Patents

Literature

68results about How to "Reduce blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

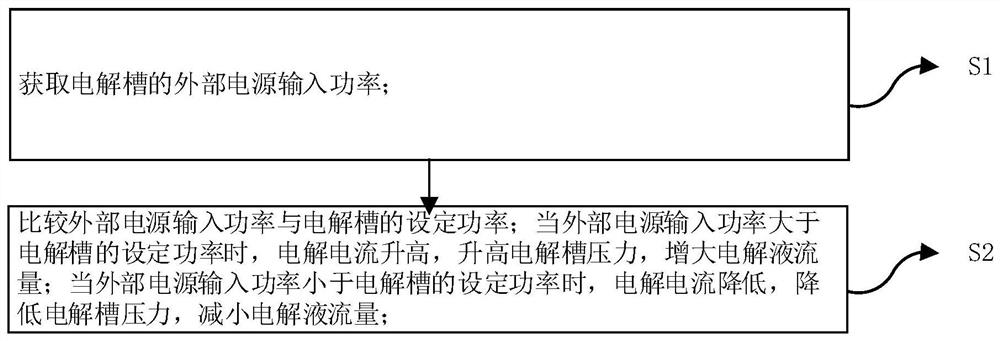

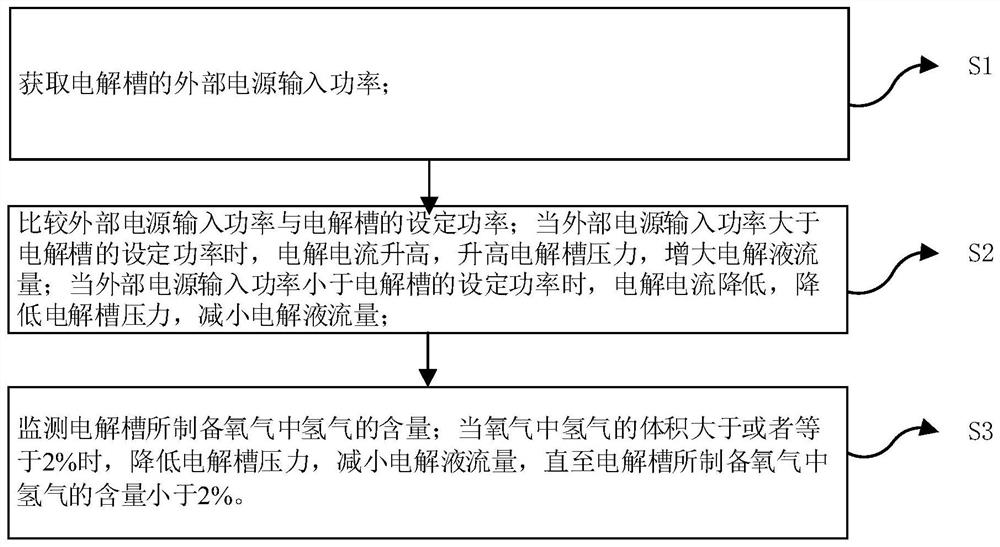

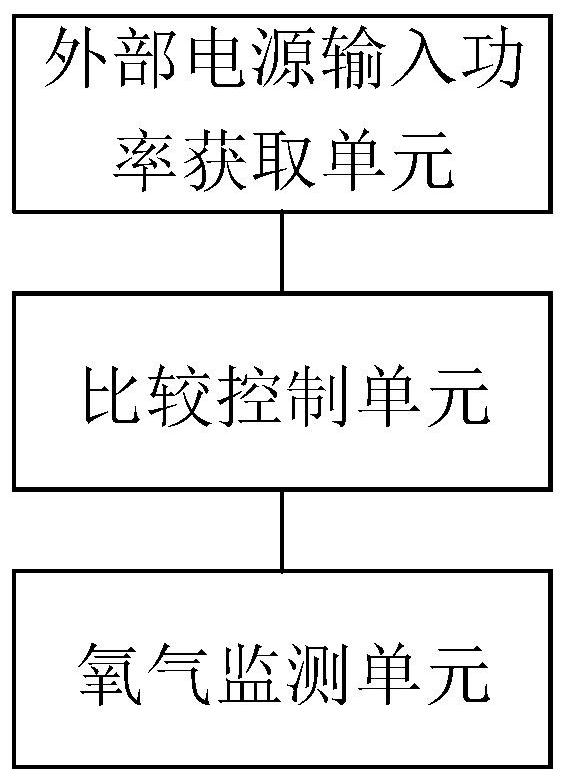

Electrolyte flow and pressure control method and system for dynamic hydrogen production electrolytic bath

ActiveCN113373477AIncrease pressureRelieve pressureElectrolysis componentsEnergy inputElectrolytic agentThermodynamics

The invention belongs to the field of renewable energy sources and hydrogen energy, and discloses an electrolyte flow and pressure control method and system for a dynamic hydrogen production electrolytic bath. The method comprises the following steps: S1, obtaining the external power supply input power of the electrolytic bath; and S2, comparing the input power of the external power supply with the preset power of the electrolytic bath; when the input power of the external power supply is greater than the preset power of the electrolytic bath, rising the electrolytic current, increasing the pressure of the electrolytic bath and increasing the electrolyte flow; and when the external power input power is smaller than the preset power of the electrolytic cell, reducing the electrolytic current, reducing the electrolytic bath pressure, and reducing the electrolyte flow. According to the invention, safe, stable and efficient operation of the electrolytic bath in the dynamic hydrogen production process is realized through automatic adjustment of the pressure and flow of the electrolyte, and absorption of renewable energy sources is realized through hydrogen production by using electrolyzed water.

Owner:HUANENG CLEAN ENERGY RES INST +9

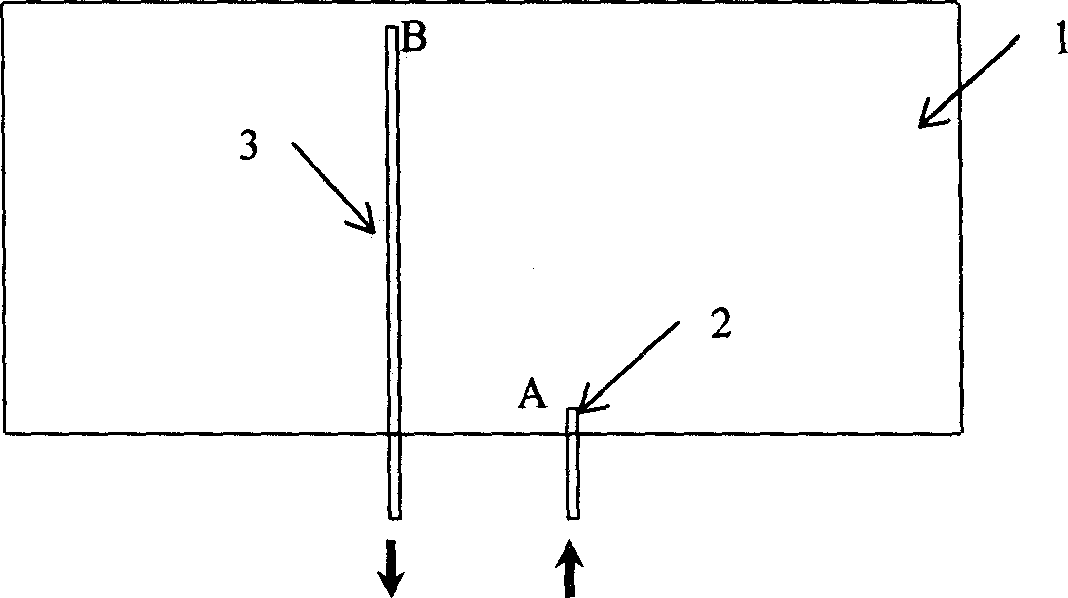

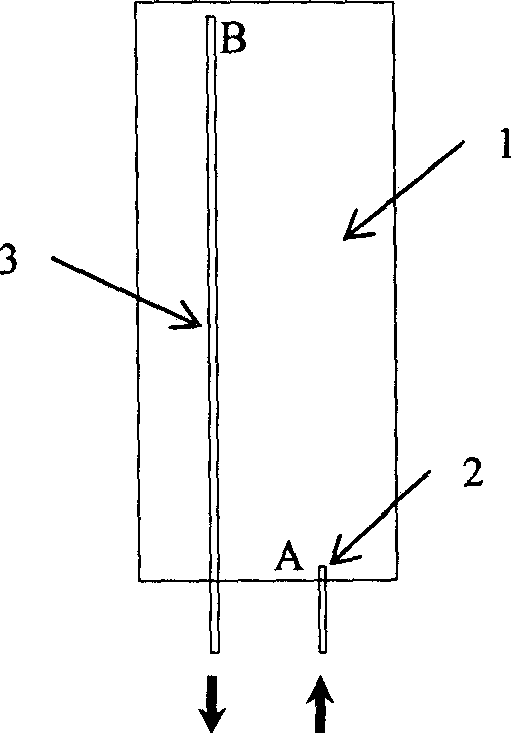

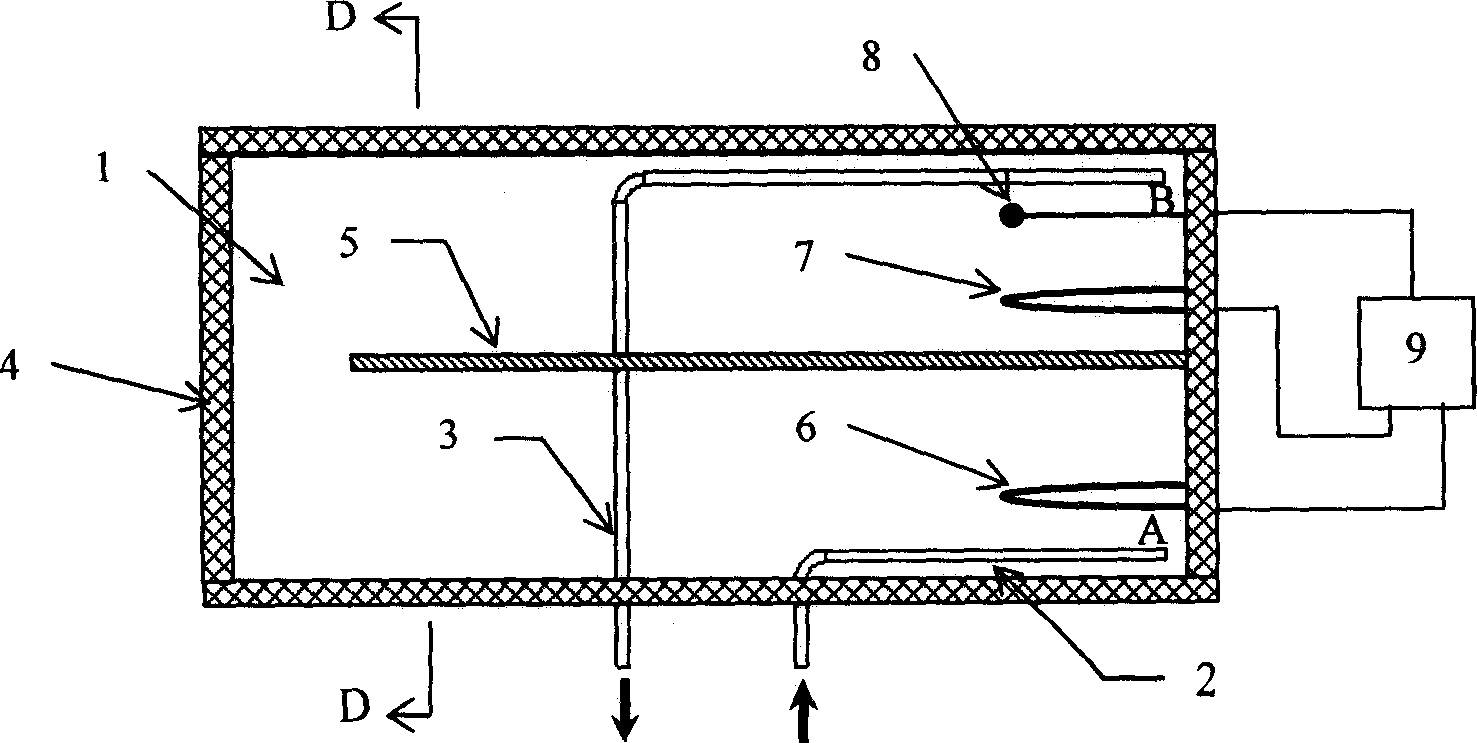

Horizontal positive-displacement energy-saving electric water heater

The invention is a transversal volumetric energy-saving electric water heater, comprising casing, inner container, cold water inlet pipe and hot water outlet pipe combined with the inner container, temperature sensor and heating component equipped in the inner container, and heating controller connected with the temperature sensor and the heating component, where a baffle for stopping cold and hot water directly mixing is arranged in the inner container, one end and two sides of the baffle are connected with the inner container and the other end is a space apart from the end face of the inner container and the space acts as a channel for cold water to enter hot water region; the part of the cold water inlet pipe inserted in the inner container is in the bottom of the inner container and the cold water outlet is opposite to and close to the end face of the inner container connected with the baffle; the part of the hot water outlet pipe inserted in the inner container is on the top of the inner container and the hot water inlet is opposite to and close to the end face of the inner container connected with the baffle. And it not only reduces the mixing degree of cold and hot water in the inner container but also solves the short-circuit problem between the cold water outlet and the hot water inlet.

