Patents

Literature

67results about How to "Reduce low frequency vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

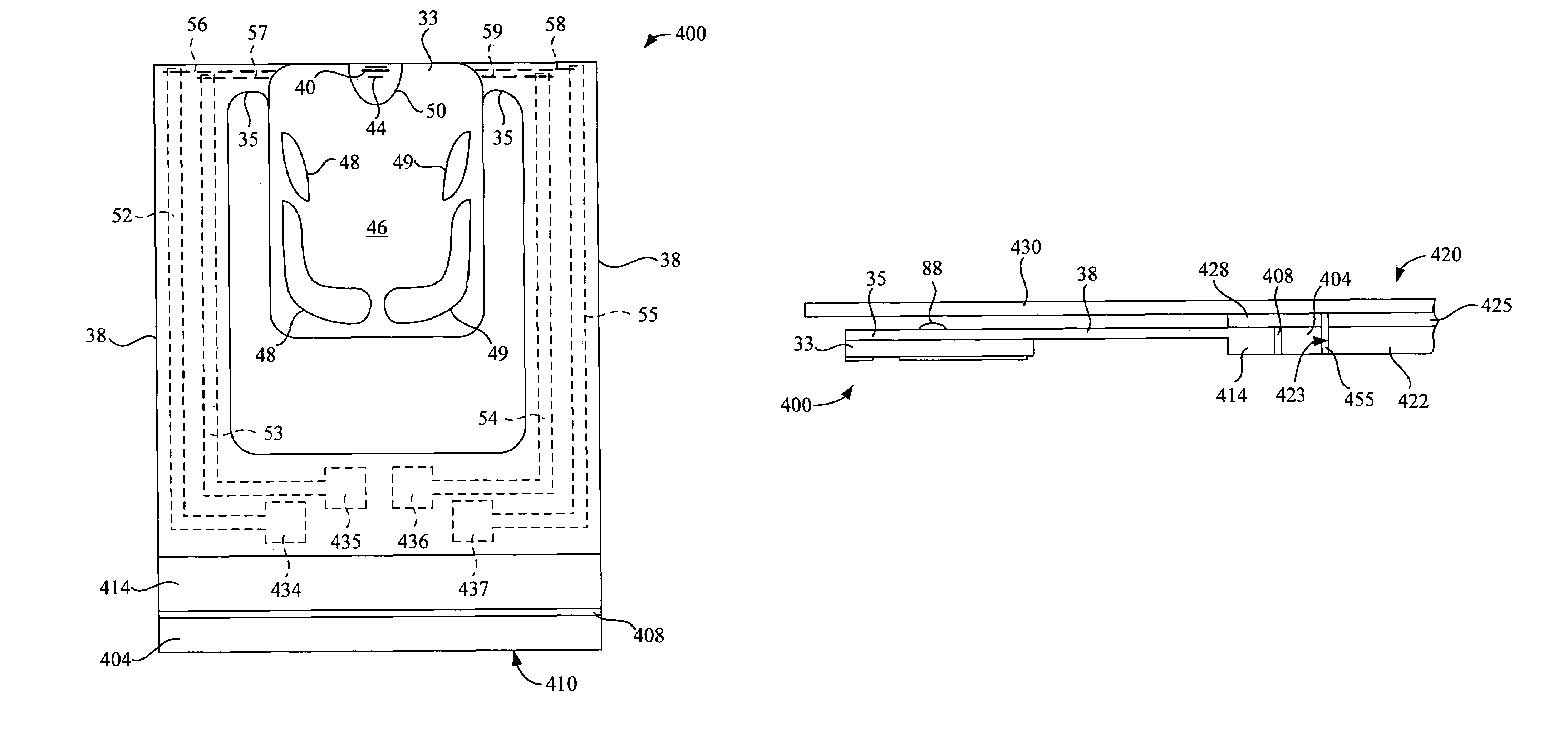

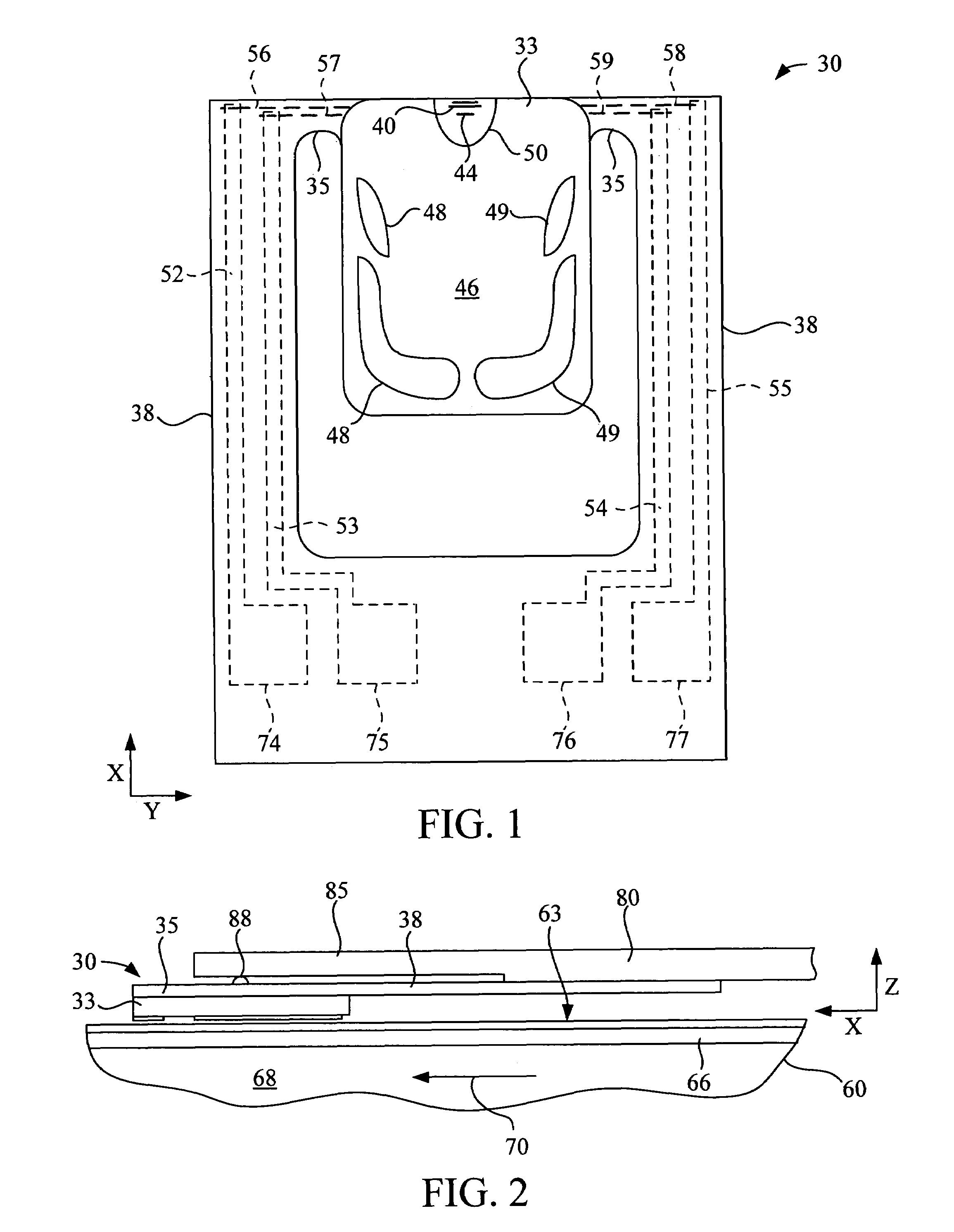

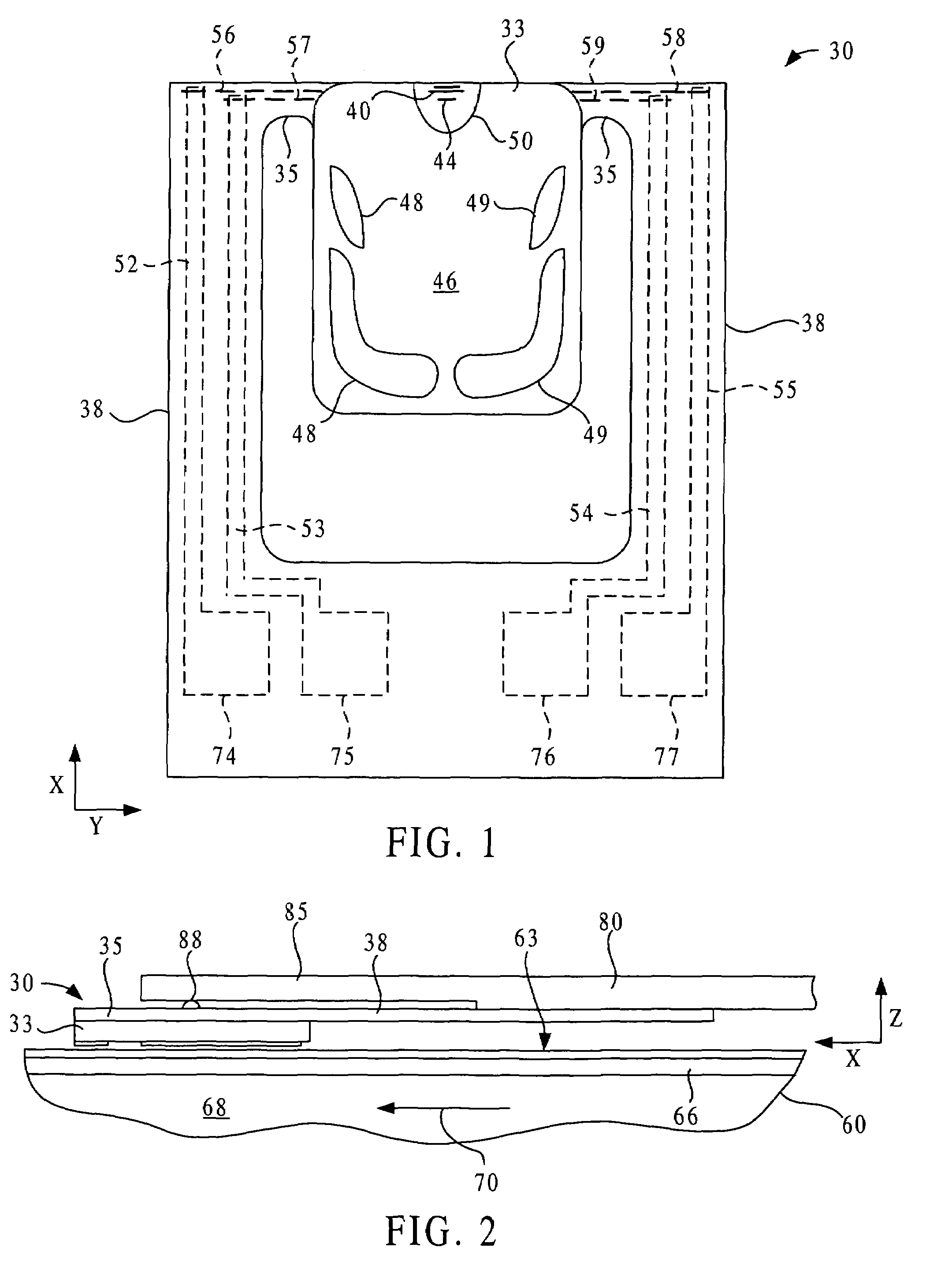

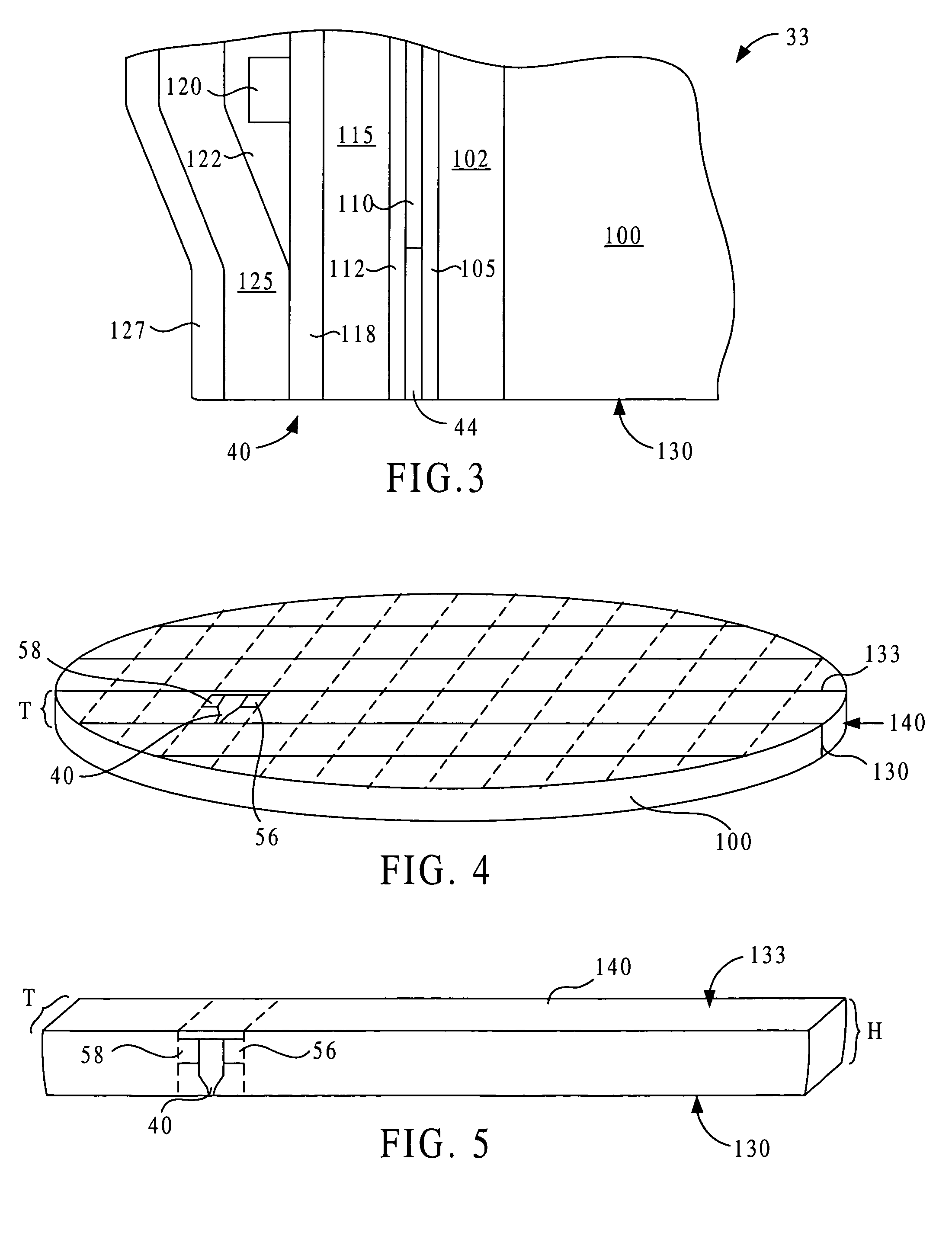

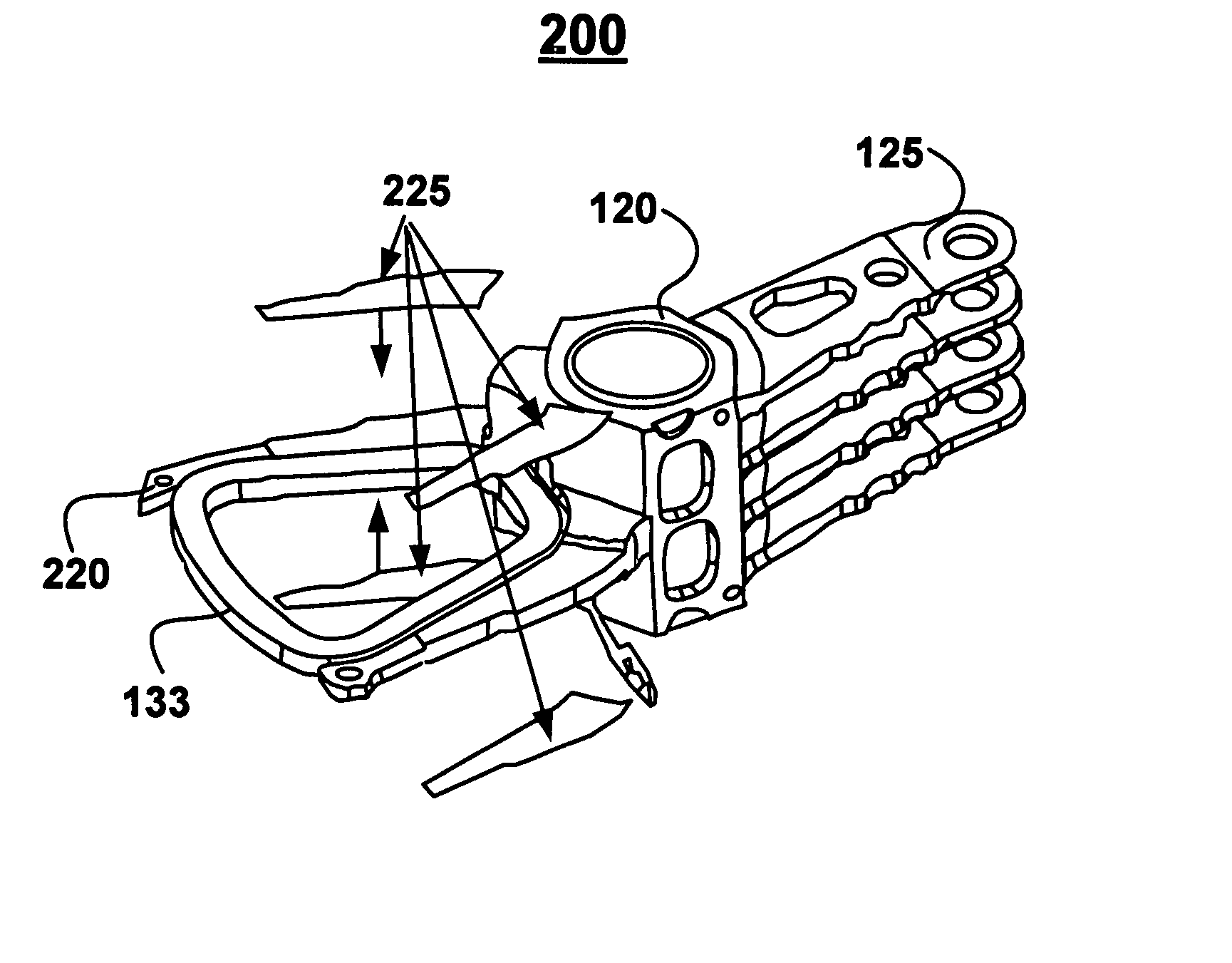

Electromagnetic heads, flexures, gimbals and actuators formed on and from a wafer substrate

InactiveUS7684158B1Improve accuracyHigh track densityElectrical connection between head and armRecord information storageAccess timePiezoelectric actuators

Devices for reading or writing electromagnetic information include a wafer substrate piece disposed between an electromagnetic transducer and an electrostrictive or piezoelectric actuator. The substrate piece is shaped as a rigid body adjoining the transducer and as a flexible element connecting the body and the actuator. To fabricate, at least one electrostrictive layer and many transducers are formed on opposite sides of a wafer that is then cut into rows containing plural transducers. The rows are processed from directions generally normal to the wafer surface upon which the transducers were formed, by removing material to form a head, flexures and a media-facing surface on the head. Conductive leads are formed on a back surface of flexures connecting the transducer with drive electronics. The flexures are aligned with forces arising from interaction with the media surface and from seeking various tracks, reducing torque and dynamic instabilities and increasing actuator access time.

Owner:LAUER MARK A

Electromagnetic heads, flexures, gimbals and actuators formed on and from a wafer substrate

InactiveUS7248444B1Improve accuracyHigh track densityElectrical connection between head and armRecord information storageAccess timePiezoelectric actuators

Devices for reading or writing electromagnetic information include a wafer substrate piece disposed between an electromagnetic transducer and an electrostrictive or piezoelectric actuator. The substrate piece is shaped as a rigid body adjoining the transducer and as a flexible element connecting the body and the actuator. To fabricate, at least one electrostrictive layer and many transducers are formed on opposite sides of a wafer that is then cut into rows containing plural transducers. The rows are processed from directions generally normal to the wafer surface upon which the transducers were formed, by removing material to form a head, flexures and a media-facing surface on the head. Conductive leads are formed on a back surface of flexures connecting the transducer with drive electronics. The flexures are aligned with forces arising from interaction with the media surface and from seeking various tracks, reducing torque and dynamic instabilities and increasing actuator access time.

Owner:LAUER MARK A

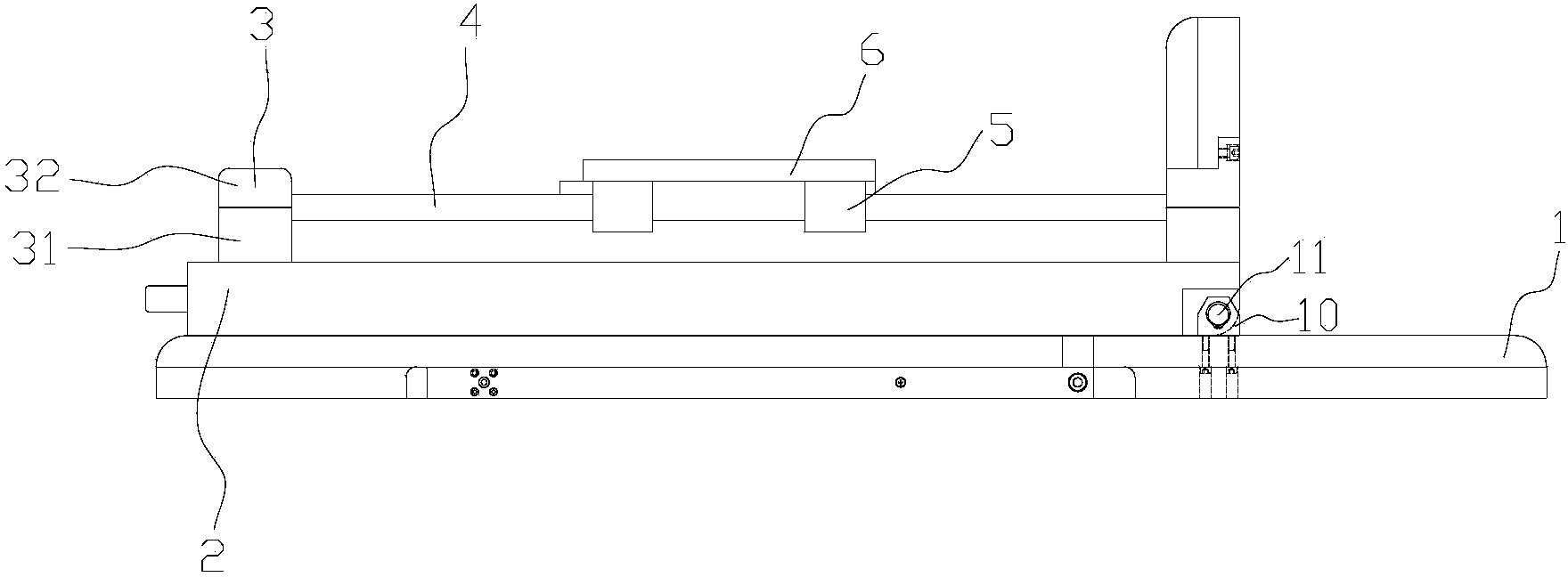

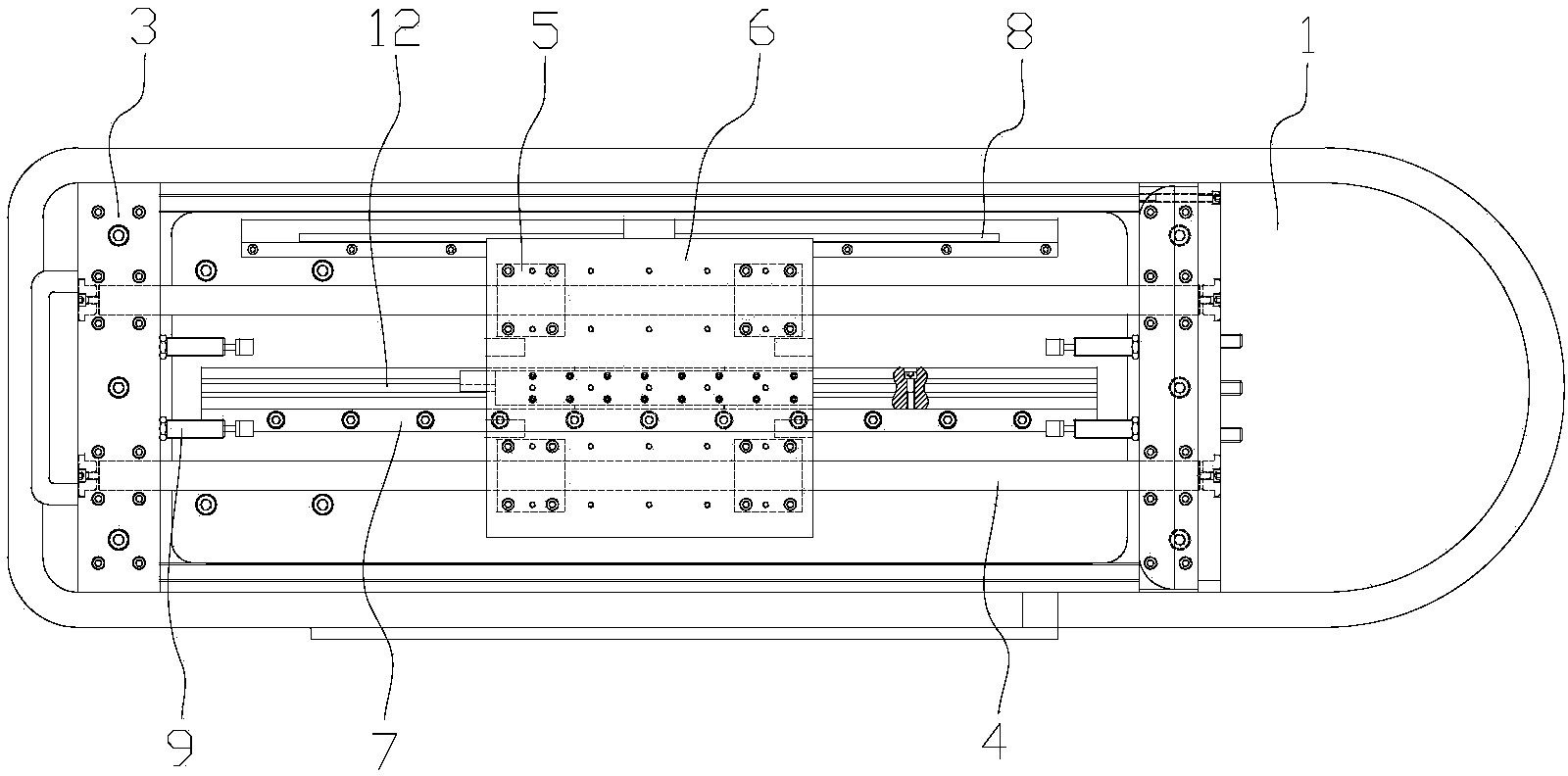

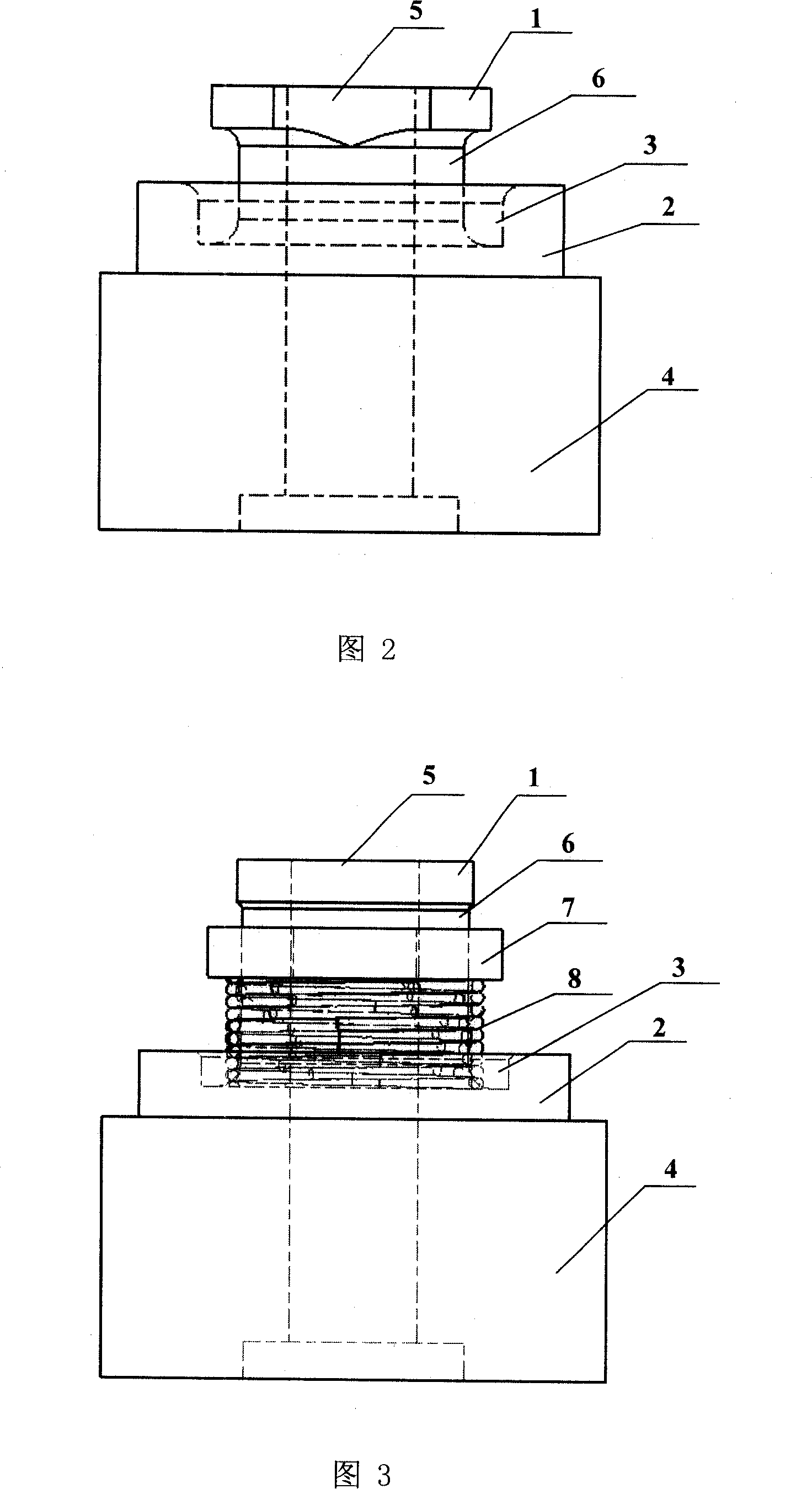

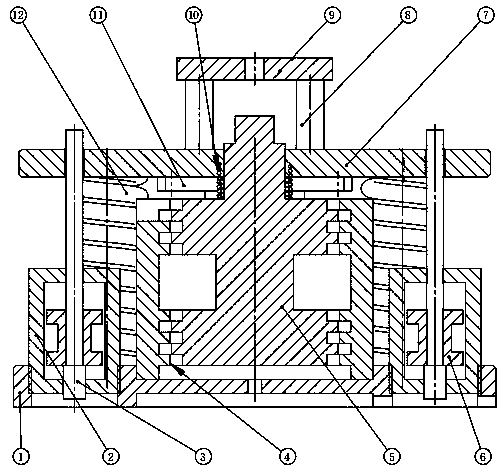

Low frequency calibration vibrating table

ActiveCN103925940AReduce low frequency vibrationLarge vibration displacementInstrumentsAir bearingGrating

The invention discloses a low frequency calibration vibrating table which comprises a mounting seat. Supports, guide shafts, a working table, a linear motor and a grating ruler are arranged on the mounting seat, the two supports are fixedly arranged at the two ends of the mounting seat respectively in the width direction of the mounting seat, at least two guide shafts are fixedly arranged between the supports in a spaced mode, at least one air bearing is arranged on each guide shaft in a sleeved mode, the working table is fixedly arranged on the air bearings, the linear motor is located between the guide shafts and is fixedly arranged on the mounting seat, the linear motor is fixedly connected to the lower end face of the working platform, and the grating ruler is fixedly arranged on one side of the mounting seat in the length direction. The low frequency calibration vibrating table has the advantages of being wide in vibrating frequency range, large in vibrating displacement and the like, is small in harmonic distortion and provides a good platform for the calibration of low frequency vibration acceleration sensors.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

Damping device and setting method thereof

InactiveCN107869546AReduce vibration disturbanceReduce vibrationMagnetic springsShock absorbersEngineeringRisk stroke

The invention discloses a shock absorbing device, comprising a main shock absorbing device, the two ends of the main shock absorbing device are provided with the shock absorbing device; the main shock absorbing device comprises a casing, the two sides of the pipe wall of the casing are symmetrical A travel groove is opened, and a first electromagnet and a second electromagnet are respectively provided at both ends of the inner sleeve, the first electromagnet and the second electromagnet are arranged coaxially, and the first electromagnet and the second electromagnet are arranged on the same axis. The polarities of the irons repel each other, the two side walls of the first electromagnet and the second electromagnet are symmetrically and fixedly connected with connecting rods matched with the stroke grooves, and the top and bottom ends of the sleeve are sleeved with sleeves. The connecting rods pass through the stroke grooves, and the connecting rods are all fixed to the connecting collars, the outer parts of the sleeves are sleeved with shock-absorbing springs, and two ends of the shock-absorbing springs are respectively connected with a ferrule. The invention utilizes the principle of repulsion of opposite sexes of electromagnets, and offsets the vibration energy through the repulsion force of the electromagnets, which can effectively reduce the vibration.

