Patents

Literature

707results about How to "Smooth vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

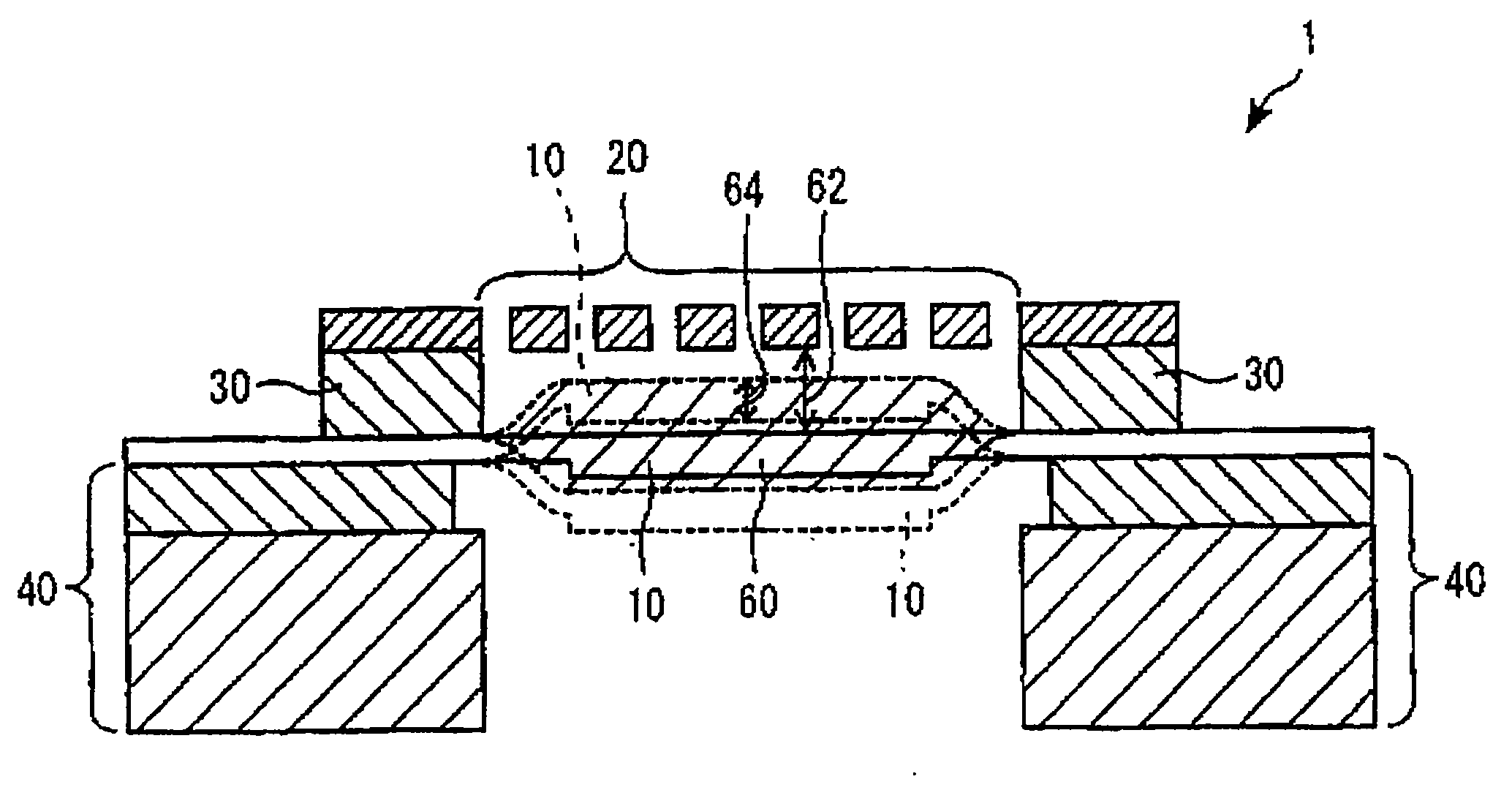

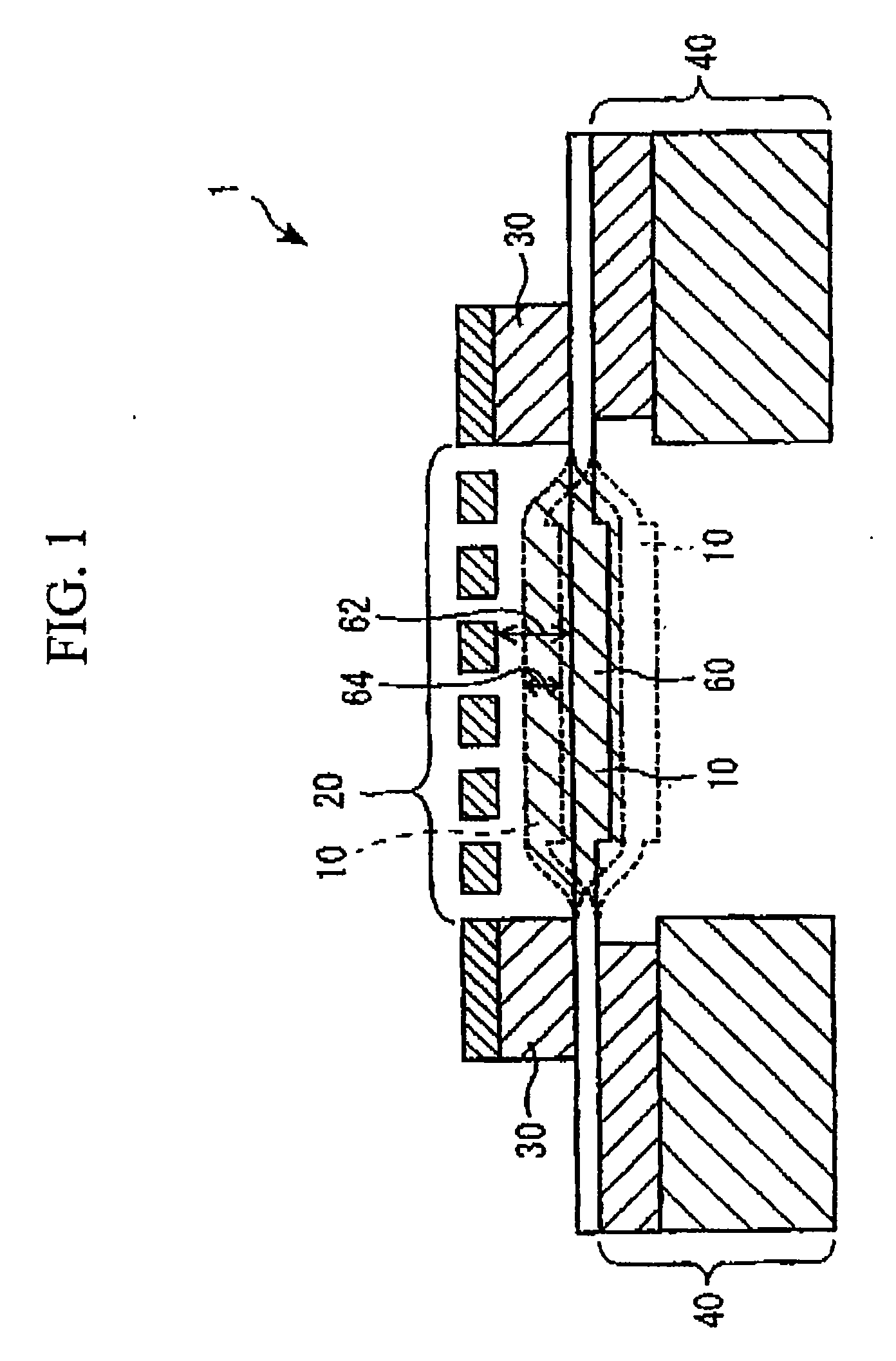

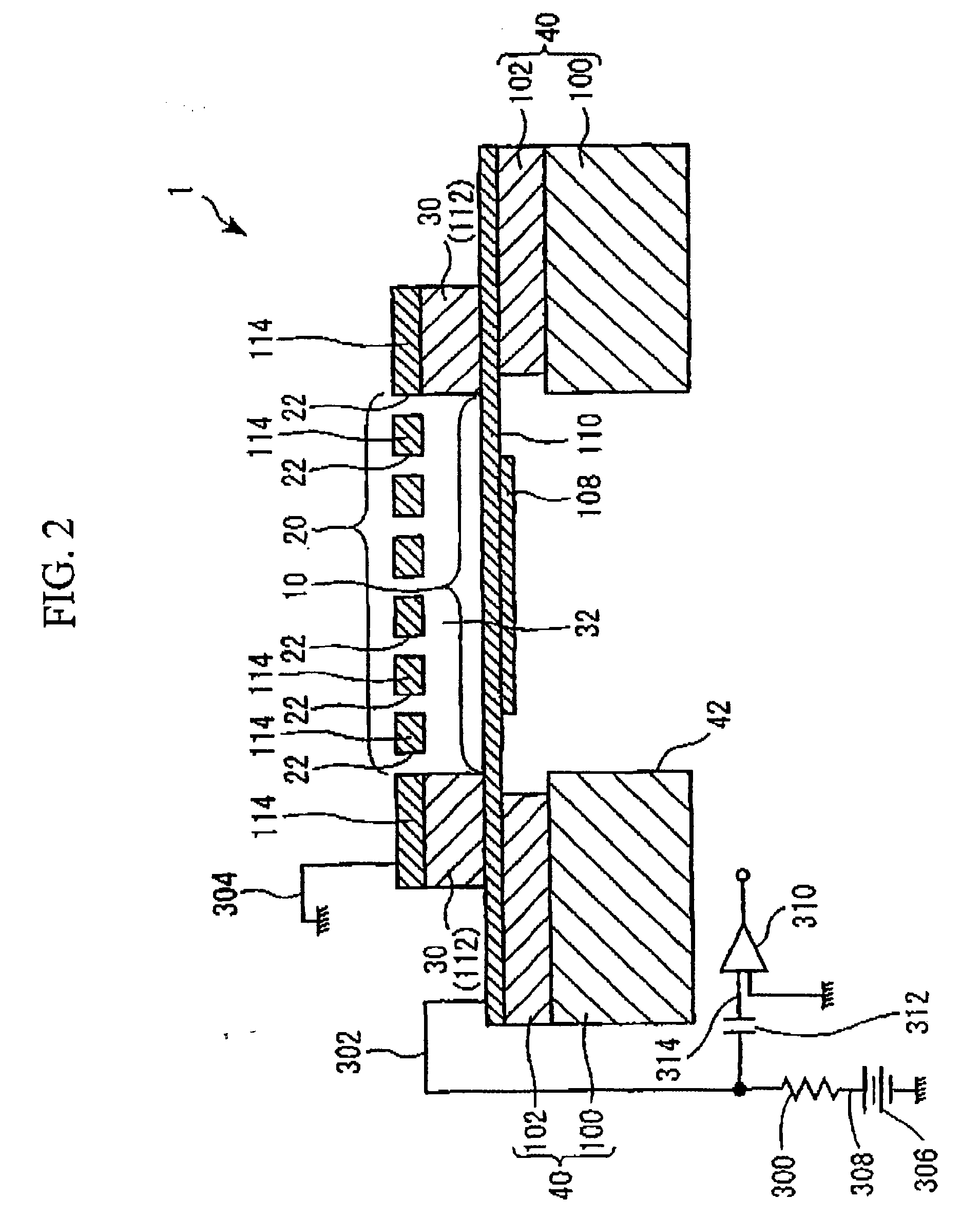

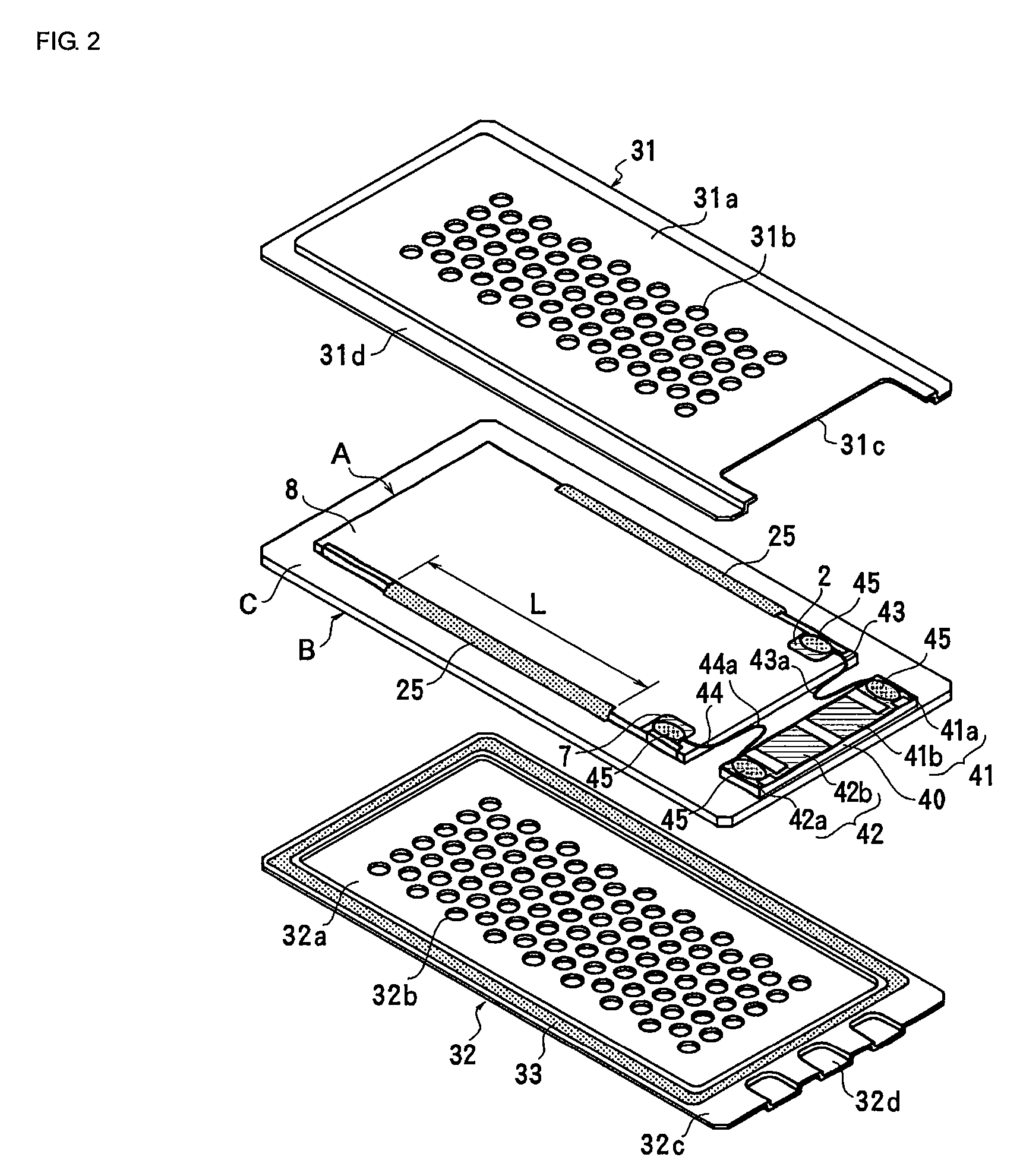

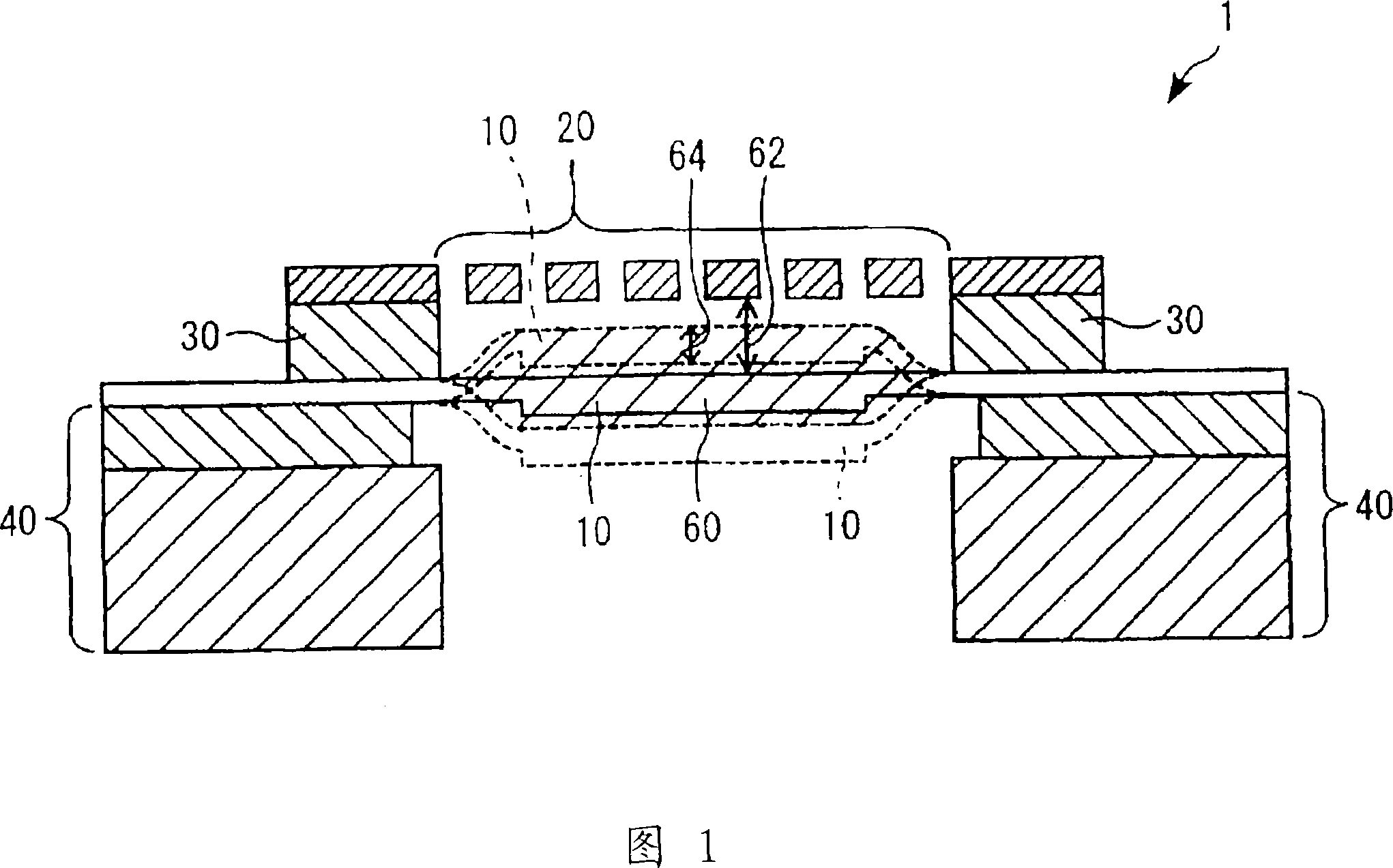

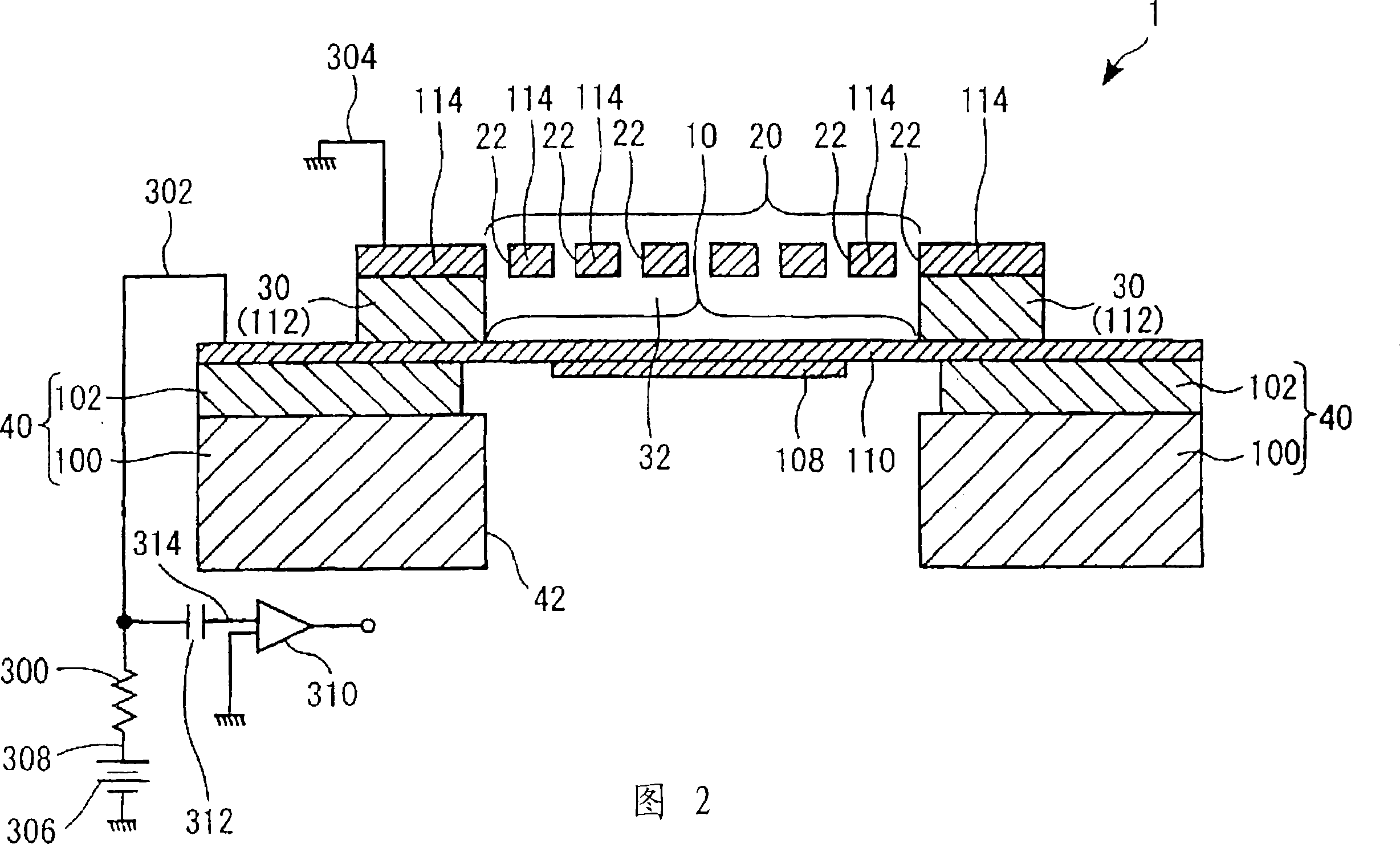

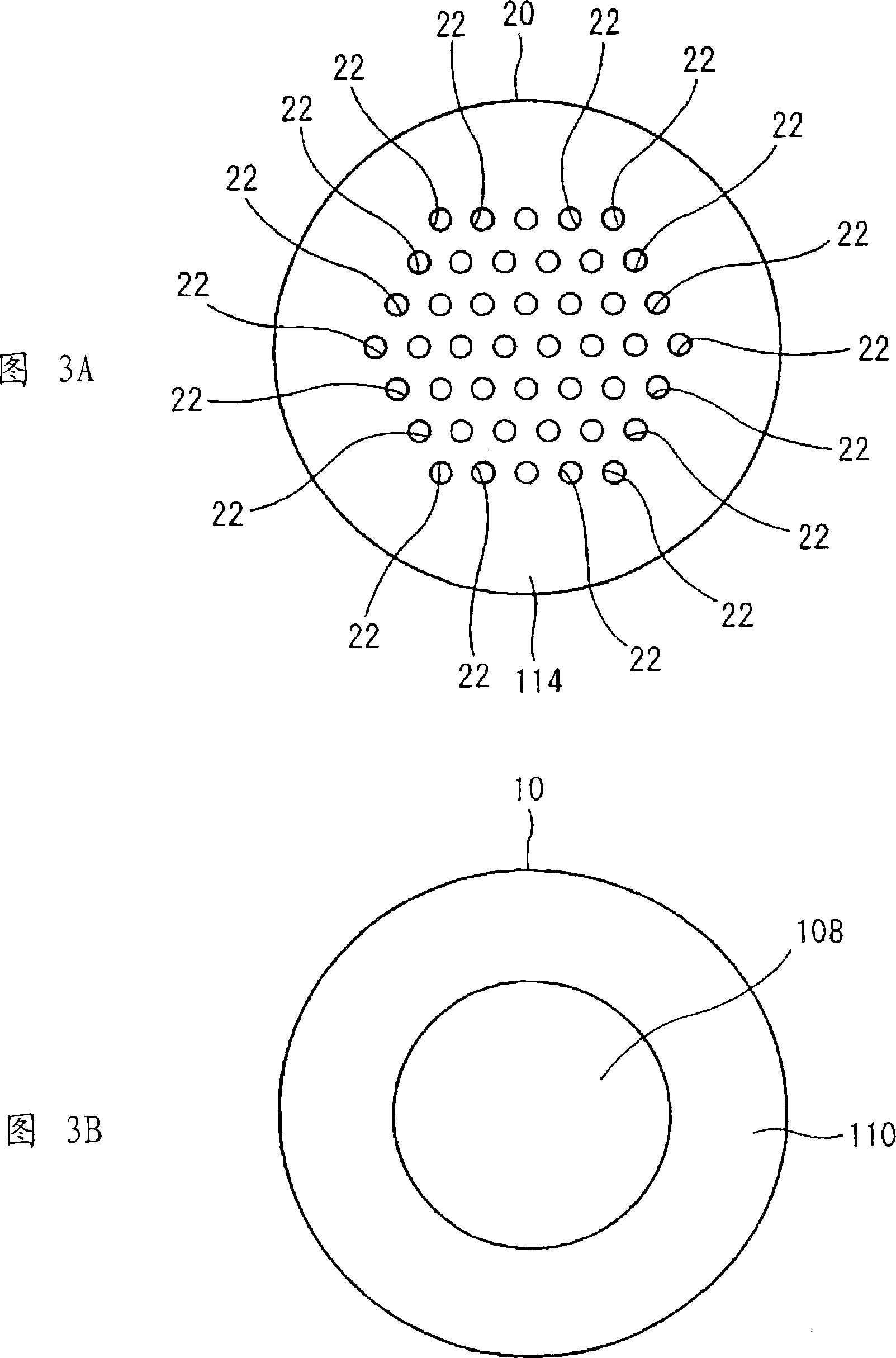

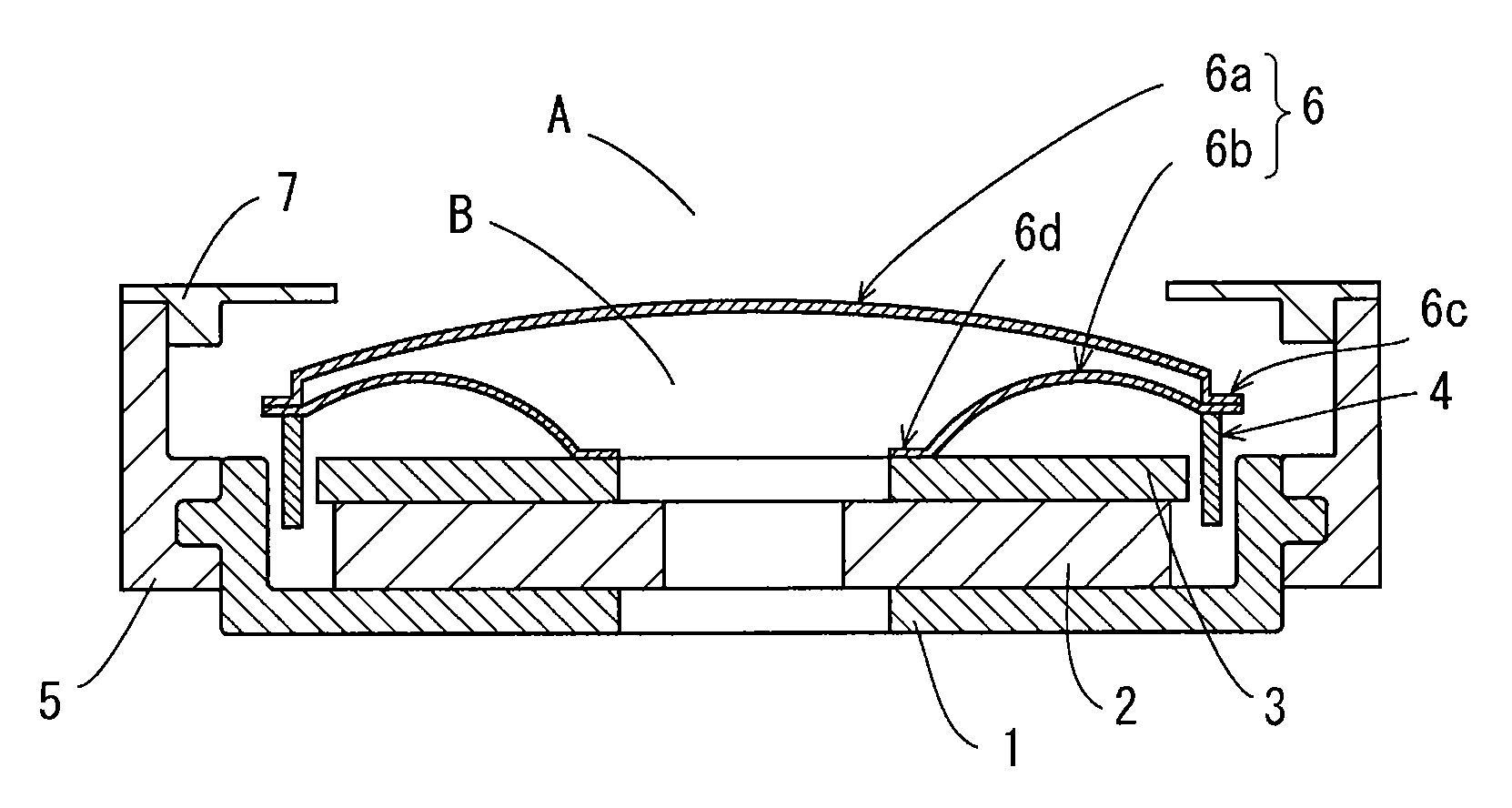

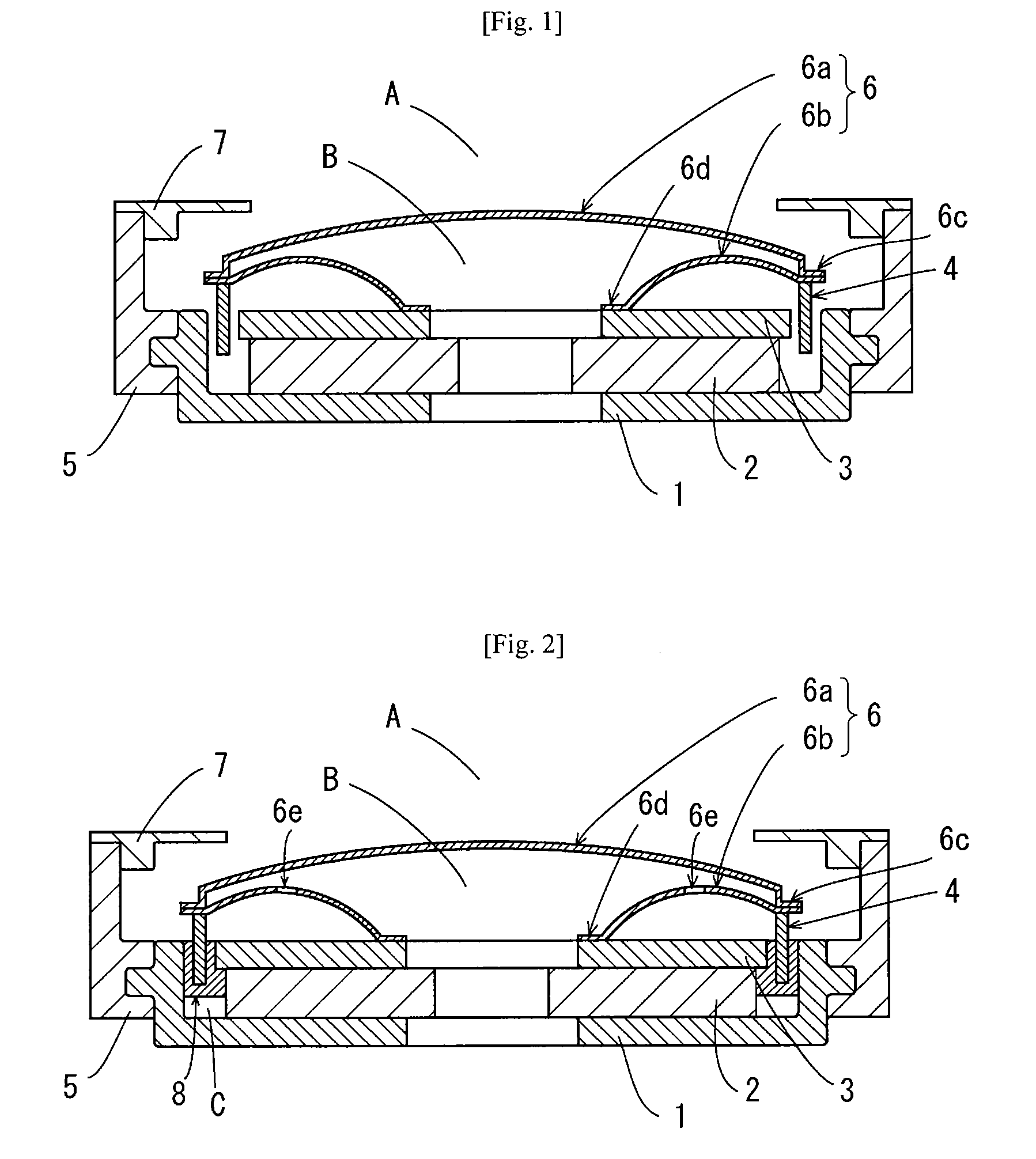

Capacitor microphone

InactiveUS20070058825A1Uniform stress distributionDegree of improvementPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersCapacitanceEngineering

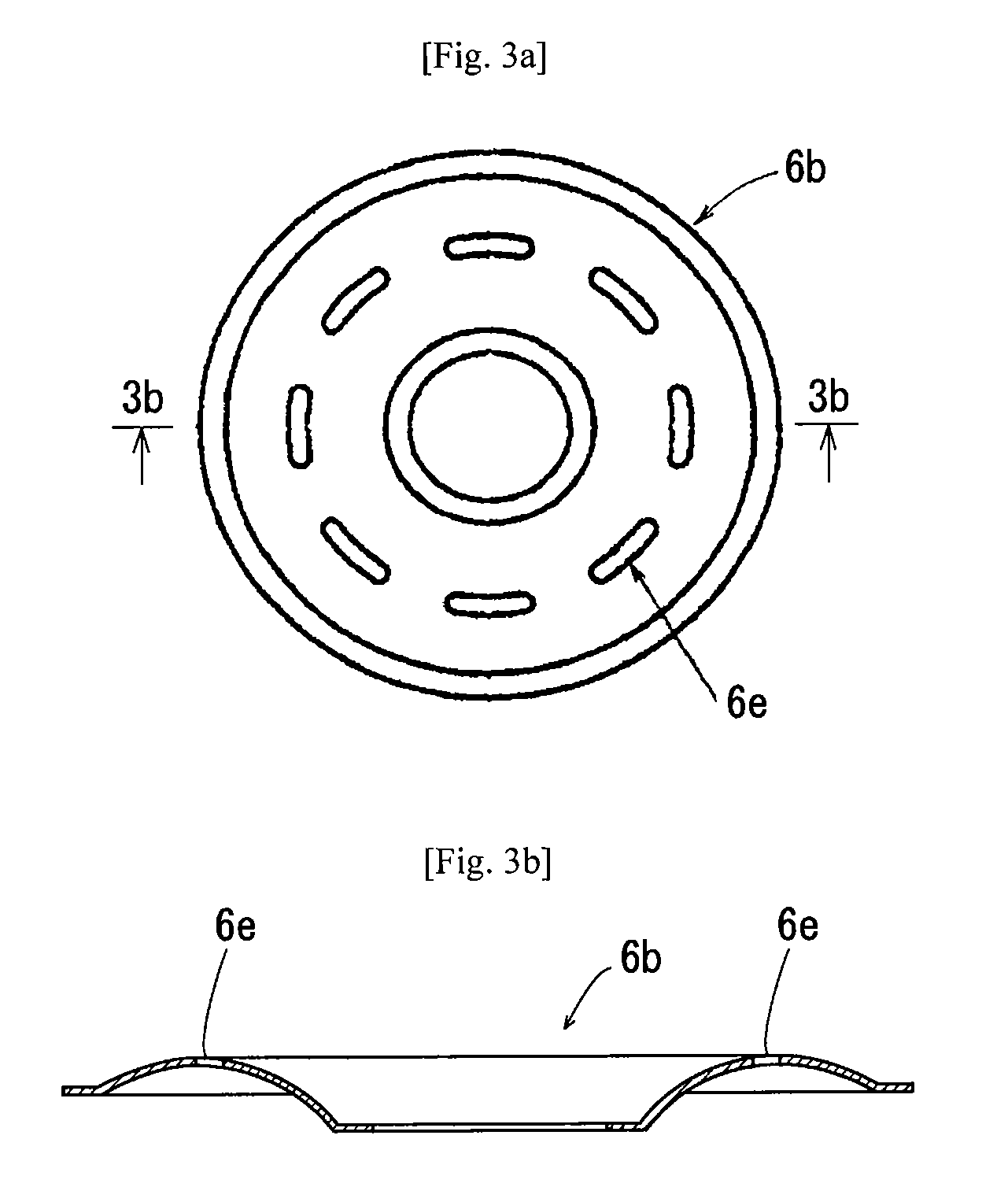

A capacitor microphone is constituted by a plate having a fixed electrode, a diaphragm including a center portion and at least one near-end portion that is fixed to the outer periphery, in which the center portion having a vibrating electrode, which is positioned relative to the fixed electrode and which vibrates in response to sound waves, is increased in rigidity in comparison with the near-end portion; and a spacer that is fixed to the plate and the near-end portion of the diaphragm and that has an air gap formed between the plate and the diaphragm. Alternatively, a diaphragm electrode is horizontally supported by extension arms extended from a circular plate thereof and is vertically held in a hanging state being apart from a fixed electrode with a controlled distance therebetween.