Owner:SICHUAN UNIV

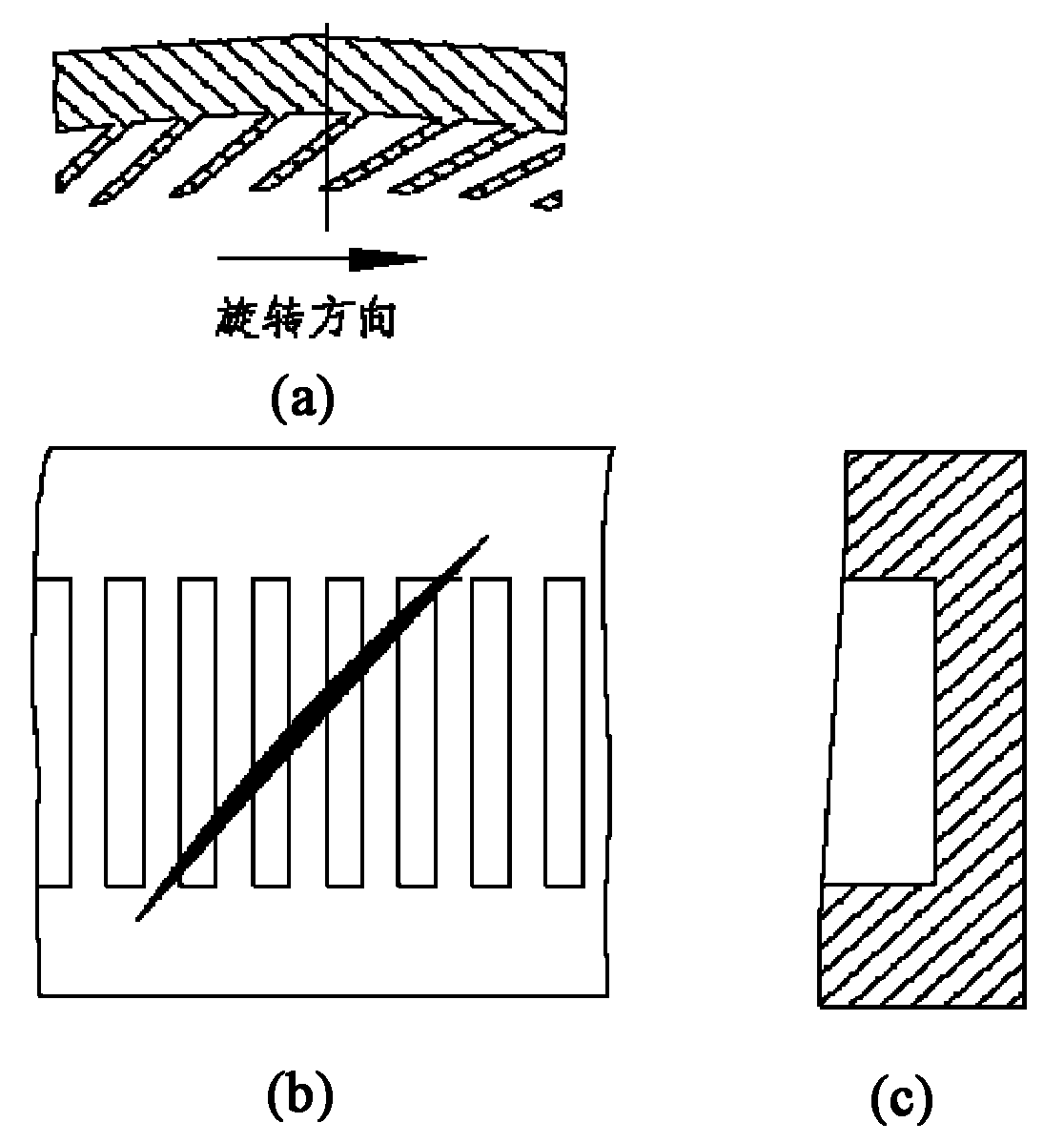

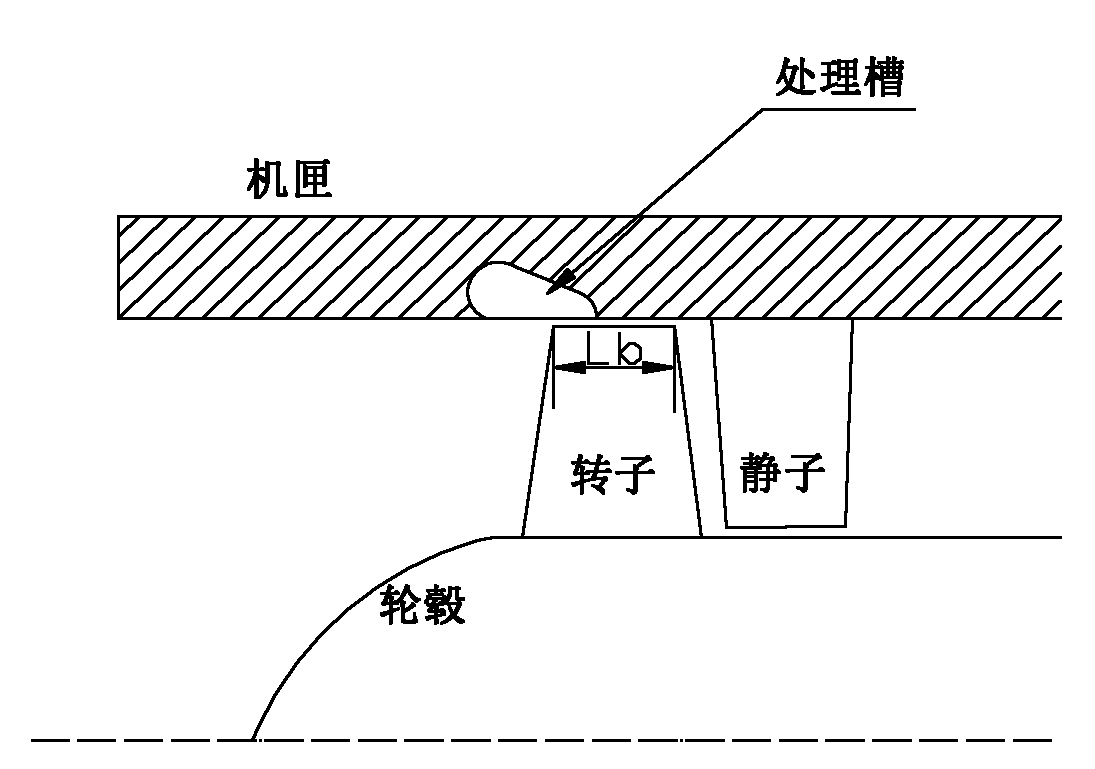

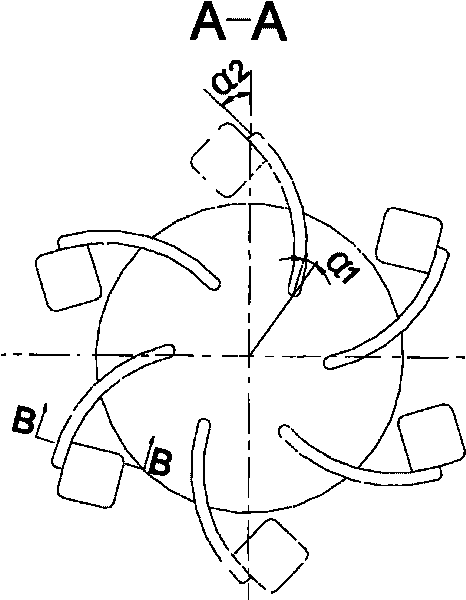

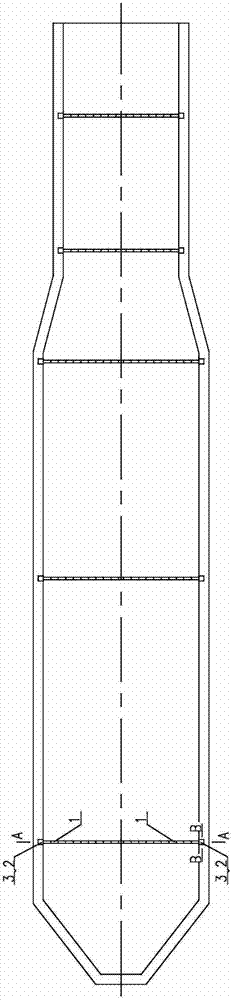

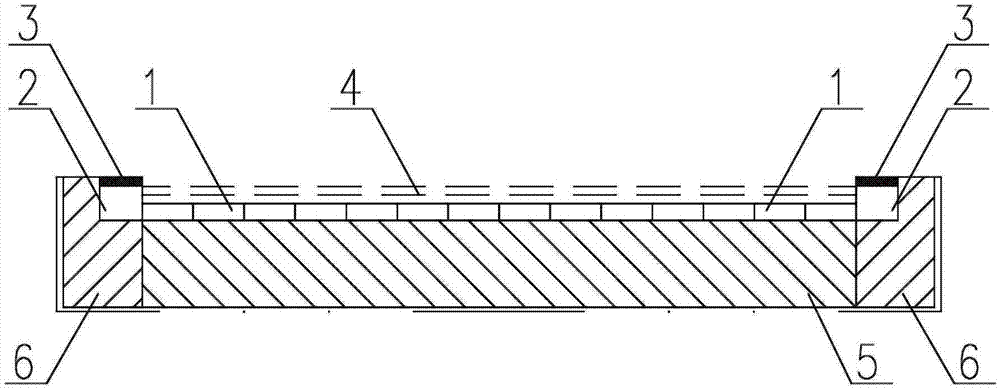

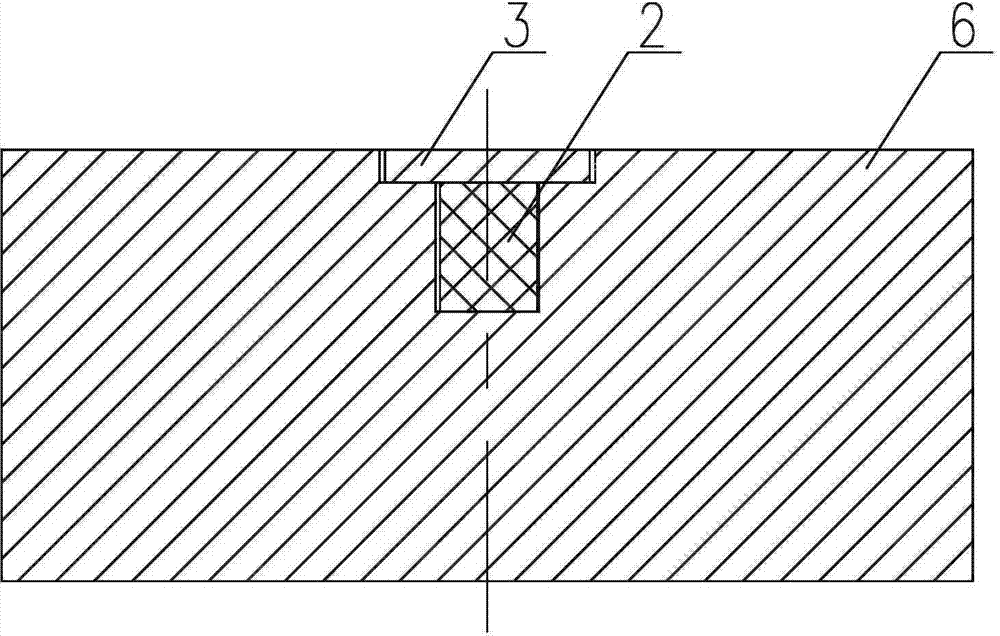

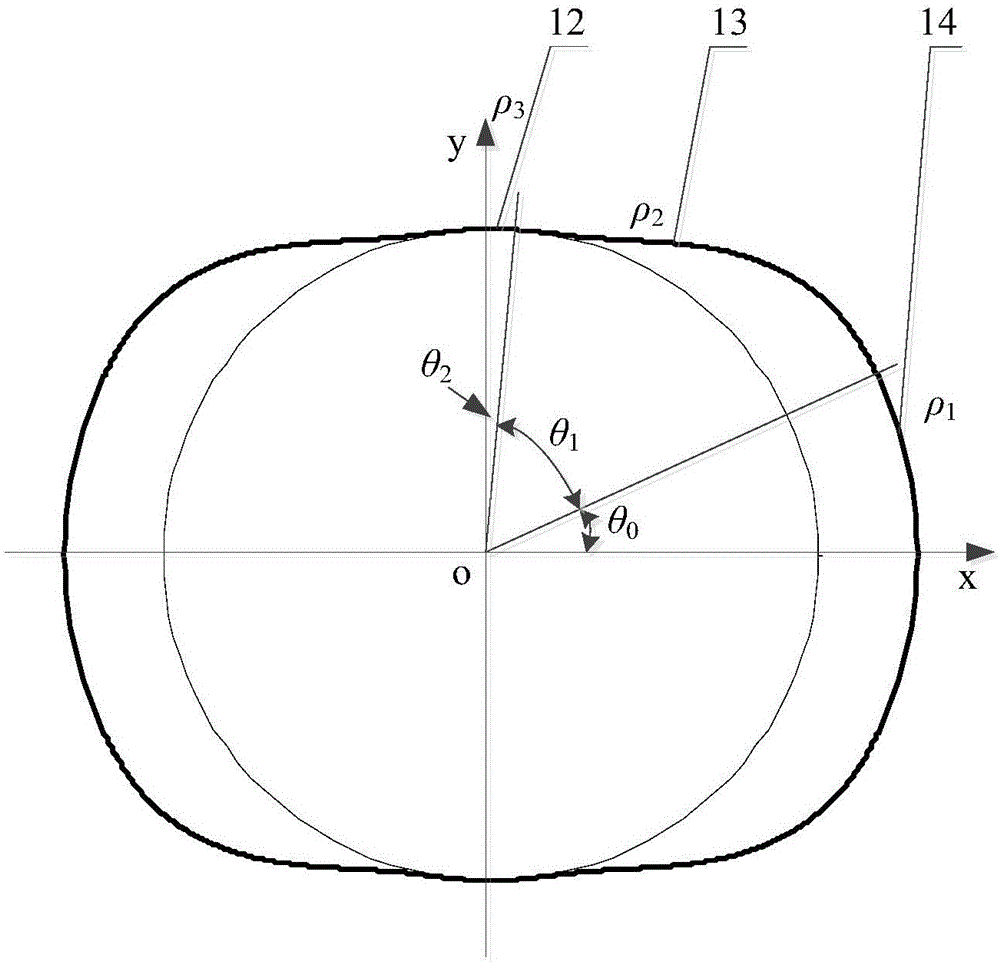

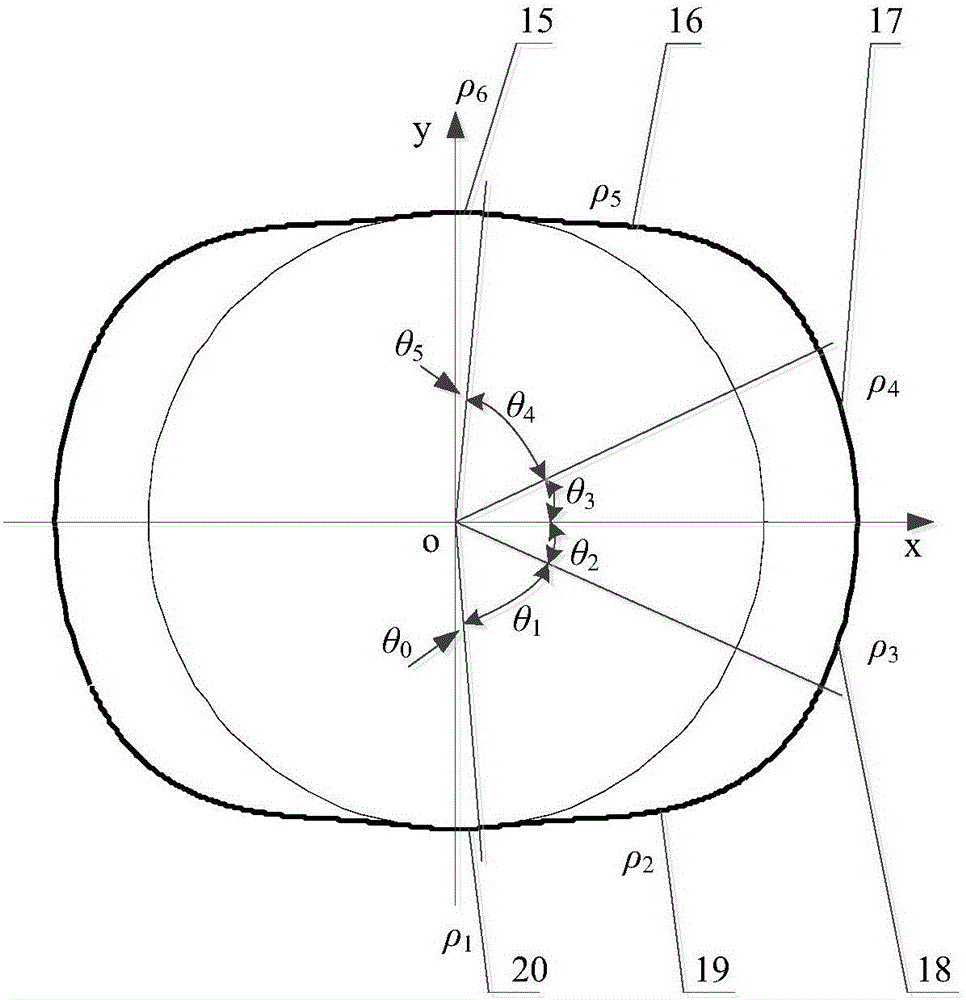

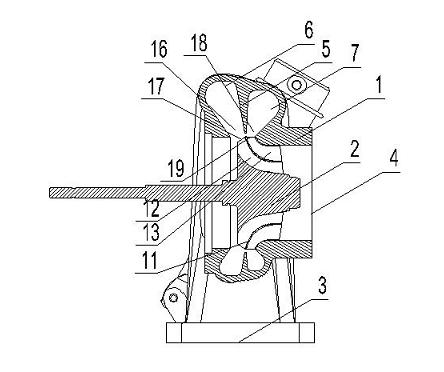

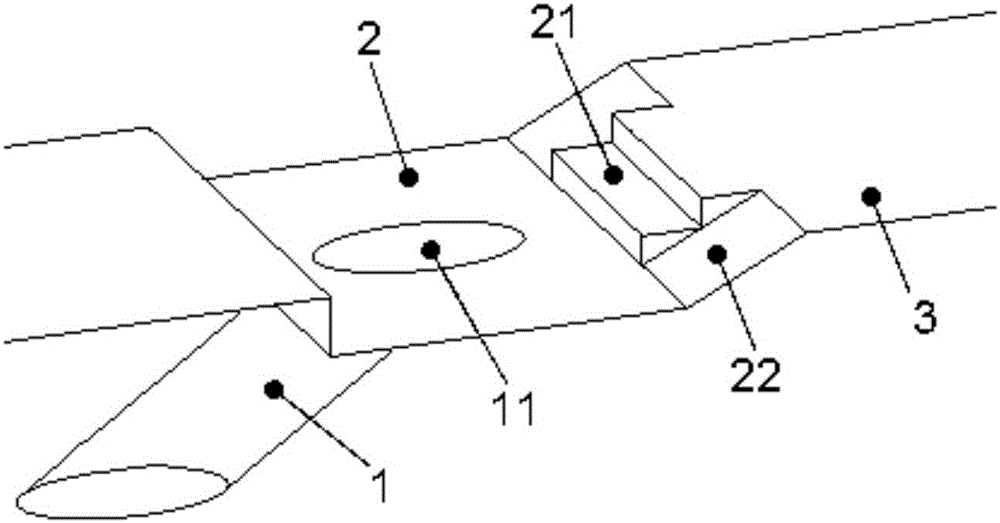

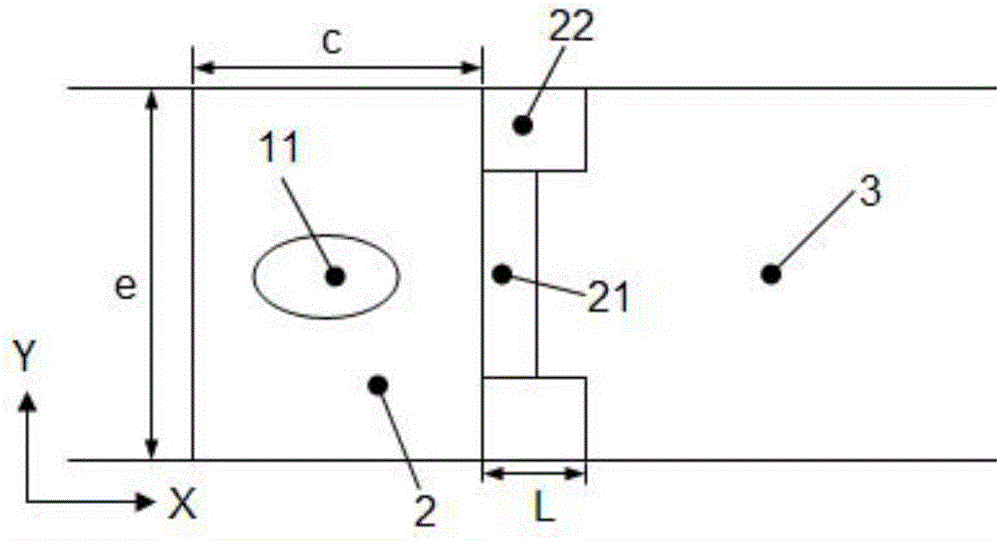

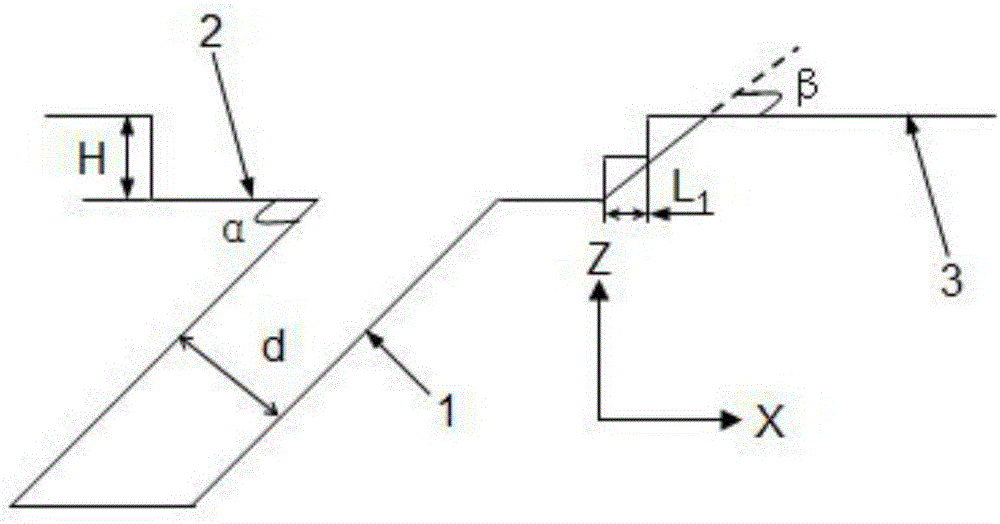

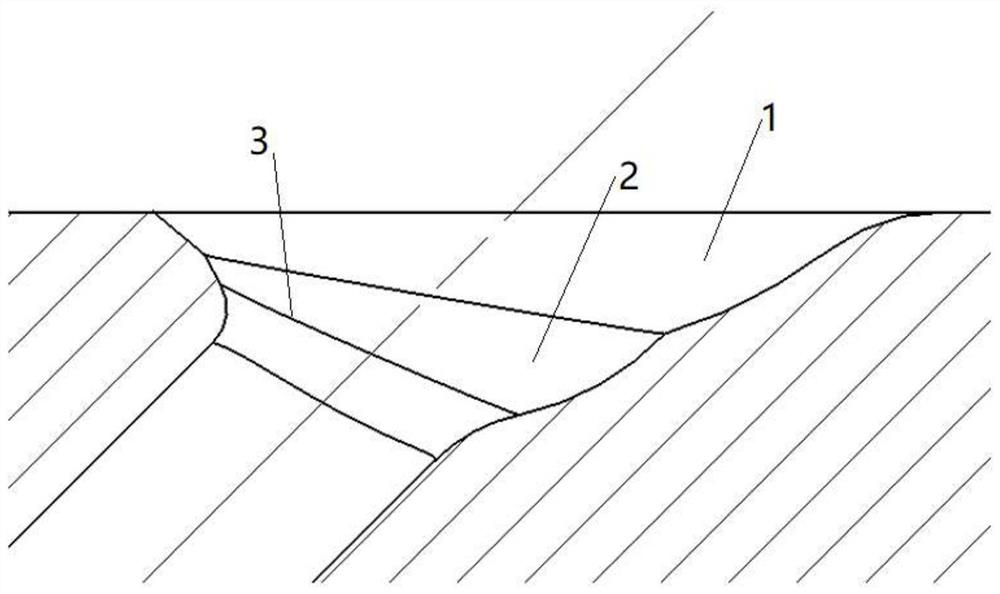

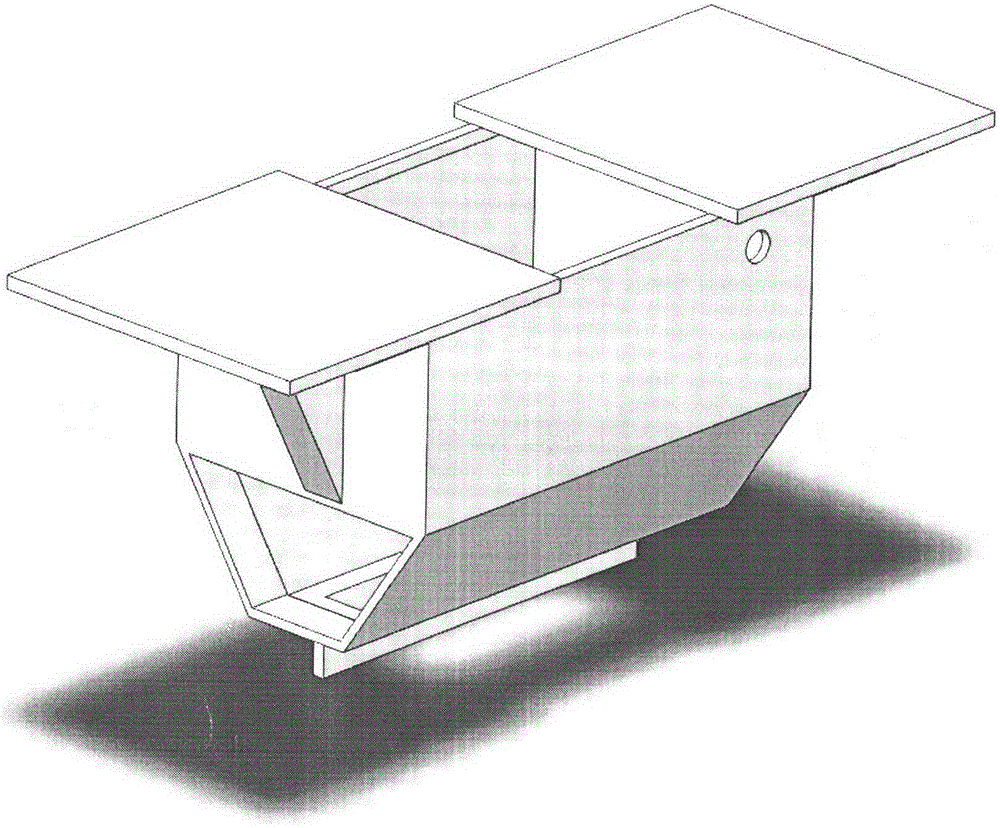

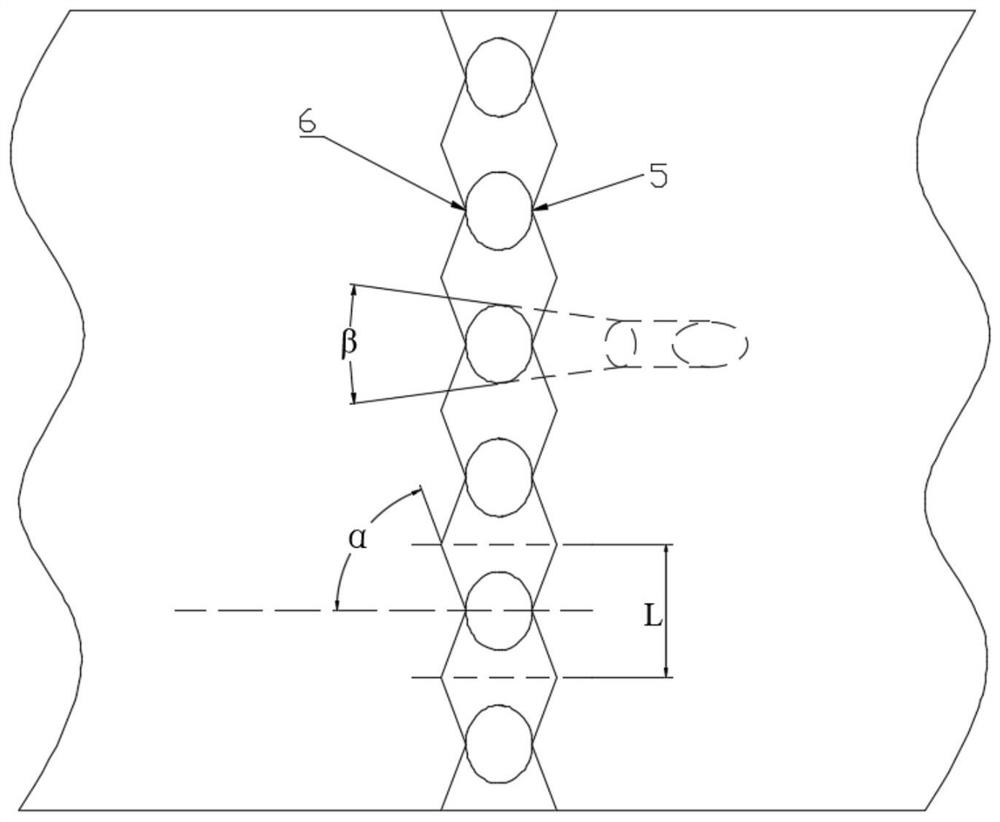

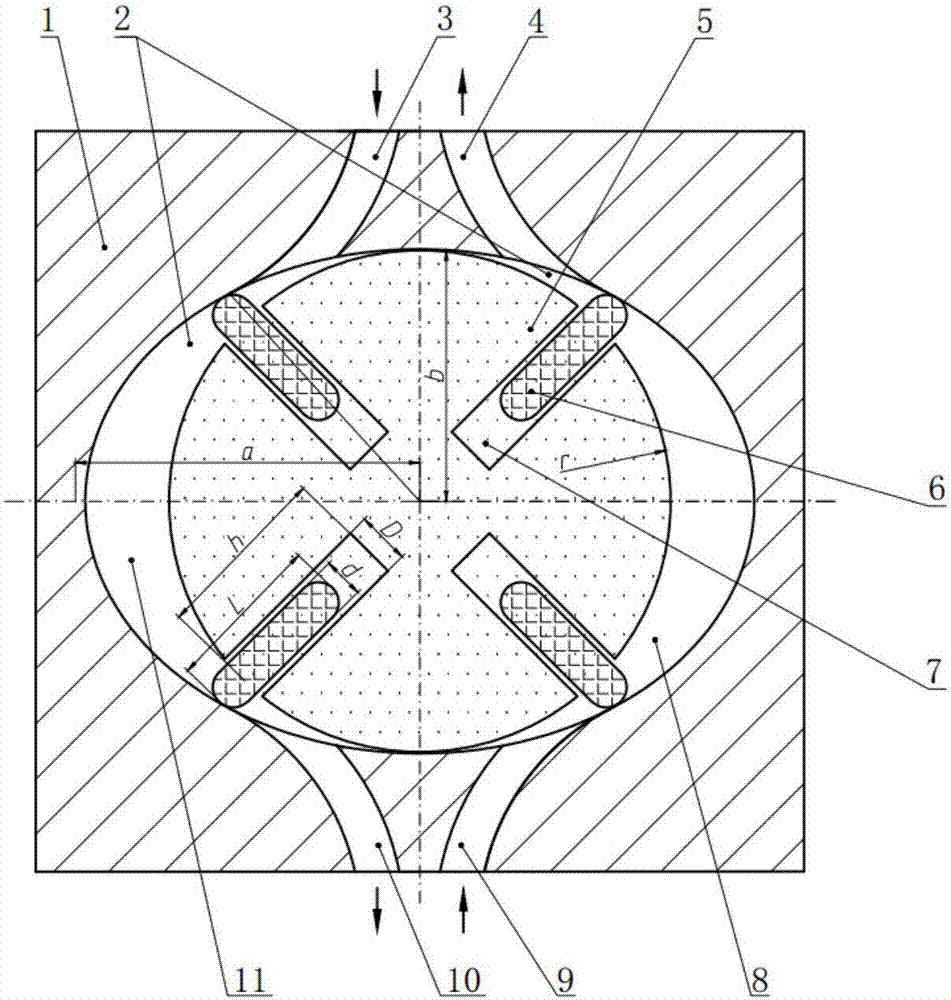

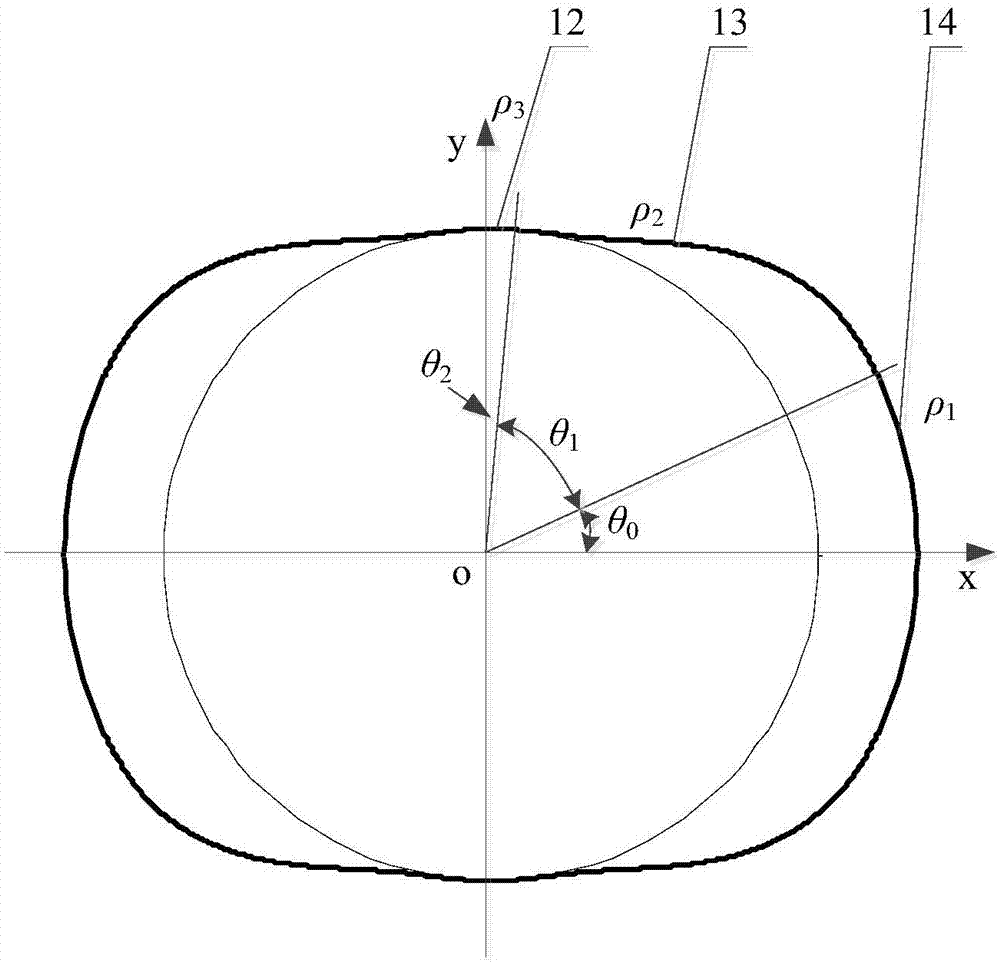

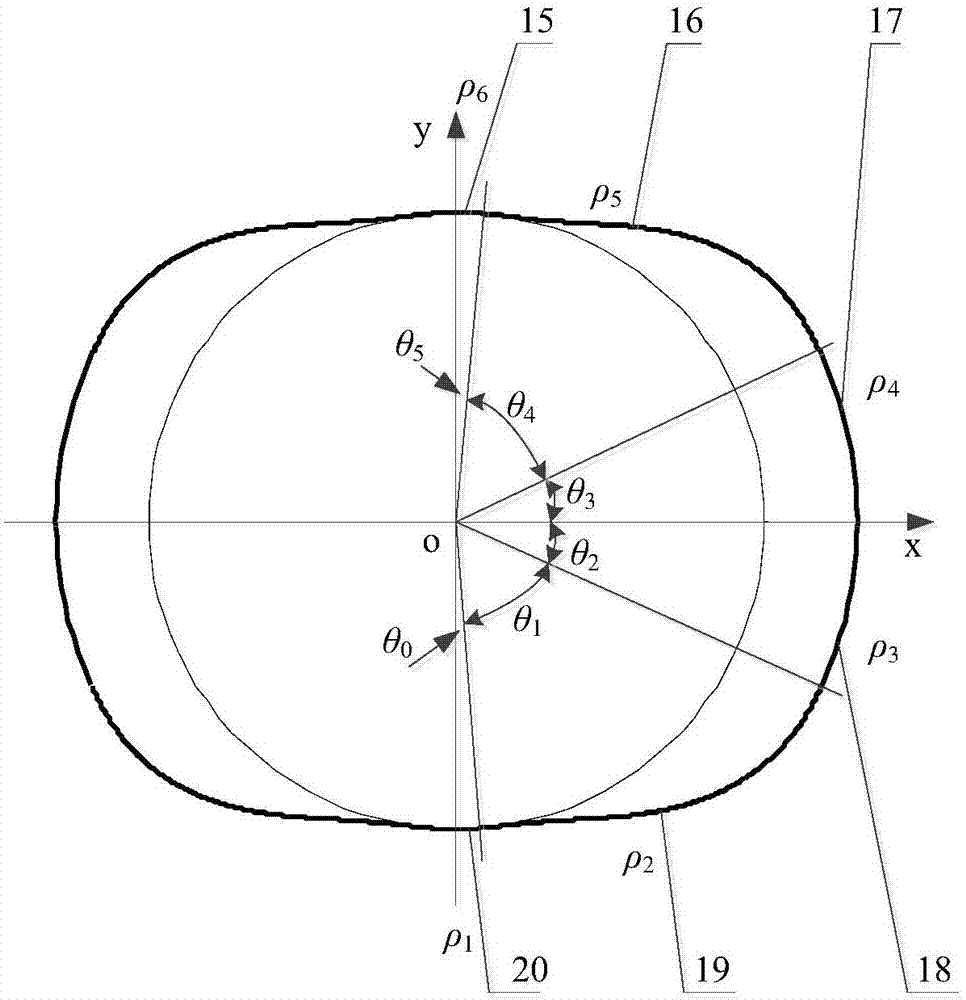

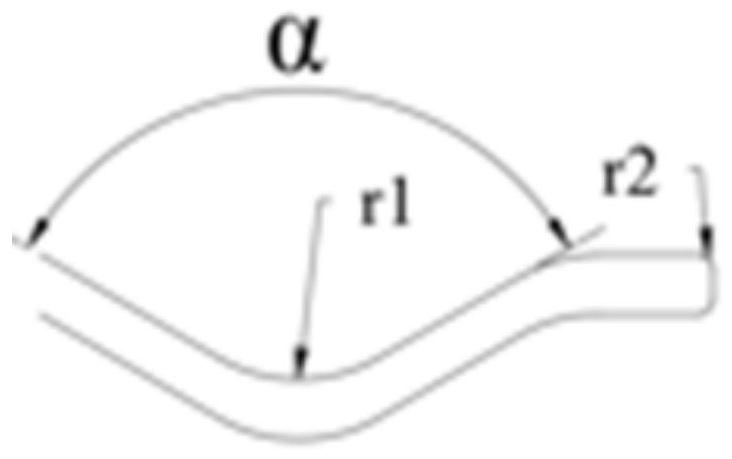

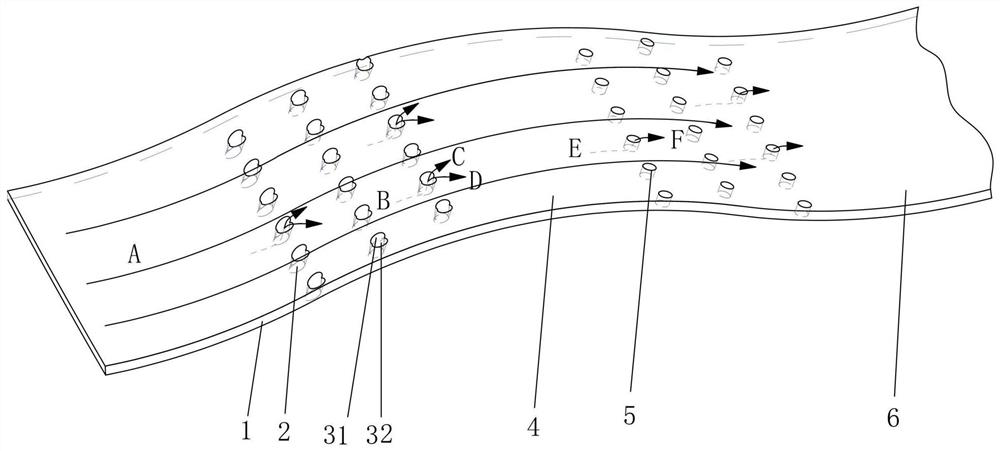

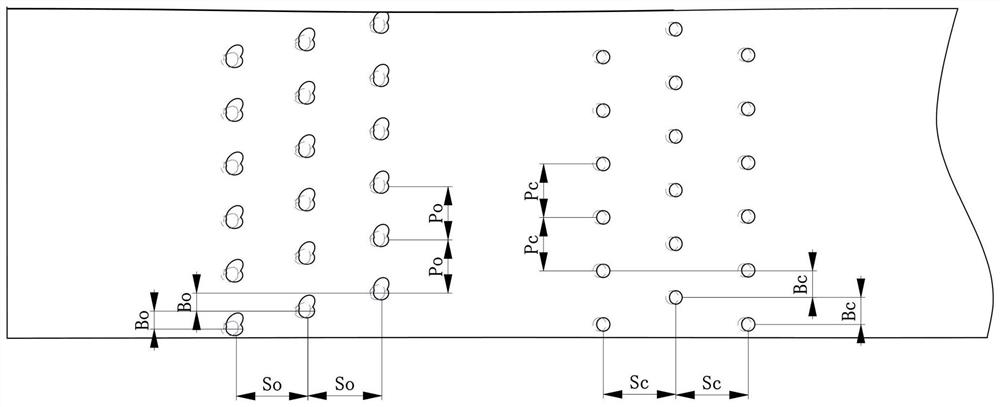

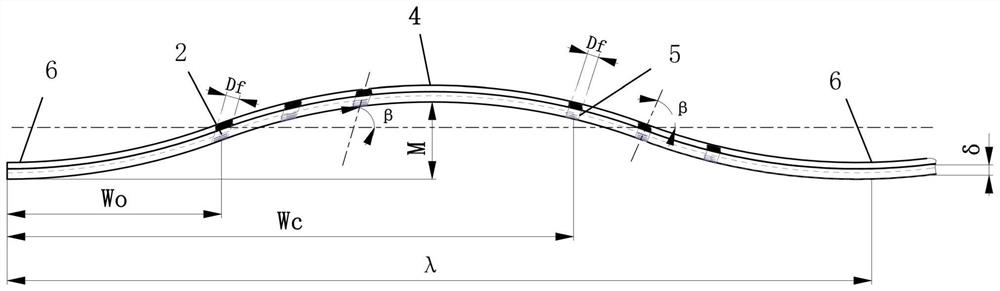

Multi-arc chute processing machine box

The invention relates to a multi-arc chute processing machine box applying to a rotor blade tip end region of an axial flow compressor. For the design of the multi-arc chute processing machine box, the greater flow loss of the processing chute caused by the rectangular and trapezoid design of the traditional processing machine box is taken into account. Through the reasonable design of a geometric construction type of the processing chute, namely the combination design that a double-arc shape is adopted at the direction of the R direction and a circular arc shape is adopted for theta (circumference), the greater low loss caused by the rectangular and trapezoid design is avoided, thus the peak value efficiency is improved slightly, meanwhile the stall margin of the compressor is improved greatly for the multi-arc chute processing machine box.