Owner:叶松

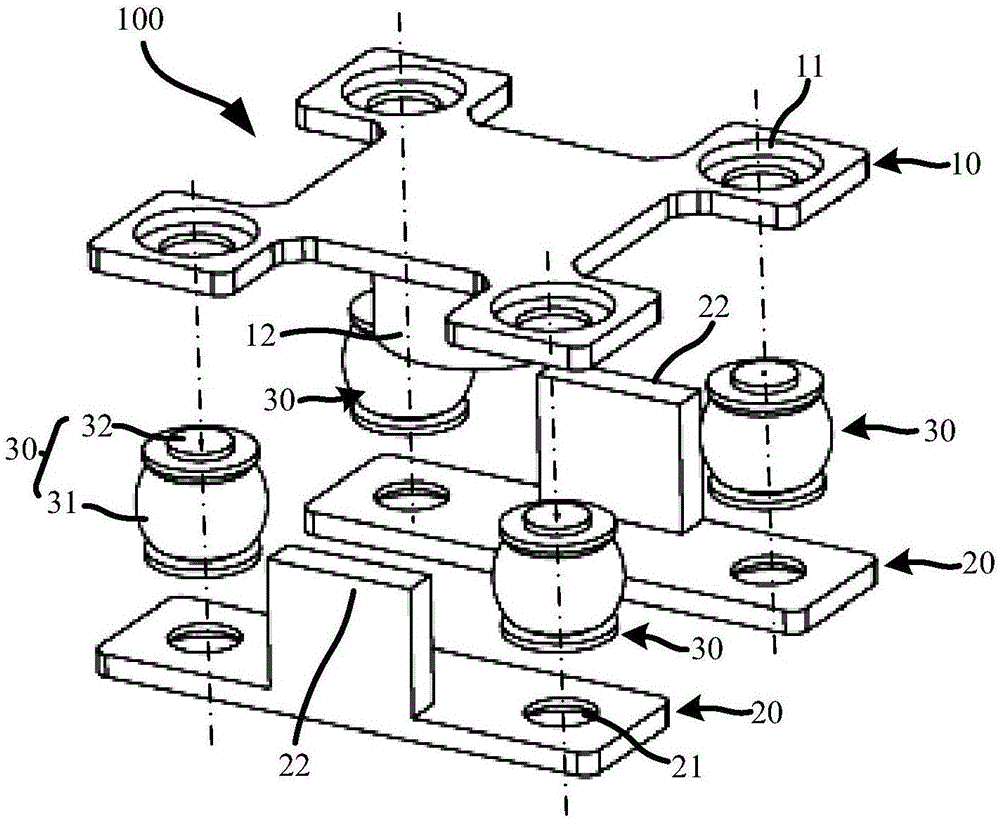

Shock-absorbing device and unmanned aerial vehicle

InactiveCN106352012AImprove stabilityReduce volumeAircraft componentsNon-rotating vibration suppressionLow frequency vibrationUnmanned spacecraft

Owner:ZHEJIANG HUAFEI INTELLIGENT TECH CO LTD

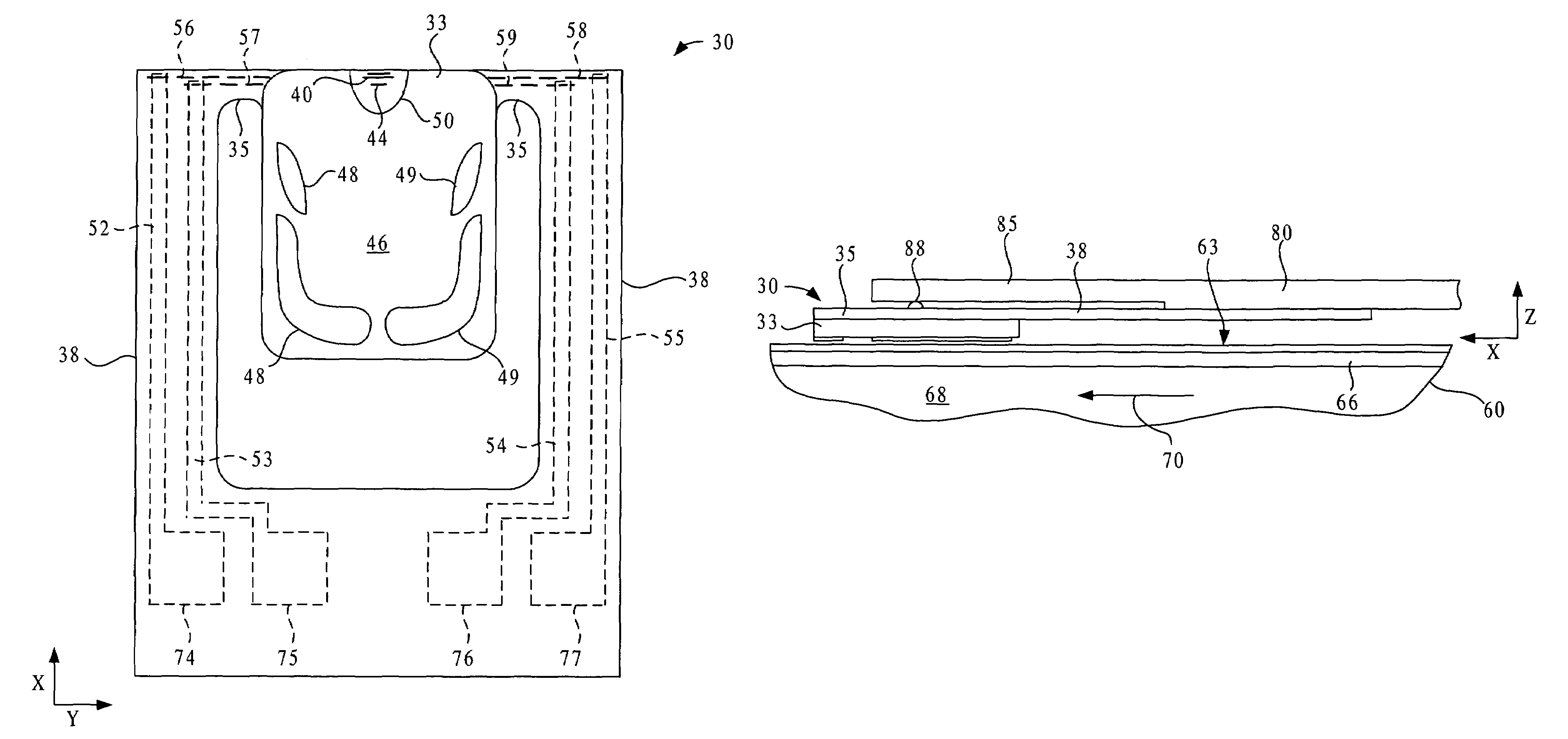

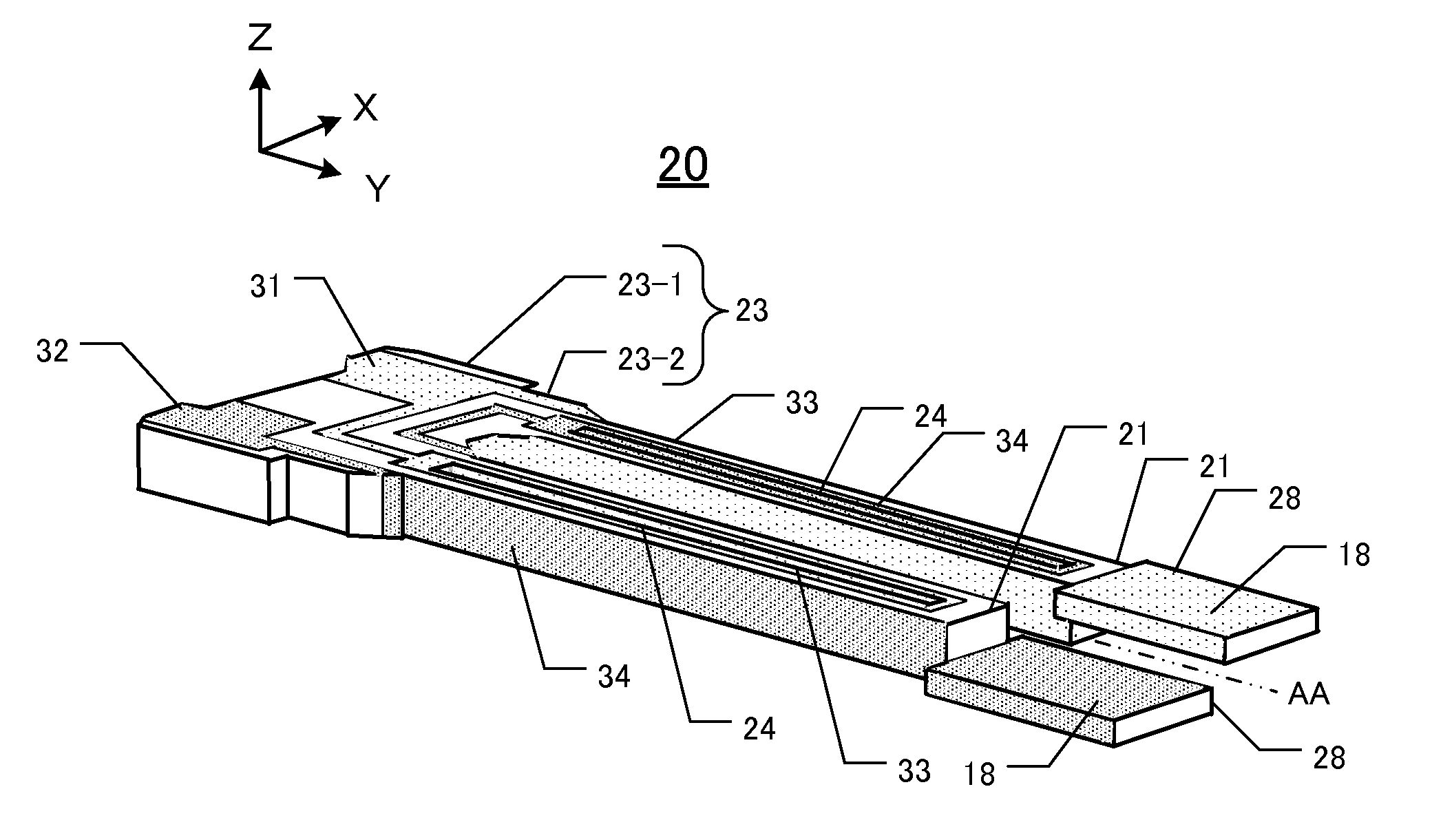

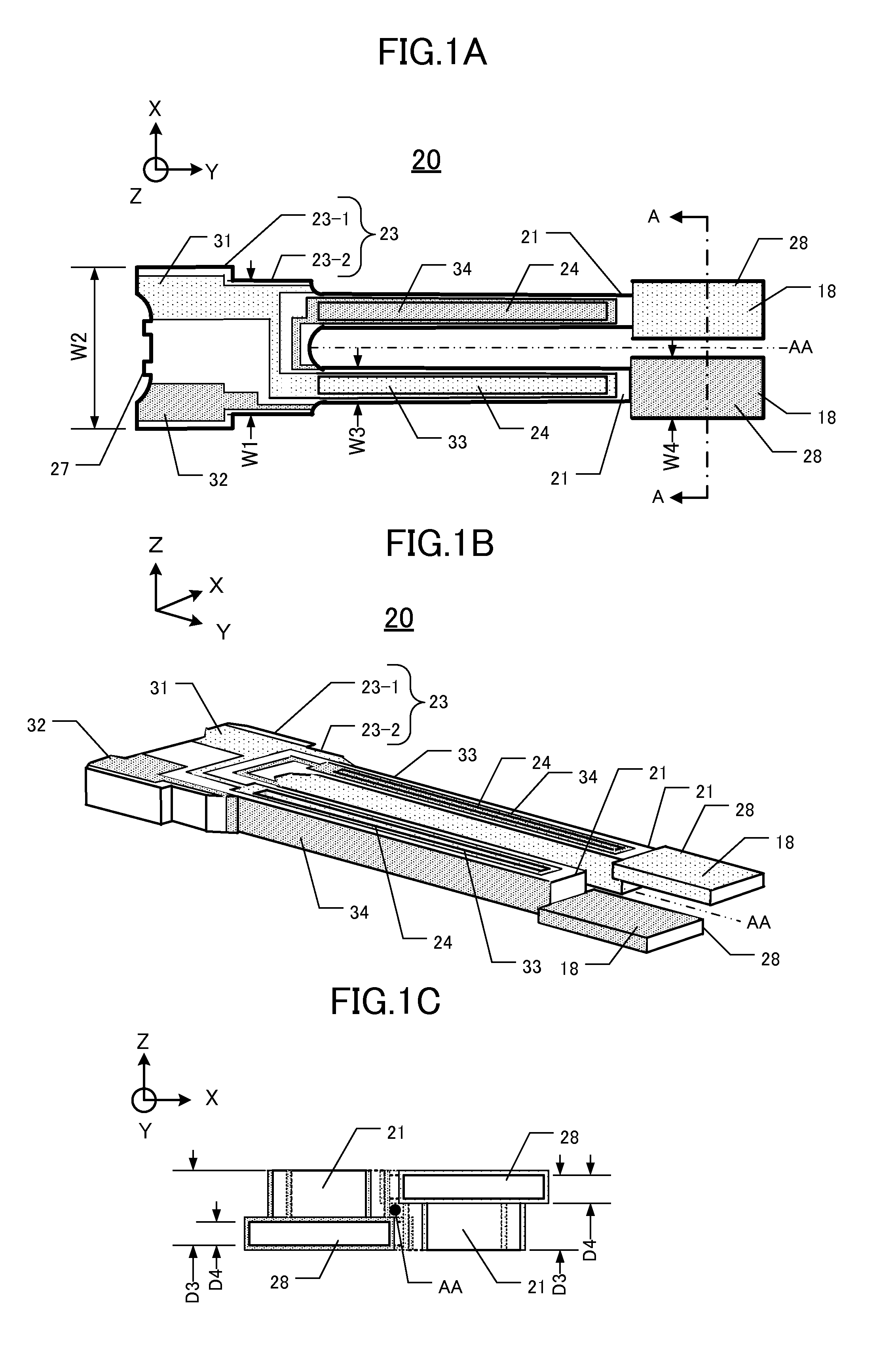

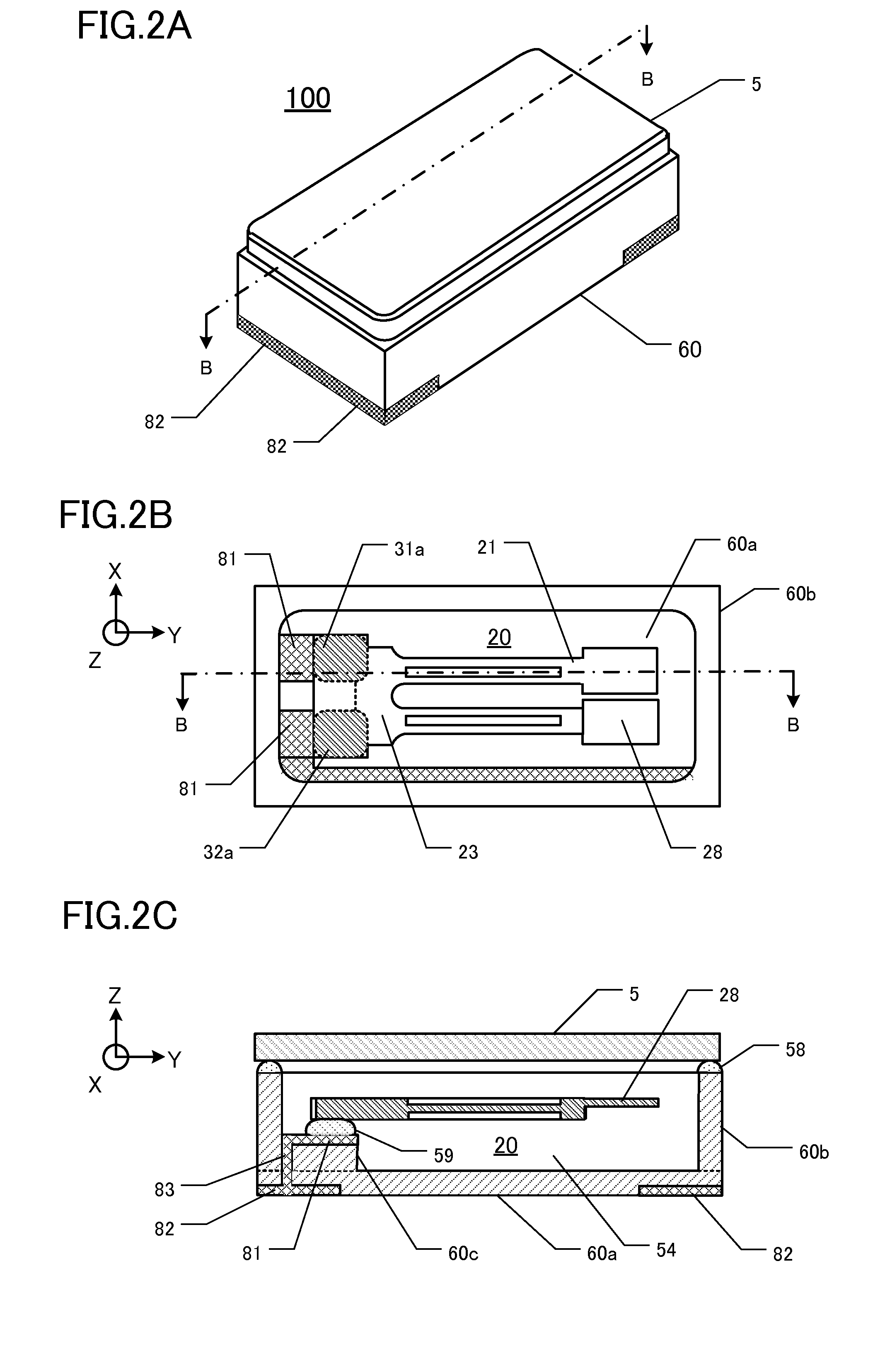

Tuning-fork type piezoelectric vibrating piece, piezoelectric frame, piezoelectric device, and a manufacturing method of tuning-fork type piezoelectric vibrating piece and piezoelectric frame

InactiveUS8203256B2Reduce thicknessReduce manufacturing stepsPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksTuning forkEngineering

A tuning-fork type crystal vibrating piece (20) is comprised of a base portion (23) comprising a piezoelectric material, a pair of parallel vibrating arms (21) with a designated thickness (D3) and width (W3) extend from the base portion, and a pair of weight portions (28) are formed by enlarging the width (W4) of the distal ends pair of vibrating arms. A cross-section of the pair of weight portions is formed symmetric with a central axis which is center of the pair of vibrating arms, and at least one portion of the pair of weight portions has a thickness which is less than the designated thickness (D3).

Owner:NIHON DEMPA KOGYO CO LTD

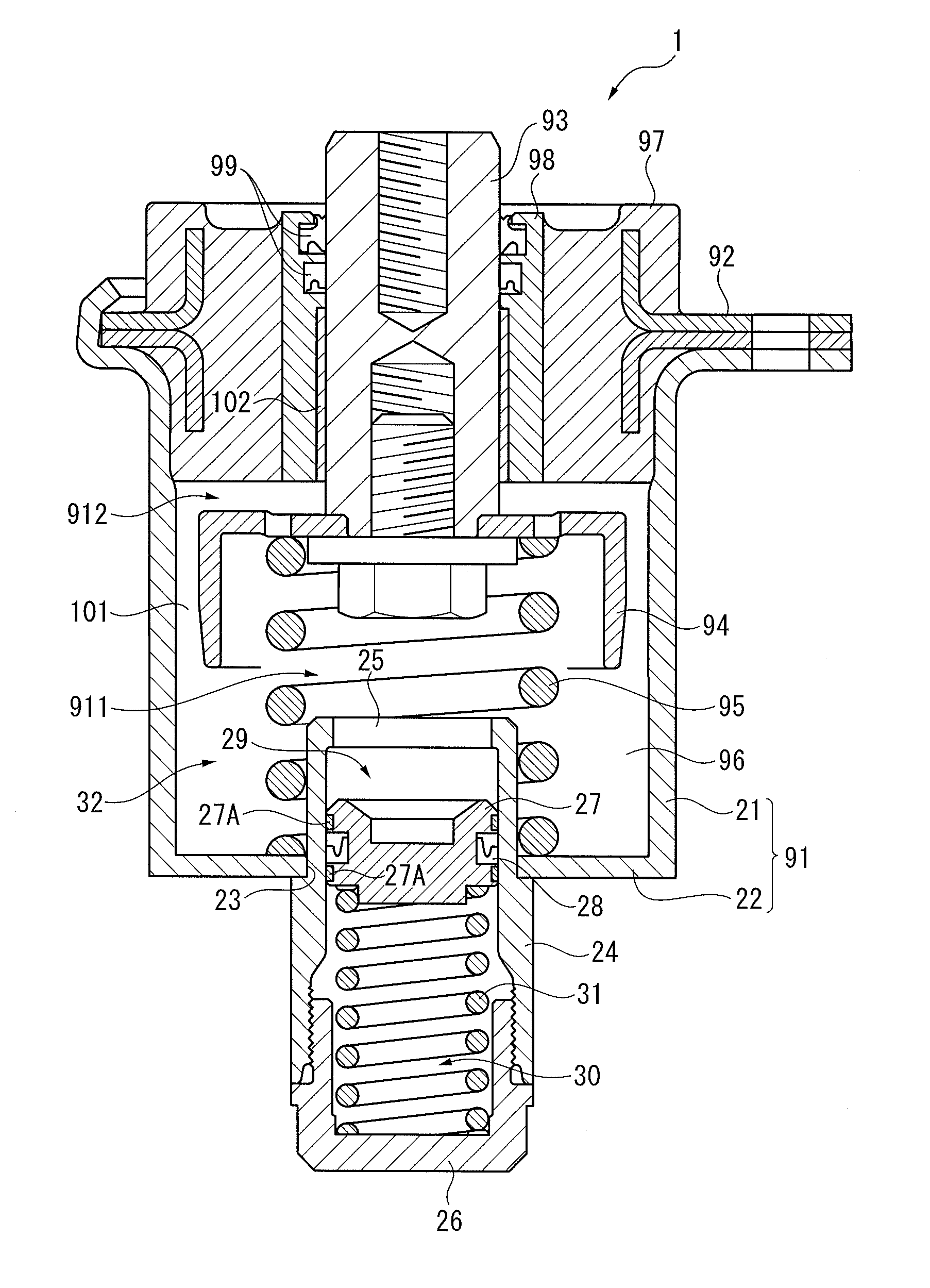

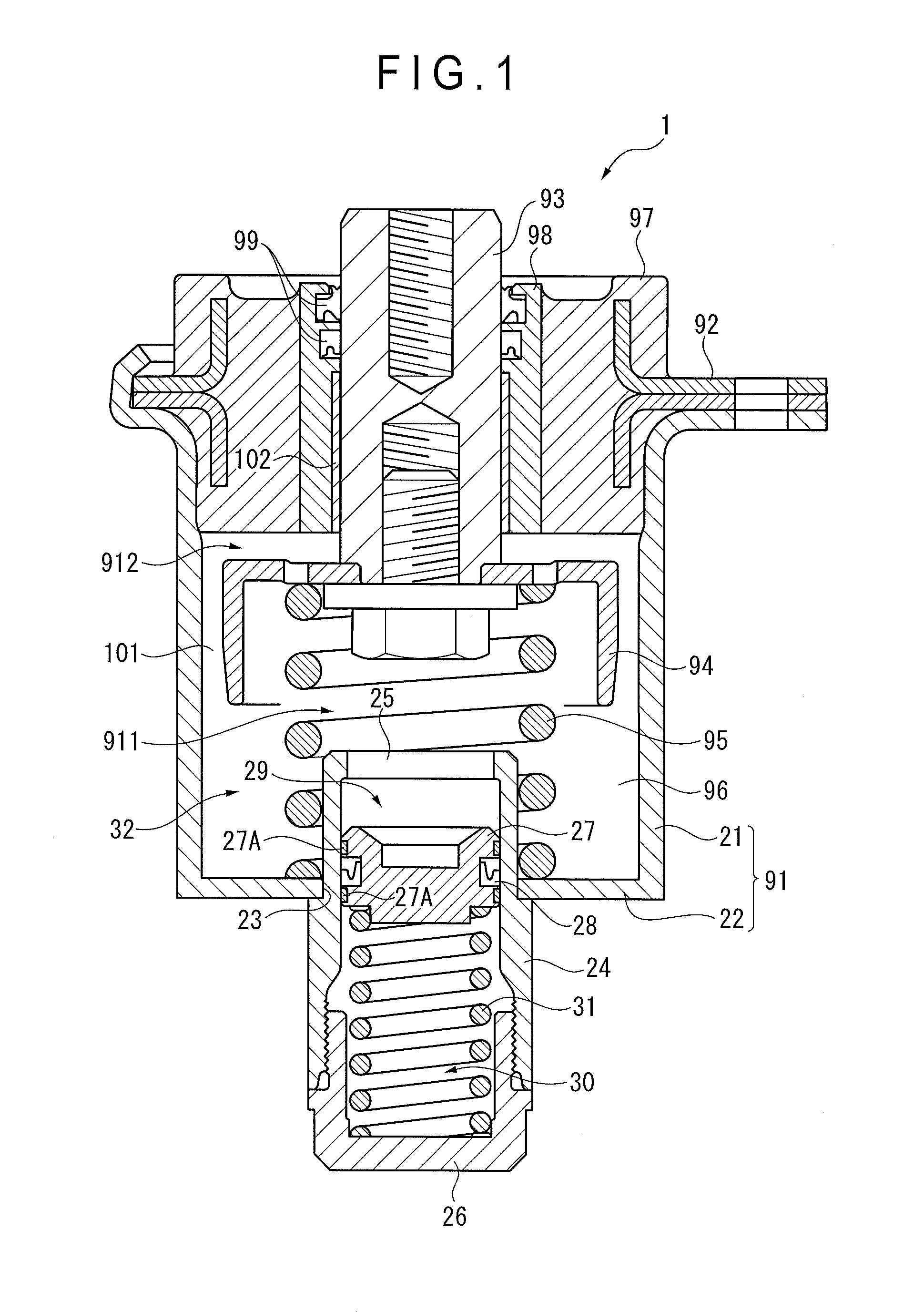

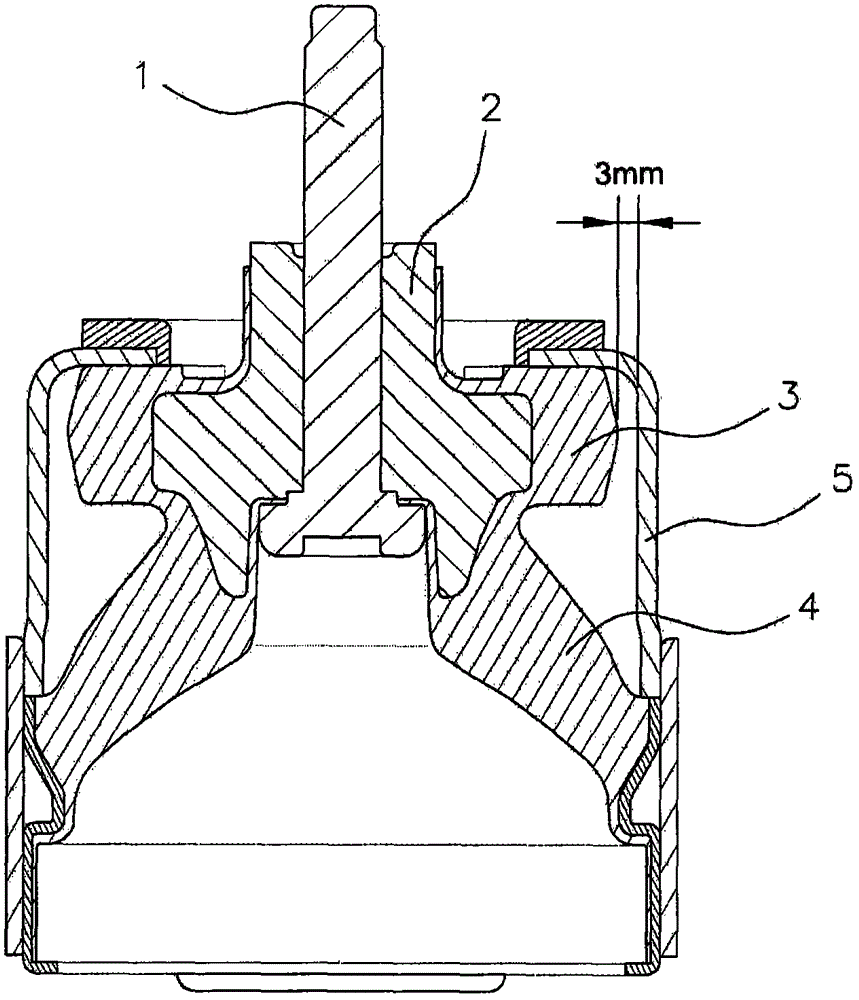

Liquid Sealed Mount

ActiveUS20110221107A1Superior anti-vibration characteristicLow fluid viscosityMachine framesLiquid springsDifferential pressureEngineering

A hydraulic mount includes: a container in which a high-viscosity fluid is liquid-tightly sealed; a rubber mount that is provided on an upper side of the container; a rod that slidably penetrates through the rubber mount; a damper plate that is provided to an end of the rod; a damping force generator that is provided by a clearance between the container and the damper plate; a main fluid chamber that includes an upper fluid chamber and a lower fluid chamber provided by dividing an interior of the container by the damper plate; a volume-variable secondary fluid chamber that communicates with the main fluid chamber; and a pressurizer that generates a differential pressure between the upper fluid chamber and the lower fluid chamber during the movement of the rod.

