Patents

Literature

216results about How to "Guaranteed construction accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

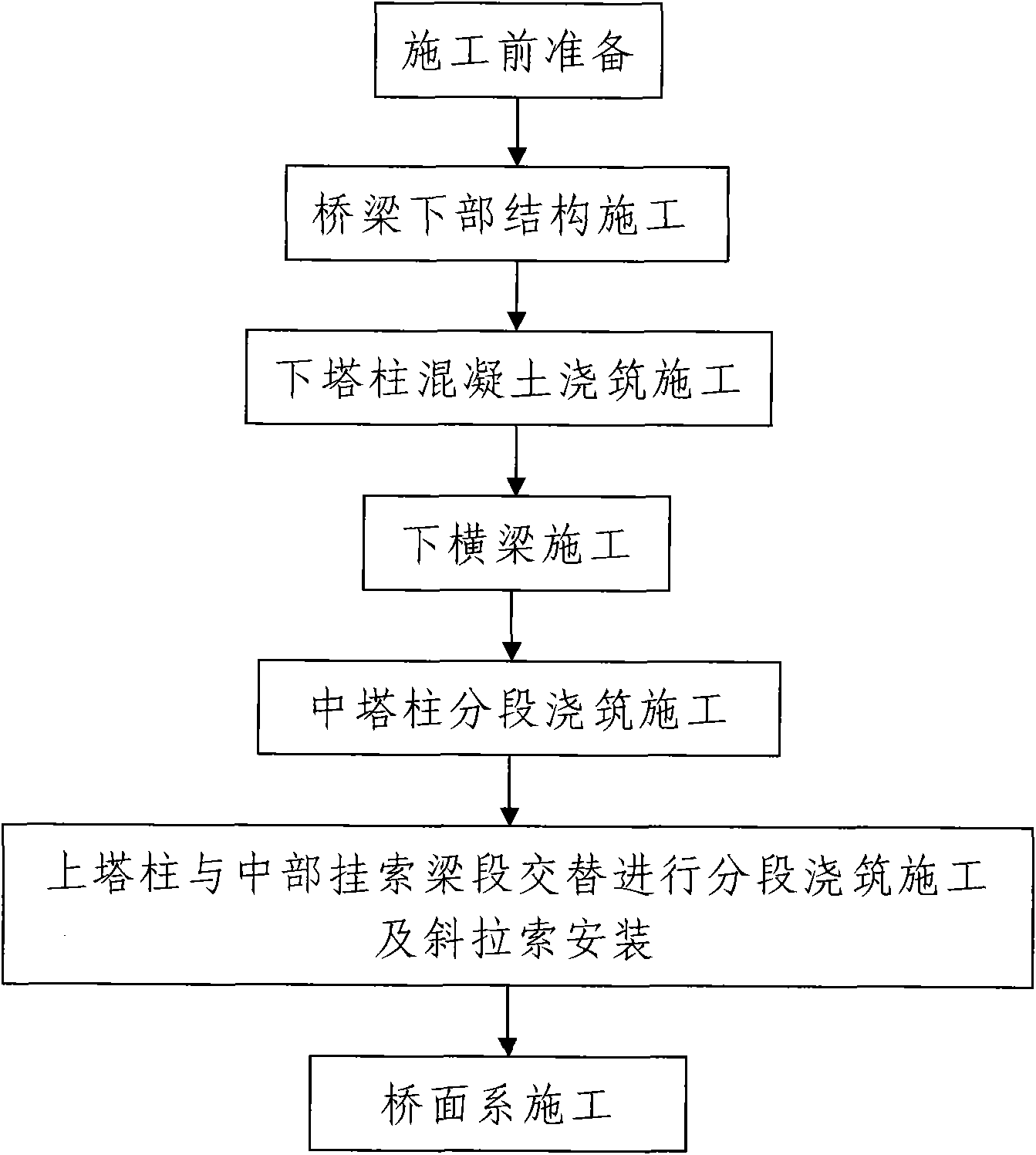

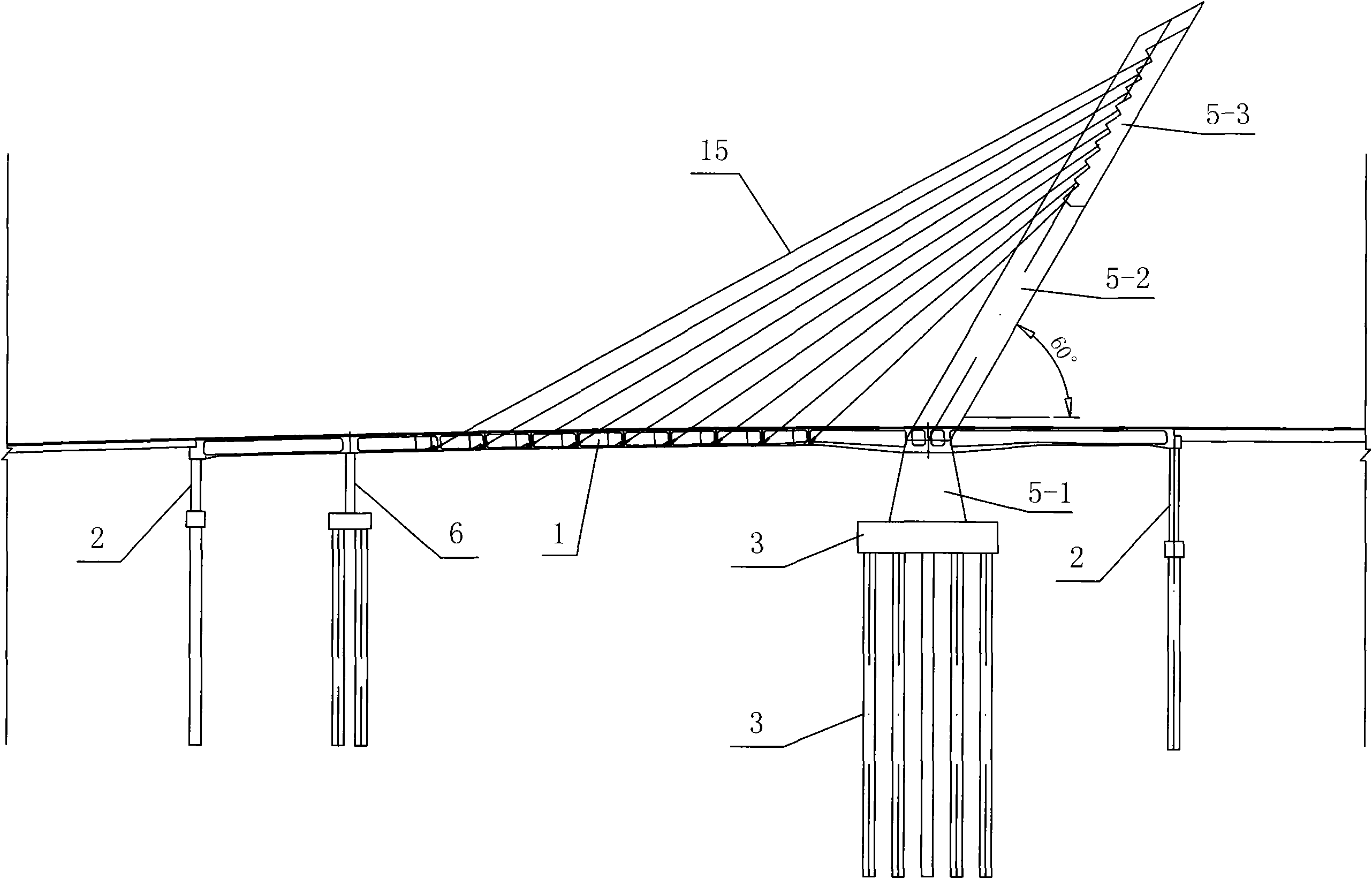

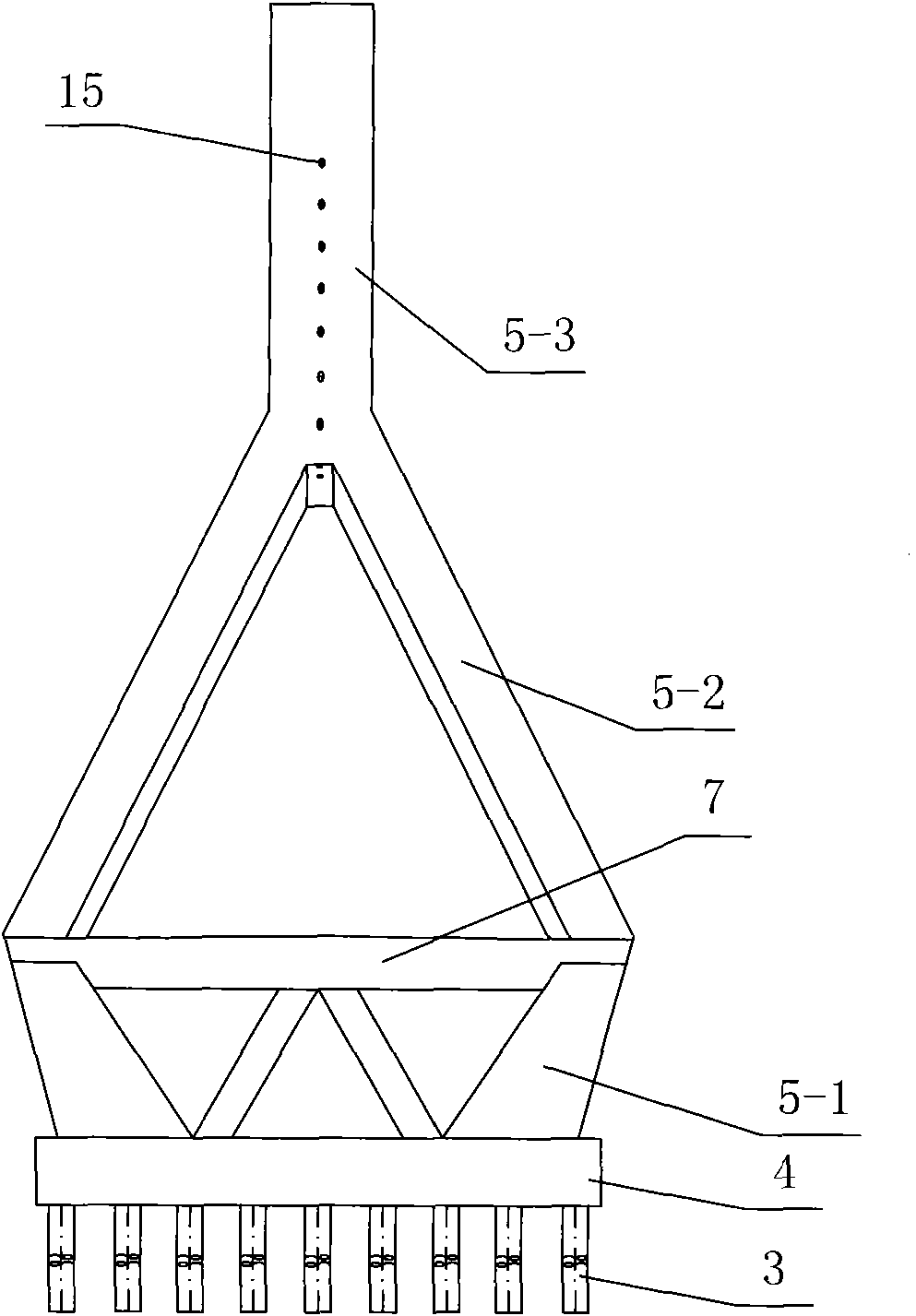

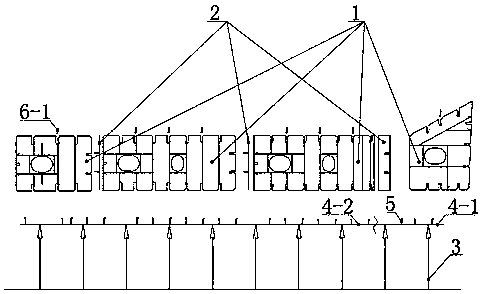

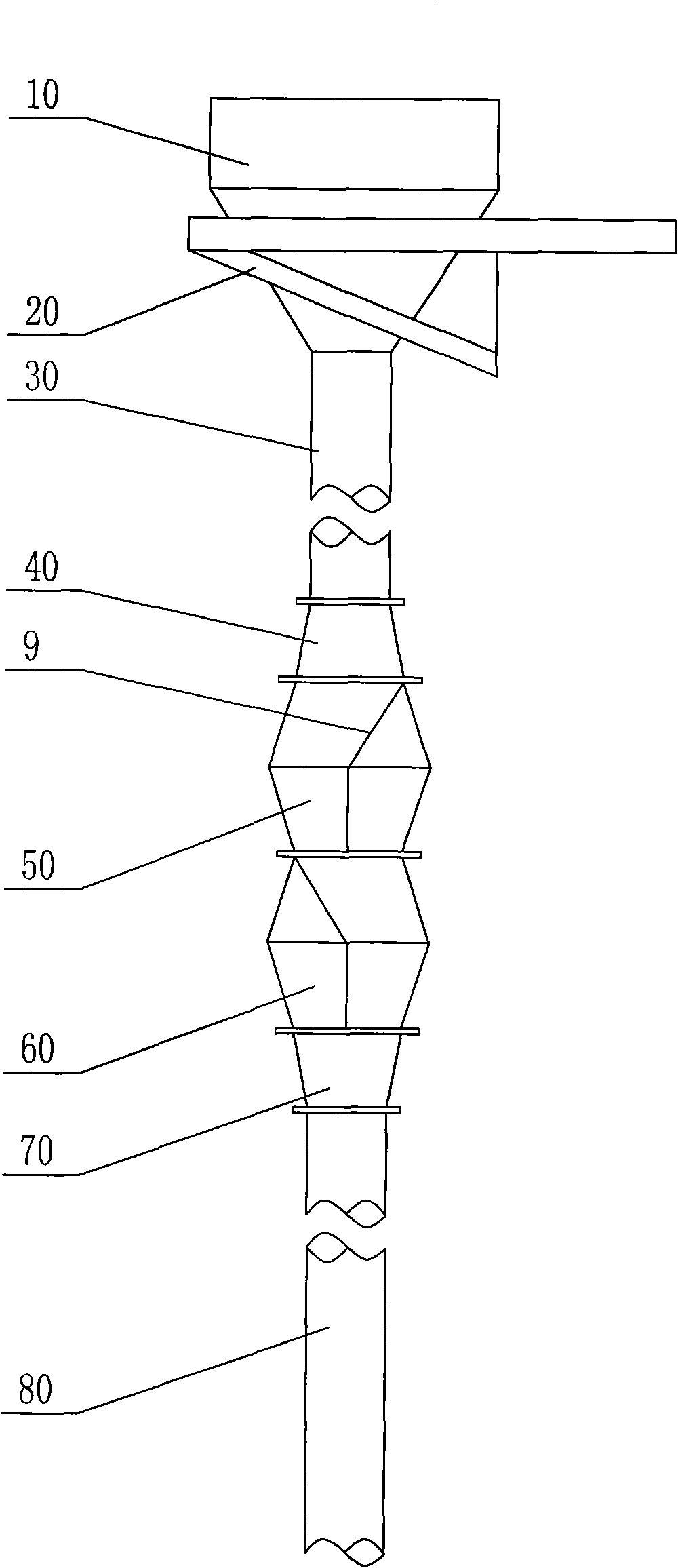

Construction method of single-pylon cable-stayed bridge without dorsal cables

ActiveCN101781879AStable structureGood construction performanceCable-stayed bridgeBridge erection/assemblyCable stayedSystem construction

The invention discloses a construction method of a single-pylon cable-stayed bridge without dorsal cables. The construction method comprises the following steps of: (1) preparation before construction; (2) lower bridge structure construction; (3) upper bridge structure construction, which comprises the following construction processes of: lower pylon concrete pouring construction, lower beam construction, middle pylon segmental pouring construction, alternate segmental pouring construction of an upper pylon and a middle suspension cable beam segment and stayed-cable mounting, wherein an integral lifting template is used for segmental construction on both the middle pylon and the upper pylon; and (4) bridge surface system construction. The construction method has reasonable step design, convenient construction, safe and reliable construction, high construction quality, short construction period and less and simple construction hardware equipment and can effectively overcomes the defects and deficiencies of complicated construction process, difficult guarantee of construction quality, various hardware equipment needed, and the like in the construction process of the single-pylon cable-stayed bridge without dorsal cables.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Manufacturing method of duplex stainless steel chemical ship side section

The invention discloses a manufacturing method of a duplex stainless steel chemical ship side section and belongs to the technical field of ship construction. The method includes the following steps of firstly, carbon steel outer plate secondary medium assembly construction, secondly, stainless steel inner longitudinal wall plate secondary medium assembly construction, thirdly, inner longitudinalwall plate flat straight section medium assembly construction, fourthly, deck medium assembly construction and fifthly, ship side section large assembly combination. In the method, when stainless steel inner longitudinal wall plate secondary medium assemblies are constructed, stainless steel molding beds are adopted, and carbon pollution caused by a common carbon steel material to a duplex stainless steel material can be effectively prevented; and through reasonable selection of the assembling sequence and the assembling pose, an automatic angle welding machine can be conveniently used for welding stainless steel, deformation of the duplex stainless steel is effectively reduced, the duplex stainless steel ship side section is divided into flat straight section medium assemblies and deck medium assemblies, the modes of same molding bed construction and medium assembly separate combination are used, the construction accuracy is guaranteed, and section construction efficiency is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Tunnel advanced support air circulated drilling construction method and drilling tool

InactiveCN101260784AAvoid disturbanceEnsure construction safetyEarth drilling toolsUnderground chambersPosition angleAir compressor

The invention provides a tunnel forepoling air circulating drilling construction method. The construction steps are as follows: a driller is firstly installed and is moved to the appointed hole position along a track, according to the tunnel position line, the position angle of the driller is adjusted to ensure that the driller is parallel with the tunnel position line, the driller is fastened with a frame; an air compressor is turned on, the wind pressure is controlled above 0.4MPa, and then the driller is turned on to ensure that a drill pipe drills towards the earth at a constant speed, the compressed air is sent to an aiguille part through an internal cavity of the drill pipe and air-cools the aiguille, drilling cuttings are blown out of the drill hole from the gap between the drill pipe and the earth; the inner part of the aiguille is provided with a guide drilling device; finally, the hole drilling is finished and the grout is cast, the grout is cast into the inner cavity of the drill pipe by a casting pipe, the grout is filled into the inner cavity of the drill pipe and the ring-shaped gap out of the drill pipe, and the next hole position is turned to construct. The tunnel forepoling air circulating drilling construction method solves the problems of low security and slow drilling of the earth layer, especially the fourth new loess area pipe roofing timbering construction, can avoid the landslide and minimize the potential safety hazard.