Owner:BEIHANG UNIV

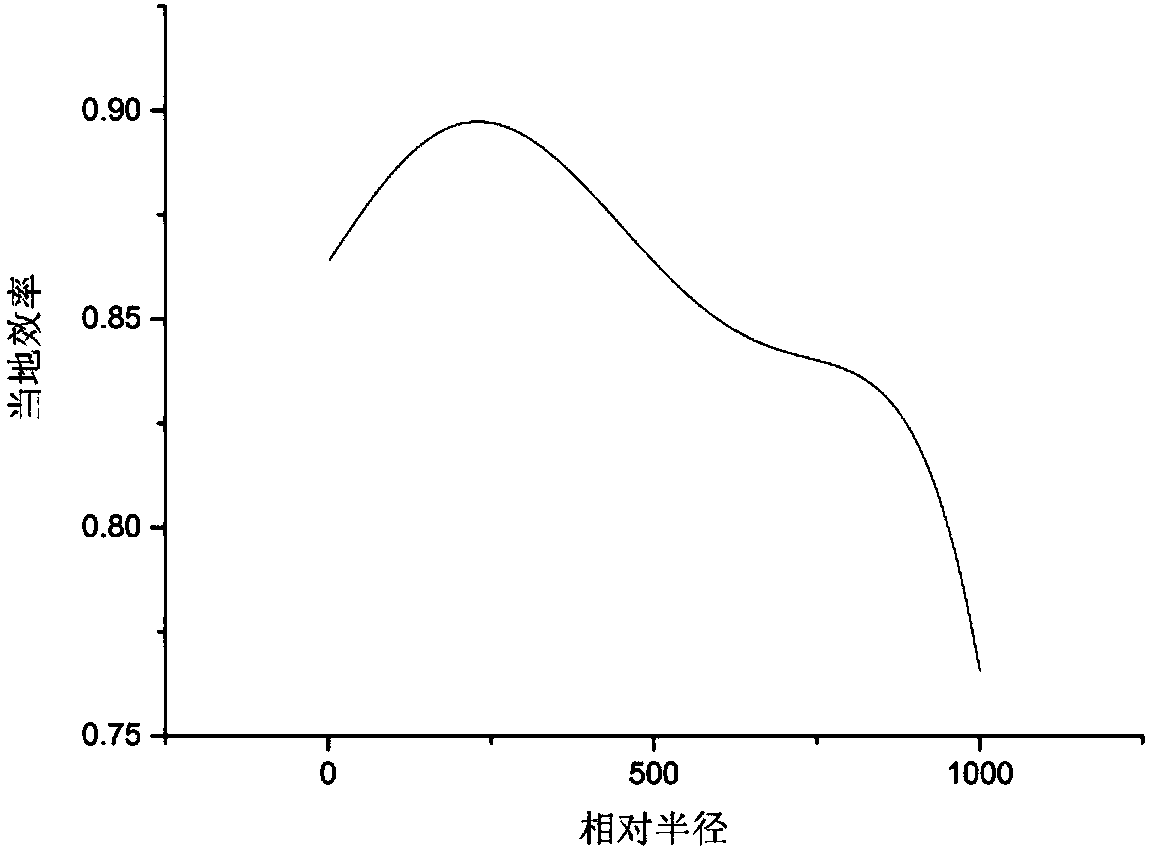

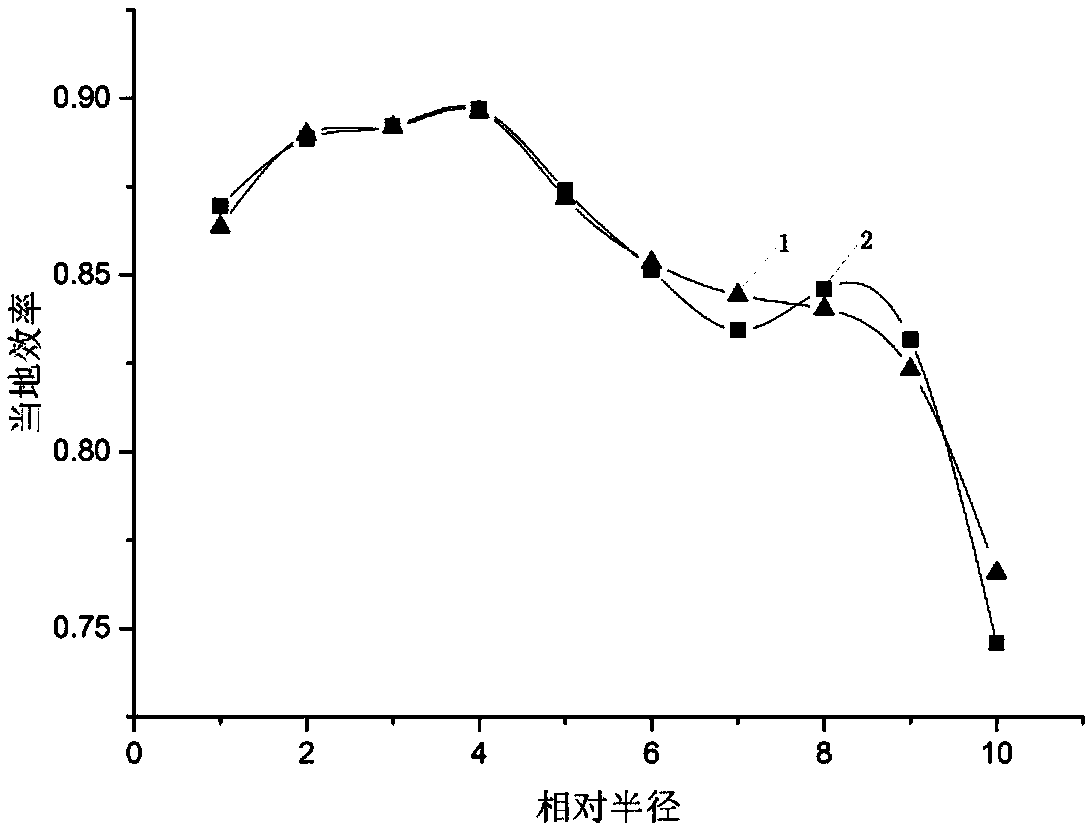

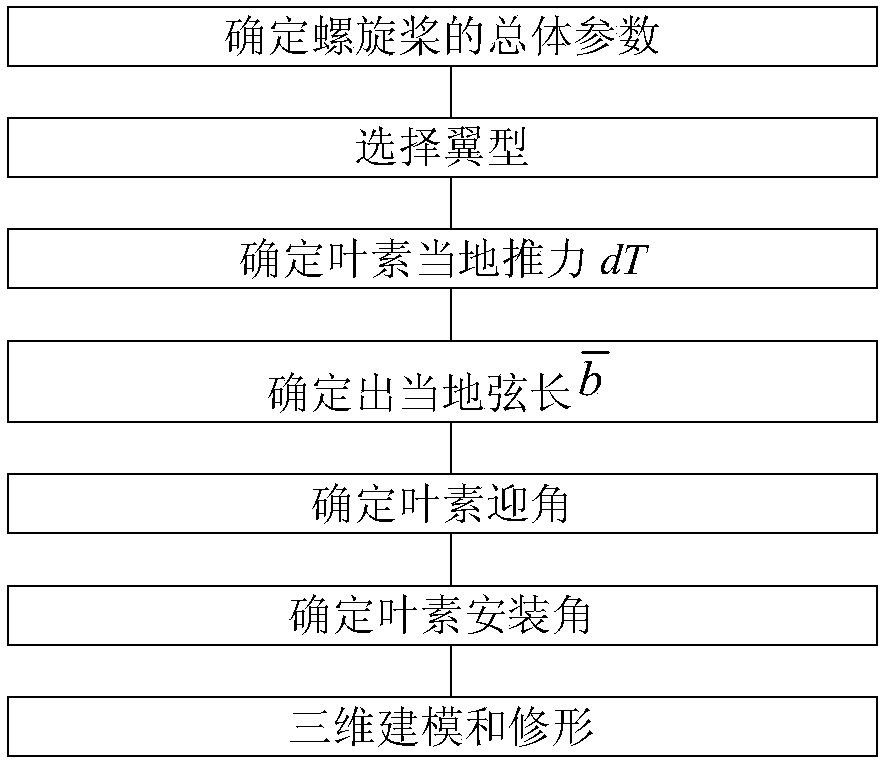

Design method for propeller blade

ActiveCN107609243AImprove aerodynamic efficiencyShorten the design cycleSustainable transportationSpecial data processing applicationsEffective powerDesign cycle

The invention discloses a design method for a propeller blade. The propeller design is performed by adopting an optimal load distribution curve; and it is concluded that a ratio of local effective power to local consumption power of a blade element has the optimal distribution curve. The propeller design is performed according to the curve, so that relatively high aerodynamic efficiency can be achieved without performing three-dimensional numerical optimization. The design cycle can be shortened and the improvement of the aerodynamic efficiency of the blade can be assisted; and the three-dimensional numerical optimization design does not need to be performed, so that the design cycle is only 1-2 days.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

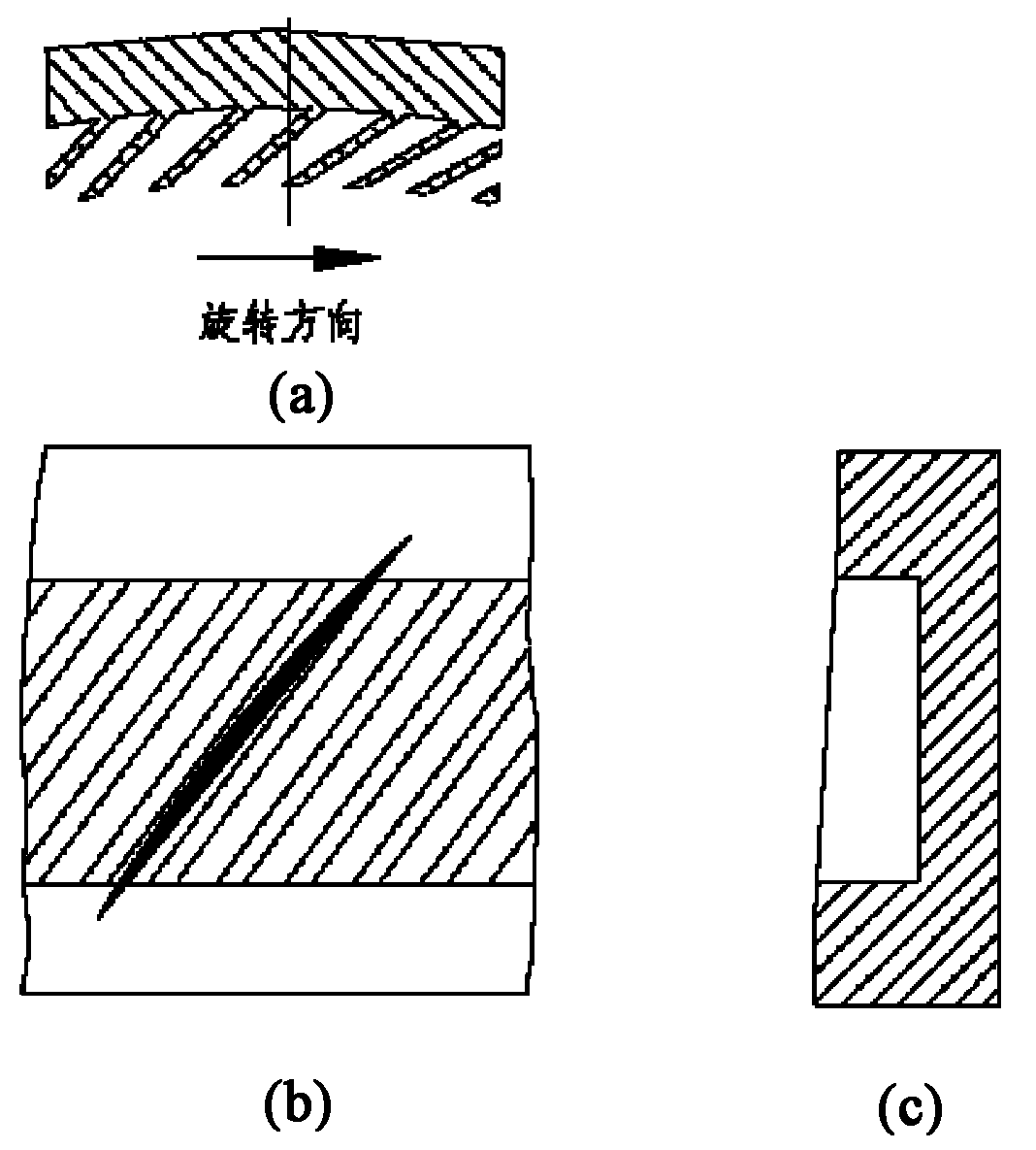

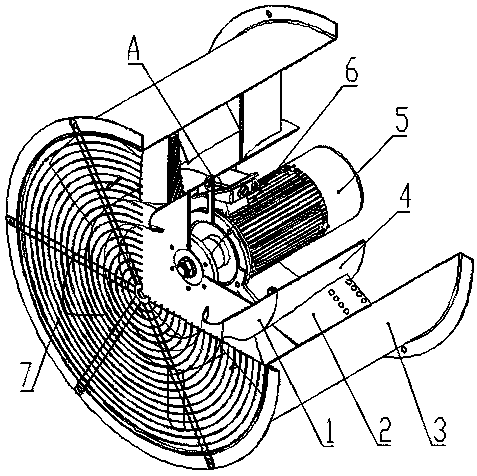

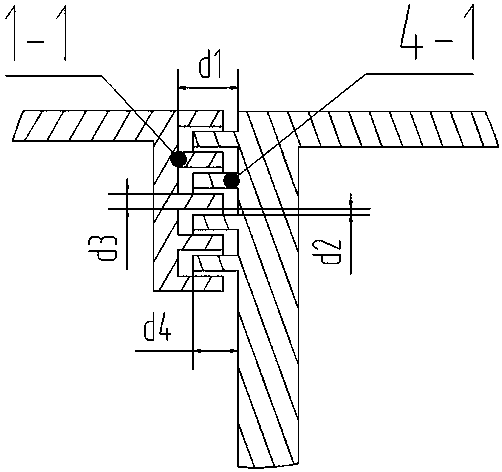

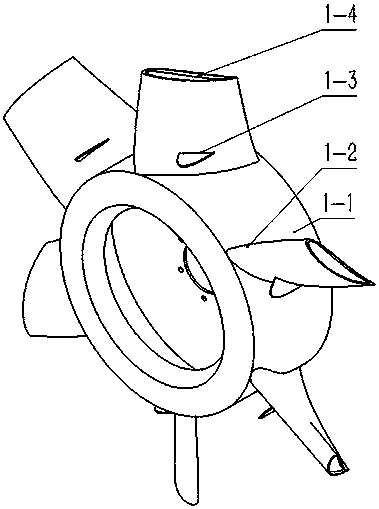

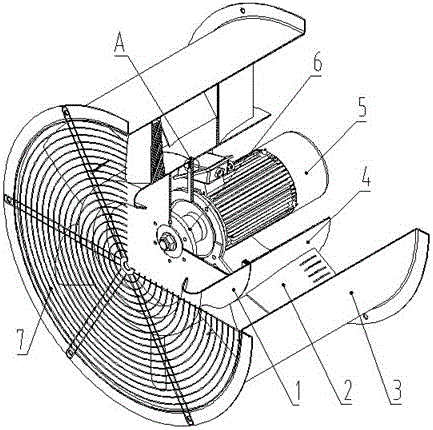

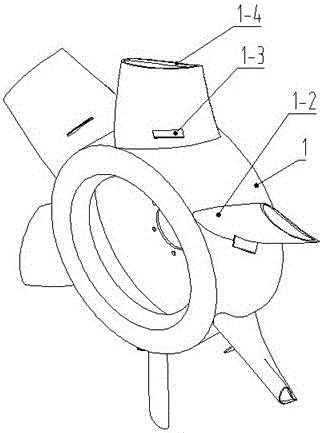

Axial flow blower

PendingCN107061329AImprove efficiencyReduce sizePump componentsPump installationsImpellerEngineering

