Patents

Literature

377 results about "Central line placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

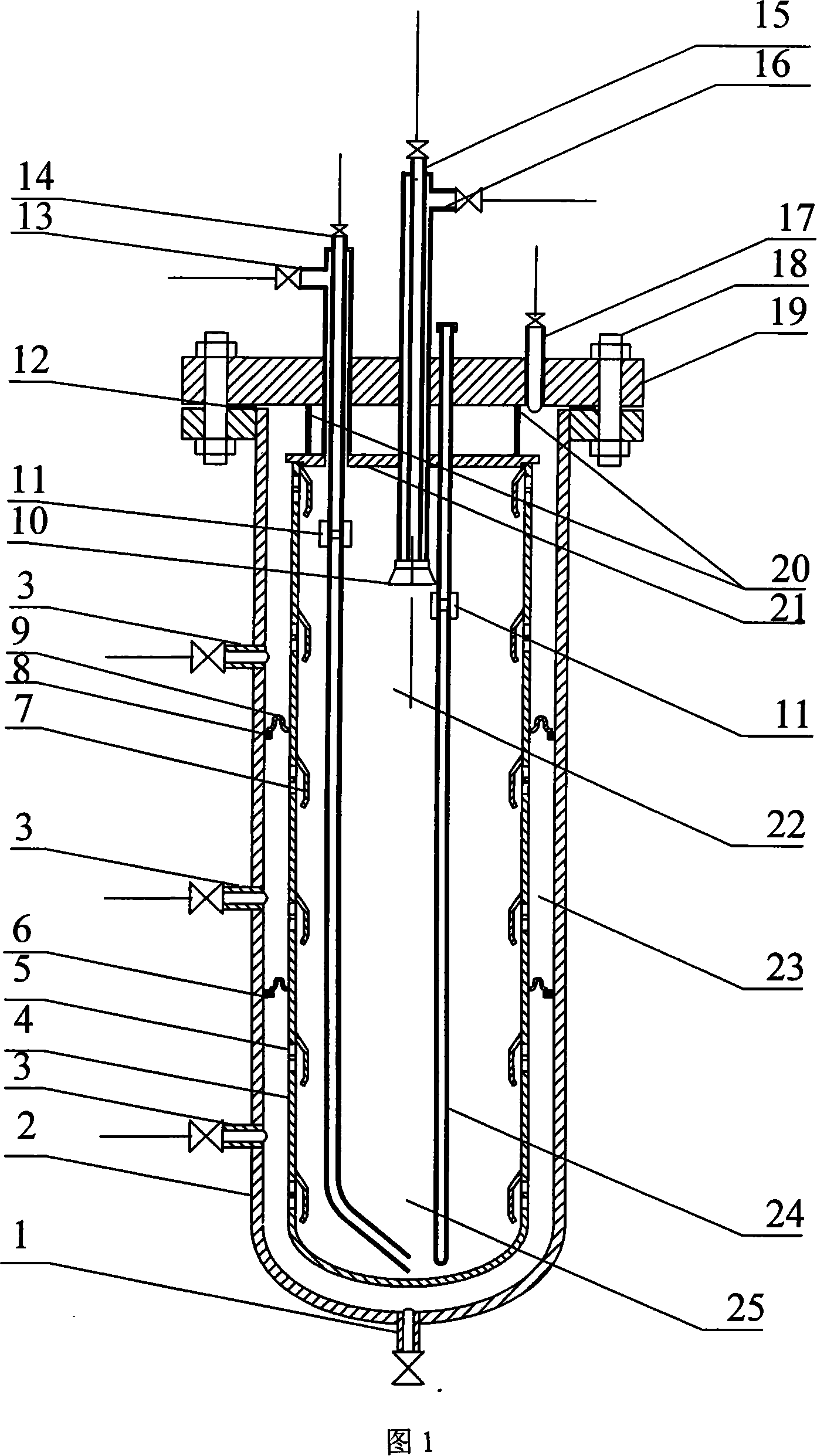

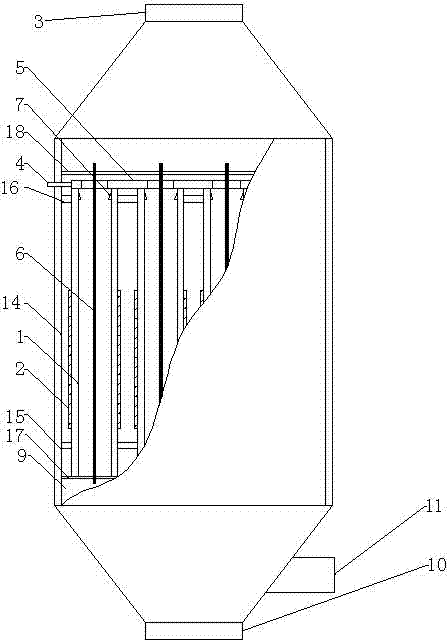

Corrosion-resisting clogging-proof overcritical water oxidization reactor

InactiveCN101164912ALarge choiceAvoid corrosionWater/sewage treatment by oxidationCentral line placementOxygen

This invention relates to a corrosion-resistance and blocking-resistance supercritical water oxidation reactor. It is composed of: a casing, a water inlet, a jacketed supporting ring and a spring ring, an annular water entrance and a water dash plate, inner cylinder of the reactor, raw material feeder, nozzle, an outlet of reactant and multi-point optical fiber online thermo-detector. In said reactor, there are a process water jacket area, supercritical water oxidation area, a sub-critical water area for dissolving inorganic salts on the bottom of the inner cylinder of the reactor. The process water jacket area is divided into two or more than two layer area by the supporting ring and the spring ring. The water, after removing oxygen and removing salts, passes through porous-wall structure enters the reaction area and forming a protective water membrance over the inner wall of the reactor. The temperature sensor and optical fiber are placed in a sleeve which is placed near the central line of the reactor. Advantages are: easy to be maintained, safety operation.

Owner:SHANDONG UNIV

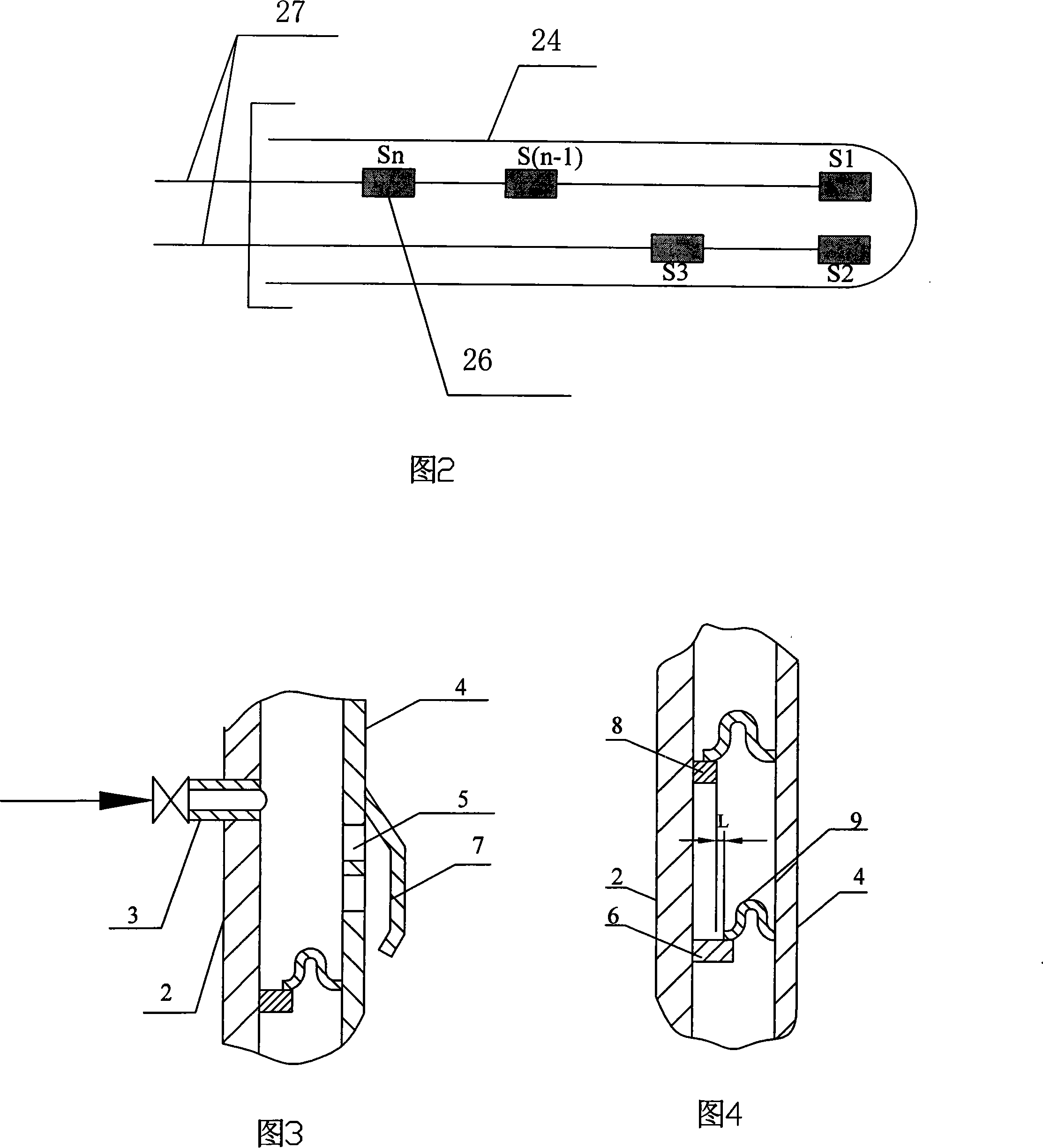

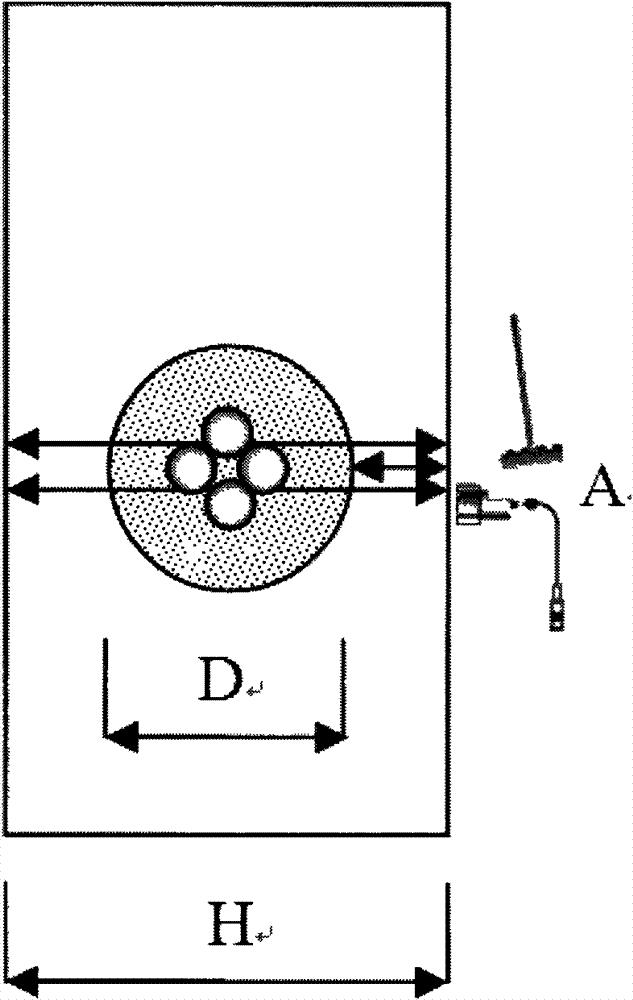

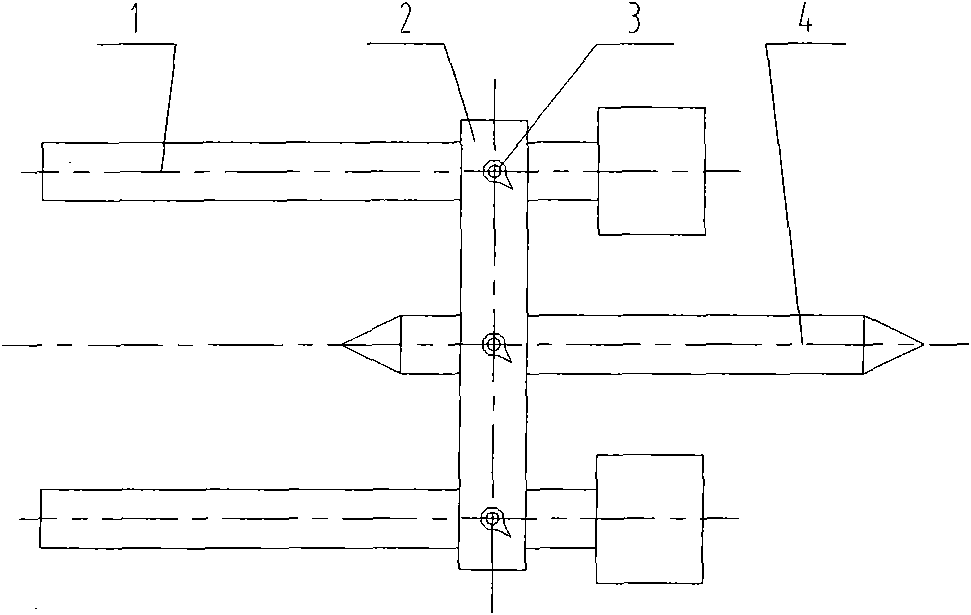

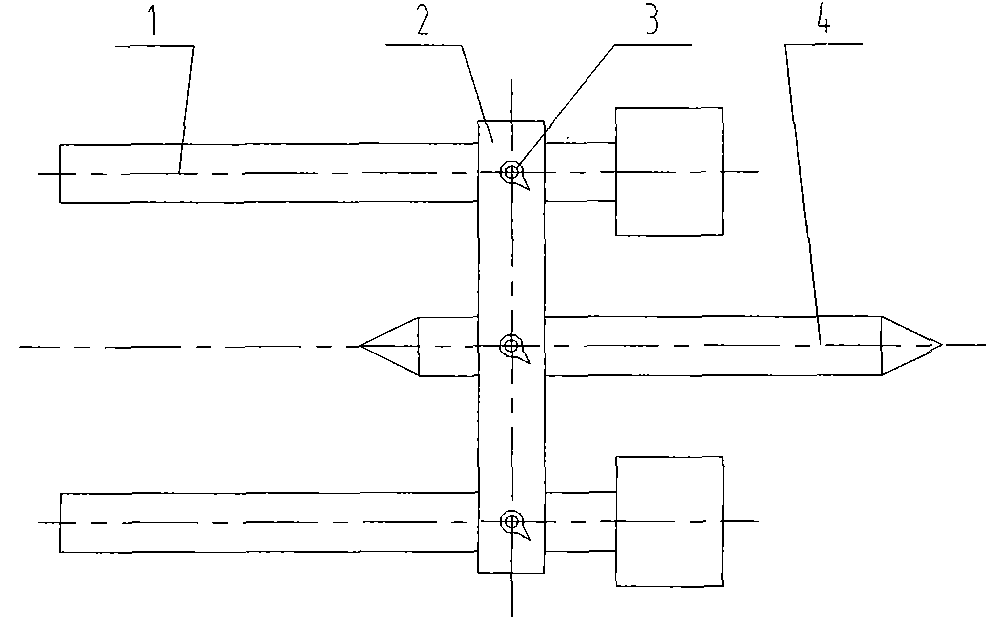

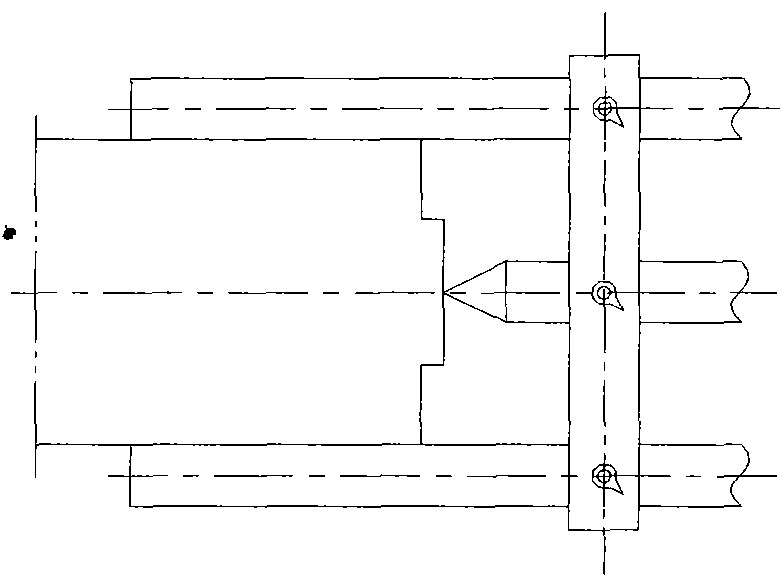

Test method and system for grouting compactness of pre-stressed duct of bridge

InactiveCN102818852AHigh precisionImprove efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructivePre stress

The invention discloses a test method and a system for grouting compactness of a pre-stressed duct of a bridge. The test method includes determining the center line position of the pre-stressed duct to be tested and fixing an acceleration transducer at the center line position; performing knocking and excitation around the acceleration transducer through an excitation hammer, and collecting elastic wave data produced by excitation through the acceleration transducer; and calculating the equivalent reflection wave velocity according to the elastic wave data and determining the grouting compactness of the pre-stressed duct of the bridge according to the equivalent reflection wave velocity. According to an embodiment of the test method and the system, the non-destructive testing technology is adopted to detect the whole grouting quality of the duct with a pre-stressed structure; and the test method and the system have the advantages of high accuracy and efficiency and low cost, have great significance for objective evaluation of quality conditions of the pre-stress structure, and are suitable for being widely applied to engineering.

Owner:杭州海儿科技有限公司 +1

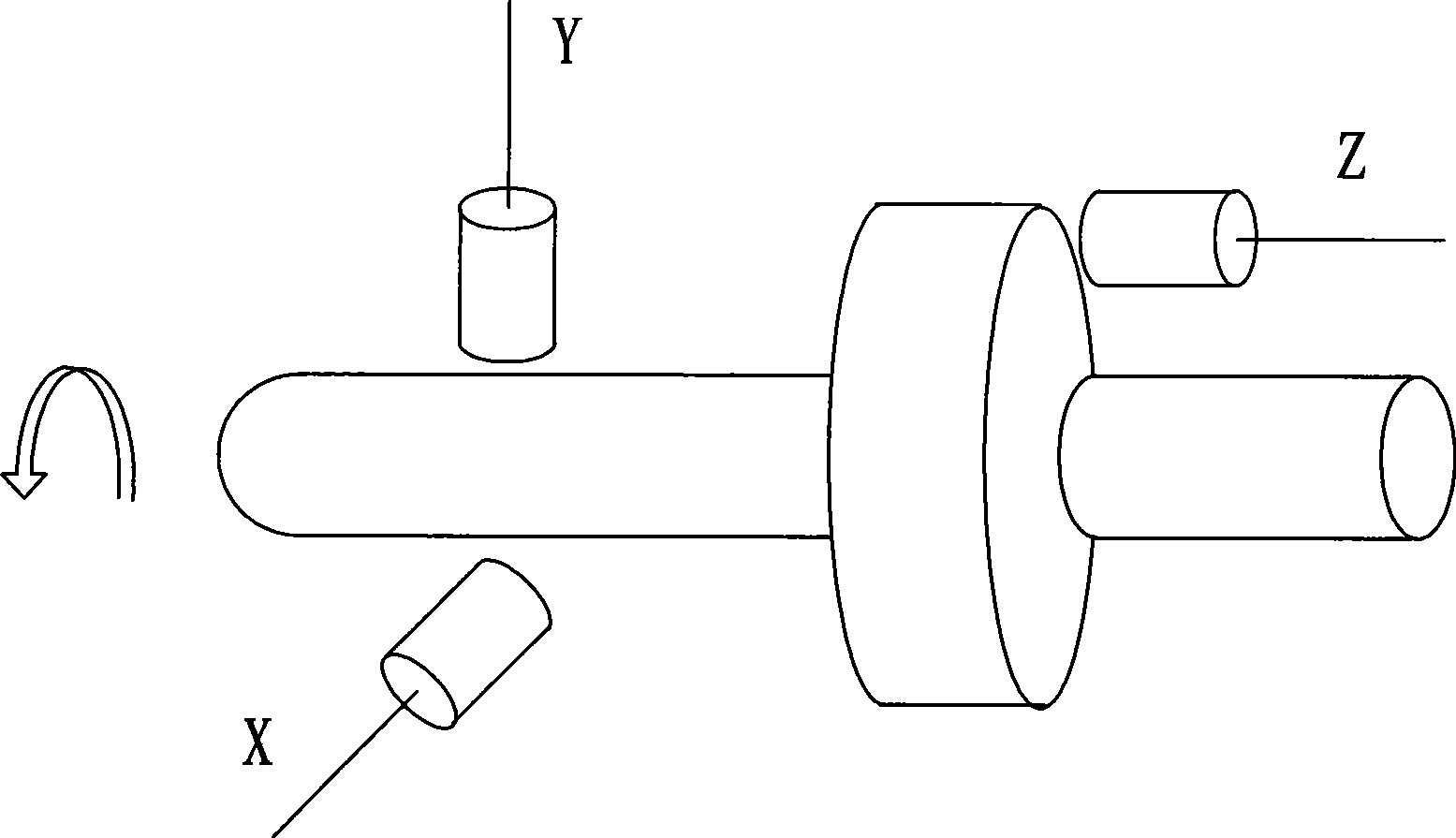

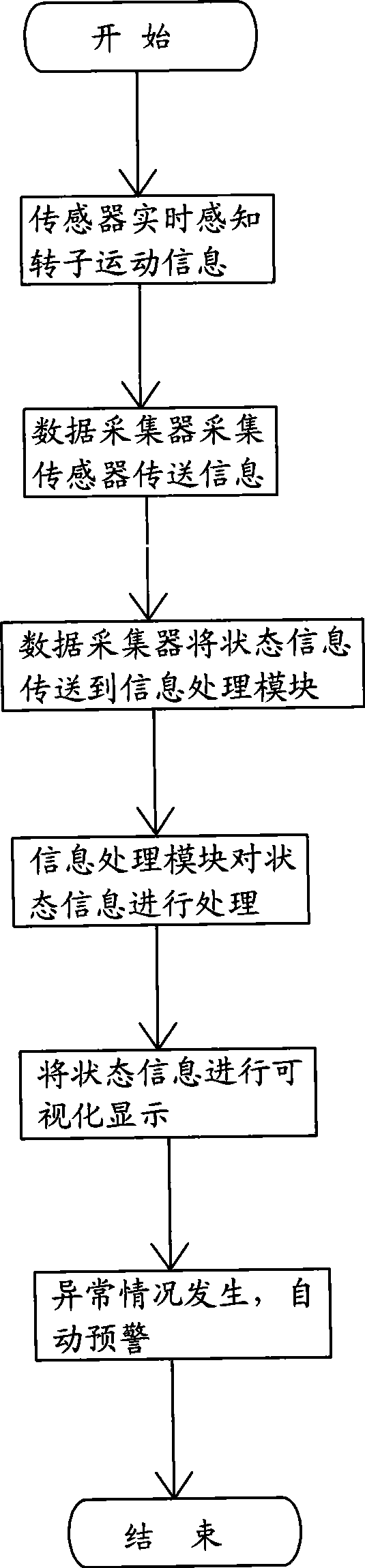

Rotor bearing system failure perfect information analytical method and apparatus

InactiveCN101387575AComprehensive descriptionAccurate descriptionMachine bearings testingInformation analysisPrecession

The invention discloses a rotor bearing system accident comprehensive information analysis method and a device thereof, wherein one section of a rotor is radial and vertically mounted with two sensors X, Y, the axle end of the rotor is axially mounted with a sensor Z, the radial and axial information of the rotor motion transmitted by the sensors are fused to analyze the motion state of the rotor bearing system, the axis center line position and the axis center track of the rotor in the X-Y, Y-Z and Z-X planes of a dimension space are described and displayed visibly to completely and accurately describe the spatial motion information of the rotor, and the information contains the unique diagnosis information as dimension space eccentricity, an attitude angle, a precession direction and vibration vector direction and the like, thereby improving the ability for visually recognizing the accidents of a rotary machine.

