Patents

Literature

631 results about "Plate pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

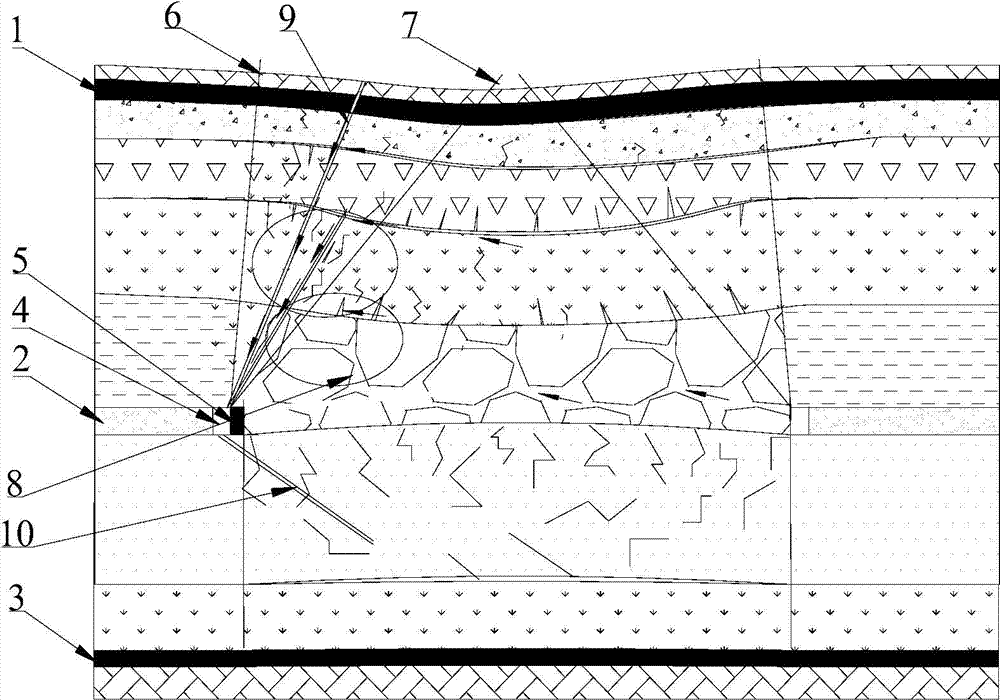

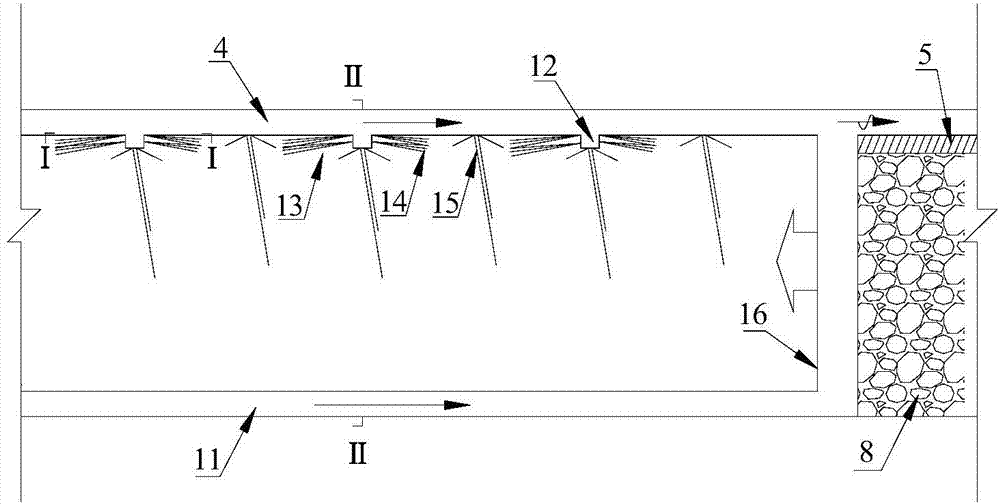

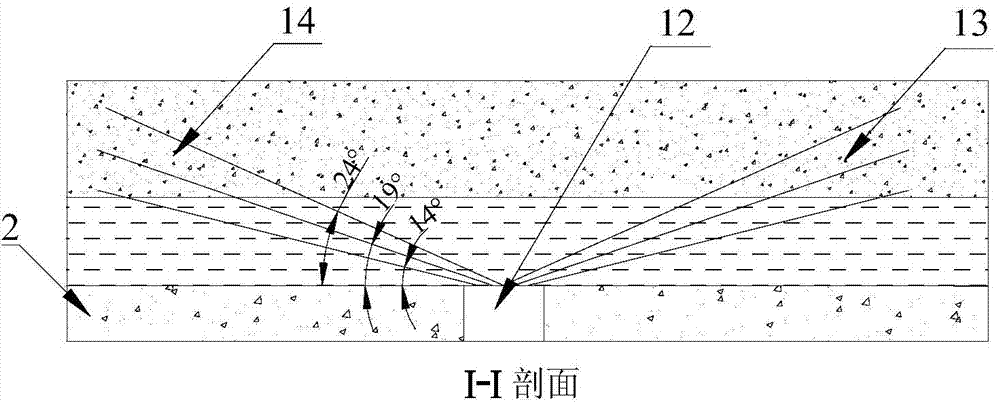

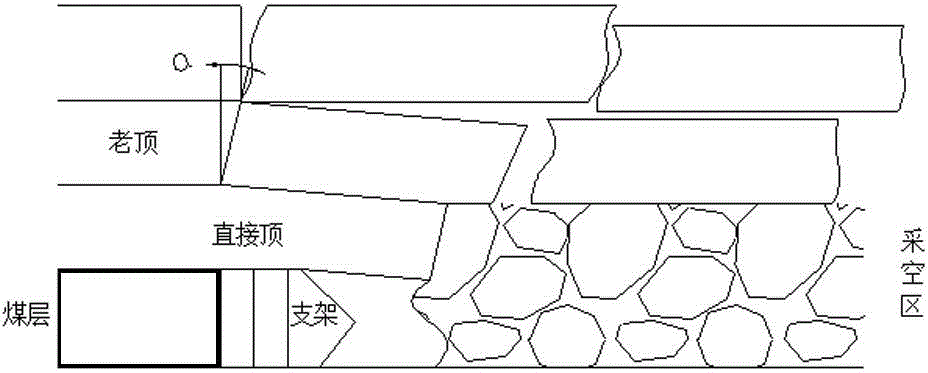

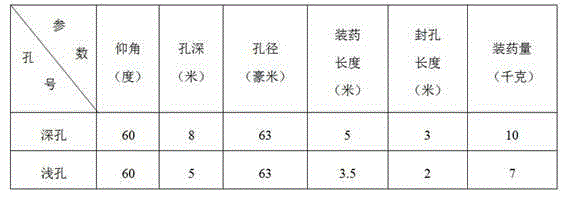

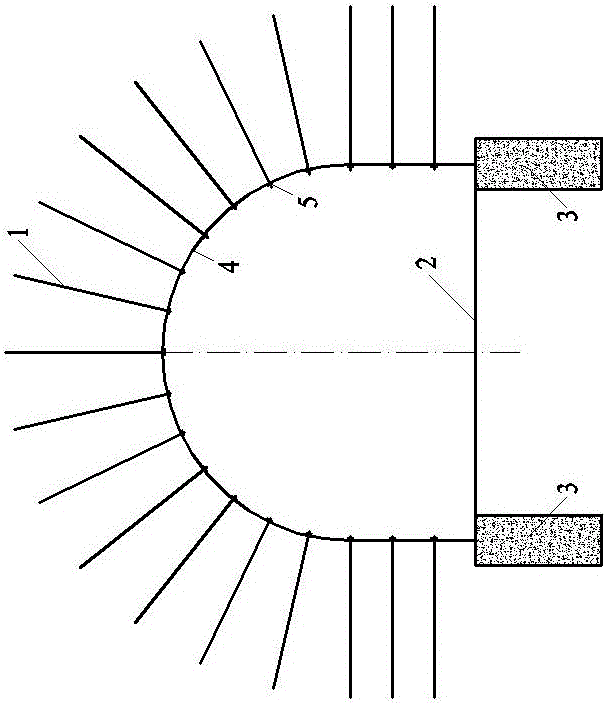

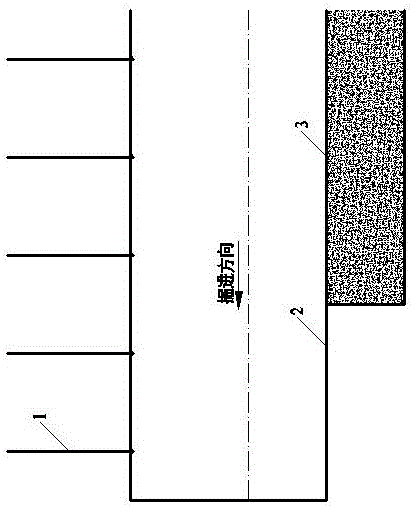

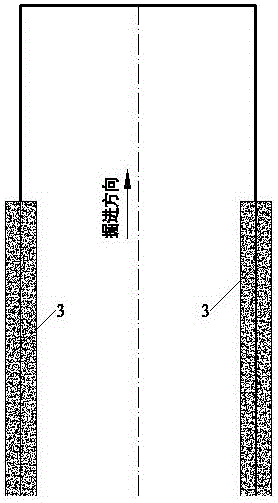

Gob-side entry retaining Y-type ventilation goaf top plate pressure relief gas pumping mining method

ActiveCN101082283ASolve the overrun problemReduce differential pressureTunnel/mines ventillationGas removalPlate pressureHigh density

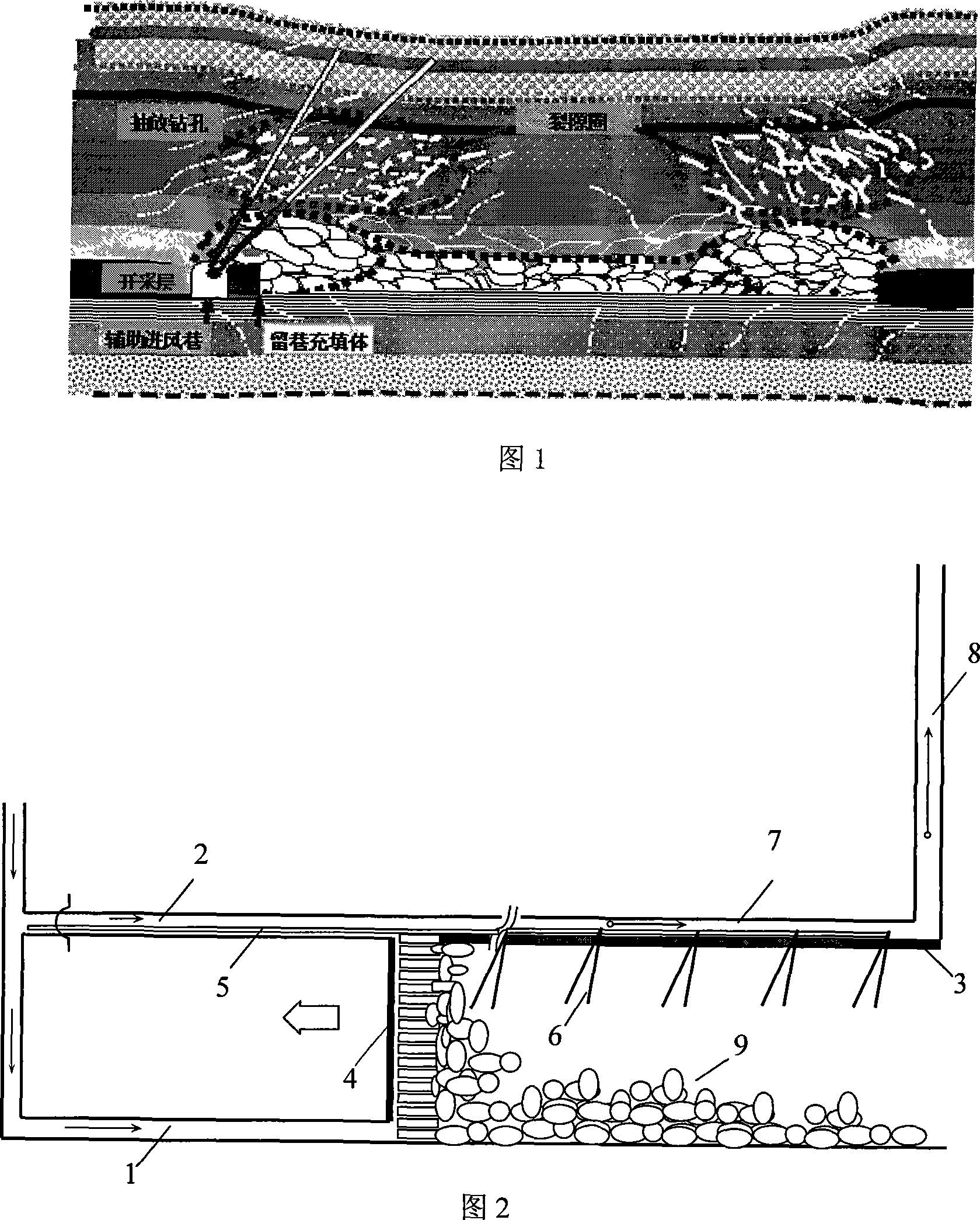

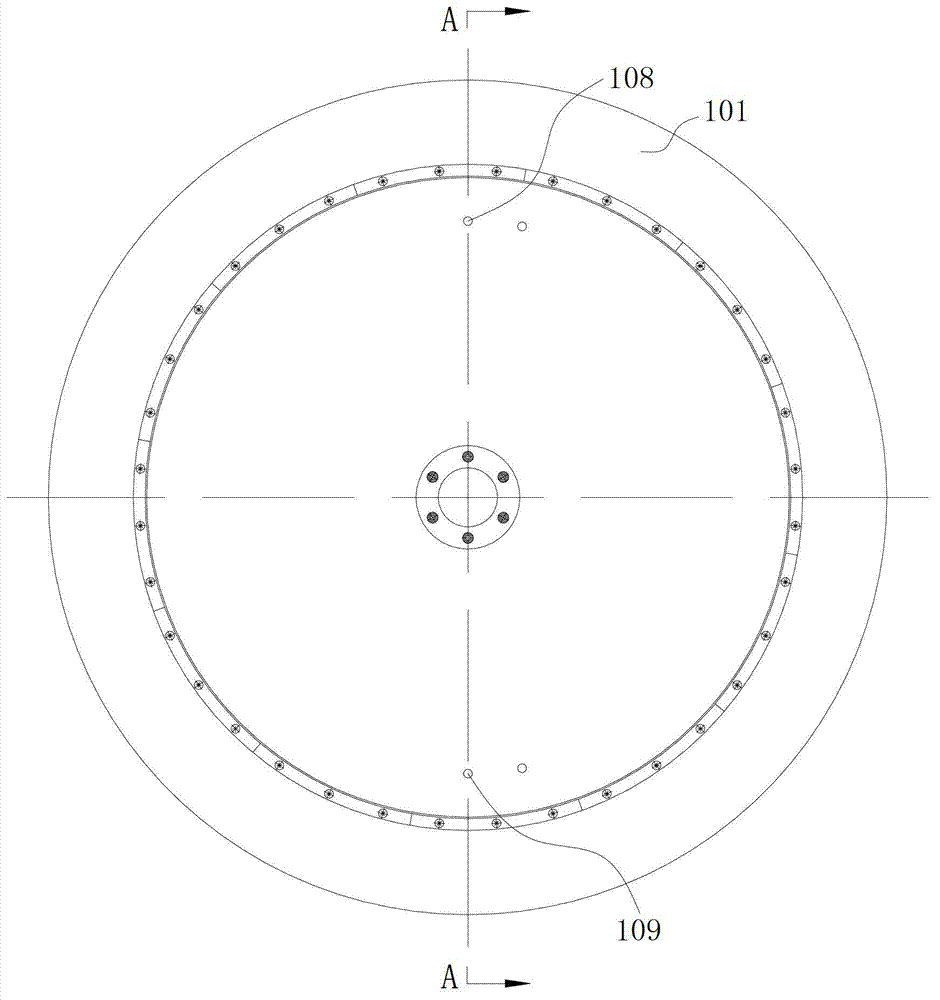

A method to suck pressure relief firedamp along Y-shape ventilating gob roof of the empty tunnel is characterized in that: in the high-firedamp coal mining working-face pressure relief zone along the empty tunnel gob roof, it sucks the stripping and free firedamp from the exploiting and pressure relief layer which gathers in the gob upper part and the ring slit loop through the slit channel formed by the mining influence on the gob upper rock stratum through the dip sucking firedamp bore-hole which are distributed in the pressure relief ring slit loop. The pressure relief ring slit loop locates in the separation layer slit zone above the caving zone on the Y-shape ventilating working-face along the empty tunnel gob roof. The invention resolves the air firedamp overrun in the corner and the return airway on the coal mining working-face basically, realizes the sucking and application of the high density firedamp, improves the resource utilization ratio, exploits the high firedamp coal seam without coal wedges, improves the mine resource recovery and assures the high-efficiency and safe exploitation of the coal mining working-face.

Owner:HUAINAN MINING IND GRP +2

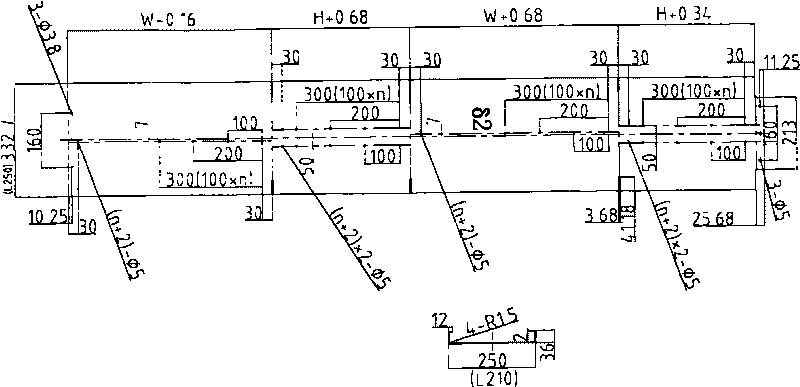

Parameter setting method of hot continuous rolling thin slab coiling device and coiling method of hot continuous rolling thin slab

The invention relates to a parameter setting method of a hot continuous rolling thin slab coiling device and a coiling method of a hot continuous rolling thin slab. The parameters to be set are as follows: an advance speed set value of each set of roller beds = a finish rolling final rack speed set value * (a total roller bed advance rate + advance rate of each set); a lagging speed set value of each set of roller beds = the finish rolling final rack speed set value * a roller bed lagging rate; the side guide plate pressure coefficient is 0.8 + / - 0.15; the side guide plate additional value is from +5 to +10 mm; and the pinch roll is set, and the pinch roll of the coiling device is standardized to ensure the regular standardization, the pinch roll advance rate, pinch roll lagging rate, pinch roll pressure coefficient, upper pinch roll diameter of the coiling device and lower pinch roll diameter of the coiling device. The coiling method is implemented by controlling the coiling device with a computer according to the setting parameters. By using the parameter setting method of the hot continuous rolling thin slab coiling device and the coiling method of the hot continuous rolling thin slab, the surface quality is improved and the rejection rate is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

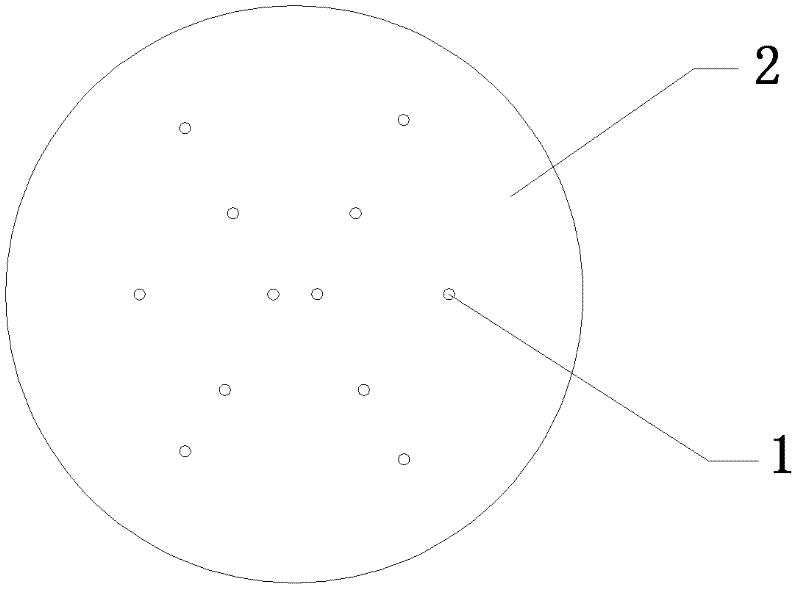

Pressure filter and pressure filtration method thereof

InactiveCN102814063AFew partsThe overall structure is simple and reliableFiltration separationPlate pressureFiltration

The present invention discloses a pressure filter, which comprises multiple groups of filter plates, wherein the adjacent filter plates are arranged in a contact manner, and each filter plate is provided with a material channel and a pressure filtration space with a variable volume and for accommodating a material. One end of the material channel is communicated with the pressure filtration space, and the other end is communicated with the pressure filtration space of the adjacent filter plate. Each filter plate is further provided with an air channel for communicating the filter plate pressure filtration space and a liquid channel for communicating the pressure filtration space of the adjacent filter plate. Filter screens are arranged on both sides of the filter plates and are positioned inside the adjacent pressure filtration space, wherein a filter cloth is covered outside the filter screen. The pressure filter of the present invention has characteristics of fewer components, simple and reliable structure, and low equipment maintenance workload. The present invention provides a pressure filtration method. According to the pressure filtration method of the present invention, two-stage pressure filtration and one-stage drying are adopted, wherein the first stage is that a driving pump is adopted to feed the material to carry out pressure filtration, the second stage is that high pressure air pressurizes the filter cloth to carry out pressure pressing, and the third stage is that the material is dried with high temperature air, such that pressure filtration efficiency is improved, and effects of automatic material unloading and filter cloth cleaning are achieved through the high pressure air.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

