Patents

Literature

37results about How to "Large amount of extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Directional hydraulic pressing penetration, permeability increase and outburst elimination method of guide groove

ActiveCN102619552ALarge range of pressure reliefImprove breathabilityFluid removalDirectional drillingMining engineeringHigh pressure water

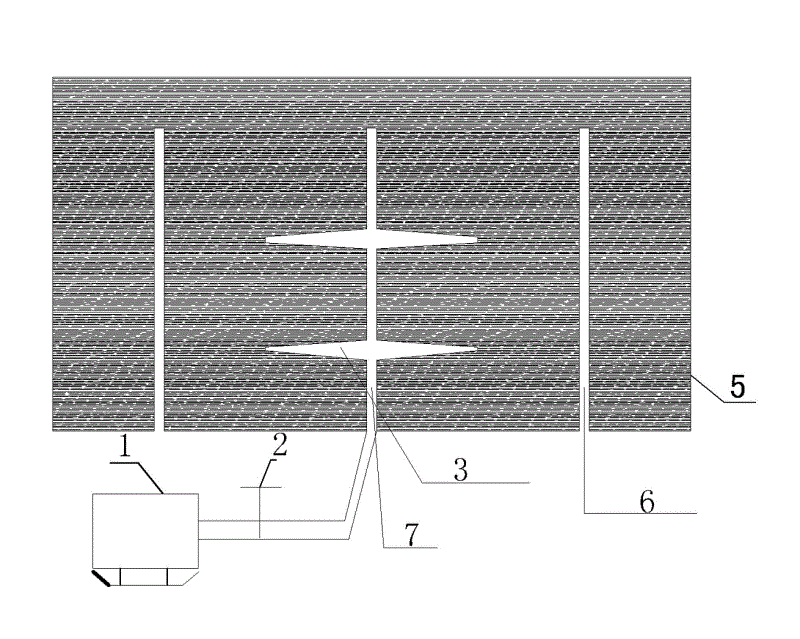

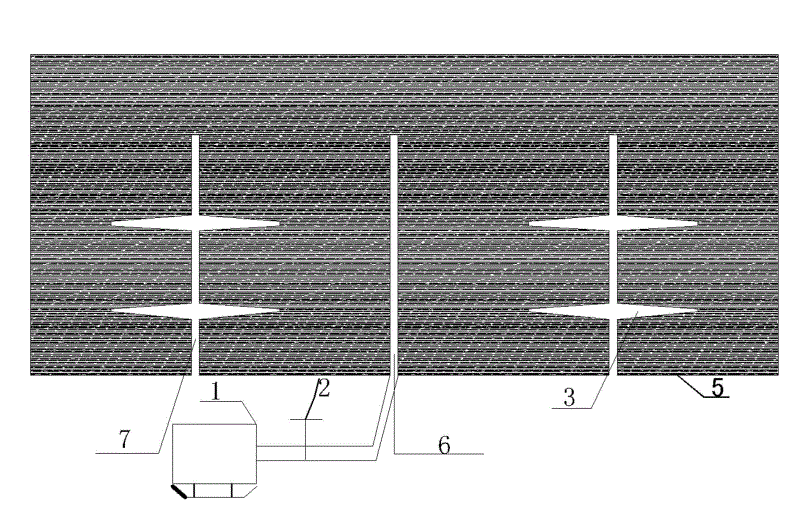

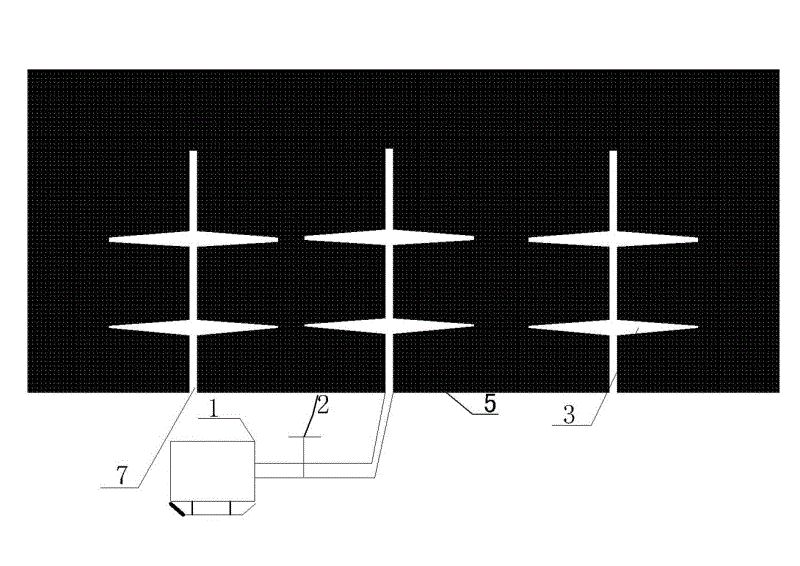

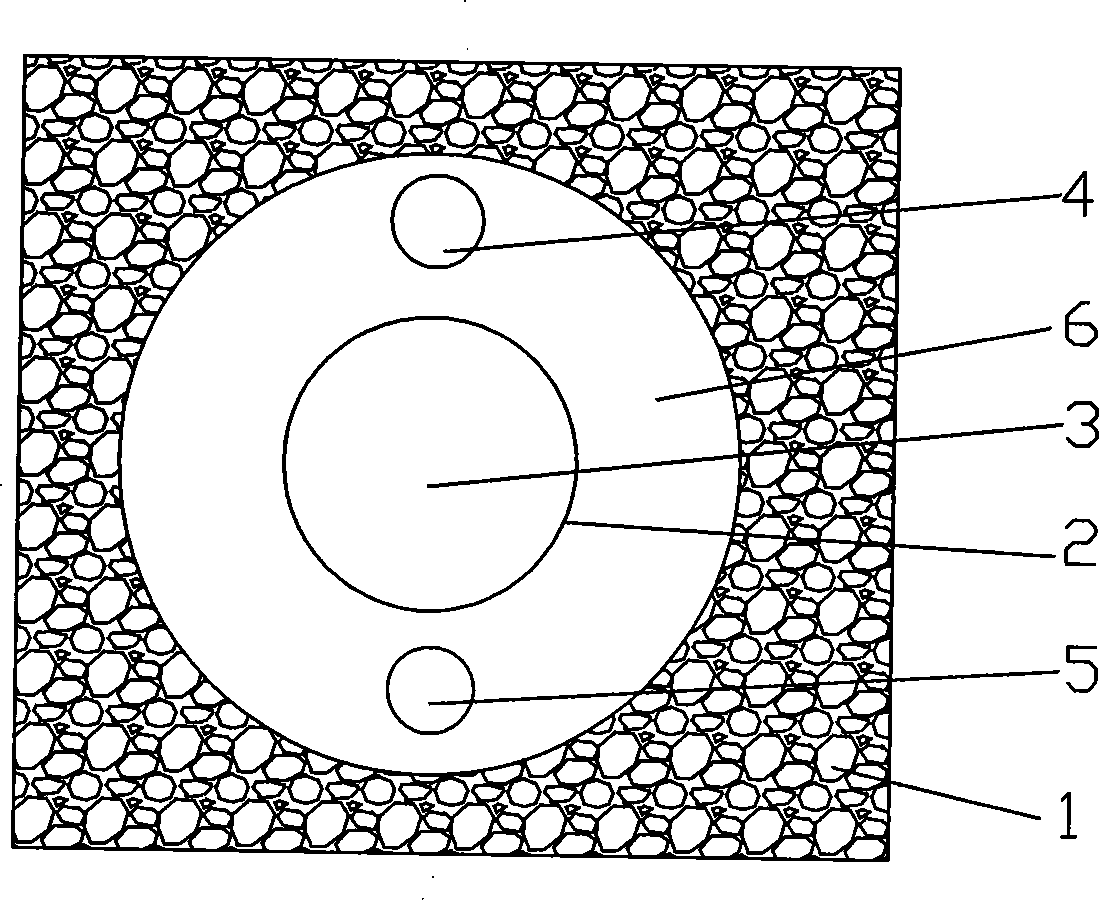

The invention relates to a directional hydraulic pressing penetration, permeability increase and outburst elimination method of a guide groove, which comprises the steps of (1) constructing a guide groove drill or the guide groove drill and control drills in a coal seam; (2) forming a guide groove in the guide groove drill in advance; (3) utilizing the guide groove drill or the control drills to perform hydraulic fractures, utilizing the guide groove and the control drills to perform directional control on the hydraulic fractures, enabling the coal body between the guide groove drill or the guide groove drill and the control drills to be pressed into penetration, forming multiple fractures among drills, and enabling a large amount of nickings to be brought out through the high-pressure water; and (4) after the fractures finish, enabling all the drills to be sealed and accessed into a drainage system, and beginning extraction. By means of the method, the number of pressing penetration of drills can be increased by 50%, the pressure relief scope of the coal seam is increased by over one time, the permeability of the coal seam is remarkably improved, gas extraction is increased by more than four times, measure drills can be reduced by about 60%, fore-pumping time is effectively reduced, area outburst elimination is achieved, and gas hazards can be reduced to the largest extent.