Owner:KOMATSU LTD

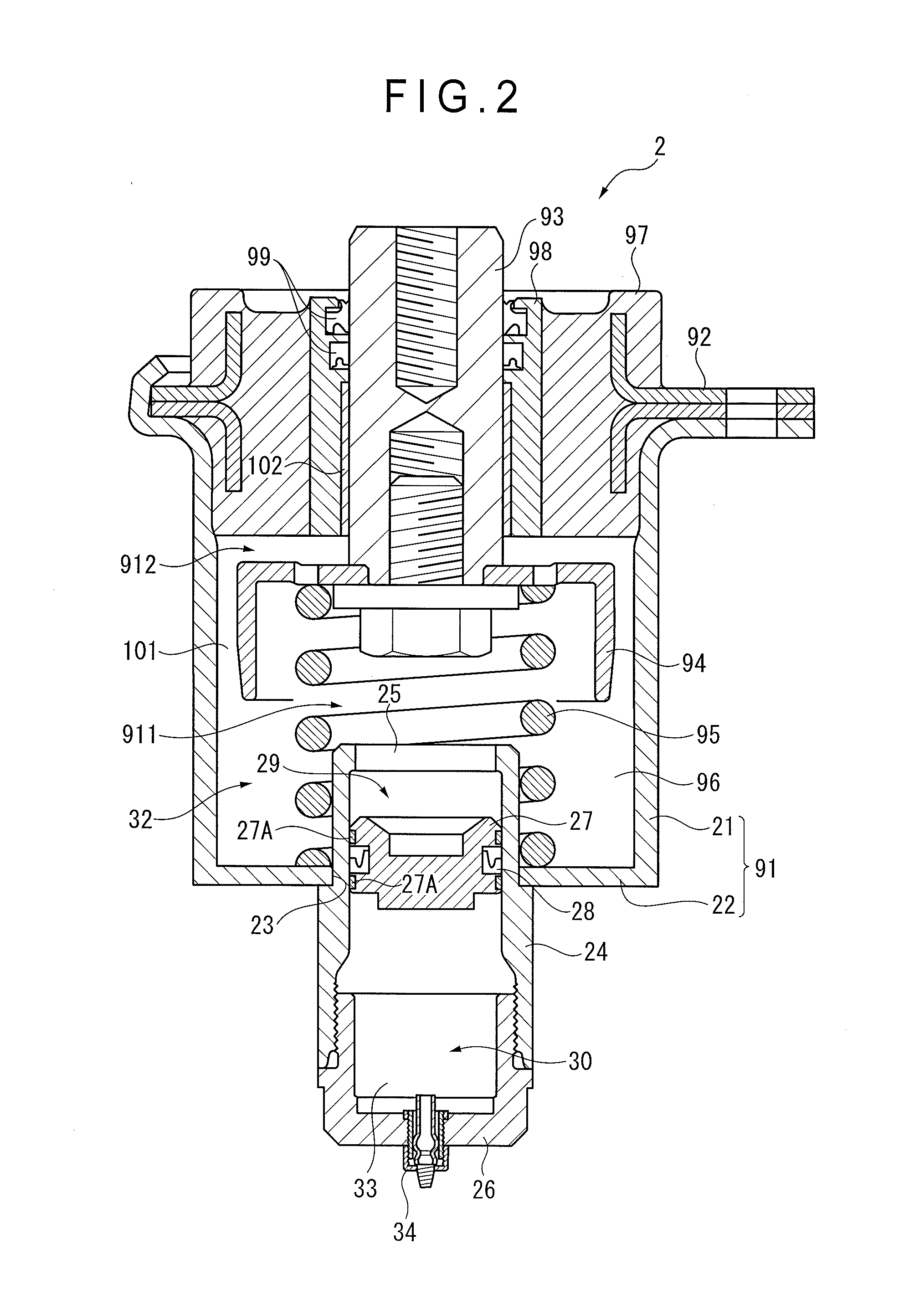

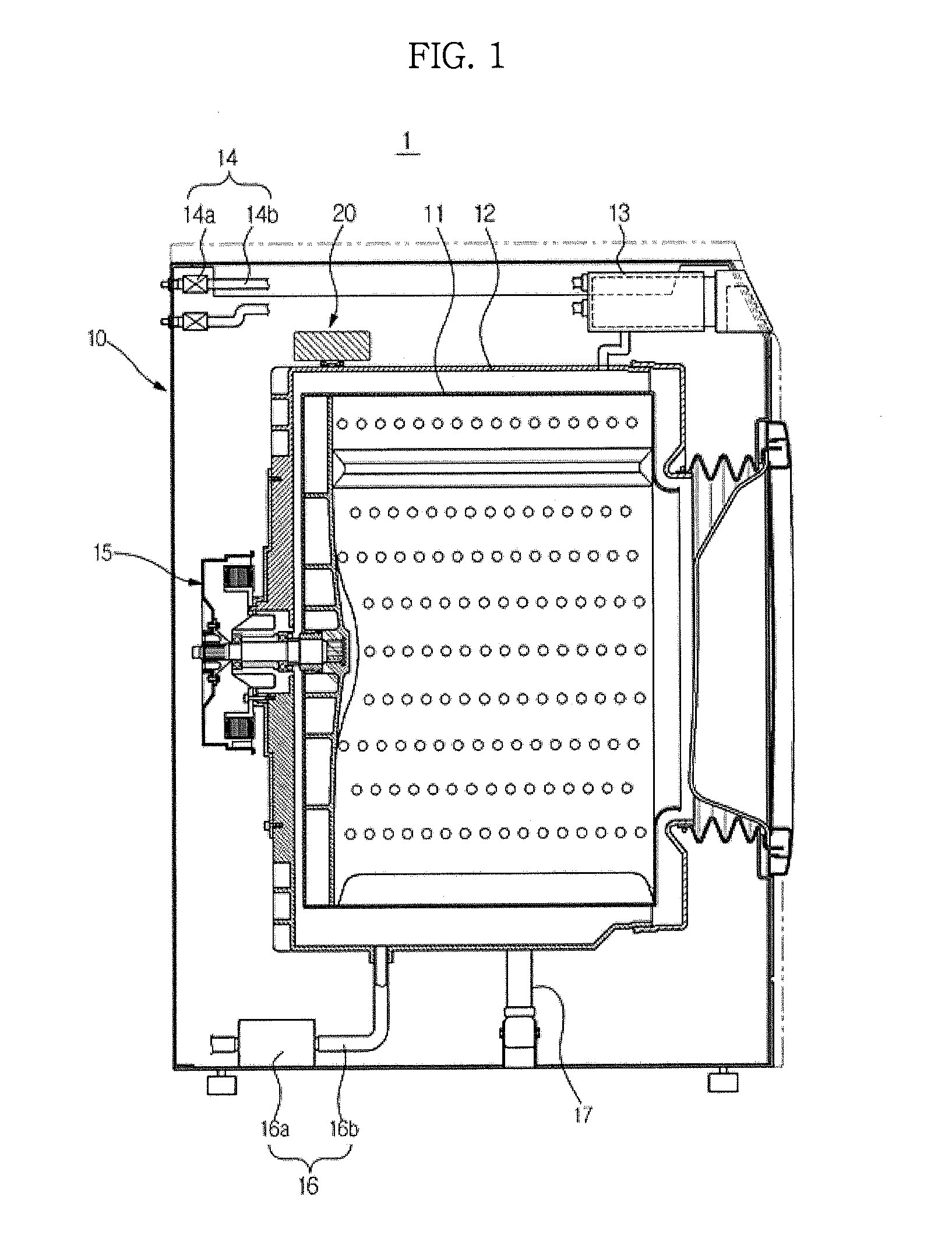

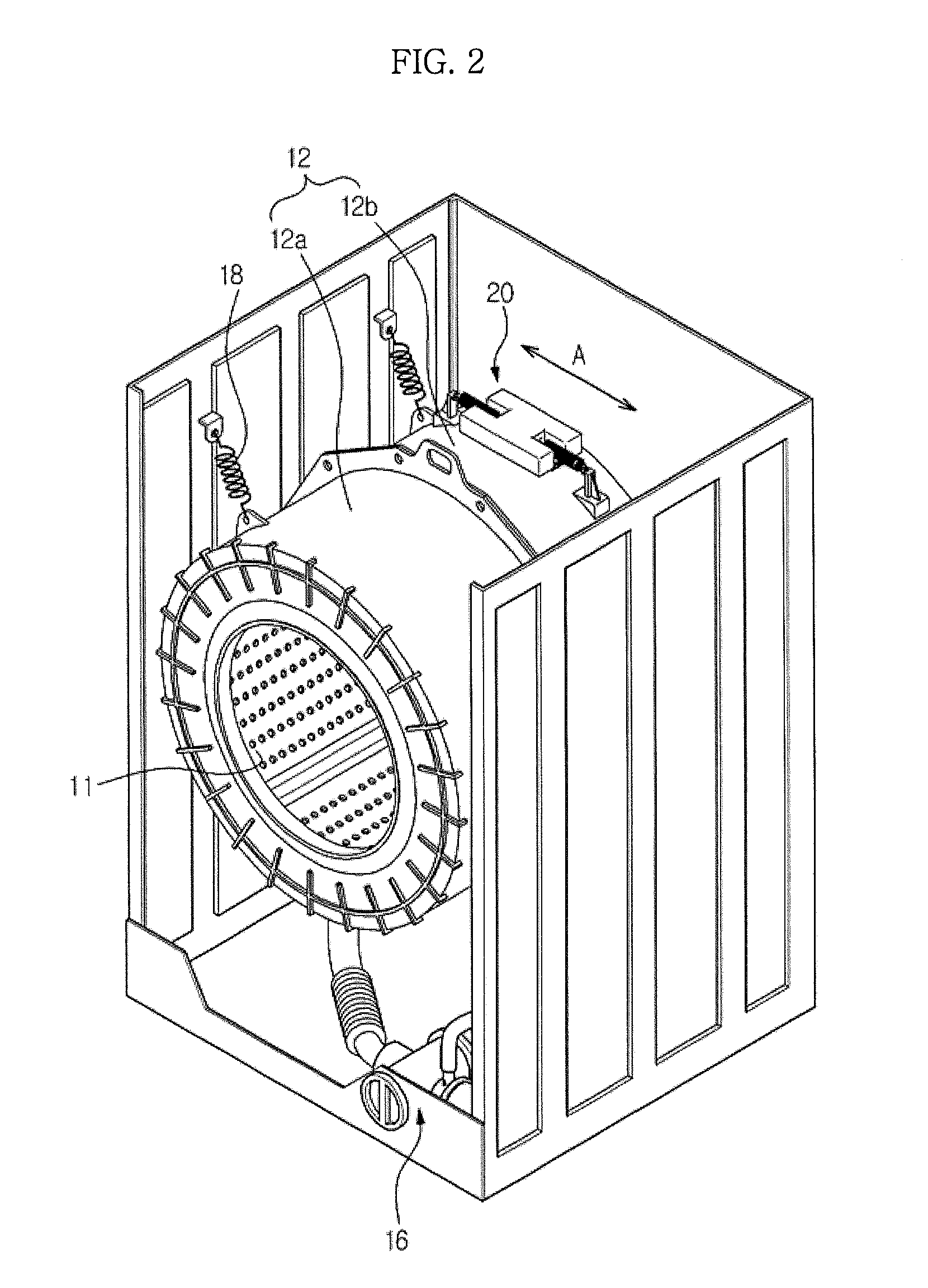

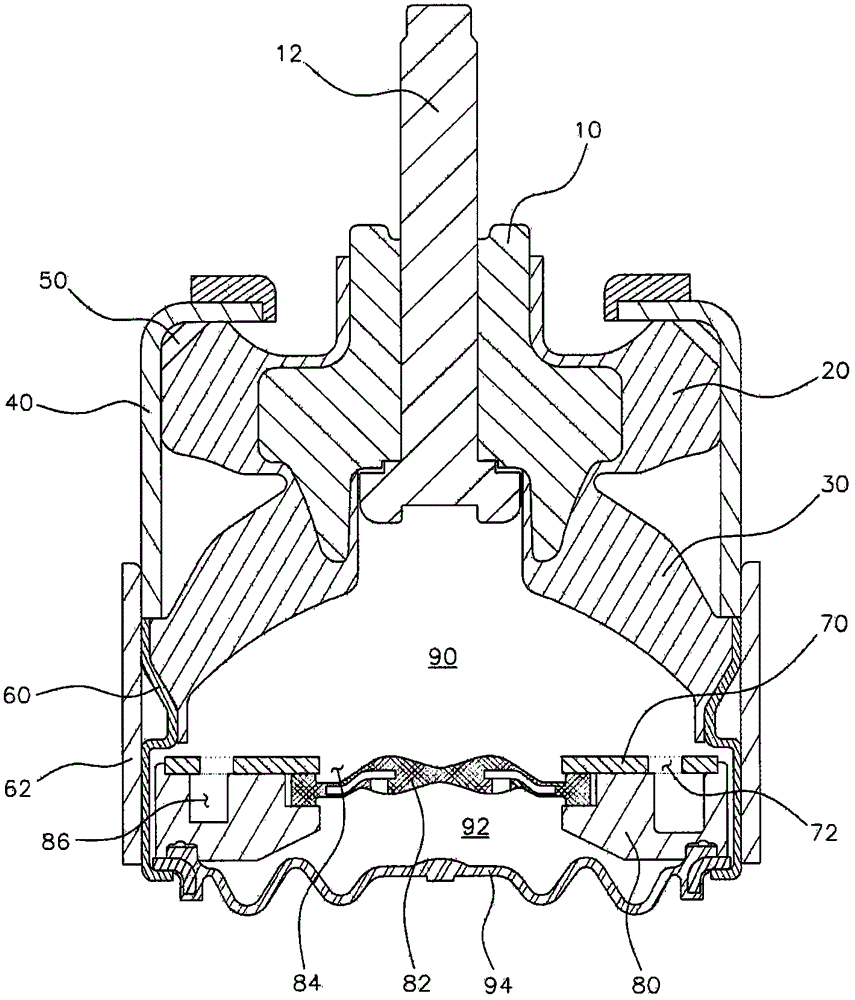

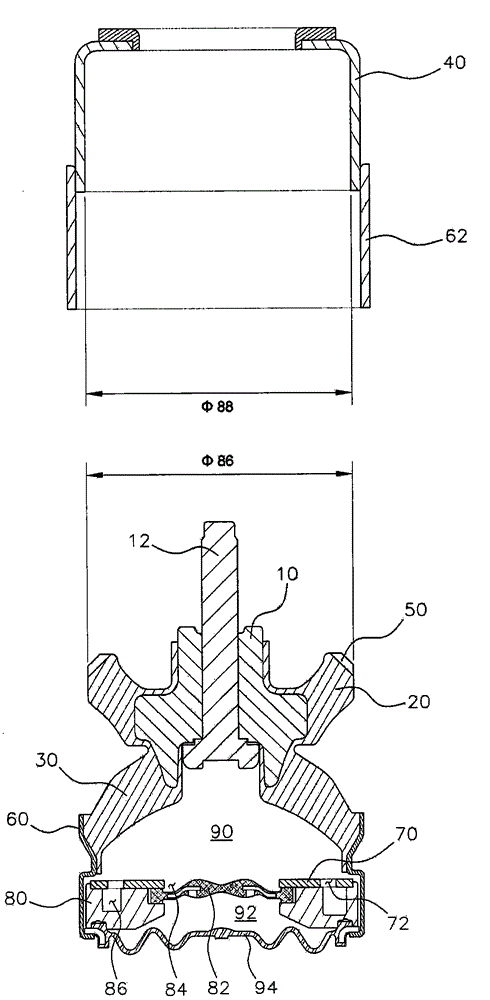

Drum washing machine

InactiveUS20130118211A1Excessive vibrationReduce vibrationRotating vibration suppressionNon-rotating vibration suppressionLow frequency bandEngineering

A drum washing machine provided with a dynamic absorber capable of reducing the vibration of a low frequency band, the drum washing machine including a body, a drum rotatably installed at an inside the body, a tub installed to vibrate while surrounding the drum, and a dynamic absorber installed at the tub to directly reduce vibration delivered to the tub, wherein the dynamic absorber includes a mass body and an elastic member configured to elastically support the mass body for the mass body to move toward a direction of the vibration of the tub to reduce the vibration of the tub.

Owner:SAMSUNG ELECTRONICS CO LTD

Vibration damping device, method of controlling vibration damping device, method of correcting offset of vibration damping device, and leaf spring

InactiveCN101557955AReduce vibrationReduce low frequency vibrationVehicle body stabilisationNon-rotating vibration suppressionEngineeringEngine mount

The invention provides a vibration damping device, a method of controlling the vibration damping device, a method of correcting offect of the vibration damping device and a leaf spring. The vibration damping device for an automobile, in which a power plant constructed from an engine and a transmission that are joined to each other is supported on a vehicle body through engine mounts in order to isolate vibration. The vibration damping device has vibration exciting means for generating vibration different from that of the engine, so that the amplitude of vibration of a seat etc. can be reduced by reaction force of the vibration exciting means. When the mode of vibration of the vehicle body is adjusted so as to have a node of the vibration near the seat, the amplitude of vibration of the vehicle body near the seat is reduced to improve ride comfort of the automobile.