Owner:BEIJING SHOUER ENG TECH

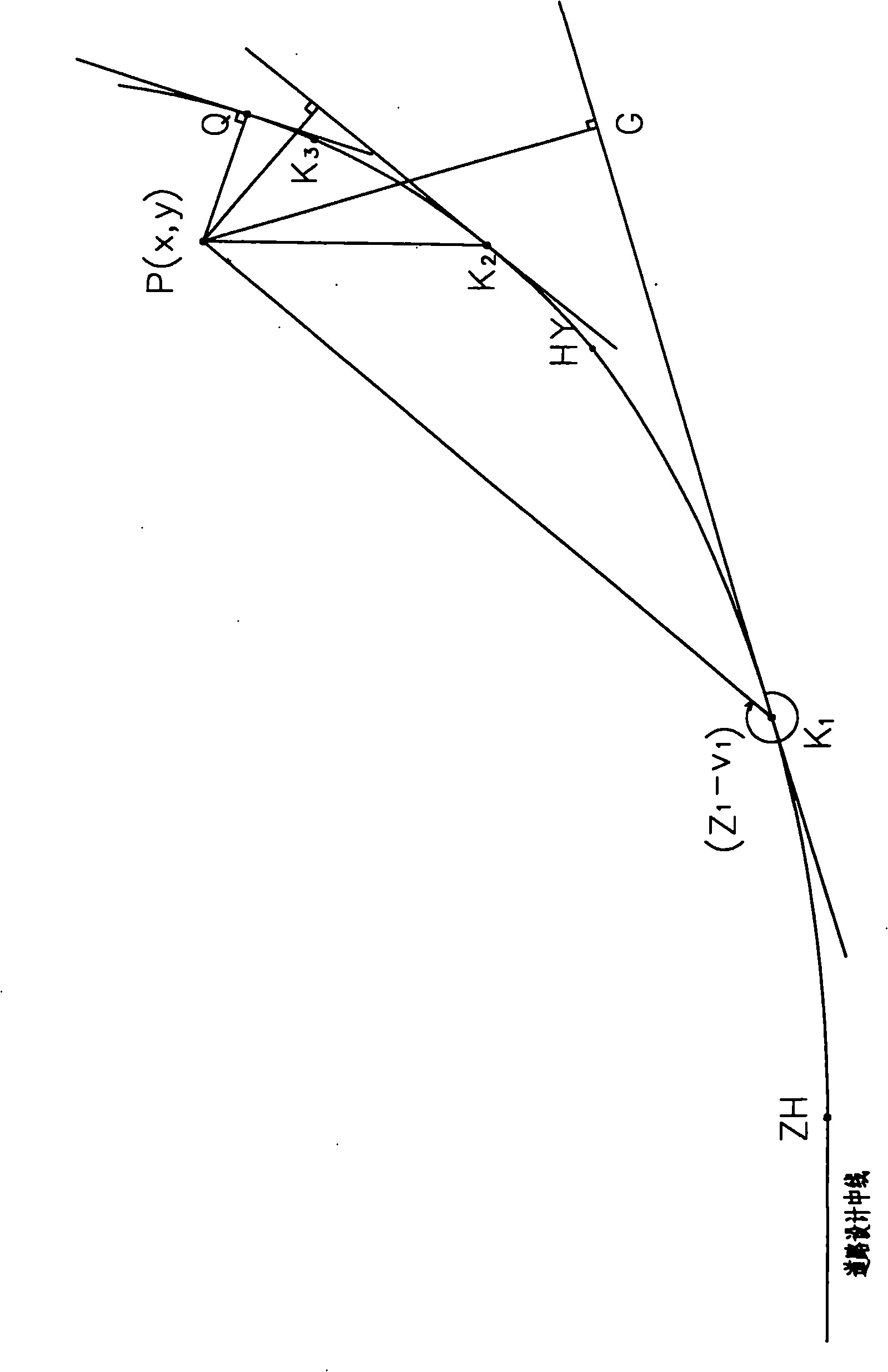

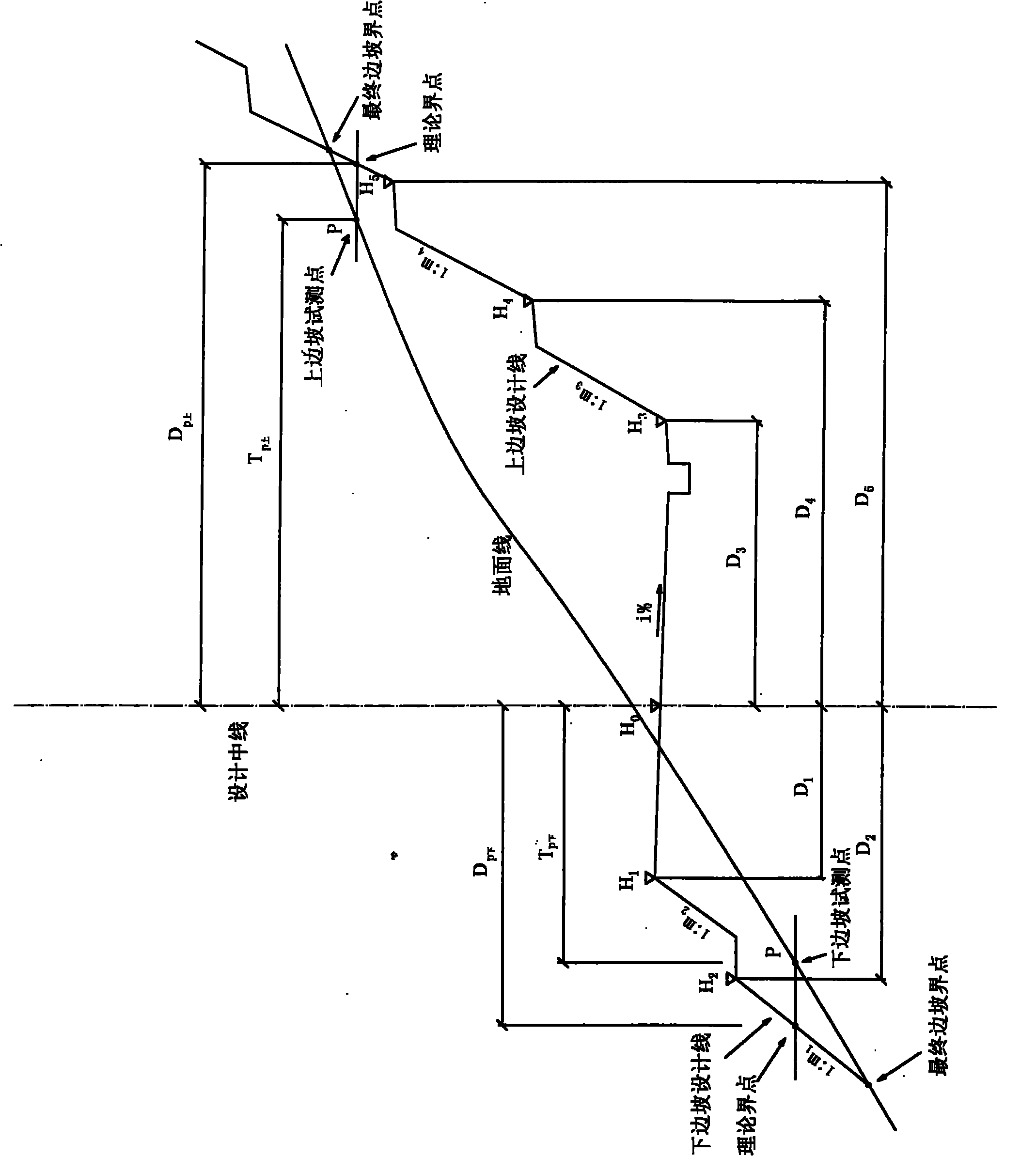

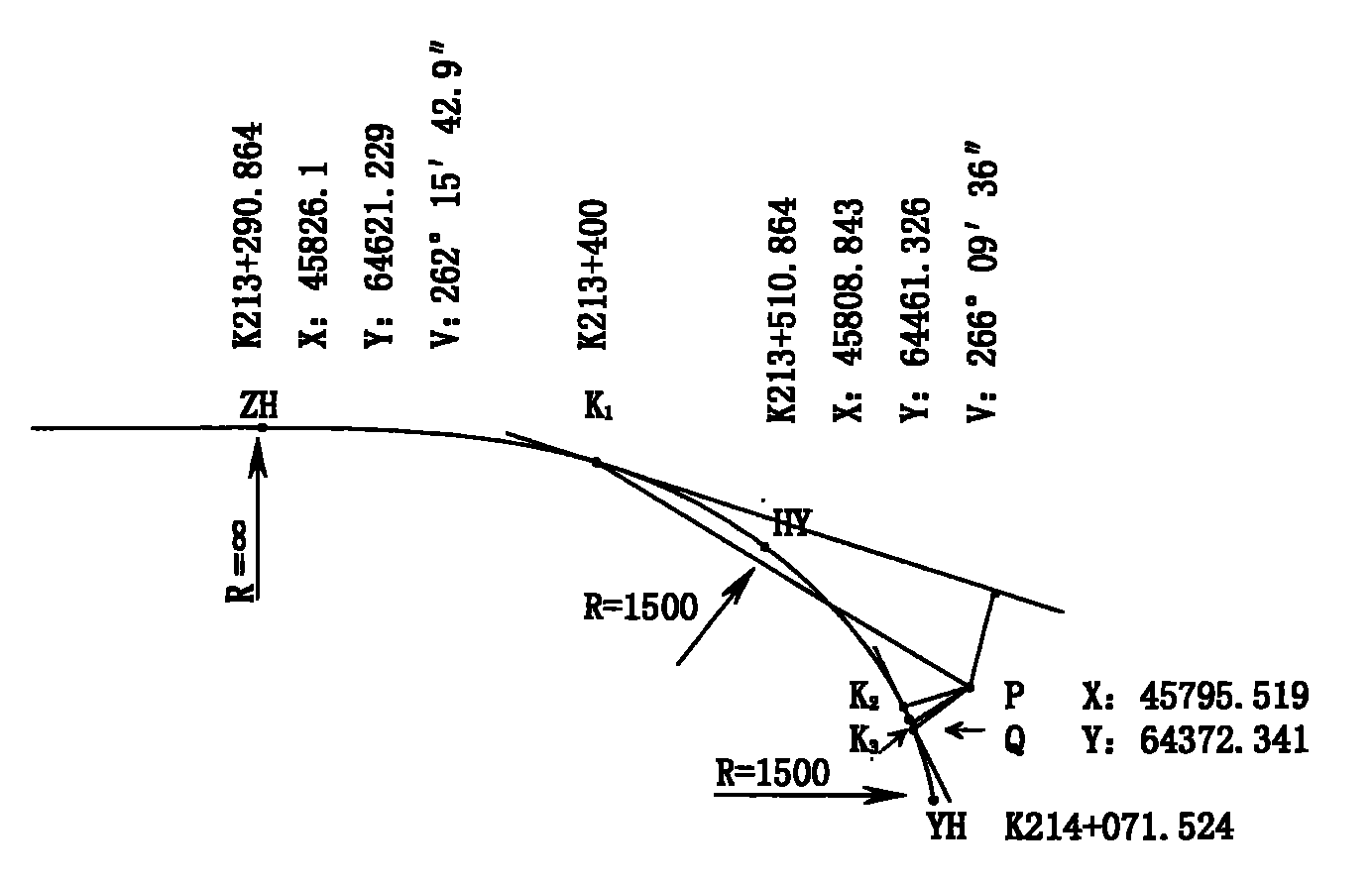

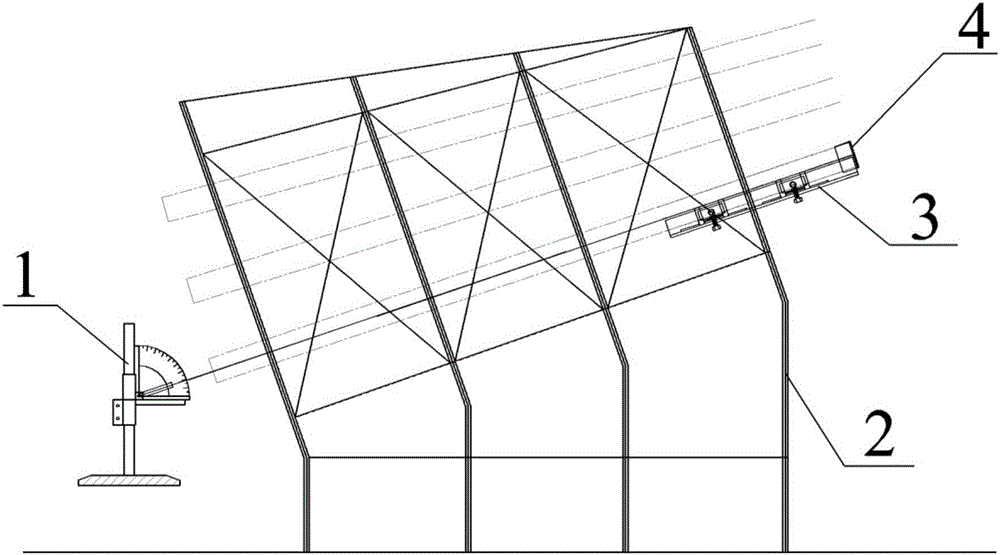

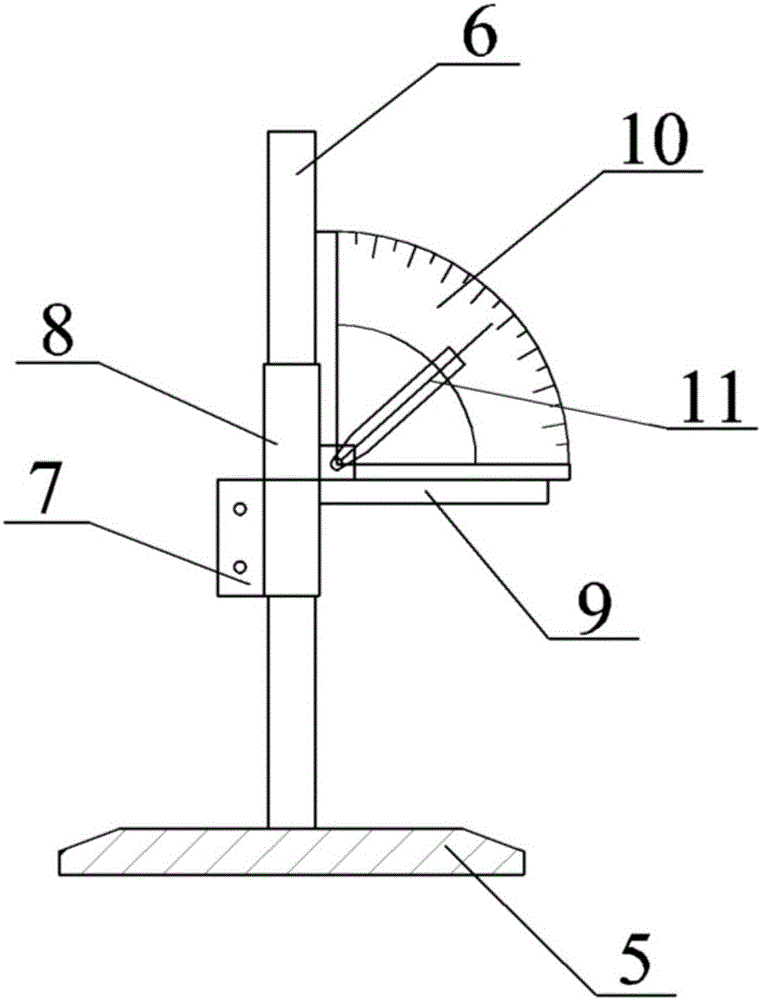

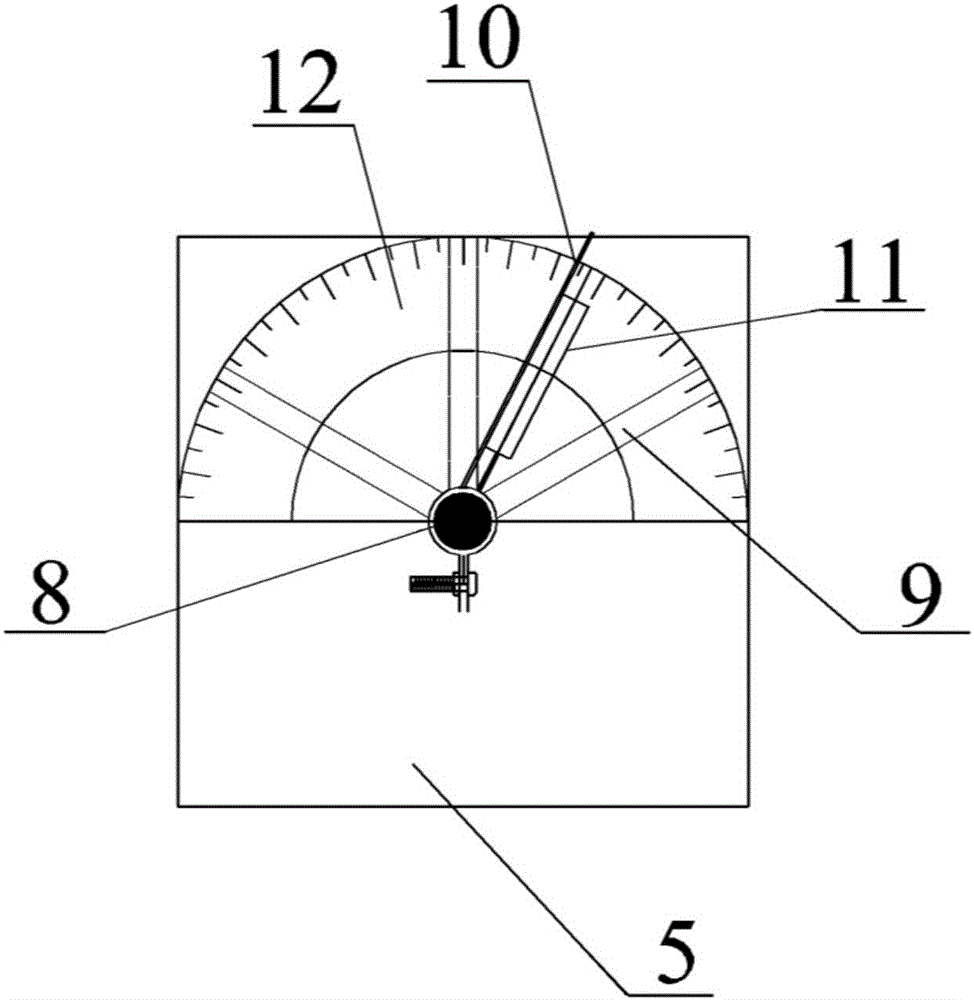

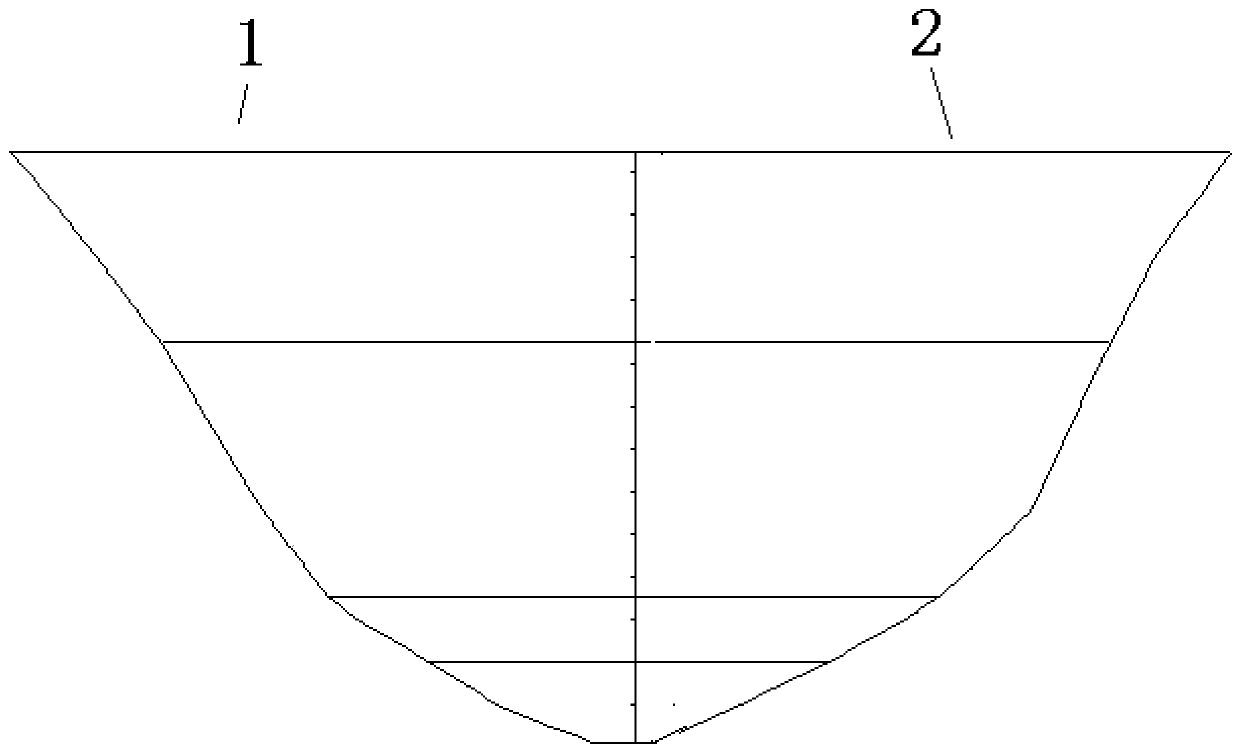

Construction paying off method for determining boundary point of side slope of subgrade on terrain line

ActiveCN101846516AImprove stakeout efficiencyGuaranteed construction accuracySurveying instrumentsExcavationsTerrainShortest distance

The invention provides a construction paying off method for determining the boundary point of a side slope of a subgrade on a terrain line, which can improve the paying off efficiency of the boundary point of the side slope of the subgrade and meet the requirement for the construction precision of the side slope of the subgrade, and can be extensively completed by testing an intervisible part of any survey station arranged outside the design center line of a road. The method comprises the following steps of: setting a mileage reference point on the center line of a road, evaluating the shortest distance between the side point of the center line and the horizontal curve of the road by using the method of uniform approach so as to determine the vertical distance and the foot-point mileage between the slope point subjected to on-site pretesting and the design center line of the road in a plane; calculating the theoretical horizontal distance between a crossover point of an elevation surface on which the pretesting point is positioned and the design line of the side slope and the design line of the subgrade according to the design parameters such as the center-line elevation and the subgrade at the mileage, the width of a structure, the slope ratios and the step numbers of the cross slope and the side slope, and the like; subtracting the vertical distance from the theoretical horizontal distance so as to obtain the displacement from the pretesting pint to the theoretical boundary point; and moving the pretesting point, and repeating the steps to make the displacement asymptotically to zero so as to determine the position of the boundary point of the side slope.

Owner:华邦建投集团股份有限公司

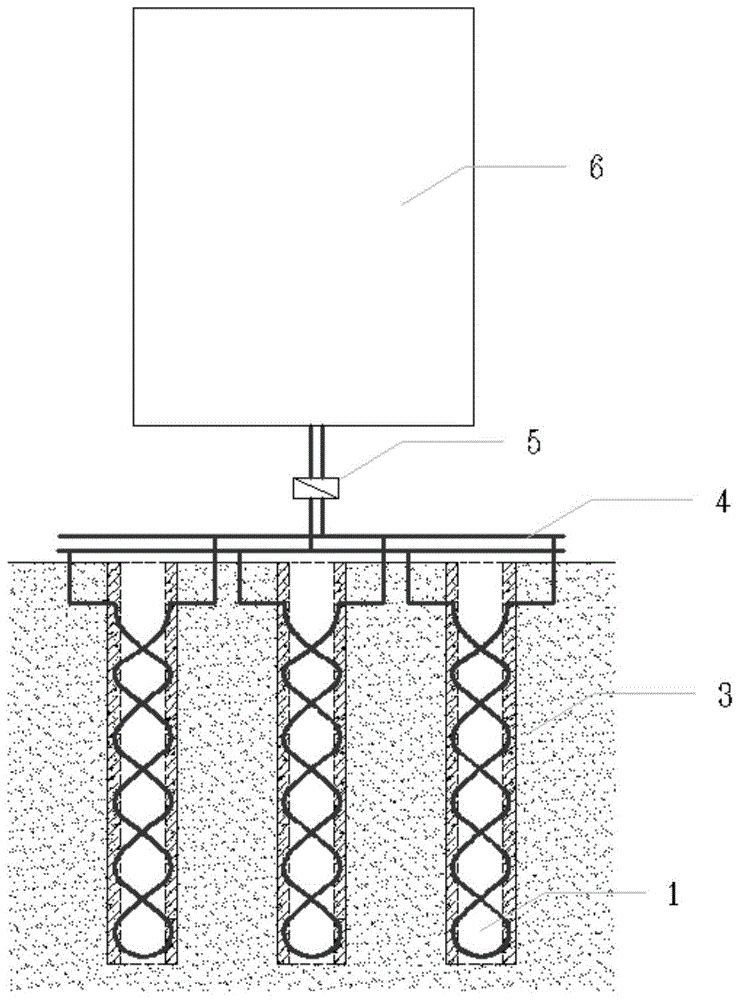

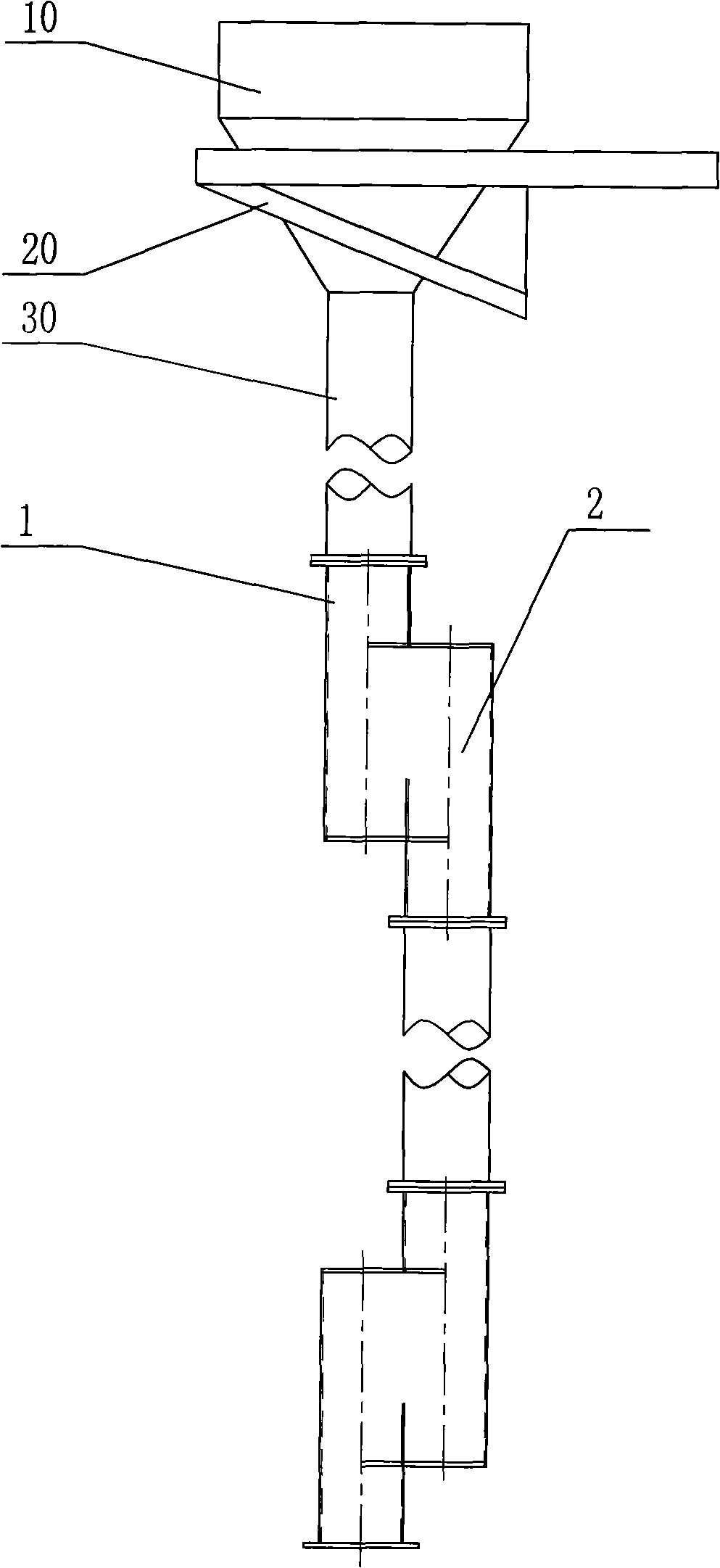

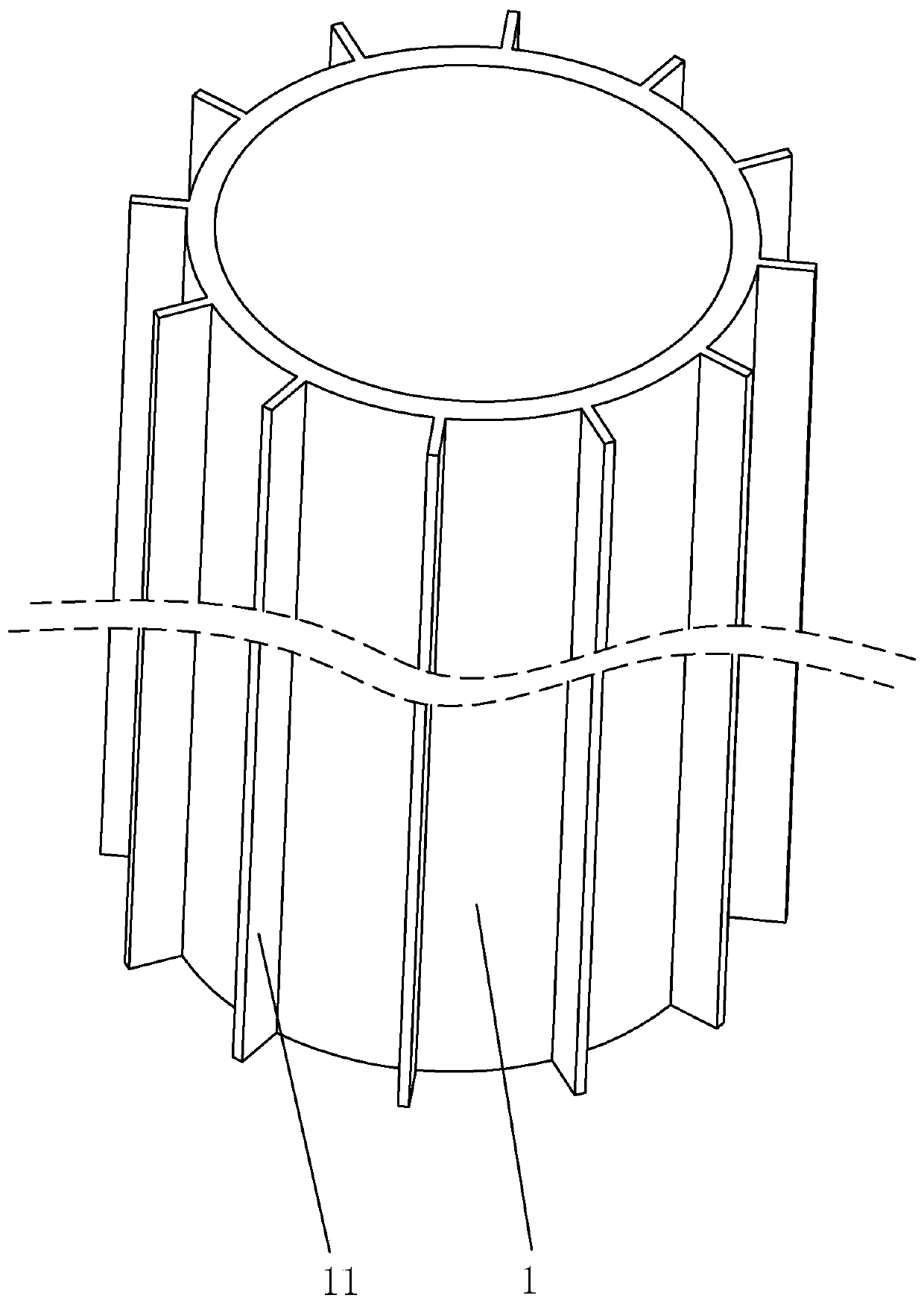

Prefabricated reinforced concrete pipe pile with ground source heat pump double-helical tubular heat exchanger

InactiveCN104314074ATo achieve the purpose of geothermal energy conversionTo achieve conversionHeat pumpsBulkheads/pilesPlate heat exchangerReinforced concrete

The invention discloses a prefabricated reinforced concrete pipe pile with a ground source heat pump double-helical tubular heat exchanger. The prefabricated reinforced concrete pipe pile comprises the double-helical tubular heat exchanger, a reinforcement cage, supporting bends, metal protective sleeves, concrete, a heat exchanger fluid inlet, a heat exchanger fluid outlet and an exchange medium. The double-helical tubular heat exchanger is tied to the inside of the reinforcement cage. The exchange medium is arranged inside the double-helical tubular heat exchanger and distributed along the whole length of the pipe pile. Both the reinforcement cage and the double-helical tubular heat exchanger are made in the concrete to form the wall of the pipe pile, by concreting. The prefabricated reinforced concrete pipe pile has the advantages that the double-helical tubular heat exchanger is tied to the inside of the reinforcement cage during pipe pile construction in a factory, the double-helical tubular heat exchanger is buried in the wall of a concrete pipe after concreting, the pipe pile serves as a carrier for the double-helical tubular heat exchanger, the double-helical tubular heat exchanger is sunk into the earth during pile sinking, and construction of a pile foundation and burying of the tubular heat exchanger in a ground source heat pump reserved hole are integrated.

