strand-based board as the core material and its fabrication method thereof. It is characterized wherein the composite container floorboard, using a structural strand-based board as a core material, comprises 2 to 4 layers of wooden veneers coated or impregnated with resin, respectively, on a top and a bottom of the surface overlay materials; or comprises one piece of impregnated paper, one piece of resin-impregnated bamboo-woven mat, and 1 to 3 pieces of double-side resin-coated or resin-impregnated wooden veneers, respectively, from an exterior to an interior of the surface overlay materials; or comprises one Keruing or Apitong wooden veneer of Southeast Asia, or other wooden veneer with similar properties and 1 to 3 pieces of double-side resin-coated or resin-impregnated wooden veneers [or partially or entirely replacing wooden veneer(s) with resin-impregnated bamboo curtain(s) or bamboo-woven mat(s)], respectively, from an exterior to an interior of the surface overlay materials.

Owner:ALBERTA INNOVATES TECH FUTURES

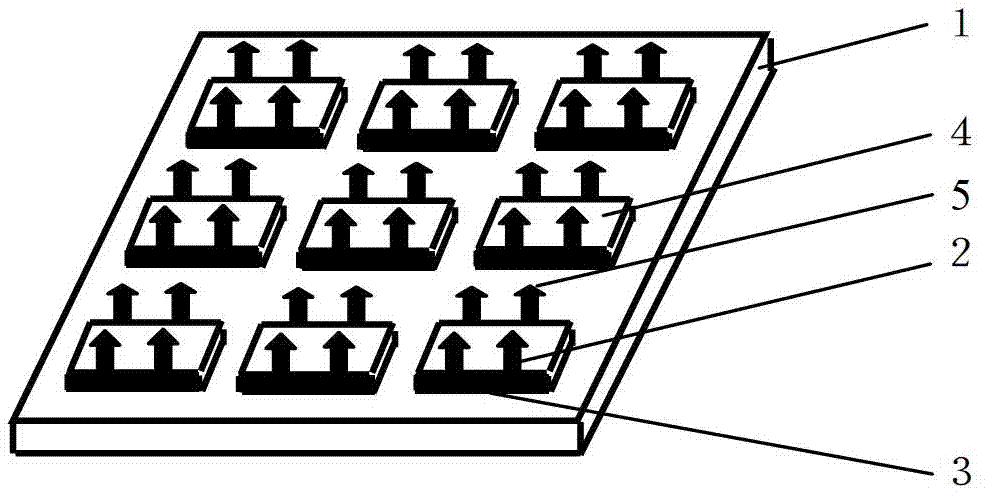

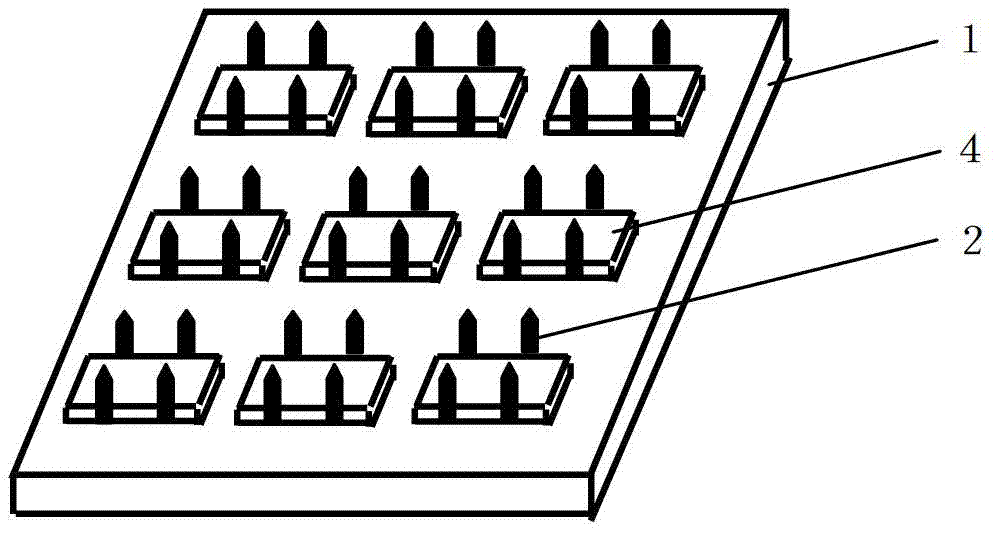

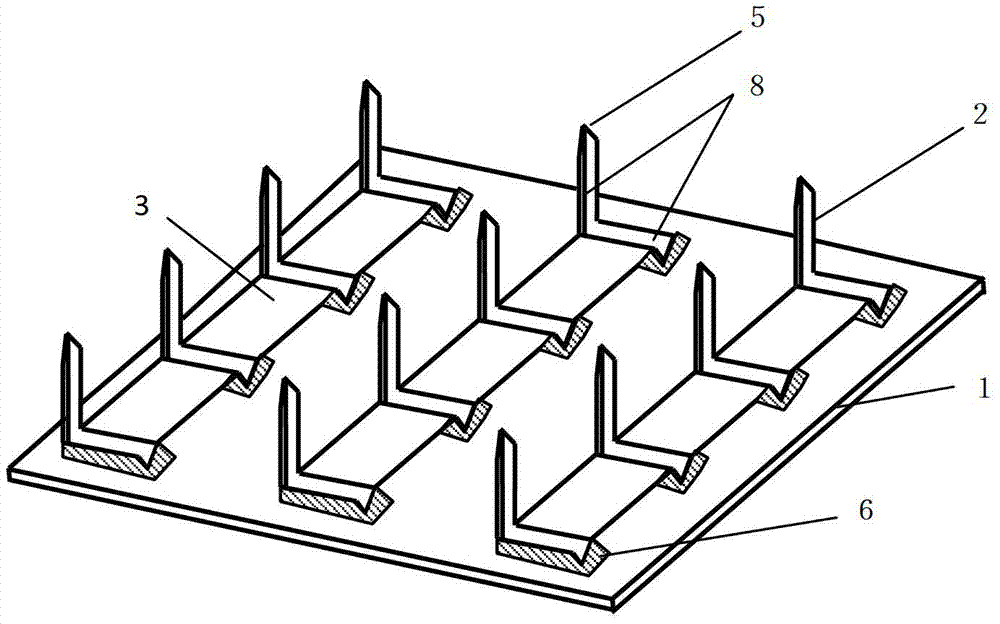

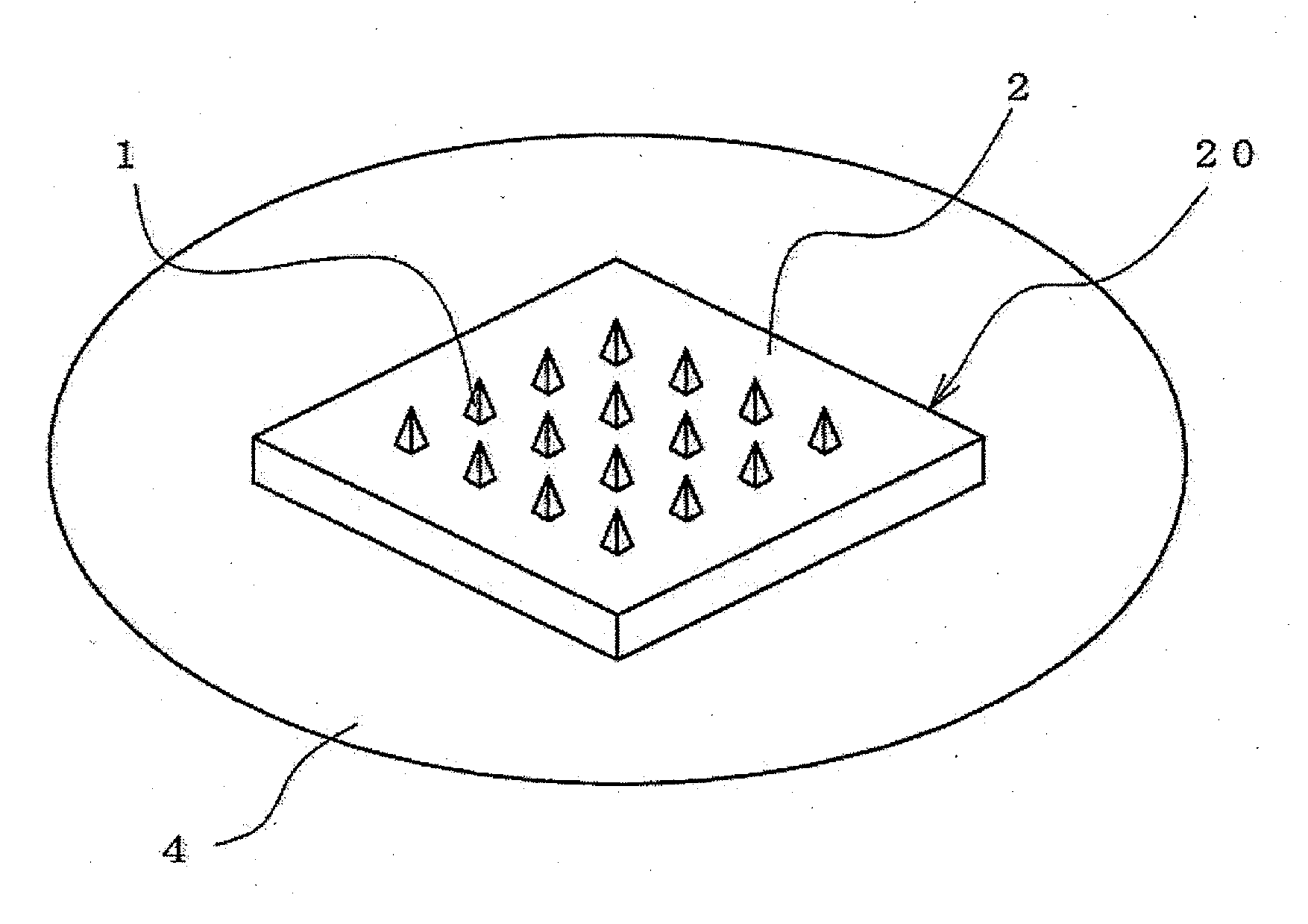

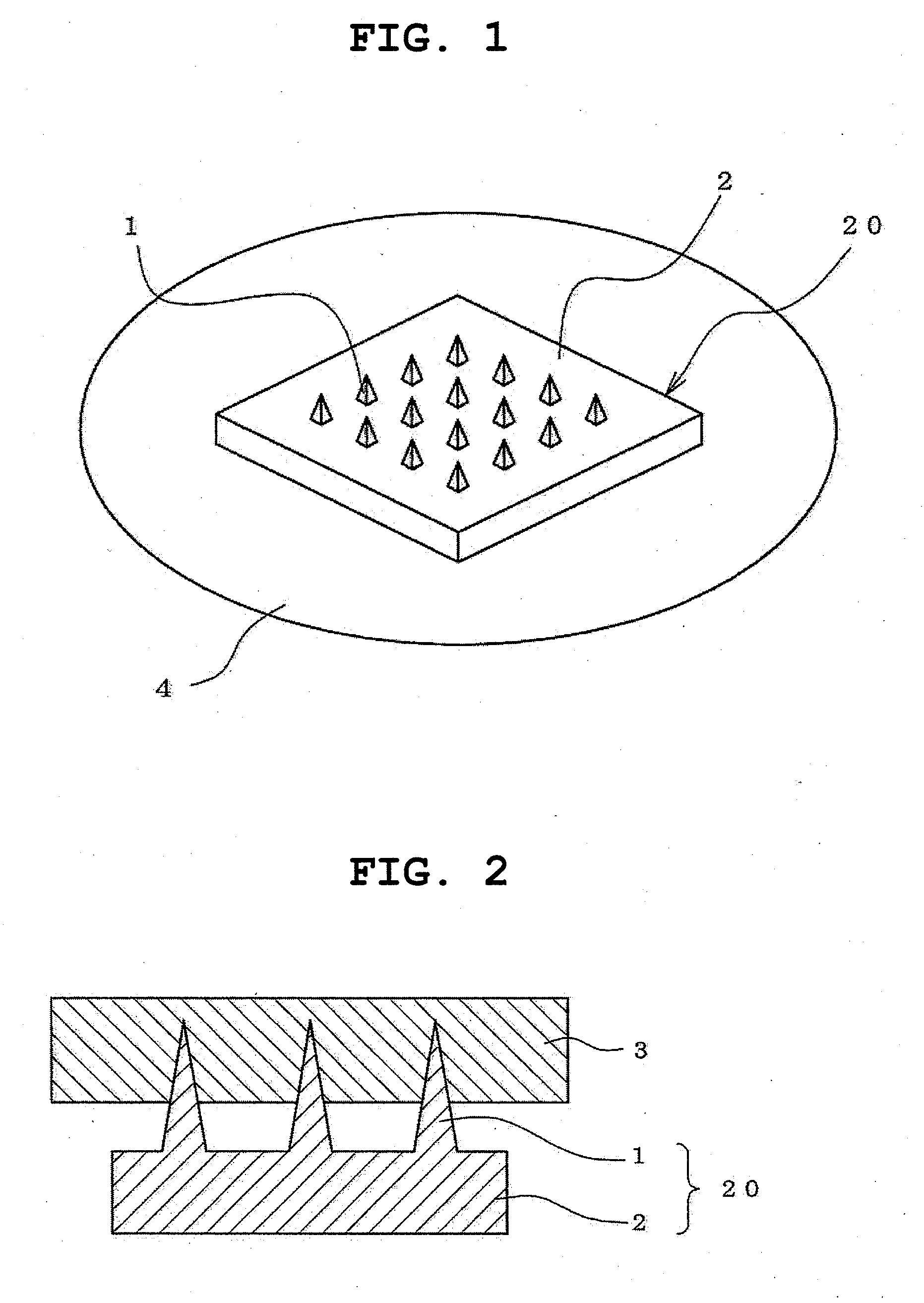

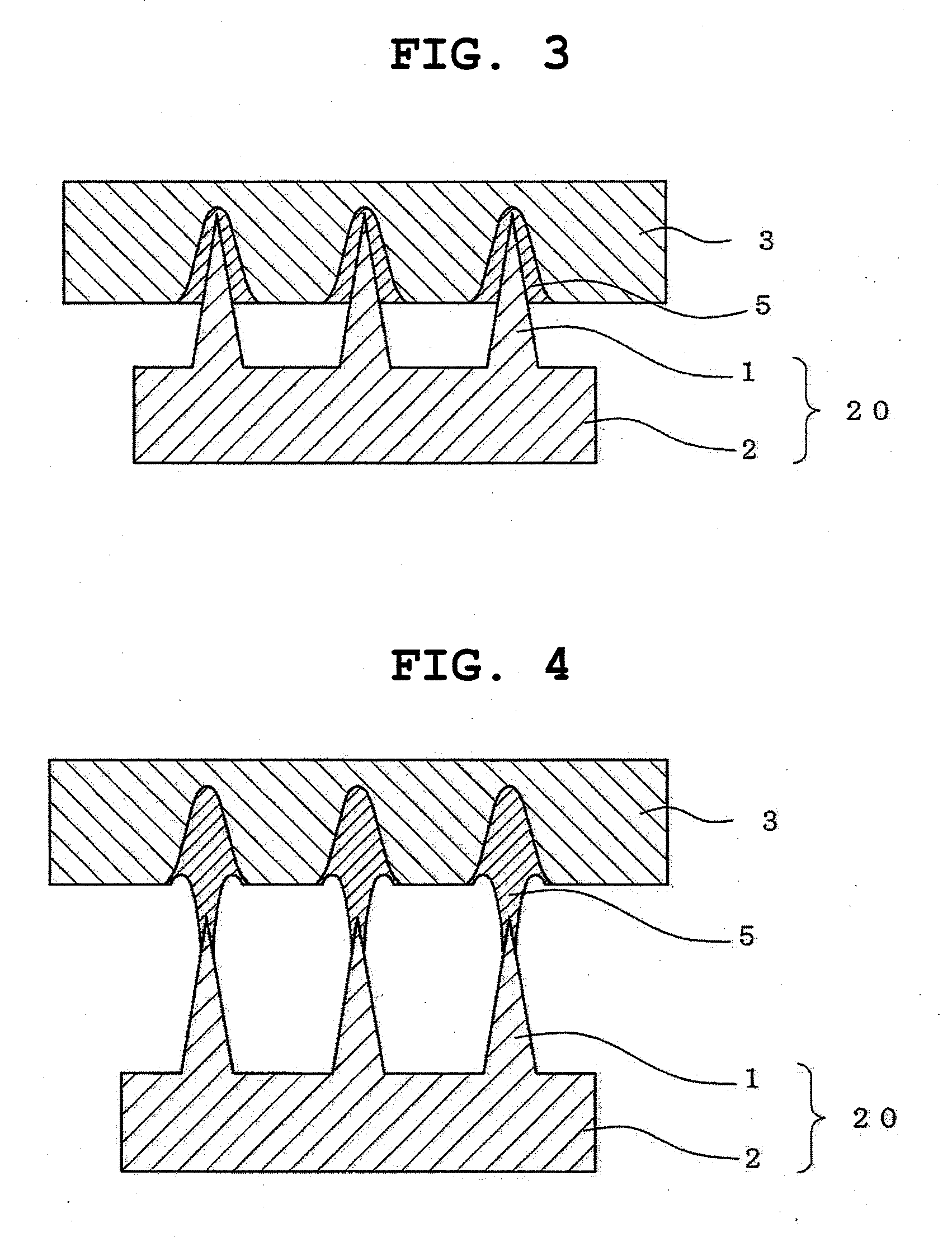

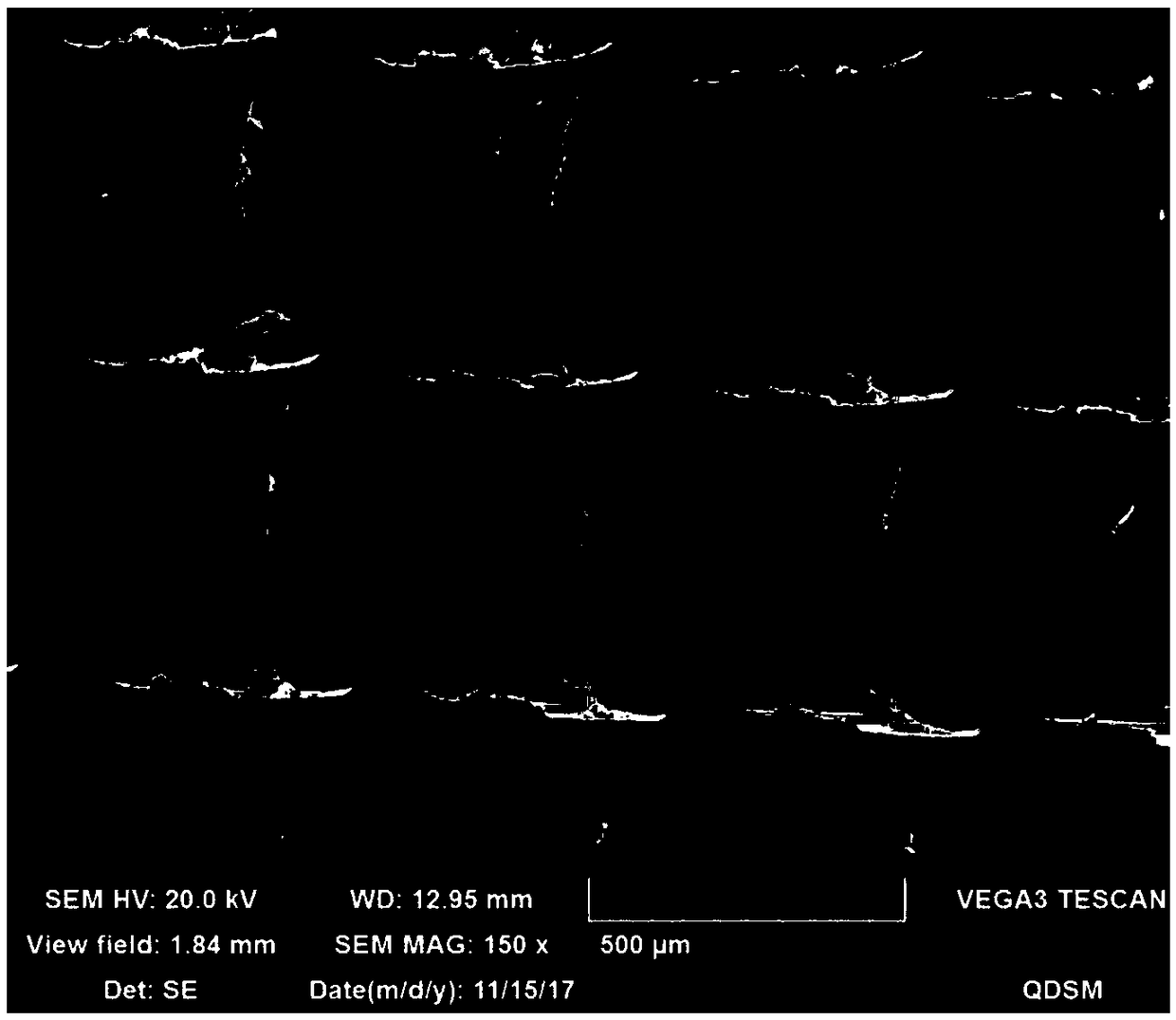

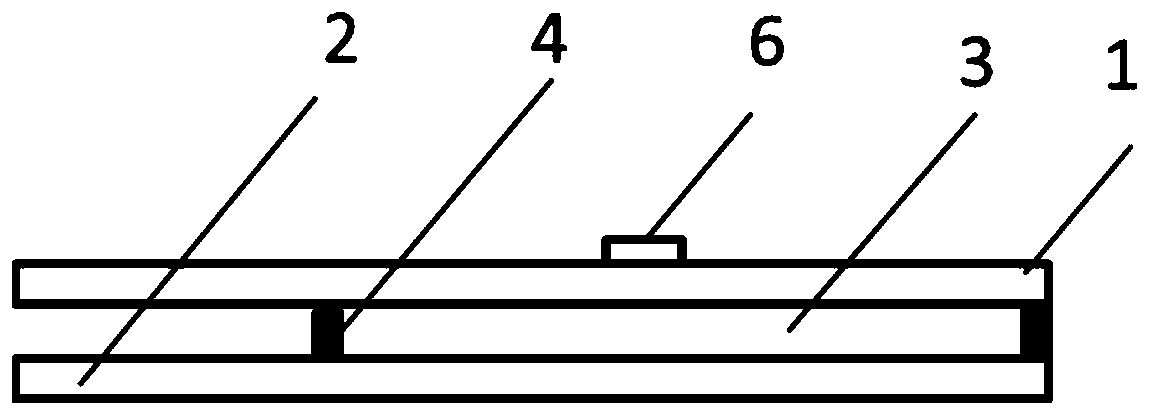

Metal micro-needle array flexible patch, transdermal applicator and transdermal application patch

ActiveCN103203072AImprove consistency and controlFeel comfortableMicroneedlesMedical devicesDrugNeedle holder

The invention discloses a metal micro-needle array flexible patch, a transdermal applicator and a transdermal application patch. The metal micro-needle array flexible patch comprises a flexible substrate and at least two metal micro-needle modules which are arranged at certain intervals and fixed on the bottom surface of the flexible substrate or partially inset in the flexible substrate. Each metal micro-needle module is a metal sheet with projecting micro-needles on the edge, or a metal sheet fixed on a needle holder and provided with projecting micro-needles on the edge, or composed of metal micro-needles separately erected and fixed on a needle holder. The micro-needles are perpendicular to the surface of the flexible substrate and are hollow or solid metal micro-needles with a tip pointing out. The micro-needle array is organically combined with the flexible substrate, so that medicine is allowed to directly pass corneum to quickly enter the human body. The metal micro-needle array flexible patch is comfortable to use and evident in efficacy.

Owner:SHANGHAI RUNTONG MEDICAL TECH CO LTD

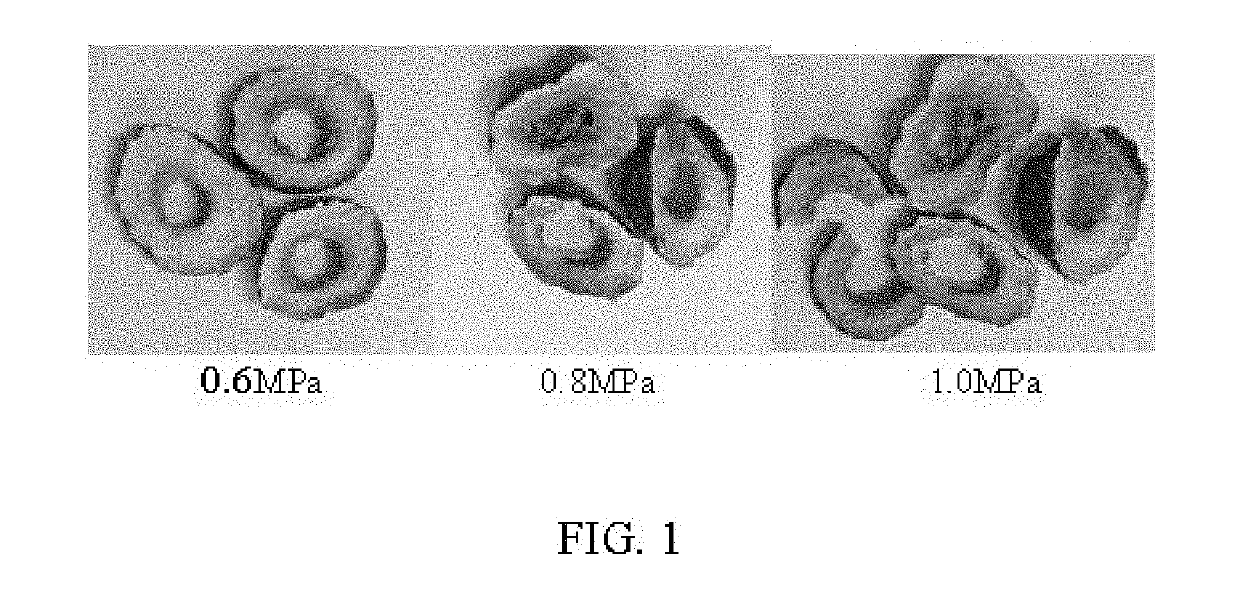

Process for producing microneedle of thermosensitive substance

InactiveUS20100004608A1Easy maintenanceEasy to implementMicroneedlesDomestic articlesEngineeringHeat sensitive

The invention provides a method of producing a microneedle. A jig is heated to a temperature above the level at which a temperature-sensitive material that exhibits thermoplastic deformation becomes viscoplastic, the jig is brought into contact with the temperature-sensitive material, and then the jig is pulled part from the temperature-sensitive material to elongate the portion of the temperature-sensitive material in contact with the jig, whereby acicular projections are formed.