Owner:YANCON CATHAY COAL CHEM +2

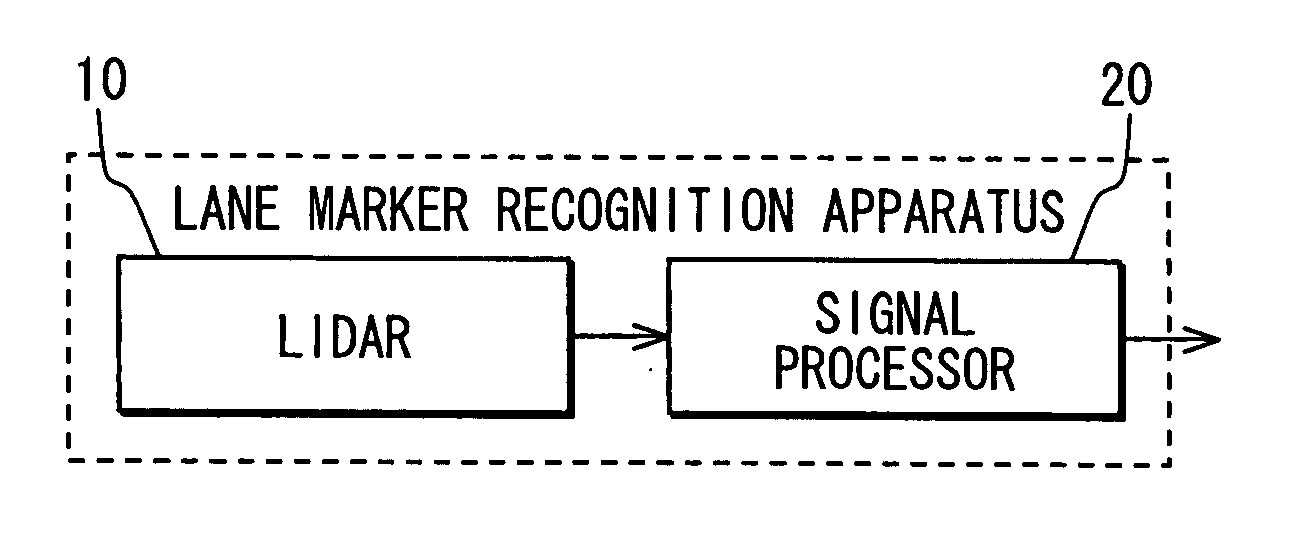

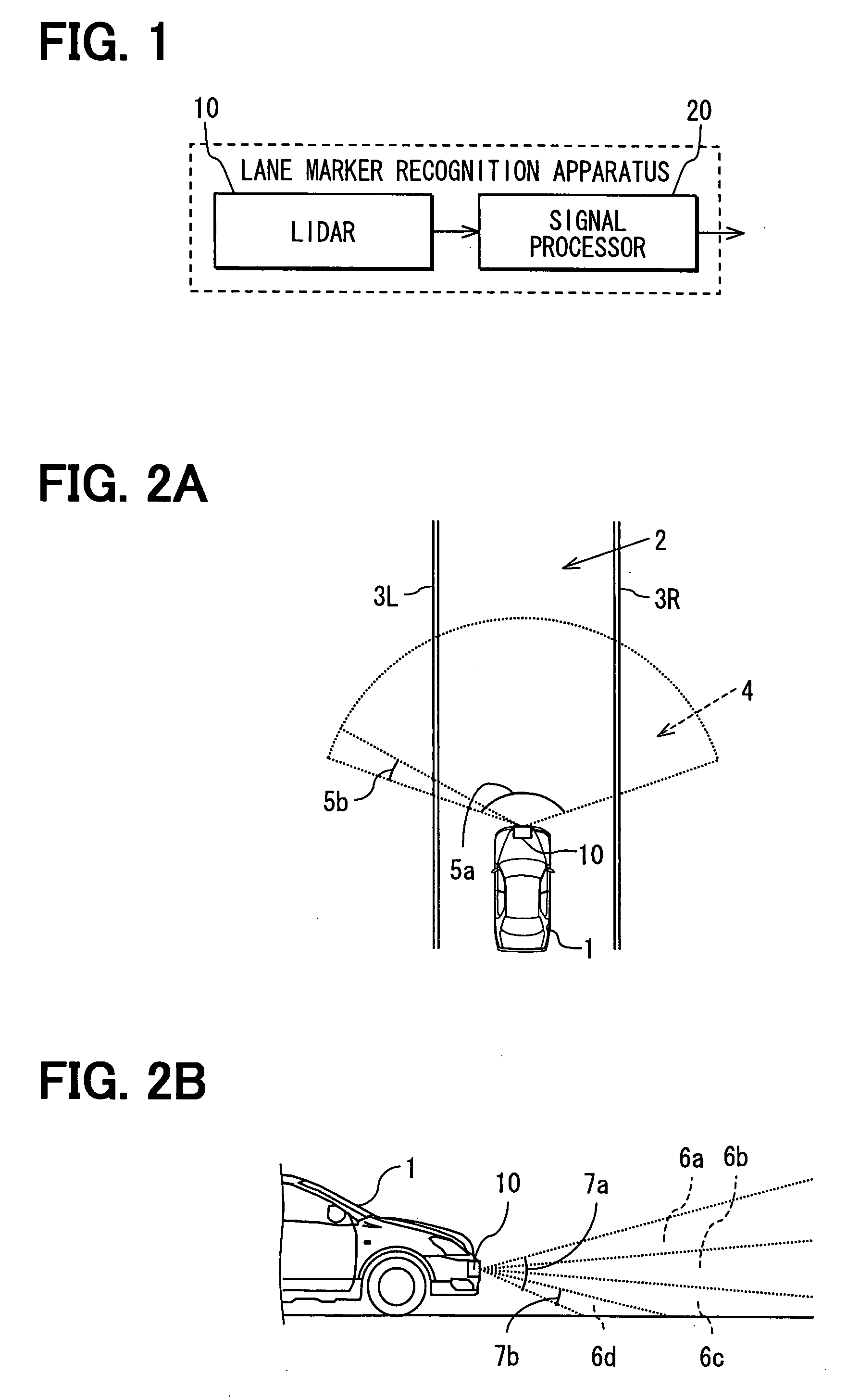

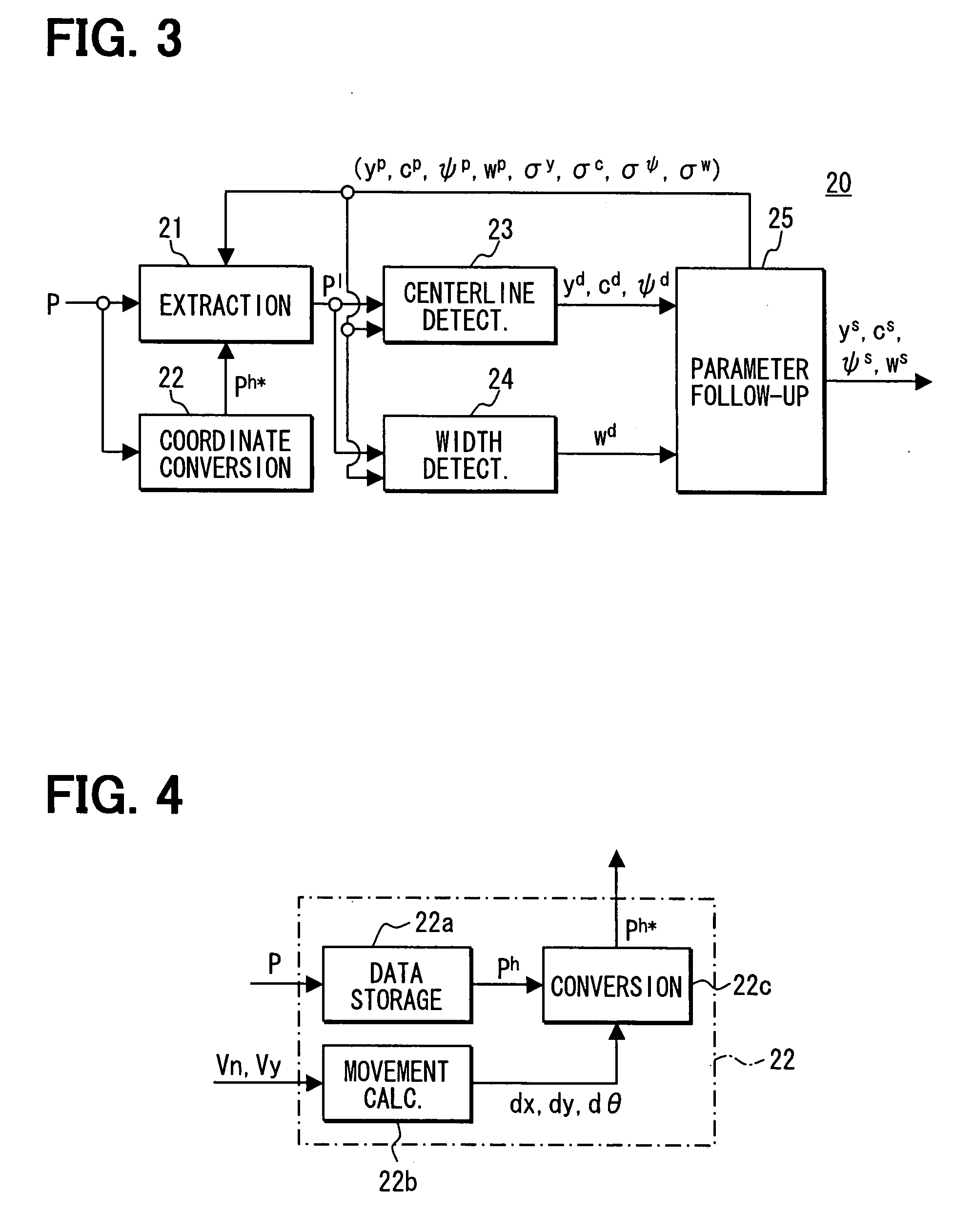

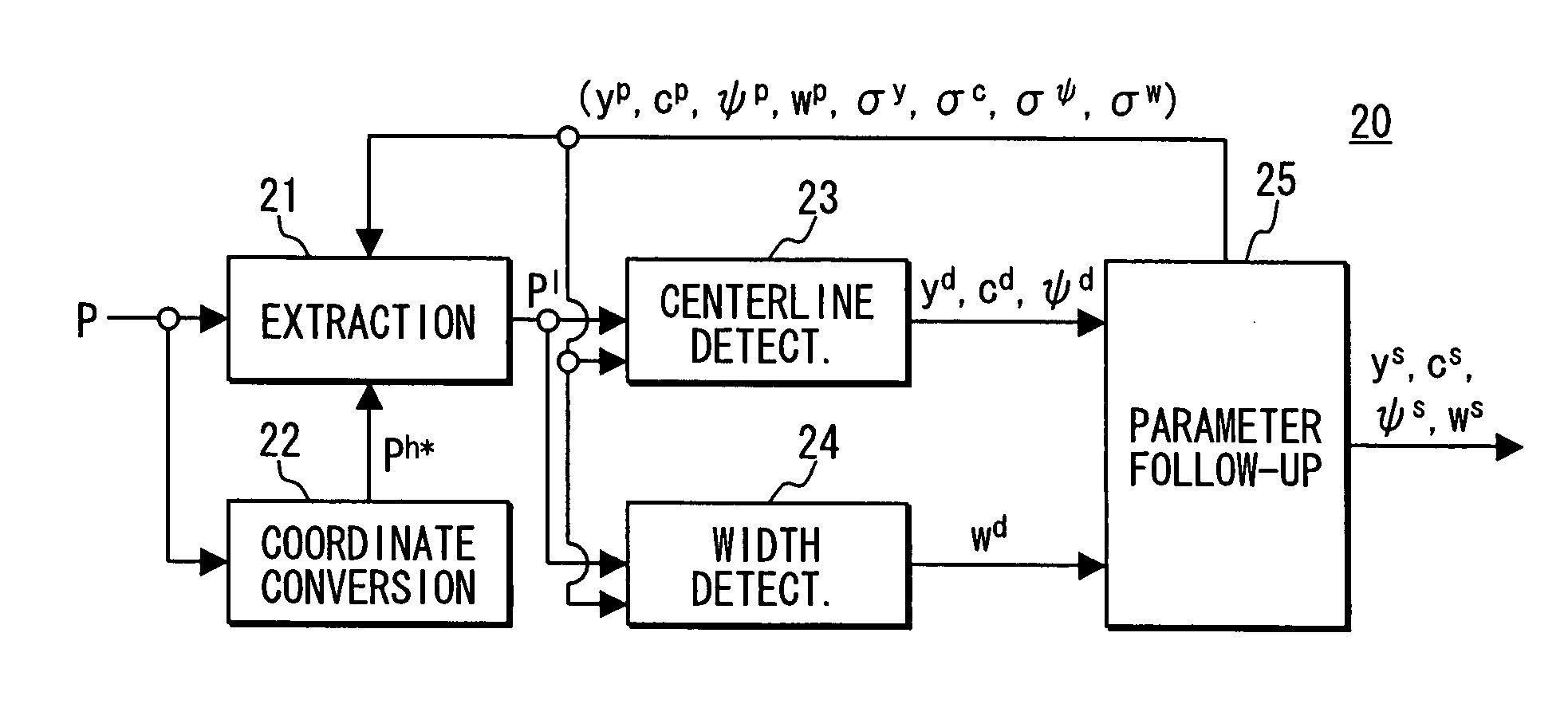

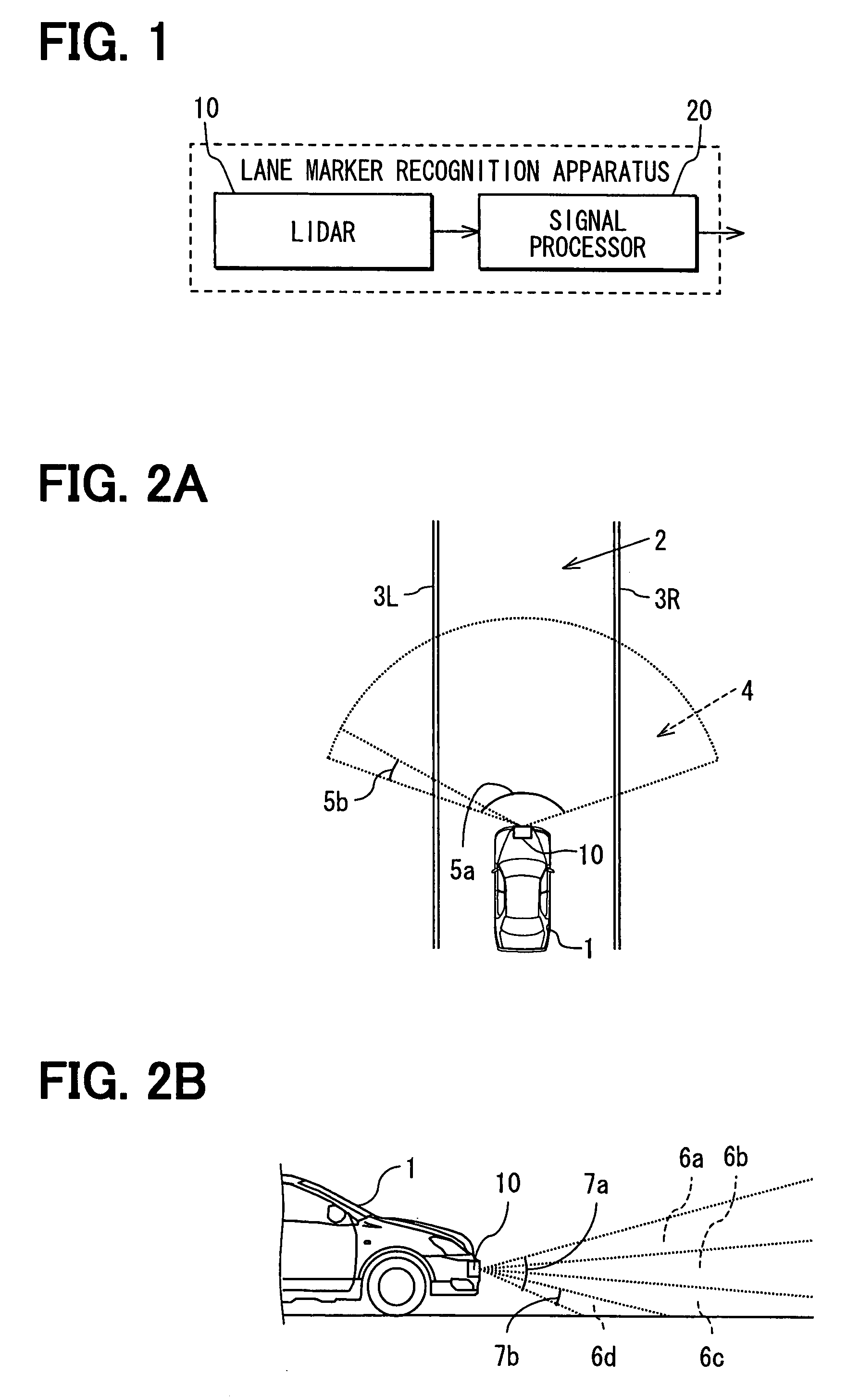

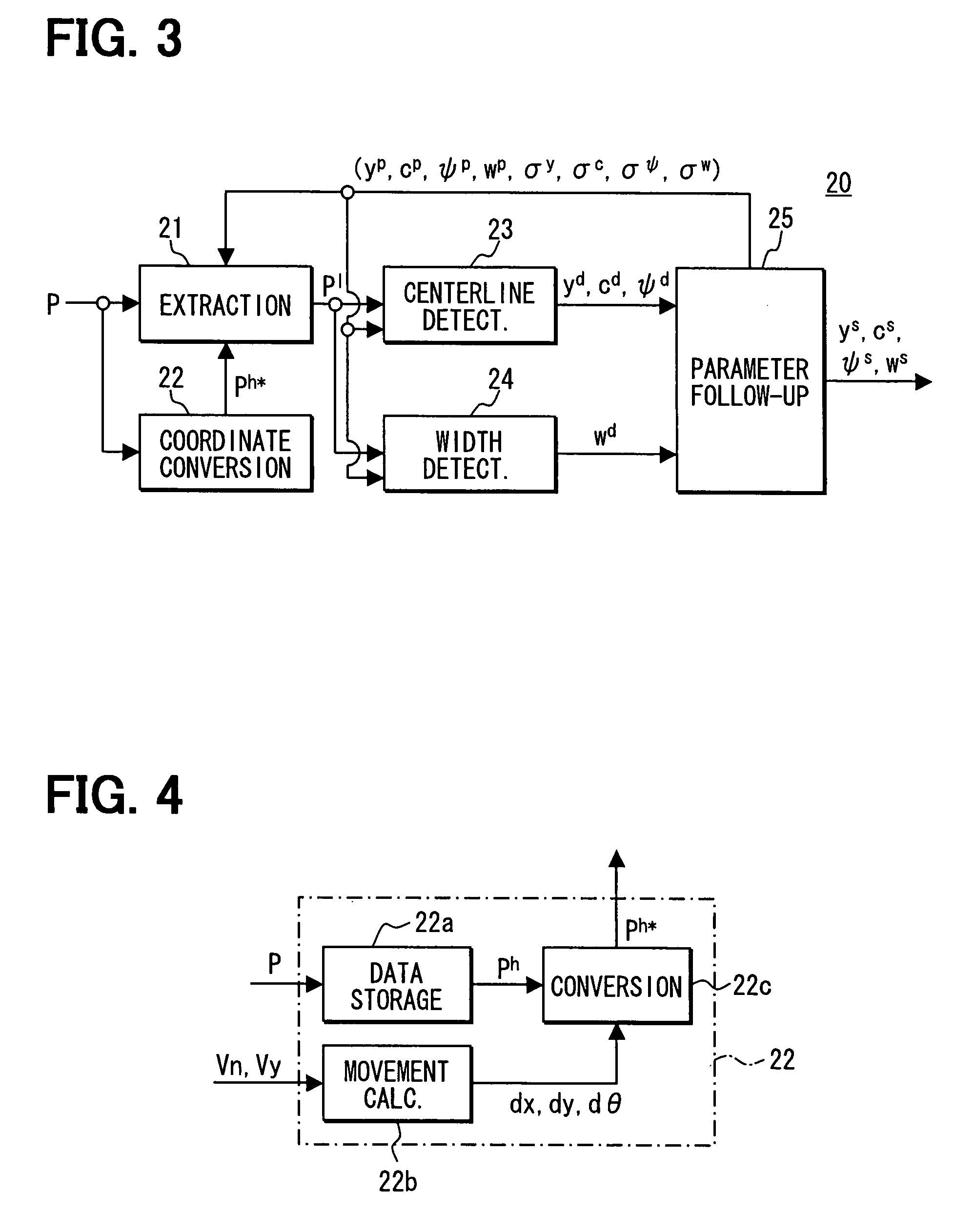

Lane marker recognition apparatus

ActiveUS20070276599A1Robustly recognizingDigital data processing detailsCharacter and pattern recognitionKaiman filterHough transform

Data on a lane marker are extracted based on a centerline position, centerline shape, and width of a lane, which are projected for the present cycle. Data on a lane centerline are generated by adjusting x-axis components of the extracted data. A centerline position and centerline shape is calculated with the Hough's transformation using the generated data on the lane centerline. A frequency distribution is calculated for opposing positions with respect to the lane centerline. A lane width of the road is calculated by calculating an auto-correlation function with respect to the frequency distribution. A centerline position, centerline shape, and lane width at the present cycle and subsequent cycles are estimated / projected with the Kalman filter.

