Patents

Literature

99results about How to "Reduce volume loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

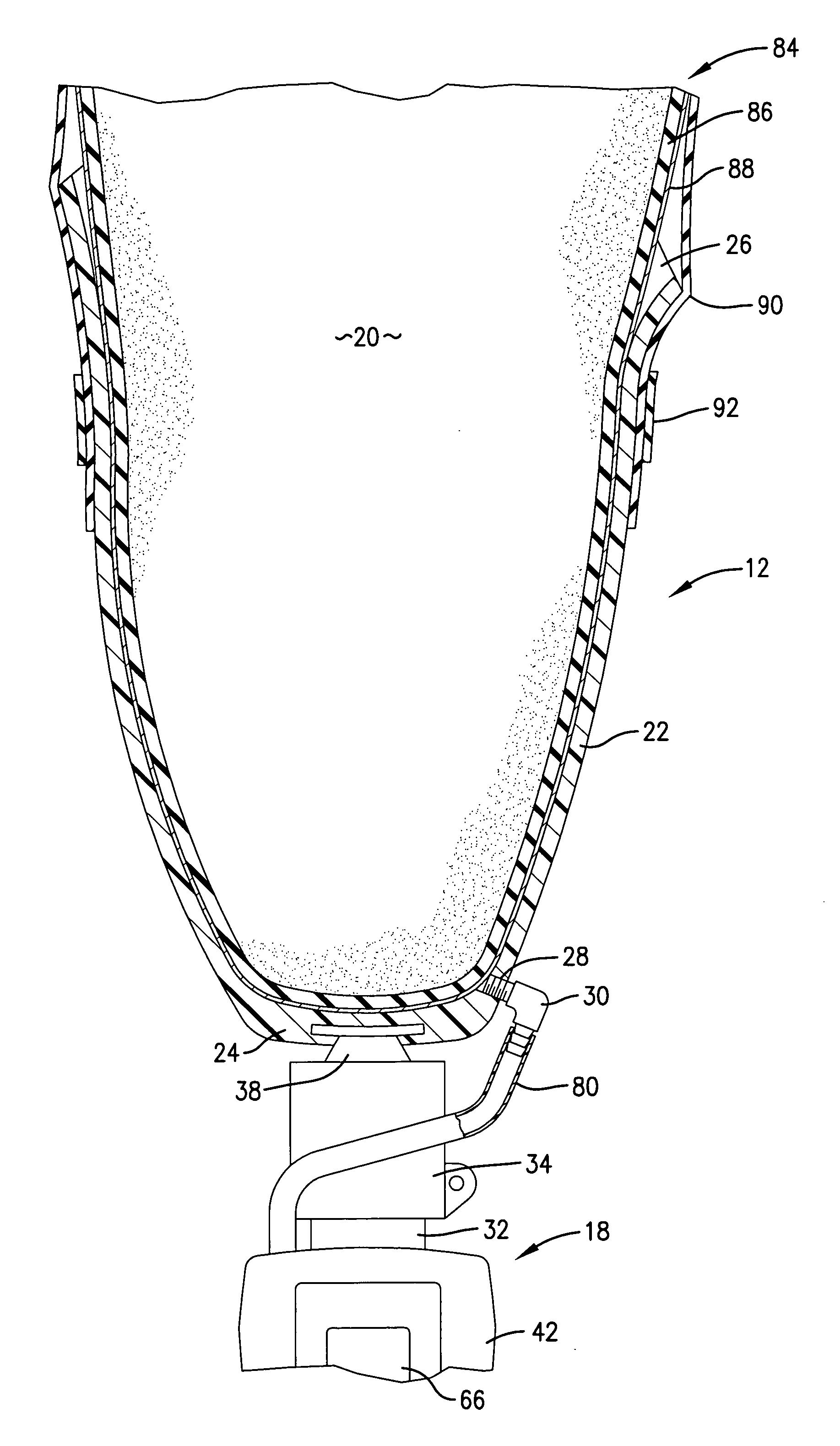

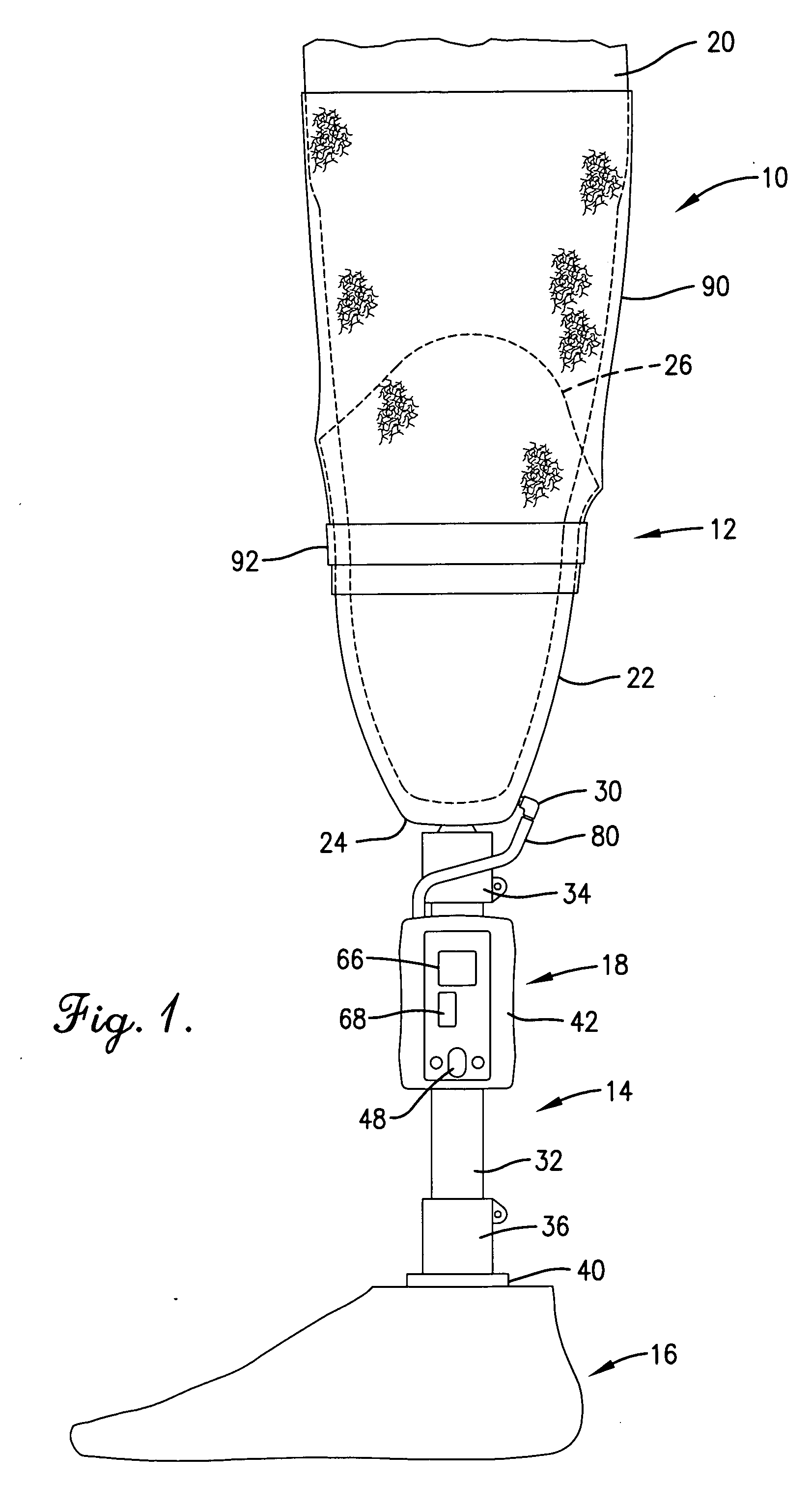

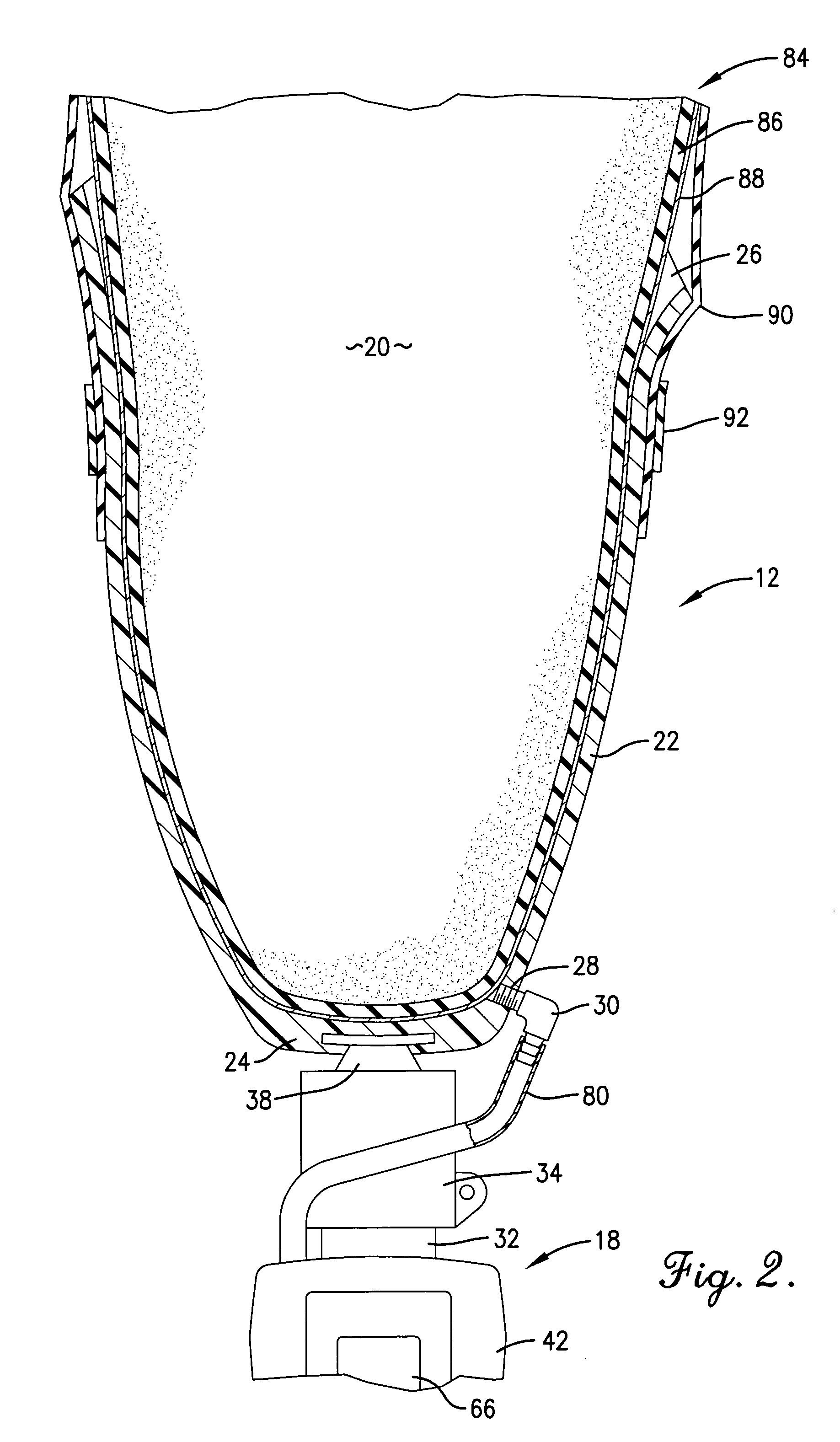

Artificial limb assembly having microprocessor-controlled vacuum pump

A vacuum-assist artificial limb assembly (10) is provided having a socket (22) for receiving a residual limb (20). The assembly (10) includes an on-board vacuum pump and control assembly (18) with a selectively operable vacuum pump (72) controlled by a microprocessor (44). The microprocessor (44) is also connected with an on-off switch (48), pressure adjust buttons (68), a pressure read-out (66), and an alarm (70). In use, a pressure transducer (74) in communication with the interior of socket (22) and coupled with microprocessor (44) monitors negative pressure conditions within the socket, and the microprocessor (44) operates pump (72) in response to transducer pressure signals. In this manner, the vacuum-assist operation of assembly (10) is essentially automatic.

Owner:JAEMS E & JOYCE E SMITH

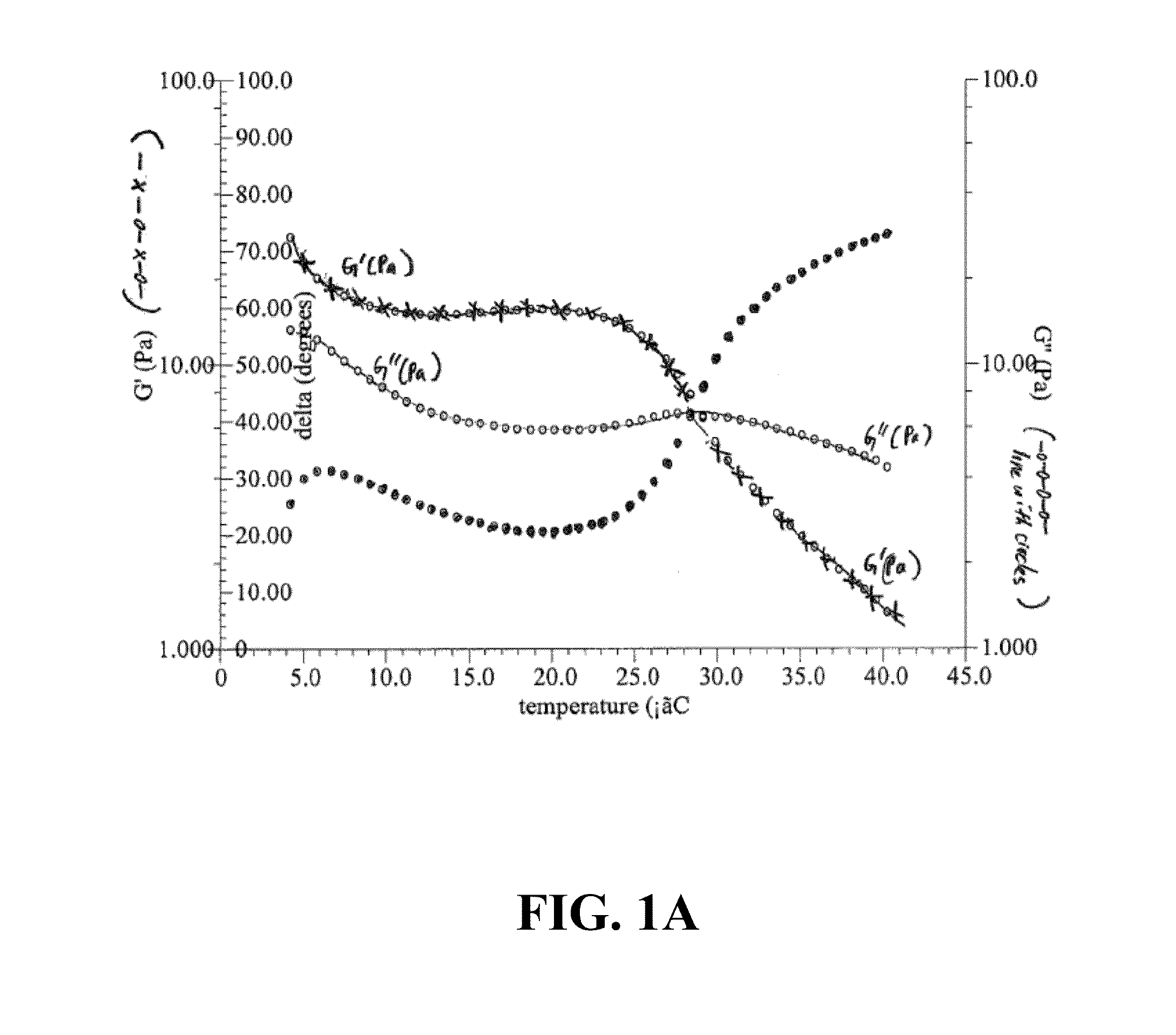

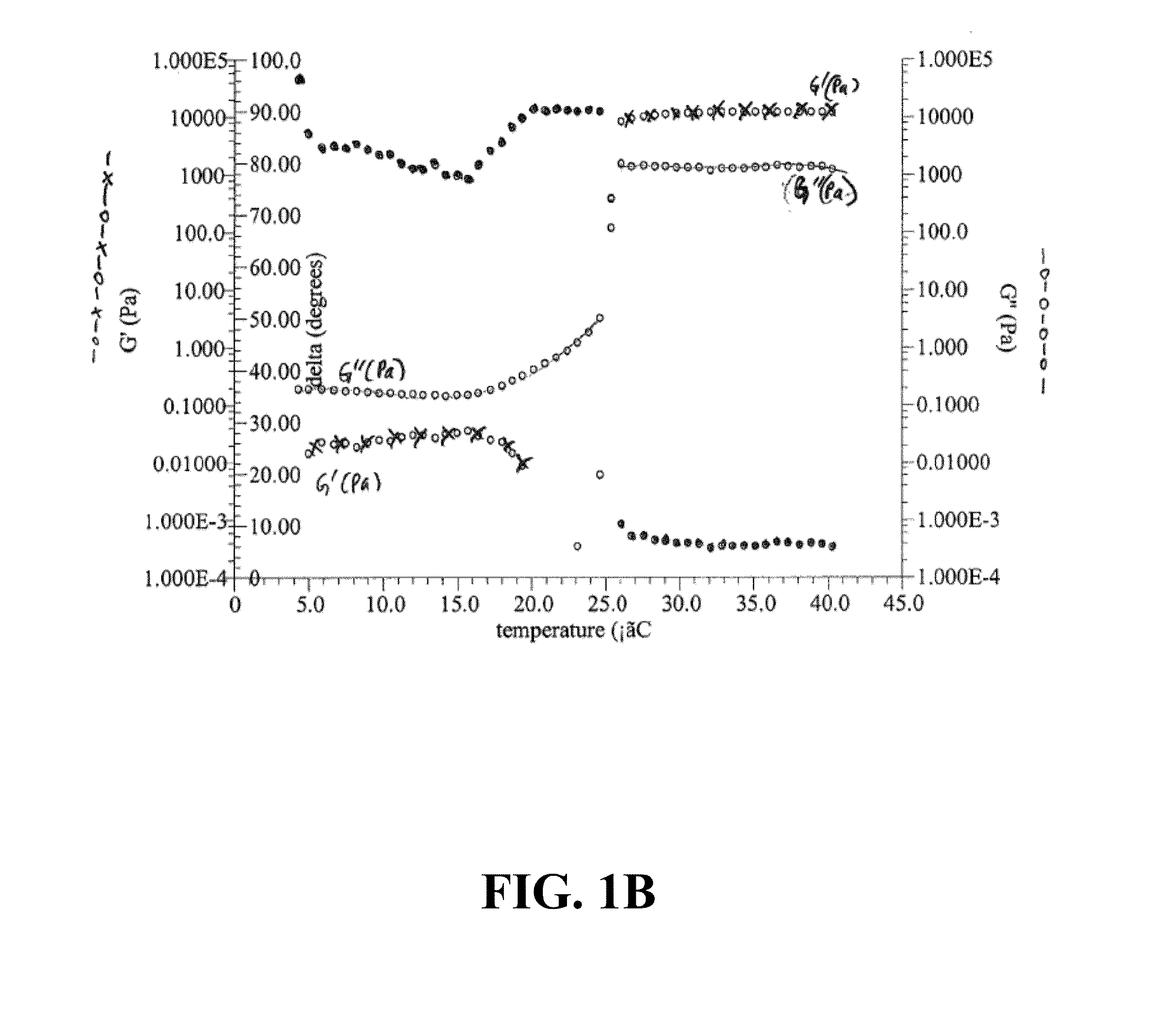

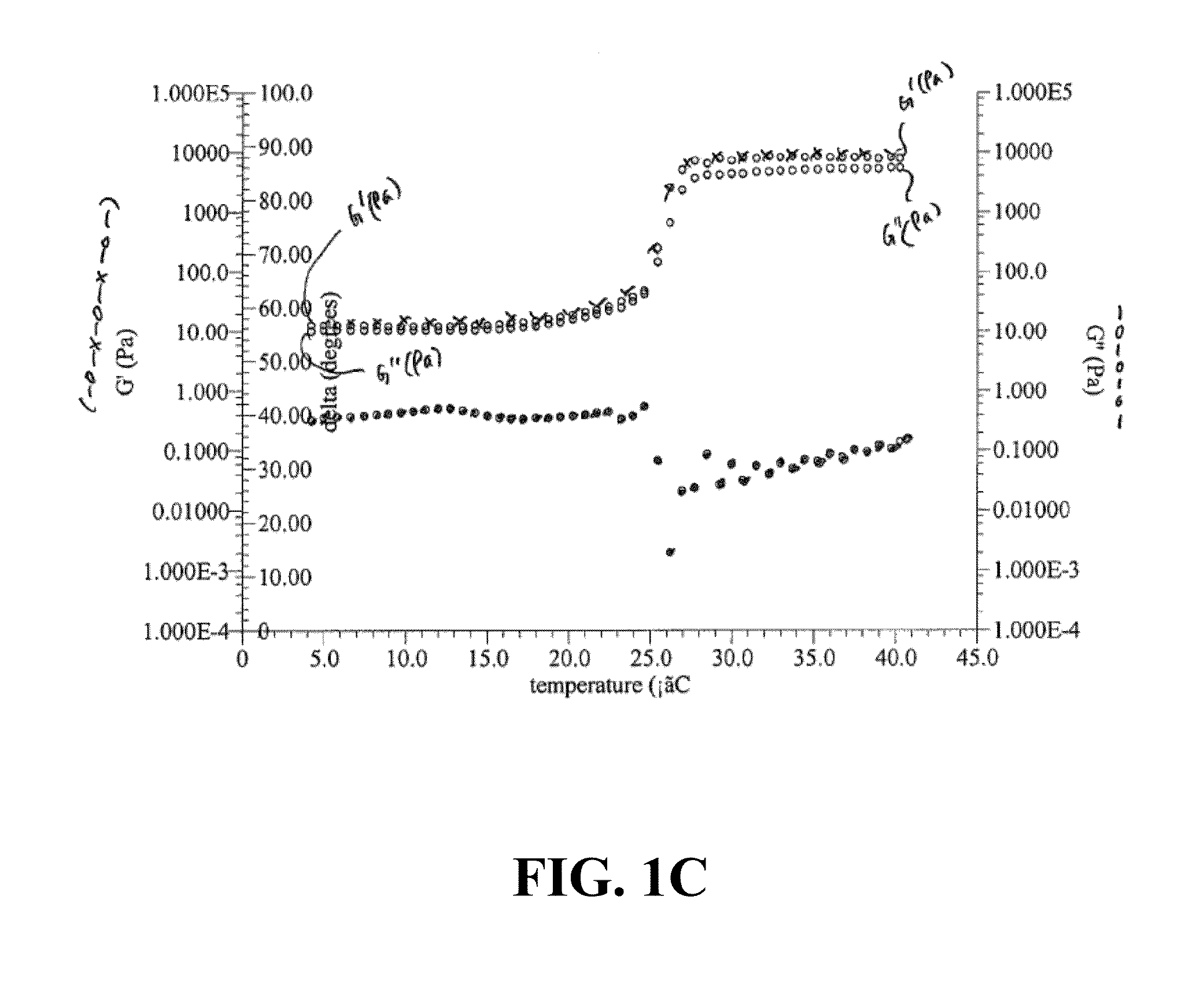

Hybrid hydrogel scaffold compositions and methods of use

ActiveUS20130115196A1Reduce usageReduce scarsBiocidePeptide/protein ingredientsHybrid materialMixed materials

The present invention includes new hybrid hydrogel scaffolds comprised of a polyoxyethylene-polyoxypropylene (block) copolymer (a “poloxamer”) and a self-assembling peptide, which maintain the mechanical and bioactive properties of its individual constituents (as compared to when the individual constituents are scaffolds or hydrogels by themselves). The hydrogels of the invention can include a combination of materials from different origins or with different properties that provides a hybrid material that meets the multiple needs of a scaffold for tissue engineering.