Owner:NANJING TECH UNIV

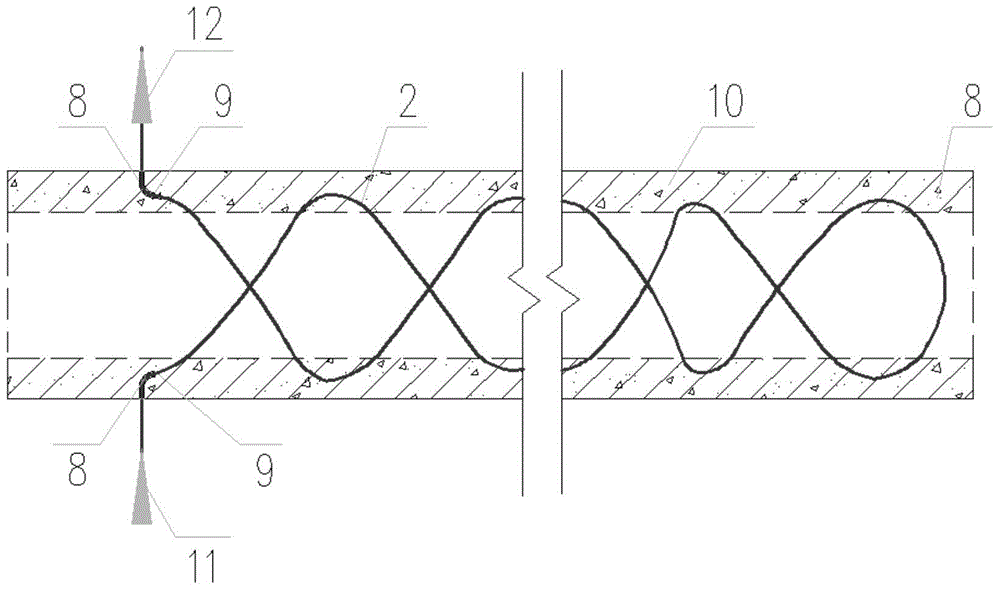

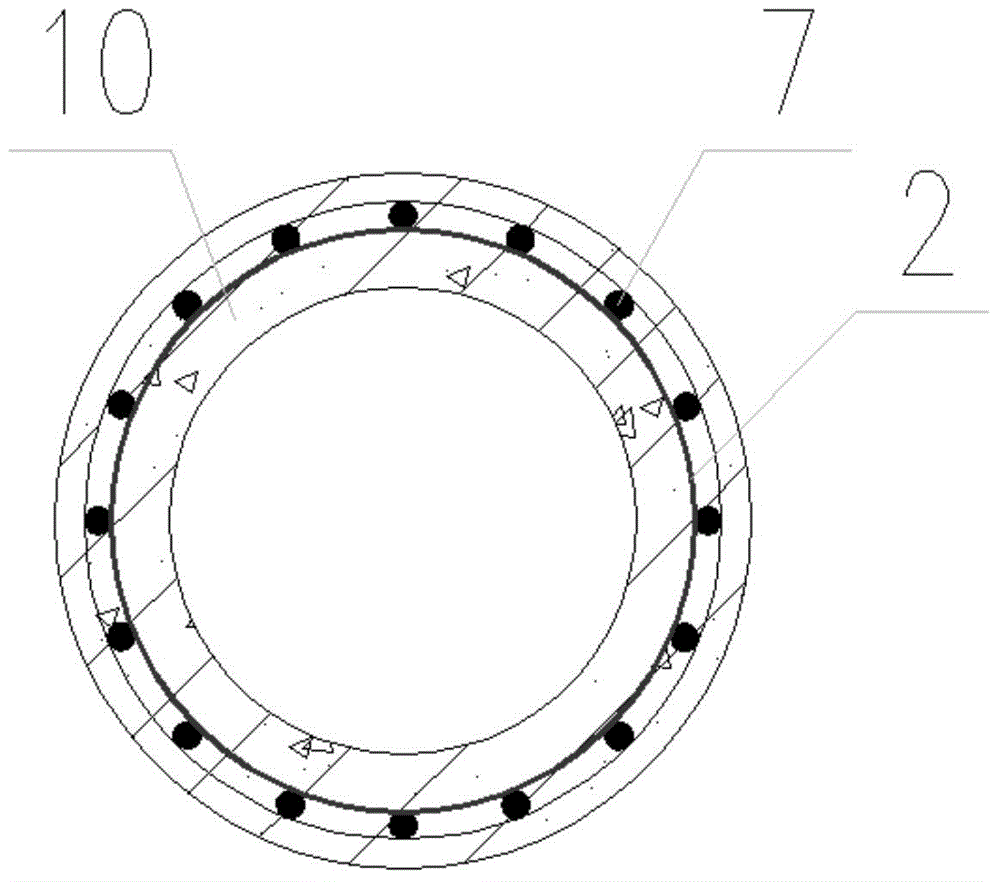

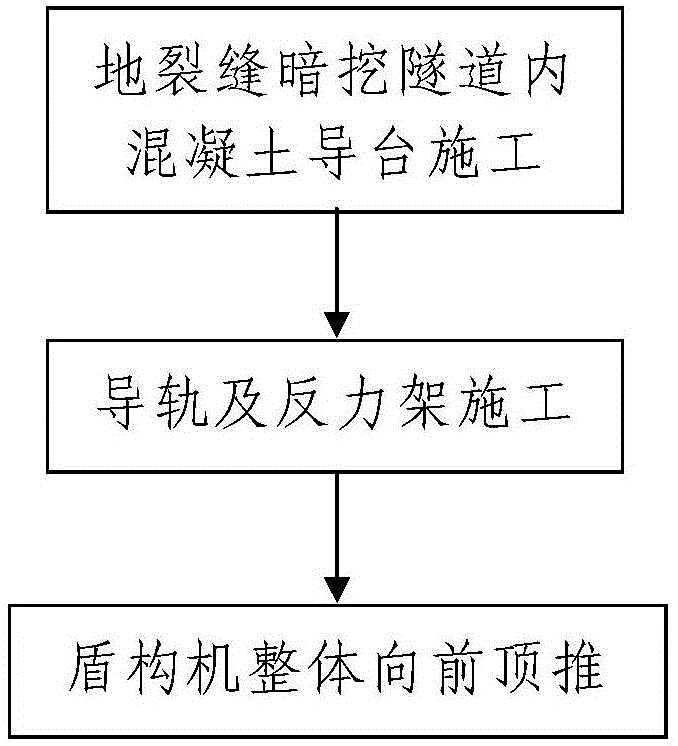

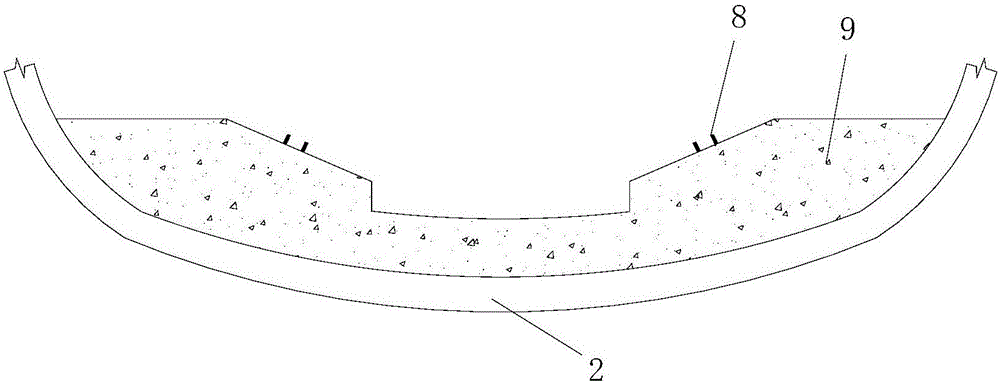

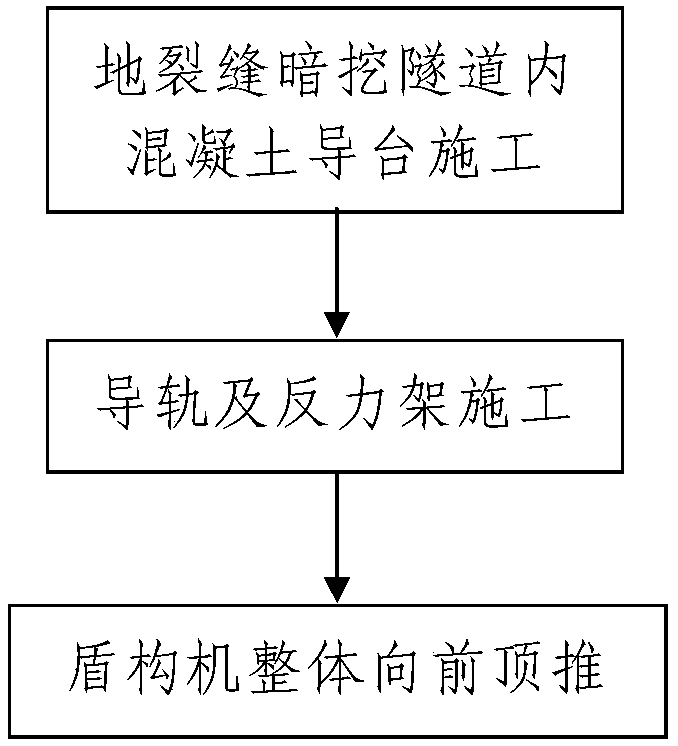

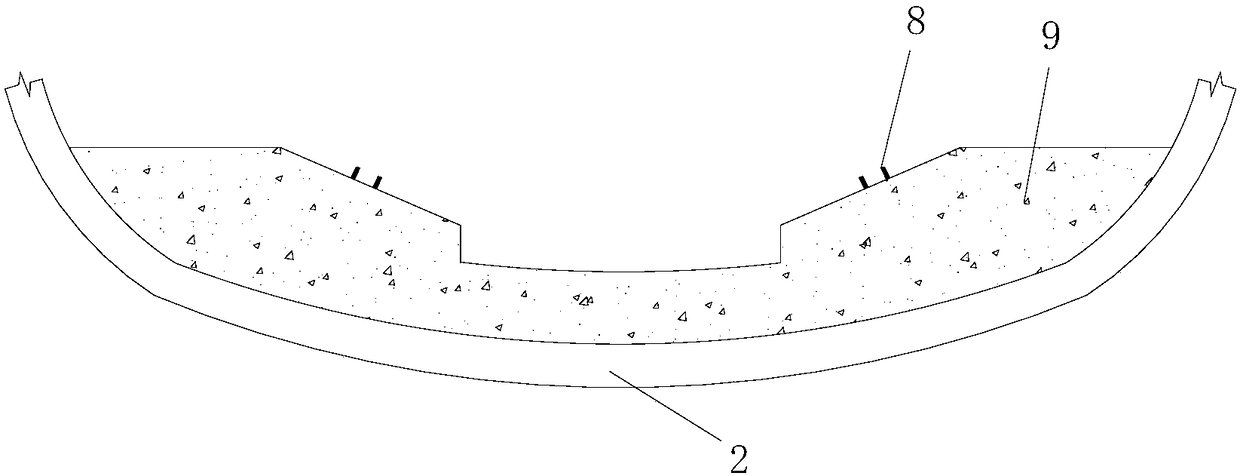

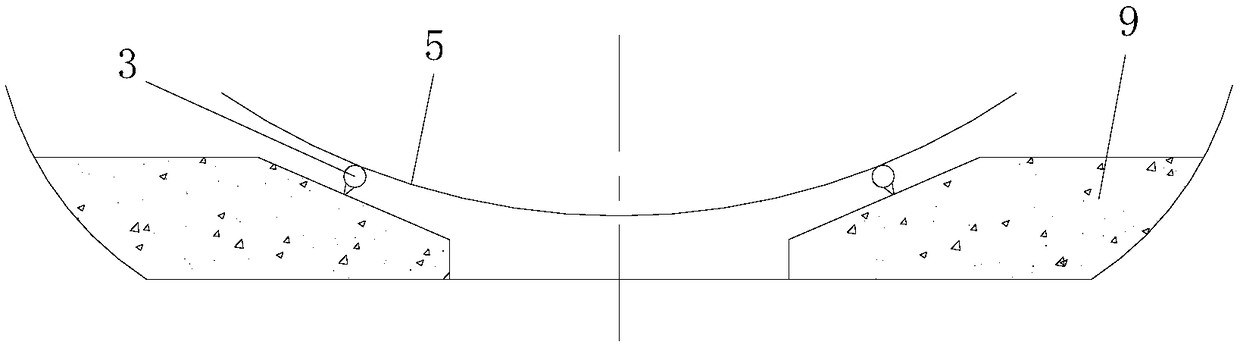

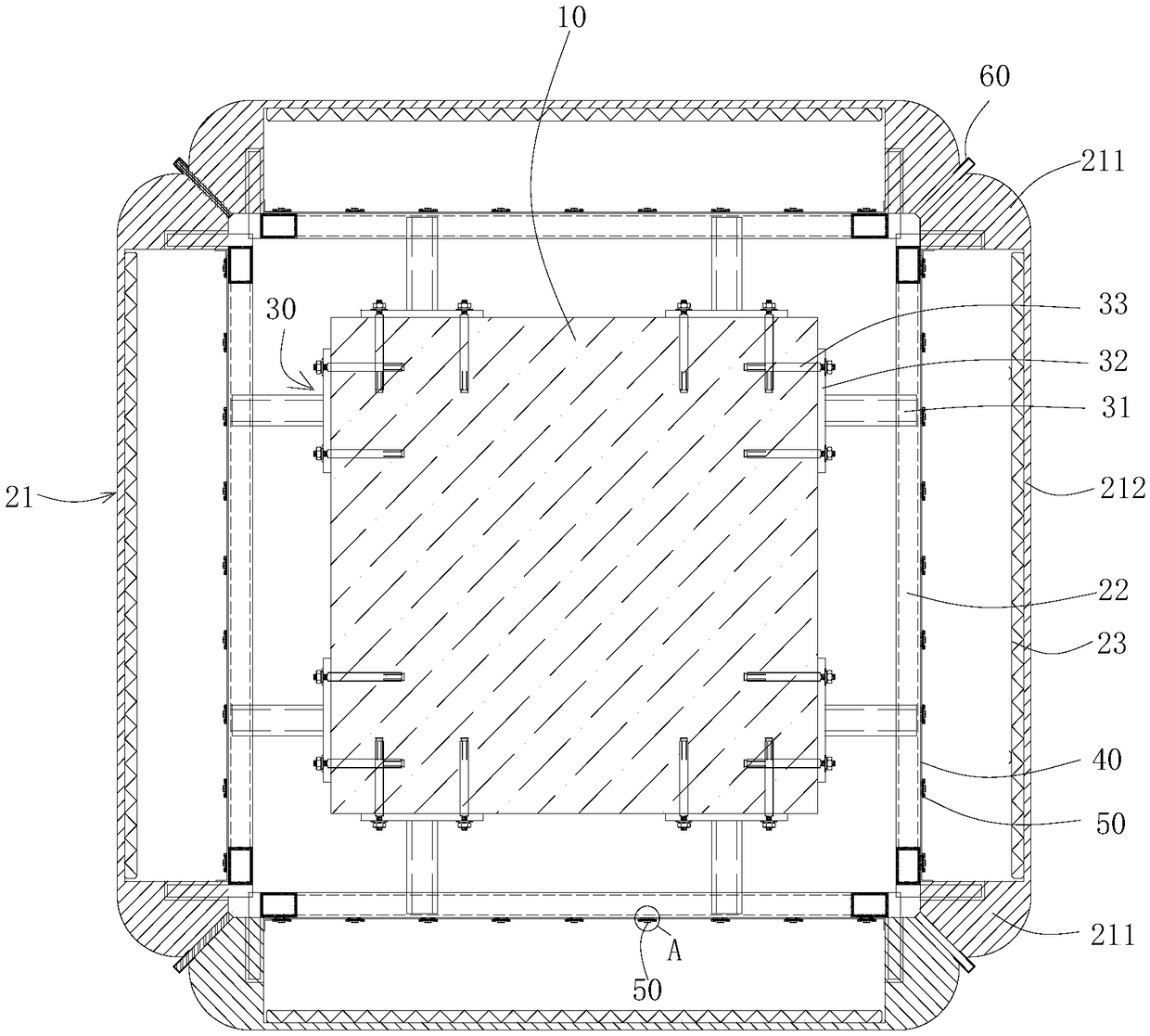

Construction method for shield driving type empty pushing ground fracture bored tunnel

The invention discloses a construction method for a shield driving type empty pushing ground fracture bored tunnel. The construction method comprises the following steps: 1) constructing a concrete guide platform in the ground fracture bored tunnel; 2) constructing a guide rail and a counterforce frame; 3) integrally forward pushing the shield tunneling machine: forward pushing the shield tunneling machine, supporting the shield tunneling machine on two guide rails, and utilizing a boosting cylinder of the shield tunneling machine and the counterforce frame to integrally forward push till being in place; in a pushing process, utilizing a shield segment assembling device for the shield tunneling machine to mount a plurality of shield segments on the concrete guide platform from back to front, wherein the shield segments are bottom segments and are located on the rear side of the boosting cylinder; supporting the boosting cylinder on the counterforce frame through the bottom segments, wherein the bottom segments form a trolley translation channel for forward moving the rear matched trolley of the shield tunneling machine. The method provided by the invention has the advantages that the steps are simple, the design is reasonable, the construction is simple and convenient, the use effect is good, the inverted arch backfill structure in the tunnel is utilized to simply and conveniently finish the construction process of the shield driving type empty pushing ground fracture bored tunnel and the construction process is safe.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

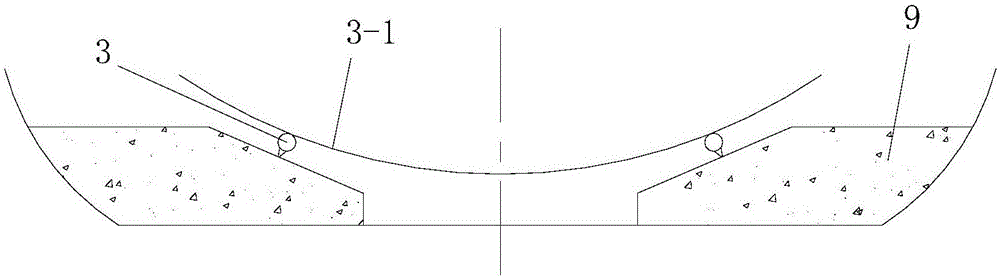

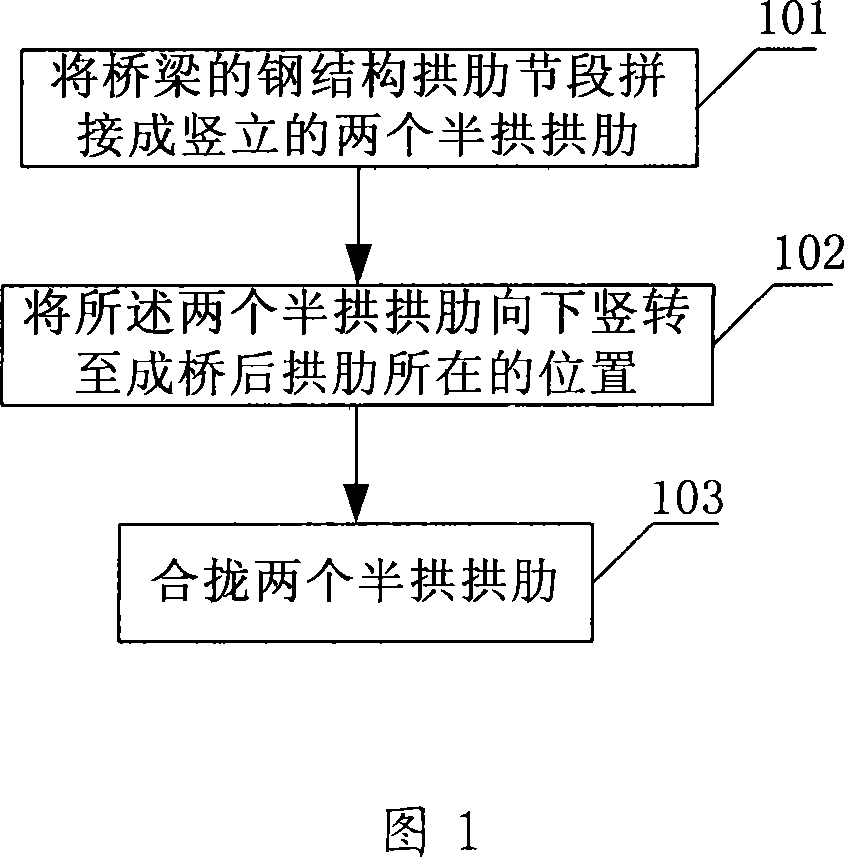

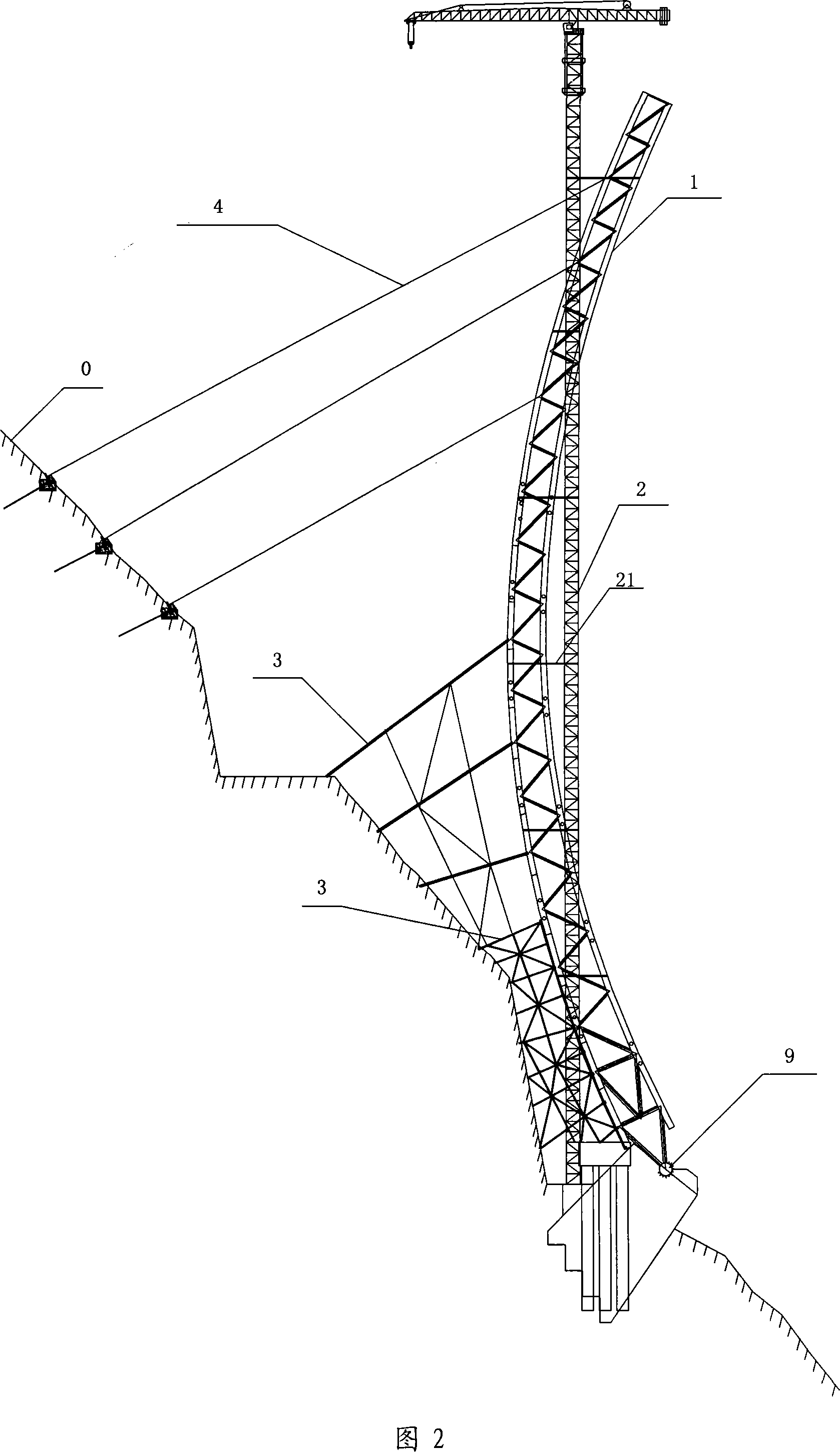

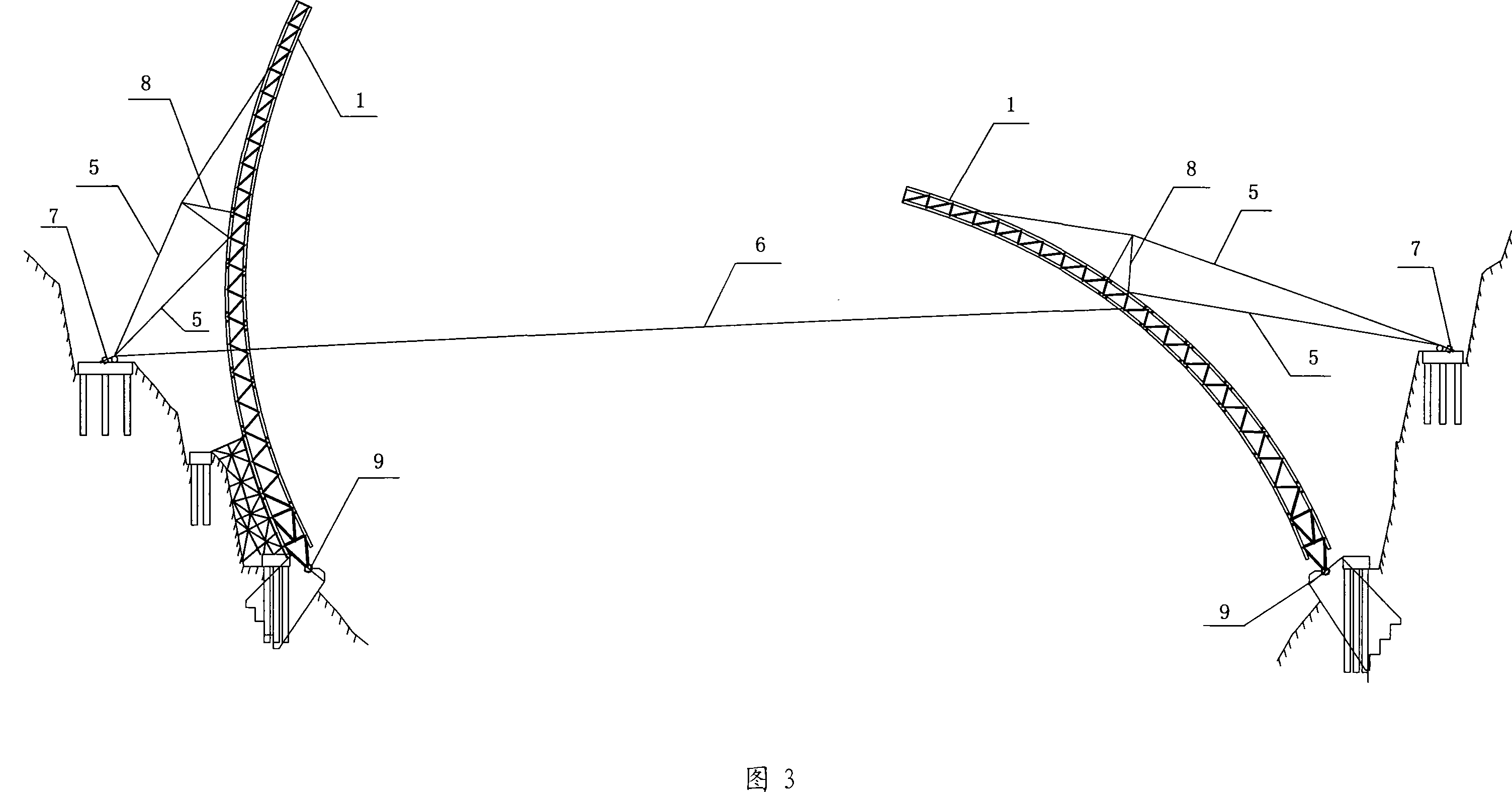

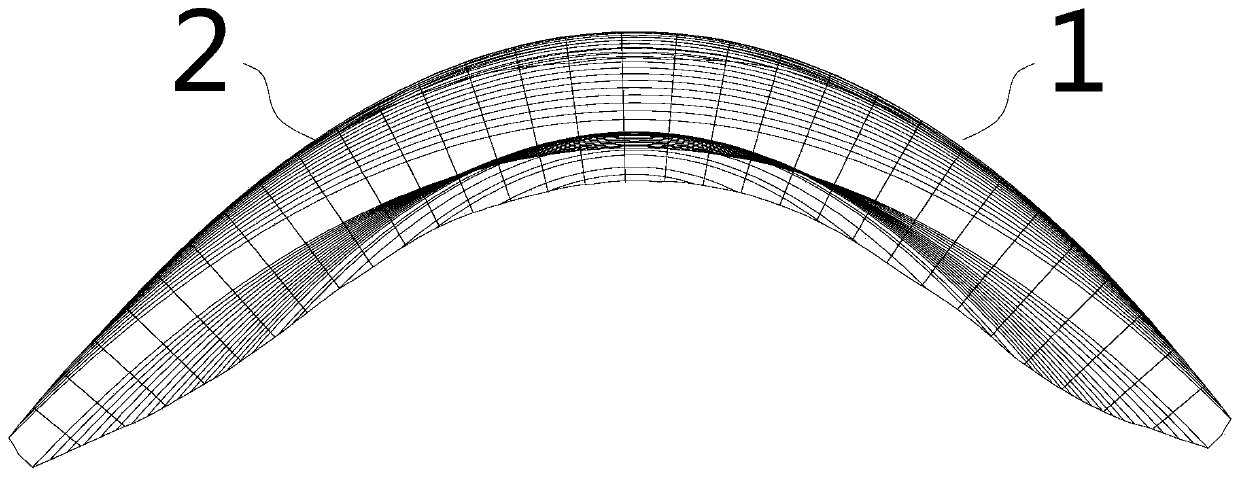

Construction method for steel structure arch rib of arch-type bridge

InactiveCN101235624AEasy constructionGuaranteed construction accuracyBridge erection/assemblyArch-type bridgeLandformBuilding construction

The invention relates to a steel structure arch rib construction method of an arch-type bridge, which comprises connecting steel structure arch rib segments of the bridge into two vertical semi-arch ribs, vertically rotating downwards the two semi-arch ribs to the position where the arch rib on the back of the bridge is located, and folding the two semi-arch ribs. The scheme is convenient for arch rib construction and guarantees the construction precision through connected the arch ribs on the vertical direction on one hand, on the other hand, the two vertical semi-arch ribs are connected, which can fully utilize the landform of steep hill-slope, and can finish the construction of the arch rib on a small field, avoids the problem that high construction cost which is caused by working in the large field requirement such as blasting which is required by the flat rotation, and saves time, largely reduces construction cycles, and further reduces construction cost.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

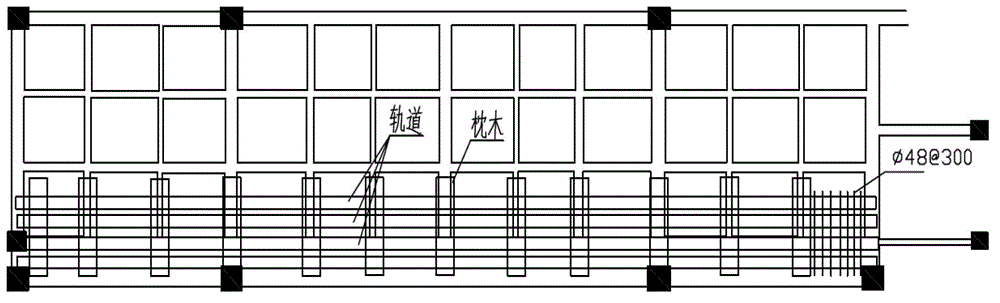

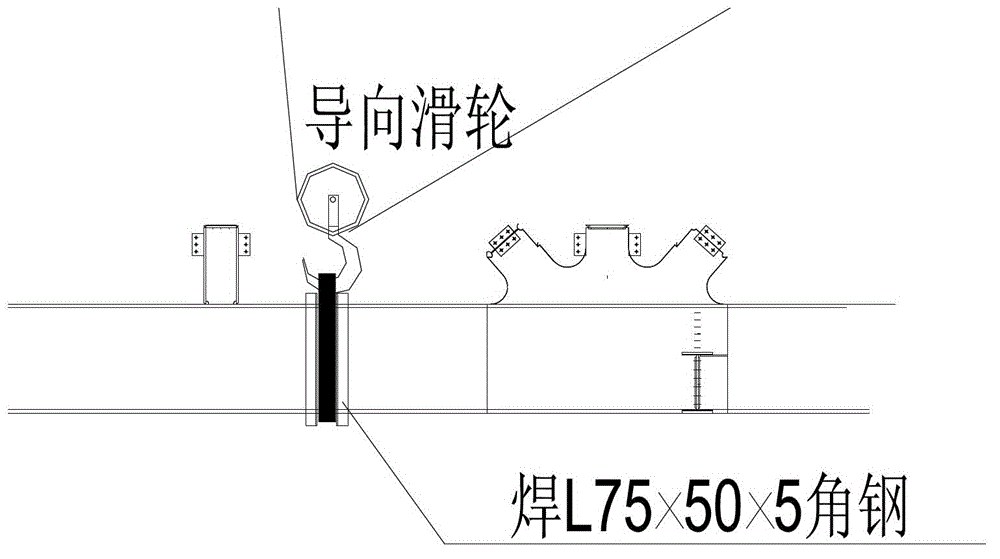

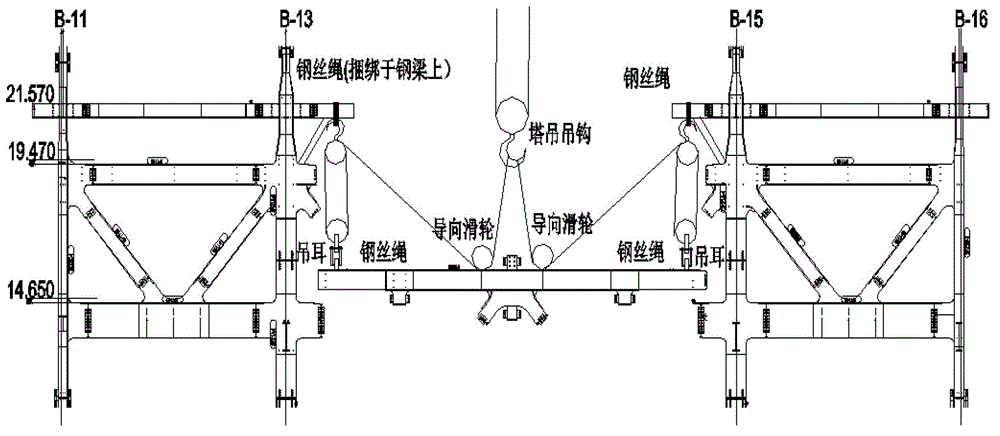

High-altitude lifting construction method for overweight steel truss of transferring layer

ActiveCN102979313ASolve the problem of high-altitude hoistingOvercome limitationsBuilding material handlingSuccessful completionTruck

The invention relates to a high-altitude lifting construction method for an overweight steel truss of a transferring layer. The high-altitude lifting construction method comprises the following steps of: firstly paving tracks on the floor at the lifting area of the transferring layer, then using a crane to lift a rod piece of the steel truss onto the tracks paved on the floor in advance, then arranging a guide pulley block, sliding the rod piece of the steel truss to be in position by the tracks, finally utilizing the matching of the pulley block and the crane, lifting the rod piece of the steel truss to the installing position and finishing the assembling construction. The innovative construction technology has the advantages that the high-altitude lifting difficulty in hoisting of a transferring truss is successfully solved, and the smooth and safe completion of the lifting operation in shortest time can be ensured. The high-altitude lifting construction method overcomes the limit of lifting of a large-tonnage truck crane adopted in the prior art, is safer and more reliable, can shorten the construction period and save the cost and the like, can lay the foundation for successful completion of a main engineering and is an optimal construction scheme for high-altitude lifting of the similar overweight steel truss of the transferring layer.