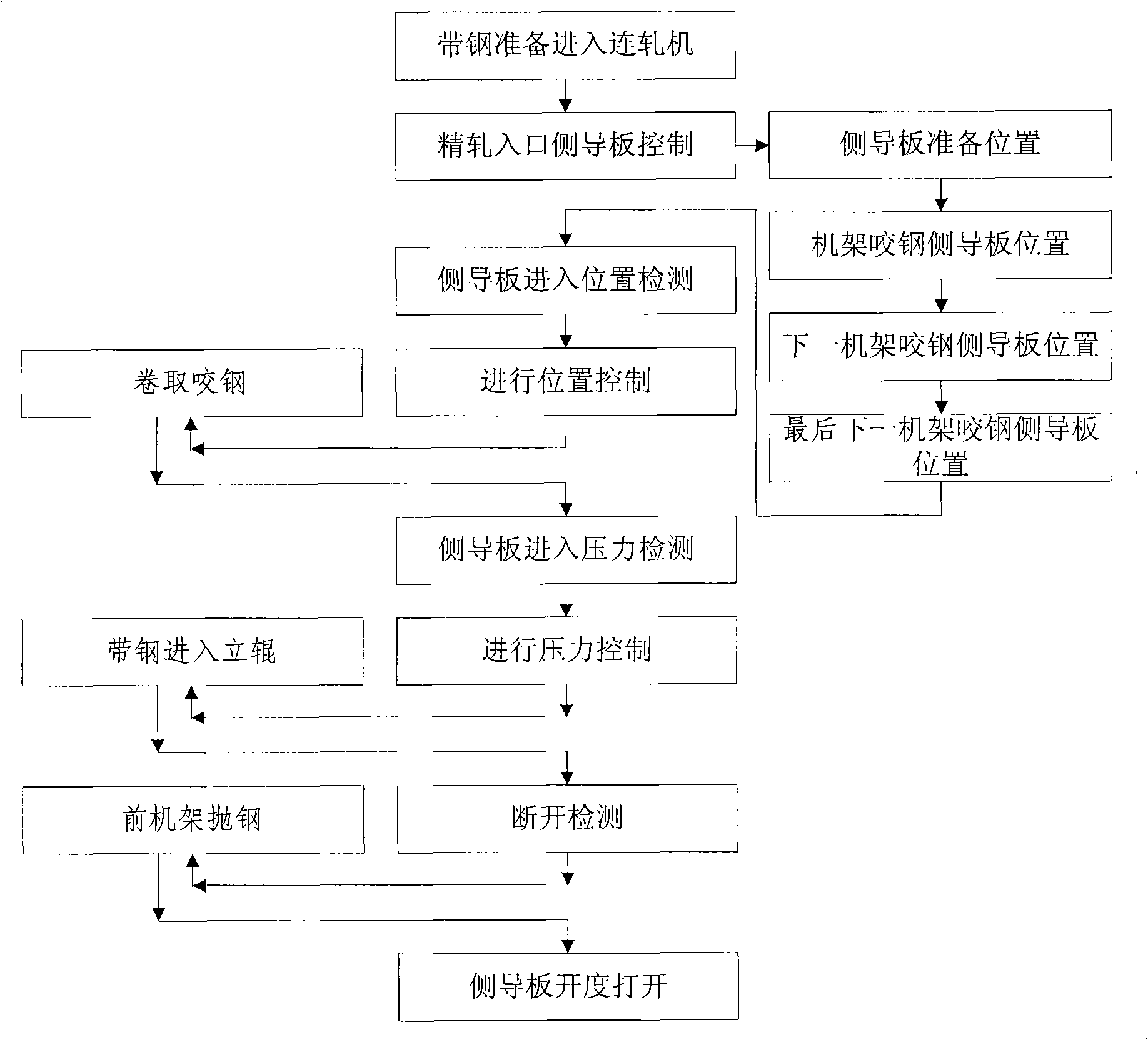

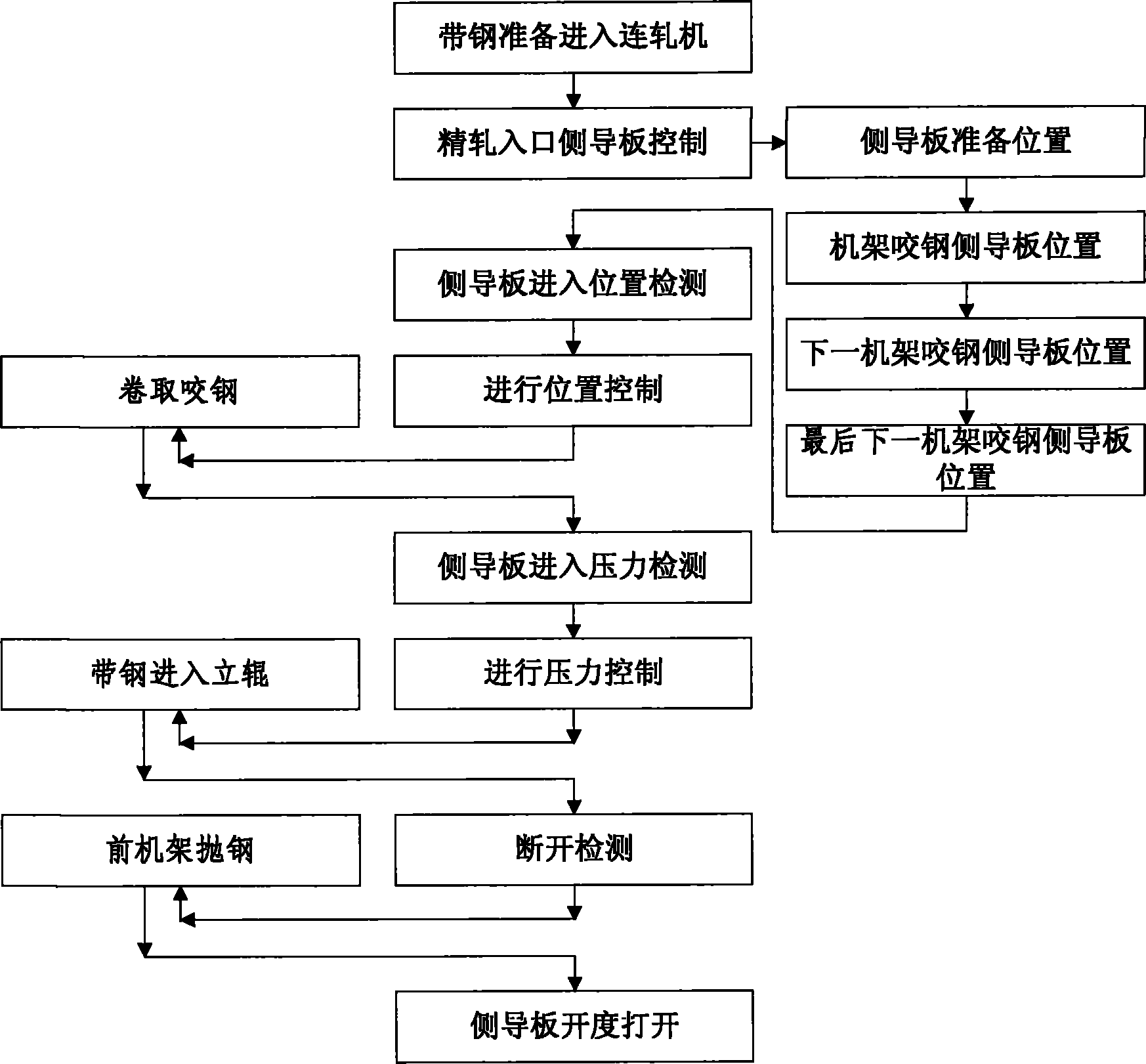

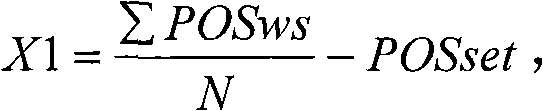

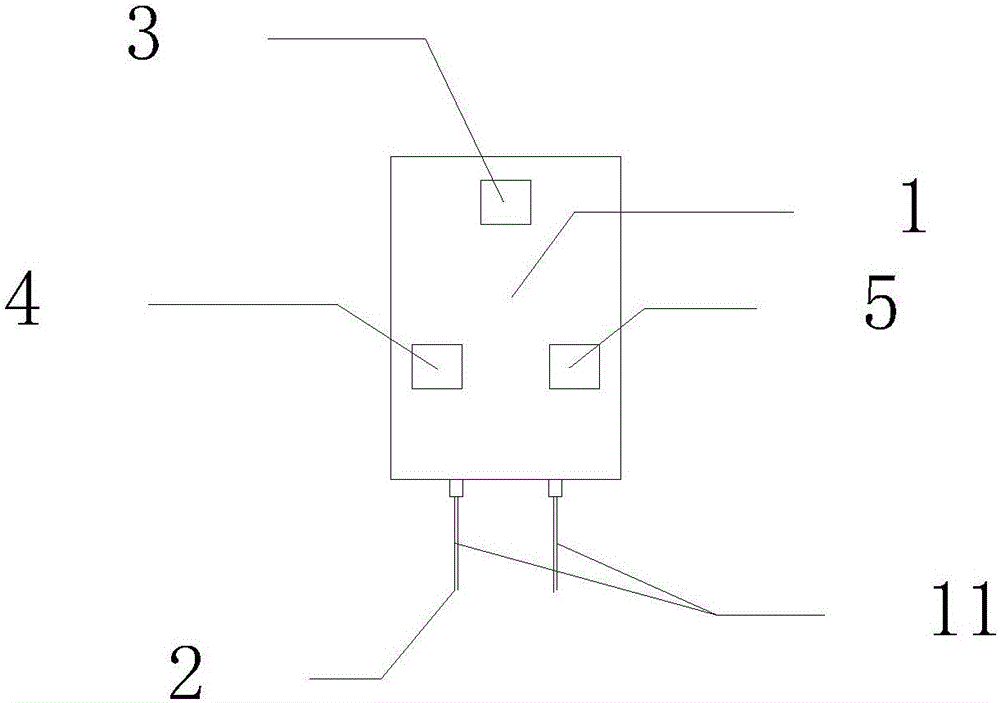

Control method of automatic deviation correction during rolling of hot continuous rolling mill

ActiveCN102120224ARealize automatic deviation correctionImprove stabilityRoll mill control devicesMetal rolling arrangementsPlate pressureStrip steel

The invention relates to the field of deviation correction in hot continuous rolling, in particular to a control method of automatic deviation correction, which comprises the following steps of: 1, controlling the opening of a side guide plate in a strip steel entering state; 2, opening the side guide plate position detection to control roller gap deviation correction; 3, opening the side guide plate pressure detection to control roller gap deviation correction; and 4, controlling the opening of the side guide plate in a strip steel throwing state, closing the side guide plate pressure detection when the tail of the strip steel leaves from a first stand, and entering the control of the opening of the side guide plate until the strip steel completely leaves from a continuous rolling stand. The control method is perfected by using the traditional equipment condition, adopts a positive and effective means for the treatment of deviation, realizes automatic deviation correction on the strip steel, improves the rolling stability, is accurate in control and capable of ensuring the stability of hot rolling production, and has wider popularization value.

Owner:BAOSHAN IRON & STEEL CO LTD

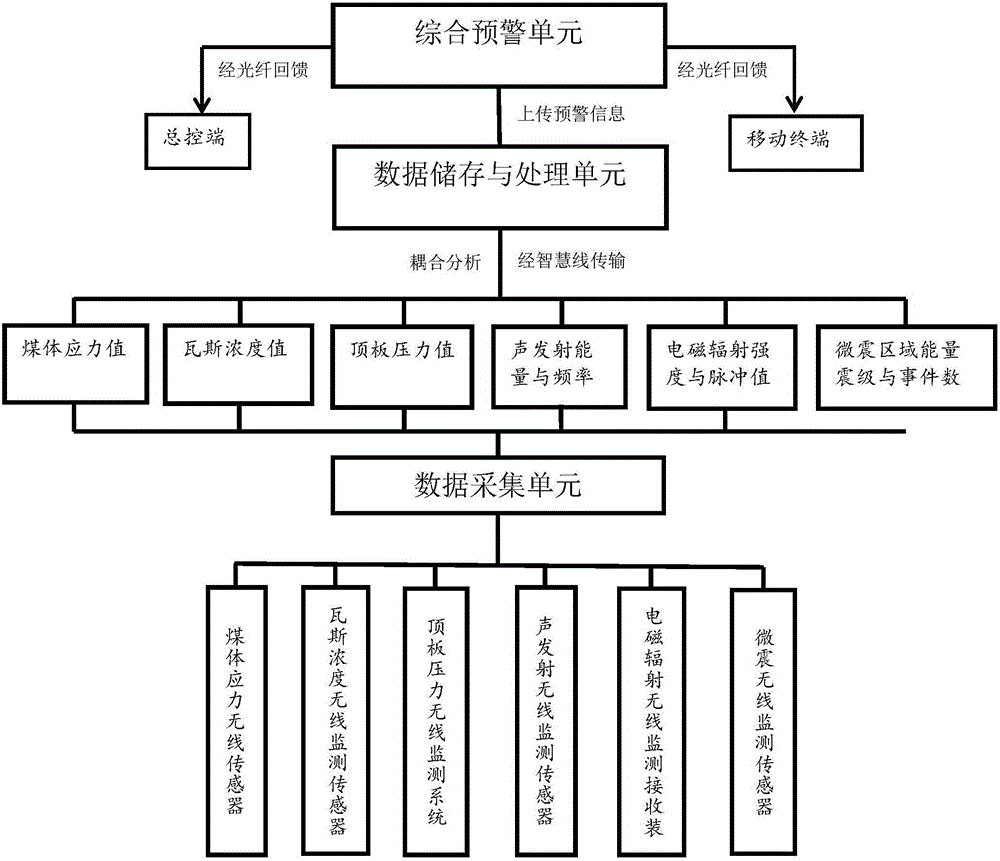

Coal and rock dynamic disaster multi-parameter wireless monitoring comprehensive early-warning technology and method

The invention discloses a coal and rock dynamic disaster multi-parameter wireless monitoring comprehensive early-warning technology and method. The technology and method involve a data acquisition unit, a data storage and processing unit and a comprehensive early-warning unit. According to the technology, on the basis of the advantage that an intelligent line supports a brand new wireless digital communication system with the high-precision positioning and wireless access capacity in a closed special environment by means of the internet of things and a communication technology, with a working face coal body physical signal as a basis, an underground coal mine gas concentration sensor, a coal body stress gauge, a top plate pressure monitoring system, a sound emitting and monitoring system, an electromagnetic radiation monitoring system, a microearthquake system and a sensor of the microearthquake system are in wireless docking with the intelligent line, an underground wireless monitoring early-warning associated equipment is researched, a coal and rock gas dynamic disaster wireless multi-parameter judgment method and coal and rock gas dynamic disaster wireless multi-parameter judgment indexes are established, a coal mine coal and rock gas dynamic disaster wireless multi-parameter remote monitoring and early-warning system is formed, and a coal mine coal and rock gas dynamic disaster wireless multi-parameter remote monitoring comprehensive early-warning platform is developed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

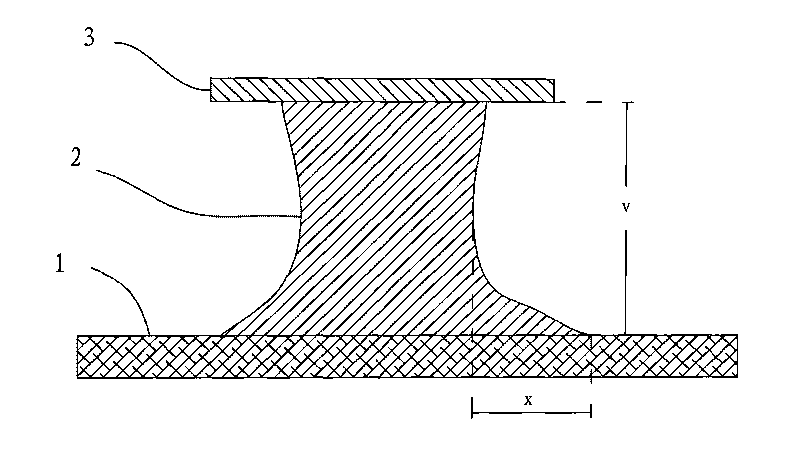

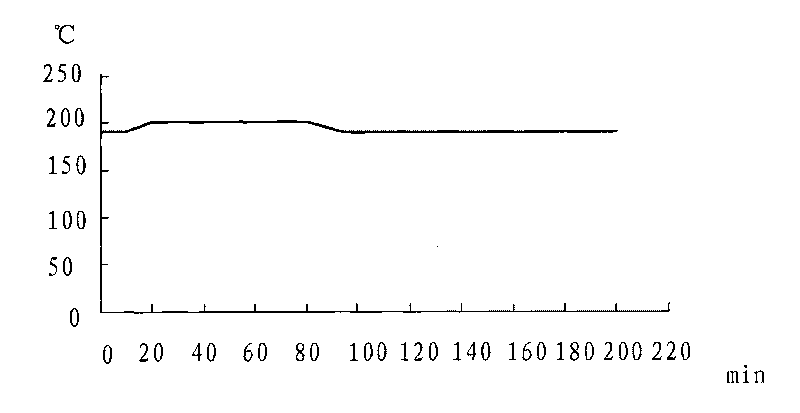

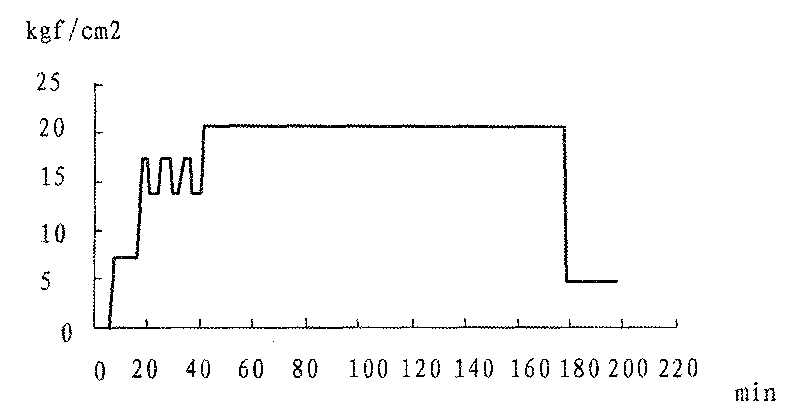

Process for manufacturing 12OZ thick copper multilayer circuit board

ActiveCN101692757AIncrease etch factorEvenly filledMultilayer circuit manufacturePlate pressureCopper chloride

The invention discloses a process for manufacturing a 12OZ thick copper multilayer circuit board. In an inner layer etching process, the concentration of CU2+ in an acid copper chloride etching solution is controlled to be 150+ / -20g / l, the temperature is 50+ / -3 DEG C, total acidity is 2.8+ / -0.6N, specific gravity is 1.30+ / -0.10, etching speed is 1.2+ / -m / min, and the number of etching times is 4 times; a plate pressing process comprises a hot pressing step and a cold pressing step, wherein the hot pressing time is 200 minutes, a system is vaccumized at absolute pressure of 10mbar between the fifth minute and the ninety-fifth minutes, the maximum press plate pressure is controlled to be 21.42Kgf / cm2, and the temperature is 190 DEG C; the time for cold pressing is 110 minutes, and the maximum press plate pressure is controlled to be 18.36Kgf / cm2; when the diameter D of a prebored hole is more than or equal to 2.0mm and is less than 4.8mm, a drill bit with diameter d of less than or equal to 1.7mm is used to prebore 4 holes, and the holes are redrilled by using a drill bit with the diameter D. The process has the advantages of improving the etching factors of the plate material of the inner layer, reducing the side etching effect with good plate pressing effect and protecting the bored holes from the phenomenon that the holes are blocked by copper scarp.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