Owner:CCTEG SHENYANG RES INST

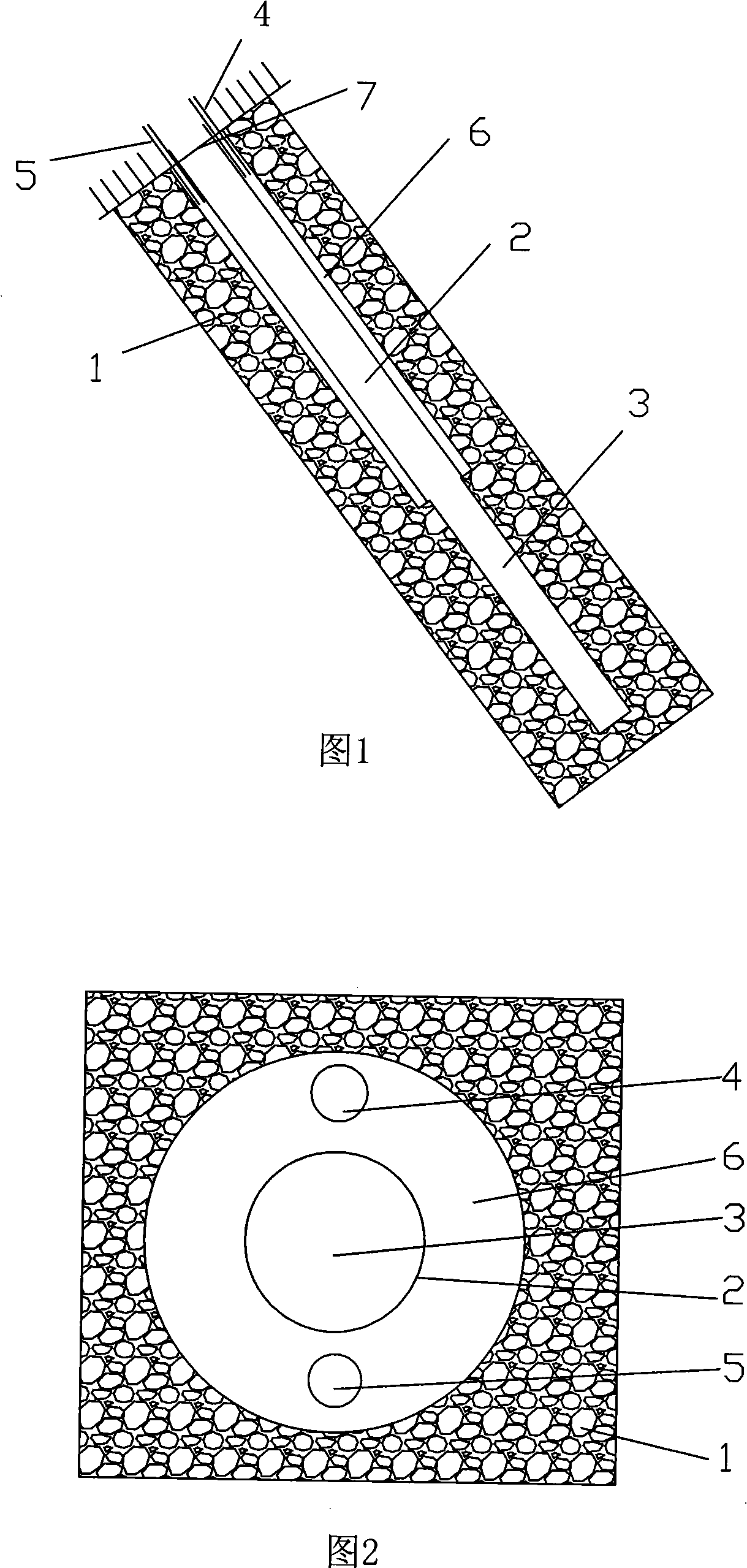

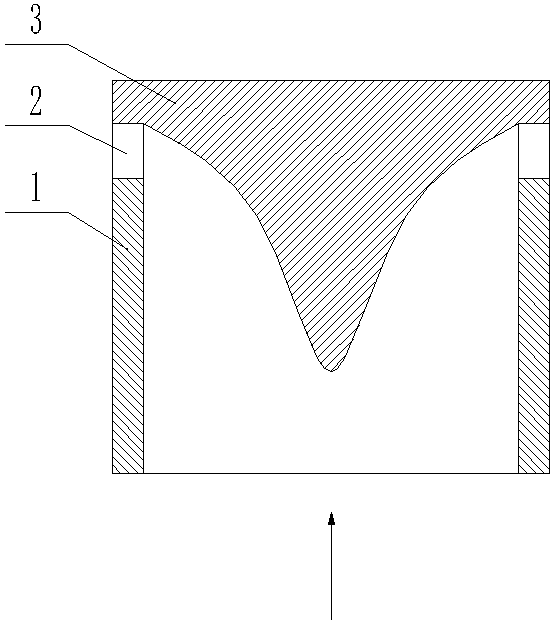

Heavy pressure slip-casting hole-sealing method for large-diameter extraction borehole

The invention relates to a method for large diameter borehole extracting and high-pressure grouting hole sealing, which is characterized in that the method comprises the following steps: at the coal seam top and in the floor roadway rock surface, an across-seam hole drilling and sealing section are constructed in the coal seam; a hole sealing pipe is positioned into the hole sealing stage; a grouting cavity is reserved between the hole sealing pipe and the hole wall of a borehole; a grouting pipe and a return pipe are respectively arranged in the two positions corresponding to the grouting cavity; the output pipe of a high pressure grouting pump communicates with the grouting pipe; grouting material is infused into the grouting cavity by the high pressure grouting pump through the grouting pipe, until the grouting material overflows out of the return pipe; the hole sealing section is formed through maintenance; across-seam hole drilling is constructed in the inner cavity of the hole sealing pipe. The method has the advantages that the hole sealing effect is good, the effective gas extraction time is long, and the construction method is simple.