Owner:SAMSUNG DISPLAY CO LTD +1

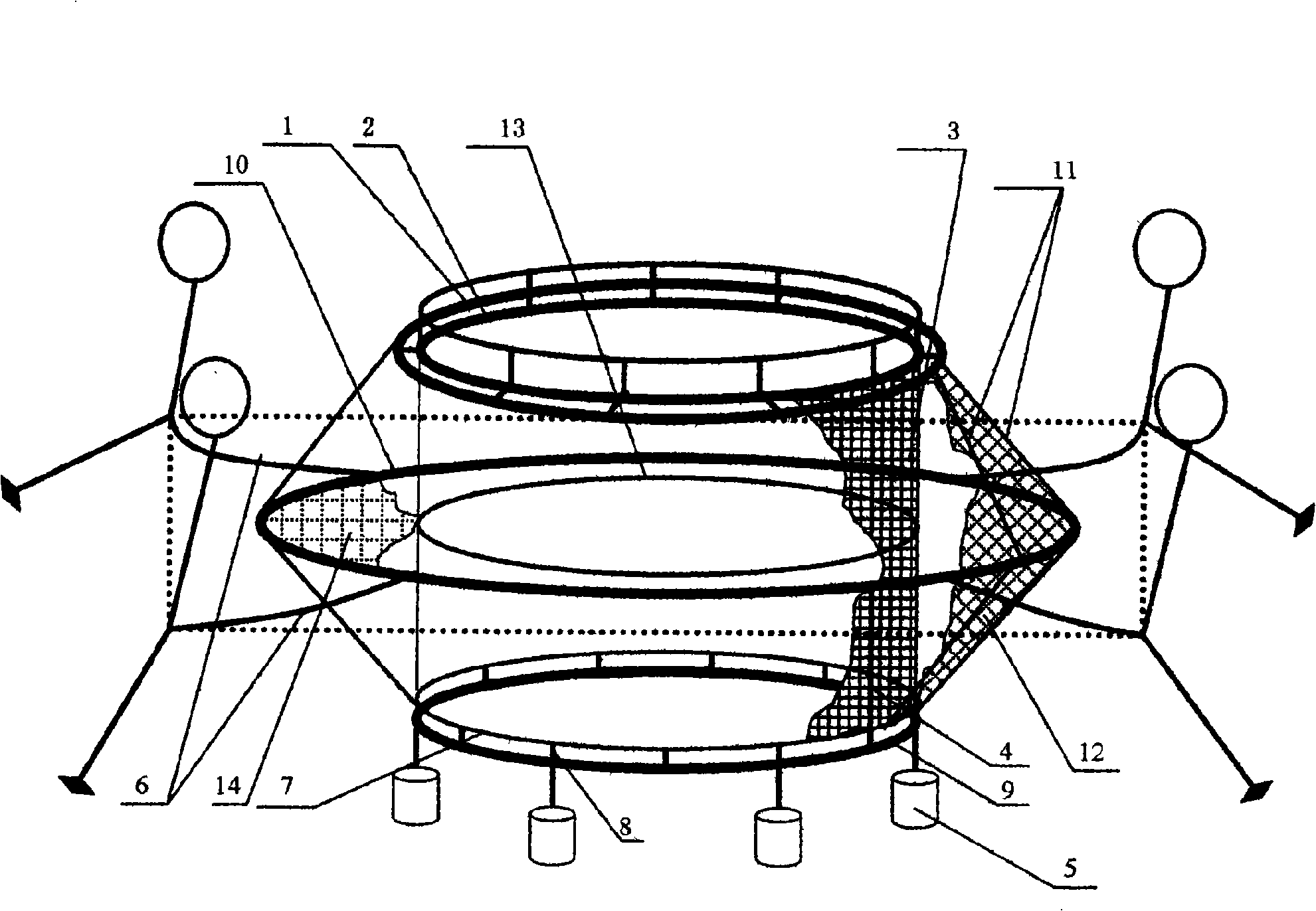

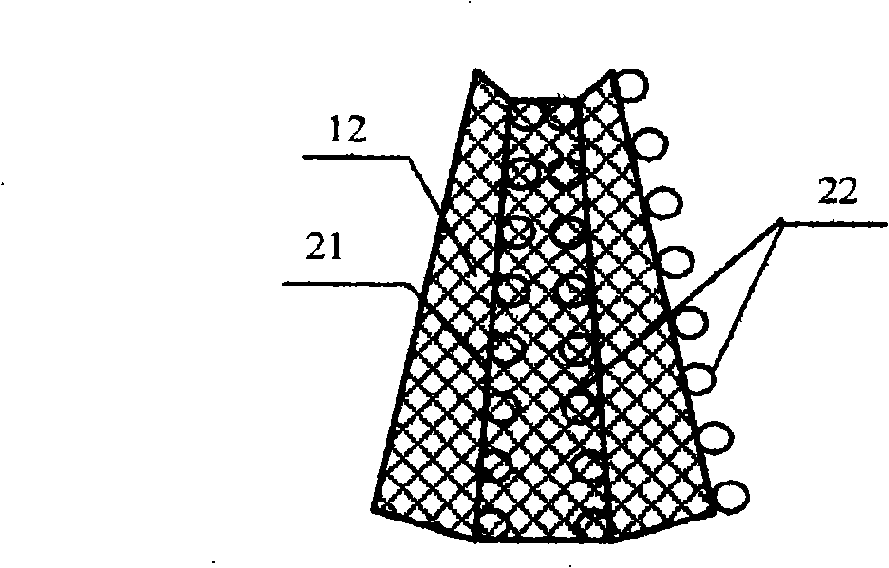

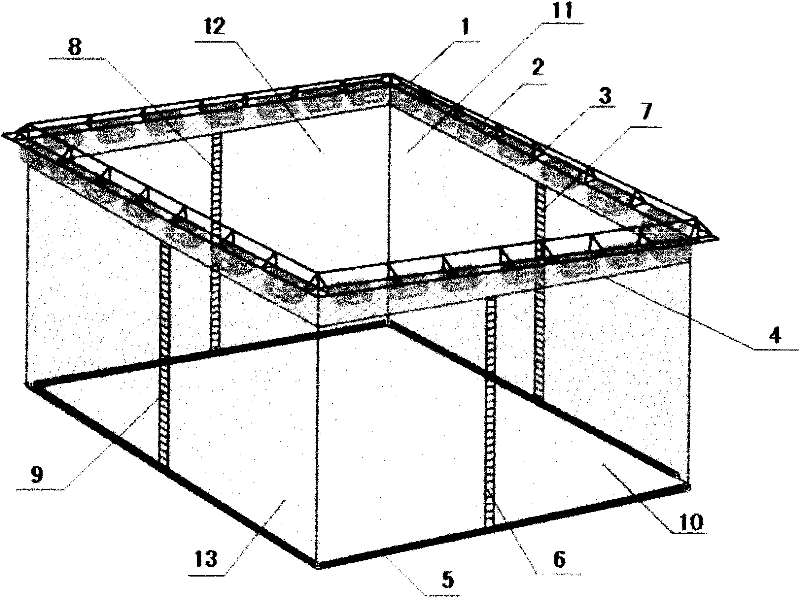

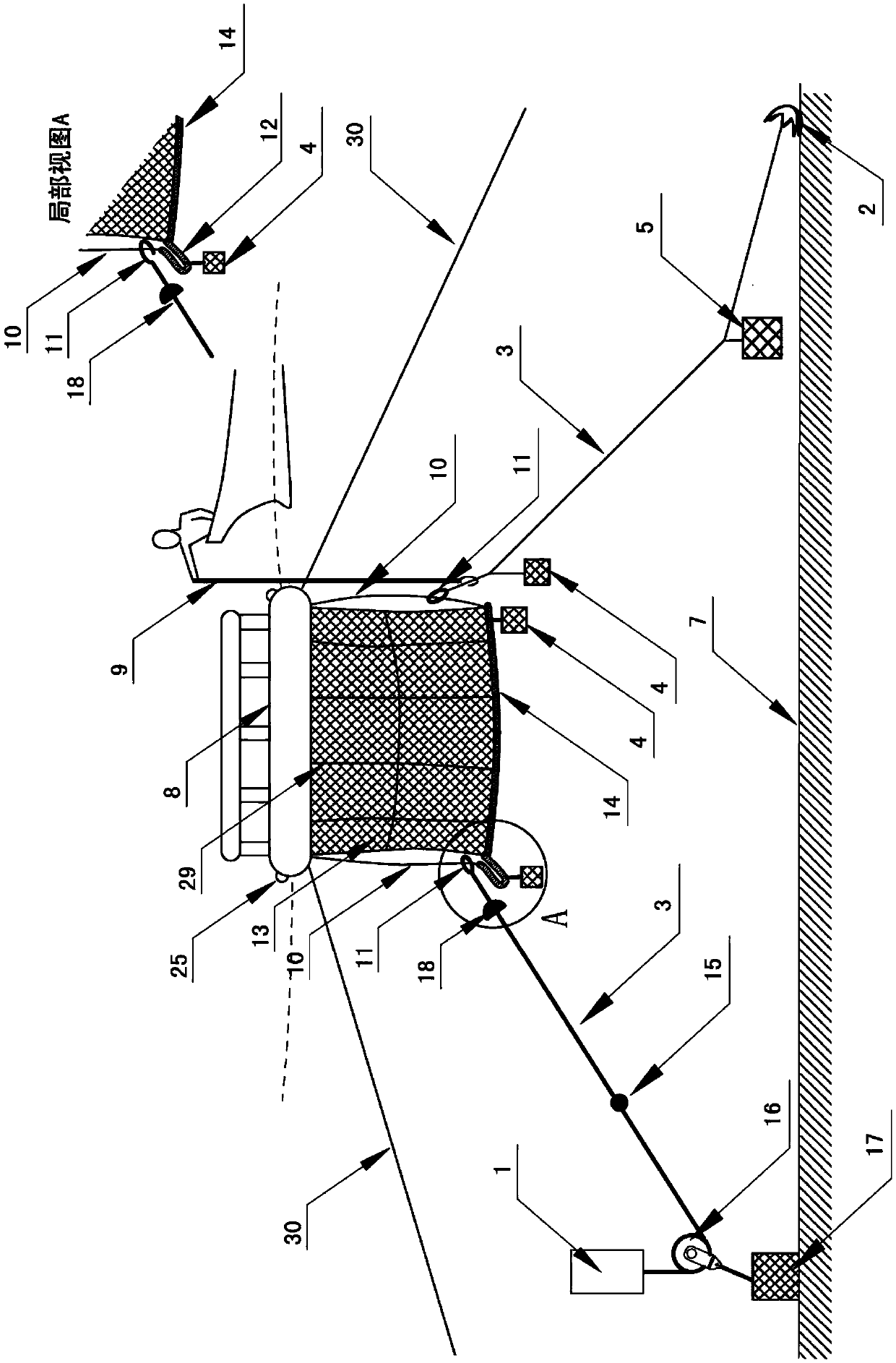

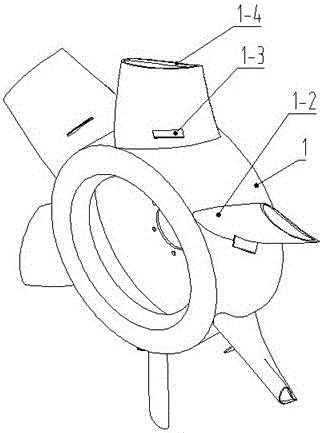

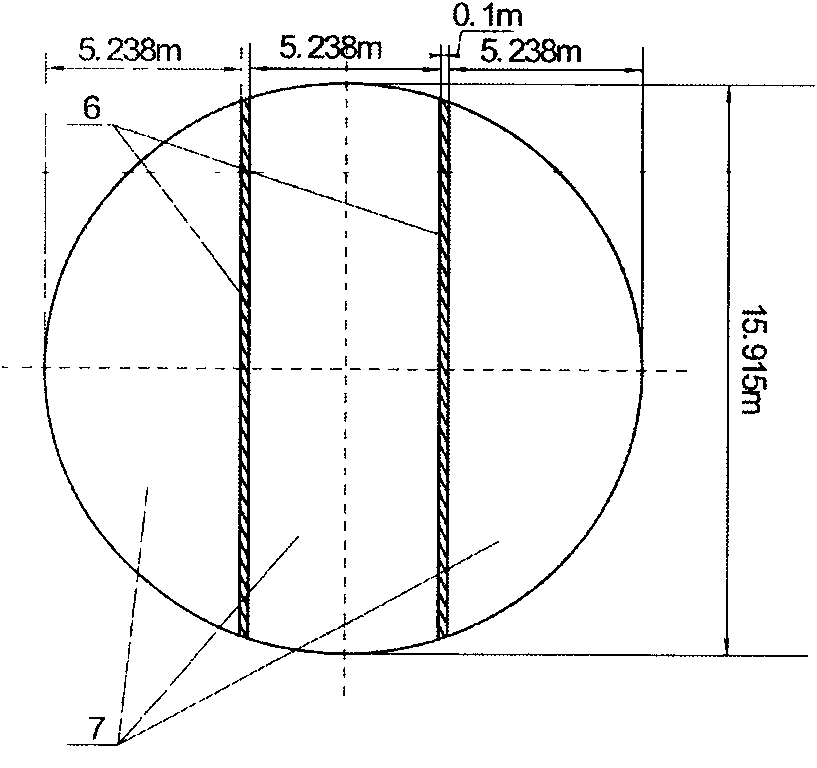

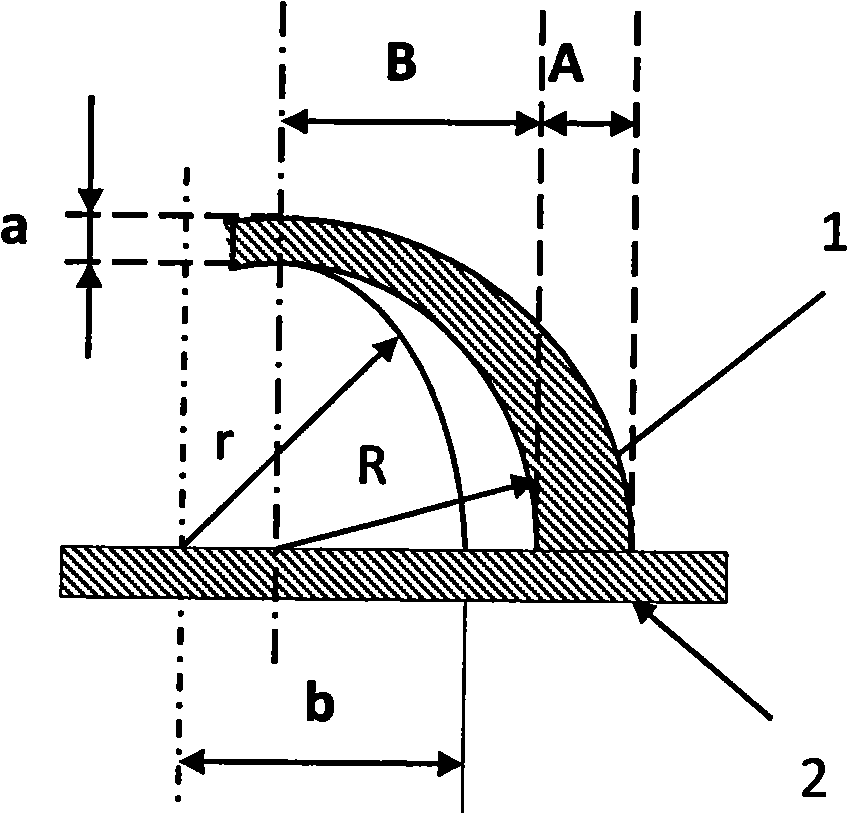

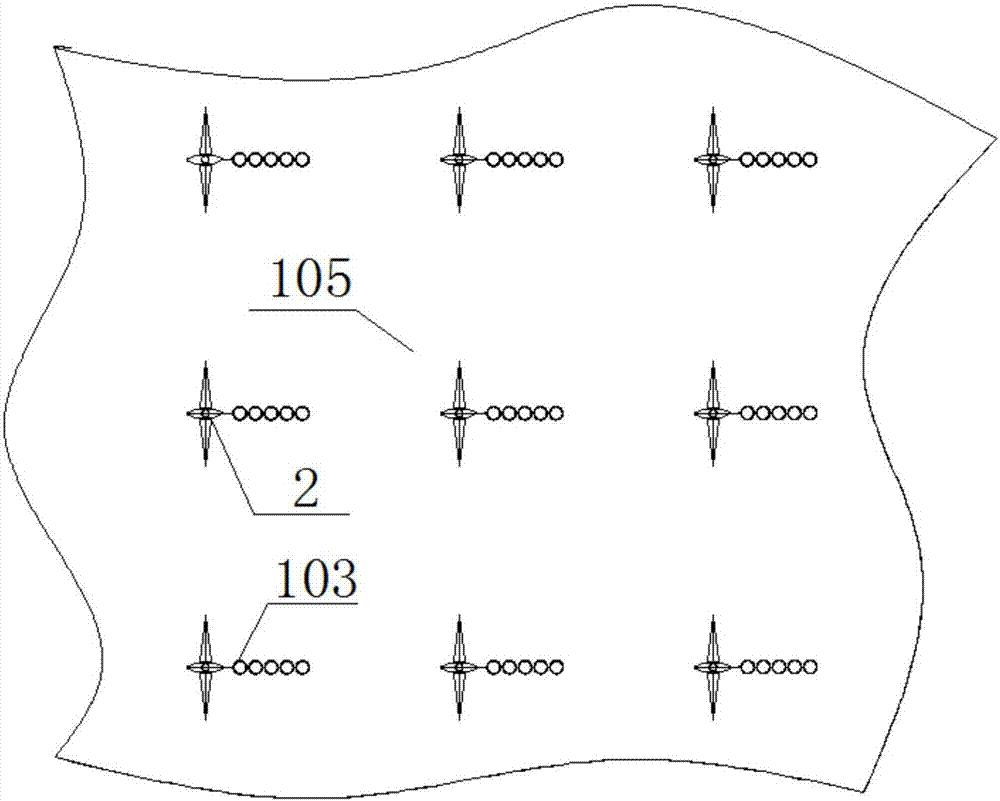

Self-reducing flow low-shape change off land deep water net cage

ActiveCN101326898AAdjust liftRegulation stateClimate change adaptationPisciculture and aquariaShape changeBand shape

The invention discloses an automatic reducing low-deformation offshore deep-water cage, relating to a cage for marine aquiculture. The invention is capable to reduce the deformation of the cage and the flow rate of the sea water inside the cage. The invention comprises a buoyancy frame, a cage, a sinking ring, a sinking block and an anchoring rope. A supporting and lifting control ring bigger than the buoyancy frame and the diameter of the sinking ring is arranged at the one second depth of the cylindrical cage; a water inlet and a water outlet are arranged in the pipe wall of the supporting and lifting control ring; a girdle rubber inner bag which regulates the lifting and descending of the cage is arranged in the ring pipe; an air-valve is installed in the rubber inner bag and connected with the air supply by a pressure hose; between the outer ring and the supporting and lifting control ring of the double-ring buoyancy frame, the bottom outline of the cylindrical cage and the bottom sinking ring, a plurality of flexible ropes are located and connected according to the ring at geometric proportion, and a netting is arranged among the connecting ropes of the three rings; and finally, a flexibly connected automatic reducing low-deformation offshore deep-water cage with a cylindrical inside and a two-cone platform outside is formed, the stress point of the anchoring rope of the cage is arranged at the supporting and lifting control ring.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

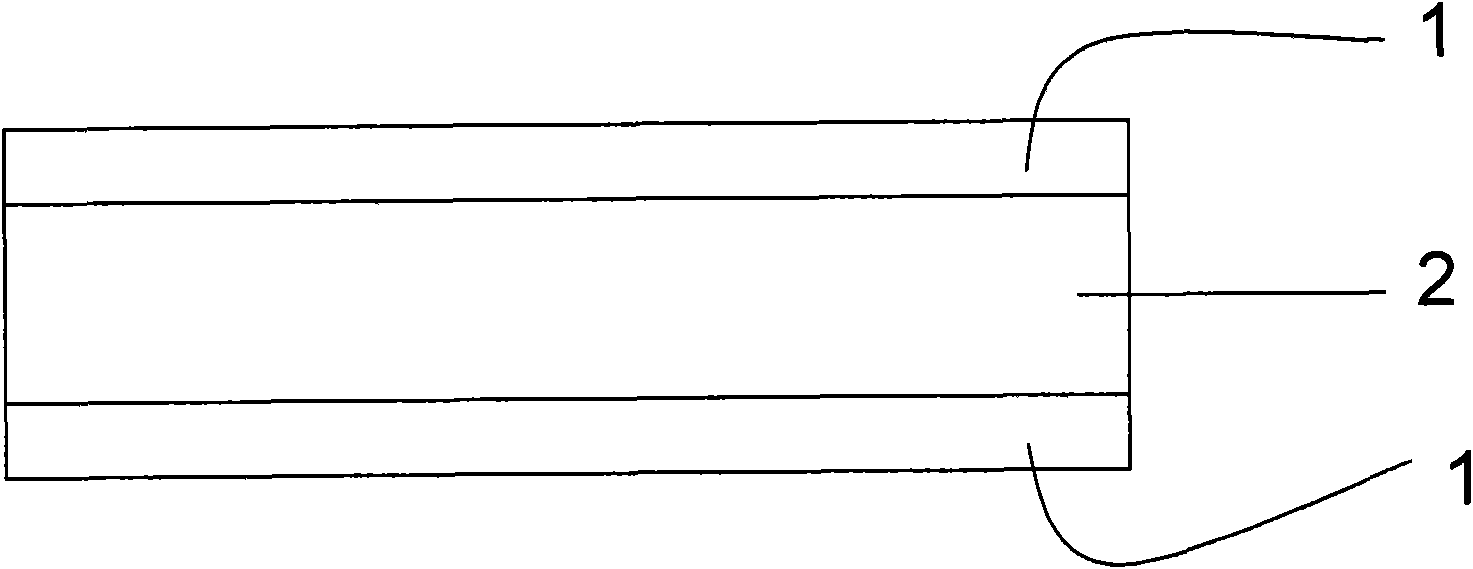

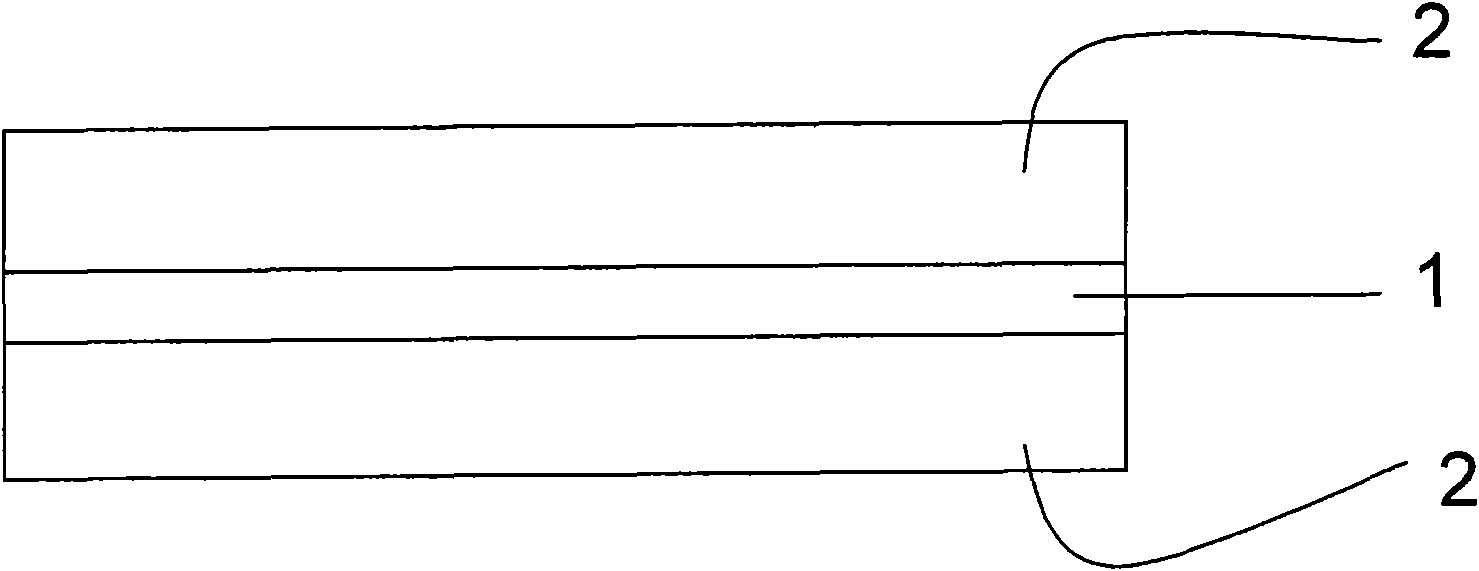

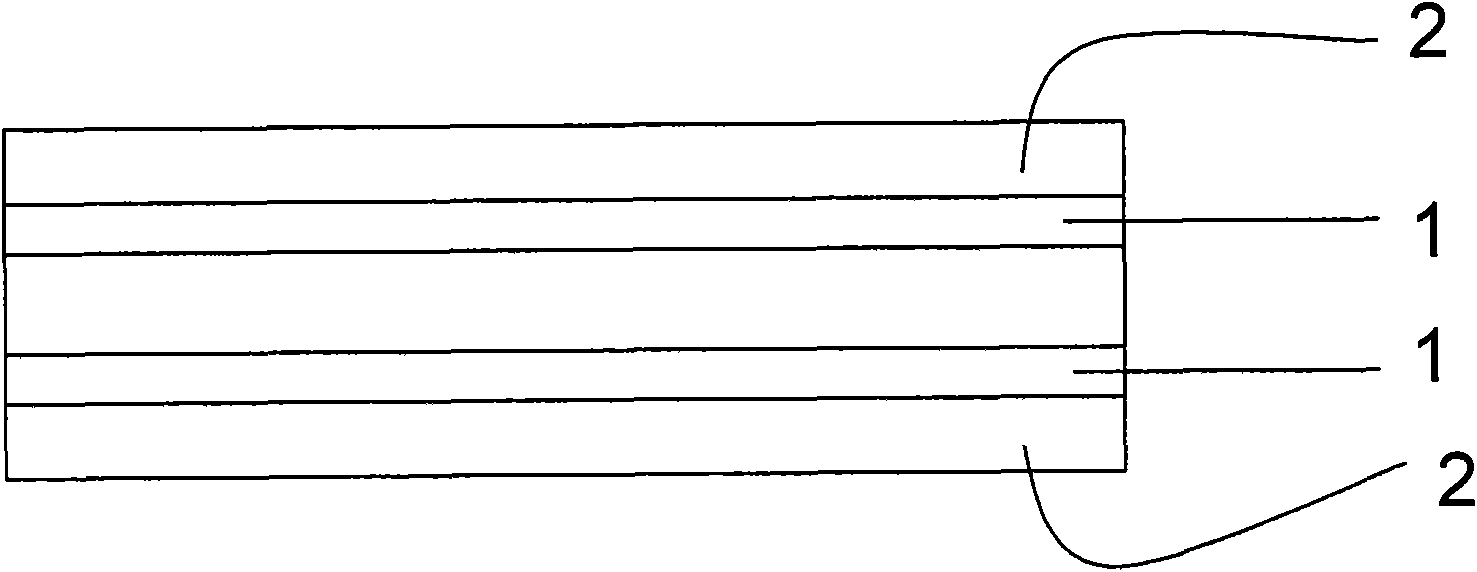

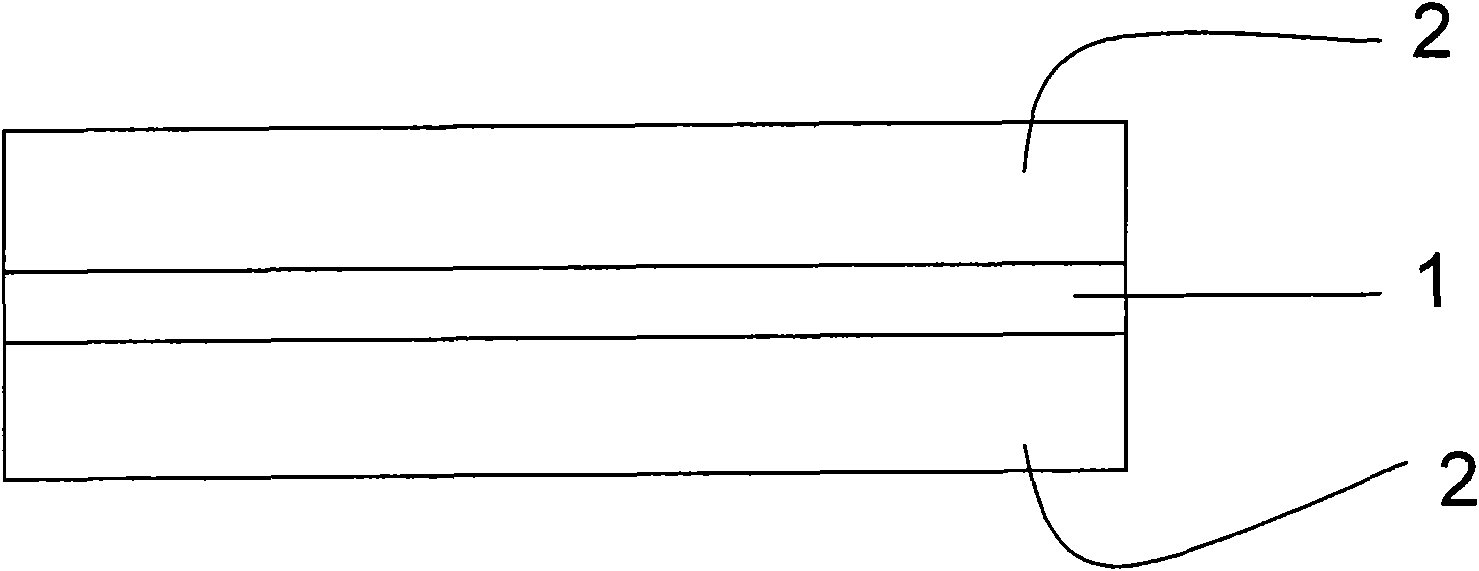

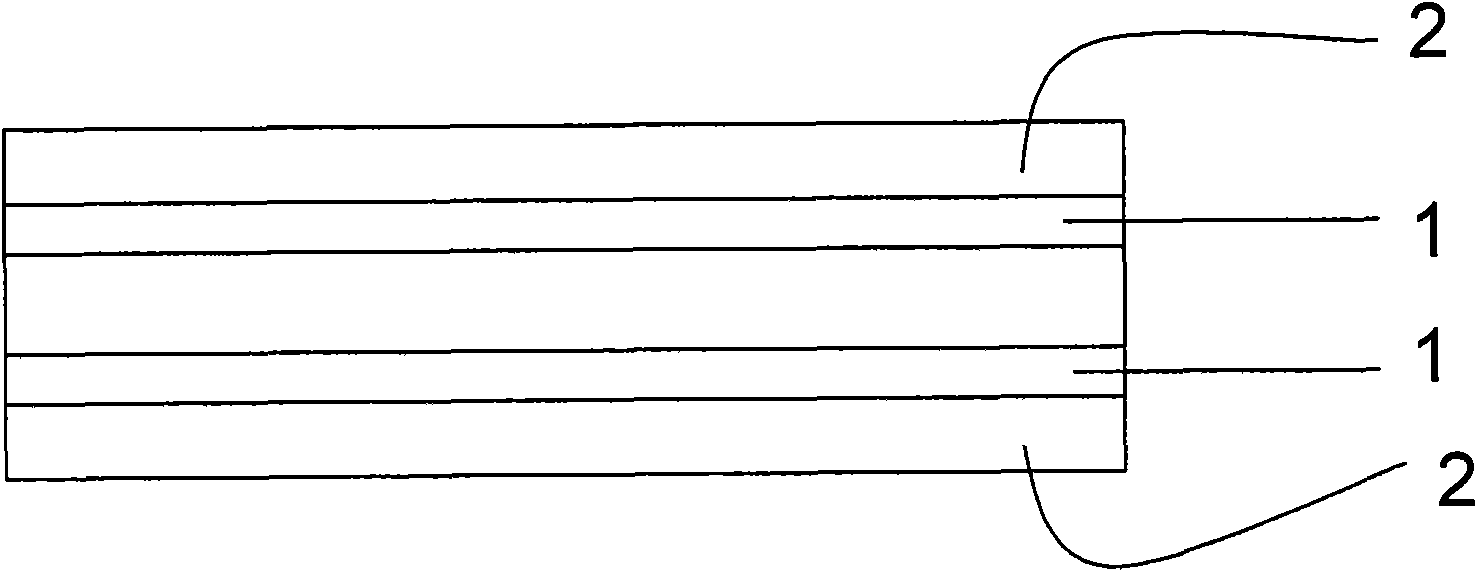

Method for densifying wood and densified wood

The invention discloses a method for densifying wood and densified wood manufactured by the same. The method comprises: sealing the cross section of wood by using a hydrophobic material, wherein the water content of the wood is less than 12 weight percent; coating softener on the surface and / or shallow layer of the sealed wood; and performing the hot pressing of the wood of which the cross section is sealed and which is coated with the softener at a temperature above the boiling point of the softener to densify the wood. The method for densifying wood can compress the wood to different extent according to needs. The method is simple and easy to operate, requires short time and simple equipment and makes product cost low. The densified wood manufactured by the method of the invention is greatly improved in surface density, hardness and wear resistance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

