Macro-molecule elastomer membrane and fabric and preparation methods thereof

A polymer and elastic technology, applied in the textile field, can solve the problems of poor moisture permeability and achieve the effect of good windproof and moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

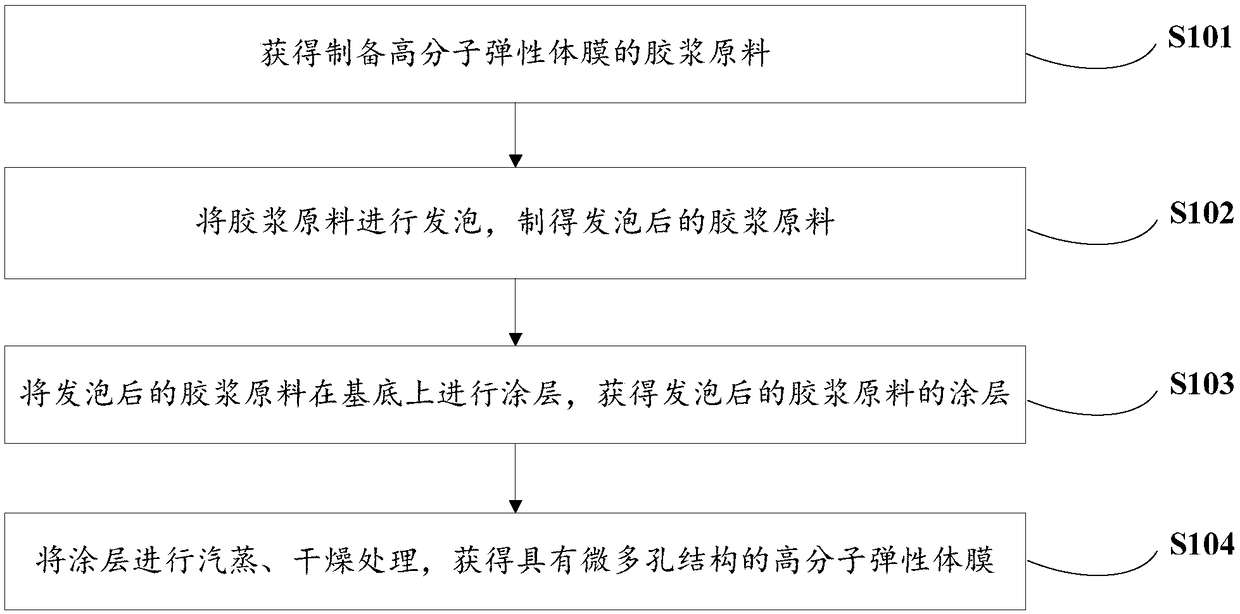

[0047] Such as figure 1 As shown, it is a flowchart of a method for preparing a polymer elastomer film of the present application. The method comprises the steps of:

[0048] Step S101, obtaining the glue raw material for preparing the polymer elastomer film.

[0049] In order to prepare a polymeric elastomer film with a microporous structure, the specific implementation process of the step S101 can use polyurethane, hydroxymethyl cellulose, sodium lauryl sulfate, silicone resin polyether, crosslinking agent and thickener Mix with demineralized water to form the mucilage raw material.

[0050] Polyurethane, hydroxymethyl cellulose, sodium lauryl sulfate, silicone resin polyether, crosslinking agent and thickener are mixed with soft water as the raw material of the glue to prepare a polymer elastomer film with a microporous structure through foaming. Wherein, the sodium lauryl sulfate has excellent foaming performance, which can rapidly foam the mortar raw material so as to ...

