Core-loosing highly effective energy-conserving vertical diagonal flow pump

A vertical oblique flow pump, high-efficiency and energy-saving technology, used in non-variable-capacity pumps, components of pumping devices for elastic fluids, pumps, etc. There are no guarantees, size matching is more sensitive, etc., to improve the efficiency of the pump, reduce the manufacturing cost, and reduce low-frequency vibration and shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

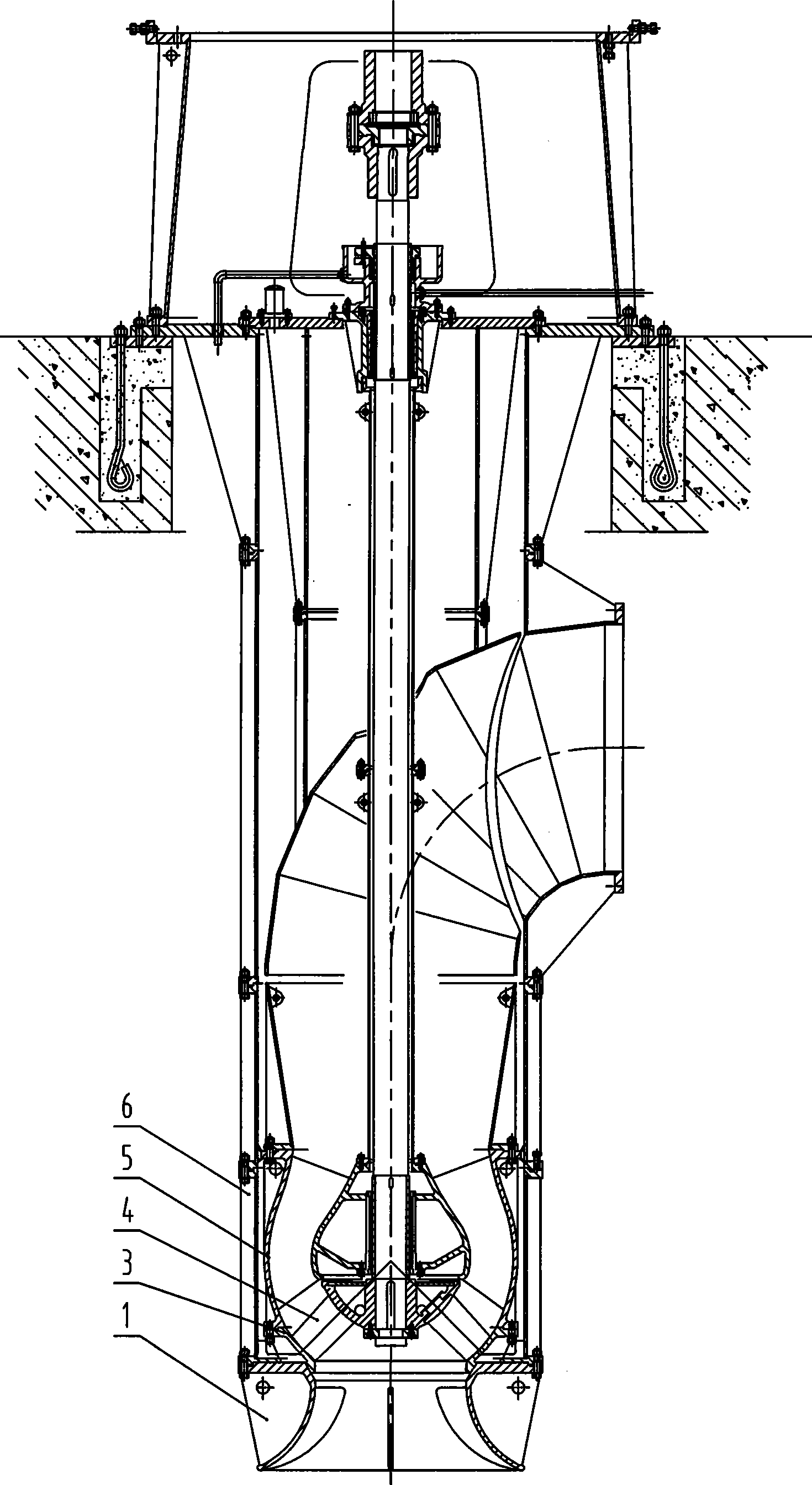

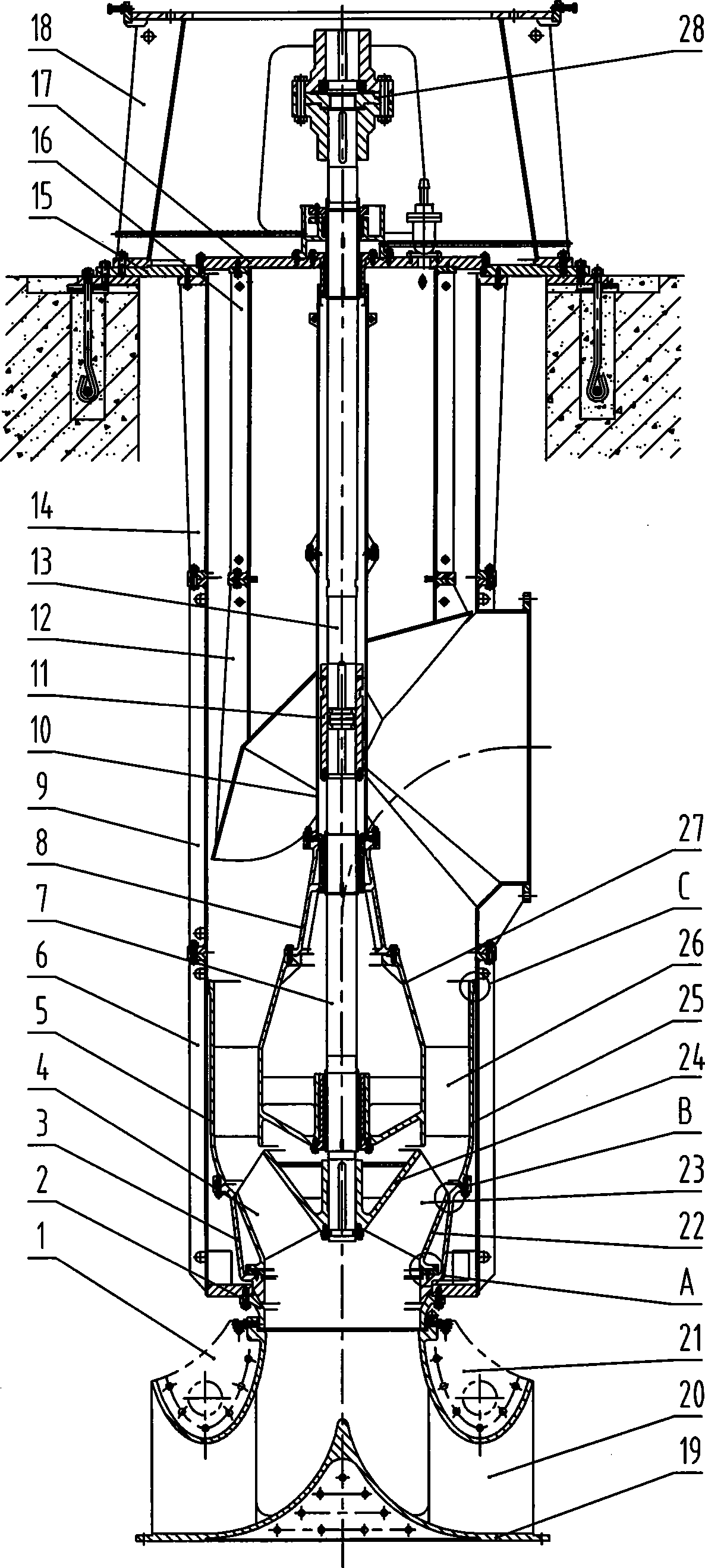

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

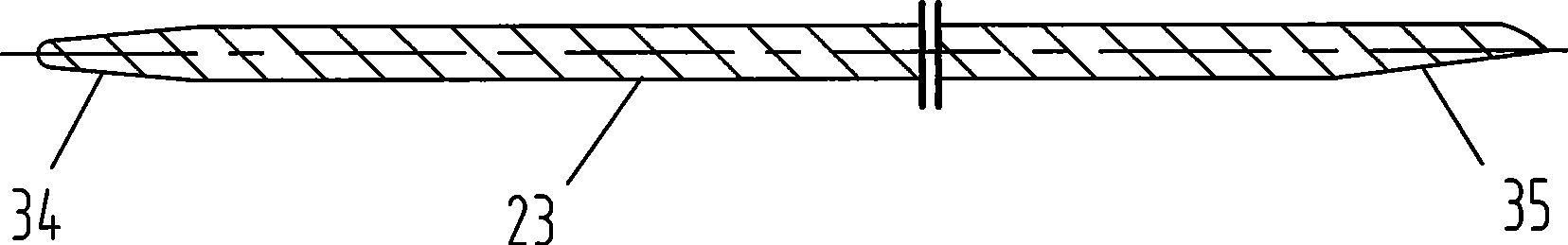

[0037] see figure 2 , the elliptical diversion pier 1 is fixed on the bottom plate of the water inlet pool, the suction pipe 2 is connected to the outlet of the oval diversion pier 1, the suction pipe 2, the lower external connection pipe 6, the water outlet elbow 9, the upper external connection pipe 14, and the support plate 15 , connected together from bottom to top to form the outer cylinder part without core-pulling; impeller chamber 3, guide vane body 5, bearing housing 8, and protective tube 10 are connected together from bottom to top to form the fixed part of the core-pulling part inserted into the outer cylinder In the barrel part; the impeller 4 is installed on the lower main shaft 7, and the upper main shaft 13 and the lower main shaft 7 are connected by the sleeve coupling 11 to form the rotating part of the core-pulling part; Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com