Owner:浙江省三建建设集团有限公司

Track gauge correction method for double-block type ballastless track construction

ActiveCN103452018ACorrect installation errorsEasy to operateMeasuring apparatusControl theoryCorrection method

The invention discloses a track gauge correction method for double-block type ballastless track construction. The method comprises the following steps of: (1) manufacturing a track gauge correction device; (2) adjusting the track gauge accuracy of the track gauge correction device by using a tool track of a group of track panels; (3) correcting a track gauge in construction, properly loosening fastener screw spikes before the track panels are raised, inserting the track gauge correction device from the start end of the tool track to press four pairs of track gauge correction wheels against two sides of the track wrist of the tool track, arranging supporting traveling wheels on the track surface of the tool track, longitudinally moving the device along the tool track, arranging a sleeper between front and back track gauge correction wheels to enable the track gauge correction wheels to apply force to the tool track so as to realize track gauge correction, manually screwing the fastener screw spikes, and fixing a track gauge relationship between the tool track and the sleeper to complete the track gauge correction operation of the sleeper; (4) sequentially performing the track gauge correction operation, in the step (3), on all sleepers.

Owner:THE 2ND ENG CO LTD OF CHINA RAILWAY 17 BUREAU GRP

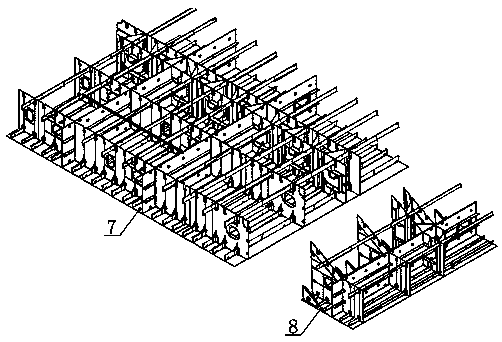

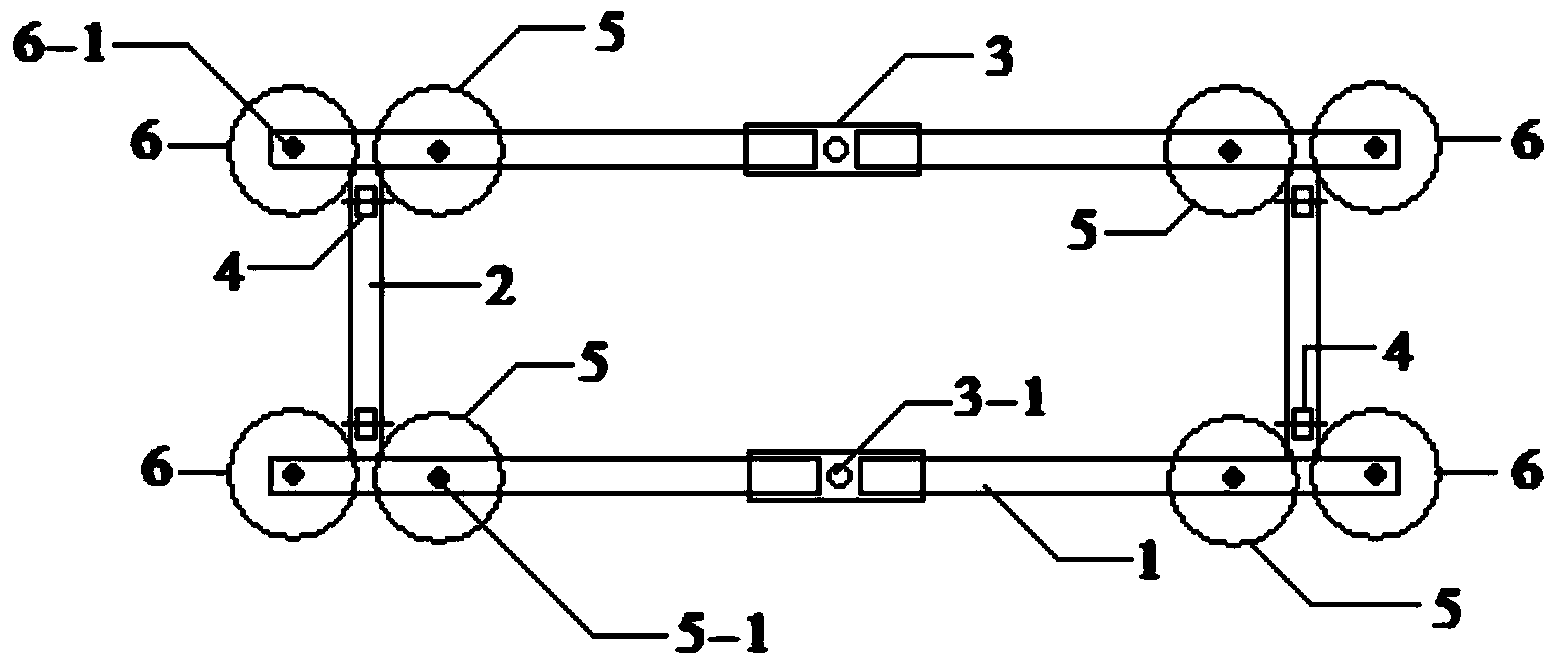

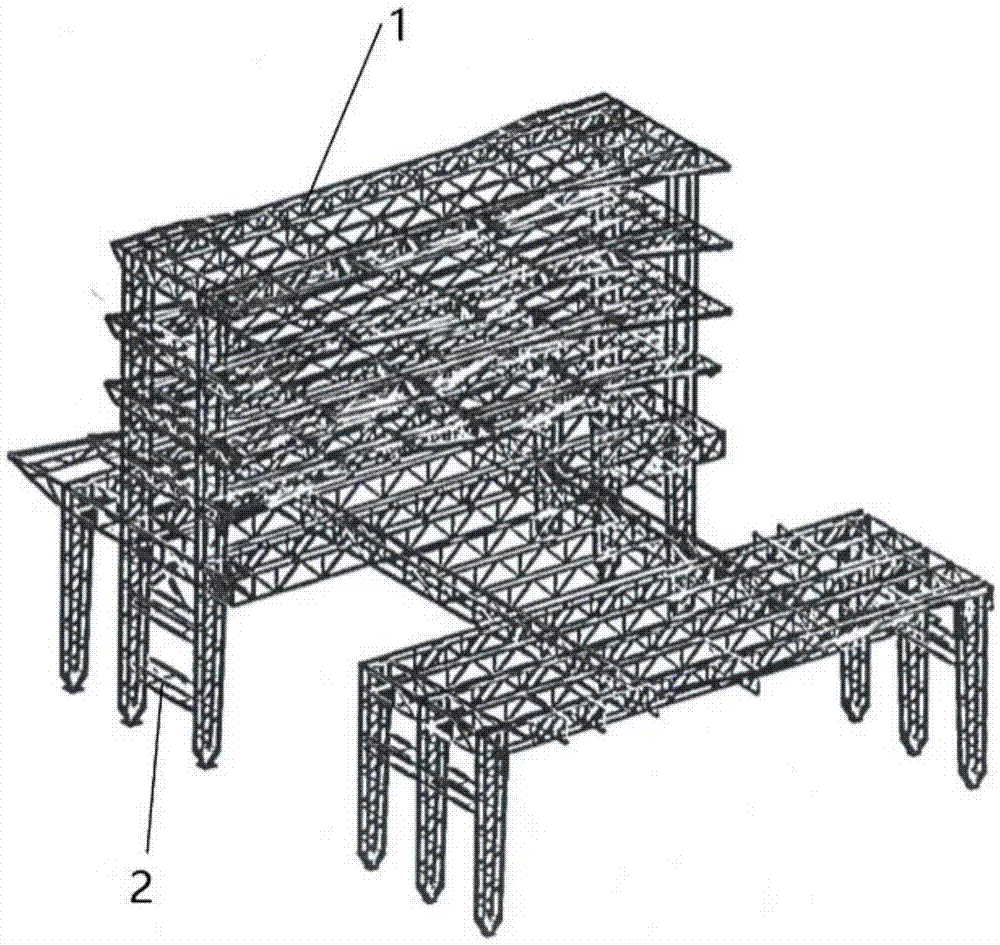

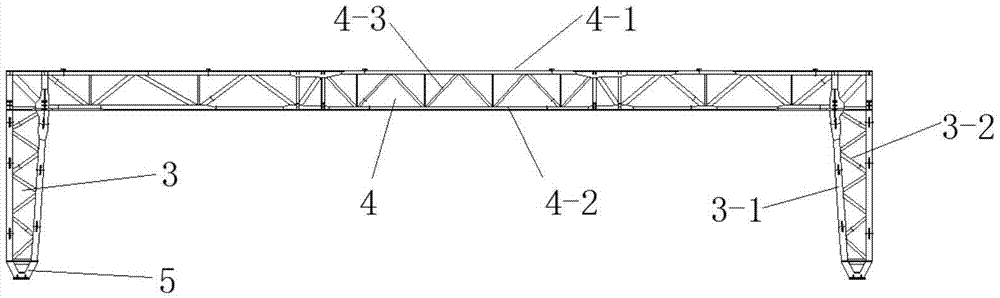

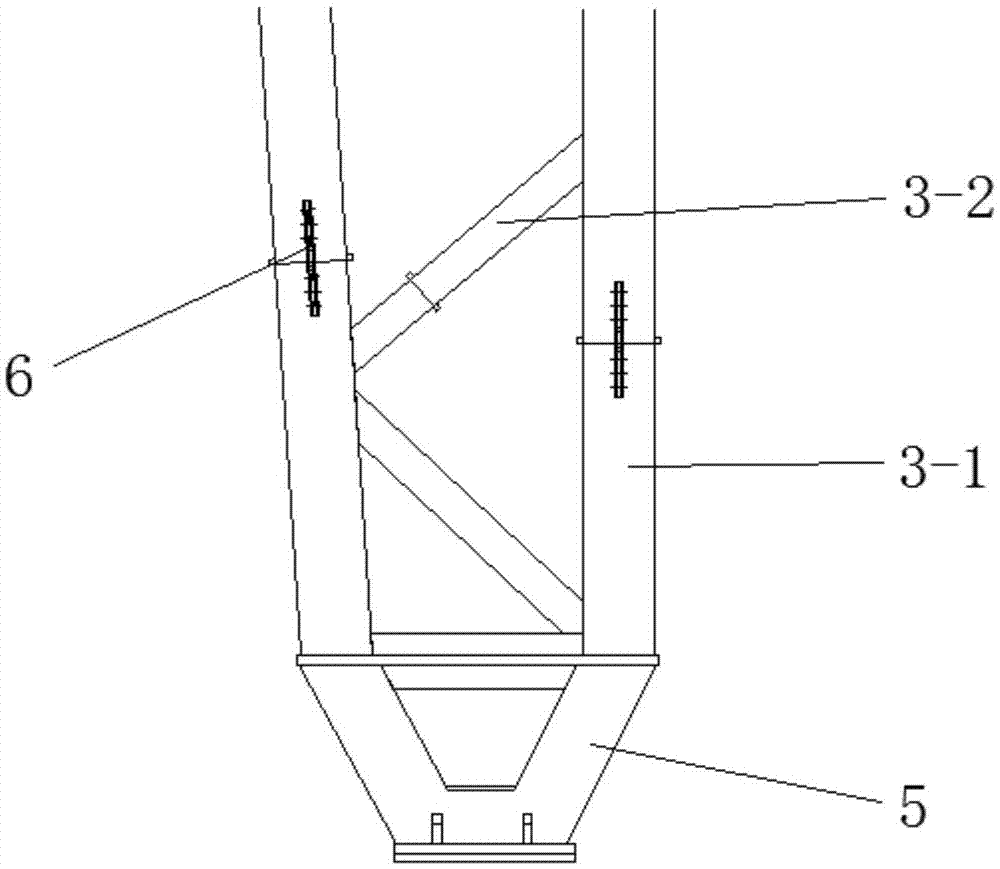

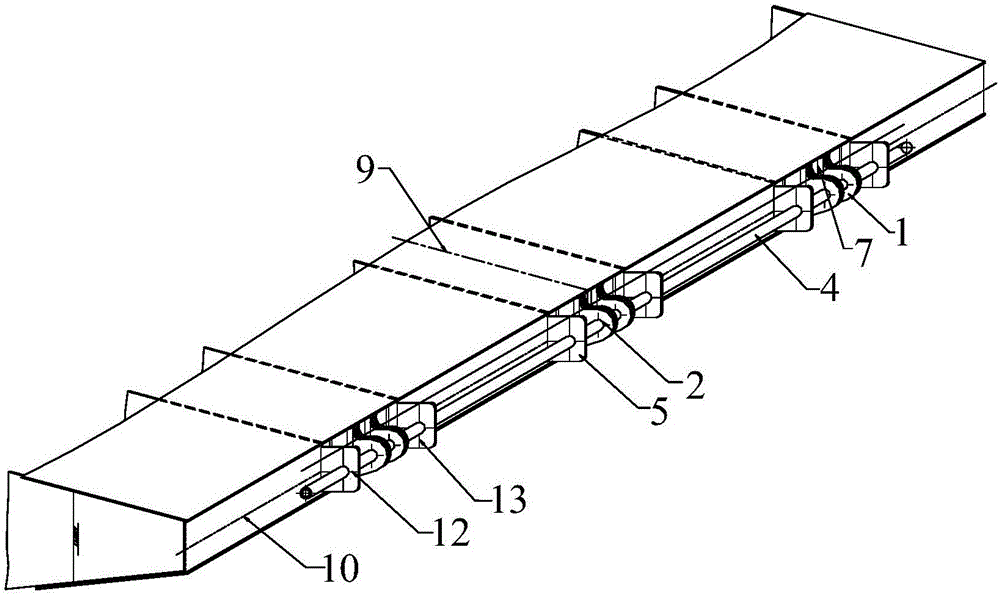

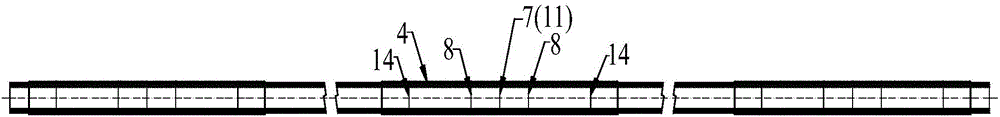

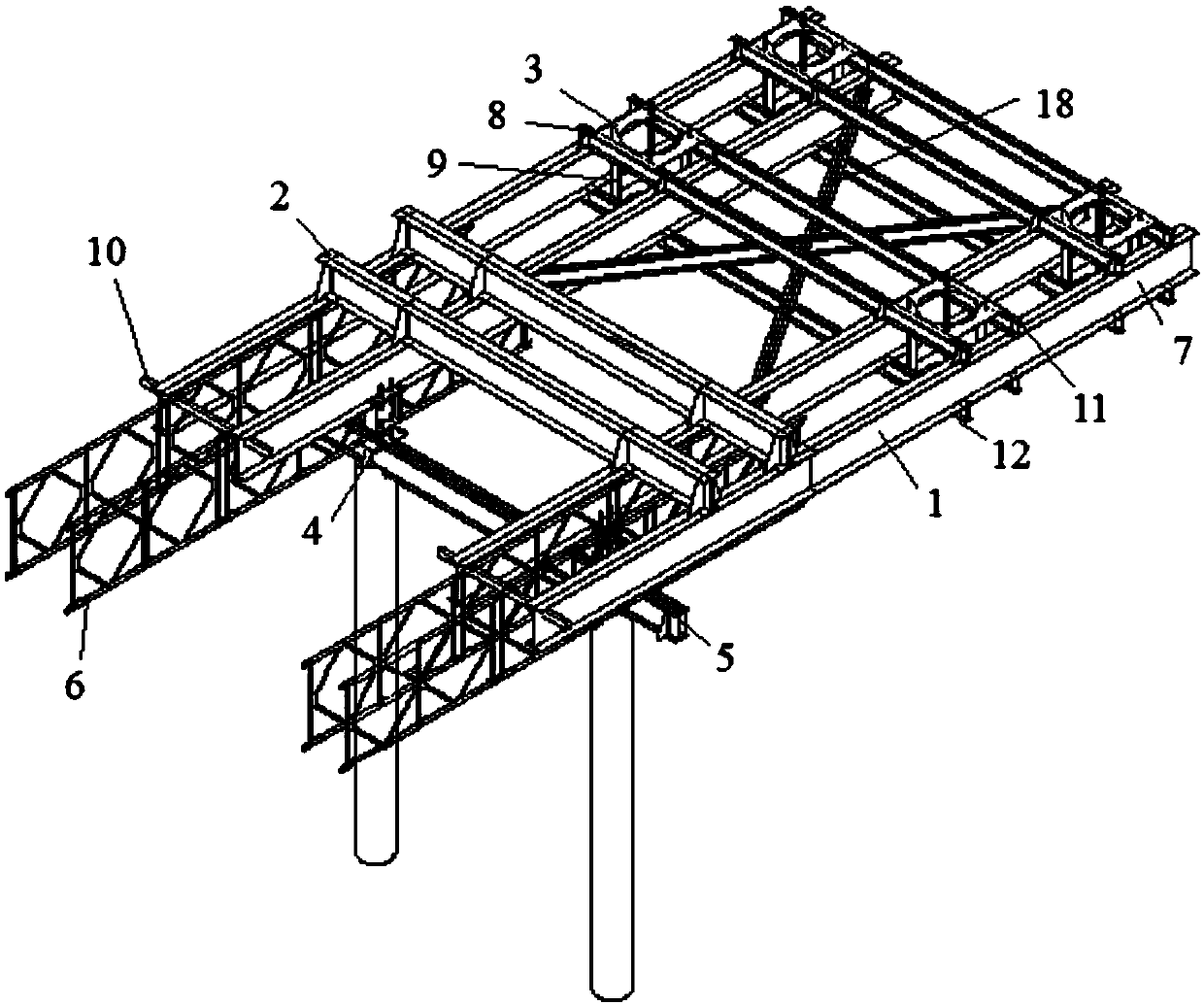

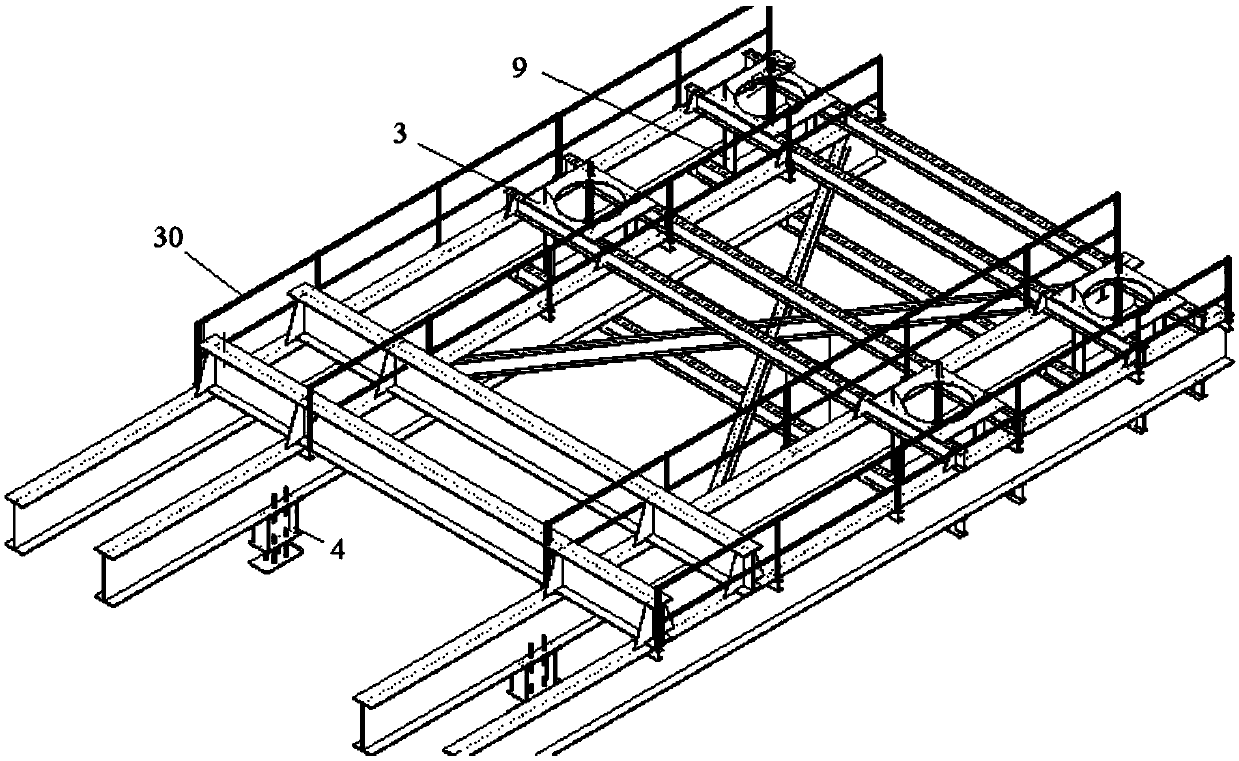

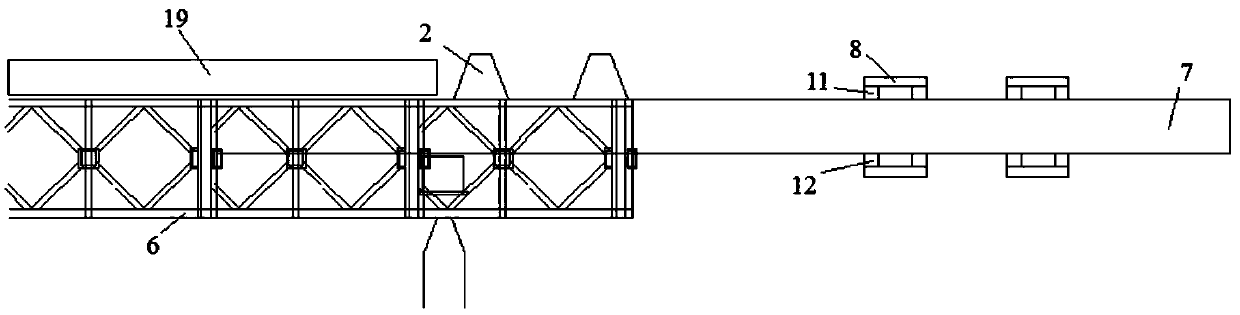

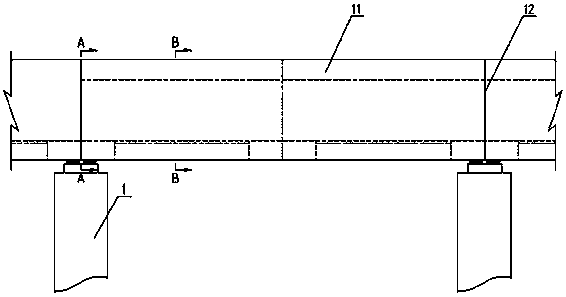

Large-span steel truss structure and installation method thereof

The invention discloses a large-span steel truss structure and an installation method thereof. The large-span steel truss structure comprises one group of steel frames and secondary trusses which are located between the adjacent steel frames and are vertically connected with the steel frames; each steel frame adopts a double-truss combined truss and comprises two supporting columns and a main truss located at the tops of the supporting columns; column pins are arranged at the lower parts of the supporting columns; each supporting column comprises one group of steel columns and reinforcing ribs which are alternatively distributed between the steel columns; each main truss comprises one group of upper chord plates, one group of lower chord plates and webs located between the upper chord plates and the lower chord plates. According to the installation method provided by the invention, a long slippage rail is paved at the lower part and a lot of labor force is alleviated; the whole structure can be divided into different construction regions according to different structures so that the construction is more convenient and rapid.