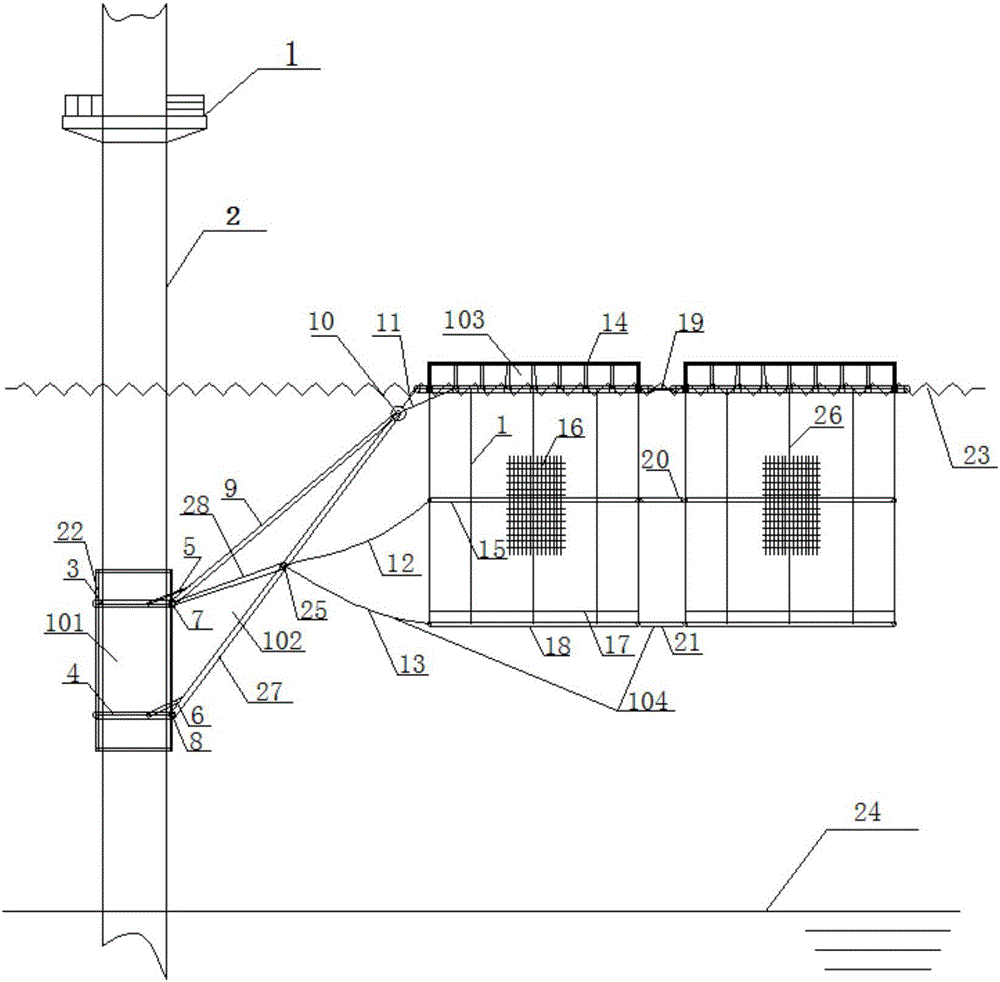

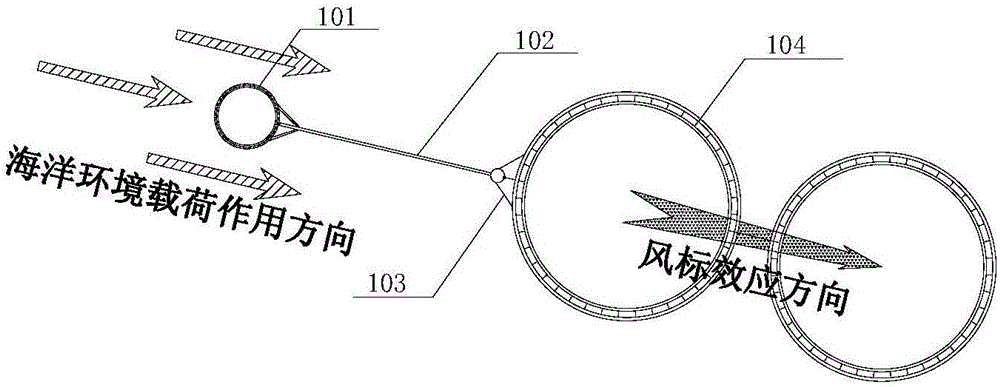

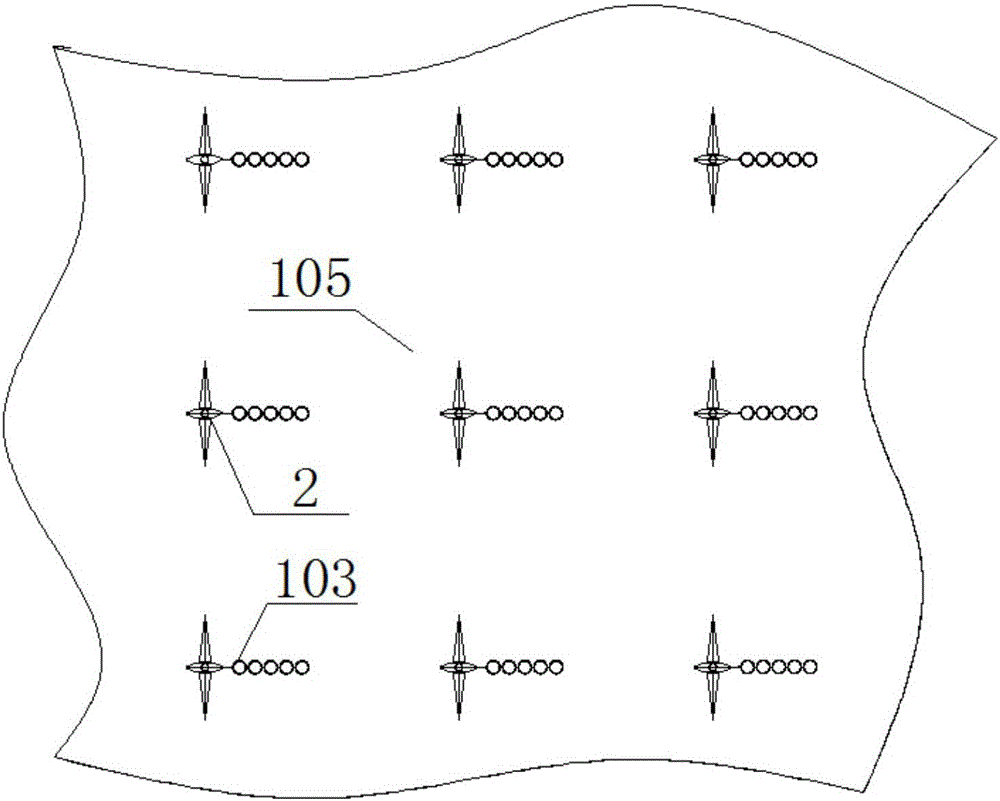

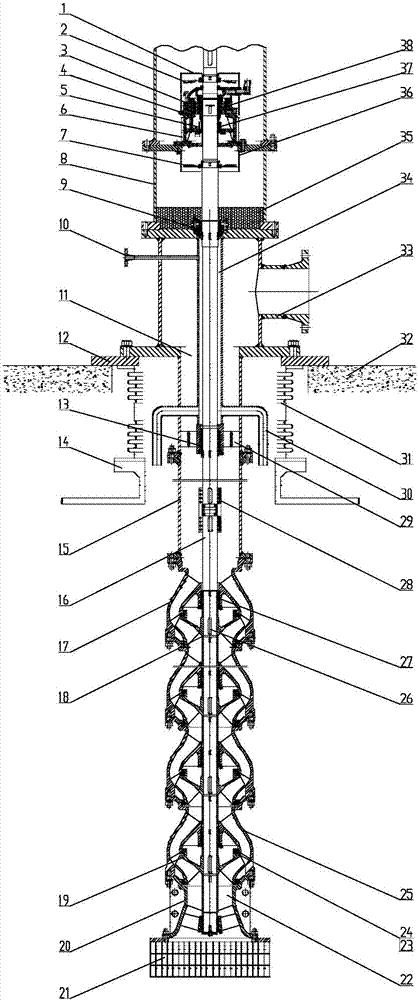

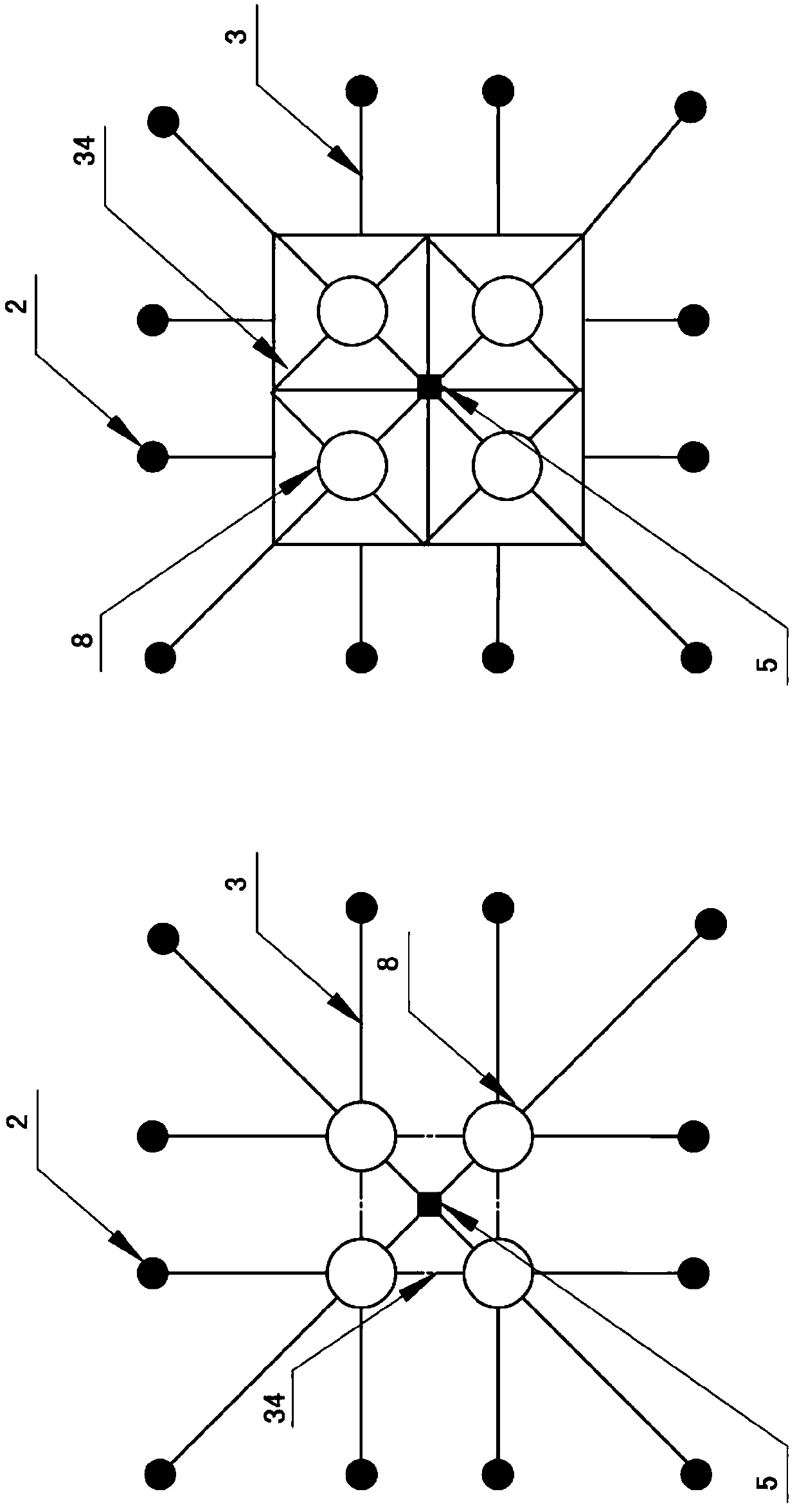

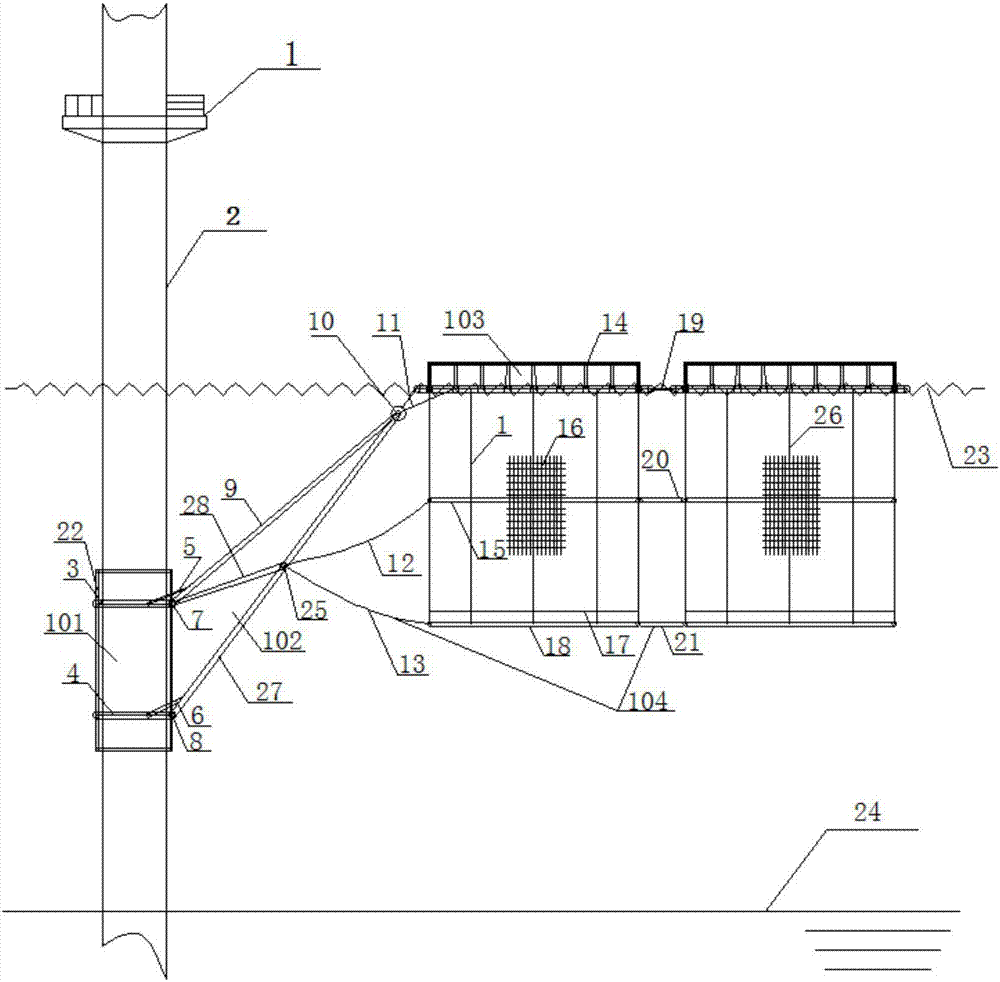

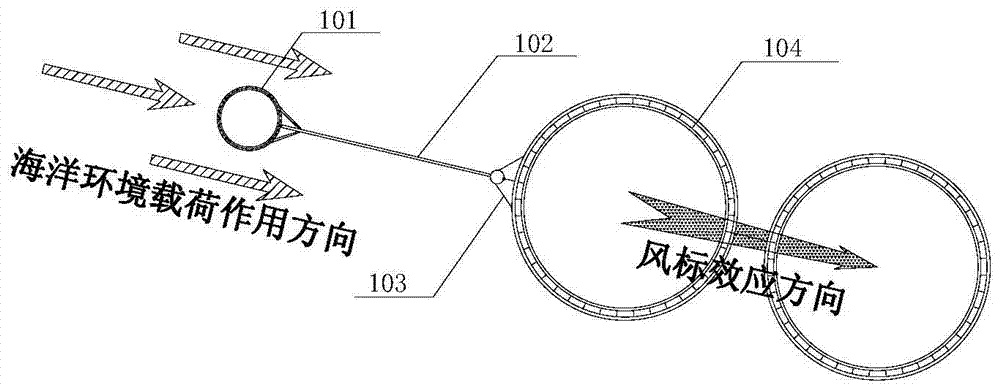

Deep sea net box cultivating apparatus for offshore wind field

ActiveCN105104271AReduces the effects of oxidation and corrosionIncrease stiffnessClimate change adaptationAgricultural fishingWind forceElectric energy

The invention discloses a deep sea net box cultivating apparatus for offshore wind field, which comprises an offshore wind turbine foundation, wherein an operation platform is mounted on the top portion of the offshore wind turbine foundation; a rotary sleeve ring fixing system is mounted on a lower end of the offshore wind turbine foundation; the rotary sleeve ring fixing system is connected to a rotary arm mechanism; the rotary arm mechanism is connected to an offshore net box module through a cable connecting rod component; the rotary sleeve ring fixing system comprises a reinforced cylinder sleeve; an upper rotary sleeve ring and a lower rotary sleeve ring are respectively mounted on an upper end and a lower end of the reinforced cylinder sleeve; and the upper rotary sleeve ring and the lower rotary sleeve ring are respectively connected to the rotary arm mechanism through an upper connecting buckle and a lower connecting buckle. According to the utility model, by adopting the apparatus provided herein, the offshore wind field can be applied with various purposes; organic combination between the offshore wind power generation and the offshore net box cultivation is realized; the space of the offshore wind field and the offshore wind power are fully utilized, thus improving the overall economy benefits.

Owner:佛山市榕岸海洋工程装备有限公司

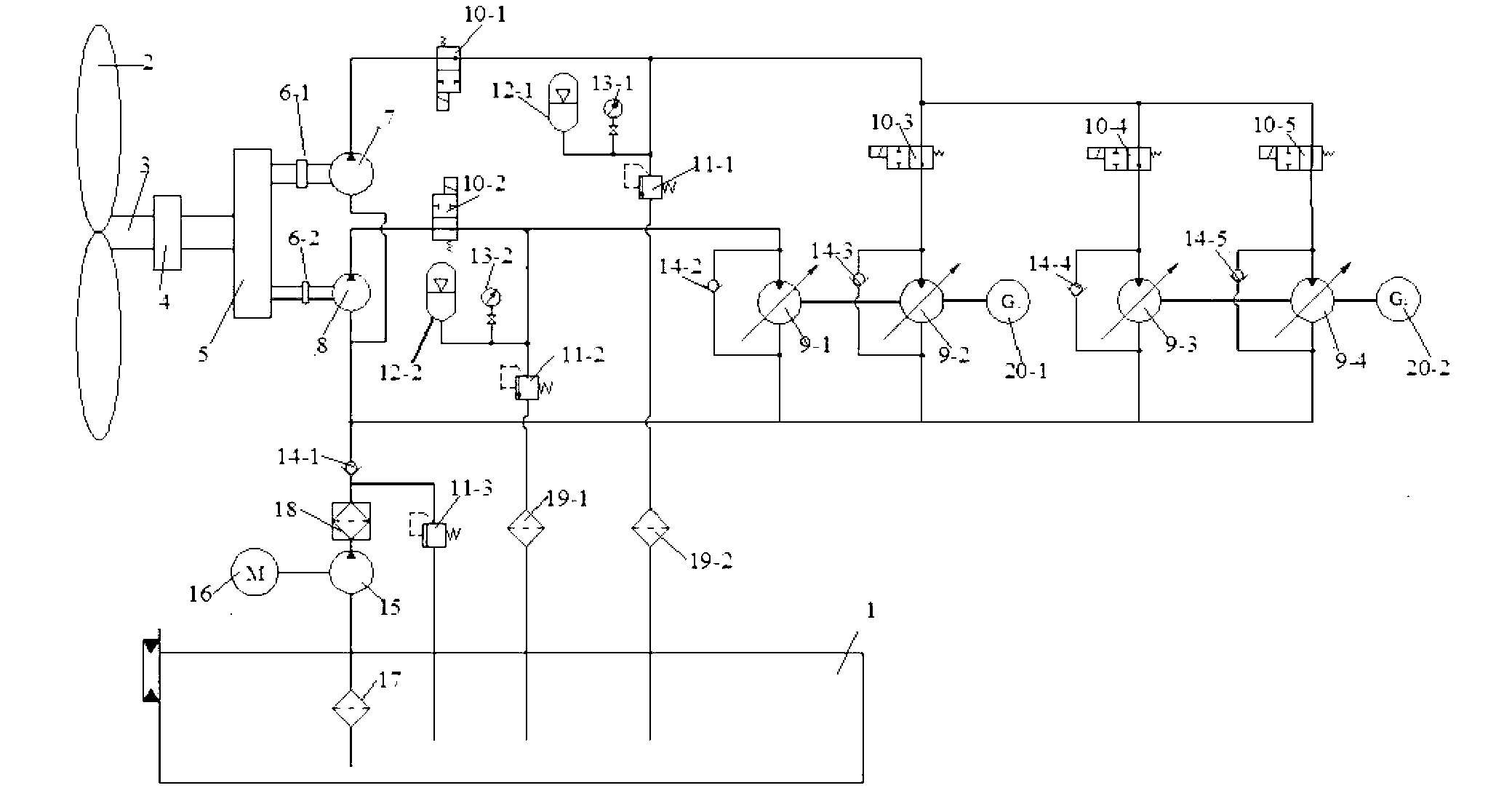

Novel full-hydraulic wind power system

InactiveCN103291550ALow costReduce volume lossEnergy industryWind motor combinationsFuel tankHydraulic pump

The invention relates to the technical field of wind generator sets, in particular to a novel full-hydraulic wind power system comprising an oil tank, a wind turbine, a turbine rotating shaft, a speed and torque sensor, a single-input double-output gearbox, a first clutch, a second clutch, a large-displacement quantitative hydraulic pump, a small-displacement quantitative hydraulic pump, a first variable displacement motor, a second variable displacement motor, a third variable displacement motor, a fourth variable displacement motor, a first reversing valve, a second reversing valve, a third reversing valve, a fourth reversing valve, a fifth reversing valve, a first overflow valve, a second overflow valve, a third overflow valve, a first accumulator, a second accumulator, a first pressure gauge, a pressure gauge switch, a second pressure gauge, a pressure gauge switch, a first one-way valve, a second one-way valve, a third one-way valve, a fourth one-way valve, a fifth one-way valve, an oil supplement pump, a motor, a suction oil filter, a precision oil filter, a first oil filter, a second oil filter, a first generator and a second generator. The novel full-hydraulic wind power system has the advantages of higher operating efficiency and higher stability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

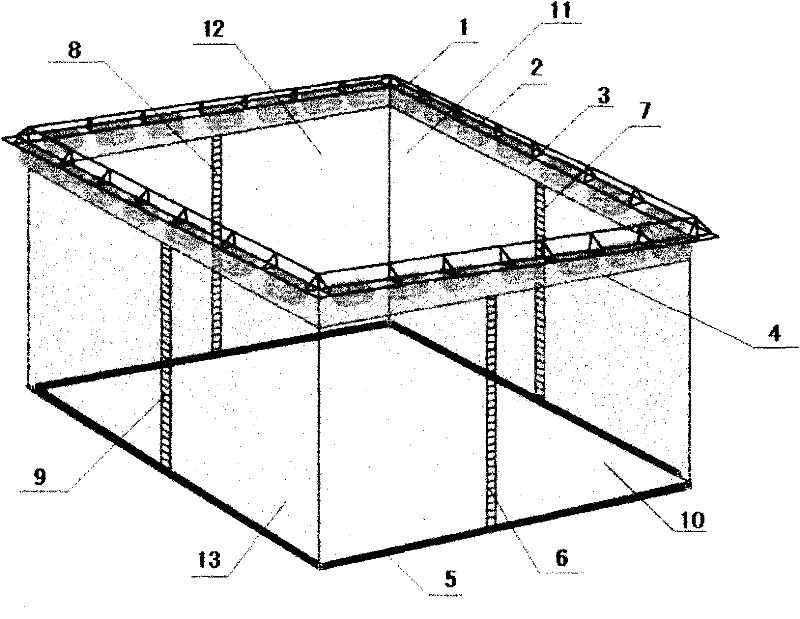

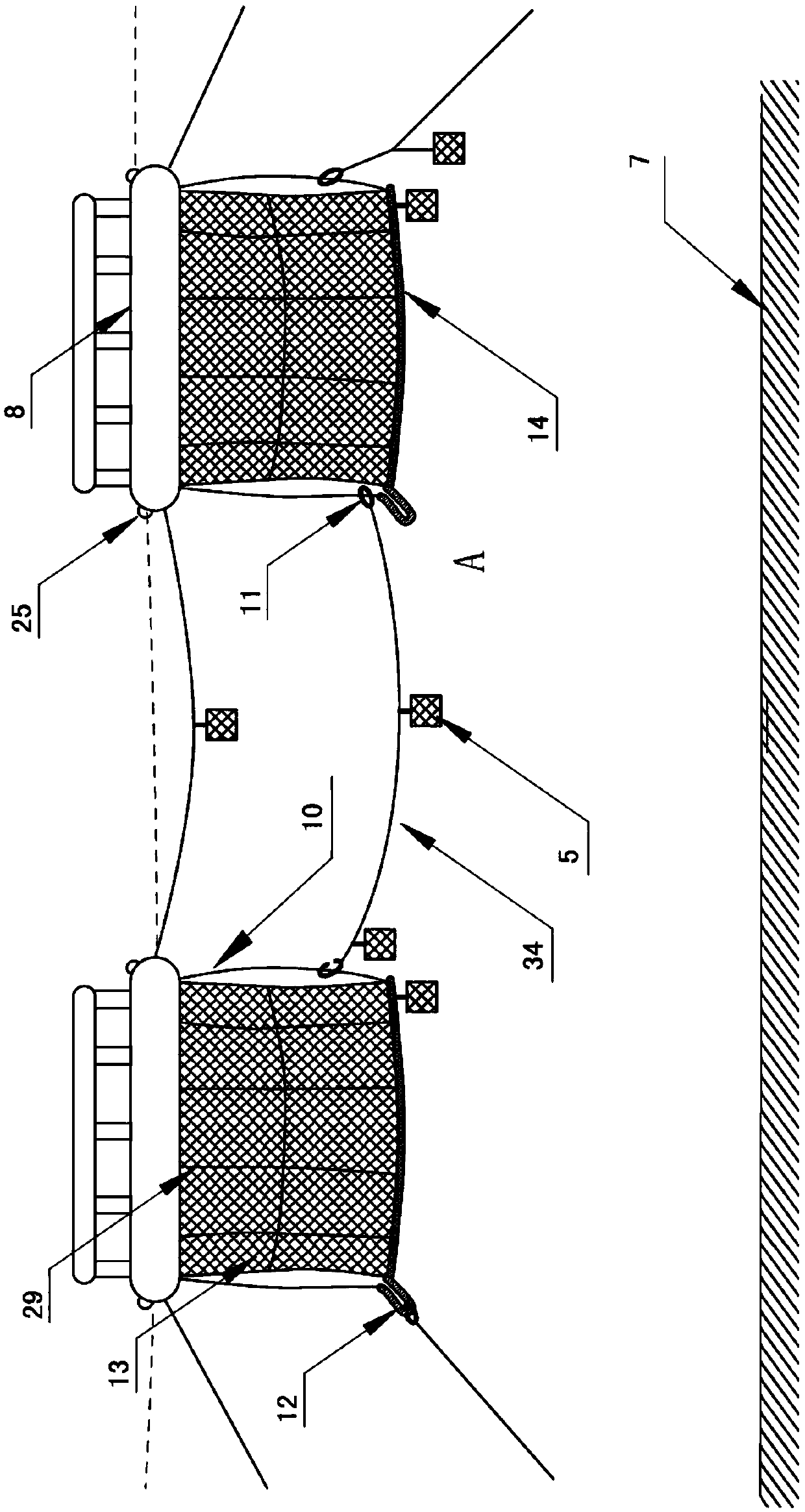

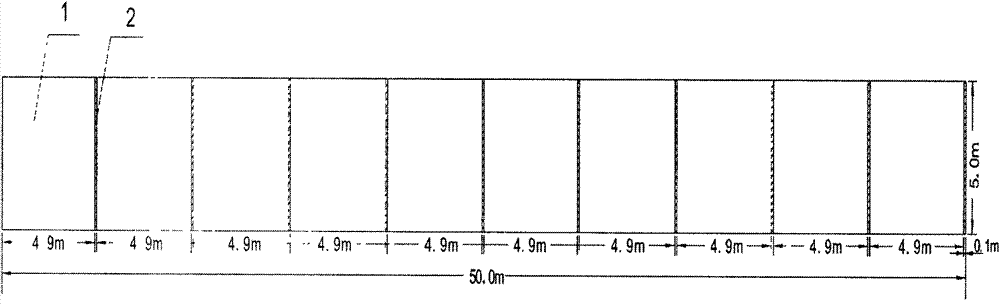

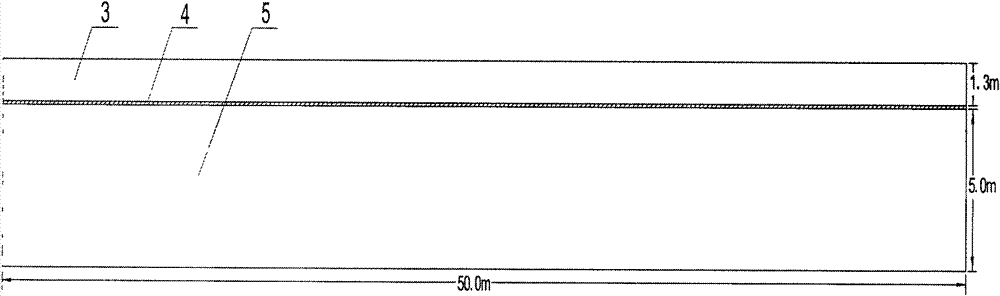

Combined fishnet square net cage used for mariculture

InactiveCN102239817AReduce deformation and volume lossImprove volume retentionClimate change adaptationPisciculture and aquariaDouble rowSeawater