Owner:HUAINAN MINING IND GRP

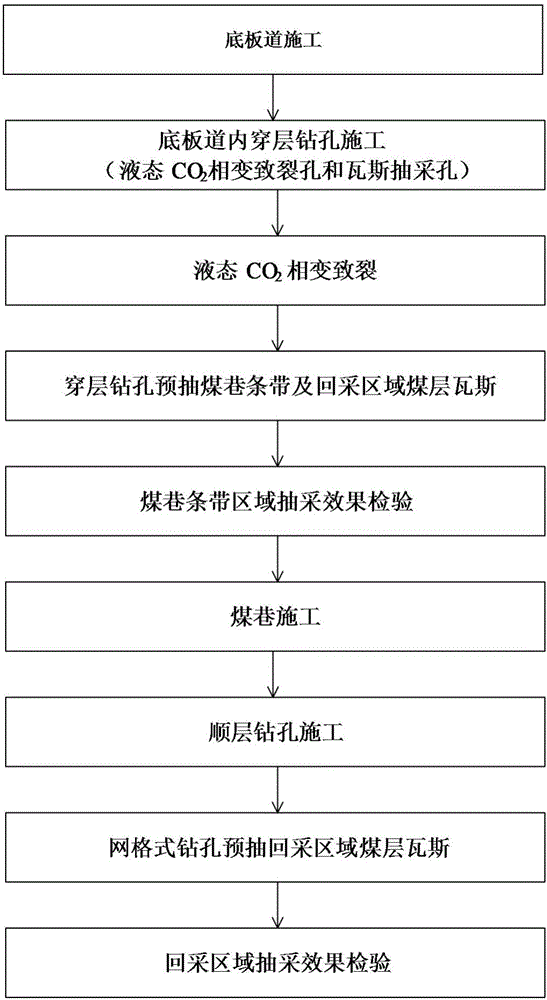

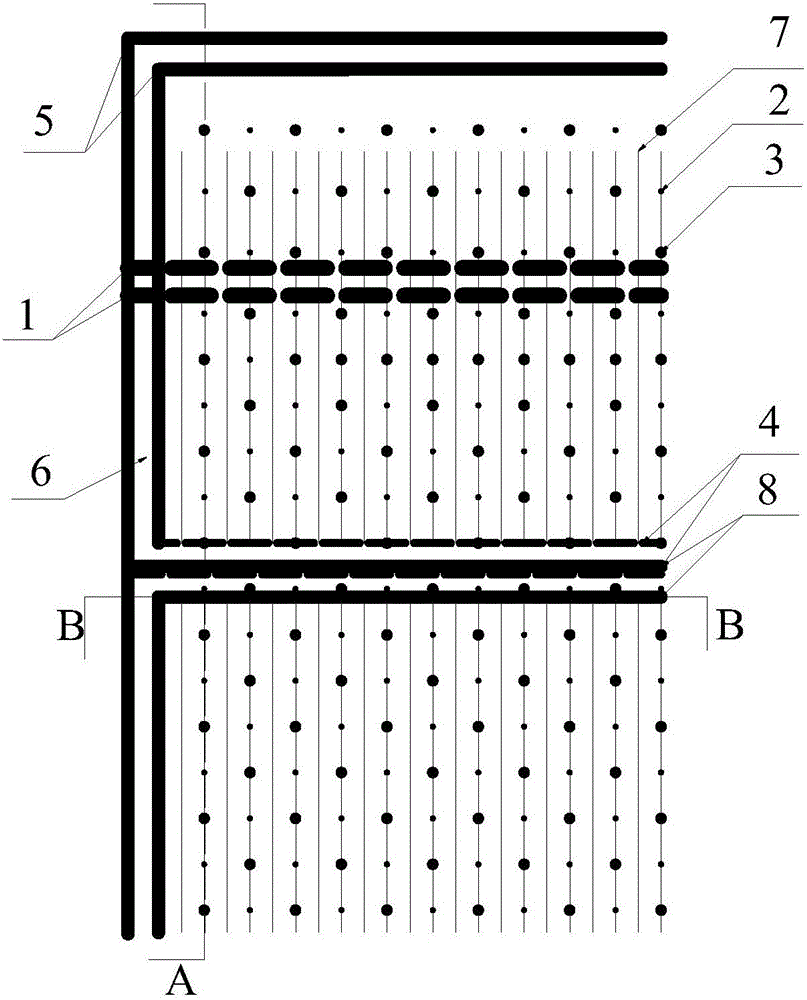

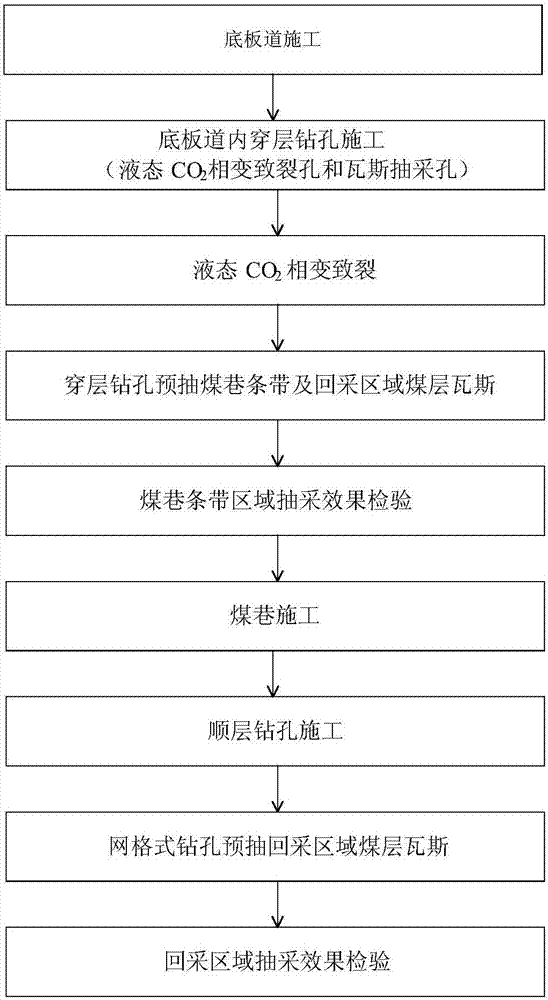

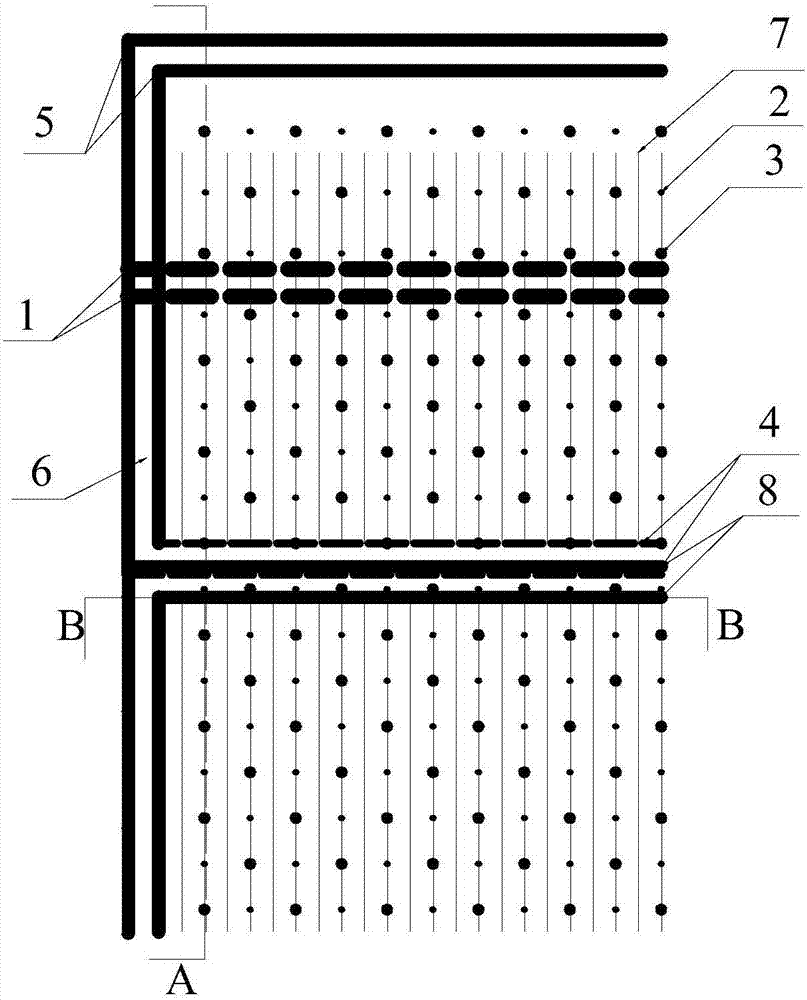

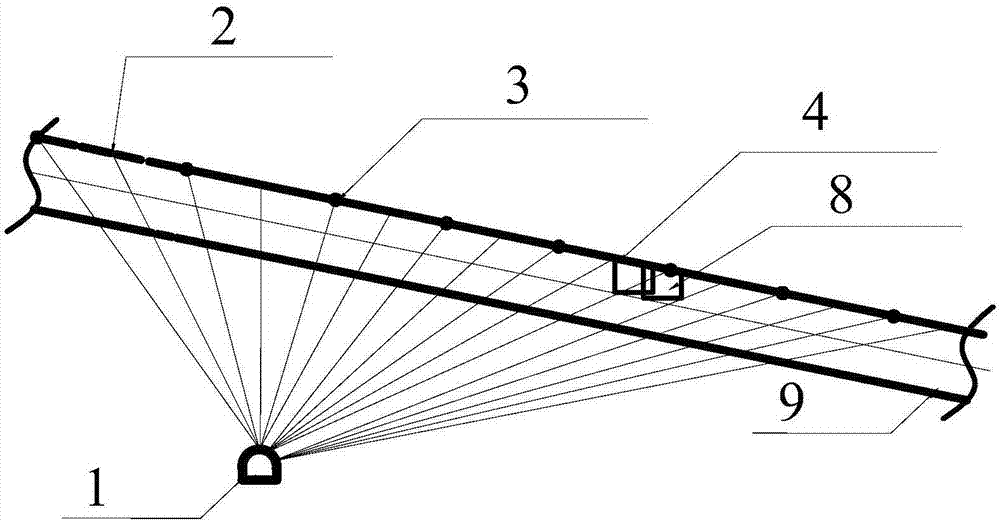

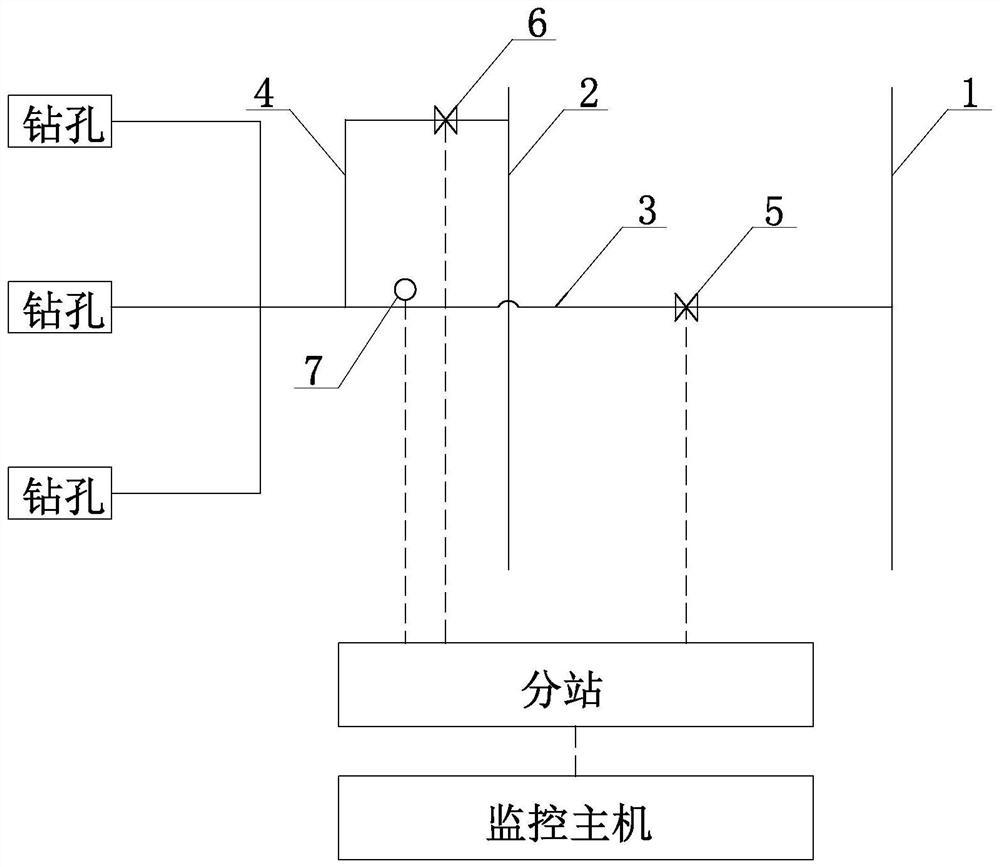

Liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for low-permeable coal seam

ActiveCN106194244AIncrease gas extractionEliminate outstanding hazardsFluid removalGas removalDrill holeProcess engineering

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

Gas extraction method for parallel hole arrangement of L-shaped drilling and fracturing weakening top plate

InactiveCN105927270ABreach of integrityReduce the appearance of strong mine pressureFluid removalGas removalExtraction methodsFissure

The invention relates to a gas extraction method for parallel hole arrangement of an L-shaped drilling and fracturing weakening top plate. The gas extraction method comprises the following steps: firstly, determining drilling positions and selecting drilling parameters on the ground corresponding to a working face of a coal mining seam; secondly, performing L-shaped fracturing drilling and L-shaped gas extraction drilling construction; thirdly, after the L-shaped fracturing drilling construction is finished, arranging a casing pipe and fracturing equipment in an L-shaped drilling hole; fourthly, after the L-shaped gas extraction drilling construction is finished, arranging a gas extraction pipe with air holes in L-shaped gas extraction drilling hole; fifthly, performing fracturing in advance on a coal