Owner:YAMAHA CORP

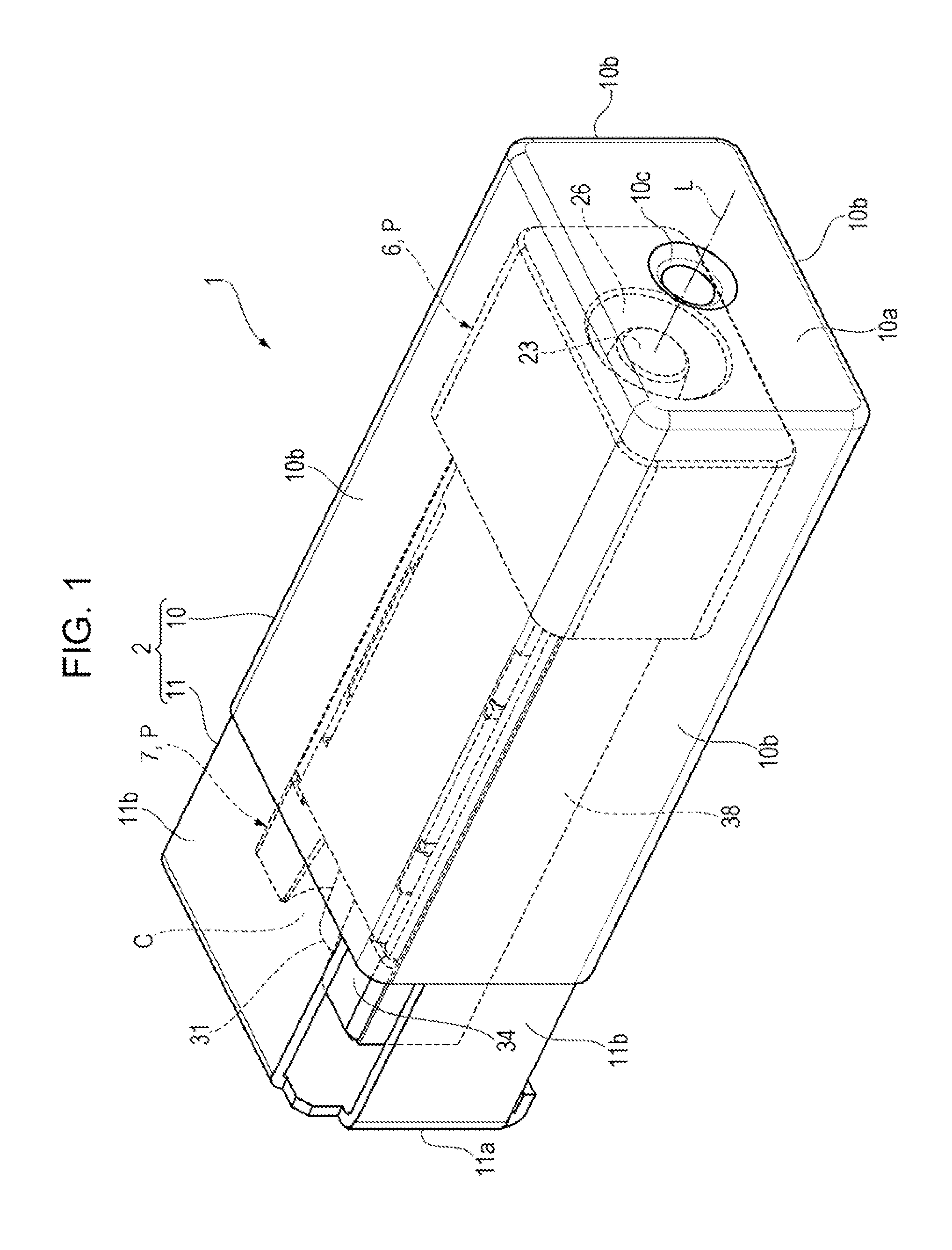

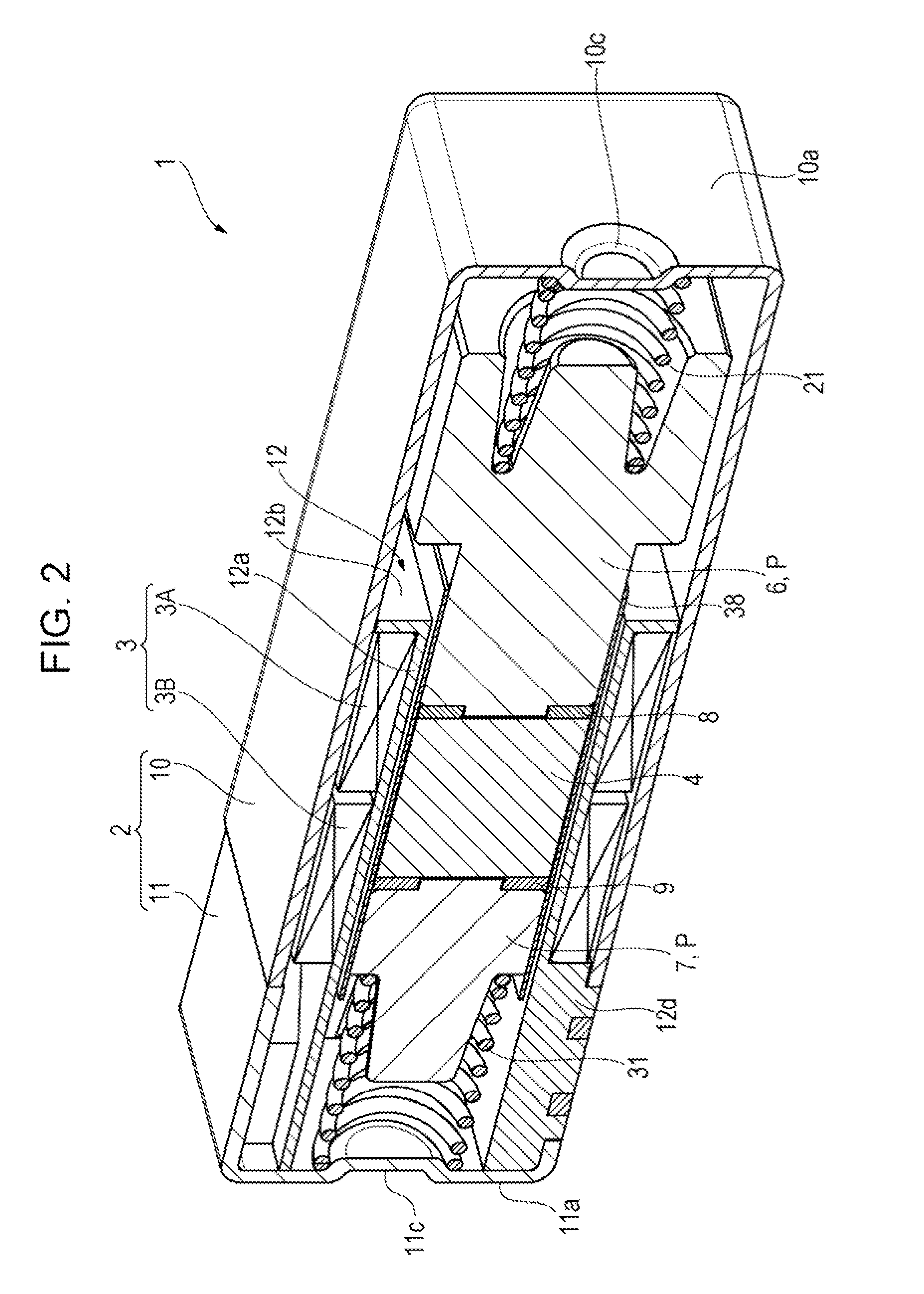

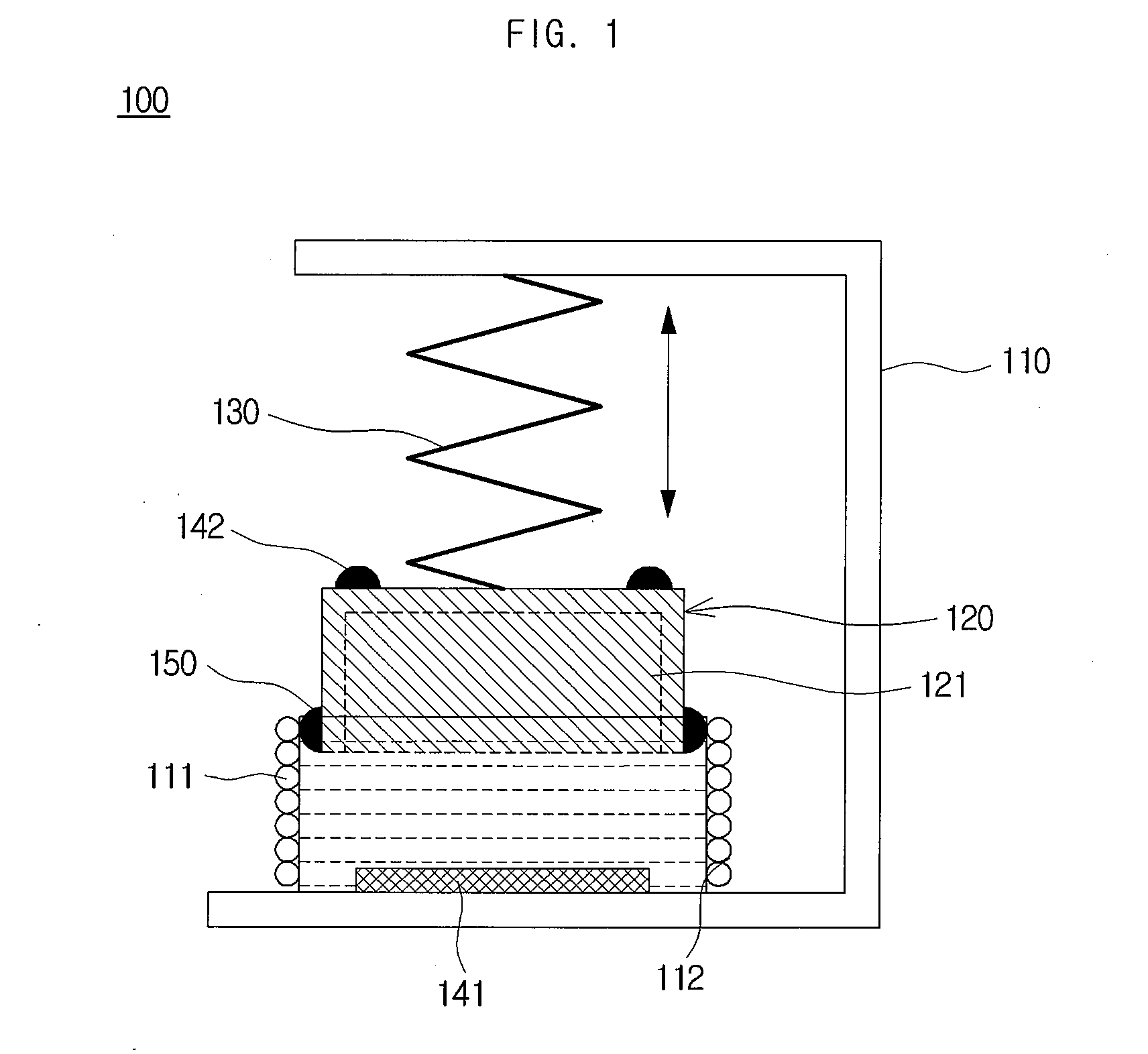

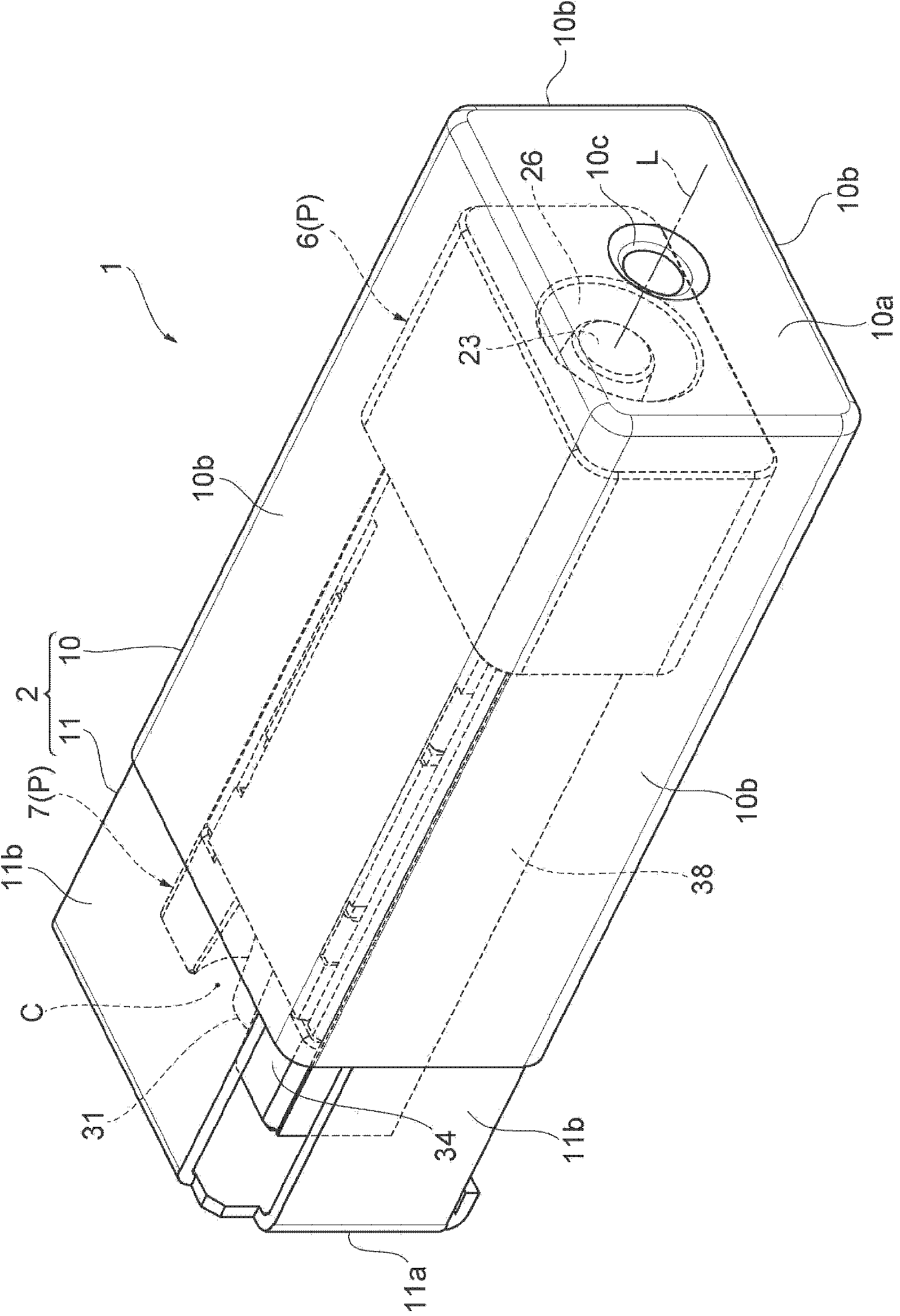

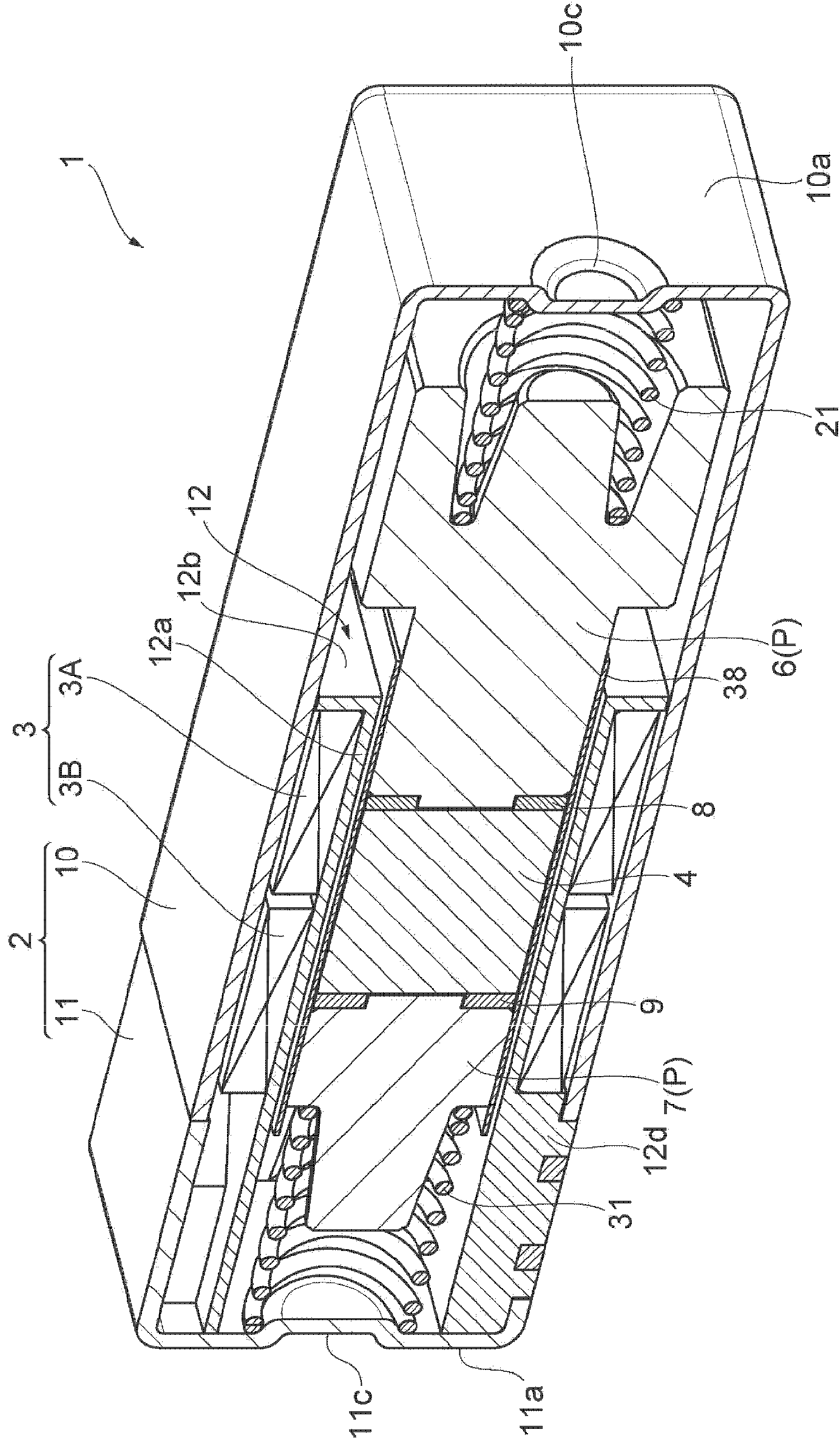

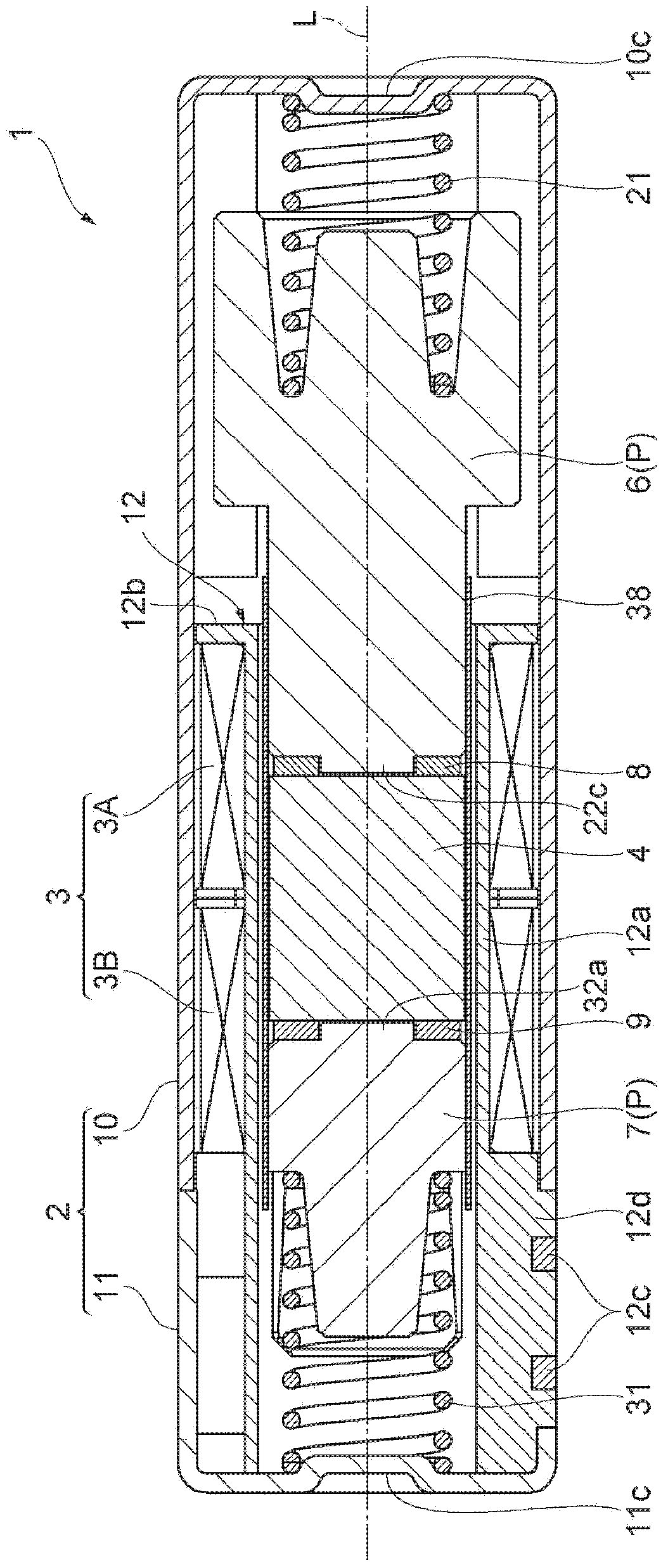

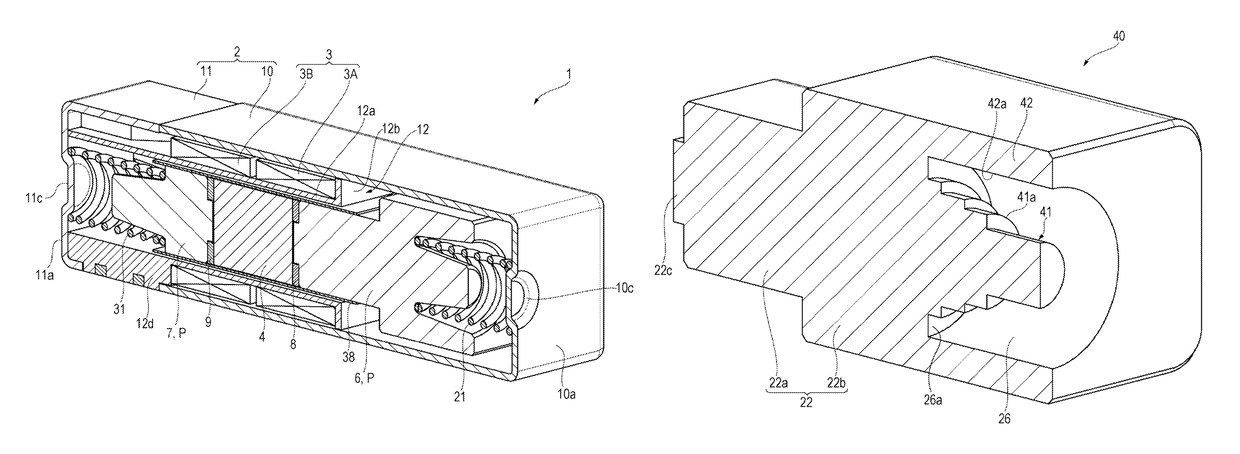

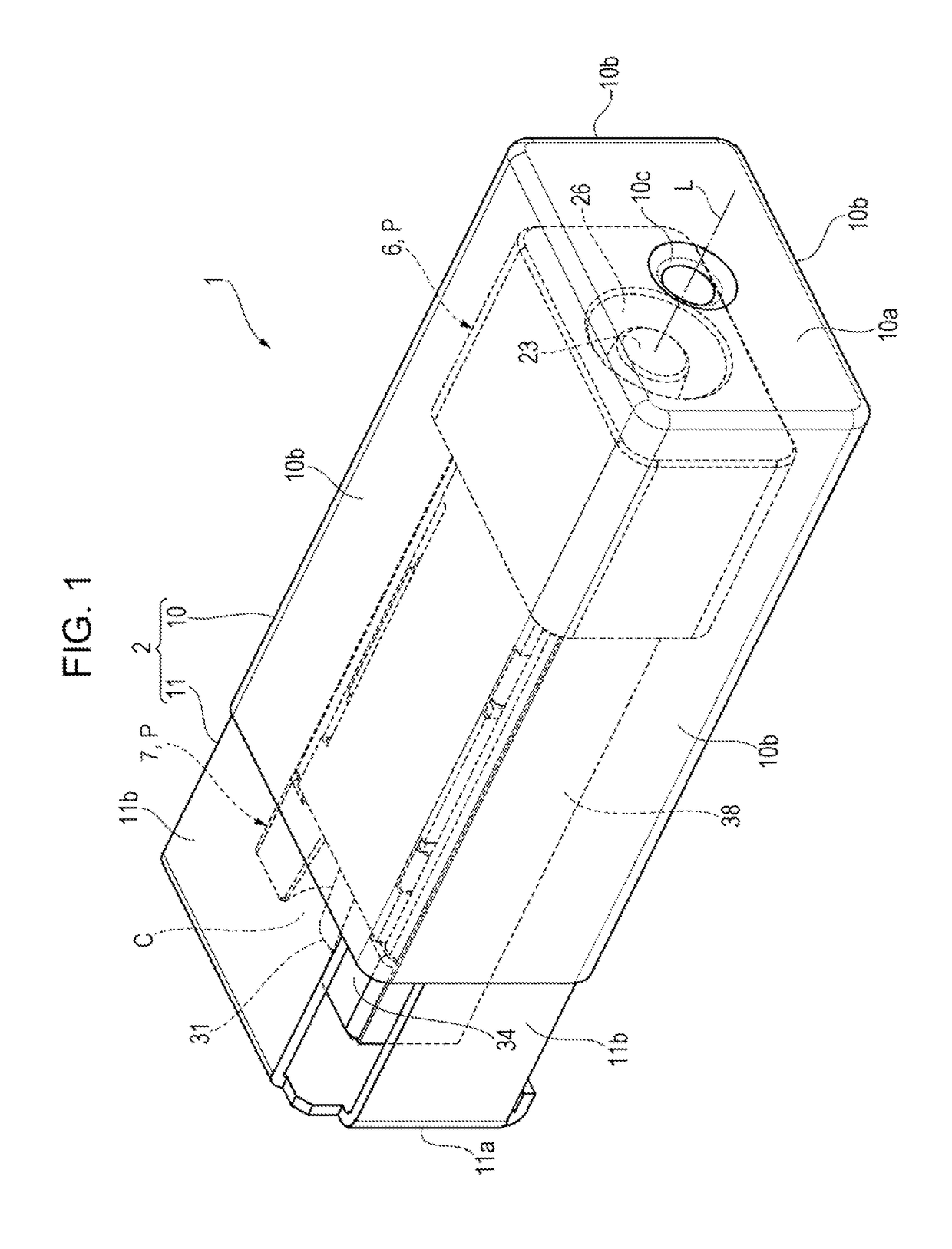

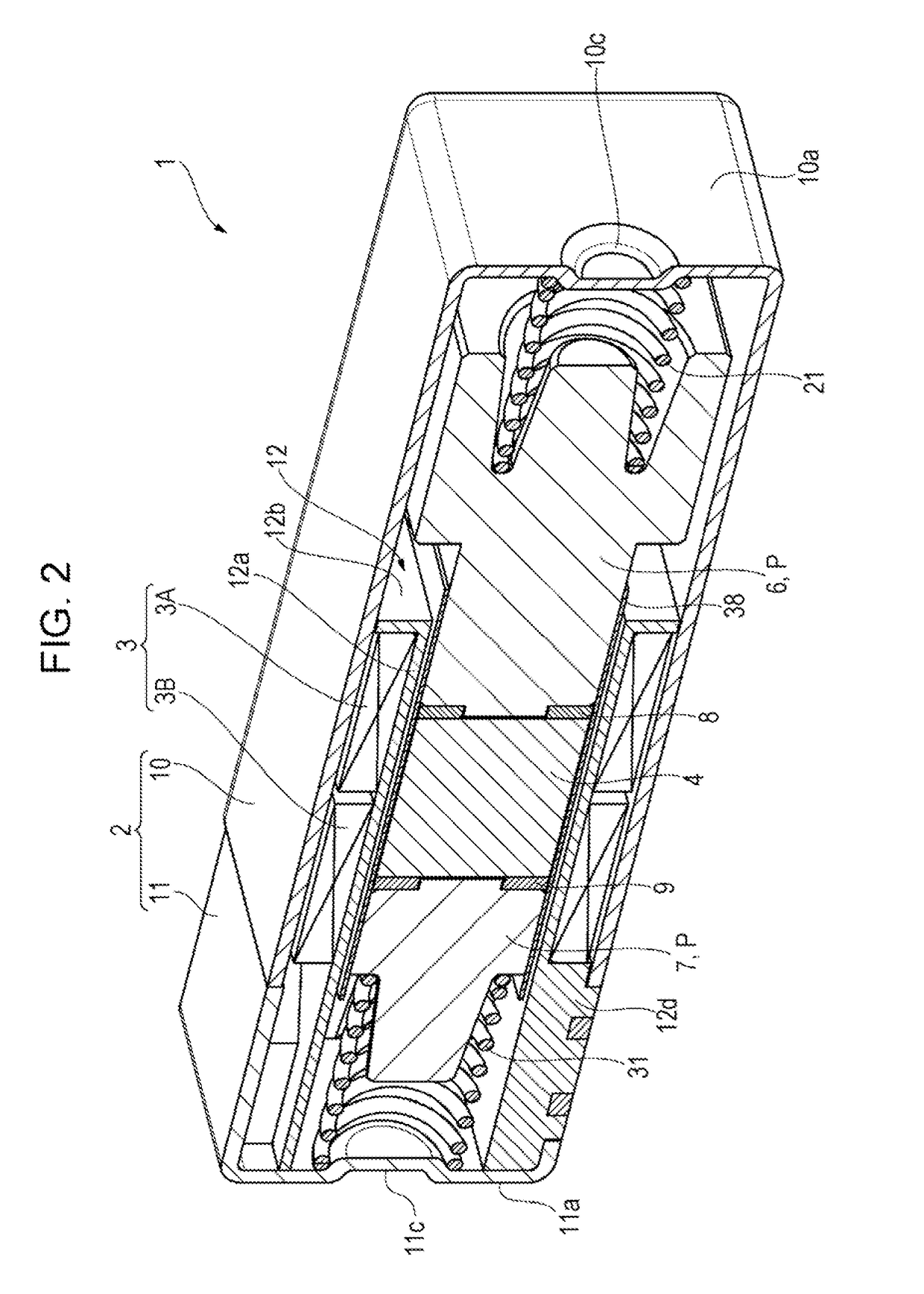

Vibration actuator

ActiveUS20140035397A1Prevent abnormal noiseStable vibrationDynamo-electric machinesEngineeringCoil spring

A first weight portion of a vibration actuator includes an inner-side enlarged portion that protrudes from an end portion of a solid head in a direction of a vibration axis and that is inserted into an opening portion extending within a first compression coil spring along the direction of the vibration axis. An outer peripheral surface of the inner-side enlarged portion becomes continuously smaller in diameter from a base end towards a free end, with the vibration axis being the center of the diameter. That is, the inner-side enlarged portion has the shape of a truncated cone. The inner-side enlarged portion is inserted into the opening portion of the first compression coil spring and the opening portion is utilized to change the length of the inner-side enlarged portion in the direction of the vibration axis, thereby changing the mass of the first weight portion.