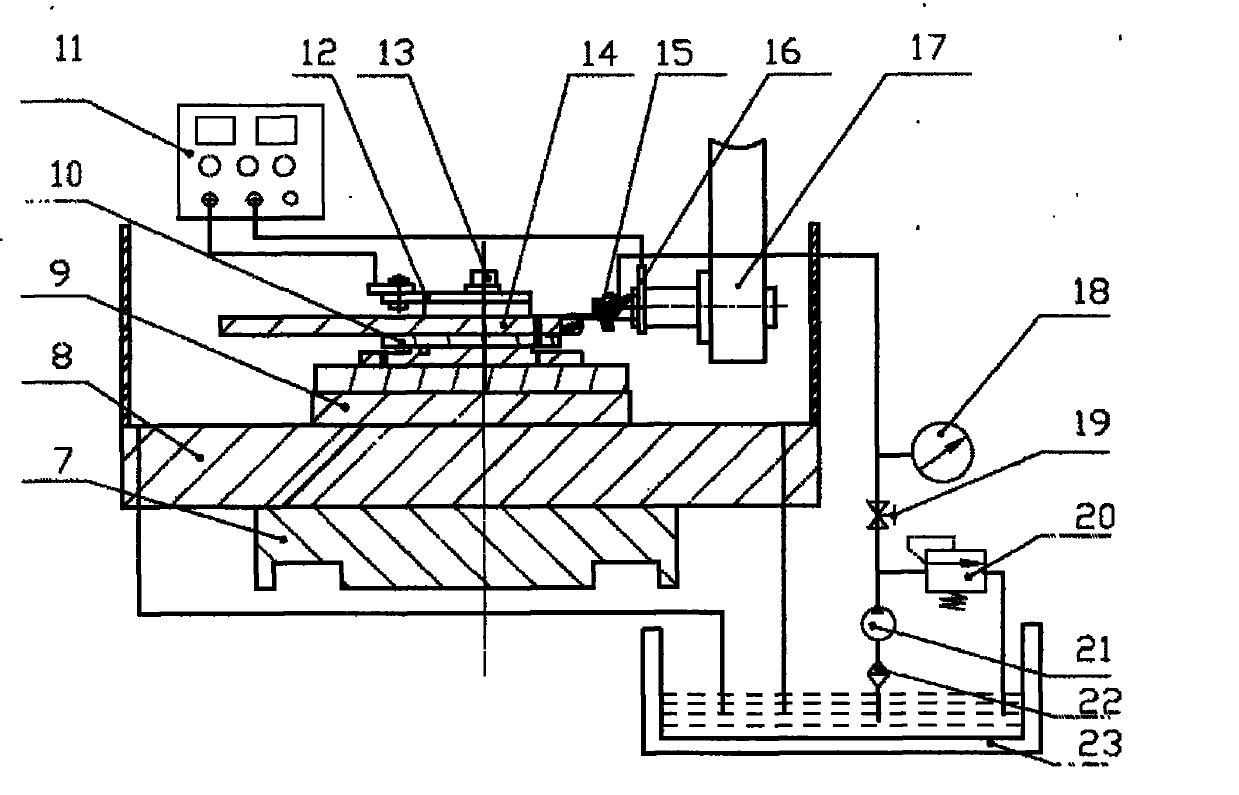

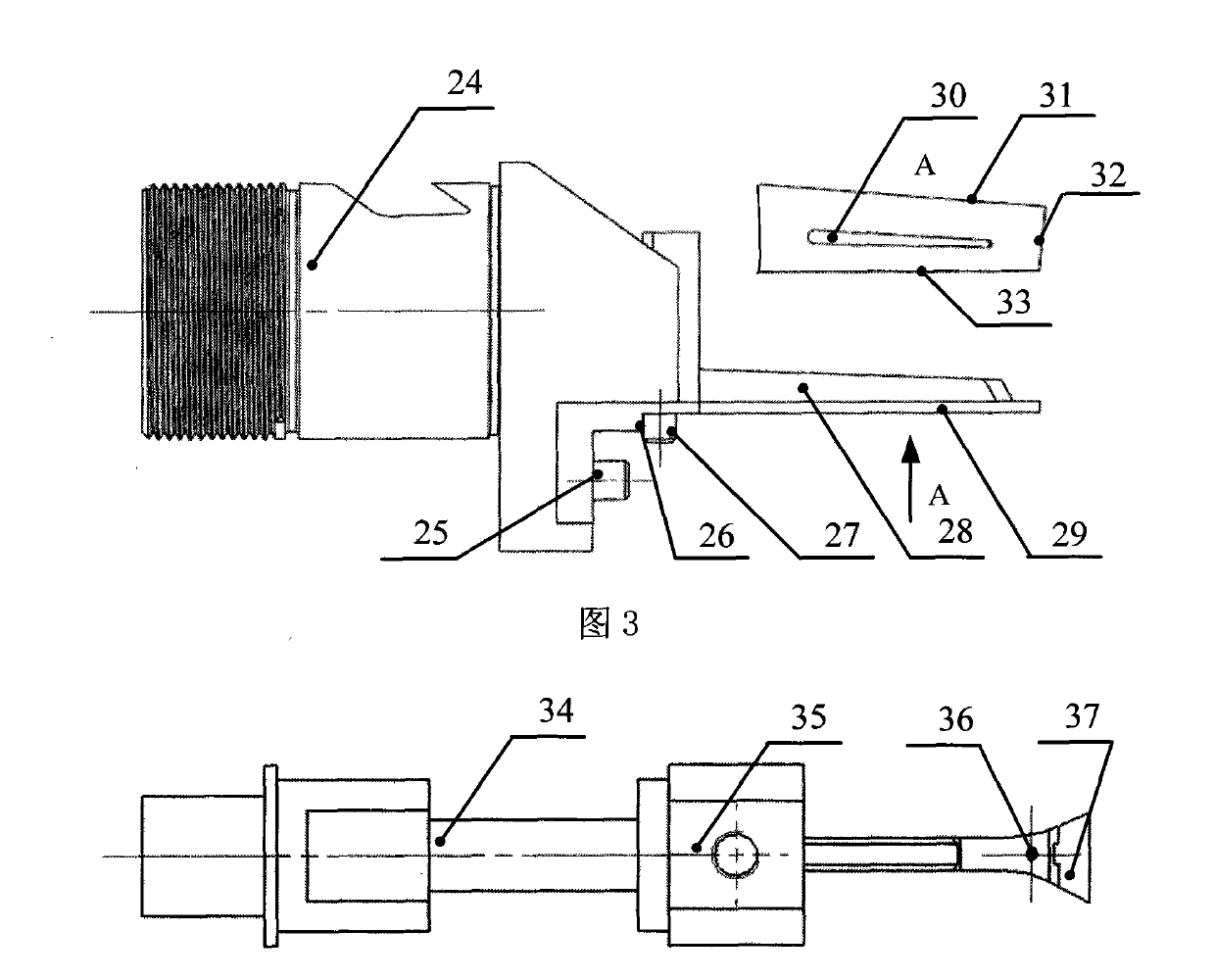

Step and zone type integral impeller electrolytic processing process and device

InactiveCN101767233AGuaranteed machining accuracyImprove machining accuracyElectrochemical machining apparatusImpellerElectrolysis

The invention discloses step and zone type integral impeller electrolytic processing process and device, which belong to the field of impeller electrolytic processing. The integral impeller electrolytic processing has three processing procedures of impeller disc, impeller back and impeller root. The impeller back is firstly processed, then the impeller disc is processed, and the impeller root is processed. The impeller disc, the impeller back and impeller root can be respectively processed along the respective profile by a sweeping forming method. The device comprises an X-axis slide unit, a Y-axis slide unit, a Cw-axis rotary table, an index plate, a processing power supply, an anode conductive plate, a center shaft, a cathode, a cathode conductive plate, a pressure gauge, a ball valve, a water pump, a filter and an electrolytic tank. The invention effectively solves the problem of blade processing of the integral impeller, and is suitable for processing the integral impellers of aerospace engines and advanced power units.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

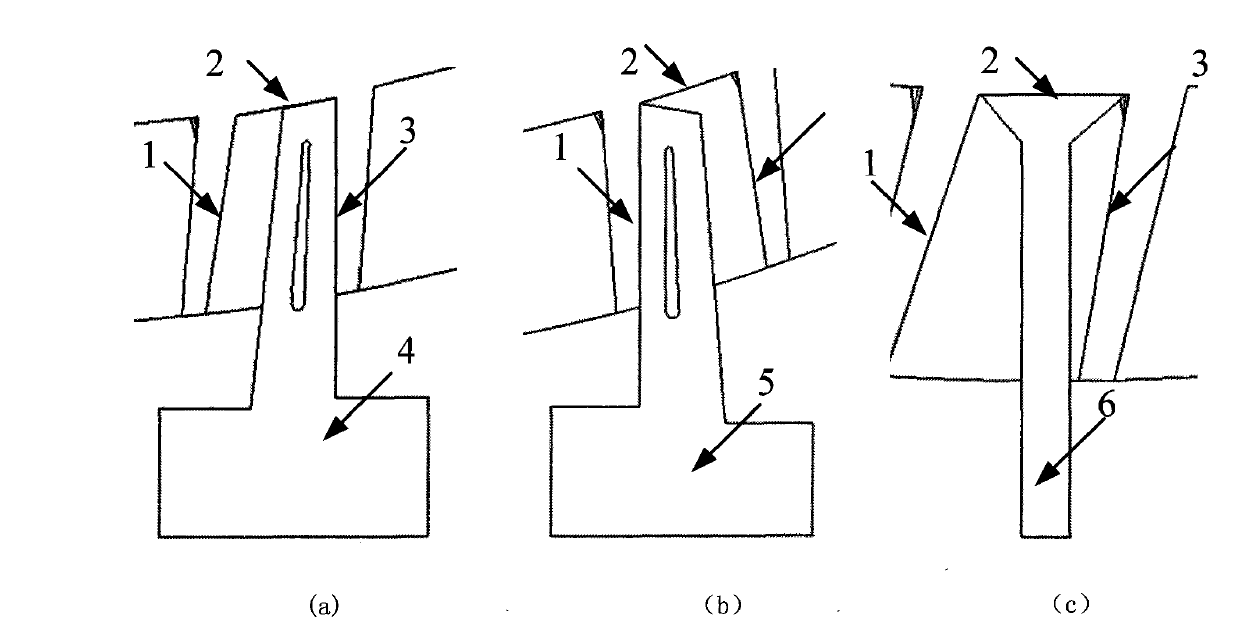

Coal seam group with high gas content pressure relief and co-mining method based on gob-side entry retaining of working face of first mining total rock pressure relief

InactiveCN104712358ALayer selection is flexibleSolve the outstanding problem of safe miningFluid removalGas removalLithologyPlate pressure

The invention discloses a coal seam group with high gas content pressure relief and co-mining method based on gob-side entry retaining of a working face of first mining total rock pressure relief. When a first mining pressure relief coal seam can not be selected, the coal and rock seams are moved and broken through the working face of first mining total rock pressure relief, an upper covered coal seam with high gas and a lower covered coal seam which high gas are subjected to pressure relief and swollen, fractures of a surrounding rock mass are developed, the gas permeability is increased, the gas is subjected to desorption and transportation, and finally a top plate pressure relief annular fracture area and a bottom plate pressure relief annular fracture area are generated. To create a favorable stress environment of retained roadway surrounding rock, retained roadway mining empty side cantilever crest truncation is conducted to first advance mining drill site toward and backward the working face in a bi-directional mode, according to the top plate lithologic characters, the first advance is subjected to top plate deep hole pre-splitting and cover caving so that it is guaranteed that the top plate is sufficiently collapsed to fill a worked out section. By means of the method, the prominent problems of exhausting and mining of coal seam group pressure relief gas and safe mining when the first mining pressure relief coal seam of the coal seam group with high gas content is difficult to select are solved.

Owner:CHINA UNIV OF MINING & TECH

Parameter setting and reeling method of thermal tandem rolling stainless steel band reeling equipment

ActiveCN101716617AReduce the number of scrap coilsImprove production stabilityComputer controlMaterials science

The invention relates to a parameter setting and reeling method of thermal tandem rolling stainless steel band reeling equipment. The method sets the following parameters: an advance speed set value of each sets of roller ways=a final finish rolling frame speed set value*(a total roller way advance rate+a corresponding grouped advance rate); a lagged set speed value of each sets of roller ways=a final finish rolling frame speed set value*a roller way lagged rate; the setting of the openness of a side guide plate; the pressure coefficient of the side guide plate of 0.5-0.8; the added value of the side guide plate of 0 to +15mm; and the settings of a pinch roll: calibration of the pinch roll of the reeling machine by guaranteeing normal calibration, the advance rate and the lagged rate of the pinch roll, the pressure coefficient of the pinch roll, the diameter of an upper roll of the pinch roll of the reeling machine, and the diameter of a lower roll of the pinch roll of the reeling machine. In the reeling method, a computer controls reeling equipment to reel according to the set parameters. The parameter setting and reeling method of thermal tandem rolling stainless steel band reeling equipment improves the appearance and surface quality of steel rolls.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

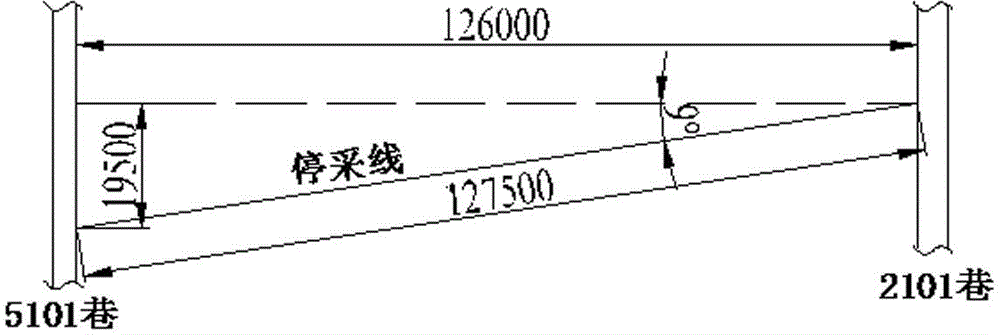

Safety recovery method of island working surface under complicated condition

ActiveCN104453899ADoes not affect normal recoveryNormal recovery guaranteeUnderground miningSurface miningRecovery methodPlate pressure

The invention relates to a safety recovery method of an island working surface under a complicated condition. An innovated manner of pre-discharging before mining and mining while discharging is adopted, and normal recovery of the working surface is not influenced by deposited water of a goaf. Other relative rock burst prevention and treatment methods including drilling and pressure relief, bottom plate pressure relief and blasting, coal seam water injection and the like are adopted by rock burst prevention and treatment, so that the accuracy degree of predication is improved, the possibility of rock burst is reduced and guarantees are provided for the normal recovery of the working surface. A working surface mining stopping position is comprehensively determined by adopting a manner of combining adjusting slope of tail mining of the working surface and avoiding a periodic pressure position, the length of the working surface is in a cutting range of a coal mining machine and the two ends of the working surface avoid the periodic pressure position, and the middle part of the working surface does not avoid the periodic pressure position.

Owner:DATONG COAL MINE GRP

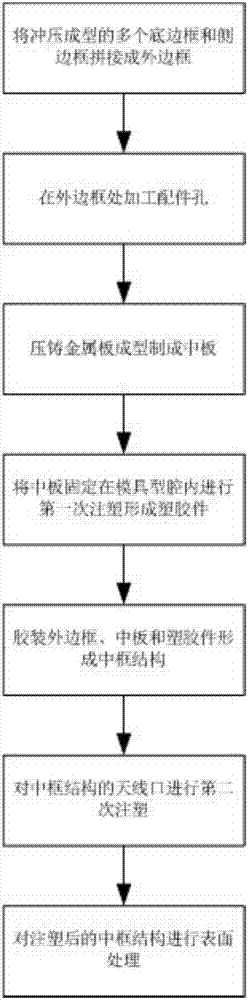

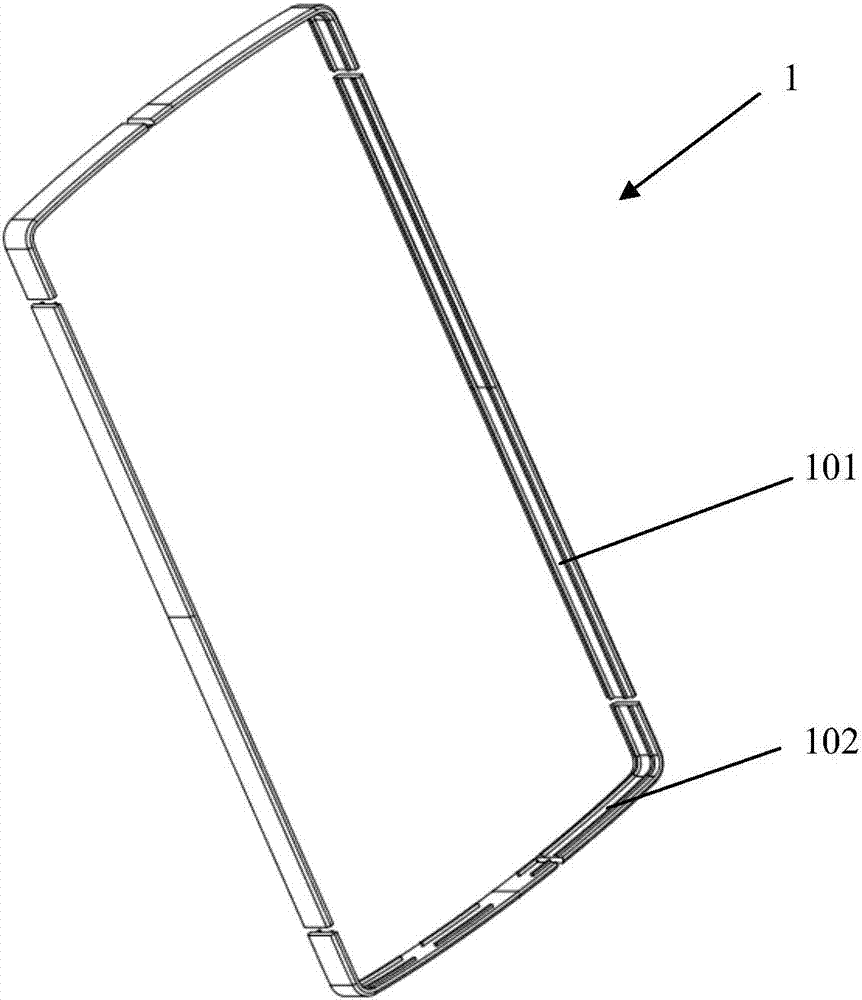

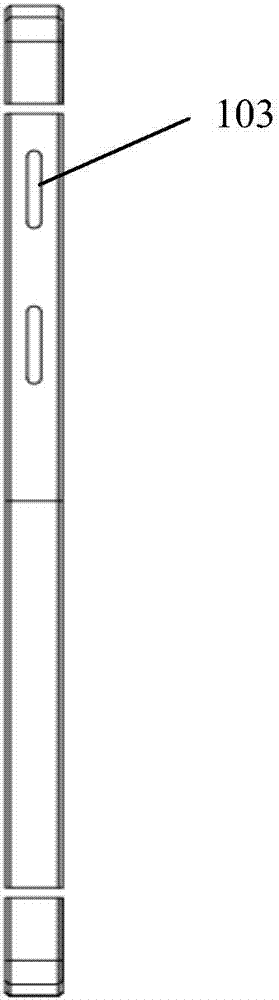

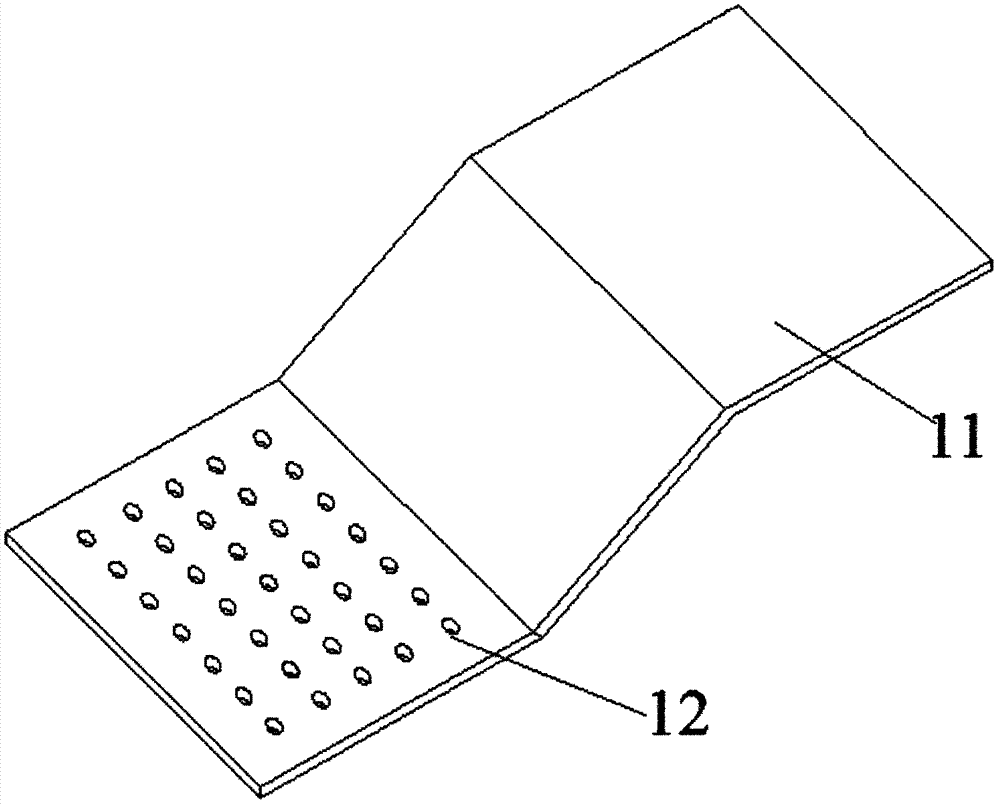

Middle frame manufacturing method and middle frame structure

InactiveCN107244034AIncrease profitSimplify processing stepsCasings/cabinets/drawers detailsDomestic articlesPlate pressurePressure casting

The invention discloses a middle frame manufacturing method and a middle frame structure and belongs to the technical field of 3C small household electrical appliances. The middle frame manufacturing method provided by the invention comprises the following steps: after splicing a plurality of bottom borders and a plurality of side borders, which are manufactured by punching metal profiles, into an outer border and conducting pressure casting on a metal plate to manufacture a middle plate, fixing the middle plate in a die cavity, carrying out primary injection molding to form a plastic part, then conducting glue binding on the outer border, the middle plate and the plastic part to form the middle frame structure, and finally carrying out secondary injection molding and surface treatment on the middle frame structure. As for the method, by adopting a metal plate pressure casting and injection molding technology, processing steps are simplified, the processing difficulty is lowered, the processing time is saved, the utilization ratio of raw materials is also increased, and thus the processing cost is lowered. The middle frame structure processed and formed by the method has attractive, fashionable, high-end and elegant appearance and has the advantages of simple structure, strong integrality, low cost, good heat dissipation performance, high whole strength and the like.

Owner:洪鸿莎

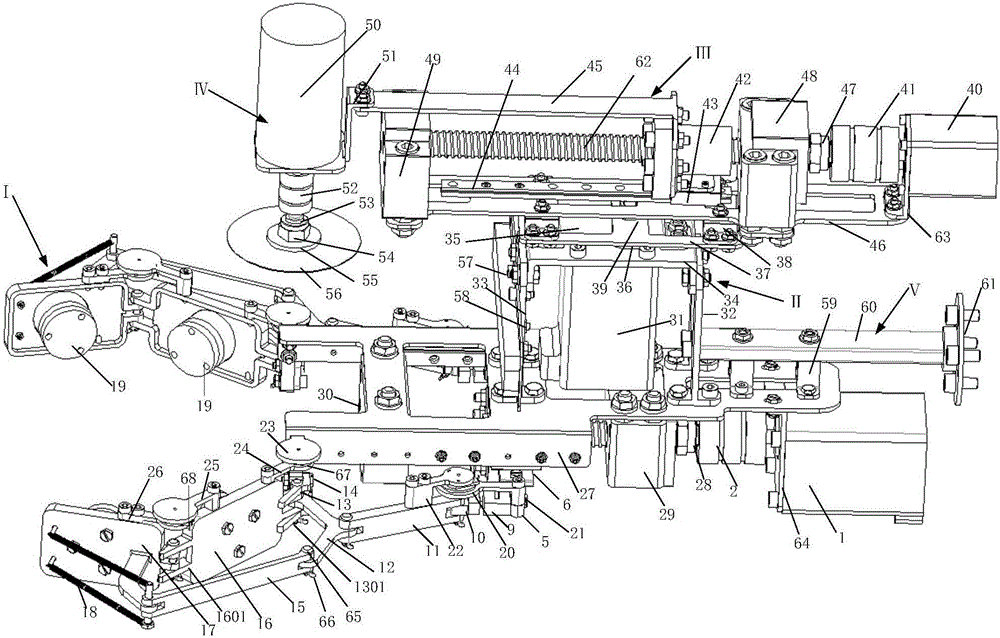

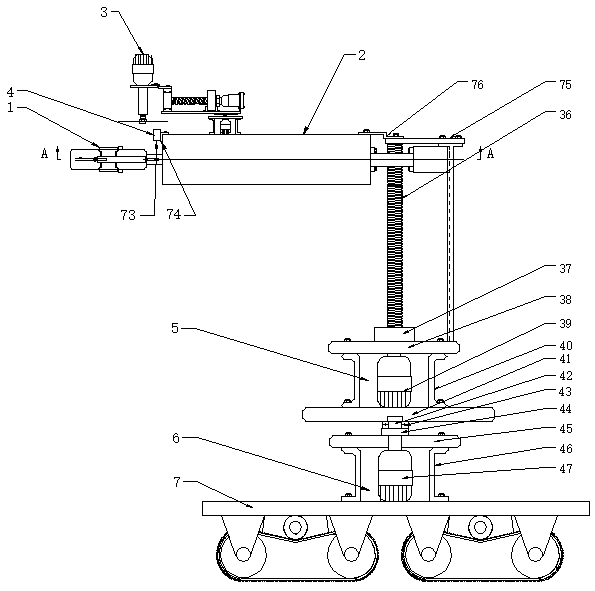

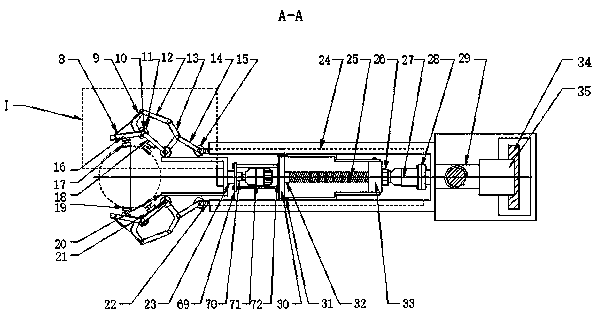

Clamping rotary cutting type underactuated two-finger grape picking device

ActiveCN106342484AWith envelope grabbing functionImprove stabilityPicking devicesCircular discClosed loop

The invention provides a clamping rotary cutting type underactuated two-finger grape picking device, which mainly comprises underactuated finger mechanisms, a rotation mechanism, a pushing mechanism, a rotary cutting mechanism, a wrist connecting mechanism, a main support plate and a binocular camera, wherein the underactuated finger mechanisms are distributed at two sides of the main support plate; the wrist connecting mechanism is connected with the rotation mechanism; the rotation mechanism is connected with the main support plate; the pushing mechanism is connected with the rotation mechanism; the rotary cutting mechanism is connected with the pushing mechanism; the wrist connecting mechanism is connected with the waist of a mechanical arm; a motor A drives the underactuated finger mechanisms to move; through the effects of an S-shaped pressure sensor, a potentiometer, a flat plate pressure sensor and a tension spring, the flexible target object gripping and the closed loop real-time control on the underactuated finger mechanisms by a controller are realized; the rotary cutting mechanism controls a circular disc cutter blade to realize rotary cutting action on target fruit stems through a direct current motor. The grape picking device has the advantages that the structure is ingenious; the flexibility is high; the finger pose work space is large; high picking success rate can be obtained; the mechanical damage to plants and fruits can be reduced; the picking on clustered fruits such as grapes can be realized; the characteristics of self-adaption capability to the fruit shape and contact force controllability are realized.