The invention discloses an axial flow blower, which comprises a net cover, an impeller, a guide vane, an inner cylinder, an outer cylinder, a motor and a shaft sleeve. The net cover is fixed on the outer cylinder, is of a concentric structure and is formed by weaving iron wires; the impeller comprises a wheel hub and vanes, and the vanes are airfoil vanes which are designed through a constant circulation isolated airfoil method; a fin-shaped vortex breaking structure is arranged on a part, close to the root, of the suction surface of each vane; the top parts of the vanes are machined into an airfoil groove structure; and a labyrinth seal structure is formed in a gap between the wheel hub of the impeller and the inner cylinder. The shark fin-like vortex breaking plate is additionally arranged on the part, close to the root, of the suction surface of each vane of the impeller of the axial flow blower, the airfoil groove is formed in the top of each vane of the axial flow blower, and the labyrinth seal structure is formed in the gap between the wheel hub of the impeller and the inner cylinder, and different positions of the axial flower blower are improved, so that the efficiency of the axial flow blower is relatively high, the noise is relatively low, and the energy conservation and environment protection are achieved preferably.

Owner:ZHEJIANG SCI-TECH UNIV

Axial flow fan with blade suction surfaces having vortex breaking structures and with grooves formed in blade tops

The invention discloses an axial flow fan with blade suction surfaces having vortex breaking structures and with grooves formed in blade tops. The vortex breaking structures are additionally arranged on the portions, close to roots, of the suction surfaces of blades of an impeller, the airfoil grooves are machined in the tops of the blades, a labyrinth seal structure is additionally arranged in the clearance between a hub and an inner barrel, rectangular grooves are machined in the tails of the suction surfaces of guide vanes, the size of channel vortexes in an impeller passenger can be restrained, and radial secondary flow is reduced. Development of leakage flow can be impeded, mixing of the leakage flow and main flow is weakened, and therefore leakage losses of the blade tops are reduced. A high throttling effect can be generated, the stability of airflow on an outlet of the impeller is improved, and the leakage amount of airflow at the roots of the blades is reduced. The thicknesses of boundary layers on the tails of the guide vanes can be well controlled, separation of the boundary layers is avoided, disengagement of the vortexes is restrained, and the disengaging frequency of the vortexes is reduced. By improving different positions of the axial flow fan, the axial flow fan is higher in efficiency, lower in noise and more environmentally friendly and saves more energy.

Owner:嘉兴笼列电子商务有限公司

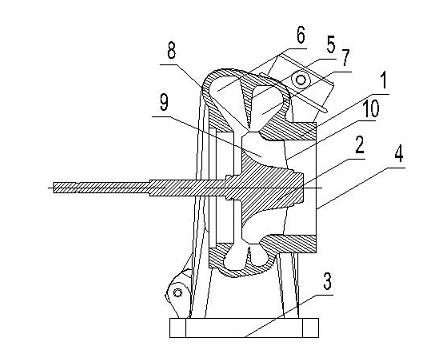

Air inlet sectioning device for internal combustion engine

ActiveCN101858281AReduce blendingImprove enduranceValve arrangementsCombustion-air/fuel-air treatmentCombustionExternal combustion engine

The invention discloses an air inlet sectioning device for an internal combustion engine in the field of four-stroke internal combustion engines. The device comprises at least one air inlet passage and at least two air inlet pipes; an air inlet aid control valve is arranged between the air inlet passage and the air inlet pipes; and when the opening and closing of the air inlet aid control valve are timed, the air inlet process of the air inlet passage is divided into at least two air inlet durations, and the air inlet passage is sequentially communicated with the corresponding air inlet pipes in the divided air inlet durations respectively. When the air inlet sectioning device is applied to the four-stroke internal combustion engine, gases with different components and / or gases with different pressures can be sectioned and sequentially pass through the air inlet passage in different air inlet durations to enter a cylinder so as to reduce the discharge of the internal combustion engine and / or improve the transient response performance of a turbocharged engine.

Owner:谢国华

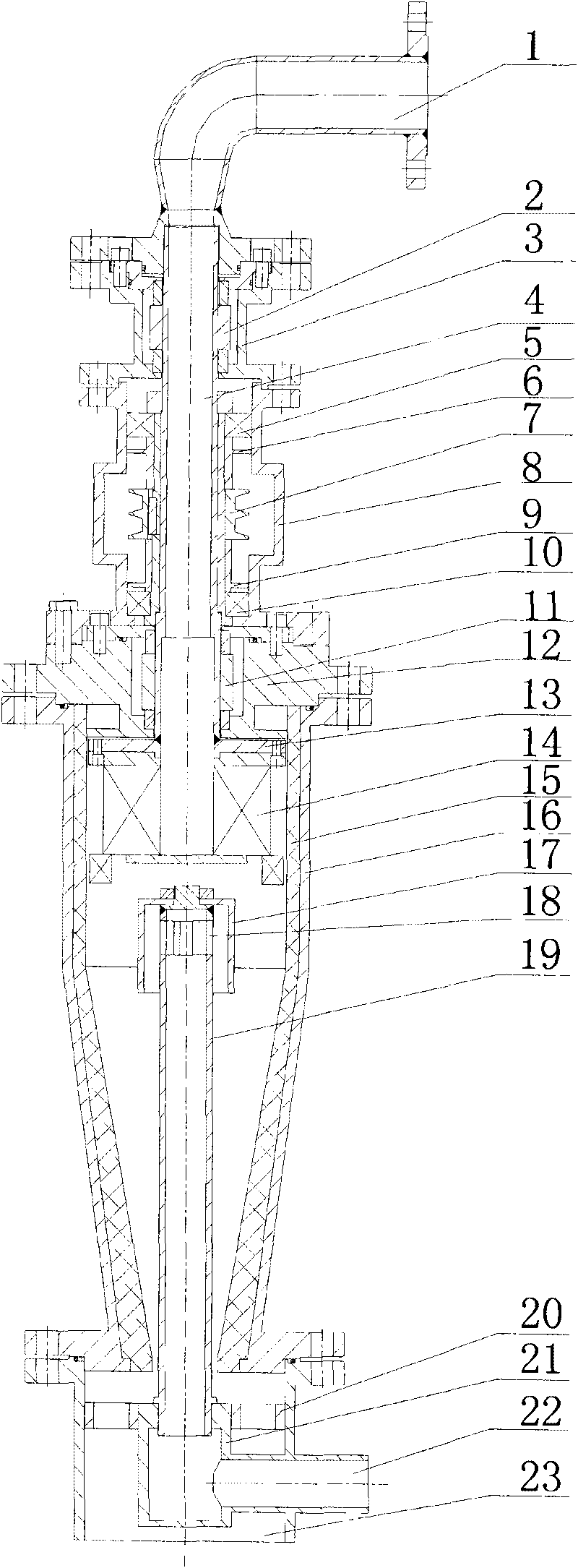

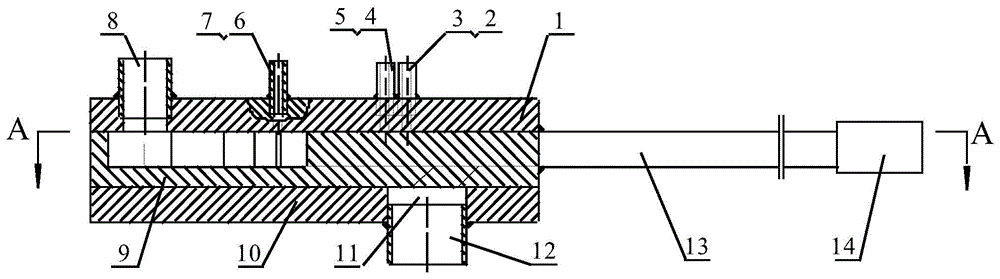

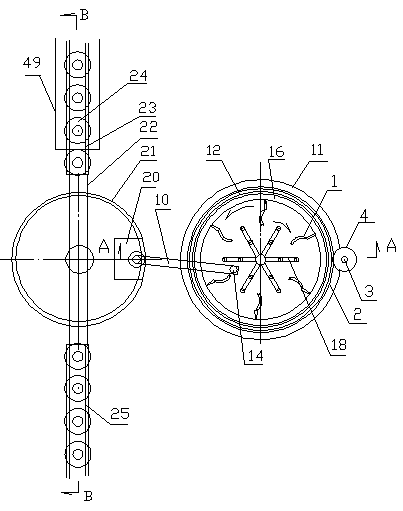

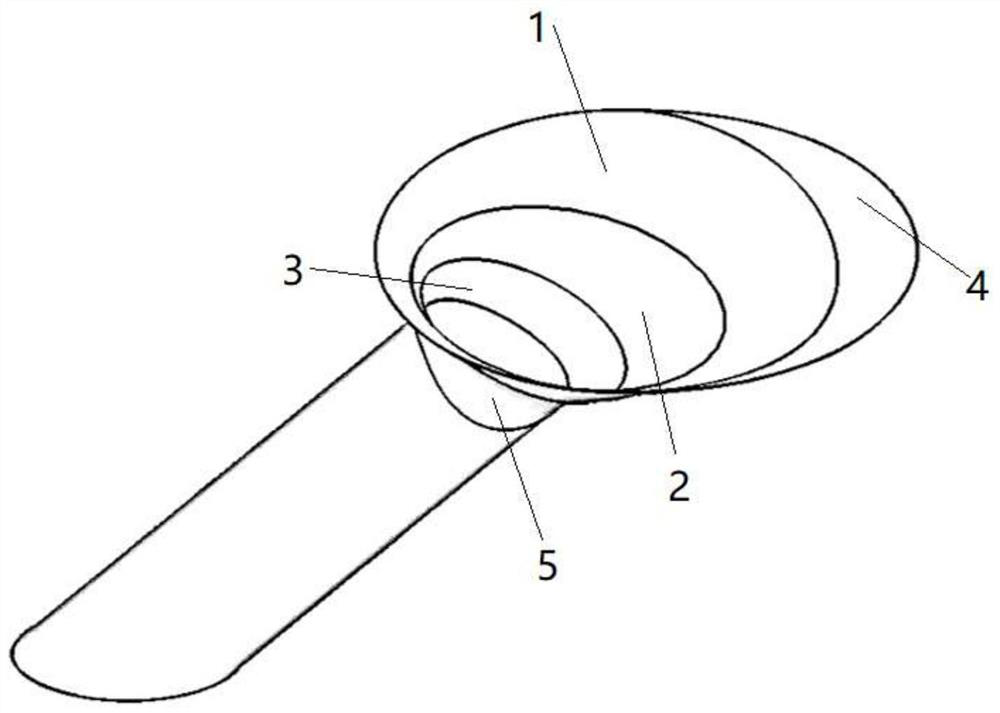

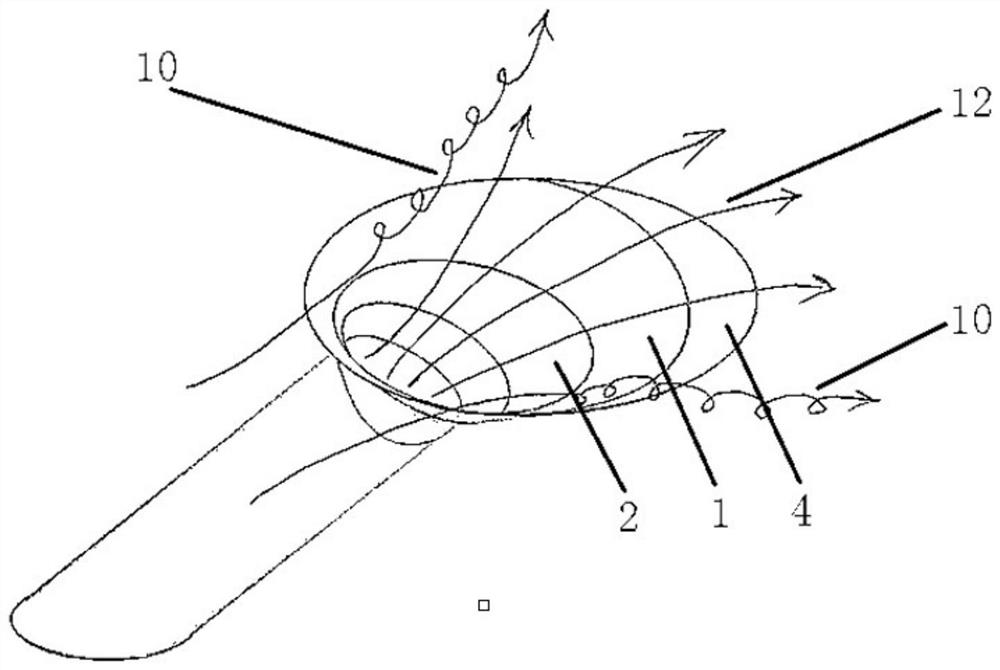

Dynamic prewhirl and axial push type hydrocyclone

The invention relates to a dynamic prewhirl and axial push type hydrocyclone which is composed of a medium prewhirl part and a hydrocyclone separating part. The invention is characterized in that materials are fed along the axial direction, a turnstile is used for prewhirl, the axial dimension of the turnstile is short and is not easy to vibrate; and the turnstile also has the function of boosting pressure, the pressure drop of the hydrocyclone is very low; a ring-shaped material axial propelling and accelerating structure is arranged in the outer ring area of the end part of the turnstile so that the axial flow on the periphery of the hydrocyclone is increased, the heavy component on the border can faster reach a heavy liquid outlet, the treatment capacity is increased, the outflow of the unseparated inner medium is reduced, and the axial velocity gradient between layers is reduced, thus avoiding entrainment and blending. A short-circuit-proof baffle cap is arranged at the outlet of light liquid which flows backward so that the feed mixed medium is prevented from flowing to the outlet of light liquid, namely short circuit outflow while the separating efficiency is increased. The invention is applicable to the efficient separation of liquid-solid two-phase with solid particles or oil-water two-phase with solid particles.

Owner:DALIAN UNIV OF TECH

Tin liquor processing method for float glass and ultra-thin float glass

The invention relates to the technical field of glass production equipment, and in particular to a tin liquor processing method for float glass and ultra-thin float glass, and is characterized in that a baffle bank is arranged in a high-temperature region in which the flattening and the polishing of the float glass are finished to control the flow of the tin liquor; and a tin liquor slot is divided into a plurality of temperature control regions according to the manufacturing technique of the tin liquor, and the temperature control regions are formed by arranging a plurality of corresponding horizontal baffle bank structures in the tin liquor slot, so as to control the convection of tin liquor in each region. The method overcomes the defects of the prior art, remarkably solves various problems of the prior art, and has the advantages that the structure is novel, the production is stable, the tin liquor flow is effectively reduced and controlled, and no air bubble can be generated. The mounting and production operation of the upper edge sealing of a side wall brick can not be affected, if the baffle bank are required to be taken out during production, a metallic pressure plate is moved, and a side baffle bank can automatically float off under the action of tin liquor buoyancy force; and a middle baffle bank is hooked to a slot of the side wall brick and also can automatically float off, and the operation is safe and reliable.

Owner:CHINA TRIUMPH INT ENG

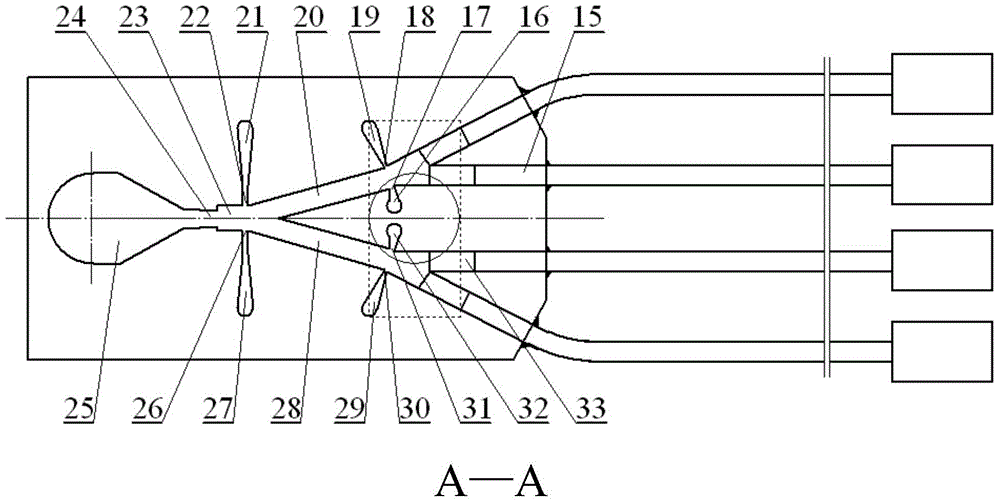

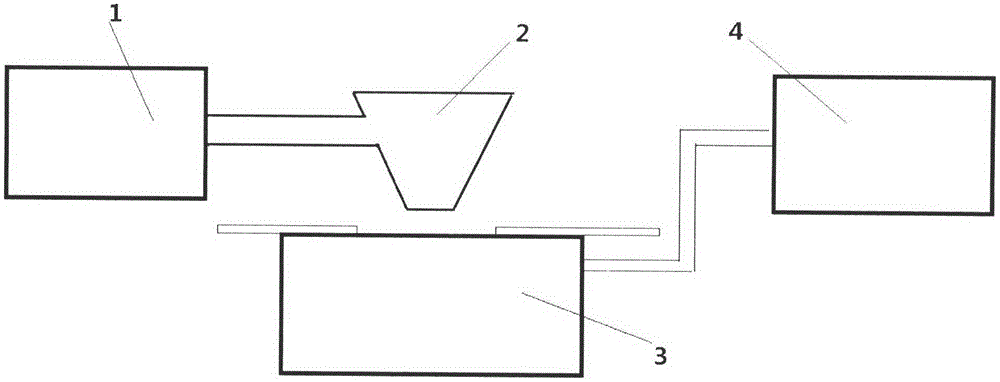

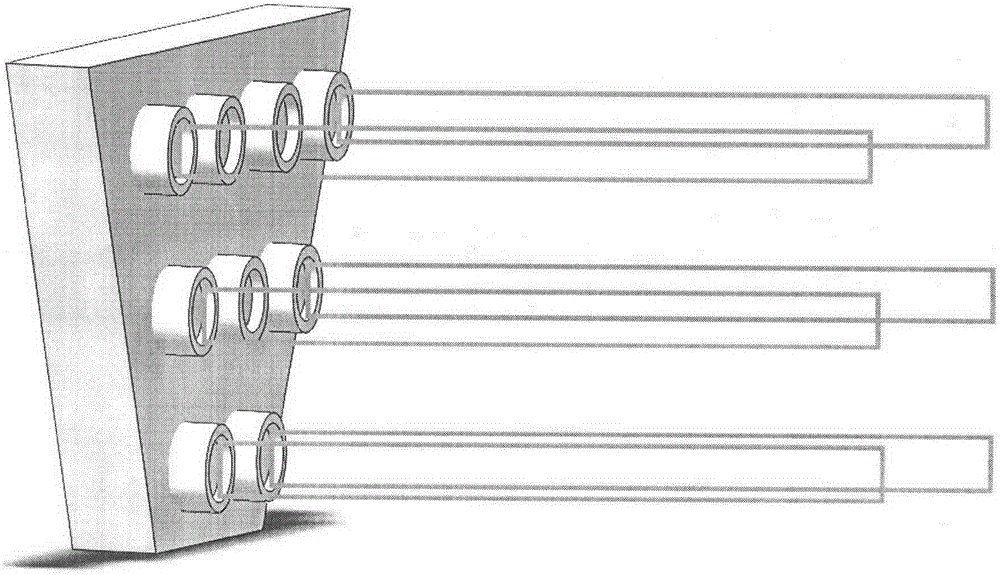

External-excitation multi-stage oscillation jet flow gas wave refrigerator

InactiveCN104315740AShort time to overcome jetSolve uneven traffic distributionCompression machinesRefrigeration componentsJet flowEngineering

The invention discloses an external-excitation multi-stage oscillation jet flow gas wave refrigerator. The external-excitation multi-stage oscillation jet flow gas wave refrigerator adopts a structure for halving a main jet flow passage by multiple times; excitation microstreams which switch time sequences through external modulation are used for exciting a main jet flow to successively generate multi-order mural switching oscillation; the main jet flow is sequentially distributed into multiple receiving tubes so as to achieve refrigeration. The external-excitation multi-stage oscillation jet flow gas wave refrigerator overcomes mechanism defects of an original single-tube or multi-tube static gas wave refrigerator, can greatly improve the refrigerating efficiency, also eliminates inherent defects that self-excited oscillation is large in jet energy loss, difficult in start-up and difficult to adjust oscillation frequency and the like, and has the advantages of small energy loss, easy start-up, adjustability of oscillation frequency, load matching and the like; the external-excitation multi-stage oscillation jet flow gas wave refrigerator can be applied to a scattered pressure energy utilization occasion and high-pressure and bad occasions, and has the effects of high pressure energy conversion efficiency, free maintenance, reliable operation and the like.