Owner:DENSO CORP

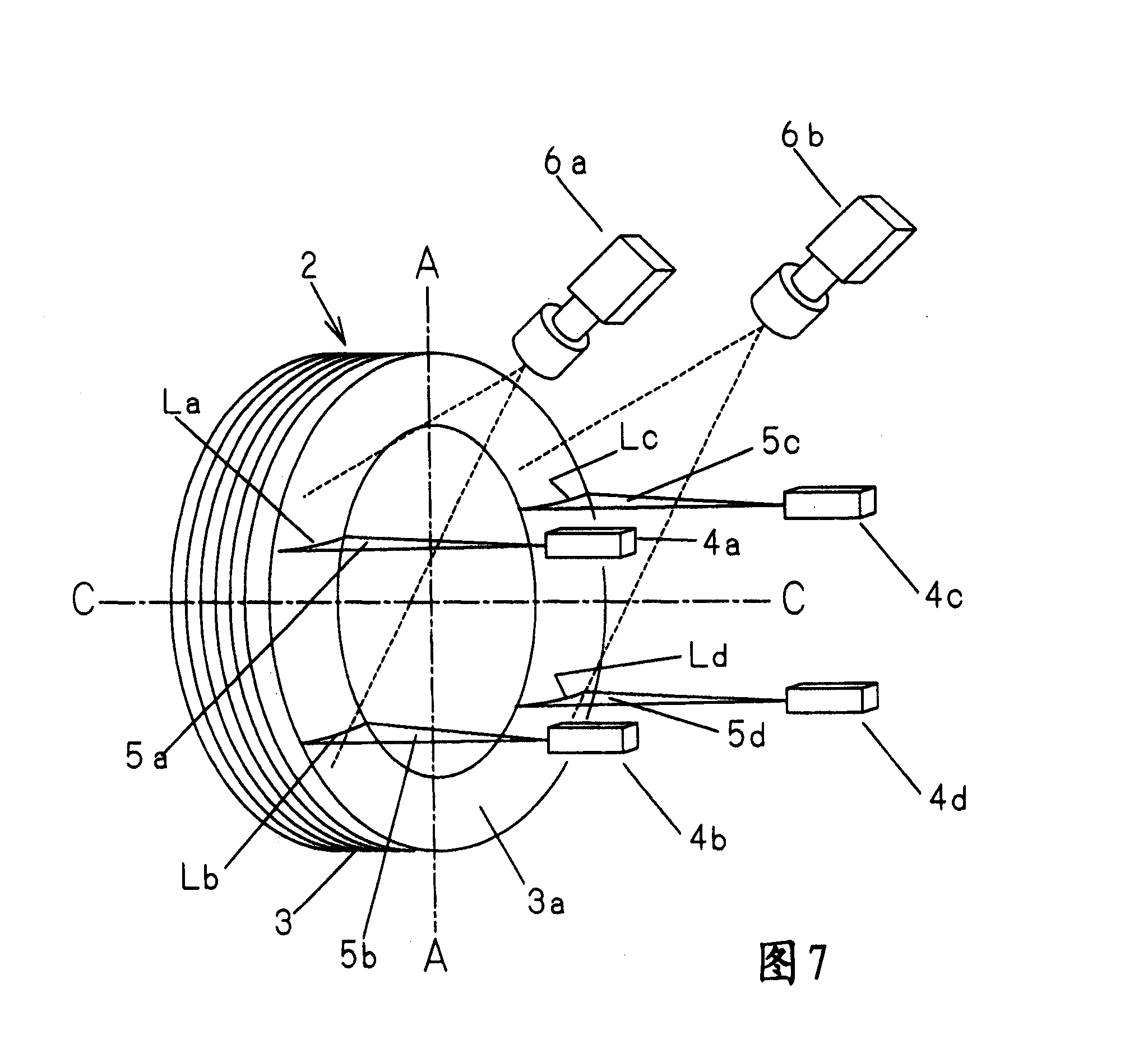

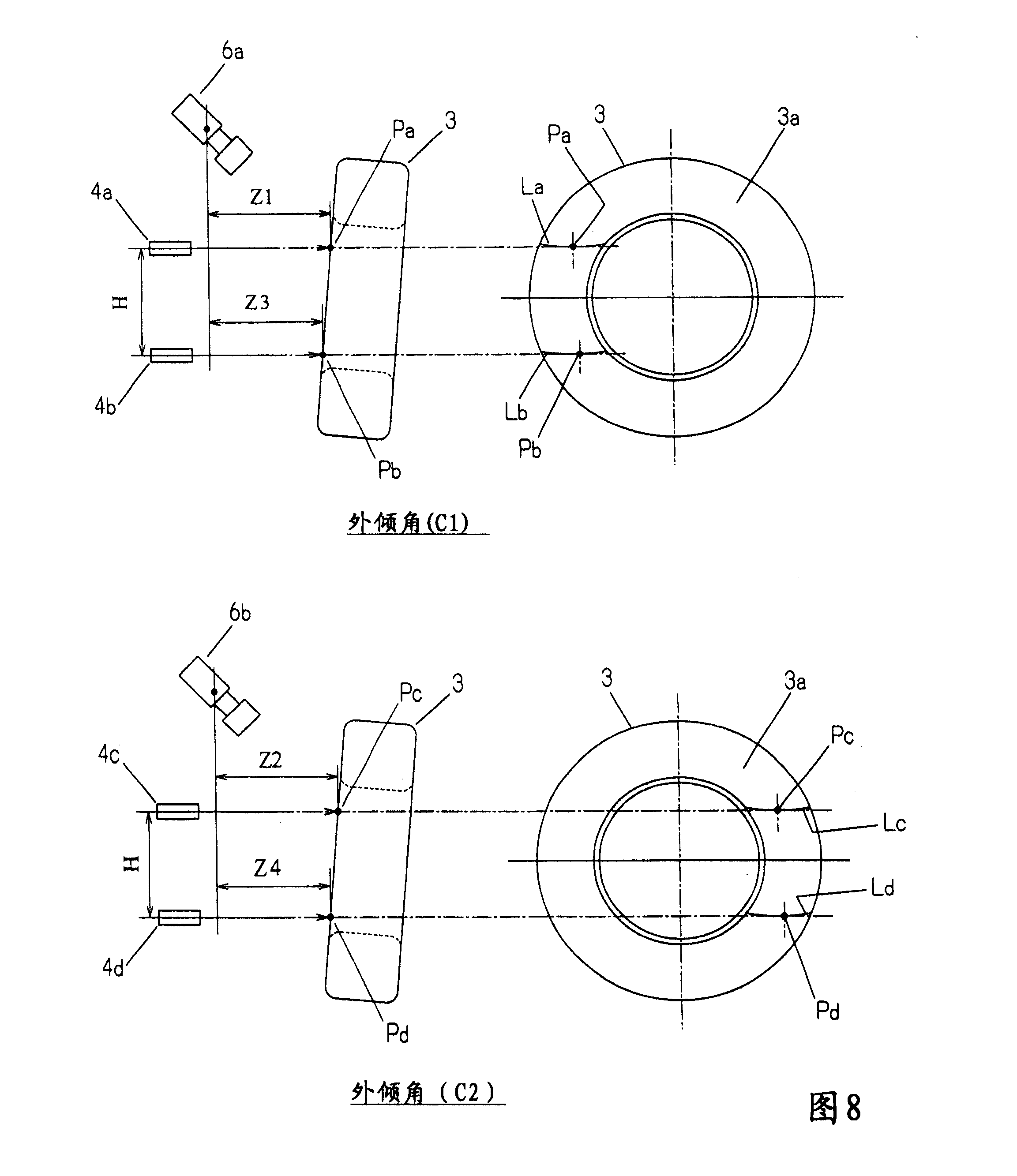

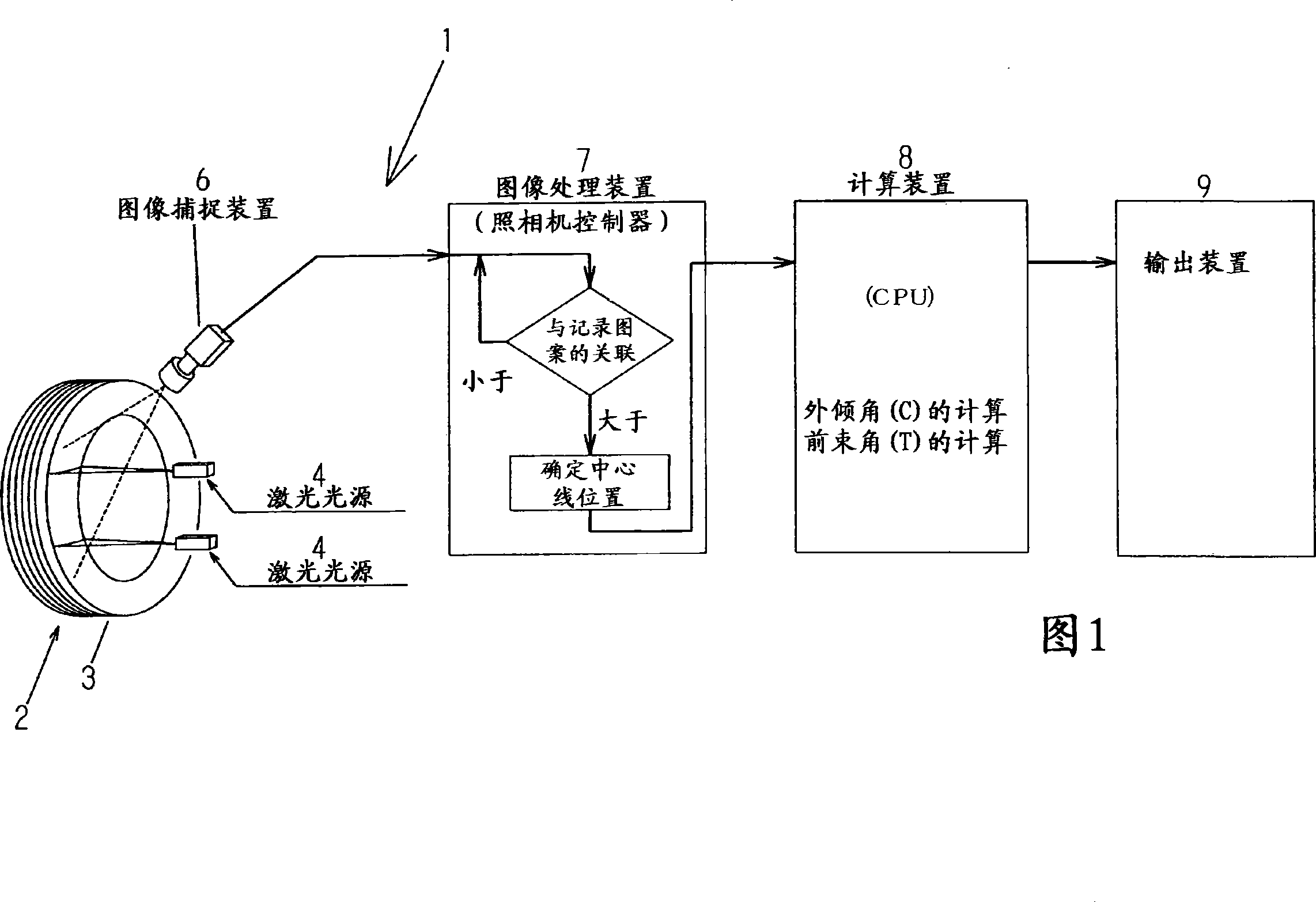

Wheel positioning measuring device

The invention relates to a non-contact type wheel positioning and measuring device, which has a simple structure and can measure the toe-in angle and the camber angle with high accuracy. The device comprises a pair of laser sources used for horizontally emitting a beam of laser to the side of the wheel, the pair of laser sources are vertically arranged and separated from each other so as to form two vertical and mutually separated illuminating outline patterns; a pattern catching device which is arranged at the outer side of the laser sources and at a same face with the laser sources so as to catch the outline patterns which is taken as the measured images; an image processor which is used for determining and recording the midline position data of each illuminating outline pattern, the midline position data are images caught by the image catching device and comprise outlines, and each prior recorded image which comprises outline pattern, compared with the caught images, the selected recorded images which comprise the outline patterns have a certain degree of or higher relativity; and a calculating device which gains the position of the wheel through calculating the recorded midline position data.

Owner:YASAKA SEIKI

Lane marker recognition apparatus

ActiveUS7933433B2Character and pattern recognitionElectromagnetic wave reradiationKaiman filterHough transform

Data on a lane marker are extracted based on a centerline position, centerline shape, and width of a lane, which are projected for the present cycle. Data on a lane centerline are generated by adjusting x-axis components of the extracted data. A centerline position and centerline shape is calculated with the Hough's transformation using the generated data on the lane centerline. A frequency distribution is calculated for opposing positions with respect to the lane centerline. A lane width of the road is calculated by calculating an auto-correlation function with respect to the frequency distribution. A centerline position, centerline shape, and lane width at the present cycle and subsequent cycles are estimated / projected with the Kalman filter.

Owner:DENSO CORP

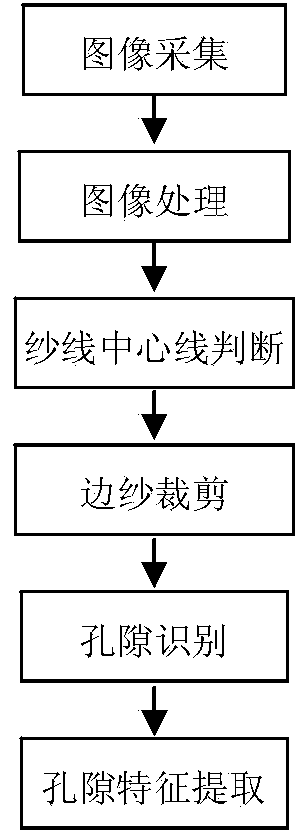

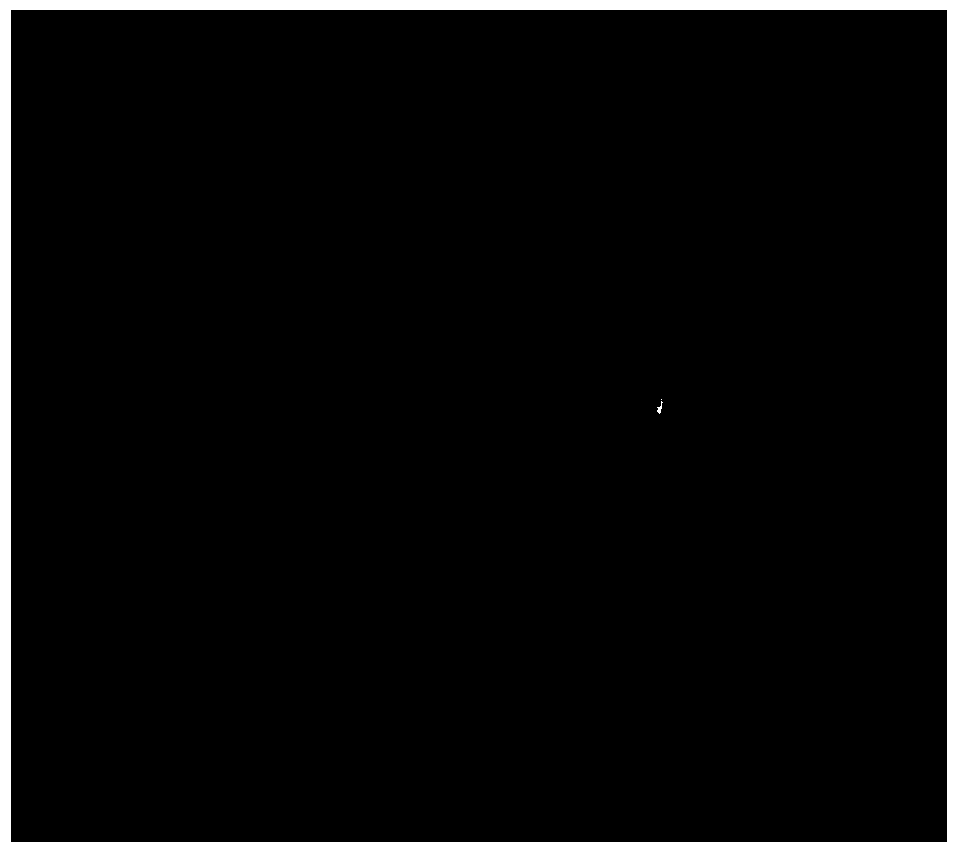

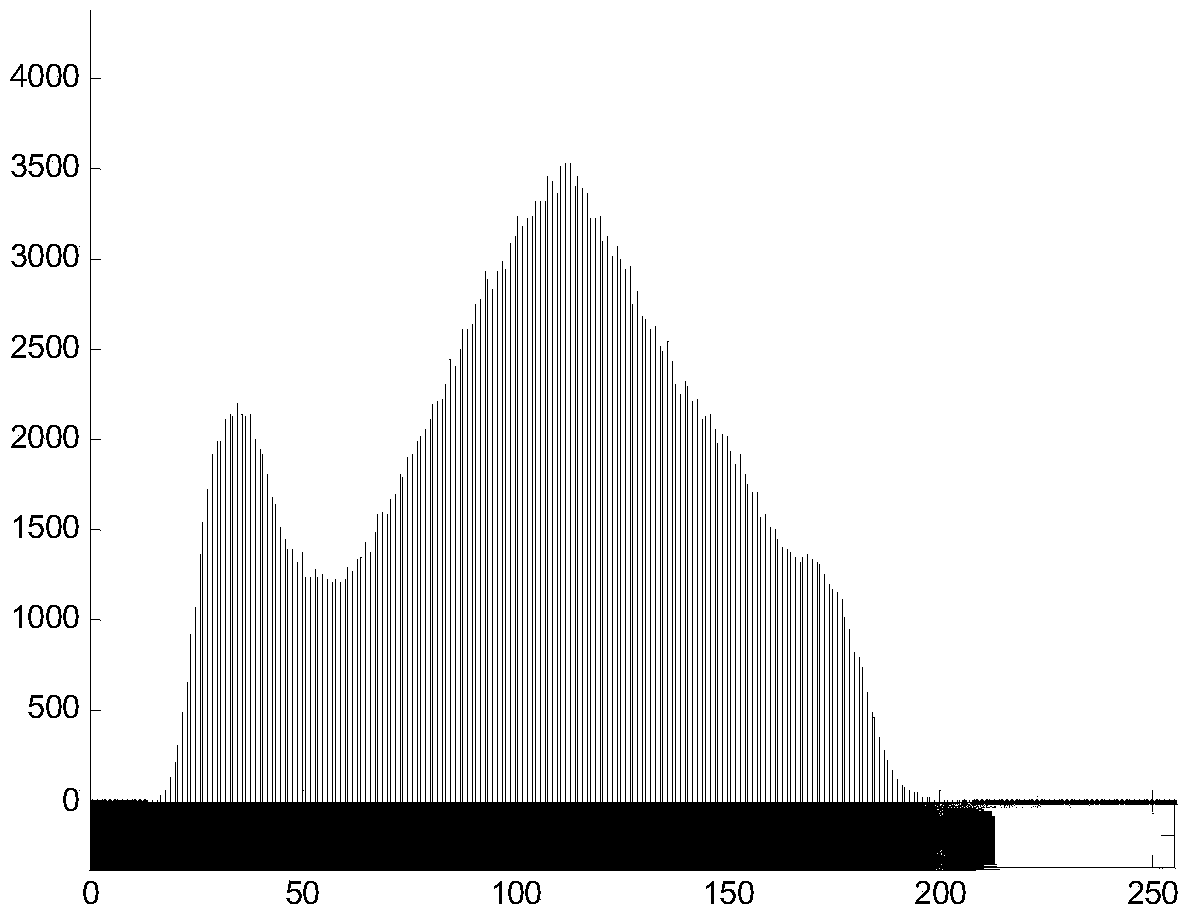

Method for determining porosity characteristics of fabric through image method

ActiveCN103471973APore features are accurateObjective pore characteristicsImage analysisPermeability/surface area analysisPorosityFiltration

The invention relates to a method for determining the porosity characteristics of a fabric through an image method, and in particular relates to a method for determining the porosity characteristics of a latticed sparse fabric through an image method. The method comprises the following steps of converting a gray image into a binary image according to a gray histogram two-peak method threshold of a fabric image, setting the pixel of a yarn region in a binary matrix corresponding to the binary image as 1, respectively projecting the binary matrix in the warp yarn direction and the weft yarn direction, analyzing the central line positions of warp yarns and weft yarns, and cutting off an image region out of the central line positions of side yarns to obtain a new image; identifying the porosity of the fabric in the new binary image, and retaining a true porosity region in the fabric by virtue of pseudo porosity elimination in a main yarn area and an area filtration method; performing statistic analysis on the porosity of the fabric to obtain the characteristics, such as actual porosity, non-uniform porosity and porosity size distribution, of the fabric. By the adoption of the method, a porosity characteristic index can be objectively, accurately and quickly calculated.

Owner:DONGHUA UNIV

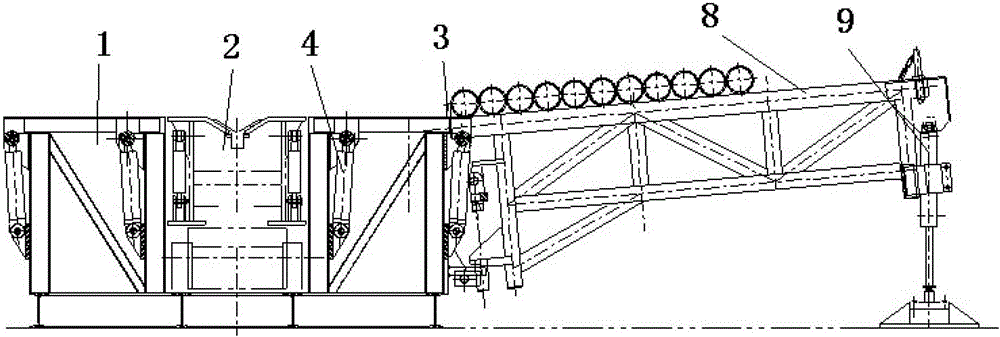

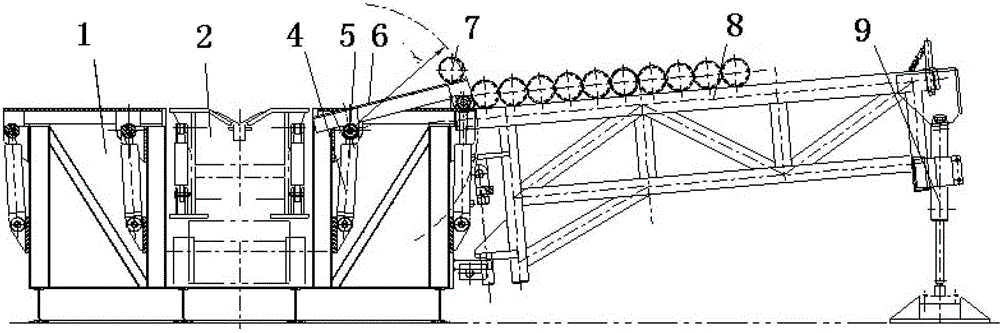

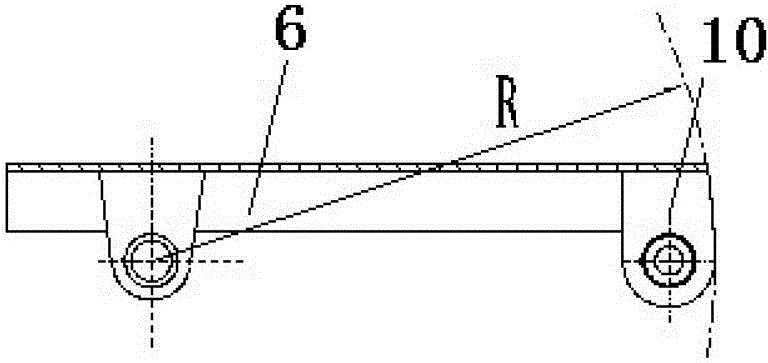

Motive power catwalk pipe wane and pipe loading method of motive power catwalk pipe wane

ActiveCN102720447AReduce consumptionReduce labor intensityDrilling rodsDrilling casingsHydraulic cylinderCentral line placement

The invention discloses a motive power catwalk pipe wane device. The longitudinal center line position of a catwalk base is provided with a drill string conveying device, a panel of the catwalk base is embedded with a wane in a flush way, two ends of the lower surface of the wane are respectively provided with a lug plate, each lug plate is hinged with the piston end head of an inclined hydraulic cylinder of the wane, and the other end of the inclined hydraulic cylinder of each wane is hinged on a connecting seat of the catwalk base; the part of each wane arranged at the outer side of the catwalk base is provided with a pipe rack, the inner side edge of the pipe rack is hinged with the edge of the catwalk base, the lower surface of the outer side of the pipe rack is provided with a main lug plate, the main lug plate is hinged with the piston end head of an inclined hydraulic cylinder of the pipe rack, and the bottom end of a cylinder body of the inclined hydraulic cylinder of the pipe rack is supported on the ground. The invention also discloses a method for pipe loading by using the motive power catwalk pipe wane device. The device and the method disclosed by the invention have the advantages that the energy source consumption is greatly reduced, the work efficiency is improved, and the labor intensity is reduced.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

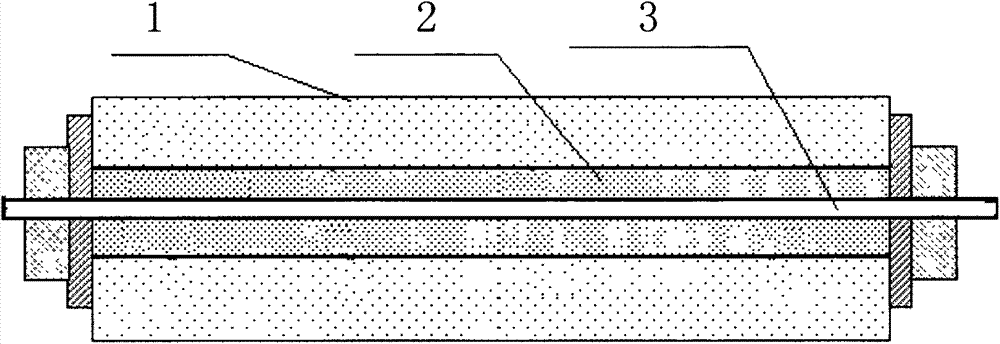

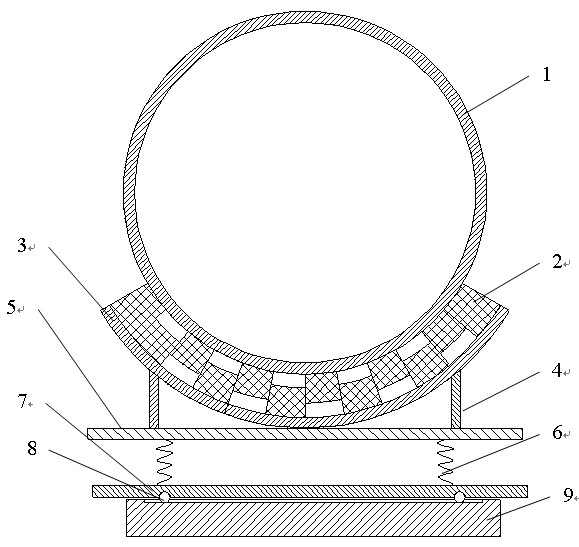

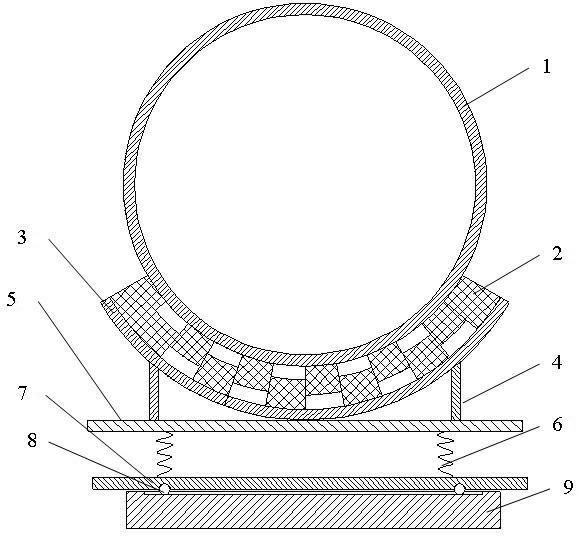

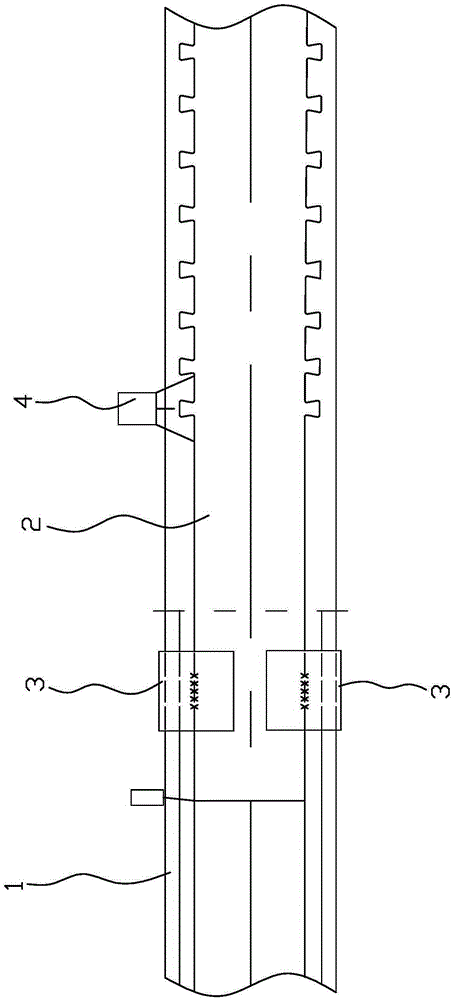

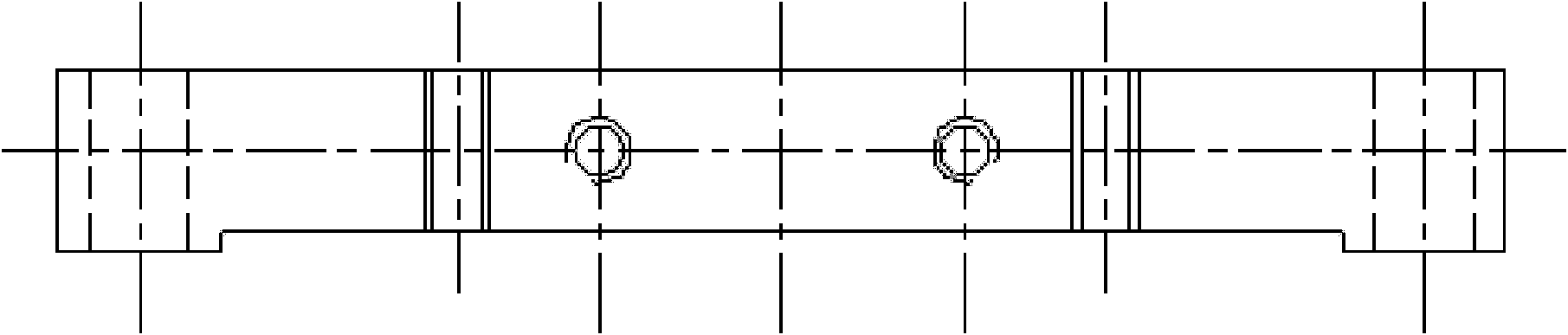

Double-layer vibration damper with temperature varying pipeline capable of stretching freely

InactiveCN102606808AGuaranteed even pressure distributionMeet multi-dimensional size changesPipe supportsSize changeEngineering

The invention discloses a double-layer vibration damper with a temperature varying pipeline capable of stretching freely, which belongs to the technical field of vibration damping and comprises a vibration damping bracket used for supporting a pipeline. The vibration damping bracket is fixed on a panel under the vibration damping bracket through symmetrically installed vibration damping bracket supports, and a spring absorber is installed under a panel. The spring absorber comprises a vibration damping spring, a spring vibration damping base plate, a rolling steel ball and a base support. One end of the vibration damping spring is installed on the lower end face of the panel, the other end of the vibration damping spring is installed on the spring vibration damping base plate, and the spring vibration damping base plate is installed on the base support through the rolling steel ball and is capable of rolling on the base support. The double-layer vibration damper enables a pipeline to be arranged in the support of the double-layer vibration damper, moves with the change of the axial size and the radial size of the pipeline and maintains the position of a damping system in the pipeline. The double-layer vibration damper has the advantages of being capable of enabling multiple-dimension size change of the pipeline in the vibration state caused by temperature change to be removed through the rolling steel ball under the double-layer damping system and simple in structure.