Owner:MEDRX CO LTD

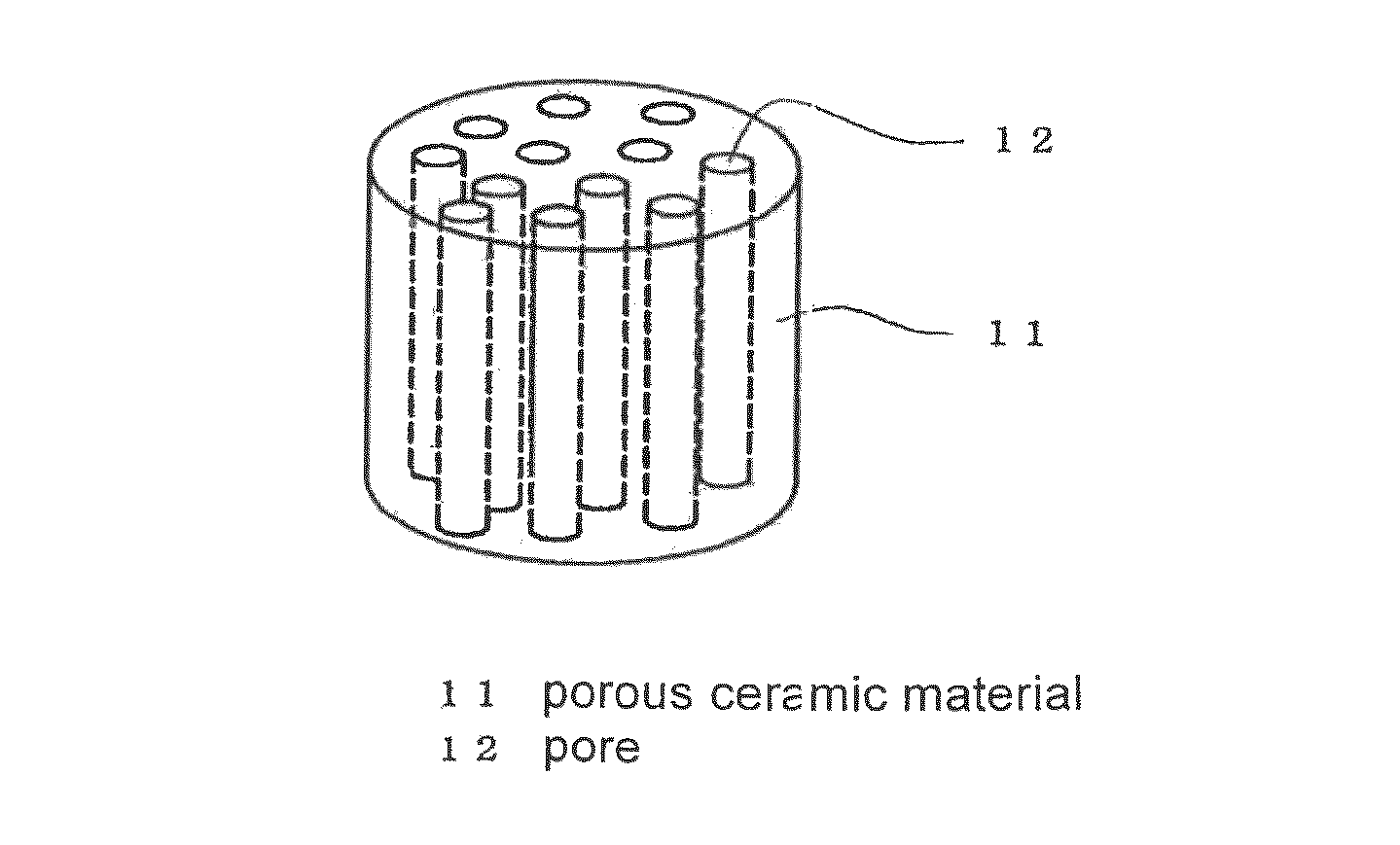

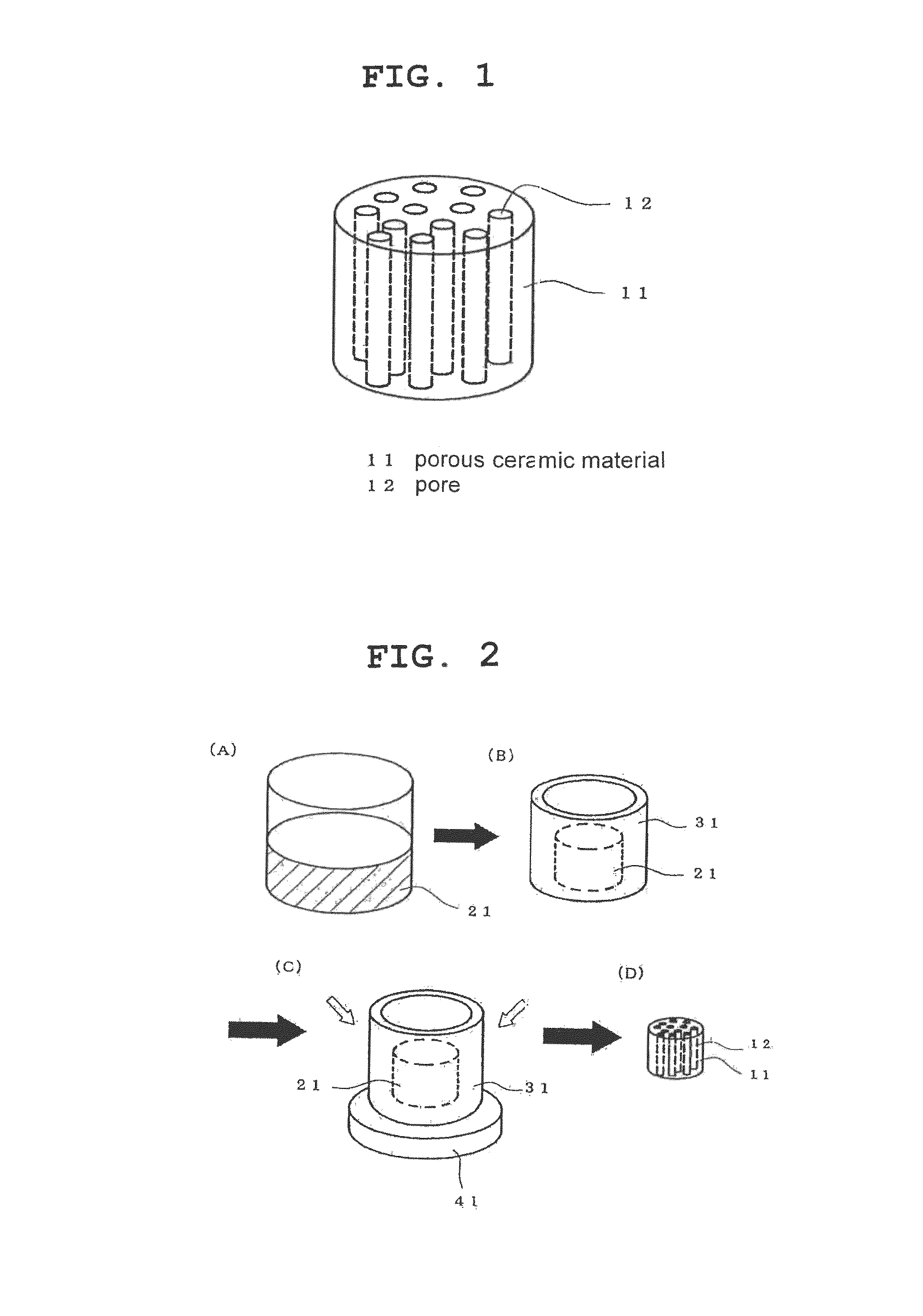

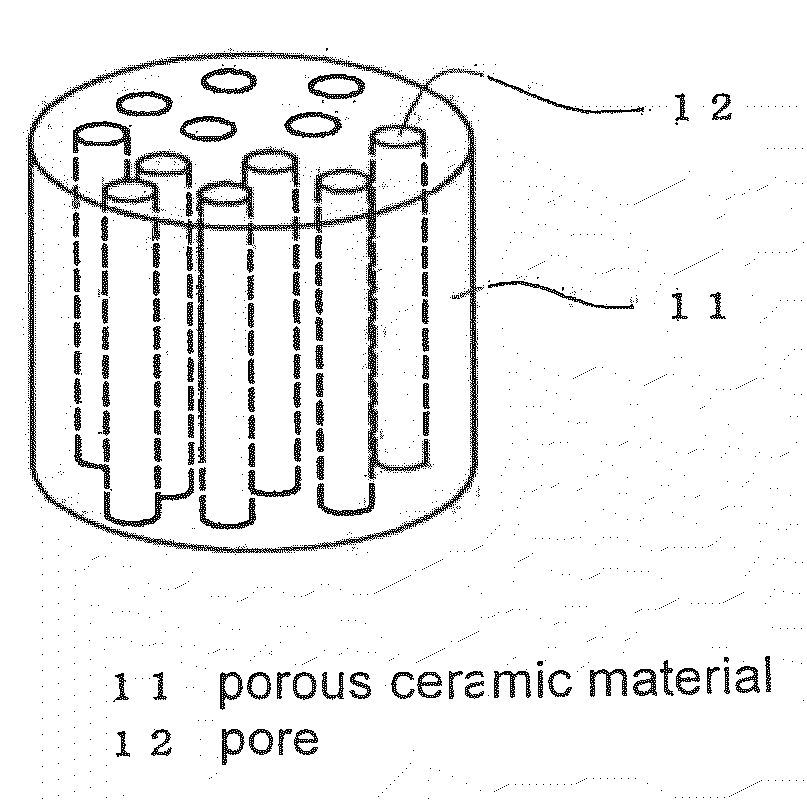

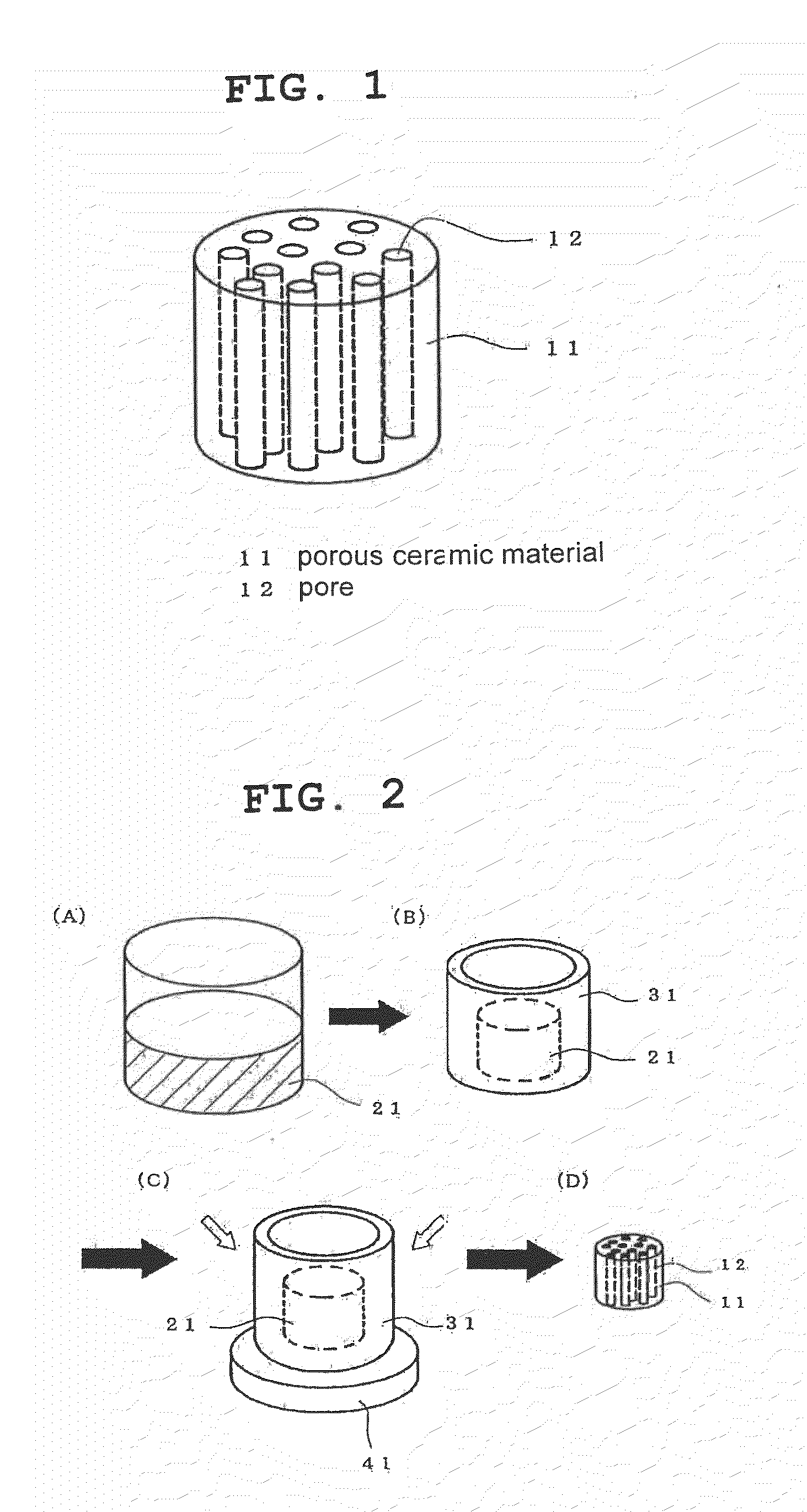

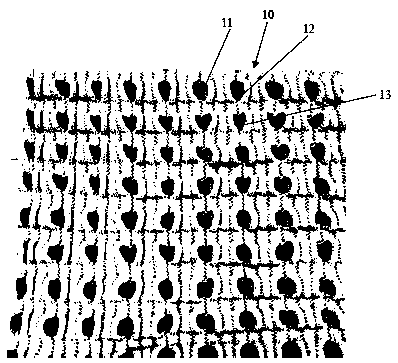

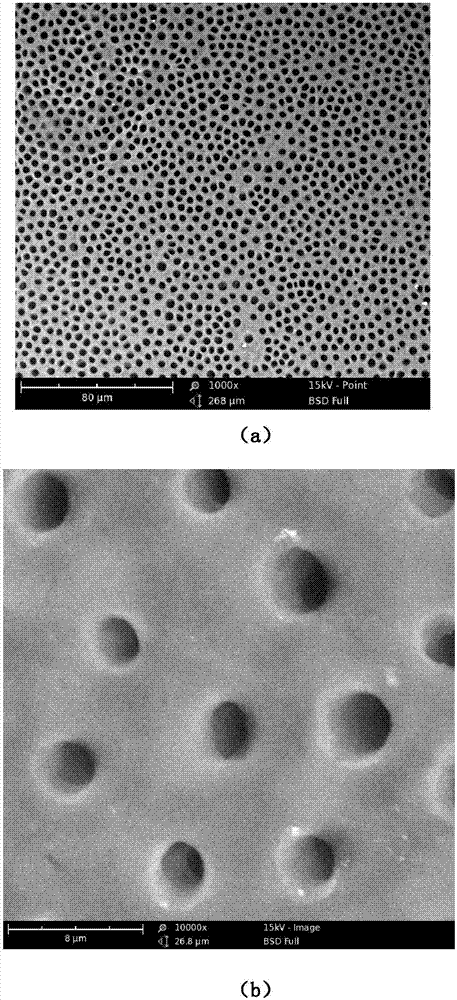

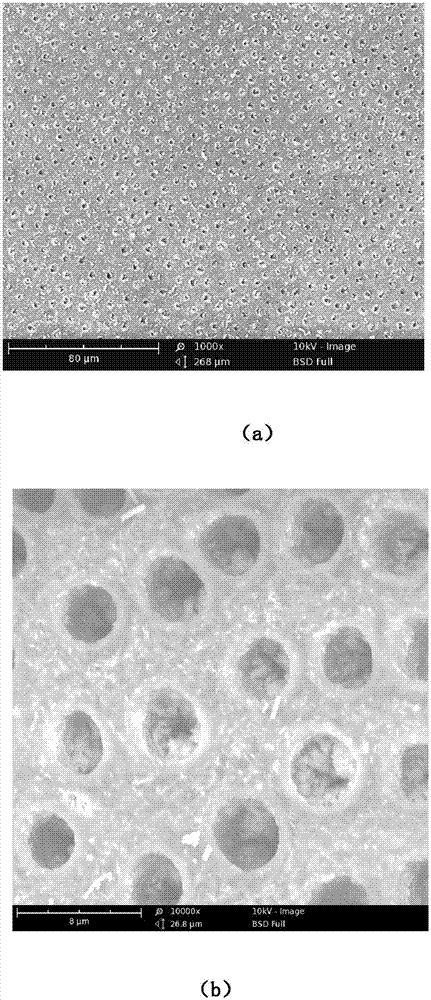

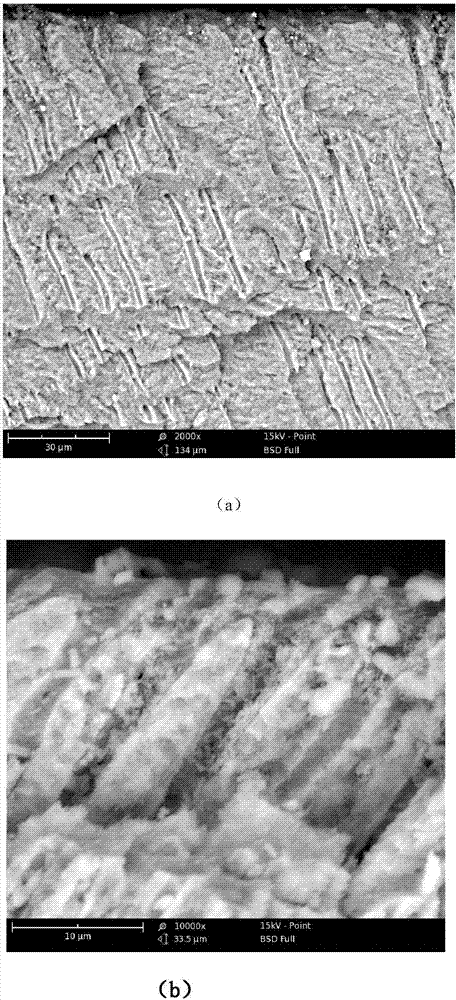

Porous ceramic material and method of producing the same

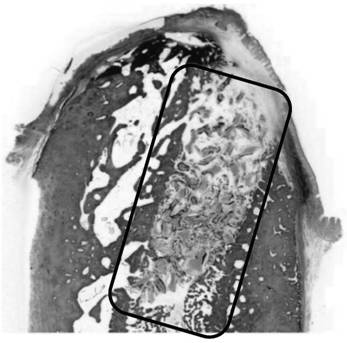

ActiveUS8609235B2High compressive strengthSuitableBone implantCeramic shaping apparatusBone tissuePolyethylene glycol

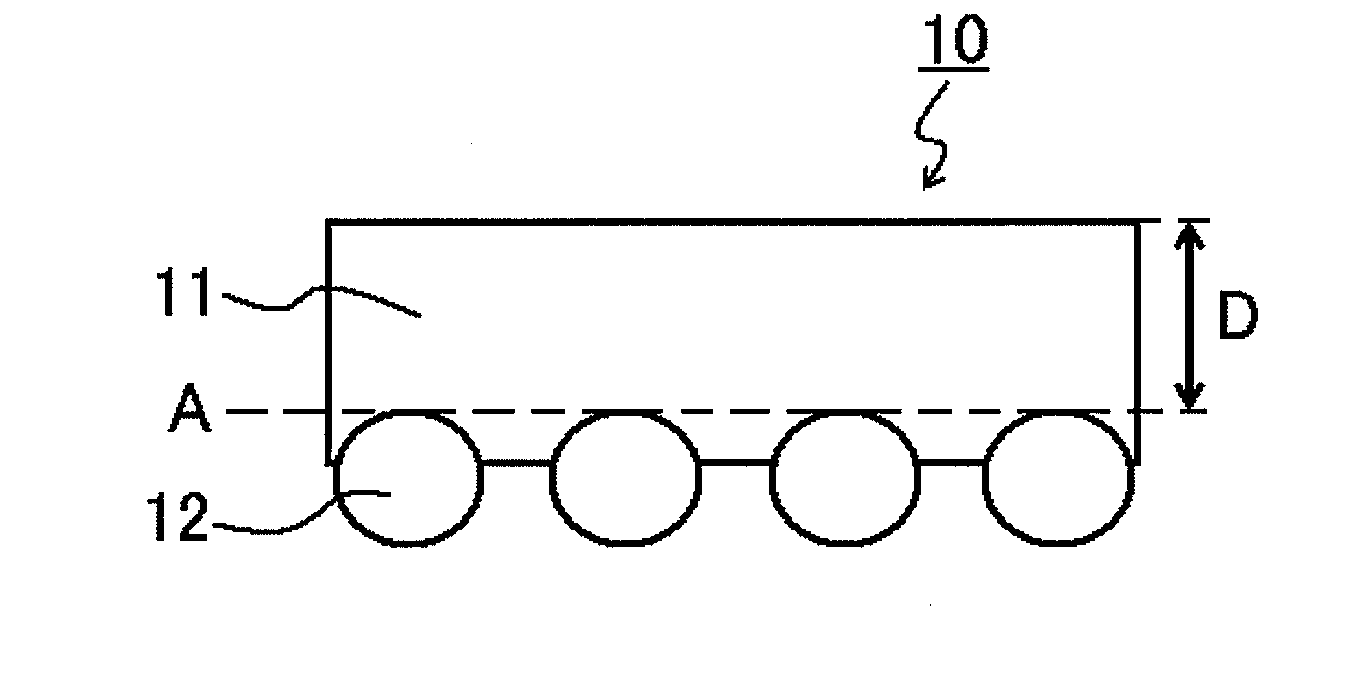

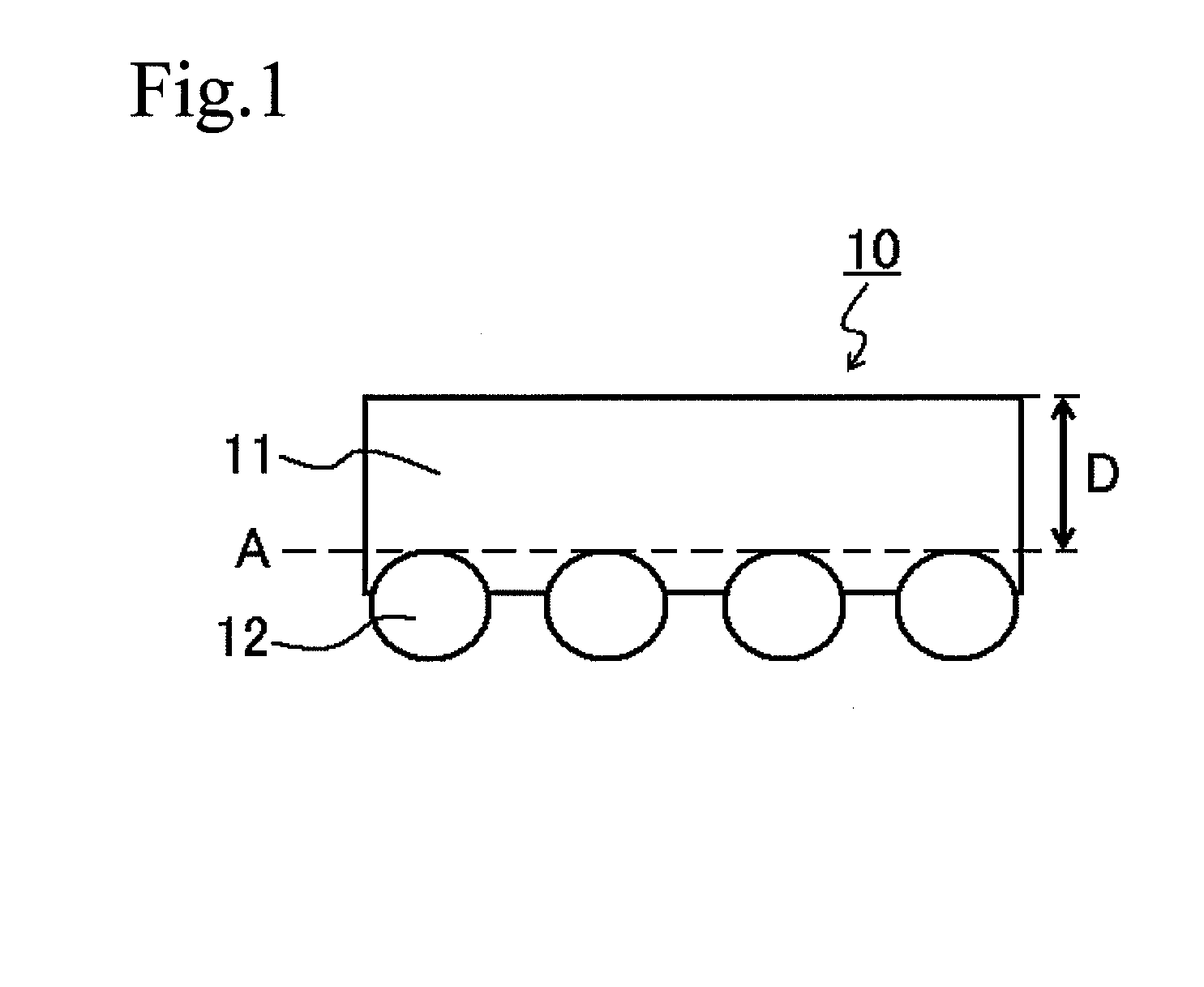

Provision of a porous ceramic material which rapidly induces bone tissue formation and has practical strength.A porous ceramic material 11 having substantially unidirectionally oriented pores 12, a porosity of 40-90%, and an average open area of one pore of 0.05×10−3-50×10−3 mm2 both in a first sectional surface perpendicular to the pore 12 orientation direction and a second sectional surface parallel to the first sectional surface and 5 mm distant from the first sectional surface in the pore 12 orientation direction. Using the material 11, when a cylindrical test piece (diameter 3 mm×height 5 mm, the pore 12 array direction as a height direction) made of the material is dipped in polyethylene glycol up to 1 mm from one end thereof, polyethylene glycol permeates through the whole test piece preferably within 30 seconds.