seam top plate by using a hydraulic jet staged fracturing method; sixthly, extracting fissure zone gas by the gas extraction pipe while performing coal mining operation. According to the scheme, the problems of high mine pressure behavior and transfinite fissure zone gas in a goaf in a coal mining process in the prior art are solved.

Owner:CHONGQING UNIV

Method for gas extraction by coal seam roof weakening through L-shaped drilling staged fracturing

The invention relates to a gas extraction method for L-shaped borehole staged fracturing of a weakened coal seam roof, which comprises the following steps: 1) selecting the drilling position and parameters at the ground position corresponding to the working face of the coal seam to be mined, and constructing L 2) After the construction of the L-shaped borehole is completed, casings and fracturing equipment are arranged in the L-shaped borehole, and each preset fracturing site of the coal seam roof is fractured by means of hydraulic jet staged fracturing, to weaken the roof of the coal seam; 3) After the fracturing operation is completed, remove the fracturing equipment and connect the casing in the L-shaped borehole to the gas drainage device; 4) Start the coal mining operation at the coal mining face, and While the coal face is moving forward, the gas in the fracture zone is extracted through the gas extraction device. This solution solves the problems in the prior art that the amount of gas extraction is limited and the extraction intensity is not enough, and the coal seam gas cannot be extracted and utilized to a great extent.