Embodiment 2

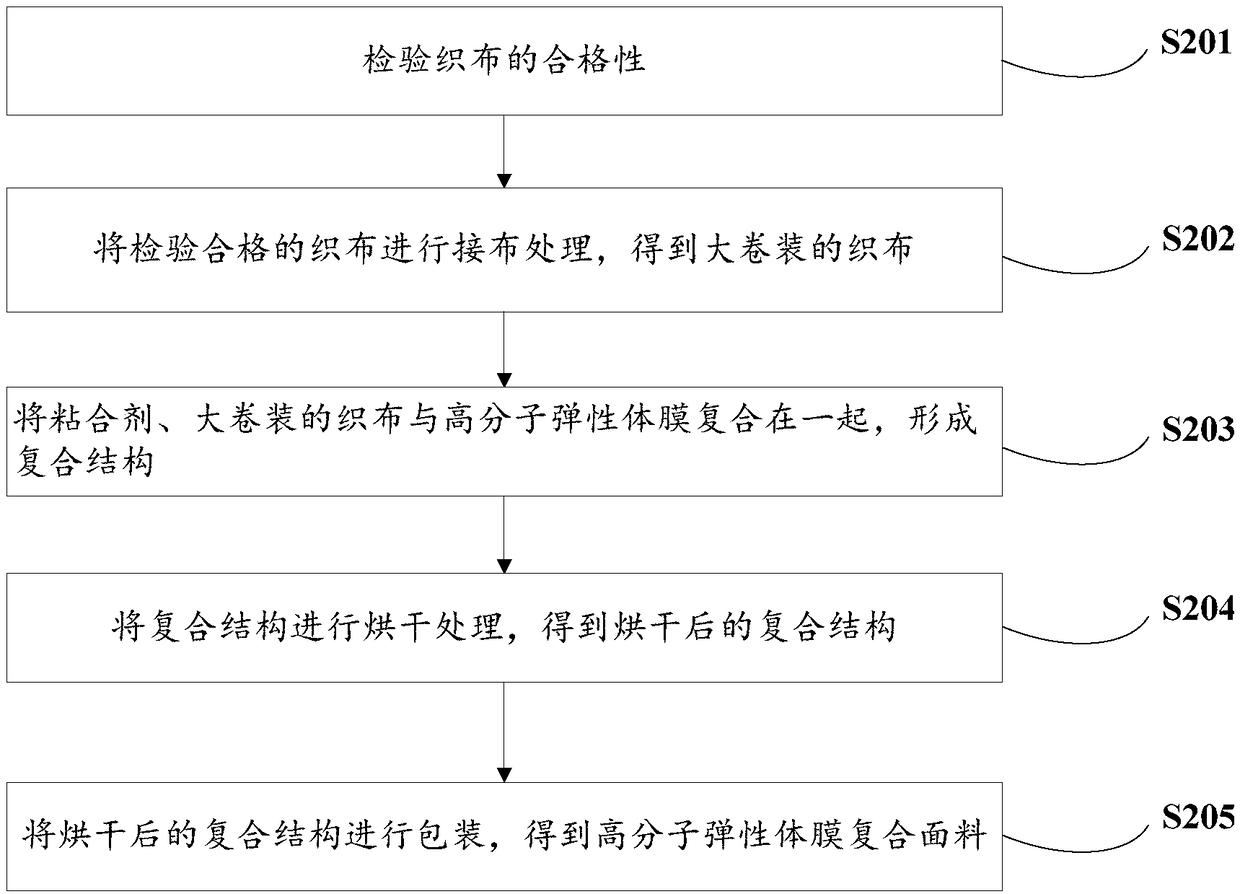

[0068] Such as figure 2 As shown, it is a flow chart of the preparation method of nylon and polyester grid-connected gray cloth. The method comprises the steps of:

[0069] Step S201, checking the eligibility of the weaving fabric.

[0070] In this implementation, the weaving cloth adopts nylon and polyester weaving cloth and checks the eligibility of the weaving cloth.

[0071] In step S202, the fabrics that pass the inspection are spliced to obtain a large package of fabrics.

[0072] After the operation of inspecting the qualified weaving in step S201, the qualified weaving is spliced to obtain a large package of weaving, so as to be compounded with the polymer elastomer film prepared in Example 1 to prepare fabrics.

[0073] Step S203, compounding the adhesive, the large package of woven fabric and the polymer elastomer film to form a composite structure.

[0074] In the present application, the adhesive can be selected from the hot-melt adhesive used for laminati...

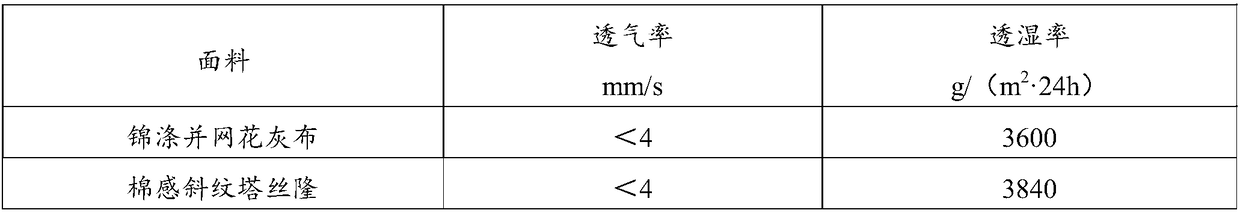

Embodiment 3

[0081] The method for preparing the cotton-feeling twill taslon fabric is described as follows:

[0082] Step S301, checking the eligibility of the woven fabric.

[0083] In this implementation, the weaving fabric is Taslan weaving fabric and the eligibility of the weaving fabric is checked.

[0084] In step S302, the woven fabrics that pass the inspection are spliced to obtain a large package of woven fabrics.

[0085] After checking the qualified operation of the weaving fabric in step S301, the weaving fabric that passed the inspection is spliced to obtain a large package of weaving fabric, so as to be compounded with the polymer elastomer film prepared in Example 1 to prepare a fabric.

[0086] Step S303, compounding the adhesive, the large package of woven fabric and the polymer elastomer film to form a composite structure.

[0087] In the present application, the adhesive can be selected from the hot-melt adhesive used for lamination, and the adhesive, the woven cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com