Owner:KURARAY CO LTD +1

Medical needle having a closed tip

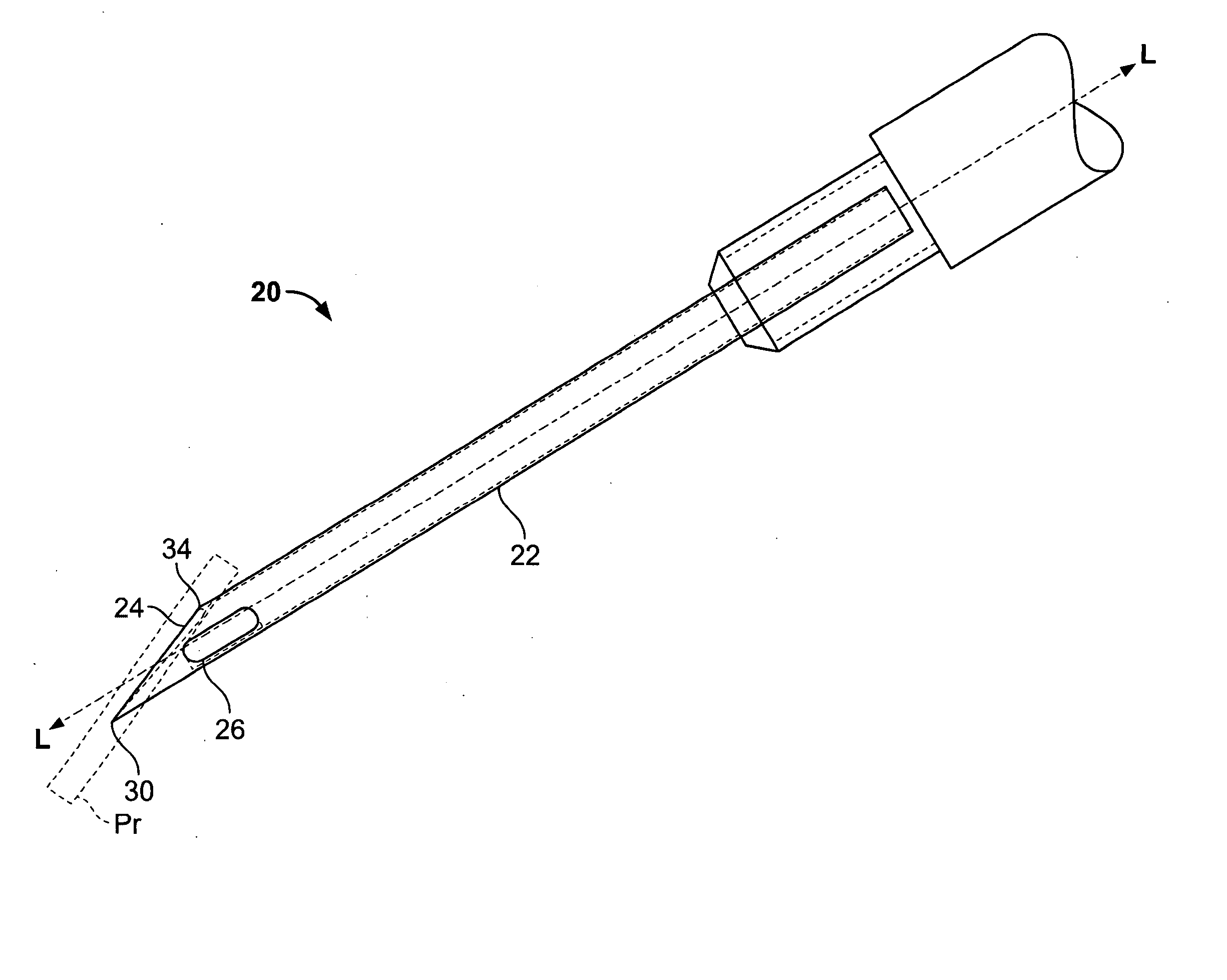

A needle is provided, having a closed tip configured to minimize tissue damage from penetration of the needle. The needle includes a tubular side wall defining an internal bore. The needle further includes an end wall angled relative to the needle's longitudinal axis and disposed at the distal end of the needle. The needle defines a distal opening spaced from the closed tip, providing access to the internal bore to facilitate fluid transfer. Preferably, the needle is configured to create a crescent-shaped penetration mark. The number and positioning of openings can be varied across embodiments of the invention, while maintaining a closed tip. For example, in certain embodiments, the needle comprises two distal openings defined by the side wall. A distal opening can also be provided by the end wall singly or in combination with additional distal openings.

Owner:ATIL PLARIDEL CERNA

Microneedle patch and preparing method thereof

ActiveCN109045460APromotes skin repairGood cosmetic effectCosmetic preparationsToilet preparationsPolymer solutionGelatin

The invention discloses a microneedle patch and a preparing method thereof, and belongs to the microneedle technology for medical cosmetology. The microneedle patch comprises a needle layer and a lining layer, and the needle layer is connected with the lining layer, wherein the needle layer is prepared from, by weight, 100 parts of degradable polymer materials, 5-10 parts of cosmetic function molecules and 1-2 parts of enhanceosome. A microneedle array can pierce through the skin, the polymer materials in the array can be degraded in the skin and are harmless to the human body, the cosmetic function molecules dissolved in the polymer materials can be released and directly act on the interior of the skin, and thus the effects of replenishing water to the deep layer, reducing wrinkles and beautifying the skin are achieved. The preparing method of the microneedle patch comprises the steps that a vacuum jetting method is adopted for injecting a polymer solution into a micropore cavity of amicroneedle mold, after the polymer solution is cured, the needle layer is obtained, one side of the needle layer is coated with dissoluble binder, then a layer of gelatin is poured, and after the gelatin is formed, the cured microneedle patch is taken out of the microneedle mold.

Owner:江苏熙美生物科技有限公司

Dried fresh jujube slices and energy-saving process technology for differential pressure expansion drying

PendingUS20190269160A1Difficult to chewIncrease investmentFood coatingFood shapingFreeze-dryingDifferential pressure

A method for processing dried fresh jujube slices includes the following steps: preparing jujube slices, coring and removing stems, quick-freezing and retaining freshness of the jujube slices, thawing frozen jujube slices, protecting color treatment, expanding jujube slices under differential pressure, preparing superfine mixed seasoning powder, and coating of the superfine mixed seasoning powder. For one hand, this method solves problems that the dried fresh jujube slices will be deeply oxidized and brown when dried by the hot air at a high temperature of 90-110° C., the jujube slices with compacted cells will become harder and be difficult to chew because of 6-8 h rapid dehydration. On the other hand, it solves problems that exist in freeze drying at a vacuum degree of 1.3-13 Pa, and at a low temperature of −10-50° C., such as high energy consumption, long processing cycle, high equipment investment, small size of slices, and poor taste.

Owner:NINGXIA ZHONGXI JUJUBE IND LTD LTD +1

Adhesive sheet for water jet laser dicing

InactiveUS20090311474A1Smooth penetrationAvoid precisionFilm/foil adhesivesLayered productsFiberEngineering

An object of the present invention is to provide an adhesive sheet which, through improvement in the permeability of liquids originating in a liquid stream during water jet laser dicing, allows chips, IC components, or the like to be detached, prevents machining precision from being compromised such as by chipping or the scattering of chips and the like, and allows extremely thin semiconductor wafers or materials to be processed. The adhesive sheet for water jet laser dicing of the present invention comprises an adhesive layer laminated on a base film, the base film made of mesh fiber.

Owner:NITTO DENKO CORP

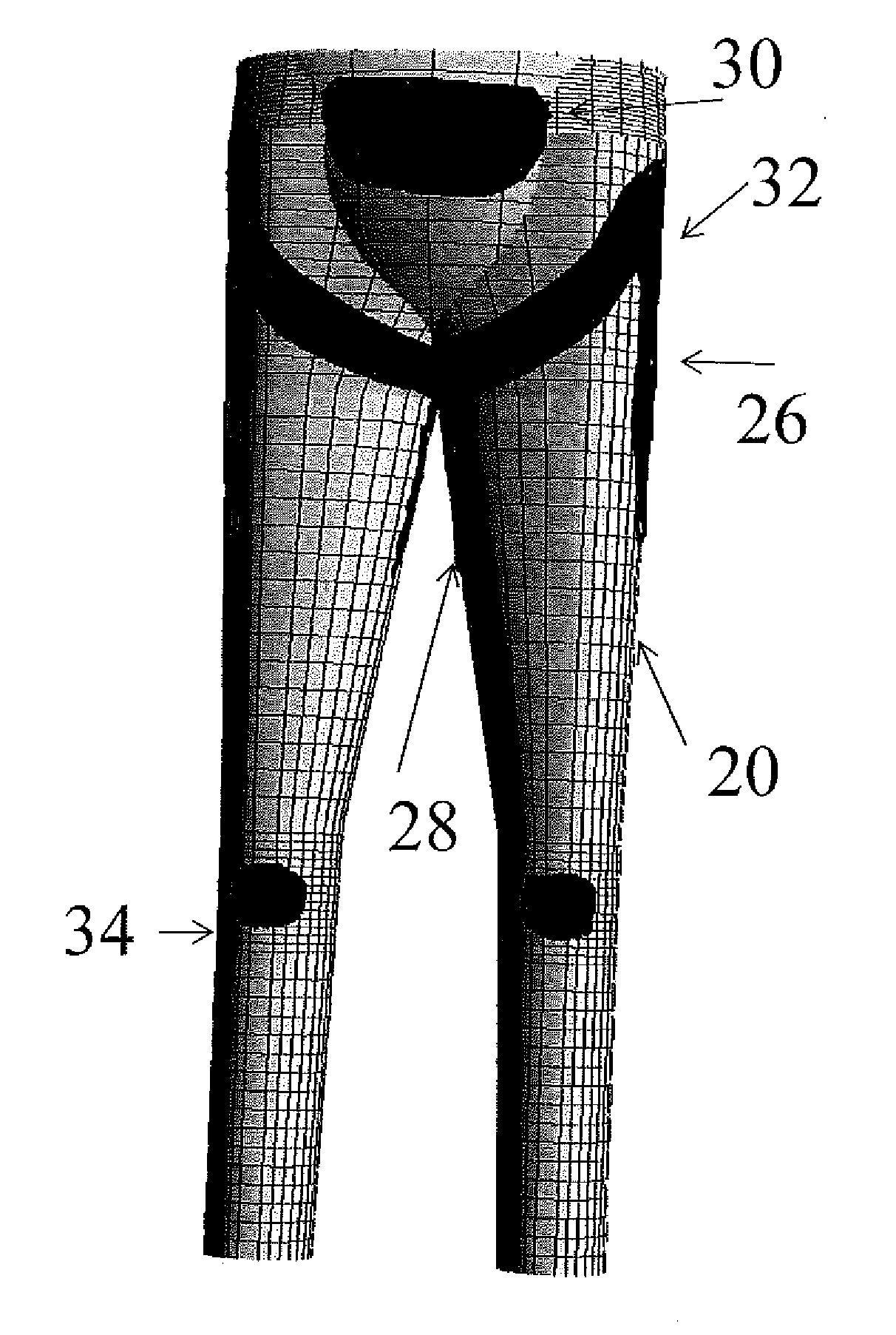

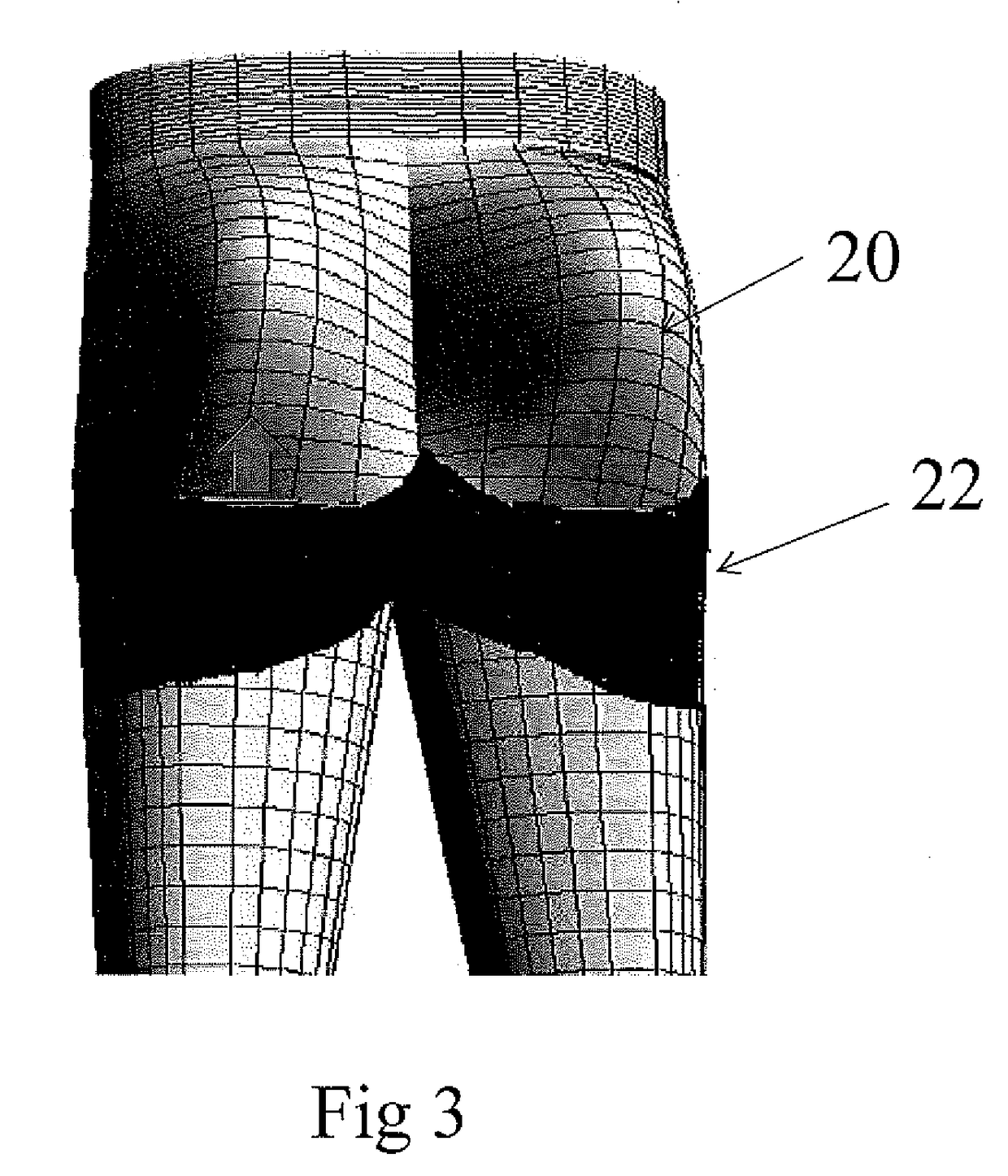

Shape enhancing garments with discontinuous elastic polymer composition

ActiveUS20170172219A1Easy to shapeGood lookingGarment special featuresTrousersEngineeringPolymer composition

A garment with shape enhancing function. The garment includes an elastic fabric and polymer composition to enhance shaping.

Owner:THE LYCRA CO LLC

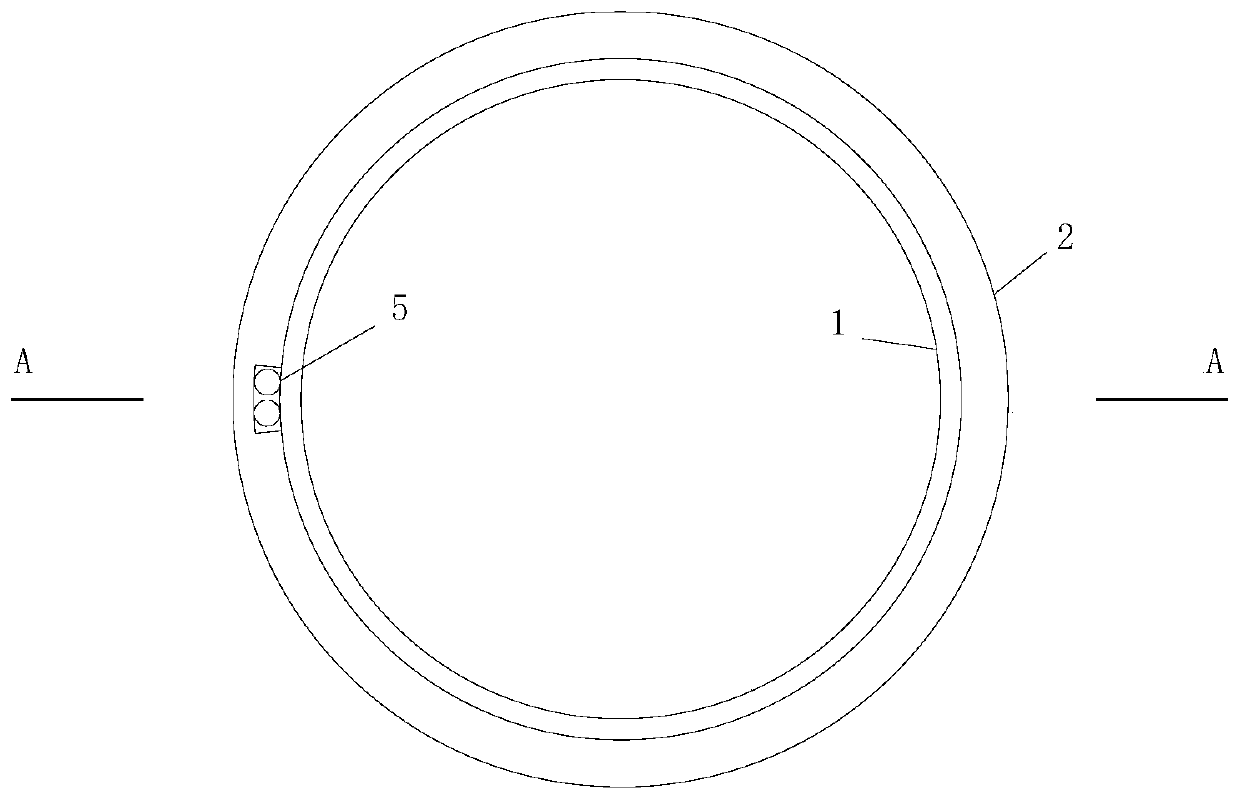

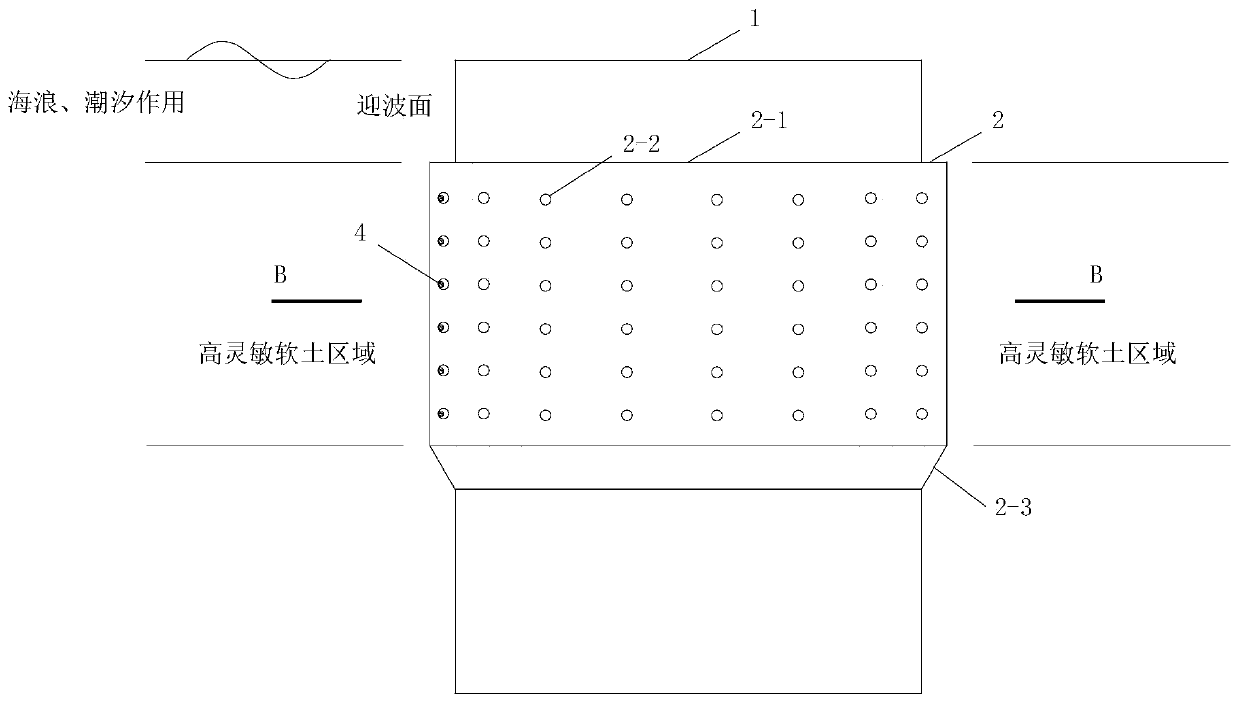

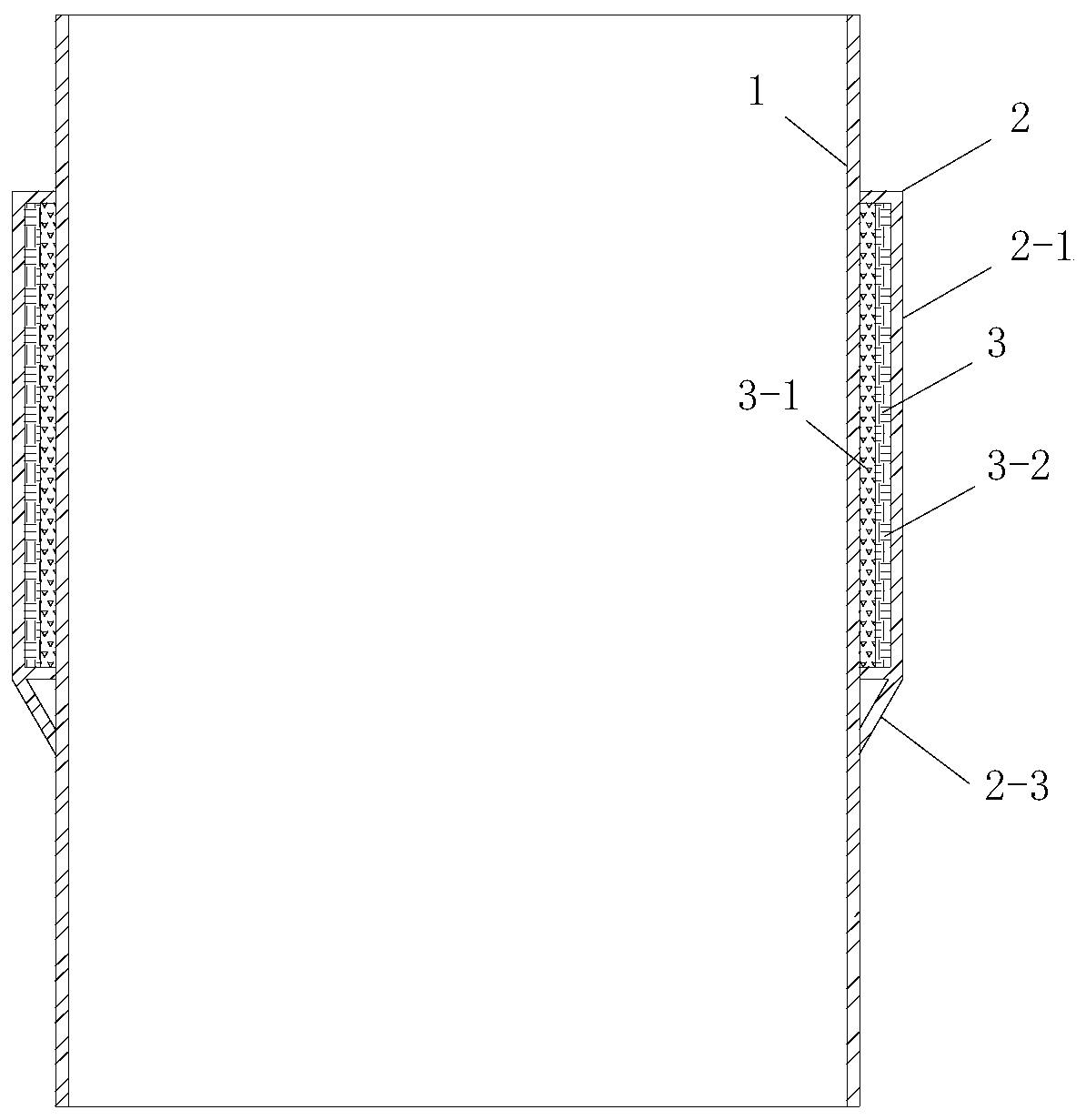

Anti-skid drill cast-in-place pile foundation in high-sensitivity soft soil area and construction method thereof

InactiveCN111042120AImprove installation efficiencyReduce the risk of liquefactionBulkheads/pilesSoil preservationRebarDrill hole

The invention discloses an anti-skid drill cast-in-place pile foundation in a high-sensitivity soft soil area and a construction method thereof. The anti-skid drill cast-in-place pile foundation comprises novel steel protecting cylinders, a steel protecting cylinder installing device and a drill cast-in-place pile main body. The drill cast-in-place pile main body comprises common steel protectingcylinders, a steel reinforcement cage and concrete. All the novel steel protecting cylinders and all the common steel protecting cylinders are sequentially connected in a sealed manner from bottom totop. The steel protecting cylinder installing device comprises a suction barrel and a magnetic installing ejection cap. According to the anti-skid drill cast-in-place pile foundation, the novel steelprotecting cylinders with automatic hole pressure adjusting systems are adopted, and thus during the operation stage of the anti-skid drill cast-in-place pile foundation in the high-sensitivity soft soil area, hole water pressure in a periphery soil body of the pile foundation can be adjusted automatically. The suction barrel technology is adopted for installing the steel protecting cylinders, itis ensured that in the construction process, the soil body on the periphery of an anti-skid drill cast-in-place pile is reduced as much as possible, and the liquefaction risk of the soil body on the periphery of the pile foundation during the construction period is effectively reduced. The construction method is safe, reliable, convenient and rapid, and has a wide project application prospect.