Owner:CHONGQING UNIV

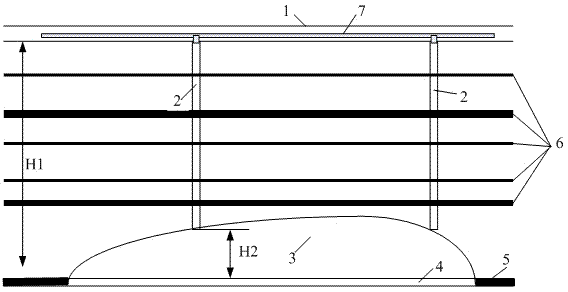

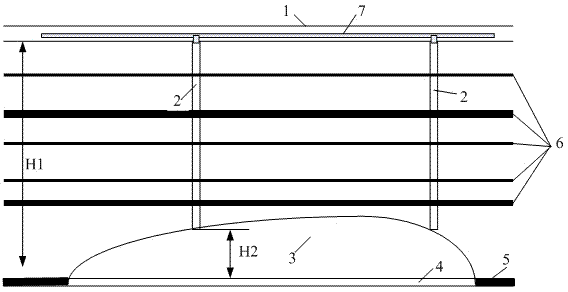

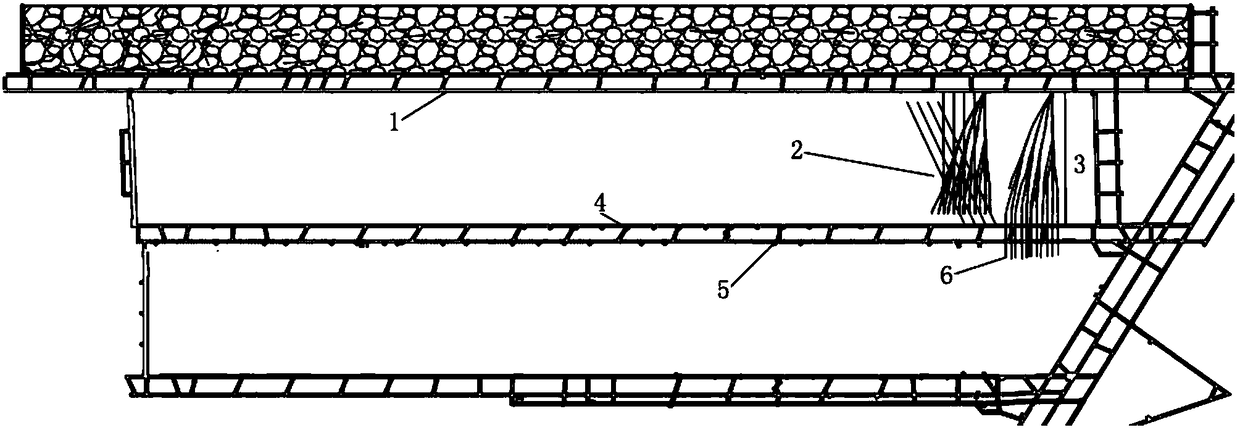

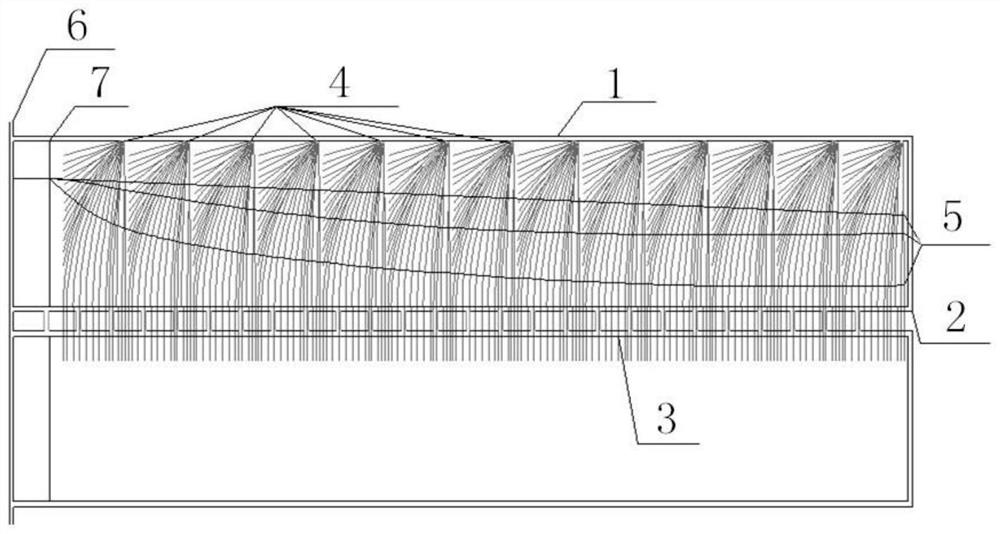

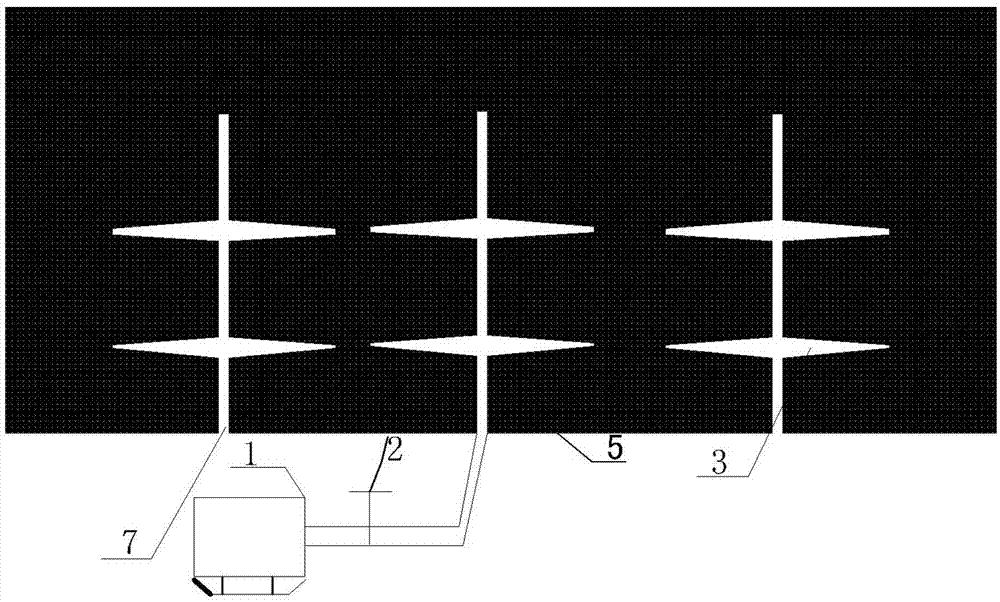

Underground dark mining drilling well gas extraction method

ActiveCN102226412ALarge amount of extractionIncrease extraction concentrationGas removalTunnelsWell drillingCoal

The invention discloses an underground dark mining drilling well gas extraction method, comprising the following steps: firstly constructing a gas extraction lane in a hard rock layer below an upper-group coal seam worked out area or above an unmined coal seam of the vertical distance of a firstly mined coal seam; carrying out middle construction on the gas extraction lane along the pushing direction of the firstly mined working face; starting the construction from a dark mining well of an open-off cut side and the part of the open-off cut in the gas extraction lane after construction; constructing the dark mining well the bottom of which is vertical to the top plate of the firstly mined working face at intervals; arranging an extraction pipe connected with the gas extraction pipeline; and connecting the extraction pipelines in the dark mining well into a mine gas extraction system through the gas extraction pipeline for gas predraining before mining, gas extraction in mining and gas extraction after mining. The method has the advantages of a ground drilling well extraction coal seam group, namely large extraction amount, high extraction concentration and good extraction effect, is good in stability and small in work amount, has low possibility to break and is easy to drain.

Owner:CHINA UNIV OF MINING & TECH

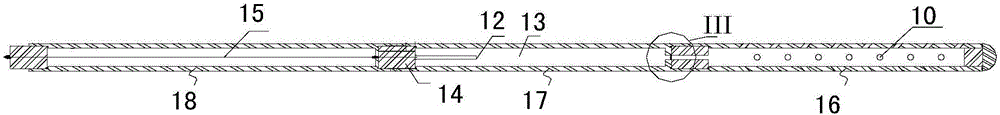

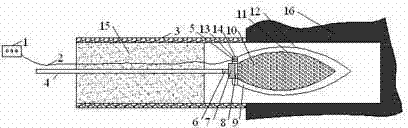

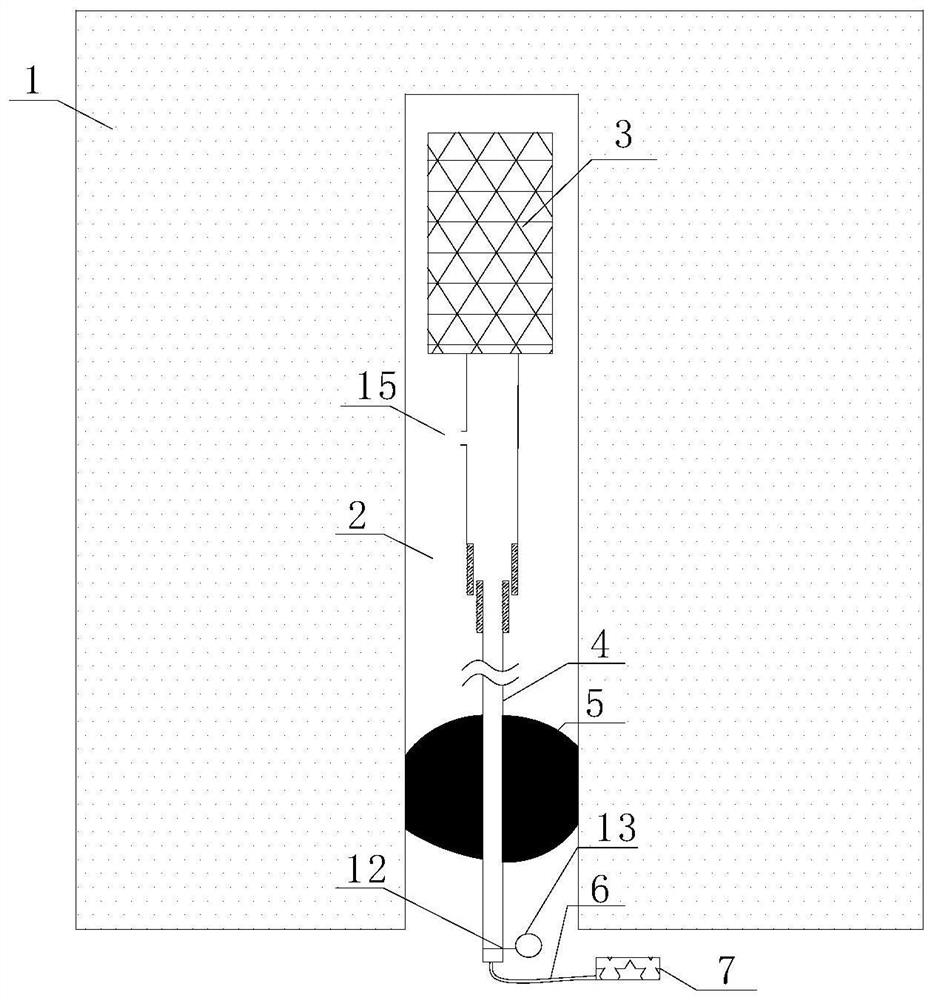

Dry ice explosion and air-permeability-enhancing device and method for drawing out gas by using same

