Dynamic speed control system of coal mining machine for coal mine high-gas fully mechanized coal mining face

The technology of fully mechanized mining face and coal shearer is applied in the field of shearer speed dynamic control system, which can solve the problems of low coal output in high-gas mines, and achieve the advantages of improving the safety factor, increasing the production output of coal mines, and improving the level of automatic production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

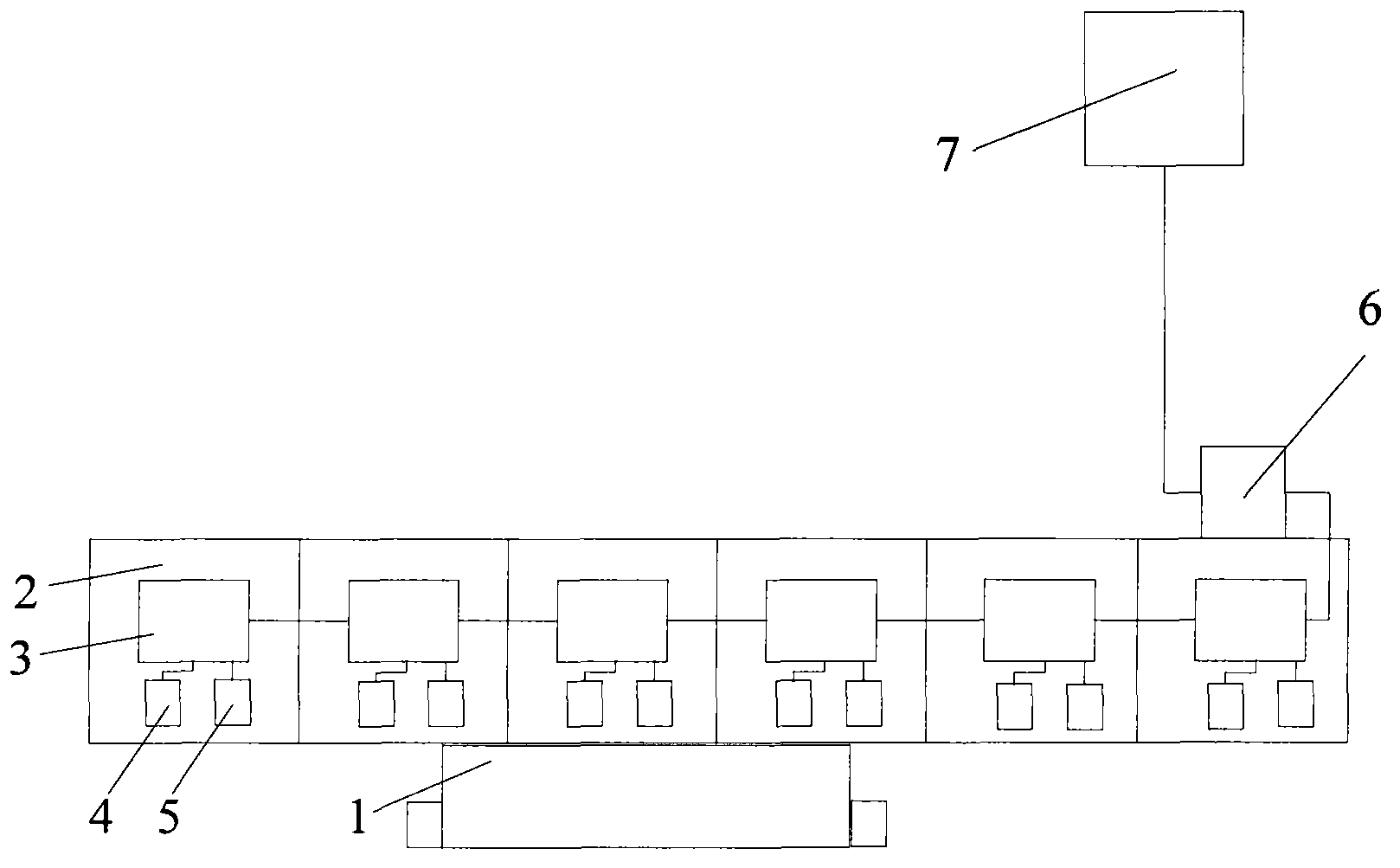

[0013] See attached figure 1 , which describes the connection diagram of the automatic control system for automatic adjustment of the coal cutting speed according to the gas concentration of the fully mechanized coal mining face of the high-gas coal mine according to the present invention. It has the automatic control function of the coal cutting speed of the shearer according to the gas concentration parameters, and mainly includes the shearer, hydraulic support, support controller, pressure sensor, gas detector, signal converter and monitoring host.

[0014] The fully mechanized mining face includes multiple hydraulic supports, and each hydraulic support is equipped with a support controller, pressure sensor and gas detector, and the support controller on each support is electrically connected to the pressure sensor and gas detector of the support. connection, the pressure sensor is used to detect the pressure of the roof of the working face, and the gas detector is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com