The invention discloses a combined fishnet square net cage used for mariculture, relating to a mariculture net cage. In the combined fishnet square net cage, a cupronickel B10 stretching net, a brass HA177-2 stretching net, a high-strenght single-fast-knot polyethylene fibre net, a high-strength nylon warp knitting net, a fishing high-strength polyethylene monofilament rope, a galvanized iron pipe and a cylindrical foam buoy are adopted. The combined fishnet square net cage is characterized in that a frame system used for the net cage is of a square double-row galvanized iron pipe frame structure. In a fishnet system used for the net cage, a double-layer synthetic fibre fishnet serves as a first fishnet, a combined copper alloy stretching net serves as a second fishnet, and the first fishnet and the second fishnet are in longitudinal semi-soft connection; a square synthetic fibre fishnet is in a combined fishnet form of the fishnets used for the net bottom of the net cage; the combined fishnet used for the net bottom of the net cage is hung on the square double-row galvanized iron pipe frame; and the square double-row galvanized iron pipe frame of the net cage is connected with a float line frame of a mooring system by a mooring rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

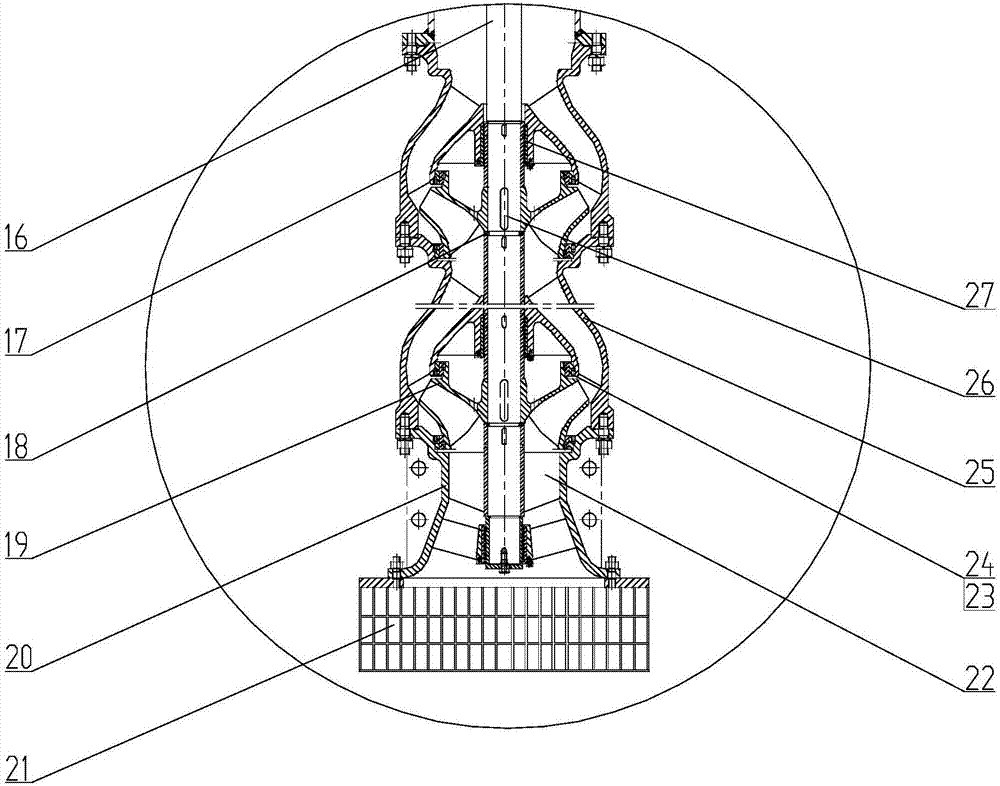

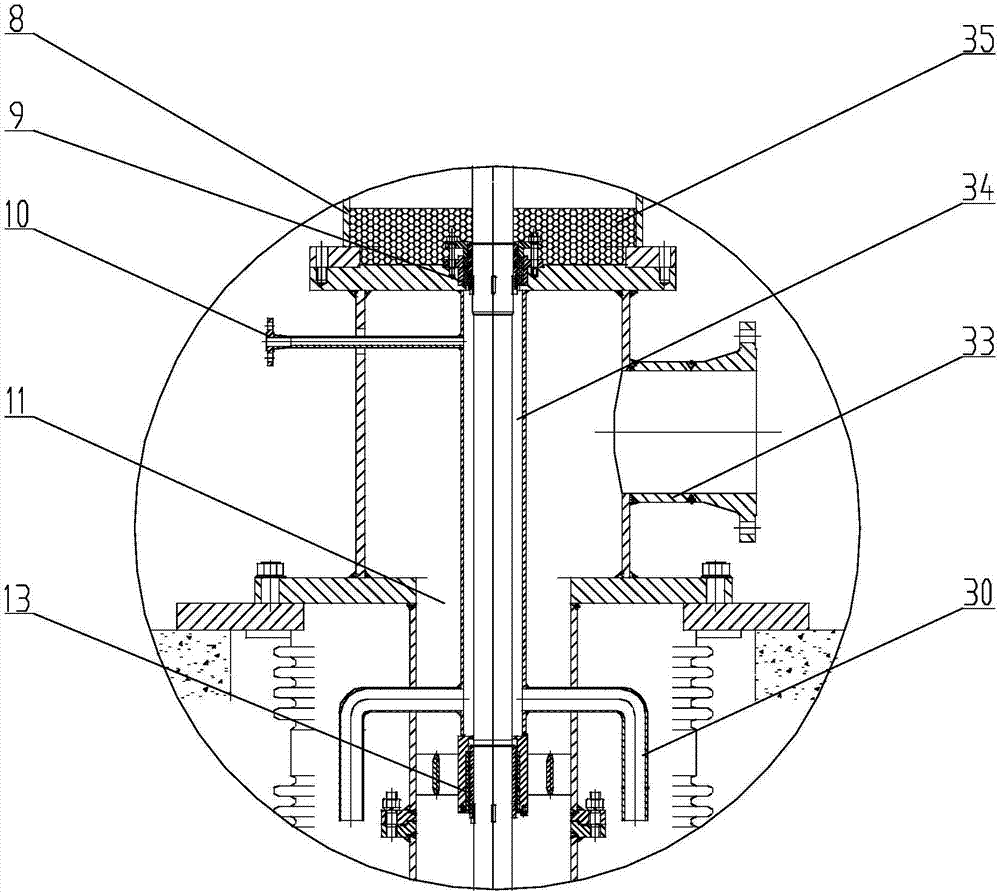

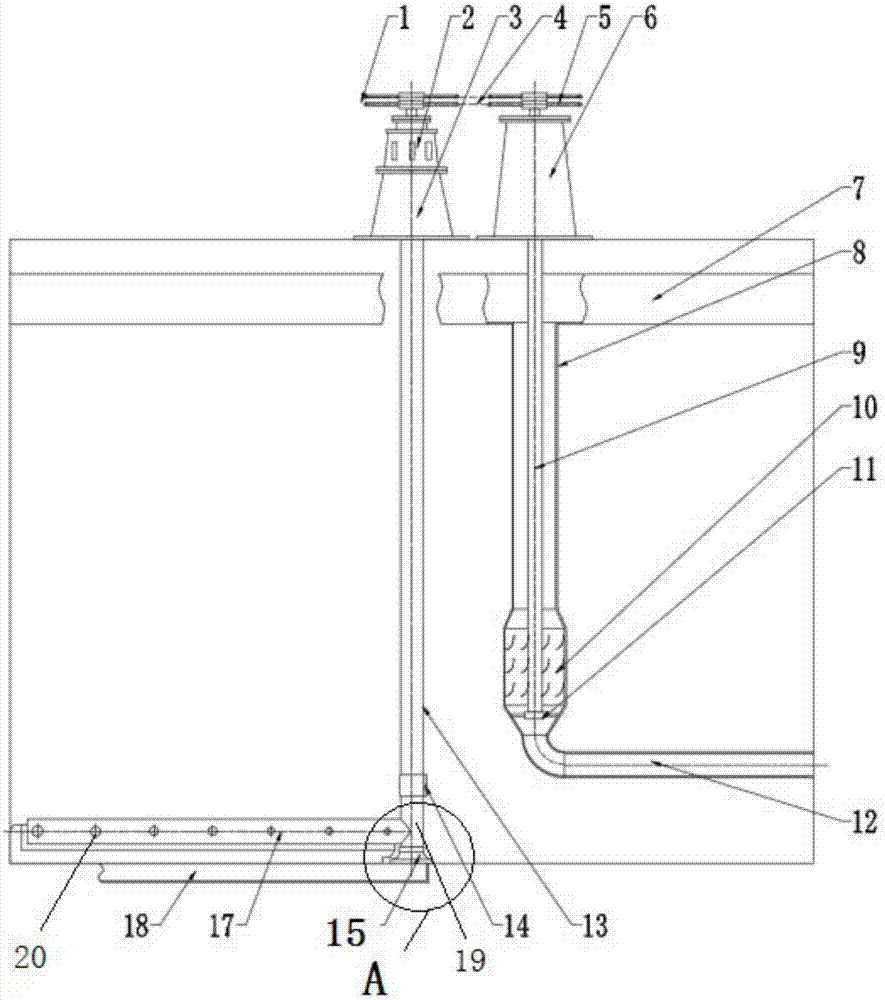

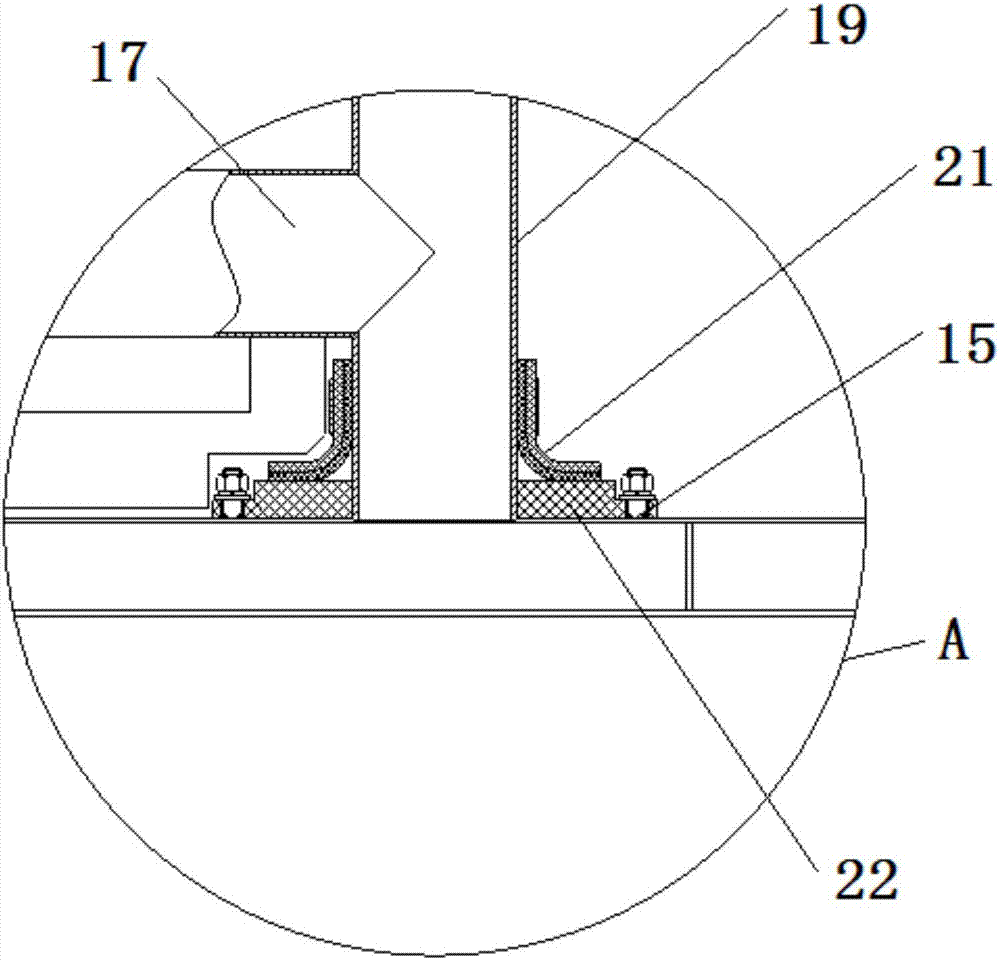

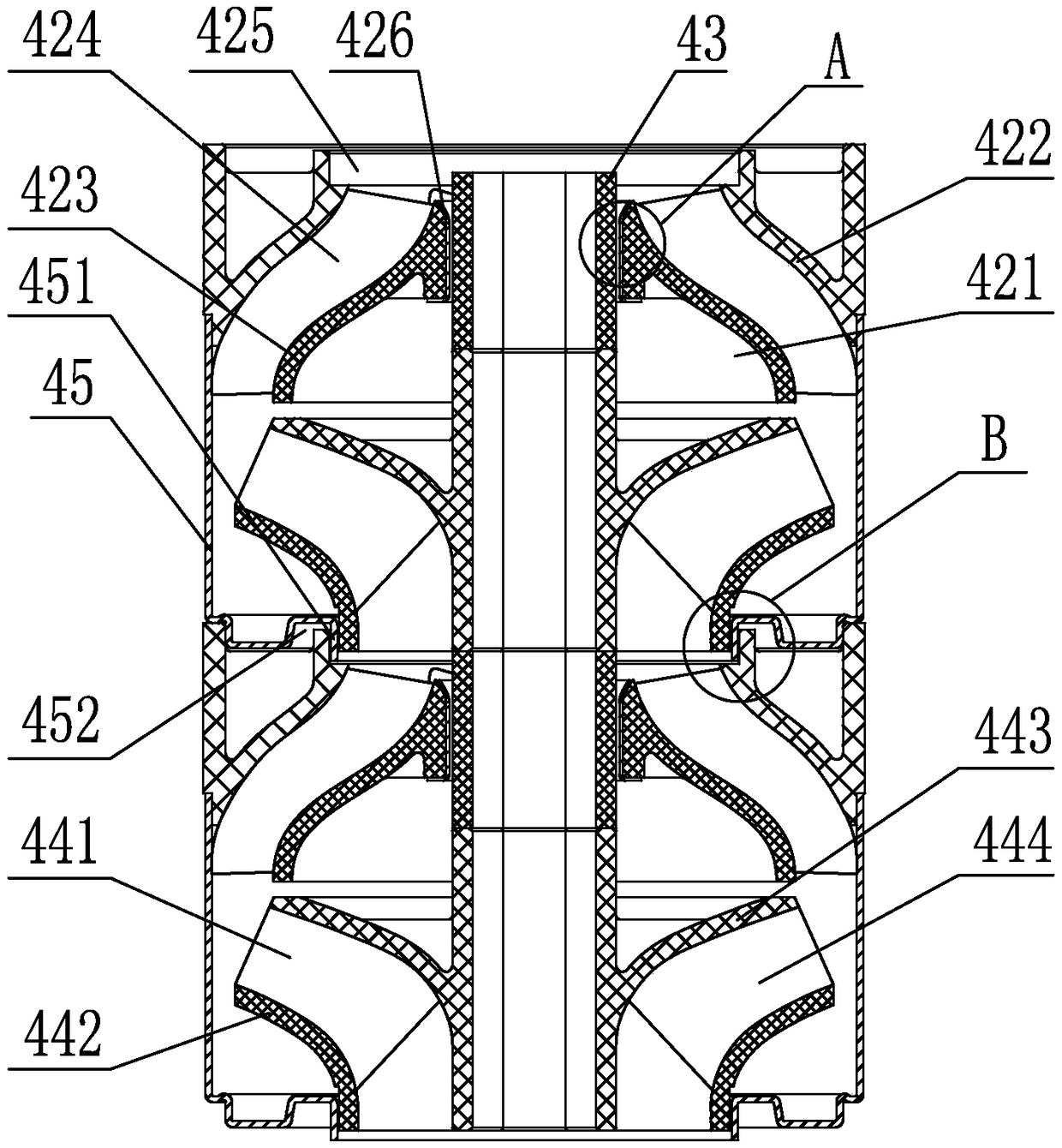

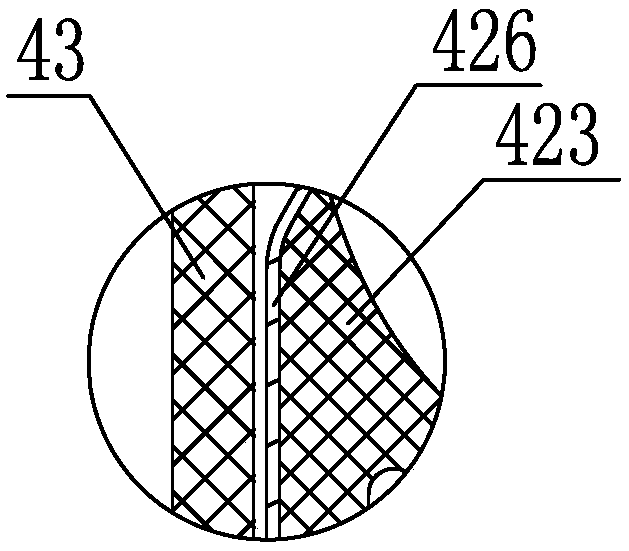

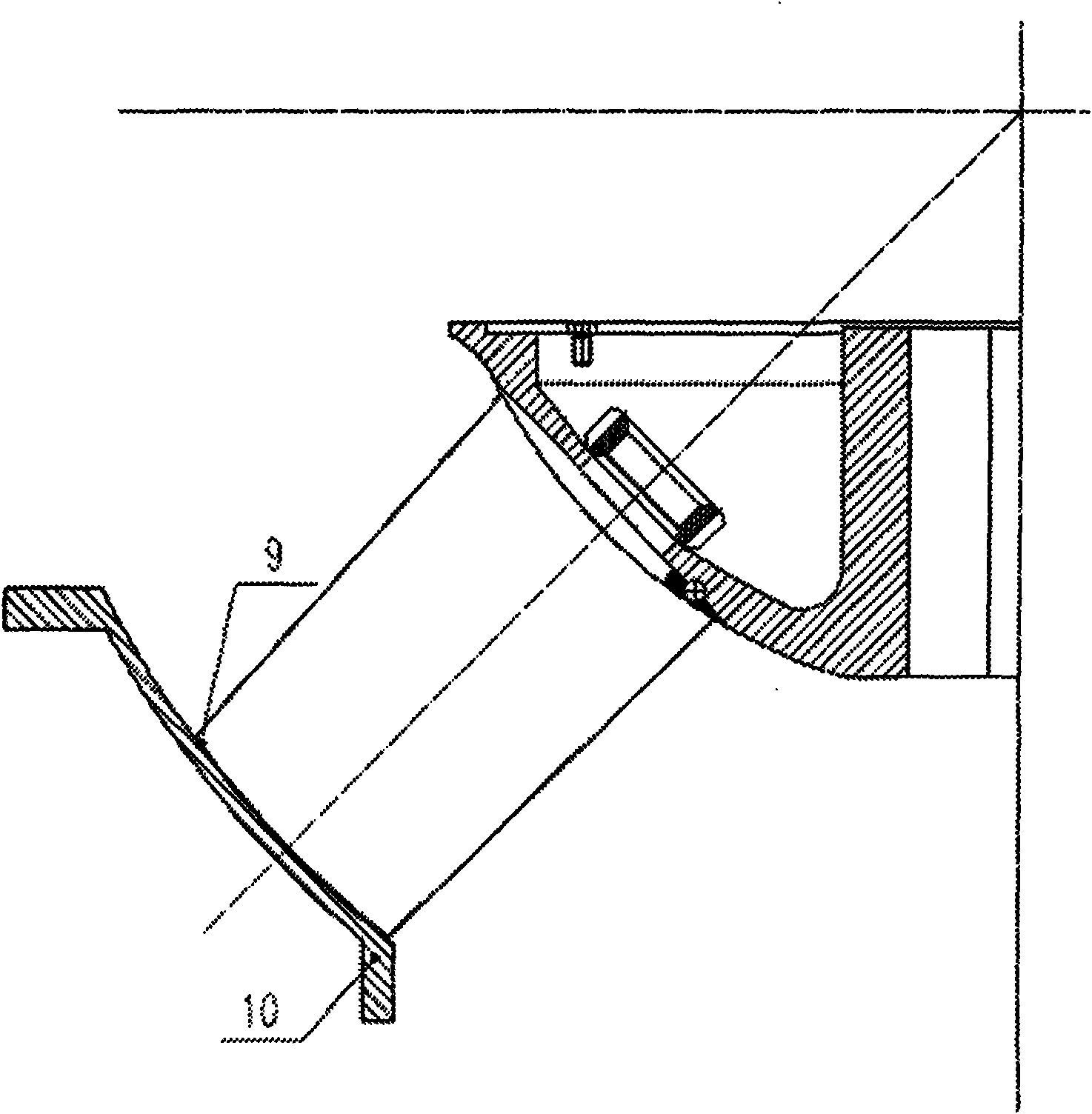

Solar thermal power high-temperature long shaft molten salt pump

PendingCN107355389AFlow state is stableMaximize power generationSpecific fluid pumpsPump componentsThermal dilatationMolten salt

The invention discloses a solar thermal power high-temperature long shaft molten salt pump. The solar thermal power high-temperature long shaft molten salt pump comprises a pump shaft, a hydraulic part, a supporting vibration reduction structure, a fluid seal structure and a bearing cooling device are sequentially arranged on the pump shaft from bottom to top, a suction segment is arranged at the front end of the hydraulic part, a blade grid type filter is arranged on the front end of the suction segment, a tail stage flow guide shell is arranged at the tail end of the hydraulic part, the tail end of the tail stage flow guide shell and the front end of a supporting pipe of the supporting vibration reduction structure are fixedly connected, and the tail end of the supporting pipe of the supporting vibration reduction structure is fixedly connected with the bottom of the outlet segment of the fluid seal structure through a flange plate. The solar thermal power high-temperature long shaft molten salt pump is designed to be in the center flow-out manner, thermal expansion uniformity under the high-temperature state can be ensured, through solution schemes of reliable fluid seal design, reasonable cooling structures, flange type expansion joint vibration reduction configuration and the like, safe, reliable and efficient running of the solar thermal power high-temperature long shaft molten salt pump is ensured, and meanwhile, various property indexes are met.

Owner:DALIAN DEEP BLUE PUMP CO LTD

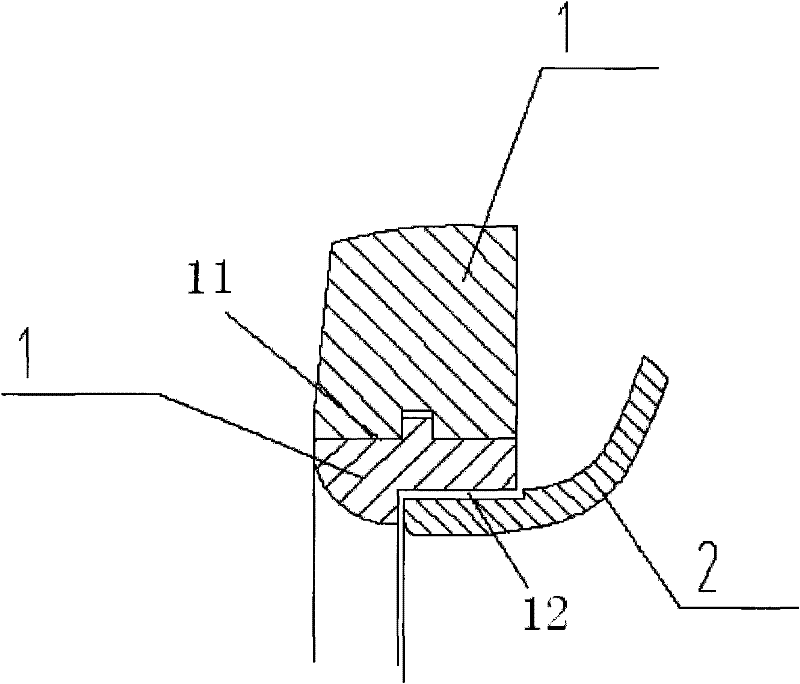

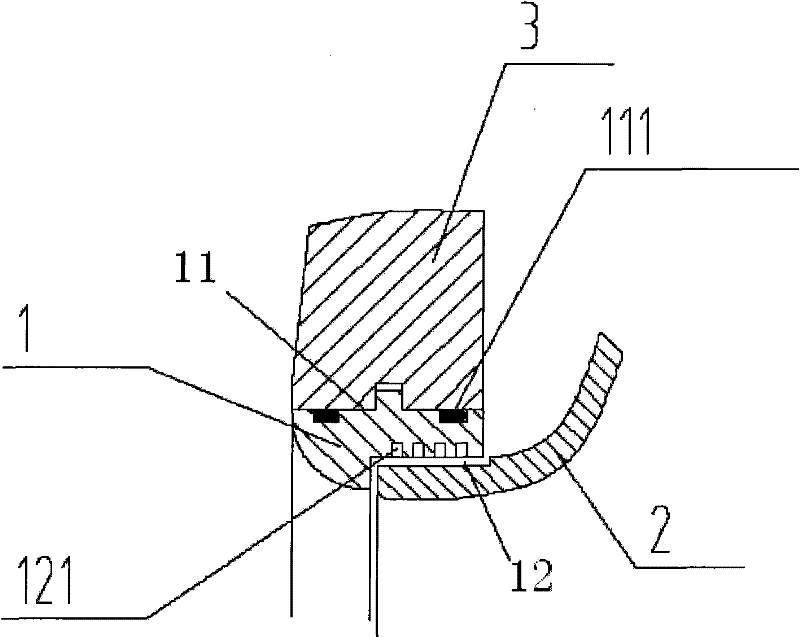

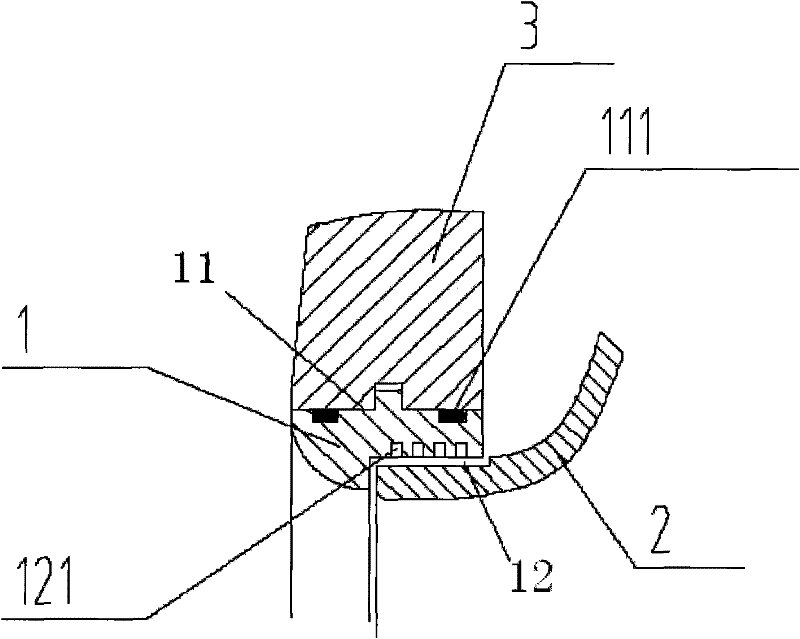

Floating type net cage underwater quick detachable binding structure

ActiveCN105494178AEasy to operateEasy to break awayClimate change adaptationPisciculture and aquariaMooring systemUnderwater

The invention provides a floating type net cage underwater quick detachable binding structure and belongs to the field of net cages. Concretely, a guide rope is arranged outside the net cage; one end of the guide rope is tied to a floating pipe or a net rib on the upper end of the net cage and the other end is tied to a net rib on the bottom end of a mesh; the end part of a mooring cable of a mooring system is provided with a lifting hook sleeved on the guide rope; the bottom end net rib close to the guide rope is tied with a sinker; and a position on the mooring cable and close to the lifting hook is provided with a sinker or a gravity rope knot. When unfixation is required, a user on the water can insert a hook rod into the water to hook the mooring cable, so the mooring cable can be hooked to the water surface; and the net cage can be unfixed.