Owner:SINFONIA TECHNOLOGY CO LTD

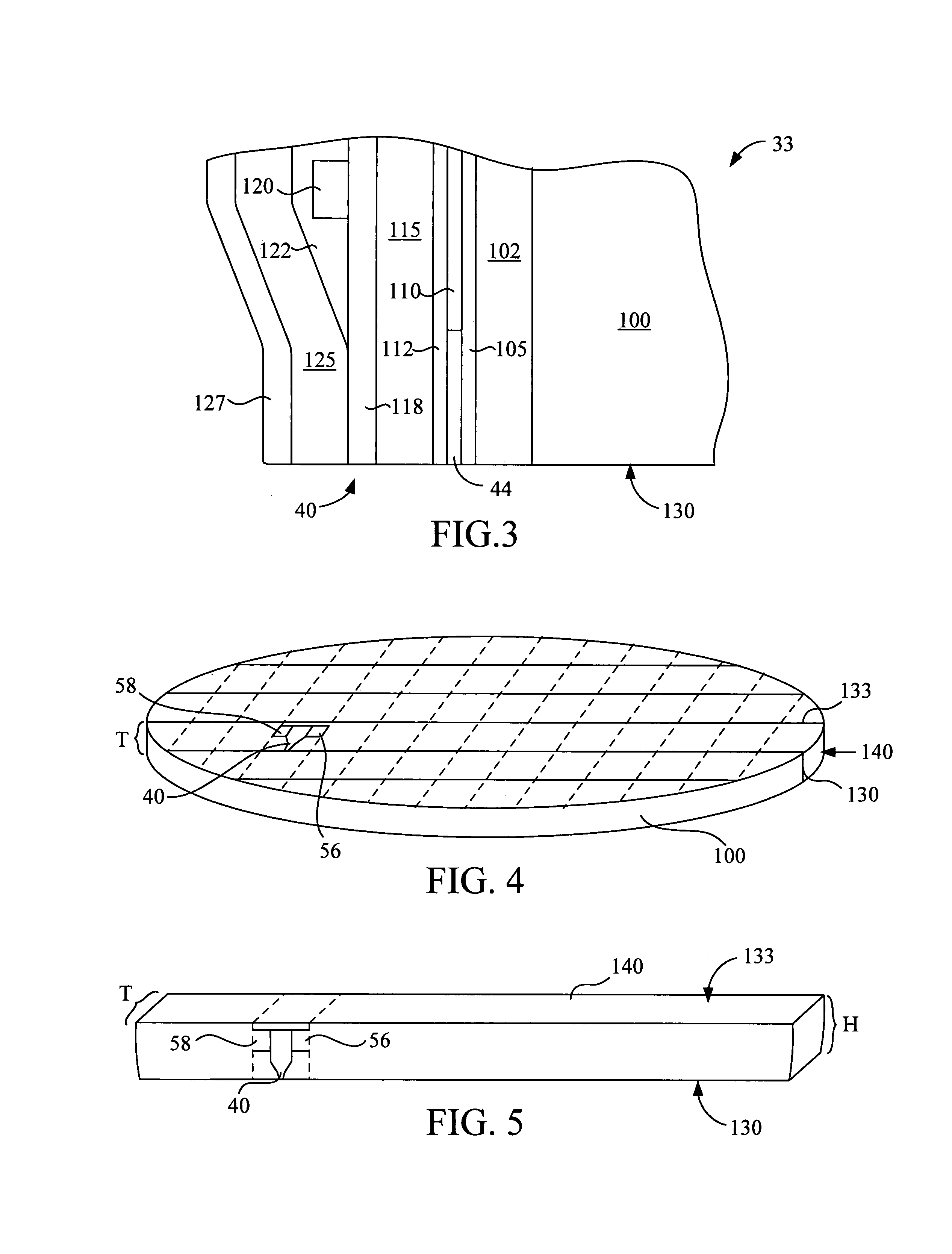

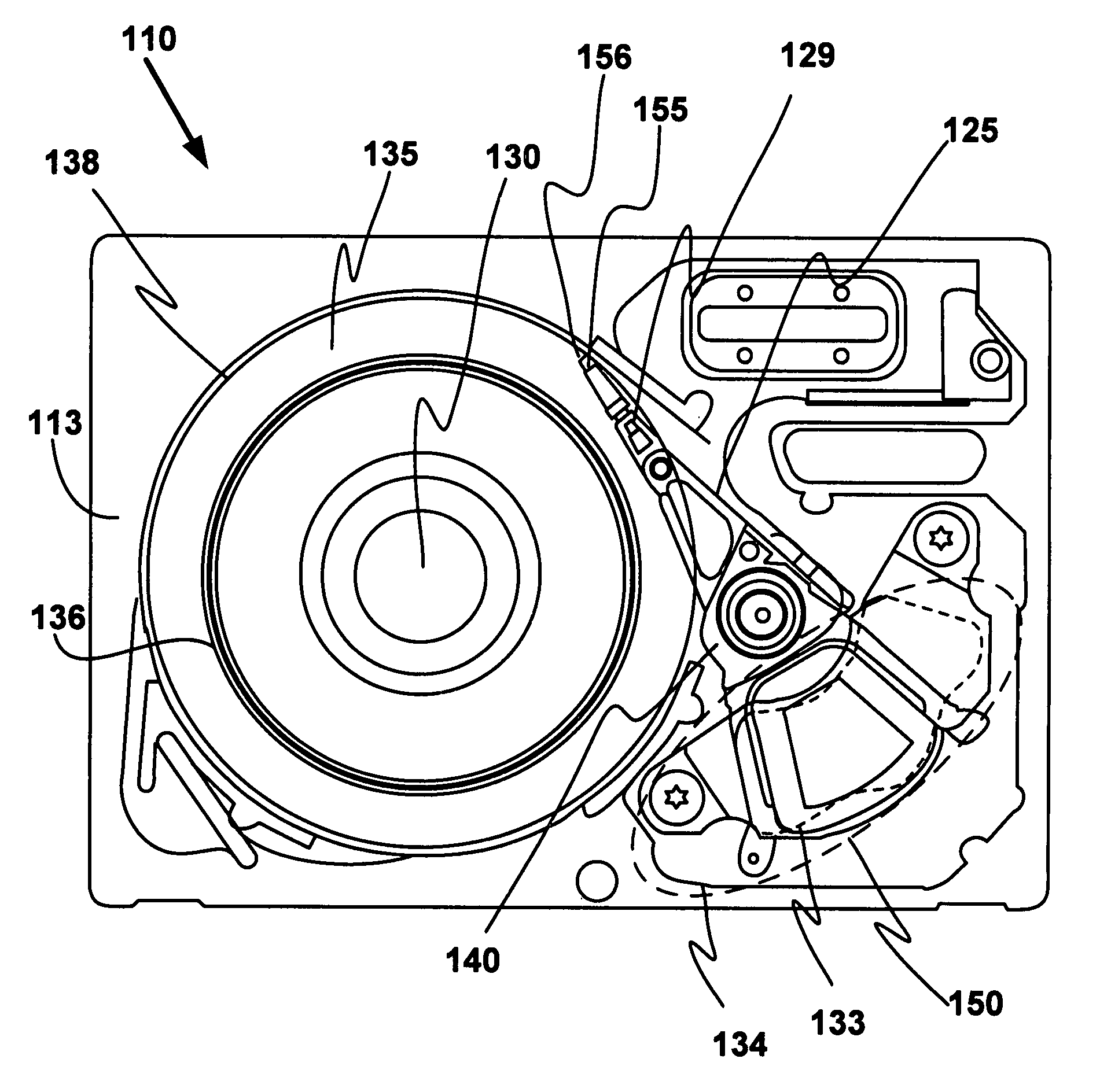

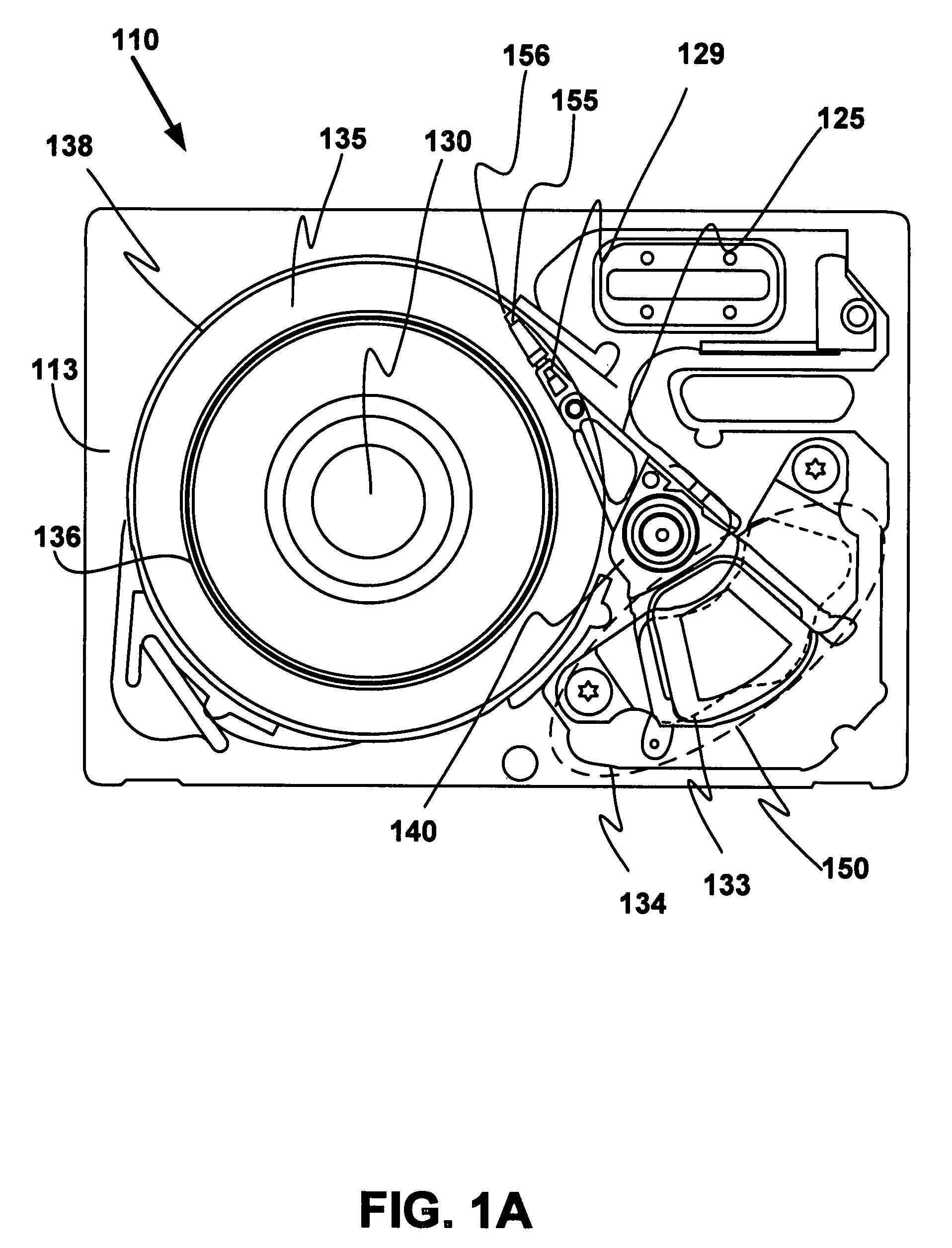

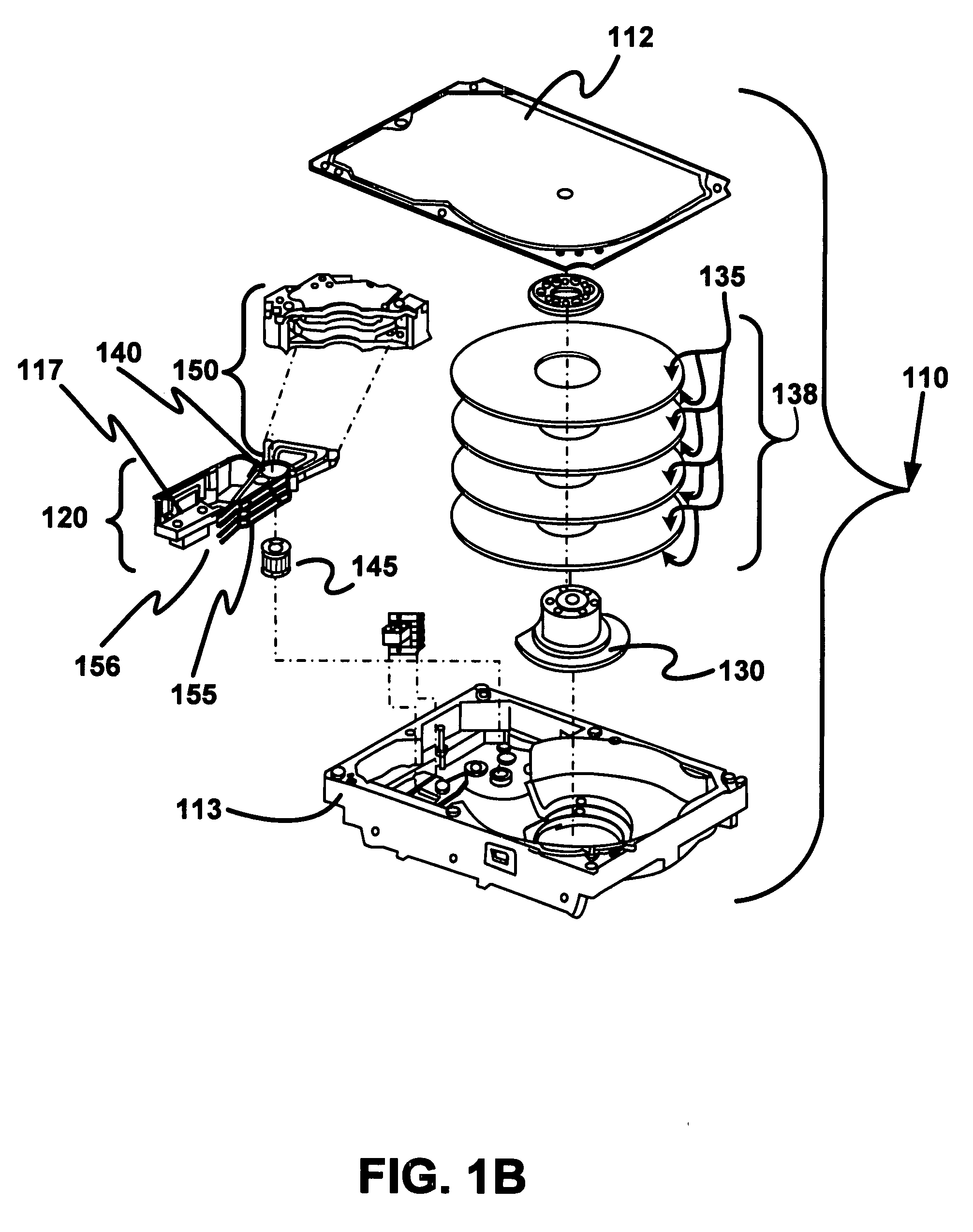

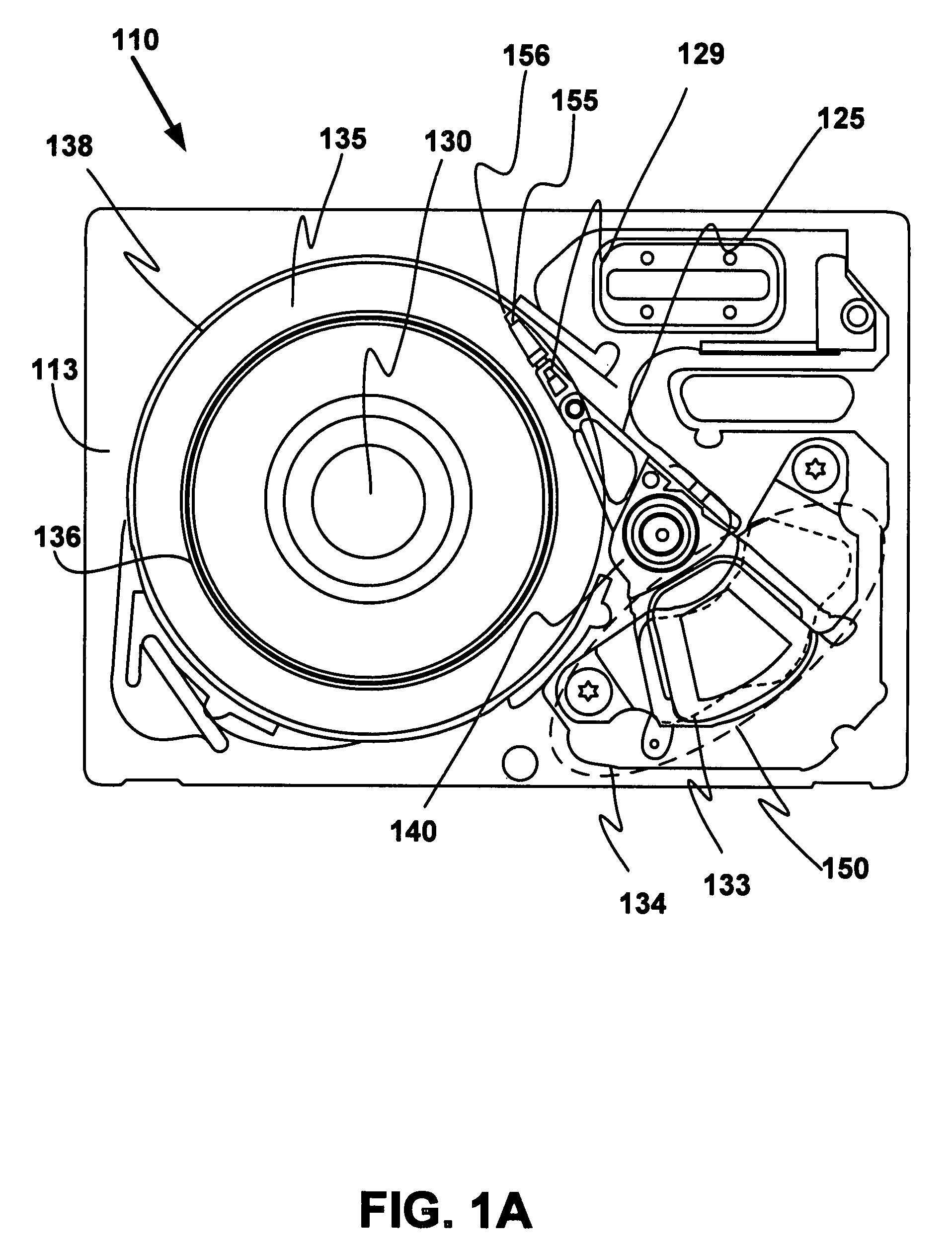

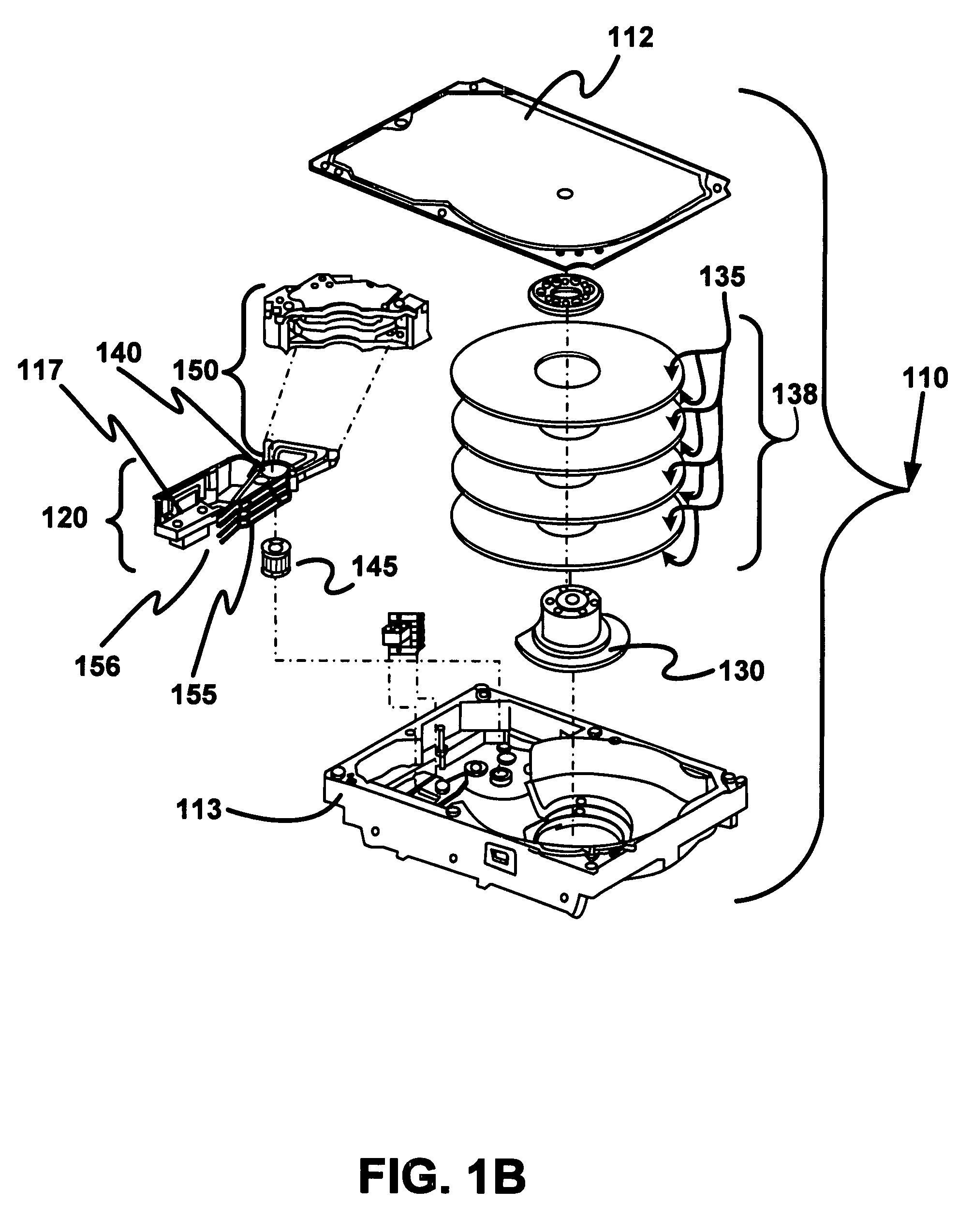

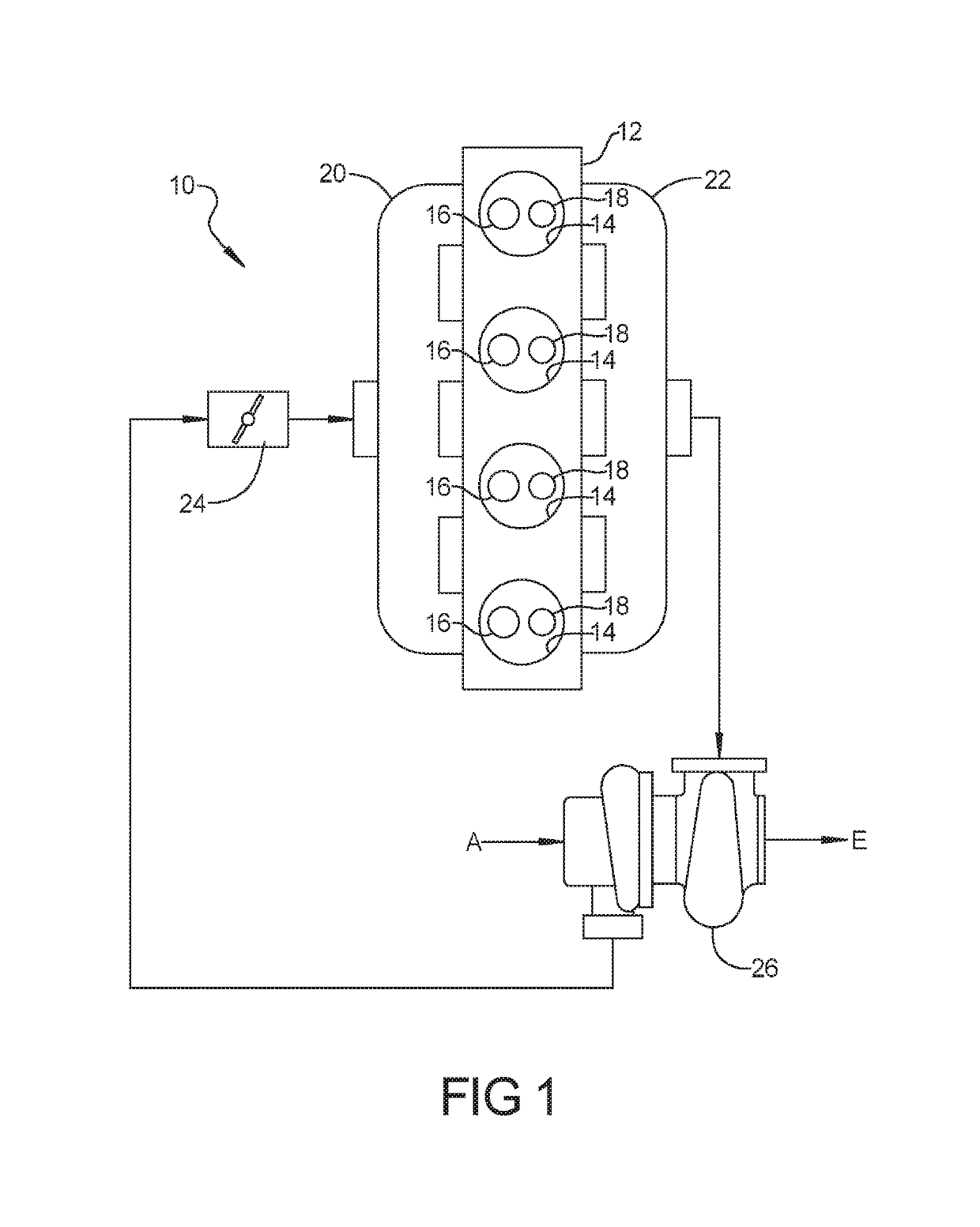

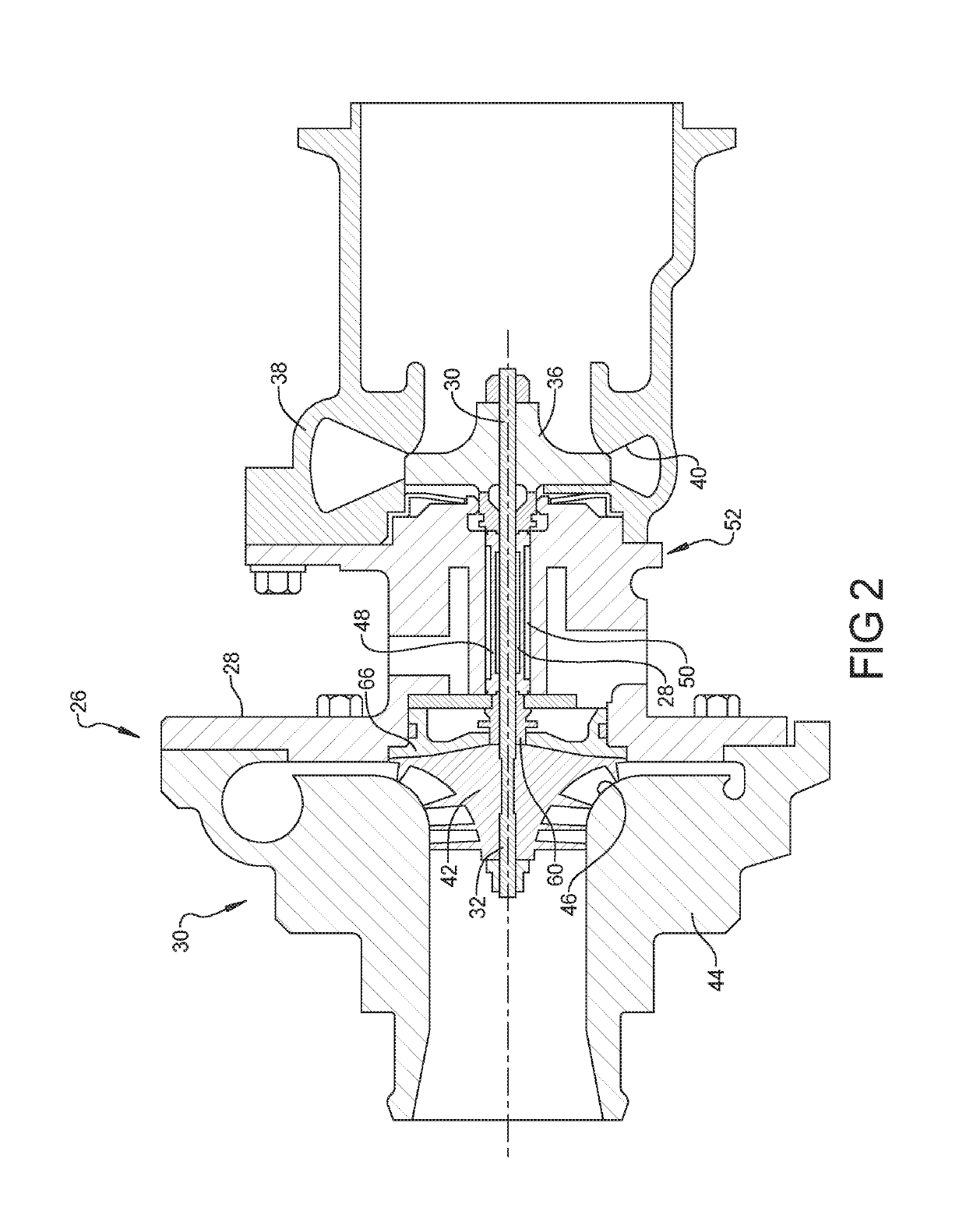

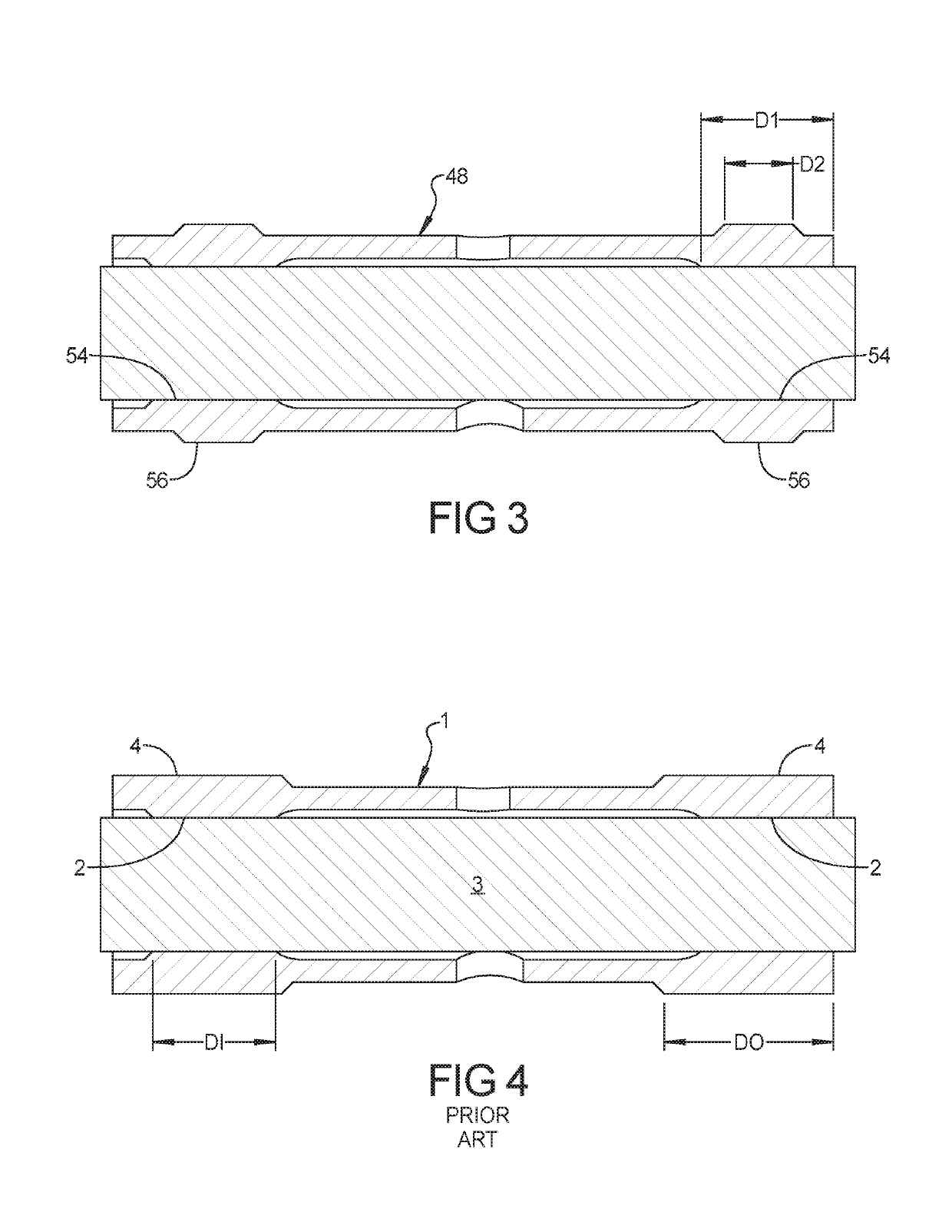

Plurality of non-magnetic dampers on a voice coil yoke arm

InactiveUS20080310054A1Reduce low frequency vibrationReduce vibrationDisposition/mounting of recording headsUndesired vibrations/sounds insulation/absorptionResonanceEngineering

A plurality of non-magnetic dampers on a voice coil yoke arm for reducing low frequency vibration in a hard disk drive is disclosed. One embodiment provides housing and at least one disk coupled with the housing. In addition, an actuator is coupled to the housing, the actuator having a coil region with a voice coil and a plurality of voice coil yoke arms. At least one of a plurality of non-magnetic dampers is also coupled with each of the plurality of voice coil yoke arms and not with the voice coil. In so doing, the plurality of non-magnetic dampers are able to damp low frequency actuator coil torsion and coil bending resonances.

Owner:WESTERN DIGITAL TECH INC

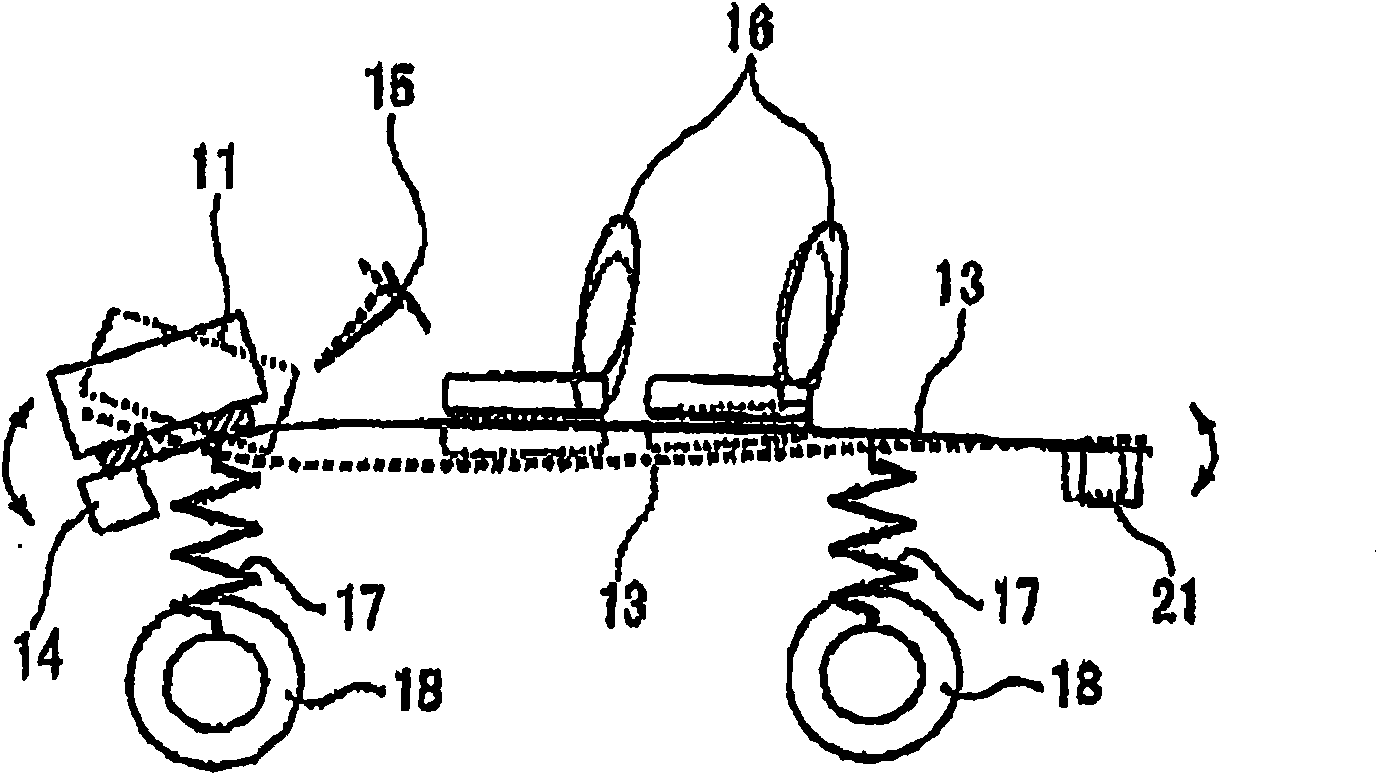

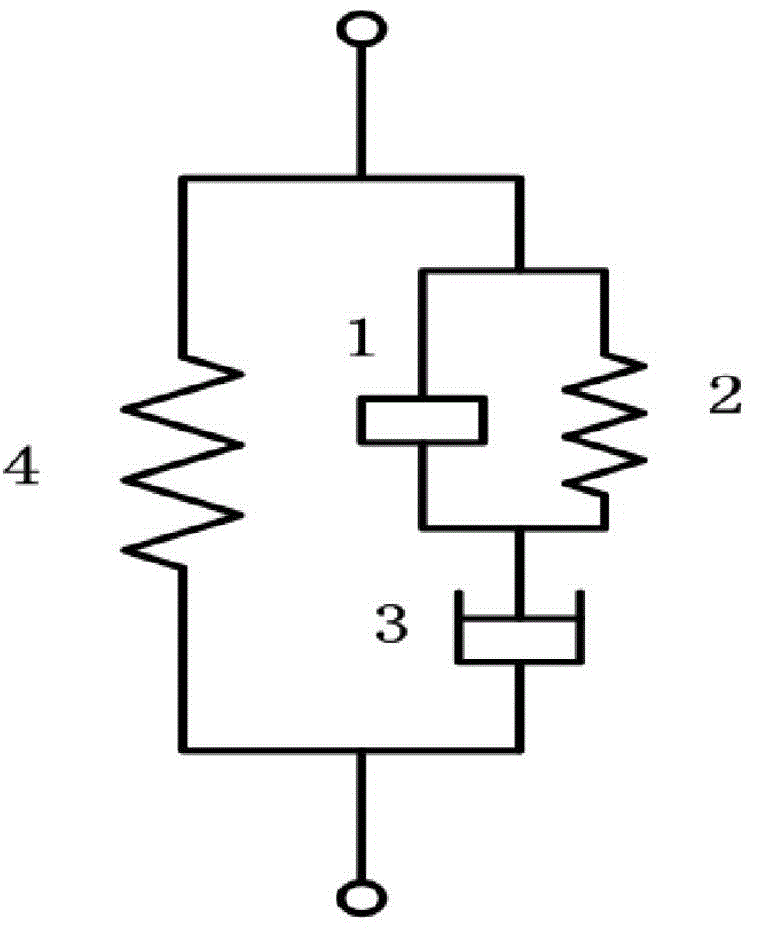

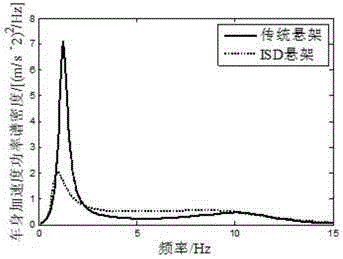

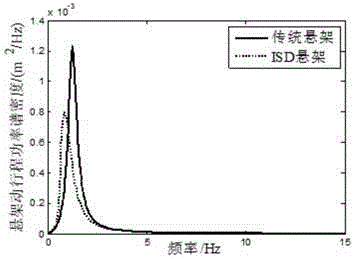

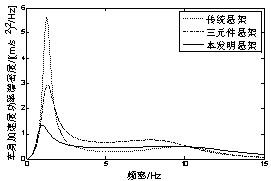

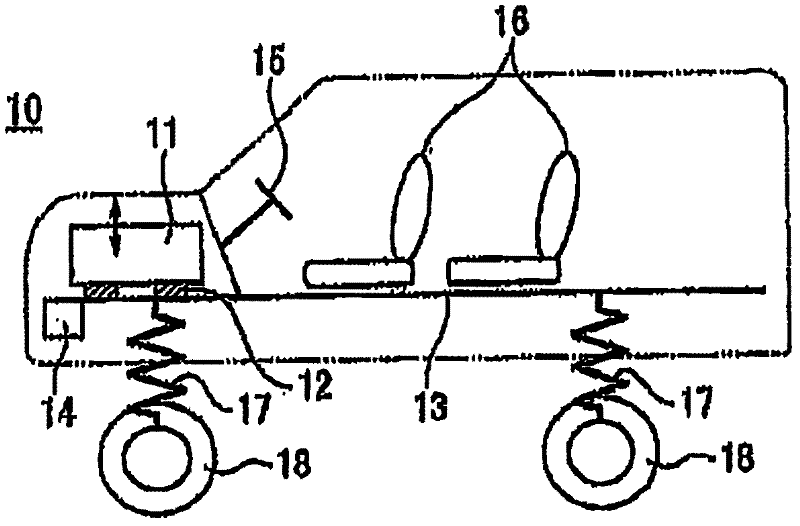

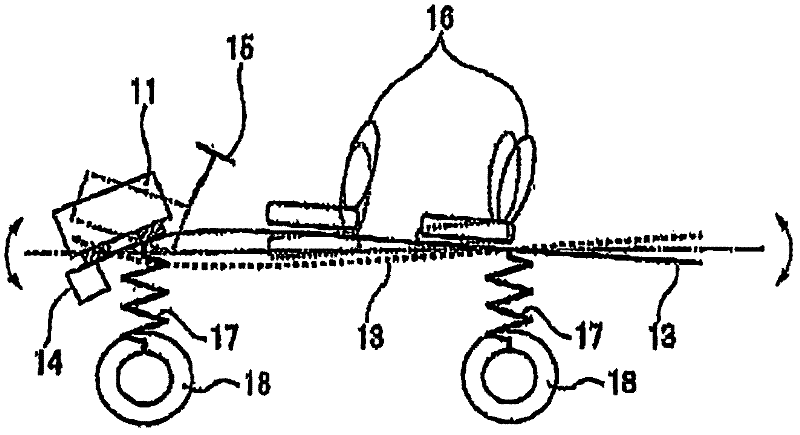

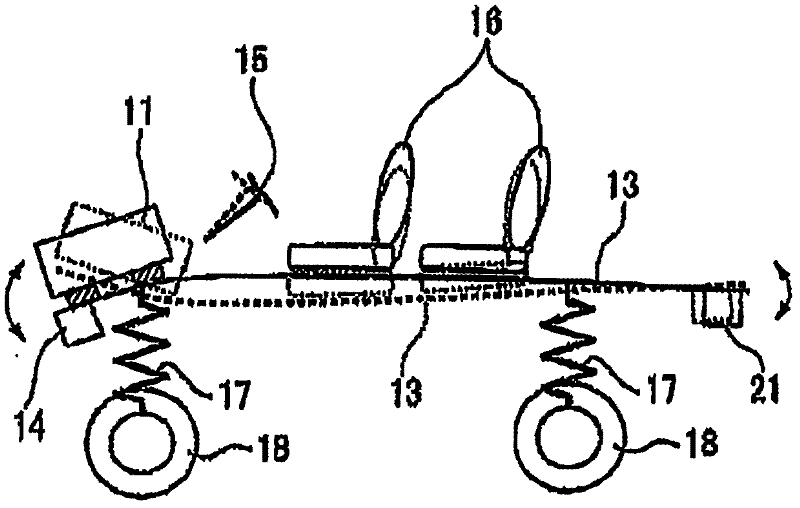

Inerter suspension of vehicle

InactiveCN104691264AImprovement of root mean square value of tire dynamic loadImprove ride comfort and ride comfortResilient suspensionsAutomotive engineeringEngineering

The invention provides an inerter suspension of a vehicle, and belongs to the field of a vehicle suspension. According to the inerter suspension of the vehicle, an auxiliary spring is connected with an inerter in parallel and then is connected with a damper in series, and in order to solve the problem of overload failure of a passive mechanical element because of bearing for the vehicle body weight, a main spring is added and connected in parallel with a two-stage structure formed by the auxiliary spring, the inerter and the damper. Compared with a traditional suspension, the performance of the inerter suspension is remarkably improved, and three vehicle running smoothness evaluation indexes including a vertical acceleration root-mean-square value of a vehicle body, a dynamic travel root-mean-square value of the suspension and a dynamic load root-mean-square value of each tire are remarkably reduced. The novel inerter suspension of the vehicle has certain application value in the field of the vehicle suspension.