Owner:ZHEJIANG UNIV CITY COLLEGE

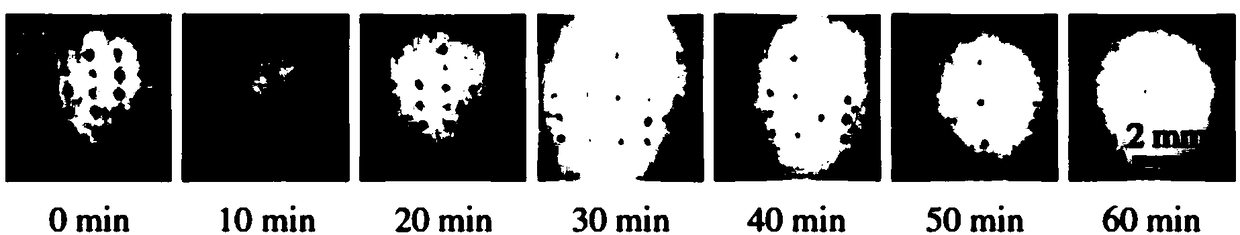

Porous ceramic material and method of producing the same

ActiveUS20090281633A1High compressive strengthSuitableBone implantCeramic shaping apparatusBone tissuePolyethylene glycol

Provision of a porous ceramic material which rapidly induces bone tissue formation and has practical strength.A porous ceramic material 11 having substantially unidirectionally oriented pores 12, a porosity of 40-90%, and an average open area of one pore of 0.05×10−3-50×10−3 mm2 both in a first sectional surface perpendicular to the pore 12 orientation direction and a second sectional surface parallel to the first sectional surface and 5 mm distant from the first sectional surface in the pore 12 Orientation direction. Using the material 11, when a cylindrical test piece (diameter 3 mm×height 5 mm, the pore12 array direction as a height direction) made of the material is dipped in polyethylene glycol up to 1 mm from one end thereof, polyethylene glycol permeates through the whole test piece preferably within 30 seconds.