Owner:NIDEC COPAL CORPORATION

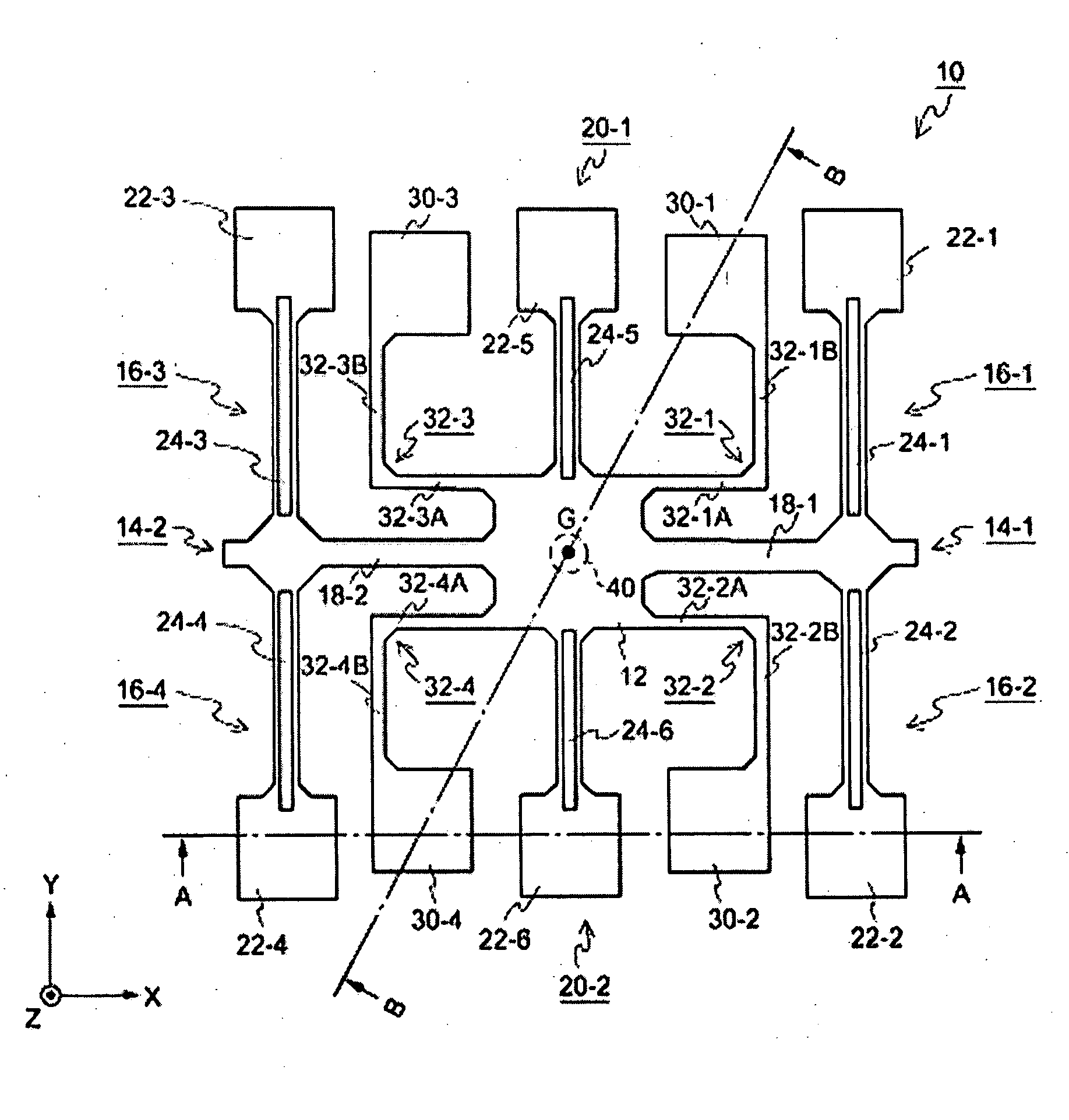

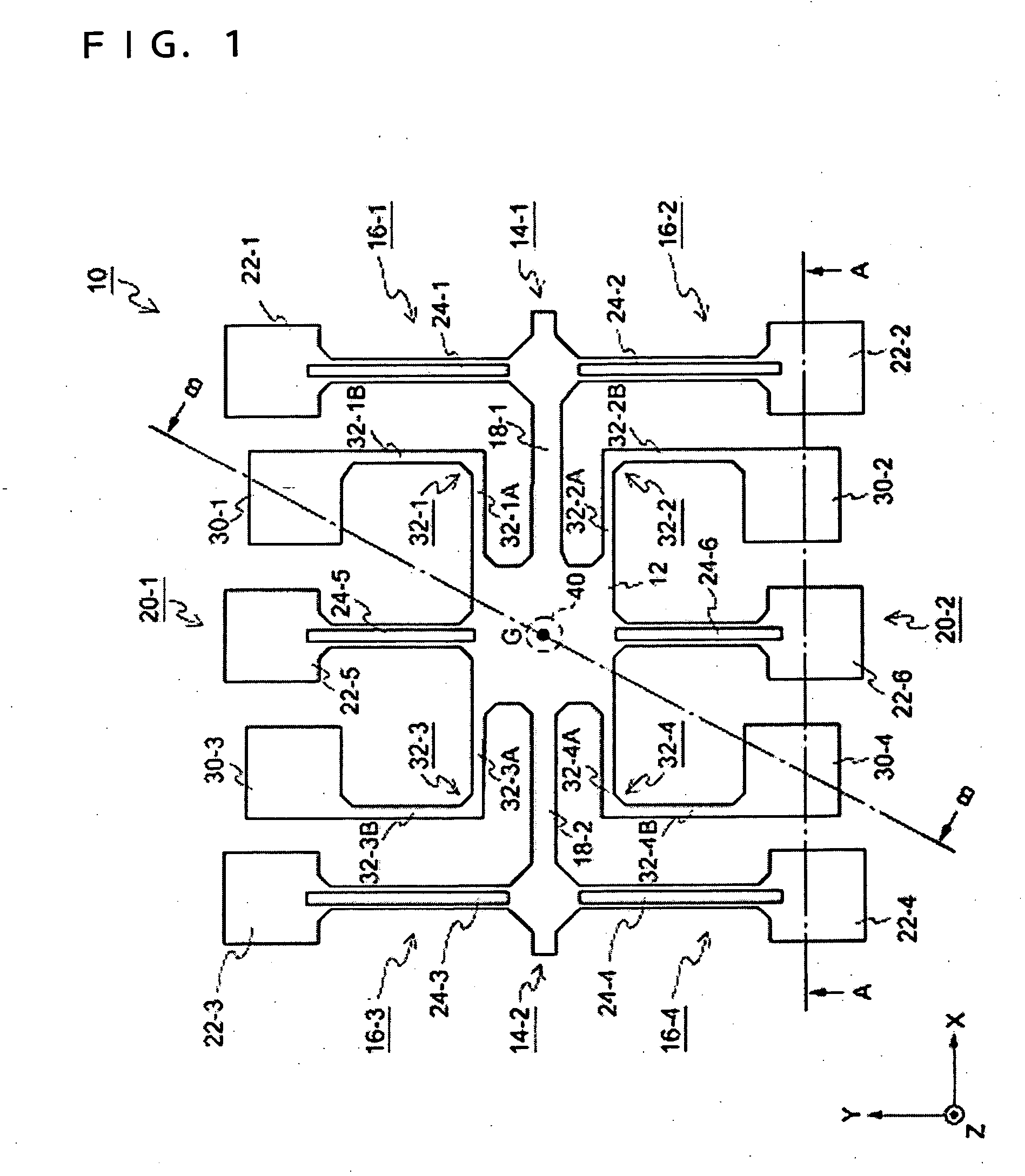

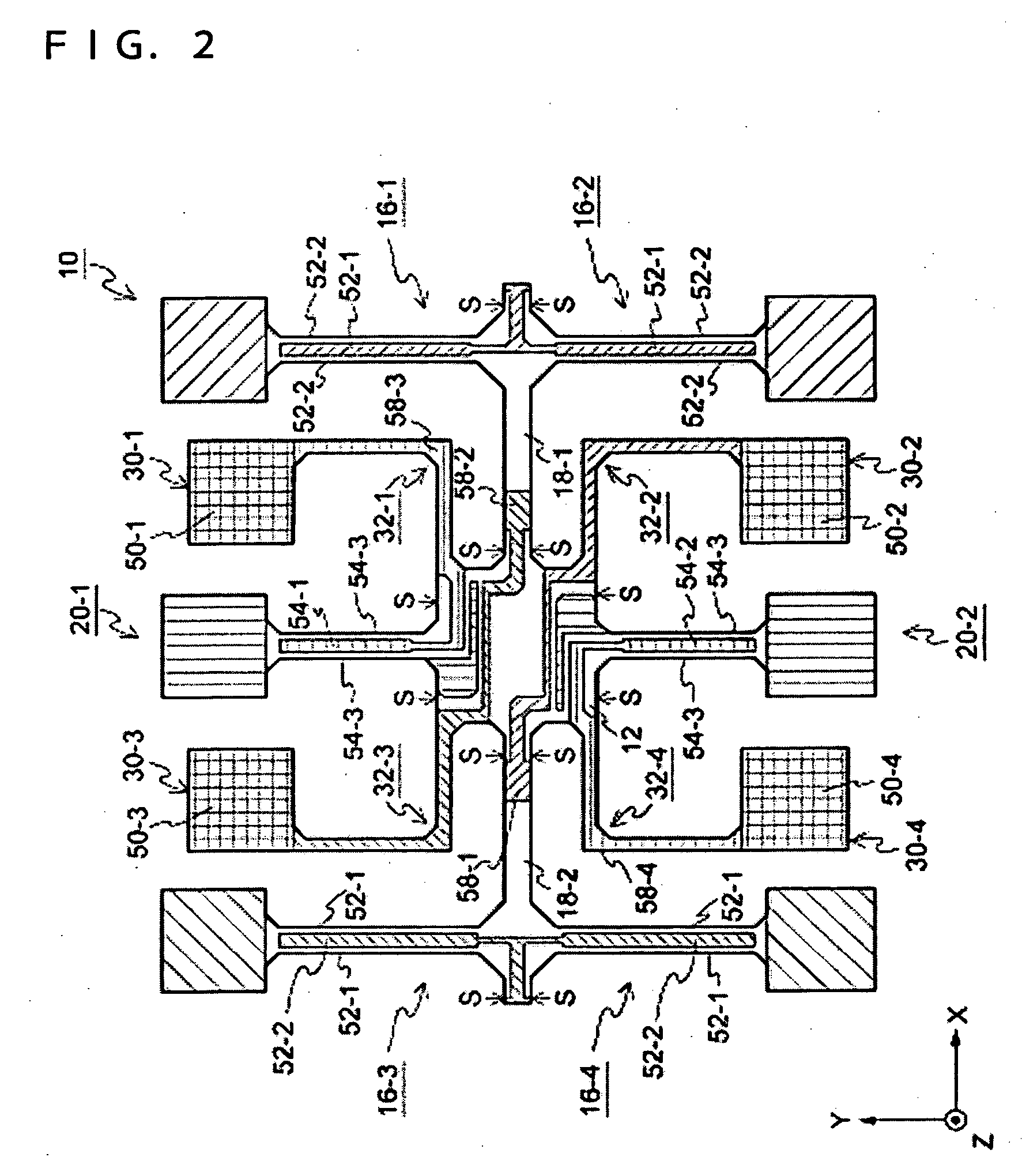

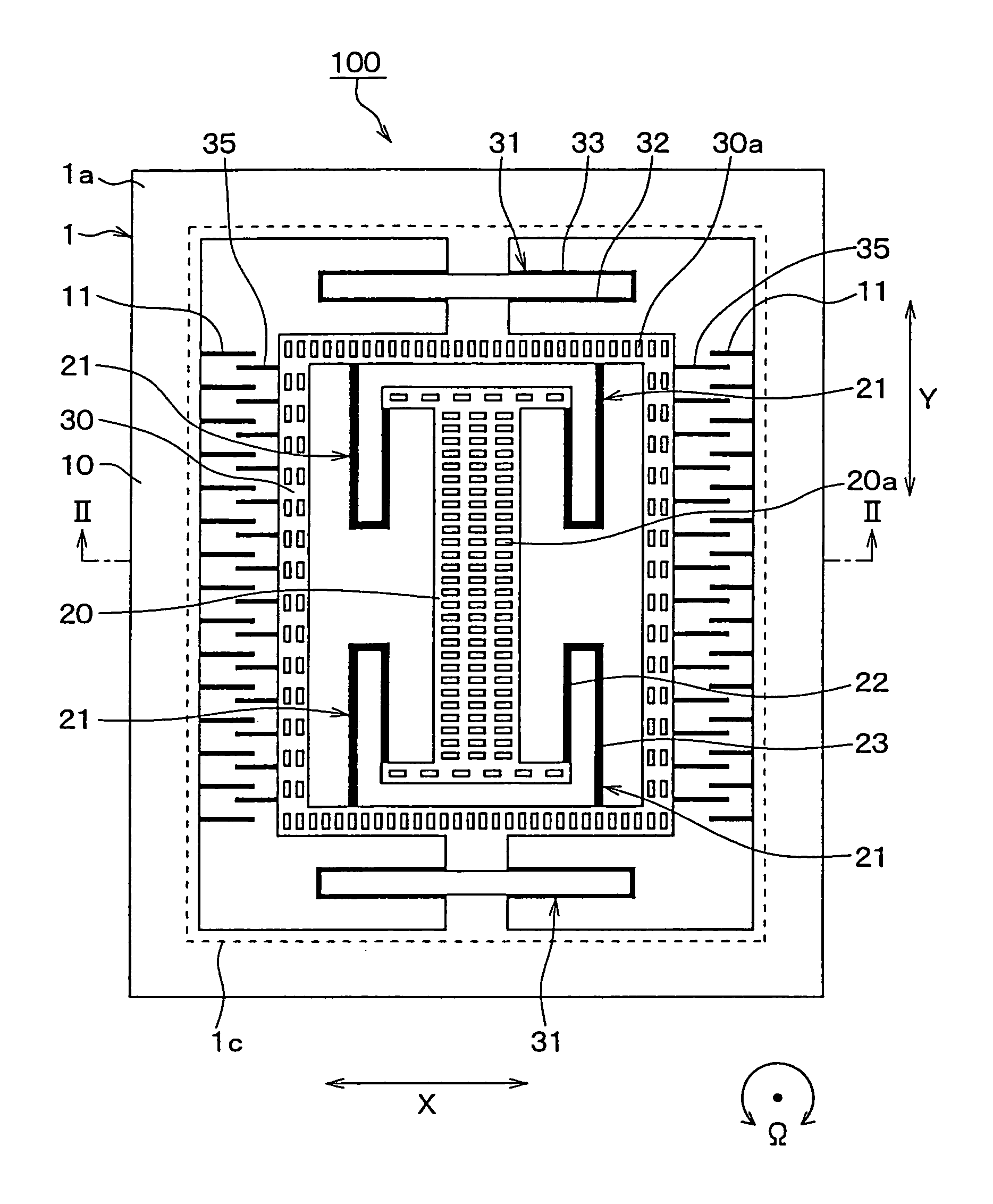

Piezoelectric vibrating segment, supporting structure for piezoelectric vibrating segment, piezoelectric vibrator, and piezoelectric vibrating gyroscope

InactiveUS20050284223A1Smooth vibrationDifficult to suppressPiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesGyroscopeDevice material

Aspects of the invention can provide piezoelectric vibrating segment, a supporting structure for the piezoelectric vibrating segment, piezoelectric vibrator, and the piezoelectric vibrating gyroscope capable of maintaining stable excited vibrations and stable sensing vibrations. The piezoelectric vibrating segment can include a base section, a plurality of excited vibration arms and sensing vibration arms radially extending from the base section in a single plane. A plurality of first beams having elasticity extending from the base section and between the vibration arms and, at least, a first supporting section formed on the tips of the beams can be formed. The excited vibration arms and the sensing vibration arms are provided with electrode patterns formed thereon to be connected to and driven by a semiconductor device. The piezoelectric segment is encapsulated by a container composed of a base member and a lid member to form a piezoelectric vibrator and a piezoelectric vibrating gyroscope, and stable excited vibrations and stable sensing vibrations are maintained.

Owner:SEIKO EPSON CORP

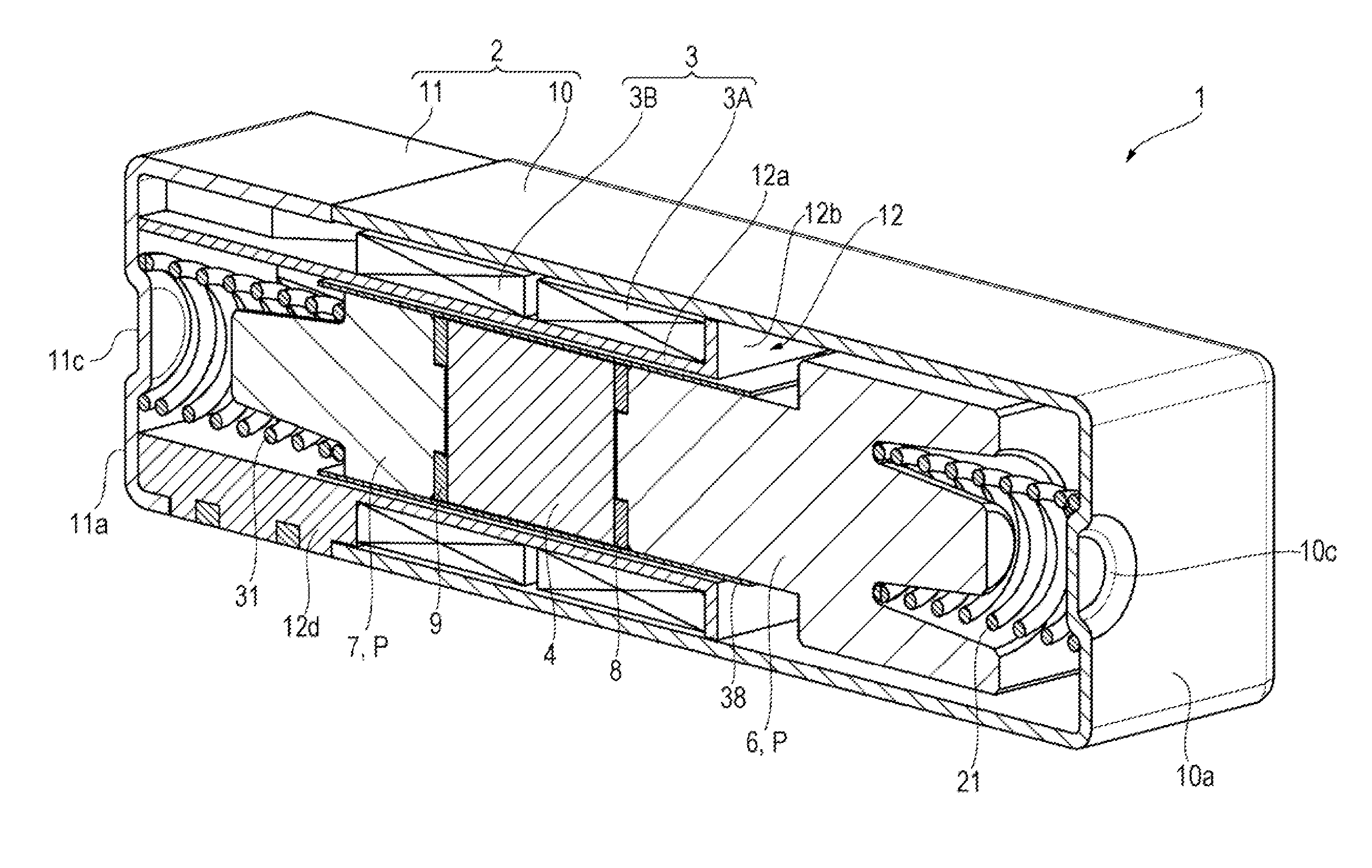

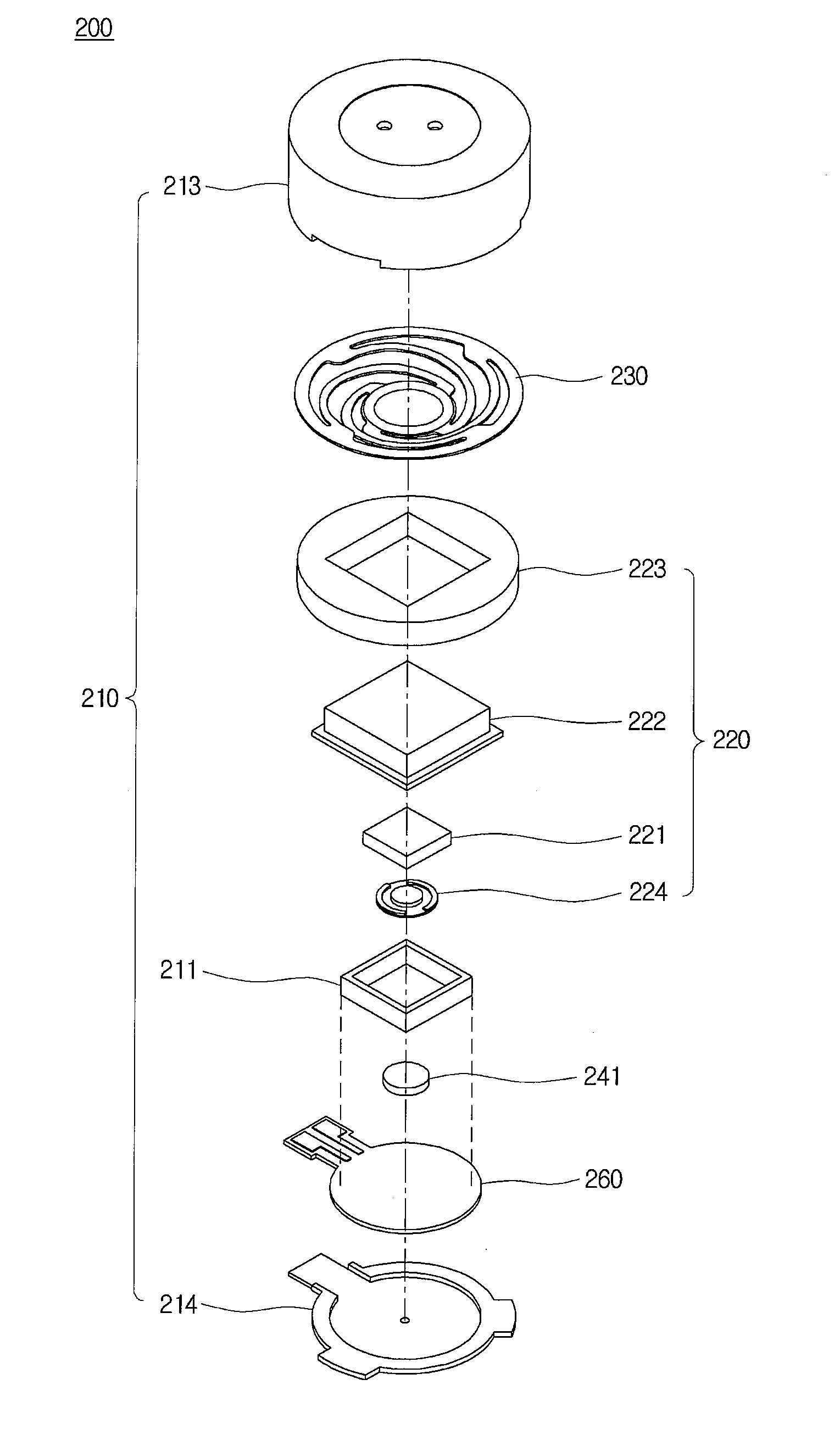

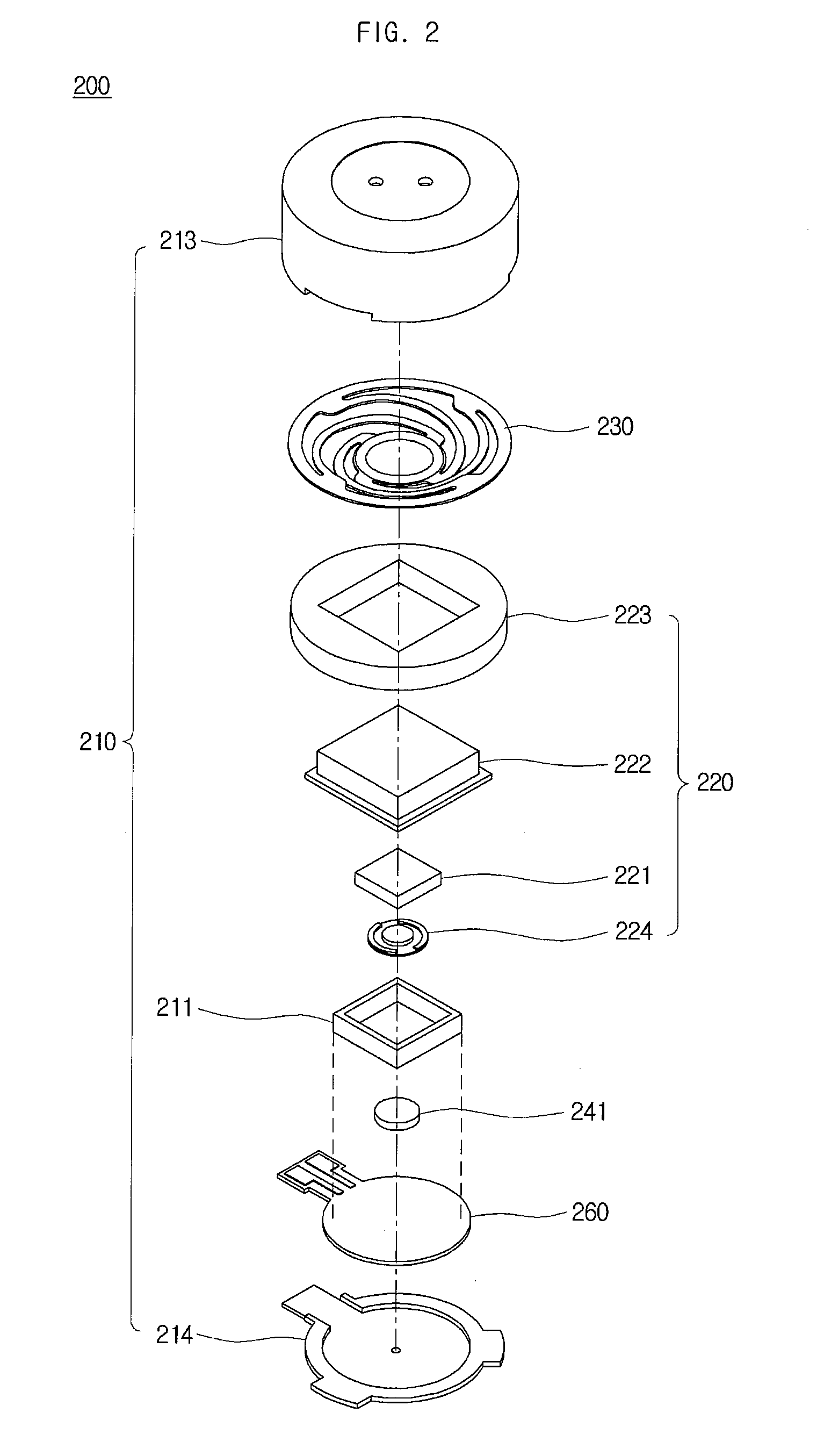

Linear vibration generator

InactiveUS20110089773A1Stable linear vibrationAvoid noiseDynamo-electric machinesInput/output processes for data processingPrismLinear vibration

A linear vibration generator is disclosed. The linear vibration generator in accordance with an embodiment of the present invention includes a stationary part, which has a polygonal-prism-shaped coil and in which the polygonal-prism-shaped coil induces a magnetic field by having an electric current supplied, a vibrating part, which has a polygonal-prism-shaped magnet and in which a portion of the polygonal-prism-shaped magnet is inserted into the coil, an elastic member, which is coupled to the stationary part and elastically supports the vibrating part such that the vibrating part can move linearly, and a lubricating band, which is formed on an outer circumferential surface of the magnet.

Owner:MPLUS

Vibration actuator

ActiveCN103567135APrevent abnormal soundSmooth vibrationMechanical vibrations separationDynamo-electric machinesCircular coneCoil spring

A first weight portion of a vibration actuator includes an inner-side enlarged portion that protrudes from an end portion of a solid head in a direction of a vibration axis and that is inserted into an opening portion extending within a first compression coil spring along the direction of the vibration axis. An outer peripheral surface of the inner-side enlarged portion becomes continuously smaller in diameter from a base end towards a free end, with the vibration axis being the center of the diameter. That is, the inner-side enlarged portion has the shape of a truncated cone. The inner-side enlarged portion is inserted into the opening portion of the first compression coil spring and the opening portion is utilized to change the length of the inner-side enlarged portion in the direction of the vibration axis, thereby changing the mass of the first weight portion.

Owner:COPAL CO LTD

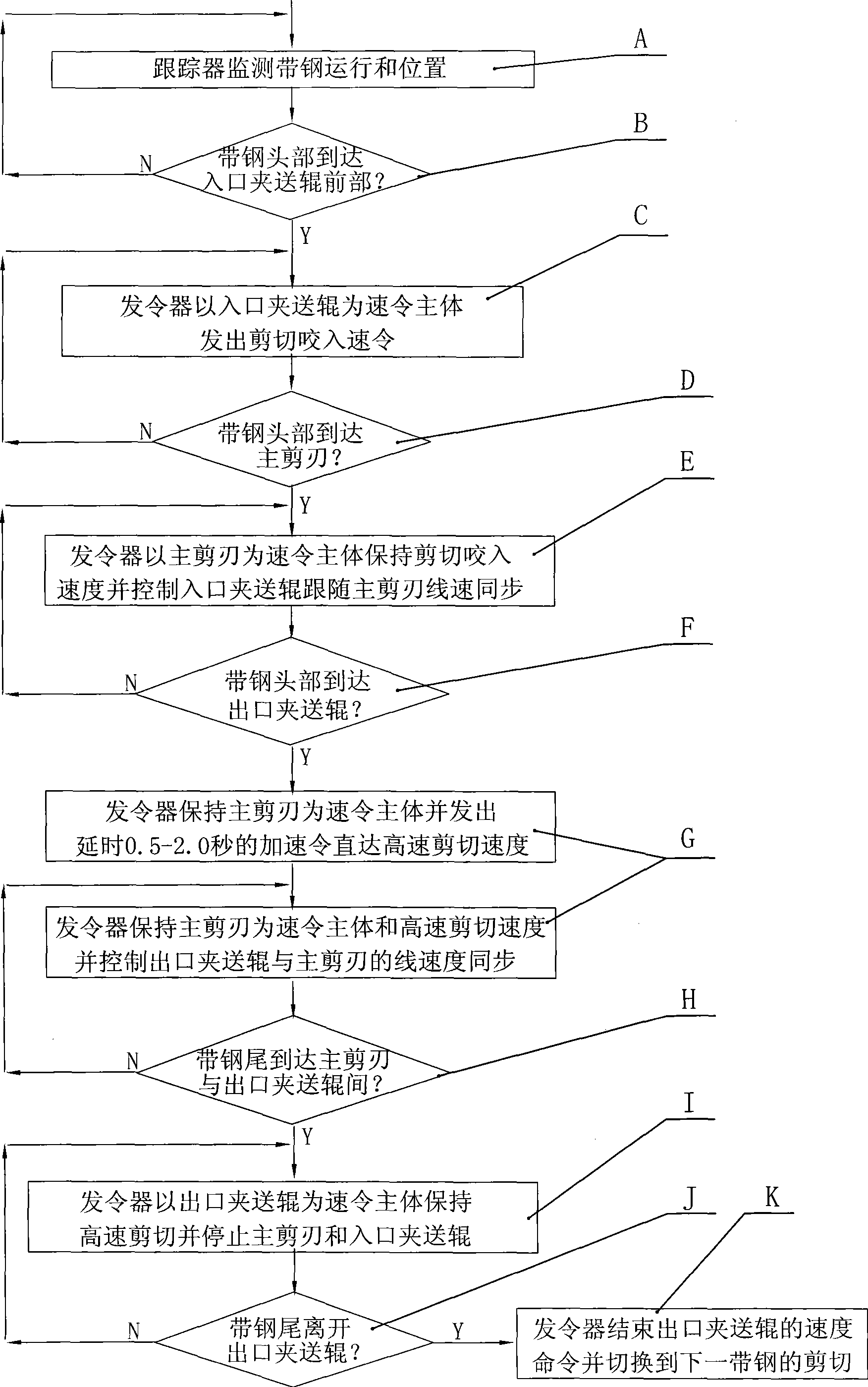

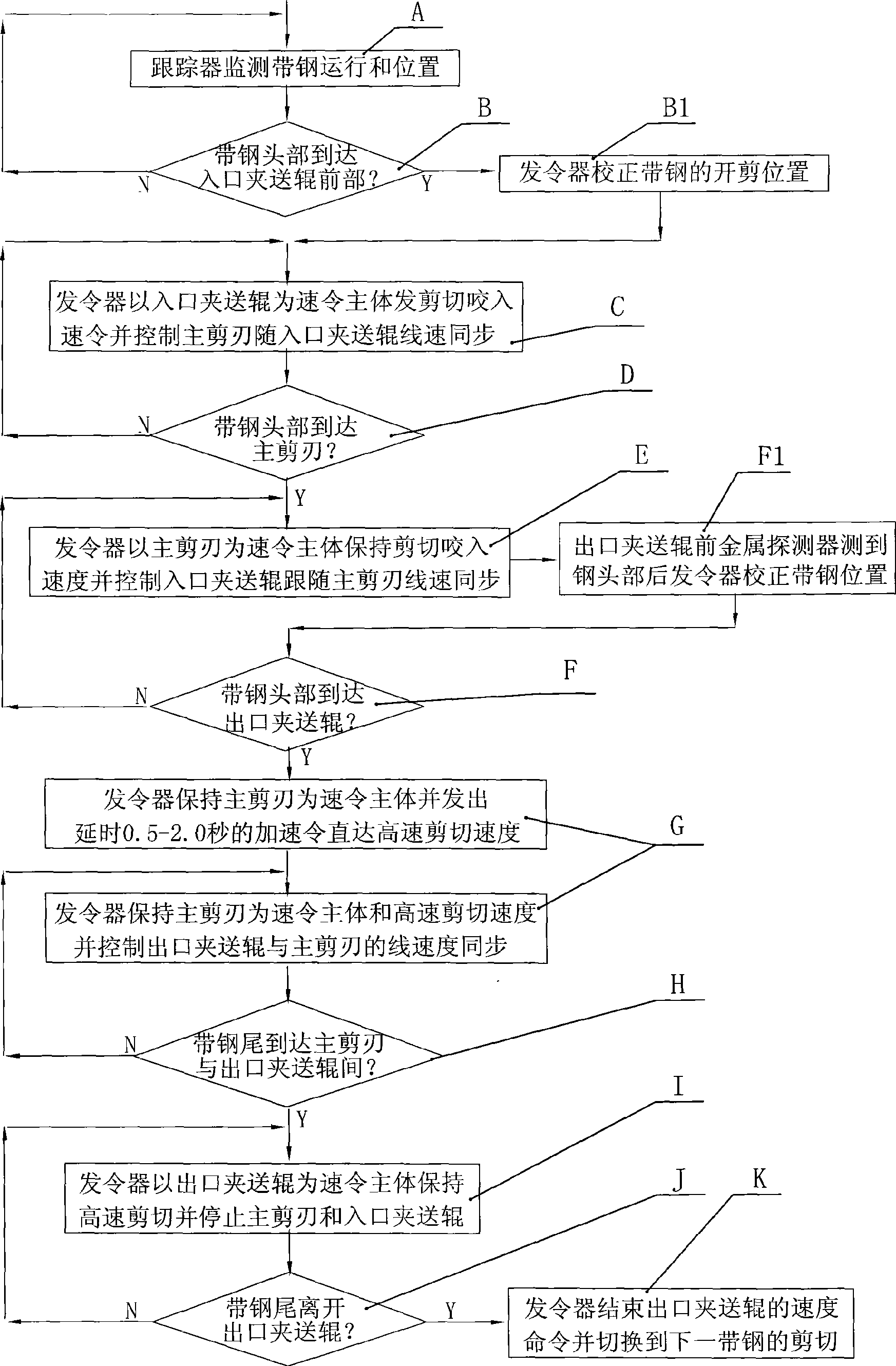

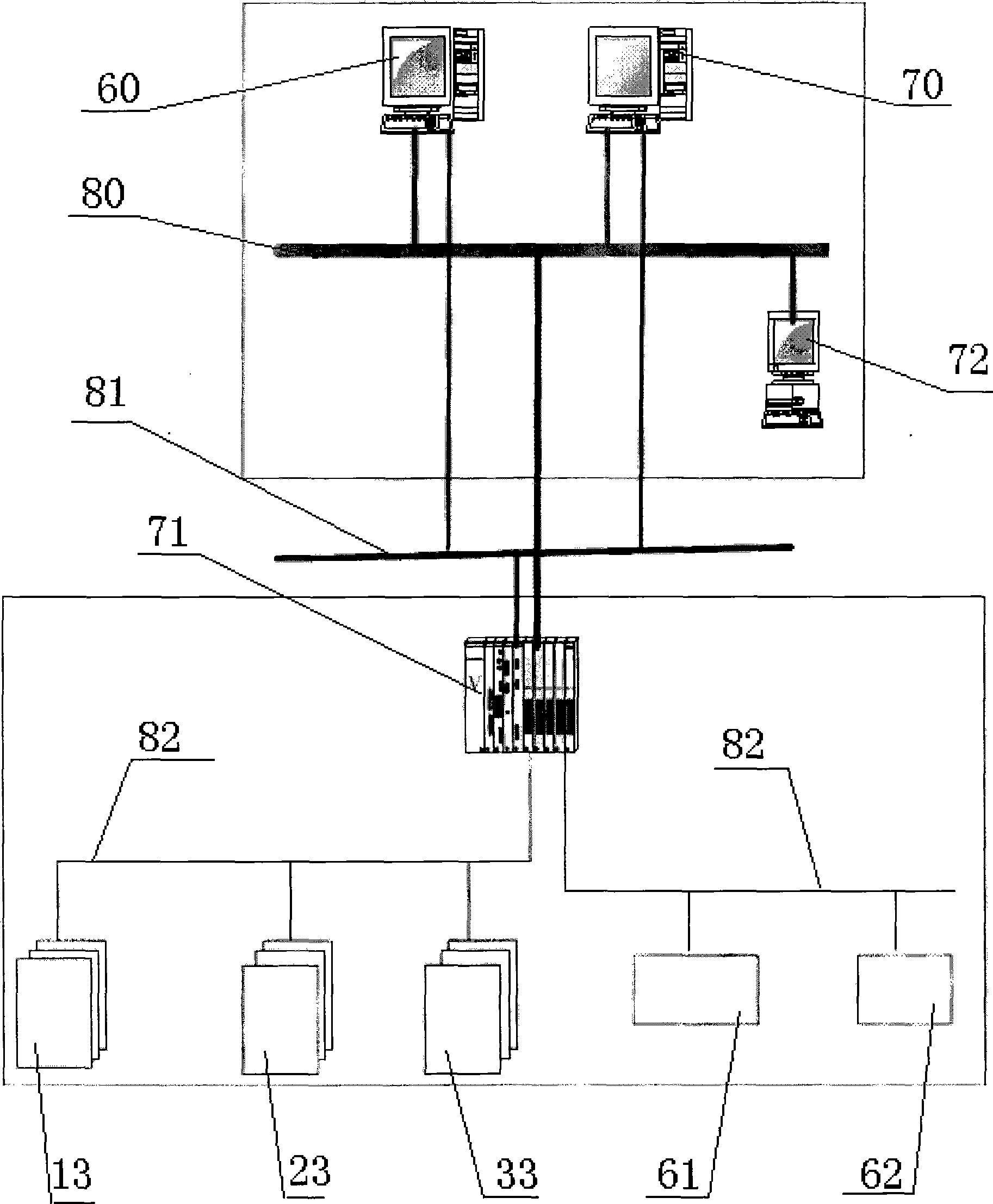

Shearing control method and control device of disc shear

ActiveCN101441462ALow failure rateStable and efficient failure rateShearing machinesNumerical controlCircular discFailure rate

The invention relates to a shearing control method and a shearing control device for circle shears. The method comprises the following steps: when the head of a steel strip reaches the front parts of entrance pinch rolls, a command sender takes the entrance pinch rolls as a speed command body to send a shearing and biting speed command; when the head of the steel strip reaches a main cutting edge, the command sender takes the main cutting edge as the speed command body, maintains the shearing and biting speed, and controls the entrance pitch rolls to follow and be synchronous with the linear speed of the main cutting edge; and when the head of the steel strip reaches exit pitch rolls, the command sender takes the main cutting edge as the speed command body to send an acceleration command, controls the main cutting edge to speed up to achieve the shearing speed required in a high-speed shearing command within 0.5 to 2 seconds, and controls the exit pinch rolls to follow and be synchronous with the linear speed of the main cutting edge. The control method and the control device effectively reduce instantaneous impact loads withstood by all mechanical parts at the time of biting, prolong the service life of shearing equipment, reduce maintenance cost, reduce the failure rate of a clamping chute at a cutting edge, and improve equipment stability and utilization rate.