Owner:SHANGHAI DATUN ENERGY

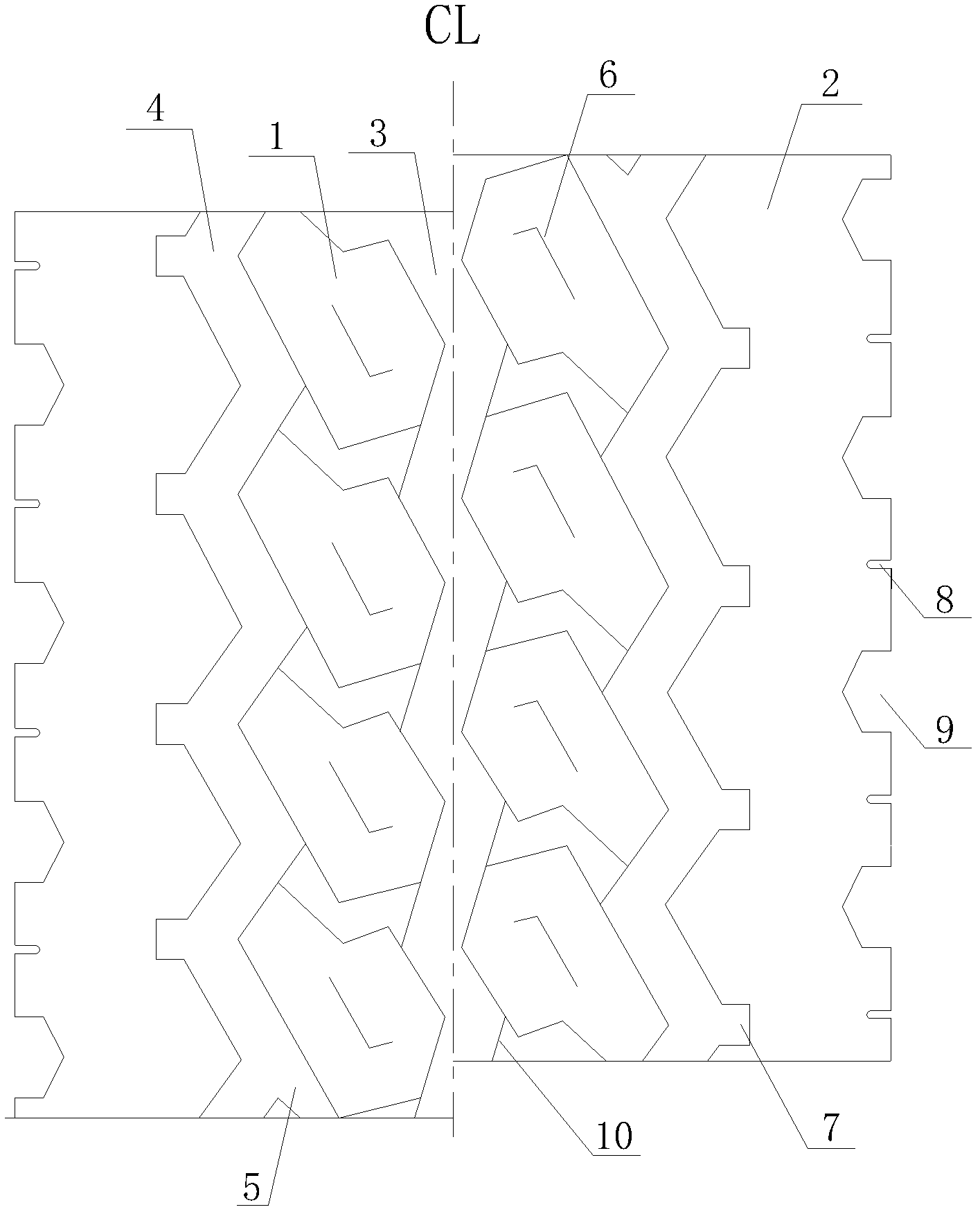

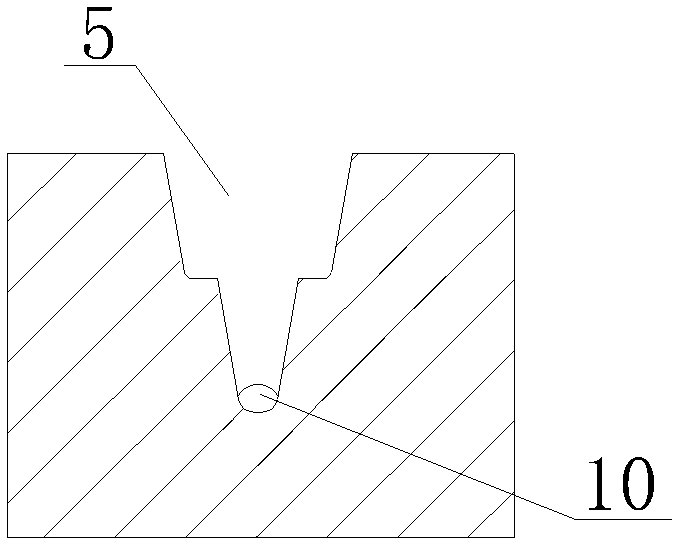

Tire tread of cargo truck

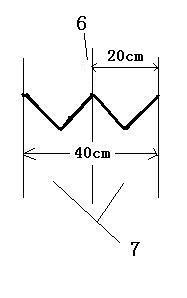

InactiveCN103158444ASufficient braking forceImprove maneuverabilityTyre tread bands/patternsWave shapePoint symmetry

The invention relates to a truck tire, in particular to a tire tread pattern structure of a truck tire. A tire tread of a cargo truck comprises a central longitudinal circumferential pattern groove which is arranged at the position of a longitudinal center line of the tire tread and enables the tire tread to be evenly divided into two symmetrical parts in a left-right mode. Side part pattern blocks and tire shoulder pattern blocks are sequentially arranged on two sides of the central longitudinal circumferential pattern groove form interior to exterior. The side part pattern blocks and the tire shoulder pattern blocks are separated by an auxiliary longitudinal circumferential pattern groove. Each two adjacent side part pattern blocks along the circumferential direction are separated by an auxiliary pattern groove. The central longitudinal circumferential pattern groove and the auxiliary longitudinal circumferential pattern groove are respectively in a wave shape. Two ends of each auxiliary pattern groove are respectively communicated with the central longitudinal circumferential pattern groove and the auxiliary longitudinal circumferential pattern groove. The side part pattern blocks on two sides of the central longitudinal circumferential pattern groove are in point symmetry and arranged in a vertically staggered mode. The tire shoulder pattern blocks are integral pattern blocks. According to the tire tread of the cargo truck, mixed patterns are adopted. The tire tread of the cargo truck has sufficient braking force and good operational properties, and is attractive.

Owner:QINGDAO YELLOWSEA RUBBER

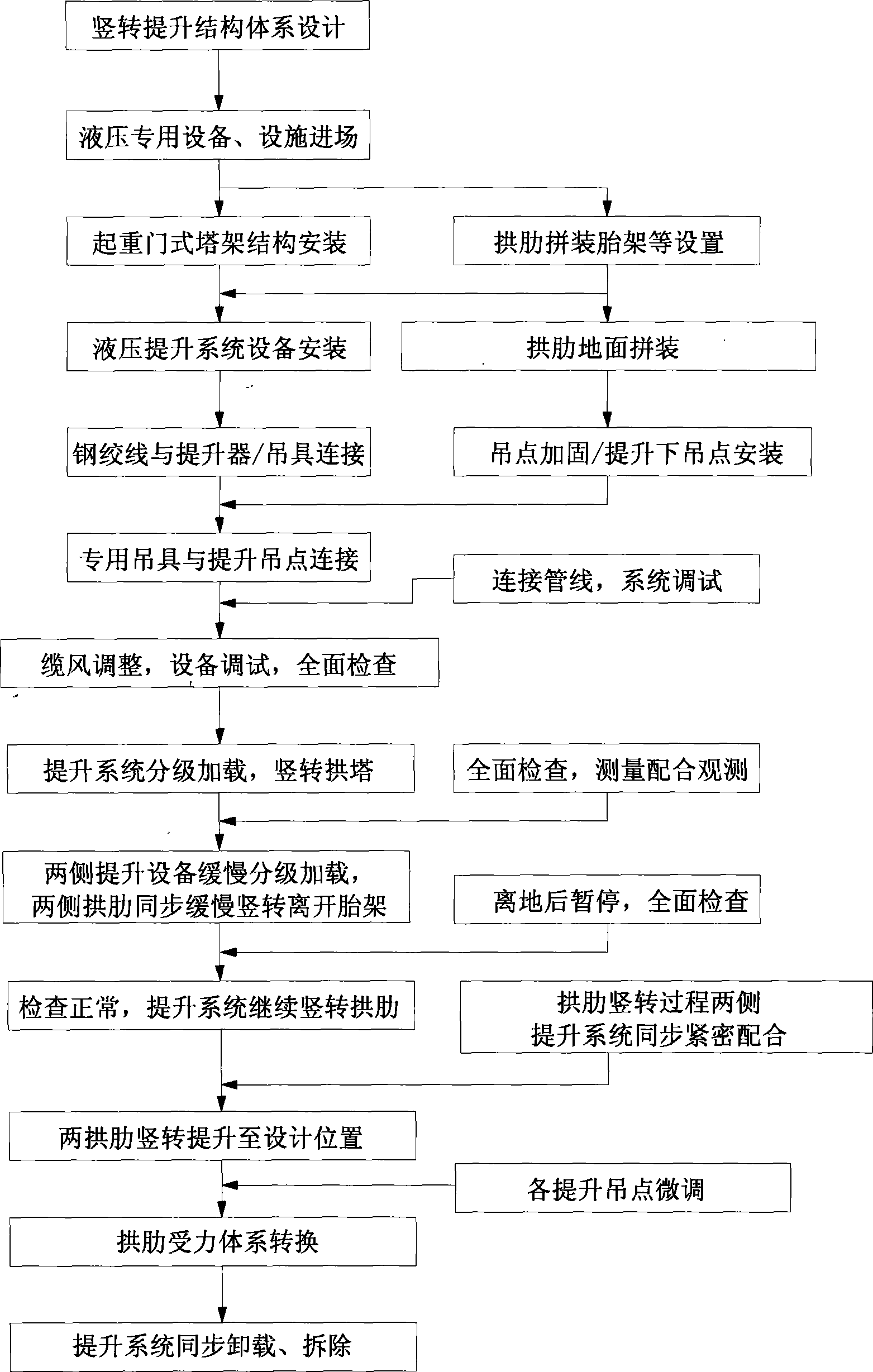

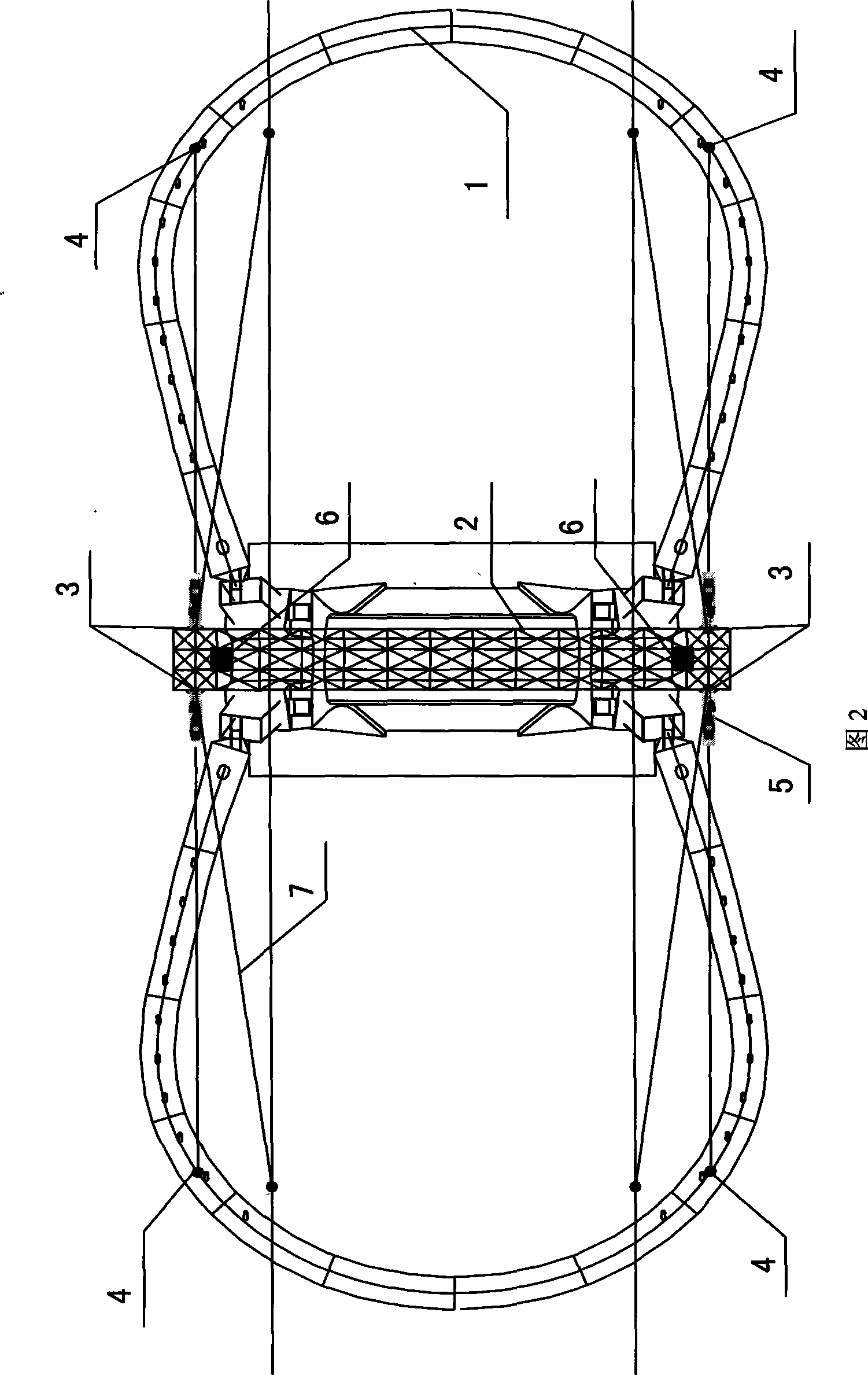

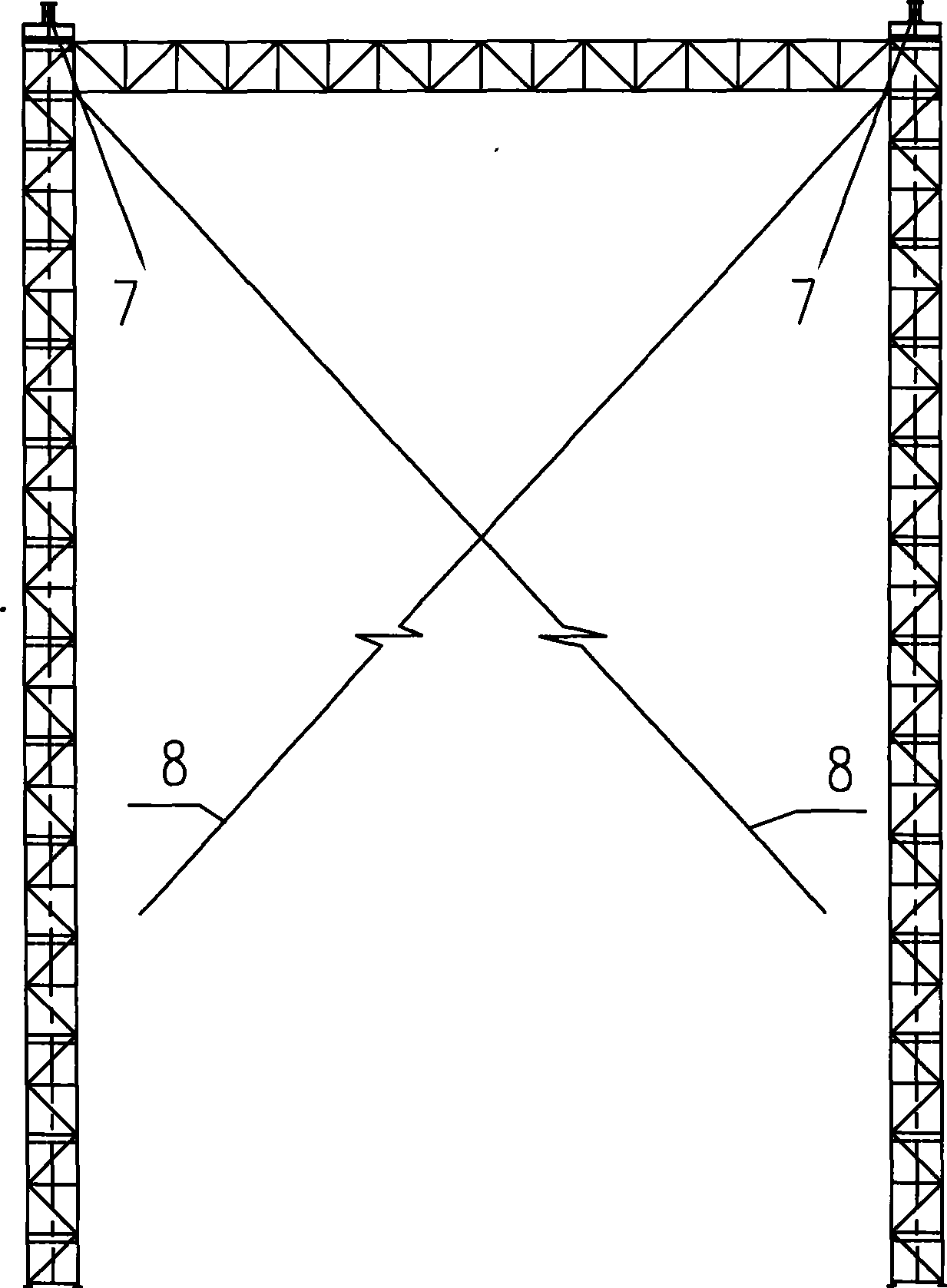

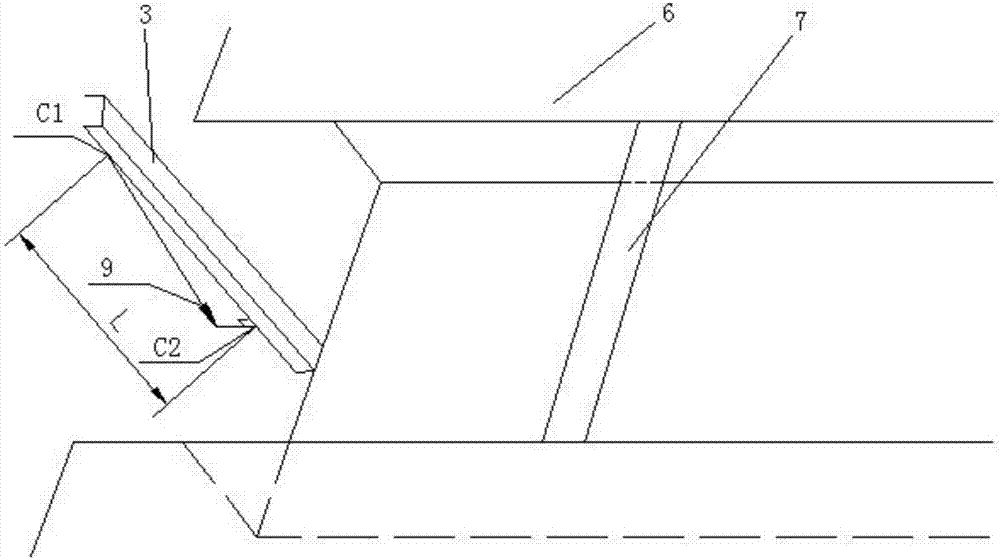

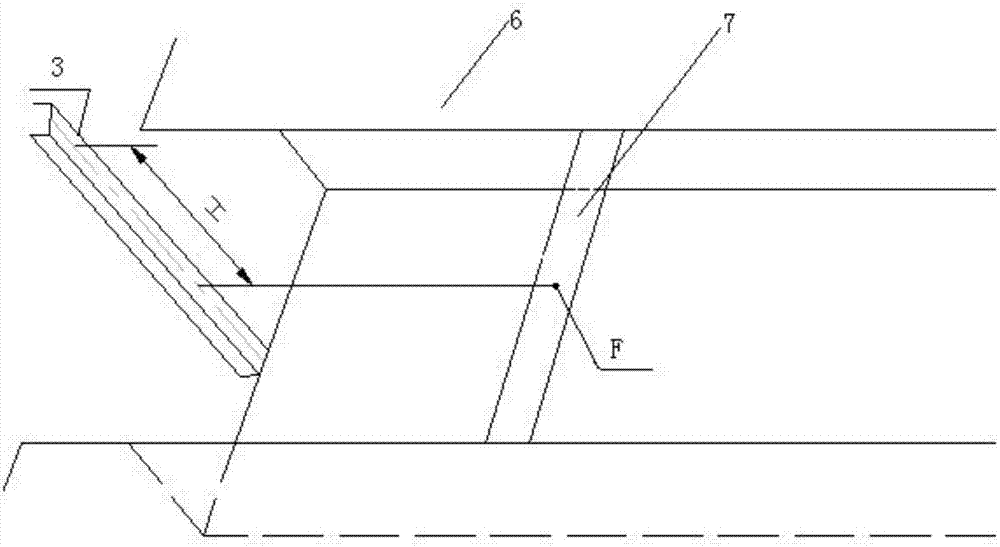

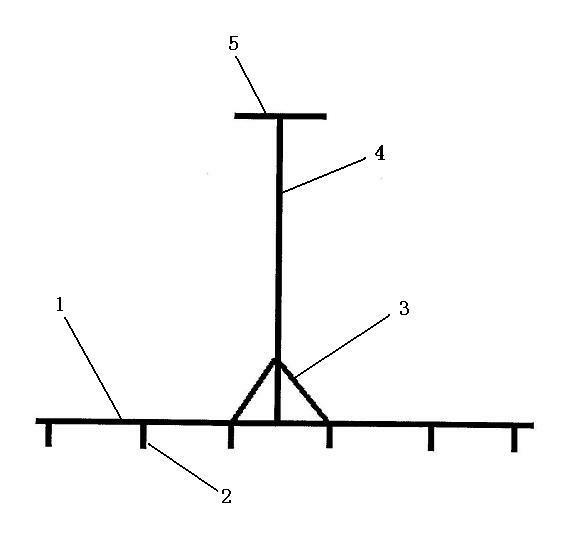

Synchronous vertical swing lift construction method for double inclination arc tower

ActiveCN101446075AIncrease the volume of the facilityReduce weightBridge erection/assemblyReinforced concreteCentral line placement

The invention discloses a synchronous vertical swing lift construction method for a double inclination arc tower. The method comprises the following steps: arranging a vertical swing winch at the combination of two gate-shaped arch ribs and reinforced concrete, arranging a bearing gate type lifting tower at the position of the symmetrical central line of the arch ribs, arranging an upper lifting sustained center and a lower lifting sustained center at the top of the tower and on the arch ribs respectively, and performing symmetrical synchronous vertical swing lift through two pairs of hydraulic lifters by utilizing the symmetry character of the double arch ribs, so as to achieve the purpose of vertically swinging the arch ribs from the planimetric position to the mounting position. The construction method has the advantages that the arc tower construction difficulty is reduced, tools and materials are saved, the construction period is shortened, and the installation of two mammoth arch rib structures can be completed with high precision and high quality; aloft work of the arch ribs is converted into ground integral assembly work, the construction efficiency is high, the safety protection work is easy to organize, and the construction quality is easy to guarantee; machines and equipment required for the construction are in a small quantity, the process is simple, and the operation is safe; the construction speed is high, the manufacture cost is low, and the investment is saved.

Owner:JIANGSU HUNING STEEL MECHANISM

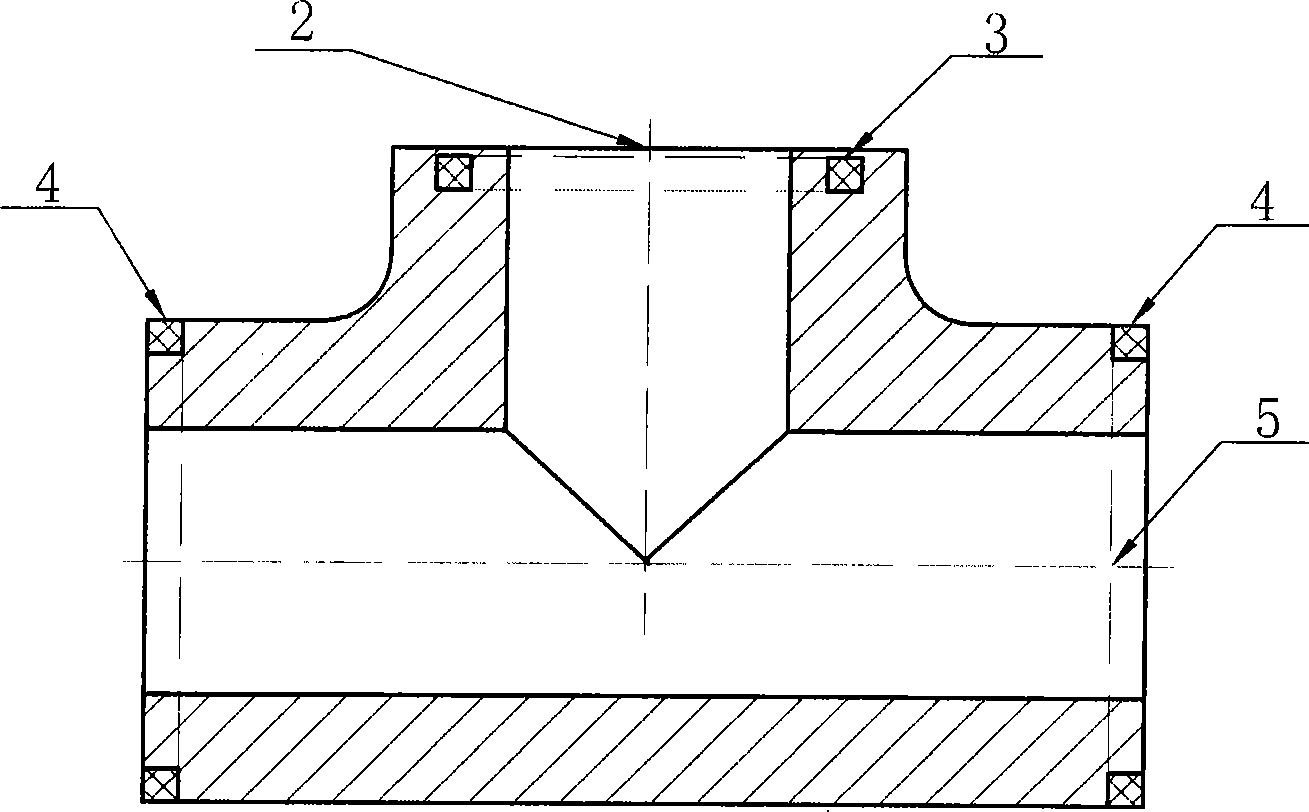

Forging bearing straight three-way production method

InactiveCN101249600AEliminate the defect of loose materialReduce manufacturing costMetal-working apparatusPunchingEngineering

The invention relates to a pipeline for pressure vessels, in particular to a method for manufacturing high-pressure and high-temperature resistance large straight-tees. The method comprises the following steps: preparing the blank to be forged; then carrying out the molding treatment of the straight-tee main and branch holes, wherein the molding treatment is carried out by forging punching holes and enlarging holes, and when forging the punching holes, the position of the center line of the main hole forged deviates from the position of the center line of the blank; and finally, carrying out after-forging treatment, including the re-treatment of the main hole and the branch hole. The method has the advantages of replacing the status of the imports all year round, reducing the cost of production, greatly saving the manpower and time, and decreasing the processing period. Furthermore, the method uses the forged punching, thereby eliminating the defect that the material inside the solid core of the large billet is loose, and significantly improving the mechanical performance of the product when tested by the United States ASME SA182 standard.