Owner:KURARAY CO LTD +1

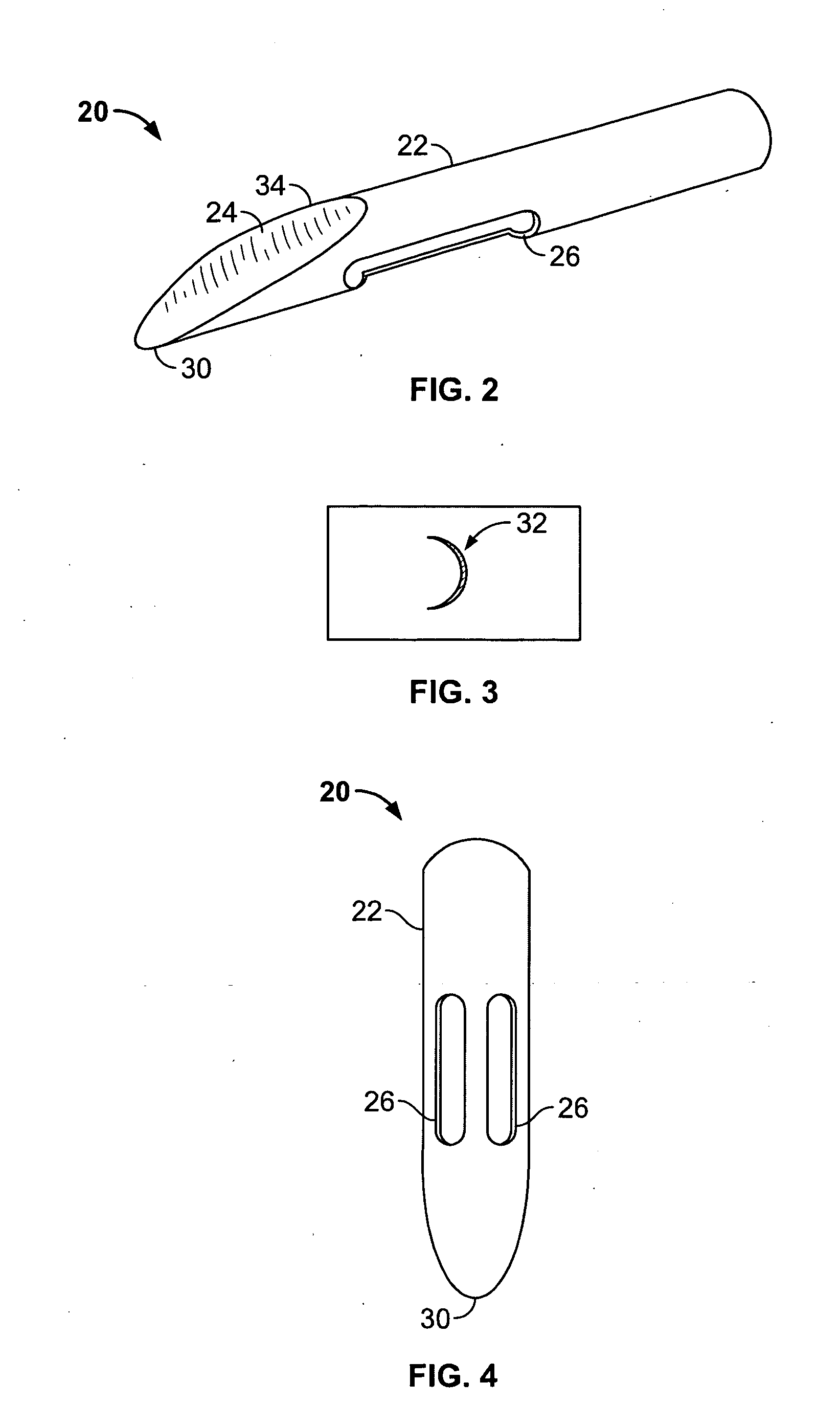

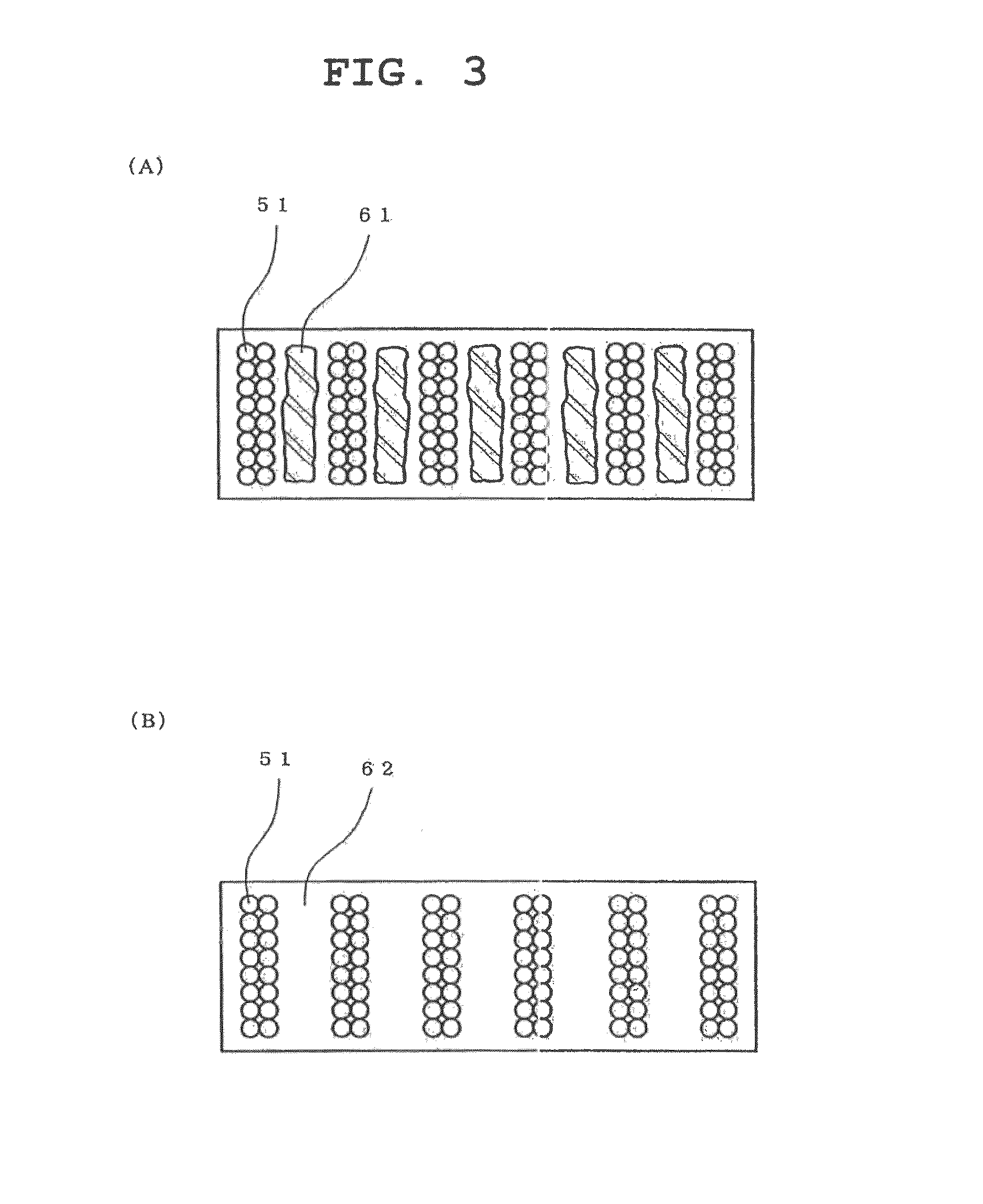

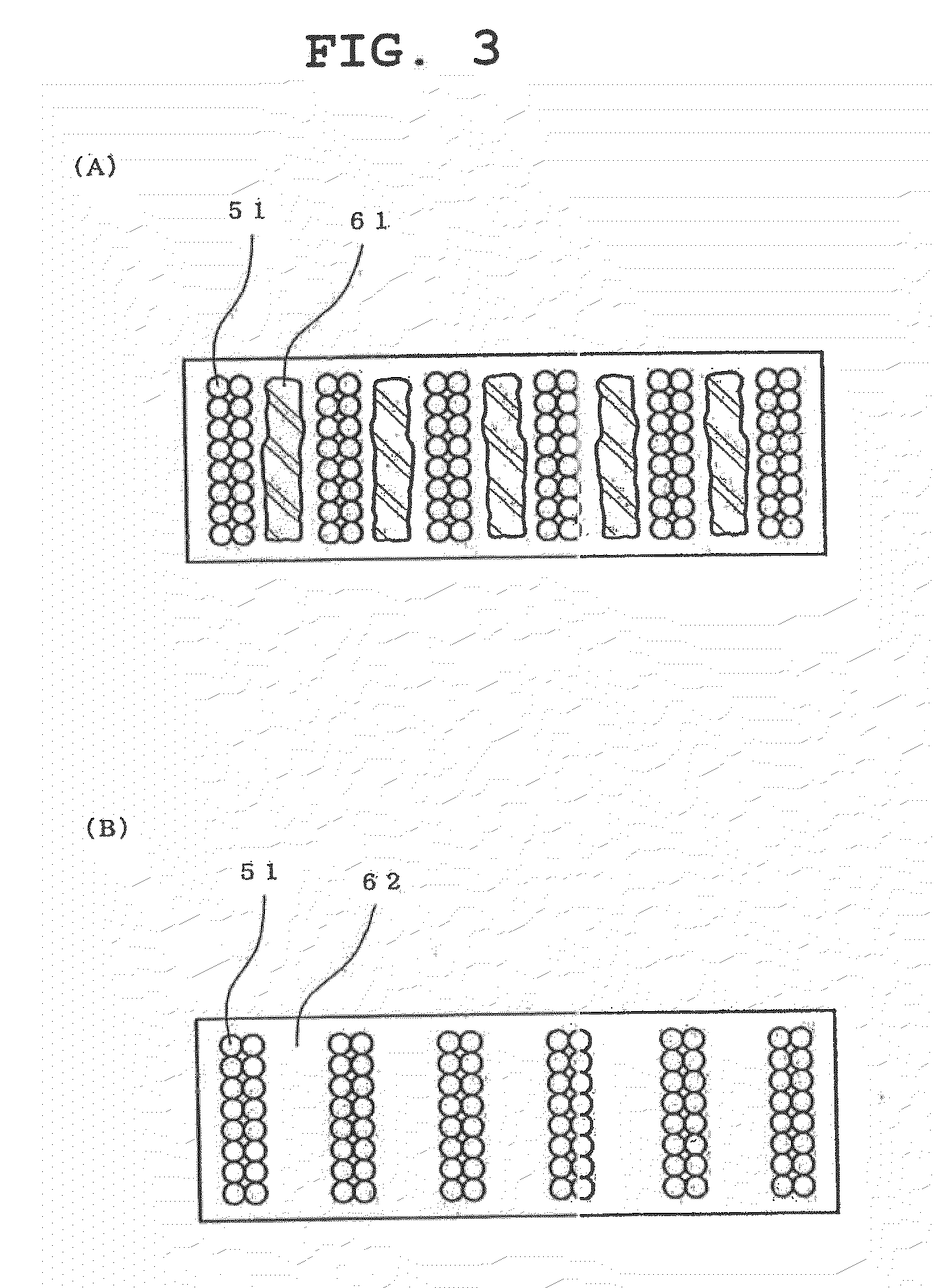

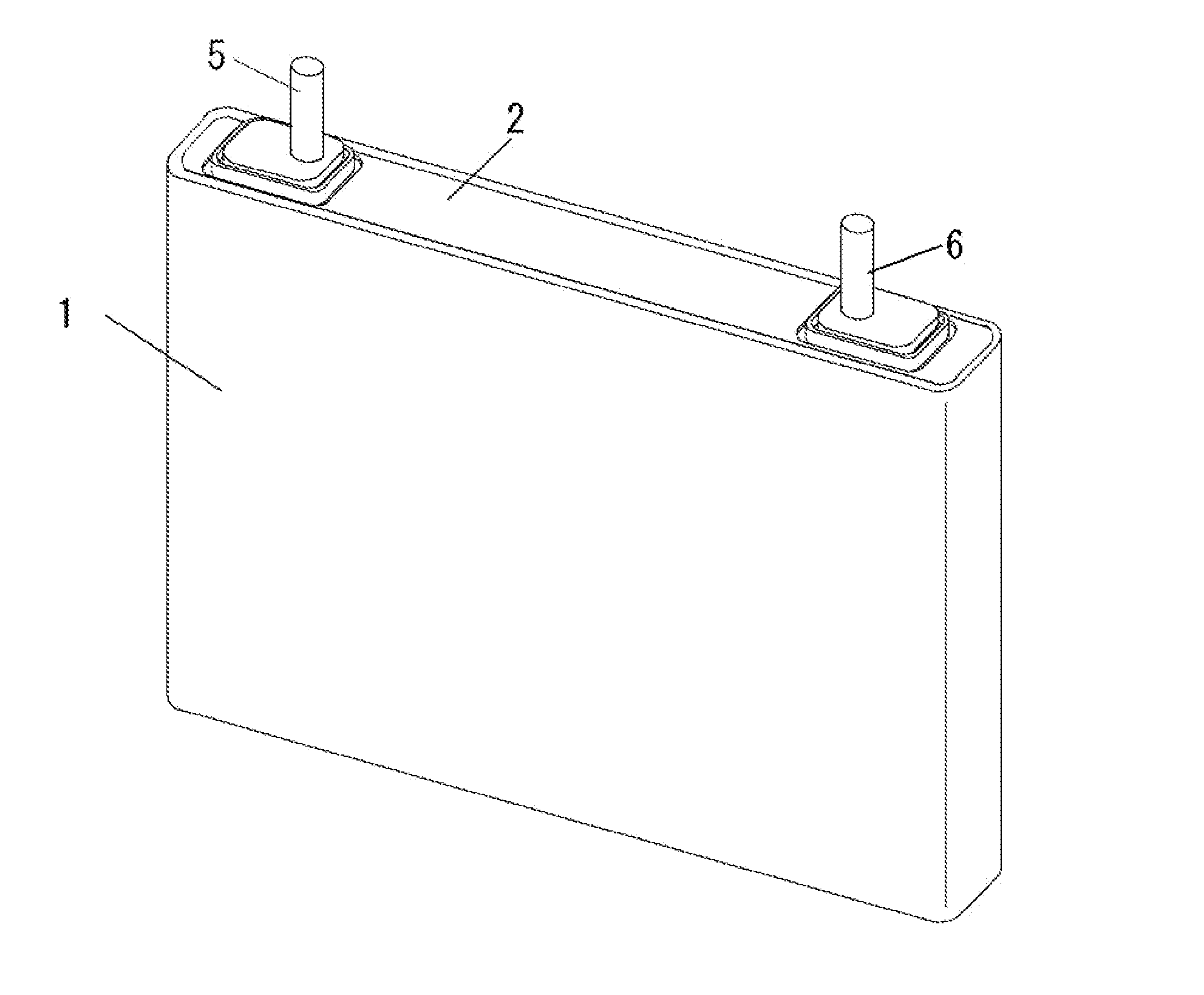

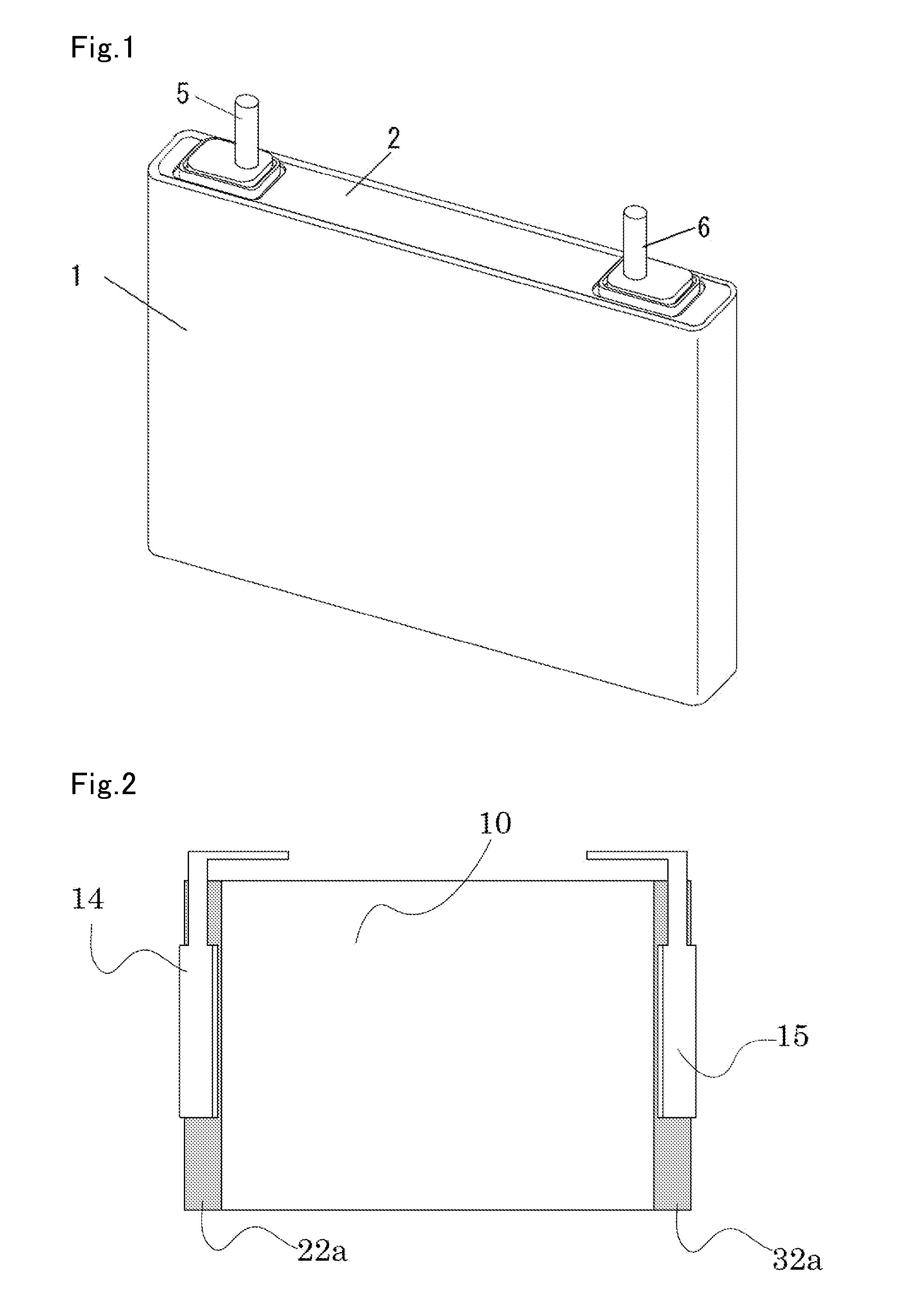

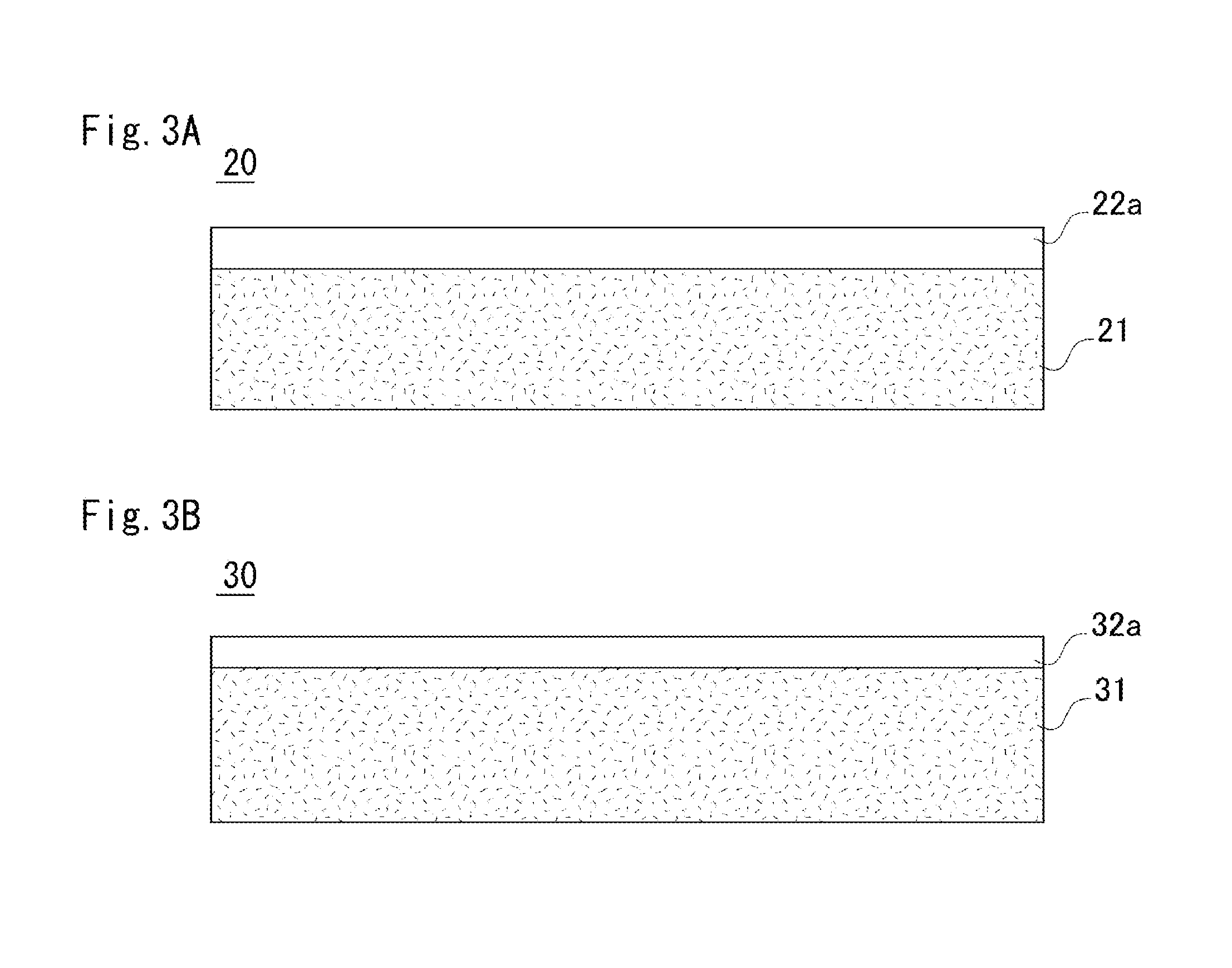

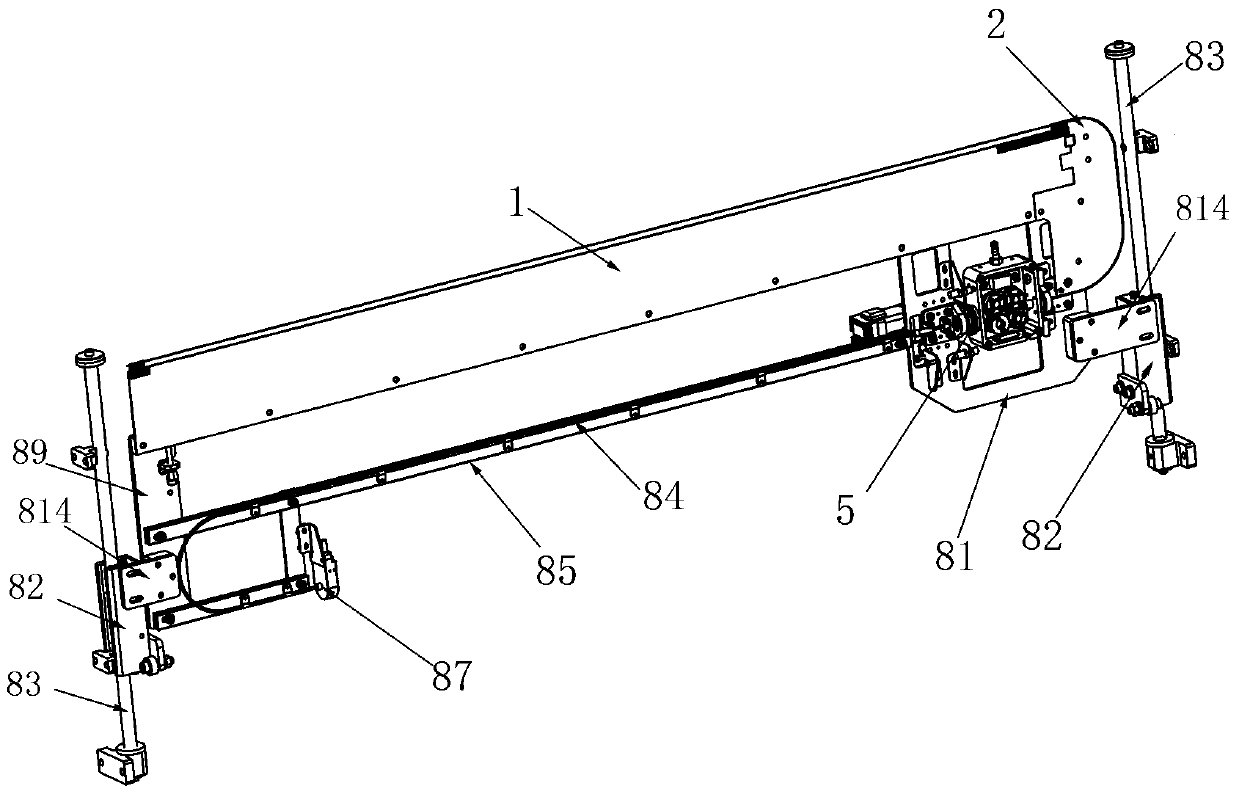

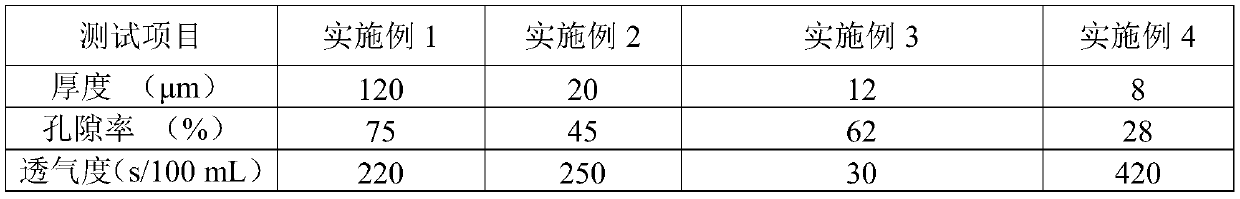

Non-aqueous electrolyte secondary cell

InactiveUS20140023915A1Good liquid permeabilityExcellent characteristicsCell seperators/membranes/diaphragms/spacersCell electrodesPorosityLithium compound

The present invention aims to productively provide a non-aqueous electrolyte secondary cell having high capacity. This object can be achieved by adopting the following configuration. A non-aqueous electrolyte secondary cell comprises a non-aqueous electrolyte and an electrode assembly having a positive electrode, a negative electrode and a separator; the positive electrode has a positive electrode core and a positive electrode active material layer; the negative electrode has a negative electrode core and a negative electrode active material layer; a protective layer is provided on the positive electrode active material layer and / or the negative electrode active material layer; the total thickness of the protective layers is 10 to 40% of that of the separator; a porosity of the protective layer is larger than that of any of the positive and negative electrode active material layer; and the non-aqueous electrolyte contains a non-aqueous solvent and two or more kinds of lithium compounds.

Owner:SANYO ELECTRIC CO LTD

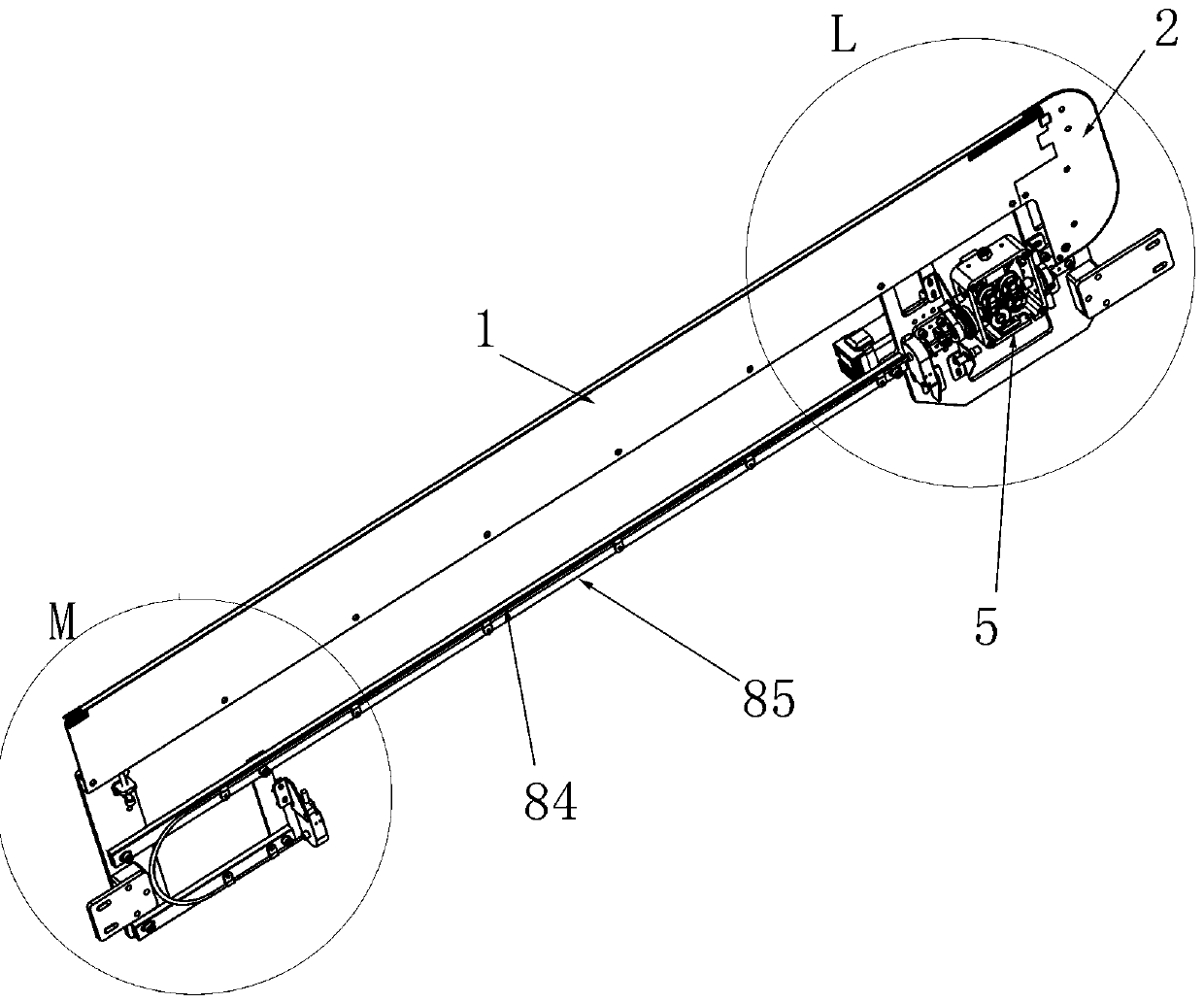

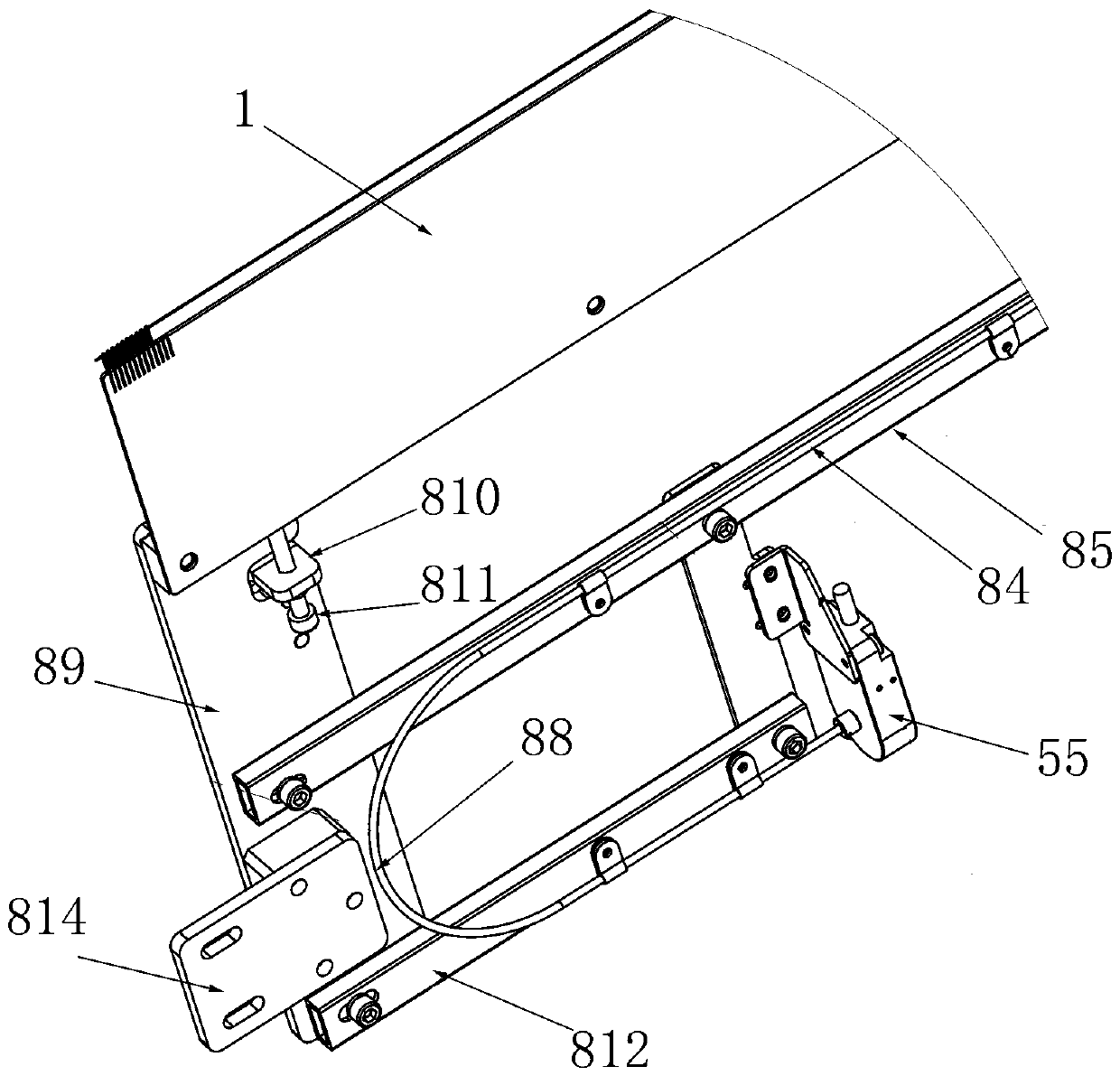

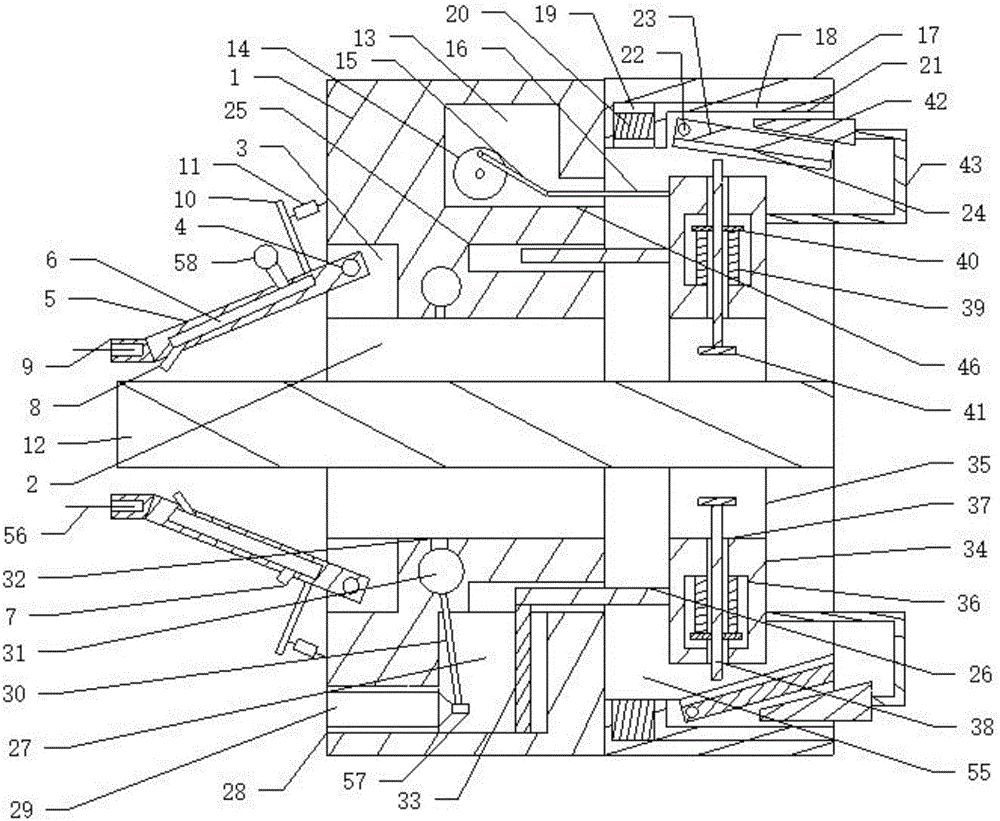

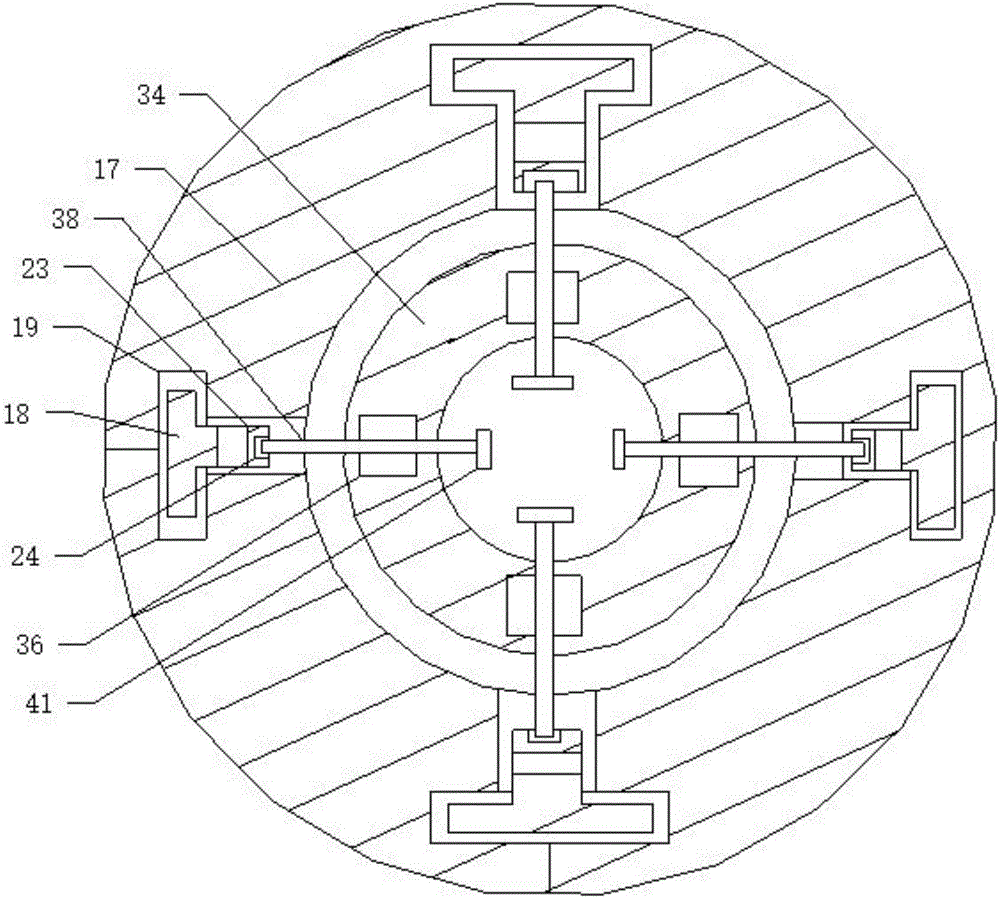

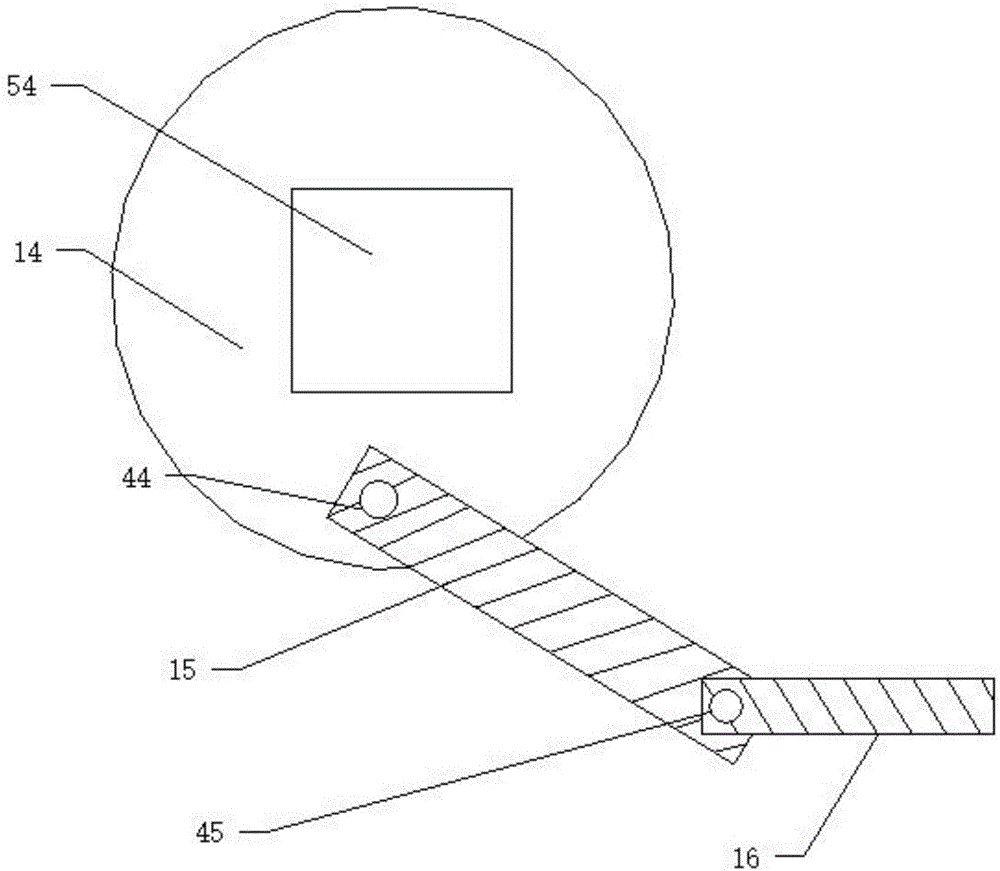

Threading plate bottoming device of flat knitting machine

PendingCN110846803ASimple structureReduce weaving cost and labor costWeft knittingYarnStructural engineering

The invention discloses a threading plate bottoming device of a flat knitting machine. The threading plate bottoming device of the flat knitting machine comprises a threading plate assembly, a steelwire and a steel wire conveying assembly, and further comprises a steel wire pipe, wherein the threading plate assembly is formed by clamping and fixing a threading plate and a wire guiding plate; thethreading plate is provided with a row of bottoming needles; a threading hole is formed in the head of each bottoming needle; steel wire grooves are formed in the edges of the wire guiding plate; thesteel wire conveying assembly comprises a wire feeding motor and a gear box, a wire feeding wheel and a wire pressing wheel which are movably matched with the wire feeding motor are arranged in the gear box, and two sides of the gear box are respectively provided with sleeves for the steel wires to pass through; sensors are separately arranged at two ends of the steel wire pipe; the steel wire slides along the steel wire pipe, the gear box and the steel wire grooves of the wire guiding plate, can outwards slide relative to the steel wire grooves, and penetrates through the threading holes ofthe bottoming needle. The structure is simple, a woven piece can be completely pulled down under the states of no bottoming fabric and no bottoming tissues, so that no waste yarn is directly taken outof any woven piece, and the weaving cost and the labor cost are greatly reduced.