Owner:SGIS SONGSHAN CO LTD +1

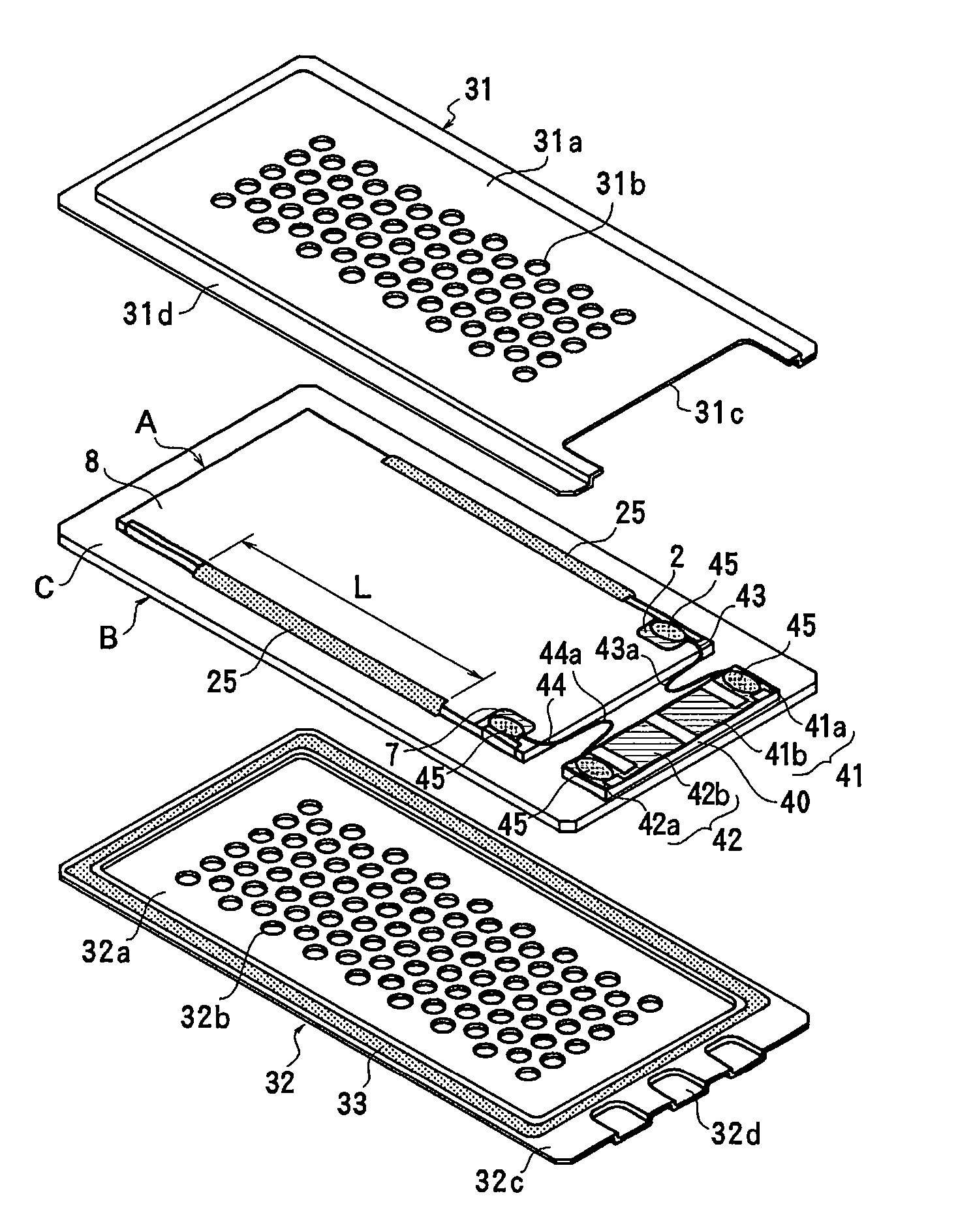

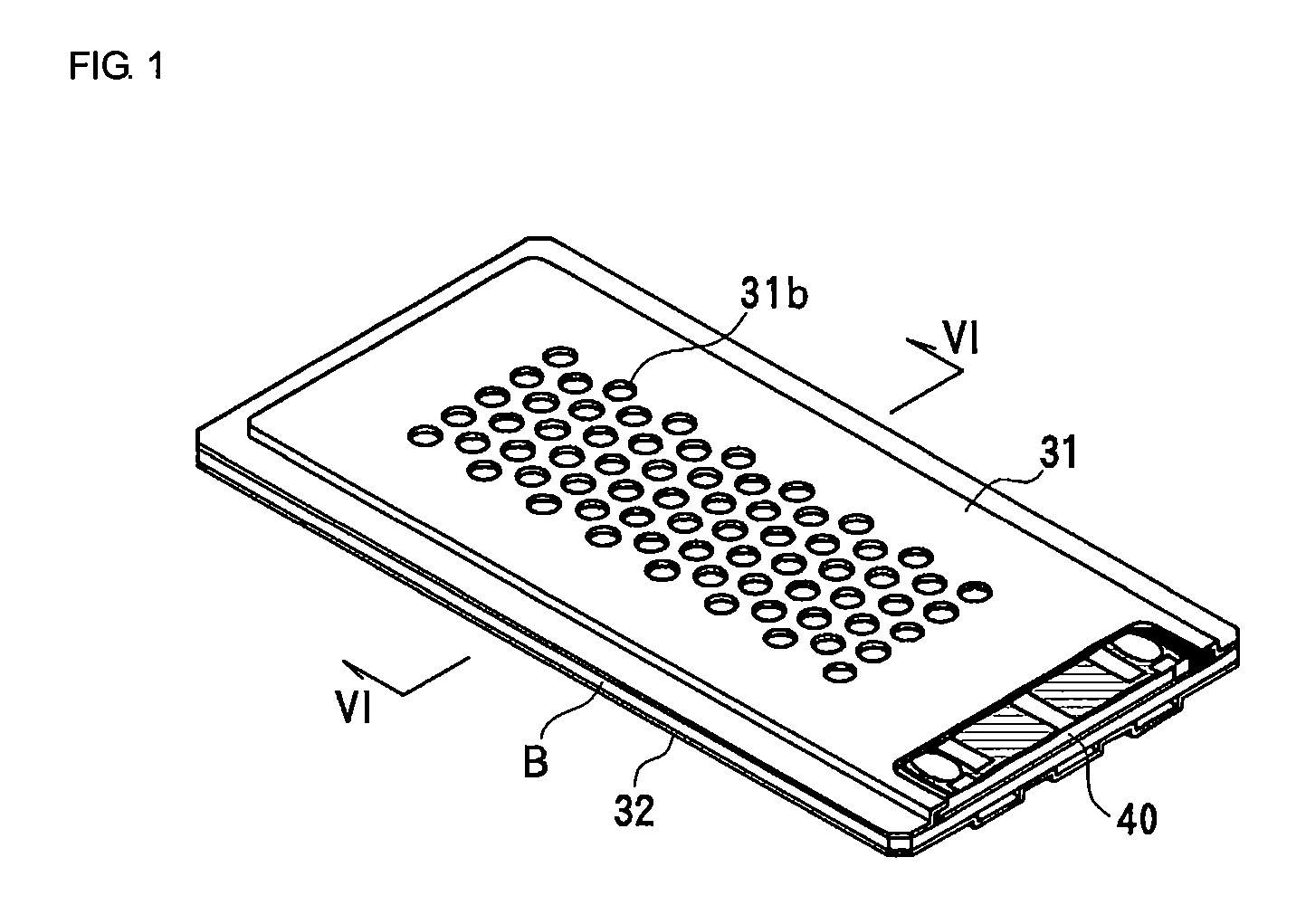

Piezoelectric Sounding Body

ActiveUS20070228893A1Thin and low-cost piezoelectric sounding bodyAttaching process can be simplifiedPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersAdhesiveEngineering

A piezoelectric sounding body in which a stable high sound pressure can be obtained over a wide frequency band. The piezoelectric sounding body includes a resin film, a piezoelectric vibrating plate attached to the center of one surface of the resin film with a tackiness layer, and a case supporting the periphery of the resin film. The piezoelectric vibrating plate is formed in a rectangular shape. An adhesive is applied between the middle of each long side of the piezoelectric vibrating plate and the resin film, along each long side of the piezoelectric vibrating plate. The separation between the piezoelectric vibrating plate and the tackiness layer can be prevented during sounding, and a stable sound pressure can be obtained for a prolonged period.

Owner:MURATA MFG CO LTD

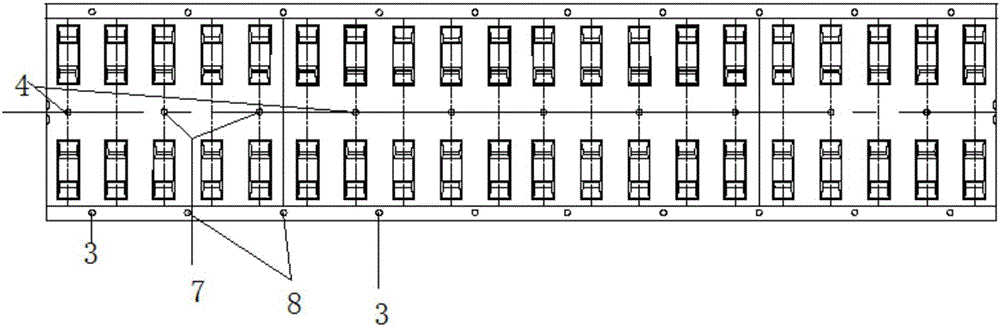

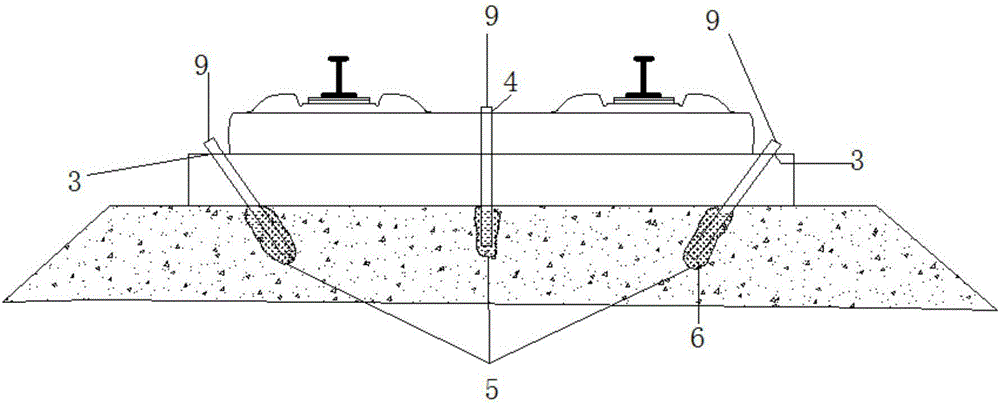

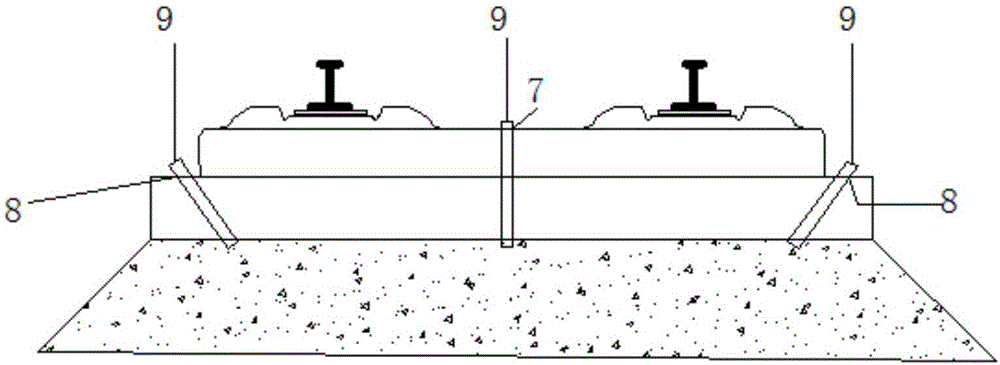

Ballastless track grouting lifting and lifting correcting method

InactiveCN106758591AFast constructionPractical and reliableRailway track constructionEngineeringHigh polymer

The invention discloses a ballastless track grouting lifting and lifting correcting method. The method comprises the following steps: step 1: before lifting, using a high-precision level gauge to measure the track surface and under-track empty area, according to the measuring result, determining the lifting position and lifting quantity of a track board, and determining the arrangement position, space distance, hole diameter and hole depth of a grouting hole; step 2: calculating and determining the cutting position of a closing layer, and cutting the closing layer; step 3: arranging the grouting holes in the position to be lifted, preparing a polymer bag and arranging holes in the polymer bag; step 4: inserting a grouting pipe into the polymer bag, and fixing; step 5: installing the grouting pipe and the polymer bag in the grouting hole; step 6: executing the grouting lifting, monitoring in real time during the lifting process, and guaranteeing the track lifting elevation; and step 7: after executing certain amount of the grouting lifting, correcting the part to be corrected, monitoring the correcting process in real time, and guaranteeing the correcting displacement of the track. After completing the grouting, the high polymer bag and a grouting material carry out the compaction with the surrounding soil so as to form a self-formation pile. The solution is capable of realizing the rapid and accurate lifting of the upper structure of the track.

Owner:BEIJING RUIWEI TIEKE HIGH SPEED RAIL ENG CO LTD

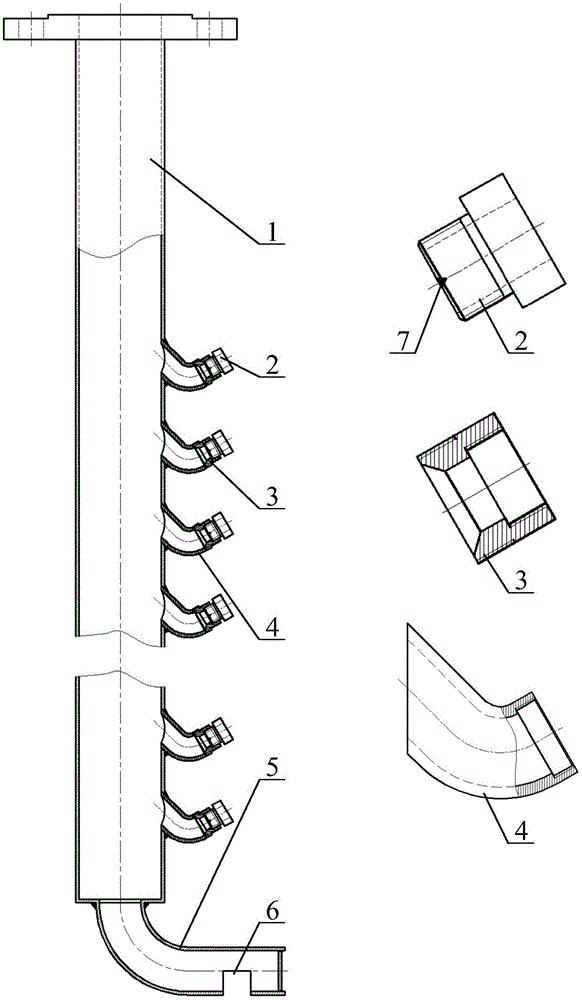

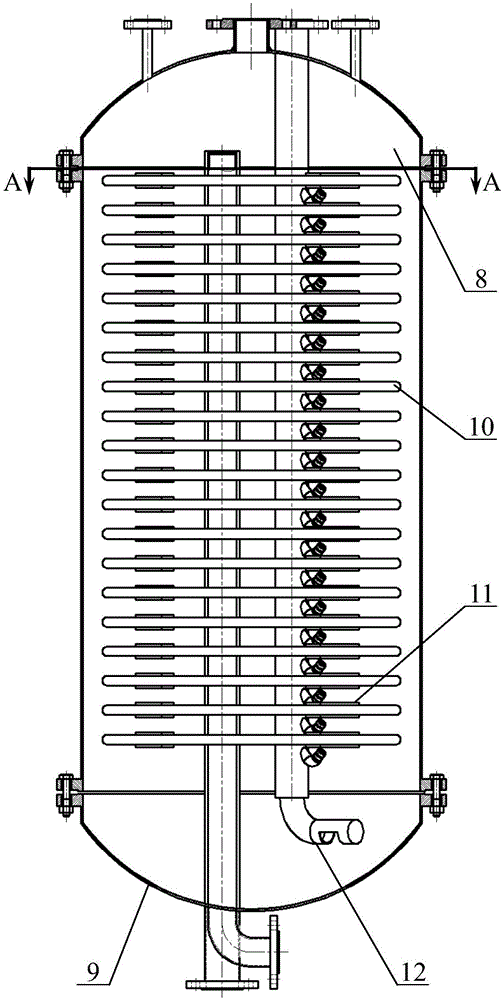

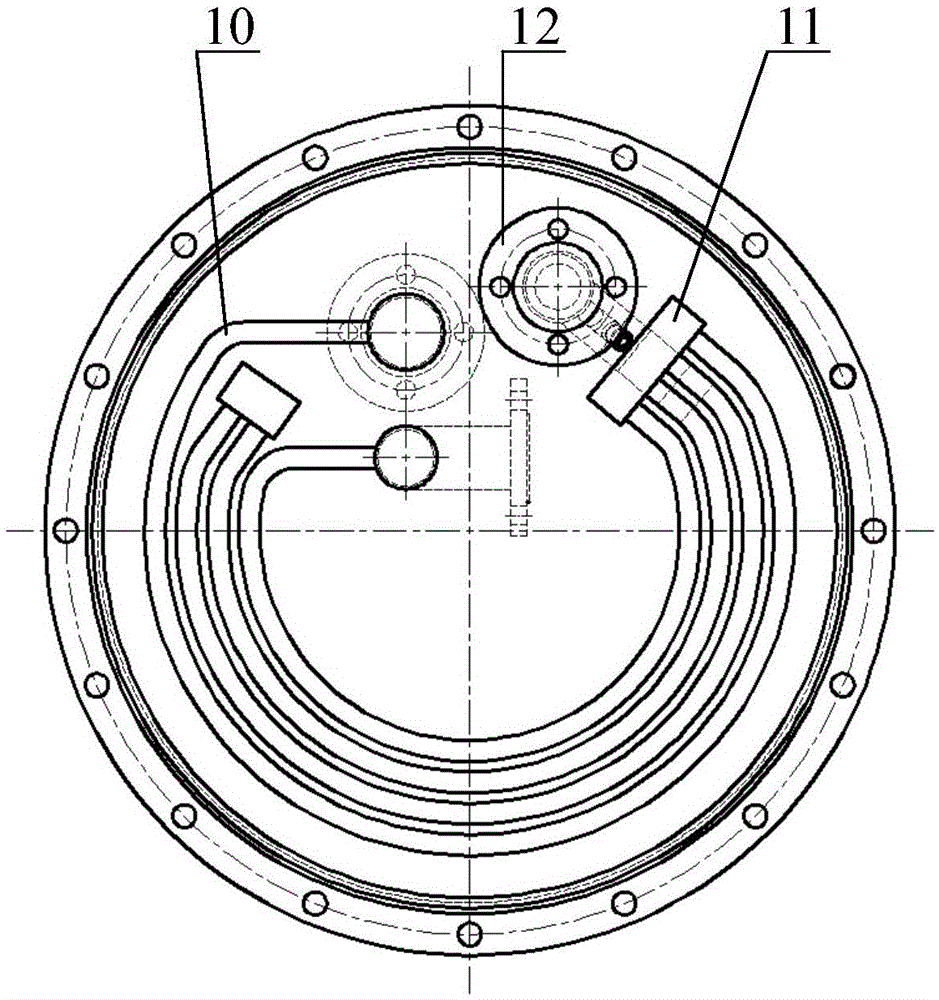

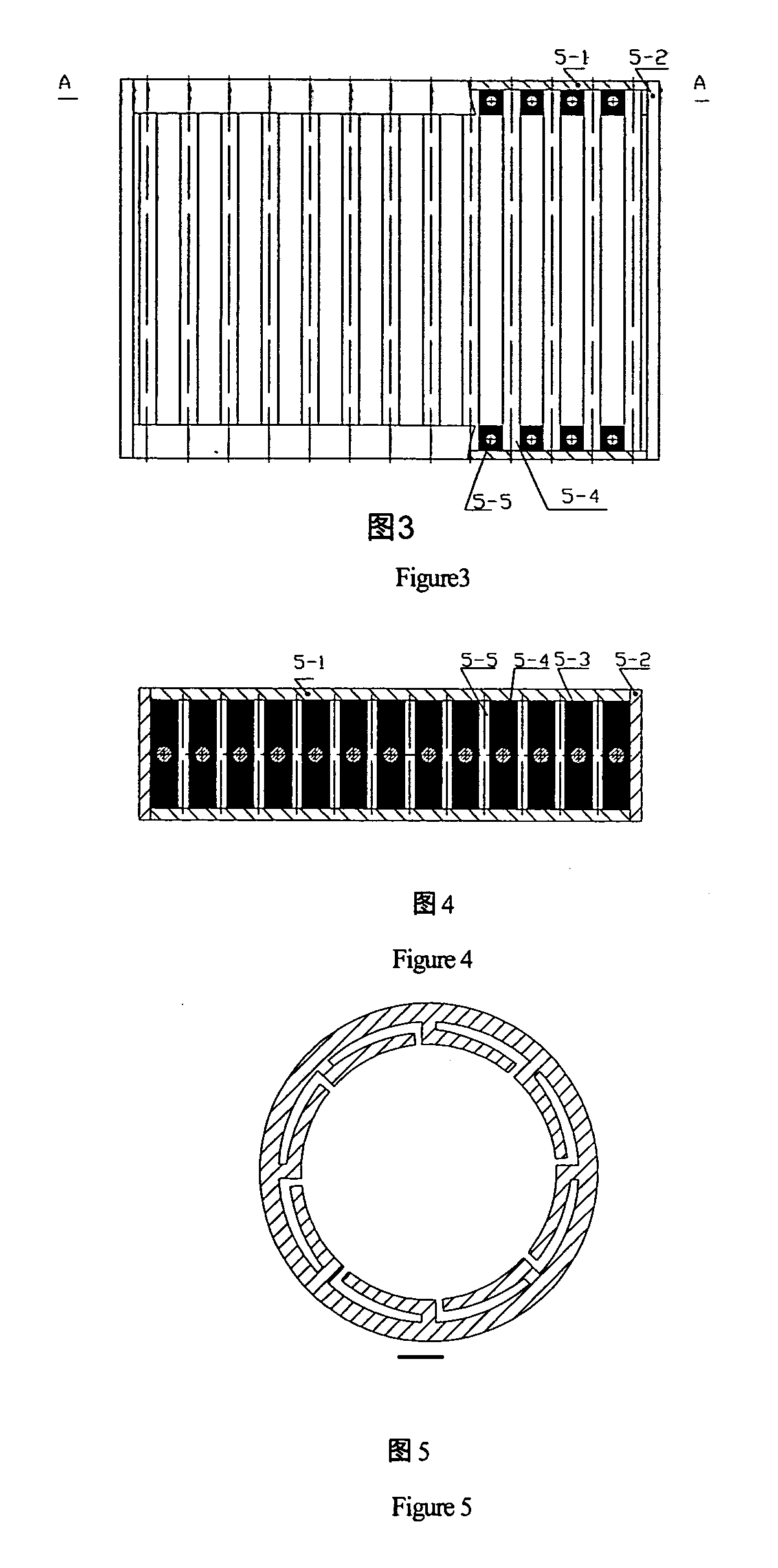

Uniform distribution type pulsating flow generating device for vibration induction of elastic tube bundles inside heat exchanger

ActiveCN105135931AImprove heat transfer effectRealize rationalityHeat transfer modificationEngineeringUltimate tensile strength

A uniform distribution type pulsating flow generating device for vibration induction of elastic tube bundles inside a heat exchanger comprises a vertical pipe, branch bent pipes, guide pipes, pulsating flow pipes, turbulator bodies and a shell pass water inlet pipe. The branch bent pipes consistent in spacing are distributed on the vertical pipe, the guide pipes are connected to the corresponding branch bent pipes, the pulsating flow pipes are connected to the guide pipes, and the turbulator bodies are arranged on the pulsating flow pipes. The shell pass water inlet pipe is arranged at the bottom end of the vertical pipe. When the uniform distribution type pulsating flow generating device is used, one end of the uniform distribution type pulsating flow generating device is fixed to an upper seal head of the heat exchanger, and the other end of the uniform distribution type pulsating flow generating device is suspended at the bottom of the heat exchanger. The uniform distribution type pulsating flow generating device can generate uniform and consistent pulsating flow having certain frequency and strength at outlets of the pulsating flow pipes by controlling the flow of a fluid flowing into the vertical pipe, induces the elastic tube bundles inside the elastic tube bundle heat exchanger to vibrate evenly, can achieve expected vibration required for heat transfer strengthening of the elastic tube bundle heat exchanger and avoids fatigue failures of the tube bundles due to vibration.

Owner:SHANDONG UNIV

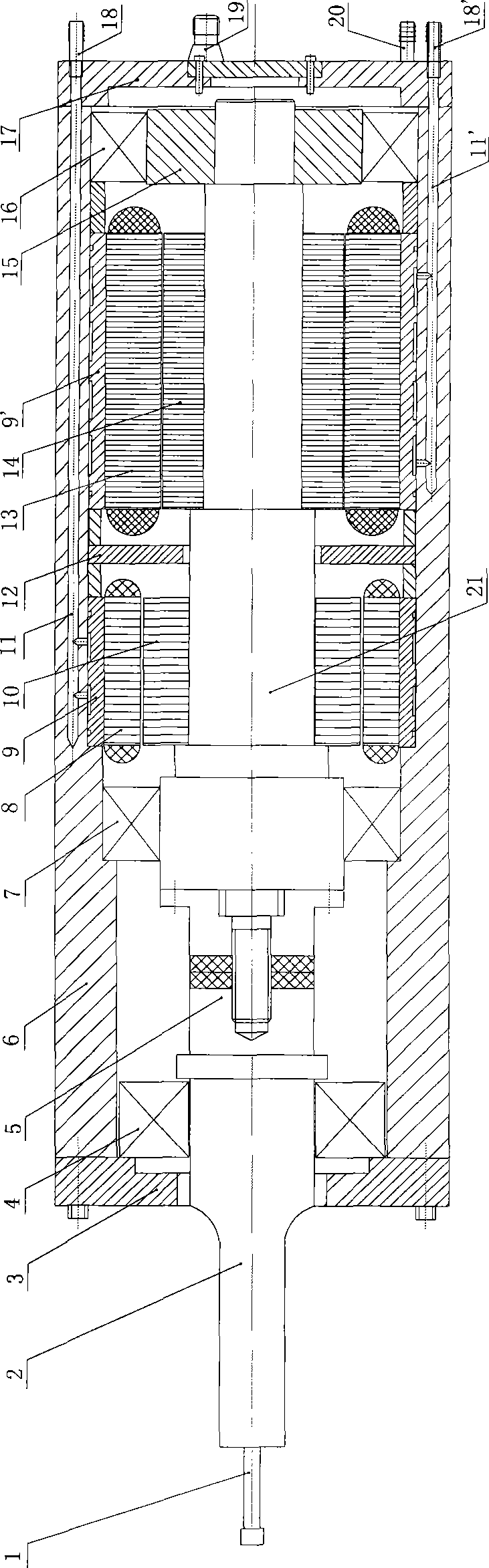

Induction type ultrasound electric principal shaft

InactiveCN101369757ASmooth vibrationIncrease speedPiezoelectric/electrostriction/magnetostriction machinesAsynchronous induction clutches/brakesTransducerContact type

The present invention discloses a induction type ultrasound electric principal shaft, which is composed of two parts: the rear part being an electric principal shaft and the front part being a ultrasound vibration system, electromagnetic field interference between the two parts being insulated by a shield ring, the motor making the principal shaft to rotate in high speed; the ultrasound vibration system is composed of an ultrasound transducer, a amplitude-variation lever and a tool head, and generates an axial ultrasound vibration of the principal shaft; an ultrasound driving signal is transmitted between a ultrasonic transmitter and a ultrasonic receiver with induction mode, wherein the non-contact type transmission signal being capable of omitting electrical brush, avoiding brush wear, reducing heating and improving greatly the rotary speed of the principal shaft; the principal shaft is supporting by a fore bearing, a middle bearing and a rear bearing, therefore the stiffness and rotating accuracy of the principal shaft can be improved, and the fore bearing is supported on the wave node point of the ultrasound vibration system, thus the vibration can be reduced; water-sealing covers are packed outside the motor and the ultrasound signal transmission system, and the cooled water ensures the principal shaft to be used in normal temperature all the time.