Owner:SHANGHAI DINGFU MACHINERY MFG

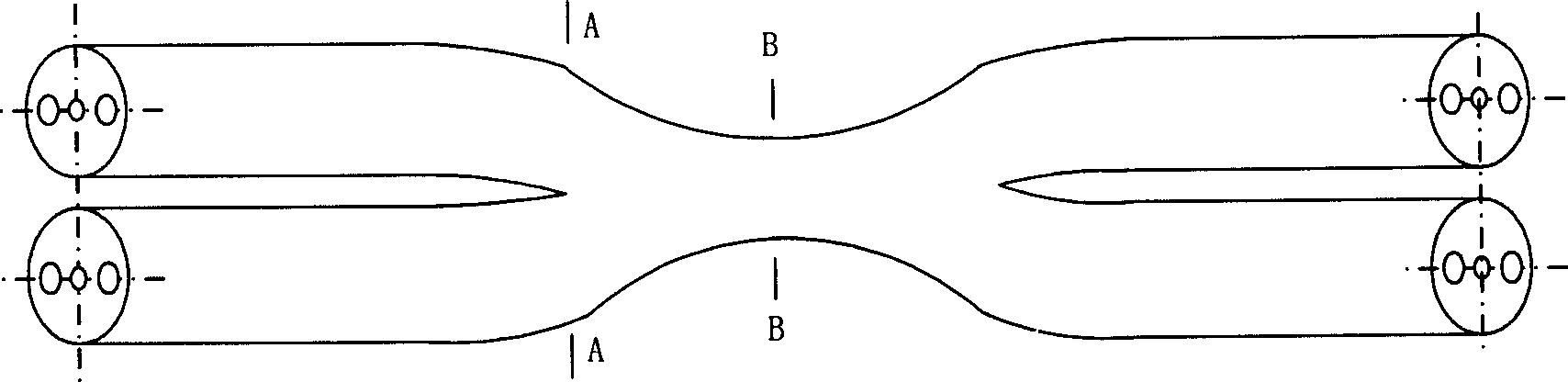

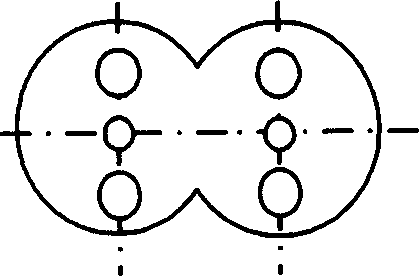

Automated fused biconical taper device for polarization maintaining fiber coupler

InactiveCN1763570AImprove performancePrecise positioningCoupling light guidesMicroscopic imageFiber coupler

The invention discloses an automatic deflection-keeping optical fiber coupler fusion cone-stretching device, which comprises the following parts: working bench, automatic shaft-shoot system on the working bench, medium approximate system, fusion cone-stretching system, on-line packaging system and main control computer, wherein the left and right symmetrical distribution mechanic platforms and control panel are set on the working bench; the automatic shaft-shoot system contains four groups of the same structure electric rotary system, light source and microscopic image system with four groups of diagonal shape electric rotary system on the left and right mechanic platforms as well as light source and microscopic image system on the working bench; the medium approximate system is set on the central line position of left and right mechanic platforms; the fusion cone-stretching system contains heat source and motion cone-stretching system; the left and right mechanic platforms are fixed on the motion cone-stretching system separately.

Owner:NAT UNIV OF DEFENSE TECH

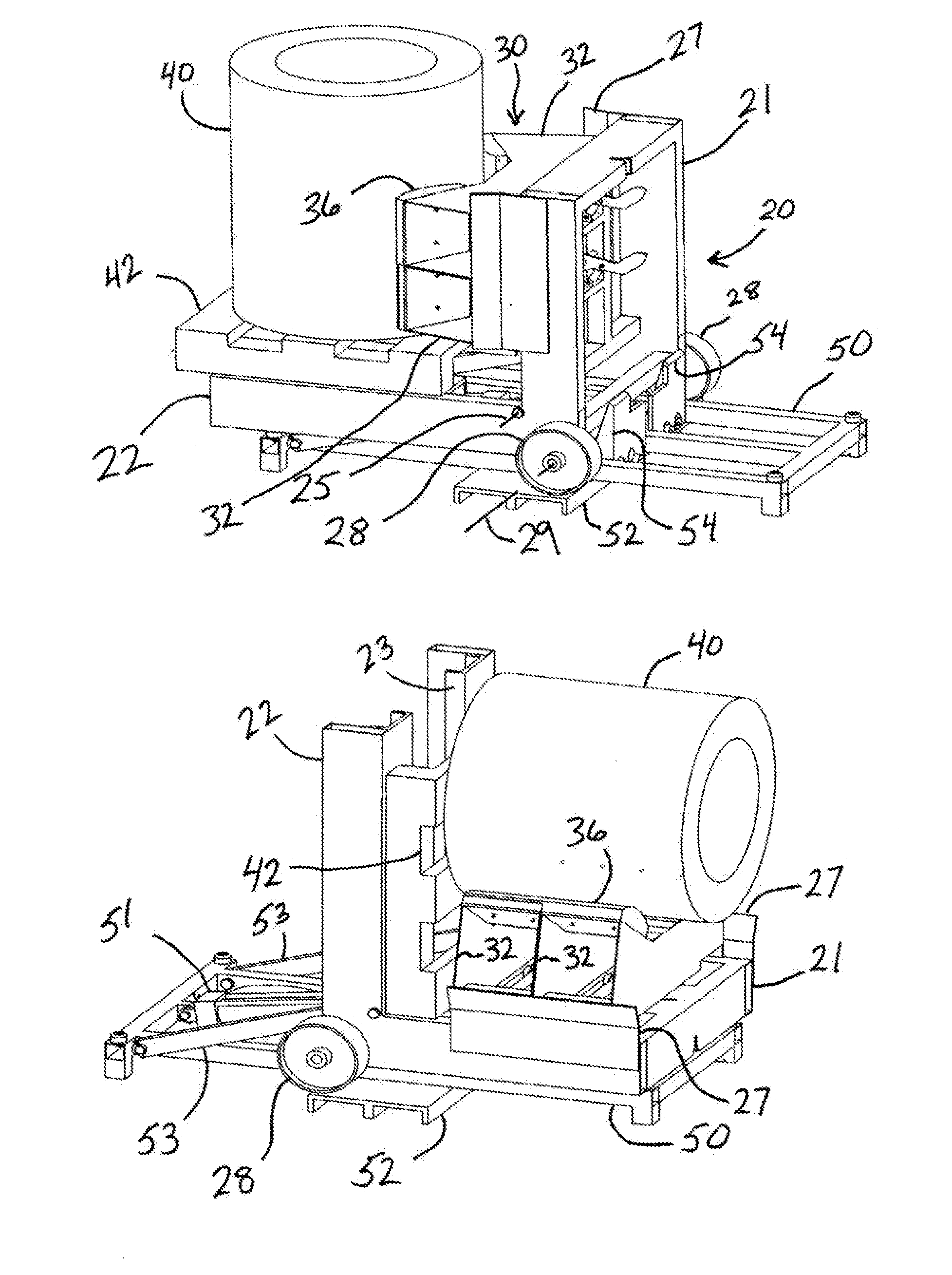

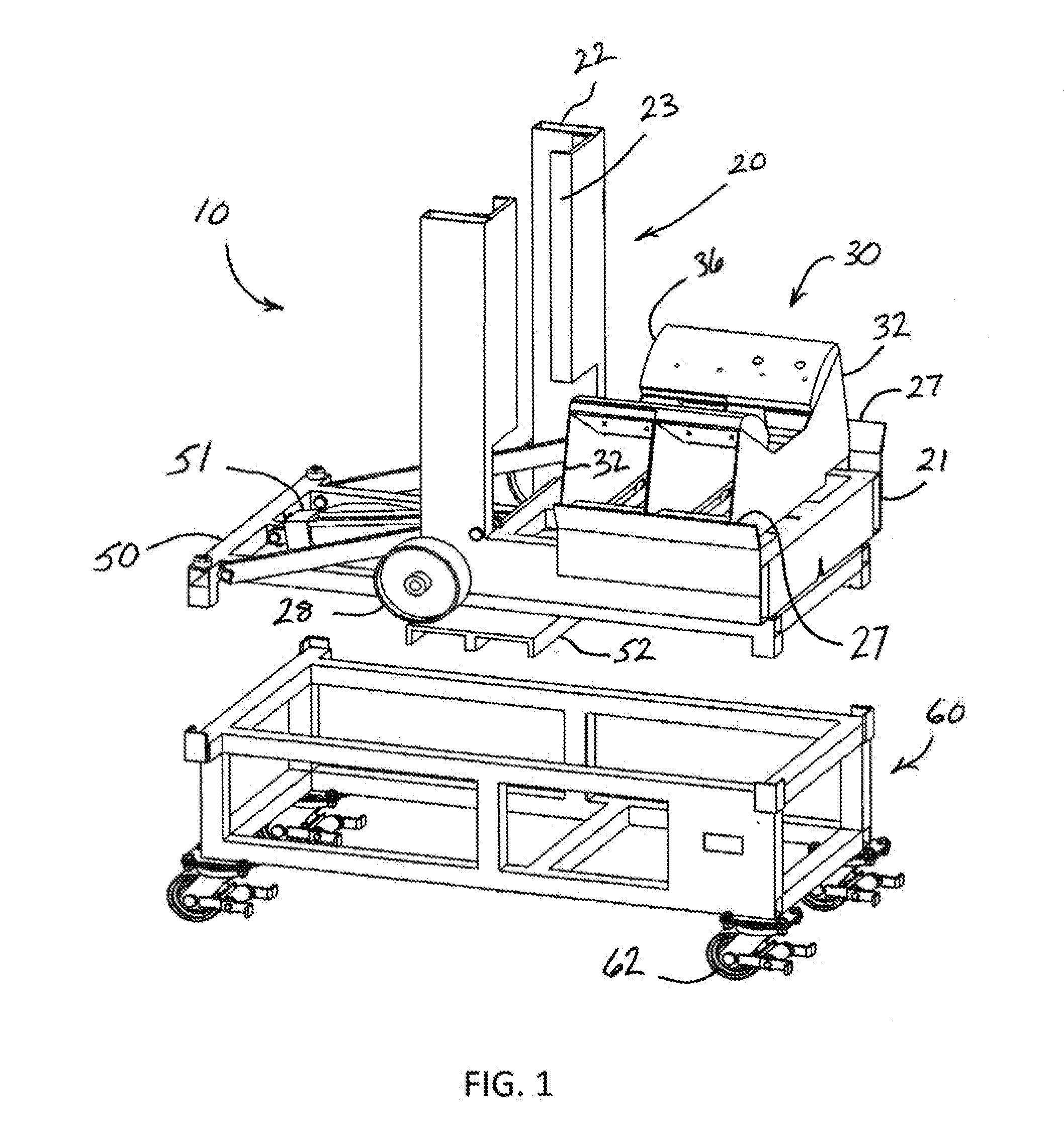

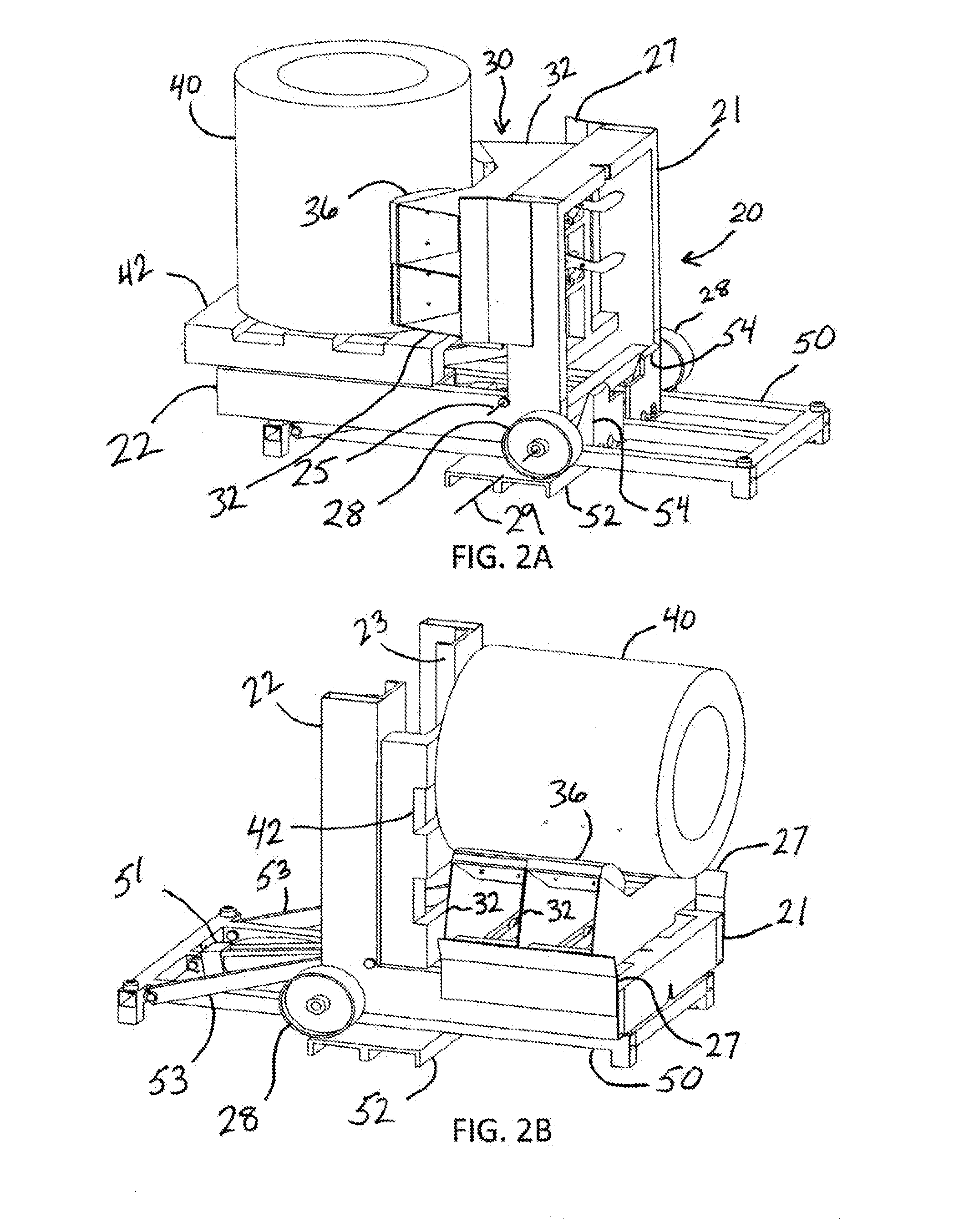

Compact Mobile Roll Tilter

The roll filler supports a palleted roll of sheet or thin plate material and re-positions the roll for mounting to an unrolling fixture. The roll tilter received the roll resting on a pallet in a vertical centerline position and rotates the palleted roll from the vertical position to a position with the roll center line in a horizontal position to facilitate mounting the roll on an unrolling fixture.

Owner:ENGLISH CALVIN FRANCIS

Construction measurement method of plate type convex barricade with unballasted track

InactiveCN101761003AGuaranteed construction accuracyImprove construction efficiencyMeasuring apparatusTemplate basedComputer module

The invention discloses a construction measurement method of a plate type convex barricade with an unballasted track. The method comprises the following steps of: fixedly installing a small prism on an installed convex barricade template; arranging a total station at the center line of a track line and freely stationing based on a foundation pile control net; lofting by a small prism installed on a total station measurement template by using a polar coordinate method and transmitting the measurement data to an operational computer via a wireless module; comparing the returned measurement data with the theoretical design value which is input to the operational computer in advance, and computing the deviation between the actual position and the design position by construction measurement software of the convex barricade; and adjusting the position of the convex barricade template based on the adjustment value shown on the computer. By freely stationing the polar coordinates for lofting the convex barricade template, the method can realize the planar and elevational lofting and has the advantages of high measurement precision and high efficiency.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

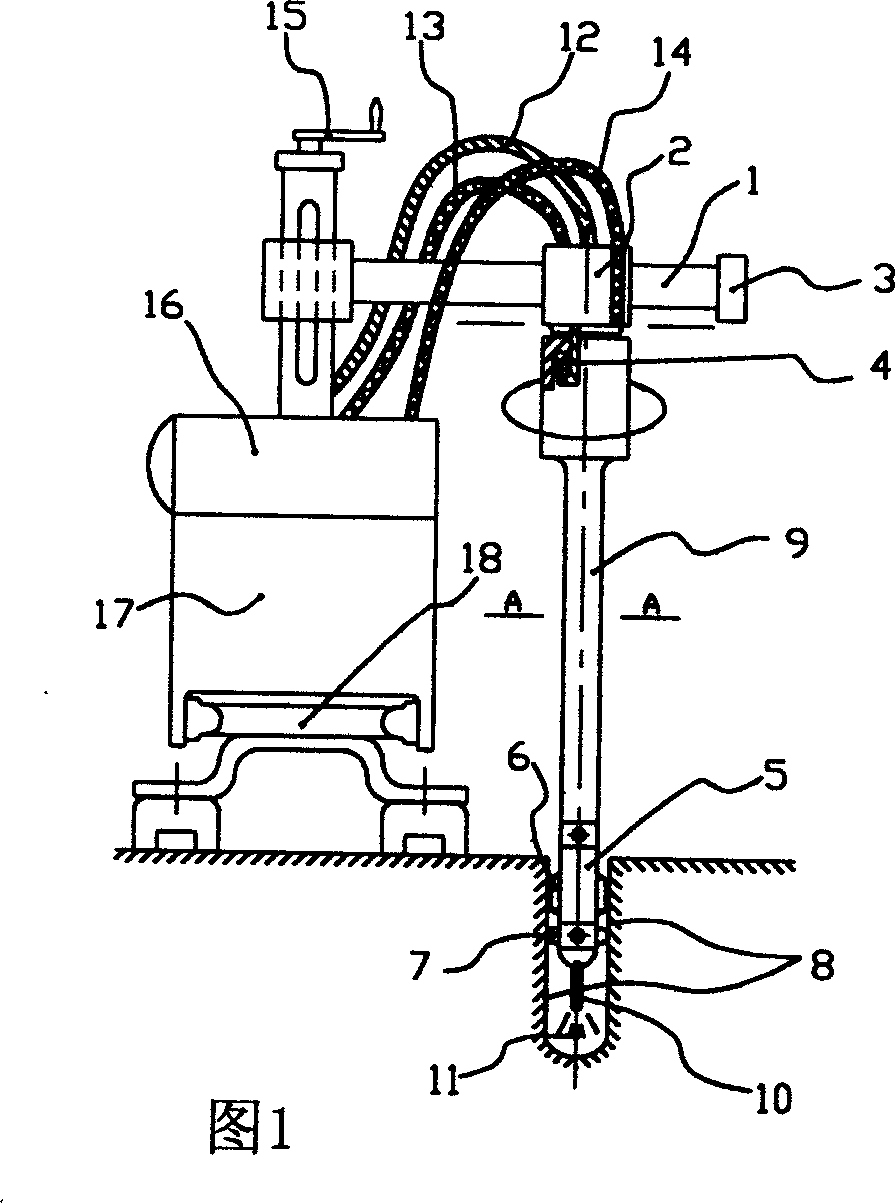

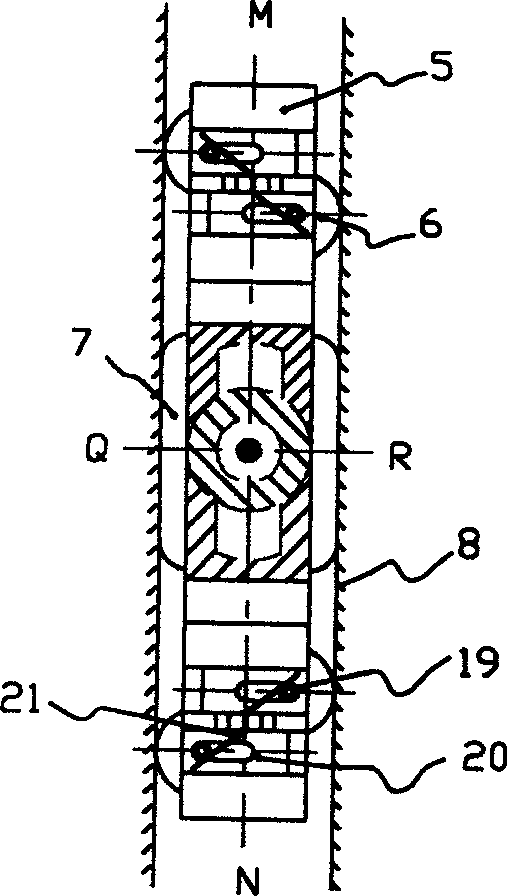

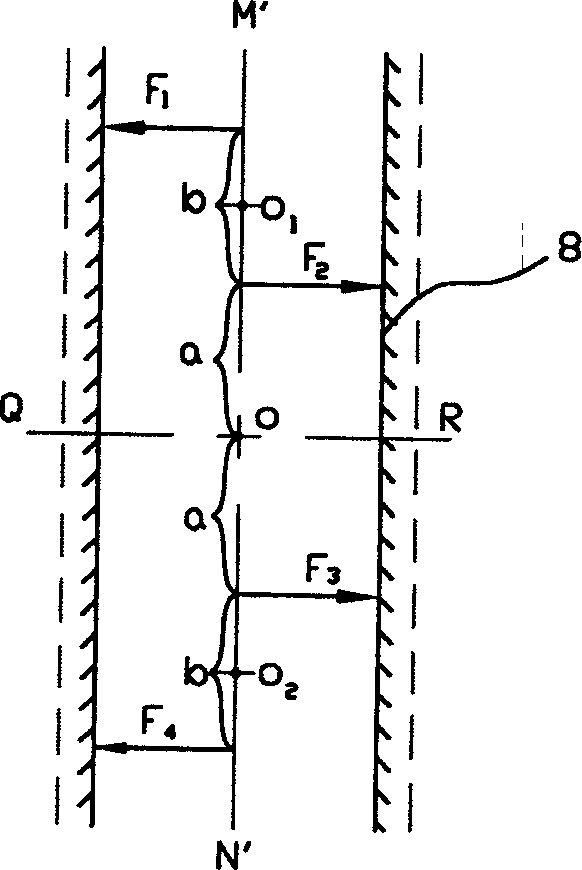

Automatic device in transverse direction for tracking welding line line by floatation force of welding-torch

InactiveCN1600487AMeet the horizontal tracking accuracy requirementsEliminate Tracking ErrorArc welding apparatusAutomatic controlEngineering

An automatic transverse weld tracking apparatus for welding torch is composed of a welding carriage with a guide rod on which the welding torch moves transversely, a slide sleeve on said guide rod, a welding torch with a base connected to said slide sleeve and rotary relatively to the slide sleeve and a welding wire outlet, and the front and back force couple bodies with elastic detecting rollers for making the welding wire always on the central line of two bevel surfaces to be welded.