Owner:JIANGSU HUNING STEEL MECHANISM

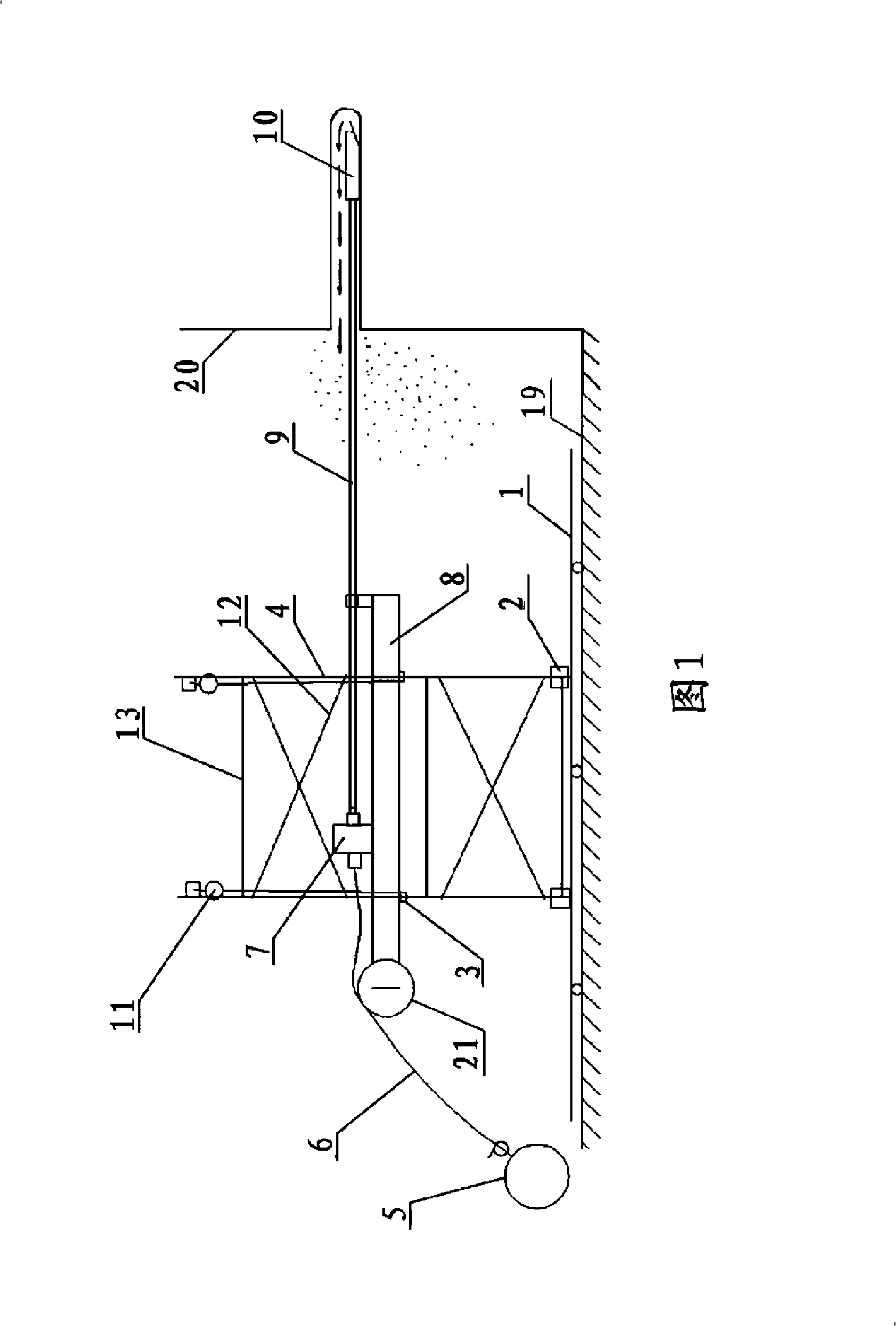

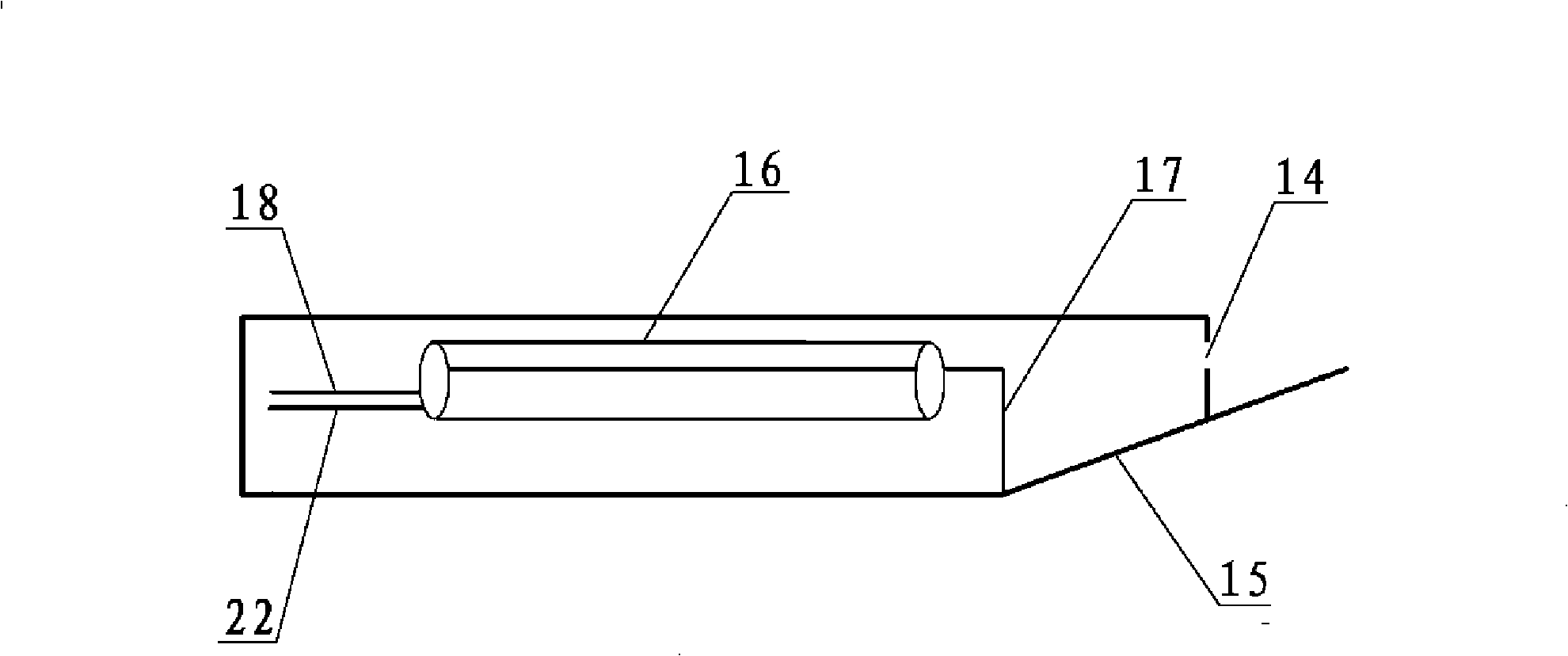

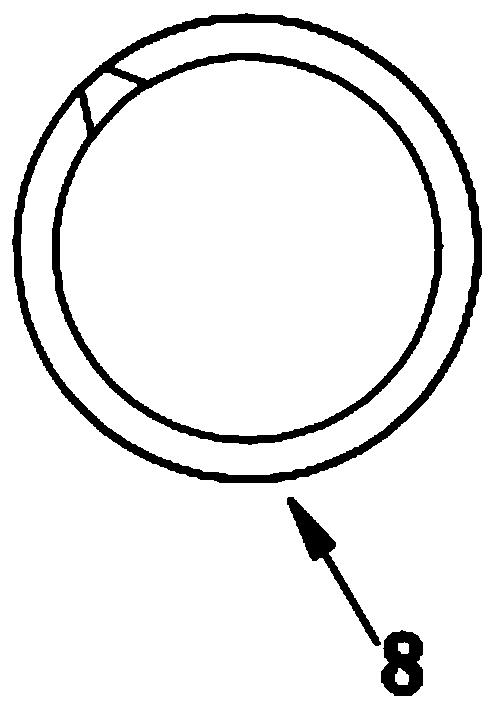

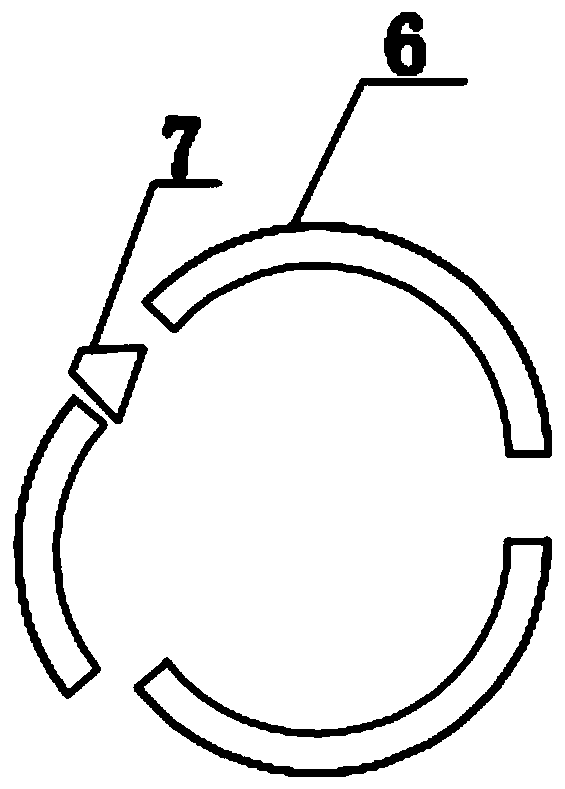

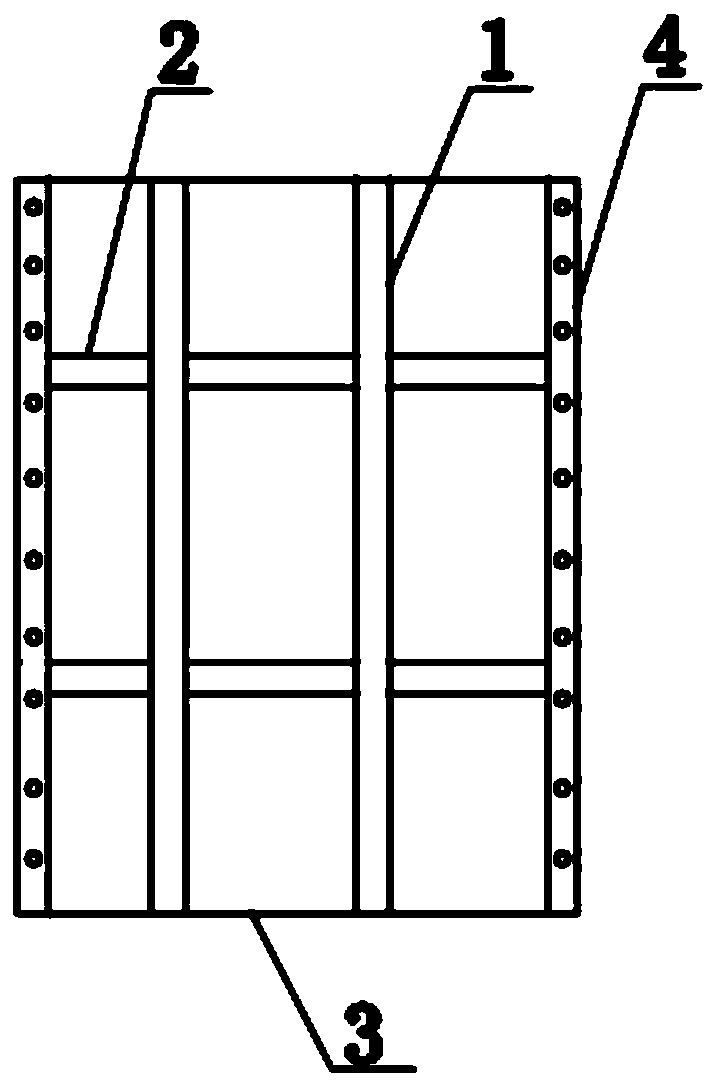

Concrete vertical conveying descent control device

InactiveCN101280627AImprove workabilityAvoid separationBuilding material handlingAerospace engineering

The invention discloses a descent control device for vertically conveying concrete, which comprises a left circular tube and a right circular tube; the central lines of the left circular tube and the right circular tube are in parallel and the left circular tube and the right circular tube are arranged alternately at the direction of height; cuts of certain length are arranged on both the left circular tube and the right circular tube; the cut on the left circular tube and the cut on the right circular tube correspond to each other at the direction of length; in addition, the front lateral sides and the rear lateral sides of the cut on the left circular tube and the cut on the right circular tube are correspond to each other and connected with each other by a front-side connecting plate and a rear-side connecting plate; the upper end parts and the lower end part of the left circular tube and the right circular tube are connected with an upper sealing board and a lower sealing board correspondingly; the left circular tube and the right circular tube form a communicated containing cavity by the corresponding connection of the front-side connecting plate, the rear-side connecting plate, the upper sealing board and the lower sealing board; the inner surface of the lower sealing board is provided with a clapboard in parallel to the central lines of the circular tubes at two sides. When used for vertically conveying concrete, the descent control device can prevent the concrete from separating, effectively improves the workability of the concrete; the descent control device has long service life, no frequent examination and repair or replacement, simple structure and low manufacturing cost.

Owner:SINOHYDRO BUREAU 14 CO LTD

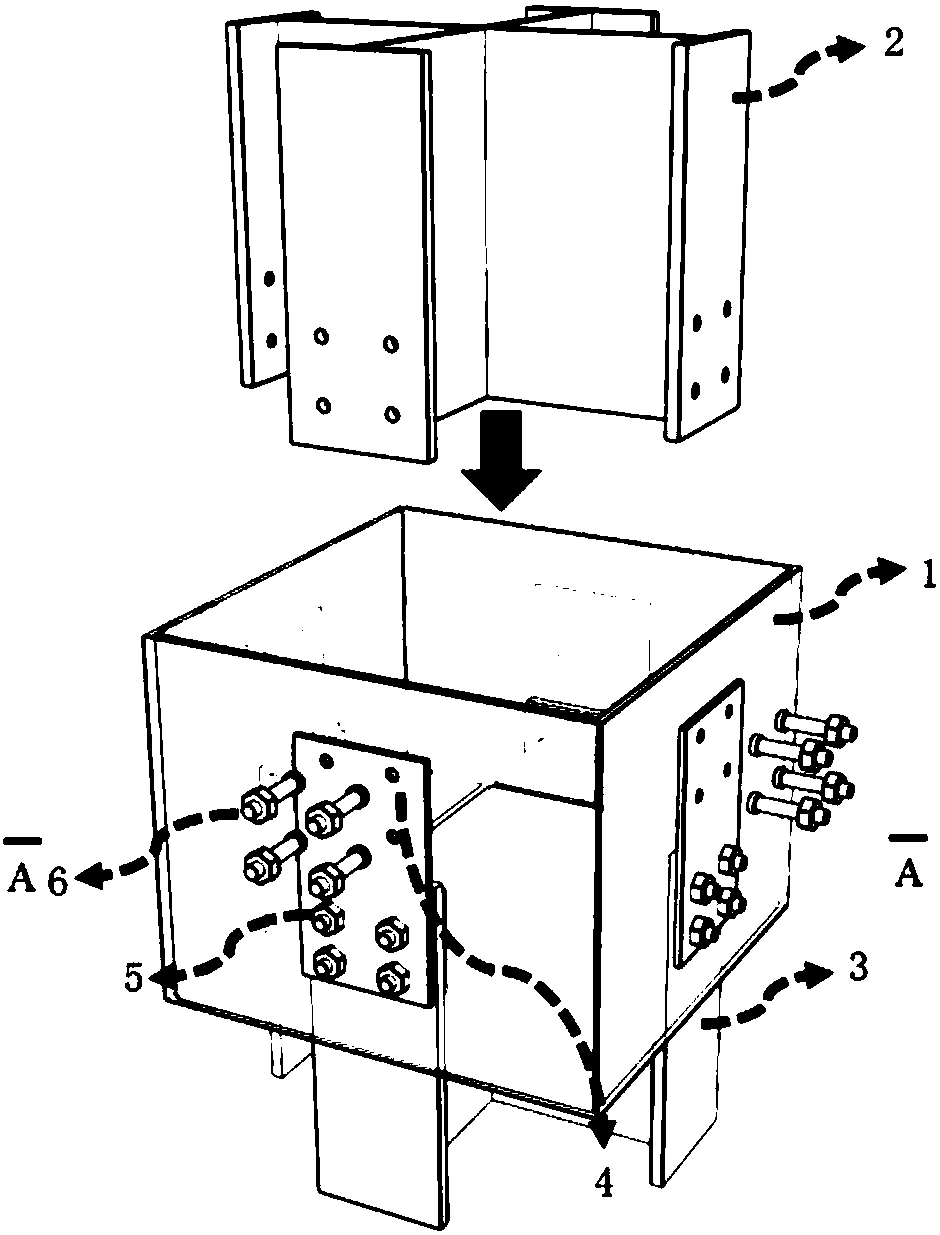

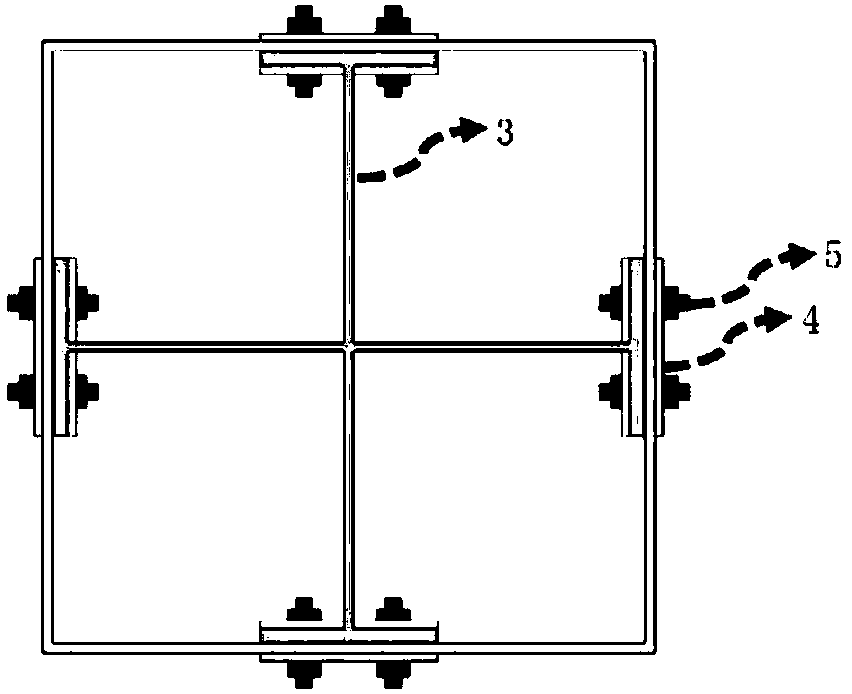

Joint bar construction structure and method

Owner:CHENGDU CONSTR ENG GROUP CORP

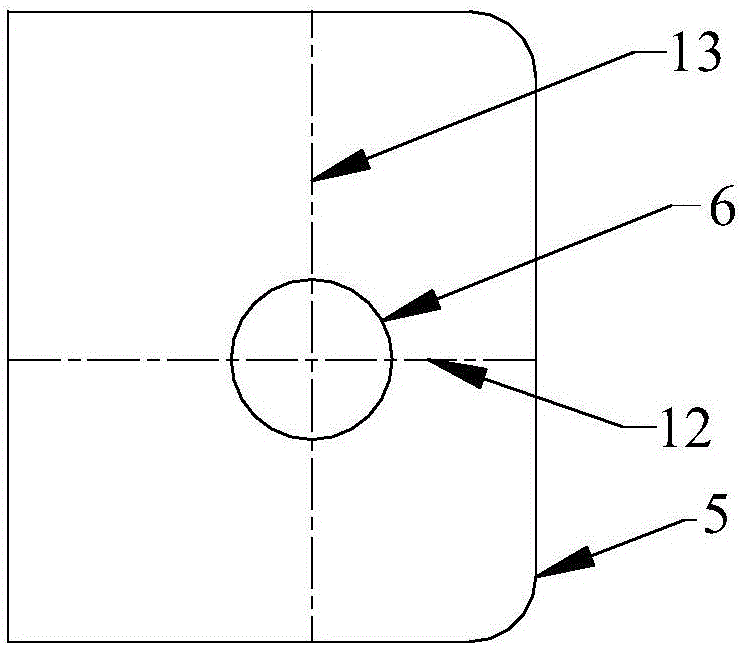

Marine opening and closing hinge installation tool and method

ActiveCN106628009ABreak through the technical problem of difficult construction in assembly and weldingResolve parallelismCargo handling apparatusPassenger handling apparatusSternReference line

The invention provides a marine opening and closing hinge installation tool and method. The installation tool comprises a positioning shaft (4) and positioning reinforcing plates (5), positioning holes (6) are formed in the positioning reinforcing plates (5), and positioning shafts (4) penetrate through the positioning holes (6) in the positioning reinforcing plates (5) and pin holes (2) in a plurality of hinge components (1). The installation method comprises the steps that reference lines are marked on the bow or stern and a gangplank (3) of a ship, accurate positioning during opening and closing hinge installation can be achieved according to the corresponding relation between reference lines on the tool and the reference lines on the ship, the phenomenon that different shrinkages and stresses generated in the construction process, and vertical and front-back size shrinkage malposition are avoided, hinge perpendicularity and center line parallelism can be ensured, the precision is effectively controlled, and installation pairing of the hinge is achieved finally.

Owner:JIANGNAN SHIPYARD GRP CO LTD

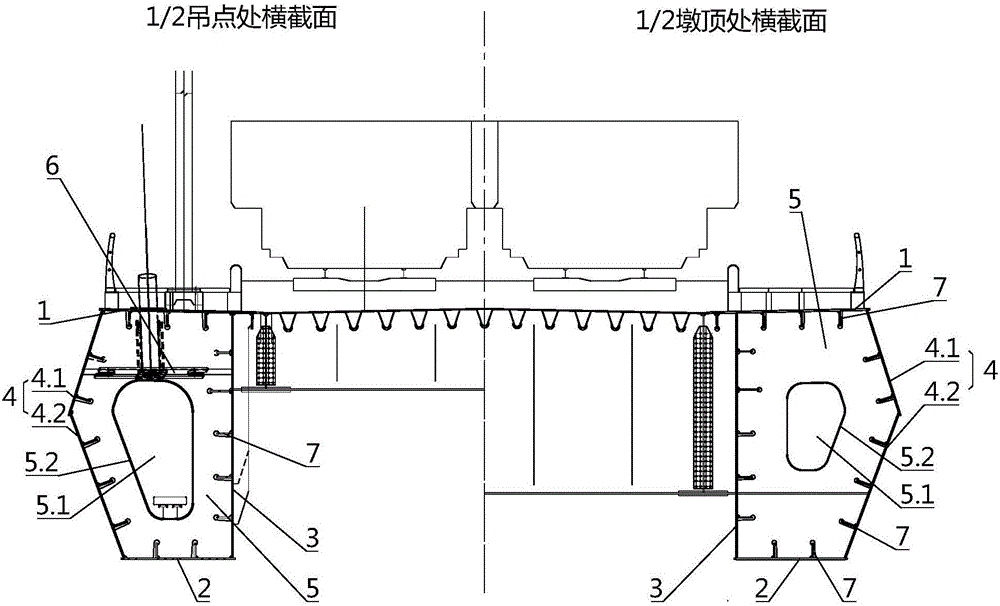

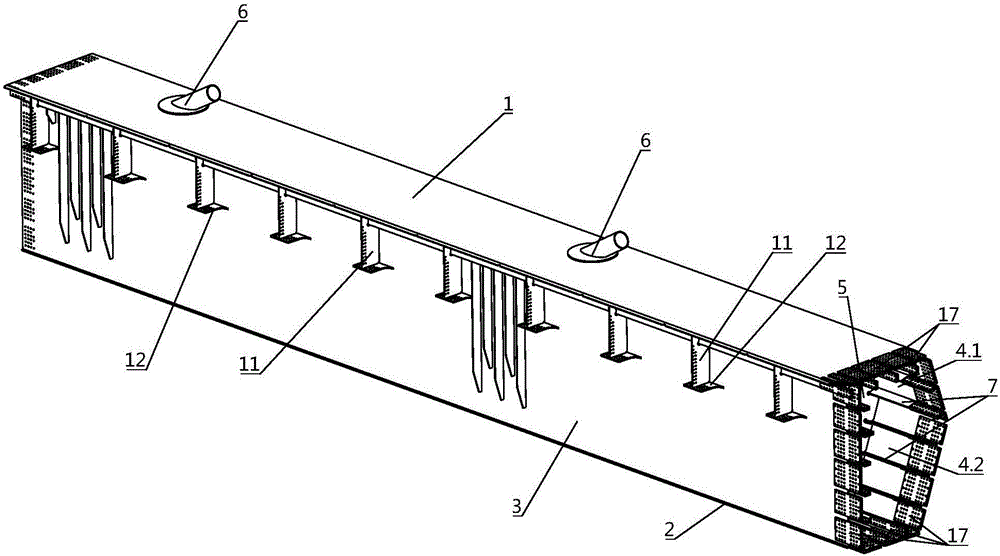

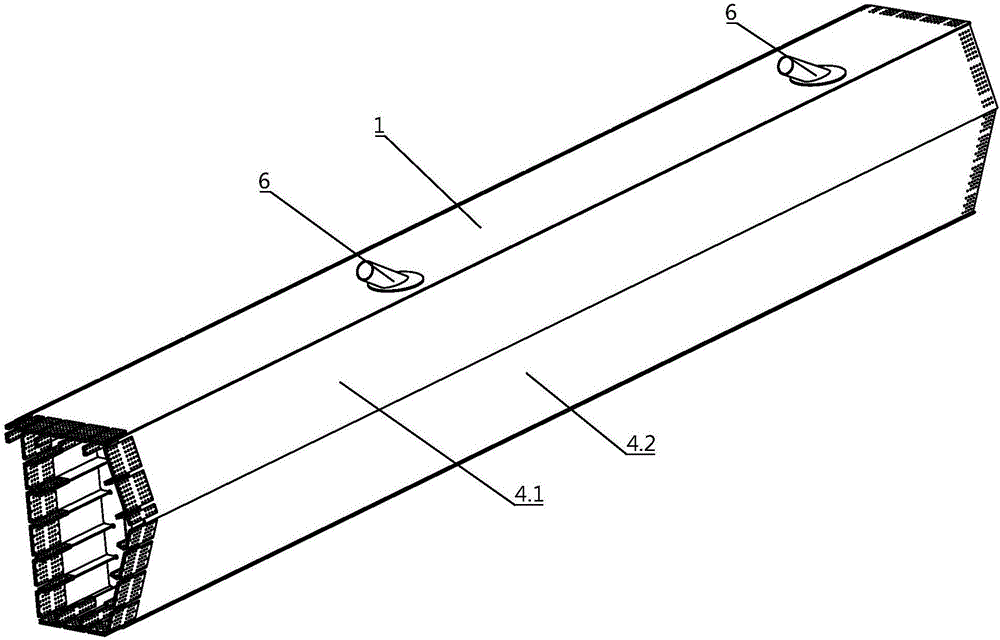

Railroad bridge separating type double-box steel main girder structure without independent tuyere

InactiveCN106544949AShort construction periodEconomicalBridge structural detailsBridge materialsEngineeringStructural engineering

The invention discloses a railroad bridge separating type double-box steel main girder structure without an independent tuyere. The railroad bridge separating type double-box steel main girder structure comprises a bridge deck system, and separating time side box girders are arranged on the two sides of the bridge deck system in the cross bridge direction. One side of each separating type side box girder is connected to the bridge deck system in a stud welded manner. Each separating type side box girder comprises a plurality of separating type side box girder segments arranged in the bridge direction, and the separating type side box girder segments which are adjacent in the bridge direction are spliced through bolts. The designed main girder structure is definite in stress, and the number of local stability problems is relatively small. Compared with an integrated steel box girder, the railroad bridge separating type double-box steel main girder structure has the beneficial effects that the structural size is reduced, the structure can be prefabricated in a factory, on-site joint welding is avoided, and the construction precision and the construction quality are guaranteed; compared with a steel longeron, the railroad bridge separating type double-box steel main girder structure has the beneficial effects that the trival splicing work between joints is reduced, the steel amount is reduced, the structure is simple and concise in outer surface, and the maintenance amount is low; and the railroad bridge separating type double-box steel main girder structure is good in wind-resistant performance for medium and small span bridges.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Simply-supported slab bridge jack-up method and height-adjustable combined cushion structure applied therein

ActiveCN103726450AImprove applicabilityImprove construction accuracyBridge erection/assemblyBridge strengtheningOperabilityRisk stroke

The invention discloses a simply-supported slab bridge jack-up method and a height-adjustable combined cushion structure applied therein. The simply-supported bridge jack-up method includes: firstly, setting up distributive girders under a girder, arranging jacks and putting up temporary supports, and then entirely synchronously jacking up a simply-supported slab to the height 1-3mm higher than design elevation; preliminarily supporting the bridge by the aid of the height-adjustable combined cushion structure and supports prior to performing zero-clearance girder falling to the designed elevation, and then demounting the jacks and the temporary supports. The height-adjustable combined cushion structure comprises a precast portion composed of precast supports and a height-adjustment combined mechanism capable of adjusting the height of the precast supports and a cast-in-situ portion coating a height-adjustable mechanism and part of the precast supports. The simply-supported slab bridge jack-up method and the height-adjustable combined cushion structure applied therein have the advantages of high applicability, controllable security, high construction precision, high operability, high economical efficiency, good application prospect and the like, thereby being capable of being used in support replacement projects of expressways and the bridges of urban roads and especially applicable to jack-up engineering when jack-up height of a sole-across simply-supported girder (slab) is larger than the stroke of one jack.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