Owner:GUANGDONG UNIV OF TECH

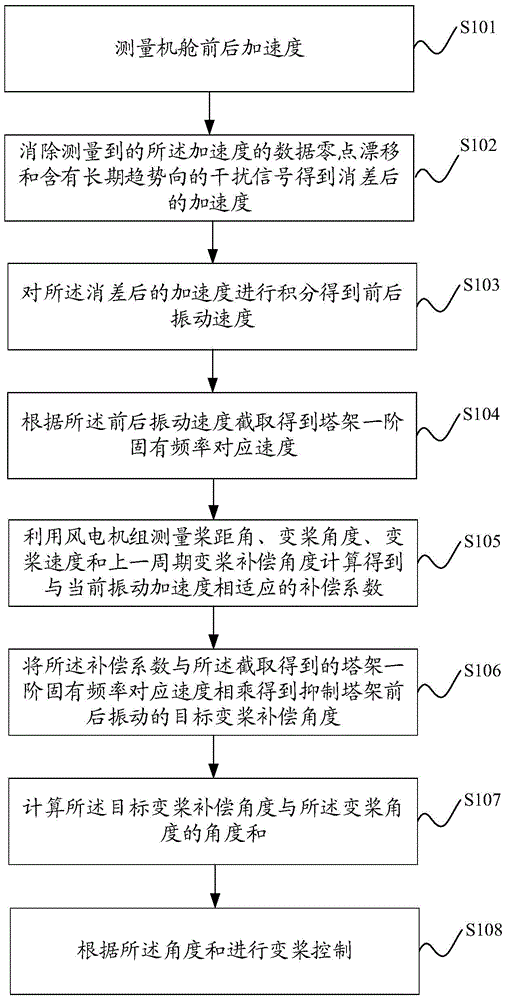

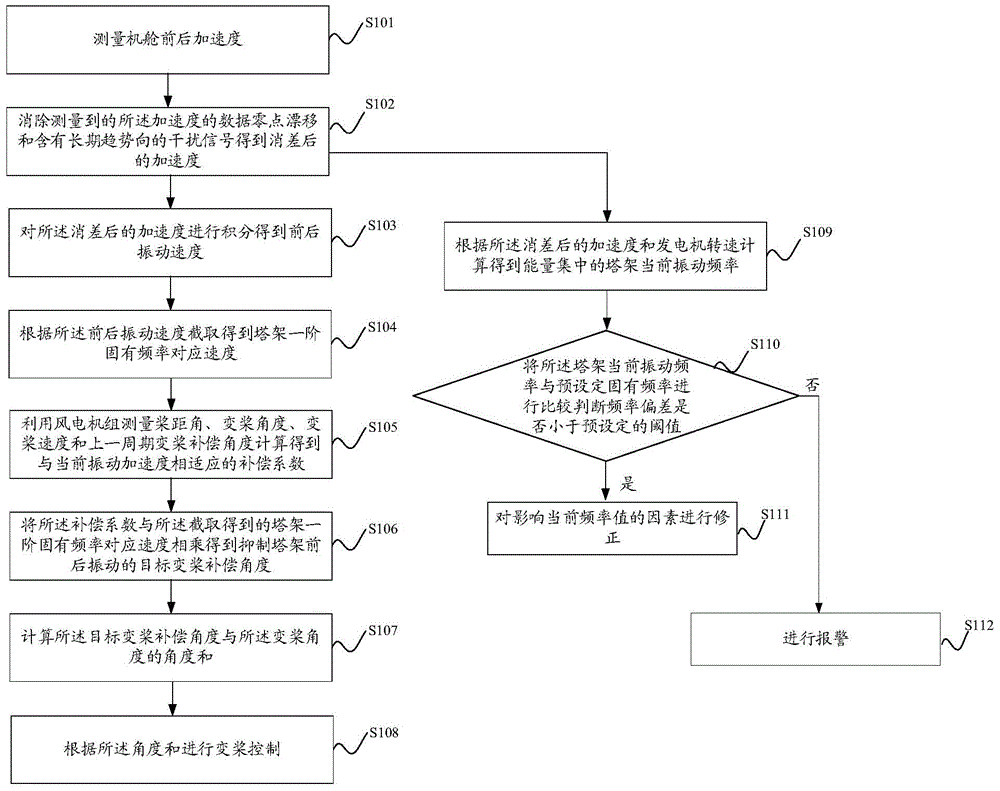

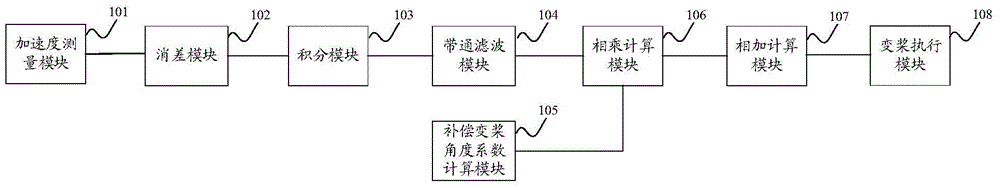

Method and system for suppressing tower vibration

ActiveCN104533717AReduce vibrationDampen front and rear vibrationsWind motor controlMachines/enginesTowerControl theory

The invention discloses a method and a system for suppressing tower vibration. Errors of sagittal acceleration are eliminated, compensation variable pitch angle coefficients are calculated to obtain compensation variable pitch angles needing adjustment for variable pitch control, and sagittal tower vibration can be accurately and stably suppressed by adjusting the compensation variable pitch angles without changing the running state of a unit.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

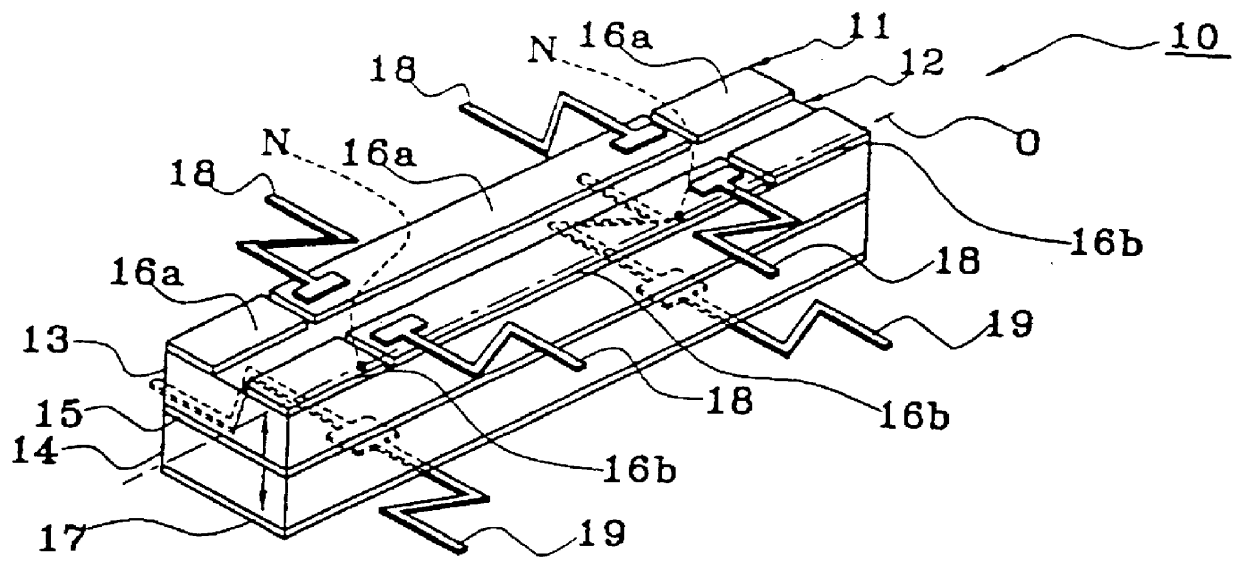

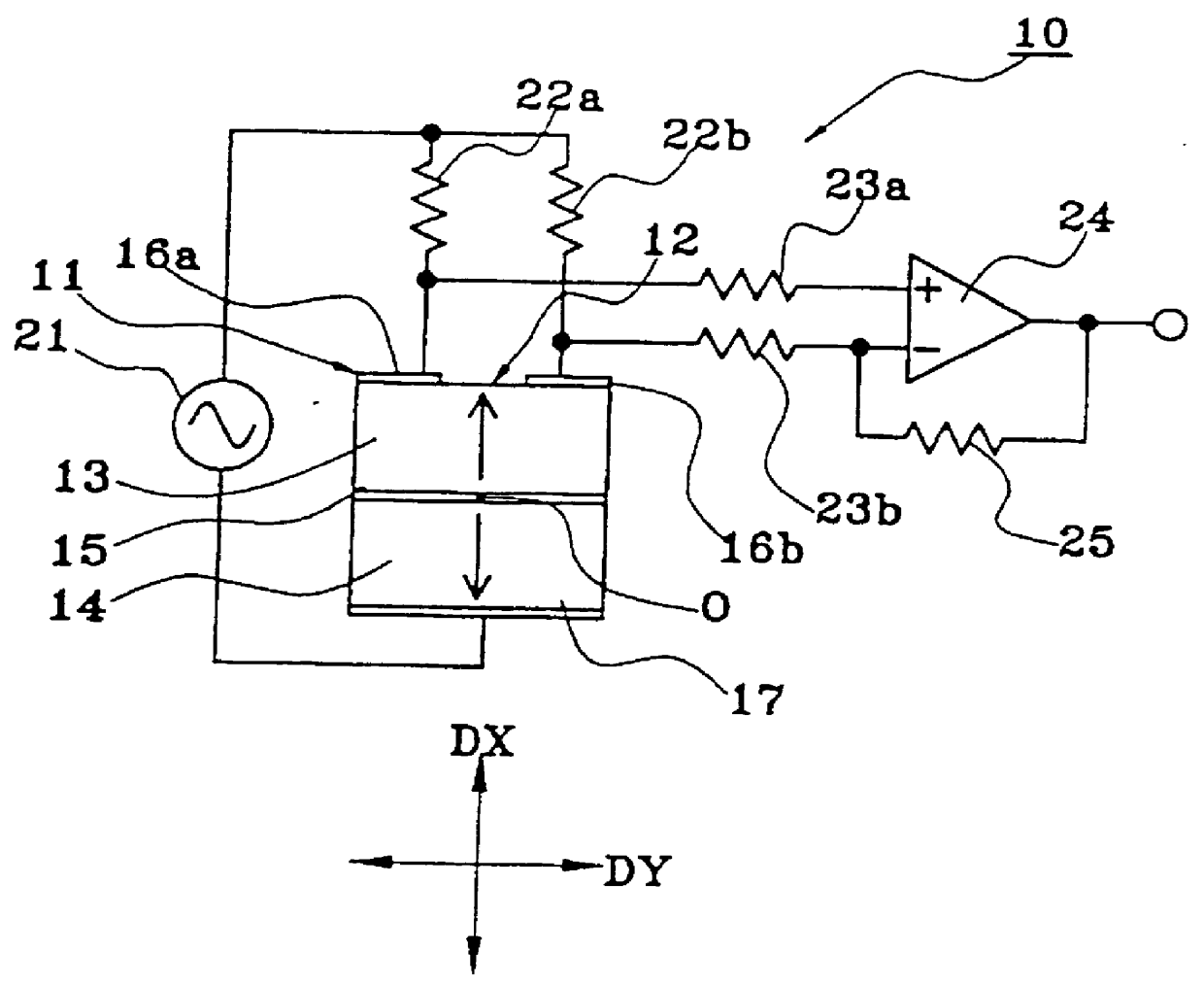

Vibrating gyroscope and adjusting method therefor

InactiveUS6023973ASmooth vibrationResonant frequencyAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesGyroscopeDiagonal

A vibrating gyroscope includes a columnar vibrator, a driver and a detector. The columnar vibrator includes first and second piezoelectric substrates polarized in mutually opposite directions along the thickness directions thereof and stacked with each other. Two divided electrodes are formed on one main surface of the first piezoelectric substrate and spaced in the direction perpendicular to the longitudinal direction of the first piezoelectric substrate, and a common electrode is formed on one main surface of the second piezoelectric substrate. The driver drives the vibrator in the thickness direction of the first and second piezoelectric substrates and is connected between the divided electrodes and the common electrode. The detector detects a displacement caused by bending vibration of the vibrator, and is connected to the divided electrodes. The vibrator has substantially the same resonant frequency in the two diagonal directions which diagonally connect four edges elongating in the longitudinal direction of the vibrator.

Owner:MURATA MFG CO LTD

Vibration actuator

Owner:COPAL CO LTD

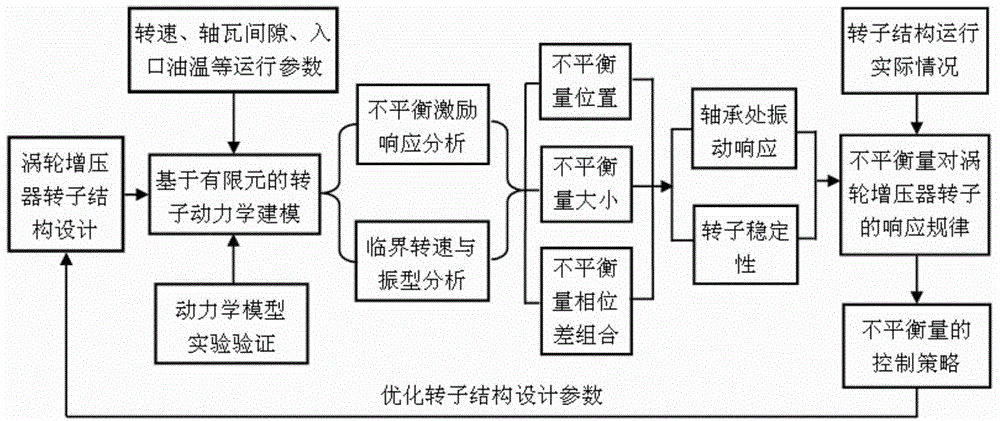

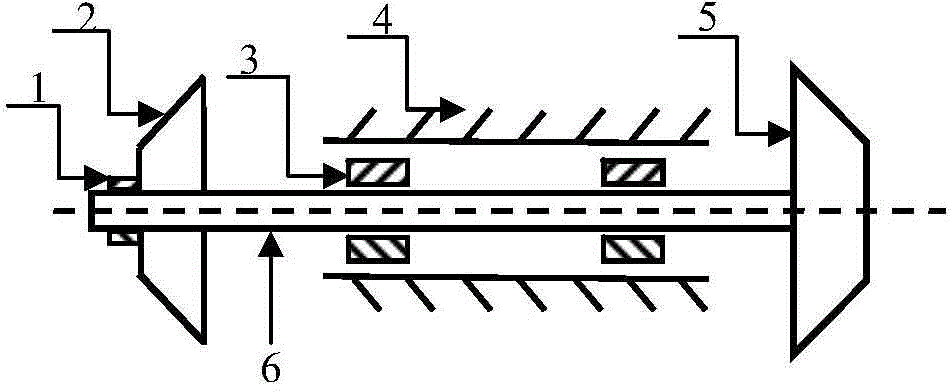

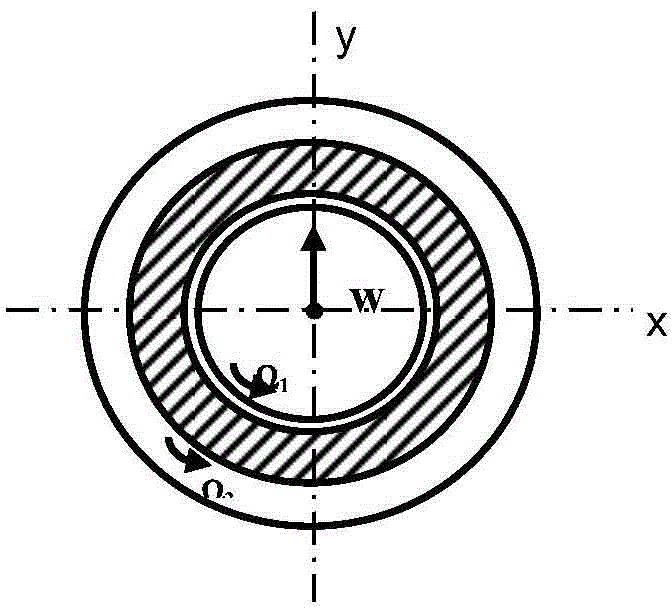

Turbocharger rotor unbalance amount control method based on dynamic characteristics

ActiveCN104458128AReduce unbalanced vibration failuresReduce maintenance costsStatic/dynamic balance measurementSystem dynamicsVibration amplitude

The invention discloses a turbocharger rotor unbalance amount control method based on dynamic characteristics. The method comprises the steps that a turbocharger rotor bearing system dynamics finite element solid model is built; (2) different unbalance amount excitation modes are applied to the dynamics finite element solid model, and vibration responses and stability rules of turbocharger rotor unbalance position, size and phase difference to the measuring points of two bearings are summarized; (3) the optimum allocation scheme of unbalance excitation on the rotor position, size and phase difference is determined with the minimum root-mean-square value of the vibration amplitude as the judging criteria; (4) turbocharger rotor structure parameters are optimized until the vibration amplitudes at the positions of the two turbocharger rotor bearings are the minimum and the stability at the positions of the two turbocharger rotor bearings is the best. According to the turbocharger rotor unbalance amount control method, unbalance control is applied in the turbine end and air pressing end structure design and manufacturing process, stable and efficient running of the whole machine can be achieved, and unbalance vibration faults caused in the rotor running process are effectively reduced.

Owner:宁波丰沃增压科技股份有限公司

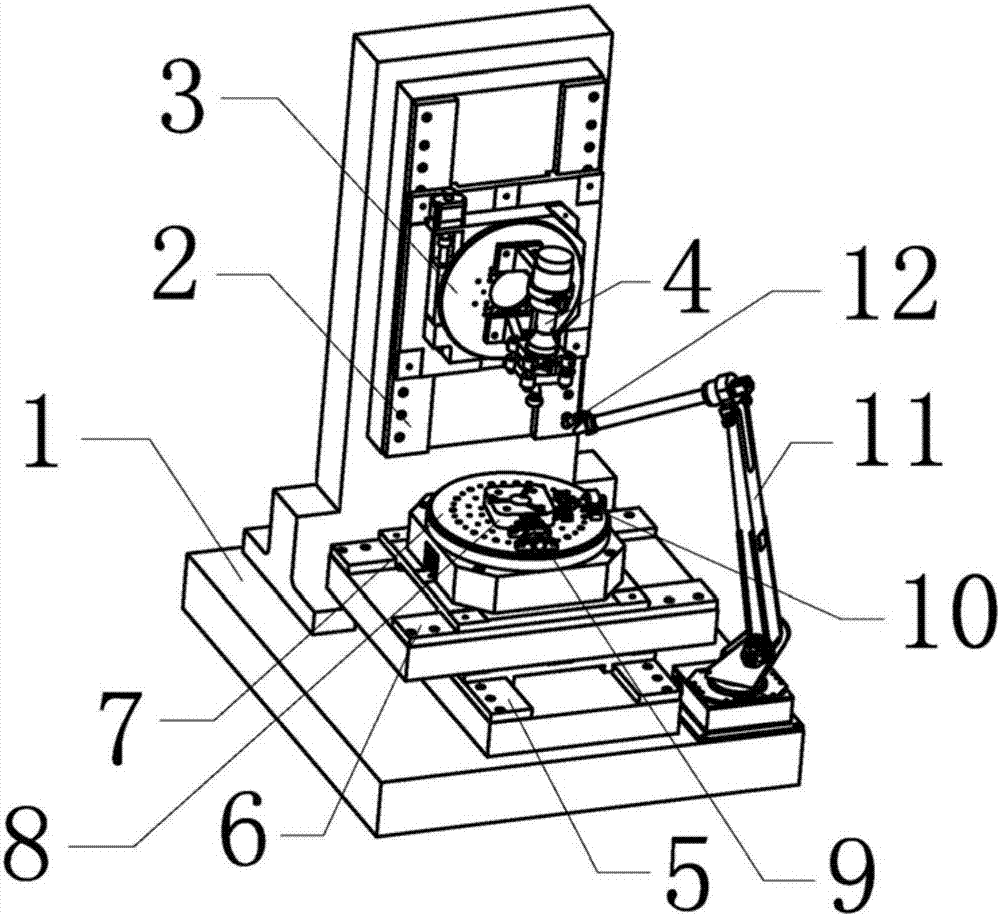

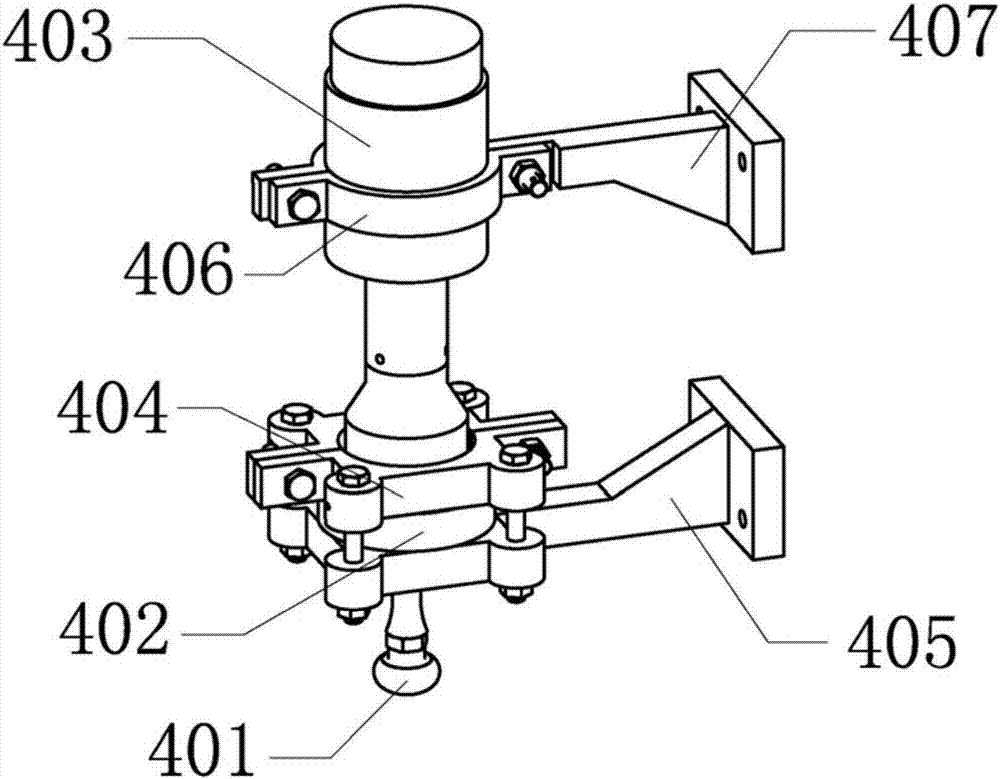

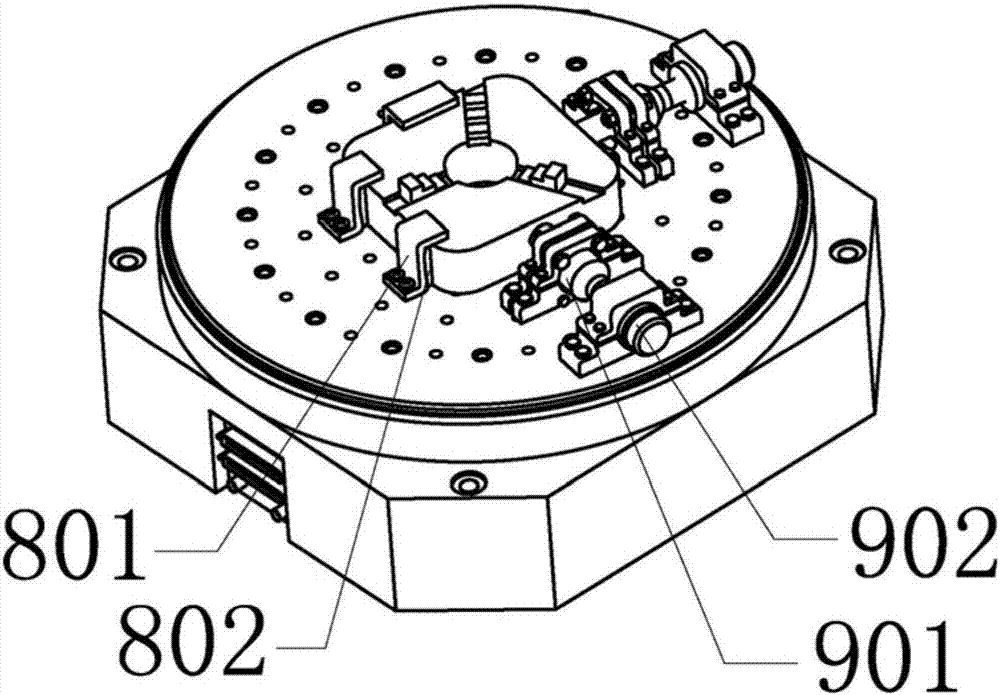

High-precision five-shaft multi-dimensional ultrasonic polishing device

PendingCN107009200AChange processing characteristicsSmooth vibrationGrinding carriagesPolishing machinesRotary stagePolishing

The invention relates to a high-precision five-shaft multi-dimensional ultrasonic polishing device, and belongs to the field of polishing of a complicated curved surface element which has high precision and is difficult to machine. An upright guide rail is arranged at the upper part of an L-shaped base; an upright rotary table capable of moving up and down is arranged on the upright guide rail; a polishing tool head vibrator assembly is arranged on the upright rotary table; a horizontal guide rail I is arranged at the lower part of the L-shaped base; a horizontal guide rail II capable of moving forwards and backwards is arranged on the horizontal guide rail I; a horihzontal rotary tool table capable of moving leftwards and rightwards is arranged on the horizontal guide rail II; the vibration radiation surfaces of ultrasonic vibration exciting assemblies I and II in the horizontal rotary tool table are respectively in contact with two mutually perpendicular side surfaces of a workpiece clamp; one end of a three-degree-of-freedom mechanical arm is connected to the lower part of the L-shaped base in a rotatable manner; and an ultrasonic atomization spraying head is arranged at the other end of the three-degree-of-freedom mechanical arm. The device comprises multiple guide rails and the rotary table, thus providing five degrees of freedom, and can realize polishing of a complicated curved surface to complete machining of a complicated part which is difficult to machine with an existing machine tool.

Owner:NORTHEASTERN UNIV LIAONING

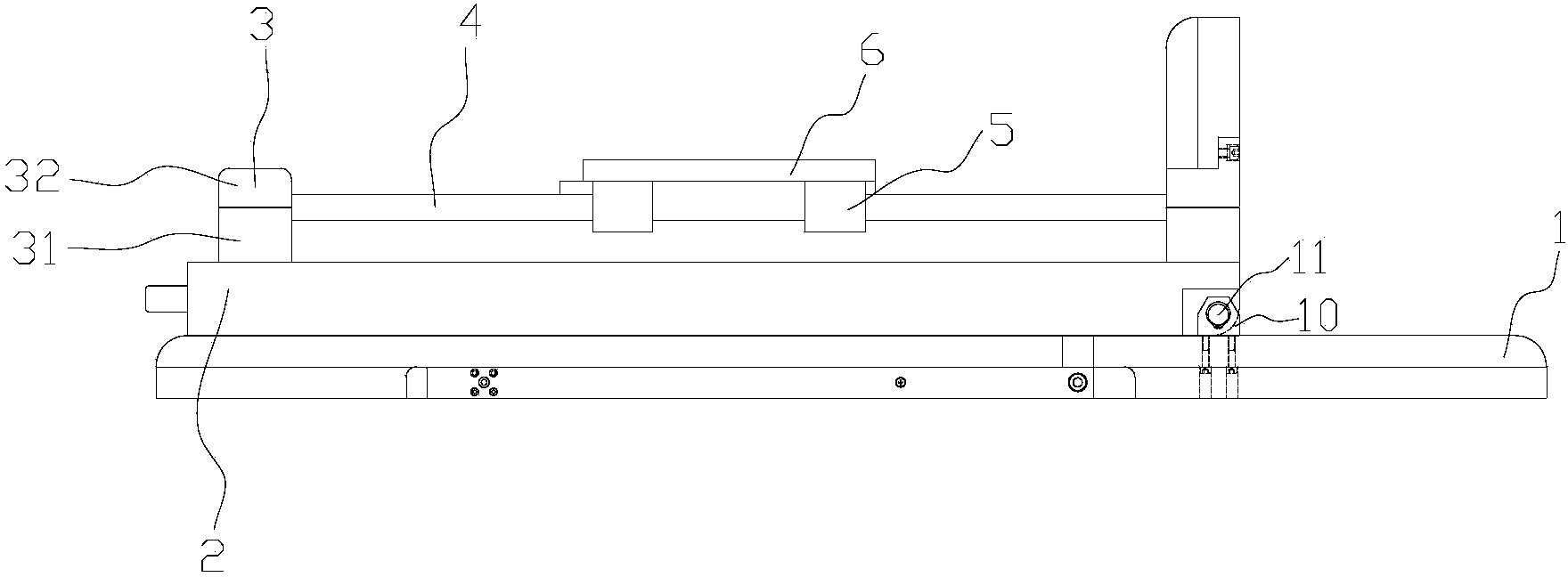

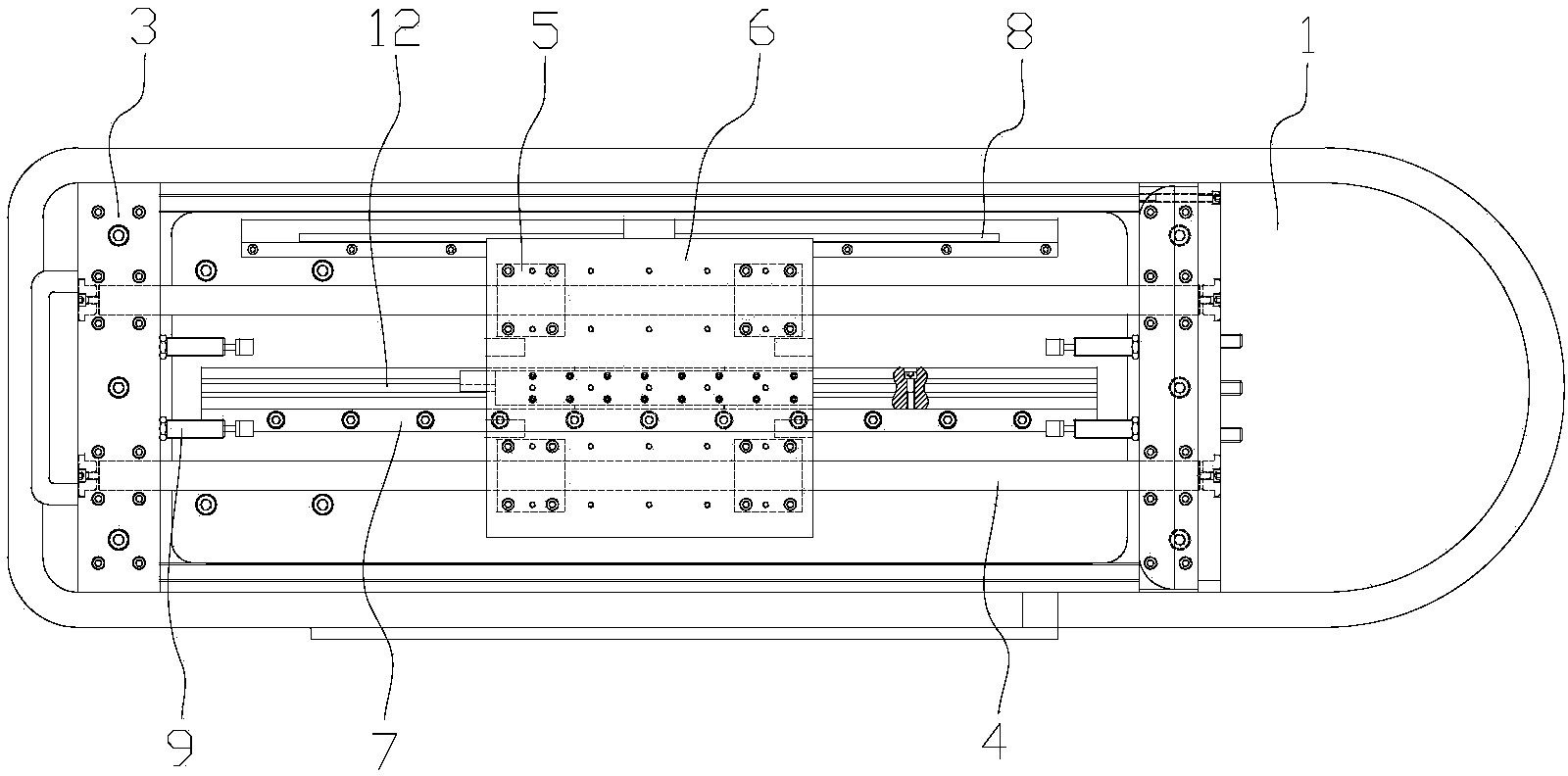

Low frequency calibration vibrating table

ActiveCN103925940AReduce low frequency vibrationLarge vibration displacementInstrumentsAir bearingGrating

The invention discloses a low frequency calibration vibrating table which comprises a mounting seat. Supports, guide shafts, a working table, a linear motor and a grating ruler are arranged on the mounting seat, the two supports are fixedly arranged at the two ends of the mounting seat respectively in the width direction of the mounting seat, at least two guide shafts are fixedly arranged between the supports in a spaced mode, at least one air bearing is arranged on each guide shaft in a sleeved mode, the working table is fixedly arranged on the air bearings, the linear motor is located between the guide shafts and is fixedly arranged on the mounting seat, the linear motor is fixedly connected to the lower end face of the working platform, and the grating ruler is fixedly arranged on one side of the mounting seat in the length direction. The low frequency calibration vibrating table has the advantages of being wide in vibrating frequency range, large in vibrating displacement and the like, is small in harmonic distortion and provides a good platform for the calibration of low frequency vibration acceleration sensors.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

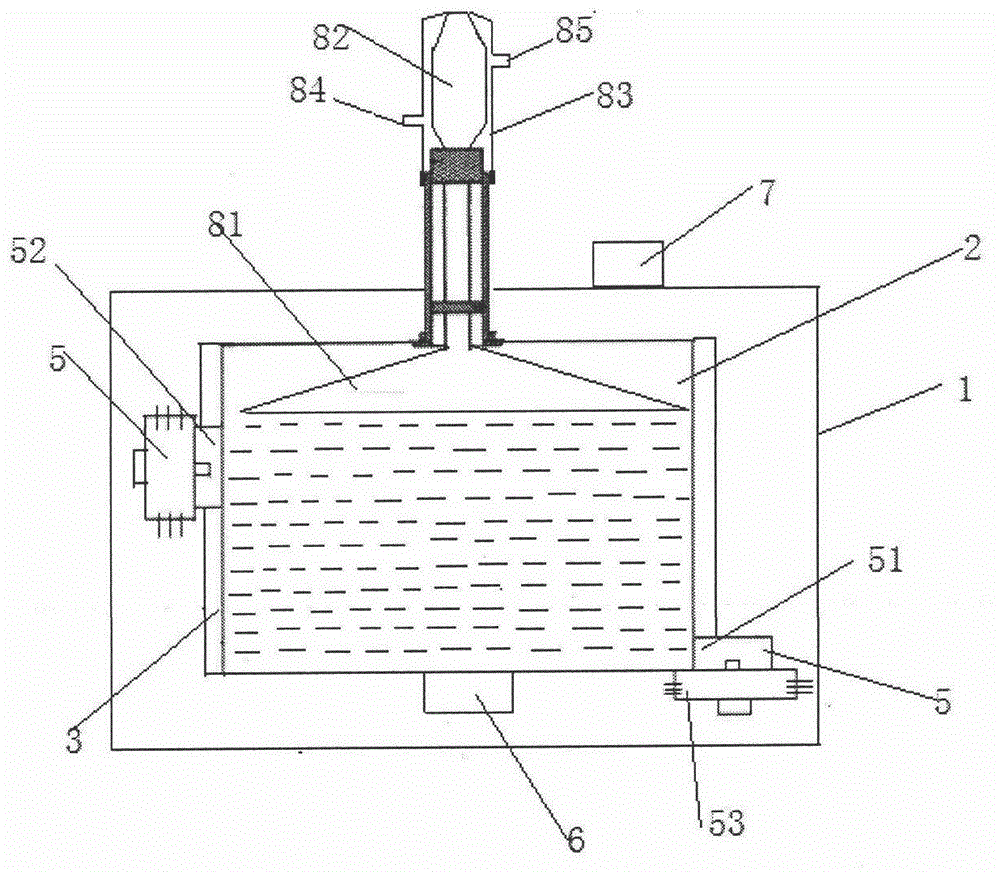

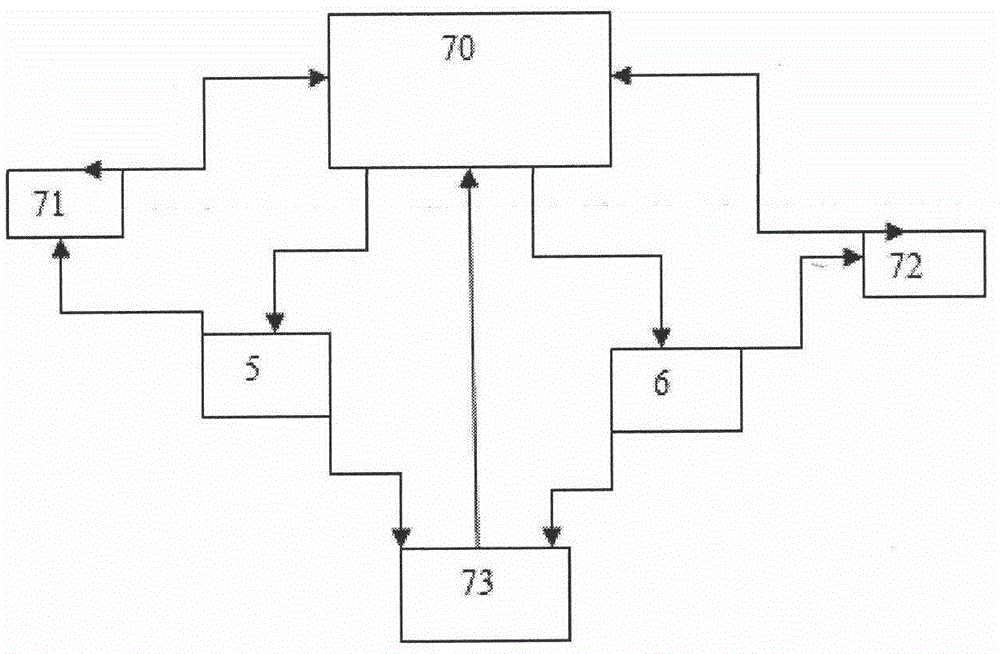

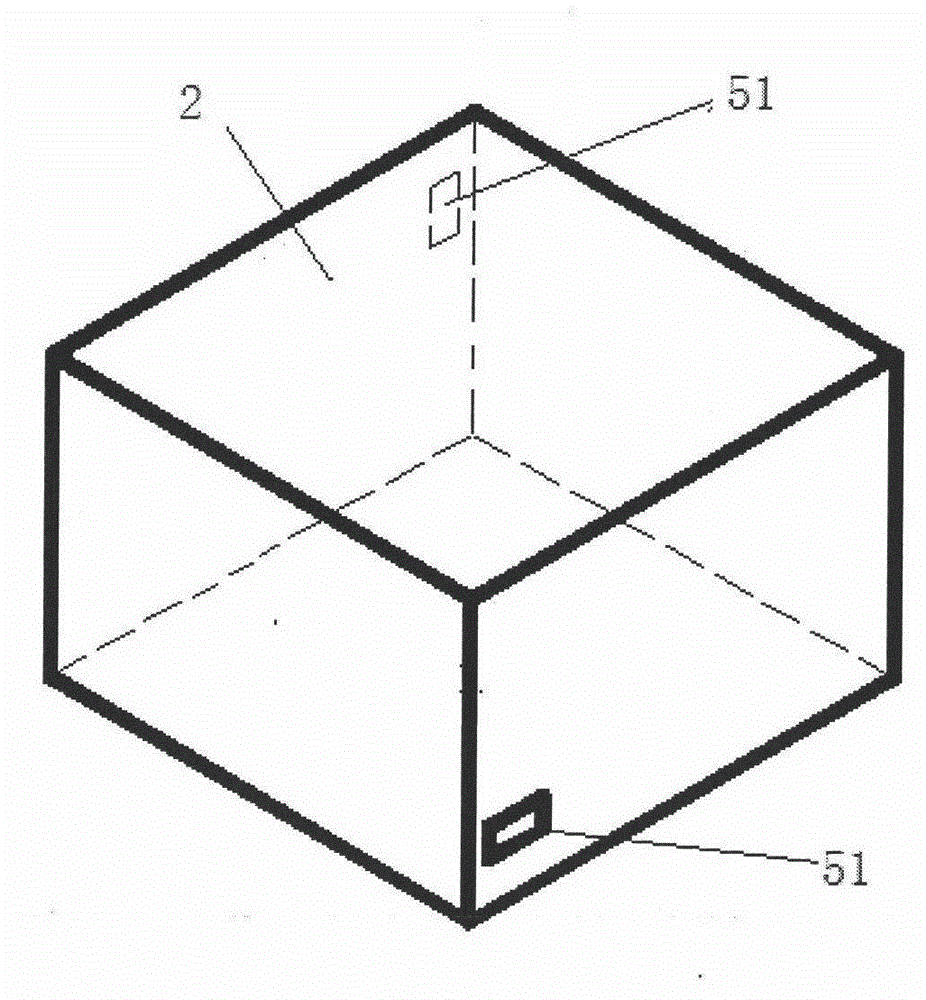

Ultrasonic wave and microwave extraction system with reflux devices

InactiveCN104014158AShear vibration field strengthExpand the vibration areaEnergy based chemical/physical/physico-chemical processesSolid solvent extractionStopped workMicrowave

The invention provides an ultrasonic wave and microwave extraction system for traditional Chinese medicines. The system is provided with a coordinated regulation device, wherein a first alarm device, a second alarm device and a third alarm device are arranged on the coordinated regulation device; the coordinated regulation device firstly controls microwave lead-in devices to lead in microwaves, after a certain time, the first alarm device sends an alarm signal to the coordinated regulation device, and the coordinated regulation device controls an ultrasonic wave lead-in device to lead in ultrasonic waves; after a certain time, the second alarm device sends an alarm signal to the coordinated regulation device, and the coordinated regulation device controls the microwave lead-in devices and the ultrasonic wave lead-in device to change the operating powers to be respectively lower than the initial powers of the microwave lead-in devices and the ultrasonic wave lead-in device; the third alarm device sends an alarm signal to the coordinated regulation device after the microwave lead-in devices and the ultrasonic wave lead-in device work with the changed operating powers for a certain time, and the coordinated regulation device firstly controls the microwave lead-in devices to stop working and then controls the ultrasonic wave lead-in device to stop working. The best matching effects of ultrasonic waves and microwaves are achieved by arranging the coordinated regulation device to strictly control the lead-in time, lead-in order, lead-in powers and closing time of the ultrasonic waves and the microwaves.