Owner:DALIAN UNIV OF TECH

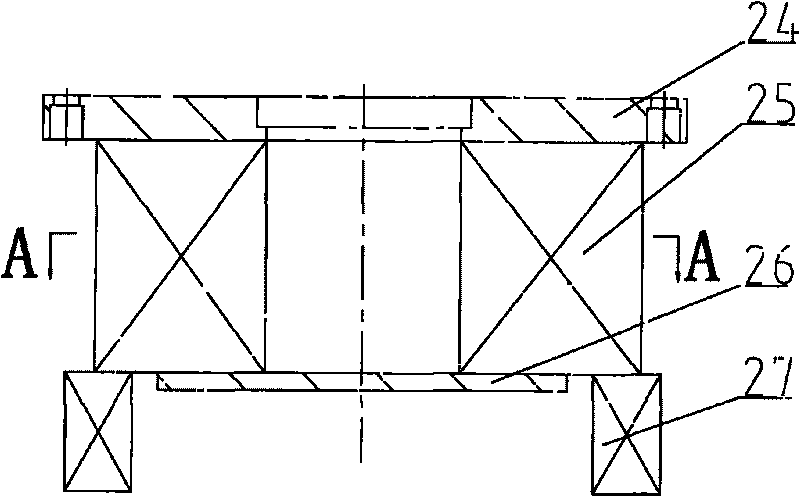

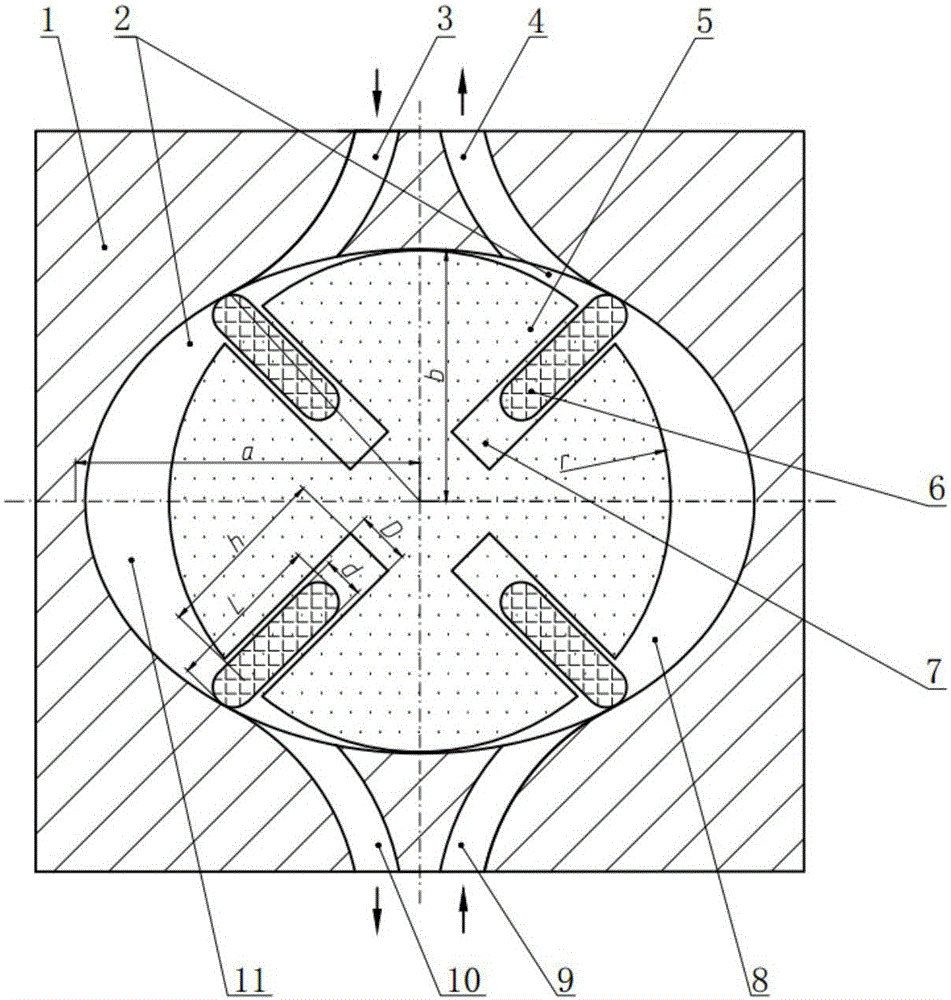

Sliding sheet type overpressure recovery equipment

ActiveCN105782021ASimple structureLow processing and installation accuracy requirementsRotary piston pumpsRotary piston liquid enginesStream flowEngineering

The invention discloses sliding sheet type overpressure recovery equipment and belongs to the technical field of overpressure recovery. According to the sliding sheet type overpressure recovery equipment, main curved sections of cylinder profile lines in left and right cavities are in an arched shape; flow inlets and outlets are streamline pore channels; a cylinder inner cavity profile line is formed by connecting an arched sealing section, a curve transition section with an arched main curve section; and two adjacent curves are in a second order continuous manner. When being bilaterally symmetric mold cavities, working cavities can be applied to treating the working condition of same stream flow on the two sides; when being the mold cavities without bilateral symmetry, the working cavities can be applied to treating the working condition of different stream flows on the two sides. The sliding sheet type overpressure recovery equipment has a simple structure, is little in mixing fluids and lower in requirement for processing installation accuracy and can be applied to treating the working conditions of same or different flows on the two sides. Through the sliding sheet type overpressure recovery equipment, the overpressure of high-pressure, pressurized and low-pressure fluids are recycled and reused and has important significance of lowering system energy consumption and production cost and promoting energy conservation and emission reduction.

Owner:苏州小步快跑科技有限公司

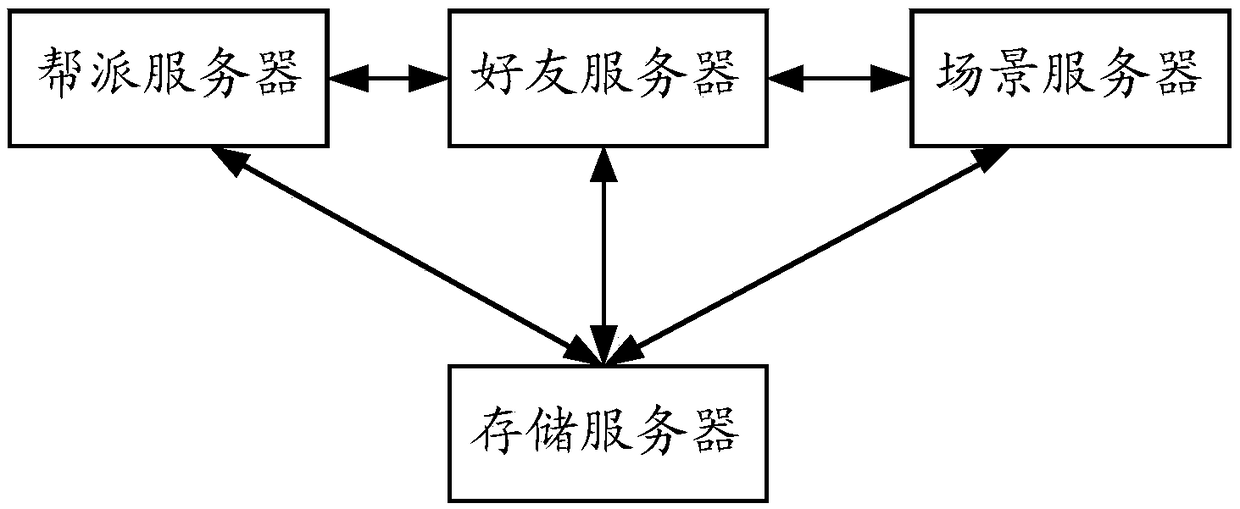

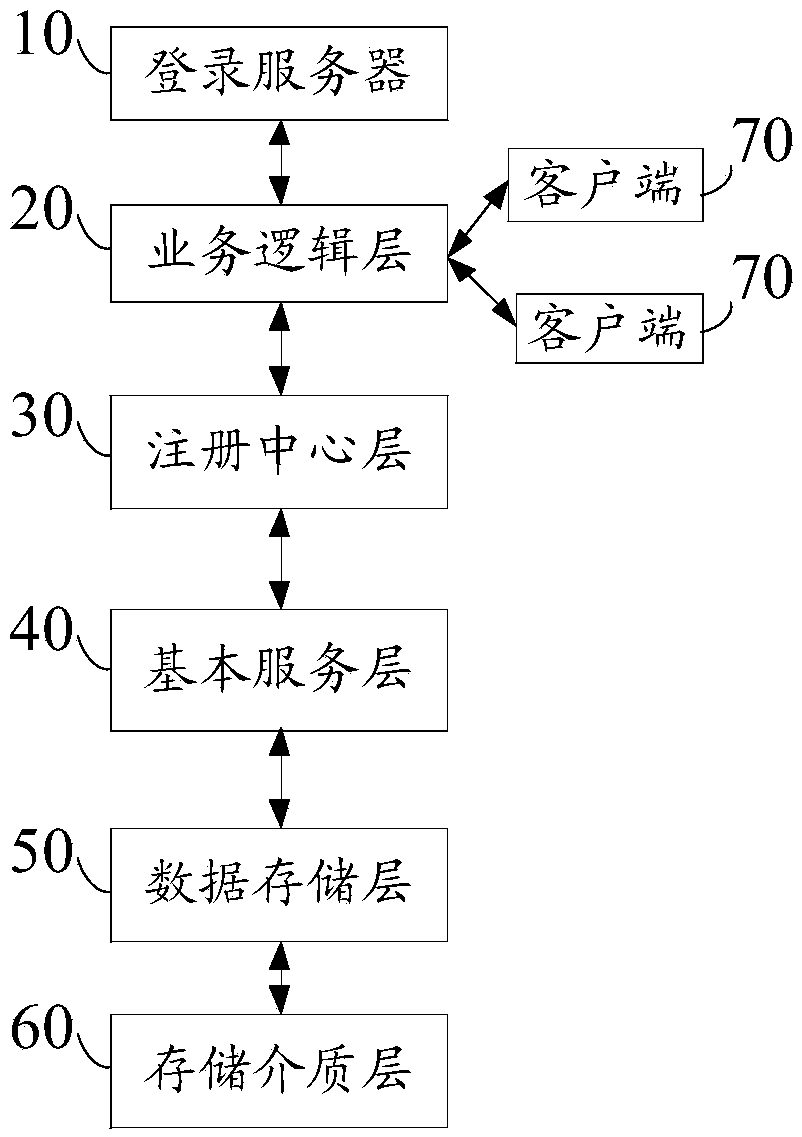

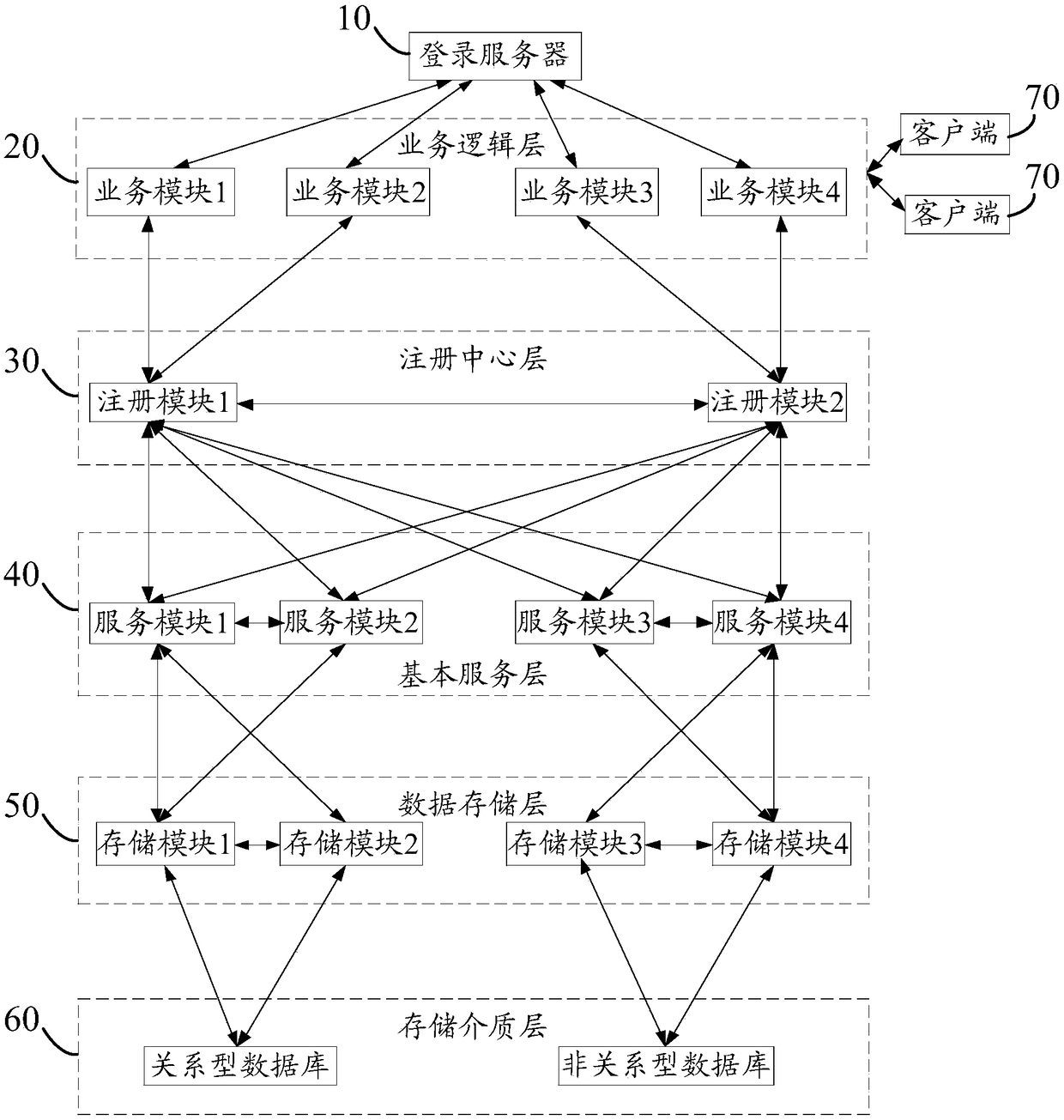

Game service system and implementation method thereof

The embodiment of the invention provides a game service system and an implementation method. The game service system includes a login server, a service logic layer comprising a plurality of service modules respectively connected with the login server, a client and a registration center layer, a registration center layer comprising a plurality of registration modules connected with the basic service layer, a basic service layer comprising a plurality of service modules connected with a data storage layer, a data storage layer comprising a plurality of storage modules, the data storage layer being connected with a storage medium layer, and a storage media layer including a storage medium. Since each layer includes multiple independent functional modules, forms a distributed connection so asto form a distributed system, and each layer is responsible for different business data processing. On the one hand, even if one module in each layer is down, the corresponding business processing canbe carried out by other modules in this layer, which will not affect the operation of the whole game service system. On the other hand, each module in each layer is independent of each other, which reduces the degree of integration between each layer and the difficulty of system development.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

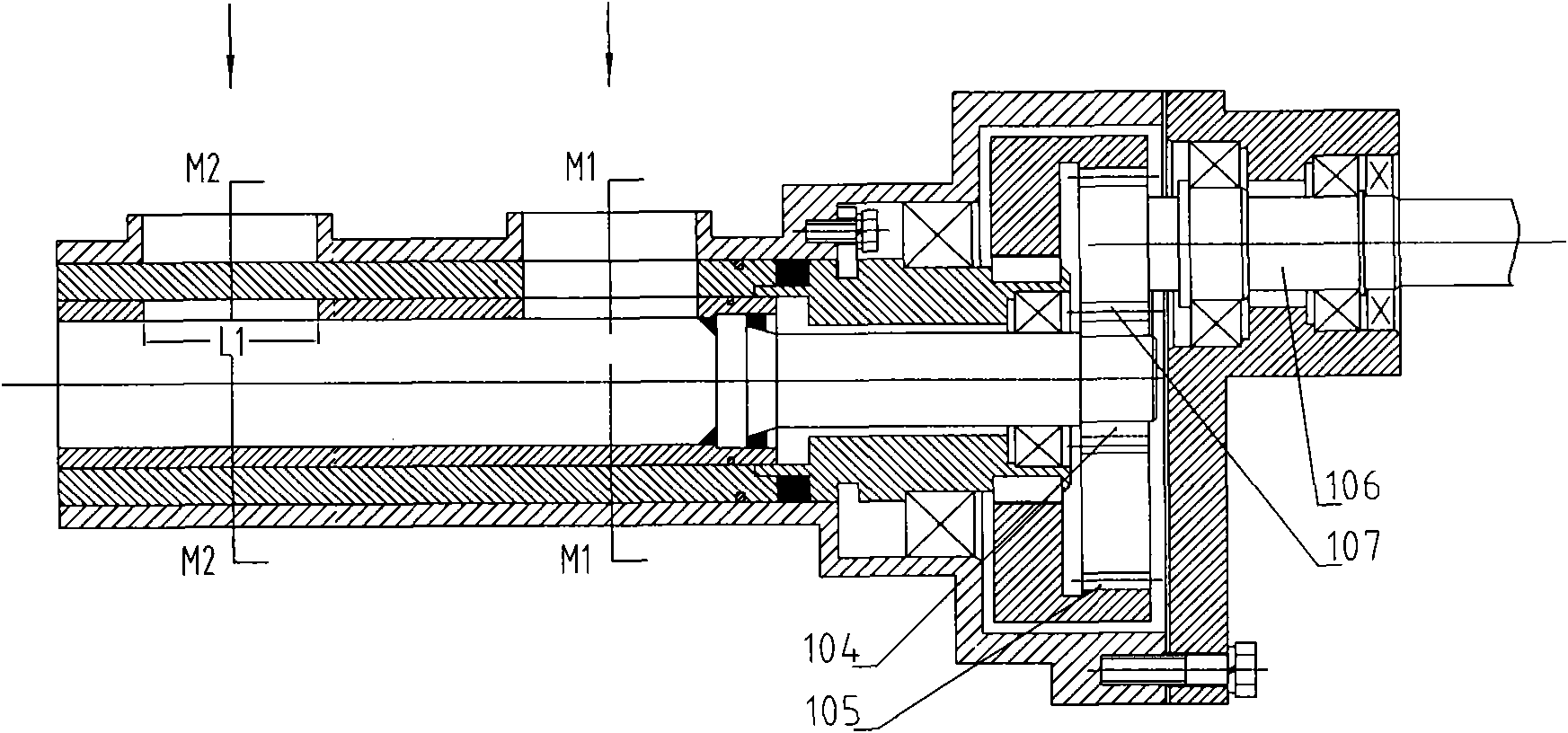

Dual-zone turbine for turbocharging

InactiveCN102661180AImprove efficiencyIncreased torque outputInternal combustion piston enginesStatorsImpellerTurbine blade

The invention discloses a dual-zone turbine for turbocharging. The dual-zone turbine comprises a turbine volute, wherein a turbine impeller is arranged in the turbine volute; a turbine blade is arranged outside the turbine impeller; a turbine air inlet, a volute air inlet runner and a volute air outlet are arranged on the turbine volute; a turbine impeller air inlet, a turbine impeller air inlet runner, a turbine impeller air outlet and a turbine impeller blade are arranged on the turbine impeller; separation boards which are arranged according to the circumferential direction are arranged between the turbine impeller air inlet and the turbine impeller air outlet of the turbine impeller; and the turbine impeller air inlet runner is divided into an inner turbine impeller air inlet runner and an outer turbine impeller air inlet runner by the separation boards. According to the dual-zone turbine disclosed by the invention, the supercharging requirement of an engine within the all-condition range can be effectively met; the phenomenon that gas suddenly expands at a single runner air outlet of the volute at low flow can be reduced; and the efficiency of the turbine at low flow can be further increased.

Owner:KANGYUE TECH

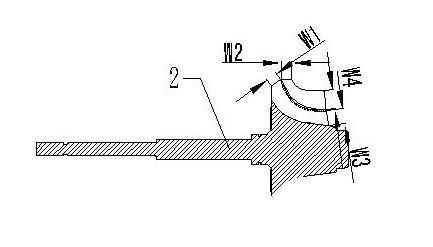

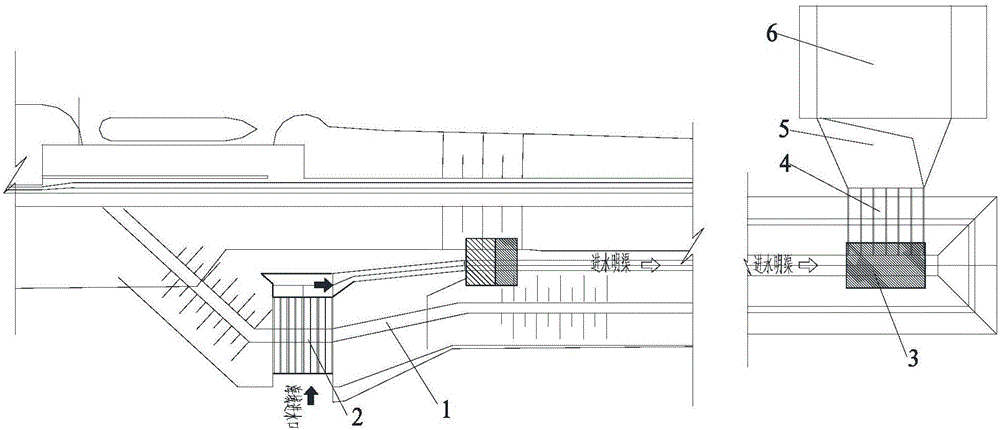

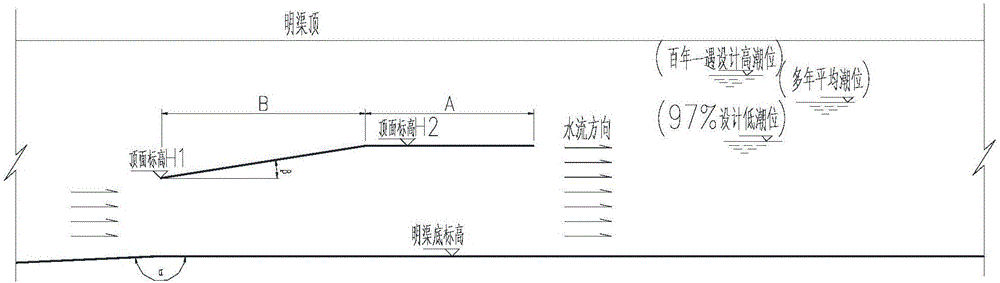

Electric power plant water diversion open ditch flow guide heat insulation device and design method thereof

ActiveCN106227980AObvious stratificationWater flow rate is smallGeometric CADDesign optimisation/simulationEconomic benefitsEngineering

The invention discloses an electric power plant water diversion open ditch flow guide heat insulation device and a design method thereof. The device comprises a folded plate type flow guide plate and a flat plate type flow guide plate, wherein the folded plate type flow guide plate comprises a first inclined plate and a first flat plate; one end of the first inclined plate is arranged at an entrance position of an open ditch; the other end of the first inclined plate is connected with the first flat plate; the side edge of the first inclined plate and the side edge of the first flat plate are fixed on the side wall of the water diversion open ditch; the flat plate type flow guide plate is arranged in a connecting position of an exit of the open ditch and a water inlet rectifier box, and comprises a second flat plate; the side edge of the second flat plate is fixed on the side wall of the water diversion open ditch. According to the design method provided by the invention, the design parameters of the current water diversion open ditch and rectifier box culvert and the like is obtained; hydromechanics software is used for building the open ditch flow state of the device provided by the invention; the value calculation optimization is further performed to achieve the goal. The electric power plant water diversion open ditch flow guide heat insulation device and the design method have the advantages that the temperature rise influence of sun radiation on the water body in the water diversion open ditch conveying process can be effectively reduced; the cooling water taking temperature of an electric power plant is reduced; the efficiency of a power generating set is improved; high economic benefits and application popularization values are realized.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

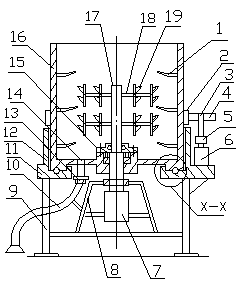

Glaze mixing and glazing surface dry integrated device for cylindrical porcelain insulator

ActiveCN110843107AIncrease productivityReduce labor costsRotating receptacle mixersTransportation and packagingEngineeringIntegrated devices

The invention discloses a glaze mixing and glazing surface dry integrated device for a cylindrical porcelain insulator. The glaze mixing and glazing surface dry integrated device comprises a glaze mixing mechanism and a glazing surface dry mechanism, wherein the glaze mixing mechanism comprises a machine frame, a flange seat and a stirring barrel, the flange seat is arranged on the machine frame,the stirring barrel can rotate on the flange seat, a main shaft is arranged on the barrel bottom of the stirring barrel, the rotating direction of the main shaft is opposite to that of the stirring barrel, cross bars are arranged on the main shaft at intervals, inner stirring plates are arranged on the cross bars at intervals, and outer stirring plates are arranged on the inner side wall of the stirring barrel at intervals; and the glazing surface dry mechanism comprises a glazing barrel, an input frame, an output frame, a tunnel type drying furnace and a lifting device, wherein the lifting device comprises a rolling wheel which can move left and right, a rope roller is arranged on the rolling wheel, a steel rope capable of lifting the supporting frame up and down is arranged on the roperoller, and a clamping head capable of opening and closing is fixedly arranged in the bracket According to the glaze mixing and glazing surface dry integrated device, the labor hour cost can be reduced, the surface quality of a glaze layer can be improved, the working environment is improved, the production efficiency is improved, and large-scale mass production is facilitated.