Owner:JIANGSU UNIV

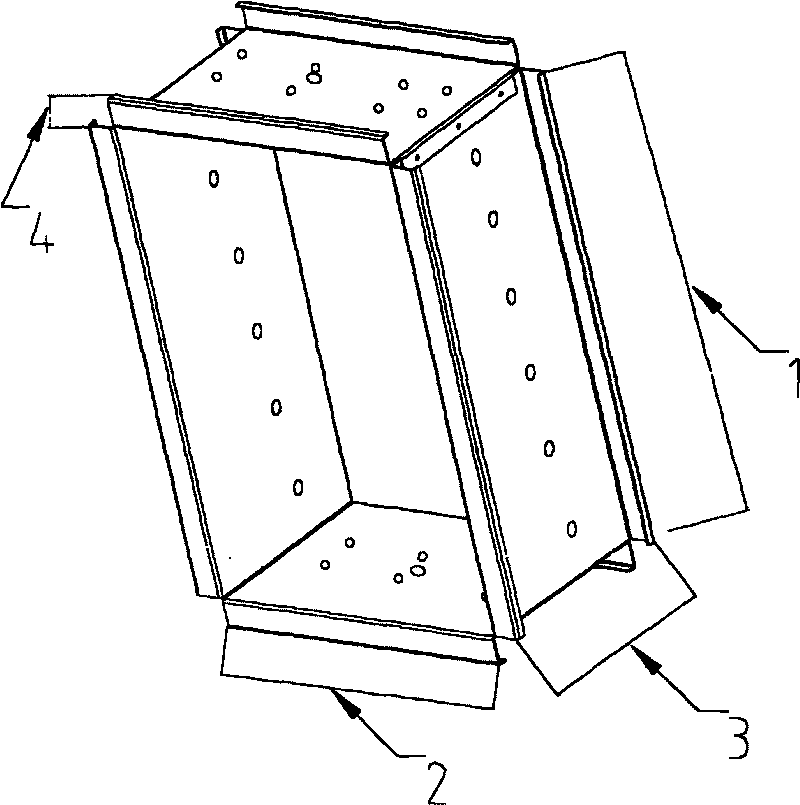

Manufacturing method of integrated square fire-resisting damper valve buckle body molding and rolling forming device thereof

The invention provides a manufacturing method of integrated square fire-resisting damper valve buckle body molding, comprising the following process steps: carrying out blanking on a complete board with a plate shearing machine according to the ordered size of the valve body and cutting into a rectangular panel veneer; carrying out working procedure processing like corner cutting, notching, punching and the like on the panel veneer with a press tool; performing bending operation of the flange edge at the two sides of the panel veneer with a bending machine; carrying out molding operation on the square frame body with a valve body molding device; and finally adopting welding or riveting operation at the seam position to finish the processing of the valve body frame body in the end. The invention has the following advantages: the method only needs shearing the board once, and the manufacturing can be completed through press working; compared with the current board-shearing and tailor welding four times, the method in the invention leaves out a plurality of working hours and reduces the disadvantages of size deformation; the total processing time of the frame body can be saved by 59.5%, thus the cost of the valve body is substantially lowered; the integrated board is under press working with almost no deformation; and welding is only carried out on the joint at one side, and the generated air leakage rate of the weld porosity is reduced to 25% of the original air leakage rate.

Owner:大荣空调设备(南京)有限公司

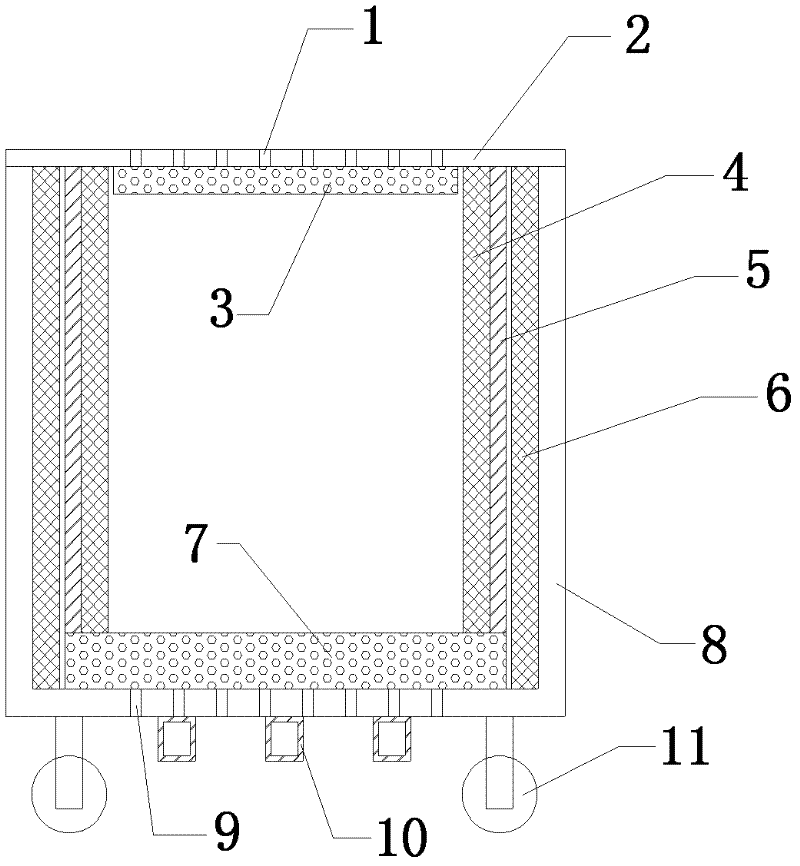

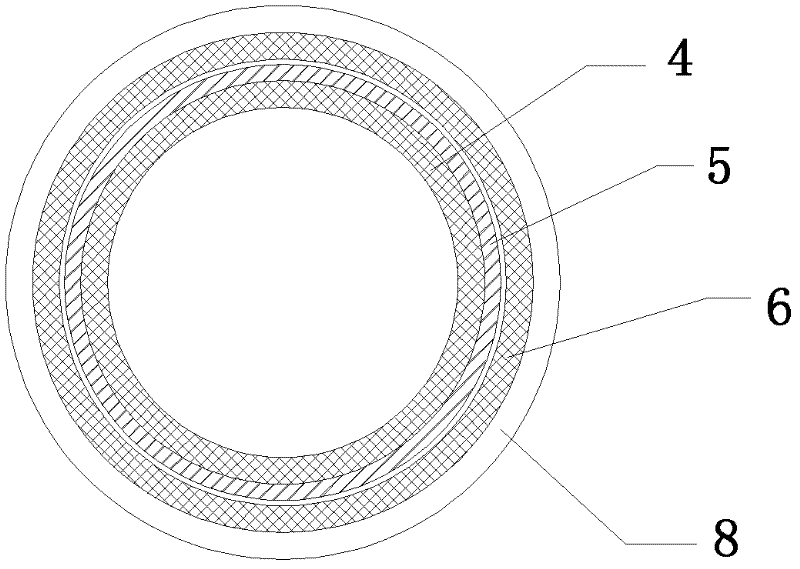

Pressure relief type explosion-proof tank

The invention discloses a pressure relief type explosion-proof tank, which comprises a tank body and a tank bottom, wherein a cover plate with cover plate pressure relief holes is arranged on the top of the tank body; the tank body consists of an inner cylinder and an outer cylinder; the outer cylinder consists of an outer cylinder wall and an outer cylinder buffer layer arranged in the outer cylinder wall; the tank bottom is provided with an outer cylinder wall bottom plate; a buffering base plate is arranged on the upper part of the outer cylinder wall bottom plate, on the inner side of the outer cylinder buffer layer and on the lower part of the inner cylinder; outer cylinder wall pressure relief holes are formed on the outer cylinder wall bottom plate; the inner cylinder consists of an inner cylinder wall and an inner cylinder buffer layer in the inner cylinder wall; a buffering lining plate is arranged on the lower part of the cover plate and on an inner side of the inner cylinder buffer layer; the buffering lining plate and the buffering base plate are made of porous foam metals; the inner cylinder buffer layer and the outer cylinder buffer layer are made of closed pore foam metals; and the thickness of the buffering base plate is greater than that of the buffering lining plate. By the explosion-proof tank, fragments produced through explosion can be prevented from flying out of the tank so as not to damage surrounding equipment and crowd, the internal pressure of the tank body can be reduced through pressure relief, and the safety performance of the explosion-proof tank is improved.

Owner:XI AN JIAOTONG UNIV

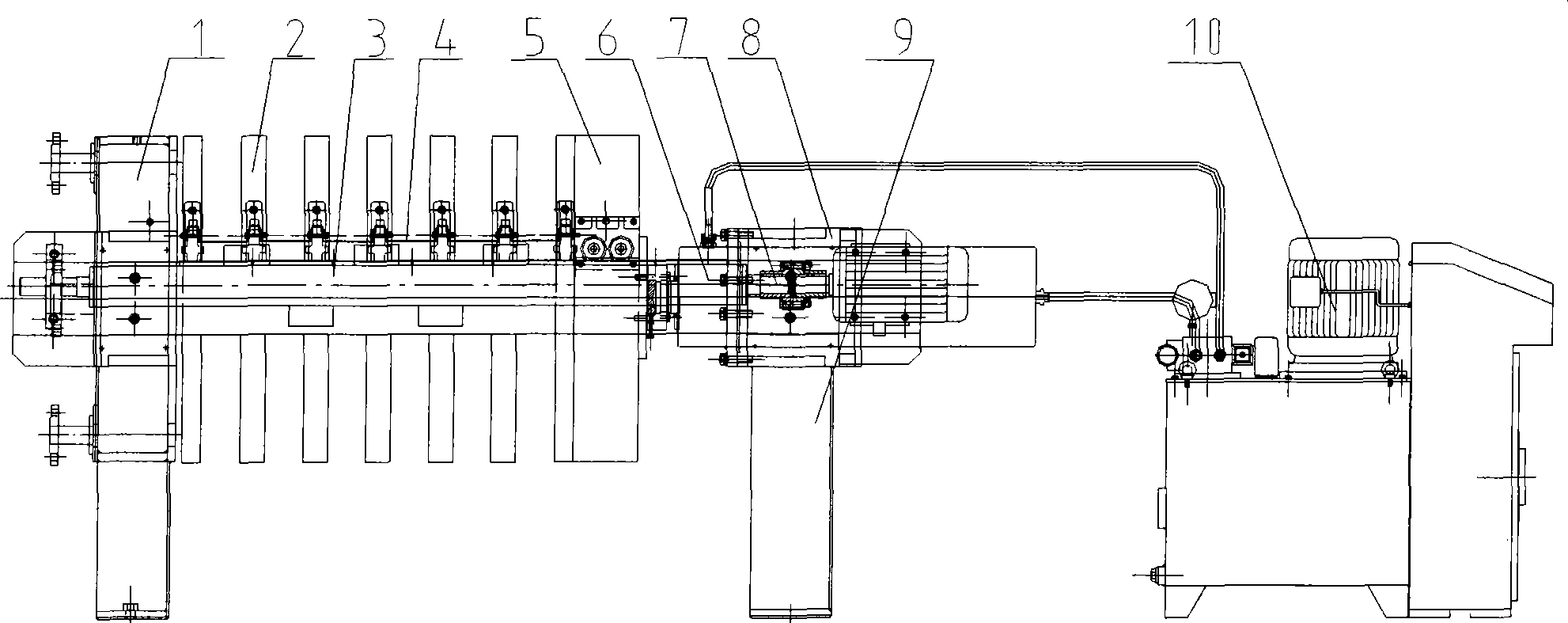

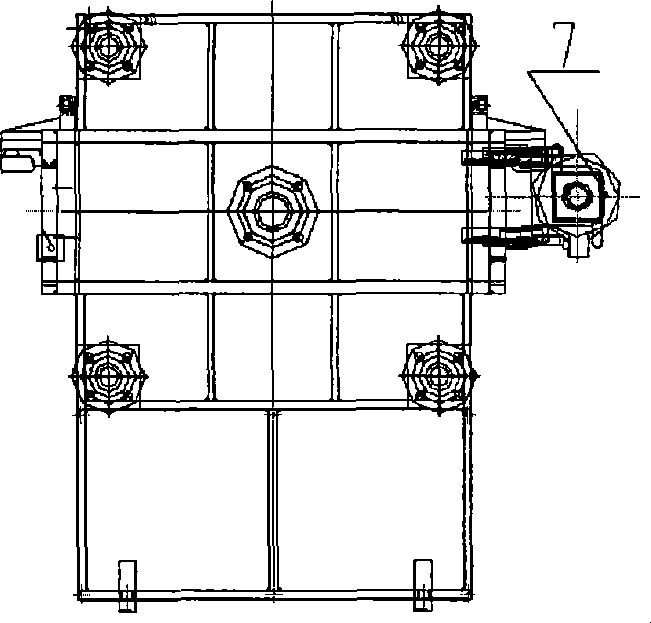

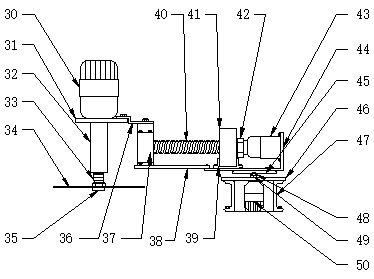

Disposable tension vibration pressure filter and vibration method

ActiveCN101380528ASolve the fully automatic controlSolve the current situation of low work efficiency, high labor intensity and poor working environmentFiltration separationPlate pressureElectrical control

The invention relates to a one-off undrawn vibration filter plate pressure filter used in the small and medium type solid-liquor separation industry, which comprises a thrust strip, a filter component, a girder, a pressure strip, a cylinder, a cylinder seat, a frame, a hydraulic system and an electric control system. A draw plate system connects all filter plates of the filter component with the pressure strip, the vibration filter plate system is positioned under the filter plate handle of the filter component, and the filter plate handles are corresponding to vibration bump blocks respectively. The pressure filter has the advantages: firstly, the problem of low automation is solved, total automation control in the process of solid-liquid separation is realized conveniently; secondly, the present situations of low work efficiency, high labor intensity and bad working environment are changed; thirdly, the shortcomings are solved that the effect of cake-discharging existing in background technology is not ideal and manual assistance in cake-discharging is needed, thus leading to realizing the automation in the process of cake-discharging, and the effect of cake-discharging is better.

Owner:HANGZHOU XINGYUAN FILTER TECH

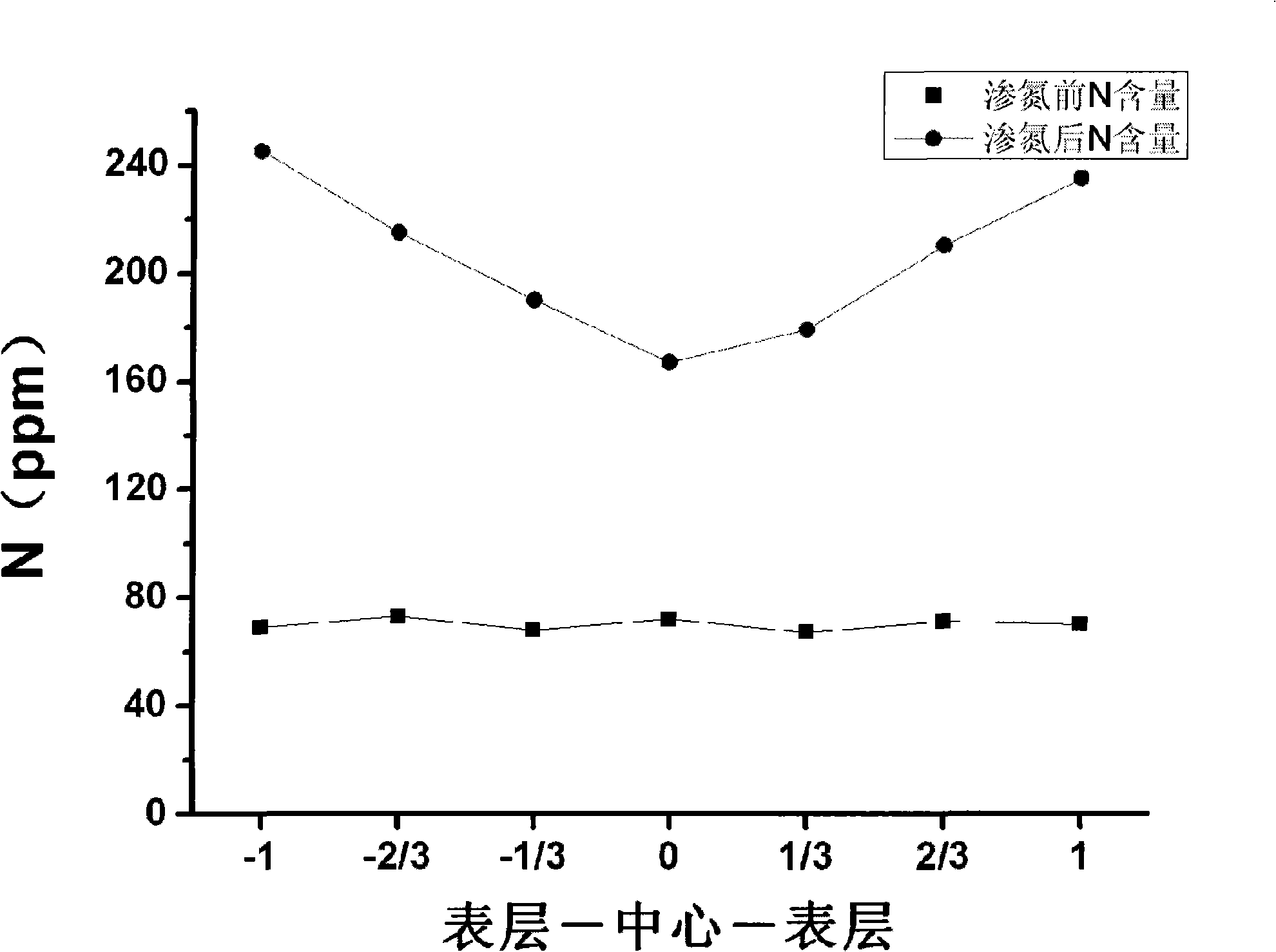

Nitrogen case hardening method of orientation silicon steel

ActiveCN101294268AUniform secondary recrystallizationUniform nitriding effectVacuum evaporation coatingSputtering coatingPlate pressureNitrogen

The invention discloses a nitriding method of an oriented silicon steel, which is mainly characterized in that the plasma nitriding treatment is performed in a plasma nitriding chamber; the infiltration capacity and the distribution of N elements, and the size of nitride are controlled through controlling the conditions in the plasma nitriding chamber, wherein, the N element and nitride are permeated into the oriented silicon steel; the plasma nitriding chamber satisfies the conditions that nitriding temperature ranges from 500 to 700 DEG C, the nitriding time is 10 to 30 seconds, nitriding atmosphere comprises H2 which accounts for 0 to 10 percent, NH3 which accounts for 0 to 5 percent, and N2 which accounts for the rest, the vacuum degree of the plasma nitriding chamber ranges from 1000 to 2000Pa, and the polar plate pressure is 700 to 1000V. The plasma nitriding method is adopted in the manufacture of the oriented silicon steel can lead the nitriding effect to be uniform, enhance the inhibitory capacity of an inhibitor, and increase the technologic stability.