Owner:武汉卓创智能设备有限公司

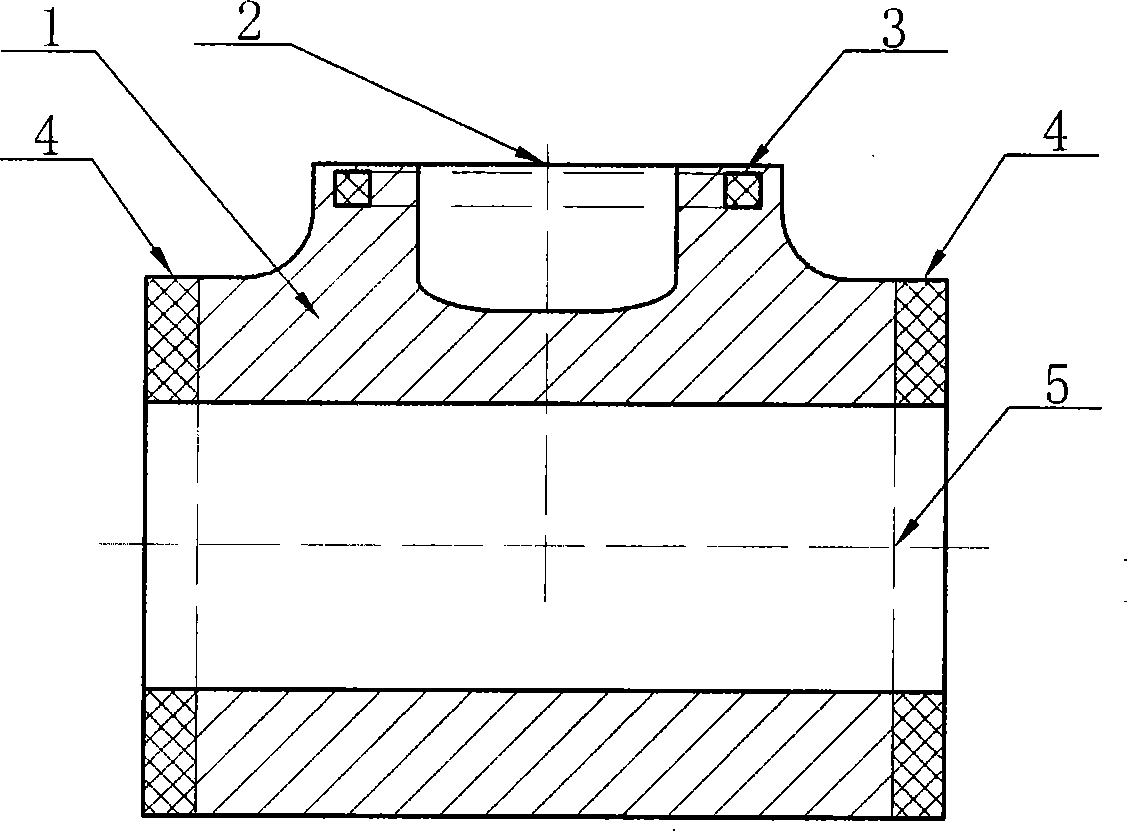

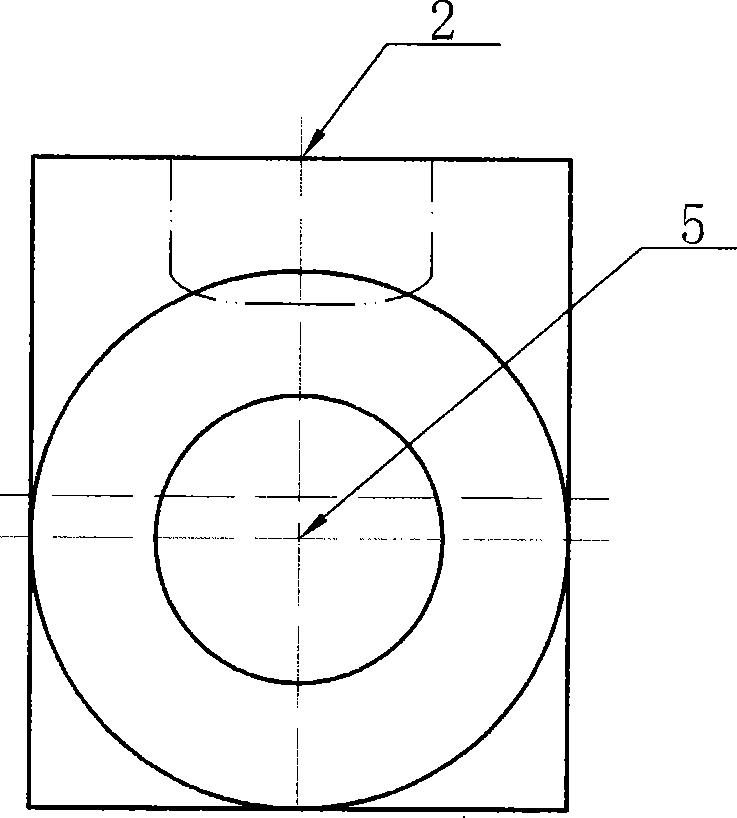

Manufacturing method of cross forging

ActiveCN102284673ACompact structureNo wasteMetal-working apparatusDomestic articlesCentral line placementEngineering

The invention relates to a manufacturing method of a cross-shaped forging piece. The manufacturing method comprises the following steps of: a) pressing into a square shape; b) chamfering; c) pressing into marks: pressing into a round groove at the central line position of four chamfers of a blank; d) pressing into small angles: aligning the edge of a small triangular knife to the round groove, then pressing out a small triangular groove at each chamfering position of the blank respectively by adopting a pressing machine, and setting the length of the right-angled edge of the small triangular knife to be 0.08-0.12 of that of the cross-shaped forging piece; e) pressing large angles: arranging a large triangular knife in the small triangular grooves, then pressing out a large triangular groove at each small triangular groove respectively by adopting the pressing machine, and setting the length of the right-angled edge of the large triangular knife to be 0.25-0.40 of that of the cross-shaped forging piece; f) pressing with anvils: respectively arranging an upper anvil and a lower anvil at the two corresponding large triangular grooves, and then carrying out anviling on four bosses of the blank in sequence by adopting the pressing machine, thus obtaining a cross-shaped forging piece blank; and g) shaping. The manufacturing method is applicable to manufacture of the cross-shaped forging piece.

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING

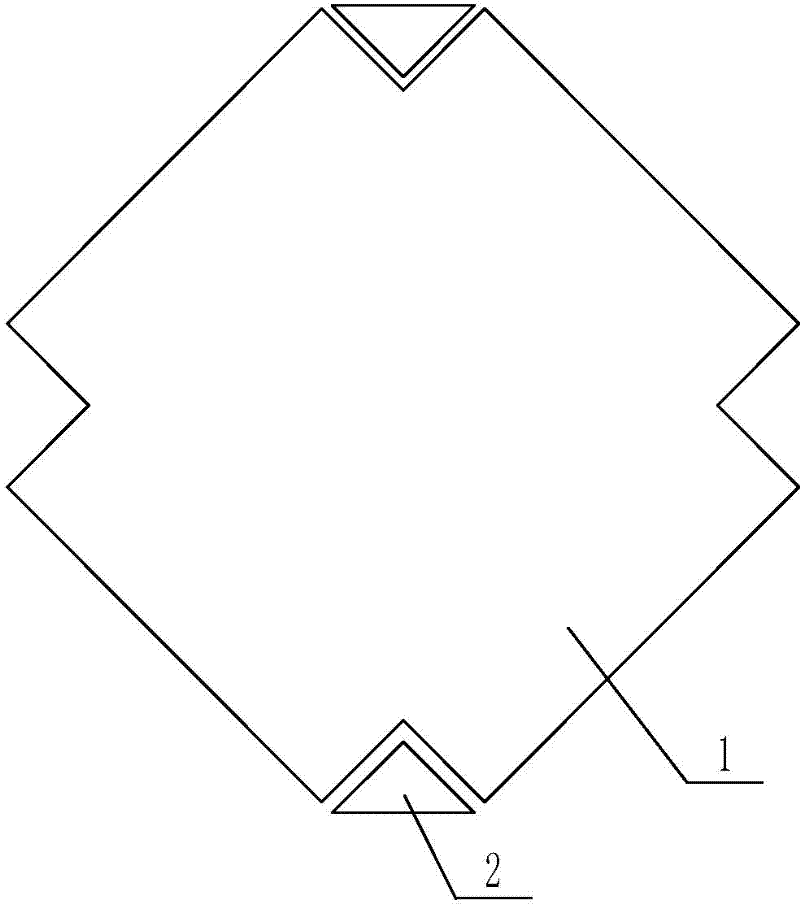

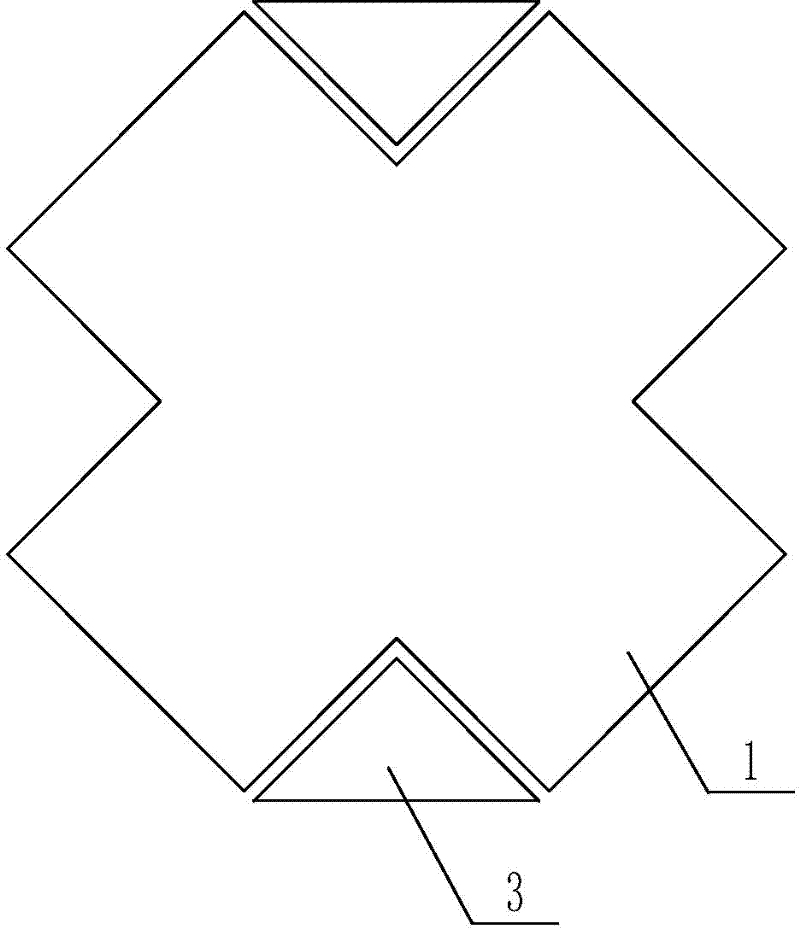

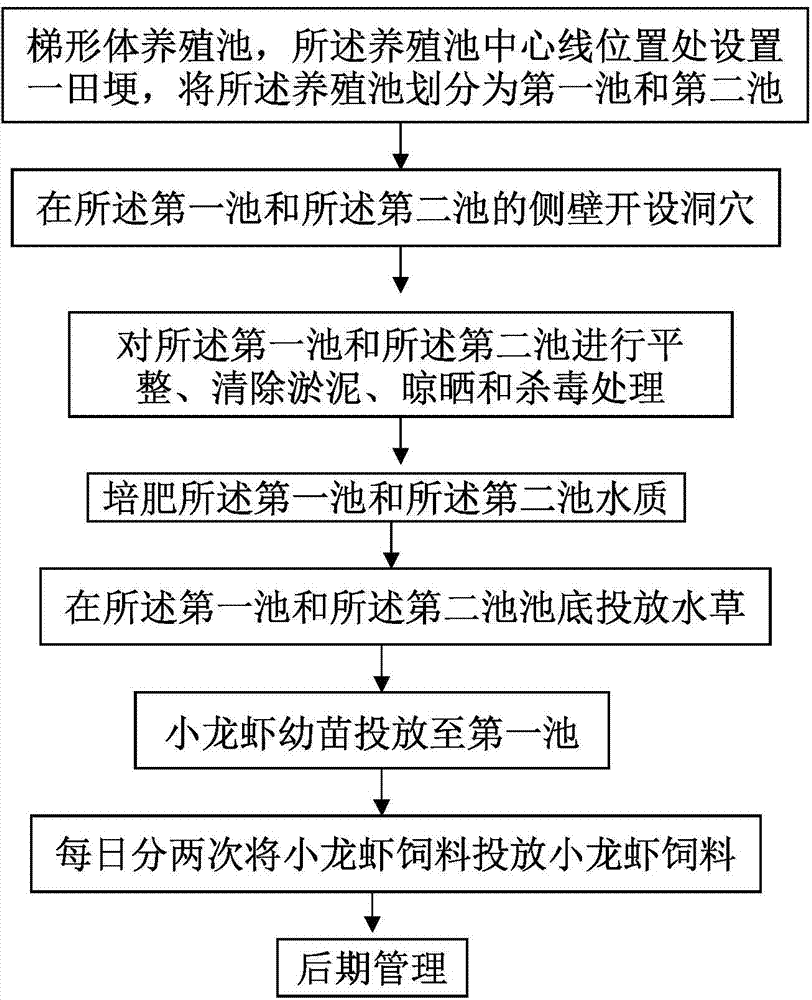

Culture method for increasing survival rate of crays

InactiveCN104839059APrevent climbing outAvoid lossClimate change adaptationPisciculture and aquariaShrimpWater quality

The invention provides a culture method for increasing survival rate of crays. The method includes: (1) building a culture pond which is a trapezoid, arranging a ridge at the position of the center line of the culture pond, and dividing the culture pond into a first pond and a second pond via the ridge; (2) constructing cray caves, to be more specific, forming the caves in the side walls of the first pond and the second pond; (3) pretreating the culture pond, leveling the first pond and the second pond, and performing desludging, airing and disinfection; (4) performing fertility betterment of water; (5) putting in aquatic plants, tying the aquatic plants into stacks with ropes, and putting the stacks into the bottoms of the first pond and the second pond at an interval of 5 meters; (6) putting in cray fries; (7) putting in feed, to be more specific, putting in cray feed twice every day; (8) performing later period management. In the cray culture process, the crays are cultured in the first pond and the second pond alternatively so as to disinfect the first pond or the second pond thoroughly, and survival rate of the crays is increased.

Owner:许玲

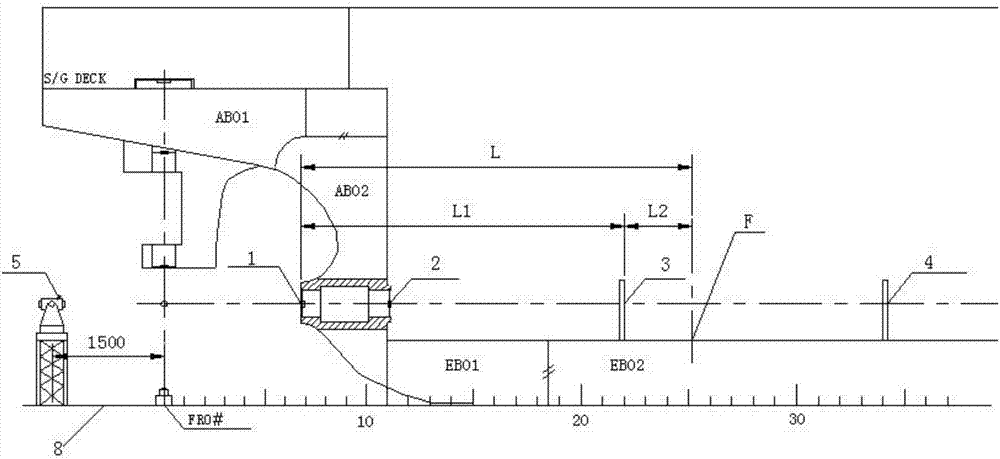

Method for positioning marine main engine foot bolt hole

InactiveCN106853861AGuarantee product qualityGuaranteed production cycleVessel partsMarine engineeringCentral line placement

The invention discloses a method for positioning a marine main engine foot bolt hole. Firstly, a centering target A is placed at the rear end face of a stern shaft tube, a centering target B is placed at the front end face of the stern shaft tube, and the up, down, left and right positions of the centering target A and the centering target B are adjusted till the connecting line of the centers of the two targets coincide with an axial hole center line of the stern shaft tube; secondly, according to a marine midship line, a channel steel target C is installed at the rear end of a first foot bolt hole of a marine main engine, and the channel steel target C is required to be straight and perpendicular to a base plate; thirdly, the actual center line position of a shaft system is determined according to the center line of the stern shaft tube, and then the center of the channel steel target C is adjusted to be flush with the actual center line of the shaft system on the basis. By accurately positioning the marine main engine foot bolt hole, the installing size precision and usage performance of relevant accessories of the shaft system can be ensured, further the hidden danger that a seal behind the stern shaft tube produce oil leakage is avoided, the quality of ship products can be ensured, and a ship production cycle can be also ensured.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

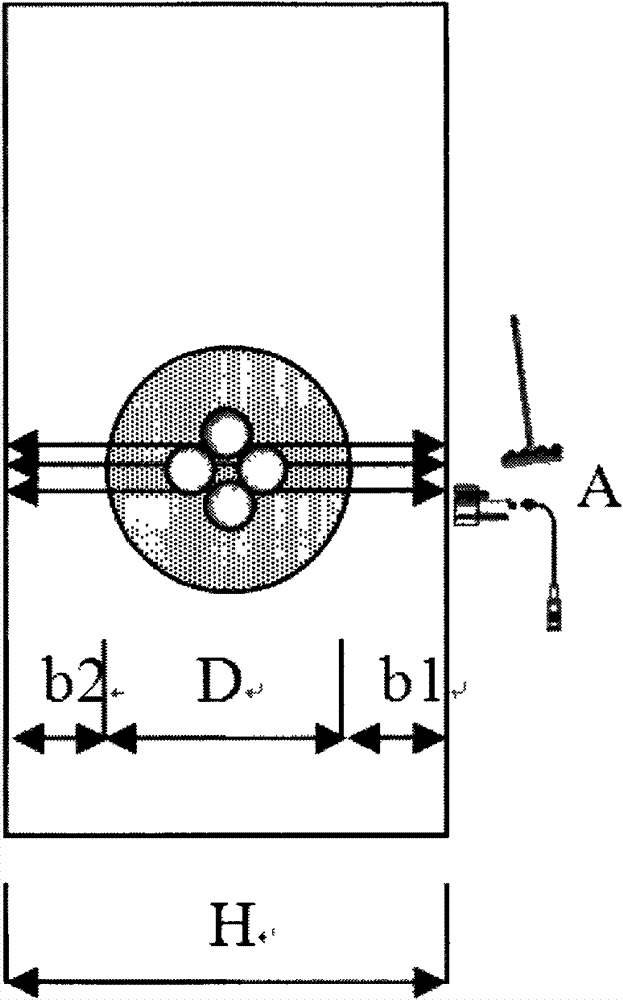

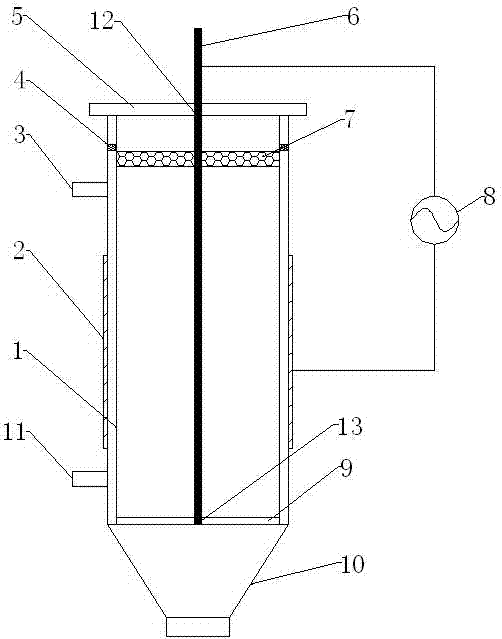

Integrated purification device for gaseous pollutants

ActiveCN103480261ASolve the problem of collaborative controlSimple structureCombination devicesMulti pollutantCentral line placement

The invention relates to an integrated purification device for gaseous pollutants. The device comprises a reactor body, a high-voltage electrode, a grounding electrode and a power supply system, wherein a gas inlet is formed in the lower part of the reactor body, and a gas outlet is formed in the upper part of the reactor body; the high-voltage electrode is arranged in a position of a longitudinal central line of the reactor body, and the grounding electrode is arranged on a casing of the reactor body; an overflow groove is formed in the upper part of the inner side of the reactor body, and a wind distribution plate is arranged at the lower part of the inner side of the reactor body; a drainage port is formed in the bottom of the reactor body; a plurality of through holes which are taken as water inlets are uniformly formed in a wall, above the overflow groove, of the reactor body; the high-voltage electrode is connected with an output end of the power supply system through a high-voltage lead; and the grounding electrode is connected with a grounding end of the power supply system through a grounding lead. According to the integrated purification device for the gaseous pollutants, innocent treatment of various pollutants in exhaust gas can be performed in the purification device simultaneously, the efficiency is improved, and generation of secondary pollution is prevented at the same time.

Owner:ZHEJIANG UNIV

High-speed and high-precision tab cutting method and device based on vision guidance

ActiveCN105290621AImprove cutting accuracyReduce defective rateMetal working apparatusLaser beam welding apparatusLaser cuttingEngineering

The invention discloses a high-speed and high-precision tab cutting method and device based on vision guidance. The tab cutting method comprises the following steps: placing a tab material band on a synchronous conveyor belt; utilizing a main transmission motor to drive the synchronous conveyor belt to move, and conveying the synchronous conveyor belt forwards; through a feedback encoder, triggering and driving an industrial camera to carry out vision detection on the tab material band, and obtaining the position image of the tab material band; extracting positions corresponding to the two edge lines of the tab material band; calculating the actual central line position of the tab material band; calculating the central position deviation value of the tab material band; immediately transmitting the central position deviation value of the tab material band to a laser cutting device; and by the laser cutting device, according to the deviation numerical value obtained through the vision detection of the tab material band, immediately triggering laser to make corresponding position adjustment when the tab material band reaches the cutting position of the laser cutting device. The high-speed and high-precision tab cutting method and device based on vision guidance have the advantages of being high in cutting precision, being high in product quality and the like.

Owner:海目星(江门)激光智能装备有限公司

Method for preventing deformation of reinforcement steel plate welded on top flange of crane girder

The invention discloses a method for preventing the deformation of a reinforcement steel plate welded on a top flange of a crane girder. When the reinforcement steel plate is welded on the top flange of the crane girder, firstly, at least 3 through holes are made in the centerline position of the reinforcement steel plate along the length direction, the reinforcement steel plate is placed on the top flange of the crane girder, and the positions between edges at two sides of the top flange of the crane girder and the reinforcement steel plate are welded. The welding method comprises the following steps of: (1) intermittent welding; and (2) alternate repair welding on both sides. The method for performing intermittent welding and alternate repair welding on the edges at two sides of the top flange of the crane girder is adopted and the through holes are made on the reinforcement steel plate, not only the welding stress generated during welding can be effectively eliminated, but also the deformation of the reinforcement steel plate during welding can be effectively prevented. The method not only can effectively reduce and prevent the possibility of deformation when the reinforcement steel plate is welded on the top flange of the crane girder, but also has the advantages of simple structure and convenience for construction.