Owner:江西省萍乡市鑫泰瓷业有限责任公司

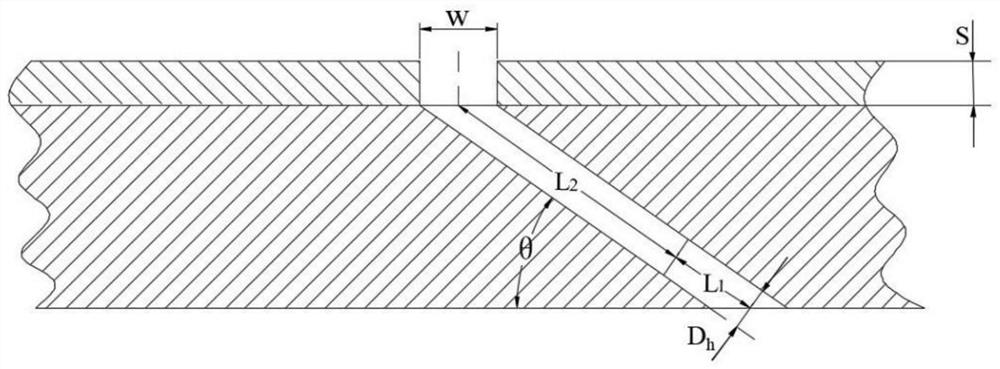

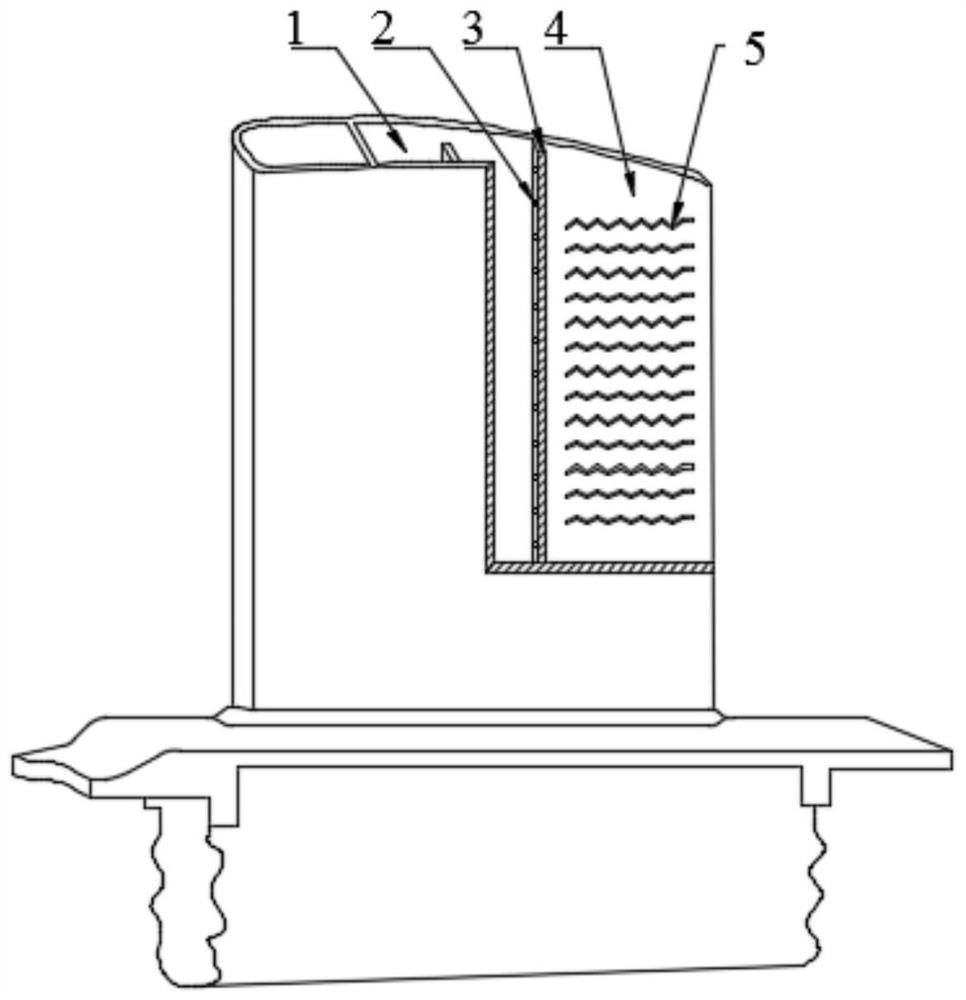

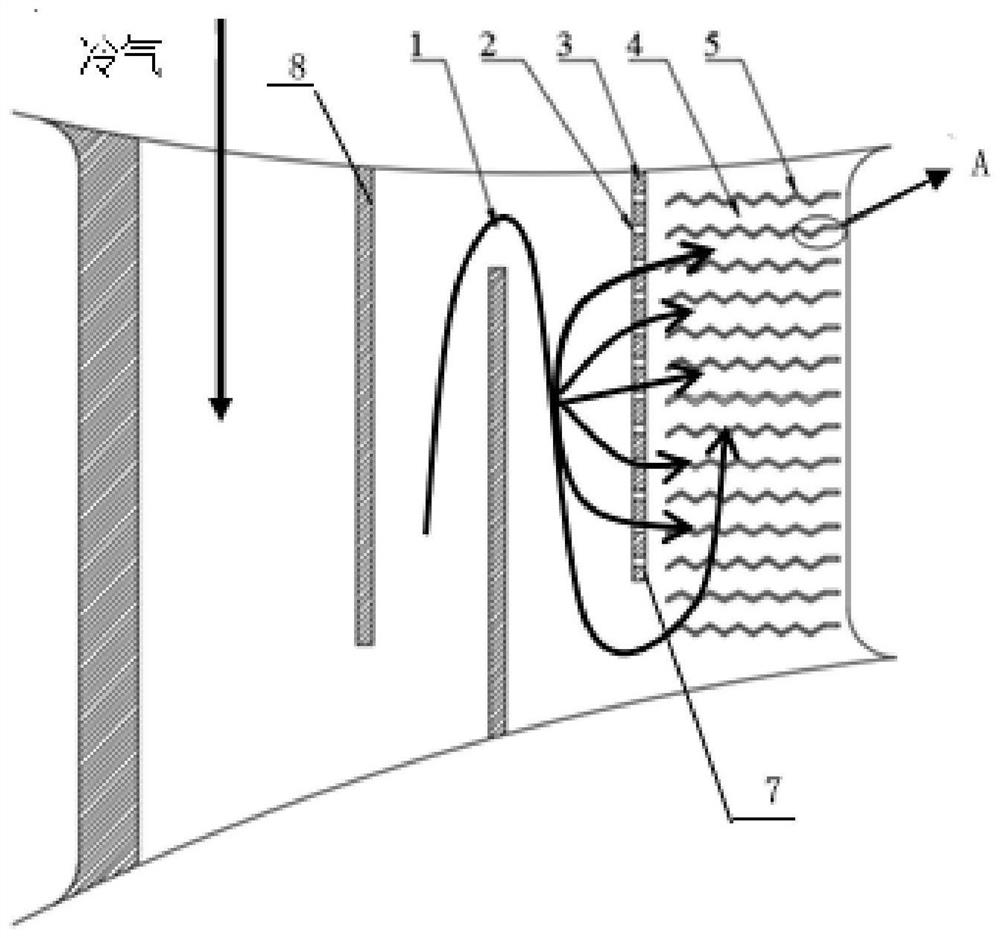

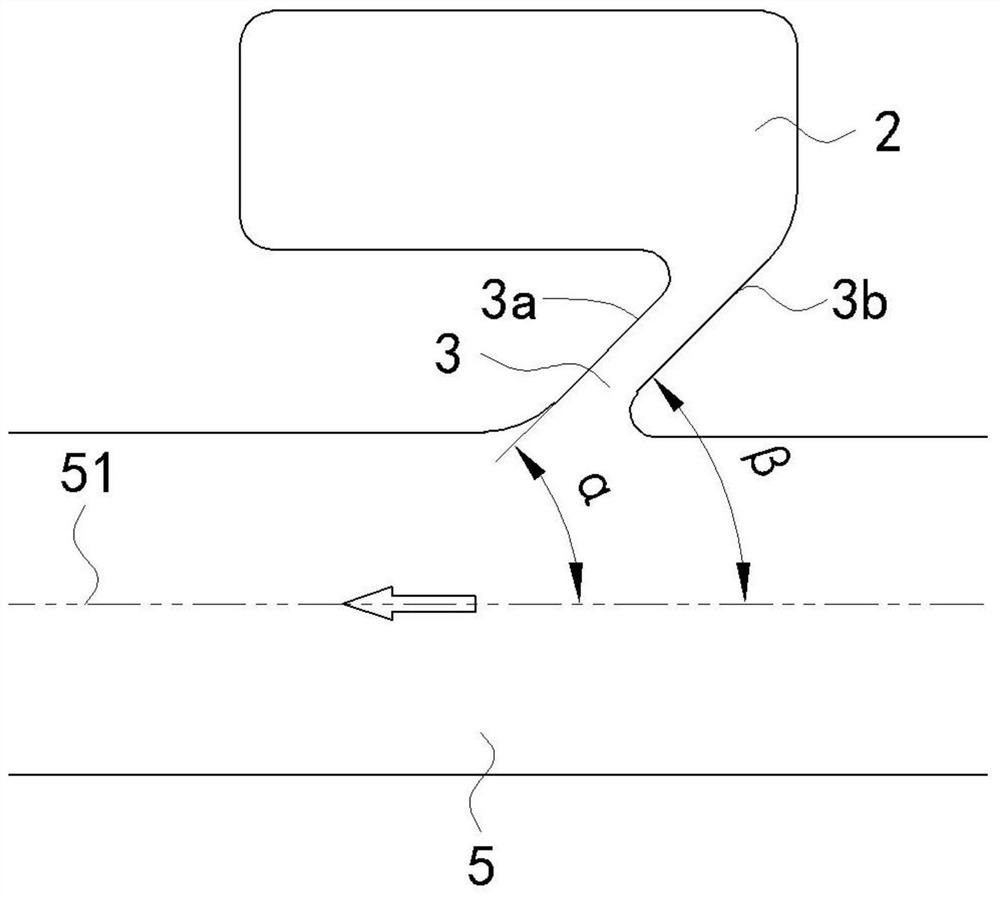

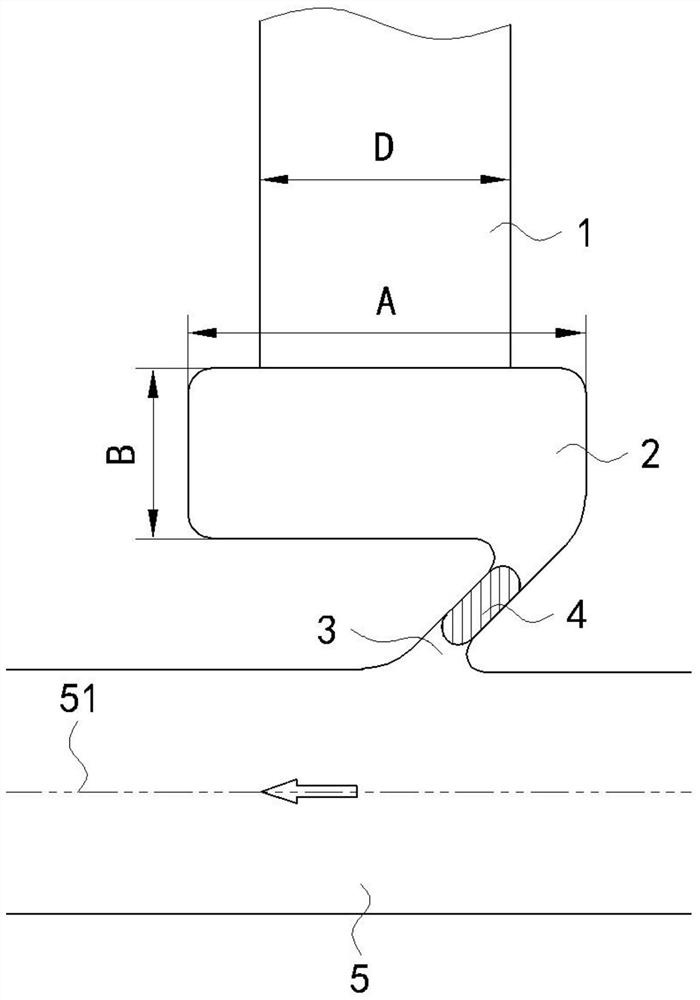

Novel air film cooling slotting structure

ActiveCN105822355APlay the role of diversionReduce resistanceBlade accessoriesMachines/enginesEngineeringElectrical and Electronics engineering

The invention relates to a novel air film cooling slotting structure which comprises an air film hole, a transverse slot and a wall face. The air film hole is formed in the upstream area of the wall face, and the transverse slot is formed in an outlet of the air film hole. The novel air film cooling slotting structure is characterized in that a down-flow stair is formed at the middle position of the downstream slot wall of the transverse slot of the structure; flow guide faces are symmetrically arranged on the two sides of the down-flow stair; the plane, in the incoming flow direction, of the down-flow stair is perpendicular to the wall face; the lowest point of the down-flow stair is flush with the bottom face of the transverse slot, and the highest point of the down-flow stair is flush with the downstream wall face of the transverse slot; the down-flow stair is arranged symmetrically with the center line as an axis, wherein the center line passes through the center of an air outlet hole of the air film hole and is parallel to the wall face; a slope with the included angle ranging from 15 degrees to 75 degrees is formed between each flow guide face and the wall face; and the ratio of the maximum projection longitudinal length of one step of the down-flow stair in the expanding direction of the wall face to the aperture of the air film hole ranges from 0.25 to 1.0, and the ratio of the maximum projection length of the down-flow stair in the transverse direction of the wall face to the aperture of the air film hole ranges from 1.0 to 4.0.

Owner:HEBEI UNIV OF TECH

Air film cooling structure with surface recesses, turbine blade and turbine

ActiveCN112780356AReduce processing costsImprove processing efficiencyBlade accessoriesMachines/enginesTurbine bladeEngineering

The invention provides an air film cooling structure with surface recesses. The cooling structure comprises a recess structure and an air film hole, and the air film hole is smoothly connected with the recess structure; airflow spreads to the recess structure through the air film hole to form an air film, and the air film spreads to the surface of a turbine blade; the recess structure comprises a first recess and a second recess, the second recess is arranged on the inner wall surface of the first recess, and the air film hole is formed in the inner wall of the second recess; an air film hole opening of the air film hole is provided with a rounding structure or a beveling structure; and / or the edge of the rear part of the first recess is provided with a rounding structure or a beveling structure. The invention further provides the turbine blade. Air film cooling structures arranged in an array manner are arranged on the wall face of the turbine blade. The recesses restrain reverse vortex pairs formed by air film flowing on the downstream wall surface; and the air film hole and the double-recess structure enable airflow flowing out of the air film hole to be tightly attached to the wall face. Compared with a conventional inclined hole, the air film cooling structure has the advantages that the air film cooling efficiency and the machining efficiency are higher, and the machining cost is lower.

Owner:SHANGHAI JIAO TONG UNIV

Garbage treatment incineration furnace with laminar plasma as heat source

InactiveCN105020718AEfficient and mobile useEasy to assembleIncinerator apparatusCore temperatureEngineering

The invention discloses a garbage treatment incineration furnace with laminar plasma as a heat source; an incineration system uses domestic unique high-power laminar plasma equipment, and adopts the most advanced laminar plasma incineration technology in the world at present; and the core temperature of laminar plasma gas can reach 20,000 DEG C. Laminar plasma generation electrode spraying holes are staggered; the incineration furnace adopts a horizontal structure; and a garbage inlet and a residue treatment outlet are both electrically controlled, so that full automation is realized. The system can be applied to a mobile platform locomotive or a ship; and all functions are modularly designed and configured. The treatment furnace can be totally closed, so that the interior of the furnace is located in a low oxygen state, and fewer poisonous substances are generated when garbage is decomposed. The garbage treatment system is high in automation degree, modular in design, convenient for use and maintenance, thorough in garbage incineration and low in pollution.

Owner:龙伟 +1

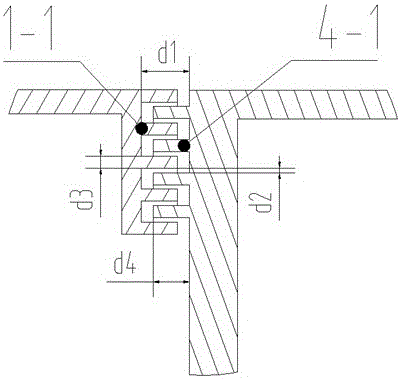

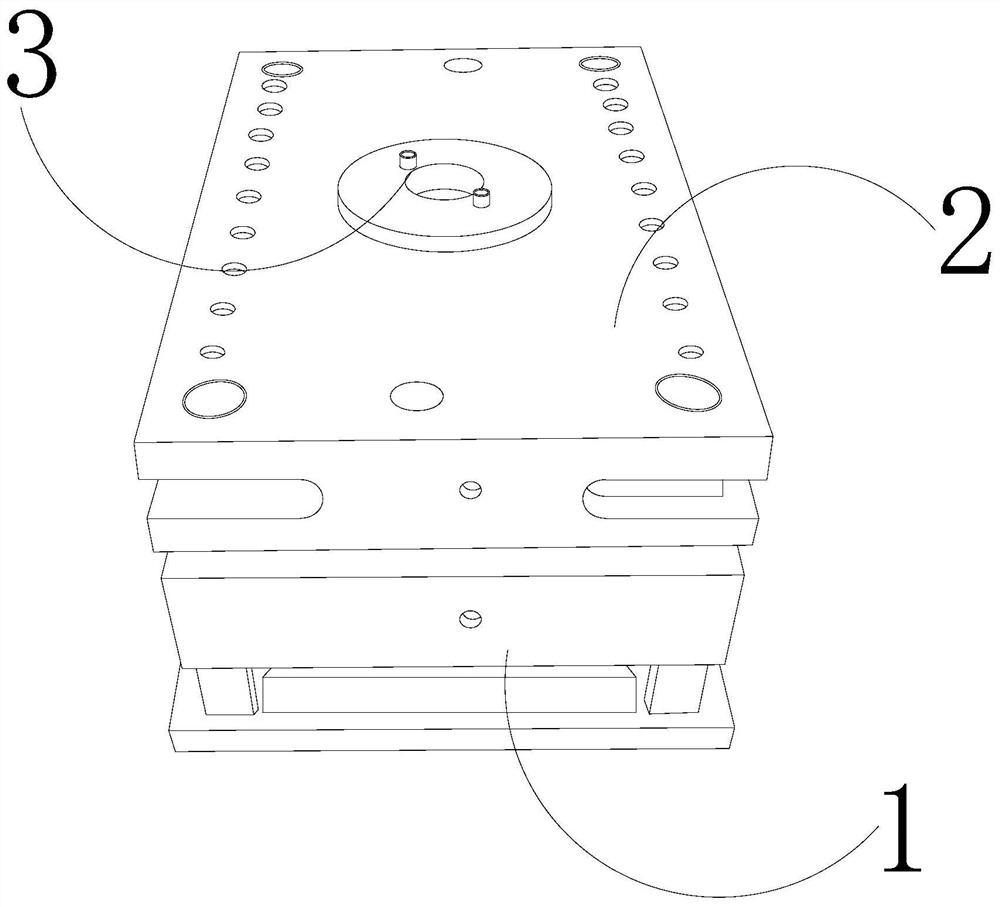

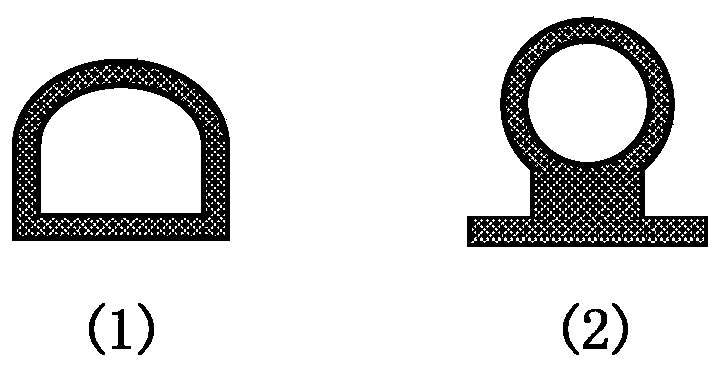

Self-supporting optical cable sheath extrusion die

InactiveCN112078114AEasy injection moldingUse time does not changeFibre mechanical structuresParticle packingInjection moulding

The invention discloses a self-supporting optical cable sheath extrusion die which structurally comprises a supporting seat, an upper module and an injection molding port. The upper module is movablymatched with the top of the supporting seat. When the die is used for injection molding of a sheath, as a polypropylene solution is easy to be scorched into particles and accumulated on the inner wallof a forming cavity, the polypropylene solution flows to push an eliminating block to move along the inner wall of the forming cavity and a brushing block on the top of a moving block of the eliminating block eliminates the scorched particles on the inner wall of the forming cavity to reduce the probability that the scorched particles are accumulated on the inner wall of the forming cavity, so that injection forming of the sheath is protected favorably. A using time of the protecting sheath is not changed. As the particles brushed by the brushing block fall downward and are easily blended inthe solution, the scorched particles in a clamping block are collected, and the scorched particles blended in the solution are reduced, so that the quality of injection molding of the protecting sheath is protected. A baffle plate changes along with a moving position of an eliminating ring, so that a chip inlet of the clamping block is opened and closed, and therefore, the particles are collectedfavorably and backflow of the particles is reduced.

