Tin liquor processing method for float glass and ultra-thin float glass

A technology of float glass and processing method, which is applied in the field of glass production equipment, can solve the problems that the convection of tin liquid cannot be effectively controlled, and the quality of glass plates cannot be guaranteed for production stability, and achieve the effect of simple shape and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be further described in conjunction with accompanying drawings, and the structure and principle of this device and method are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

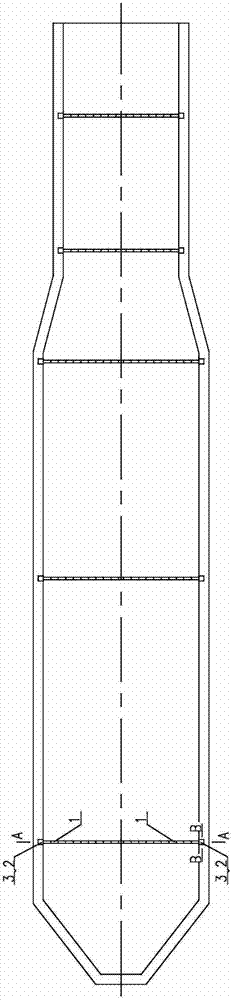

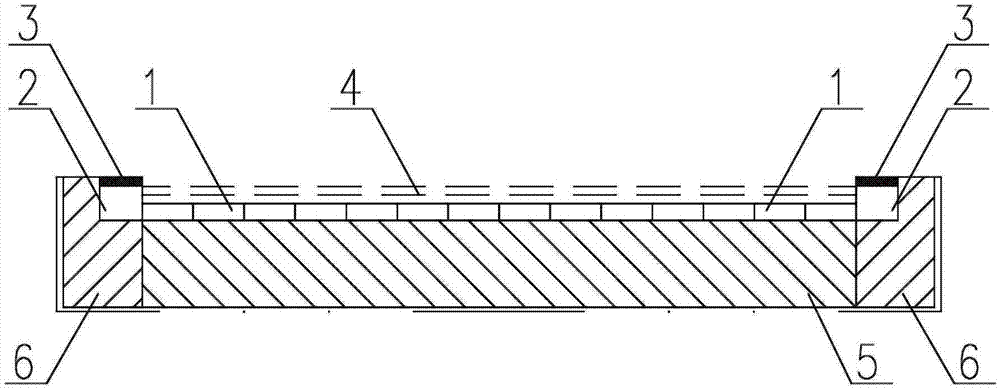

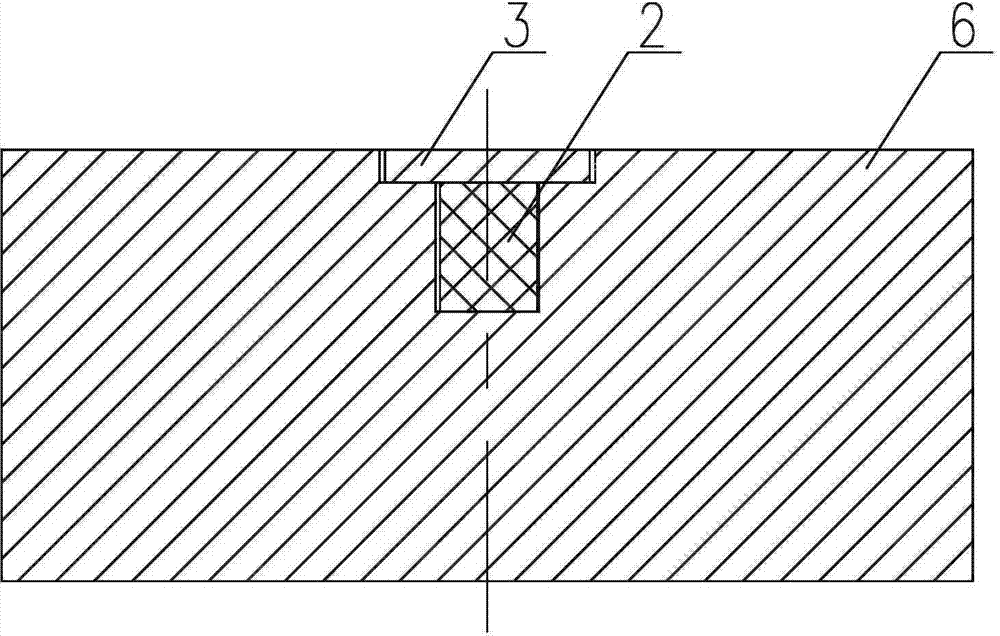

[0028] The present invention is a kind of tin liquid processing method that is used for float glass and ultra-thin float glass, such as Figure 1 ~ Figure 3 As shown, the retaining sill is installed horizontally along the tin bath, and the retaining sill is composed of many small retaining sills, and the length of the entire retaining sill is basically equal to the inner width of the tin bath. When the sill is installed, the lower part is embedded in the slot of the bottom brick of the tin tank, and the upper part is immersed in the tin liquid, leaving a certain distance of 3~20mm from the tin liquid for the glass ribbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com