InactiveCN103510979ALarge amount of extractionImprove breathabilityFluid removalGas removalShock waveCoal

The invention relates to a dry ice explosion and air-permeability-enhancing device for a low-air-permeability coal seam and a method for drawing out gas by using the dry ice explosion and air-permeability-enhancing device. The dry ice explosion and air-permeability-enhancing device is characterized in that an explosion initiation device consists of an explosion initiator arranged outside a drill hole, a lead arranged in the drill hole and a detonator connected with the lead; a heat-insulating storage device consists of a dry ice storage chamber arranged in a coal body, an inner housing arranged outside the dry ice storage chamber, a first vacuum chamber arranged outside the inner housing, an outer housing arranged outside the first vacuum chamber, a sealed male thread connected with the dry ice storage chamber and a conveying rod, a sealed female thread connected with the sealed male thread and a detonator cavity connected with the sealed female thread; a hole sealing device consists of polyurethane arranged in the drill hole; the explosion initiation device utilizes gas formed by heat-absorbing sublimation of the dry ice to generate high pressure in a limited and sealed space to cause a physical explosion to damage the inner housing of the heat-insulating storage chamber, and the coal body is damaged by shock waves generated by the explosion, so that a channel is provided for gas transportation, the air permeability of the coal seam is improved, the gas drainage ratio is increased, and safety is guaranteed.

