Waterproof ventilated coated cloth

A waterproof, breathable and coated cloth technology, applied in the field of textiles, can solve the problems of poor hand feeling, environmental damage, high burning temperature, etc., and achieve the effect of easy natural degradation, good waterproof and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be further described in detail below.

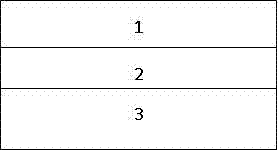

[0021] Such as figure 1 As shown, a waterproof and breathable coated cloth of the present invention includes a base material cloth 1, and one side of the base material cloth 1 is sequentially printed with a primer coat 2 and a top coat 3.

[0022] The composition and weight ratio of primer coating 2 are: 76-80% polyurethane, 0.9-2.2% 5-50um artificial zeolite powder, 16-20% DMF solvent, 0.5-2.0% anionic surfactant, 0.7~0.8% defoamer.

[0023] The composition and weight ratio of the top coat 3 are: 72-76% polyurethane, 2.5-3.5% 5-50um artificial zeolite powder, 15-18% DMF (dimethylformamide) solvent, 0.3-1.5 % anionic surfactant, 0.7-2% non-ionic surfactant, 0.7% defoamer, 0.07% leveling agent, 4.0-5.5% white color paste.

[0024] The process of making the waterproof breathable coated cloth of the present invention comprises:

[0025] Glue adjustment: Stir the above base glue a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com