Owner:威海晟龙明科机电设备有限公司

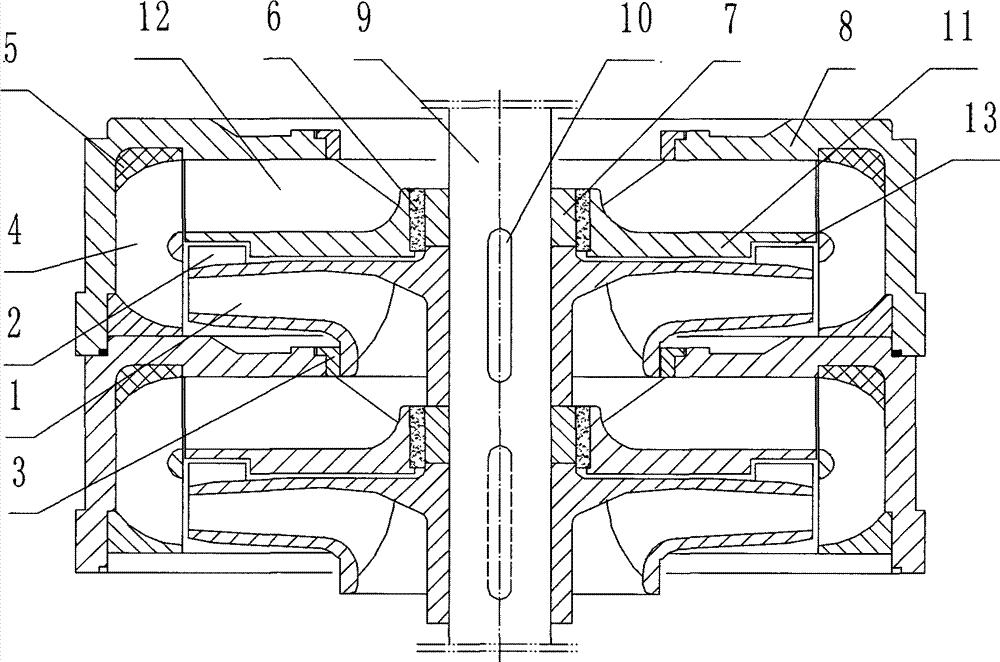

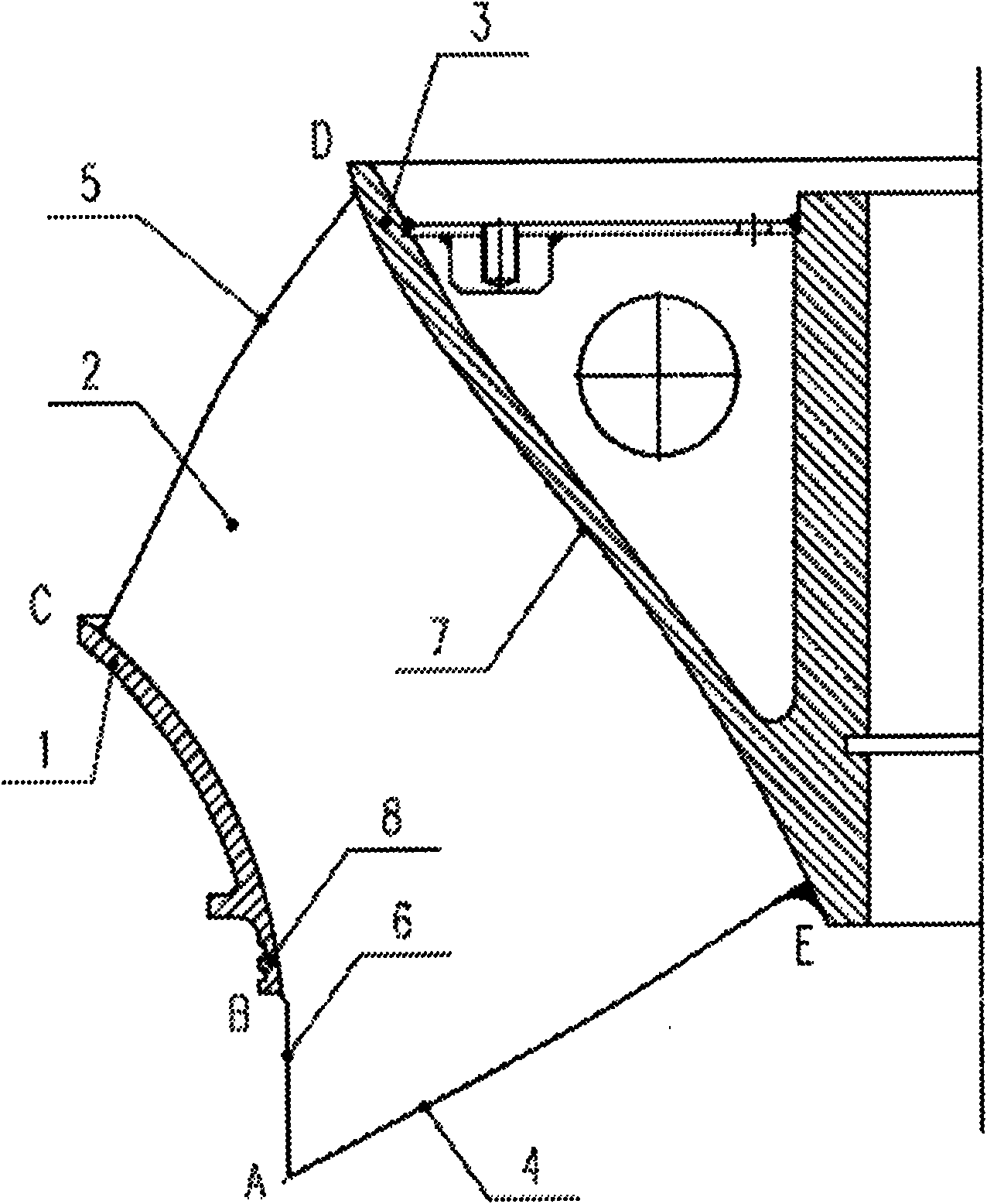

Single-section structure of sectional-type multi-stage pump for sewage

InactiveCN104121203AReduce radial sizeReduce axial sizePump componentsRadial flow pumpsAxial forceEngineering

The invention relates to a sectional-type multi-stage centrifugal pump, in particular to a single-section structure of a sectional-type multi-stage pump for sewage. The single-section structure of the sectional-type multi-stage pump for the sewage is composed of impellers, impeller back vanes, impeller inlet seal rings, spatial guide vanes, guide vane flow guide pads, bearings, shaft sleeves, middle sections, spindles and flat keys. The single-section structure is characterized in that the spindles, the impellers, the shaft sleeves and the flat keys form the rotor part of the single-section structure of the sectional-type multi-stage centrifugal pump for the sewage; the middle sections, the spatial guide vanes, the guide vane flow guide pads, the impeller inlet seal rings and the bearings form the stator part of the single-section structure of the sectional-type multi-stage centrifugal pump for the sewage. The single-section structure has the axial force balancing function of the pump and the independent supporting function; moreover, the spatial guide vanes are adopted, the radial size of the single-section structure is smaller than that of a structure with radial-type guide vanes adopted by more than 5%, liquid flowing out from the impellers is collected separately through single flow channels and is independently conveyed to next-stage impeller inlets respectively and the fluid hydraulic loss is less than that of an existing structure by about three percent.

Owner:杨丽萍

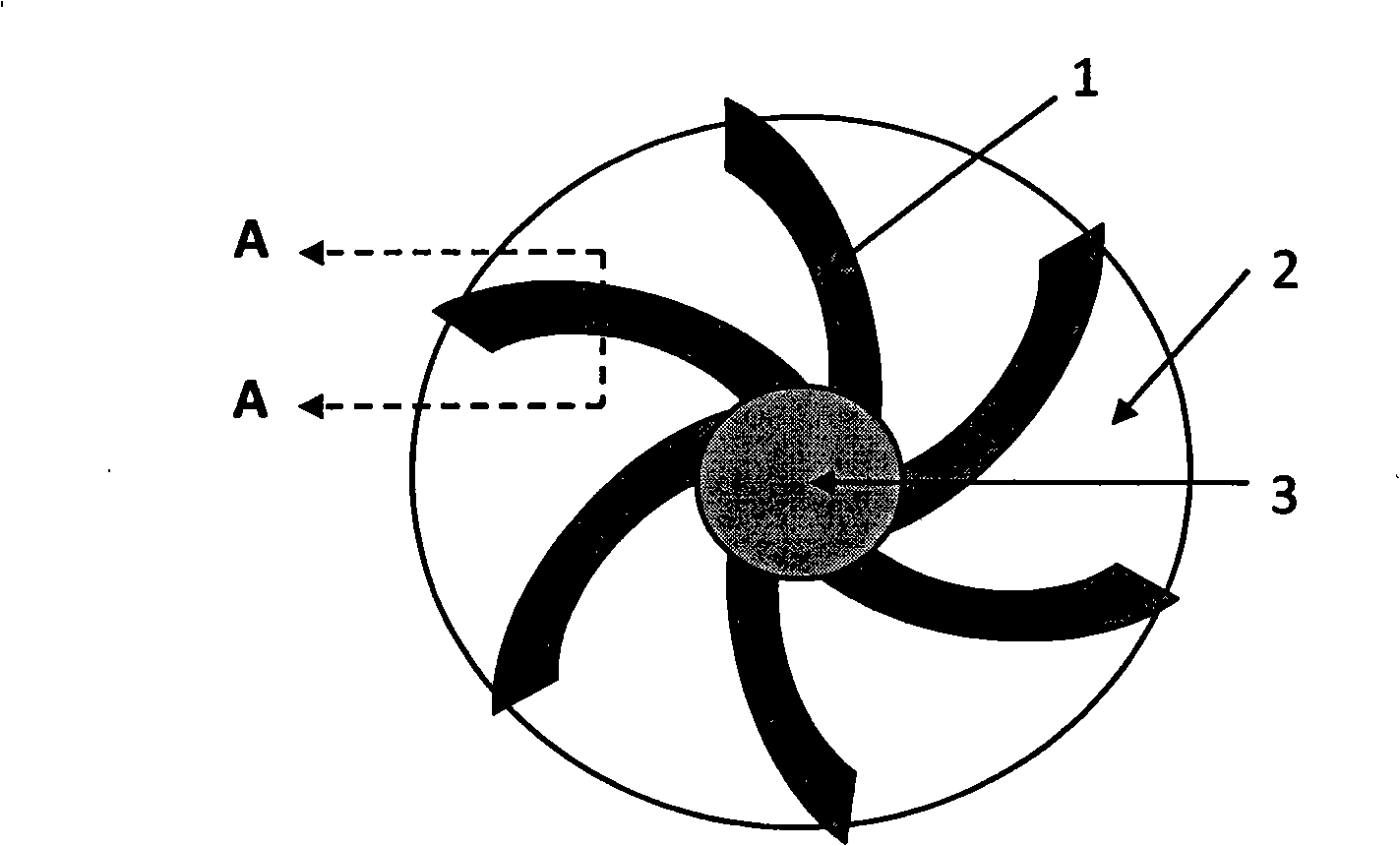

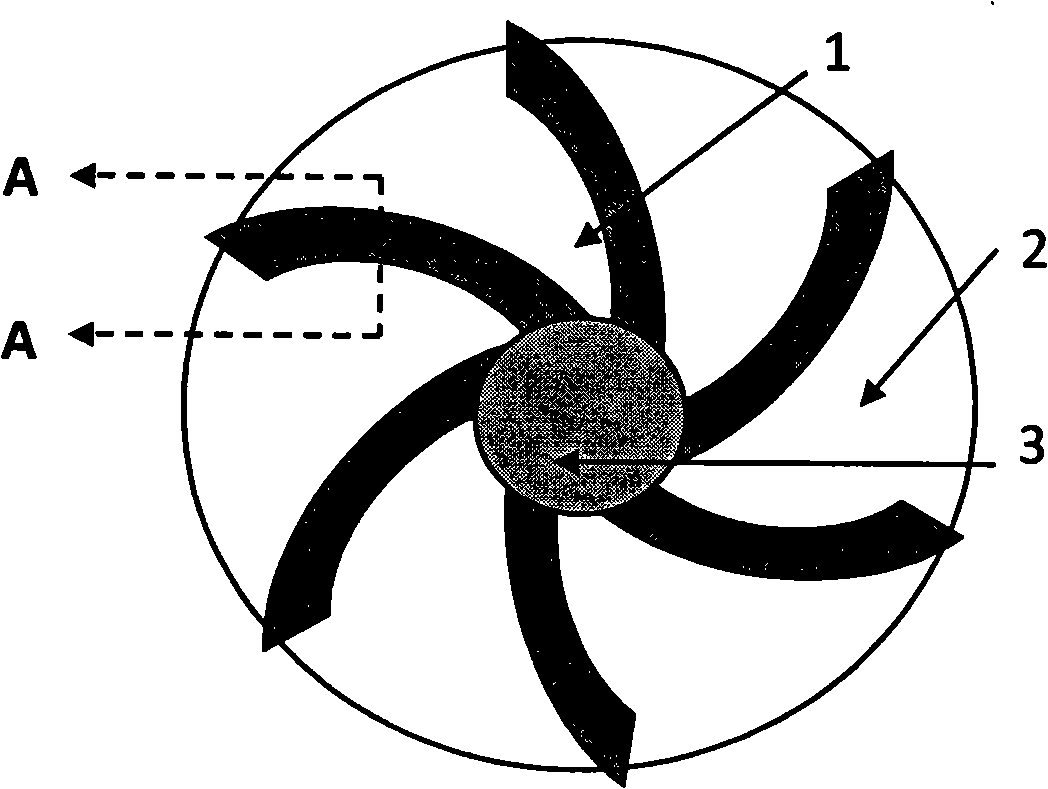

High-efficiency and energy-saving multifunctional centrifugal blower fan

InactiveCN101303025AExtend your lifeReduce volume lossPump componentsRadial flow pumpsSocial benefitsImpeller

The invention discloses a multifunctional centrifugal blower with high efficiency and energy saving, which comprises a shell, an impeller, an impeller chamber, an gas spin chamber, an air inlet, an air outlet and a motor, wherein, the impeller consists of at least one group of arc-shaped channel vanes closed at one side and amplified axially; the shell is internally provided with a round dual chamber or multi-chamber provided with the air inlet and the air outlet. The efficiency of the centrifugal blower is over 80 percent, the energy is saved by more than 10 percent while the noise is lower than 80dB; the impeller is not easy to wear basically and the material is saved by more than one second; also the centrifugal blower has various functions such as ventilation, air supply, air inducing, smoke exhaust, and material absorption and discharge, etc. The comprehensive economic and technical indexes of the centrifugal blower achieve the leading level both at home and abroad, the energy saving effect, the exhaust reduction effect and the economic and social benefits are remarkable.

Owner:SHANDONG UNIV

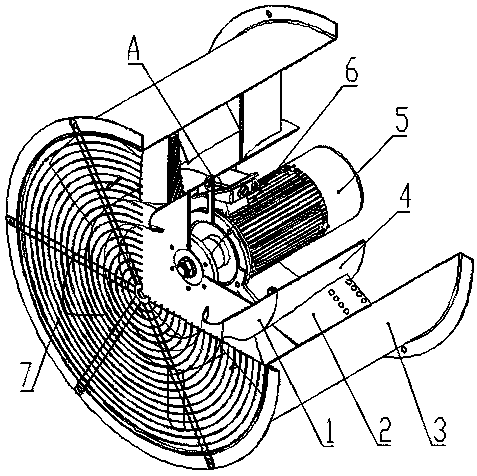

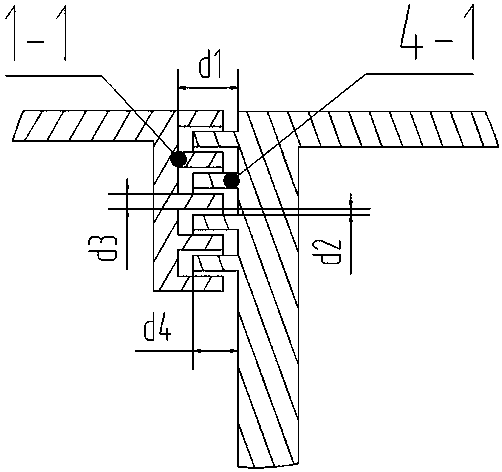

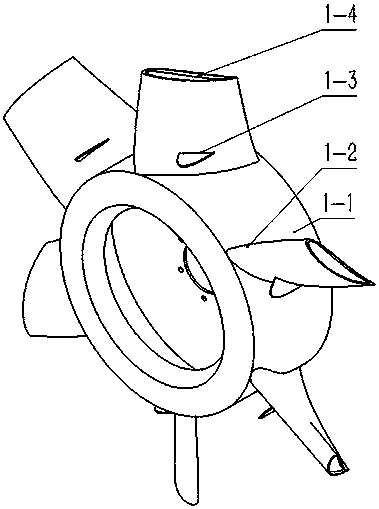

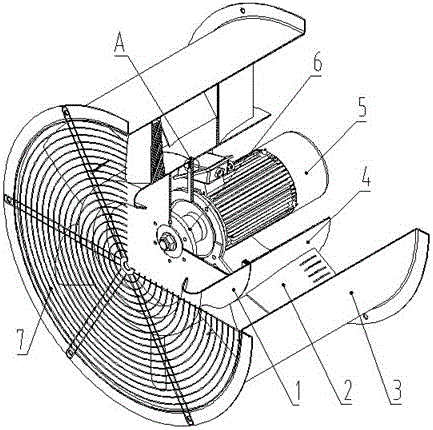

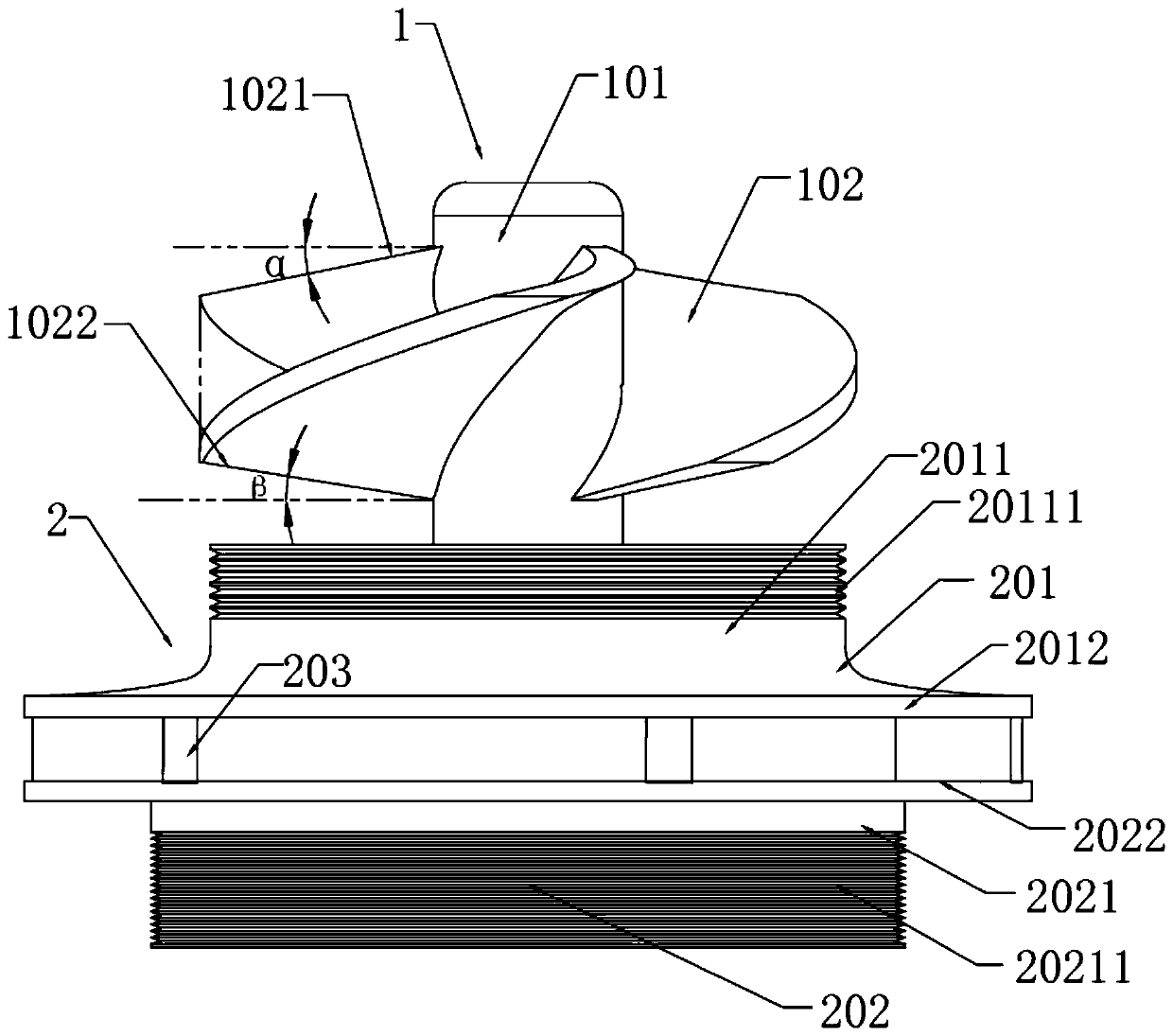

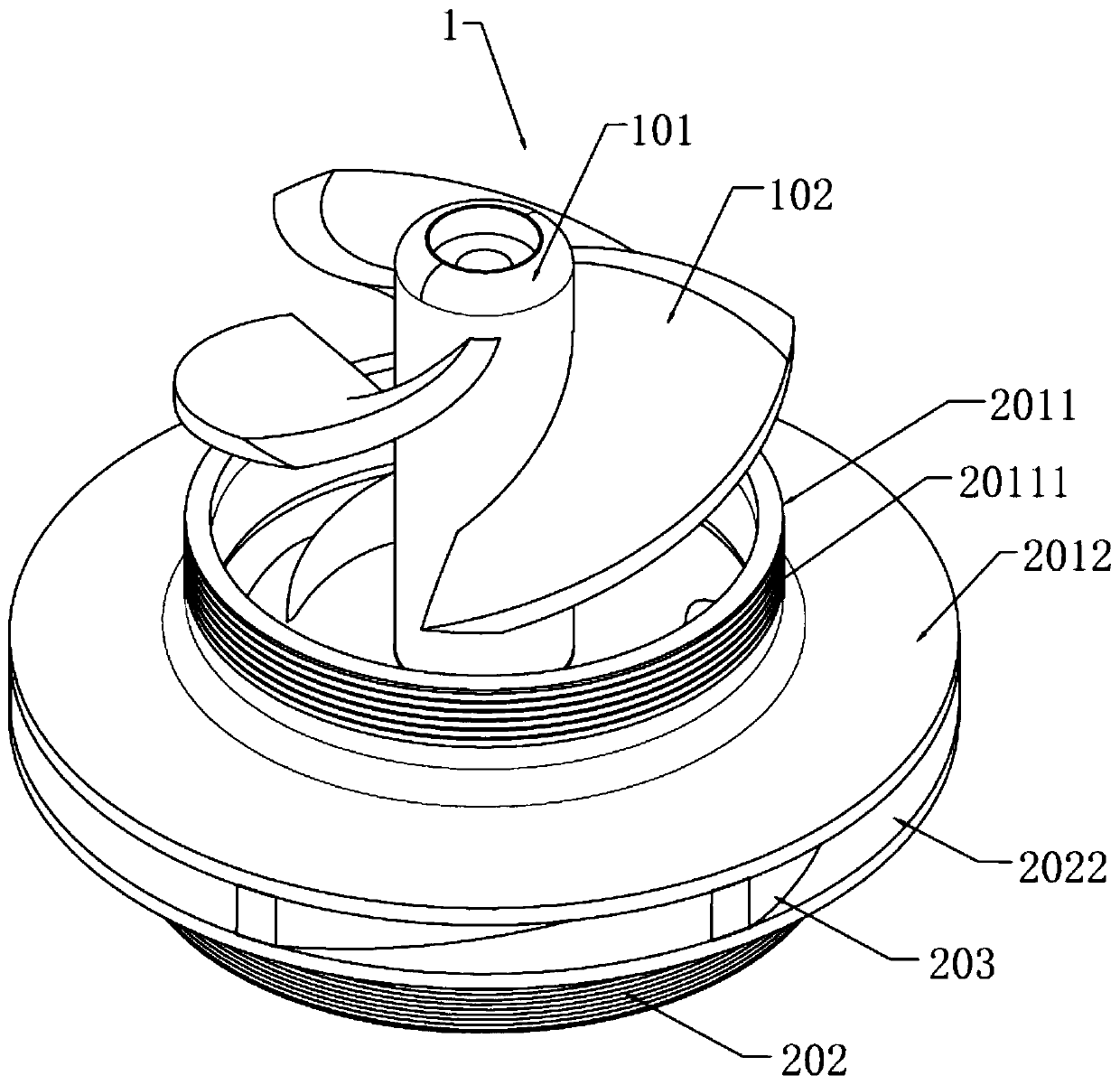

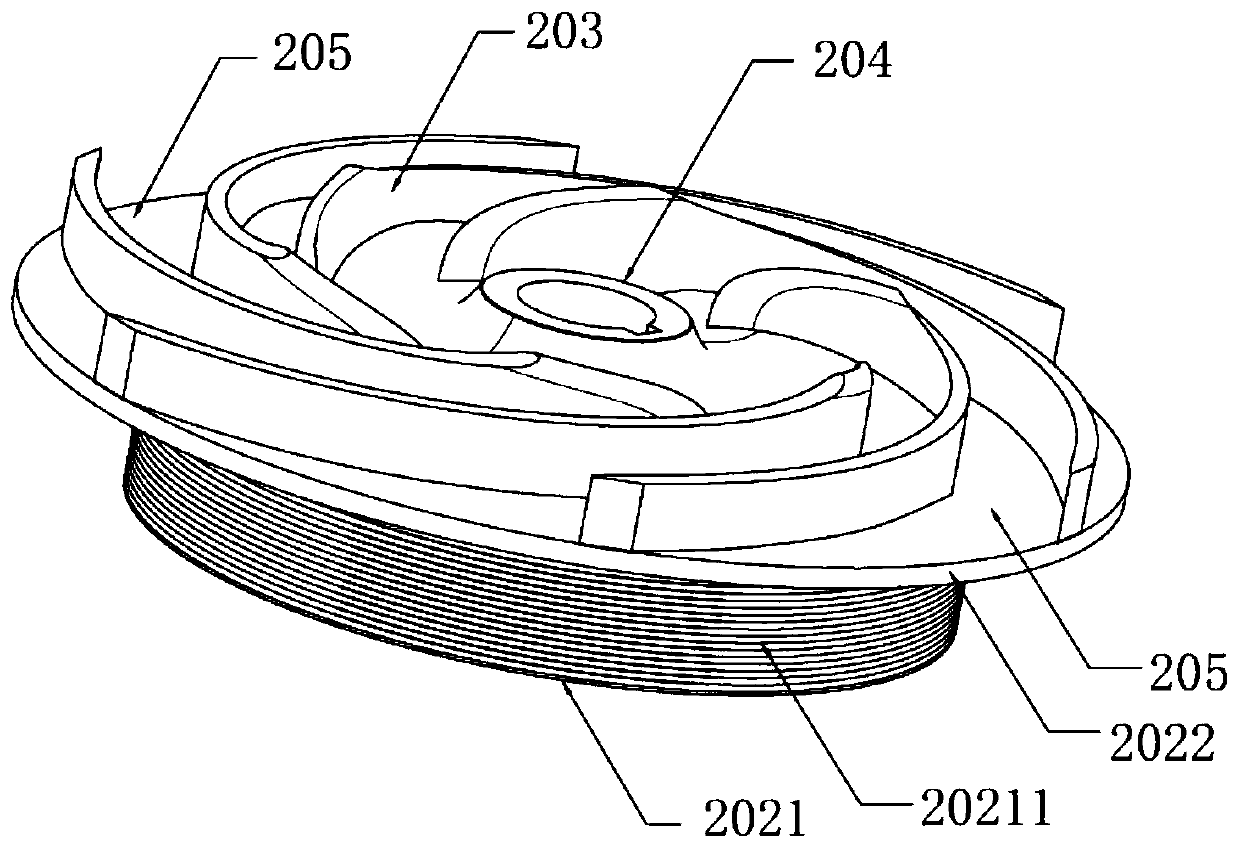

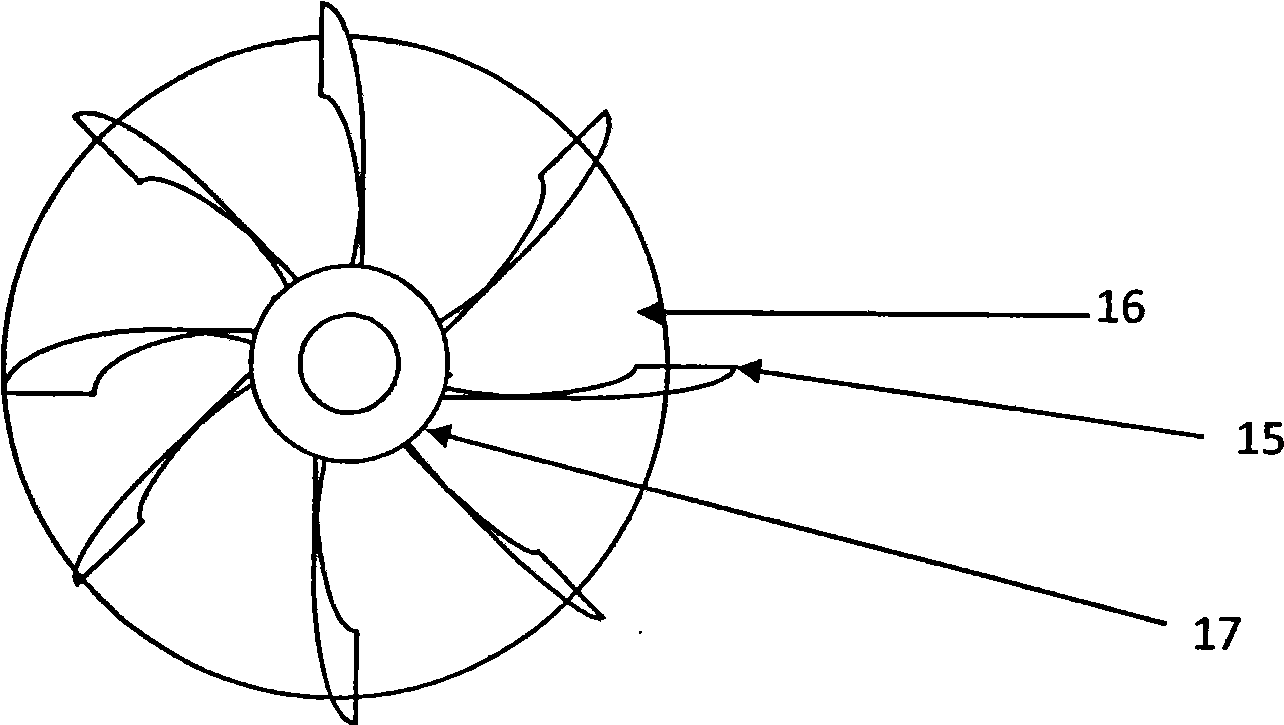

Axial flow blower

PendingCN107061329AImprove efficiencyReduce sizePump componentsPump installationsImpellerEngineering