Owner:NINGBO CIXING

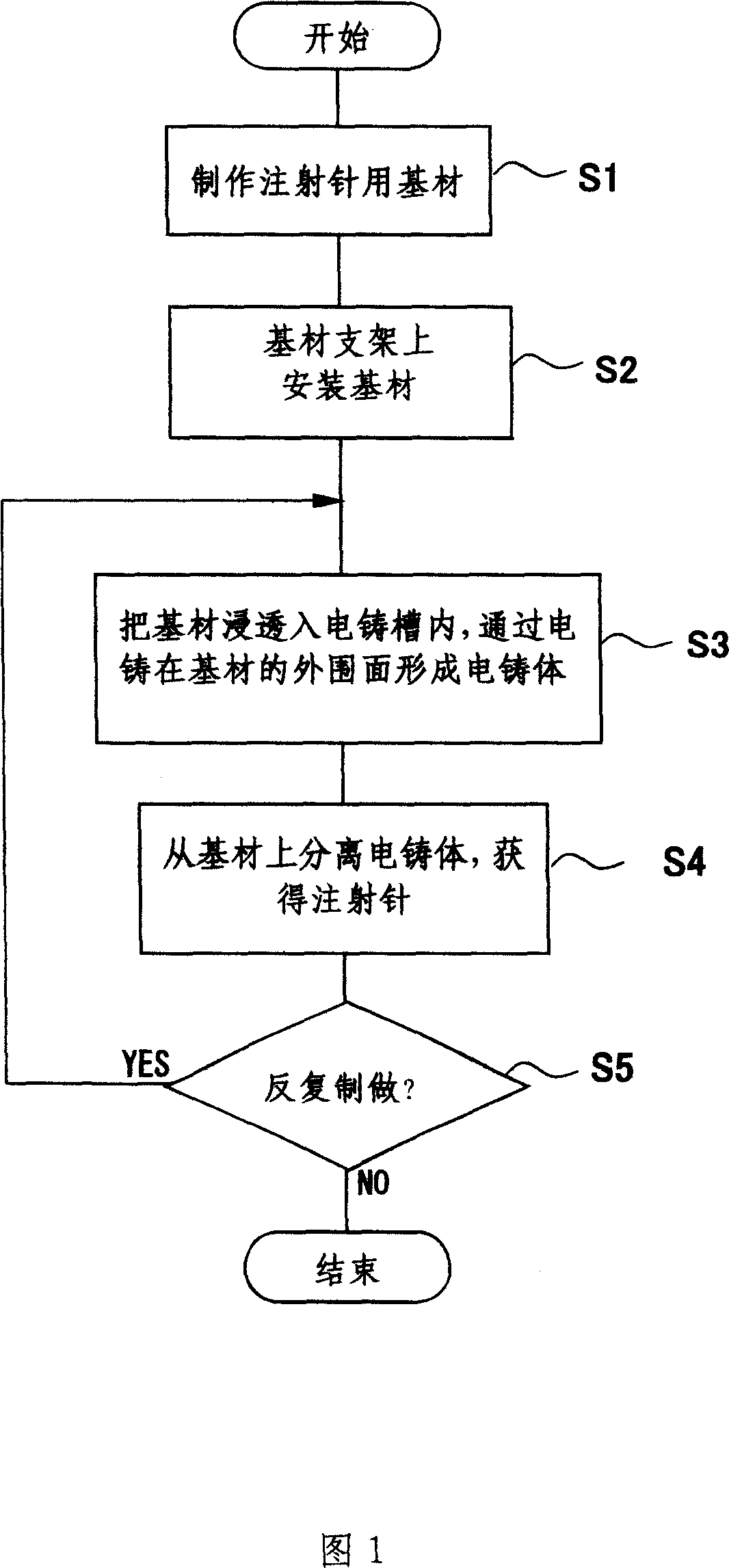

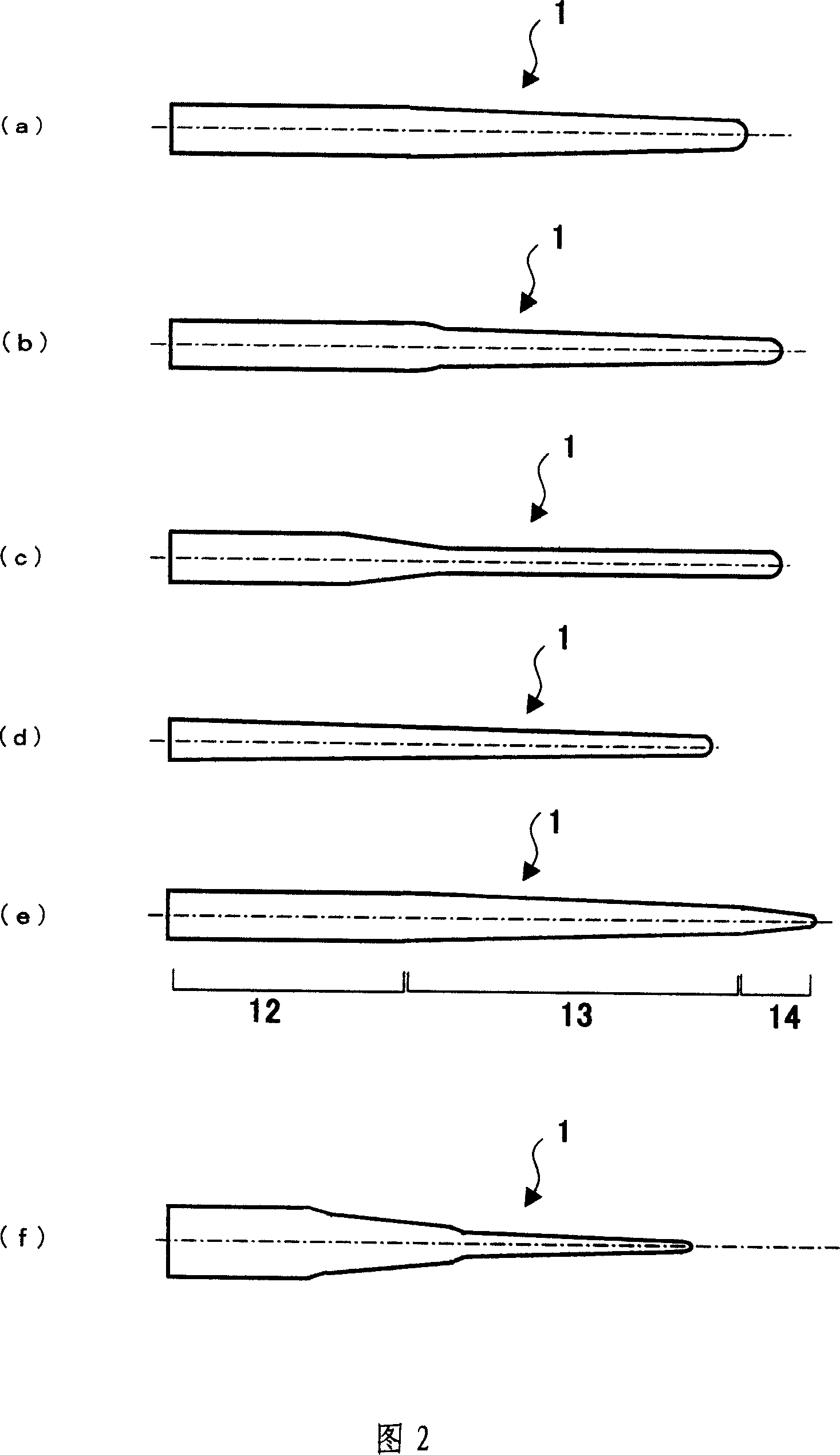

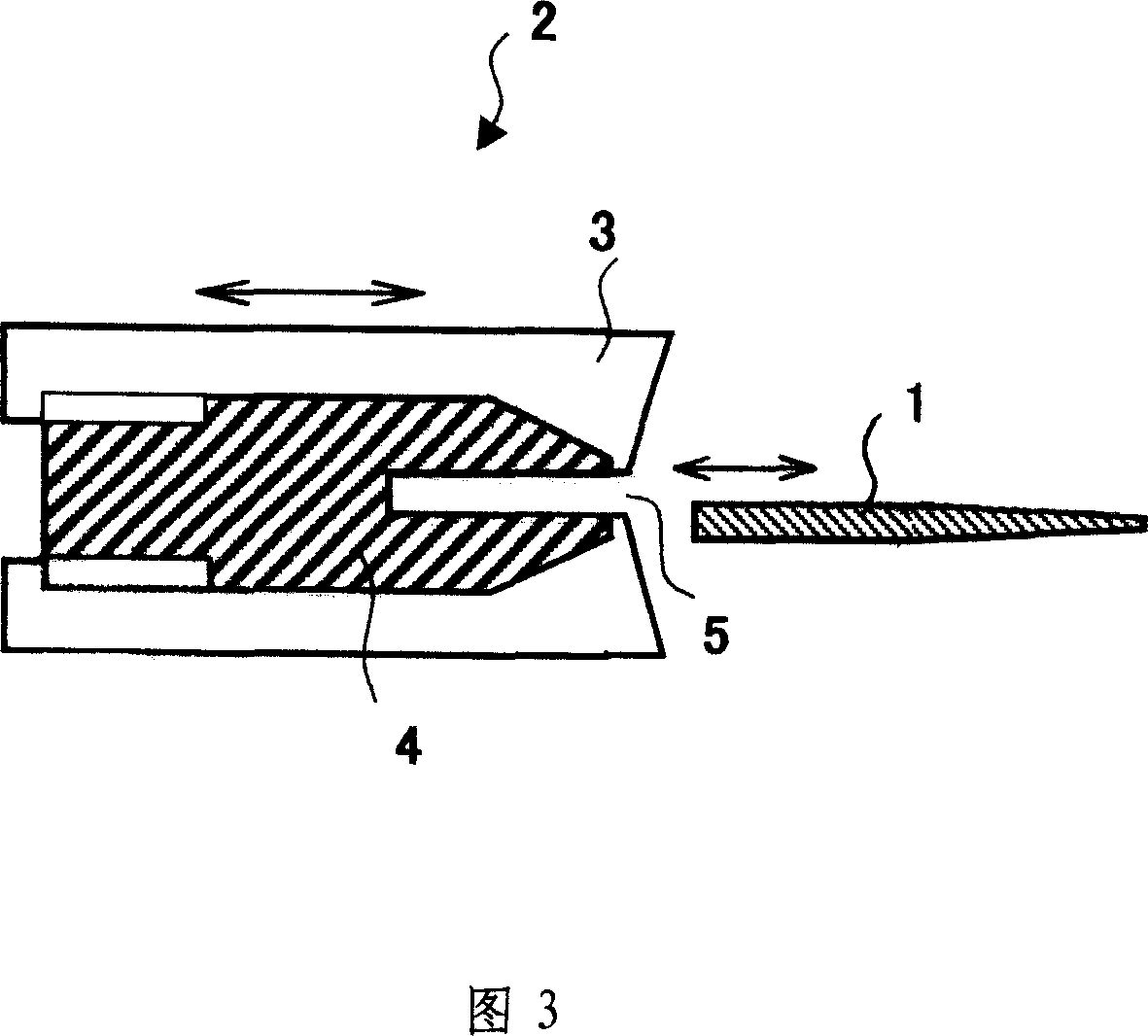

Method of manufacturing injection needle and injection needle

InactiveCN101045173ASpeed up the flowSimple manufacturing processMedical devicesInfusion needlesEngineeringMetal

The invention relates to the manufacture of injection needle, which is aimed to simply obtain an injection needle which dispenses with jointing treatment when a cylindrical shape with a small diameter is made, and enables the smooth flow of a liquid to be ensured without polishing treatment of an inner wall surface. Firstly, a master for the injection needle is made (S1); secondly, a master retaining holder is fitted with the master for the injection needle (S2); subsequently, an electroformed metal adheres to the master for the injection needle by electroforming treatment (S3); and finally, the master for the injection needle is pulled up from an electroforming tank along with the master retaining holder, so that an electroformed body as an injection needle body can be released from the master for the injection needle (S4). In the manufactured injection needle, an outside diameter of a leading end for a puncture is set on the order of 0.12 mm; and a tapered part, the outside and inside diameters of which are reduced toward the leading end, is arranged between a proximal end part and the distal end part for the puncture. The invention simplifies the manufacture of injection needle, and enables the smooth flow of a liquid in the injection needle, further, greatly reduces the pain in puncture.

Owner:日本插芯株式会社

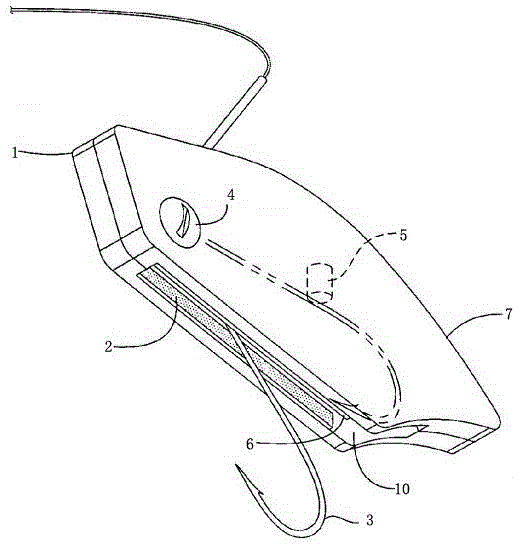

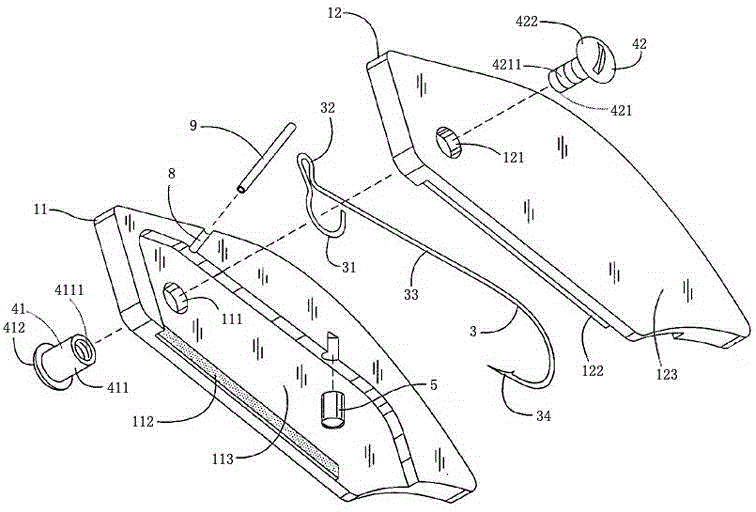

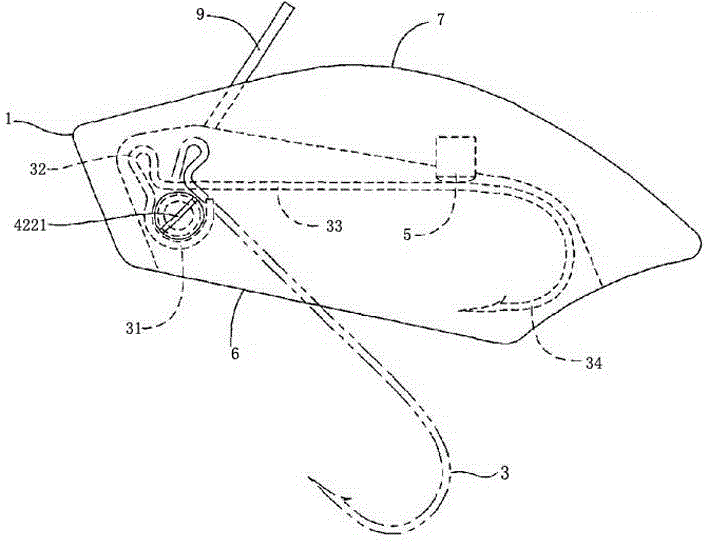

Bait

The invention belongs to the field of fishing equipment, and particularly relates to bait. The bait structurally comprises a simulated bait body and is characterized in that the bait body comprises an upper light portion and a lower heavy portion, a cavity is formed inside, an outlet facing the lower heavy portion is formed in one end of the cavity, a rotating shaft is arranged inside the cavity and is in rotating connection with the inner wall of the cavity, a fishhook is arranged on the rotating shaft, the fishhook is composed of a shaft ring, a fish line ring and a barb, the barb faces the outlet, a connecting rod is arranged between the barb and the fish line ring, the shaft ring is fixedly connected with the rotating shaft, a magnet is arranged on the inner wall of the cavity, the magnet is right opposite to the back of the barb, the barb is in magnetic connection with the magnet, a fish line channel is arranged on the upper light portion, an acute angle is formed between the fish line channel and the connecting rod, and the outlet is matched with the fishhook in size. According to the bait, the fishhook is hidden, the confusion degree is high, the fishhook is used in cooperation with a fish line so that the fish flesh puncture hit rate of the fishhook can be high, and the fish running probability is decreased.

Owner:ZHEJIANG OCEAN UNIV

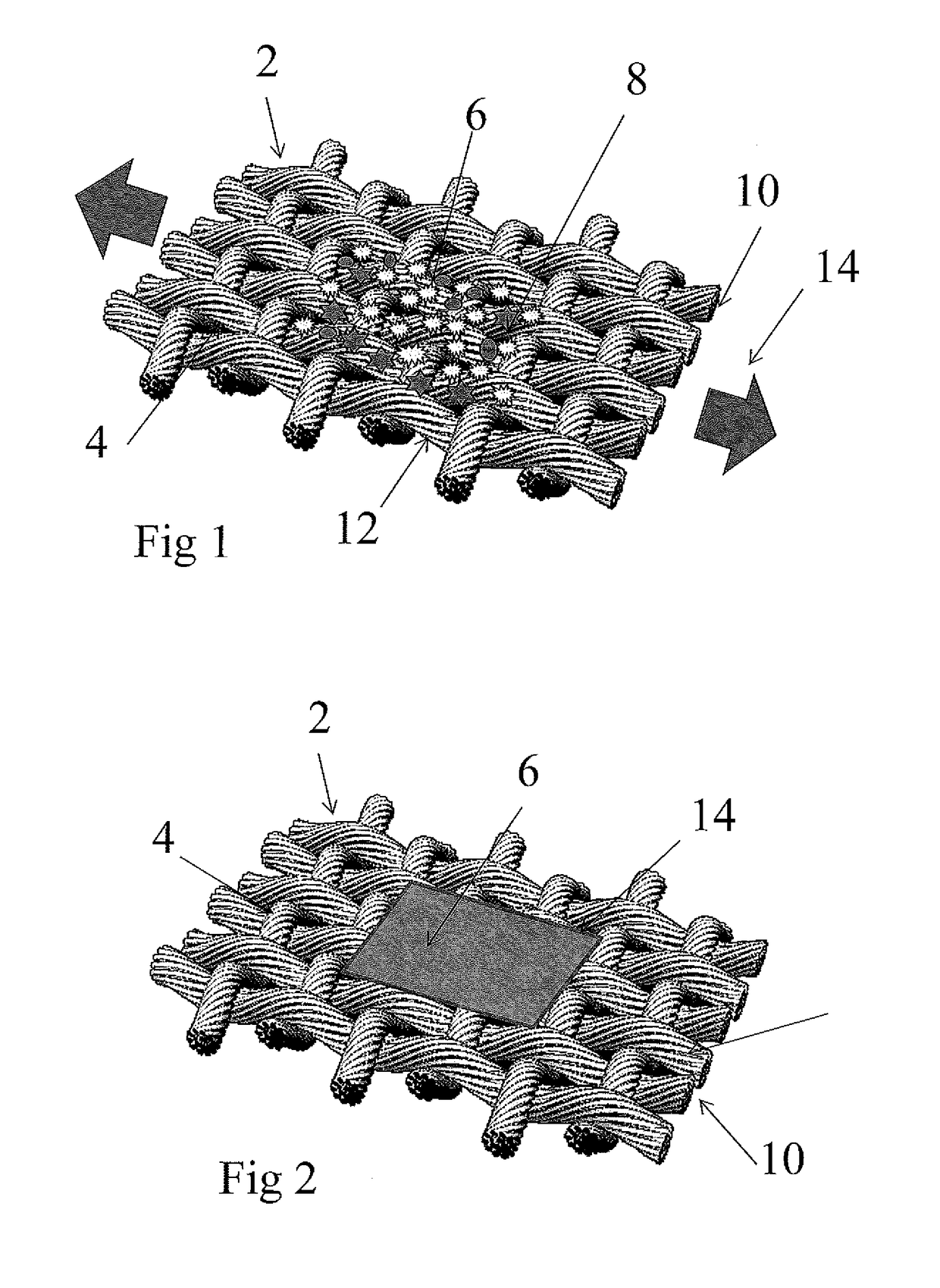

Bone induction regeneration membrane as well as preparation method and application thereof

ActiveCN111617320APlay a role in inducing osteogenesisSmooth penetrationInorganic material artificial filamentsConjugated cellulose/protein artificial filamentsFiberGlass fiber

The invention relates to a bone induction regeneration membrane as well as a preparation method and application thereof. The bone induction regeneration membrane comprises first fibers and second fibers, wherein the first fibers and the second fibers are interwoven to form a staggered structure; the first fibers are derived from a degradable high polymer material; the second fibers are derived from bioglass or a bioglass solution; and the bone induction regeneration membrane has a porous structure with the porosity being 30-90% and the average pore size being 0.1-50 microns. The bone inductionregeneration membrane at least has one of the following characteristics: (1) after the membrane is implanted, glass fiber filaments are in direct contact with a bone defect part, so that the bone induction regeneration membrane can directly play a role in inducing osteogenesis; (2) a nanofiber three-dimensional network structure can enable nutritional ingredients to smoothly permeate and new blood vessels to grow in, so that the formation of new blood supply of the defect part is promoted; and (3) the degradation rate is matched with defect repair, so that the long-time mechanical property can be maintained, and a secondary operation for taking out the membrane is not needed.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

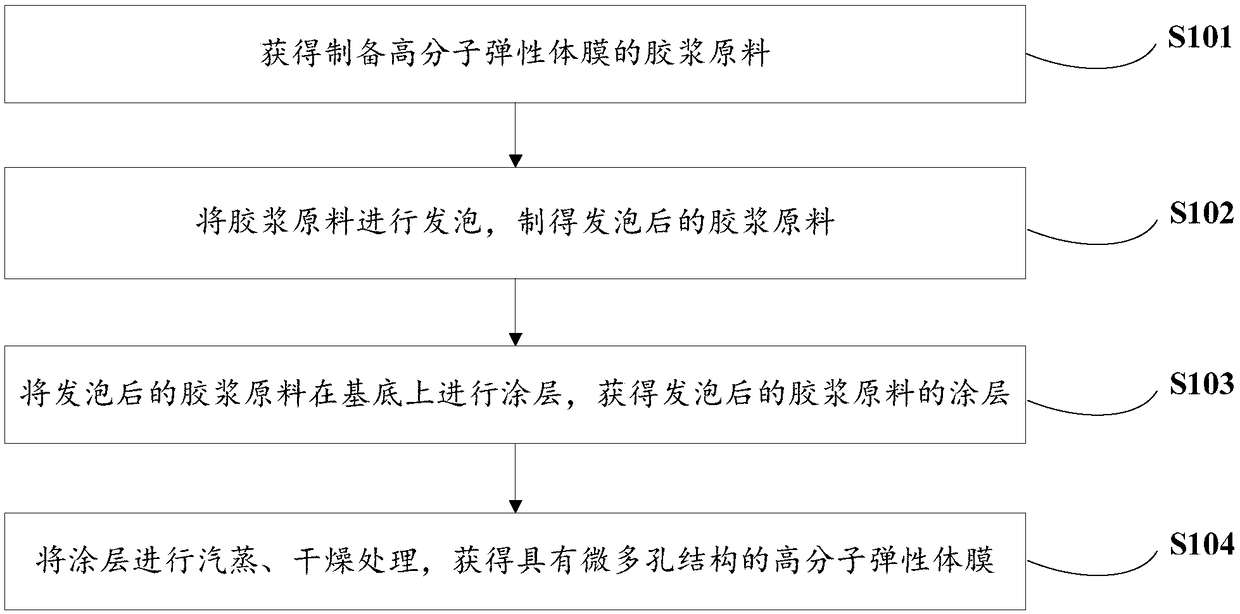

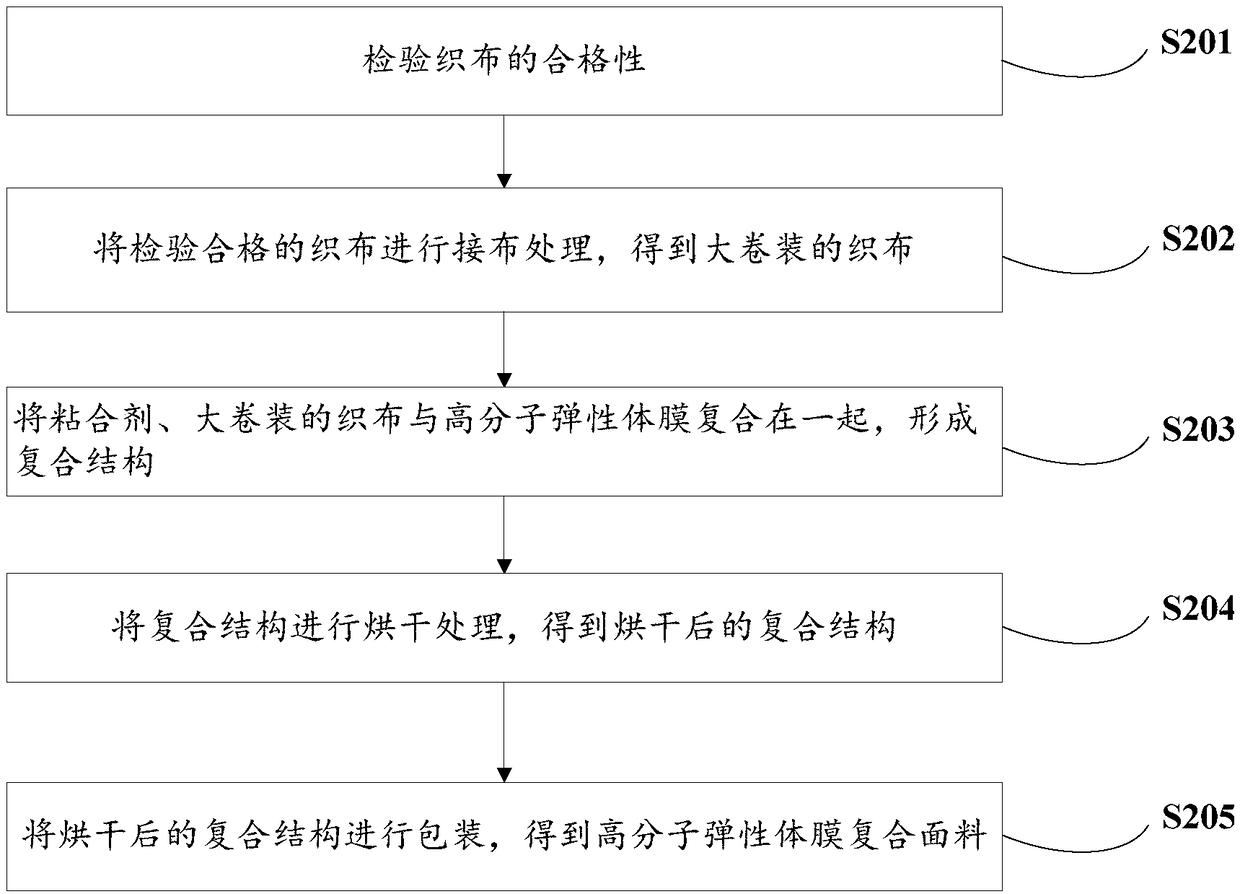

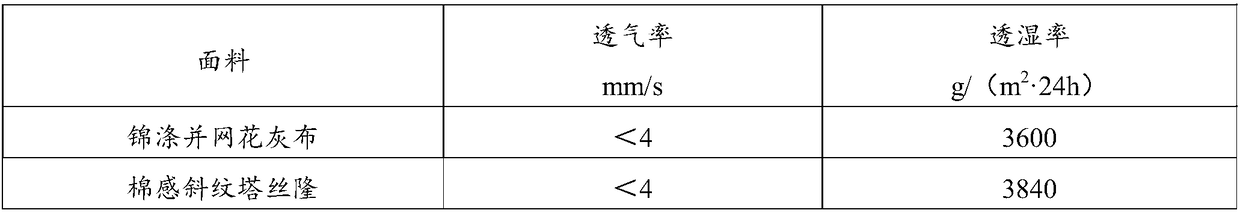

Macro-molecule elastomer membrane and fabric and preparation methods thereof

InactiveCN109504064AAchieve moisture permeabilitySmooth penetrationLamination ancillary operationsSynthetic resin layered productsElastomerWater vapor

The invention provides a preparation method of macro-molecule elastomer membrane. The method comprises the steps that a mucilage raw material for preparing the macro-molecule elastomer membrane is obtained; the mucilage raw material is subjected to foaming to prepare a foamed mucilage raw material; the foamed mucilage raw material is subjected to coating on a matrix to obtain a foamed mucilage rawmaterial coating; the coating is subjected to steaming and drying treatment to obtain the macro-molecule elastomer membrane of a microporous structure. The macro-molecule elastomer membrane which isprepared through the preparation method and a foaming technology has the microporous structure, the microporous structure is micropores of different scale and size, and vapour can smoothly penetrate through the micropores, so that the moisture-penetrability of the macro-molecule elastomer membrane is achieved.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

Methods for manufacturing fiber molded articles

InactiveUS20060082025A1Prevent materialAvoid flowWood working apparatusCeramic shaping apparatusFiberBoiling point

A method is taught for manufacturing a fiber molded article that comprises a fibrous material and a binder material. The method includes the steps of molding a base product under heat and pressure, the base product including the fibrous material and a binder material liquid that comprises the binder material fluidized by a fluidizer, and drying the base product under heat and pressure in order to evaporate the fluidizer contained in the base product before the base product is molded. The drying step is performed at a temperature between the boiling point of the fluidizer minus 20° C. and the boiling point of the fluidizer plus 20° C. and below the melting point of the binder material.