Owner:JIANGSU UNIV

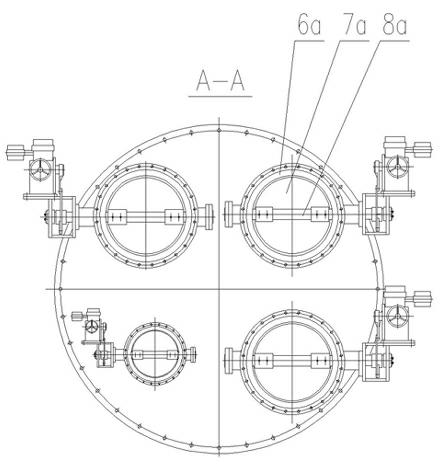

Pressure regulating valve group of pressure regulating cone valve

ActiveCN102359631AReduce turbulenceSolve the damageBlast furnace componentsValve members for absorbing fluid energyDrive shaftEconomic benefits

The invention relates to pressure regulating valve group equipment which controls top gas pressure of an iron making blast furnace and can control the top pressure of the blast furnace in a range required by an iron making process. The equipment comprises a front pipe, a front guide pipe, a pressure regulating cone valve, a rear guide cone pipe and a rear pipe, wherein a guide cylinder is arranged in a shell of the pressure regulating cone valve; a valve flap is arranged in the guide cylinder and provided with a sealing ring; a flow guide plate is arranged in the shell and connected with a valve seat; sealing surfaces which are mutually matched are arranged between the valve flap and the valve seat; the valve flap is connected with a valve rod; a rocker is connected with a transmission shaft through a key; and when a driving device drives the transmission shaft to rotate, the rocker and a connecting rod are driven to rotate, and the valve rod and the valve flap move back and forth, sothat the opening and closing process of the pressure regulating cone valve is operated. The circulation area of gas flow between the valve flap and the valve seat is changed by moving the valve flap back and forth to fulfill the aim of pressure regulating, so that the service life of a pressure regulating valve group can be greatly prolonged, the safe, reliable and high-efficiency production of the blast furnace is ensured, and economic benefits and social benefits are obvious.

Owner:SHIJIAZHUANG SHITE VALVE

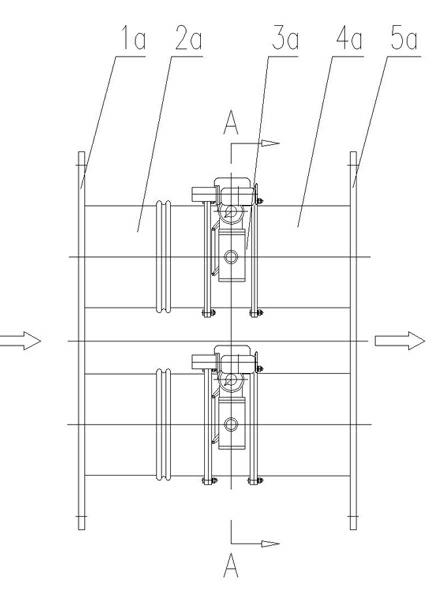

Hydro-pneumatic spring device with inerter and damper connected in parallel

InactiveCN103711827AIncreased sprung massImprove ride comfort and handling stabilitySpringsShock absorbersCylinder blockImpact

The invention discloses a hydro-pneumatic spring device with an inerter and a damper connected in parallel. The hydro-pneumatic spring device comprises a single air chamber hydro-pneumatic spring and a hydraulic motor. In the hydro-pneumatic spring device, a hydraulic cylinder and a gas spring are connected in series and of an integral structure and can buffer and attenuate high-band impact and vibration from a road surface. When external force from a vehicle body and the ground is exerted on a piston rod inside a working cylinder in the axial direction of a shock absorber, a piston does linear movement relative to a cylinder body, the pressure difference is formed between an upper cavity of the hydraulic cylinder and a lower cavity of the hydraulic cylinder, working oil passes through a damper valve, the hydraulic motor and the gas spring, the inerter function is achieved, and the effect that the inerter and the damper are connected in parallel and then connected with the gas spring in series is achieved through combination with the electromechanical analog theory. The hydro-pneumatic spring device can buffer and attenuate impact and vibration from the rough road surface within the full-frequency-domain range, is compact in structure and flexible to arrange, and has certain engineering application value.

Owner:JIANGSU UNIV

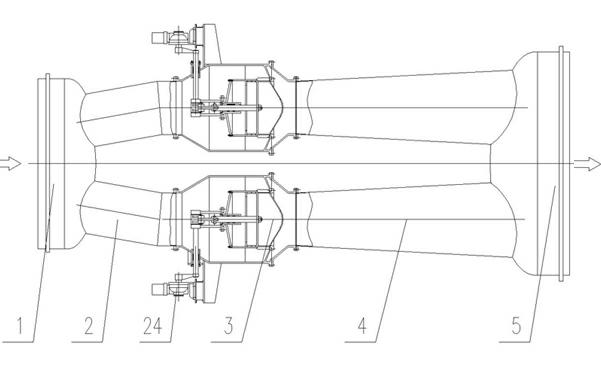

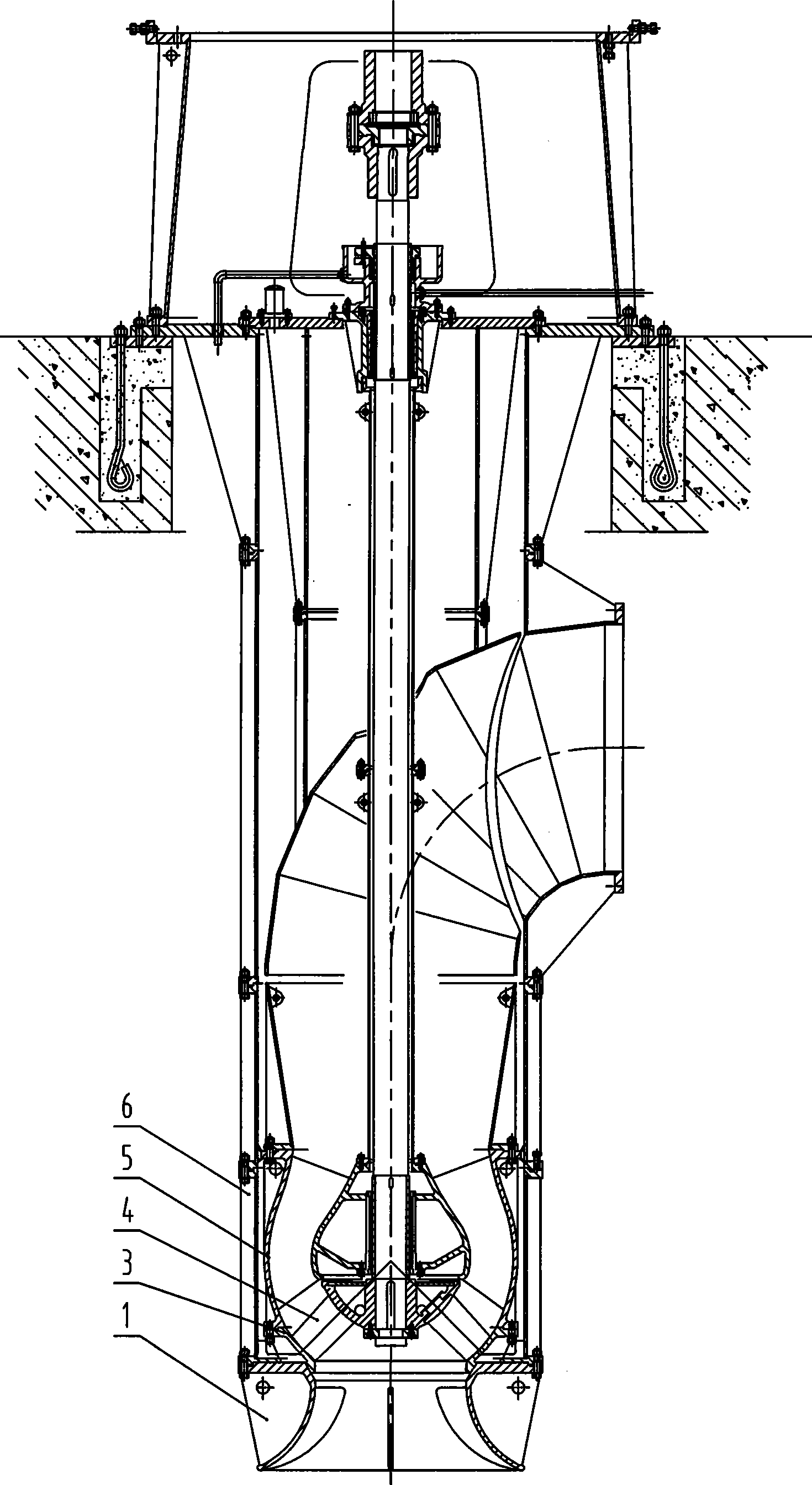

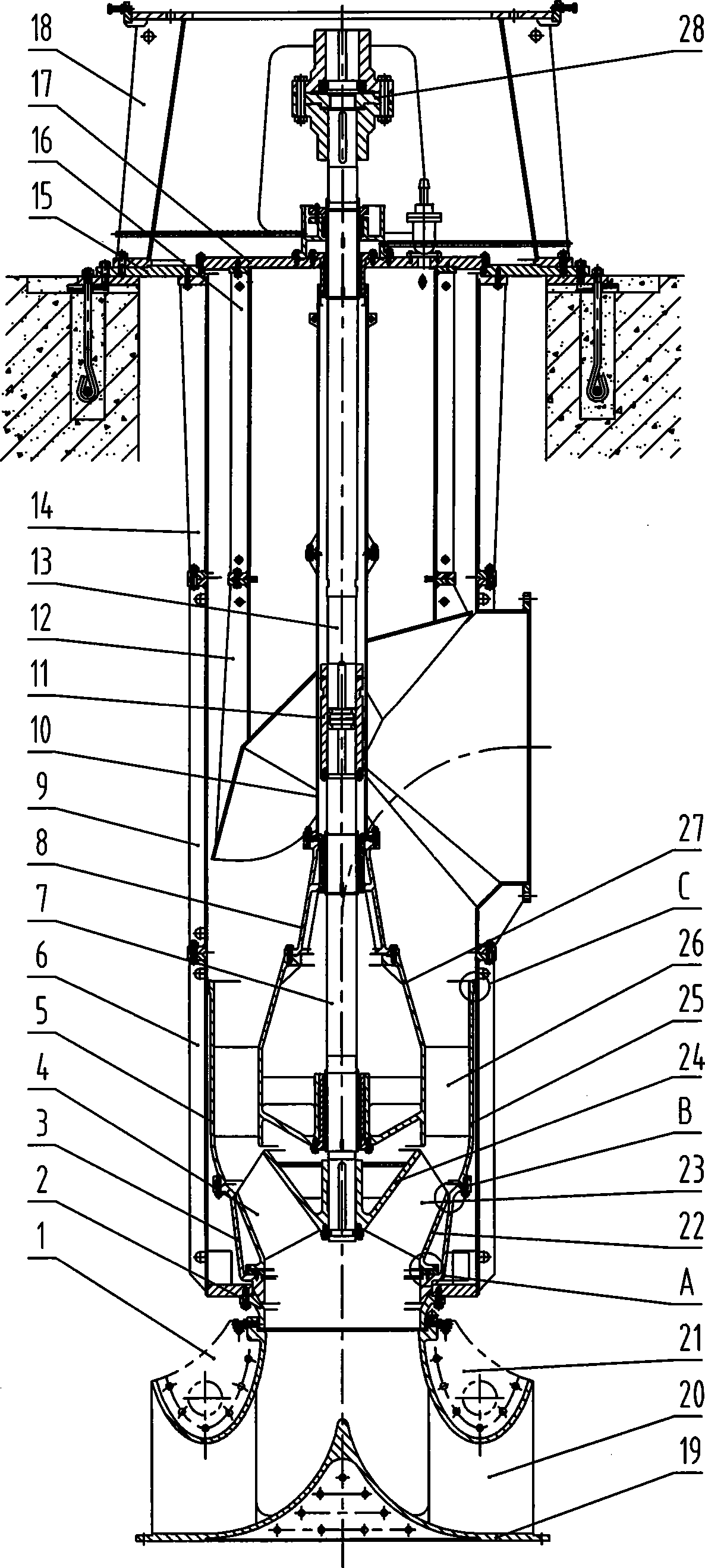

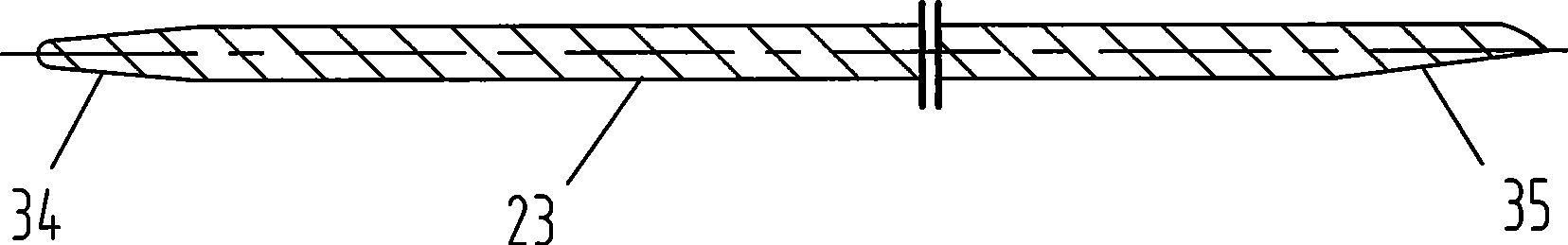

Core-loosing highly effective energy-conserving vertical diagonal flow pump

InactiveCN101418814AImprove water flowReduce hydraulic lossPump componentsPumpsImpellerEffective energy

The invention discloses a core-pulling high efficiency energy saving vertical diagonal flow pump, an elliptic diversion pier (1) fixed on the bottom plate of an water input pool, an inhale pipe (2), a lower outer connected pipe (6), a water outlet bending pipe (9), an upper outer connected pipe (14), and a support plate (15) which are connected together down to up to form an outer cylinder part of a non core-pulling part; an impeller chamber (3), a guide vane (5), a bearing seat (8), and a protection pipe (10) which are connected down to up to form the fixed part of the core-pulling part; an impeller (4) fixed on a lower main shaft (7), an upper main shaft (13), and the lower main shaft (7) which is connected with the upper main shaft (13) through a sleeve coupling (11) to form the rotation part of the core-pulling part; a diversion casing (12), a connection pipe (16), and a cover plate (17) which are connected together down to up and fixed on the support plate; and a motor base (18) fixed on the support plate (15). The invention has high efficiency, simple structure, low manufacture cost, stable operation, convenient maintenance, and reliable safety.

Owner:利欧集团湖南泵业有限公司

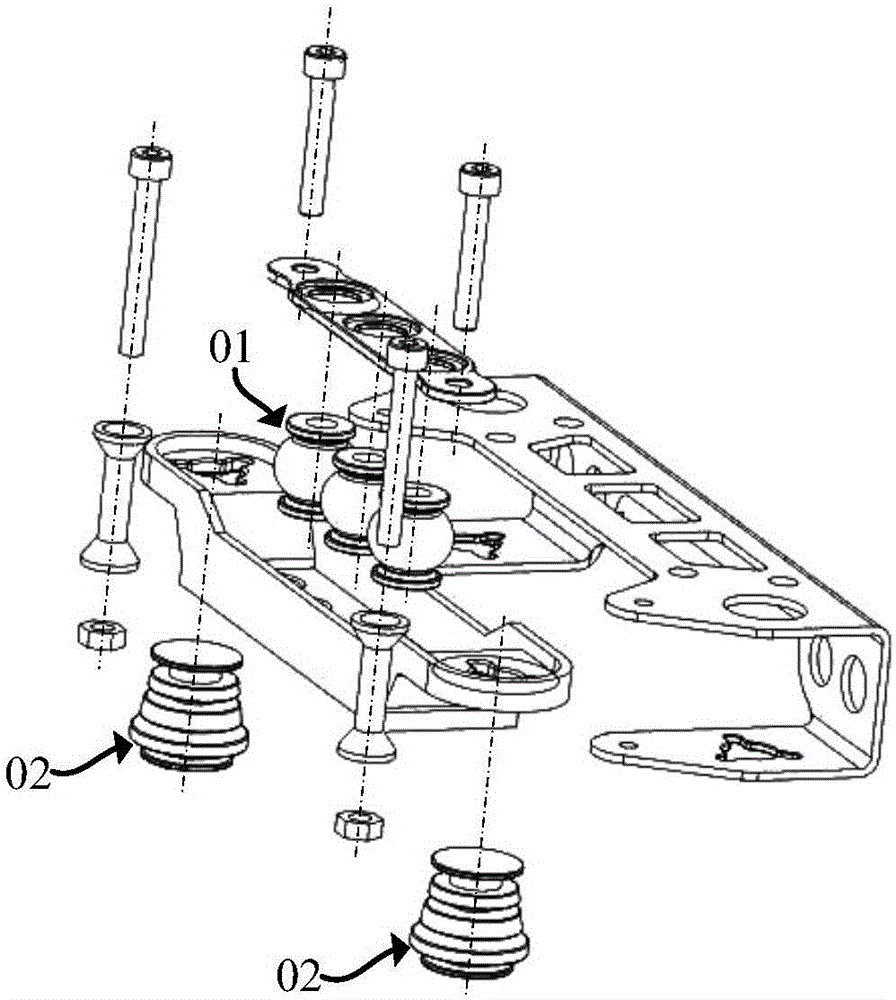

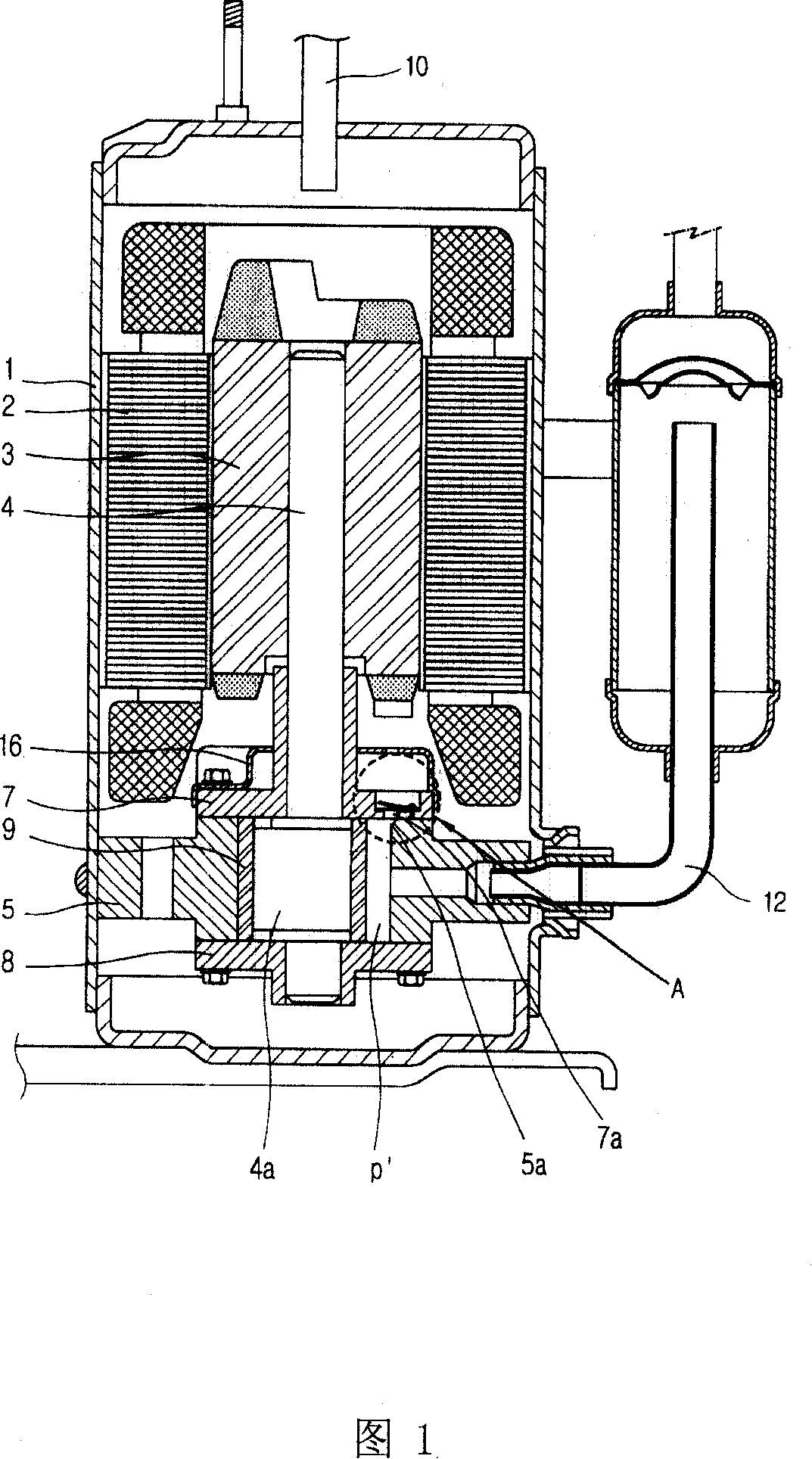

Compressor bottom corner vibration damping mat

InactiveCN101122292AMeet high frequency damping and low frequency vibrationMeet the needs of high frequency dampingMachine framesNon-rotating vibration suppressionLow frequency vibrationEngineering

The invention discloses a vibration damping pad at the bottom corner of a compressor, and comprises a top layer, a middle layer and a bottom layer, which is coaxial and the diameters of which increase in sequence. A connecting pole is formed between the top layer and the middle layer, and a groove is formed in the middle of the middle layer. The bottom end of the connecting pole is in the groove, and integrated with the middle layer in the groove. The top layer, the connecting pole, the middle layer and the bottom layer are formed in an integrated way, and through-holes are formed at the center of the top layer, the connecting pole, the middle layer and the bottom layer. A rubber layer and a spring are also arranged and fit into the perimeter of the connecting pole formed between the top layer and the middle layer. The rubber layer is at the upper end of the spring, while the lower end of the spring is embedded into the groove in the middle of the middle layer. The invention is wholly made of rubber materials, and can meet the requirement for high frequency damping by a compressor. Meanwhile, the spring arranged between layers of the vibration damping pad can reduce the low-frequency vibration of the compressor. Thus, the vibration-damping pad of the invention can meet the requirement for both the high-frequency damping and the low-frequency vibration of a compressor.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Plurality of non-magnetic dampers on a voice coil yoke arm

InactiveUS7990657B2Reduce low frequency vibrationReduce vibrationDisposition/mounting of recording headsUndesired vibrations/sounds insulation/absorptionResonanceEngineering

Owner:WESTERN DIGITAL TECH INC

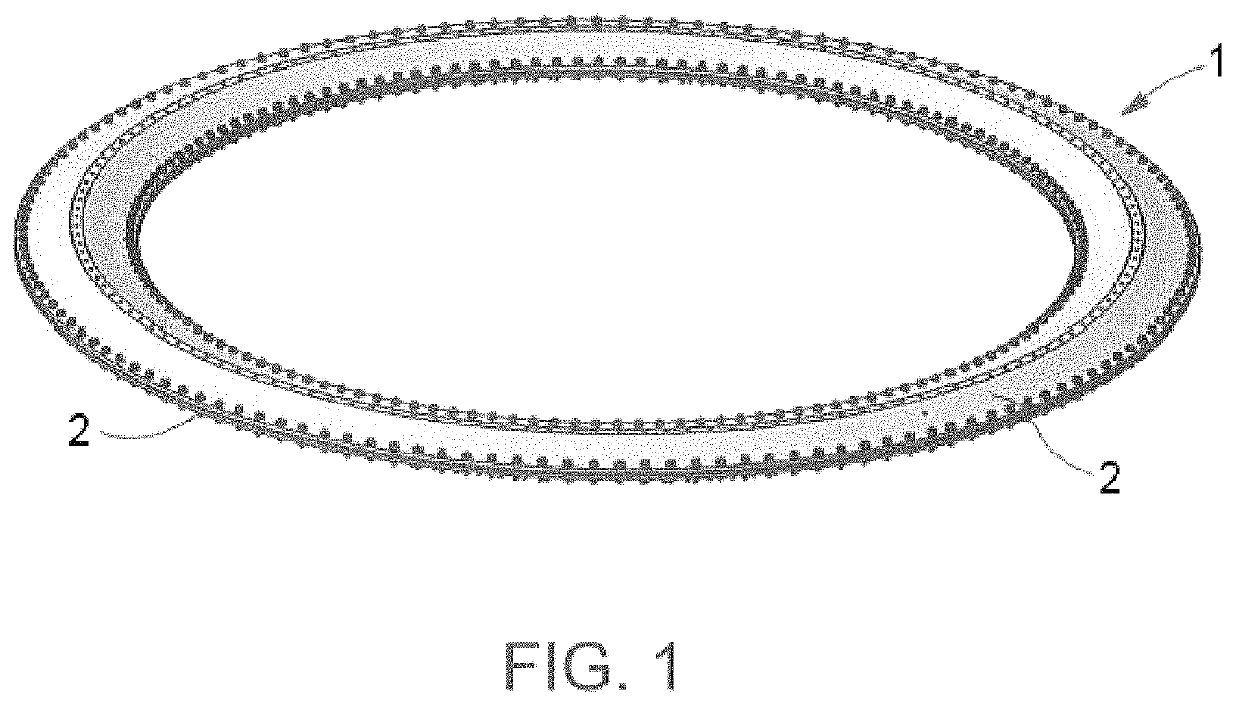

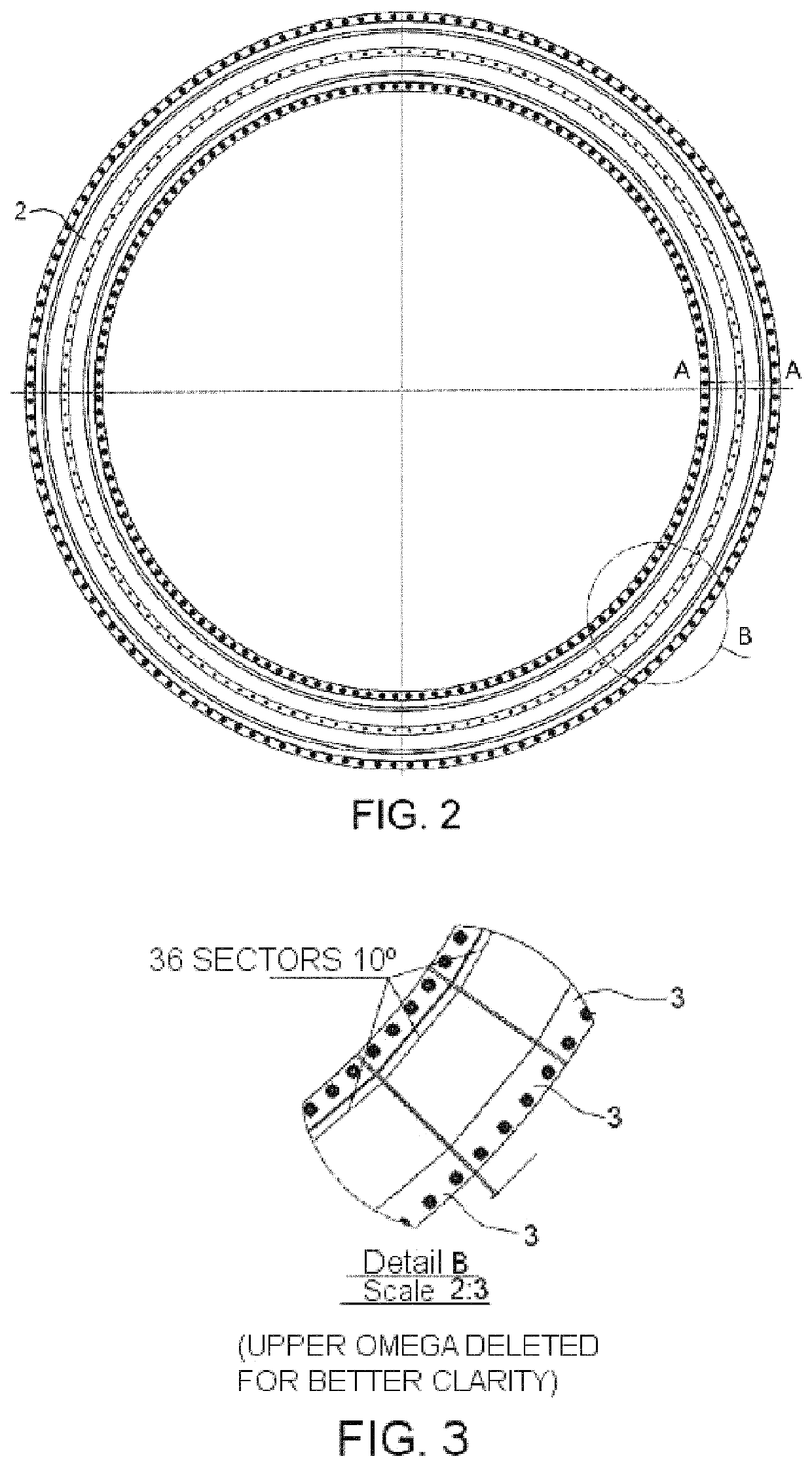

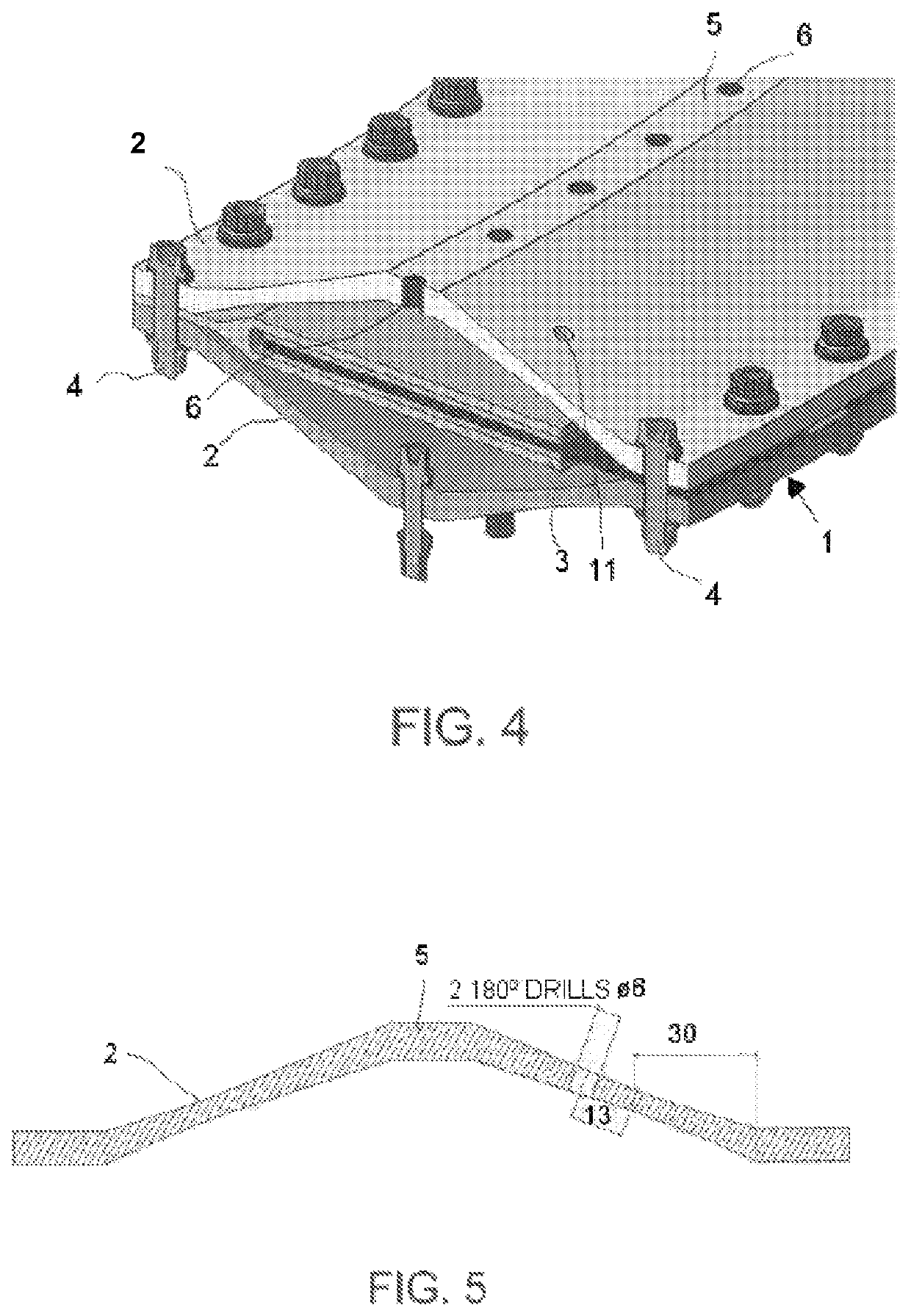

Lightweight passive attenuator for spacecraft

ActiveUS10556710B2Reduce additionalReduce low frequency vibrationRing springsCosmonautic vehiclesClassical mechanicsMechanical engineering

A lightweight passive attenuator (1) for spacecraft includes two omega cross-section rings (2), placed symmetrically and defining a gap therebetween, and being the main load path of the light passive attenuator (1). A plurality of damper elements (3) are placed in the gap defined between the two omega cross-section rings (2), and not in the main load path of the light passive attenuator (1), such that the omega cross-section rings (2) and the damper elements (3) are assembled at their ends by attachment elements. The omega cross-section rings (2) have a protruding central part (5) with a plurality of holes (6) for connection with adjacent structures (7, 8) of the spacecraft.