Owner:BAOSHAN IRON & STEEL CO LTD

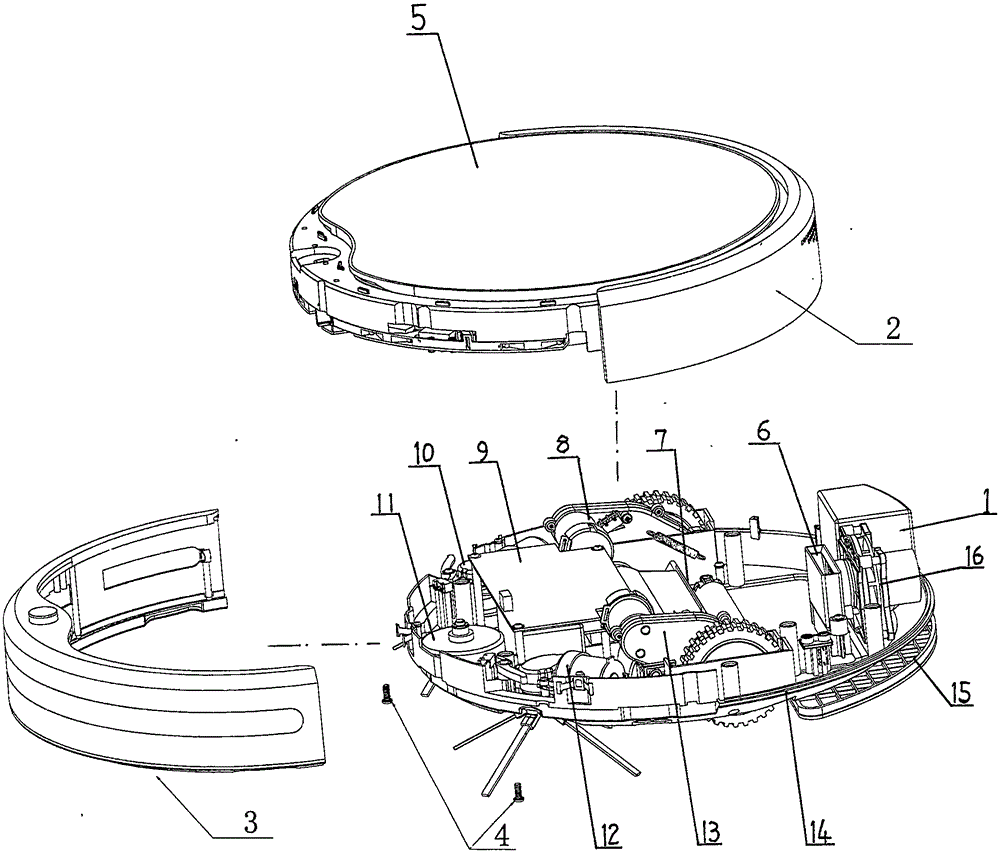

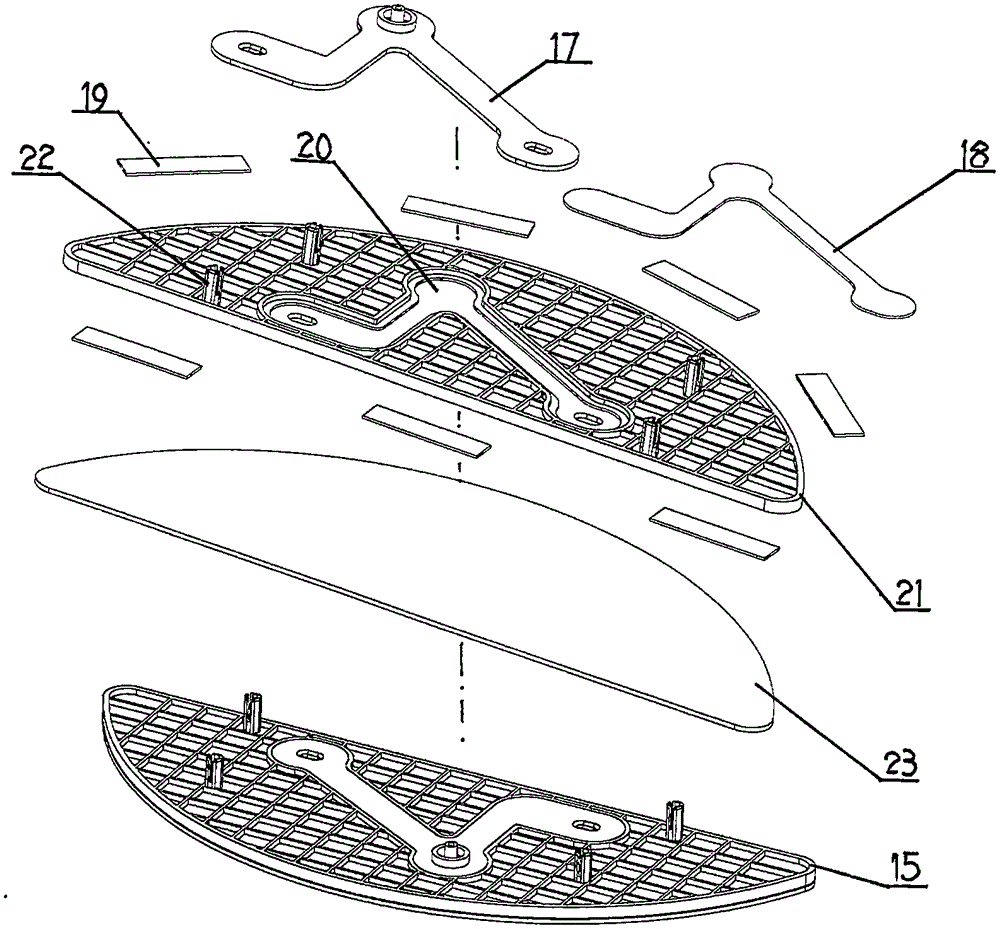

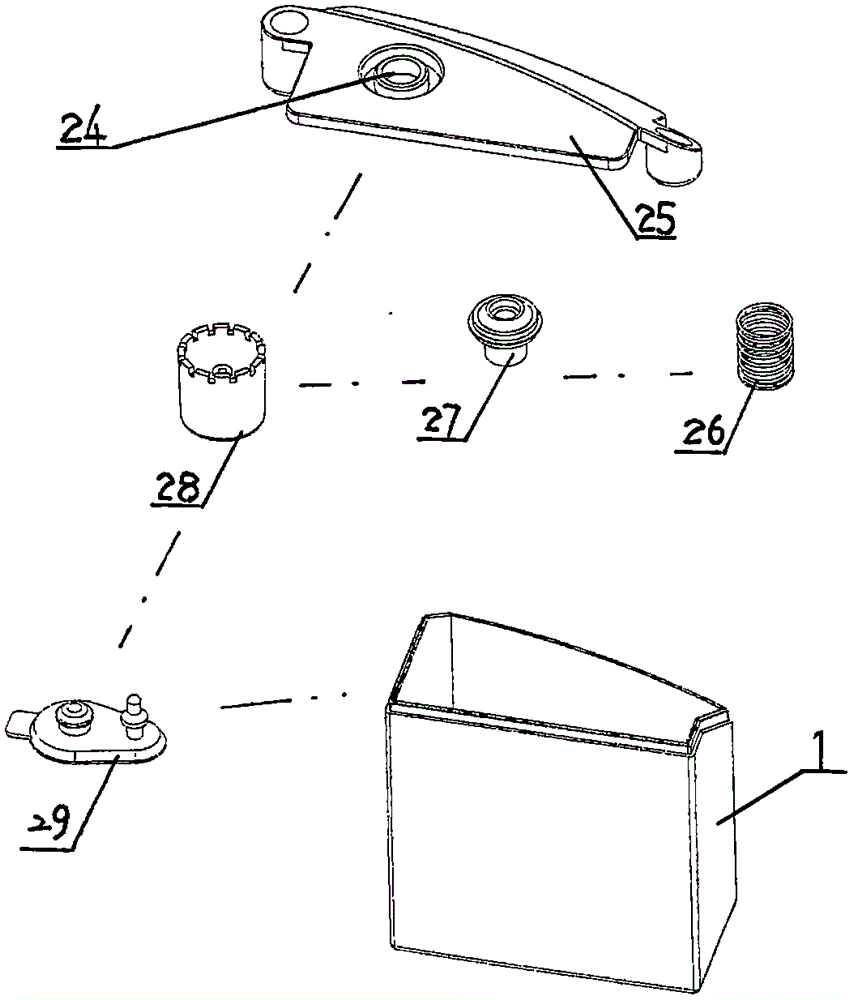

Cleaning robot

ActiveCN105662280ASimple structureReasonable layoutGas treatmentDispersed particle filtrationFiberPlate pressure

The invention discloses a cleaning robot. The cleaning robot comprises a snap-cover body, a display operation battery box body, a dust collection filter box and a dust collection filter box seat groove, and further comprises a water tank body and a mop assembly, wherein the water tank body is positioned on the back side of the upper end of a base; the mop assembly is positioned on the back side of the lower end of the base and consists of a mop plate, a mop plate pressure part, mop, quick-connection stickers and a collodion sheet; the dust collection filter box is used for filtering dust and purifying air subjected to dust filtering; an inner space of a dust collection box body between a dust inlet of the box body and an air suction hole of the box body is divided into a dust collection chamber and labyrinthic filter chambers by first and second partition plates arranged at an interval; a filter fiber material is arranged in the first filter chamber; and an active carbon material is arranged in the second filter chamber. The cleaning robot has a function of purifying indoor air in addition to floor cleaning and dust collection functions, can clean the cleaned ground by the wet mop, has the advantages of simple structure, reasonable layout, low manufacturing and use costs and good use effect, And is convenient to transform.

Owner:北京福玛特科技有限公司

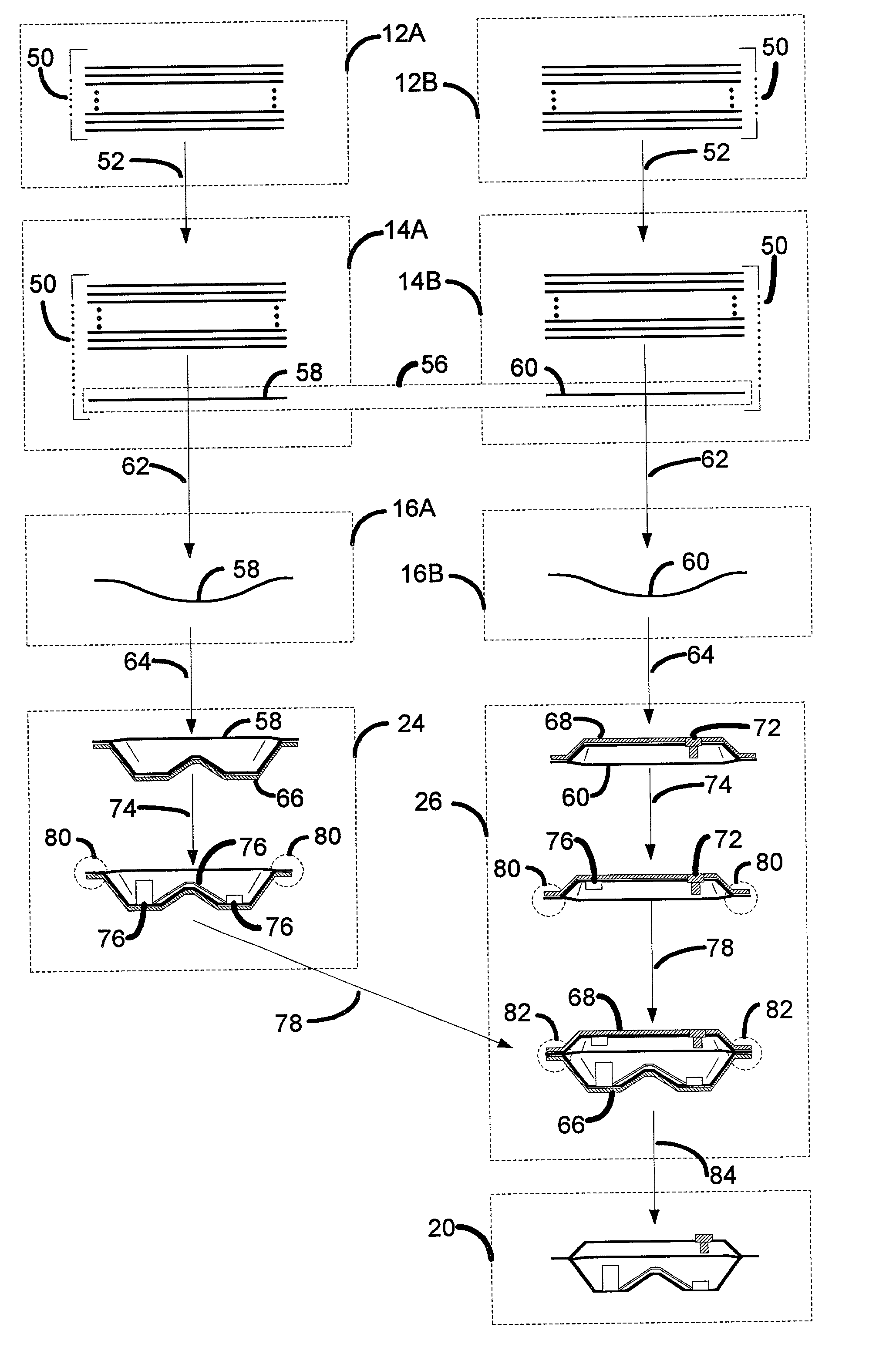

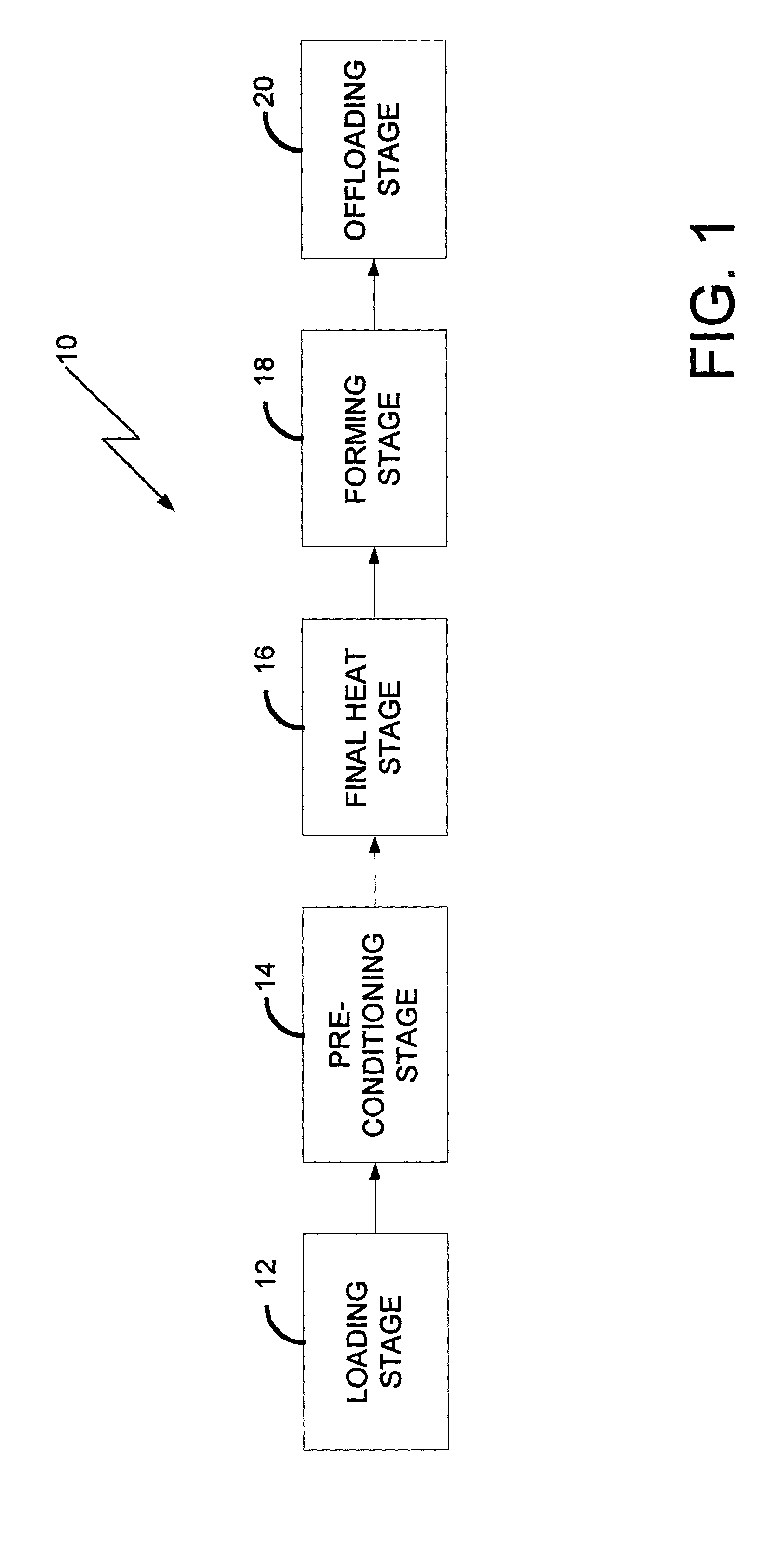

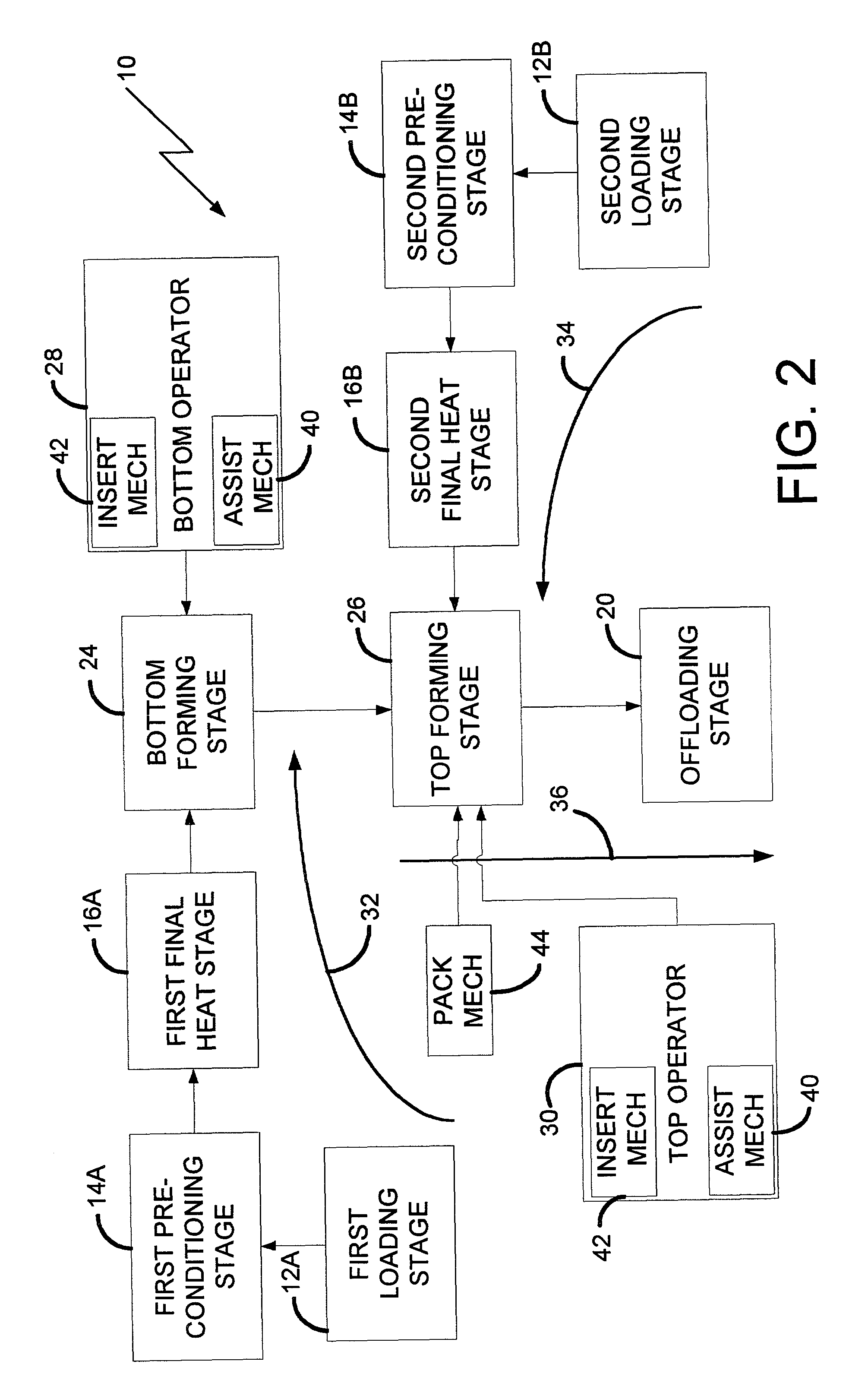

High volume production of low permeation plastic fuel tanks using parallel offset twinsheet pressure forming

InactiveUS6969485B2Increase volumeMinimizes lag timeAdhesive processesLarge containersHigh volume manufacturingFuel tank

Processes are disclosed for producing plastic containers from thermoplastic sheets where the thermoplastic sheets are processed in parallel to form a low permeation plastic container. A plurality of thermoplastic sheets are progressively heated to a first temperature in a pre-conditioning stage. A group of the thermoplastic sheets are selected from the plurality of thermoplastic sheets and rapidly heated to a second temperature in a final heat stage. The group of thermoplastic sheets are then processed in a forming stage to form the low permeation plastic container.