Owner:TOYOTA BOSHOKU KK

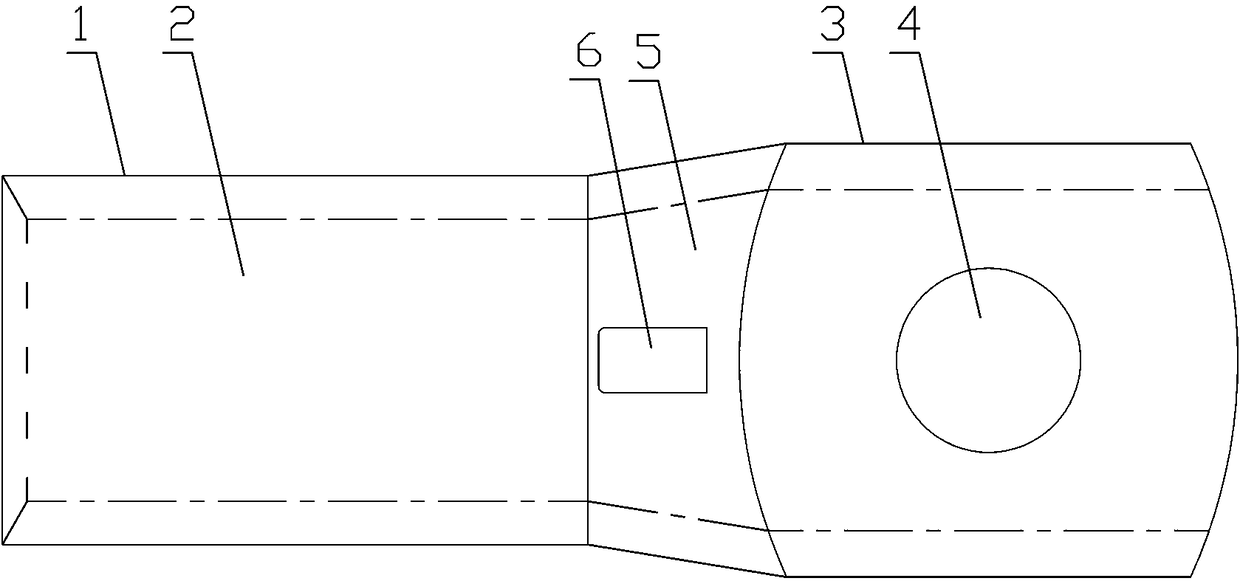

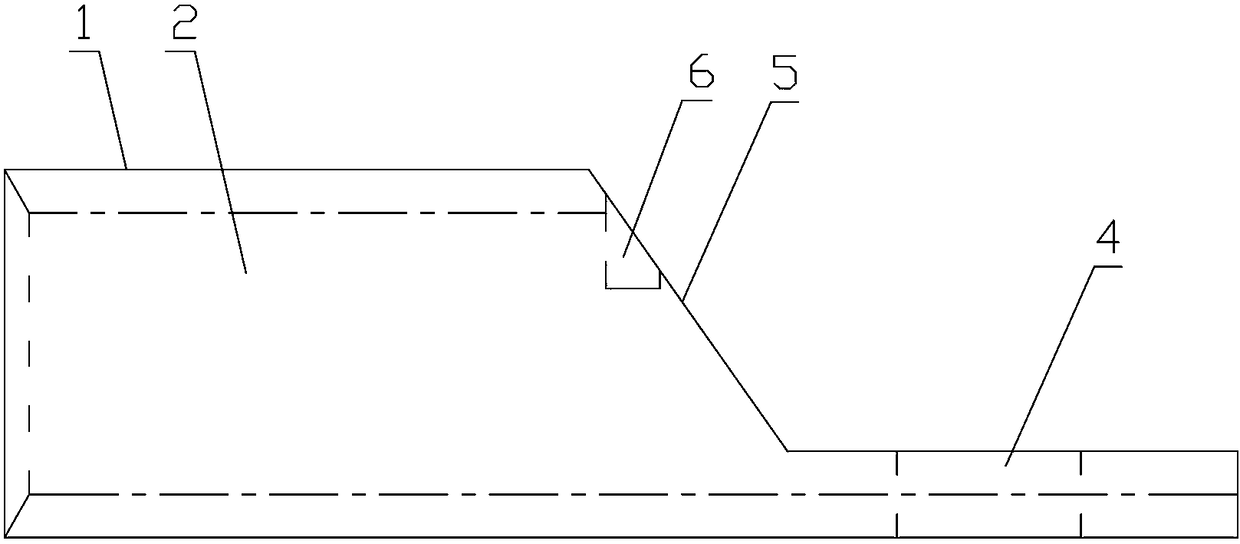

Narrow head terminal, production method of the narrow head terminal and special expanding device

ActiveCN108288770ASmooth penetrationSolve the space-saving puzzleContact member manufacturingConnections effected by permanent deformationEngineeringSquare meter

The present invention discloses a narrow head terminal, a production method of the narrow head terminal and a special expanding device. The narrow head terminal comprises: a wire-pressing part, wherein the wire-pressing part is cylindrical, and the middle of the wire-pressing part is provided with an inner cavity used for inserting wire(s) or cable(s); and a connecting part, wherein the connectingpart is flat, the parts between both sides of the two end faces of the connecting part are continuous, and the middle of the connecting part is provided with a bolt hole. The narrow head terminal ischaracterized in that: an inclined plane with a transition part forms between the wire-pressing part and the connecting part, and the inclined plane is provided with a watching opening connected withthe inner cavity of the wire-pressing part, and the narrow head terminal is made of a copper tube. The narrow head terminal is produced by adopting the method of expanding both ends of the copper tubeingeniously. If a copper tube wire-connecting terminal suitable for the wire(s) or the cable(s) with 70 square meters is produced, the terminal can ensure smooth inserting of the wire(s) or the cable(s) with 70 square meters (d=13 mm), the requirement(s) of pressing connection are satisfied (D= 17 mm), and the width of the connecting part w is less than 24.4 mm (20 mm).

Owner:乐清市国赛科技发展有限公司

Weaving method of hole interconnected double-layer warp knitted fabric

The invention discloses a weaving method of hole interconnected double-layer warp knitted fabric. The weaving method includes the following steps that (1), yarn and weave are matched, and regular holes and vertical stripes are formed on the front face of fabric; (2), jacquard knitting weave is selectively woven into loops sequentially on the front face and the rear face of the fabric, and the front face and the rear face of the fabric are connected; (3), when the holes and the vertical stripes are formed on the fabric, the yarn feeding amount in the knitting process is reduced, the region without jacquard knitting connection protrudes during shaping in the following process so that holes can be formed, and then shoe laces or decorative belts can smoothly penetrate into the holes; (4), yarnwith different degrees of contractility is used for the front face and the rear face of the fabric, and a protruding hollow spacer yarn effect can be formed on the front face as the degrees of contractility of the two faces are different. By the adoption of the weaving method, the obtained product is novel in appearance and breathable, when the product is applied to locals of shoes, the shoe laces or the decorative belts can conveniently penetrate into the holes, weakening of the performance of the fabric caused by post-processing trepanning is omitted, and the production efficiency is improved. Or the product is applied to clothing tools such as tippets and scarfs.

Owner:东莞百宏实业有限公司

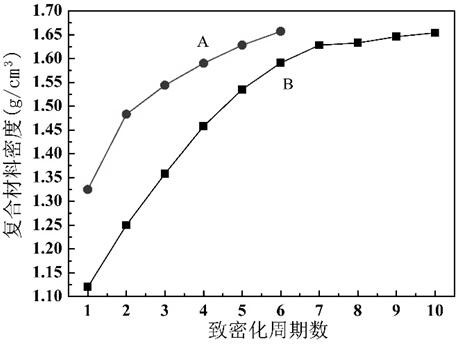

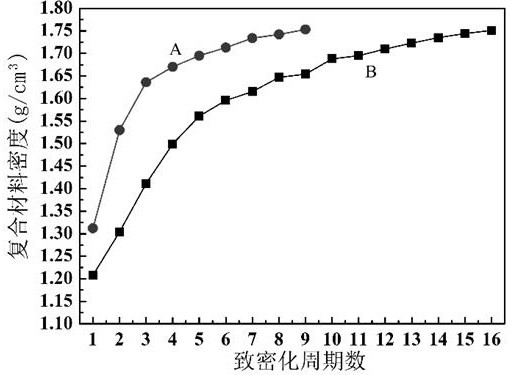

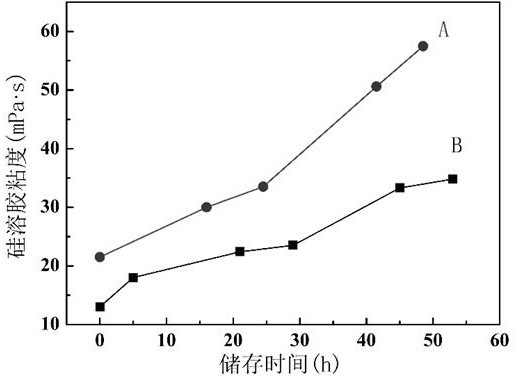

Quartz fiber reinforced quartz-based composite material and manufacturing method thereof

The invention discloses a quartz fiber reinforced quartz-based composite material and a preparation method thereof. Commercially available acidic silica sol is concentrated by adopting a reduced pressure rotary evaporation mode to obtain concentrated silica sol with the concentration of 30-47%, and the concentrated silica sol is divided into high-concentration silica sol and medium-concentration silica sol according to different concentration ranges; and a combined impregnation scheme in which silica sol with different concentrations is adopted in different densification periods is designed. Compared with a normal-pressure heating concentration method and a reduced-pressure rotary evaporation method, the concentration efficiency is high, the obtained concentrated silica sol is good in stability, the size of contained micelles is small, and full impregnation of a fiber prefabricated part is facilitated; and the densification efficiency is improved through the adopted combined impregnation scheme, and therefore efficient preparation of the SiO2f / SiO2 composite material is achieved.

Owner:NINGBO SHUXIANG NEW MATERIAL

Automatic threading apparatus for electric cabinet cable protective sleeve

ActiveCN106486929AReduce frictionStrong penetrating powerApparatus for laying cablesMechanical engineeringEngineering

The invention discloses an automatic threading apparatus for an electric cabinet cable protective sleeve. A first wire hole corresponding to a cable is formed in a first machine body; rotary first supporting shafts are arranged on the first machine body; the first supporting shafts are connected with chucks respectively; the protective sleeve is correspondingly clamped tightly by a ring of chucks; the first machine body is connected with a second machine body; a third machine body which slides on the first machine body is included in a machine body inner ring; a ring of fifth supporting shafts which slide in the third machine body are included in the third machine body; a jacking block corresponding to the cable is arranged on each fifth supporting shaft separately, so that the jacking blocks can be tightly pressed on the cables through the fifth supporting shafts; and therefore, the cable can be further inserted in the protective sleeve in the continuous sliding process of the third machine body, so as to avoid the problem of low efficiency in manual threading, thereby further improving the working efficiency.

Owner:重庆吉能电气(集团)有限公司

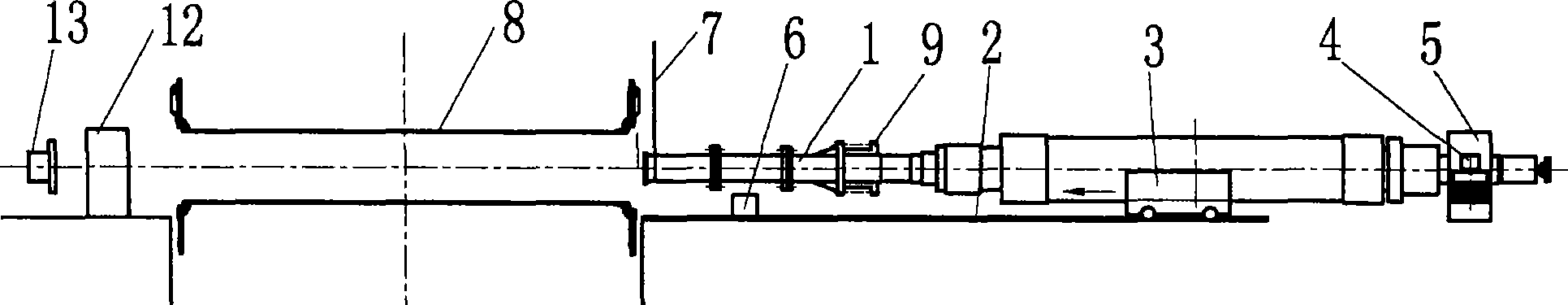

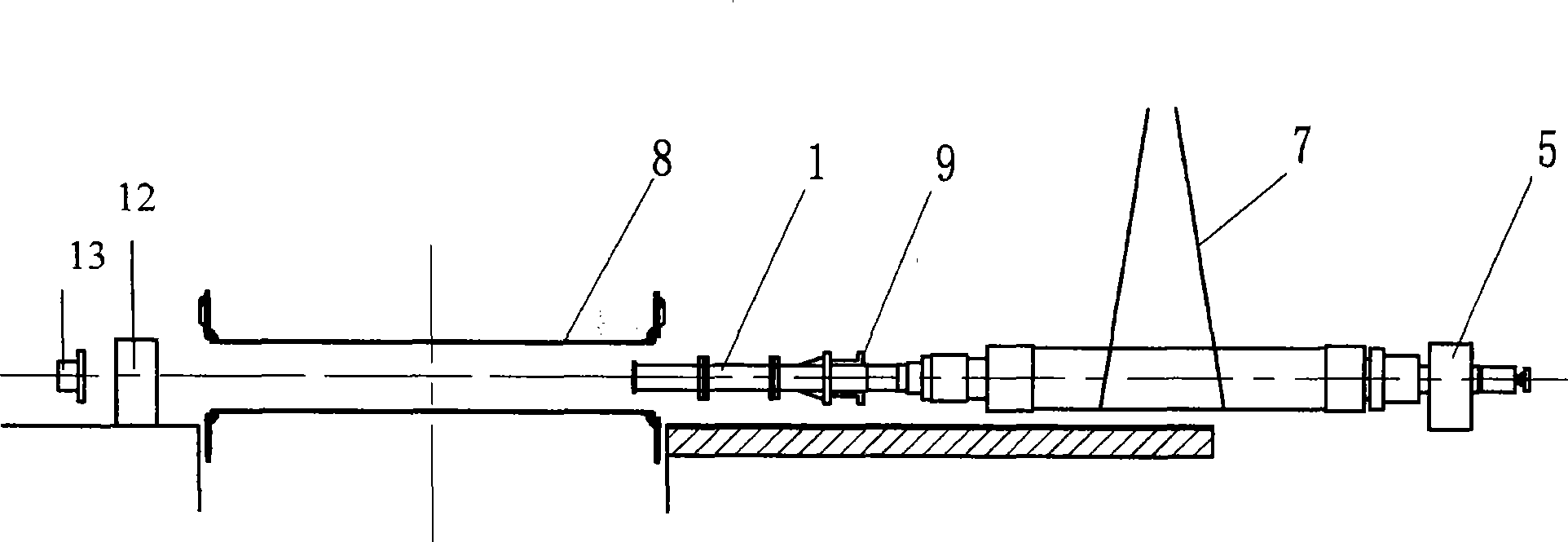

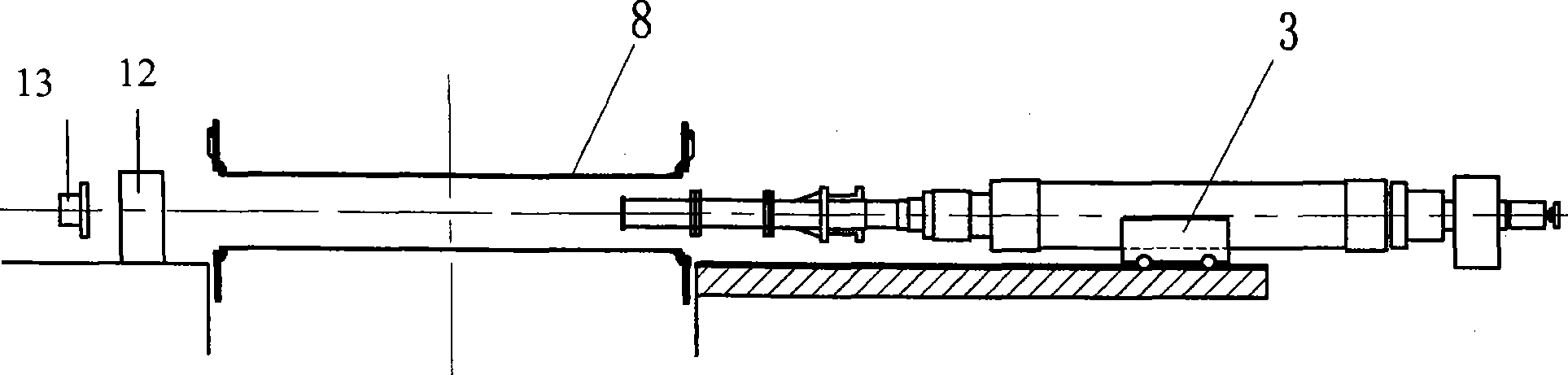

Method for little air-gap generator motor assembling

ActiveCN101453146APracticalReduce labor intensityManufacturing dynamo-electric machinesSafety coefficientElectric generator

The invention relates to a method for mounting a generator rotor with small air gap. The method comprises the following specific steps: a guide rail is fixed and is provided with a trolley; the guide rail is provided with a sleeve in the extending direction; a bearing seat at the excitation end is hung on the rotor; a generator coupler is arranged on the rotor; a connecting shaft is arranged on the generator coupler; a lifting rope of a crane lifts the rotor to the upper part of the guide rail; the rotor is placed on the trolley, and the trolley drags the rotor to pass through the sleeve; the connecting shaft extends out from the steam end of the sleeve and hangs the connecting shaft; the bearing seat at the excitation end is removed; the trolley retreats from a bearing shift of the rotor; the rotor is dragged by a bracket; the trolley drags the rotor to move forward; the rear section of the connecting shaft is filled up at the steam end through a pad block, and the front section of the connecting shaft is detached; according to the method, three sections of the connecting shaft are detached by sections; the trolley and the guide rail are detached, and the bearing seat at the excitation end is hung on the rotor; and the rotor is hung to the proper position. The method has the advantages that the method has strong practicability, relieves labor intensity, strengthens safety coefficient, improves working efficiency, provides reliable foundation for solving similar difficult problems and has popularization value.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Material for forming mineral substance in dentinal tubule by use of delayed reaction and application of material

ActiveCN106974834ASmooth penetrationPromote formationImpression capsMedical preparationsN-Butyl AlcoholSodium hydroxide

The invention discloses a material for forming mineral substance in a dentinal tubule by use of delayed reaction and application thereof, and belongs to the technical field of dentistry repairing materials. The material is characterized by comprising a reagent A, wherein the reagent A is EDTA-2Na, calcium chloride and sodium fluoride aqueous solution, the pH value is regulated by the sodium hydroxide and the hydrochloric acid; a reagent B is the mixed solution of potassium oxalate aqueous solution and n-butyl alcohol; the reagent A and the reagent B are mixed, continuously and quickly stirred to obtain a reagent C; the reagent C is immediately painted on the dental face for exposing the dentinal tubule, so that the reagent C can smoothly enter the dentinal tubule or a deep layer; the delayed reaction is started, the insoluble calcium oxalate and like mineral substances are gradually generated in the tubule of the dentinal tubule so as to block the dentinal tubule.