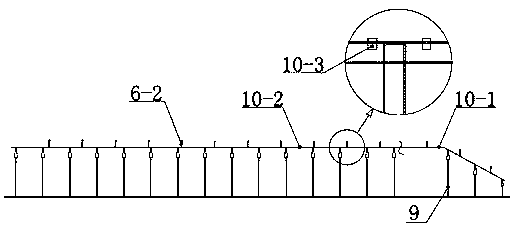

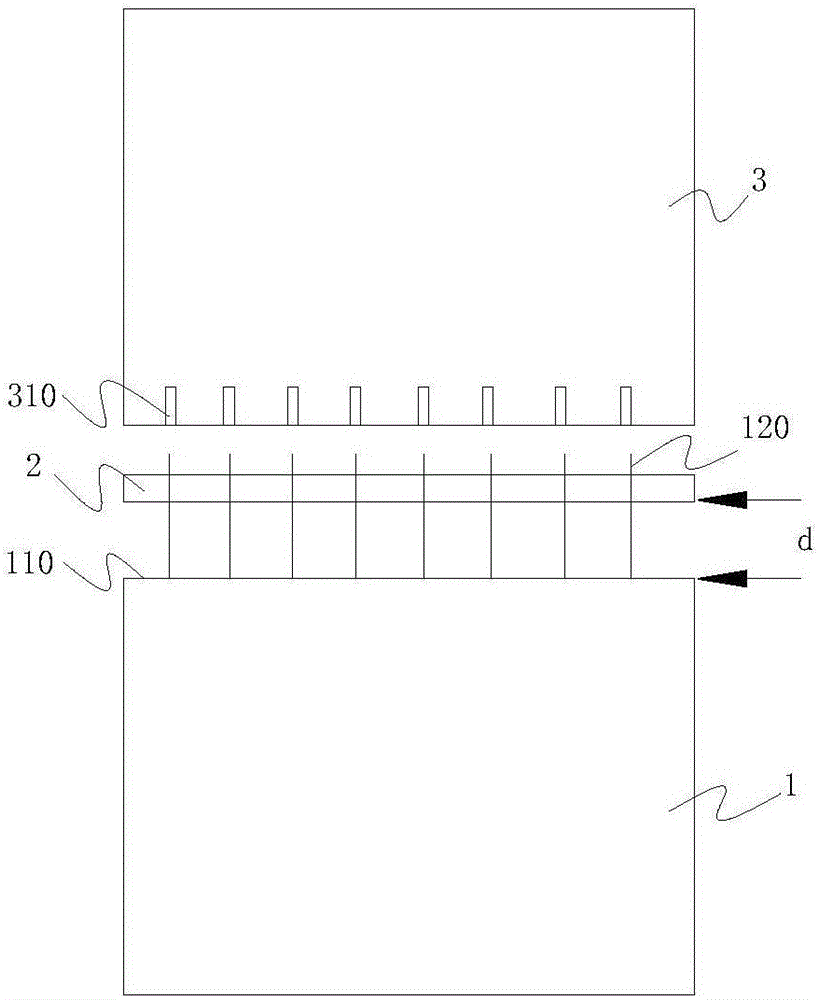

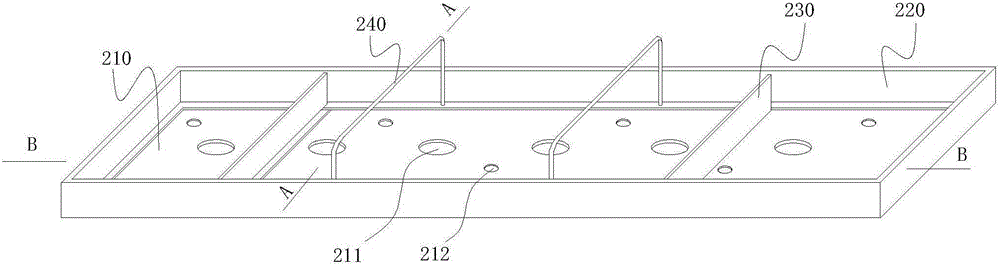

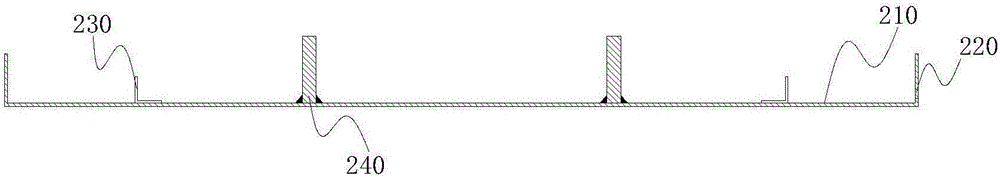

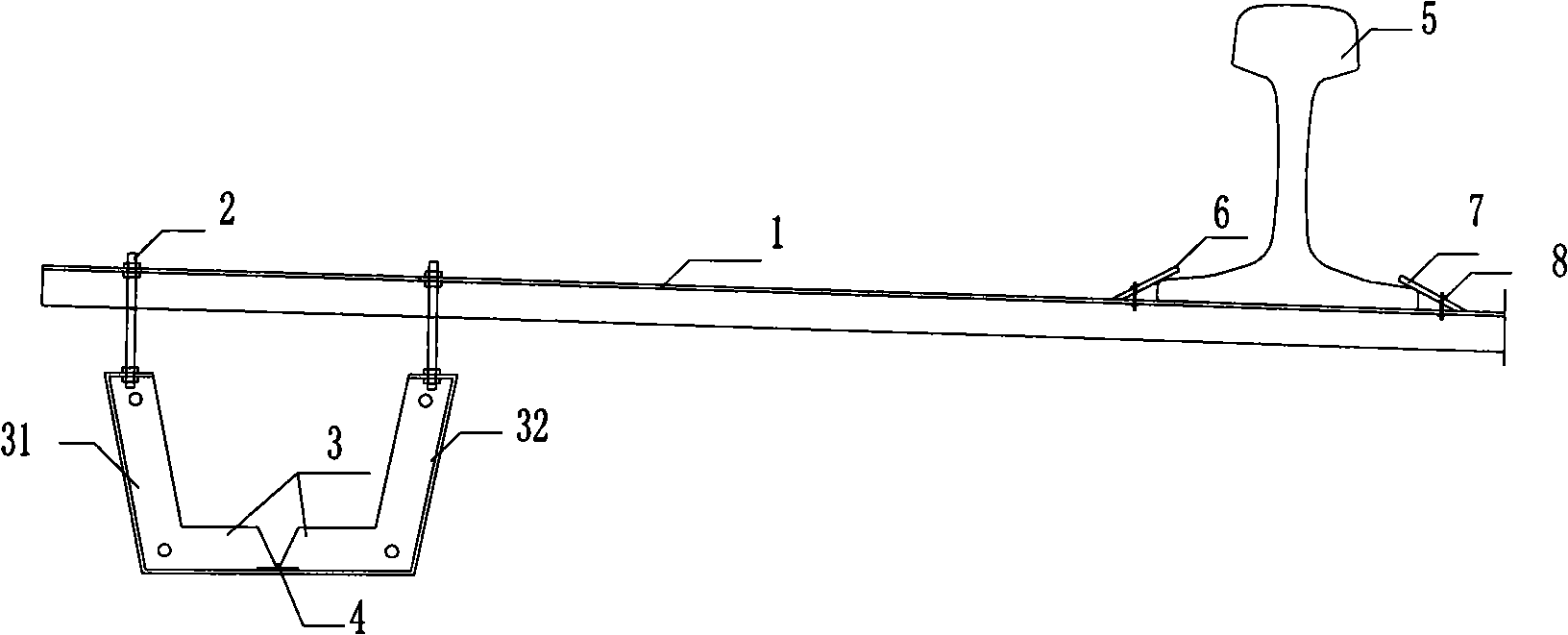

Subway unballasted track ditch construction method and used formwork

ActiveCN101324057AGuaranteed construction accuracySimplify the construction processGround-workUltimate tensile strengthBuilding construction

The invention discloses a construction method for subway unballasted track water ditch and used formworks thereof, belonging to the field of subway construction engineering. The construction method of the invention comprises the steps as follows: (1) a suspension-typed ballasted track water ditch formwork is arranged preliminarily and the formwork is arranged and suspended from the bottom of a steel rail by a hoisting rod; (2) the length of a bolt is adjusted so as to control the height of the formwork; (3) concrete is cast at the bottom and two sides of the formwork; (4) after the strength of the concrete achieves the design requirement, the suspended hoisting rod is removed and two formworks are folded towards the middle by hinges and demoulding is carried out finally to form a whole water ditch. The formwork of the invention consists of two symmetrical L-shaped formworks; the upper part of the formwork is connected with the hoisting rod by the bolt. The construction method of the invention can complete the construction of the water ditch at one time, ensures the construction precision, simplifies the construction procedure, reduces the construction difficulty, and improves the construction progress and the construction quality; the formwork of the invention facilitates demoulding, storage and transport, can be repeatedly used and reduces the construction cost.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

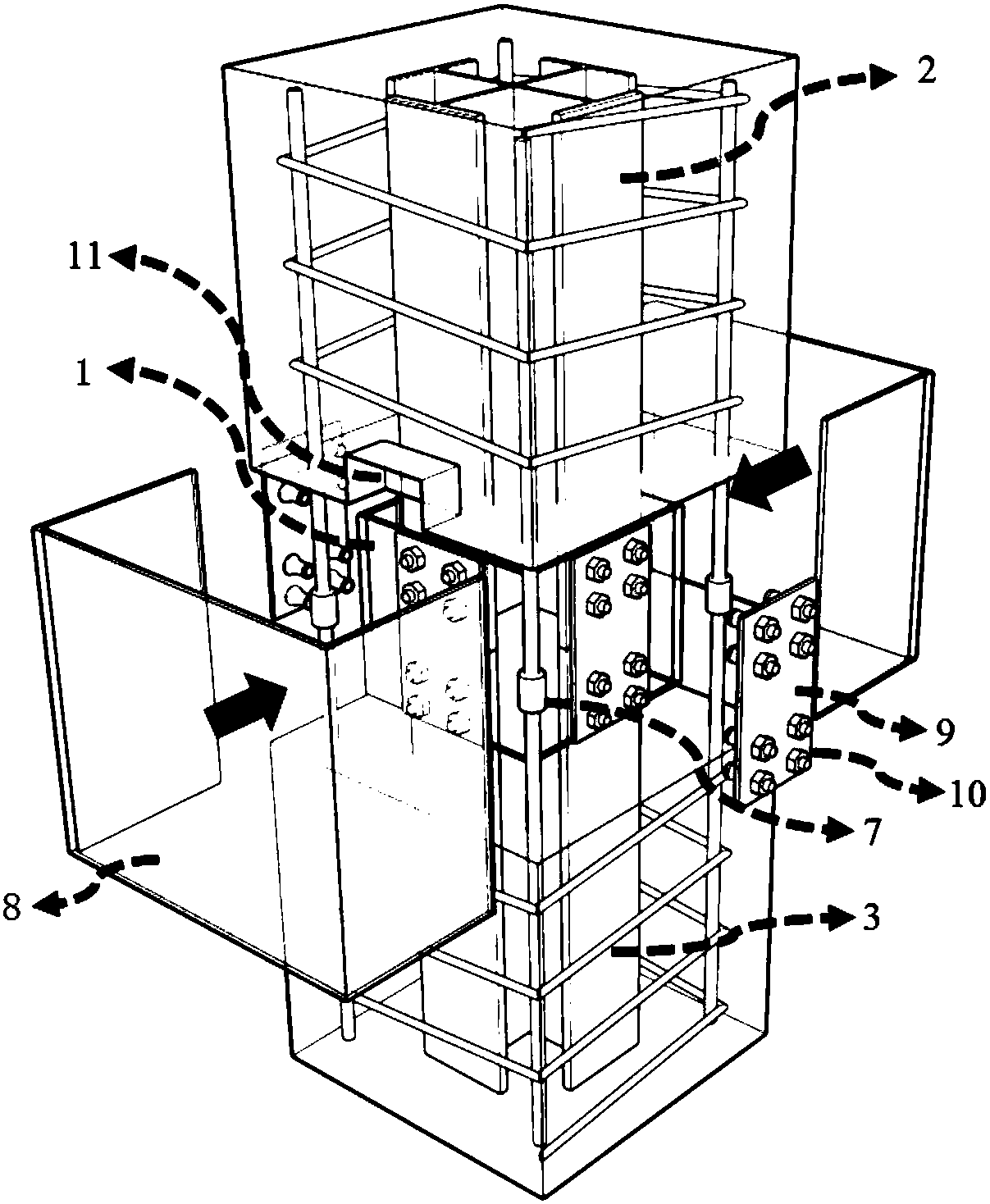

Prefabricated reinforced concrete column connection structure and method

ActiveCN108252424AEasy constructionUse fewer boltsBuilding constructionsReinforced concrete columnPerformance engineering

The invention relates to a prefabricated reinforced concrete column connection structure and method. The idea of equivalent cast-in-place is adopted, based on mechanical optimization analysis, a method connecting to the middle of a column is proposed, shape steel in the column is connected by a shape steel sleeve instead of welding and bolt connection commonly used in engineering, and the construction is simplified; rebars in the column are connected by a mechanical sleeve instead of a grouting sleeve often used in the assembled reinforced concrete structure, and the cost is reduced; the connection part is covered with a steel plate tube and no stirrups are arranged, and the construction is simplified; a hole is reserved in a prefabricated reinforced concrete column at the upper part of the connection part; and after installation of the steel plate tube is completed, high-performance engineering cement-based composite materials (ECC) can be poured to further ensure the integral strength and deformation capacity of the connection part. The prefabricated reinforced concrete column connection structure has high assembly property, the assembly mode is basically a bolt connection with convenient construction, on-site welding and large-area concrete pouring operation are avoided, and the construction is convenient. At the same time, the prefabricated reinforced concrete column connection structure and method is based on the idea of equivalent cast-in-place, and the strength and deformation capability of the connection part can be effectively guaranteed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

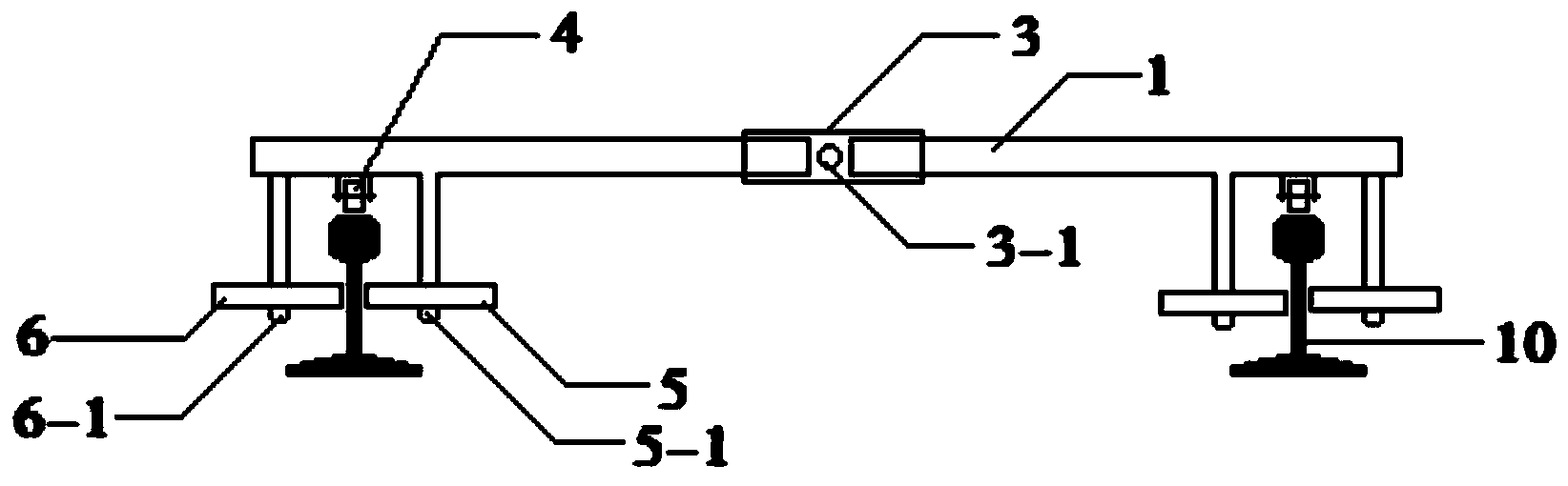

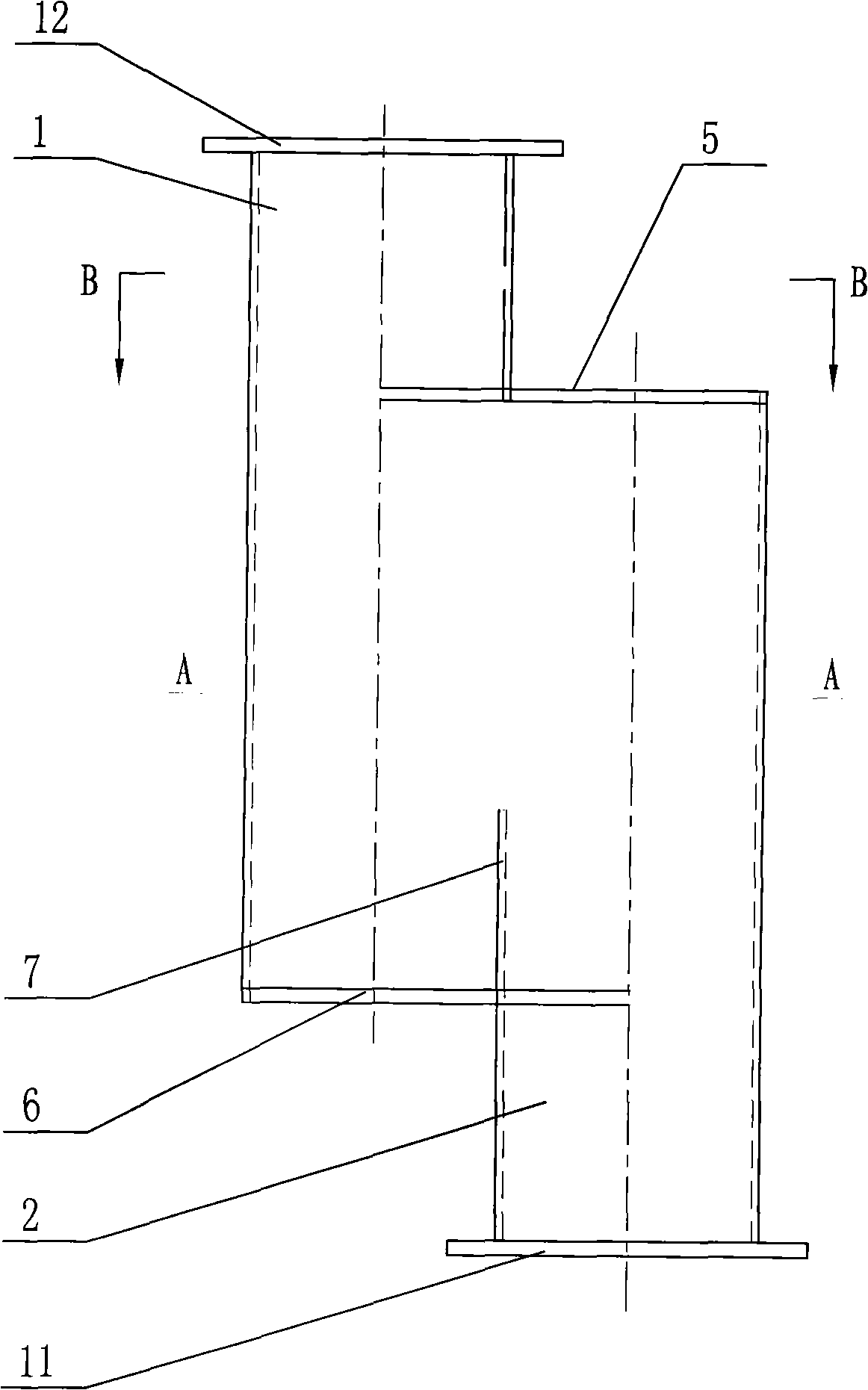

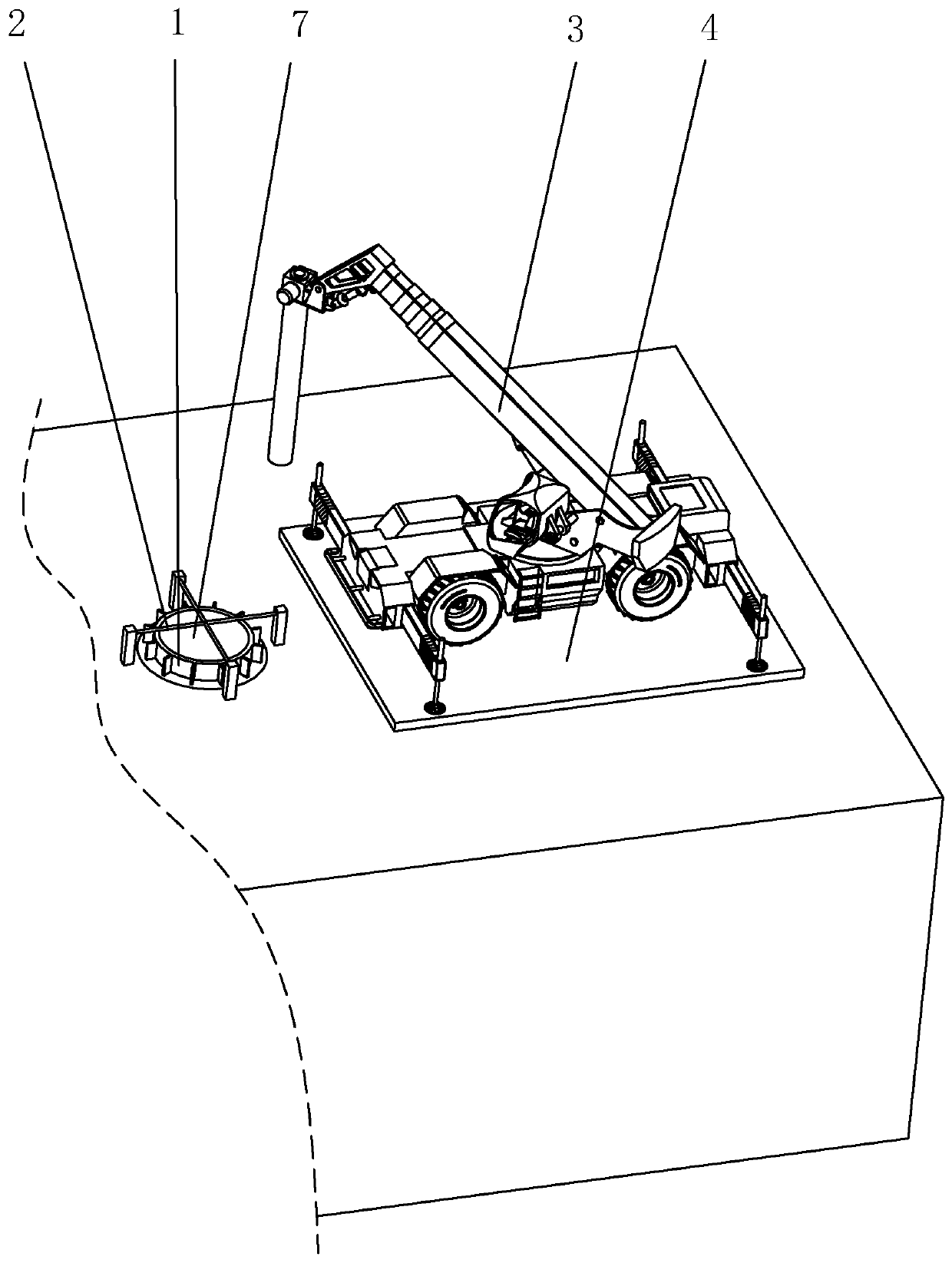

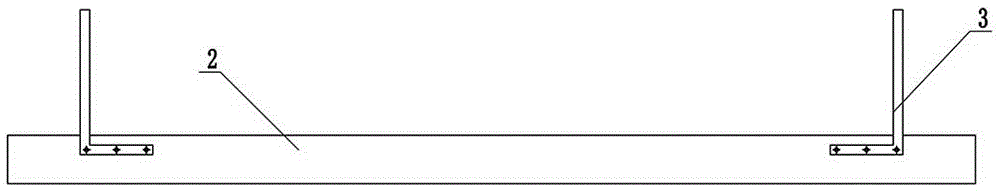

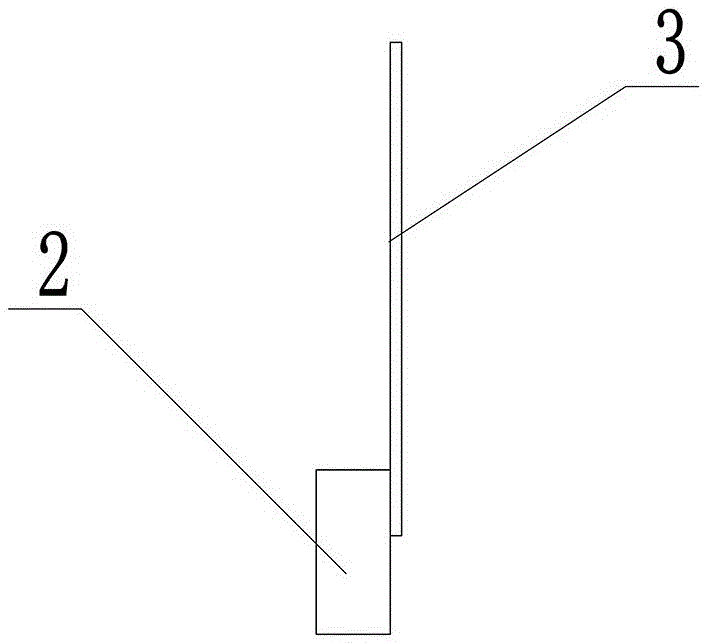

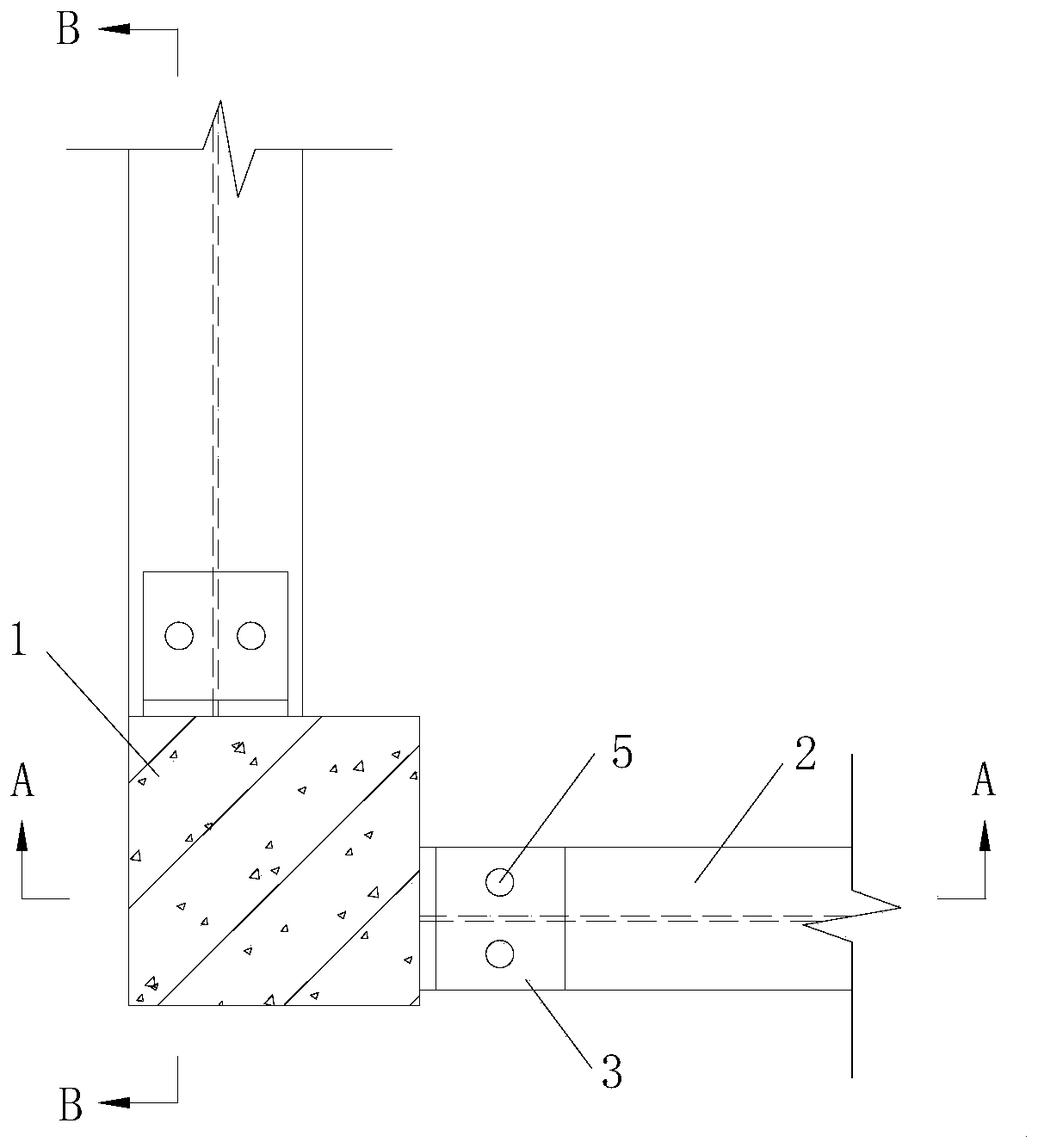

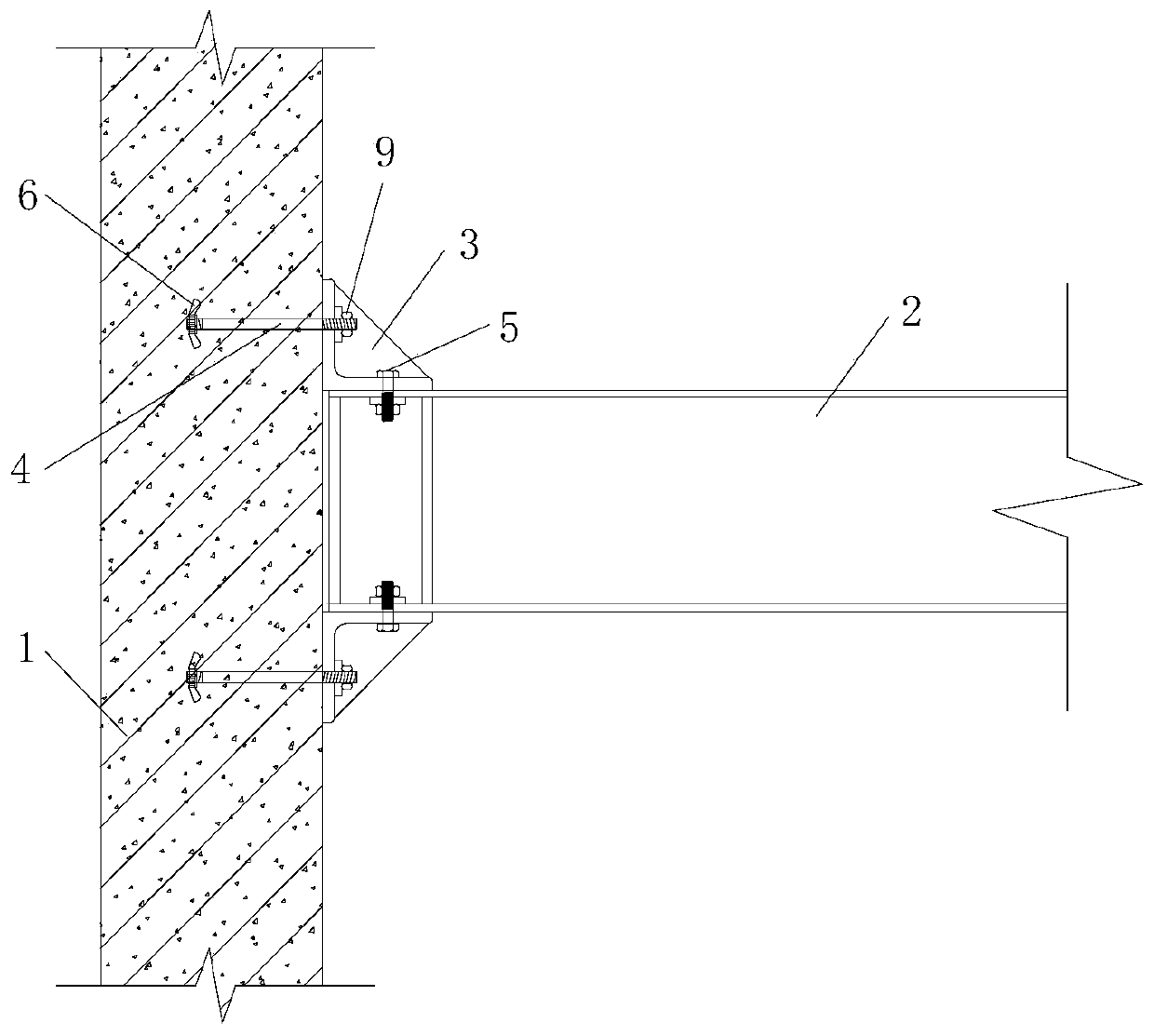

Steel pipe pile guiding frame structure and construction method

PendingCN109629569ASolve this construction problemAvoid contactBulkheads/pilesTransverse beamBuilding construction

The invention discloses a steel pipe pile guide frame structure and a construction method. The steel pipe pile guide frame structure is used for guiding in the installation process of a steel pipe pile of a trestle and comprises two sets of supporting beams, at least one transverse beam, at least two pairs of guiding frames and a pair of supporting legs; the supporting beams are longitudinally arranged along the trestle; the transverse beams are transversely fixed to the top surfaces of the supporting beams along the trestle to form an integrated structure; each pair of guiding frames are oppositely arranged on the supporting beams for guiding in the process of lowering the steel pipe pile; the supporting legs are symmetrically arranged on the bottom surfaces of the supporting beams and supported on a trestle main transverse beam constructed in the foremost portion; the height of each pair of supporting legs can be adjusted, wherein the rear end of the integrated structure in the longitudinal direction of the trestle is hinged to two Bailey truss sets at the rear side of the trestle main transverse beam, and the integrated structure can be horizontal by adjusting the height of thesupporting legs. The steel pipe pile guide frame structure has the advantages of being suitable for long-period strong surge conditions without outside sea protection and the like, and can be widely applied to the technical field of water transportation engineering construction.