Owner:HENAN POLYTECHNIC UNIV

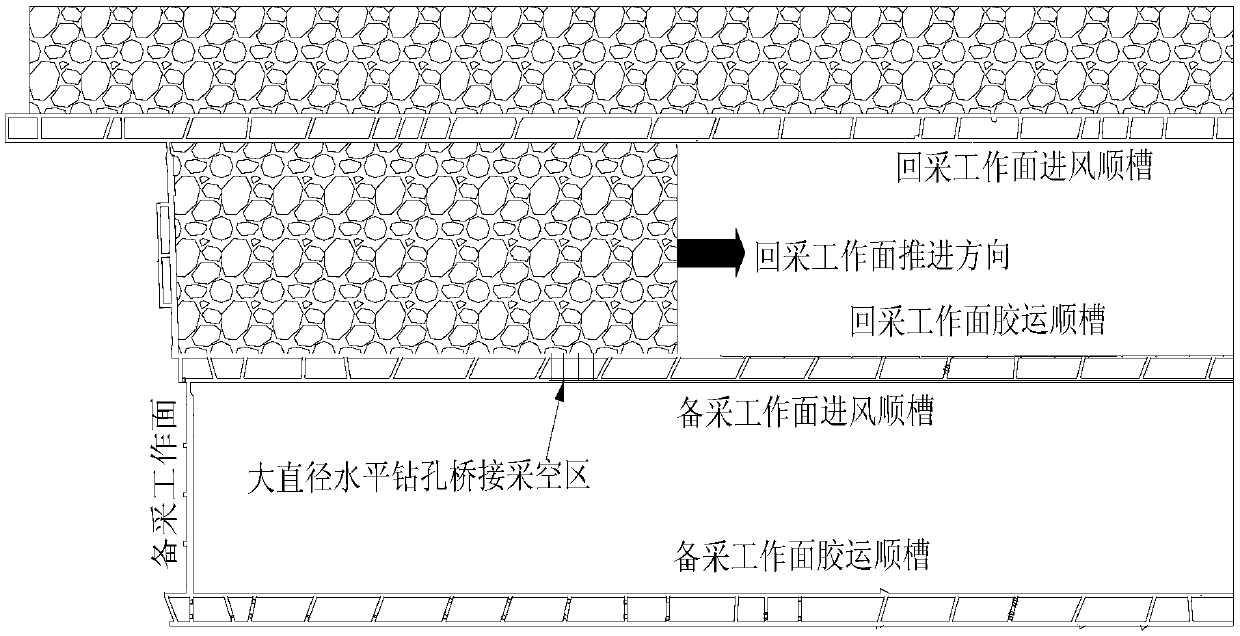

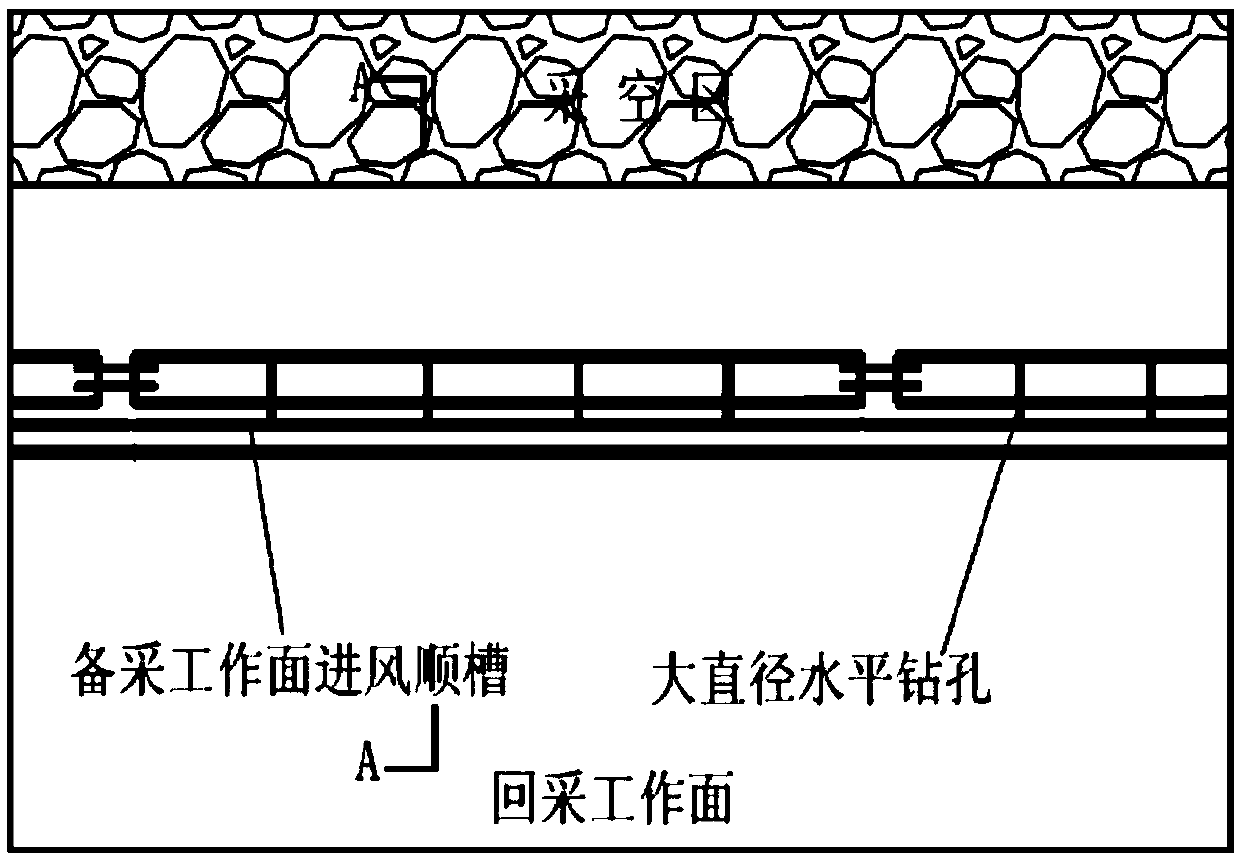

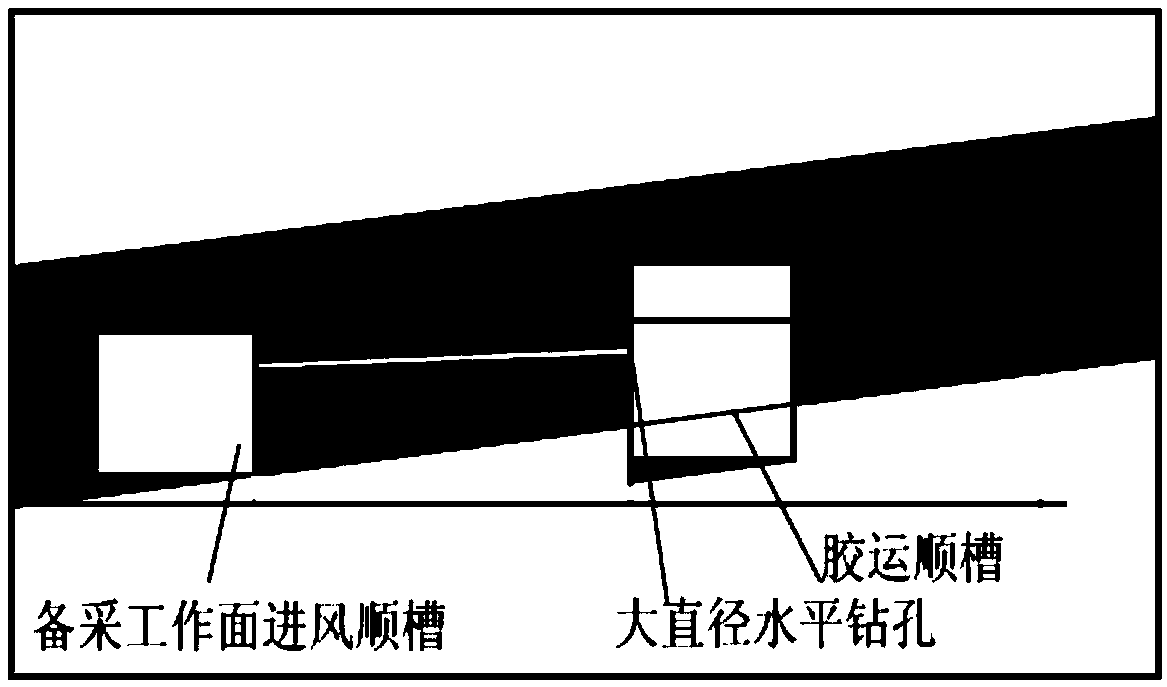

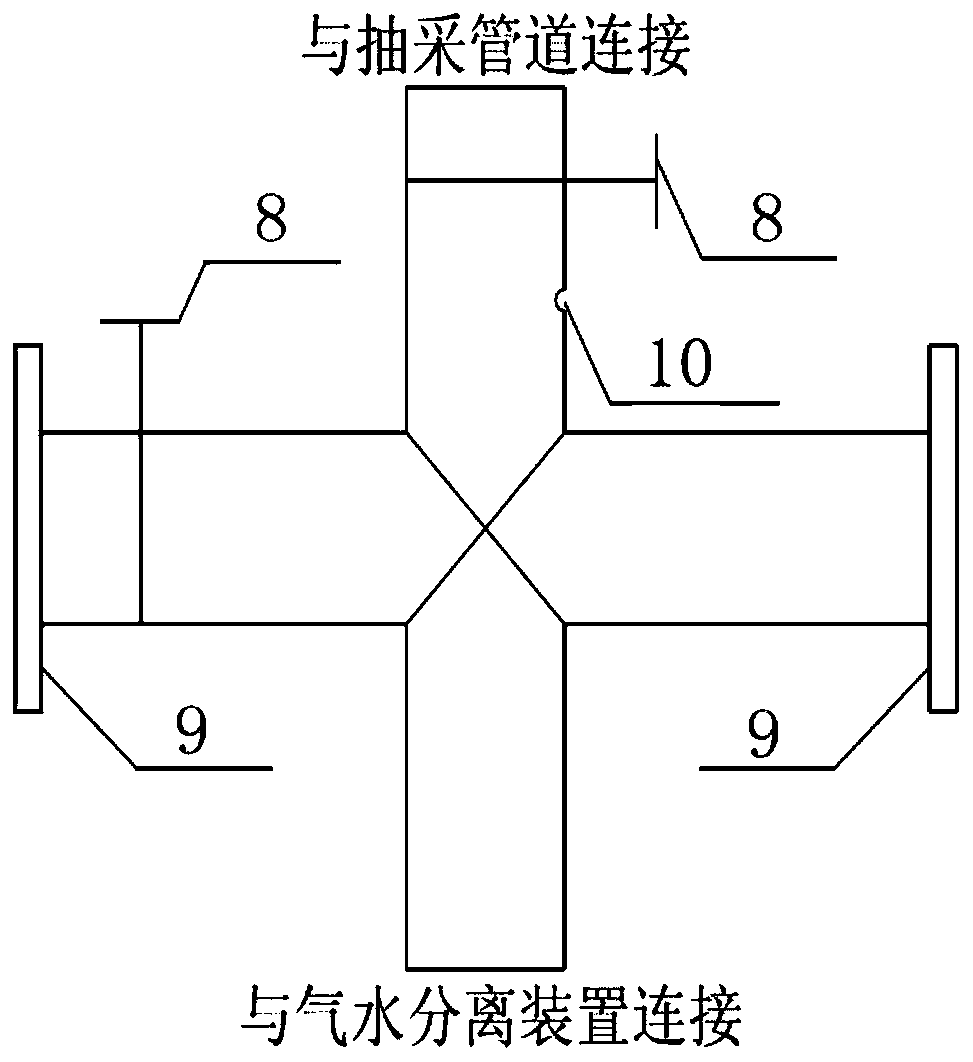

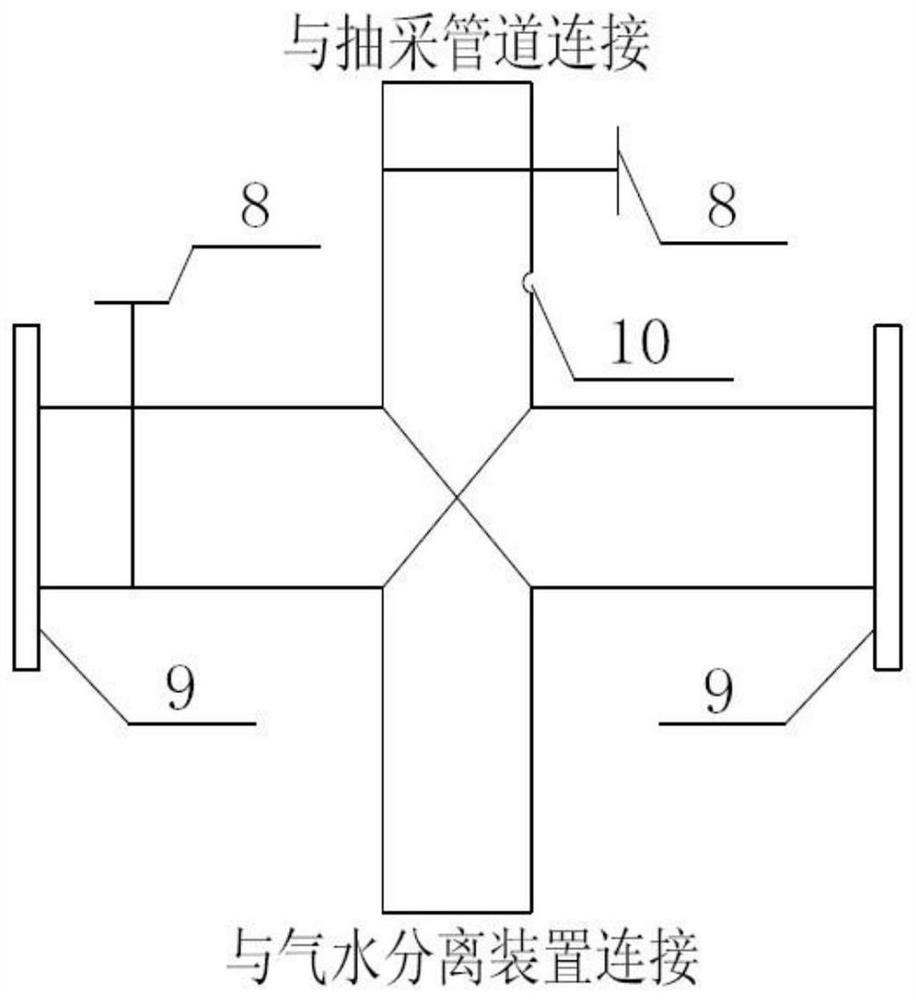

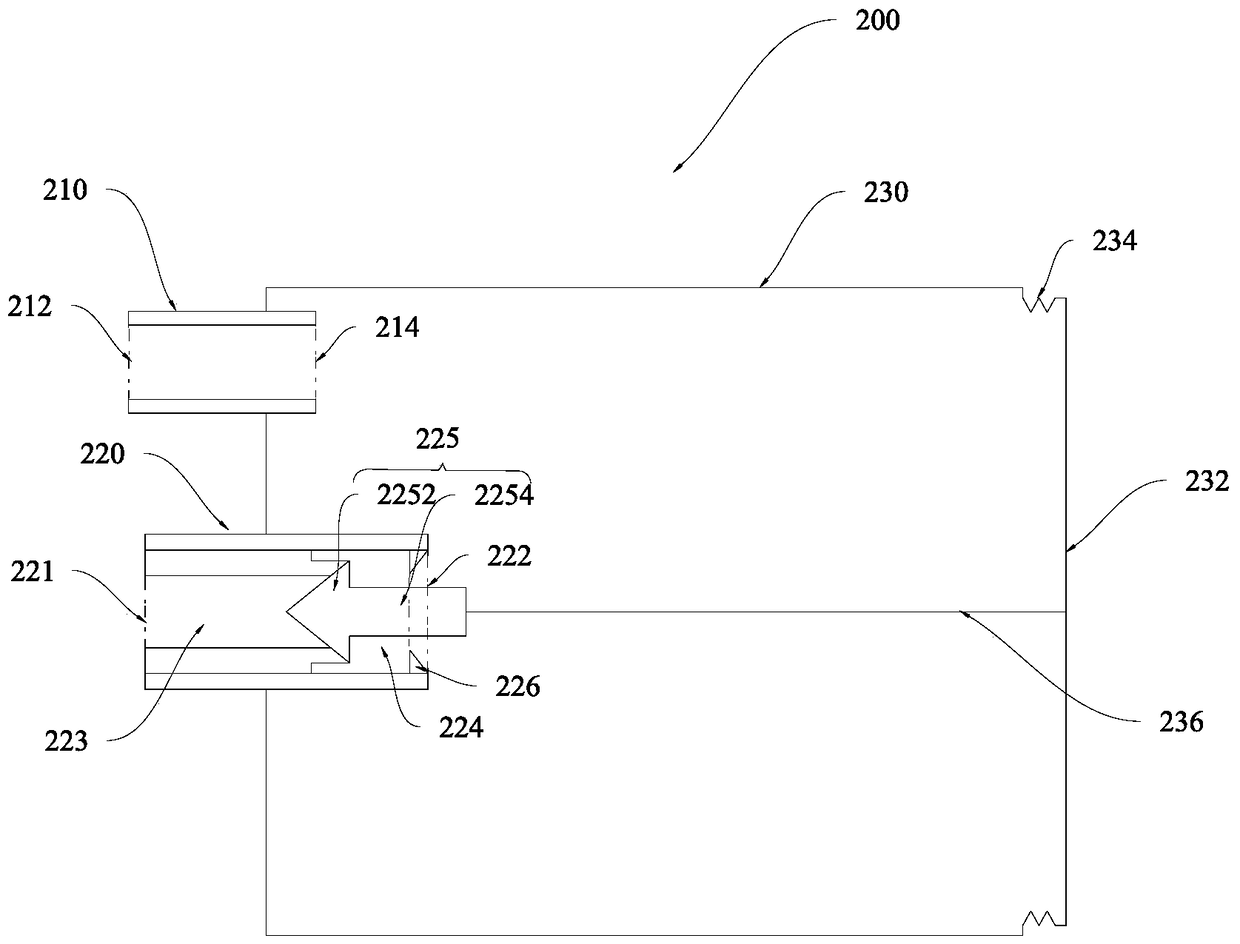

Device and method for large-diameter horizontal borehole bridging goaf gas extraction

PendingCN109519212AAchieve isolationAvoid direct inflowMining devicesGas removalSpontaneous combustionMultiple point

The invention relates to a device and method for large-diameter horizontal borehole bridging goaf gas extraction, and belongs to the technical field of coal mine gas safety. The device comprises a casing, a butterfly valve, a three-way joint and a pumping pipe. The butterfly valve is mounted on the casing, and the casing is connected to the pumping pipe through the three-way joint; the casing is placed inside a