Compaction technology and compaction device for iron core of electric reactor

A reactor and iron core technology, which is applied in the manufacture of inductors/transformers/magnets, transformer/inductor cores, circuits, etc., can solve the problems of no stock, waste of equipment resources, long-term idle, etc., and achieve simple structure, convenient use, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

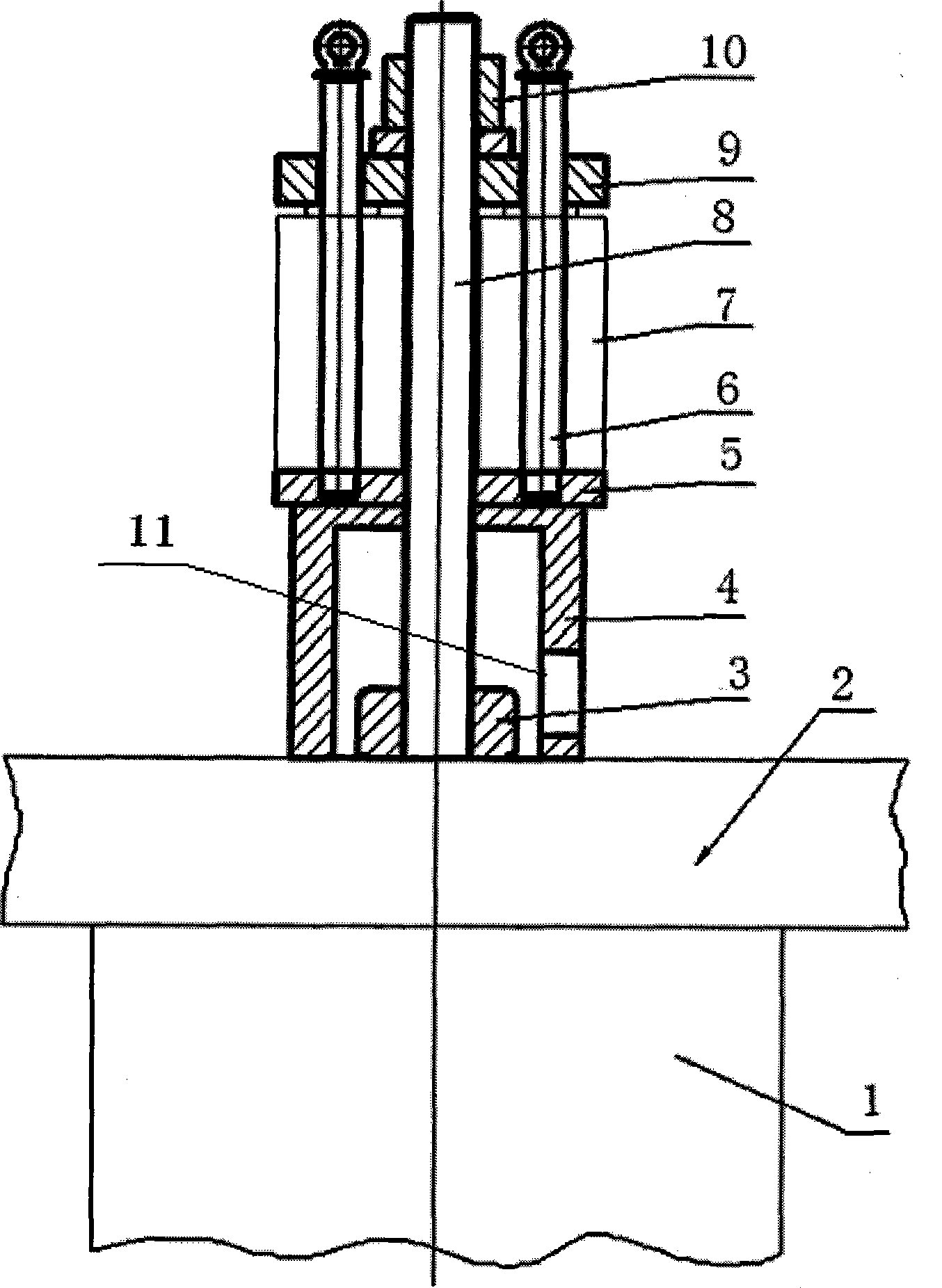

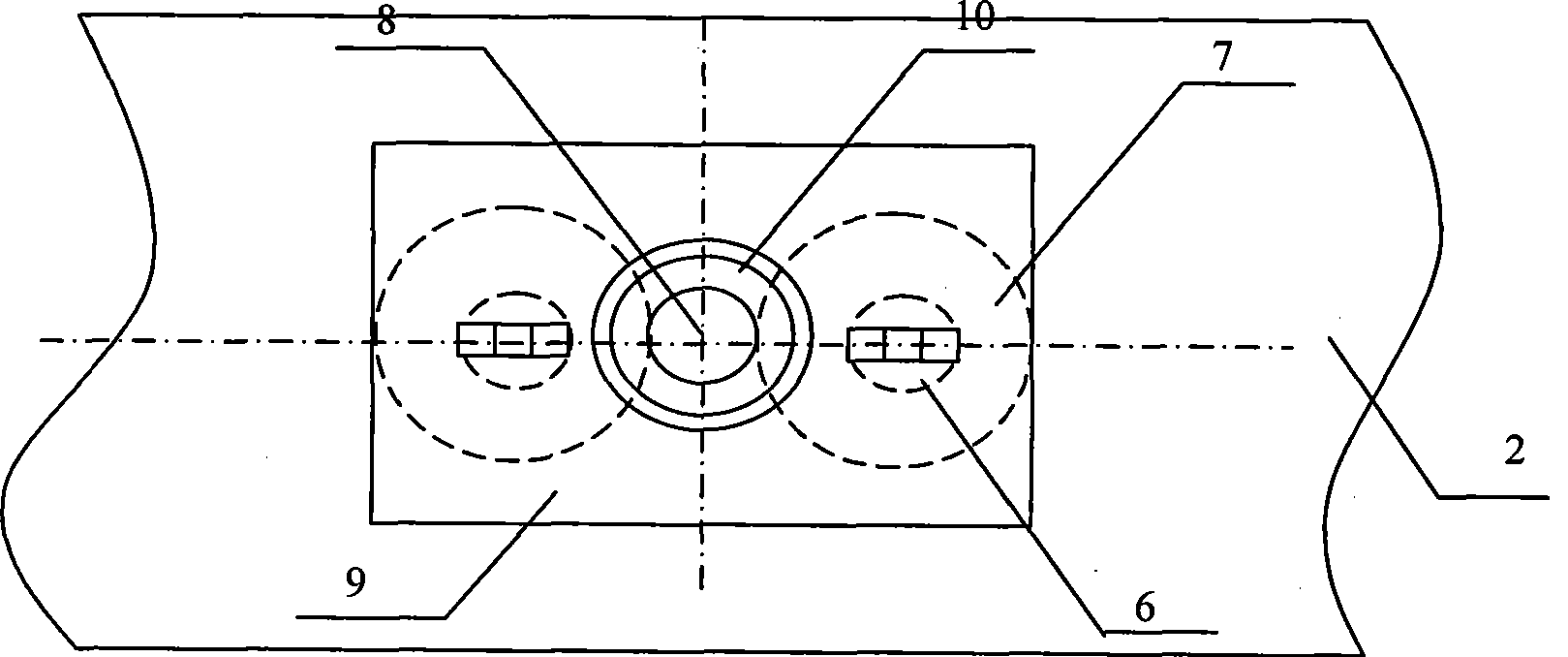

[0028] Such as figure 1 , figure 2 As shown, a symmetrical double-jack pressing device includes a pressure transmission device and a pressure application device. The pressure transmission device is a sleeve 4 with a closed upper end and a window hole 11 on the side for tightening the nut 3 . The sleeve 4 is in contact with the upper iron yoke through a screw 8 vertically fixed on the upper iron yoke 2 of the reactor, and a nut 3 is fastened at the joint between the upper iron yoke and the screw; the pressure applying device includes two upper and lower pressure plates 9, 5 , placed on the upper end surface of the sleeve 4 through the screw rod 8, two guide columns 6 are arranged between the upper and lower pressure plates, and the guide columns are symmetrically arranged relative to the screw rod 8; a small-tonnage hollow jack 7 is arranged on each guide column, and the upper pressure plate 9 The jack is fastened by a transition nut 10 .