The invention discloses an axial flow blower, which comprises a net cover, an impeller, a guide vane, an inner cylinder, an outer cylinder, a motor and a shaft sleeve. The net cover is fixed on the outer cylinder, is of a concentric structure and is formed by weaving iron wires; the impeller comprises a wheel hub and vanes, and the vanes are airfoil vanes which are designed through a constant circulation isolated airfoil method; a fin-shaped vortex breaking structure is arranged on a part, close to the root, of the suction surface of each vane; the top parts of the vanes are machined into an airfoil groove structure; and a labyrinth seal structure is formed in a gap between the wheel hub of the impeller and the inner cylinder. The shark fin-like vortex breaking plate is additionally arranged on the part, close to the root, of the suction surface of each vane of the impeller of the axial flow blower, the airfoil groove is formed in the top of each vane of the axial flow blower, and the labyrinth seal structure is formed in the gap between the wheel hub of the impeller and the inner cylinder, and different positions of the axial flower blower are improved, so that the efficiency of the axial flow blower is relatively high, the noise is relatively low, and the energy conservation and environment protection are achieved preferably.

Owner:ZHEJIANG SCI-TECH UNIV

Axial flow fan with blade suction surfaces having vortex breaking structures and with grooves formed in blade tops

The invention discloses an axial flow fan with blade suction surfaces having vortex breaking structures and with grooves formed in blade tops. The vortex breaking structures are additionally arranged on the portions, close to roots, of the suction surfaces of blades of an impeller, the airfoil grooves are machined in the tops of the blades, a labyrinth seal structure is additionally arranged in the clearance between a hub and an inner barrel, rectangular grooves are machined in the tails of the suction surfaces of guide vanes, the size of channel vortexes in an impeller passenger can be restrained, and radial secondary flow is reduced. Development of leakage flow can be impeded, mixing of the leakage flow and main flow is weakened, and therefore leakage losses of the blade tops are reduced. A high throttling effect can be generated, the stability of airflow on an outlet of the impeller is improved, and the leakage amount of airflow at the roots of the blades is reduced. The thicknesses of boundary layers on the tails of the guide vanes can be well controlled, separation of the boundary layers is avoided, disengagement of the vortexes is restrained, and the disengaging frequency of the vortexes is reduced. By improving different positions of the axial flow fan, the axial flow fan is higher in efficiency, lower in noise and more environmentally friendly and saves more energy.

Owner:嘉兴笼列电子商务有限公司

Method for manufacturing antifouling and antibiosis type yellow croaker net cage

InactiveCN102763610AReduce harmImprove survival rateClimate change adaptationPisciculture and aquariaAntibiosisEngineering

The invention discloses a method for manufacturing an antifouling and antibiosis type yellow croaker net cage, which relates to a method for manufacturing a mariculture net cage. According to the invention, the method for manufacturing the antifouling and antibiosis type yellow croaker net cage adopts a buoyancy force system and a netting system, and is characterized in that the buoyancy force system adopts a combination buoyancy force form of 'an anti-aging high-density polyethylene double-floating-pipe cylindrical frame structure + 18 cube cystosepiments with each edge length of 60cm; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting; the net cage bottom netting is assembledon a circular high-density polyethylene pipe support which is wrapped with a layer of polyamide multifilament wrap knitting net; and three cross lacing lines are installed at the bottom of the net cage, a polypropylene rope is tied at the cross point of the cross lacing lines, and two foam float bowls which are externally wrapped by double-layer seawater corrosion protection canva and nylon nets are tied at the other end of the polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

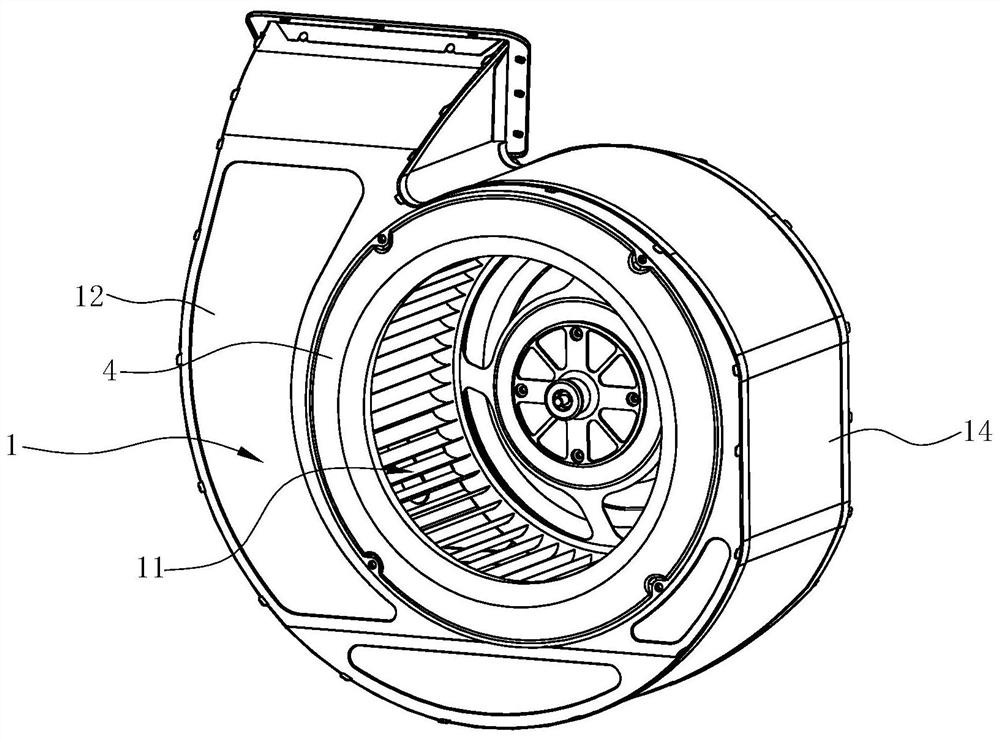

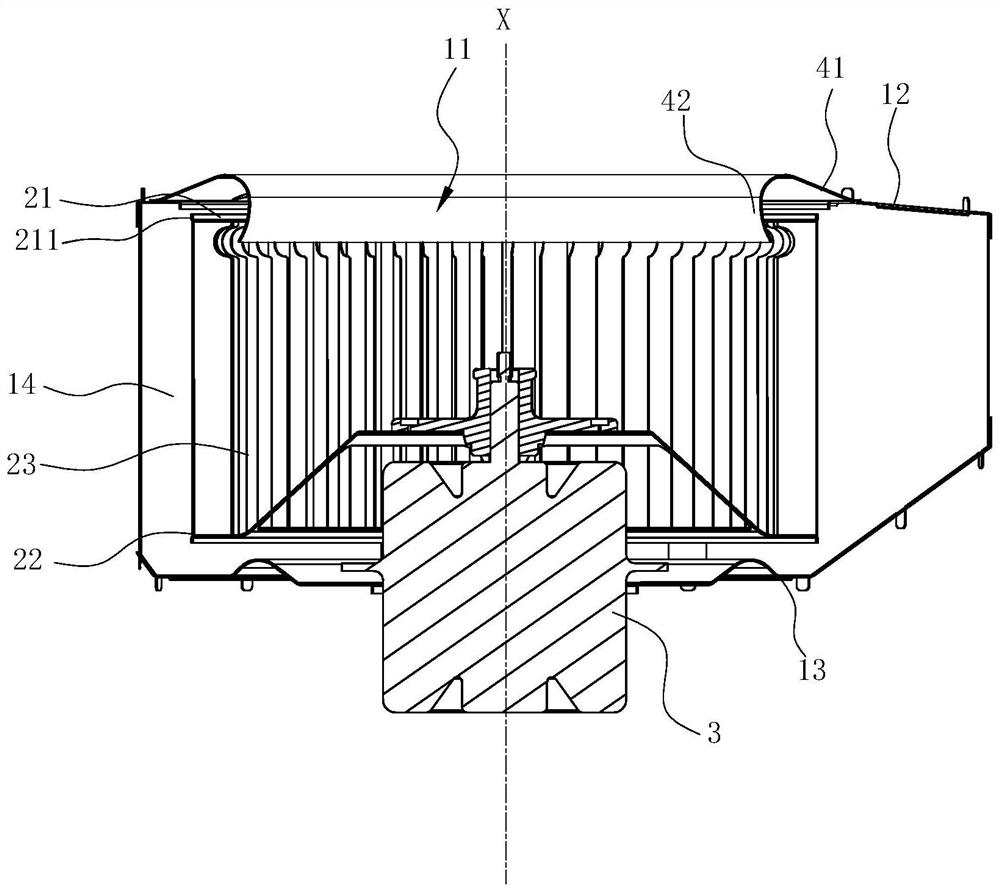

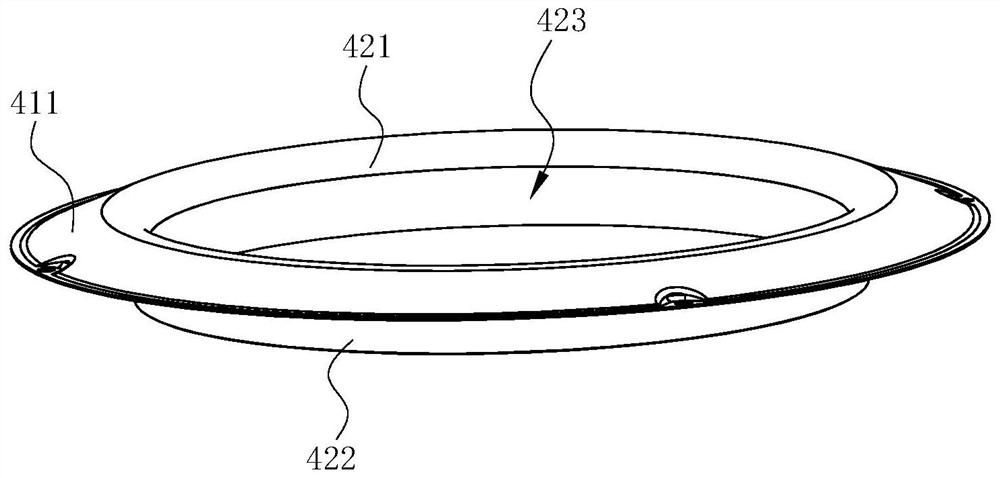

Centrifugal fan and extractor hood applying centrifugal fan

ActiveCN111852905APrevent tail swingsReduce volume lossDomestic stoves or rangesPump componentsCentrifugal fanVolute

The invention discloses a centrifugal fan. The centrifugal fan comprises a volute and an impeller and a flow collector which are arranged inside the volute, wherein an air inlet is formed in the volute, the flow collector is arranged at the air inlet position, the impeller and the flow collector are provided with a common axis, the flow collector comprises an annular installation portion connectedwith the volute and a flow guide portion used for guiding airflow, the flow guide portion comprises a radial-direction flow guide portion extending inwards from the radial-direction inner side of theinstallation portion and an axial-direction flow guide portion penetrating through the air inlet to extend to the inner portion of the volute from the radial-direction inner side of the radial-direction flow guide portion, the impeller comprises a front ring, a rear ring and blades arranged between the front ring and the rear ring, the centrifugal fan is characterized in that in the axial-direction cross section of the flow collector, the axial-direction flow guide portion is a curve expanding to the radial-direction outer side gradually from one end connected with the radial-direction flow guide portion to the impeller direction, the end portion, connected with the front ring, of each blade is formed with a concave portion, and each concave portion is formed by concaving in the directionfrom the radial-direction inner side of each blade to the radial-direction outer side of each blade.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