Owner:VISTEON GLOBAL TECH INC

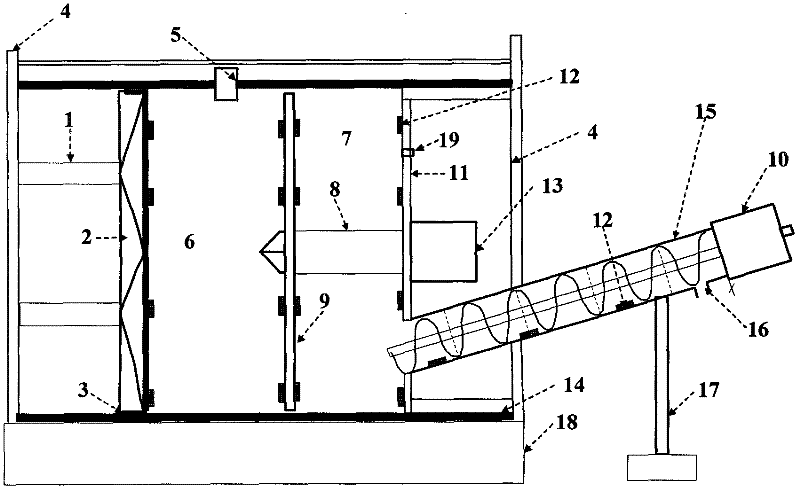

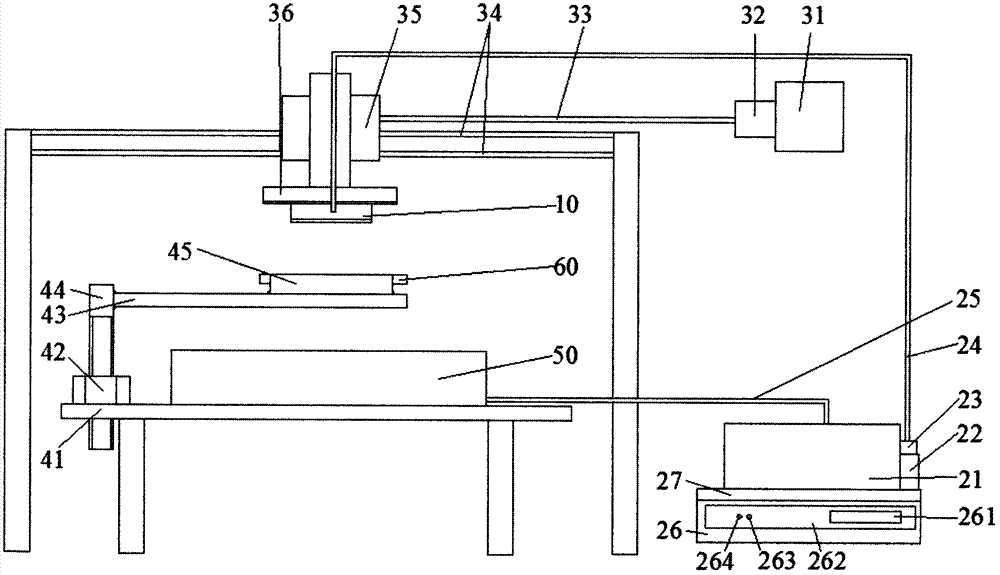

Earth pressure balance (EPB) shield residual soil pressure control model test apparatus

InactiveCN102226729AApparatus for force/torque/work measurementCompartment pressurePressure transmission

The invention discloses an earth pressure balance (EPB) shield residual soil pressure control model test apparatus. The model test apparatus mainly comprises a truss type loading system, a cutterhead, a sealed compartment, a screw conveyer and a pressure transducer system. The truss type loading system is connected with a reaction frame through a jack. Excavation surface loading can be realized by thrust of the jack. The cutterhead and the screw conveyer are driven by a motor. The pressure transducers are arranged on different positions of a sealed compartment separator plate and a screw conveyer housing. Pressure data is monitored by PC software through data an acquisition instrument. By using the apparatus, under the conditions of different modified residual soil, different sealed compartment pressure or different screw conveyer rotating speeds, and through monitoring typical position residual soil pressure of the sealed compartment separator plate and the screw conveyer, residual soil pressure transmission mechanism in the earth pressure balance (EPB) shield sealed compartment and the screw conveyer can be verified; a mapping relation between excavation surface pressure and thesealed compartment separator plate pressure and a pressure variation relation between an inlet and an outlet of the screw conveyer can be established. Therefore, an earth pressure balance (EPB) shield construction can be guided.

Owner:GUANGSHA CONSTR GROUP +1

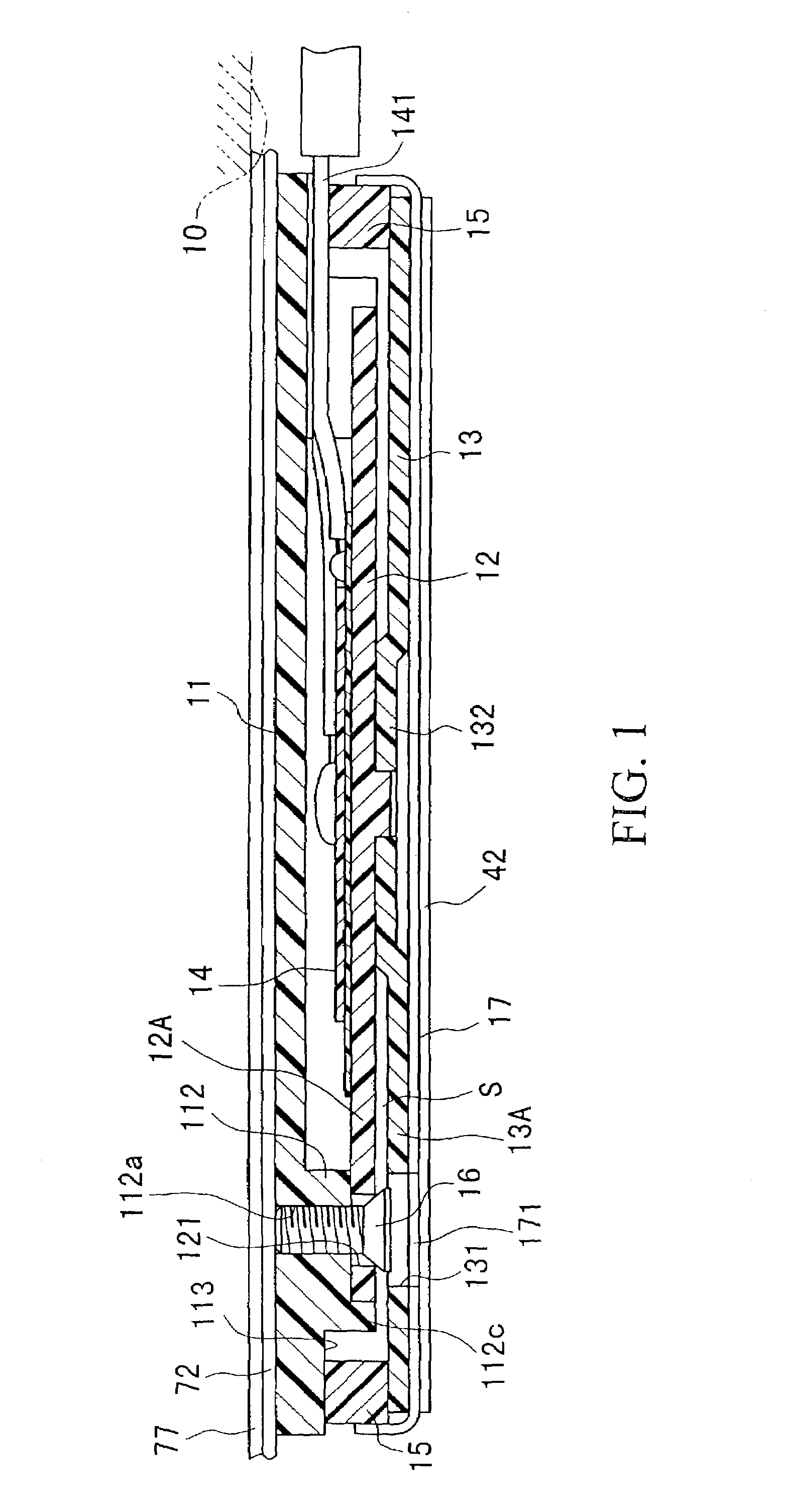

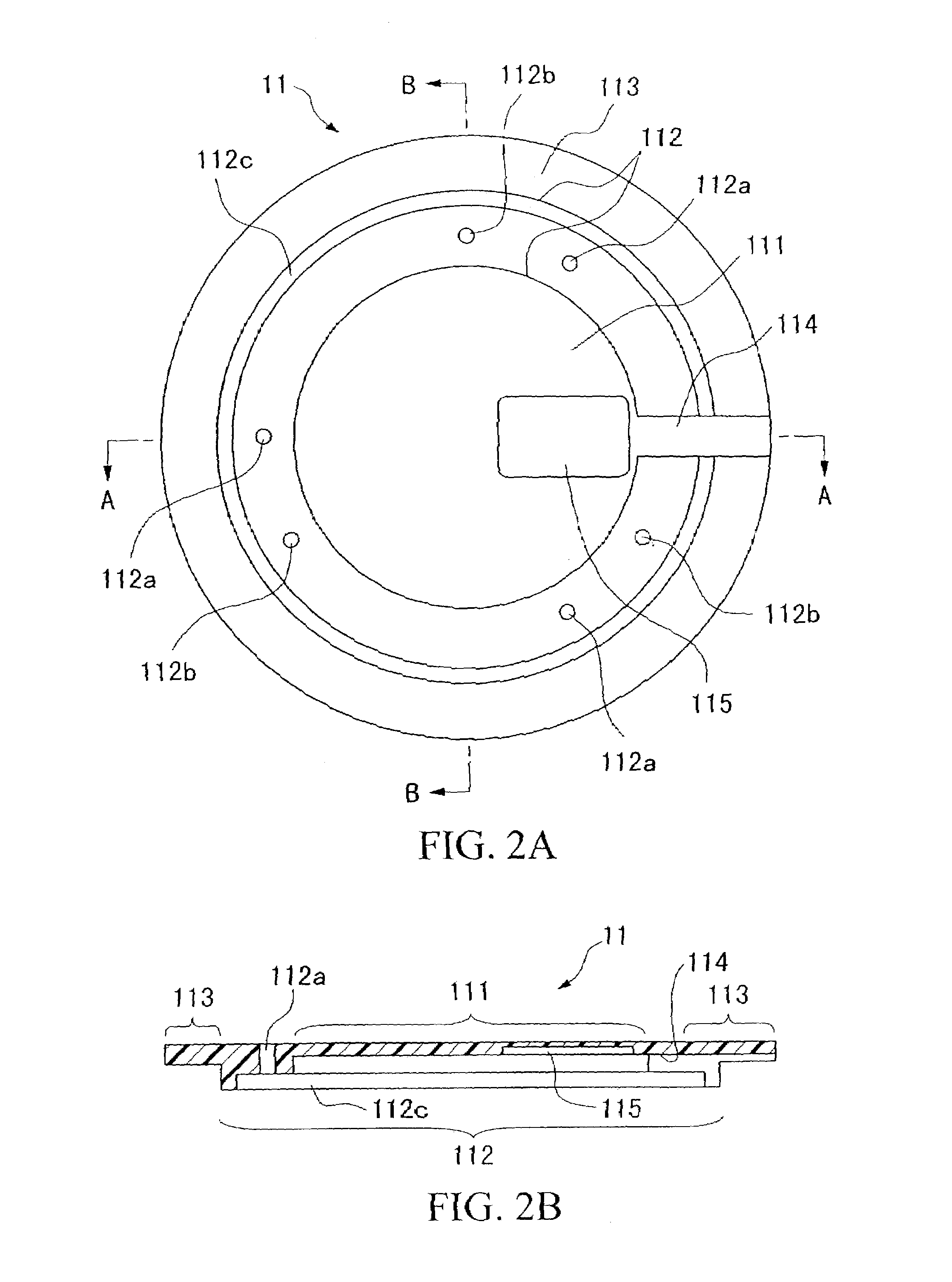

Musical tone control apparatus and sensing device for electronic musical instrument

A sensing device is constructed by a sensor case which is attached to a bottom surface of a footwear (e.g., sole of a shoe) and which contains a piezoelectric sensor, a sensor fixing member, a disc plate pressure member and an annular elastic member. The sensor fixing member has elastic deformability so that the sensor fixing member is located to face with the disc plate pressure member with an air gap in which the sensor fixing member is capable of deforming within a limit of elasticity thereof. Thus, it is possible to perform musical tone control in response to an output of the piezoelectric sensor when a foot motion is applied to the footwear. In addition, a musical tone control apparatus of a percussion instrument type is constructed using a pad unit stored in a pad storage portion of an upper case. Herein, the pad unit is constructed by a pad skin unit and a sensing unit. The pad skin unit has a beat surface to be beaten, while the sensing unit contains a piezoelectric sensor, a sensor fixing member and a radial pressure member. Both of the sensor fixing member and the disc plate pressure member (or radial pressure member) are assembled together in such a way that center parts thereof are securely fixed to each other, so the piezoelectric sensor is capable of producing a same output in response to same external force (e.g., foot step force or beat force), regardless of directions to apply such force.

Owner:YAMAHA CORP

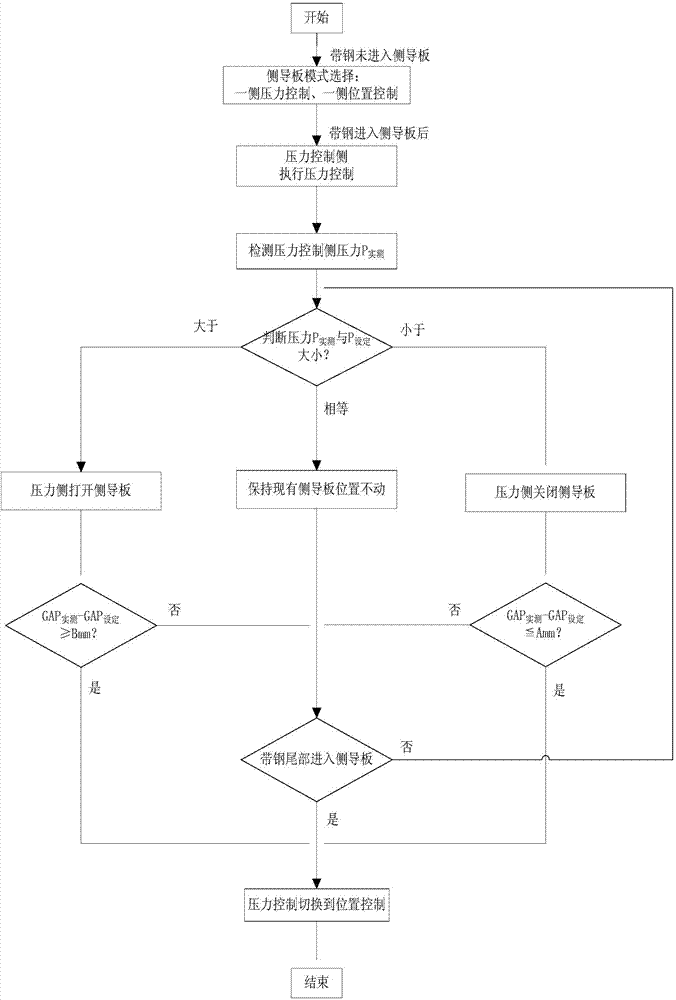

Pressure control method for coiling machine side guide plate

ActiveCN104267753AAvoid quality problemsAvoid control confusionMechanical pressure/force controlPlate pressureControl disorders

The invention discloses a pressure control method for a coiling machine side guide plate and belongs to the technical field of coiling machines. According to the selection of the pressure control method for the coiling machine side guide plate, pressure control is adopted in one side, and position control is adopted in the other side; after strip steel enters the coiling side guide plate, the side guide plate pressure control side executes pressure control, and real-time judgment is carried out on actual measurement of actual measurement pressure P and setting of a set pressure value P of the side guide plate pressure control side; judgment is carried out according to the position motion situation of the side guide plate pressure control side; finally, judgment is carried out according to the size of the actual measurement of the actual measurement pressure P and the size of setting of the set pressure value P of the side guide plate pressure control side, and the size of the actual measurement of the opening degree GAP and the size of setting of the set opening degree GAP of the two sides of the side guide plate, and the situation of the tail of the strip steel entering the side guide plate. According to the pressure control method for the coiling machine side guide plate, the problem of the steel roll tower shape caused by the fact that the side guide plate pushes the strip steel in a deviating mode can be prevented, the problem of the control disorder caused by abnormal pressure control under the circumstance of the pressure sensor failure is avoided, and layer staggering and edge cracking of steel rolls are effectively avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

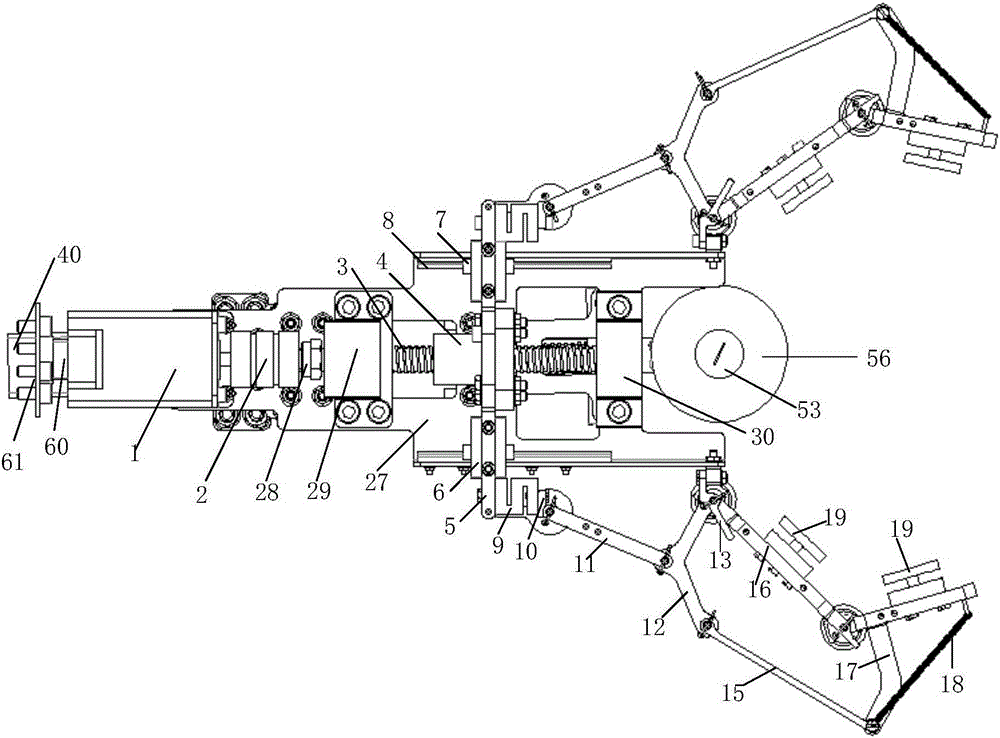

Fruit picking robot

InactiveCN109496563AWith grip functionAvoid damageManipulatorPicking devicesPlate pressureClosed loop

The invention discloses a fruit picking robot which comprises a grabbing part, an arm part, a fruit stem shearing part, a visual system, a lifting part, a rotating part and a movable base, wherein thegrabbing part is connected with the arm part, the arm part is connected with the lifting part, the visual system is located above the grabbing part and is connected with the arm part, the fruit stemshearing part is connected with the arm part, the lifting part is connected with the rotating part, and the rotating part is connected with the movable base; the fruit picking robot is exquisite in structure, the flexibility degree is high, the working space is large, and an s-shaped pressure sensor, a flat plate pressure sensor and a tension spring are utilized, so that the closed-loop real-timecontrol of a finger connecting rod mechanism I by a controller can be realized, a target object is flexibly grabbed, and mechanical damage caused by picking is reduced; the lifting part and the rotating part increase the picking freedom degree, fruit stems are retained while the target is picked by the shearing part, and fruits can be stored more easily.