Owner:GUIYANG AL-MG DESIGN & RES INST

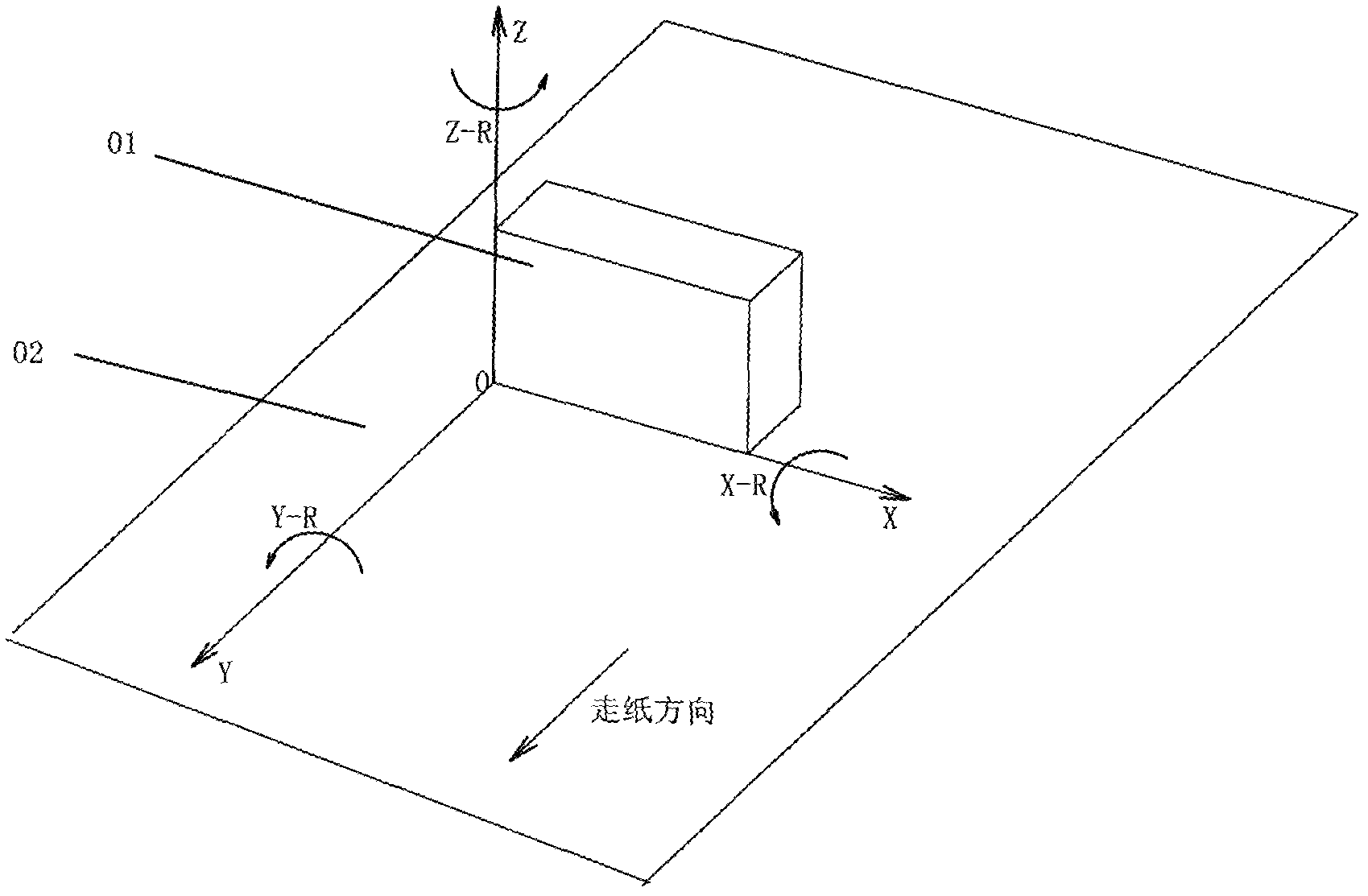

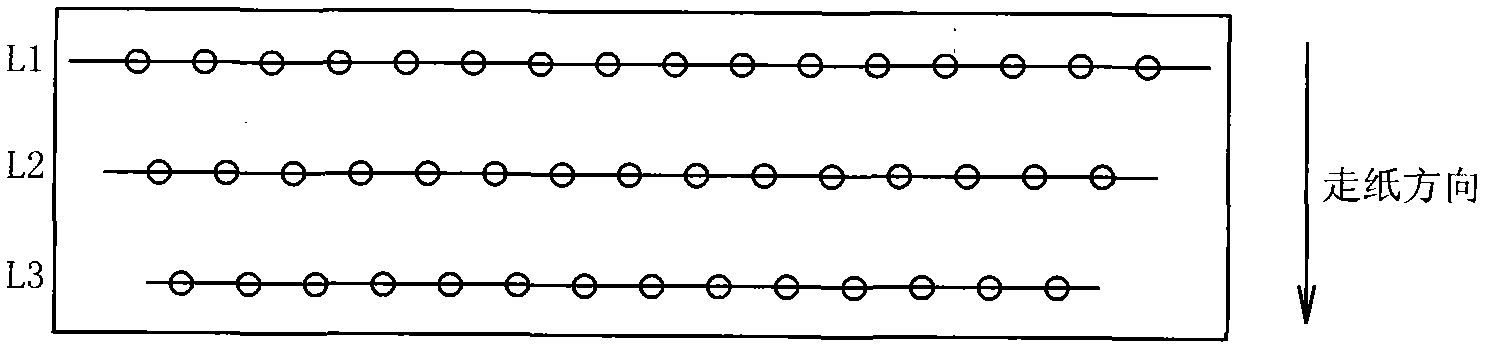

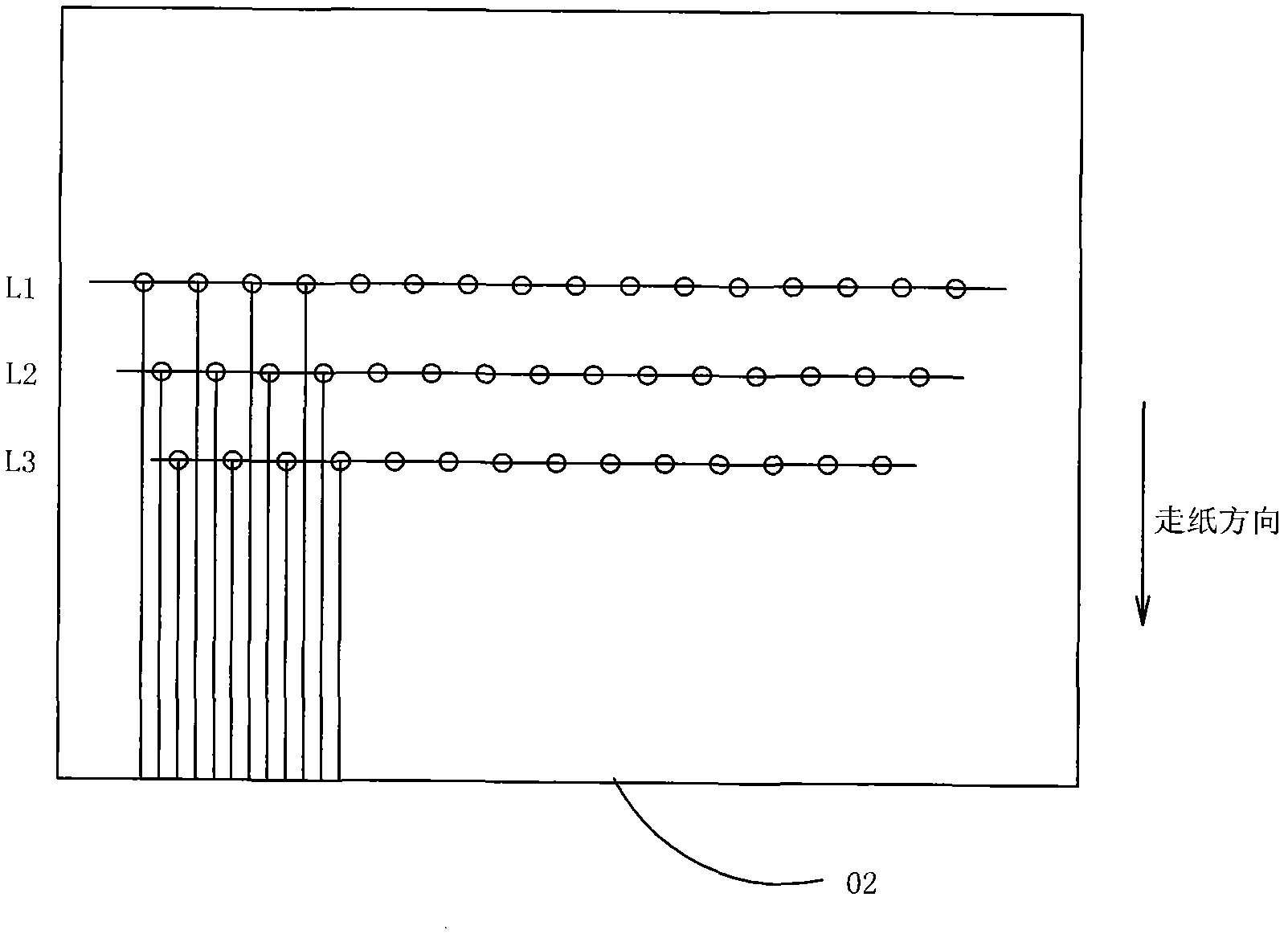

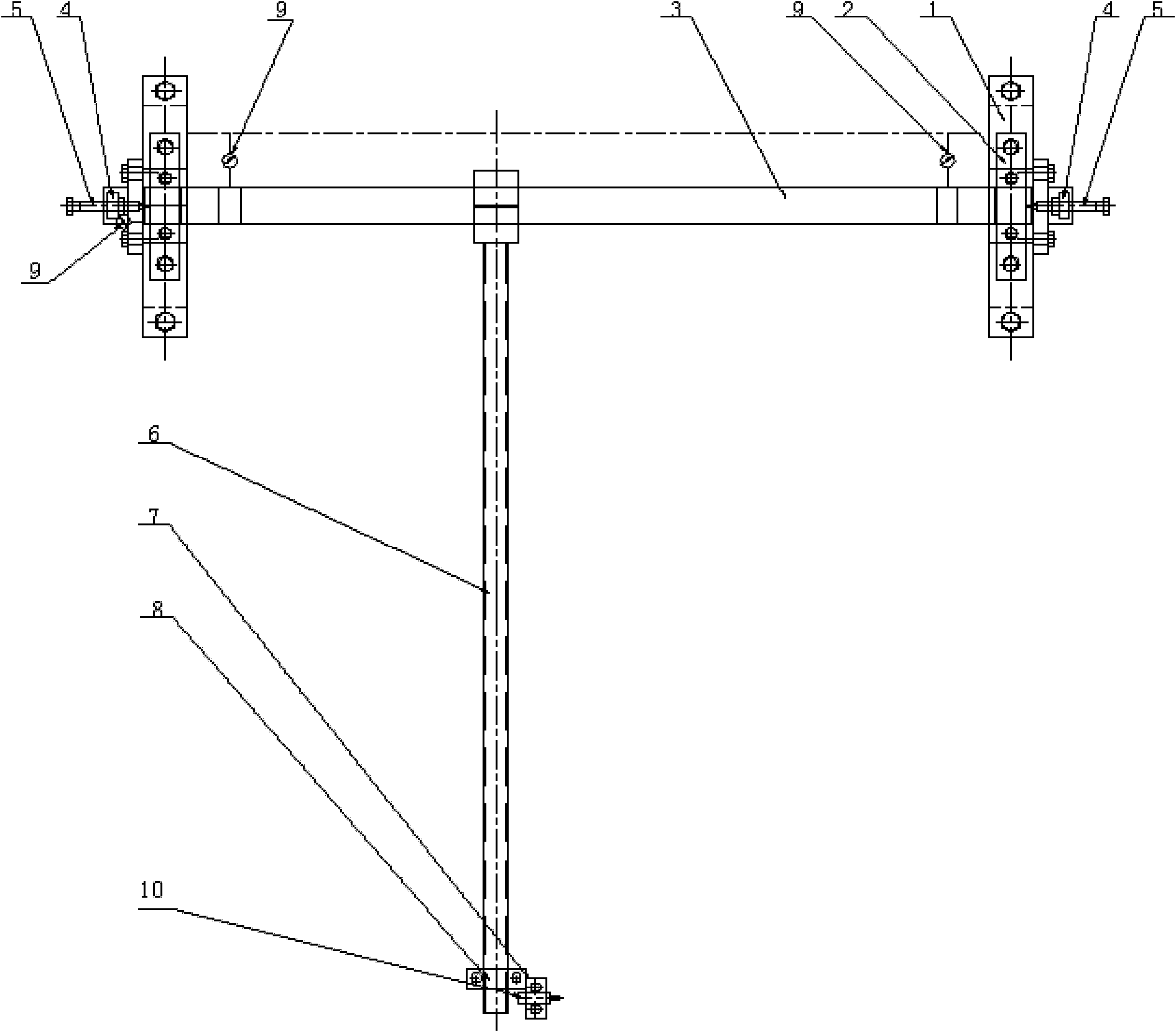

Printing module adjusting device and adjusting method thereof

InactiveCN102463749ASimple structureEasy to operatePower drive mechanismsAgricultural engineeringCentral line placement

Owner:BEIJING MEIKEYI

Method for adjusting verticality of rolling mill

ActiveCN102240680AReduce export stepsMinimize the impact of cumulative errorsMeasuring devicesMetal rolling arrangementsAxial displacementMicrometer

The invention discloses a method for adjusting the verticality of a rolling mill in mounting accuracy, and the method the following steps of: (1) erecting a piano line at a rolling center line of the rolling mill; (2) fixing a base at one side of a swinging tool on the base plate of a rolling mill rack or mounting the base on a steel levelling rule according to measuring requirements; (3) fixing two dial gauges on the base plate of the rolling mill rack or the steel levelling rule by virtue of a magnetic gauge stand, rotating the rocker arm of the swinging tool, and adjusting a sliding bearing arranged at a base at the other side of the swinging tool to cause the indications of the two dial gauges to be constant; (4) placing a third dial gauge at one lateral shaft end of the swinging tool, detecting the axial displacement of a shaft in a swinging process; and (5) mounting an inner diameter micrometer in the fixture hole of the swinging tool to cause the micrometric screw of the inner diameter micrometer to be exactly contacted with the rolling piano line of the rolling mill, reading the indication of the inner diameter micrometer, and calculating the verticality between the base plate of the rolling mill or two rolling mill memorial archways and the piano line at a rolling center. By adopting the method disclosed by the invention, the influence caused by accumulated errors is reduced.

Owner:TIANJIN XINBIN ENG TECH INSPECTION

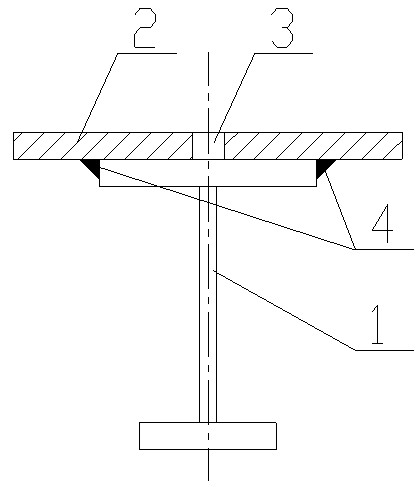

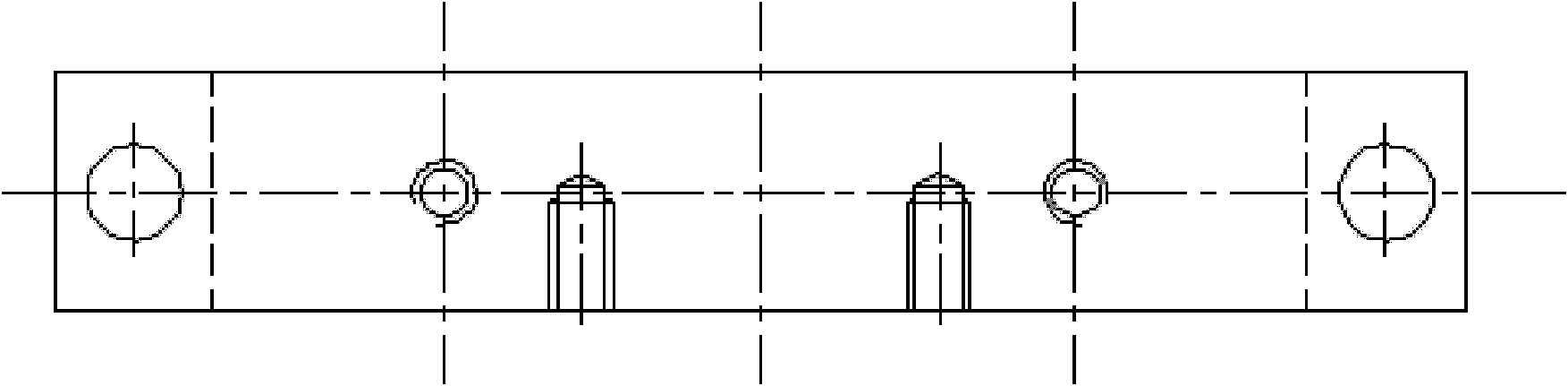

Aircraft structural strength test loading level

ActiveCN103630442AEffectively fixedAvoid uneven forceStrength propertiesCentral line placementUltimate tensile strength

The invention belongs to an aircraft structural strength test loading technique, in particular relates to a loading level used for fixing an aircraft structural strength test clearance. The aircraft structural strength test loading level comprises two strips of channel steel which are oppositely arranged; a plurality of connecting bolts are arranged on the central lines at the bottoms of the two strips of channel steel; positioning bolts are respectively arranged in positions at the two ends of the channel steel, diverging the central lines, so that the clearance between the two strips of channel steel is fixed. According to the aircraft structure strength test loading level, the clearance between the two strips of channel steel is fixed, and the situation that a connecting steel cord is compressed by the inner sides of the channel steel so as not to uniformly bear force is avoided; the position of the steel cord is limited by the positioning bolts, the steel cord is surely fixed to the connecting bolts; the connecting steel cord is prevented from being separated from the connecting bolt and hung on the channel steel, the force borne by the level can be accurately transmitted to the connecting bolt; in addition, the turn radius of the connecting steel cord is increased by adding a lining on the connecting bolt, and bending and shearing load to the steel cord are avoided. Therefore, the aircraft structure strength test loading level has the advantages of quick machining, simple and convenient use, high practicability and low cost.