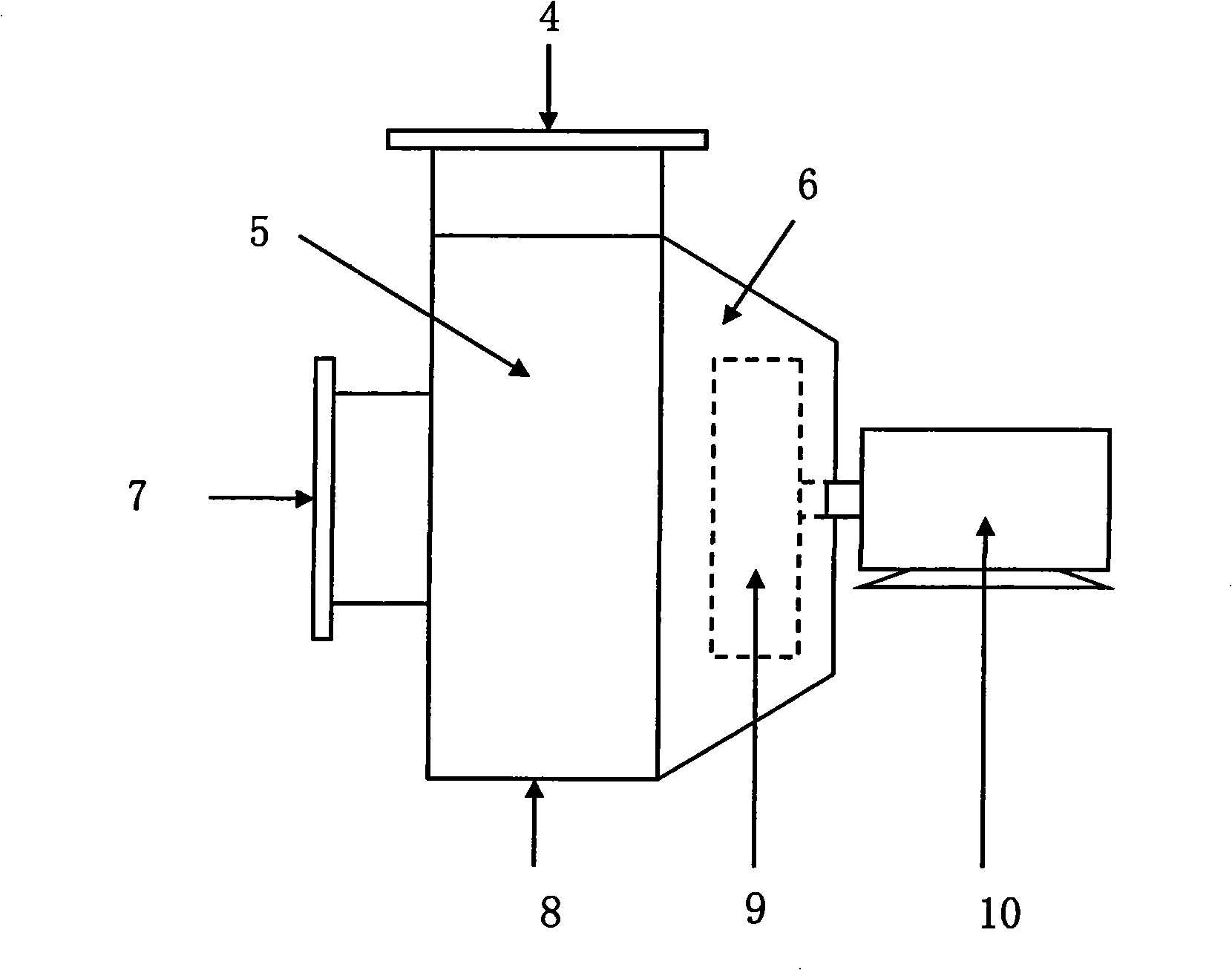

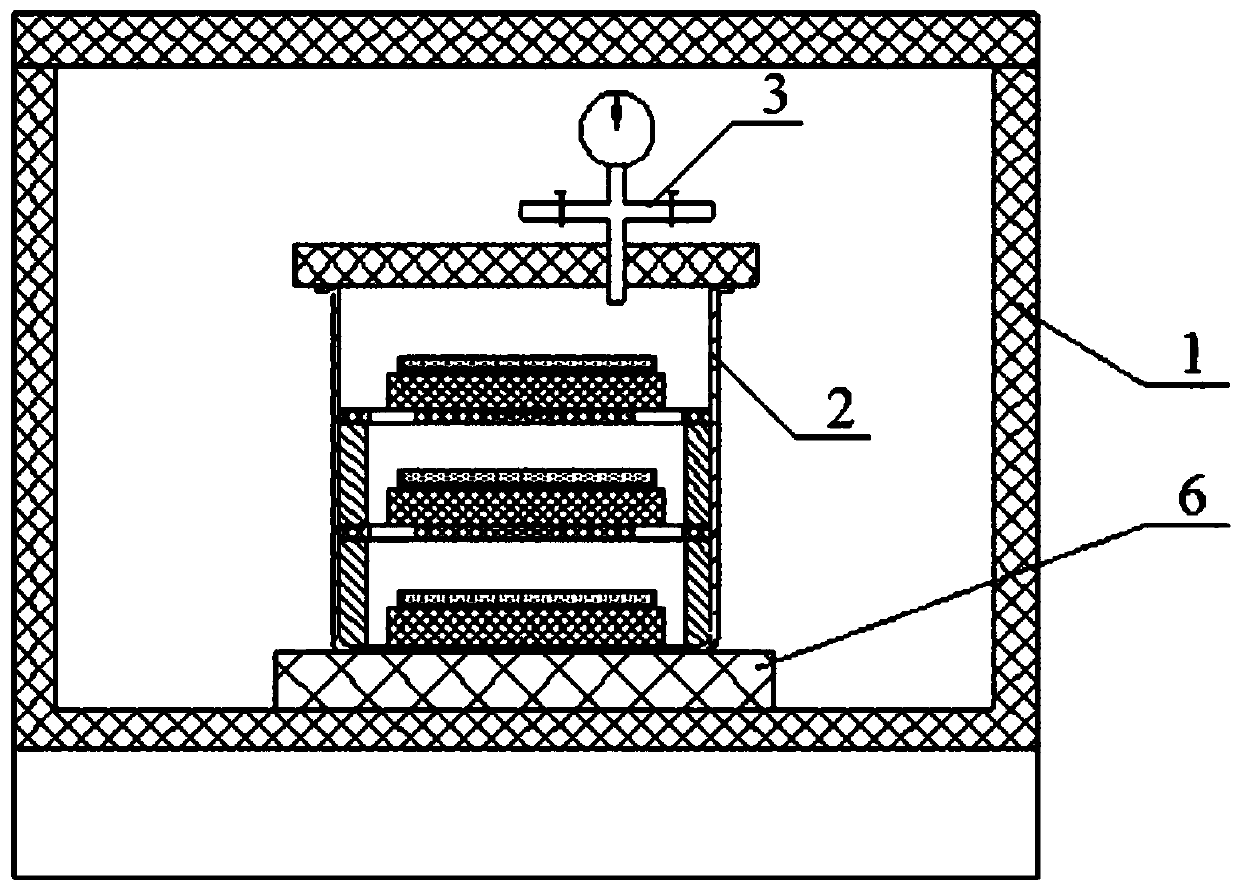

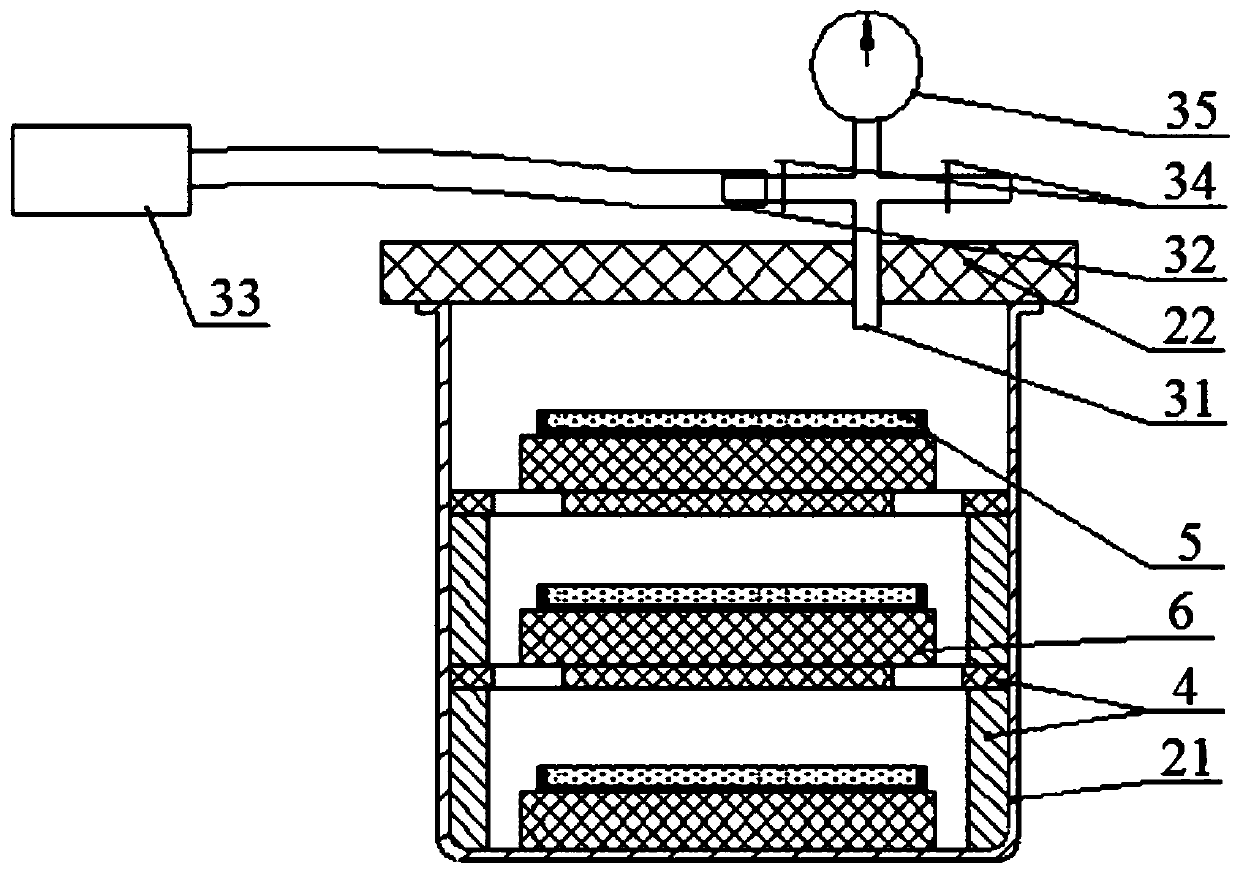

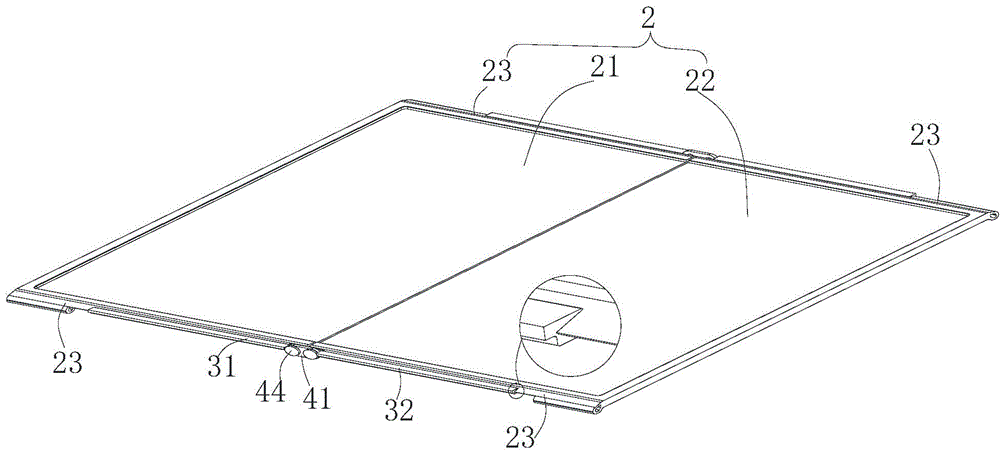

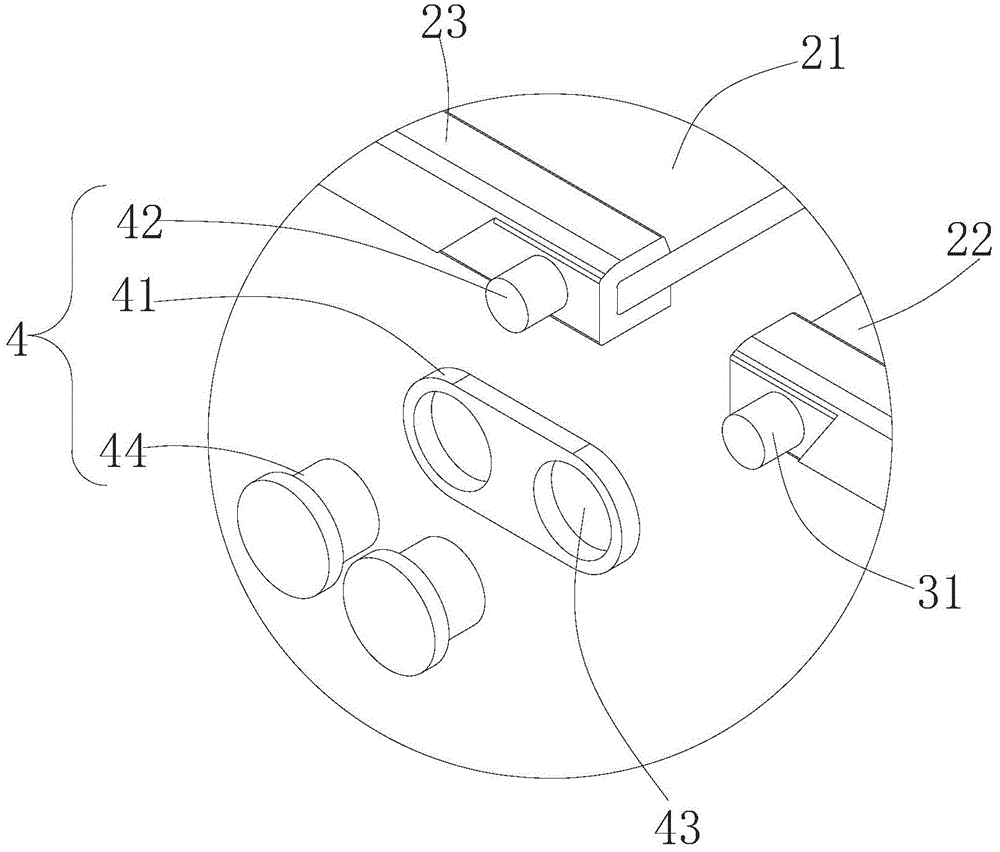

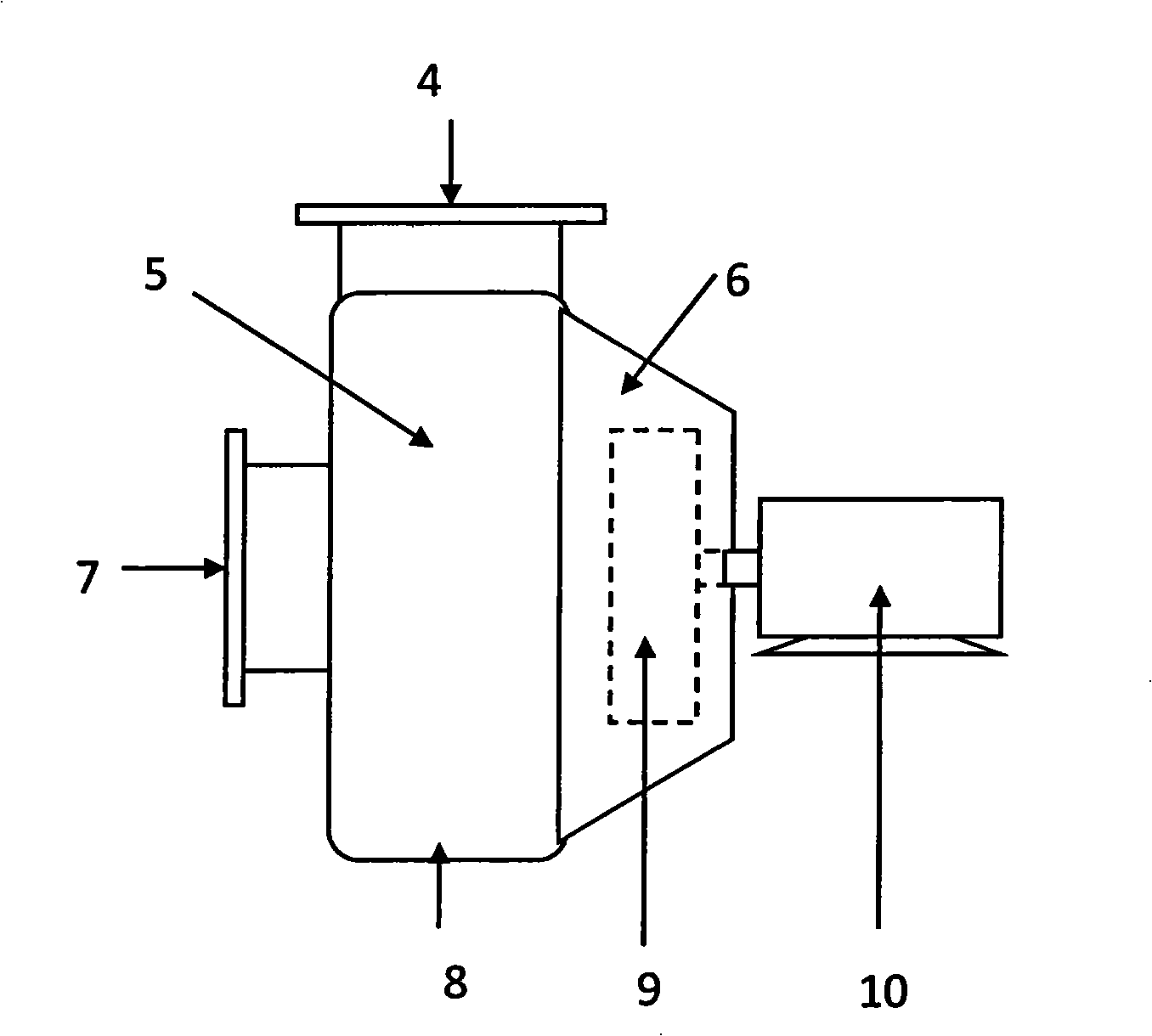

Preparation device and method of ice for complete machine ice swallowing test of aero-engine

ActiveCN111288699AReduce volume lossEasy to demouldLighting and heating apparatusIce productionTemperature controlSilicon mold

The invention belongs to the technical field of aero-engine tests, and particularly relates to a preparation device and method of ice for a complete machine ice swallowing test of an aero-engine. Thedevice comprises a temperature control freezer (1), a vacuum barrel (2) and a silica gel mold (5), wherein the vacuum barrel (2) is arranged in the temperature control freezer (1), the vacuum barrel (2) comprises a vacuum barrel body (21) and a vacuum barrel cover (22), a pressure control assembly (3) is installed on the vacuum barrel cover (22), and a partition plate assembly (4) is arranged in the vacuum barrel (2); and the silica gel mold (5) is arranged on the partition plate assembly (4). According to the preparation device of the ice for the complete machine ice swallowing test of the aero-engine, low-density ice can be prepared, the density requirement of ice for the complete machine ice swallowing test in the national military standard is met, the silica gel mold is easy to demoldand not prone to being broken, and the volume loss of the ice is reduced.

Owner:AECC SHENYANG ENGINE RES INST

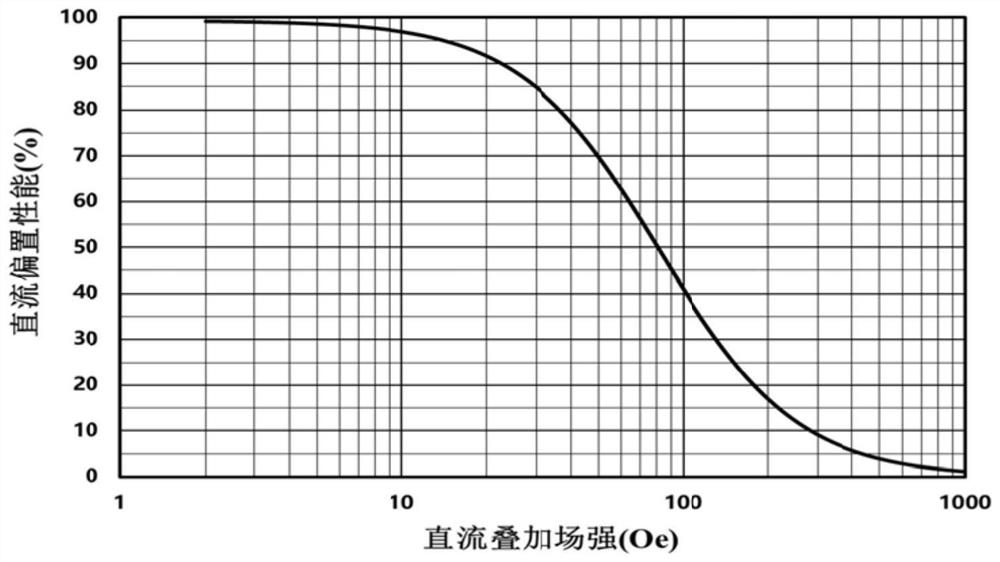

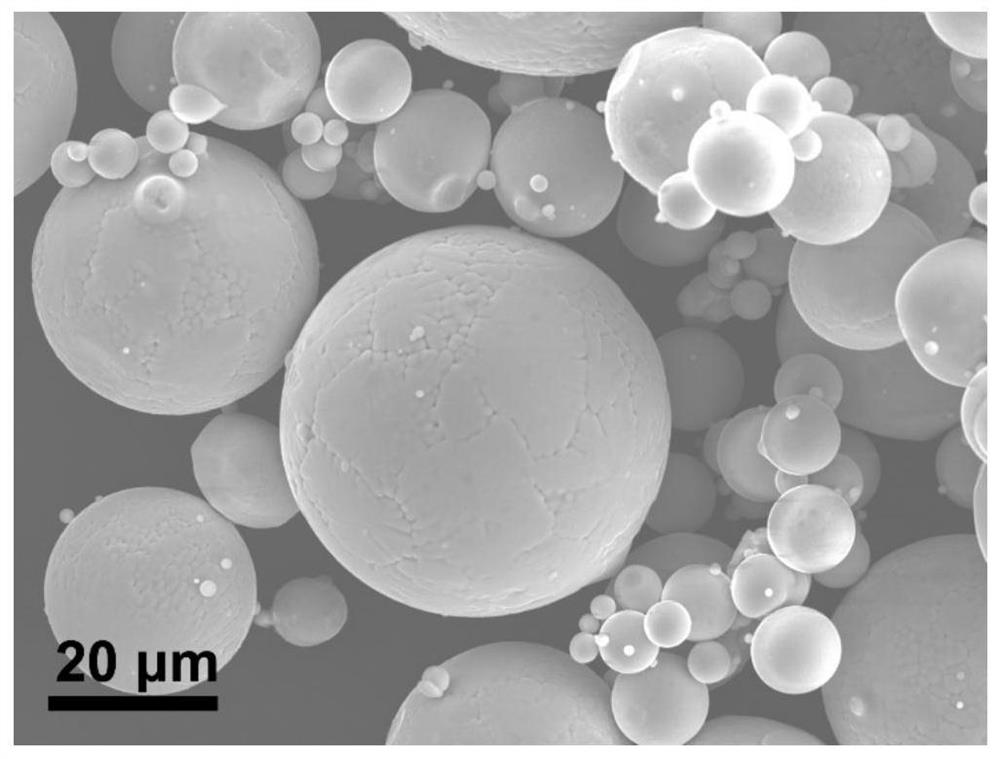

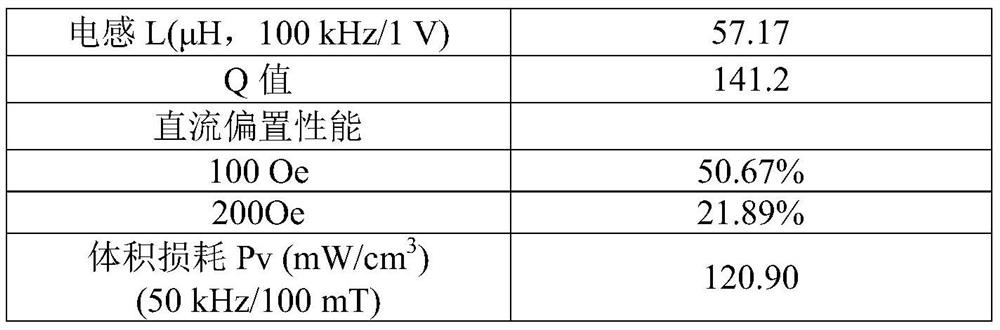

Crushing method iron-silicon-aluminum soft magnetic powder core and preparation method thereof

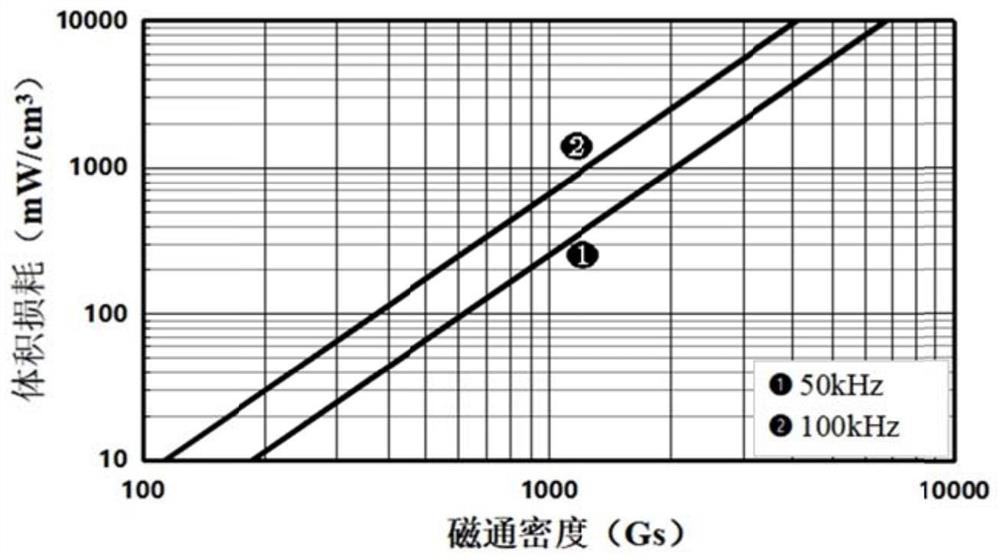

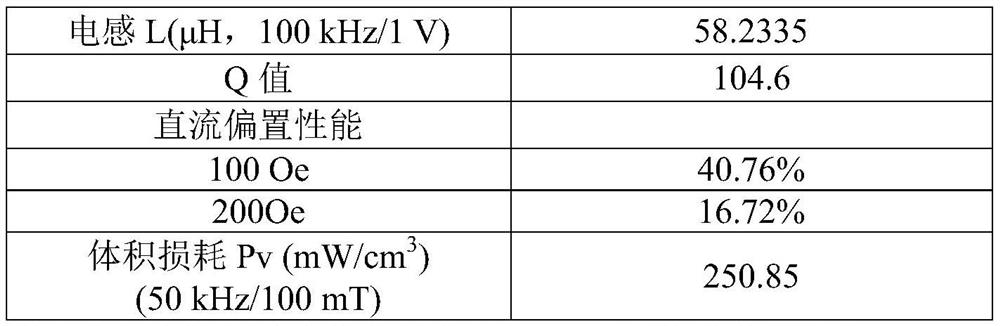

PendingCN111696746AAchieve insulationImprove magnetoelectric propertiesInorganic material magnetismInductances/transformers/magnets manufacturePhysical chemistrySilicon

The invention belongs to the technical field of soft magnetic materials, and particularly relates to a crushing method iron-silicon-aluminum soft magnetic powder core and a preparation method thereof.The preparation method includes the steps that iron-silicon-aluminum magnetic powder with the granularity smaller than 200 meshes is selected, SiO2 powder is used for conducting insulation coating treatment on iron-silicon-aluminum powder particles, and the iron-silicon-aluminum soft magnetic powder core with the effective magnetic conductivity being 75 is prepared; the preparation process is simple and easy to operate, the prepared iron-silicon-aluminum soft magnetic powder core has excellent direct-current bias performance and frequency stability, the direct-current bias performance of the powder core under the condition of 100Oe is higher than 38%, and the volume loss Pcv under the conditions of 50kHz and 100mT is lower than 260mW / cm < 3 >.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD

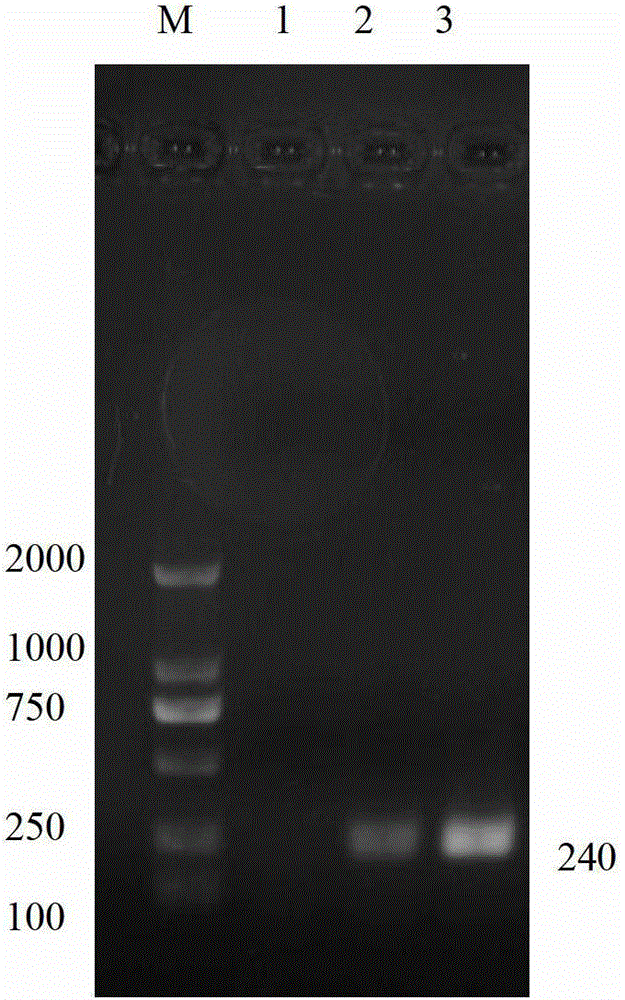

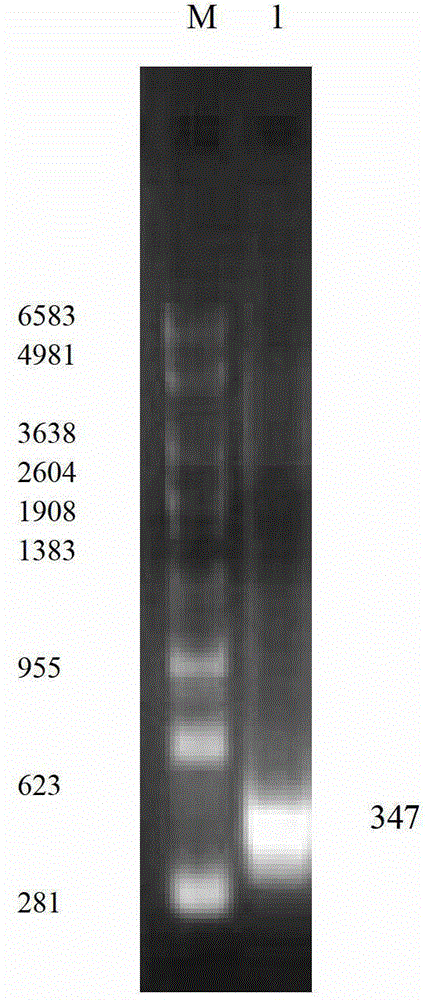

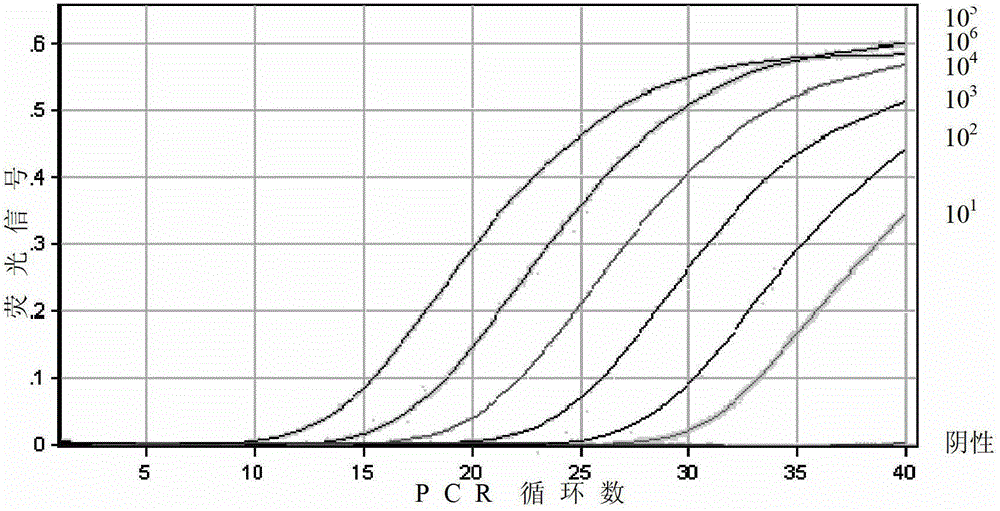

Rabbit hemorrhagic disease virus RT-PCR detection method

InactiveCN103146842AImprove reliabilityGuaranteed credibilityMicrobiological testing/measurementMicroorganism based processesTrue positive rateVirus

The invention provides a primer used for rabbit hemorrhagic disease virus RT-PCR detection, and also provides a kit containing the primer, and a method for the rabbit hemorrhagic disease virus RT-PCR detection through using the primer. The method has the advantages of accuracy, reliability, high sensitivity and high specificity, and has good clinic application values.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

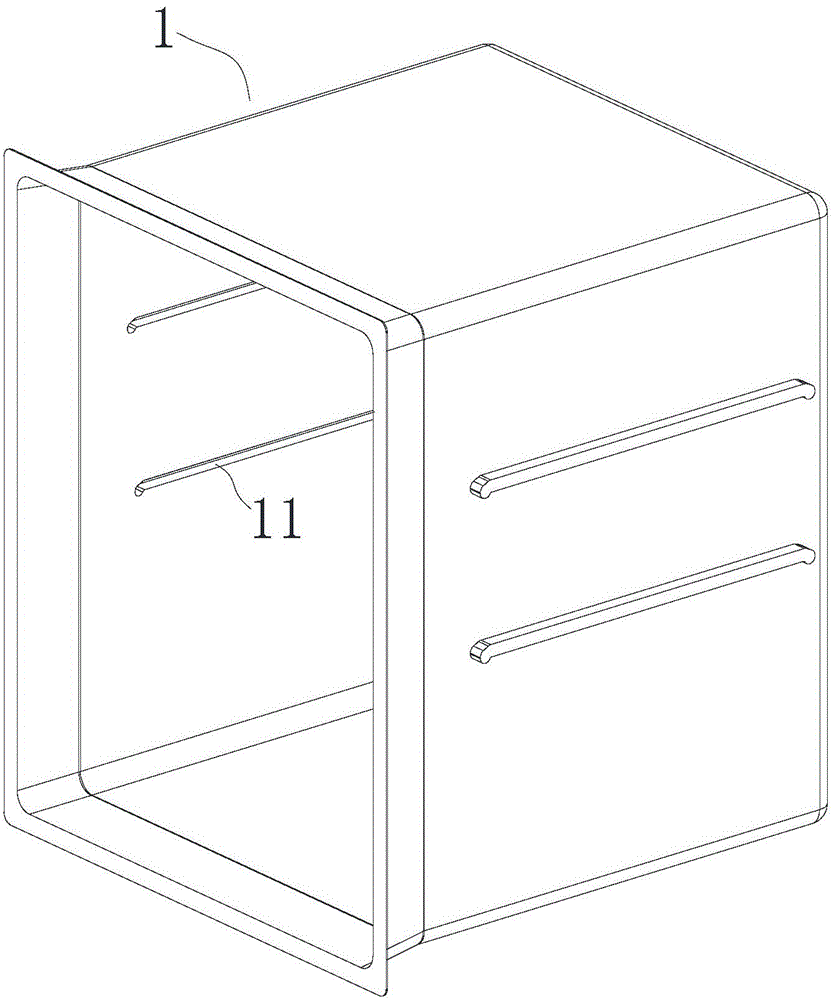

Refrigerator

ActiveCN104567185AReduce in quantityReduce volume lossLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The invention discloses a refrigerator. The refrigerator comprises a liner, a first shelf and a second shelf, and a fastener, wherein a shelf groove extending in the front-and-back direction and sunk towards the outer wall surface of the liner is formed in at least one of the left sidewall and the right sidewall of the liner; the first shelf and the second shelf are distributed in the left-and-right direction; the first shelf is pivotal relatively to the second shelf; the side edge of at least one of the first shelf and the second shelf is mounted in the shelf groove; the fastener is used for fixing the relative positions of the first shelf and the second shelf when the first shelf and the second shelf are flush with each other. According to the refrigerator in the embodiment, the shelf groove is capable of supporting the side edge of at least one of the first shelf and the second shelf, no convex rib is omitted or the number of ribs is reduced, foaming is more uniform, and the volume loss of the liner is reduced; besides, the refrigerator is relatively convenient to assemble.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

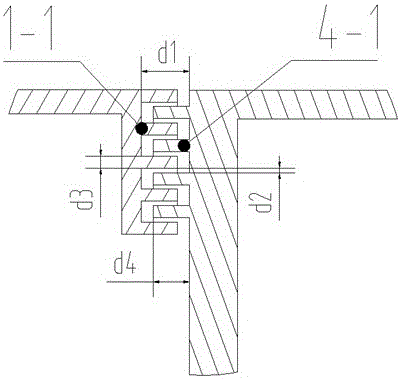

Sealing ring structure for high-flow high-lift double suction pump

The invention relates to a sealing ring structure for a high-flow high-lift double suction pump. The structure comprises a body, wherein the body comprises a sealing ring outer circle and a sealing ring inner circle; the sealing ring outer circle is provided with two O-rings matched with matching surfaces of a pump body and a pump cover; and the sealing ring inner circle is provided with at least three labyrinth seal grooves matched with a seam allowance position of an impeller. The sealing ring structure has the advantages that: A, through the labyrinth seal grooves, the leakage rate of liquid which returns from an impeller outlet (a high-pressure cavity) to an impeller inlet (a low-pressure cavity) is well reduced, volume loss is reduced, the efficiency of the pump is improved, and energy is well saved; B, the O-rings of the outer circle are used, so that water in the high-pressure cavity and water in the low-pressure cavity of a water pump are prevented from being mixed with each other, and washout caused by hydraulic impact of the liquid from the impeller outlet (the high-pressure cavity) to one side of the impeller inlet (the low-pressure cavity) is avoided; and C, a sealing ring is easy to manufacture, reliably installed and low in cost, and the service life is prolonged.

Owner:SHANGHAI KAIQUAN PUMP IND GROUP

Method for densifying wood and densified wood

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

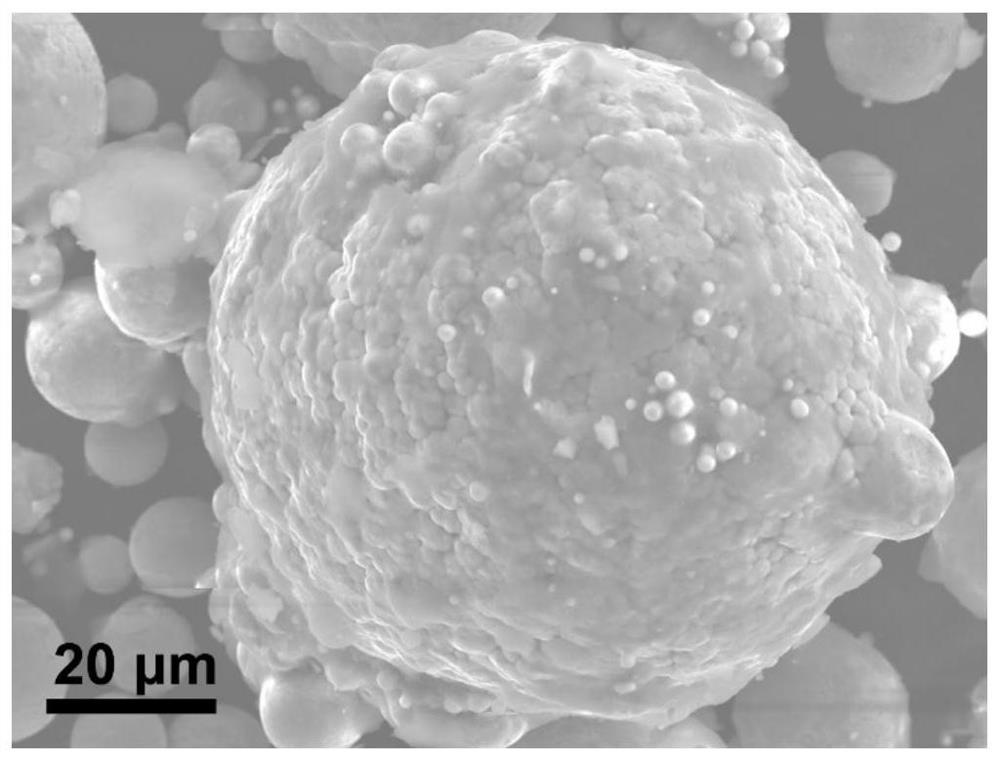

Iron-silicon-aluminum magnetic powder core microwave insulation coating method and insulation coating magnetic powder core

PendingCN112735802AAchieve insulationAchieve non-destructive insulation coatingInorganic material magnetismTransformers/inductances detailsAdhesiveSlurry

The invention discloses an iron-silicon-aluminum magnetic powder core microwave insulation coating method and an insulation coating magnetic powder core, and belongs to the field of soft magnetic materials. Aiming at the problems of low coating efficiency and poor effect of the existing magnetic powder core, the invention provides the iron-silicon-aluminum magnetic powder core microwave insulation coating method which comprises the following steps of: preparing mixed slurry; carrying out microwave heating on the mixed slurry; adding an adhesive and a release agent into the heated mixed slurry to obtain to-be-formed magnetic powder; and pressing the to-be-formed magnetic powder, and carrying out heat preservation under inert gas to obtain the insulating coating magnetic powder core. The microwave heating technology is innovatively adopted, the surfaces of iron-silicon-aluminum metal particles can be evenly coated with SiO2 powder, and the insulation effect between the particles is achieved; compared with an existing coating process, the microwave heating technology is adopted, the insulation coating time can be greatly shortened, and the lossless insulation coating of the metal powder is achieved. And the effective magnetic conductivity of the prepared magnetic powder core is 75, the direct-current bias performance under the condition of 100Oe is higher than 48%, and the preparation efficiency is high.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD

Efficient LNG conveying pump impeller

The invention discloses an efficient LNG conveying pump impeller. The efficient LNG conveying pump impeller comprises a flow guide part, and a pressurizing part which is connected to the flow guide part, wherein the flow guide part comprises a first hub, and a plurality of first spiral blades which are uniformly distributed on the first hub; the first blades are connected to the first hub throughfirst connecting surfaces; the pressurizing part comprises a first cover plate assembly, a second cover plate assembly, and a second hub which is formed on the second cover plate assembly; second blades are uniformly distributed in the circumference a spiral flowing channel is formed between every two adjacent second blades; and the second hub is connected to the first hub. With the adoption of the efficient LNG conveying pump impeller, the inlet flowing area is effectively increased, so that an inlet is effectively prevented from blockage, and eddy current is effectively prevented from generating in a turbine flowing channel; the flow guide part and the pressurizing part are designed, so that the whole conveying pump impeller has the beneficial effects of being low in gas etching, high inefficiency, and simple to process.