Owner:DONGGUAN UNIV OF TECH

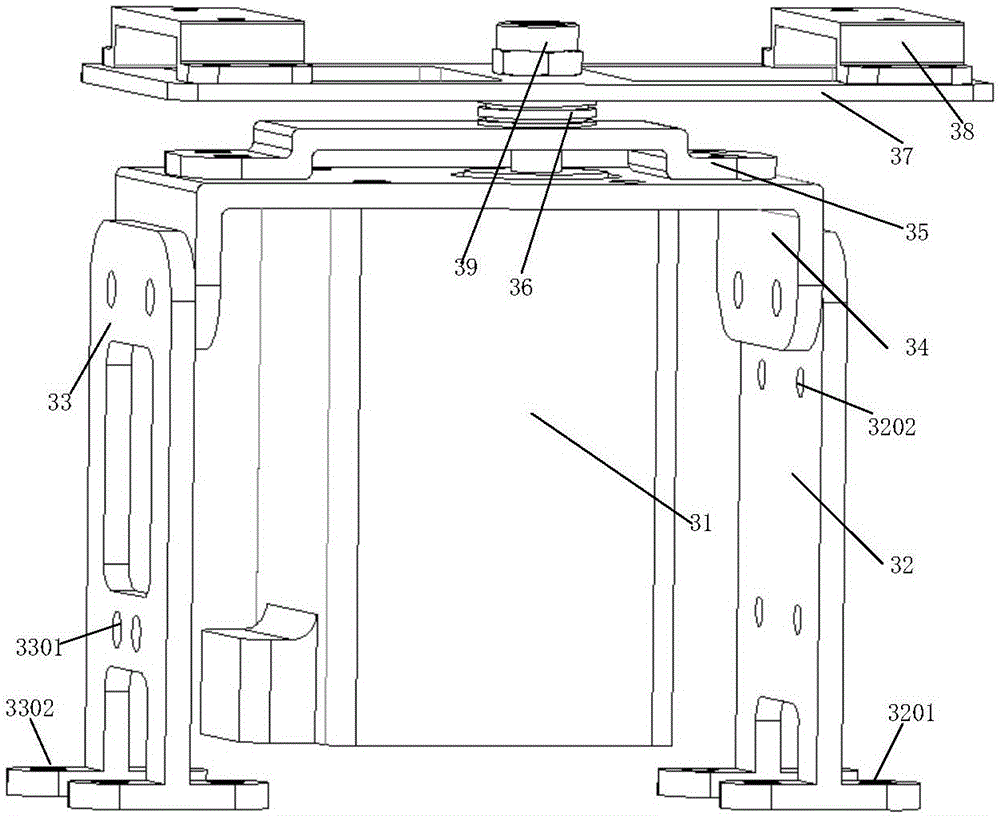

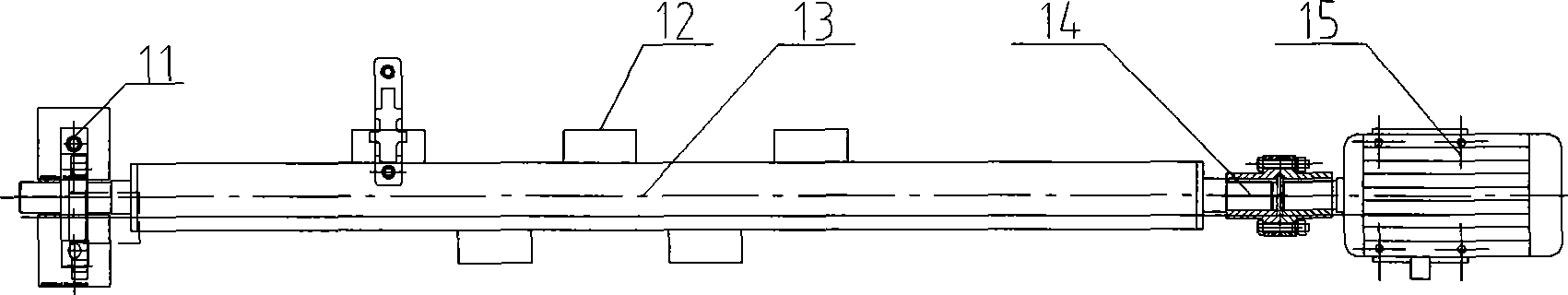

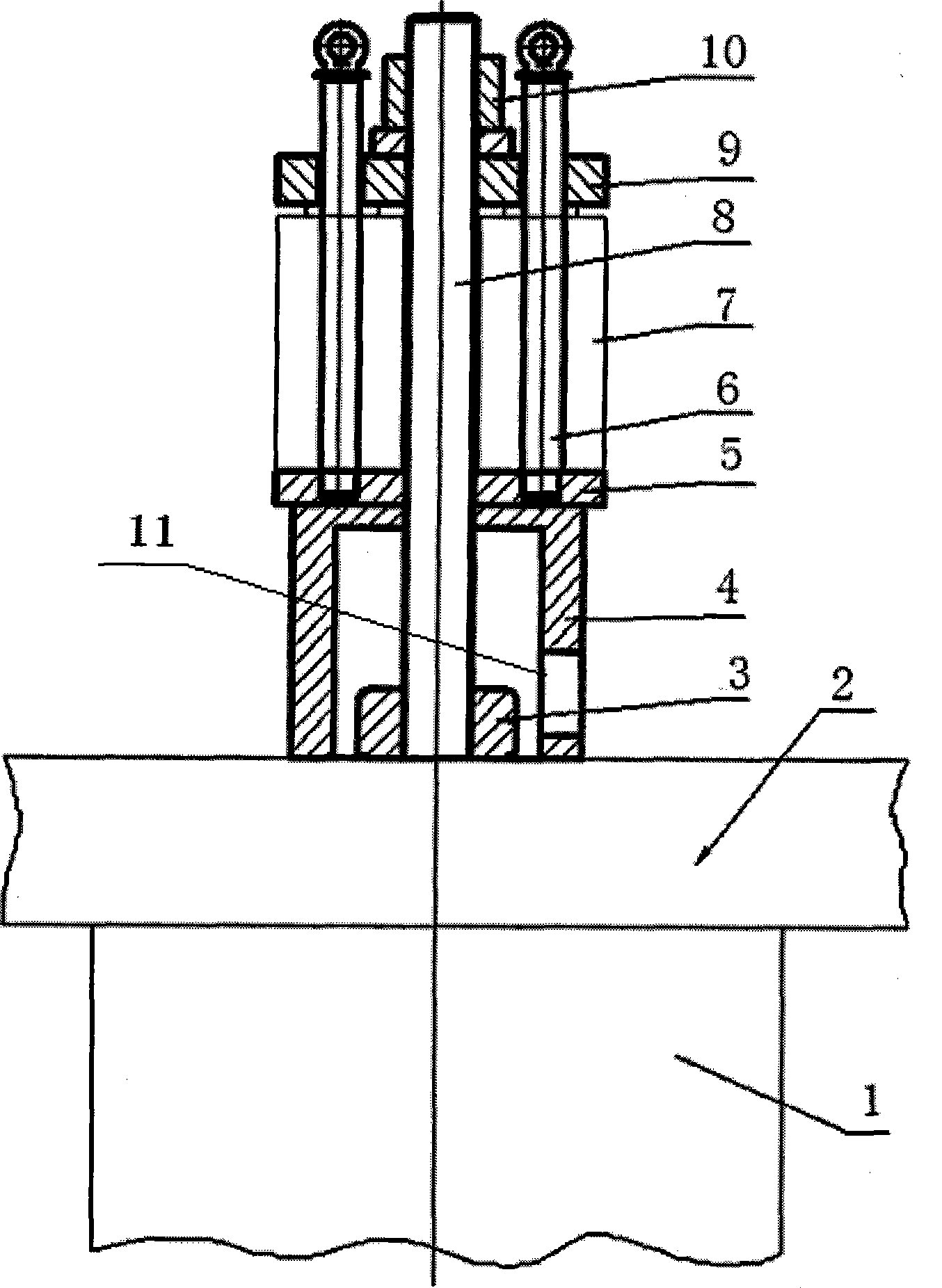

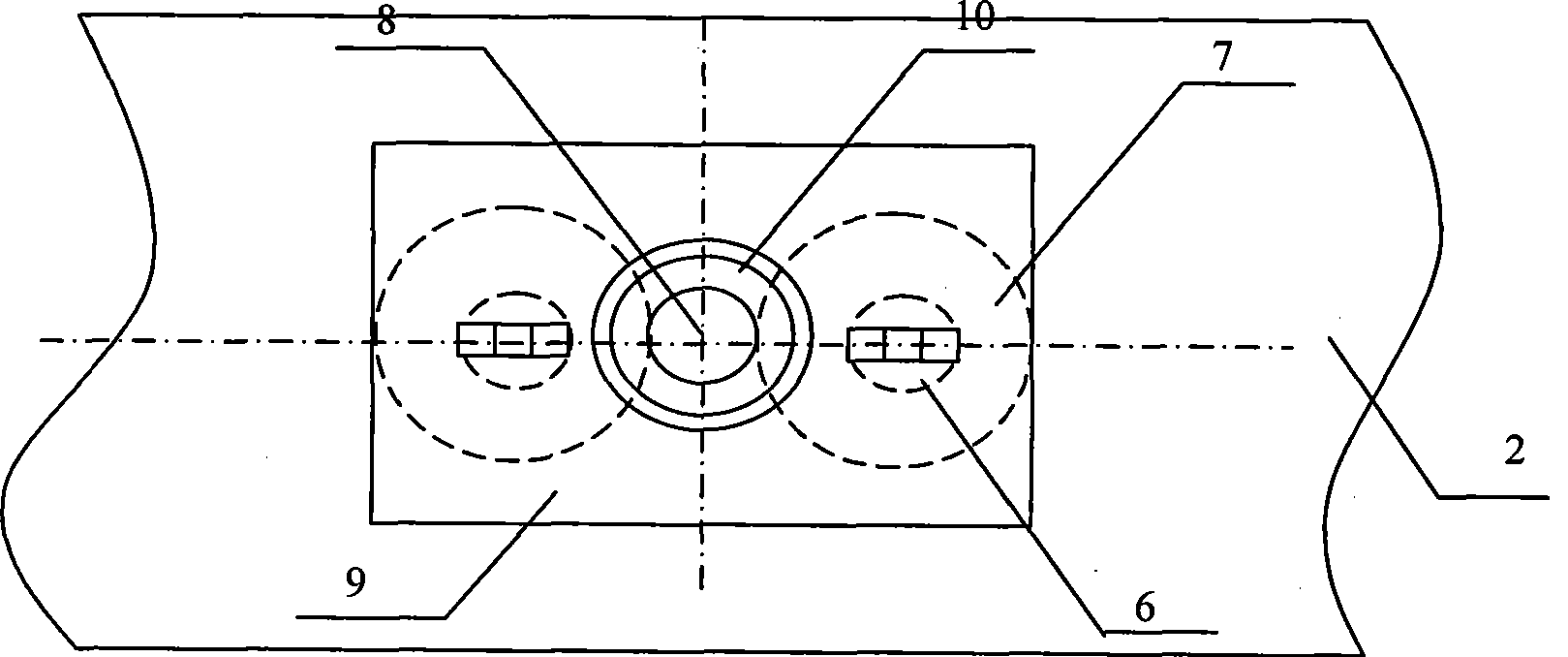

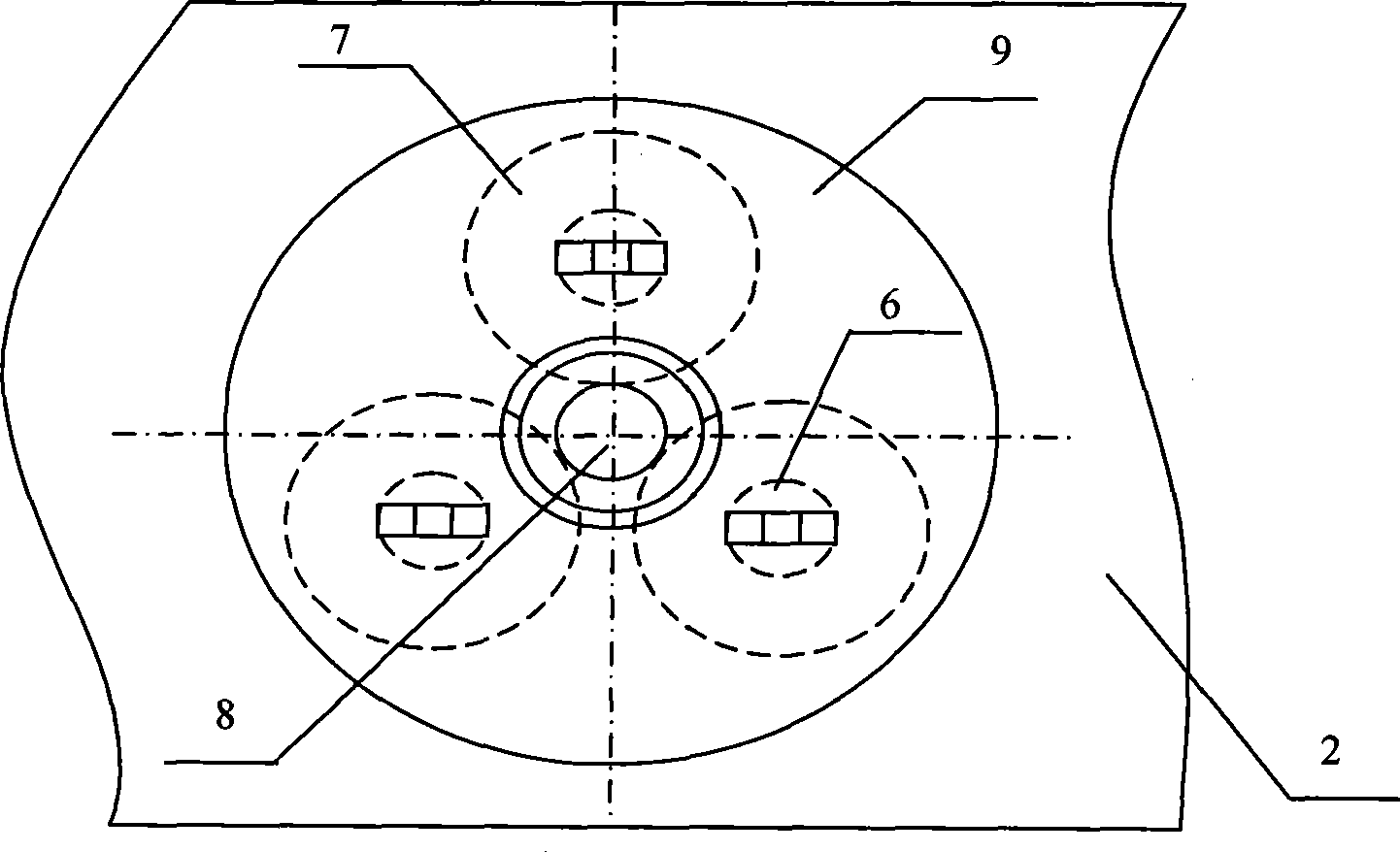

Compaction technology and compaction device for iron core of electric reactor

ActiveCN101521090AFlexible combinationSimple structureTransformers/inductances magnetic coresInductances/transformers/magnets manufacturePressure transmissionJackscrew

The invention discloses compaction technology and a compaction device for an iron core of an electric reactor. Firstly, a screw which is fixed on a lower yoke and passes through a coil and an upper yoke is firmly screwed by a nut; a pressure transfer device passes through the screw until the pressure transfer device contacts the upper yoke; a lower platen is arranged on the pressure transfer device through the screw, and is at least provided with two guide posts, and the guide posts are symmetrically arranged relative to the screw or are evenly arranged along the periphery of the screw; each guide post is provided with a small tonnage hollow jack, and the jack is fastened by an upper platen through a transition nut; a hydraulic system of each jack is simultaneously supplied with oil, the jack acts downward, and the nut is firmly screwed when a clearance appears between the nut and the upper yoke; and finally the whole compaction work is finished after the transition nuts, the upper platen, the jacks, the lower platen and the pressure transfer device are orderly removed. The compaction technology and the compaction device flexibly combine the quantity of small jacks according to the needed jack tonnage and the tonnage of the prior small jacks, and have the characteristics of simple structure, low processing cost, and convenient use.

Owner:CHINA XD ELECTRIC CO LTD

Dynamic speed control system of coal mining machine for coal mine high-gas fully mechanized coal mining face

ActiveCN103244120AGush controlImprove the level of automated productionSlitting machinesMine roof supportsPlate pressureControl system

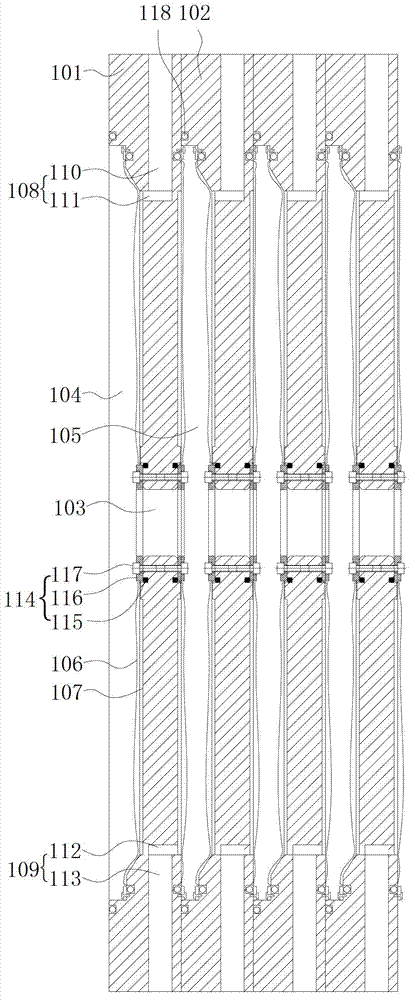

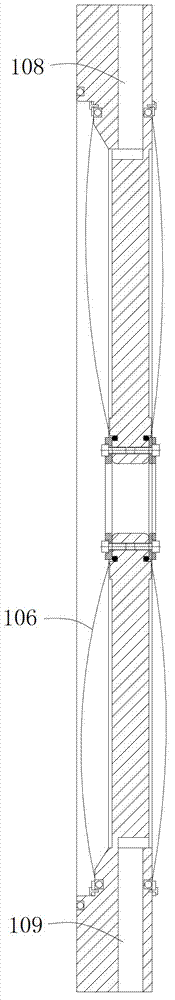

The invention discloses a dynamic speed control system of a coal mining machine for a coal mine high-gas fully mechanized coal mining face. The dynamic speed control system comprises the coal mining machine, a plurality of hydraulic brackets, bracket controllers, pressure sensors, gas detectors, a signal converter and a monitoring host, wherein the fully mechanized coal mining face comprises the hydraulic brackets; one bracket controller, one pressure sensor and one gas detector are arranged on each hydraulic bracket; the signal converter is arranged on the hydraulic bracket at the end of the fully mechanized coal mining face; the bracket controller of each hydraulic bracket is connected with the signal converter, and working face top plate pressures and working face gas concentration data are transmitted to the monitoring host at a gate road by virtue of the signal converter; and the monitoring host is used for adjusting the speed of the coal mining machine according to the working face top plate pressures and the working face gas concentration data.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

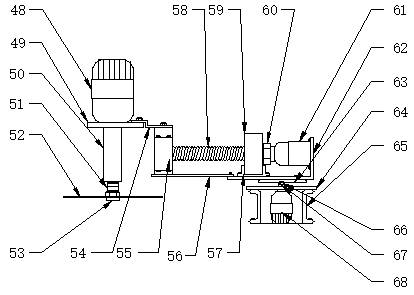

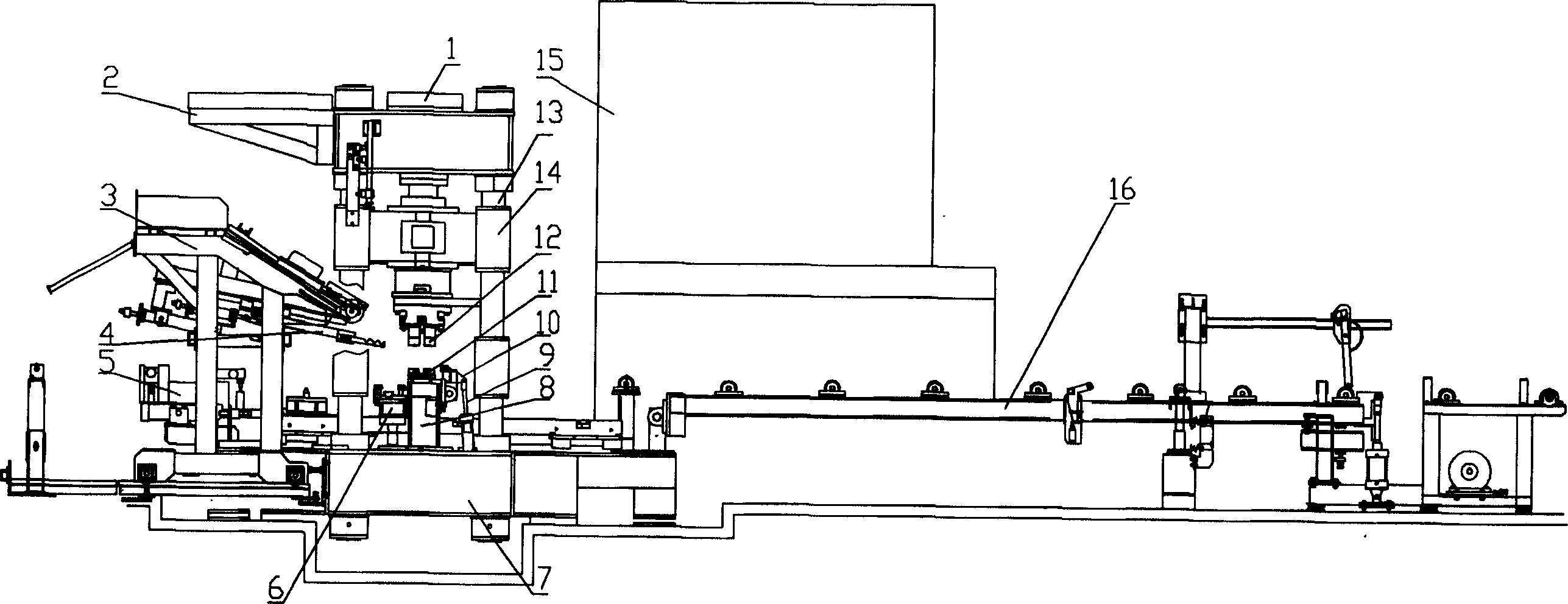

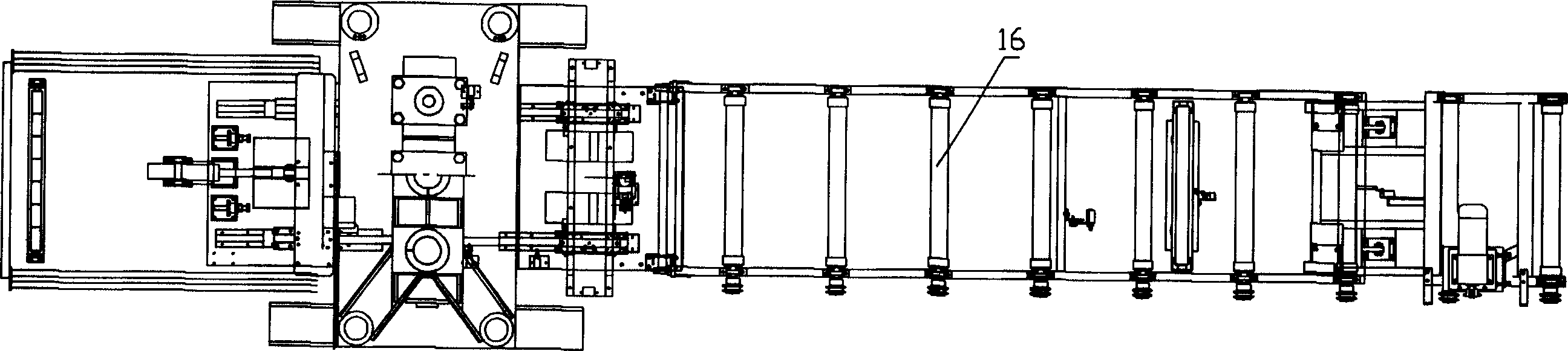

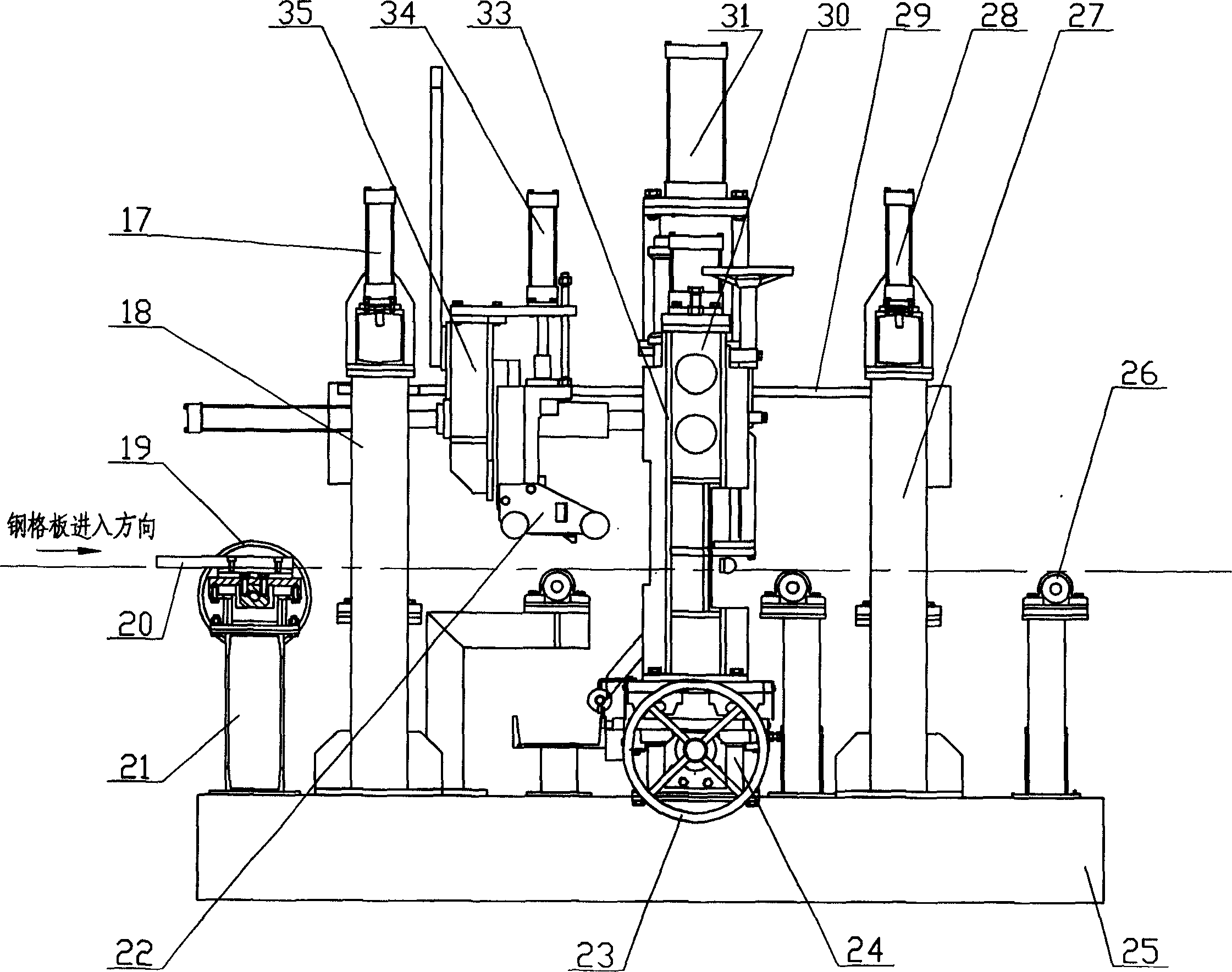

Steel checkerboard pressure welding machine

The present invention relates to a steel checkered plate pressure welding machine. It is formed from pressure welding machine, intermediate feeding roller way and head-cutting machine. Said pressure welding machine can utilize heavy current to make twist steel and flat steel be instantaneously stitched, then the progressively stitched steel checkered plate can be passed through the intermediate feeding roller way and fed into the head-cutting machine, said head-cutting can be used for cutting off the excess twist steel.