Owner:北京鸿运汇商贸有限公司

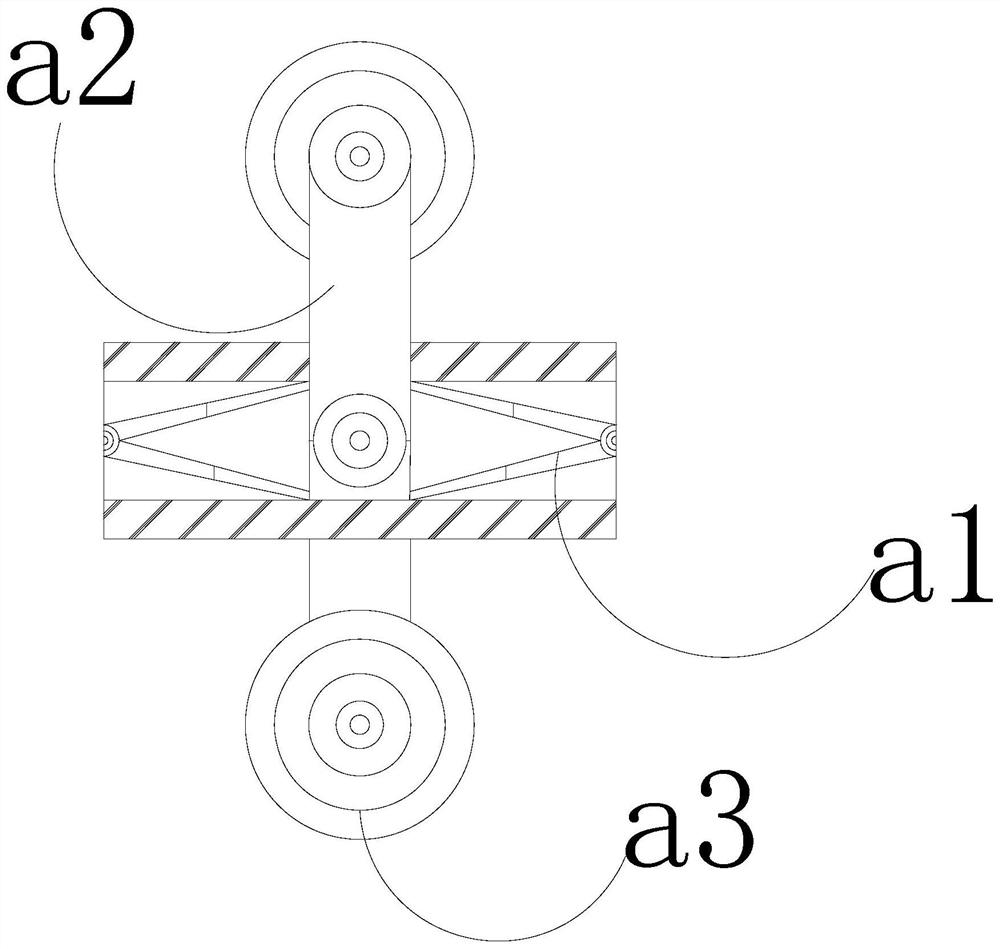

Tight coupling ring rectangular hole gas nozzle atomizer capable of improving atomization efficiency

The invention provides a tight coupling ring rectangular hole gas nozzle atomizer capable of improving the atomization efficiency which comprises a liquid guide pipe and a lower body arranged on the outer surface of the liquid guide pipe in a sleeved mode; the atomizer comprises an upper body which is a hollow tube body structure and is sleeved outside the lower body, and a closed gas parking space capable of stabilizing the gas pressure is formed between the upper body and the lower body; the inner surface of the upper body end port is a conical surface or a conical-shape surface which is inclined towards the tail end of the liquid guide pipe; the outer surface of the lower body end port is in sealing contact with the conical surface or the conical-shape surface of the upper body througha corresponding cone shape surface, between the contact of lower body and the upper body; and a plurality of rectangular gas nozzles communicating with the outside and the gas parking space are uniformly arranged along the circumference. The rectangular channel can be a two-dimensional contraction type or two-dimensional contraction-expand (laval) type gas nozzle. According to the atomizer, the efficiency for the kinetic energy of the high-speed airflow on the relatively static liquid and liquid drops is improved, and the liquid and the liquid drops are atomized into finer liquid drops.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

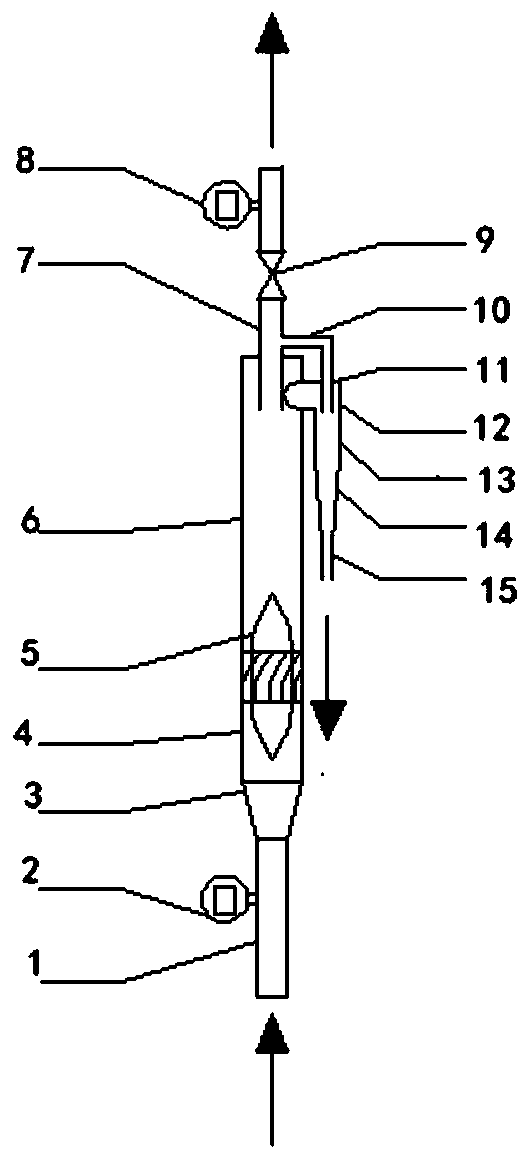

Air film cooling composite hole structure for turbine blade and turbine blade

ActiveCN113356932AReduce blendingFacilitated DiffusionBlade accessoriesEfficient propulsion technologiesCold airCompression action

The invention belongs to the technical field of heat transfer and cooling of hot end components of gas turbines, and relates to an air film cooling composite hole structure for a turbine blade. The turbine blade comprises an air film hole plate and a thermal barrier coating arranged on the air film hole plate, a plurality of composite air film holes are formed in the air film hole plate, and a dumbbell-shaped groove is formed in the thermal barrier coating; and each composite air film hole comprises a spanwise expansion section and a straight hole section which communicate with each other, the straight hole sections communicate with an inner cooling channel of the turbine blade, and outlets of the spanwise expansion sections communicate with the dumbbell-shaped groove. The guiding effect of the dumbbell-shaped groove enables cooling air flow to be diffused in the groove in the transverse direction and the longitudinal direction, the jet flow momentum is weakened, and the spanwise covering capacity is greatly improved. In addition, the dumbbell-shaped groove changes the rotating direction of a kidney-shaped vortex pair, and the vortex pair develops towards the two sides of the groove under the compression action of main flow, so that the cold air jet flow is better attached to the wall surface; and the air film holes comprise the spanwise expansion sections at the outlets, so that the jet flow momentum can be further reduced, the diffusion of an air film in the groove is accelerated, and an excellent cooling effect is achieved.

Owner:XI AN JIAOTONG UNIV

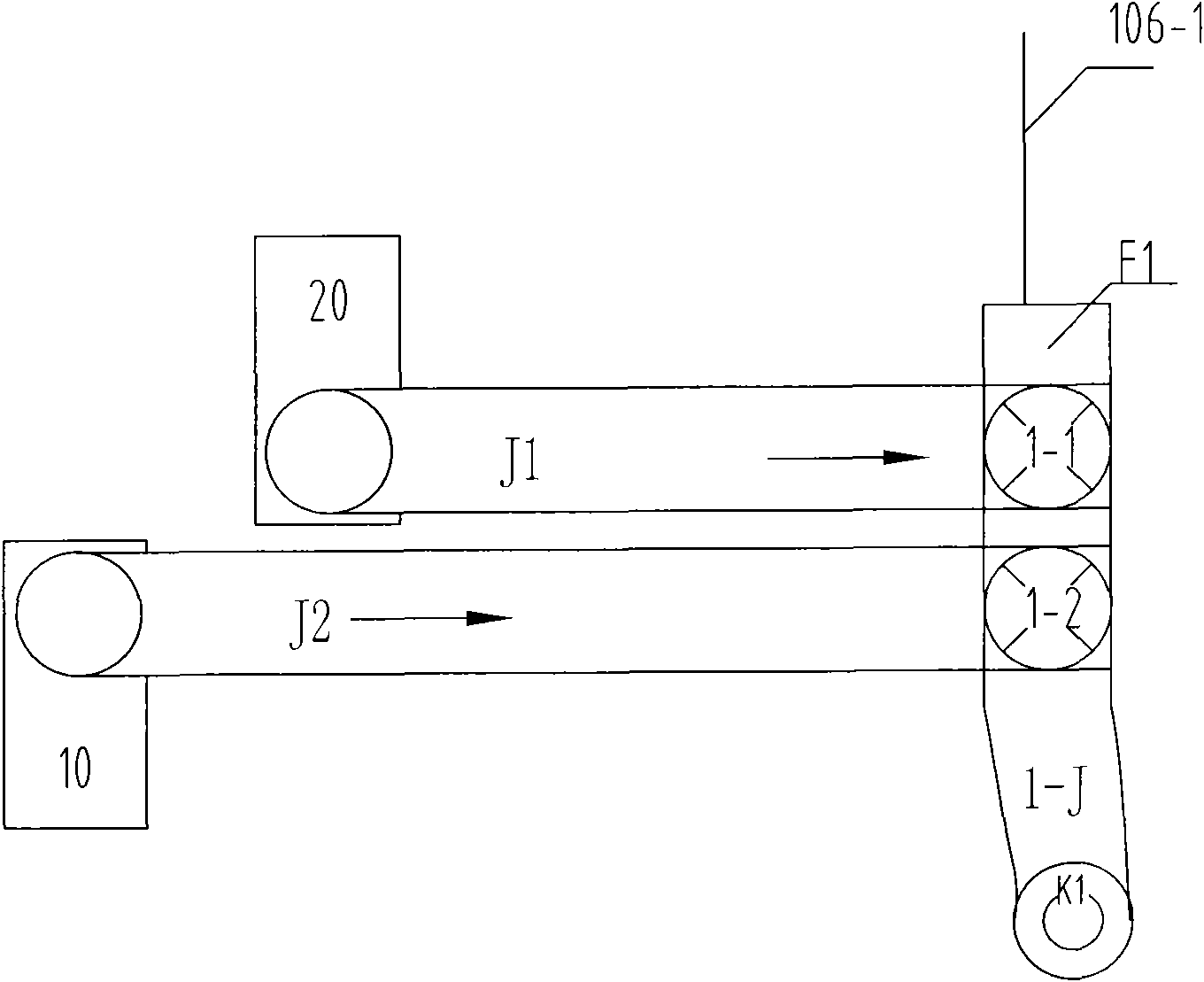

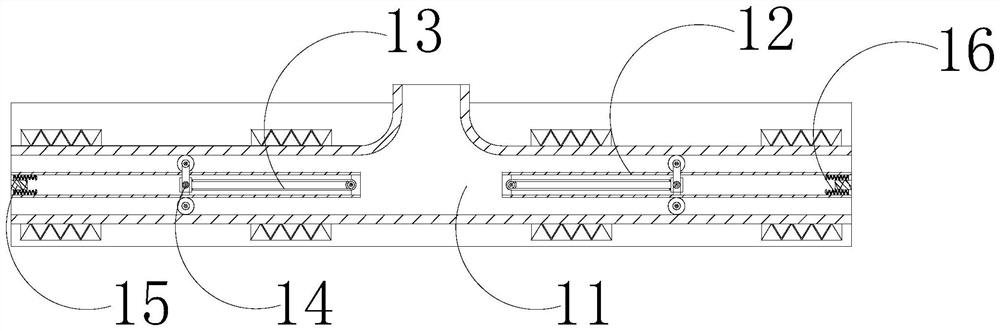

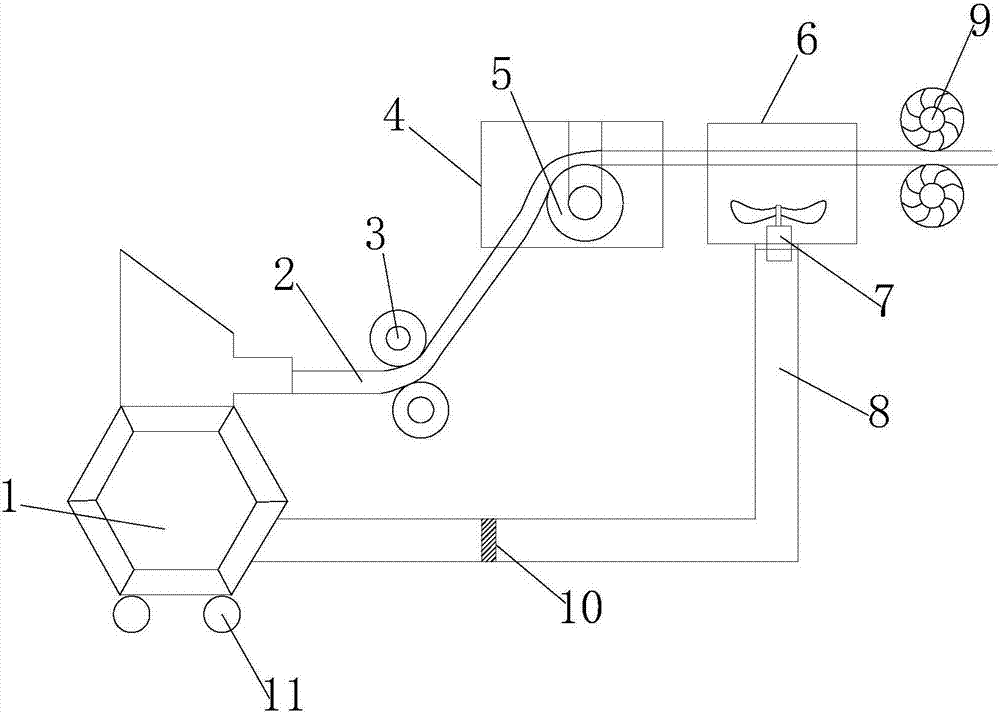

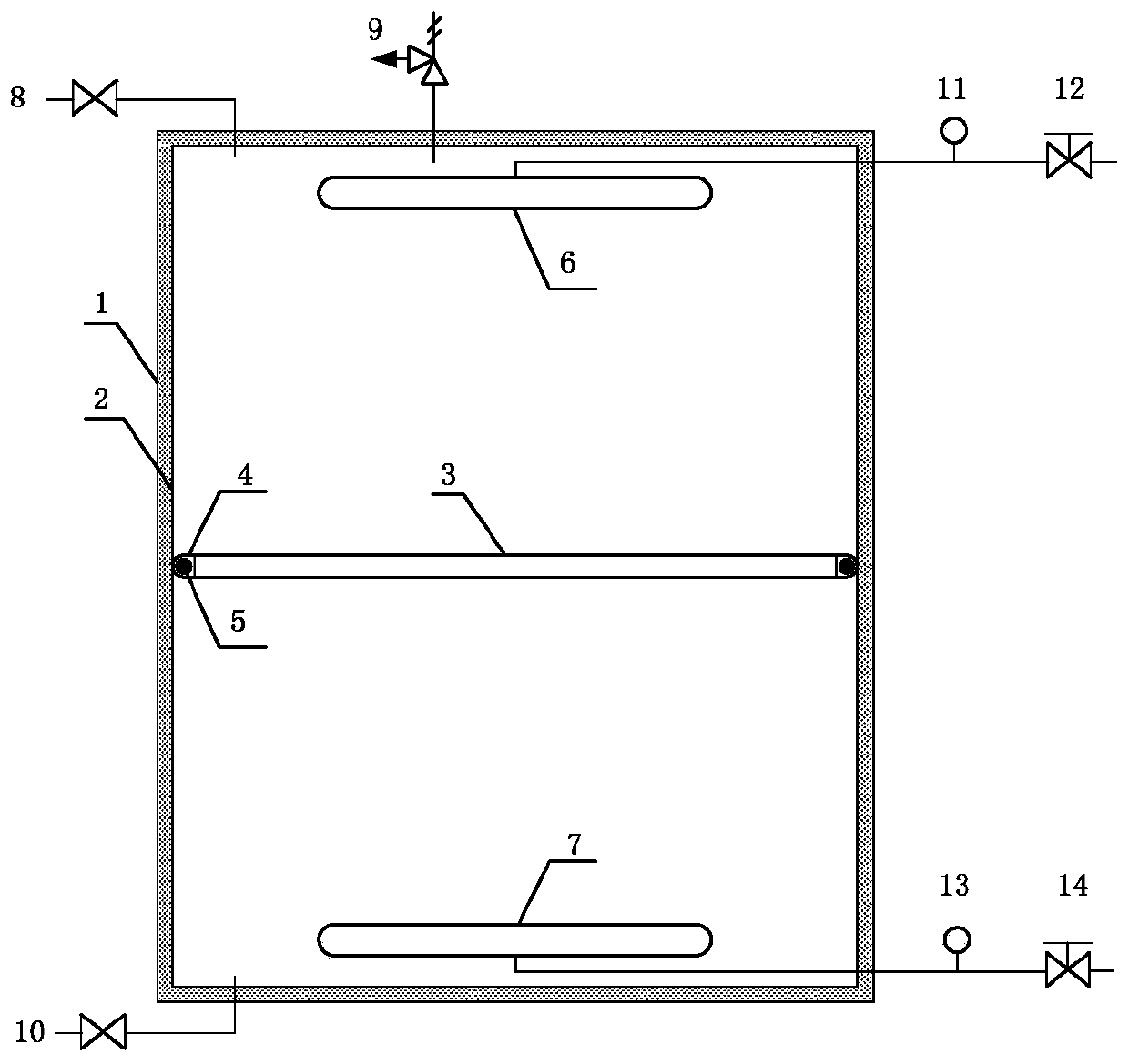

Papermaking equipment and papermaking process thereof

InactiveCN107142772AReduce blendingQuality improvementDryer sectionMachine wet endPapermakingHeat sink

The invention discloses a papermaking equipment and a papermaking process thereof, comprising: a slurry suction device, a net blanket is provided at the outlet end of the slurry suction device, and turning rollers are arranged at both ends of the net blanket, and above the turning roller A drying cylinder is provided, and a transfer roller is arranged in the drying cylinder. A heat dissipation device is provided on the side of the drying cylinder away from the turning roller, and a forming roller is provided on the side of the heat dissipation device away from the drying cylinder. Pass through turning rollers, transfer rollers, heat dissipation devices, and forming rollers; the heat dissipation device includes a heat-absorbing fan, and the heat-absorbing fan is arranged at the lower part of the heat dissipation device. The present invention is equipped with a cooling device on the outlet side of the drying cylinder. The cooling device absorbs the heat through the heat-absorbing fan and discharges it into the pipeline at the lower end. The filter in the pipeline filters out impurities and then transports the heat to the slurry suction device It is absorbed by the sucked pulp, which increases the temperature of the pulp, reduces the time required for drying the pulp, makes full use of resources, saves energy, and protects the ecological environment.

Owner:ANHUI JINYIHE SPECIALTY PAPER CO LTD

Sewage treating agent and preparation method thereof

InactiveCN107739079AGood biocompatibilityLow biological toxicityWater treatment parameter controlWater/sewage treatment by flocculation/precipitationCelluloseSulfite salt

The invention discloses a sewage treating agent and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing a star polymer by taking sodium acrylate andacrylamide as monomers and dihydroxyl diperiodiate potassium cuprate (III) as an initiator, then according to the weight parts, adding 20 parts of starch into 1000 parts of water, gelatinizing at 78-83 DEG C, then cooling the temperature to 50-55 DEG C, sequentially adding 1-1.3 parts of sodium hydroxide, 3-6 parts of cellulose, 10-12 parts of star polymer prepared in the S1, 6-8 parts of crylic acid, 18-23 parts of acrylamide, 0.35-0.38 parts of ammonium persulfate and 0.19-0.21 part of sodium sulfite, stirring for 20-30min, then adding 2-3 parts of an inorganic flocculant, and 0.032-0.045 part of N,N- methacrylamide, stirring for 30min and stopping reaction, then drying and grinding to obtain a sewage treatment agent. The prepared sewage treatment agent has the characteristics of fast flocculation speed, and low biodegradability and toxicity.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Under-well double-vortex type rotational flow oil and water separator

The embodiment of the invention relates to an under-well double-vortex type rotational flow oil and water separator. The separator is an under-well rotational flow oil and water separation plant usinga high-speed rotational flow principle, and compared with a traditional hydrocyclone, the separator comprehensively uses double same-direction rotational flows for pre-separating oil and water and double opposite-direction rotational flows for conducting under-well refining oil-contained waste water treatment. In the pre-separation process of the oil and the water, two phases of the oil and the water move in the same axial direction in a rotational flow field, so that the two phases of the oil and the water are barely mixed compared with those conducting rotational flow motion in the oppositeaxial directions, a separation effect is better, and accuracy is higher; and in the oil-contained waste water treatment process, a long and thin cone is used for increasing the rotational flow intensity, so that the oil content of the separated water phase is lower. Compared with a traditional gravity sedimentation plant, the separator is better in treatment effect and smaller in occupied space and is a physical separation plant with application prospects.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

A sliding vane type residual pressure recovery device

ActiveCN105782021BSimple structureLow processing and installation accuracy requirementsRotary piston pumpsRotary piston liquid enginesStream flowEngineering

The invention discloses sliding sheet type overpressure recovery equipment and belongs to the technical field of overpressure recovery. According to the sliding sheet type overpressure recovery equipment, main curved sections of cylinder profile lines in left and right cavities are in an arched shape; flow inlets and outlets are streamline pore channels; a cylinder inner cavity profile line is formed by connecting an arched sealing section, a curve transition section with an arched main curve section; and two adjacent curves are in a second order continuous manner. When being bilaterally symmetric mold cavities, working cavities can be applied to treating the working condition of same stream flow on the two sides; when being the mold cavities without bilateral symmetry, the working cavities can be applied to treating the working condition of different stream flows on the two sides. The sliding sheet type overpressure recovery equipment has a simple structure, is little in mixing fluids and lower in requirement for processing installation accuracy and can be applied to treating the working conditions of same or different flows on the two sides. Through the sliding sheet type overpressure recovery equipment, the overpressure of high-pressure, pressurized and low-pressure fluids are recycled and reused and has important significance of lowering system energy consumption and production cost and promoting energy conservation and emission reduction.