Owner:王茜南

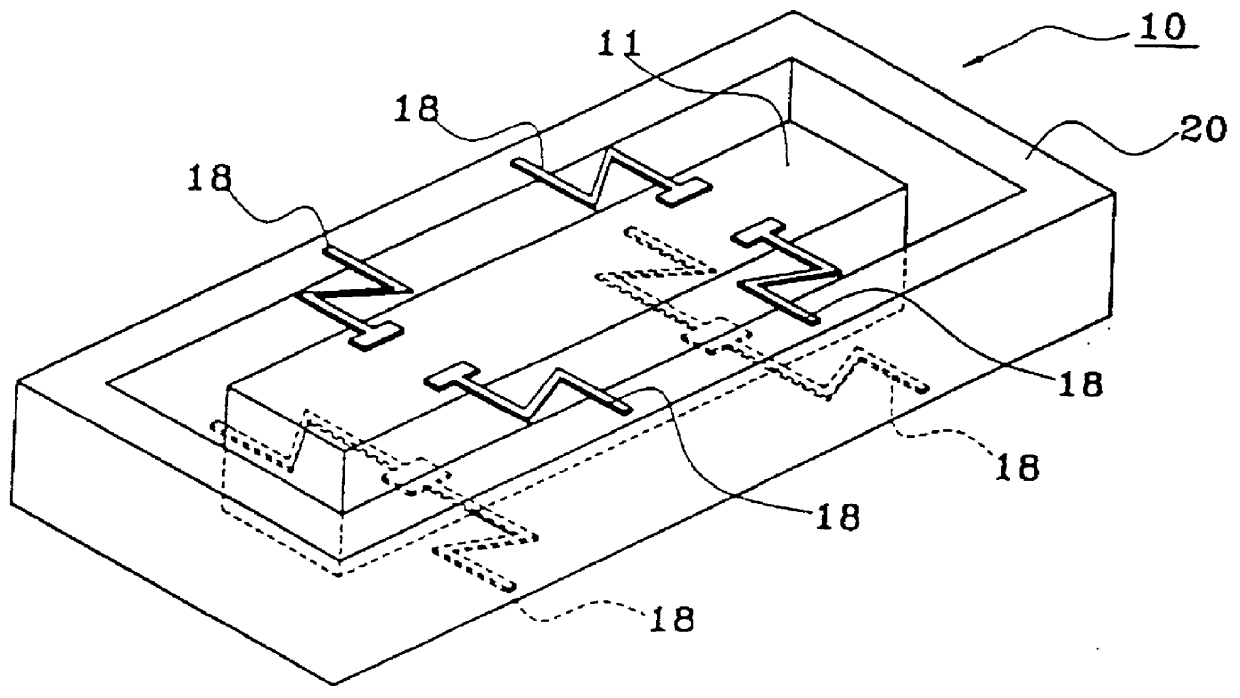

Capacitor microphone

InactiveCN101189910ASmooth vibration without disturbanceSmooth vibrationElectrostatic transducer microphonesEngineeringSound wave

A capacitor microphone is constituted by a plate having a fixed electrode, a diaphragm including a center portion and at least one near-end portion that is fixed to the outer periphery, in which the center portion having a vibrating electrode, which is positioned relative to the fixed electrode and which vibrates in response to sound waves, is increased in rigidity in comparison with the near-end portion; and a spacer that is fixed to the plate and the near-end portion of the diaphragm and that has an air gap formed between the plate and the diaphragm. Alternatively, a diaphragm electrode is horizontally supported by extension arms extended from a circular plate thereof and is vertically held in a hanging state being apart from a fixed electrode with a controlled distance therebetween.

Owner:YAMAHA CORP

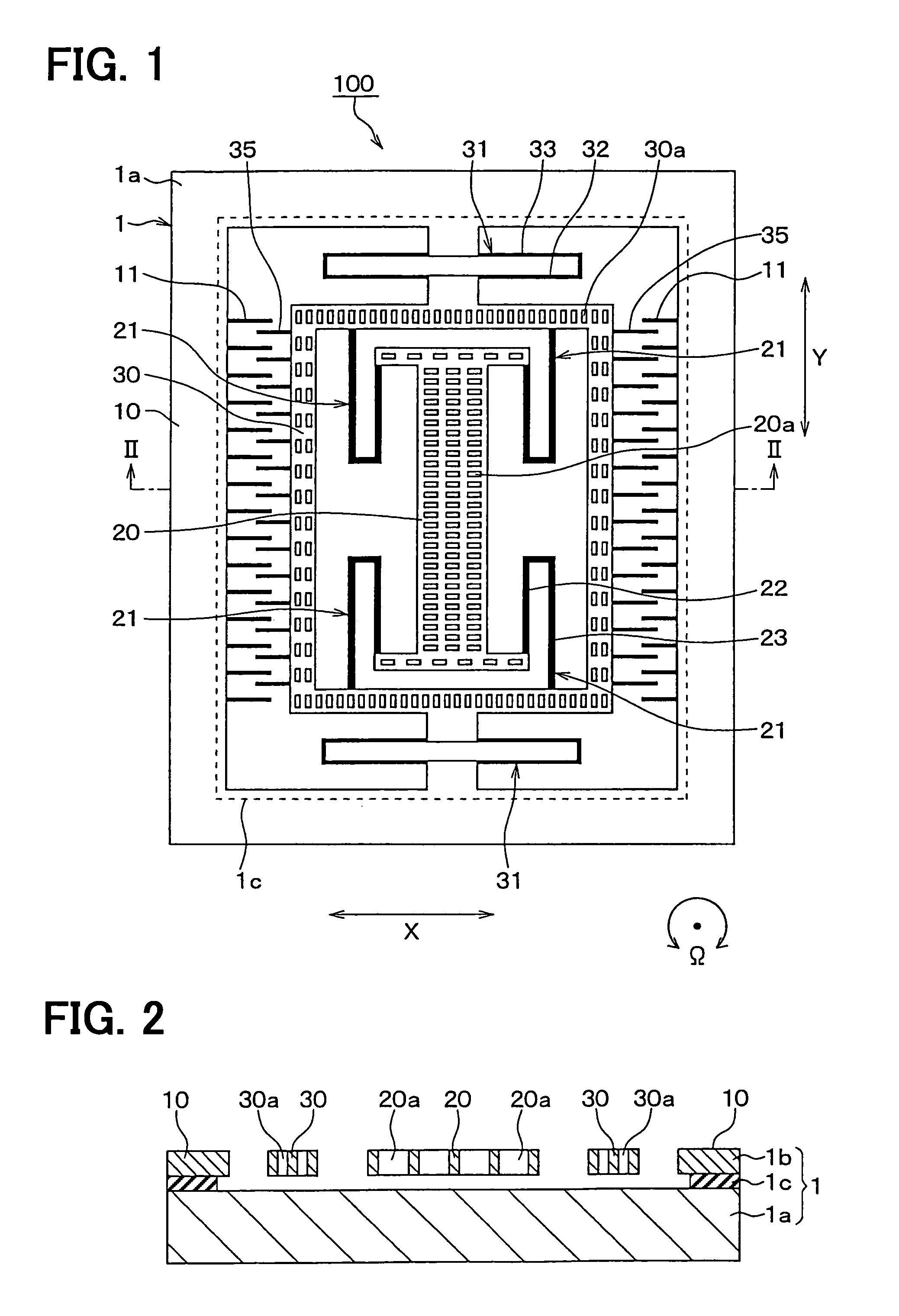

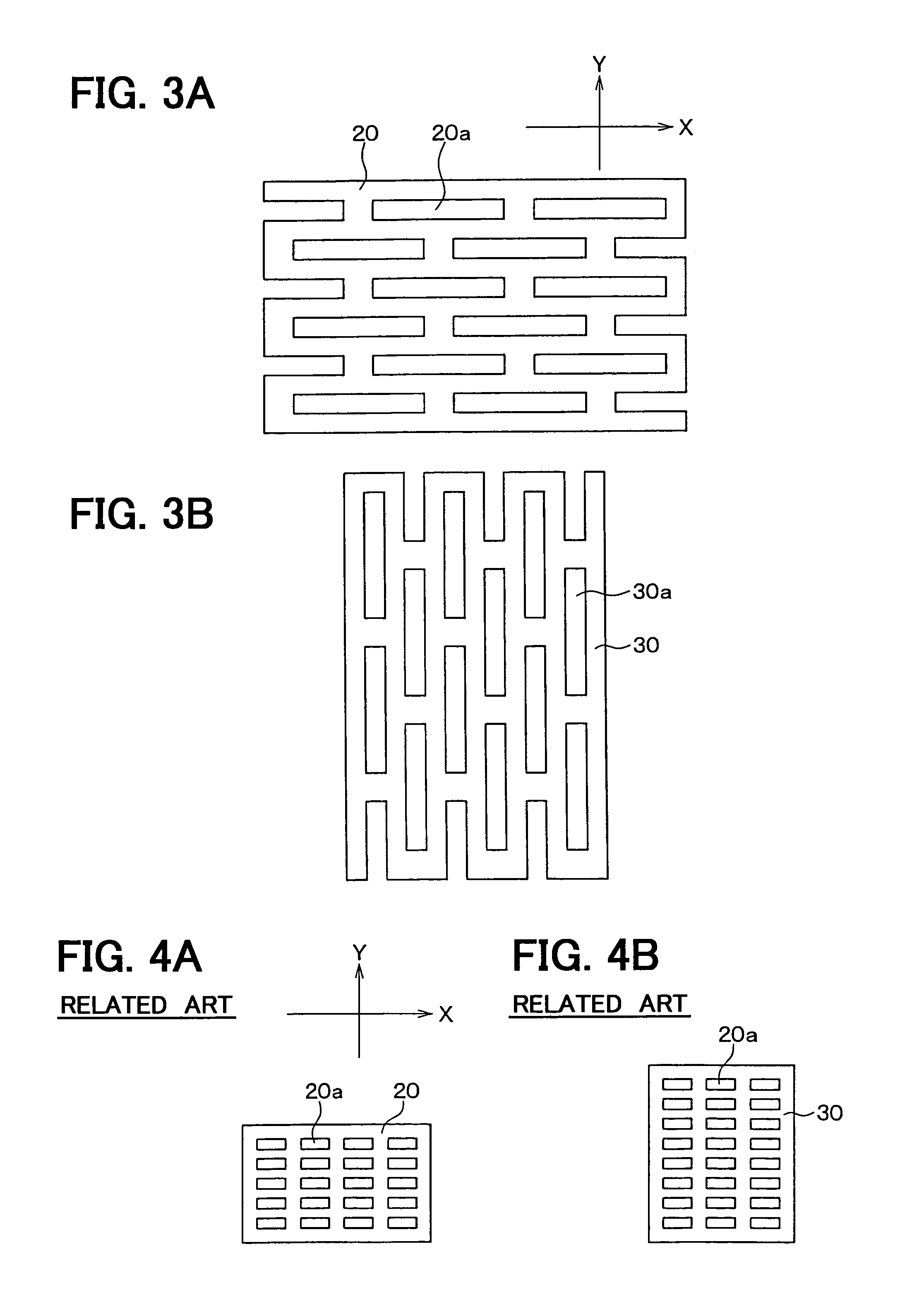

Physical quantity sensor having movable portion

InactiveUS7302847B2Smooth vibrationImprove accuracyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular rate sensorEngineering

An angular rate sensor includes: a support substrate; a semiconductor layer; and a movable portion. The movable portion includes a driving vibration portion and a detecting vibration portion. The driving vibration portion is capable of vibrating in a first direction. The detecting vibration portion is capable of vibrating in a second direction. The driving vibration portion includes through holes, and the detecting vibration portion includes thorough holes. Each through hole of the driving vibration portion has an elongated shape extending in the first direction. Each through hole of the detecting vibration portion has an elongated shape extending in the second direction.

Owner:NIPPON SOKEN +1

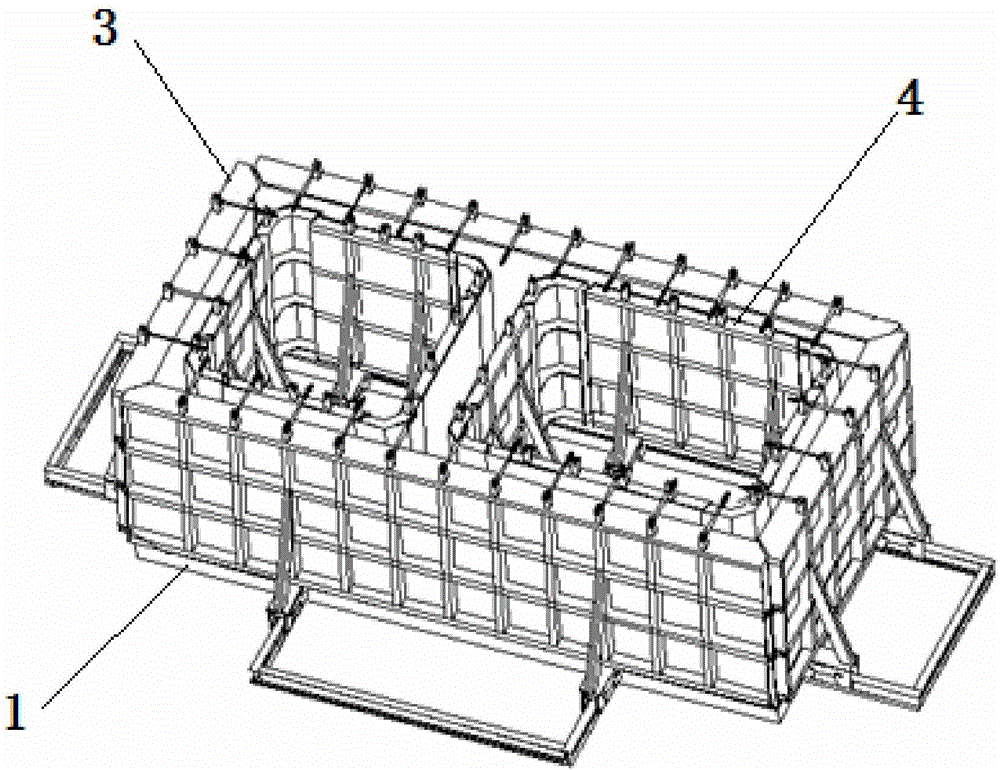

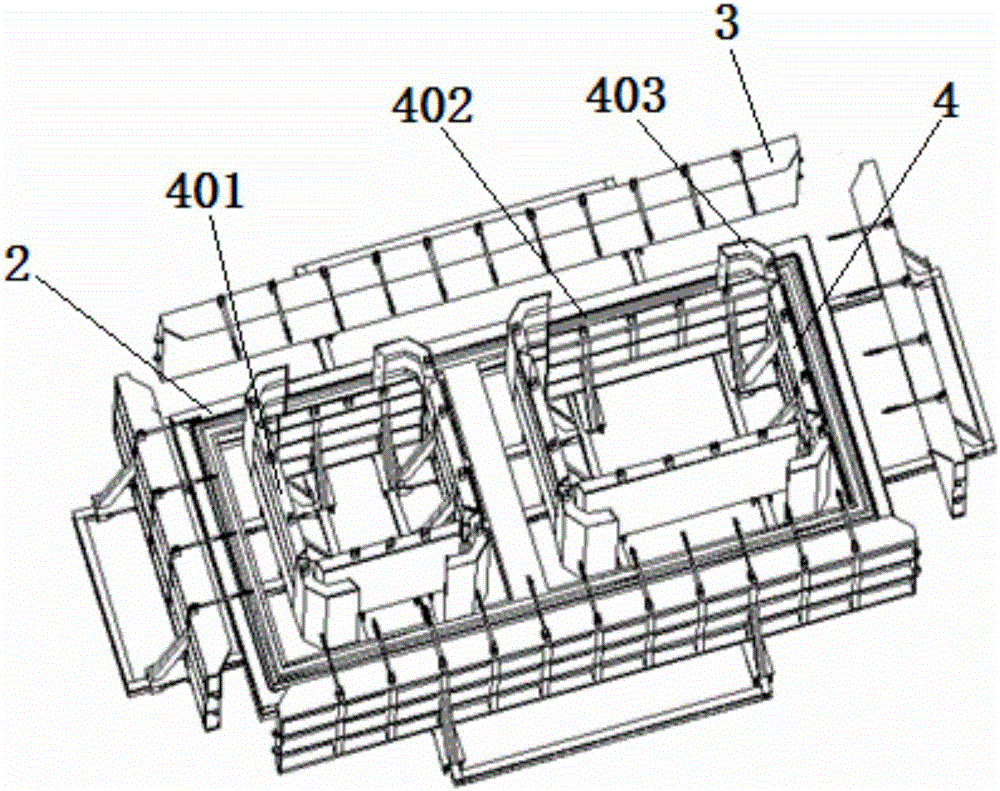

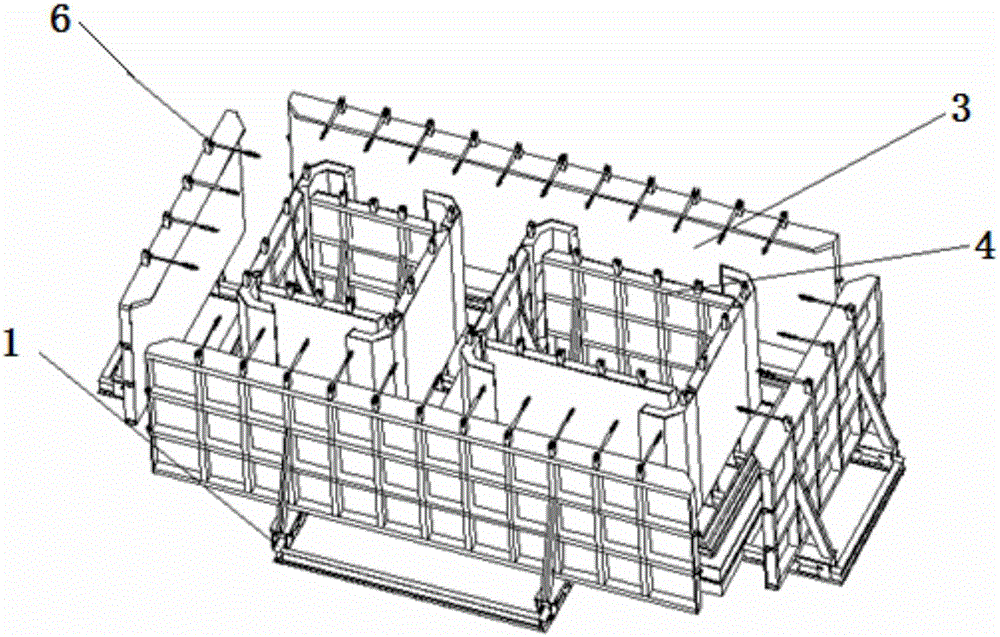

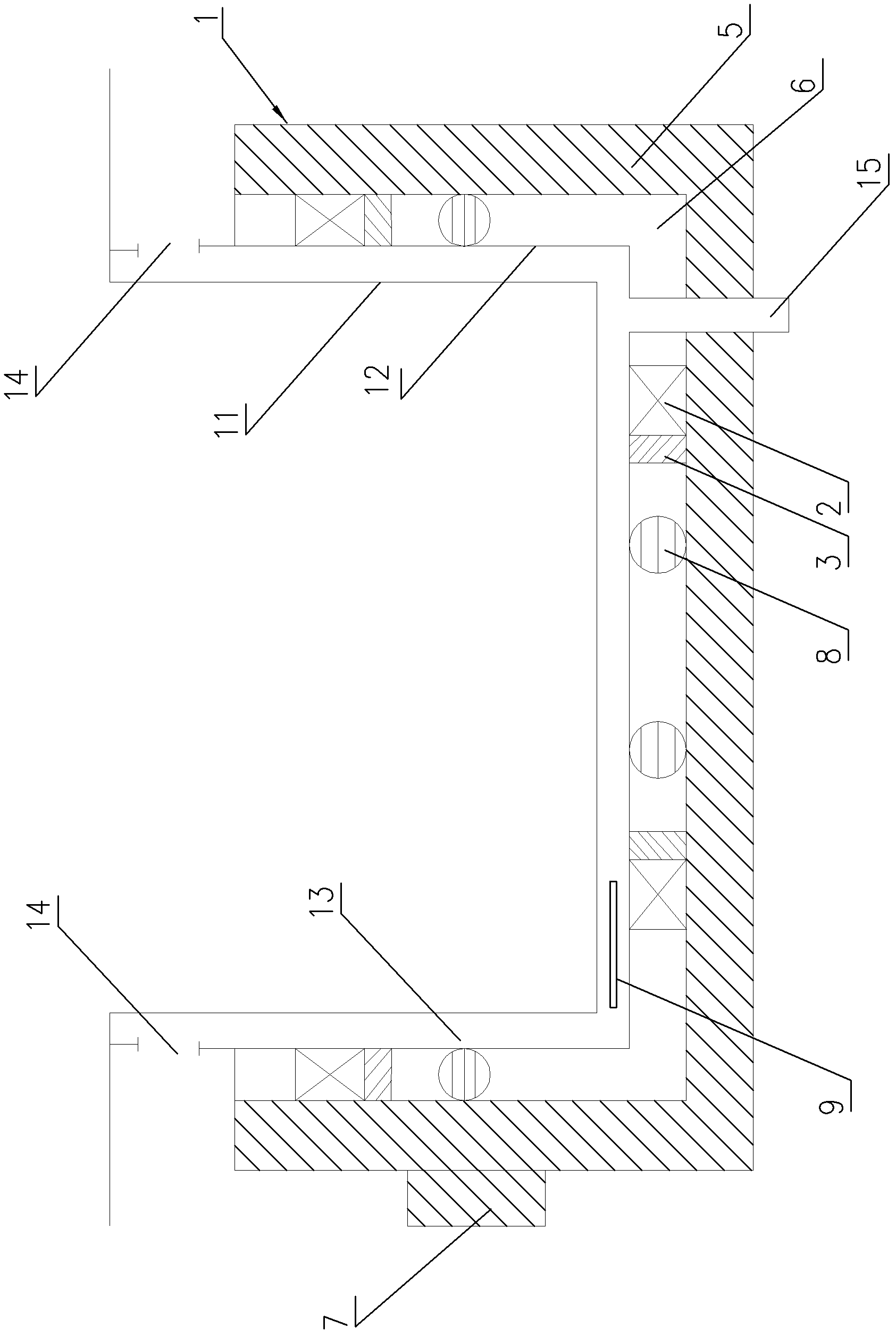

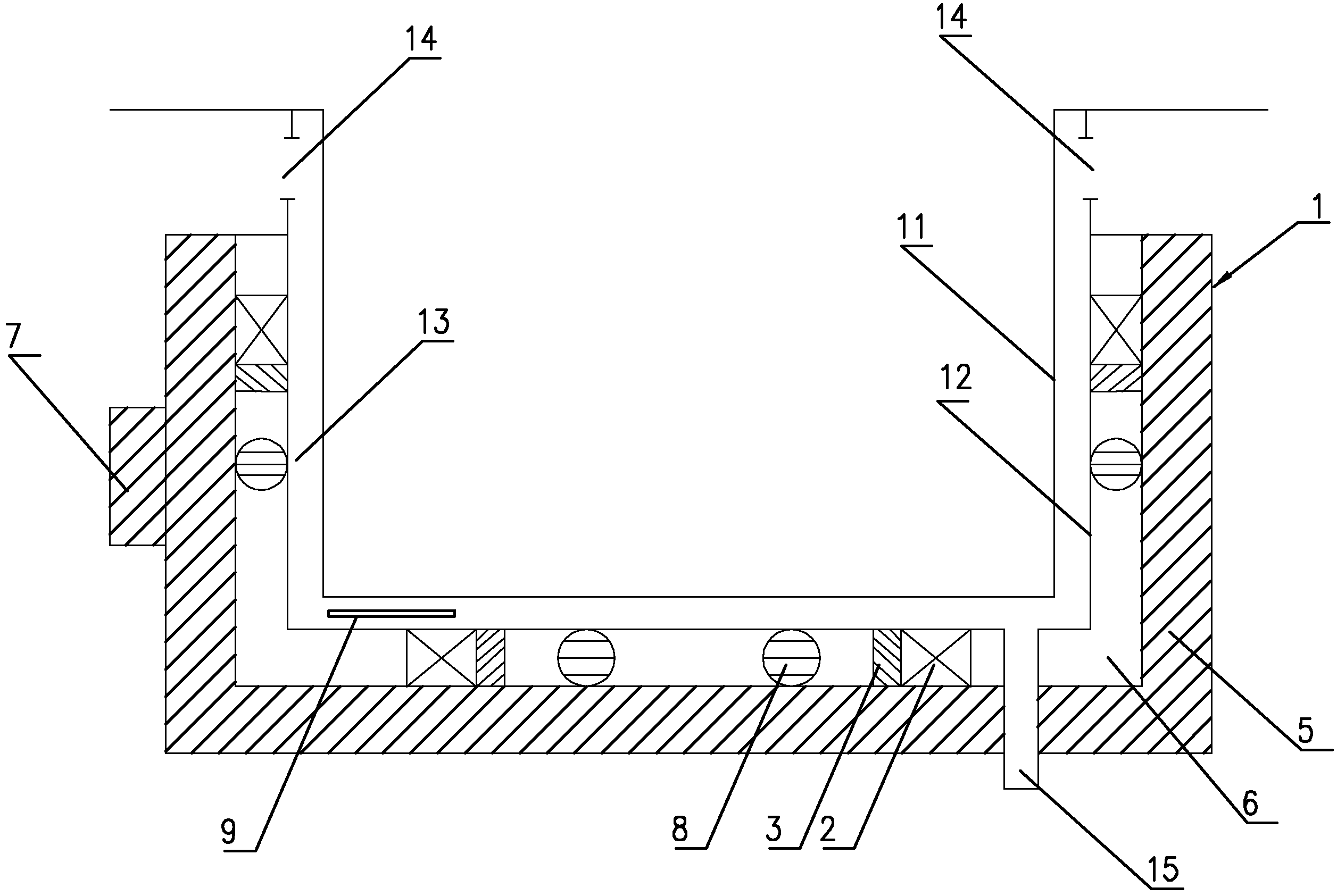

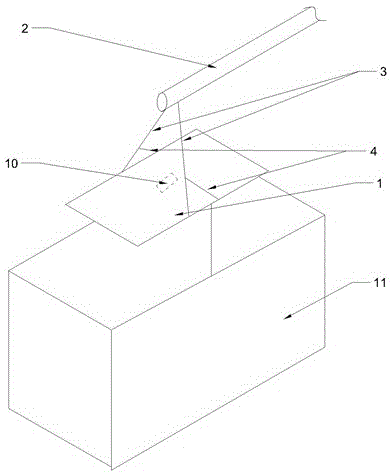

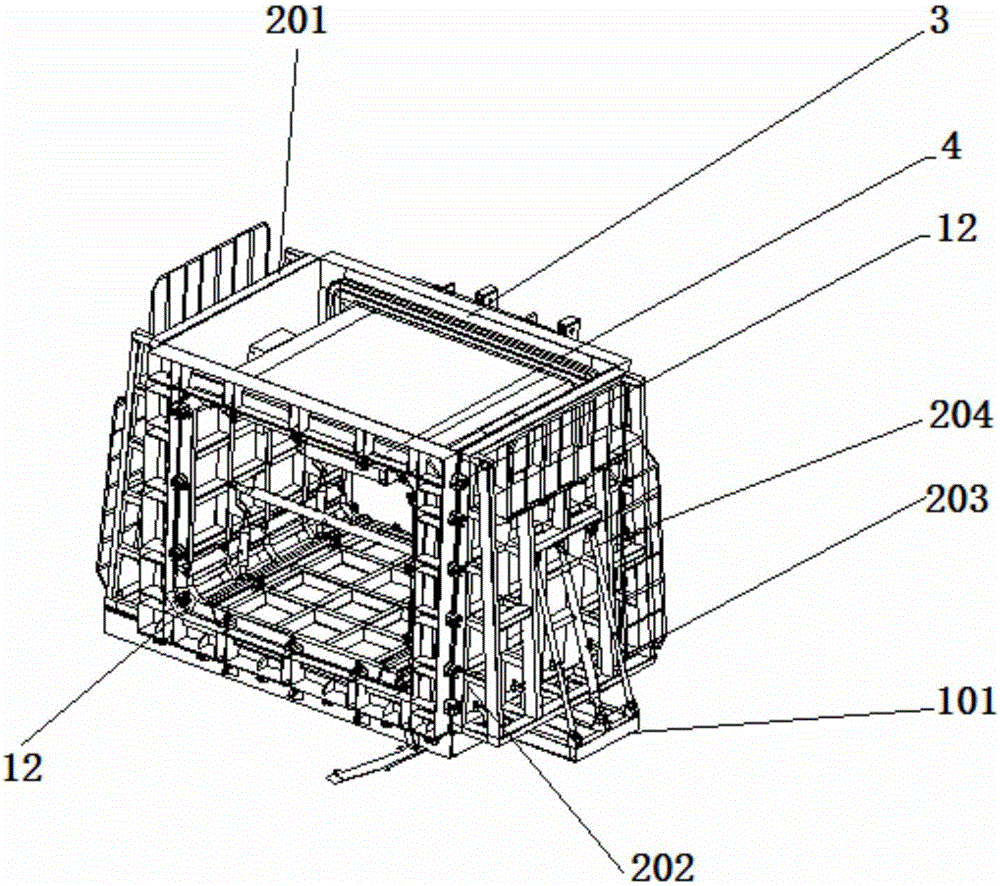

Vertical molding mold and system and application method for concrete utility tunnel

InactiveCN106346595AIncrease production capacityIncrease pouring speedMouldsMould auxillary partsUtility tunnelMaterials science

The invention discloses a vertical molding mold for a concrete utility tunnel. The vertical molding mold comprises a mold base (1), a female end mold (2), an external mold (3) and one or more internal molds (4). The mold base (1) is fixed on the ground, the female end mold (2) is arranged on the mold base (1), the external mold (3) is arranged on the mold base (1) and located on the periphery of the outer side of the female end mold (2), one or more internal molds (4) are arranged on the mold base (1) and located on the periphery of the inner side of the female end mold (2). The molding mold and system and production technology for the concrete single-cabin, dual-cabin and multiple-cabin utility tunnel is high in quality and large in scale and can be rapidly and largely produced.