Owner:XINXING DUCTILE IRON PIPES CO LTD

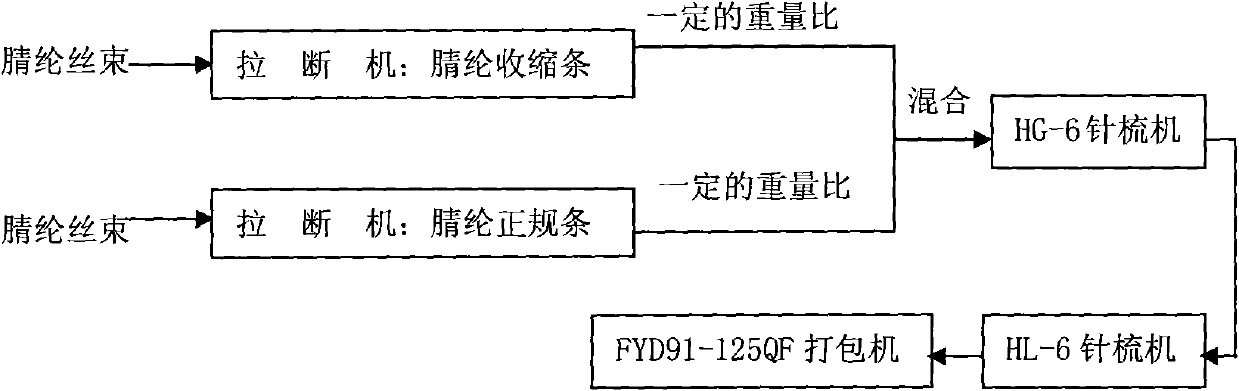

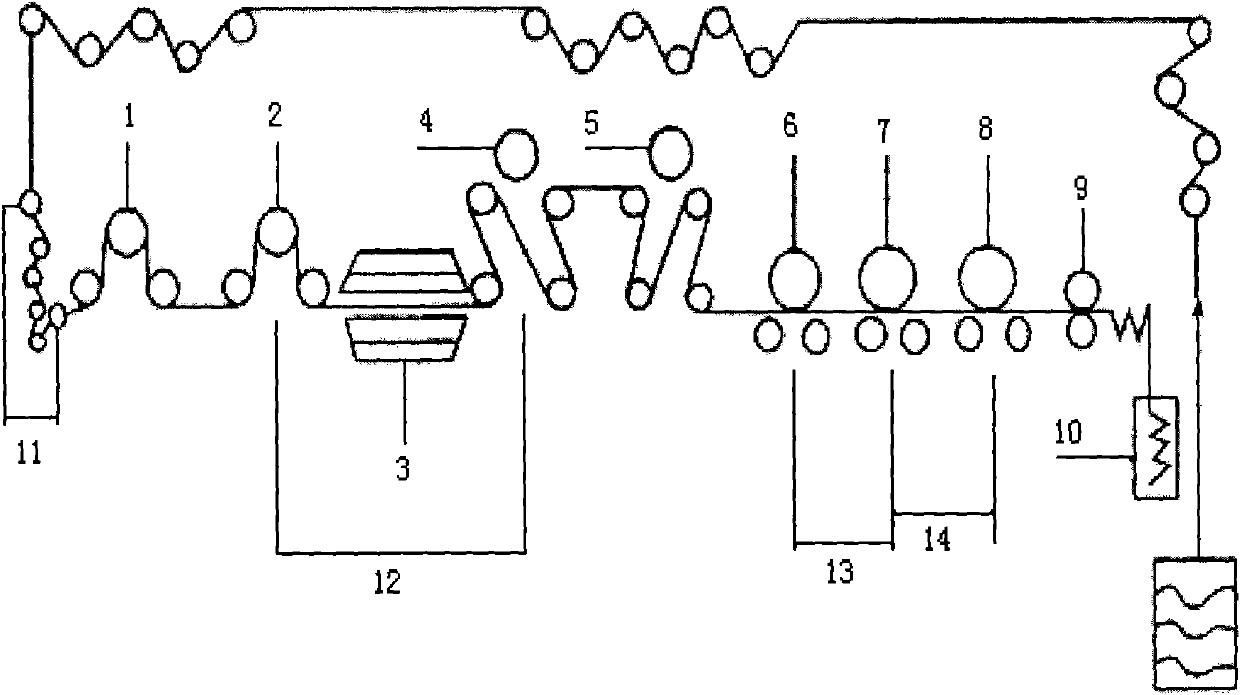

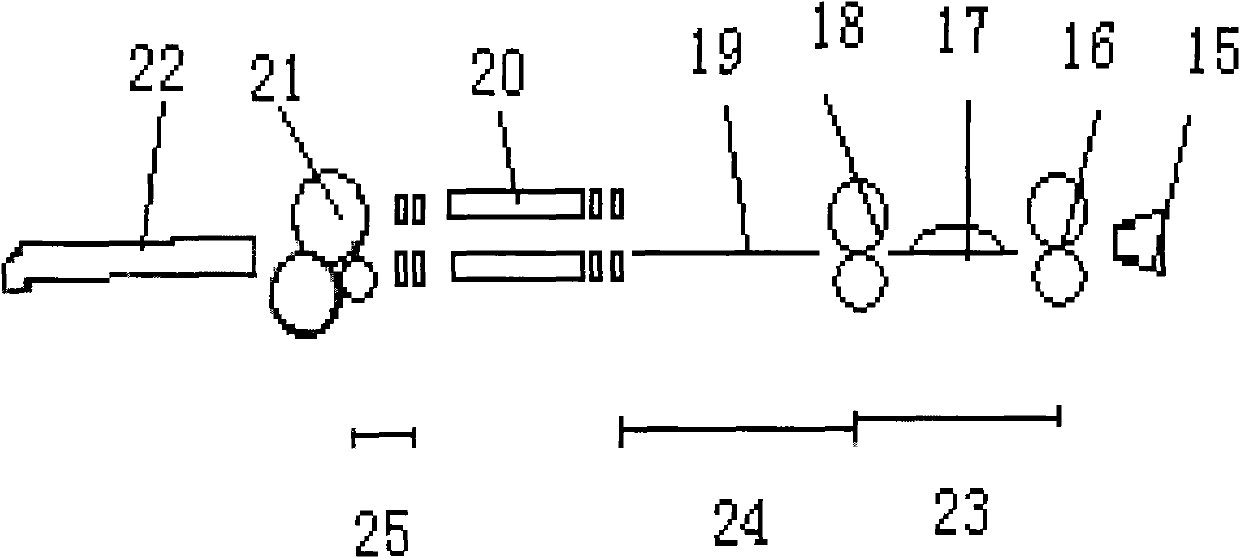

Method for producing fine denier acrylic tops

ActiveCN102021679ASuitable for productionImprove evenness qualityDrafting machinesTows to slivers/yarnsSteam pressureBiochemical engineering

The invention relates to a method for producing fine denier acrylic tops. 0.44-1.11dtex fine denier acrylic tows are taken as raw materials, and the method comprises the following steps of: manufacturing the tops by using a breaking machine, wherein the total draw ratio is 6.05-6.27, the space of rebreaking areas is 5mm greater than the conventional space, the pressure of a pressing plate in a crimping box is 1-2 buckles greater than the conventional pressure, and the steaming pressure is 0.15-0.3MPa; and manufacturing the tops by using a gilling machine, wherein the needle plate number of a comb box is NO.6-8, the draft multiple in a coiling area is 1.15-1.3, the draft multiple in a feeding area of the comb box is 0.98, the main draft multiple is 6-8, and the front roller space is 35-45mm. The quality indexes of the fine denier acrylic tops produced by the method meet the qualified product standard, and partial indexes meet the high-class product standard.

Owner:PETROCHINA CO LTD

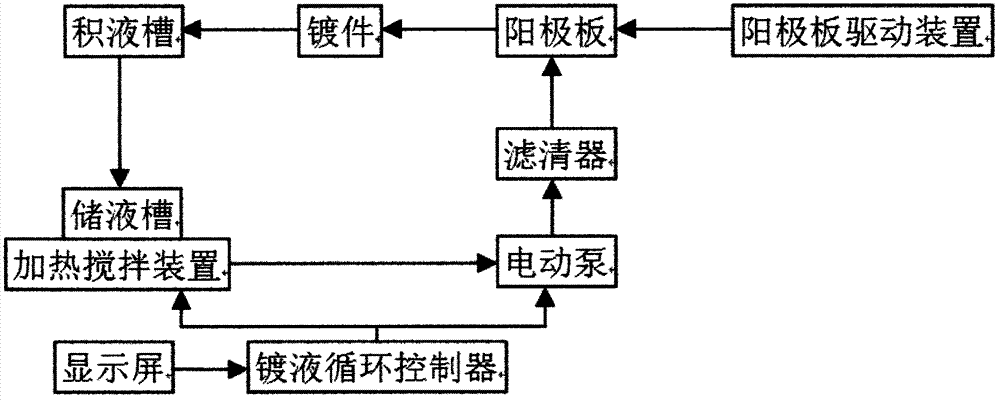

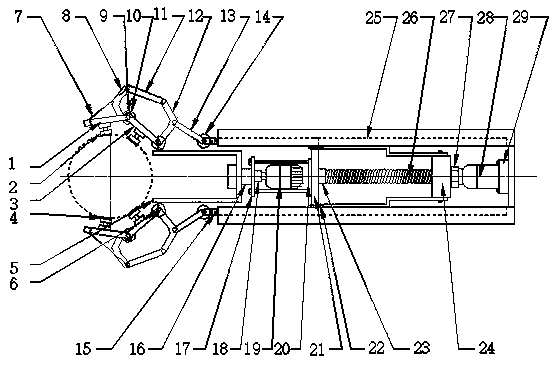

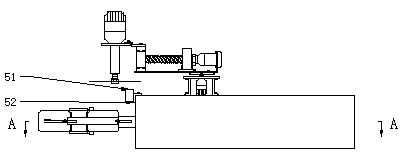

Electric brush plating equipment for flat metal parts and brush plating method

The invention relates to electric brush plating equipment for flat metal parts and a method. The equipment is characterized by comprising a plating piece clamping device, an anode plate driving device, a plating liquid circular supply device, an anode plate and a brush plating controller, wherein the plating piece clamping device includes a screw rod and the like; the anode plate driving device includes a push rod, a slide block and the like; the plating liquid circular supply device includes a liquid collecting tank, a guide pipe and the like; a liquid outlet of a liquid storage tank communicates with the anode plate; and the liquid storage tank communicates with the liquid collecting tank. The method comprises the following steps: a transmission mechanism is adjusted, so that the single-pass slide distance of a slide block is larger than the width of a brush plating part of a plating piece, the pressure between the plating piece and the anode plate reaches the process pressure requirements, the temperature of the plating liquid reaches the process temperature requirements, and the anode plate performs a reciprocating motion; and the anode plate and the plating piece respectively communicate with a positive pole and a negative pole of the brush plating controller for operation. The equipment solves such problems as dependence on labors, high labor intensity, unstable quality, low efficiency and shortage of a nanometer electric brush plating device in electric brush plating of flat plating pieces.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Mechanical hand

InactiveCN109514531AWith grip functionAvoid mechanical damageProgramme-controlled manipulatorGripping headsPlate pressureClosed loop

The invention discloses a mechanical hand which comprises a finger connecting rod mechanism, a finger connecting rod drive portion, a telescoping portion, a shearing portion and a vision system. The finger connecting rod mechanism is connected with the finger connecting rod drive portion. The finger connecting rod drive portion is connected with the telescoping portion. The shearing portion is connected with a fixed sliding rail. The vision system is connected with the fixed sliding rail. Information of a target object is collected through the vision system, then the information is fed back toa controller, the controller processes the collected information, and a motor driver drives all motors to work independently to achieve functions of clamping, locating of the clamping portion, shearing, locating of the shearing portion and the like. According to the mechanical hand, an S-shaped pressure sensor, a flat plate pressure sensor and a tension spring are utilized, the controller achieves closed loop real-time control over the finger connecting rod mechanism, the target object is grabbed flexibly, and caused mechanical damage is reduced.

Owner:DONGGUAN UNIV OF TECH

Bottom plate pressure relief and reinforcement structure for controlling floor heave of deep roadway and construction method of bottom plate pressure relief and reinforcement structure

InactiveCN106401609AGood pressure relief effectGuaranteed long-term stabilityUnderground chambersTunnel liningPlate pressureStructure of the Earth

The invention discloses a bottom plate pressure relief and reinforcement structure for controlling a floor heave of a deep roadway and a construction method of the bottom plate pressure relief and reinforcement structure. The construction method comprises the following steps: (1) excavation of a roadway and anchor mesh supporting: excavating the deep roadway, and performing the anchor mesh supporting on a surrounding rock after the surrounding rock is formed; and (2) digging of two pressure relief troughs: respectively digging a long-strip-type pressure relief trough in each of the left and right sides of a bottom plate of the roadway through an air pick along the axial direction of the roadway, wherein the cross section of each pressure relief trough is rectangular, and the pressure relief troughs take a boundary line of one side end as a symmetric line. In conclusion, a bottom plate pressure relief method is used for controlling the problems of the floor heave of the deep roadway and deformation of the surrounding rock; and on the basis of a deep roadway anchor and injection supporting technology at the present, the pressure relief effect on the surrounding rocks on the bottom plate, two ends and a top plate is improved by reasonably determining the shape, the size and the arrangement position of each pressure relief trough, the number of secondary interstices in the surrounding rocks is increased, the grouting effect on the surrounding rocks is enhanced, the problem of the floor heave of the deep roadway can be effectively controlled, and long-term stability of the surrounding rock of the deep roadway is guaranteed.

Owner:HENAN POLYTECHNIC UNIV

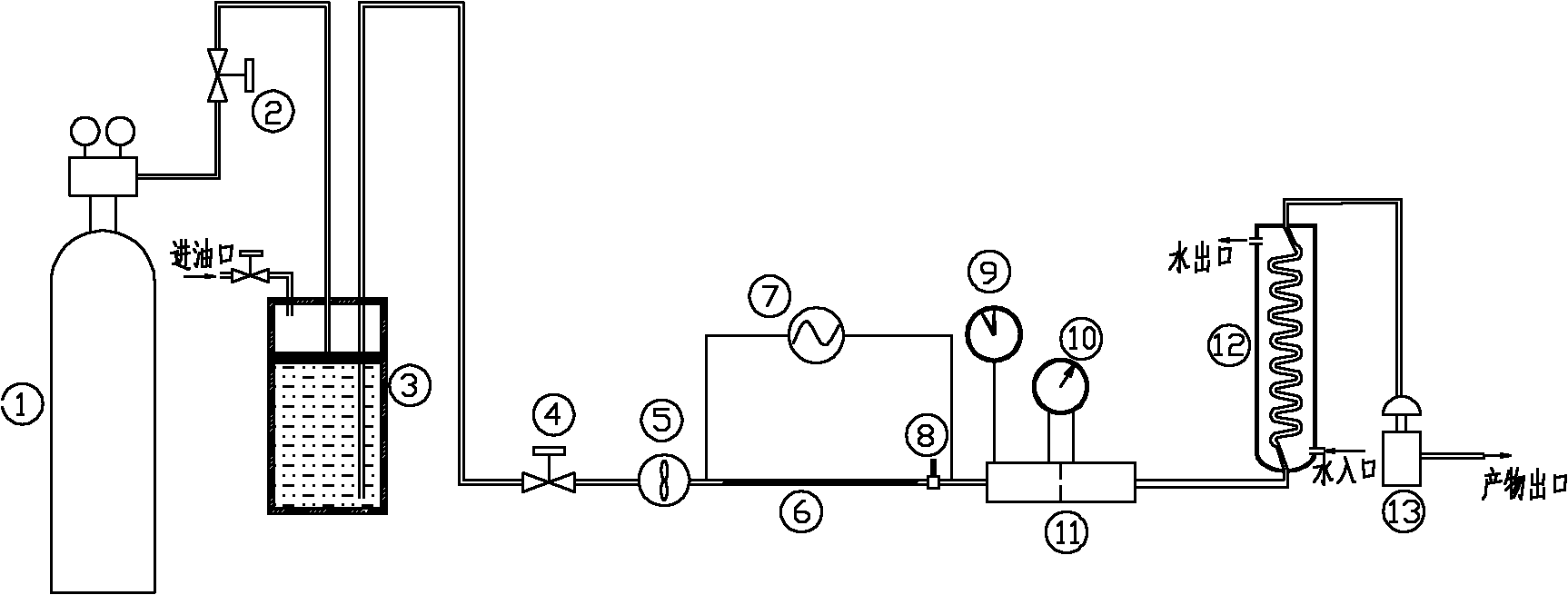

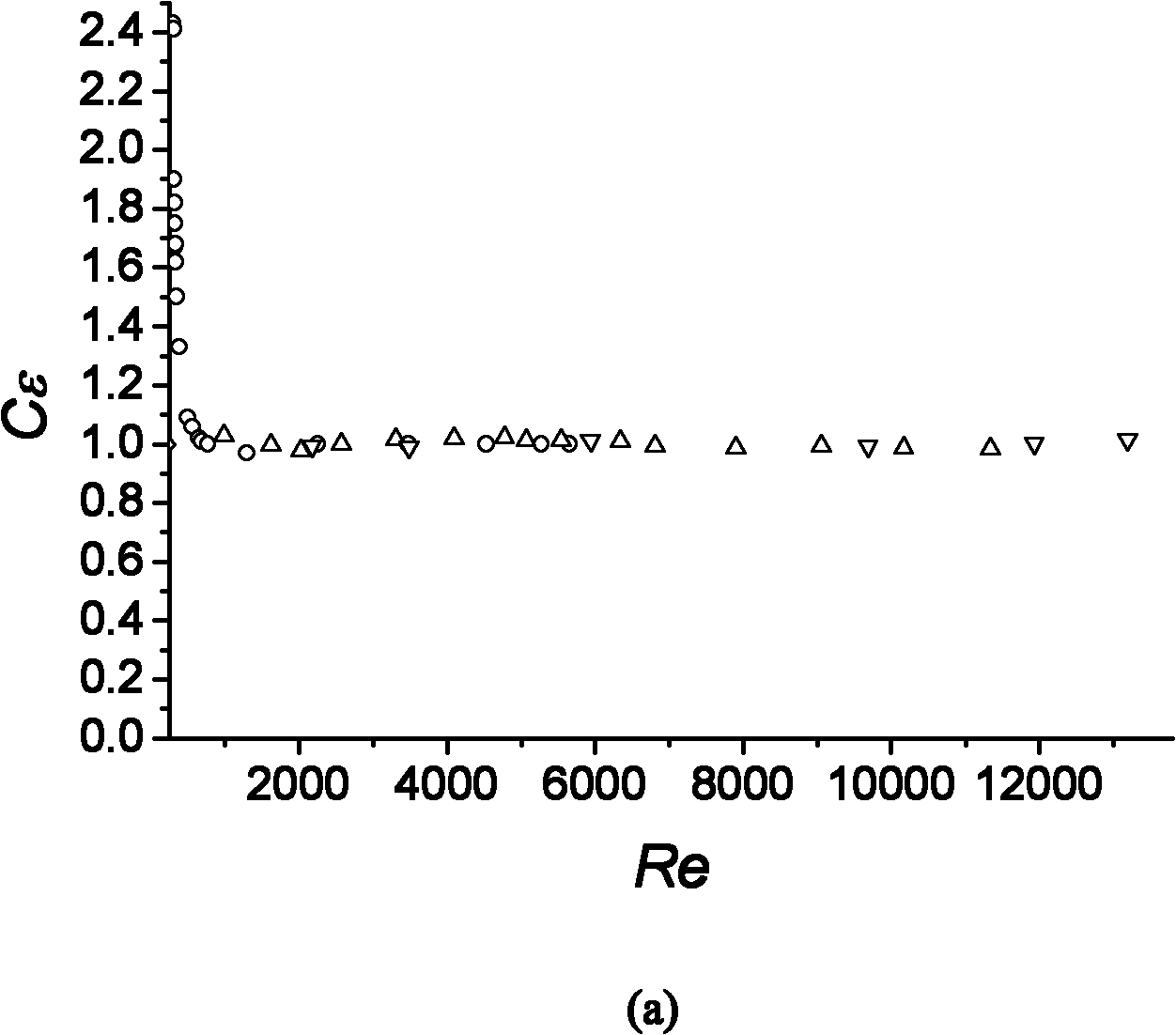

Device for measuring density and flow rate of supercritical cracking product of hydrocarbon fuel, and measurement method thereof

ActiveCN102507375AHigh densityRealize average molecular weight calculationSpecific gravity by measuring pressure differencesFluid speed measurement using pressure differenceRamjetEngineering studies

The invention discloses a device for measuring the density and the flow rate of a supercritical cracking product of hydrocarbon fuel, and a measurement method thereof. The device is characterized in that: a pressurized air source (1) is connected with an oil tank (3) through a needle valve (2); the oil tank is connected with a heating pipe (6) through a flow regulating valve (4) and a mass flowmeter (5); the heating pipe is connected with a pore plate pressure taking device (11); a pressure difference transmitter (10) is arranged on the pore plate pressure taking device (11); and a throttle orifice of the pore plate pressure taking device has the diameter of 1.5-5mm. On the basis of a mass flow measurement technology, a nonstandard small-bore pore plate pressure taking device is developed, the density and flow rate of a high temperature heterogeneous reaction medium under the condition of a small pipe diameter are measured, and a problem of on-line measurement of the density and flow rate of a medium in engineering study on supercritical cracking of an active cooling system of a supersonic combustion ramjet engine and the like.

Owner:SICHUAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com