Owner:苏州横海流体动力科技有限公司

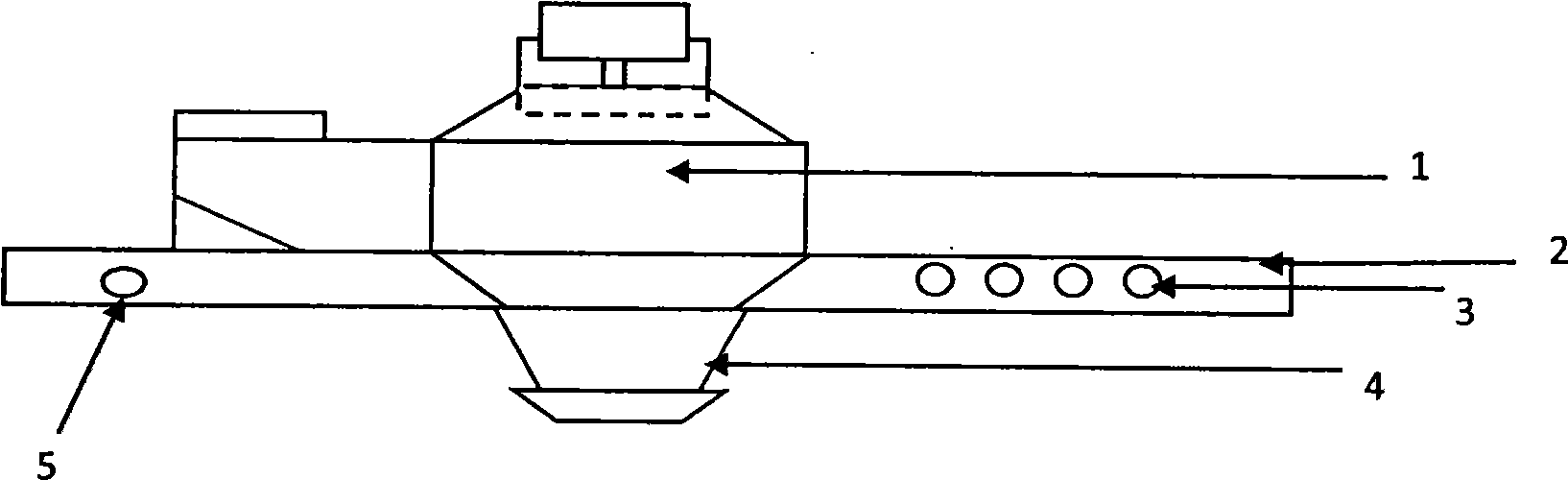

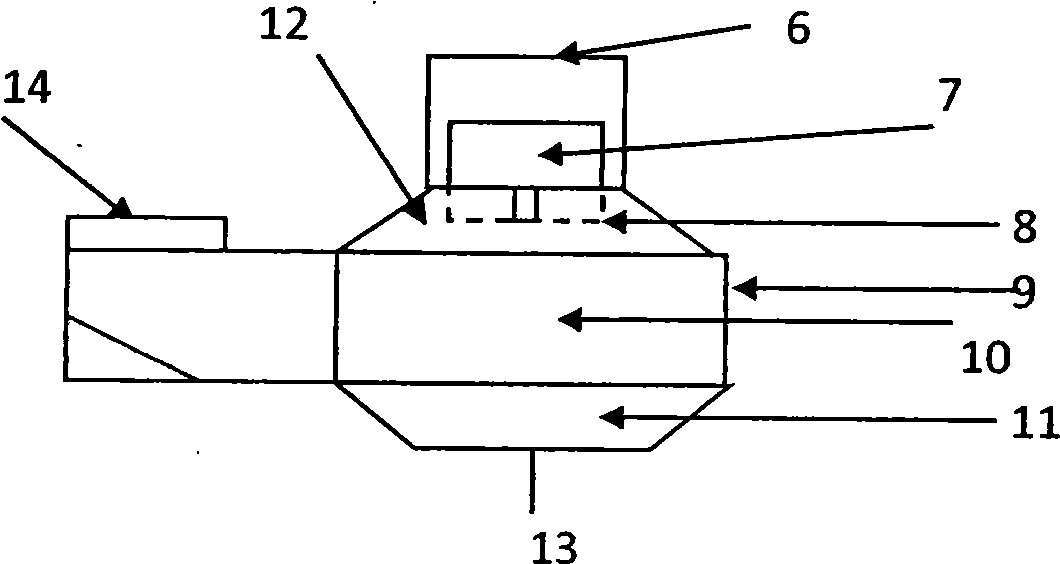

Sedimentation tank water treatment suction dredger

PendingCN106914041AGuaranteed uniformityReduce volume lossSettling tanks feed/dischargeSedimentation settling tanksWater treatmentDrive shaft

The invention discloses a sedimentation tank water treatment suction dredger. The sedimentation tank water treatment suction dredger comprises a driving mechanism which is provided with a transmission shaft inserted to the bottom of the above tank, and also comprises a mud suction tube arranged at the tank bottom, and the mud suction tube is connected with the transmission shaft; a group of mud suction holes are distributed in the mud suction tube; and the bottom of the mud suction tube is provided with a mud discharge tube communicating with the mud suction tube, and the apertures of the mud suction holes gradually decreases from the edge of the tank to the center of the tank. The sedimentation tank water treatment suction dredger effectively solves the problems of non-uniform mud suction, easiness in pipeline obstruction, and occupation of too much space of the sedimentation tank in the mud discharge process of existing sedimentation tanks.

Owner:广东新环机电装备制造有限公司

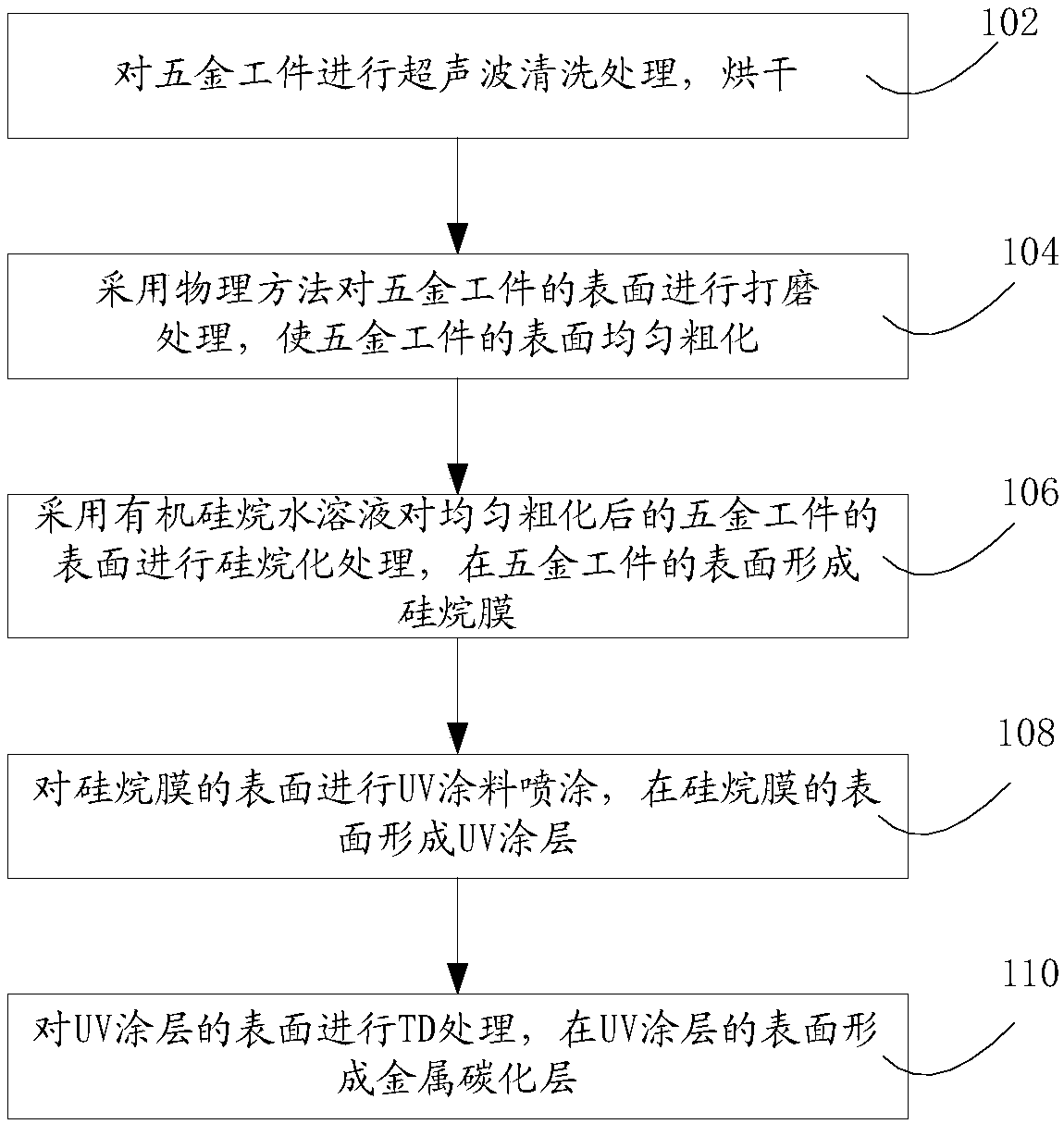

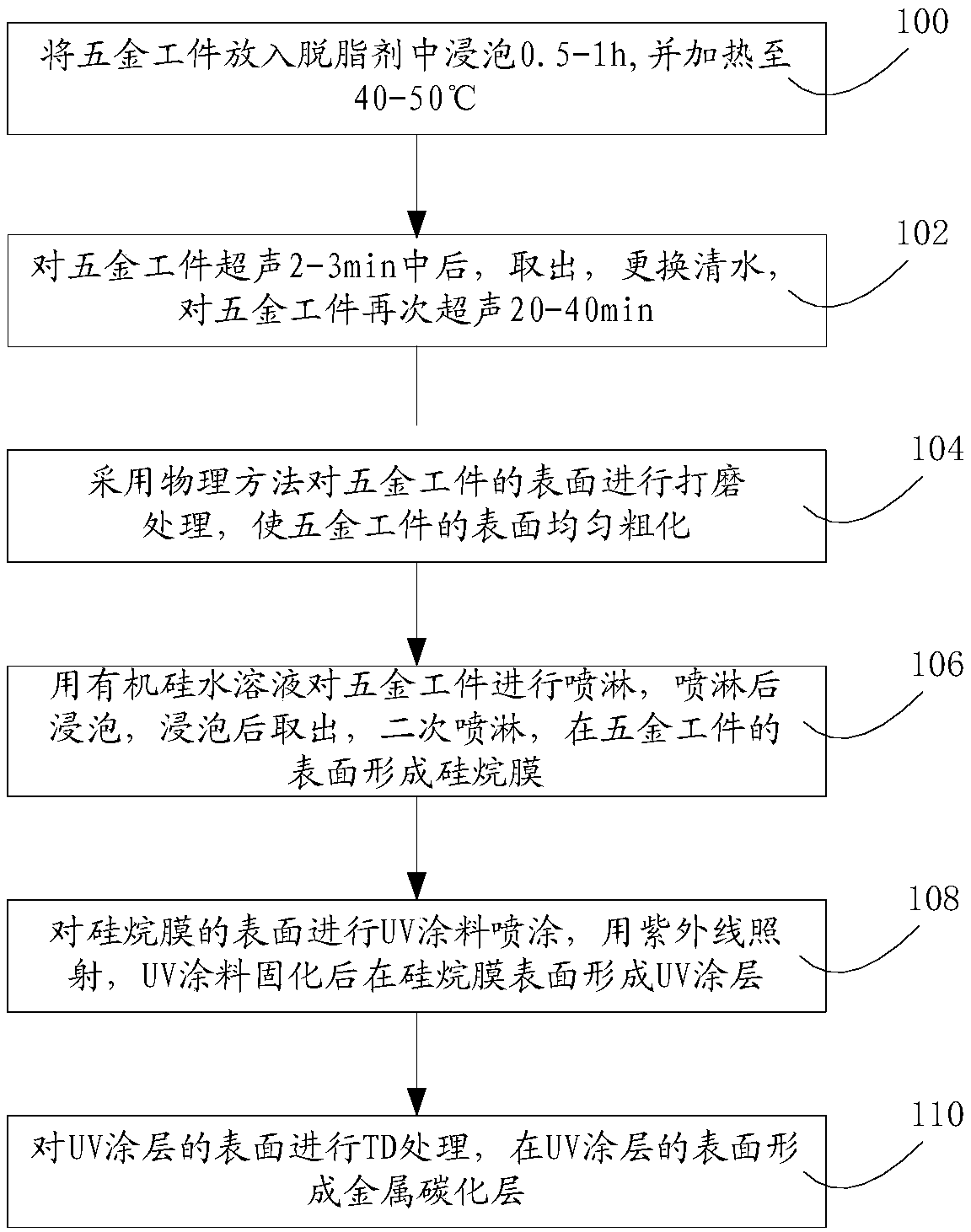

Hardware workpiece surface treatment technology

InactiveCN108690947ALong-term protectionReduce volume lossPretreated surfacesSolid state diffusion coatingCarbideMegasonic cleaning

The invention discloses ahardware workpiece surface treatment technology. The hardware workpiece surface treatment technology comprises the following steps thata base material pre-treated, specifically, a hardware workpiece is subjected to ultrasonic cleaning to remove impurities on the surface, and thehardware workpiece is dried; the base material ground, specifically, a physical method is used for grinding the surface of the hardware workpiece to uniformly roughen the surface of the hardware workpiece; silanization treatment is carried out, specifically, the uniformly roughened hardware workpiece is placed into an organosilane aqueous solution for silanization treatment, so that a silane film is formed on the surface of the hardware workpiece; middlecoating treatment is carried out, specifically, the surface of the silane film is subjected to UV coating spraying to form a UV coat on the surface of the silane film; and outeroverlaying layer treatment is carried out, specifically, thesurface of the UV coat is subjected to TD treatment to form a metal carbide layer on the surface of the UV coat. According to the hardware workpiece surface treatment technology, protection overlay layers with extreme high binding force are formed on the surface of the hardware workpiece, and the overlay layers are not liable to fall off from the surface of the hardware workpiece, so that the hardware workpiece can be protected for a long time; and the overlay layers have excellent performance of corrosion resistance and abrasion resistance.

Owner:惠州市国丰达五金制品有限公司

Novel cyclone type high-efficiency energy-saving environment-friendly range hood

InactiveCN101532691AReduce volume lossEliminate Flow LossDomestic stoves or rangesLighting and heating apparatusImpellerEngineering

The invention discloses a novel cyclone type high-efficiency energy-saving environment-friendly range hood. The range hood has the advantages of high efficiency, energy conservation, cleanness, environmental protection, economy, durability, easy processing, non-cleaning of impellers, realization of comprehensive optimization of indoor environment, environment inside the hood and outdoor environment further and the like. A structure of the novel cyclone type high-efficient energy-saving environment-friendly range hood comprises a draught fan, an oil filter, a cover shell, a lampblack cover, a jacklight and a multiposition keyswitch; a shell of the draught fan is a conical or cylindrical three-bin joint device with an air inlet and an air outlet; and the lower part of the device is provided with a lampblack filter.

Owner:朱瑞富 +1

High-efficiency long life multifunctional vane pump

InactiveCN101303024AExtend your lifeLess collisionPump componentsRadial flow pumpsImpellerNew energy

The invention discloses a multifunctional vane pump with high efficiency and long service life, which comprises a pump shell, an impeller, an impeller chamber, a fluid spin chamber, a water inlet, a water outlet and a motor, wherein, the impeller consists of at least one group of arc-shaped channel vanes closed at one side and amplified axially; the pump shell is internally provided with a round dual chamber or multi-chamber provided with the water inlet and the water outlet. The efficiency of the vane pump is over 80 percent, the energy is saved by more than 10 percent while the noise is lower than 80dB; the impeller is not easy to wear basically and the service life can be prolonged by more than 2 times; also the vane pump has various functions and can be used for pumping fluid, solid matters, and mixed fluid and solid matters, etc. The comprehensive economic, technical and performance indexes of the vane pump achieve the leading level both at home and abroad and also a new energy transmission theory is established.

Owner:SHANDONG UNIV

A deep-sea cage culture device for offshore wind farms

ActiveCN105104271BEnables multi-purpose applicationsImprove efficiencyClimate change adaptationAgricultural fishingWind fieldEngineering

The invention discloses a deep sea net box cultivating apparatus for offshore wind field, which comprises an offshore wind turbine foundation, wherein an operation platform is mounted on the top portion of the offshore wind turbine foundation; a rotary sleeve ring fixing system is mounted on a lower end of the offshore wind turbine foundation; the rotary sleeve ring fixing system is connected to a rotary arm mechanism; the rotary arm mechanism is connected to an offshore net box module through a cable connecting rod component; the rotary sleeve ring fixing system comprises a reinforced cylinder sleeve; an upper rotary sleeve ring and a lower rotary sleeve ring are respectively mounted on an upper end and a lower end of the reinforced cylinder sleeve; and the upper rotary sleeve ring and the lower rotary sleeve ring are respectively connected to the rotary arm mechanism through an upper connecting buckle and a lower connecting buckle. According to the utility model, by adopting the apparatus provided herein, the offshore wind field can be applied with various purposes; organic combination between the offshore wind power generation and the offshore net box cultivation is realized; the space of the offshore wind field and the offshore wind power are fully utilized, thus improving the overall economy benefits.

Owner:佛山市榕岸海洋工程装备有限公司

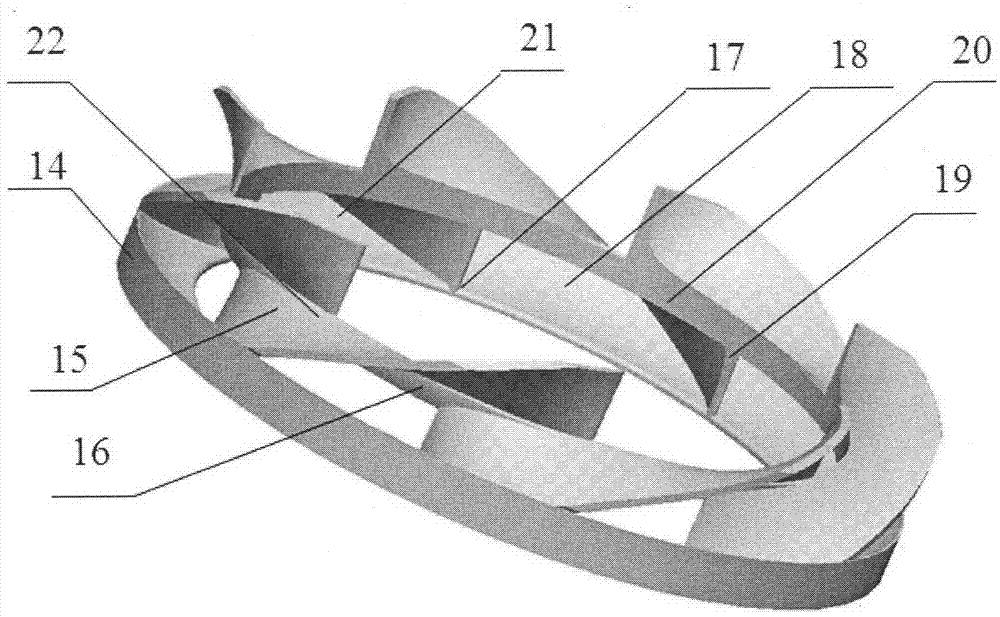

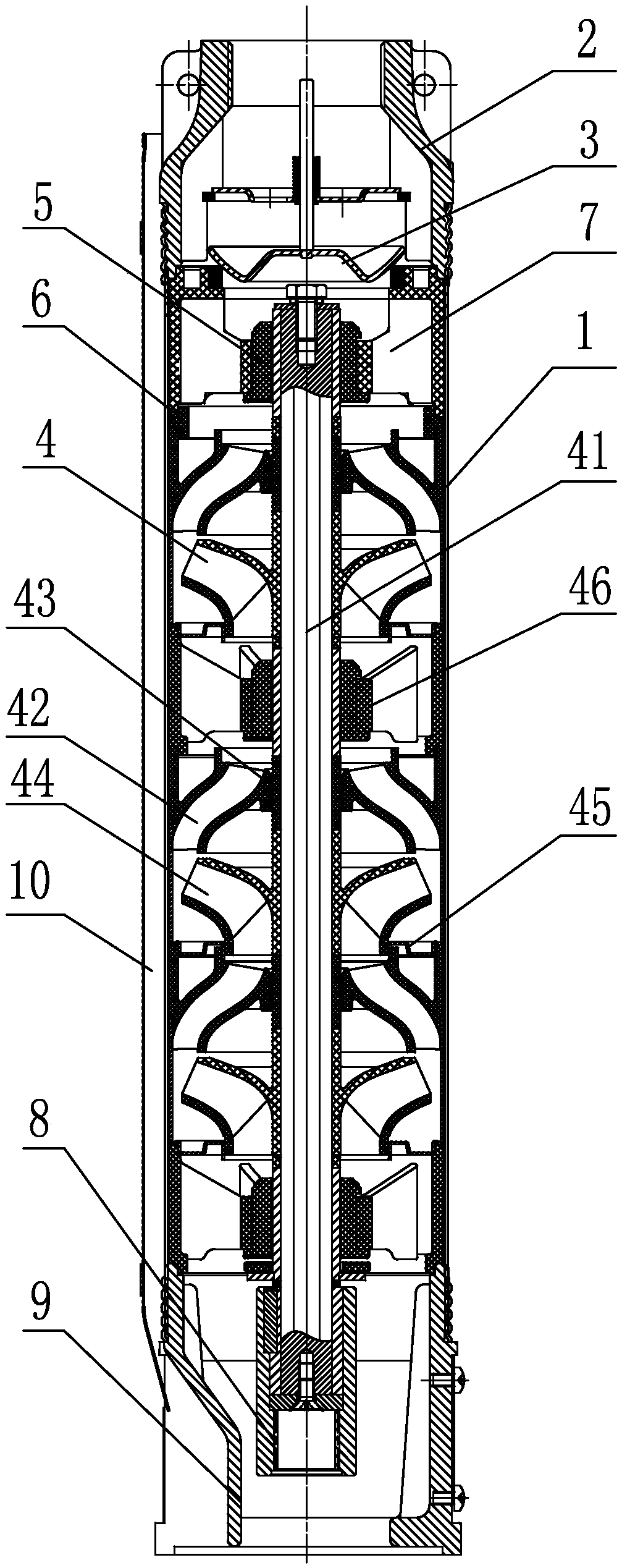

Space twisting plastic impeller type well submersible pump

PendingCN109441841ASmall pressure lossIncrease the sealing areaPump componentsPump installationsImpellerCoupling

The invention discloses a space twisting plastic impeller type well submersible pump comprising a shell, a water outlet pump head, a check valve, a bearing seat, a sliding bearing, an adjusting ring,a multi-stage impeller assembly including a hexagonal pump shaft, a guiding impeller, a shaft sleeve, an impeller, a blower inlet casing and a pump shaft bearing frame, a coupling, a water inlet baseand a wire trough; and the guiding impeller is formed by welding a guide vane seat and a fairing which are obtained through injection molding, the impeller is formed by welding a main impeller and animpeller front cover plate which are obtained through injection molding, the guide vane seat includes a conical bottom cover designed according to the Bezier curve and seven spiral guide vanes, the main impeller includes a conical back cover plate designed according to the Bezier curve and six spiral blades, the spiral direction of the blades is opposite to the spiral direction of the guide vanes,the protruding water inlet of the blower inlet casing is in clearance fit with a water inlet of the impeller front cover plate, and an annular groove surrounding the protruding water inlet is in transition fit with the end of a water outlet of the fairing for positioning. The space twisting plastic impeller type well submersible pump has the beneficial effects of being large in flow rate and highin lift, being capable of reducing the pressure loss, improving the water pump efficiency and being low in cost.

Owner:GUANGDONG RUIRONG PUMP IND

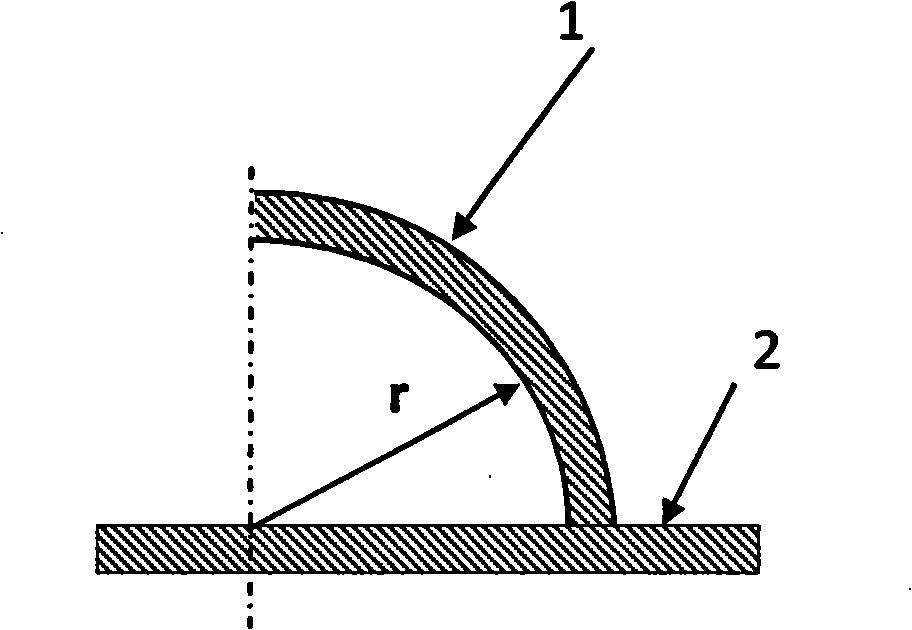

Mixed-flow pump impeller

The invention relates to an incomplete front cover board mixed-flow pump impeller which comprises an incomplete front cover board, a wheel boss and a plurality of vanes connected between the incomplete front cover board and the wheel boss. The incomplete front cover board and the front edges of the vanes are incompletely crossed, that is, a part of the front edges of the vanes is arranged in an annular chamber of the front cover board and the other part thereof is exposed outside the annular chamber of the front cover board, therefore, the impeller is called incomplete front cover board mixed-flow pump impeller. By applying the impeller to the renovation project of a diagonal flow circulating water pump impeller of a large-sized turbo generator set, the impeller has the advantages of increased stiffness, improved reliability, high efficiency and energy conservation, and ensuring stable, economic and safe operation of the set.

Owner:HARBIN ELECTRIC MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com