Embodiment 2

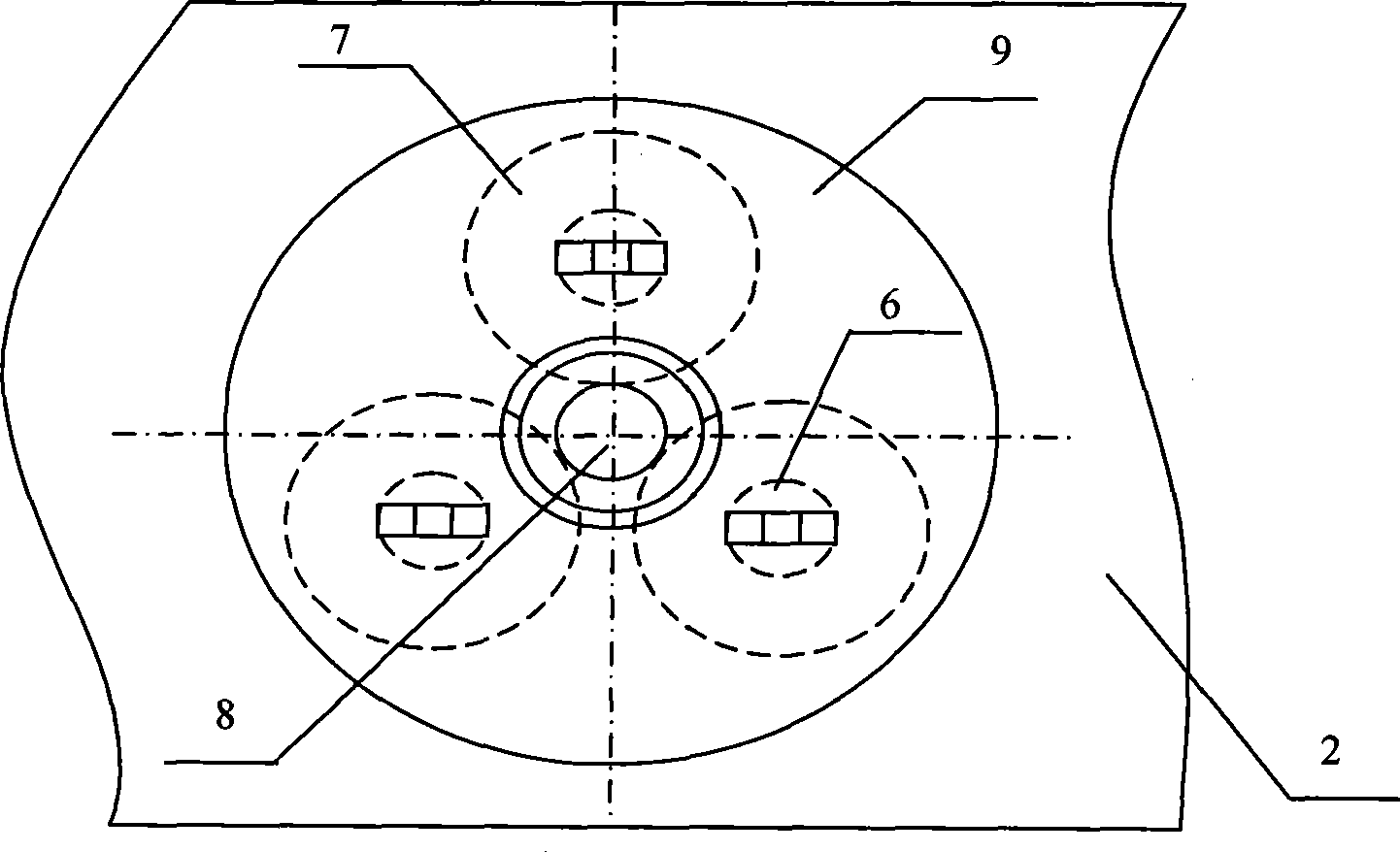

[0030] Such as image 3 As shown, in another three-jack pressing device, three guide columns are arranged and evenly arranged along the outer circumference of the screw rod 8, and three small-tonnage hollow jacks can be arranged correspondingly. All the other structures are the same as in Embodiment 1.

[0031] The pressing device of the present invention is not limited to the above two embodiments. According to the specifications of the reactor and the tonnage of the required jack and the tonnage of the existing small jack, the number of small jacks can be flexibly combined, such as from image 3 Based on the embodiment, the number of jacks can be 4, 6, 8 and other combinations. figure 1 The number of screw rods 8 fixed on the lower iron yoke 2 can be 1 to 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com