Owner:苏州小步快跑科技有限公司

Through type continuous folded plate structure suitable for tail edge part of turbine blade

ActiveCN112746872AImprove cooling effectPlay a diversion roleBlade accessoriesMachines/enginesPhysicsTurbine blade

The invention discloses a through type continuous folded plate structure suitable for a turbine blade tail edge part. The through type continuous folded plate structure comprises a U-shaped cooling channel and a blade tail edge cooling cavity which are arranged in a blade, wherein the U-shaped cooling channel is positioned at the front edge and the middle part of the blade, the blade tail edge cooling cavity is positioned at the tail edge of the blade, the U-shaped cooling channel and the blade tail edge cooling cavity are separated through a side wall face, an opening is formed in the bottom of the side wall face and serves as an outlet of the U-shaped cooling channel, a plurality of air holes are formed in the side wall face, a plurality of rows of through type continuous folded plates are arranged in the blade tail edge cooling cavity, and a tail edge crack is formed in the blade tail edge. The heat exchange can be effectively improved on the premise that the flow resistance is not large, and meanwhile the machinability is good. Due to the fact that the blocking and separating effects on cold air are obviously reduced through the folded plate type structure, the flow guiding performance is good, the turbulence degree of the cold air at an outlet of the blade tail edge cooling channel is low, the mixing loss of the cold air and mainstream fuel gas is reduced, and the aerodynamic efficiency of the blade is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

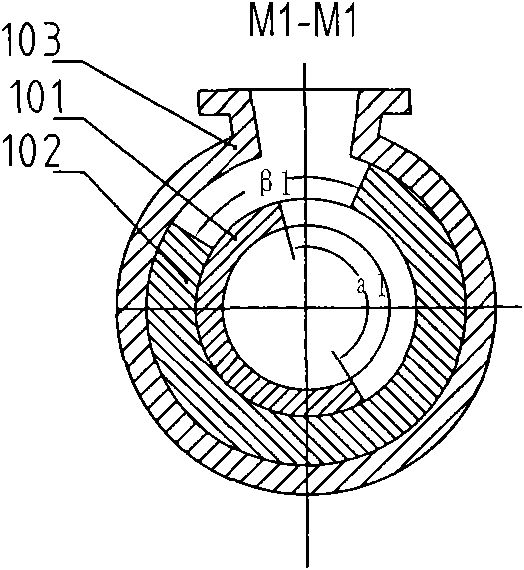

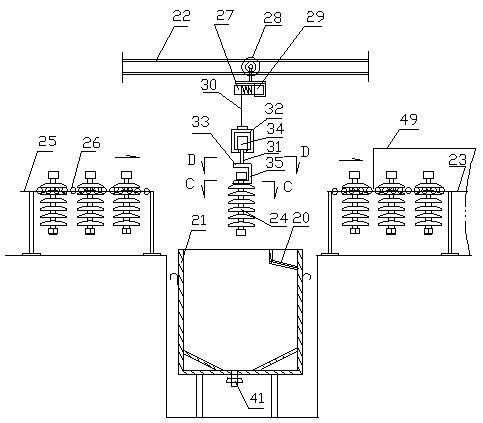

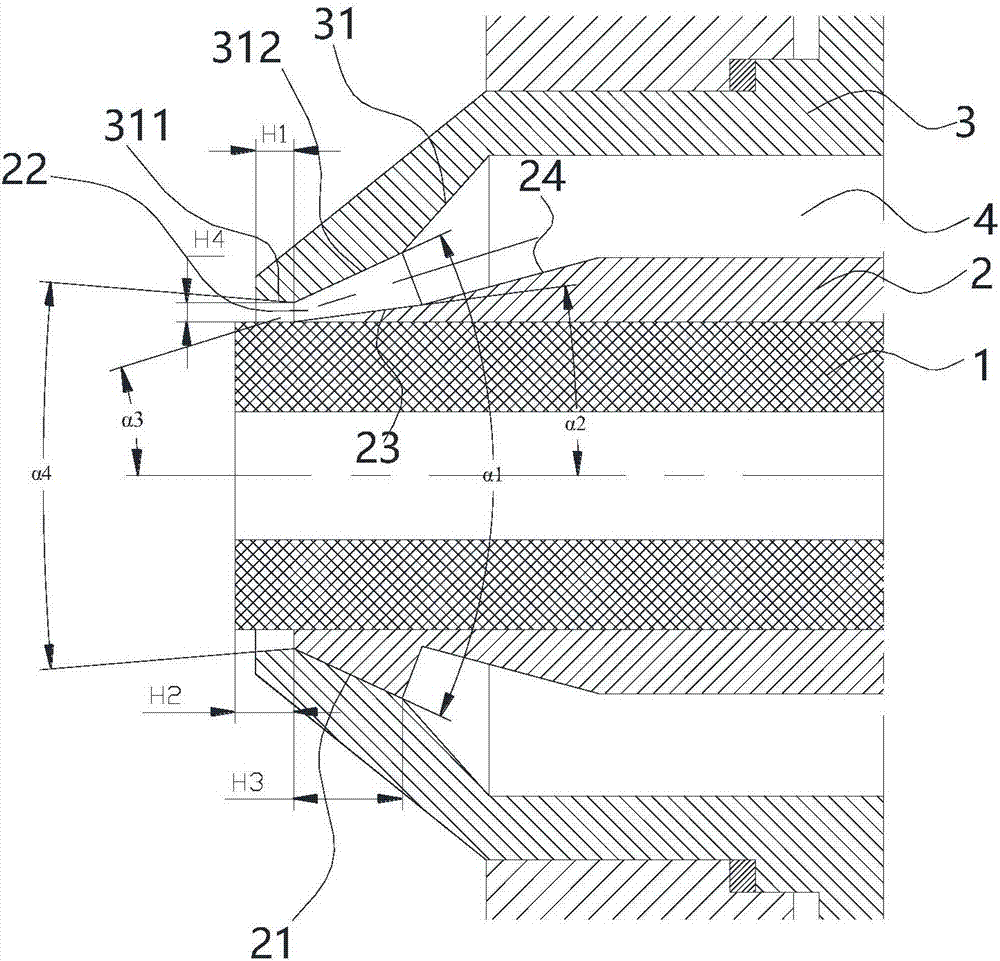

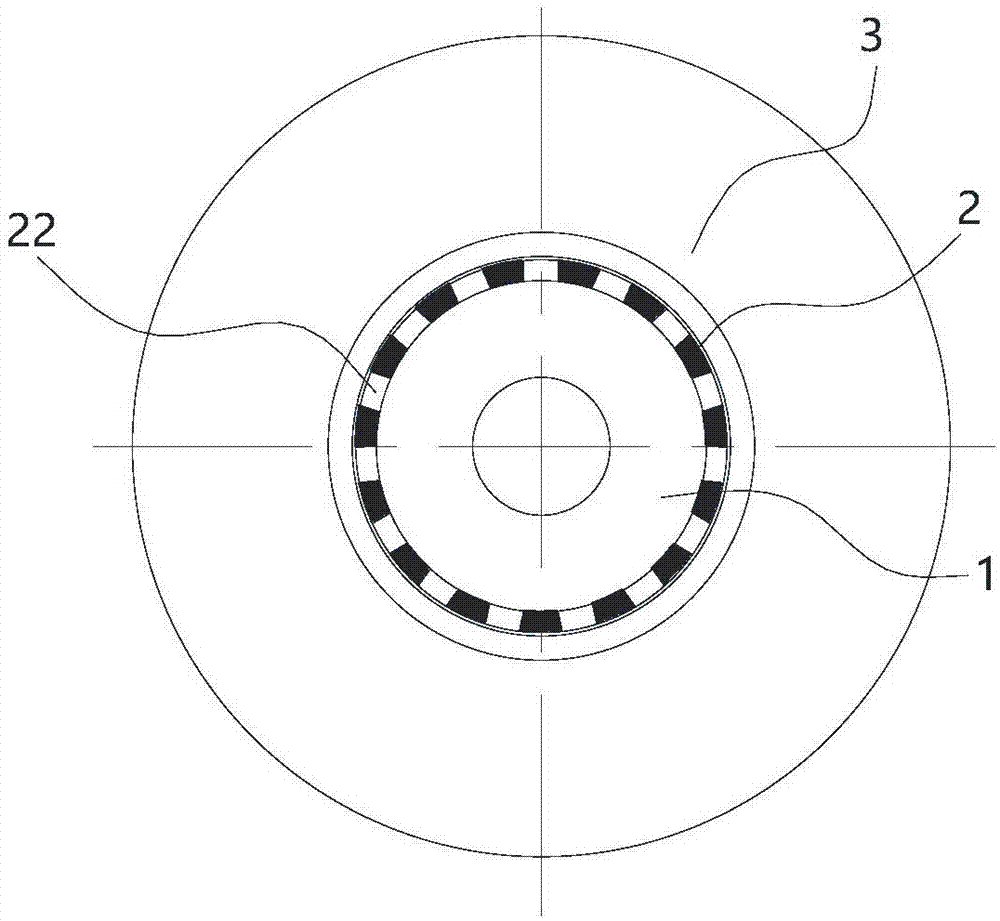

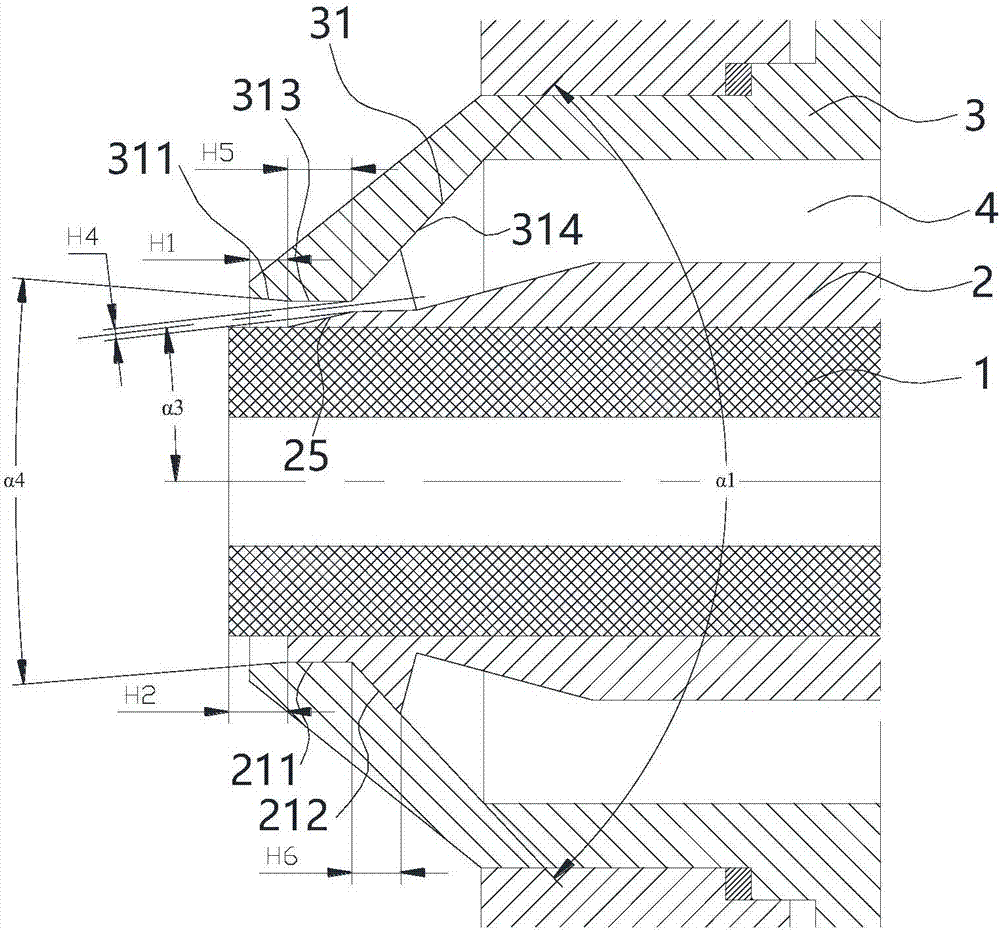

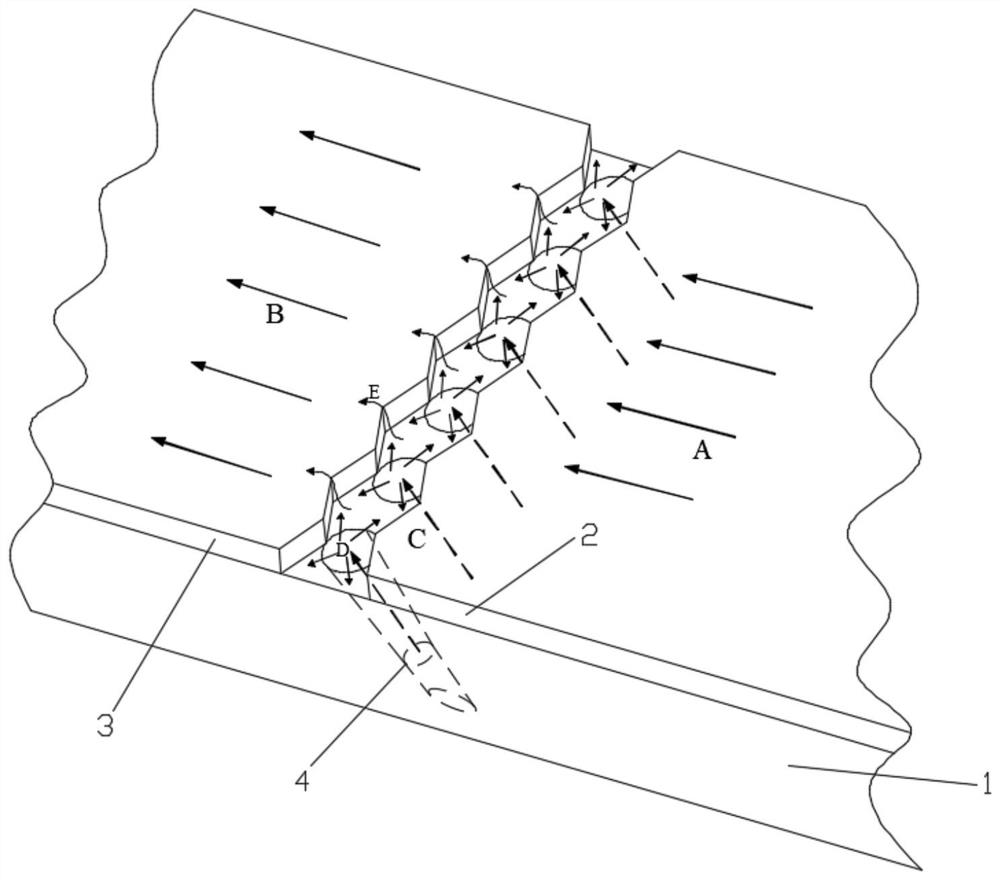

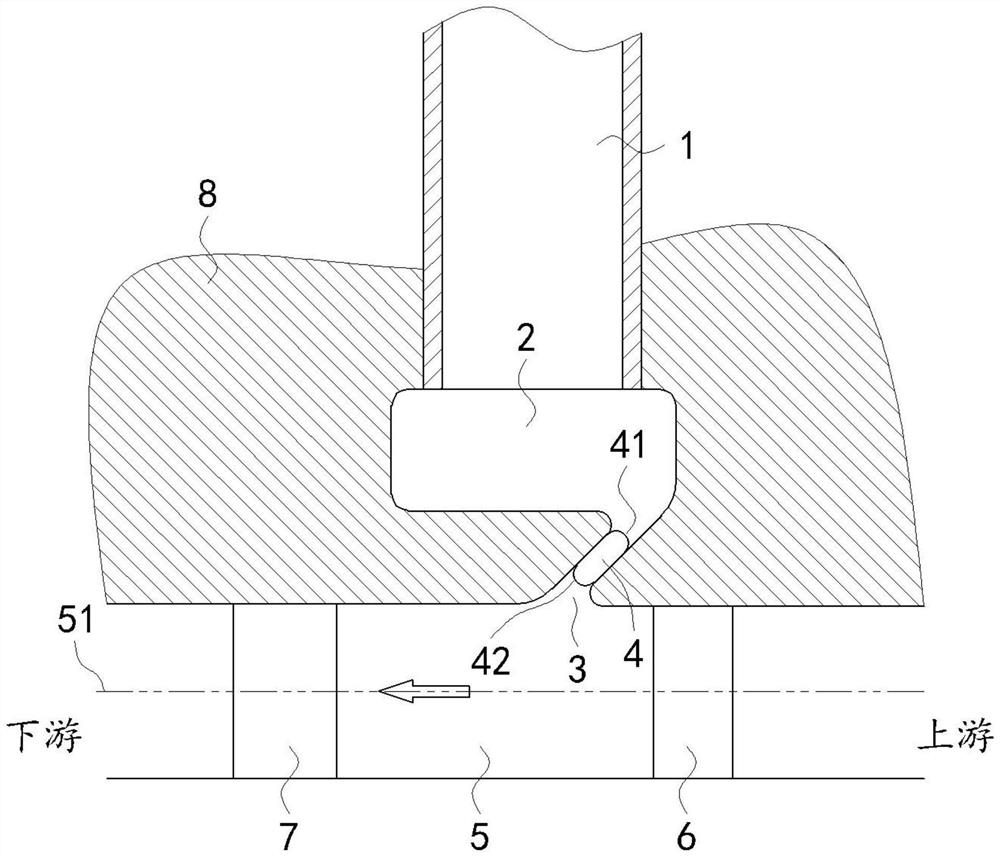

Steam supplementing chamber structure of steam turbine cylinder

ActiveCN112832875AReduce intermixingReduce blendingMachines/enginesEngine componentsEngineeringMechanics

The invention discloses a steam supplementing chamber structure of a steam turbine cylinder, and belongs to the technical field of steam turbines. The steam supplementing chamber structure of the steam turbine cylinder comprises an annular main steam flow channel formed between the cylinder and a rotor; a mixing ring cavity is formed in the cylinder in the circumferential direction of the cylinder; the outer side of the mixing ring cavity communicates with a steam supplementing channel; the inner side of the mixing ring cavity communicates with the main steam flow channel through a flow guide ring cavity; the flow guide ring cavity inclines towards the main steam flow flowing direction of the main steam flow channel; a plurality of flow guide partition plates are arranged in the flow guide ring cavity in the circumferential direction of the flow guide ring cavity; and the flow guide ring cavity is divided into a plurality of sub-cavities by the plurality of flow guide partition plates. According to the invention, the mixing degree and the mixing loss of the supplemented steam and the main steam flow can be reduced, and the influence of the supplemented steam on the stability of the rotor can be reduced.

Owner:DONGFANG TURBINE CO LTD

Device for freely separating cold and hot fluid media

ActiveCN110487096ASuppression mixingInhibition of blendingHeat storage plantsEngineeringActive support

Owner:SHANDONG UNIV

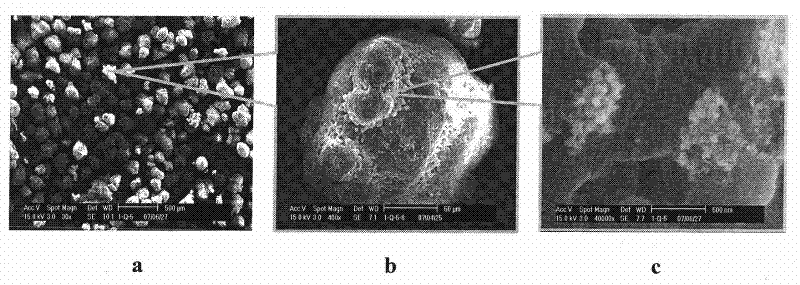

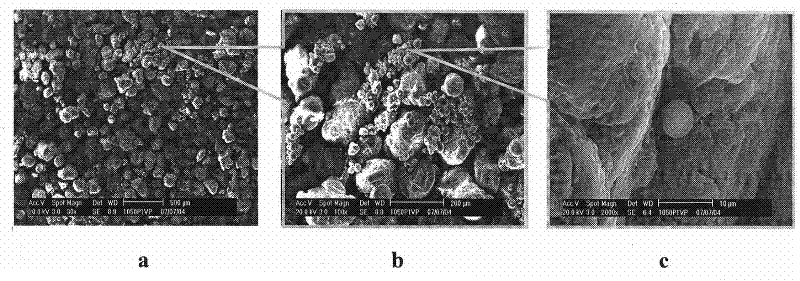

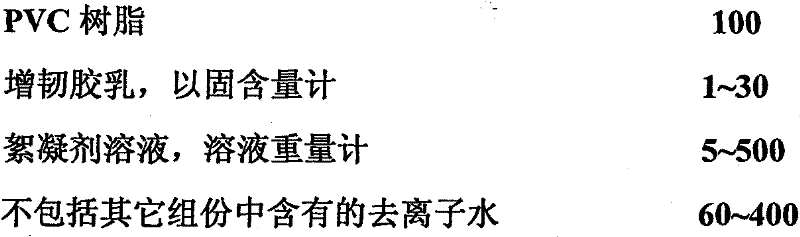

A kind of toughened type PVC resin and preparation method thereof

The invention provides a toughened PVC resin, the preparation method of which comprises the following steps: adding a flocculant to the mixture of PVC slurry and toughened rubber latex, co-flocculating, dehydrating and drying the latex and PVC to obtain a modified PVC resin. The mass parts of the raw materials are as follows: 100 parts of PVC resin, 1-30 parts of toughened latex (based on solid content), 5-500 parts of flocculant solution and 60-400 parts of deionized water. The toughened rubber in the resin evenly adheres to the surface of PVC particles, and has higher toughness than ordinary PVC resin, and the toughness of the resin is gradually enhanced with the increase of the latex addition ratio. The toughening effect of the latex flocculation toughening resin composition with a general formula is obviously better than that of the powder rubber and ordinary PVC resin blend composition.

Owner:CHINA PETROLEUM & CHEM CORP +1

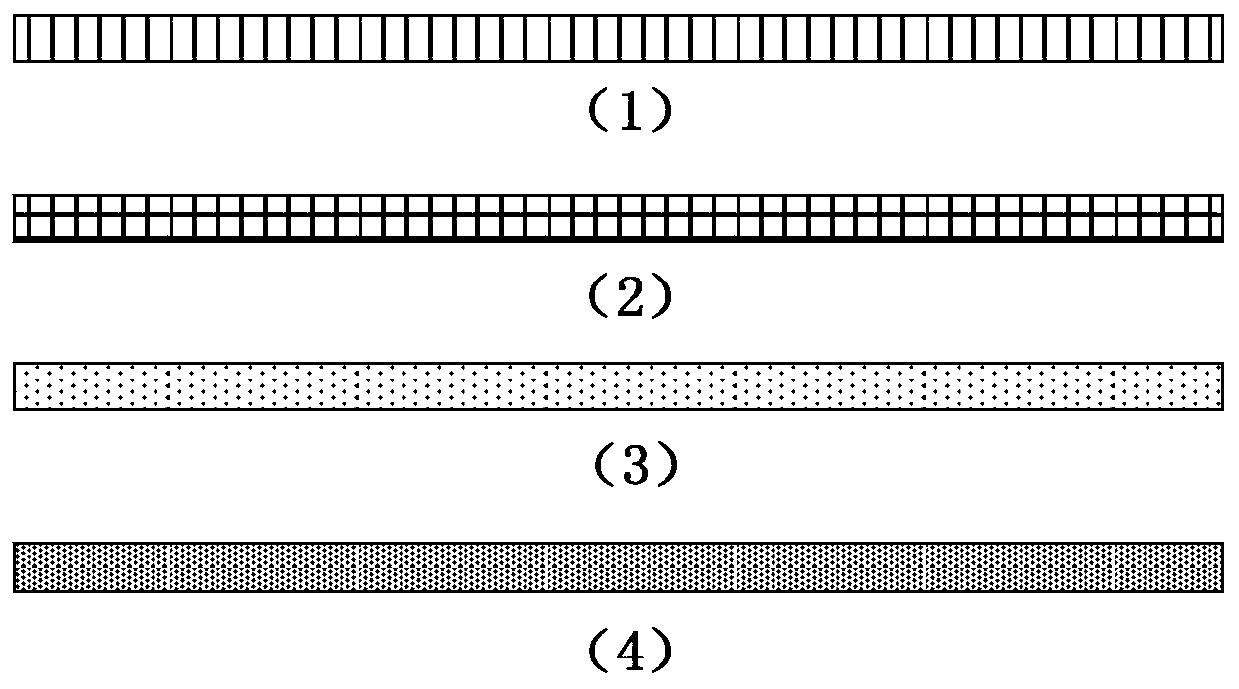

Offset hole row and cylindrical hole row combined cooling structure for corrugated heat shield

ActiveCN112178693AImprove the sticking effectReduce blendingContinuous combustion chamberRamjetCold air

The invention discloses an offset hole row and cylindrical hole row combined cooling structure for a corrugated heat shield, and belongs to the technical field of cooling of aero-engine combustion chambers. The cooling structure comprises a corrugated heat shield plate, and offset gas film hole rows and cylindrical hole rows which are arranged on the corrugated heat shield plate, wherein the corrugated heat shield plate is of a cylinder structure, a fuel gas channel is formed in the corrugated heat shield plate, an annular channel composed of the cylindrical corrugated heat shield plate and acombustion chamber outer cylinder forms a cold air channel, each corrugation of the corrugated heat shield plate comprises a windward side and a leeward side, 2-3 rows of offset air film hole rows areuniformly distributed on the windward side along the axial direction of the cylindrical corrugated heat shield plate, 3-4 rows of cylindrical hole rows are uniformly distributed on the leeward side along the axial direction of the cylindrical corrugated heat shield plate, the structure is formed by arranging a plurality of offset air film hole rows on the mainstream leeward side of a corrugated plate and arranging a plurality of cylindrical air film hole rows on the windward side, and the structure can be used for a turbofan engine afterburner or a ramjet engine combustor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com