Owner:AIRBUS DEFENCE & SPACE

Structure of motor-mount for electric vehicle

ActiveCN104868633AIncreased durabilityImprove the anti-vibration effectMultiple spring combinationsElectric propulsion mountingEngineeringElectric vehicle

A structure of a motor-mount for an electric vehicle that supports a lower part of a motor of an electric vehicle includes a core into which a bolt fastened to the motor is inserted in a center, a stopper that is coupled to surround an outer circumferential surface of the core, and is made of rubber, an insulator that is connected to a lower end of the stopper, is coupled to a lower part of the core, and has a concave lower surface, and a housing into which the core, the stopper and the insulator are forcibly inserted, where the housing has a cylindrical shape in which a bottom is opened, and an outer circumferential surface of the stopper comes in contact with an inner circumferential surface of the housing.

Owner:HYUNDAI MOTOR CO LTD

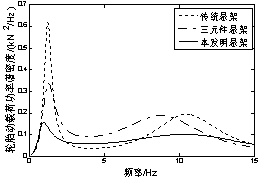

Shafting load preadjusting method of metered spring base

InactiveCN103306302AImprove stabilityReduce low frequency vibrationFoundation testingTransfer matrixFinite element method

The invention relates to a shafting load preadjusting method of a metered spring base. The method sequentially comprises the following steps of (1) collecting the elevation hi of a rigid base bearing and a spring with the rigid Ki of a spring base corresponding to the bearing; (2) obtaining a relation between a bearing load and the elevation hi at a constant speed under the rigid base by adopting a transfer matrix method; (3) obtaining the stroke of the spring; (4) solving a reynolds equation by adopting a finite element method so as to obtain the floating amount of a shaft neck under a bearing load condition; (5) obtaining the elevation of the bearing; (6) replacing hi by use of the elevation of the bearing according to the f(hi) obtained in the step (2) so as to obtain an iterated bearing load; (7) returning to the steps (3)-(7) in due time; (8) obtaining the real load and practical elevation of the bearing at a constant speed under the spring base; and (9) obtaining the preadjusting amount delta of the elevation of the bearing. The method provided by the invention can be used for effectively improving the stability of the bearing and reducing the low-frequency vibration of the bearing and is wide in application prospect.

