Axial flow blower

A technology of axial flow fan and shaft sleeve, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., and can solve problems such as exhaust noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

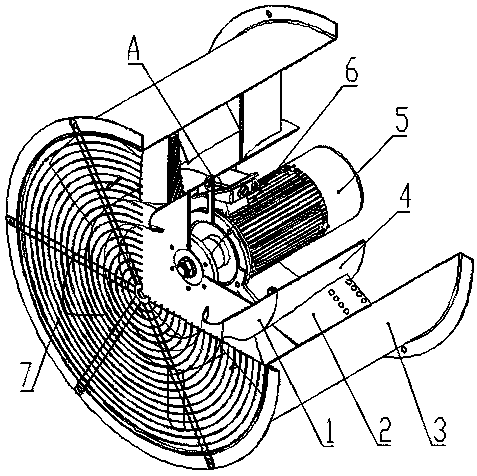

[0029] like figure 1 As shown, the axial flow fan consists of 7 parts, including 1, impeller 2, guide vane 3, outer cylinder 4, inner cylinder 5, motor 6, bushing 7, net cover; outer cylinder 3, guide vane 2 and inner cylinder 4 are fixed together by welding, the motor 5 is fixed on the web of the inner cylinder 4, the working parameters of the motor 5 are 720r / min, and the power is 4KW; the impeller 1 is fixed on the shaft of the motor 5 through the bushing 6, and the impeller 1 The gap between the wheel hub and the inner cylinder 4 is 10mm; the net cover 7 is installed on the outer cylinder 3, and has the functions of rectifying and preventing foreign matter from entering.

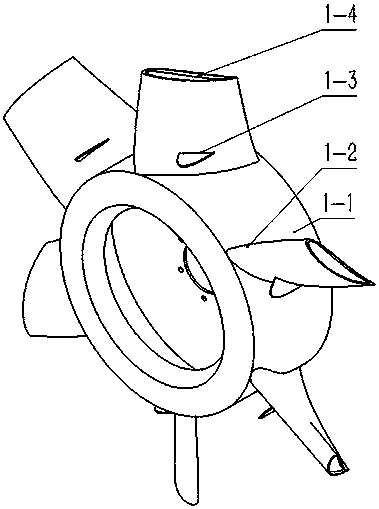

[0030] like figure 1 , 3 As shown, the impeller 1 is driven by the motor 5 to do work for the gas to increase the dynamic pressure and static pressure of the gas. The blades 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com