Owner:BEIJING STOMATOLOGY HOSPITAL CAPITAL MEDICAL UNIV

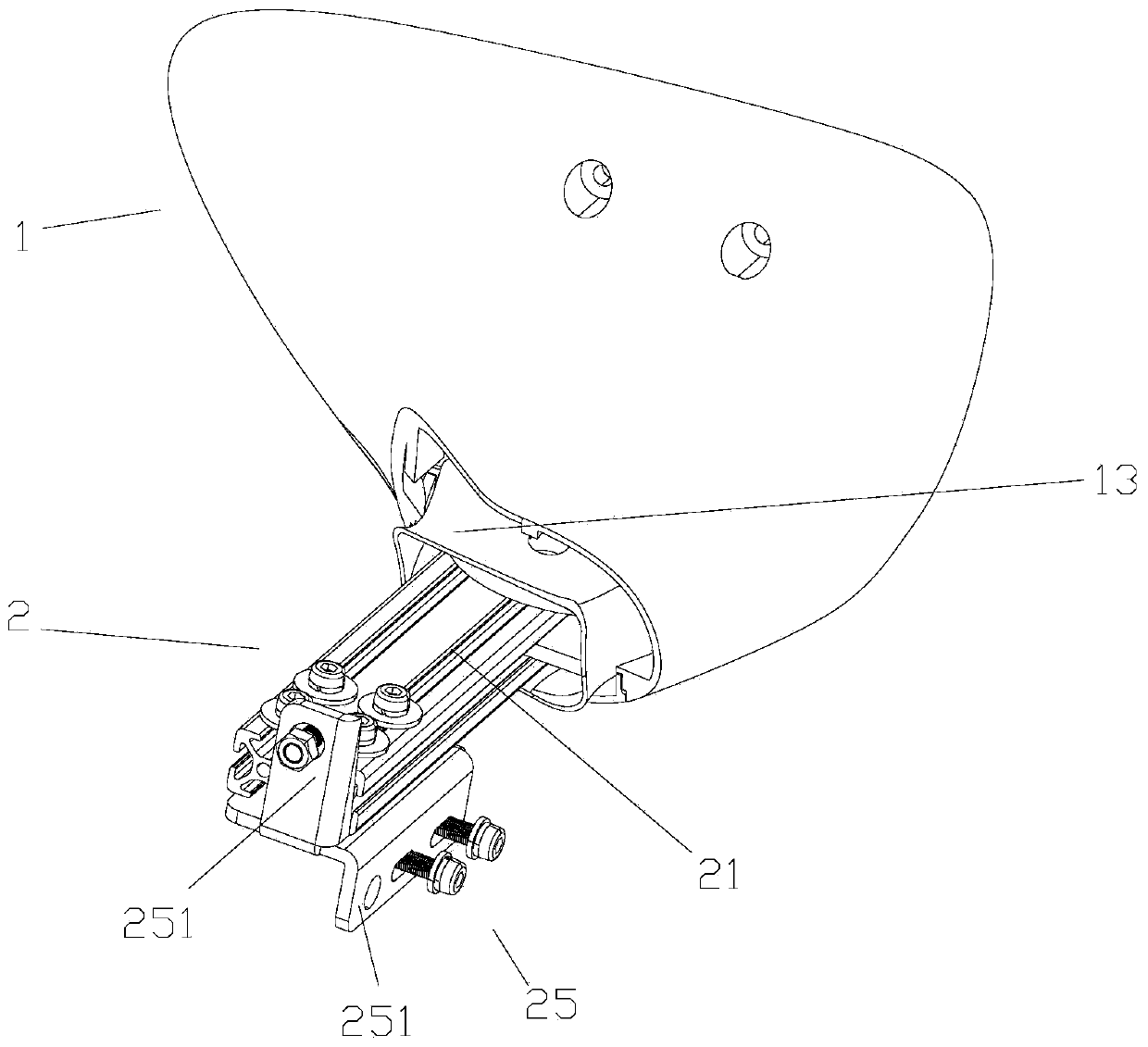

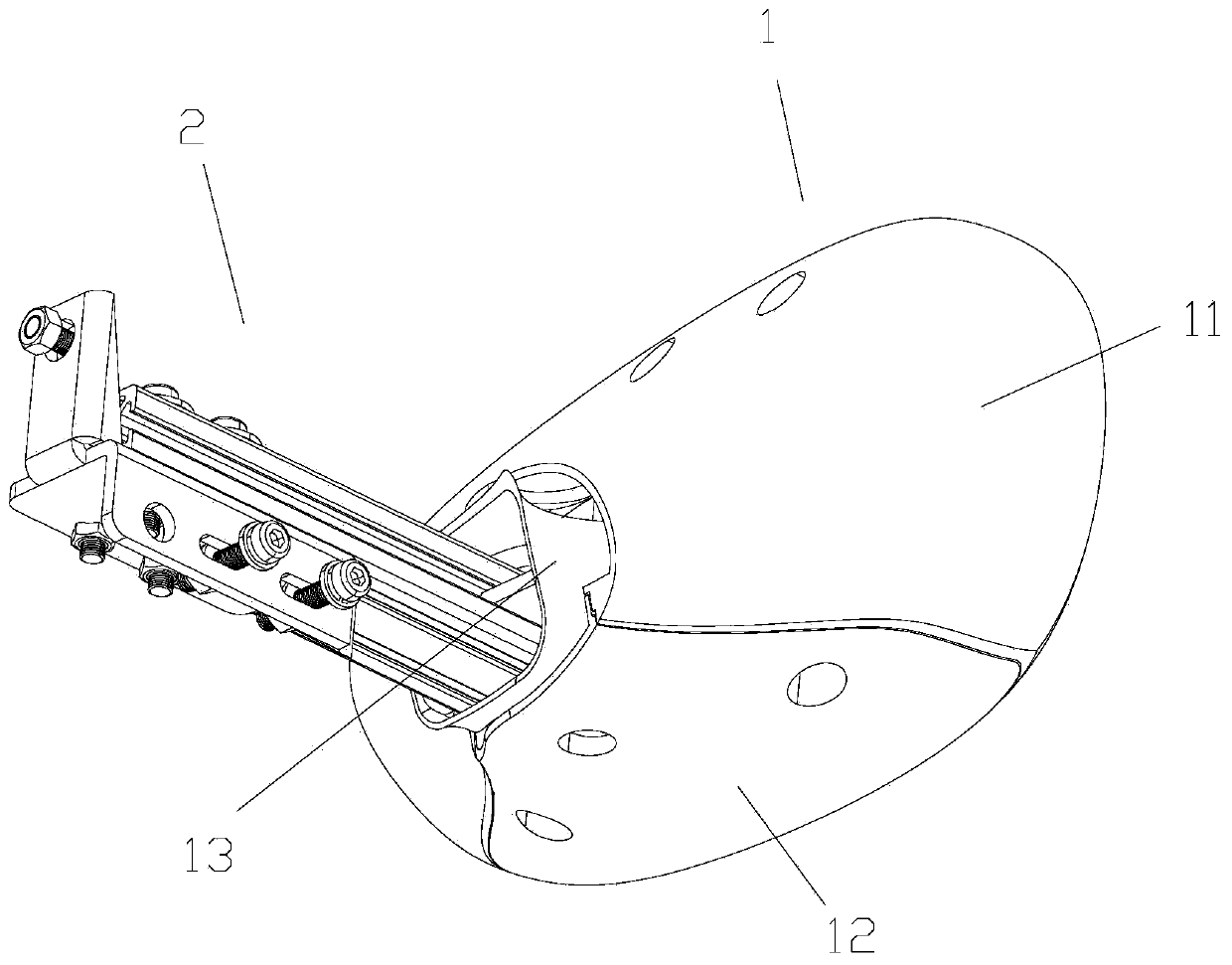

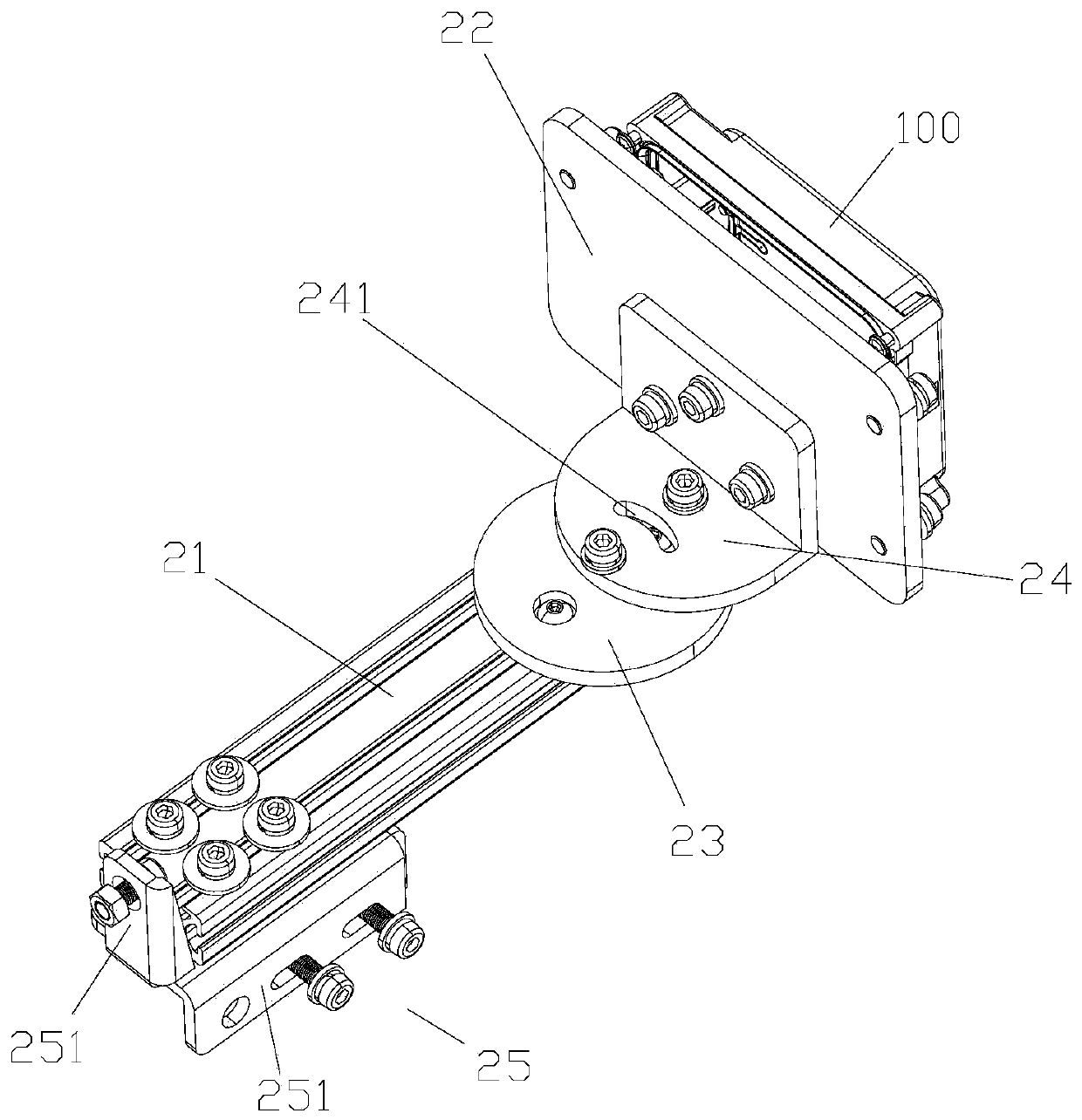

Radar mounting structure and vehicle with same

The invention provides a radar mounting structure and a vehicle with the same, the radar mounting structure comprises a protective shell, the protective shell is used for shielding at least part of aradar, the radar is provided with a transmitting surface for transmitting radar waves, the wavelength of the radar waves transmitted by the radar is a, and the protective shell is provided with a transmission part for radar waves generated by the radar to pass through; wherein the thickness of the transmission part is larger than na-0.2 mm and smaller than na + 0.2 mm, and n is a positive integer;the value range of the distance from the transmitting surface to the transmitting part is 10-20 mm; the transmission part comprises a flat plate structure, and the value range of the included angle between the surface, close to the radar, of the flat plate structure and the transmitting surface is 0-30 degrees; or the transmission part comprises an arc-shaped plate structure, and the value rangeof the included angle between the tangent plane at any position of the surface, close to the radar, of the arc-shaped plate structure and the transmitting surface is 0-30 degrees. According to the radar mounting structure, the problem that in the prior art, a radar mounting structure with a protective shell has a large shielding effect on radar waves is solved.

Owner:BEIJING XIAOMA HUIXING TECH CO LTD

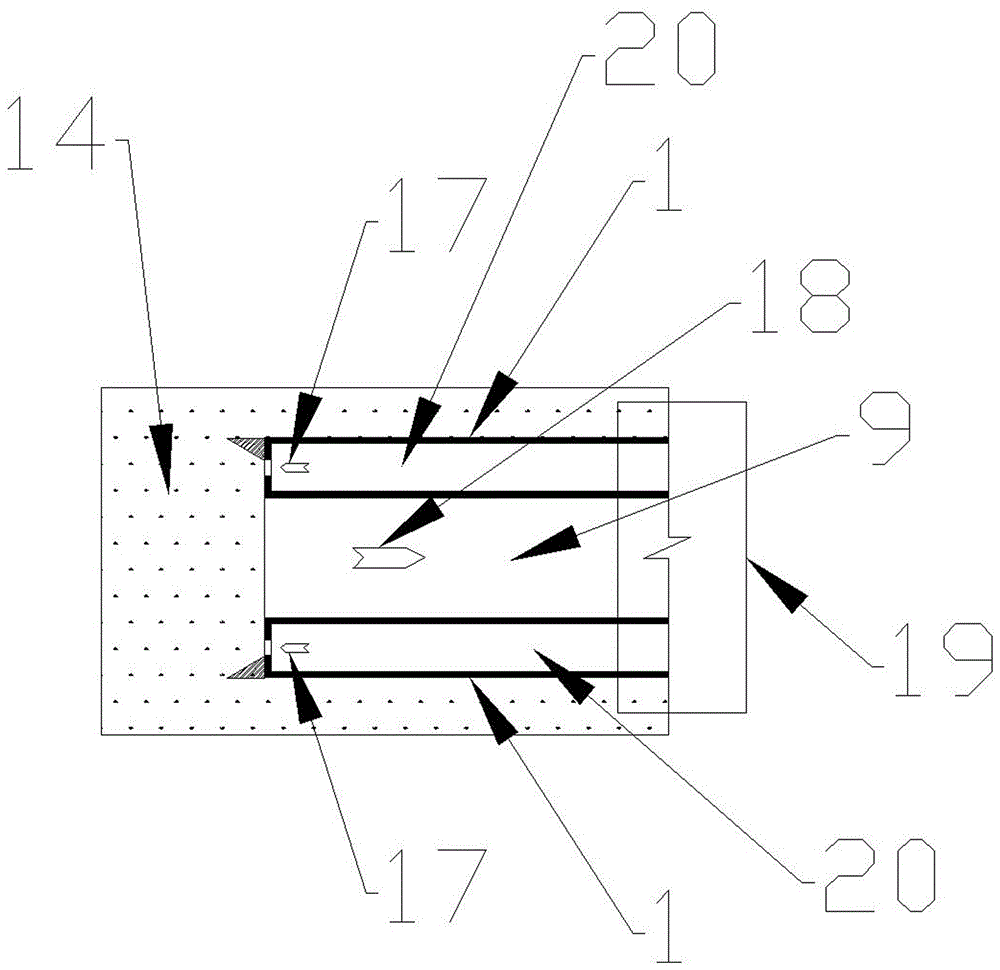

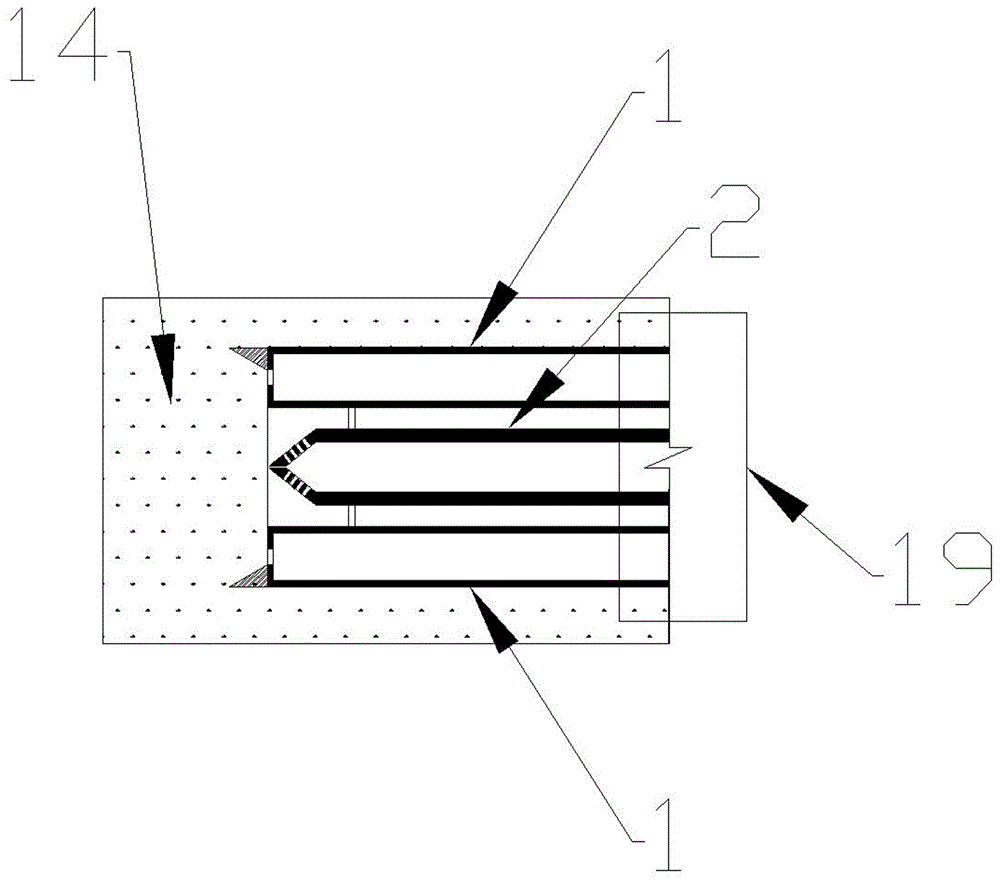

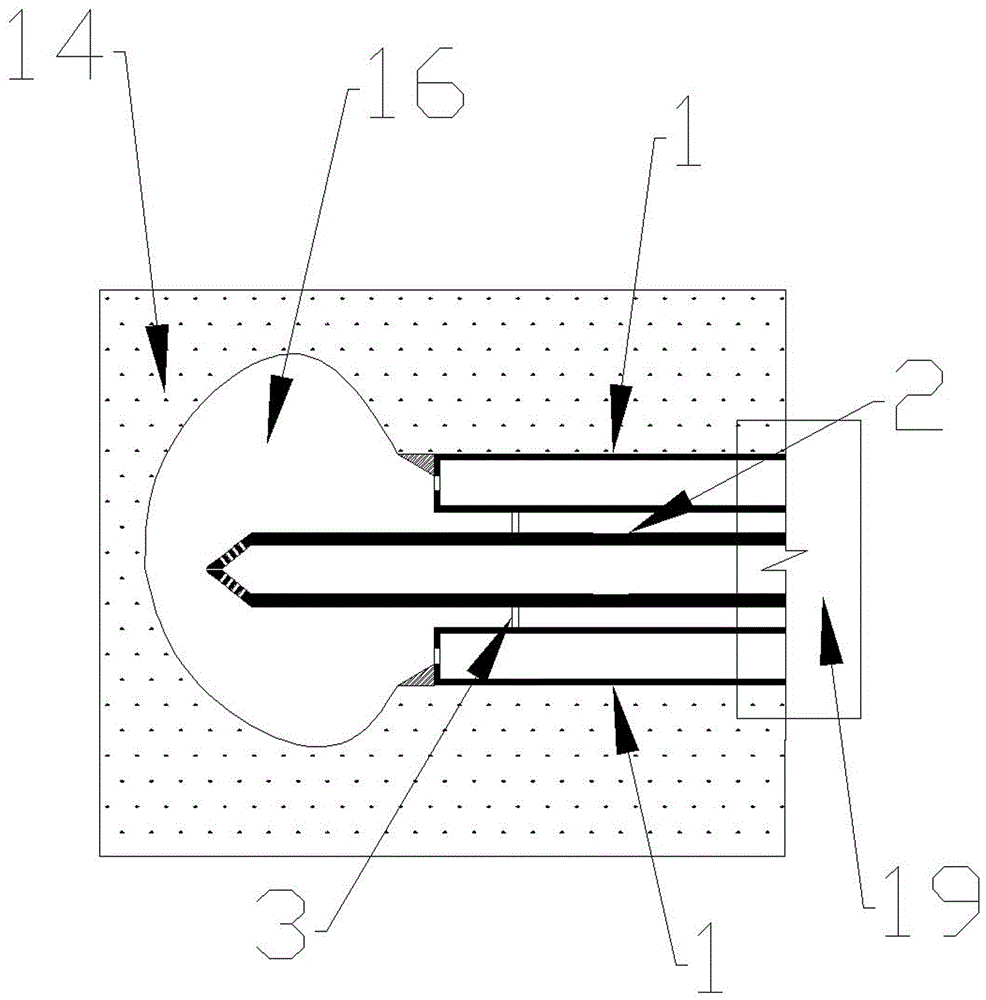

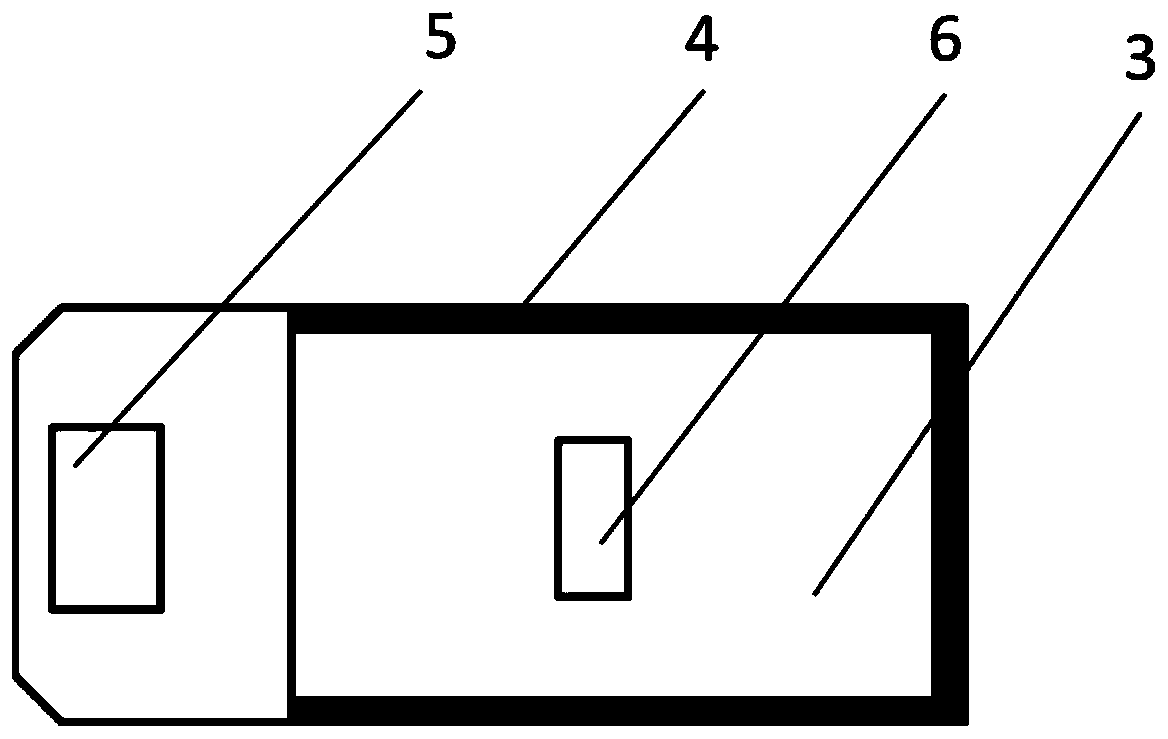

Hole collapse-incapable high-pressure water ejection drilling and broaching anchor rod pile

ActiveCN106087992AImprove permeabilityReduce weightDrilling rodsLiquid/gas jet drillingHigh pressureDrill pipe

The invention discloses a hole collapse-incapable high-pressure water ejection drilling and broaching anchor rod pile, is mainly applied to construction of the anchor rod pile in the architectural engineering field. The anchor rod pile is drilled and broached by using a high-pressure water ejection principle; drill rod equipment is simple, light in weight and low in manufacturing cost and maintenance cost; and a steel strand is inserted in a drill rod simply and easily without generating the hole collapse problem. The anchor rod pile mainly consists of a drilling injection drill rod 1, a broaching injection drill rod 2, a support frame A 3, the steel strand 4, a support frame B 5 and a circular protection cylinder 19. The main construction process comprises the following steps: the drilling injection drill rod 1 sprays high-pressure water currents to drill a pile hole; the broaching injection drill rod 2 is inserted in an overflow channel 9 for broaching a pile end soil layer; after the broaching is finished, the broaching injection drill rod 2 is pulled out; then, the steel strand 4 is inserted in an overflow channel 9 to extend in a cavity 16 at the pile end; finally, the pile hole is grouted by the drilling injection drill rod 1; and after the grouting is finished, the drilling injection drill rod 1 is pulled out to finish construction.

Owner:安徽三江建设工程有限公司

Medical sterilizing packaging material capable of efficiently sterilizing

ActiveCN111439481AImprove breathabilityReduce manufacturing costFlexible coversWrappersPolyolefinBiomedical engineering

The invention discloses a medical sterilizing packaging material capable of efficiently sterilizing. The packaging material has high air permeability, relatively high mechanical strength, very high microbial barrier performance and sterilizing agent resolving performance. A polyolefin porous film layer is introduced into at least one layer of the medical sterilizing packaging material, so that theobtained medical sterilizing packaging material has ventilation and bacteria blocking characteristics and superior air permeability; smooth penetration of a sterilizing agent during sterilizing is ensured; and the sterilizing agent can be resolved rapidly at the end of the sterilization. The material used is low in production cost, has relatively high mechanical strength, prevents bag blasting during sterilization, and does not tend to be damaged during storage and transportation. Meanwhile, the medical sterilizing packaging material has very high microbial barrier performance, and prevents sterilized products from suffering from secondary pollution.

Owner:SHENZHEN UNIV +1

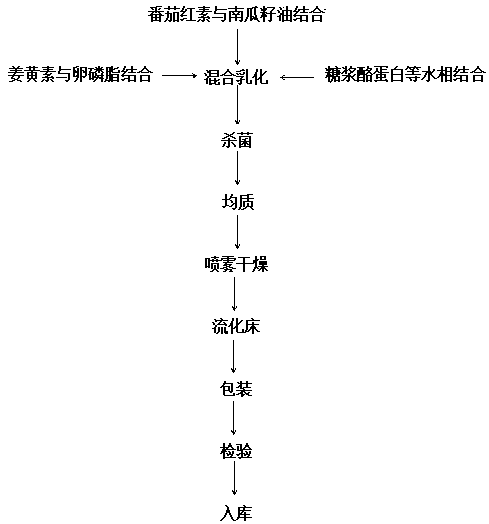

Medicine for preventing and treating prostatic hyperplasia and preparation method of medicine

InactiveCN107714770AFacilitate transmembrane absorptionAchieve preventionSugar food ingredientsHydrocarbon active ingredientsDiseaseHealthy diet

The invention discloses a medicine for preventing and treating prostatic hyperplasia and a preparation method of the medicine. The medicine is prepared from the following raw materials in parts by weight: 2-4 parts of curcumin, 4-6 parts of lecithin, 0.5-2 parts of lycopene, 25-35 parts of pumpkin seed oil and 1-3 parts of a stabilizer. The preparation method comprises the following steps: combining curcumin with lecithin, dissolving lycopene in oil, adding the other raw materials, and carrying out mixing, emulsifying, sterilizing, homogenizing, and drying to obtain a microencapsulated productwith a small particle size of nanometer level. The medicine provided by the invention can ensure that the active ingredients can smoothly penetrate through a three-layer lipid integumentum of prostate to directly reach a focus of a disease. According to the invention, the purpose of preventing and treating prostate diseases is achieved by strengthening the nutrition of formula foods and enhancingthe transmembrane absorption of nutritional components from healthy diets, and the medicine can be stored at normal temperature for a long time with high quality, convenient transportation, convenient use and the like.

Owner:菏泽大树孵化基地有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com