Owner:JIANGSU NUCLEAR POWER CORP

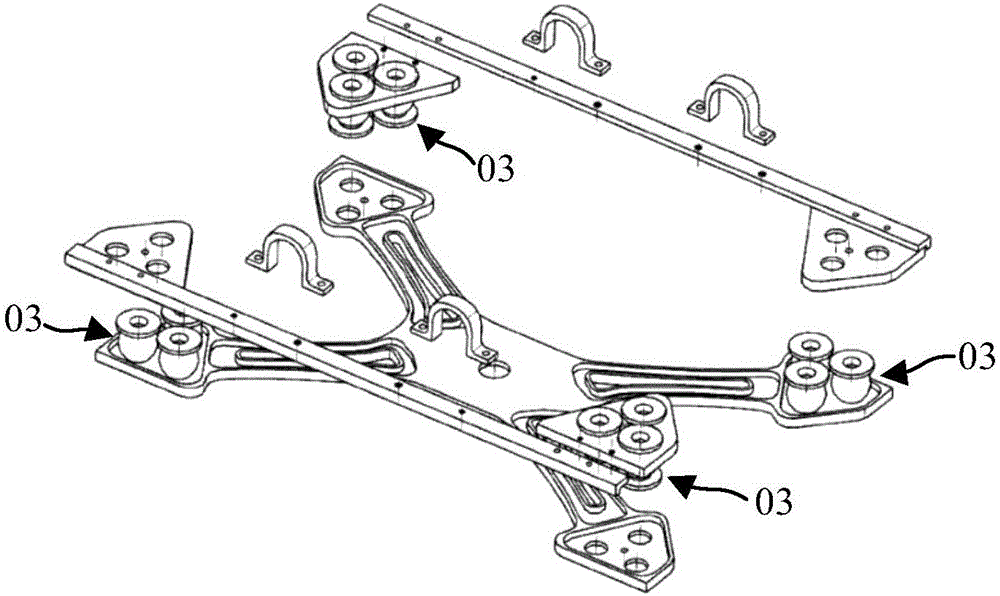

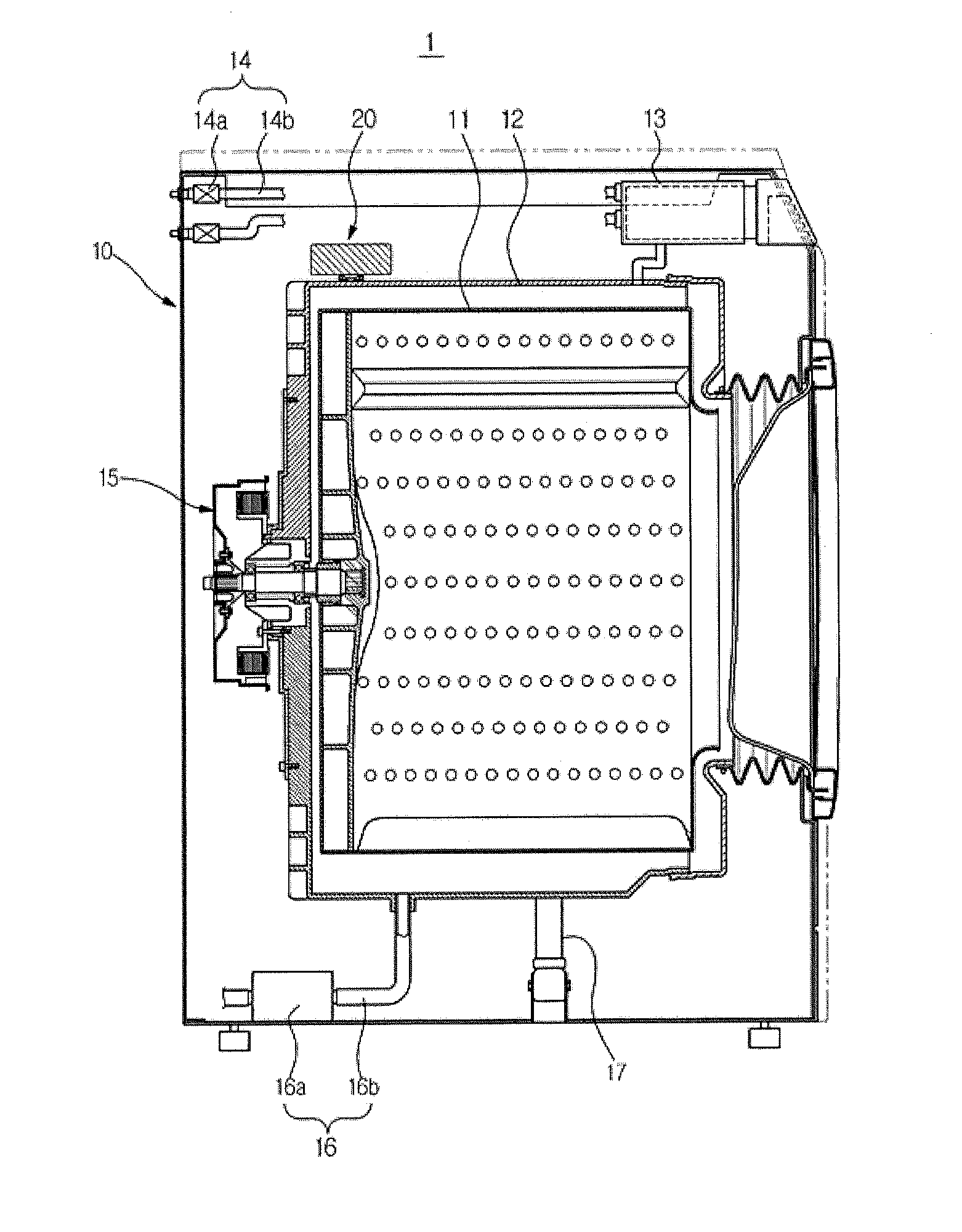

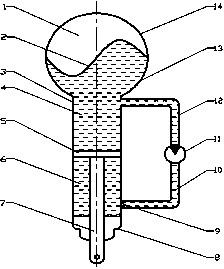

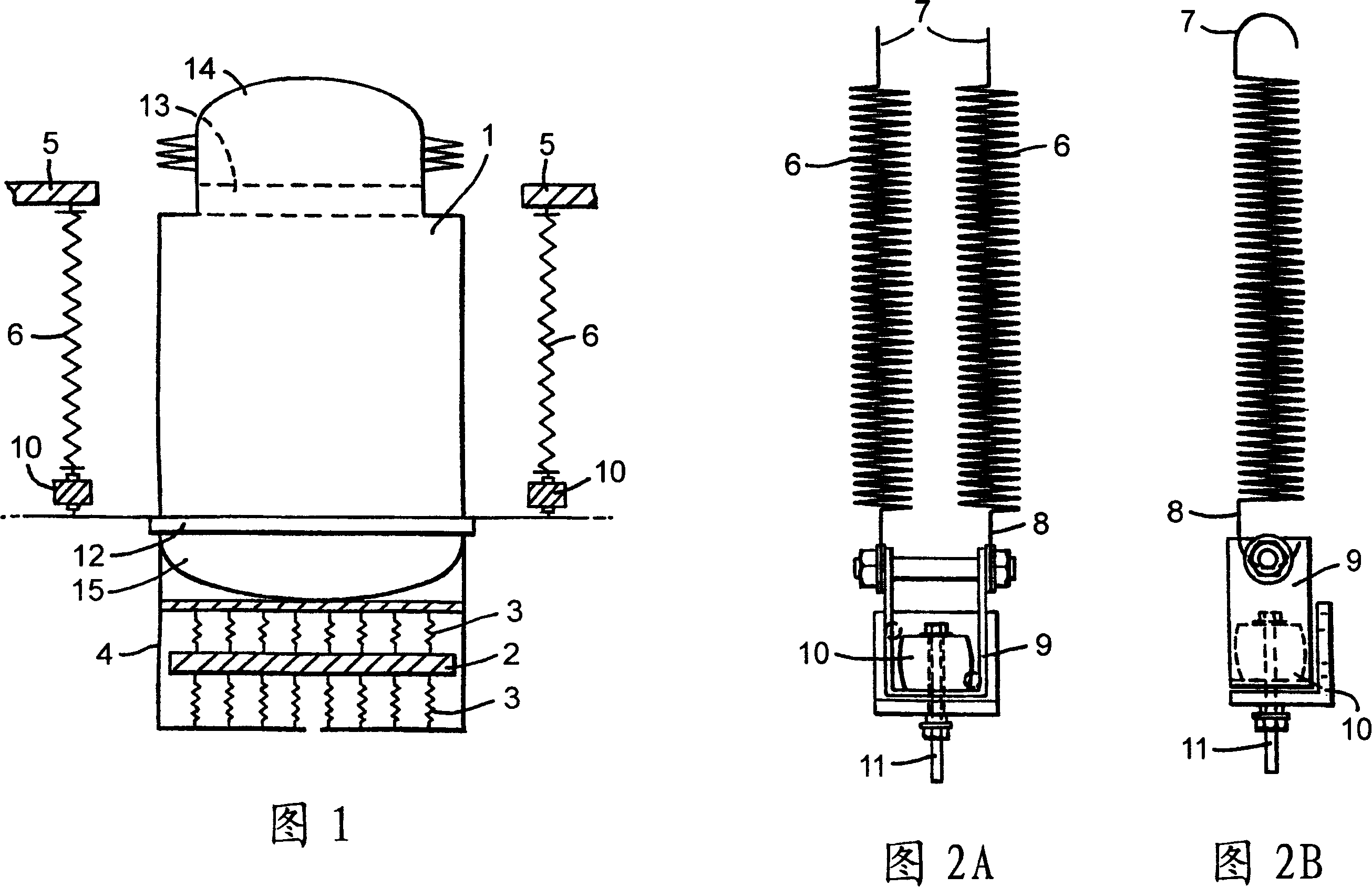

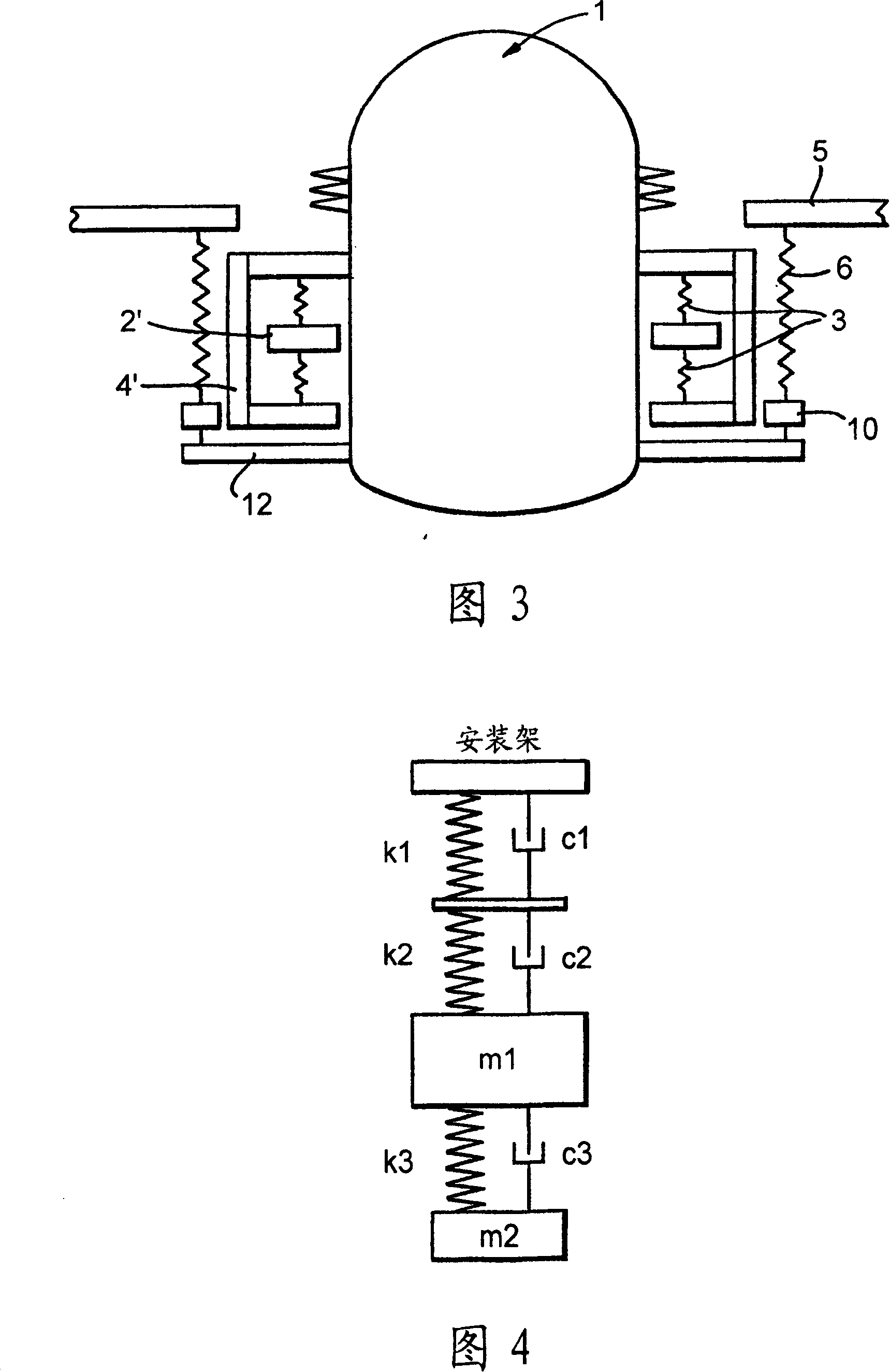

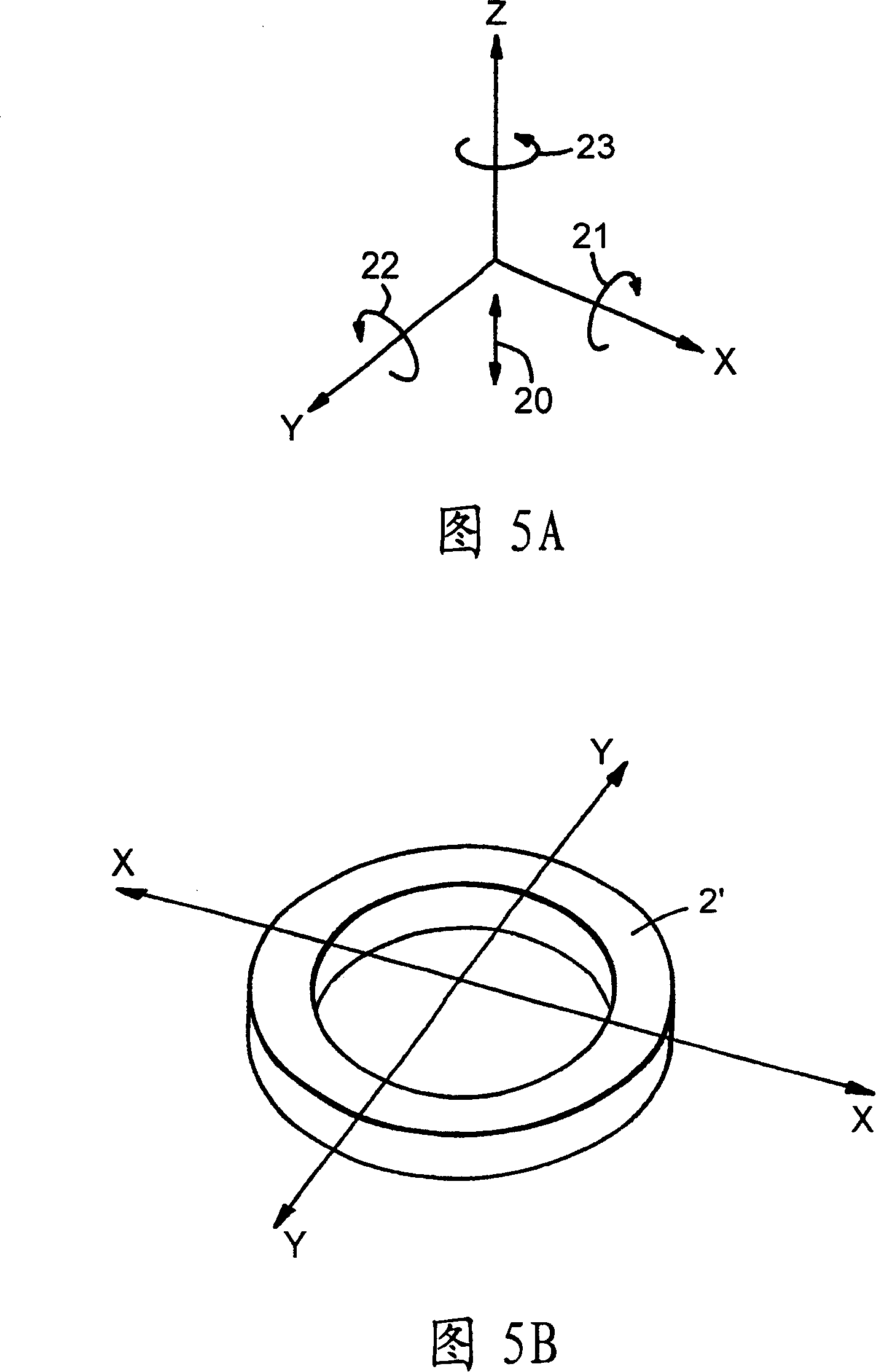

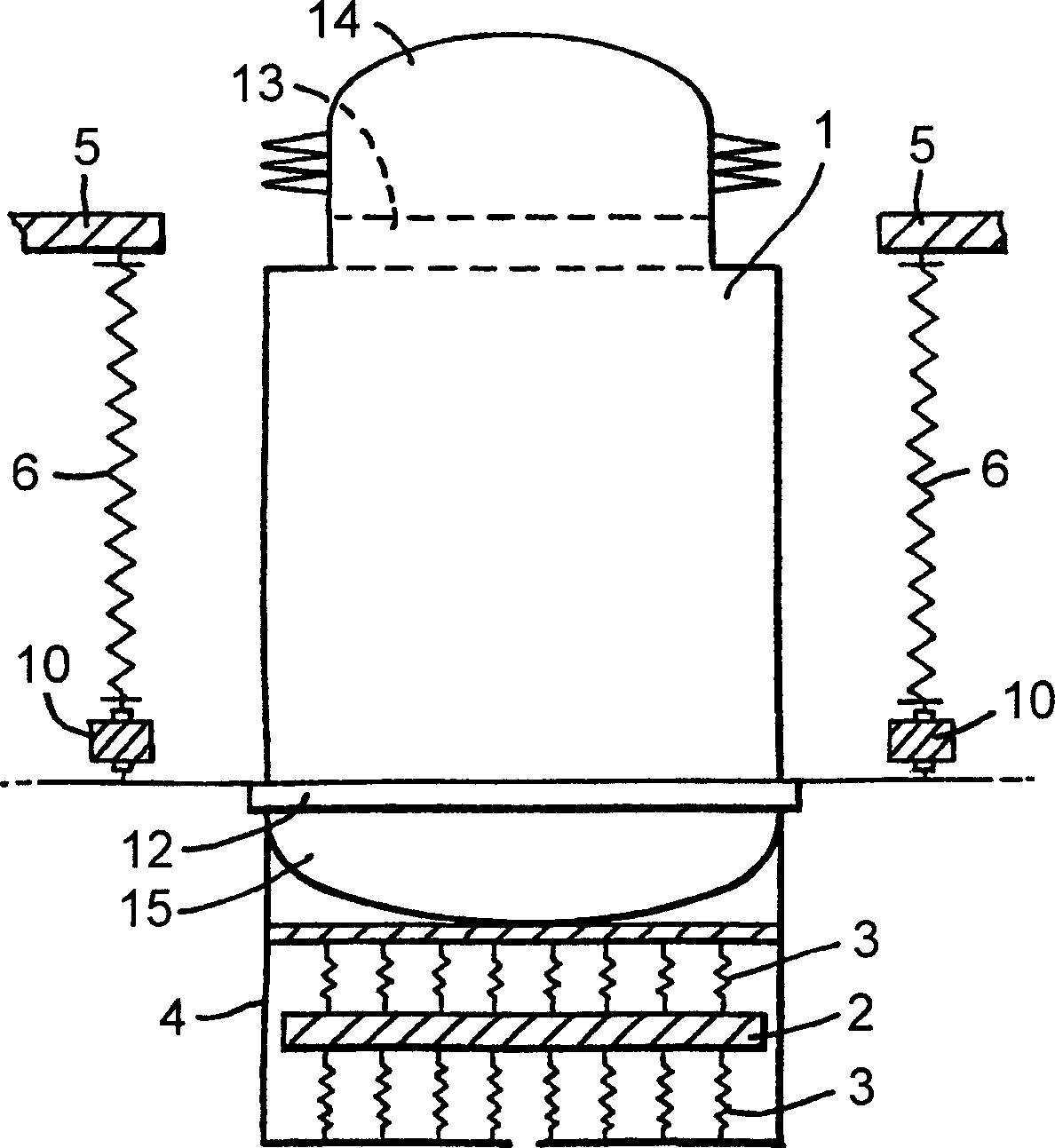

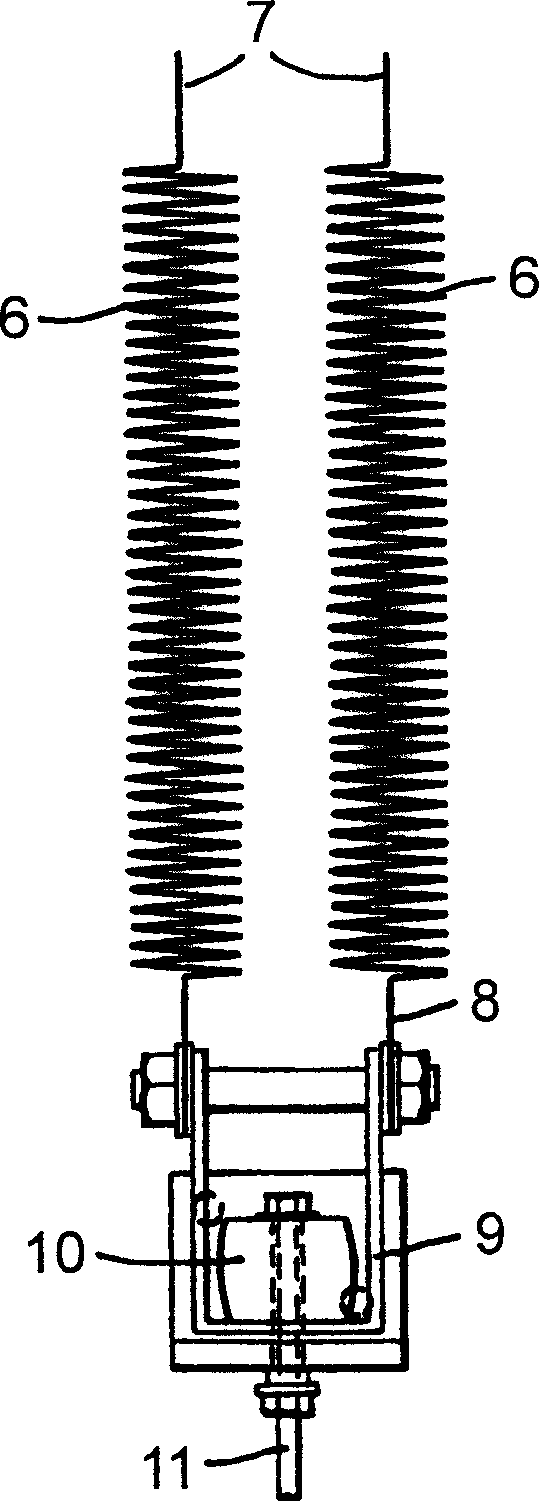

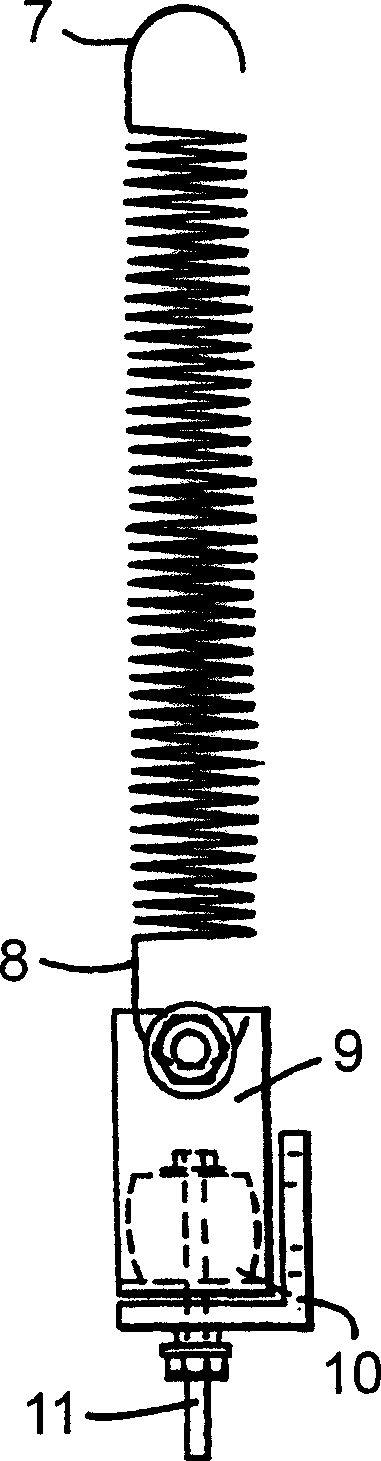

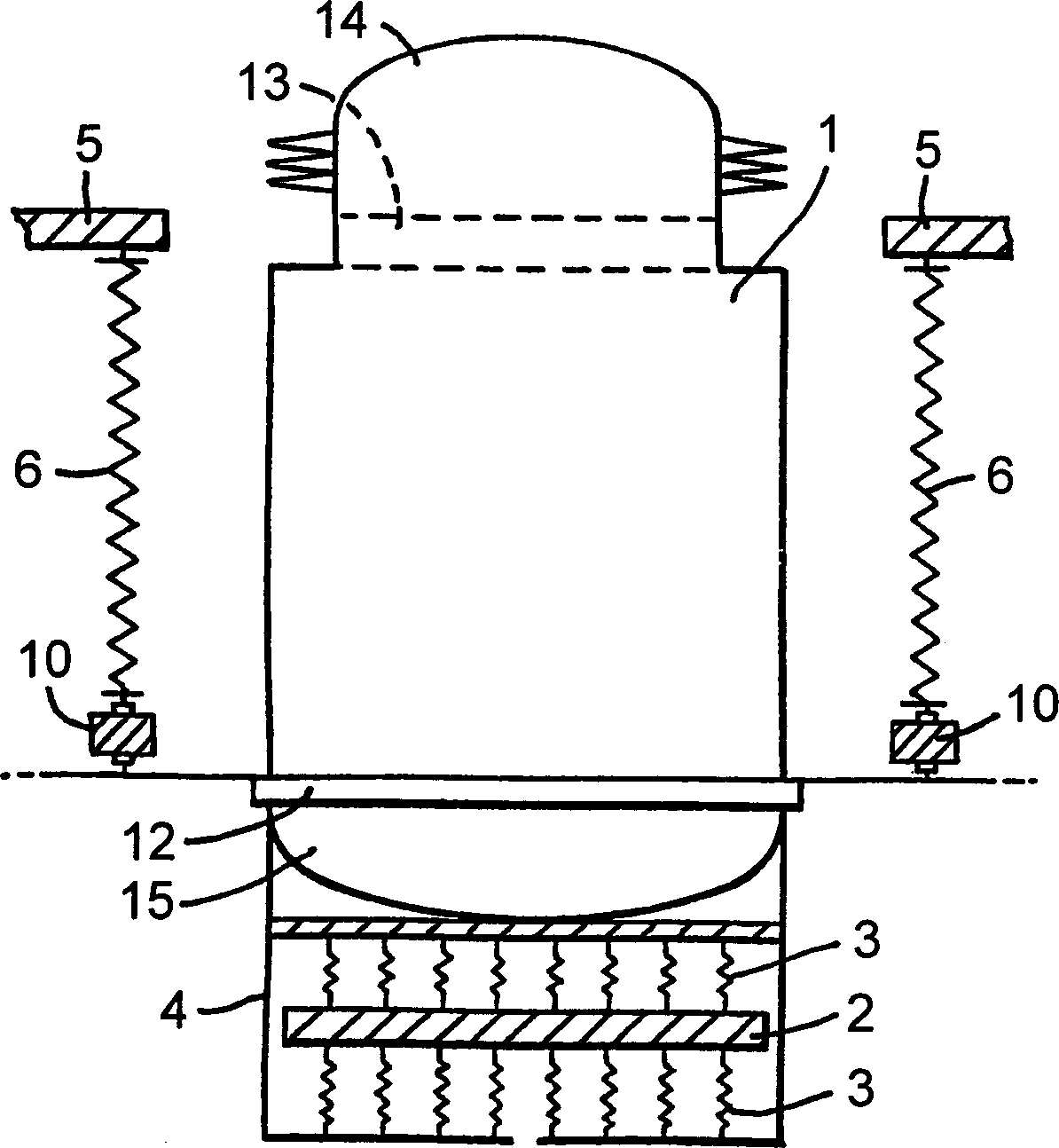

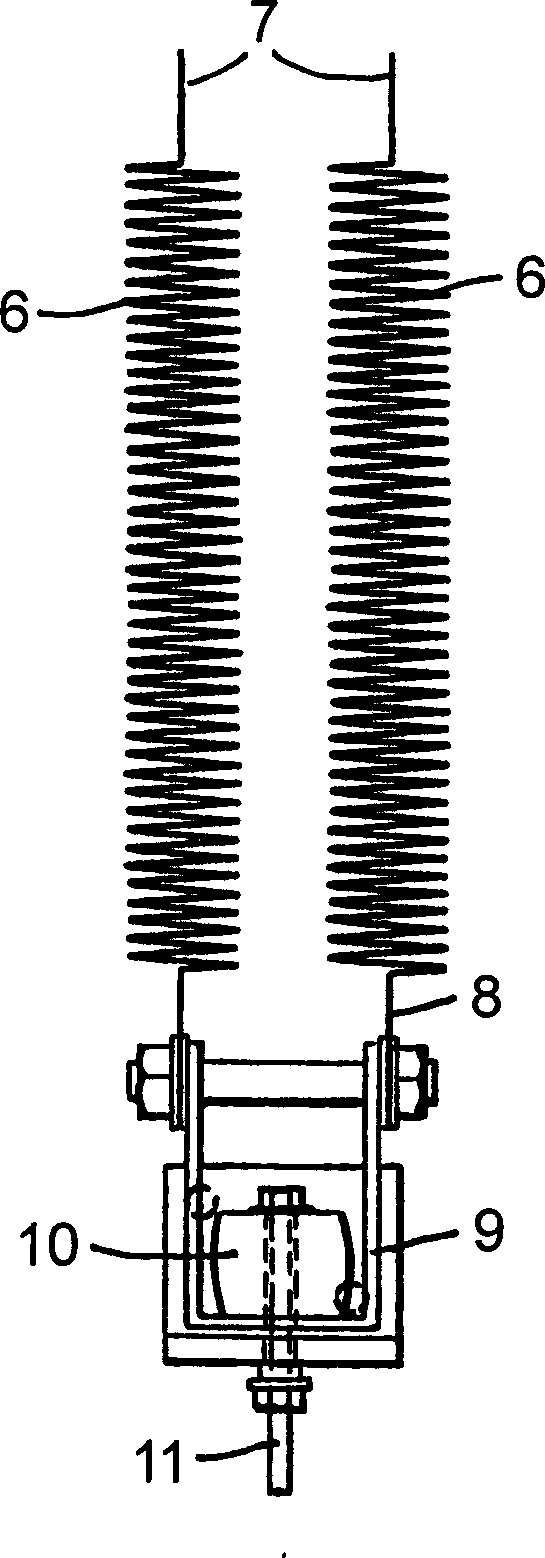

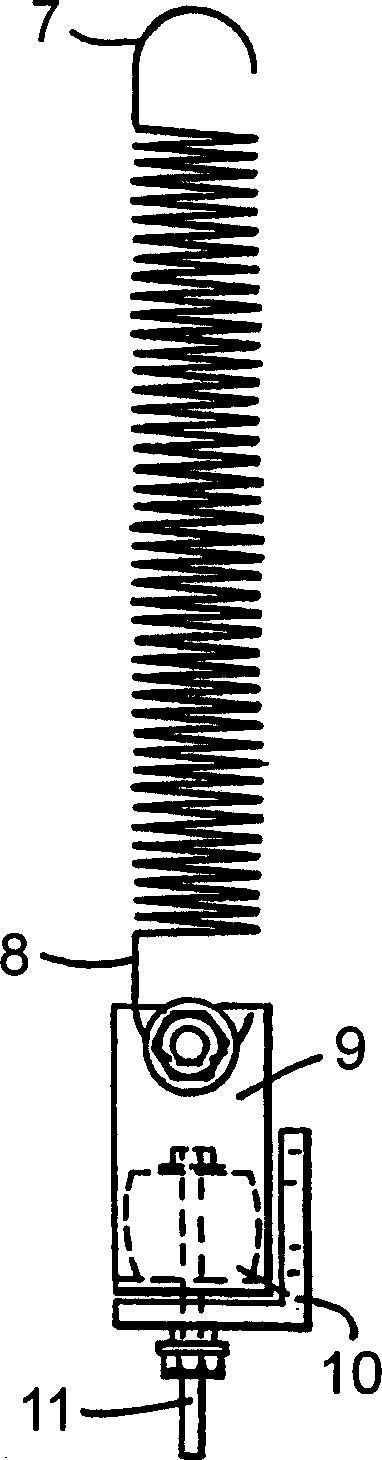

A stirling engine assembly

InactiveCN100376780CReduce low frequency vibrationNon-rotating vibration suppressionHot gas positive displacement engine plantsEngineeringStirling engine

A Stirling engine assembly for a DCHP system. A Stirling engine (1) is suspended from a mounting frame (5) by a plurality of tension springs (6). An annular absorber mass (2) surrounds the Stirling engine and is suspended from the engine on a plurality of resilient members (3) arranged asymmetrically about the main axis. The asymmetric arrangement is provided by members of different stiffnesses, or irregular spacing of the members. The absorber mass (2) itself may be reduced adjacent to the resilient members.

Owner:MICROGEN ENGINE CORP HLDG BV

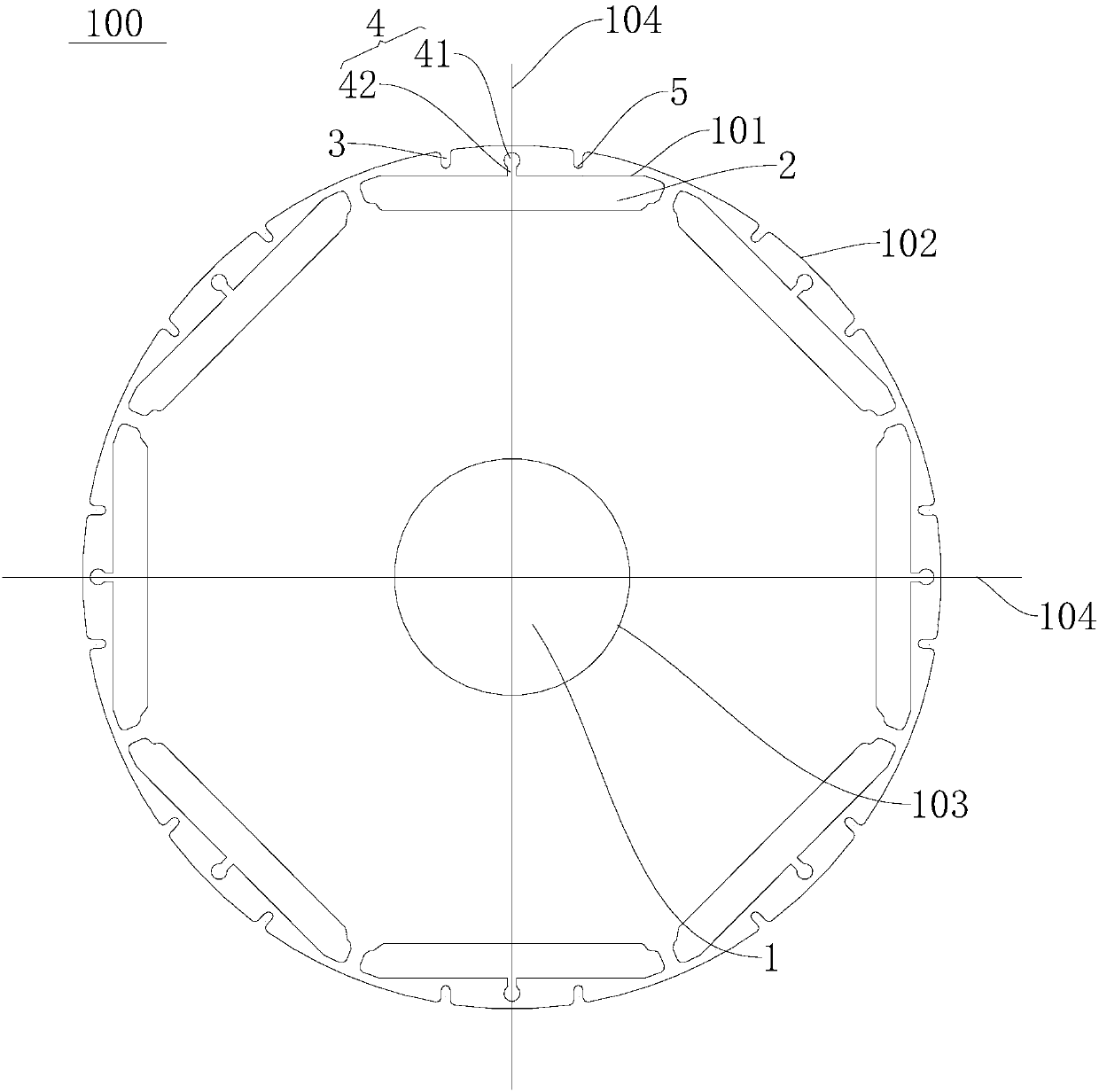

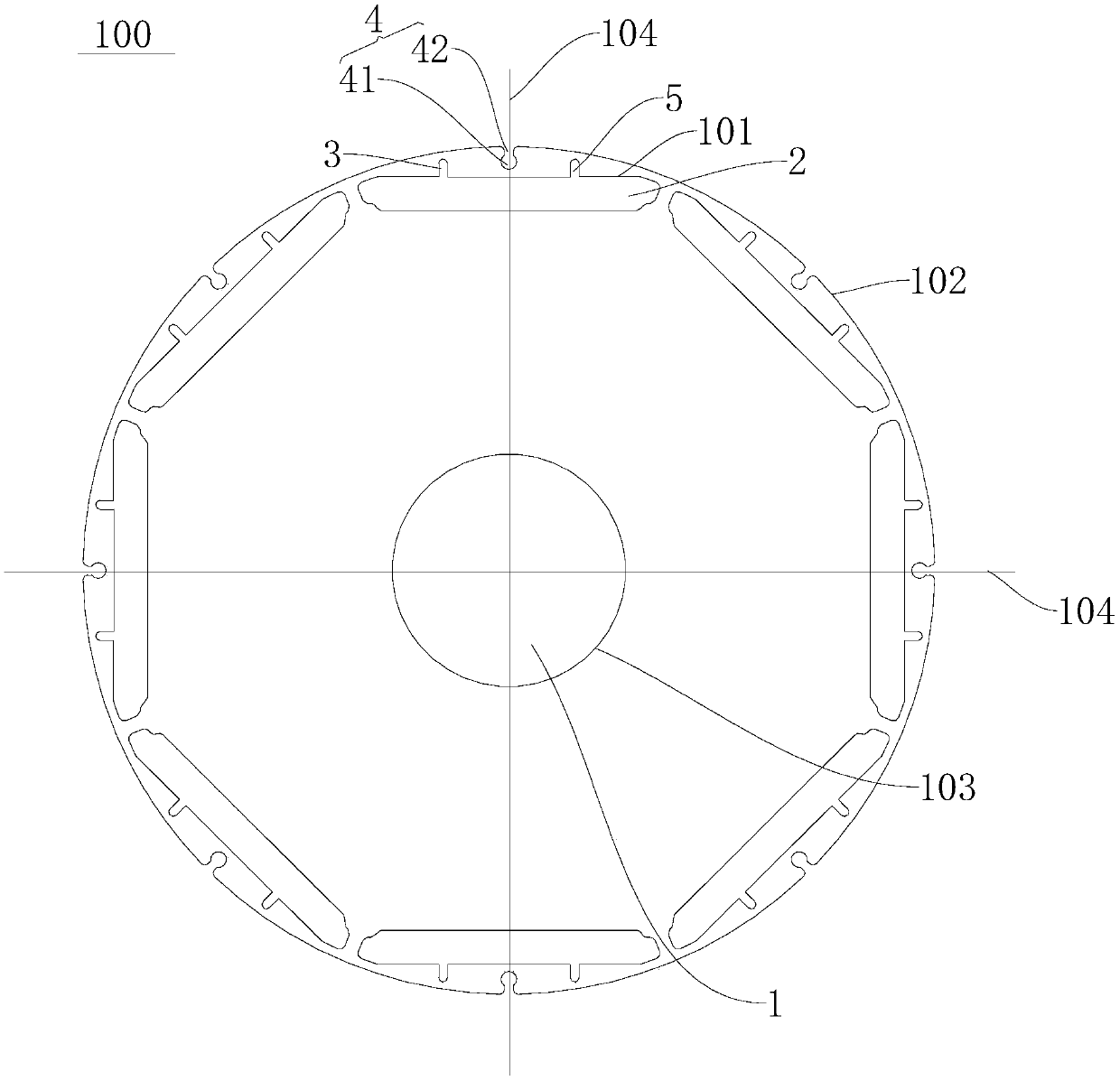

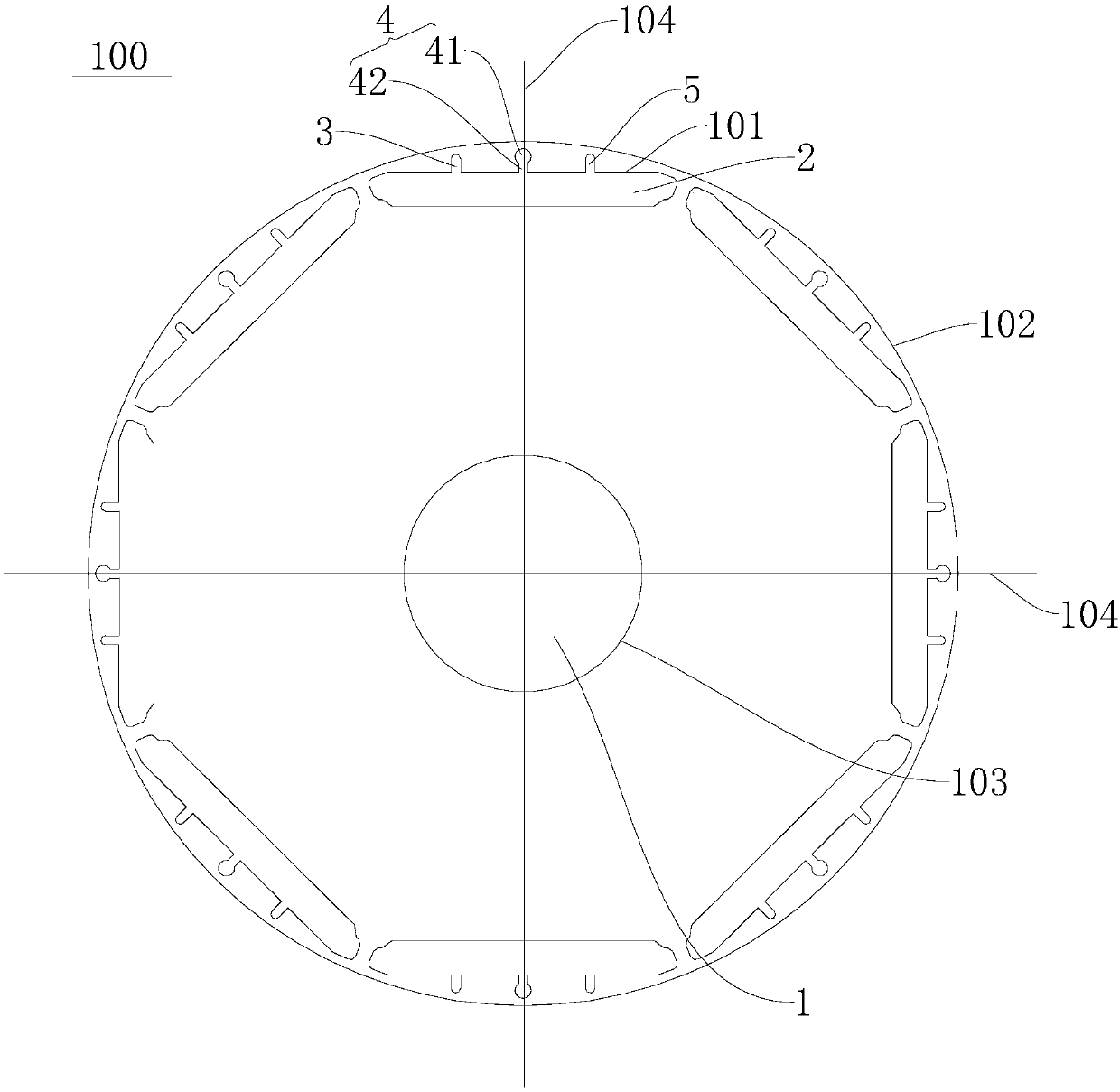

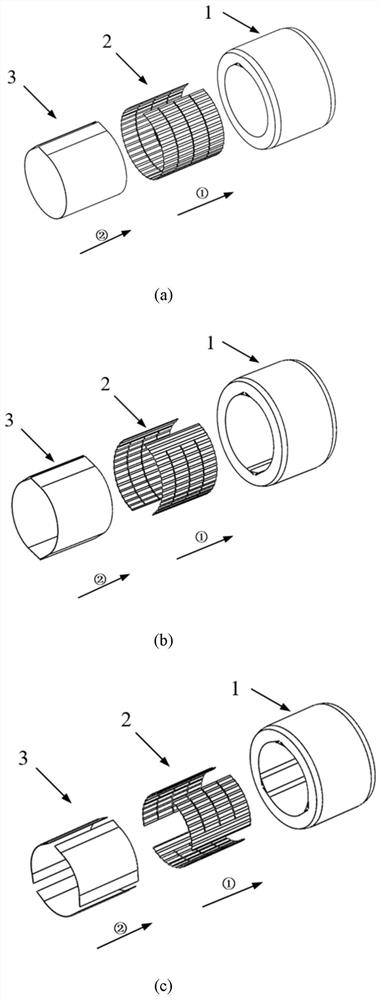

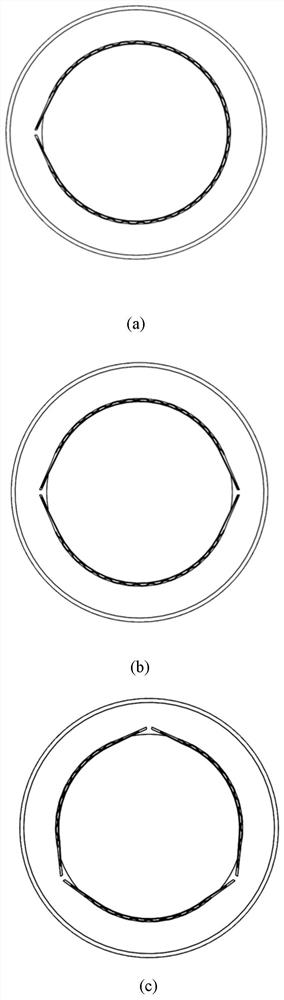

Rotor punching sheet, rotor core, motor, and compressor

ActiveCN107591911AReduce low frequency radial forceReduce low frequency vibrationMagnetic circuit rotating partsManufacturing technologyPunching

The invention discloses a rotor punching sheet, a rotor core, a motor, and a compressor. The cis provided with an axle hole and a plurality of magnet grooves surrounding the circumference of the axlehole at intervals; a first through hole, a second through hole and a third through hole which are separated along the circumference at intervals and penetrate through the rotor punching sheet in the thickness direction, are formed between each magnet groove and the outer contour of the rotor punching sheet; the second through hole is located between the first through hole and the third through hole; the first through hole, the second through hole and the third through hole can penetrate through one of the circumferential wall of the magnet groove and the outer circumferential wall of the rotorpunching sheet; and at least one of the first through hole, the second through hole and the third through hole penetrates through the circumferential wall of the magnet groove. The rotor punching sheet can give consideration to the concentricity between the stator and the rotor, and can reduce the low space order low frequency radial load of the motor at the same time, thus improving the motor performance and being simple in manufacturing technology.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

A stirling engine assembly

InactiveCN1721682AReduce stiffnessIncrease deflectionNon-rotating vibration suppressionHot gas positive displacement engine plantsStirling engineEngineering

A Stirling engine assembly for a DCHP system. A Stirling engine (1) is suspended from a mounting frame (5) by a plurality of tension springs (6). An annular absorber mass (2) surrounds the Stirling engine and is suspended from the engine on a plurality of resilient members (3) arranged asymmetrically about the main axis. The asymmetric arrangement is provided by members of different stiffnesses, or irregular spacing of the members. The absorber mass (2) itself may be reduced adjacent to the resilient members.

Owner:MICROGEN ENGINE CORP HLDG BV

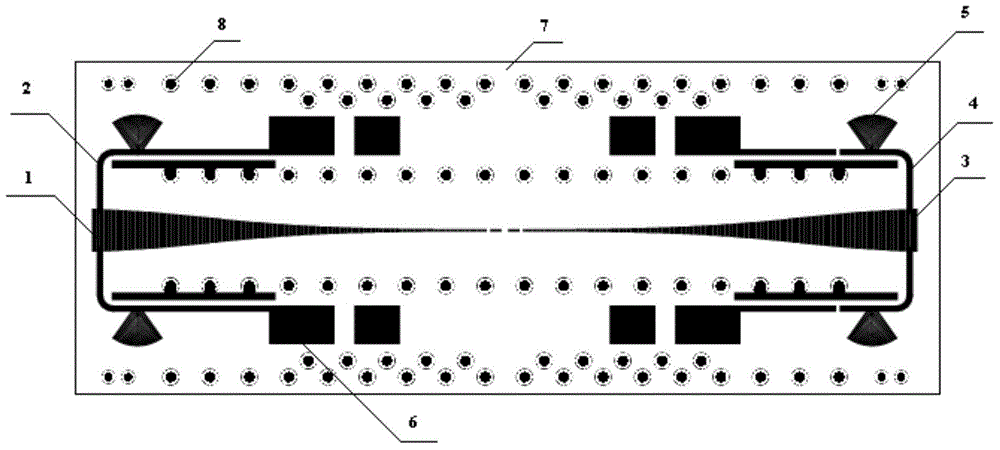

Low-impedance broadband test fixture

InactiveCN104698227AReduced Impedance MismatchReduce low frequency vibrationElectrical testingMeasurement instrument housingEngineeringTest fixture

An improved low-impedance test fixture comprises: an impedance converter and a support piece. The impedance converter is fixed on the support piece. The impedance converter comprises: a first tapered microstrip line, a first bias circuit, a second tapered microstrip line, and a second bias circuit. The first tapered microstrip line, the first bias circuit, the second tapered microstrip line, and the second bias circuit are printed on a PCB board. The first tapered microstrip line and the second tapered microstrip line hold an LDMOS device under test. The first bias circuit and the first tapered microstrip line are connected. The second bias circuit and the second tapered microstrip line are connected. By using a tapered microstrip line, the improved low-impedance test fixture increase an impedance conversion range of the test fixture, reduces a degree of impedance mismatch between the fixture and an LDMOS device under test, reduces low-frequency oscillations, and reduces a risk of transistor burnout.

Owner:SHANGHAI LIANXING ELECTRONICS

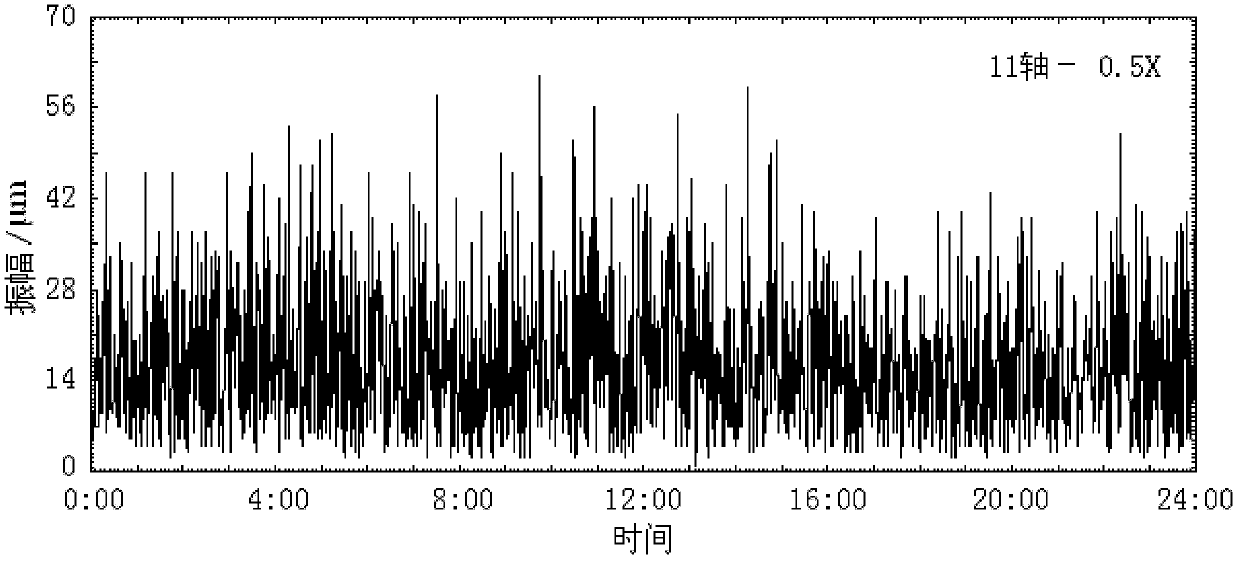

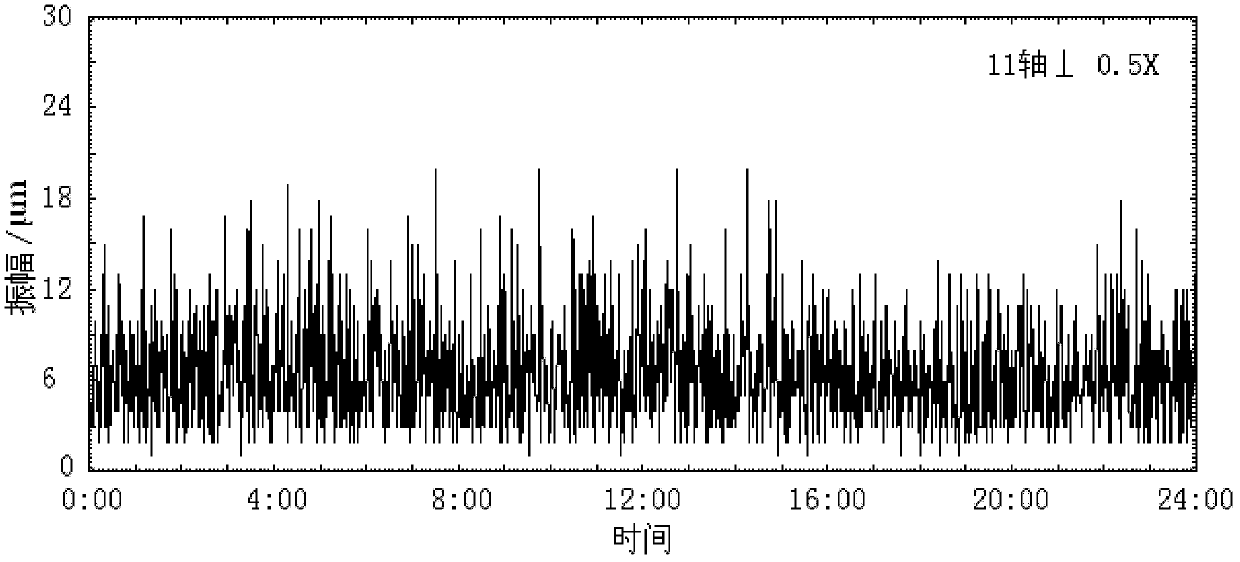

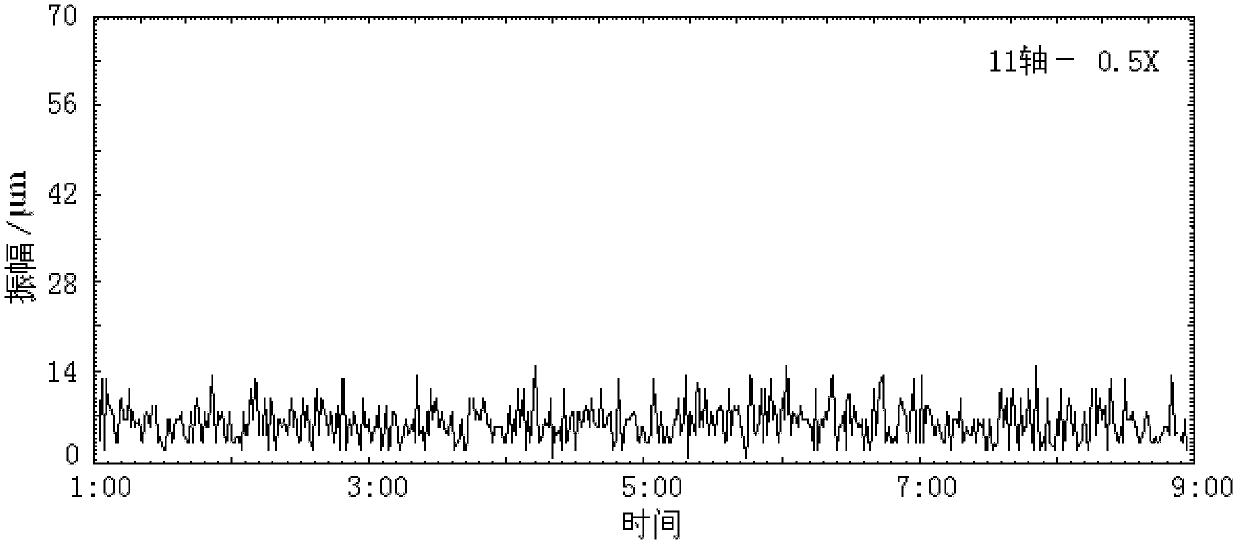

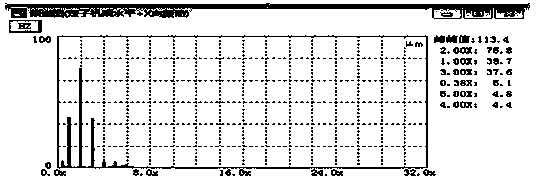

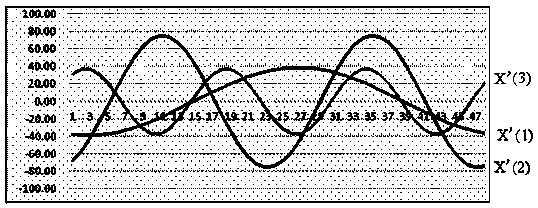

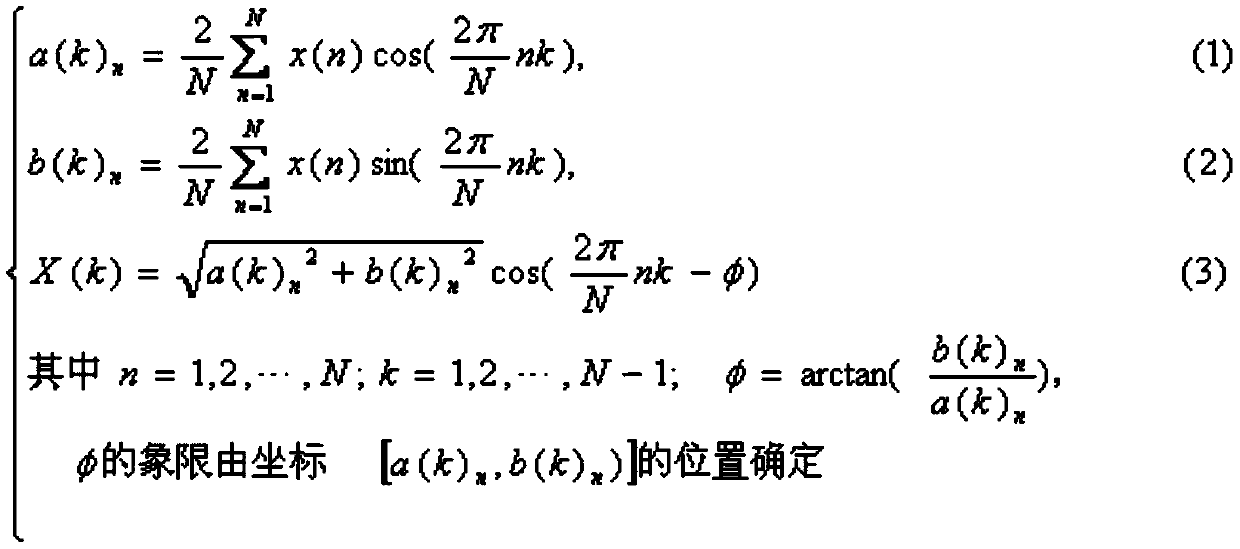

A method for reducing low-frequency vibration of a generator stator based on air gap characteristic values

ActiveCN110635635AReduce limitationsReduce low frequency vibrationGeneration protection through controlManufacturing stator/rotor bodiesLow frequency vibrationDynamo

The invention provides a method for reducing low-frequency vibration of a generator stator based on air gap characteristic values. The method comprises the following steps: collecting stator low-frequency vibration amplitude, frequency spectrum data and generator dynamic air gap function values; numbering magnetic poles according to the rotating direction of a generator set; collecting generator air gap function values, and calculating each order component of the air gap characteristic value according to an air gap characteristic value calculation formula; reading actual amplitude of the low-frequency vibration of the stator; carrying out substitution correction on the amplitude in the calculated generator air gap characteristic values; with the magnetic pole number n being as a horizontalcoordinate and the corrected generator air gap characteristic values being as a vertical coordinate, drawing a generator air gap characteristic value schematic diagram, and obtaining a larger generator air gap characteristic value; and adjusting and verifying the air gap function and determining magnetic poles needing generator pit adjustment. Therefore, the low-frequency vibration of the generator stator can be effectively reduced, and the working efficiency is greatly improved.