Owner:CHANGSHA CHUHONG MACHINERY

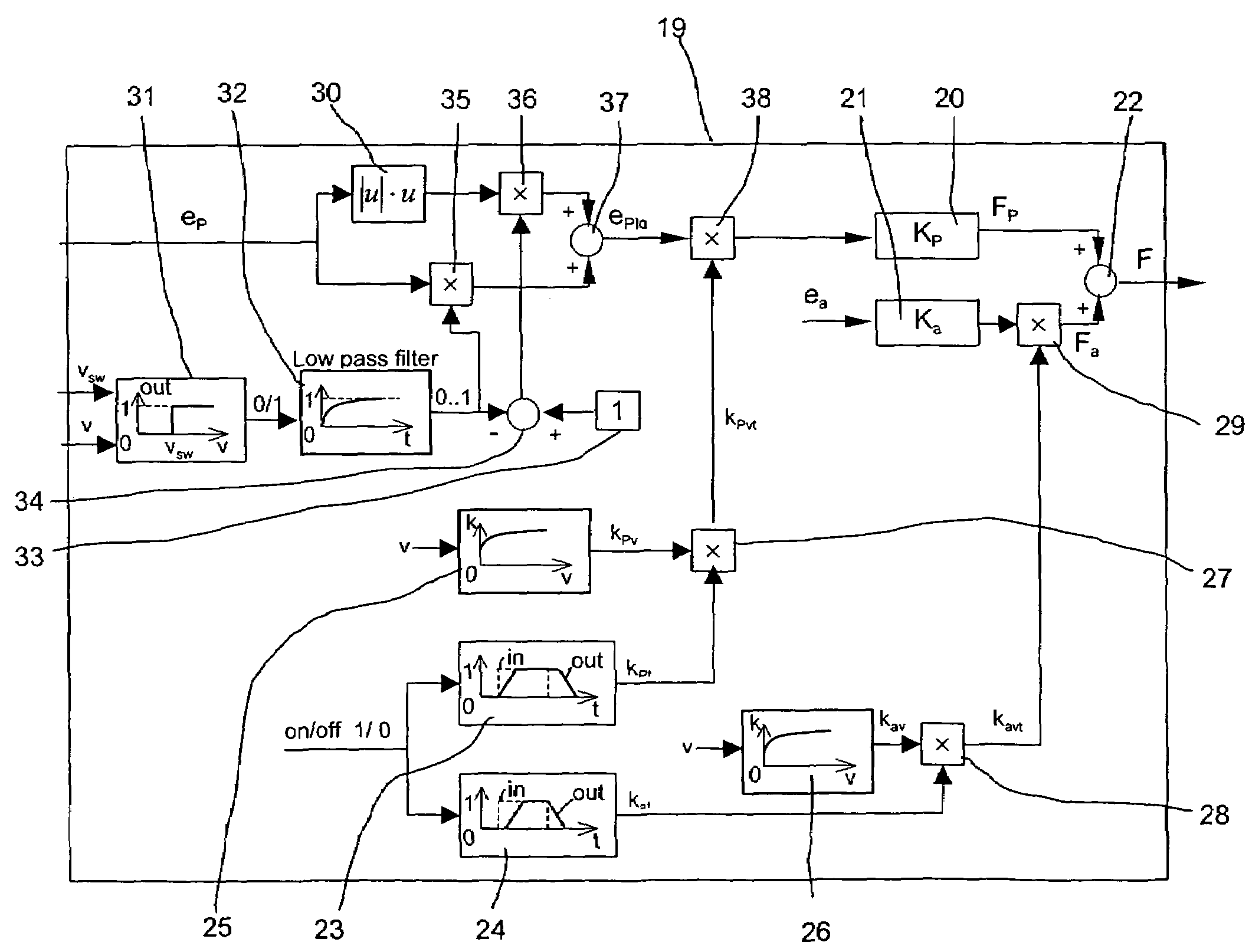

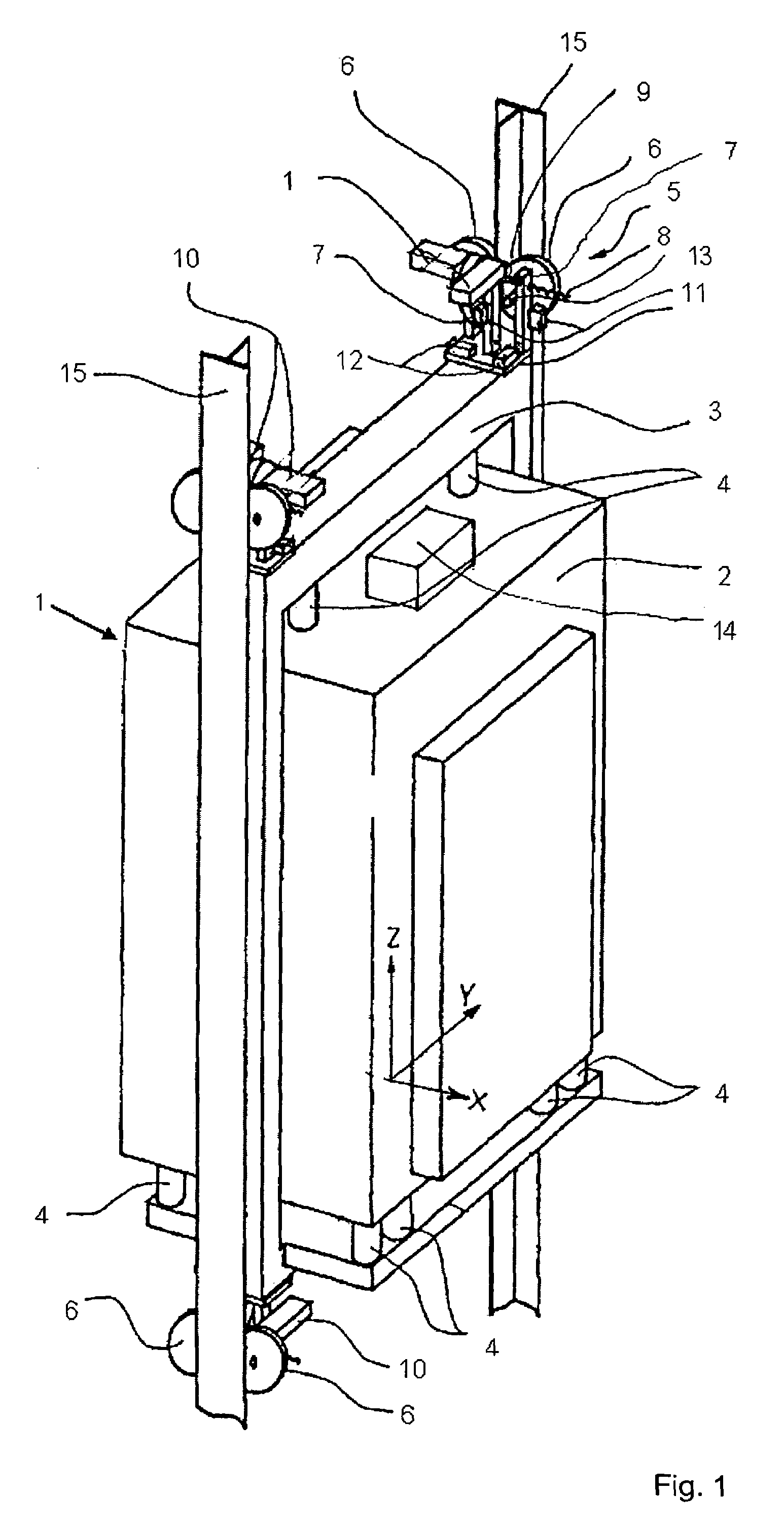

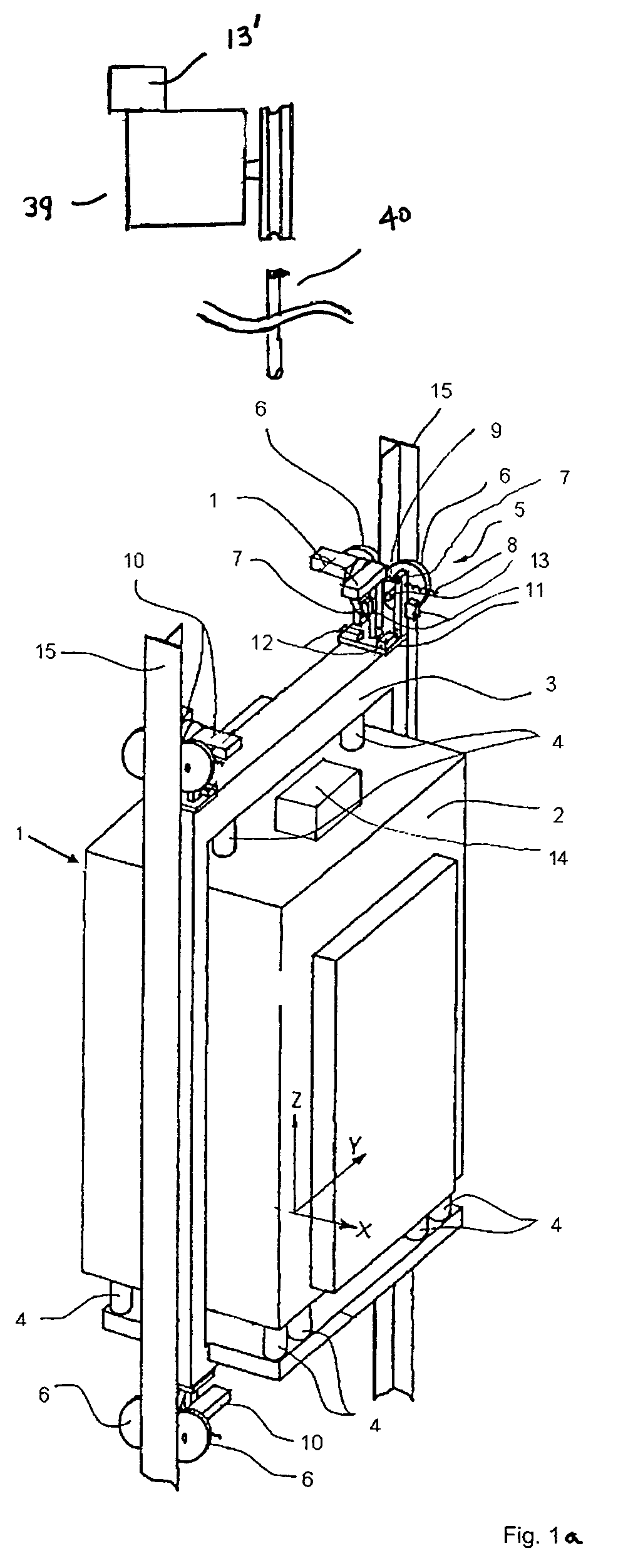

Equipment for vibration damping of a lift cage

Equipment for reducing vibrations of a lift cage guided at rails comprises a plurality of guide elements for guiding the lift cage along the rails, a sensor for detecting positional changes of the lift cage and / or of accelerations occurring at the lift cage, an actuator arranged between the lift cage and the guide elements and a regulating device which, on the basis of the values transmitted by the sensor, controls the actuator for changing the position of the cage relative to the rails. The regulating device has an amplification which is variable in dependence on the vertical speed of the lift cage. The amplification of the regulating device is continuously raised after activation of the regulating device and continuously lowered after switching-off of the regulating device.

Owner:INVENTIO AG

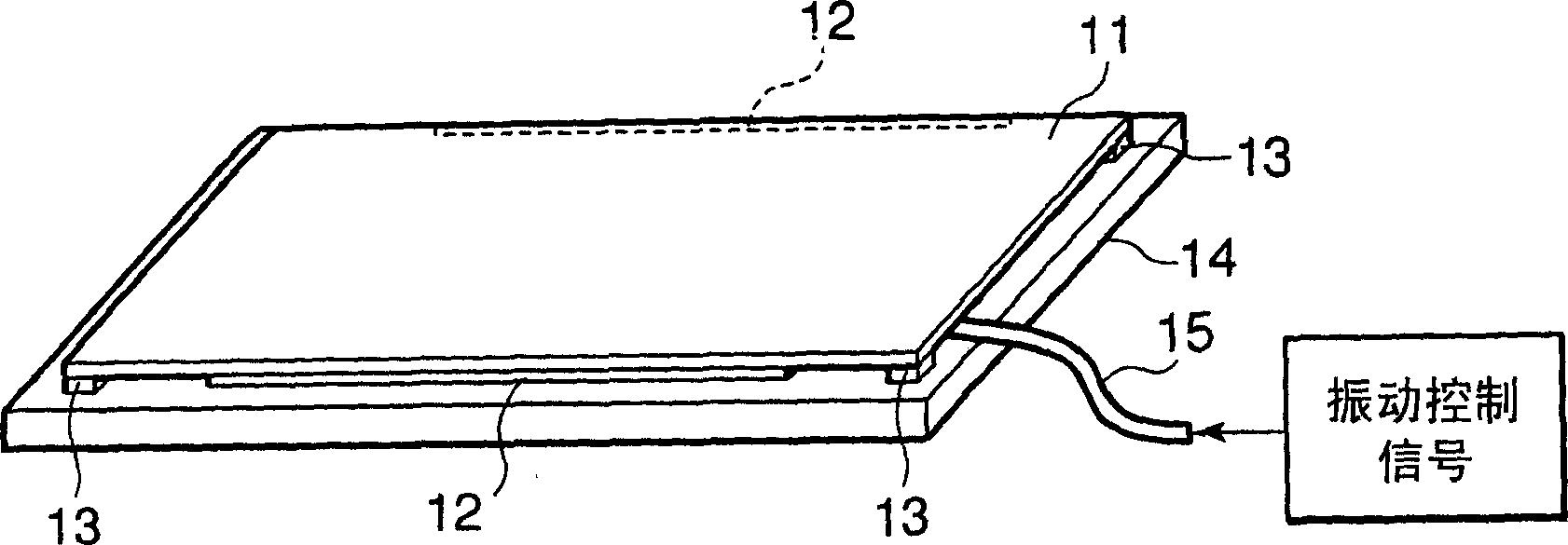

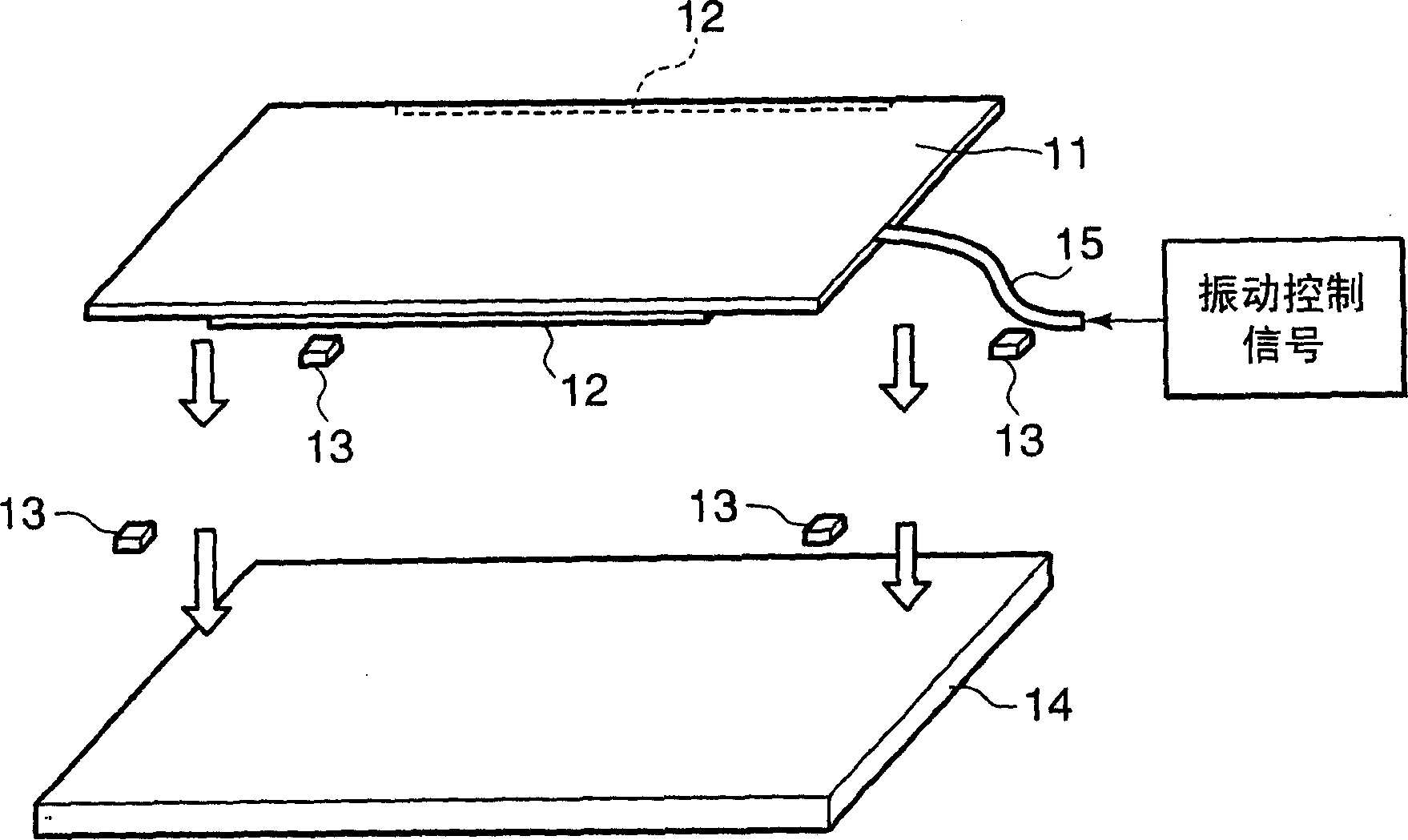

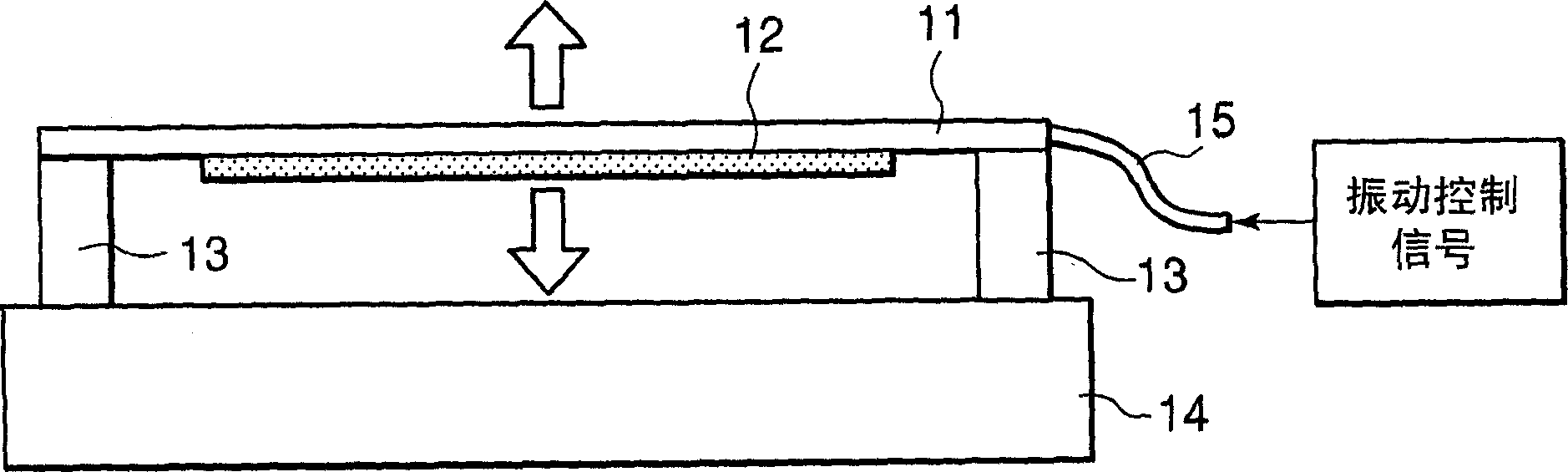

Electronic apparatus

InactiveCN1821935ASmooth vibrationBig vibrationInput/output for user-computer interactionDigital data processing detailsFixed frameEngineering

In an electronic apparatus having a touch panel, four fixing cushions are fixed at four corners of a rear surface of the touch panel. The fixing cushions are further fixed to a fixing frame to support the touch panel against to the fixing frame. Pair of vibrating elements are fixed to the rear surface of the touch panel along edges, which are parallel to each other, of the touch panel. The vibrating elements elastically bend the touch panel to cause flexural vibration to the touch panel. The fixing cushions have softness to allow the touch panel to vibrate and hardness to serve as fulcrums of the flexural vibration of the touch panel.

Owner:NEC INFRONTIA CORP

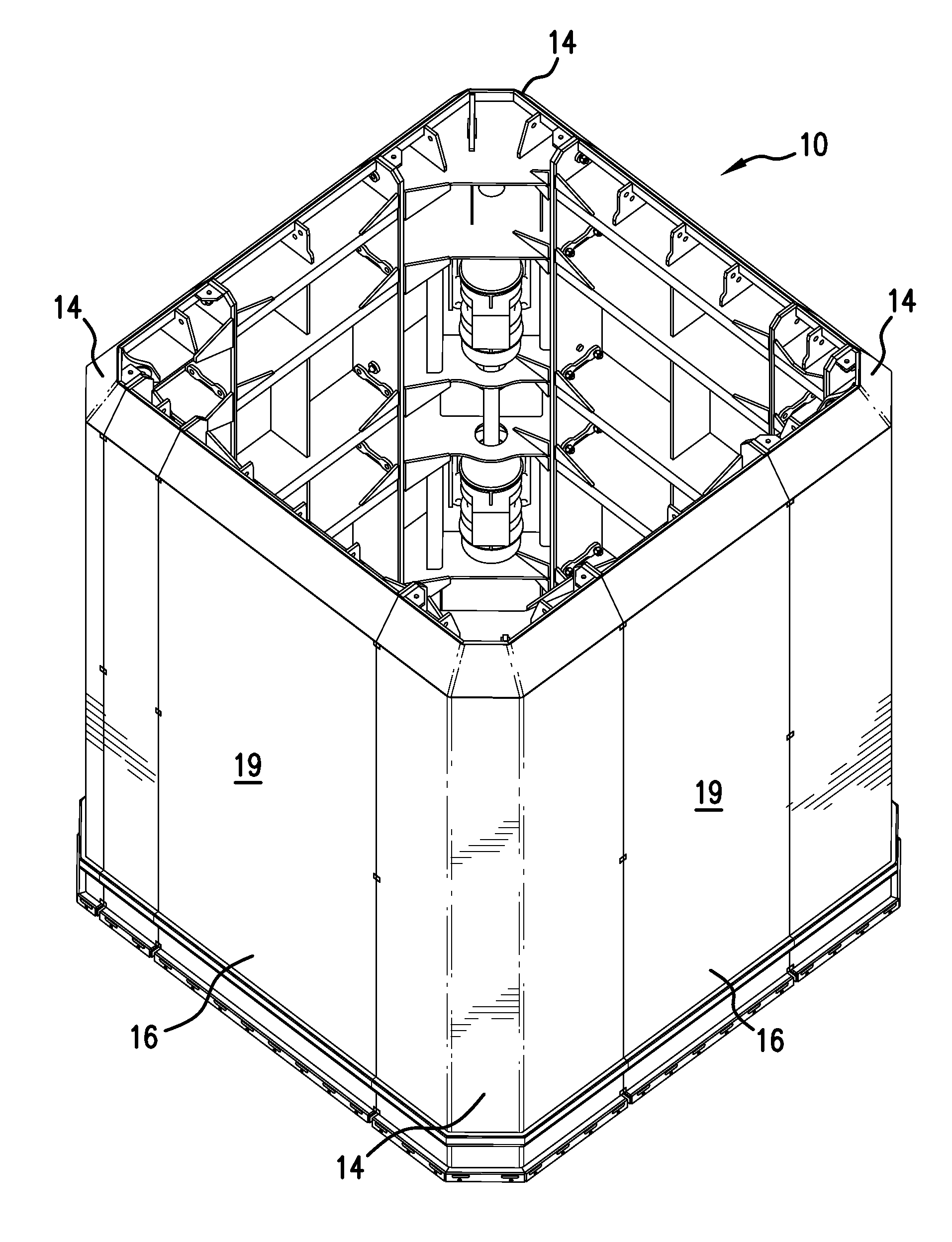

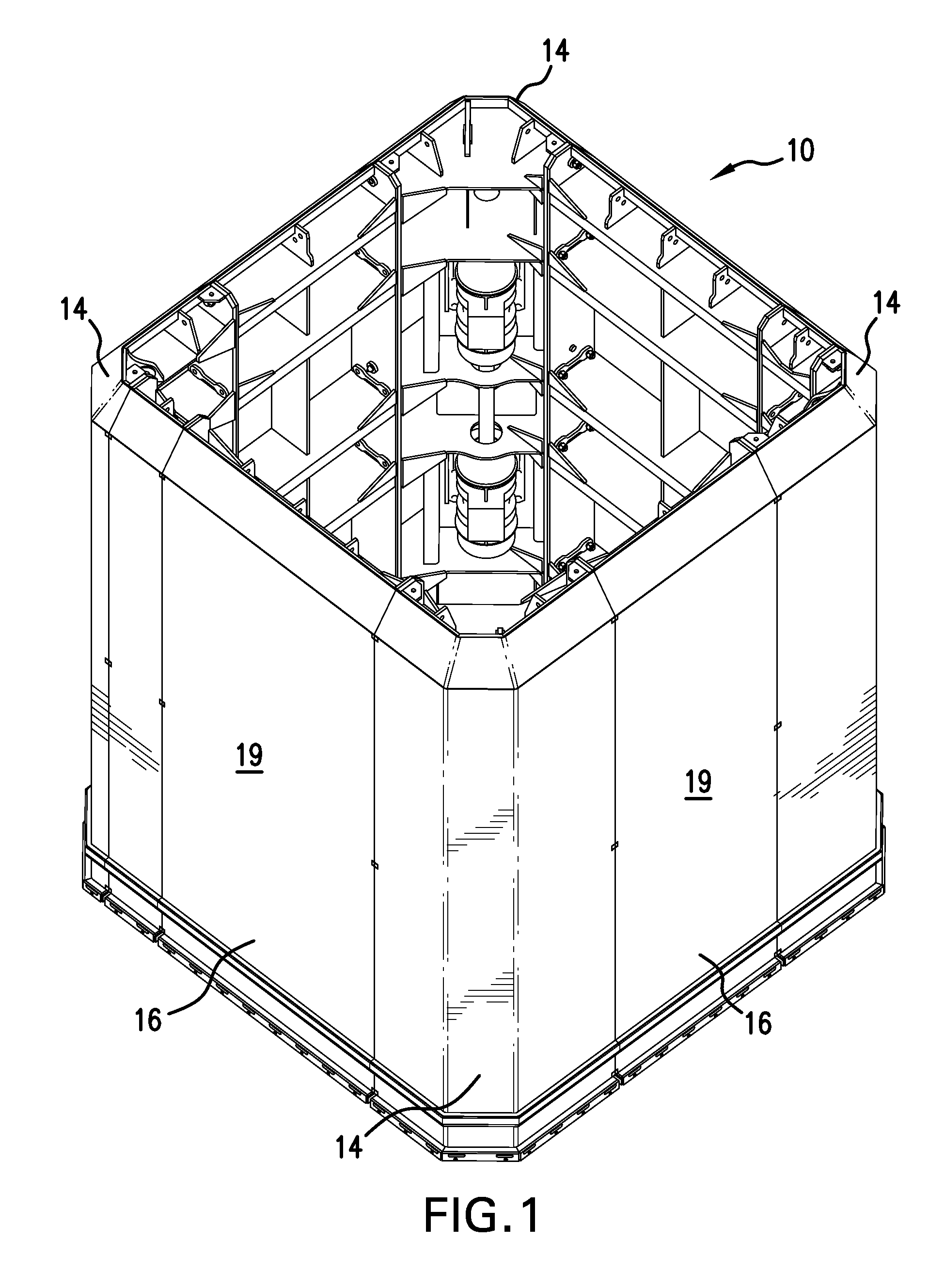

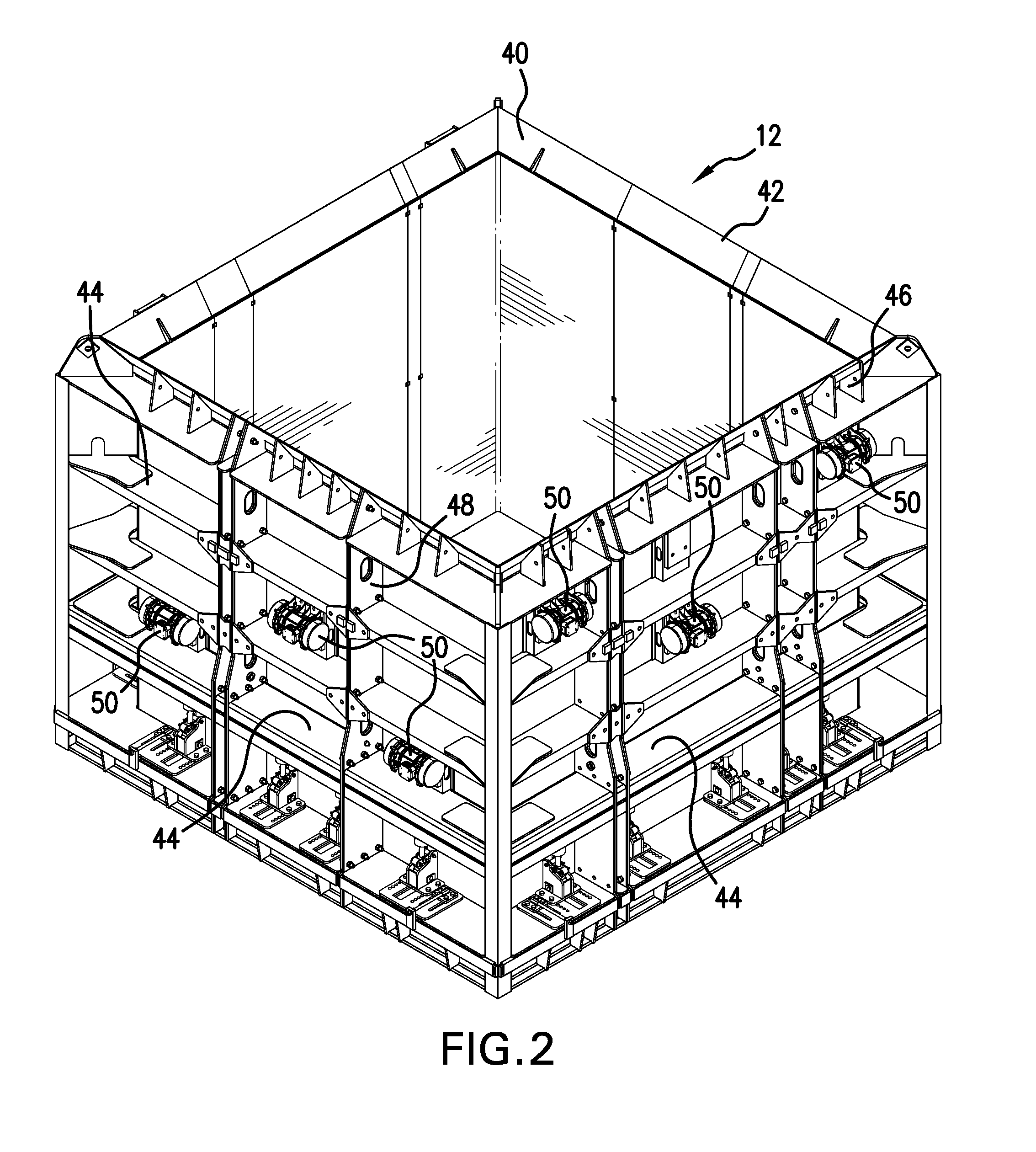

Vibration system for concrete pipe making machines

ActiveUS8926311B1Superior uniform vibration systemSmooth vibrationMouldsConfectioneryRigid coreEngineering

A vibration system for concrete pipe making machines using the dry cast method and which employ adjustable molds comprised of corner panels joined to intermediate panels. Two coupled vertically spaced-apart vibrators are mounted in two opposite corner panels of the mold core. The vibrators are mounted on shelves welded to the interior of the walls that form the mold surface. The shelves are also welded to vertical end walls that extend inwardly to form the box-like corner panel. The corner panels and intermediate panels are secured together by removable fasteners that join the vertical end walls of the corner panels to the corresponding vertical end walls of the side panels. The joined corner panels and side panels provide a rigid core structure similar to a solid core and allow the entire core to become the vibration structure.

Owner:HAWKEYEPEDERSHAAB CONCRETE TECH INC

Electroacoustic transducer

An electroacoustic transducer includes a magnetic circuit unit that forms a magnetic gap, a voice coil inserted into the magnetic gap, and a diaphragm to which the voice coil is connected. The diaphragm has a central portion having an outer peripheral edge and an annular portion disposed underneath the central portion. The annular portion has an outer peripheral edge corresponding to the outer peripheral edge of the central portion, and an inner peripheral edge secured to the magnetic circuit unit. The diaphragm further has a joint portion formed at the outer peripheral edges of the central and annular portions, and the outer peripheral edges are joined together. The voice coil is disposed underneath the central portion of the diaphragm and joined to the joint portion.