Owner:CHINA AIRPLANT STRENGTH RES INST

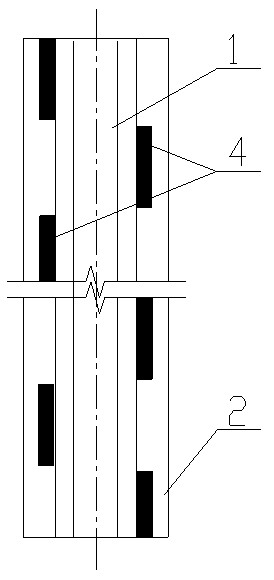

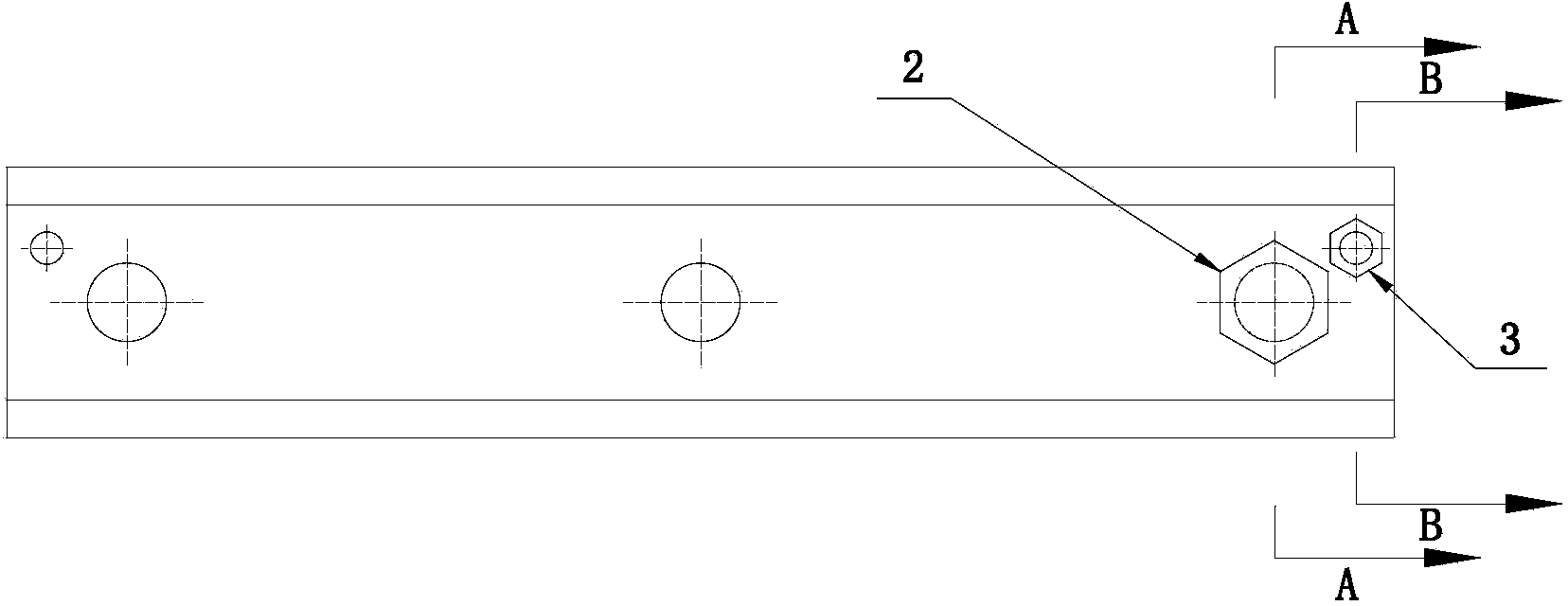

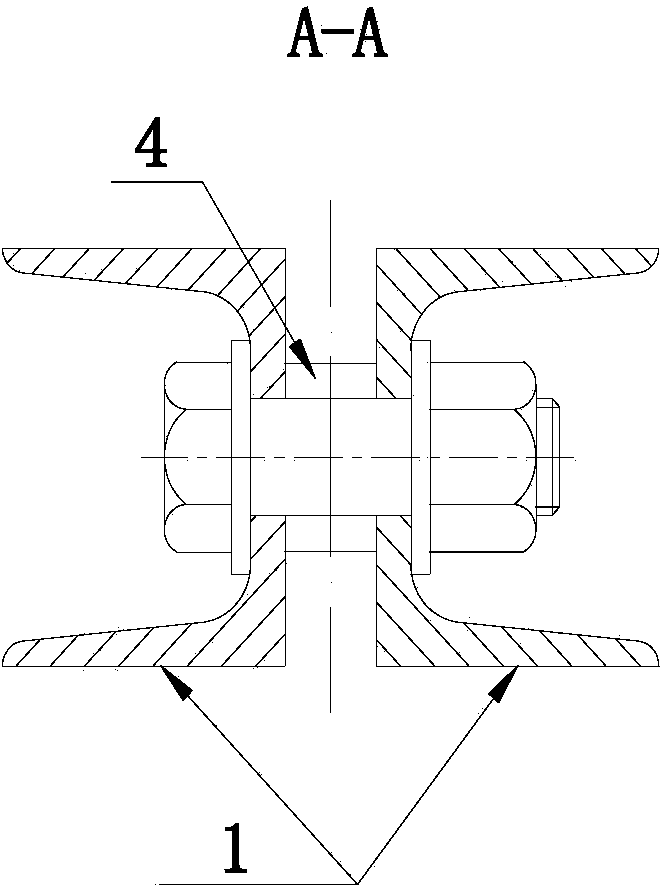

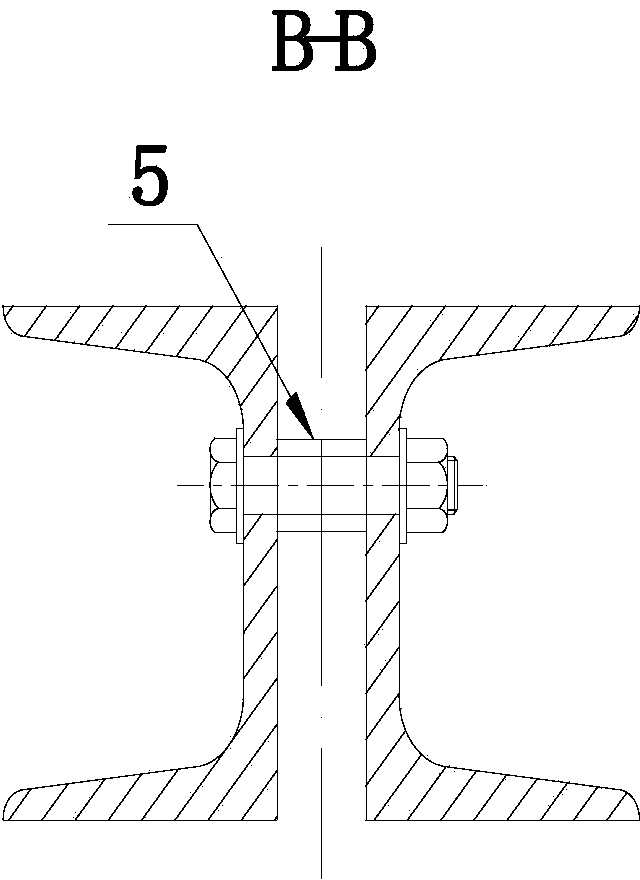

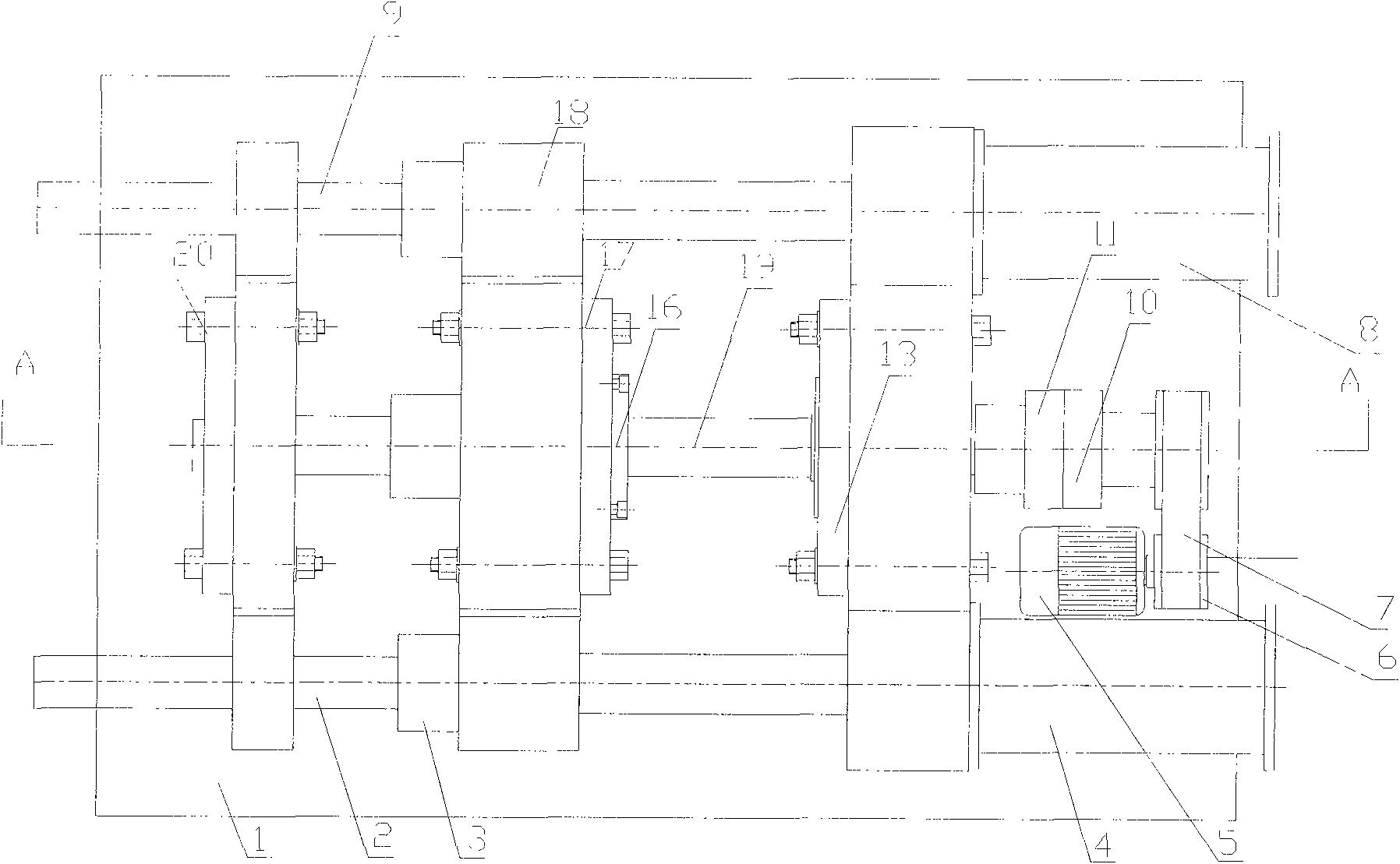

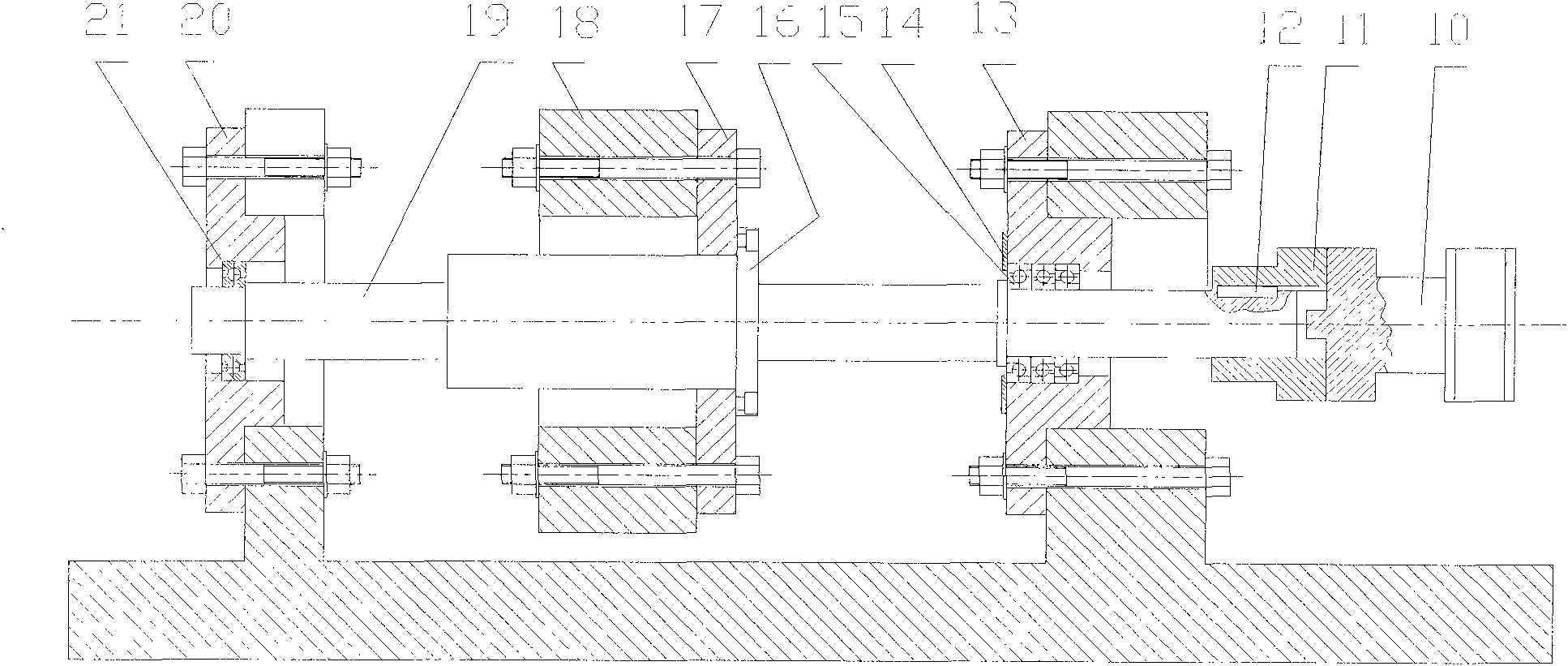

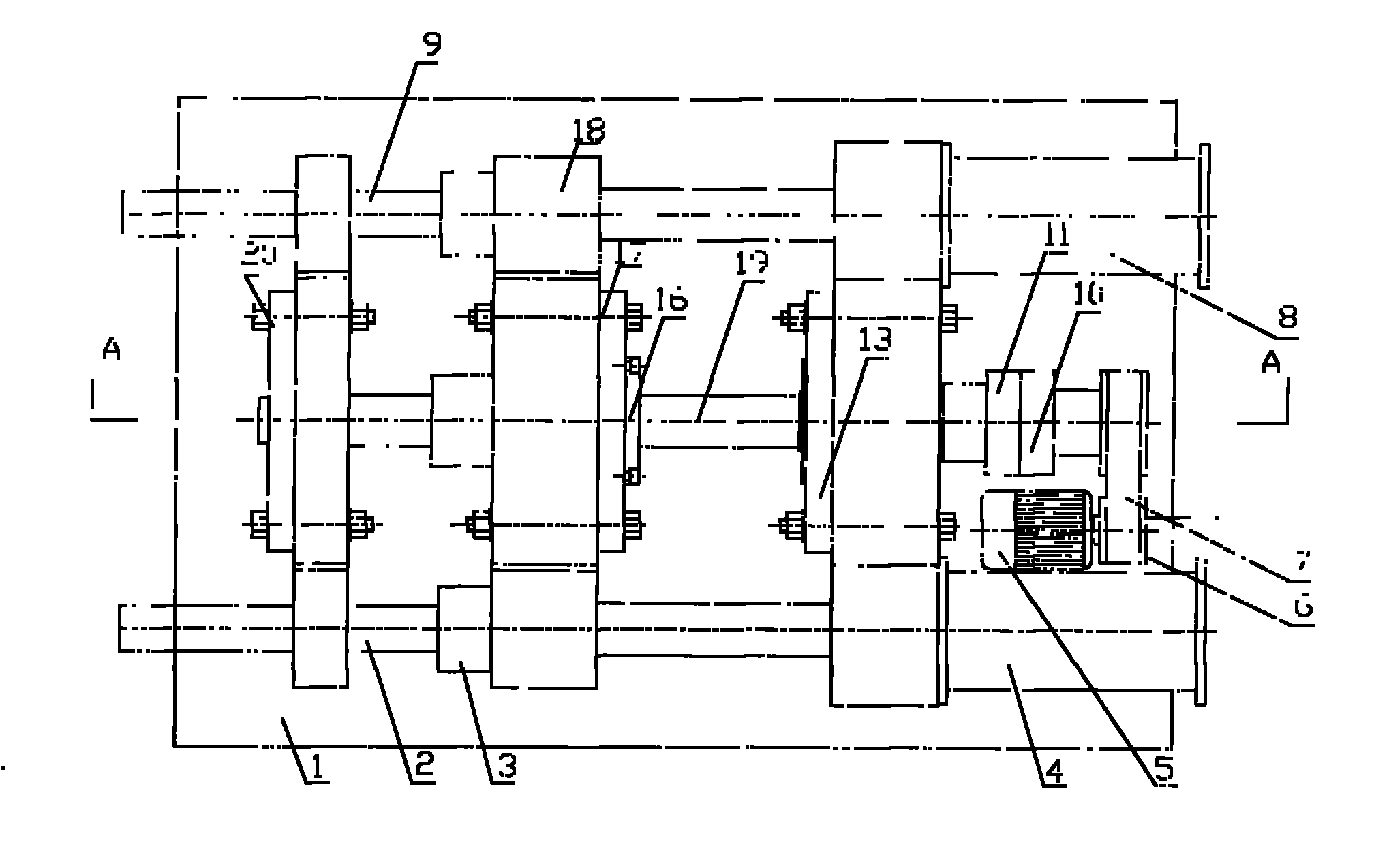

Double-oil cylinder loaded ball screw assembly test bed

InactiveCN101782460AImprove performanceEasy to operateMachine part testingHydraulic cylinderBall screw

The invention discloses a double-oil cylinder loaded ball screw assembly test bed, which comprises a base, wherein the base is fixed with two symmetric hydraulic cylinders which are provided with piston rods respectively; a ball screw is arranged at the position of a central line between the two hydraulic cylinders; the two ends of the ball screw are supported by two screw flanges respectively; the two screw flanges are fixed on the base; one end of the ball screw is connected with a big belt pulley; the big belt wheel is connected with a small belt pulley arranged on a servo motor; a ball nut is sleeved on the ball screw; the ball nut and a nut flange are fastened together; the nut flange is connected with a sliding plate; and the two sides of the sliding plate are fastened with two piston rods respectively. When the test bed operates, the two hydraulic cylinders provide loads for the ball screw assembly, and the simulation of the operating conditions of the ball screw assembly can be realized by regulating the threshold value of a proportional relief valve a hydraulic system and the rotating speed of the ball screw. The test bed has the advantages of simple structure, easy operation, stable performance, wide load adjustment range and high precision.

Owner:ZHEJIANG UNIV

Centre line marking device

ActiveCN101811299AImprove marking efficiencyImprove efficiencyOther workshop equipmentMedial axisCentral line placement

Owner:CRRC TAIYUAN CO LTD

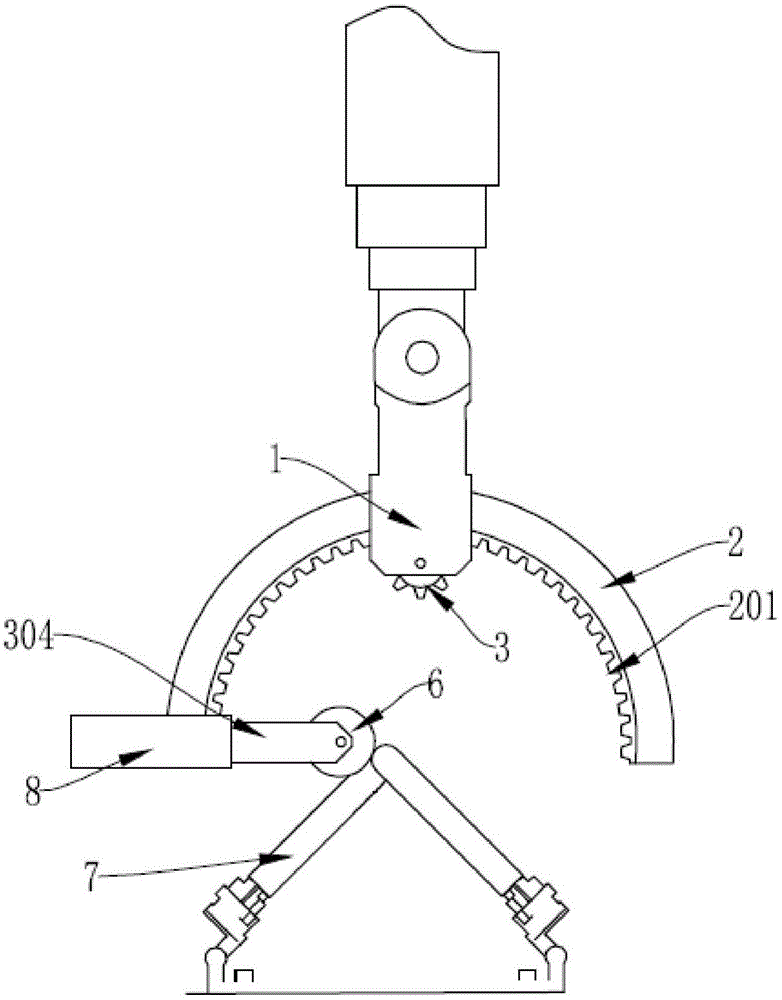

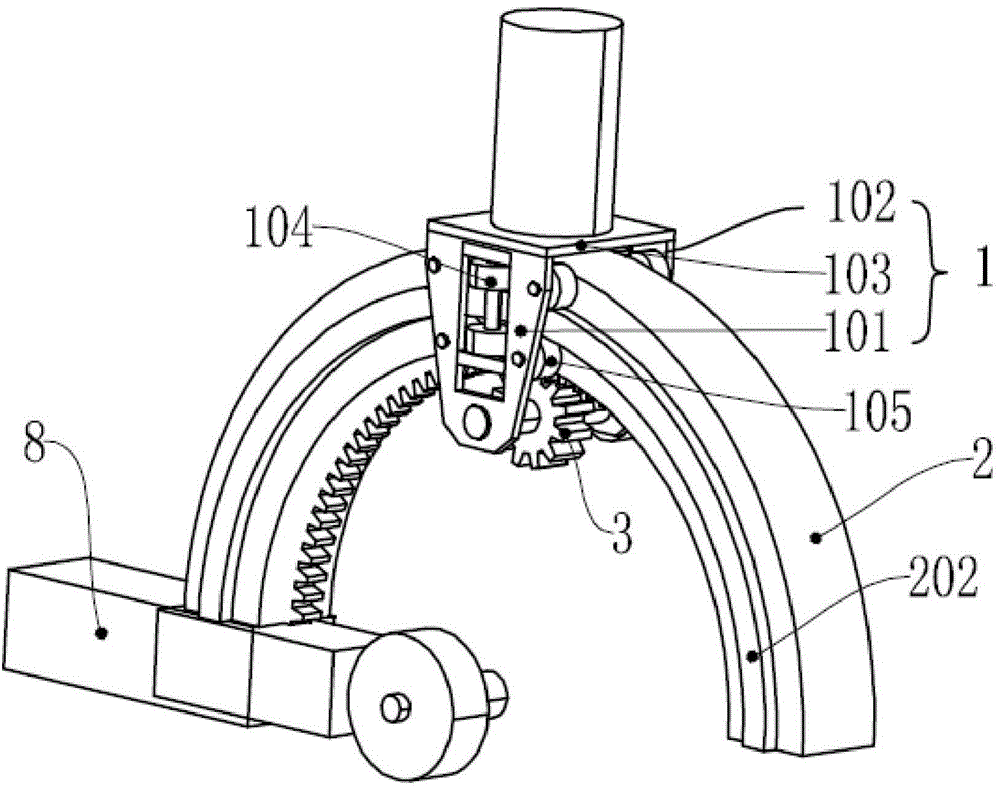

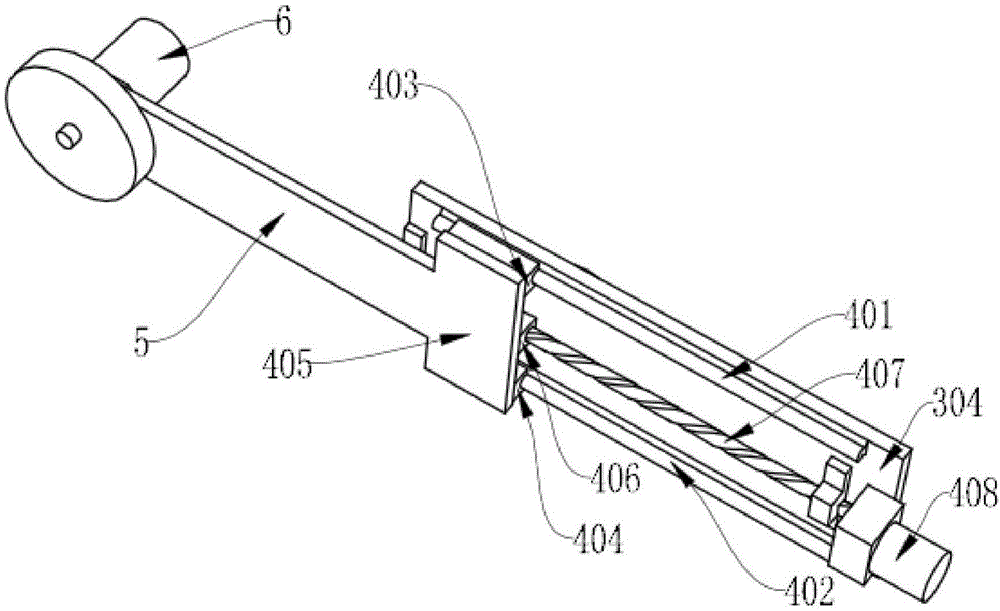

Compact-structure multifunctional robot

InactiveCN104942799ALess freedomLow costProgramme-controlled manipulatorPositioning apparatusCentral line placementIndustrial engineering

The invention discloses a compact-structure multifunctional robot. The compact-structure multifunctional robot comprises an installation base, an arc-shaped planar rail, an arc-shaped rack, a rack driving mechanism, a stretchable mechanism, a working arm and a working head. The working head is arranged at one end of the working arm. The arc-shaped planar rail is sleeved with the installation base, is matched with the installation base through a sliding pair or a rolling pair and is in an arc shape with the curved and non-closed center line. The arc-shaped rack is fixedly installed on the arc-shaped planar rail. Teeth of the arc-shaped rack can be installed towards the inner side or the outer side of the arc-shaped planar rail. The working arm is arranged at the tail end of the arc-shaped rack. The working head can be stretched under the driving of the stretchable mechanism. Before operation is carried out, a user only needs to know the position of the center line of a pipe and does not need to know the accurate position of the contour of the pipe, and the compact-structure multifunctional robot has the advantages that the freedom degree required by achieving operation movement around the whole circumference of the pipe is small, the manufacturing cost is low, and use and maintaining are convenient.

Owner:FOSHAN XINHENGCUI MATERIAL TECH CO LTD

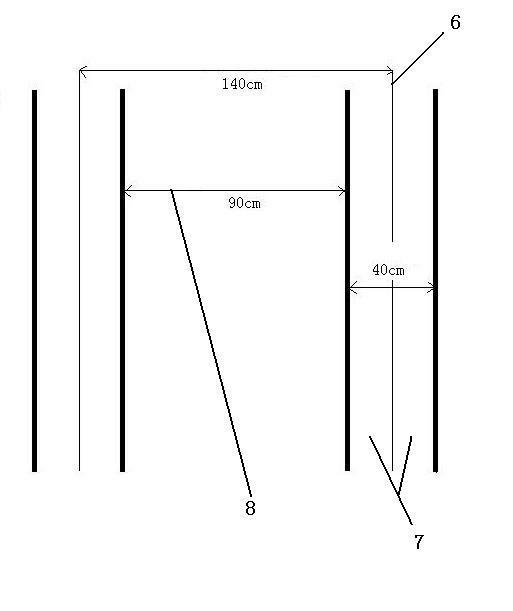

Planting method for using mulch on corn field to collect rainwater and perforator

The invention relates to a planting method for using mulch on a corn field to collect rainwater and a perforator. In corn planting, lines are spread or lime lines (composite belts) are marked at intervals of 140cm; two fertilizing ditches are dug on two sides of each line; chemical fertilizer and farm manure are spread into the ditches; the ditches are covered with thin soil; the soil is then wetted with water before mulch is spread; after the mulch is set, the perforator is used to perforate the mulch at the center lines of the fertilizing ditches; one to two seeds are sowed into each hole; and after sowing, the holes are covered with fine soil. Therefore, ditch faces are lower than ridge faces, rainwater dropping to the ridge faces can flow into the soil along the mulch holes during raining, the rainwater can be stored in the soil around the corn seeds, and required sprouting water of the seeds is guaranteed effectively. When the seeds sprout, seedlings grow out of the holes, and mature corn plants are neat in plant spacing and row spacing, so that farm work, such as intertillage management, ventilation, fertilizing and the like, is facilitated. Corn can be provided with conditions required for normal sprouting, seedling emergence and growth even in arid climate, and accordingly high corn yield is guaranteed.

Owner:戴实忠 +2

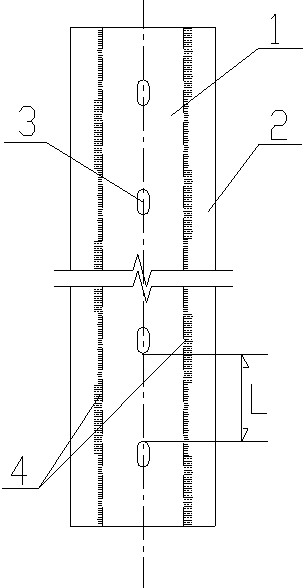

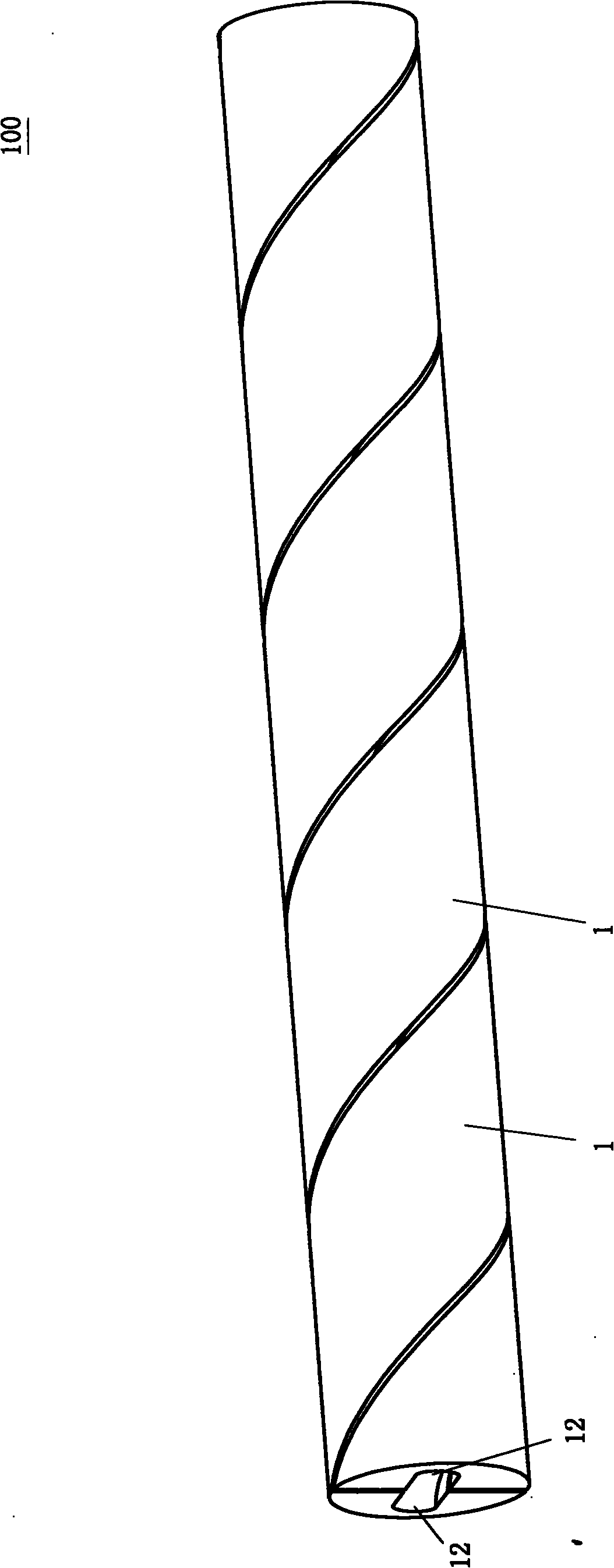

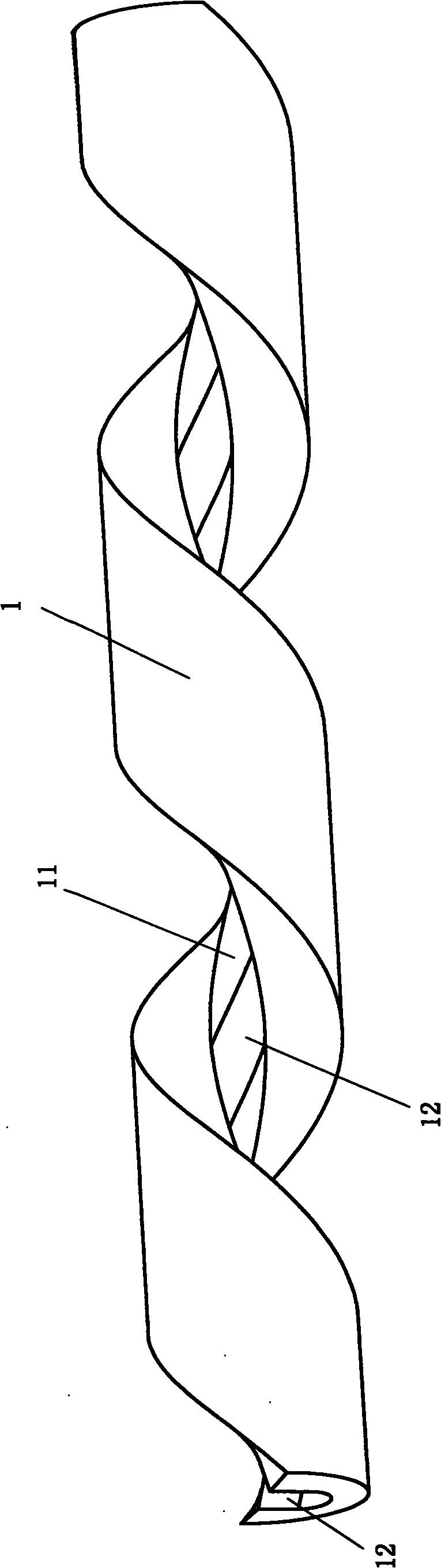

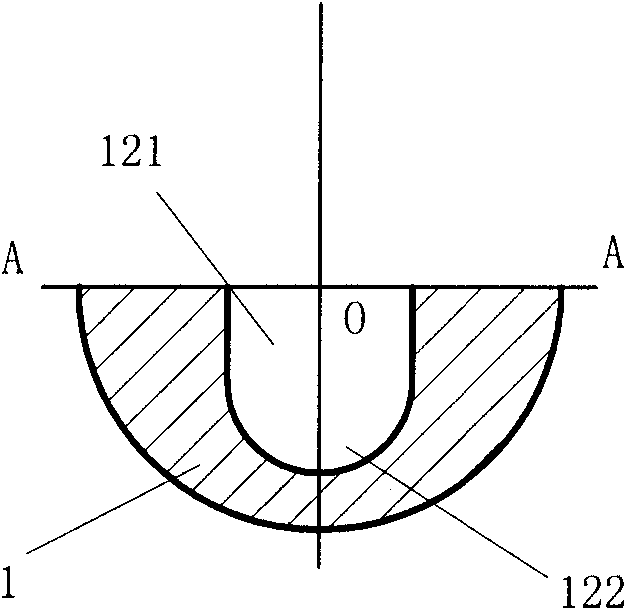

Single-screw metal screw pump stator and processing method for inner helical surface thereof

InactiveCN101892982AImprove machining accuracyImprove processing efficiencyMachines/enginesRotary/oscillating piston pump componentsEngineeringCentral line placement

The invention relates to a single-screw metal screw pump stator and a processing method for an inner helical surface thereof. The stator is formed by corresponding screwing and bonding of two helicoids of which the cross sections are semicircular in shape, and corresponding screwing surfaces of the two helicoids are helical surfaces; and a groove with a semicircular bottom is arranged in the center line position of the helical surface of each helicoid and extends along the center line, the cross section of the groove is formed by a rectangle and a semicircle which forms a smooth connection with the lower part of the rectangle, the grooves of the two helicoids are screwed in a corresponding way to form the inner helical surface of the stator, and connecting parts are correspondingly arranged on the outer walls of the two helicoids. Because the metal screw pump stator is formed by corresponding screwing and bonding of the two helicoids, an open processing method can be used by firstly processing the groove in each helicoid and then carrying out corresponding screwing and bonding on the two helicoids to form a whole. Because the grooves are processed in an open mode, the machining of the grooves is facilitated, and the processing accuracy and the processing efficiency are improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com