Owner:CCCC SECOND HARBOR ENG

Construction method of shield excavation-type air-pushed tunnel through ground fissures

The invention discloses a construction method of a shield excavation type air-push through ground fissure concealed excavation tunnel, comprising the steps of: 1. Concrete guide platform construction in the ground fissure concealed excavation tunnel; Pushing the whole machine forward: Push the shield machine forward and make the main shield machine supported on the two guide rails, and then use the propulsion cylinder and the reaction frame of the shield machine to push forward as a whole until the push is in place; During the push process, use the shield segment assembly machine of the shield machine to install multiple shield segments on the concrete guide platform from back to front. The shield segment is the bottom segment and it is located at the rear of the push cylinder. The bottom segments are supported on the reaction frame, and a plurality of bottom segments form a trolley translation channel for the rear supporting trolley of the shield machine to translate forward. The method of the invention has the advantages of simple steps, reasonable design, convenient construction and good application effect, and the construction process of the shield excavation through the ground fissure is simply completed by using the inverted arch backfill structure in the tunnel, and the construction process is safe.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

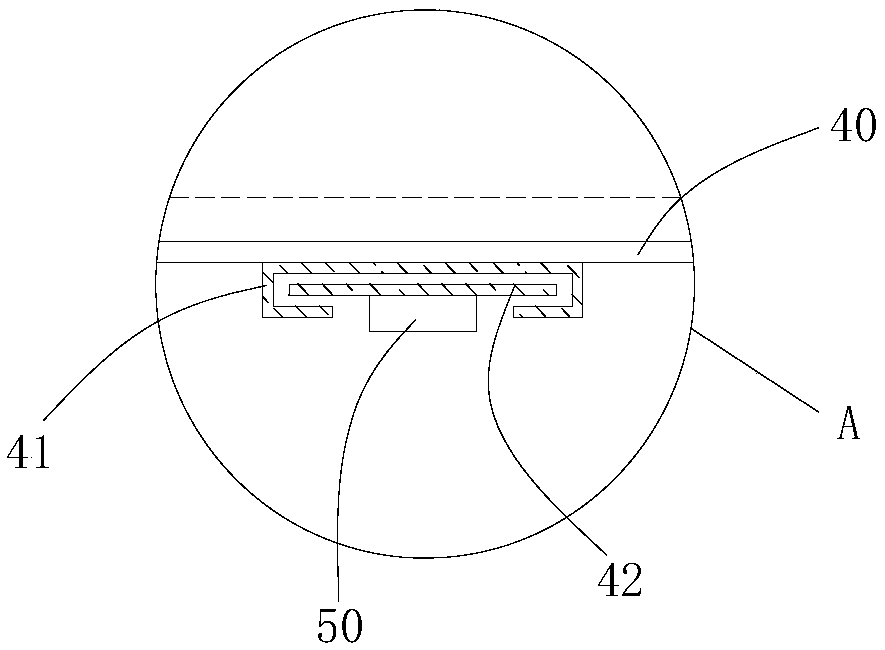

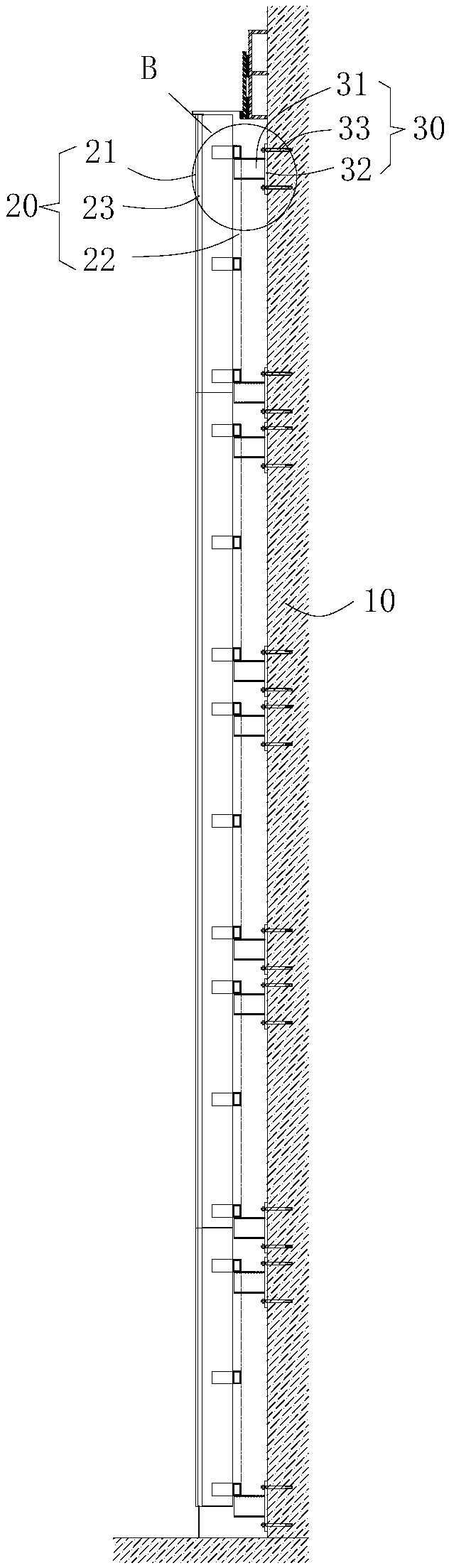

Hollow light-transmitting integral stone decoration vertical column and construction method thereof

PendingCN108915190ASolve the deformationFix damageCovering/liningsElongate light sourcesKeelSteel frame

The invention provides a hollow light-transmitting integral stone decoration vertical column. The hollow light-transmitting integral stone decoration vertical column comprises a vertical column and aplurality of stone unit plates which are hung on the side face of the vertical column, wherein a plurality of groups of keels which are distributed at intervals in the longitudinal direction are fixedto the side face of the vertical column; the keels extend out of a hanging plate along the side face vertical to the vertical column; the stone unit plates comprise stone plates, steel frames and light-transmitting plates; the stone plates comprise arc-shaped chamfered parts with the thicknesses of the two ends being larger, and planar light-transmitting parts which are positioned between two arc-shaped chamfered parts and are thinner; splicing faces positioned on the side faces of the arc-shaped chamfered parts are slopes; the light-transmitting plates are stuck to the inner side faces of the planar light-transmitting parts; the steel frames are fixedly stuck to the inner side faces of the arc-shaped chamfered parts; the steel frames are fixed to the hanging plate of the vertical column;the splicing faces of the stone unit plates on each side face of the vertical column are spliced to form a complete vertical column decoration face; the steel frames are stuck to a bottom plate; thebottom plate is provided with an LED (Light Emitting Diode) lamp strip. The hollow light-transmitting integral stone decoration vertical column has the characteristics of good decorative face integrity and high attractiveness.

Owner:SDCIC CONSTR GRP CO LTD

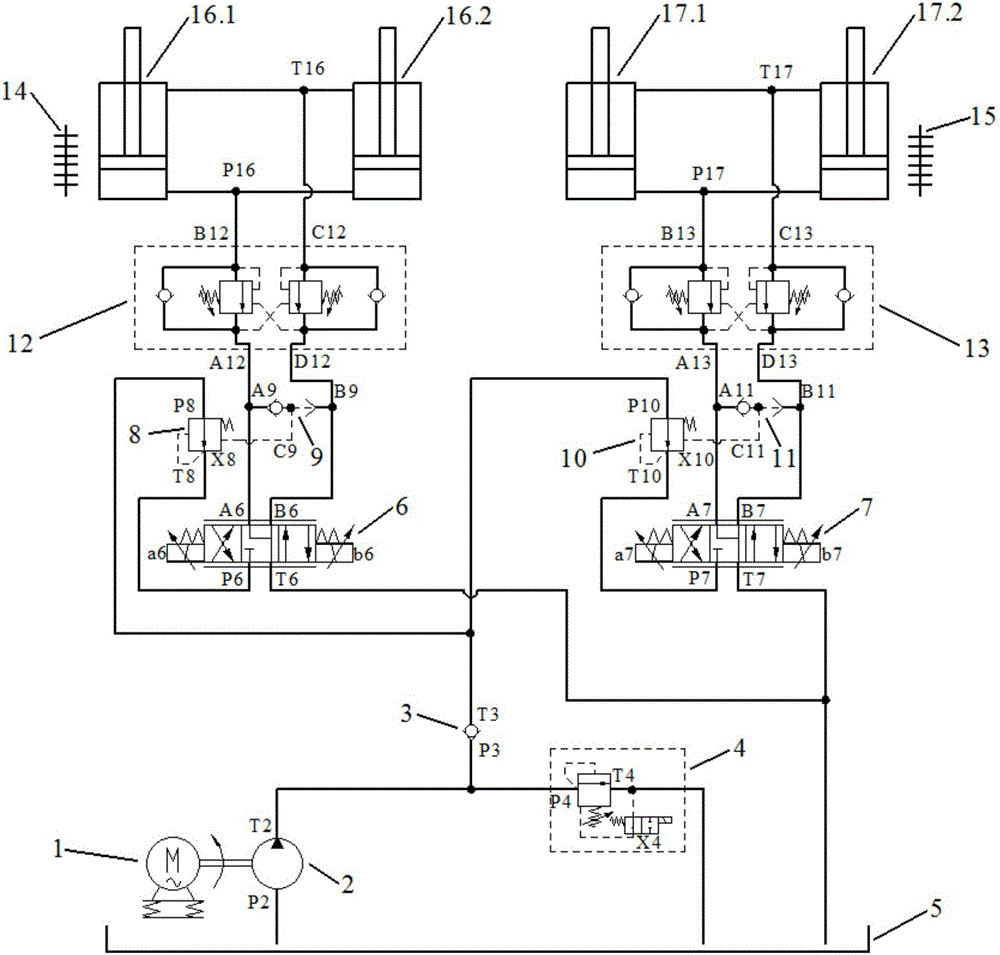

TBM vertical steering hydraulic system based on pressure compensation

InactiveCN106762884AReduce the effect of displacementGuaranteed construction accuracyServomotor componentsServomotorsWorking pressureControl engineering

The invention discloses a TBM vertical steering hydraulic system based on pressure compensation. The system comprises a motor, a high-pressure pump, an electromagnetic unloading valve, a one-way valve, two fixed differential reducing valves, two three-position four-way electromagnetic proportional reversing valves, two shuttle valves, two balance valves, two displacement sensors, four hydraulic oil cylinders and an oil tank. The TBM (Tunnel Boring Machine) vertical steering hydraulic system adopts the fixed differential reducing valves and the three-position four-way electromagnetic proportional reversing valves to adjust the system working pressure and the flow, and realizes the change of a TBM pitching angle through controlling extension and shrinkage of the hydraulic oil cylinders. Meanwhile, the pressure compensation is realized through the shuttle valves and the fixed differential reducing valves. The TBM vertical steering hydraulic system based on pressure compensation can control TBM vertical postures in real time to reduce influence on displacements of the hydraulic oil cylinders by the load pressure fluctuation so as to guarantee the construction precision and the construction efficiency.

Owner:ZHEJIANG UNIV

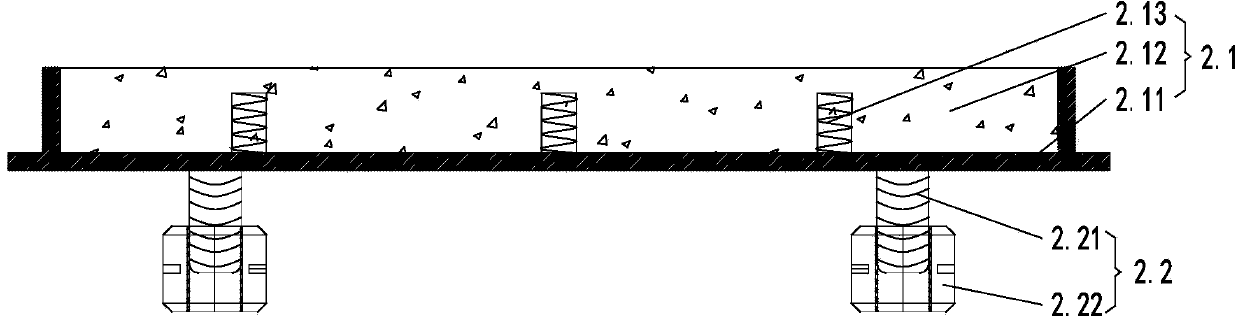

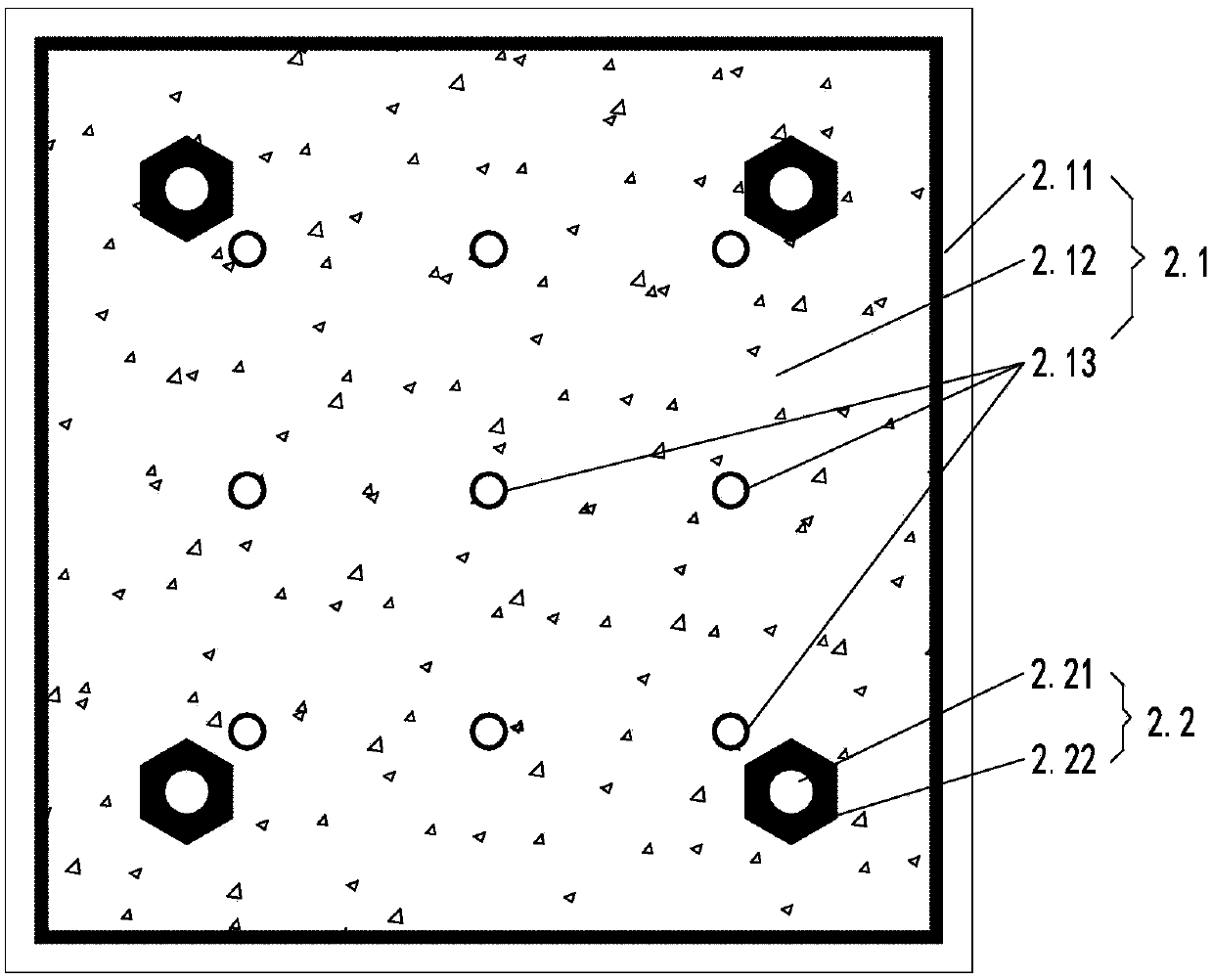

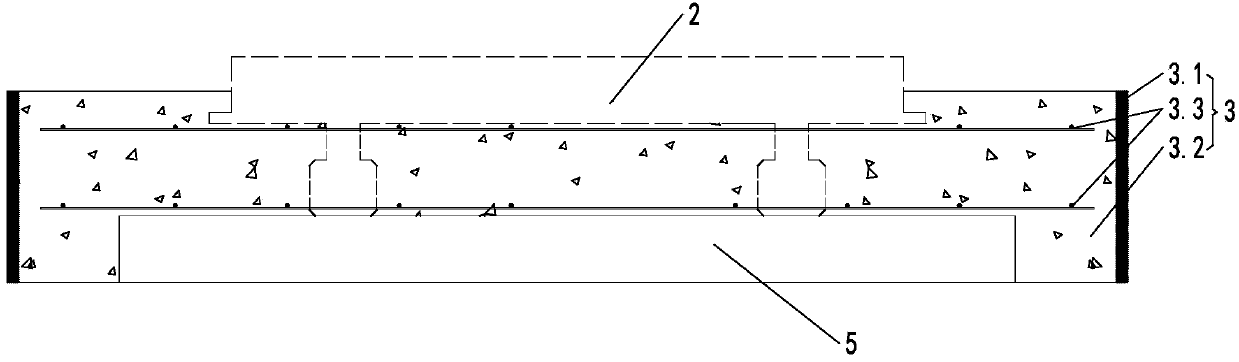

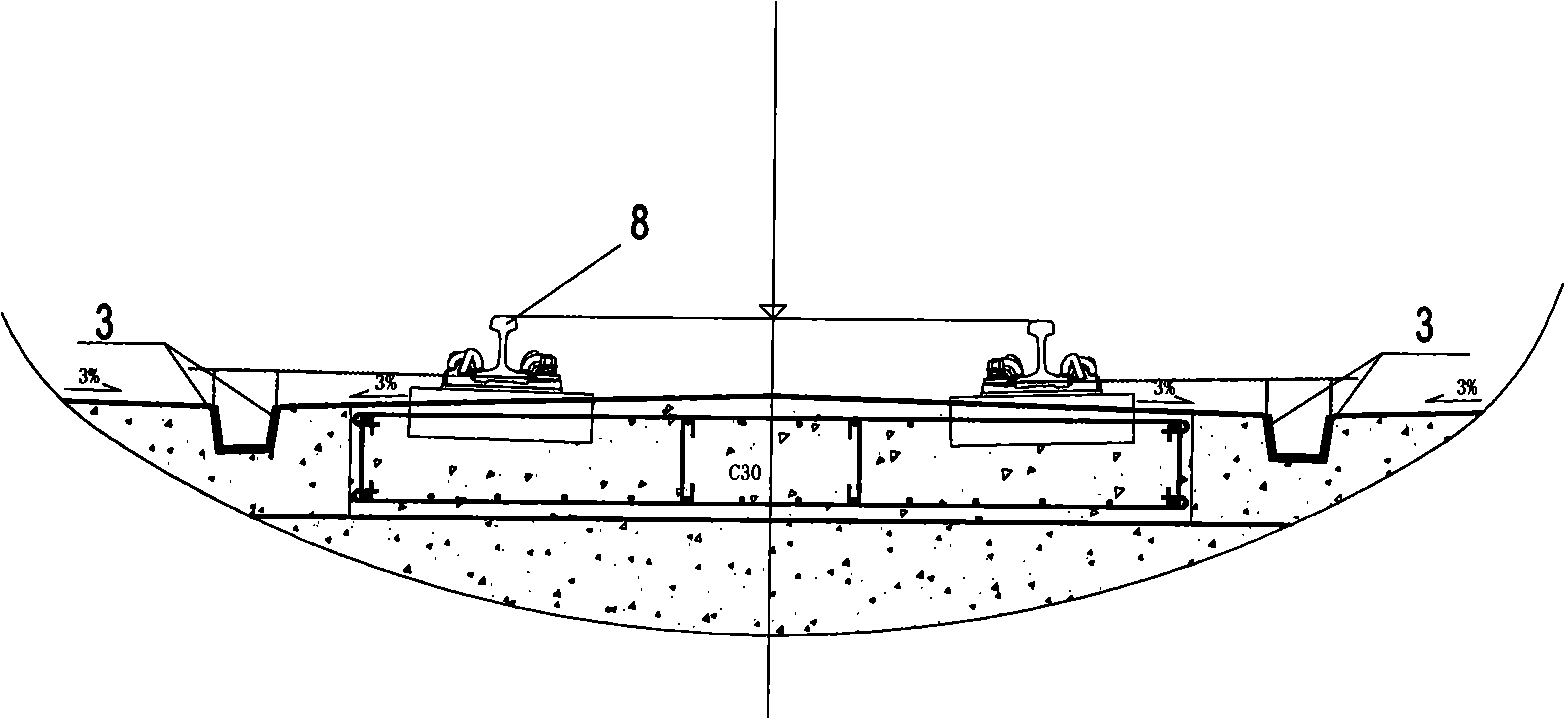

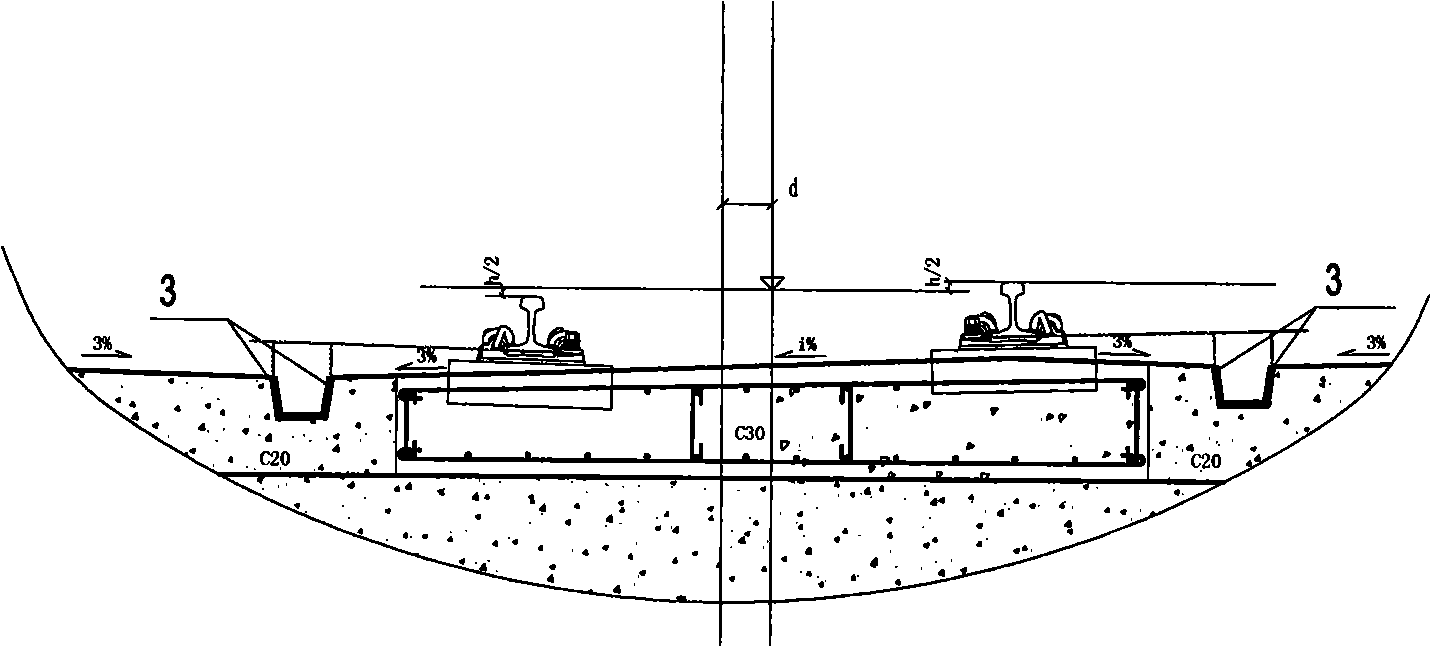

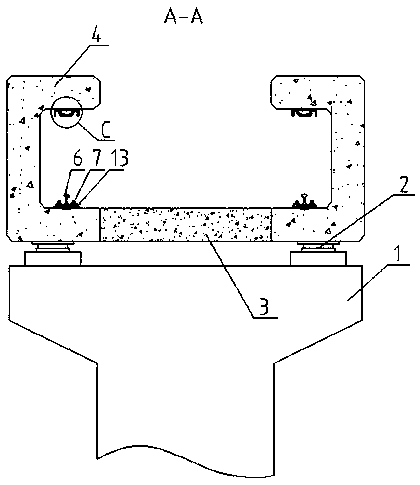

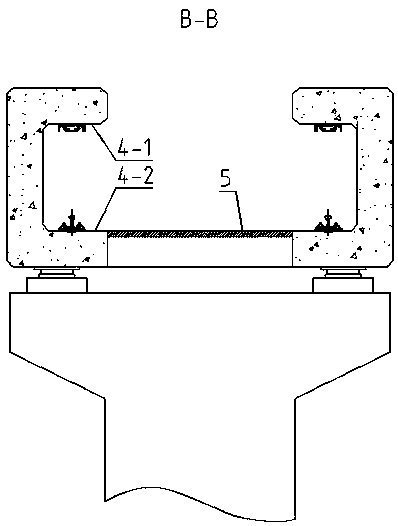

Magnetic levitation traffic track system

InactiveCN108330753AGuaranteed uptimeImprove efficiencyRailway tracksElectric propulsionShaped beamEngineering

The invention discloses a magnetic levitation traffic track system. The system comprises abutments, magnetic tracks, an aluminum induction plate and a channel beam, wherein the channel beam is connected with the abutments through supports and strides over the two abutments, the channel beam is formed by connecting a plurality of cross beams formed through horizontal in-place casting of reinforcingsteel bars reserved at the end parts of U-shaped beam lower wings of two U-shaped beam units, the magnetic tracks are mounted at the bottoms of U-shaped beam upper wings, the aluminum induction plateis arranged in the magnetic tracks, and power supply tracks are mounted on the U-shaped beam lower wings and correspond to the magnetic tracks above the power supply tracks. The system has the benefits as follows: the system adopts a levitation-traction-guide integrated overall structure and is high in structure rigidity and good in operation stability; the traction levitation gap is smaller thanbefore, and therefore, the linear motor efficiency is higher, and energy consumption is lower; a levitation system, a traction system and a guide system are all arranged in the channel beam, and in the train running process, the channel beam has a good sound insulation effect and can isolate the magnetic field of the system and reduce magnetic radiation.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

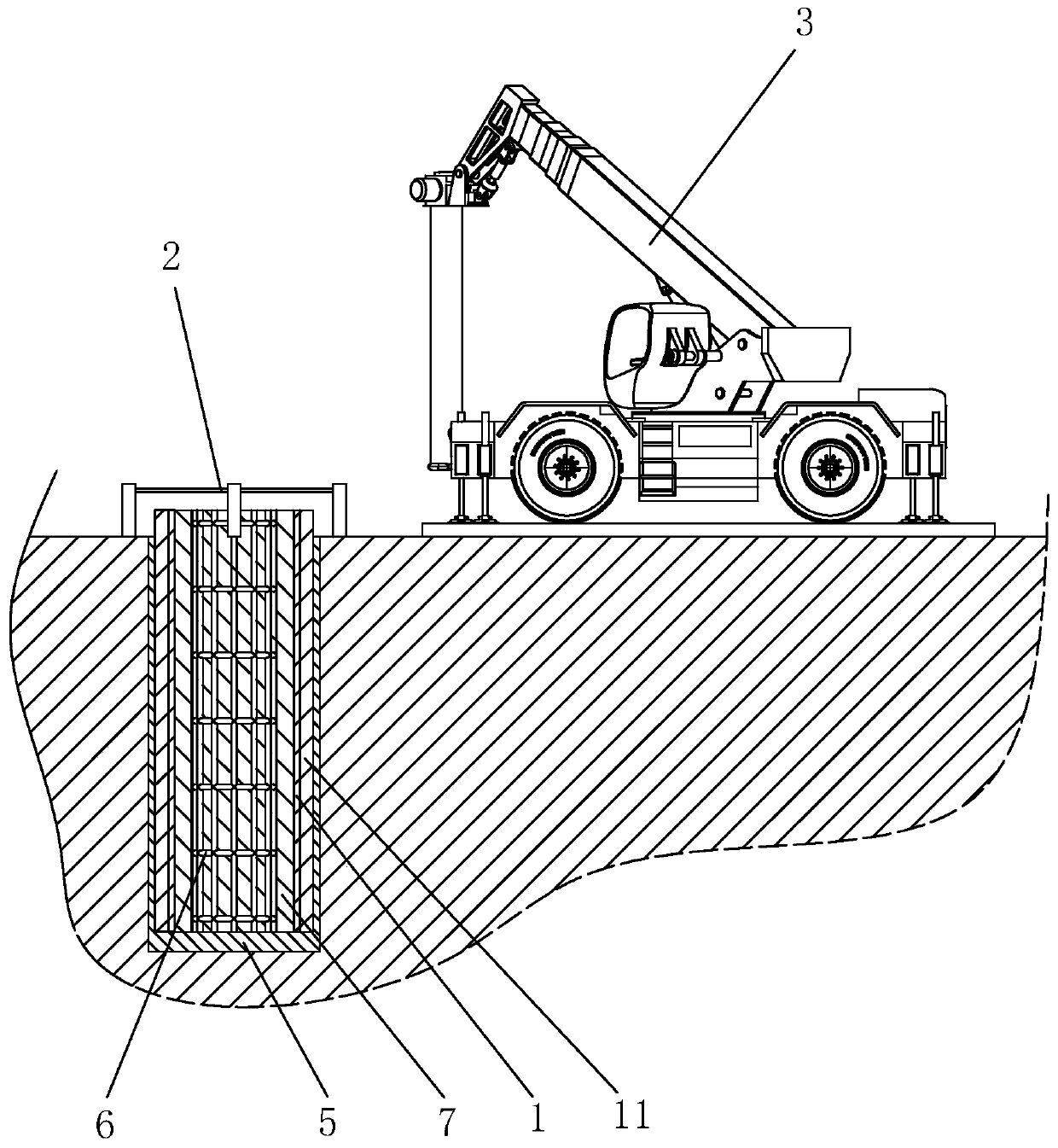

Constructing process of cast-in-situ bored piles

InactiveCN111206576AGuaranteed construction accuracyAvoid affecting drillingBulkheads/pilesArchitectural engineeringSlurry

The invention relates to a constructing process of cast-in-situ bored piles, and belongs to the technical field of building construction. According to the technical scheme, the constructing process ischaracterized by including the following steps of S1, making a preparation for construction, wherein a construction site is leveled and firmly compacted, and a road bed plate is laid at an operationposition of a drilling machine; S2, burying pile casings, wherein the soil within the burying depth range of the pile casings at pore positions are dug out through a rotary excavating drill bit, the pile casings are directly pressed into soil after being hung in place, the outer wall of each pile casing is axially and fixedly provided with a plurality of reinforcing pieces, the reinforcing piecesare evenly distributed in the circumferential direction of the pile casings, loam is firmly compacted outside the pile casings, and the height of water heads in the pile casings is 1.0-1.5 m; S3, putting the drilling machine in position, wherein the drilling machine is fixed to the road bed plate; S4, performing drilling, wherein a drill stem slowly and continuously operates during bore forming construction, and static slurry is adopted for protecting the walls in the drilling process; S5, putting down a reinforcement cage, wherein the bores are cleaned first, and then the reinforcement cage is slowly put down section by section at a constant speed; and S6, pouring cement, wherein the cement is poured continuously through a guide pipe method, and the effect of improving the burying stability of the pile casings is realized.

