Joint bar construction structure and method

A construction method and reinforcement insertion technology, which are applied in building construction, construction, and building materials processing, etc., can solve the problems of complex installation structure, time-consuming installation, displacement of insertion reinforcement, failure to achieve insertion reinforcement positioning effect, etc., so as to achieve reuse. , The structure is simple, which is conducive to the effect of precise installation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The construction structure and construction method of inserting bars in the present invention will be described in detail below through the application of the present invention in assembling integral concrete structures.

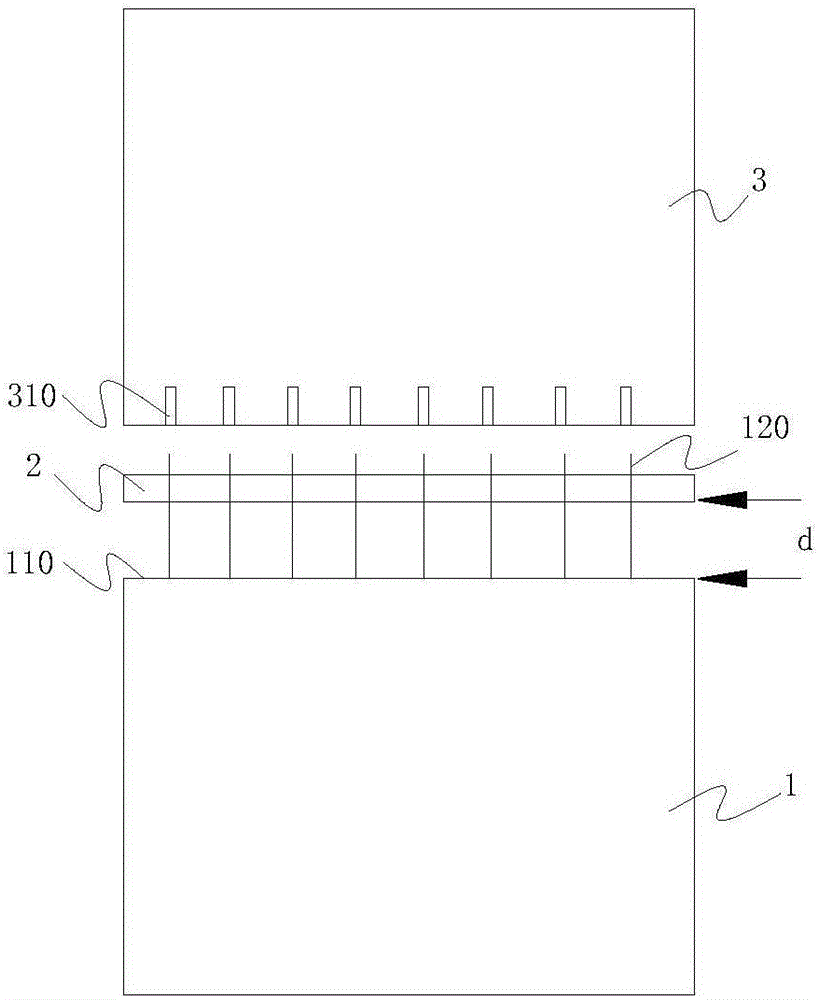

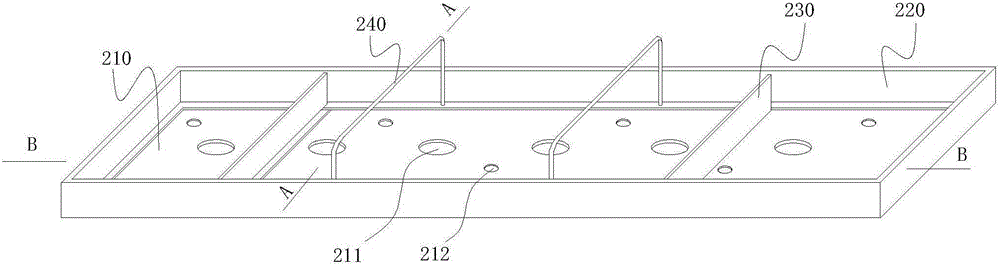

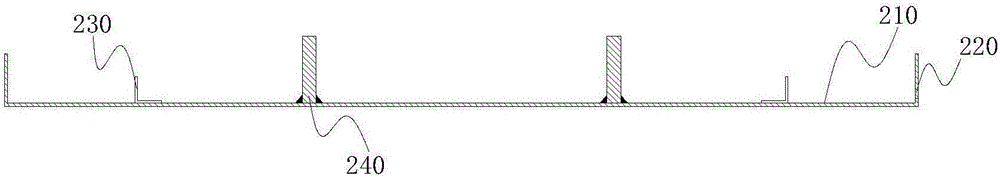

[0030] Such as figure 1 As shown, the transition layer 1 in the assembled monolithic concrete structure is subjected to reinforcement construction, the upper structure is the corresponding prefabricated component 3, and the transition layer 1 is used as the transition structure between the prefabricated component 3 and the cast-in-situ concrete wall of the lower structure. It should be further explained that after the inserting bar 120 to be positioned is inserted into the wall of the transition layer 1, the lower part of the inserting bar 120 to be positioned is generally fixed by a stirrup binding structure, and the stirrup binding structure here is different according to the specific construction situation. When there are reinforcing bars in the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com