Owner:CITIZEN ELECTRONICS CO LTD

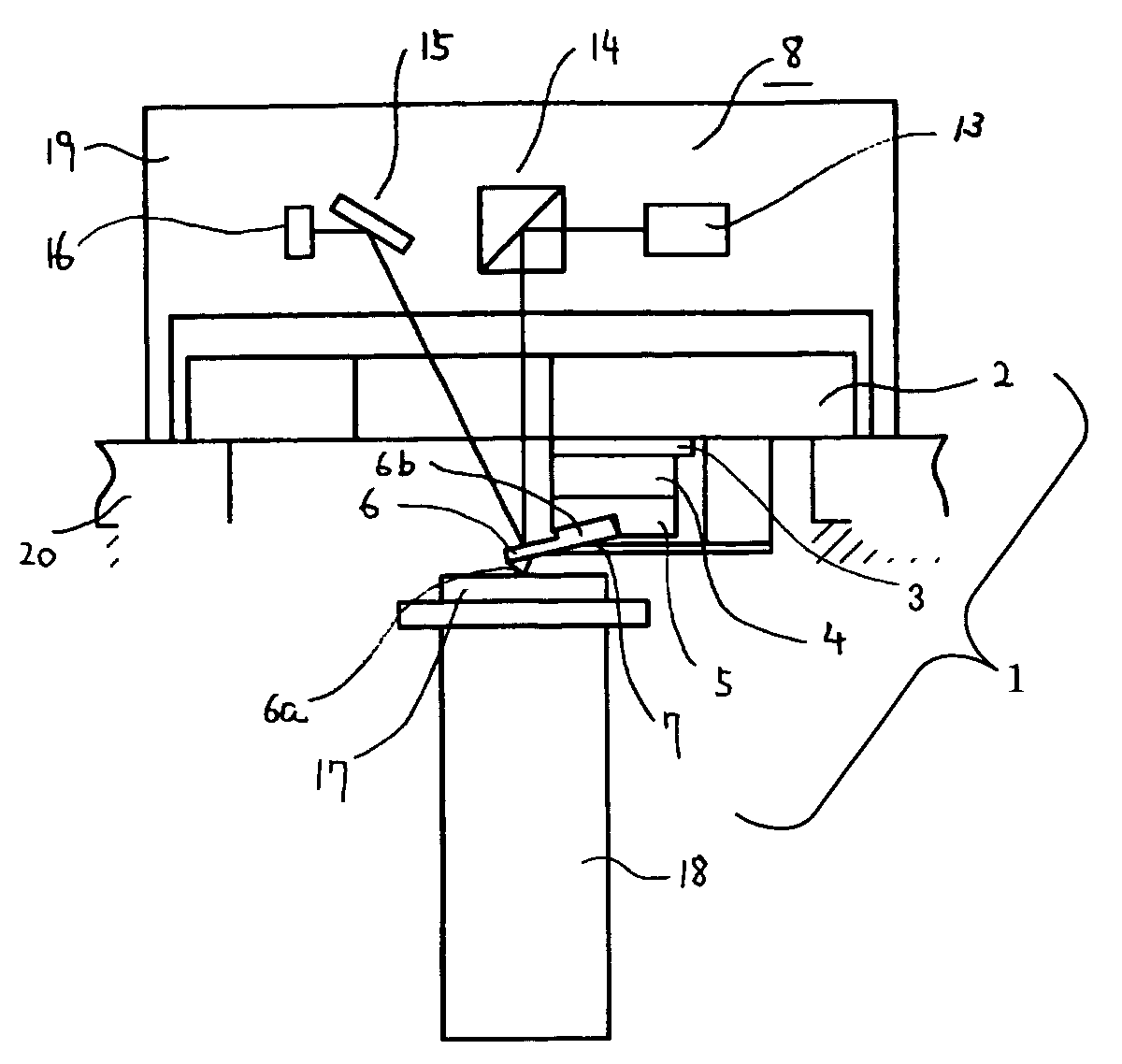

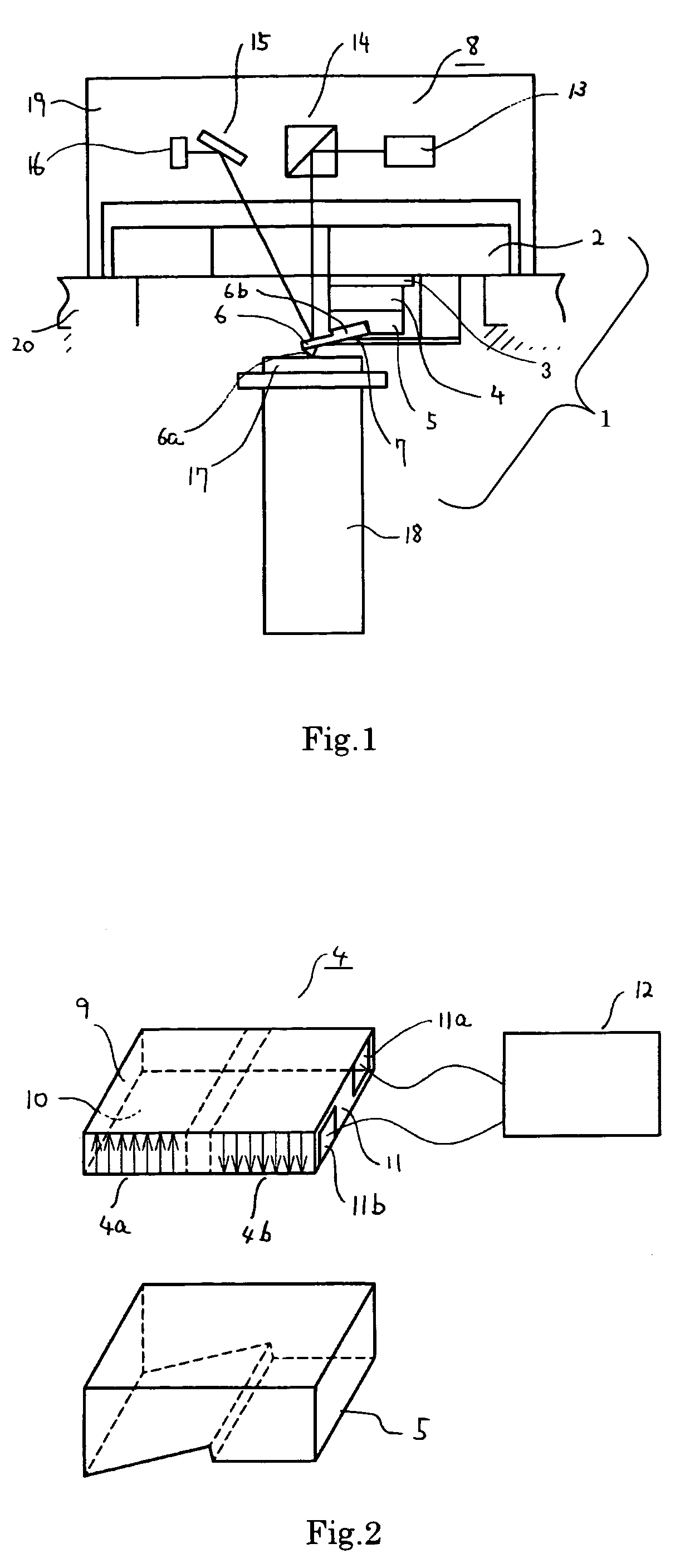

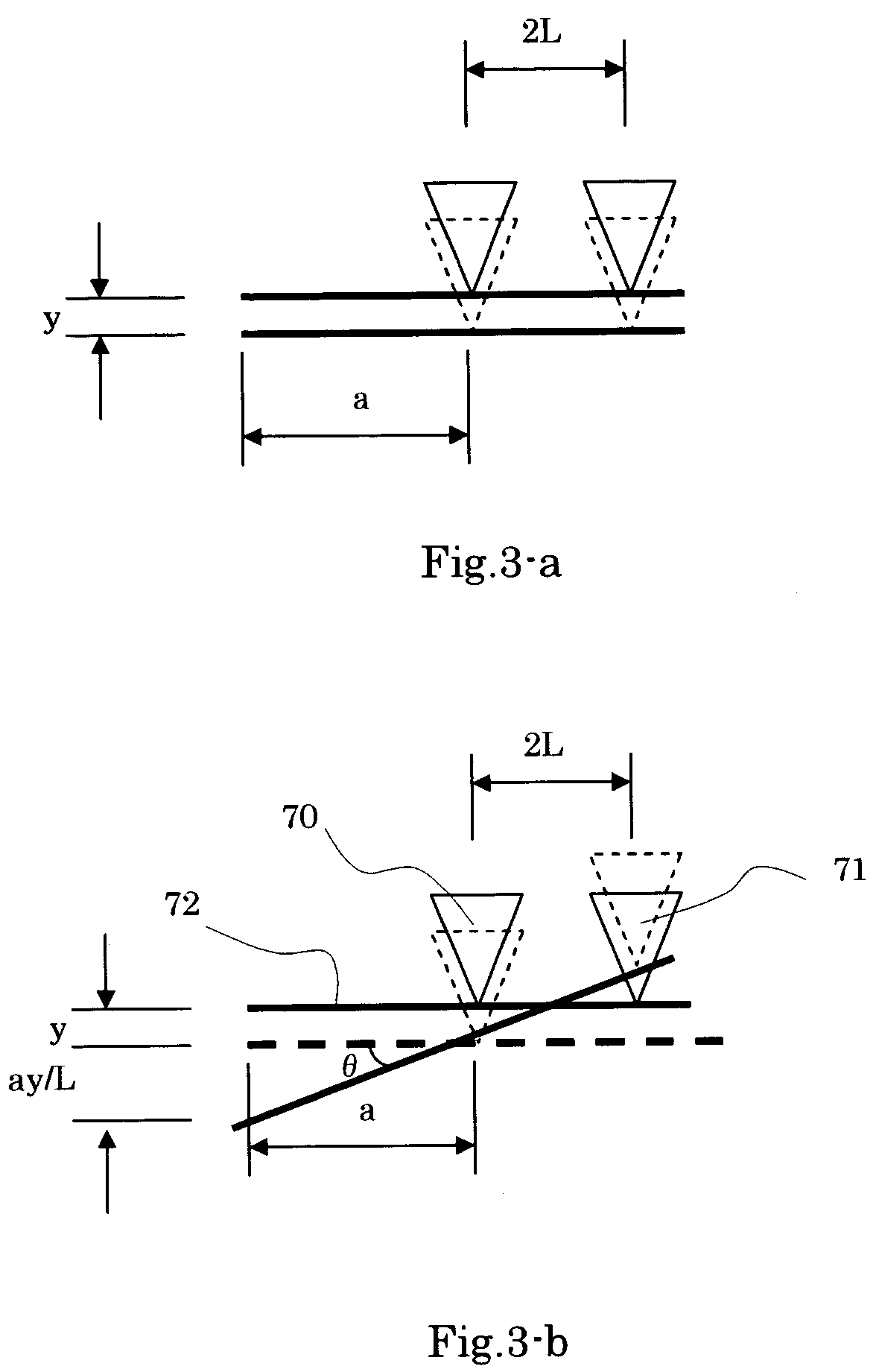

Scanning probe microscopy cantilever holder and scanning probe microscope using the cantilever holder

InactiveUS7170054B2Reduce stiffnessReduce vibrationMaterial analysis using wave/particle radiationSurface/boundary effectScanning electron microscopeScanning probe microscopy

A scanning probe microscope having a cantilever holder is provided which gives a cantilever great amplitude by a small-sized vibrator configurable in a limited space and is stably operated even in environments of high viscous drag such as a liquid. A cantilever base part of a cantilever is fixed to a fixing part of a scanning probe microscopy cantilever holder. A vibrator is mounted on the fixing part. When it is defined that the front side is the side close to a probe and the rear side is the side close to a supporting part of the fixing part along in the longitudinal direction of the cantilever, the vibrator displaces the front and rear sides of the fixing part of the cantilever holder to each other in the opposite directions within the plane orthogonal to the sample surface to vibrate the cantilever in a liquid.

Owner:HITACHI HIGH TECH SCI CORP

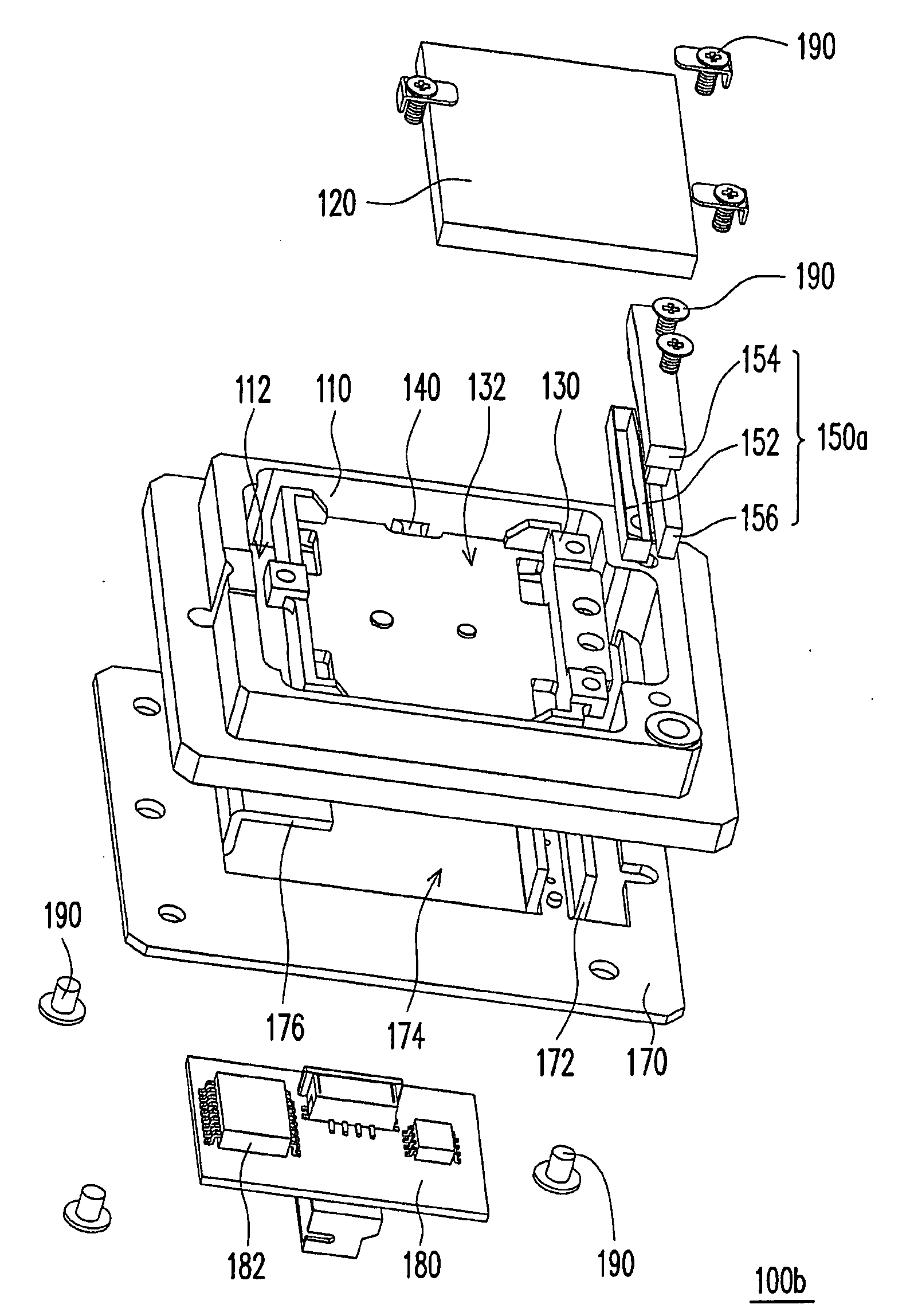

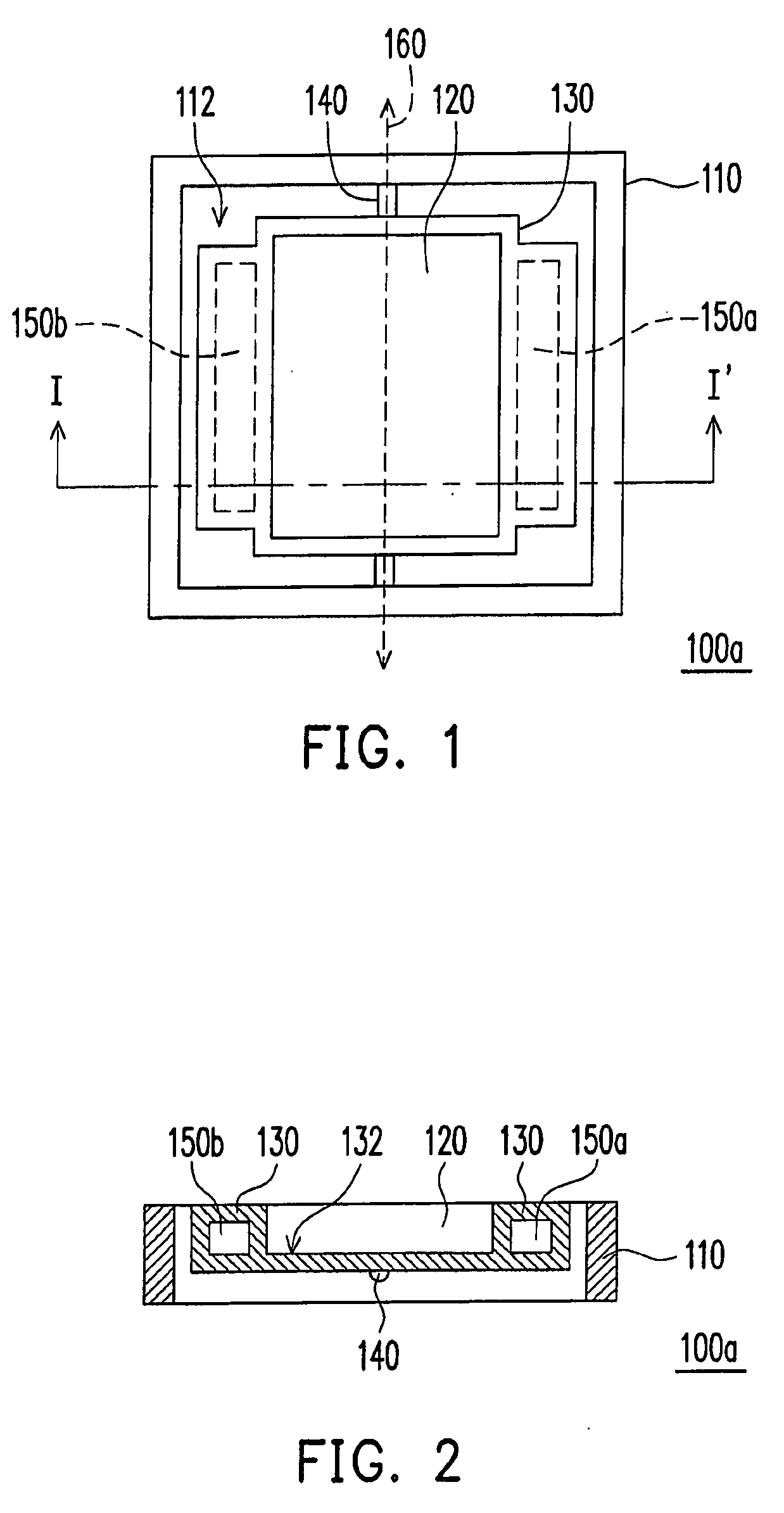

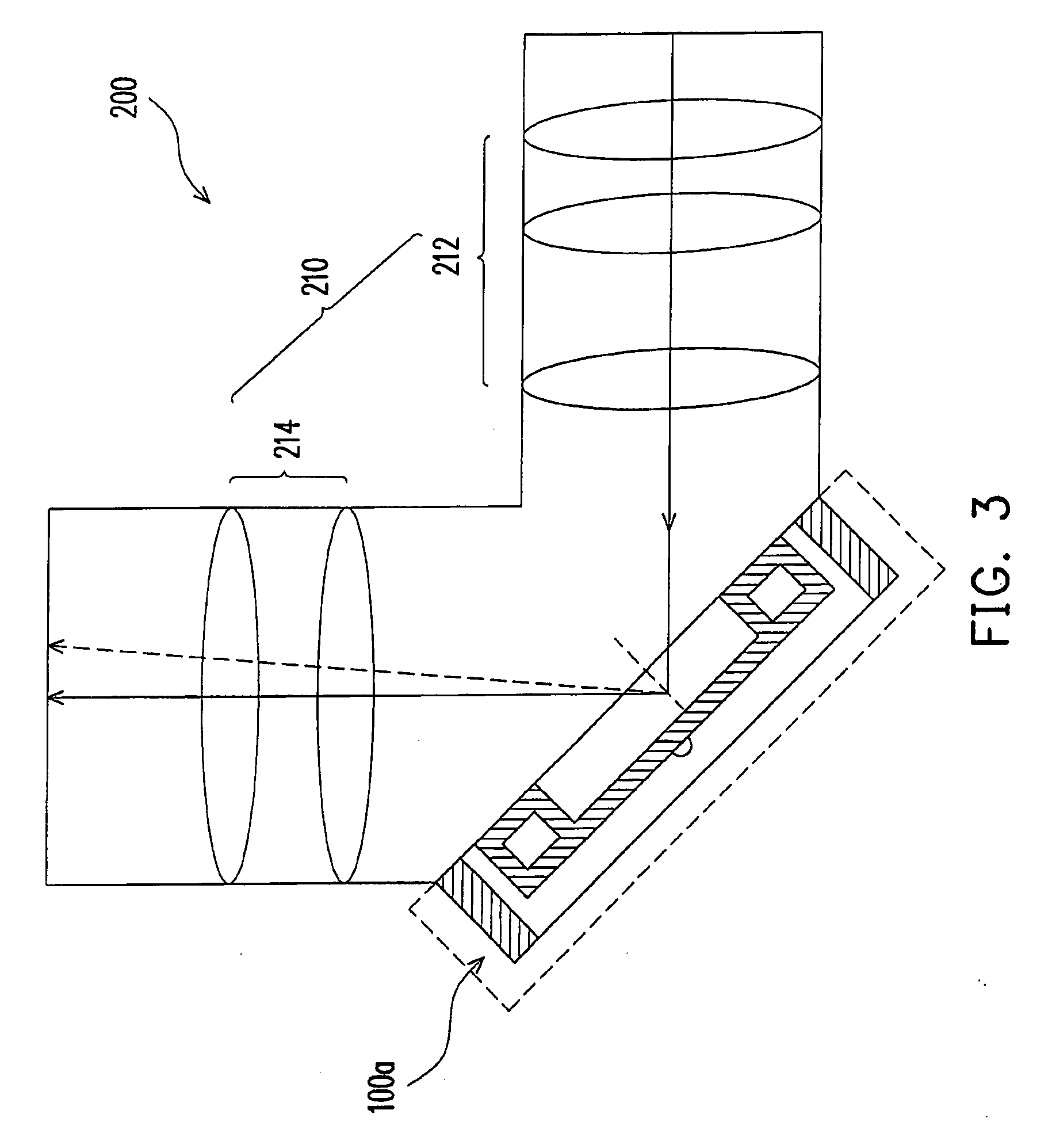

Imaging displacement module

ActiveUS20080304017A1Improve image qualitySmooth vibrationProjectorsOptical elementsEngineeringActuator

An imaging displacement module including a frame, an optical element, a carrier, a connecting portion and at least a first actuator is provided. The frame has a first opening, and the optical element, the carrier, the connecting portion and the first actuator are all disposed in the first opening. The carrier is capable of carrying the optical element, and the connecting portion connects between the frame and the carrier and capable of generating an elastic torsion around an axis. The first actuator is disposed at a side of the carrier and capable of driving the carrier to vibrate periodically.

Owner:YOUNG OPTICS

Flexible ultrasonic glue dipping device

The invention discloses a flexible ultrasonic glue dipping device. The flexible ultrasonic glue dipping device comprises a tank body, wherein the tank body is provided with an inner concave chamber for containing liquid resin, is of a two-layer structure and comprises an inner tank body and an outer tank body; a space for storing cycling medium is formed between the inner tank body and the outer tank body; the outer tank body is respectively provided with a liquid inlet and a liquid outlet which are respectively communicated with the space; and the outer wall of the outer tank body is provided with a flexible ultrasonic device with adjustable parameters such as frequency and power. The flexible ultrasonic glue dipping device disclosed by the invention has the advantages that ultrasonic waves produced by the ultrasonic device act on fiber and the liquid resin uniformly by means of the cycling medium to realize glue dipping, and after the glue dipping procedure is finished, when a glue dipping tank is cleaned, the ultrasonic waves also act on sewage in the tank body, therefore, for the glue dipping and cleaning processes, a physical means is adopted in the flexible ultrasonic glue dipping device, and on the basis of realizing glue dipping, the cleaning effect is improved, the cleaning process is simplified, and the influence on the reuse effect of the glue dipping tank is avoided.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Papermaking device for rice paper production

ActiveCN105113317AEnough space to extendAvoid breakingPaper-making machinesCardboardPaper production

The invention discloses a papermaking device for rice paper production. The papermaking device comprises a papermaking plate, a vibrating device and a control unit, wherein the edges of the papermaking plate are provided with a frame; the control unit comprises a swinging arm and connecting devices; each connecting device comprises a supporting rod, a first air cylinder and a telescopic connecting rod; two ends of the connecting rods are respectively connected to the swinging arm and the first air cylinders; piston rods of the first air cylinders are hinged to the edges of the papermaking plate; sliding grooves are formed in the papermaking plate; one end of each supporting rod is connected into the corresponding sliding groove in a sliding way; the other end of each supporting rod is hinged to the corresponding connecting rod; the piston rod of the first air cylinder and the supporting rod are symmetrically arranged at the same edge of the papermaking plate along the center line of the papermaking plate; the length of each supporting rod is equal to the total sum of the length of each connecting rod under a hinging point of the connecting rod and the length of each first air cylinder; the vibrating device comprises a vibrator and a control device; the vibrator is arranged on the papermaking plate. By implementing the scheme, the problem in an existing papermaking technology that the rice paper is not high in quality or high in cost is solved.

Owner:重庆市南川区金鑫纸业有限公司

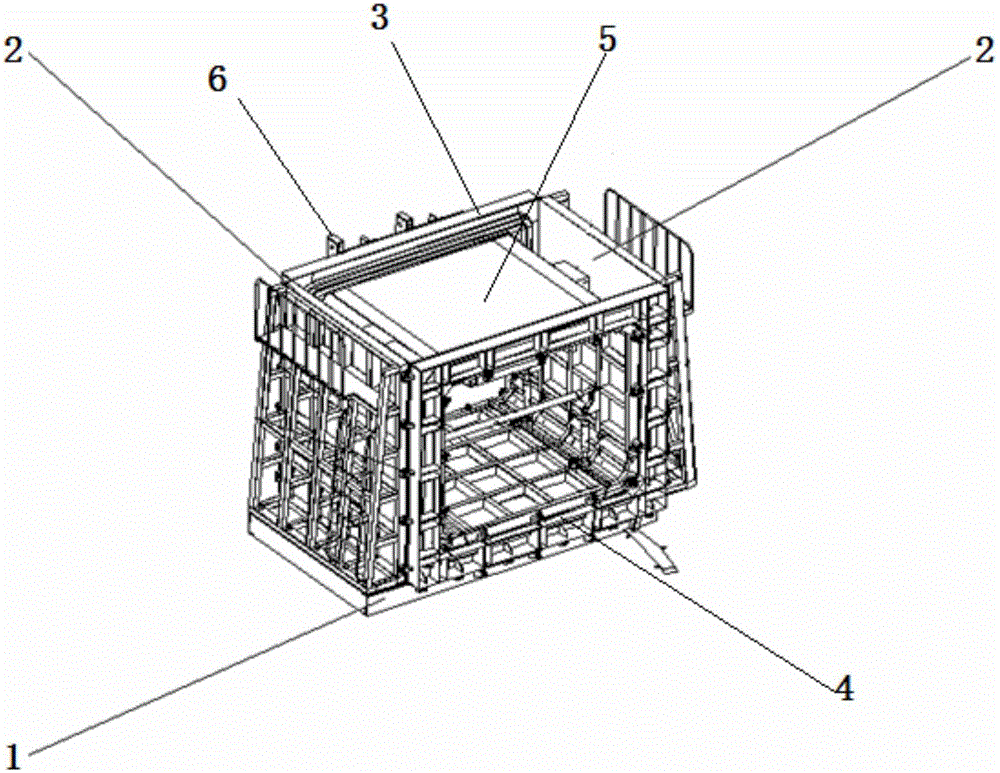

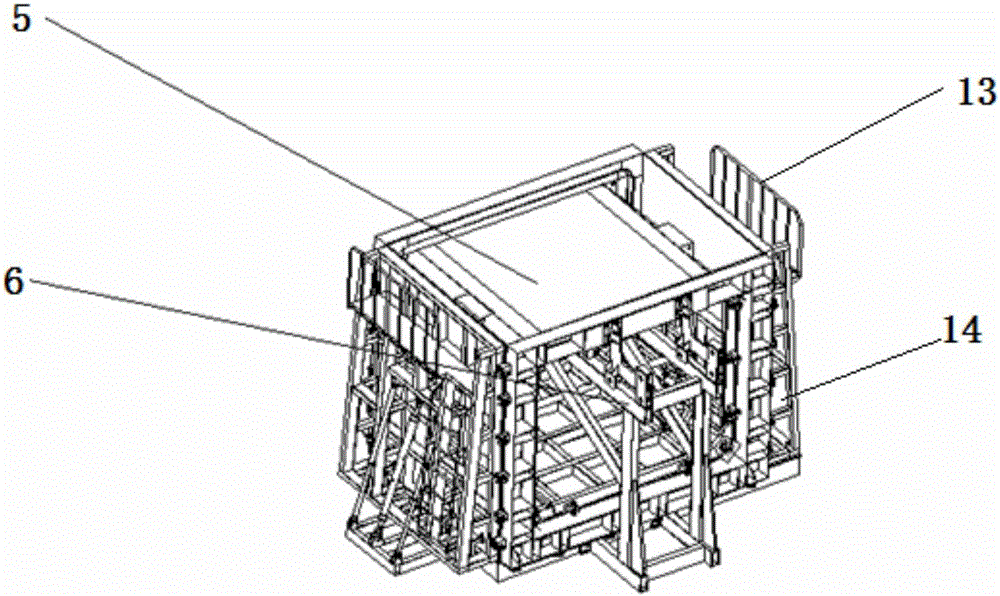

Concrete single-bin utility tunnel horizontal forming mold and system, and tunnel molding method

ActiveCN106182359AEasy to assemble and disassembleImprove efficacyDischarging arrangementMouldsShell moldingUtility tunnel

A concrete single-bin utility tunnel horizontal forming mold comprises a mold base (1), side mold bodies (2), a plug end mold body (3), a socket end mold body (4), an inner container mold body (5) and a supporting frame (6), wherein the mold base (1) is fixed on the ground; the side mold bodies (2) are arranged on two sides of the mold base (1); the plug end mold body (3) and the socket end mold body (4) are independently arranged at the front and rear ends of the mold base (1); the plug end mold body (3) or the socket end mold body (4) is fixed on the supporting frame (6); the inner container mold body (5) is arranged on the supporting frame (6); and the supporting frame (6) is arranged on the ground or the mold base (1). The invention further provides a concrete single-bin utility tunnel horizontal forming system and a production process thereof. The concrete single-bin utility tunnel horizontal forming mold and system as well as the production process have the advantages that the quality is high, the scale is large, and rapid mass production can be achieved.

Owner:CHANGSHA CHUHONG MACHINERY

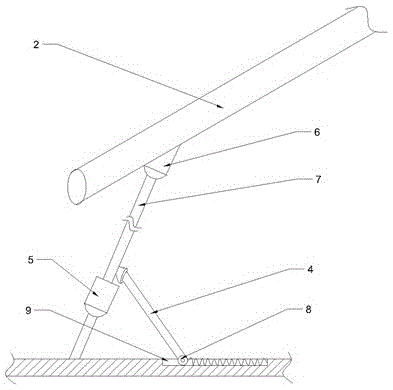

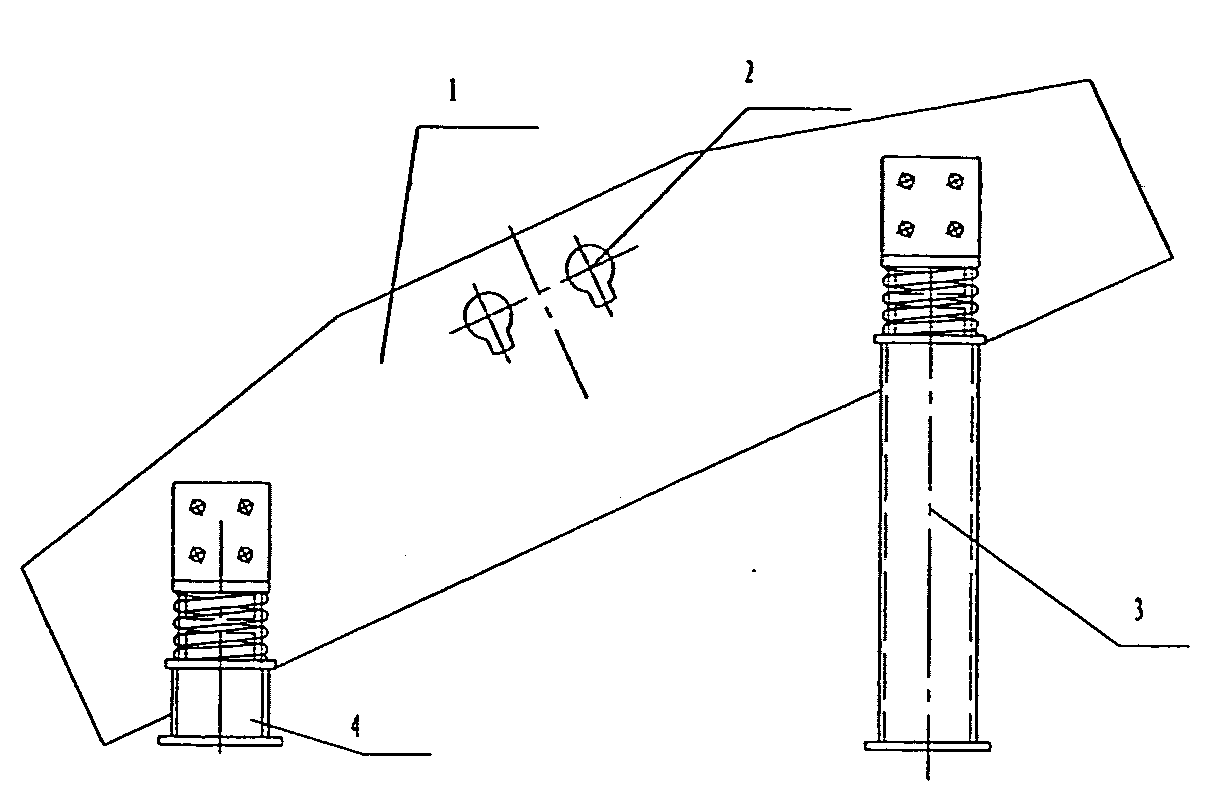

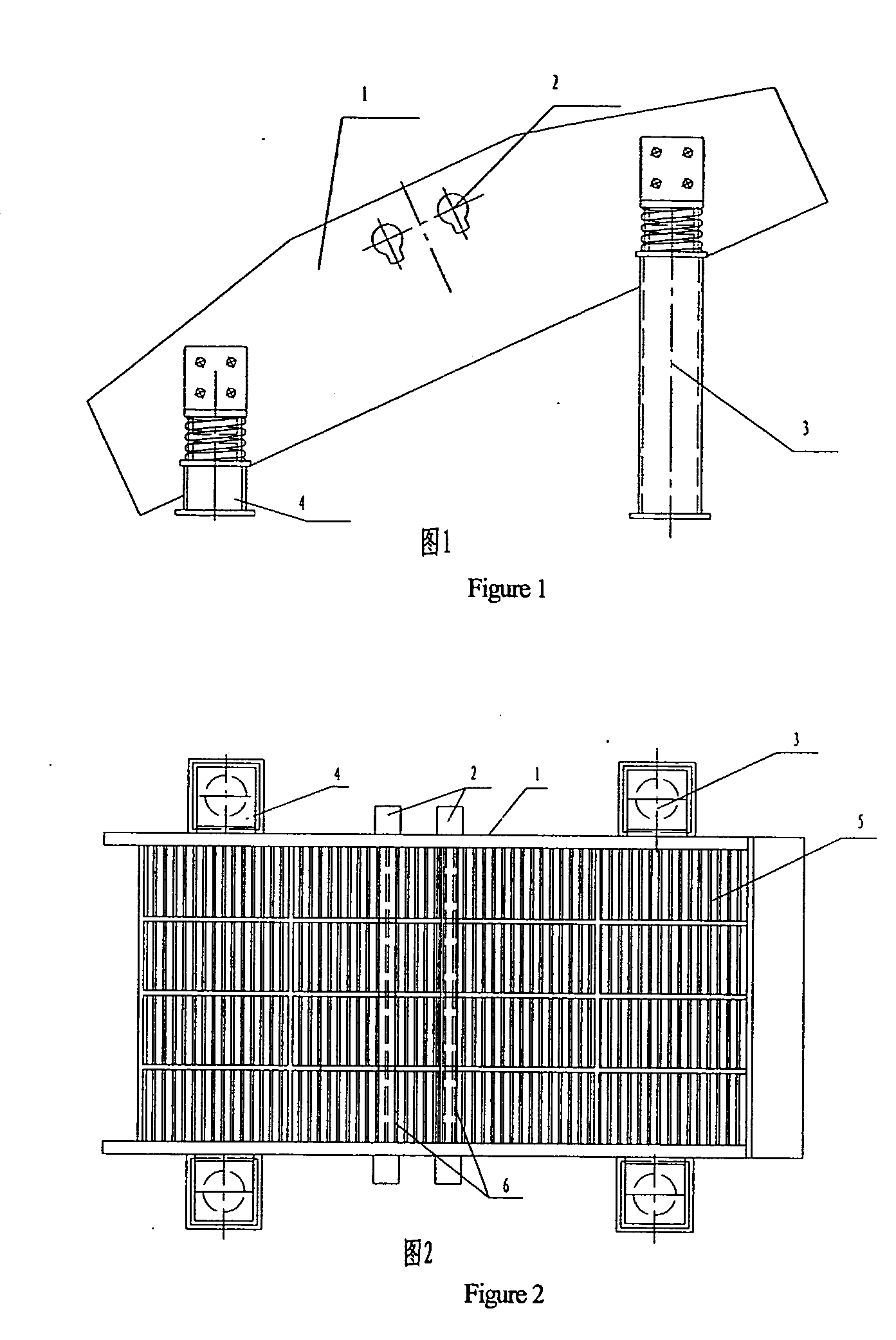

Elastic sieving technique and corresponding large-sized elastic vibration screen

InactiveUS20070261999A1Reduce power consumptionSimple and easy to and maintainSievingScreeningResonanceElastic vibration

An elastic sieving method and corresponding large-sized elastic vibration screen The present invention utilizes a screening surface and a separate sieving machine. A screen mat located on the sieve box is connected to multiple small rectangular screens. While the machine is vibrating, the resonation of screen rods located on the screen mat connected by small rectangular screens are initiated to screen the material and to cause the vibration of the whole vibration screen and realize the conveyance and lamination of materials. Because the screening surface is in a state of resonance, the vibration strength is strong enough to prevent the screen meshes from becoming plugged, allowing for high sieving efficiency. A bearing in the sieving mechanism is installed with a vibration damping ring, placing the bearing in a resonant state, allowing for a low dynamic stress level, which satisfies the process requirement for large-sized vibration screen excitation units with a screening surface as wide as 4800 mm. Thus, the production efficiency of vibration screen is high, the structure of the machine is simple and easy to repair and maintain, and energy consumption is reduced. Furthermore, the dynamic stress level of the sieving machine is low, the reliability is high, and the vibrations are stable. These properties allow the present invention to have a wide range of practical applications, including uses in the coal, metallurgic, chemical and environmental protection fields.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com