Owner:重庆渝能建筑安装工程有限公司

Laser fine-adjustment device for installing and positioning anchorage prestressing steel pipe

ActiveCN105937208APrecise positioningQuick installationBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a laser fine-adjustment device for installing and positioning an anchorage prestressing steel pipe. The laser fine-adjustment device comprise a starting device for fixing a laser pen and performing angle adjustment, a fixing support for fixing the prestressing steel pipe and a receiving device. The starting device arranges the laser pen at one end of the prestressing steel pipe, the receiving device is arranged at the other end of the prestressing steel pipe and used for receiving laser penetrating through one end of the prestressing steel pipe and emitted out of the other end of the prestressing steel pipe, a fine-adjustment device is close to one side of the receiving device and arranged on the fixing support and comprises a U-shaped sliding bracket arranged at the lower portion of the prestressing steel pipe and adjusting screws arranged at the bottom and the left and right sides of the prestressing steel pipe respectively and used for adjusting displacement of the prestressing steel pipe. The laser fine-adjustment device can achieve rapid installation and reliable positioning and is simple in structure, low in device machining and manufacturing cost and good in reliability.

Owner:SINOHYDRO BUREAU 5

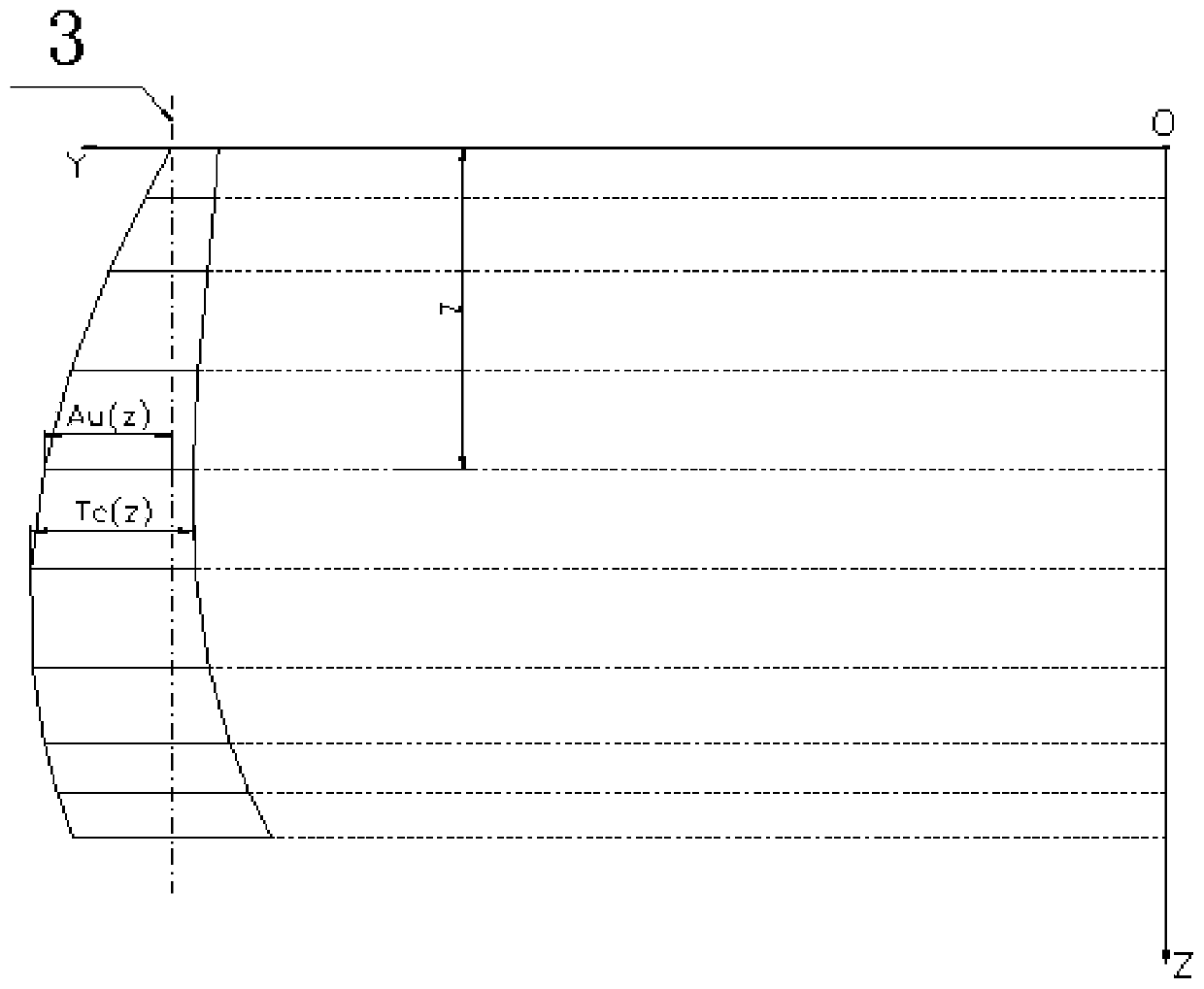

Arch dam pouring block construction control method

InactiveCN110284465AAchieve fitGuaranteed construction accuracyGeometric CADSpecial data processing applicationsElectricityCurve fitting

The invention relates to an arch dam construction control method, and belongs to the field of water conservancy and hydropower, in particular to an arch dam pouring block construction control method. According to the technical problems, the arch dam pouring block construction control method can fast and accurately determine space parameters of arch dam pouring blocks, so that arch dam structural construction is completed. The arch dam pouring block construction control method comprises the following steps that a, firstly arch dam shape parameter curve fitting is carried out; b, secondly, arch dam shape coordinate calculation is carried out; c, a coordinate formula of an intersection of a lead straight surface and upstream surface and downstream surface of an arch ring is established; d, the lowest point coordinates of the upstream surface of the lead straight surface after corner cut of the upstream surface are calculated; and e, finally by using the parameters obtained through the steps, the parameters are converted to a CAD graph through a DXF file, a plane graph, a radial profile graph and an arch dam three-dimensional shape graph of arch dam pouring block points are obtained, and construction operation is carried out through obtained structural information. The arch dam pouring block construction control method is especially suitable for water and electricity large dam arch dam pouring block construction.

Owner:POWERCHINA CHENGDU ENG

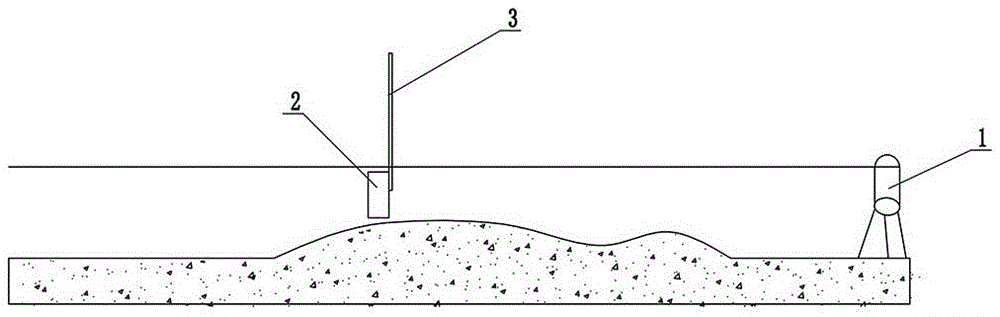

Control system for flatness of large-span concrete floor and use method

InactiveCN105986676AReduce usageReduce in quantityBuilding material handlingControl systemStructure of the Earth

The invention discloses a flatness control system for a large-span concrete floor and a use method. The flatness control system comprises a horizontal scraping ruler, a laser level meter and a corner ruler, wherein a short side of the corner ruler is fixed on the horizontal scraping ruler, and a long side of the corner ruler is vertical to the horizontal scraping ruler. The flatness control system and the use method are applicable to the construction of the large-span concrete floor. The flatness control system is simple in structure, convenient to operate and high in control precision, the number of detection and construction workers is decreased, the construction efficiency is improved, the consumption of concrete is saved, and the construction cost is lowered.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Dry construction connecting structure of duct corners and girder for building with fabricated frame structure

PendingCN109914616AAvoid displacementGuaranteed aestheticsProtective buildings/sheltersShock proofingRebarUltimate tensile strength

The invention discloses a dry construction connecting structure of duct corners and a girder for a building with a fabricated frame structure. The structure comprises prefabricated columns and the steel girder; the steel girder is connected with the prefabricated columns by means of the duct corners which are respectively arranged at the upper side and lower side of the end of the steel girder; split bolts are pre-buried in the prefabricated columns; one ends of the split bolts are arranged in the prefabricated columns, and the other ends of the split bolts extend outside the prefabricated columns and pass through a first connecting plate; the split bolts are positioned in the prefabricated columns and are connected with longitudinal steel bars in the prefabricated columns in a welding way. According to the connecting structure provided by the invention, the split bolts and the longitudinal steel bars form a whole, so that the ultimate bearing capacity and anti-seismic property of theframe structure are improved; furthermore, the pre-buried split bolts are prevented from shifting in a construction process of the prefabricated columns, so that the construction accuracy is guaranteed. The connecting structure is simple in structure and convenient for construction, and greatly improves the construction quality and shortens the construction period under the premise of guaranteeingthe construction structuring strength of the frame structure.

Owner:中民筑友房屋科技集团有限公司

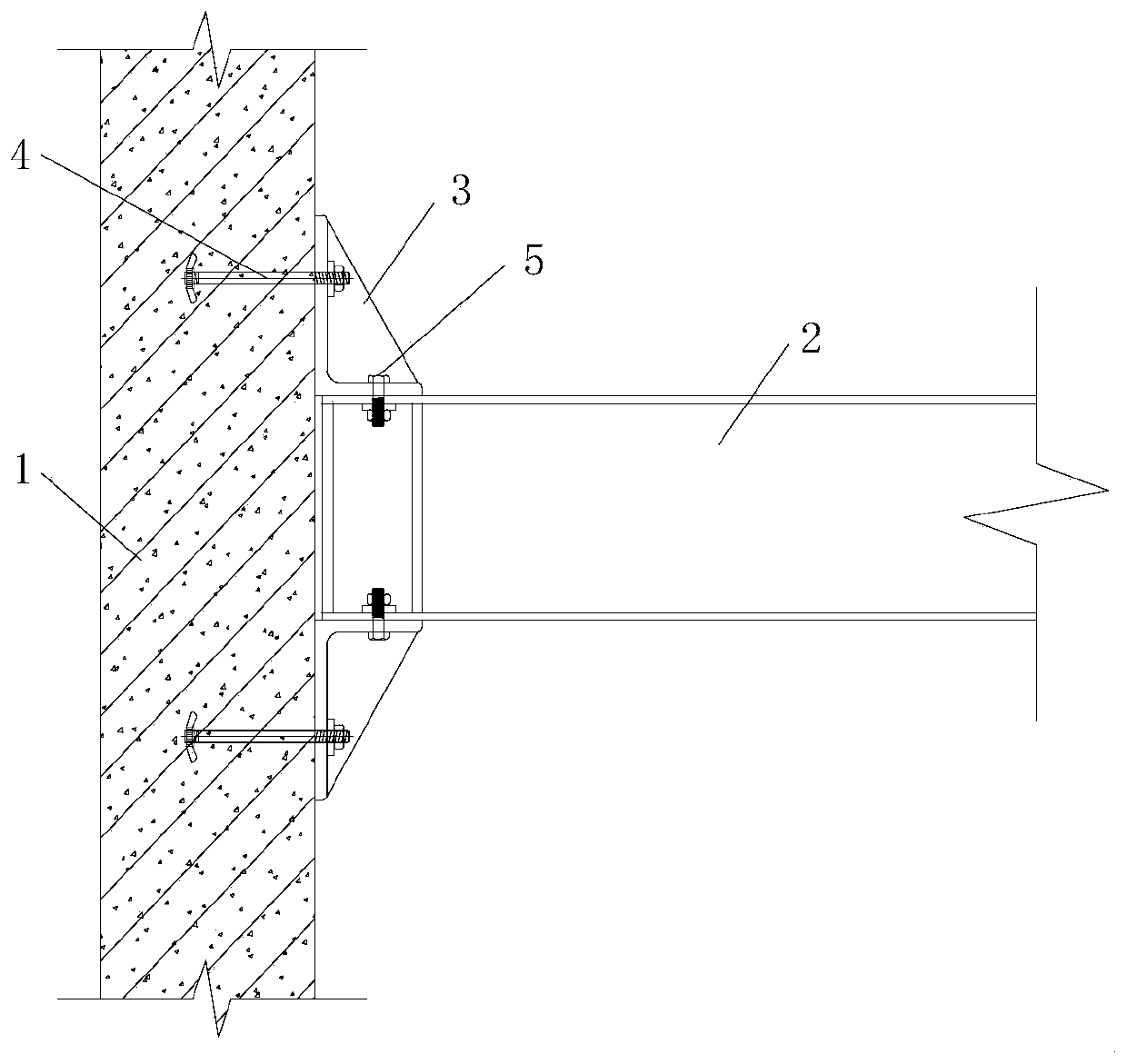

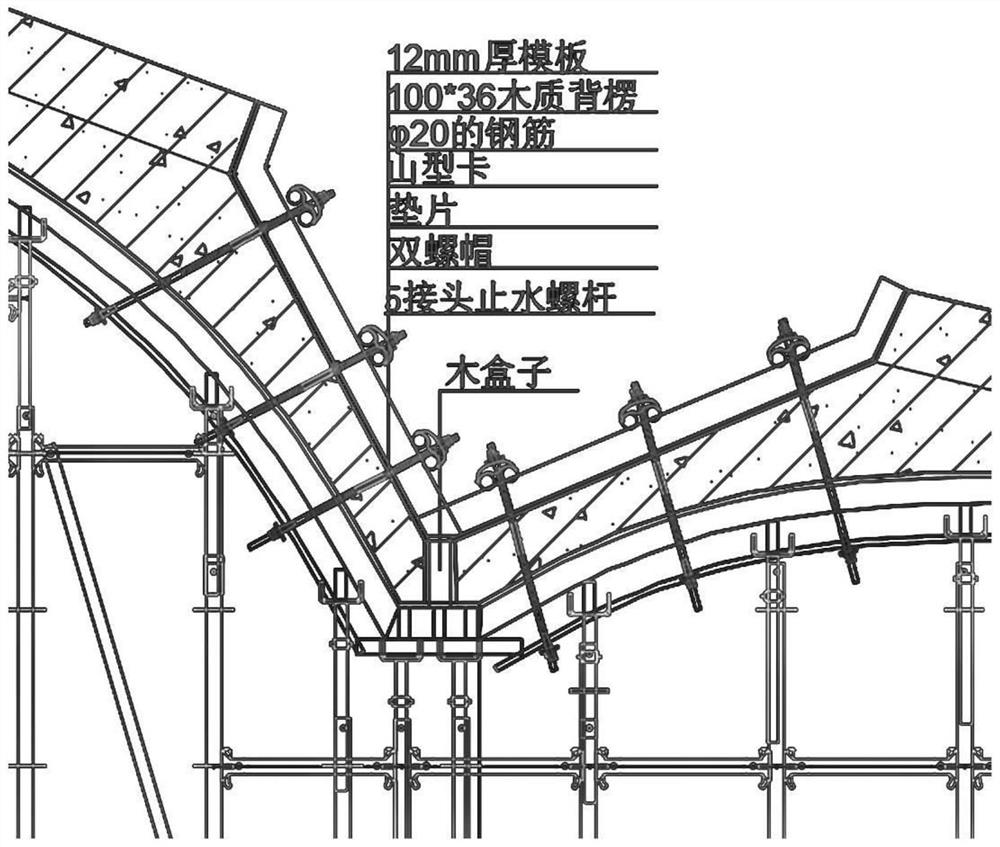

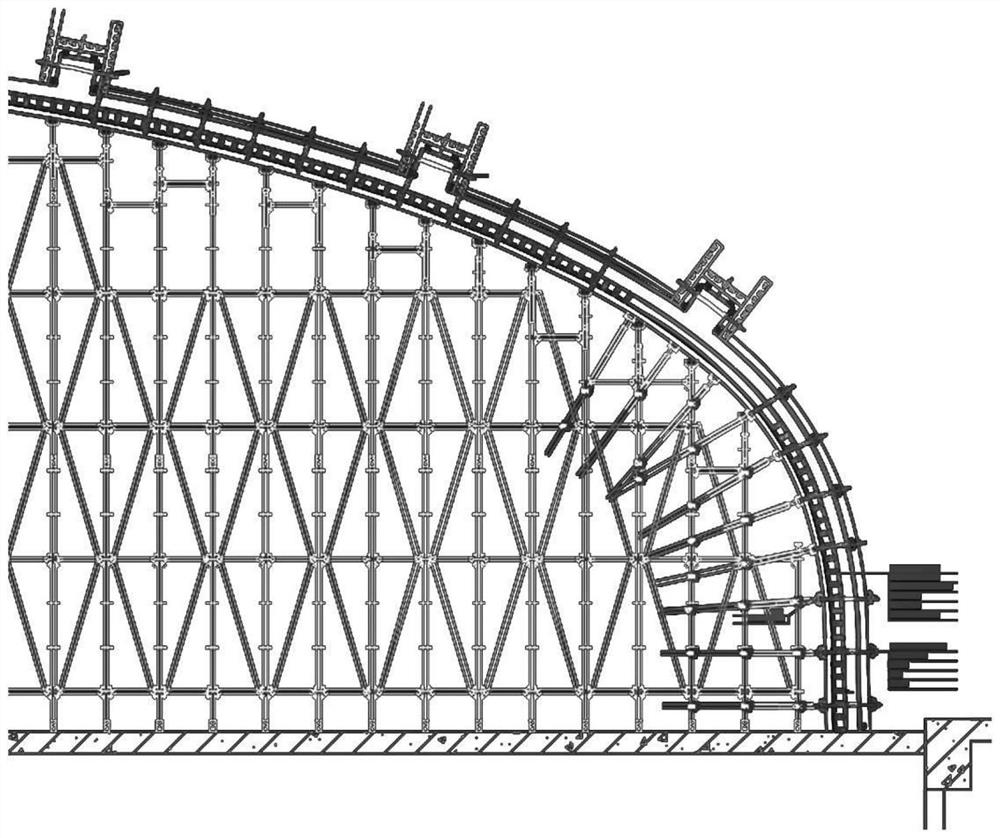

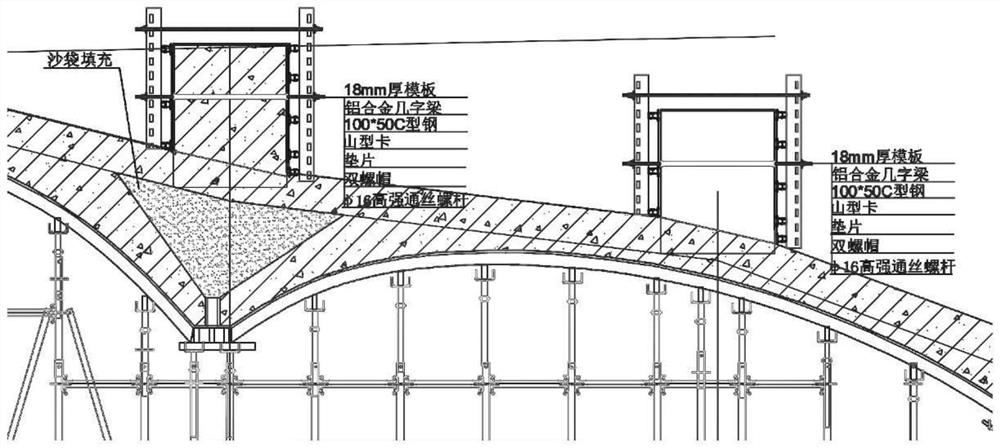

Assembling method of special-shaped double-curved-surface bare concrete wall

ActiveCN113914605AGood flexibilityGuaranteed construction accuracyForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSteel tubePipe

The invention belongs to the technical field of civil engineering concrete pouring, and particularly relates to an assembling method of a special-shaped double-curved-surface bare concrete wall. The assembling method comprises the sequent following steps that a steel pipe frame is erected; a wooden arc-shaped keel is mounted; a wooden lining plate is mounted; a bare plate is mounted; an opposite-pull screw rod is mounted; an outer formwork is reinforced and mounted; checking and accepting are carried out; and concrete is poured. A special-shaped double-curved-surface model can be spliced by mounting the wooden arc-shaped keel; and the whole special-shaped double-curved-surface bare concrete wall is more stable due to the fact that the opposite-pull screw rod and the outer formwork are mounted for reinforcement.

Owner:北京益汇达清水建筑工程有限公司 +1

Small-diameter observation well set-shaped steel formwork pouring construction method

ActiveCN109826233AAvoid the risk of displacementImprove construction progressArtificial islandsUnderwater structuresPattern perceptionUltimate tensile strength

The invention relates to the technical field of observation well construction, in particular to a small-diameter observation well set-shaped steel formwork pouring construction method. The method includes the following steps of mounting of formwork sets for supporting; foundation concrete dabbing, cleaning, reinforcement cage mounting, inner steel formwork mounting, outer steel formwork mounting,formwork set correcting, concrete pouring, concrete curing and formwork detaching. The construction difficulty is lowered, the construction period is shortened, the construction quality is guaranteed,a large number of supporting steel pipes, buckles and other materials can be saved, the construction cost is low, the construction precision is high, the materials can continuously and cyclically circulate for use, mounting is easy and convenient, the strength and the rigidity are high, the deformation is low, the perception quality is high, detachment is easy in narrow space, the labor intensityis reduced, the construction mechanization level is improved, and use of labor force is reduced.

Owner:车明凤

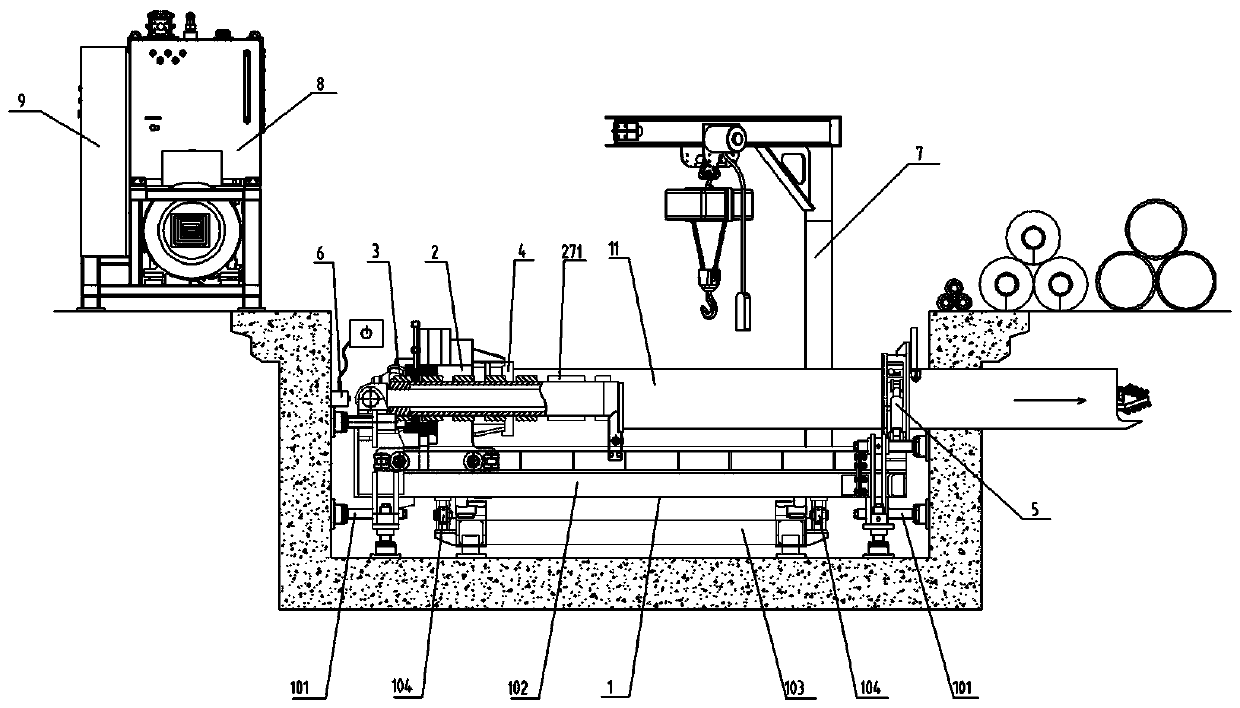

High-precision multifunctional horizontal spiral drilling rig

ActiveCN106761405AFunctional diversityEasy and safe operation controlDrilling rodsConstructionsShortest distanceFunctional diversity

The invention relates to the field of single-foundation-pit short-distance pipeline excavation tunnel construction, in particular to a bilayer translation rack, a jacking walking device, a driving power device, a rotation device and a pipe-paving direction adjusting device and further comprises an optical guide device, a hoisting device, a hydraulic pump station and an electric appliance cabinet. Stability of the whole drilling rig is improved, structure of the whole drilling rig is improved, and jacking movement tracks are more accurate; the driving power device can be used for driving a drilling stem to rotate and can be used for efficient connection among sleeves, so that pipe paving efficiency is improved; the drilling rig is flexible in construction and high in construction accuracy; the drilling rig is suitable for various strata, diverse in function, convenient and safe to operate and control, low in equipment manufacturing cost, economical and practical.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com