Owner:HUANENG LANCANG RIVER HYDROPOWER

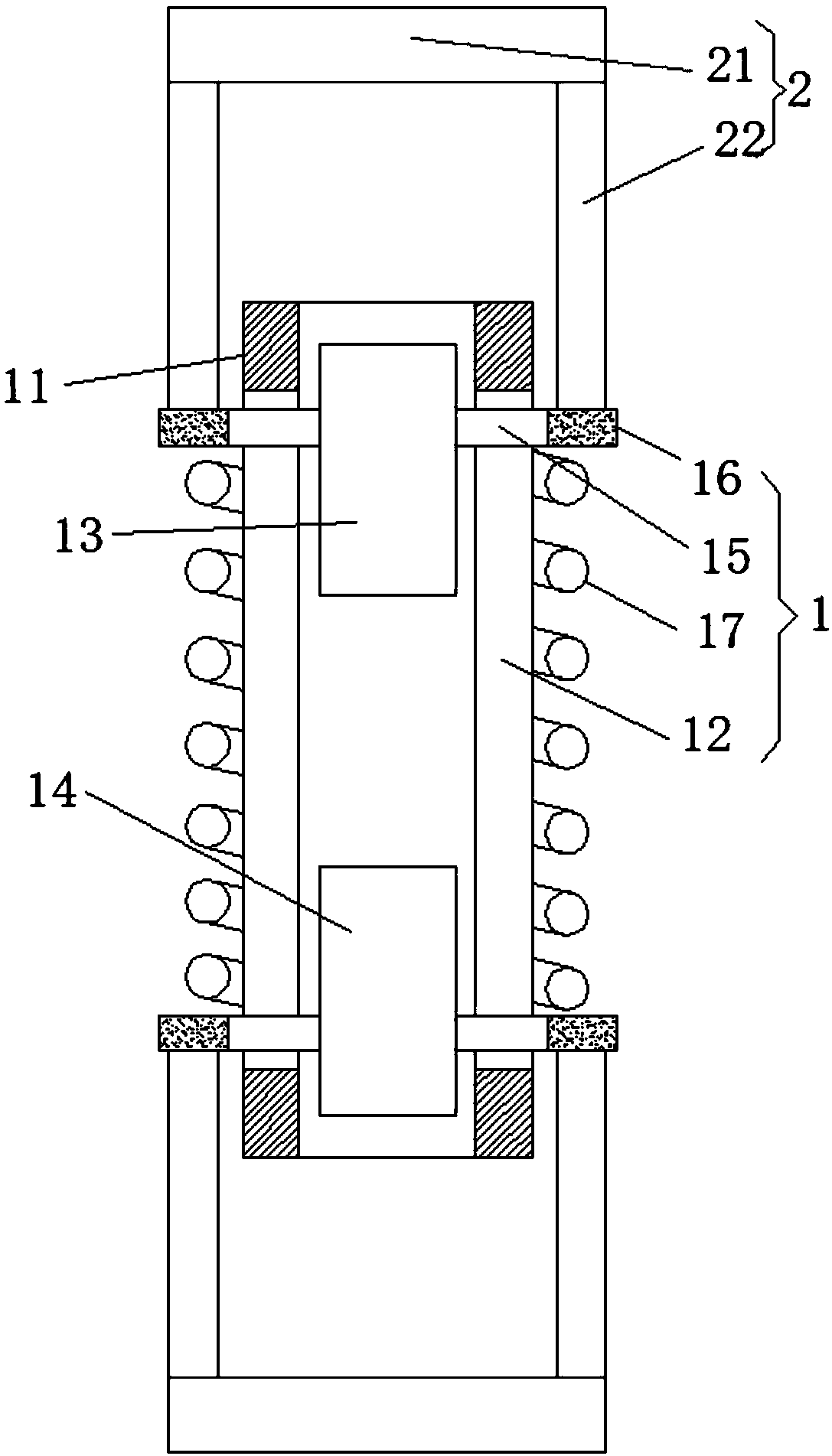

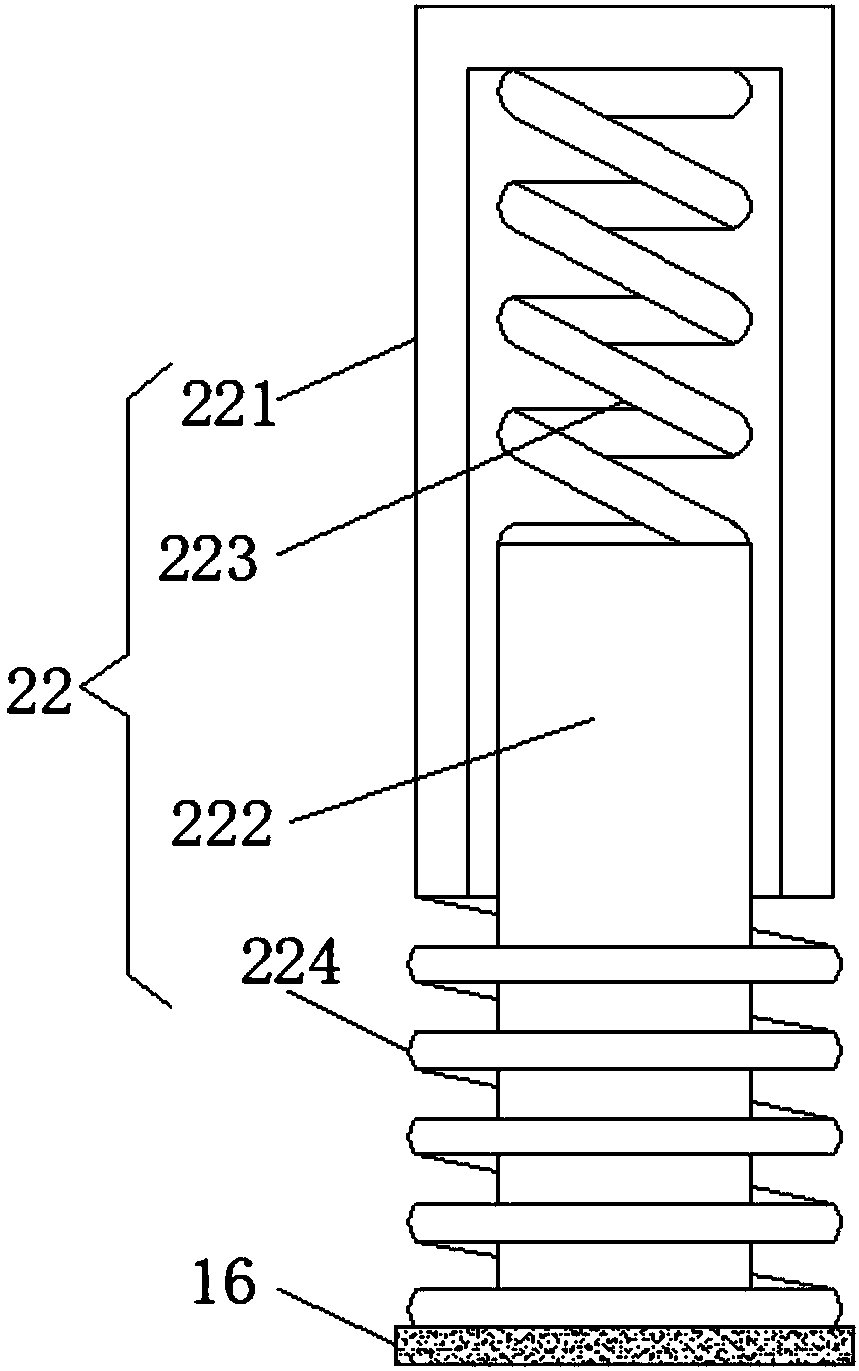

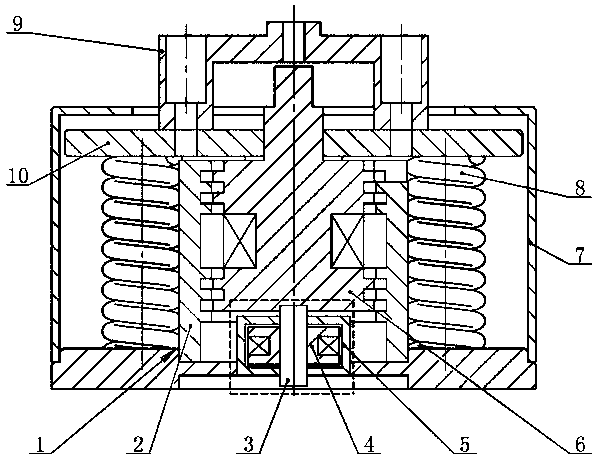

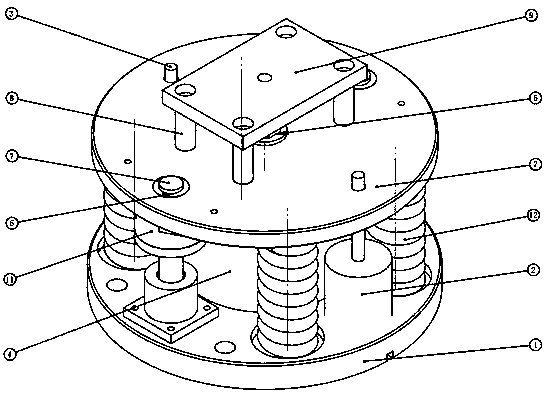

Multifunctional compound vibration isolator

ActiveCN110848314ARealize online adjustmentLower natural frequencyNon-rotating vibration suppressionMagnetic springsMagnetoMagnetic stiffness

The invention provides a multifunctional compound vibration isolator with both stiffness and damping being adjustable, and the multifunctional compound vibration isolator combines a high static stiffness and low dynamic stiffness vibration isolation technology and a variable damping technology. The structure of the multifunctional compound vibration isolator is mainly formed by an electromagneticvibration isolator with the high static stiffness and low dynamic stiffness feature and a magneto-rheological damper through parallel connection. The electromagnetic vibration isolator and the magneto-rheological damper are independently electrified, the multiple functions are achieved, and meanwhile the problem that the vibration damping performance deteriorates due to a jumping phenomenon when an existing negative stiffness technology is applied can be well solved. The electromagnetic vibration isolator adopts a magnetic tooth structure, by changing the input exciting current, online adjustment of electromagnetism stiffness can be achieved, and therefore the inherent frequency of the vibration isolation system is lowered. The variable damping technology adopts the magneto-rheological damper, and the damper of this type achieves damping change also through change of the input current. When the multifunctional compound vibration isolator works, the mode that the electromagnetic vibration isolator works alone, or the mode that the magneto-rheological damper works alone, or the mode that the electromagnetic vibration isolator and the magneto-rheological damper simultaneously work canbe selected.

Owner:中国人民解放军92578部队

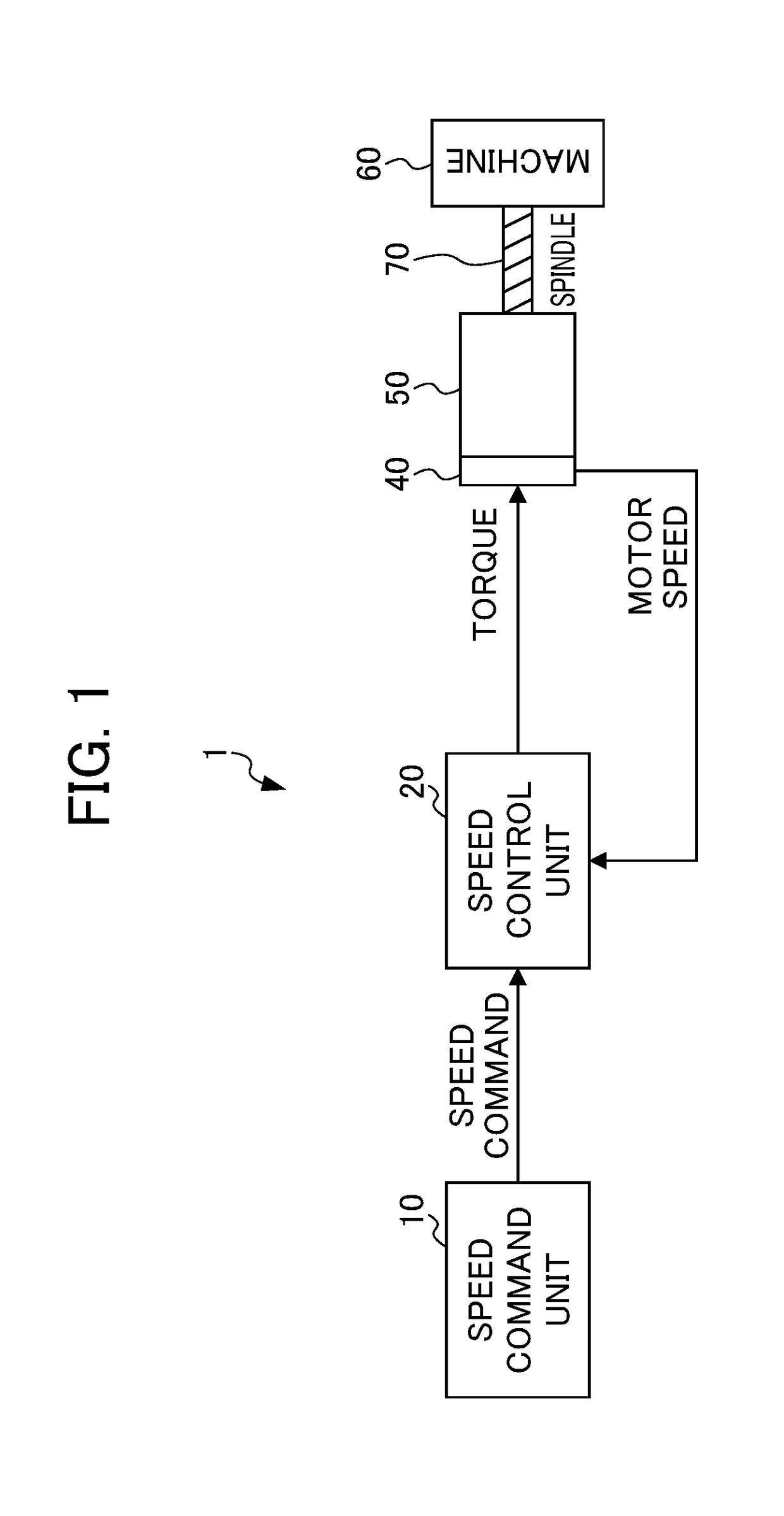

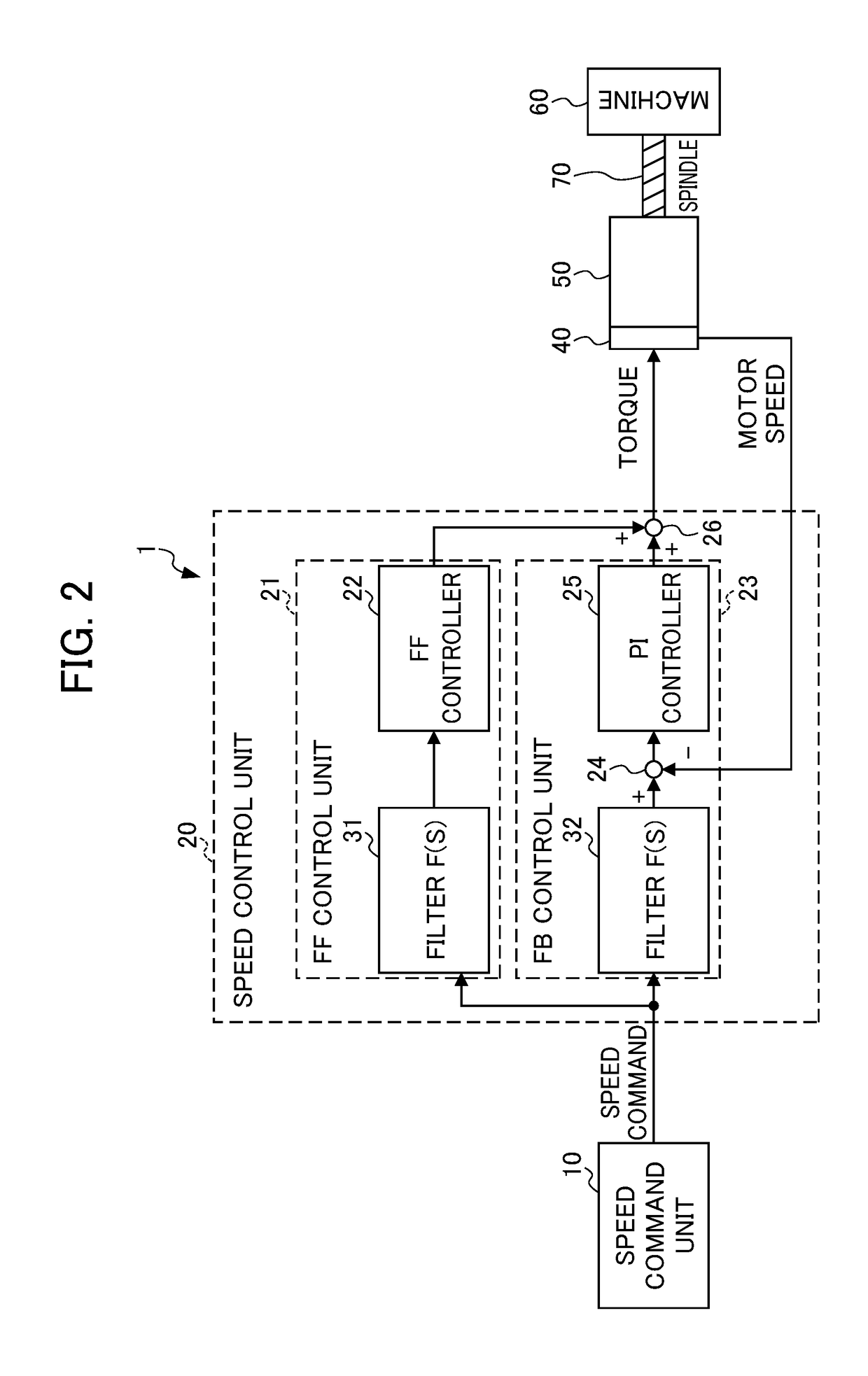

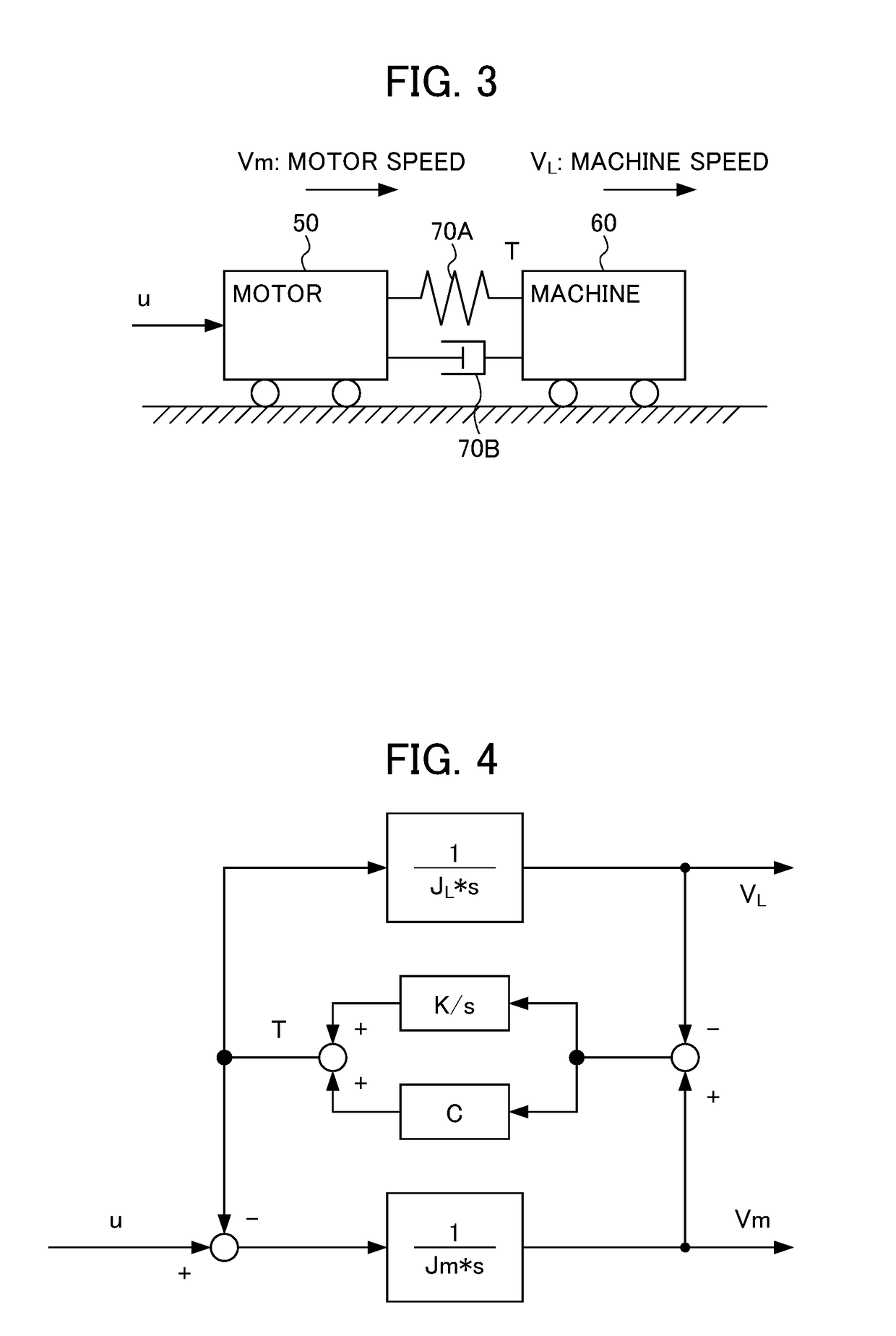

Motor controller

ActiveUS20180373221A1Reduce vibrationReduce low frequency vibrationGeneral control strategiesNumerical controlDamping factorMotor speed

A motor controller which controls a servo motor for driving a machine, includes: a speed command unit which commands the speed of the machine; a speed detection unit which detects the speed of the servo motor; and a speed control unit which produces a torque command based on a speed command and a motor speed detected so as to control the speed of the servo motor, where the speed control unit includes a filter which approximates the inverse characteristic of a transmission characteristic from the servo motor to the machine, the filter has a transmission characteristic F(s) based on a frequency ω, a vibration damping coefficient ζ and a cutoff frequency ωadj which are adjustment parameters and the frequency ω is adjusted so as to be equal to or more than an antiresonant frequency ω0 of the machine but less than a resonant frequency ωp.

Owner:FANUC LTD

Vibration damping device, method of controlling vibration damping device, method of correcting offset of vibration damping device, and leaf spring

InactiveCN102653220AReduce the amplitudeImprove ride comfort performanceNon-rotating vibration suppressionResilient suspensionsVibration amplitudeEngineering

An automobile vibration damping device for an automobile in which a power plant in which an engine, a transmission and the like are combined is supported by a vehicle body, including a vibrating means that generates vibration separate from vibration of the engine. Thereby, it is possible to reduce the vibration amplitude of a seat portion by the reaction force of the vibrating means. Also, if the vibration mode of the vehicle body is adjusted so as to become a node in the vicinity of the seat portion, the vibration amplitude decreases in the vicinity of the seat portion, and improves riding comfort.

Owner:SINFONIA TECHNOLOGY CO LTD

Turbocharger bearing with improved durability and noise reduction

Owner:GM GLOBAL TECH OPERATIONS LLC

Stirling engine assembly

InactiveCN1531625AReduce stiffnessIncrease deflectionStirling type enginesNon-rotating vibration suppressionEngineeringStirling engine

A Stirling engine assembly for a DCHP system. A Stirling engine (1) is suspended from a mounting frame (5) by a plurality of tension springs (6). An annular absorber mass (2) surrounds the Stirling engine and is suspended from the engine on a plurality of resilient members (3) arranged asymmetrically about the main axis. The asymmetric arrangement is provided by members of different stiffnesses, or irregular spacing of the members. The absorber mass (2) itself may be reduced adjacent to the resilient members.

Owner:MICROGEN ENGINE CORP HLDG BV

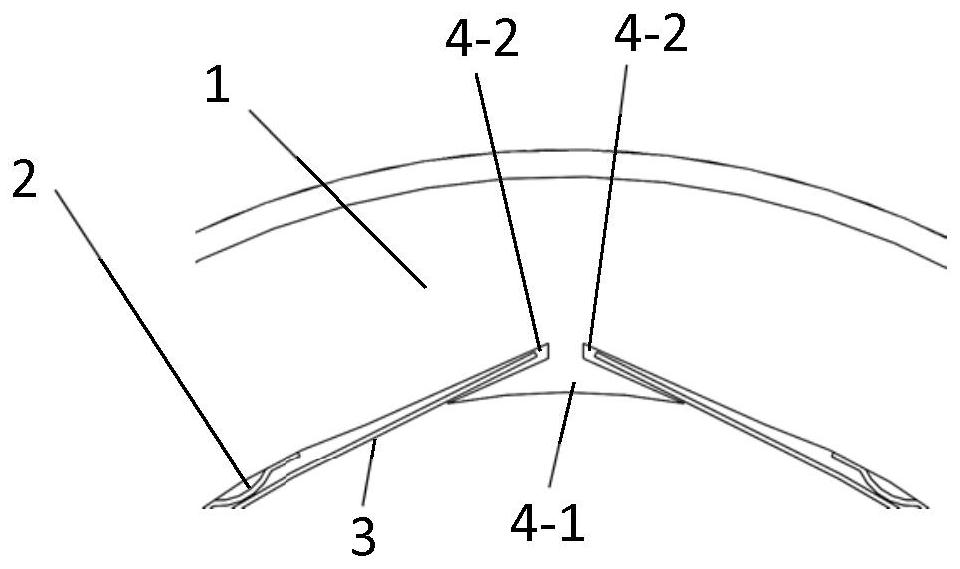

Aerodynamic radial foil bearing with forward and reverse rotation directions and dovetail-shaped structure

ActiveCN112855747AImprove stabilityIncrease installation clearanceSliding contact bearingsAir bearingStructural engineering

The invention discloses an aerodynamic radial foil bearing with forward and reverse rotation directions and a dovetail-shaped structure, belongs to the technical field of air bearings, and aims to solve the problems that the existing aerodynamic radial foil bearing rotates in one direction; when the bearing is installed, the rotating direction assembly error is generated, and the shaft system failure is easily caused, and the existing air dynamic pressure foil bearing has poorer stability during operation. According to the technical key points, at least one dovetail-shaped structure is formed in the inner wall of a bearing sleeve in the axial direction in a penetrating mode, a top foil is fixed by inserting the top foil into the dovetail-shaped structure, and the dovetail-shaped structure is characterized in that a dovetail-shaped boss is arranged in the middle of the dovetail-shaped structure, and two slender grooves allowing the top foil to be inserted are symmetrically formed in the two sides of the dovetail-shaped boss. By reducing the cross stiffness of the bearing during operation, the stability of the bearing during operation can be effectively improved, and moreover, as the two ends of the top foil are simultaneously inserted into the slender grooves in the two sides of the dovetail structure, and a corrugated foil is fixed below the top foil in a welding manner, the bearing can be suitable for the forward rotation direction and the reverse rotation direction of a rotor.

Owner:宙斯能源动力科技(大连)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com