horizontal borehole; the horizontal borehole is formed in a coal pillar between a belt transporting crossheading of the working face and an air inlet duct of the adjacent working face and penetrates the coal pillar; a device for determining the flow rate, the temperature and the gas and carbon monoxide gas concentration is installed on the pumping pipe to monitor the gas extractionin a horizontal borehole bridging goaf. The device and method solve the difficulty in gas control of the return air corner on the high-strength working face under the condition of the 'Y' type ventilation mode, achieves multiple-point continuous controllable pumping of the gas in the goaf and monitors spontaneous combustion of the residual coal in the goaf in real time while effectively controlling corner gas emission.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

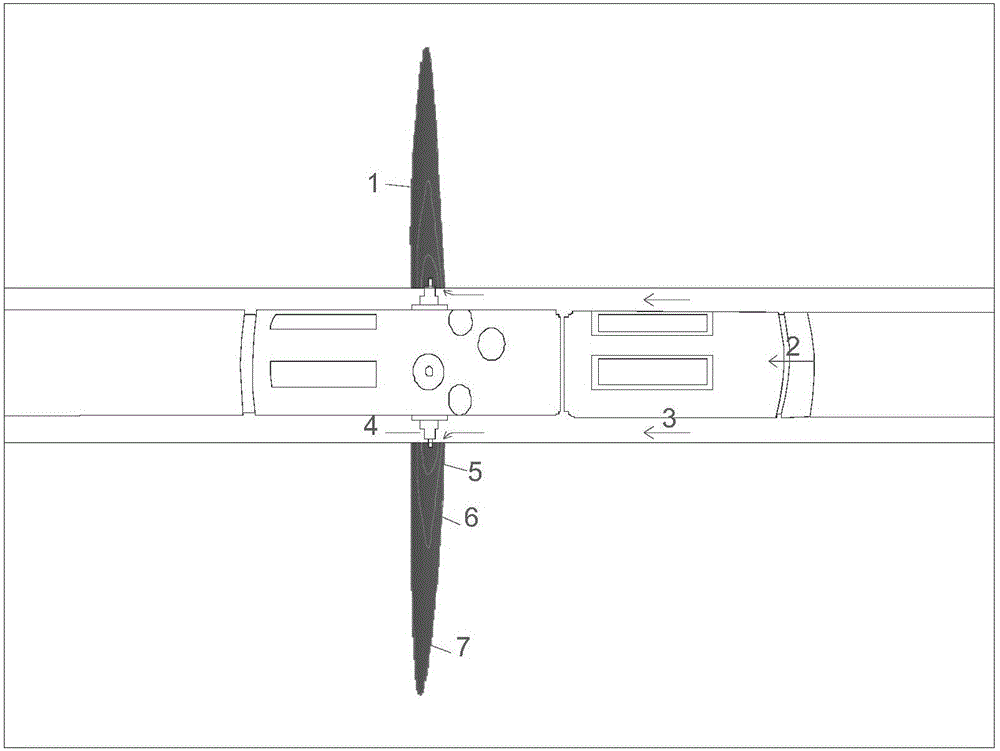

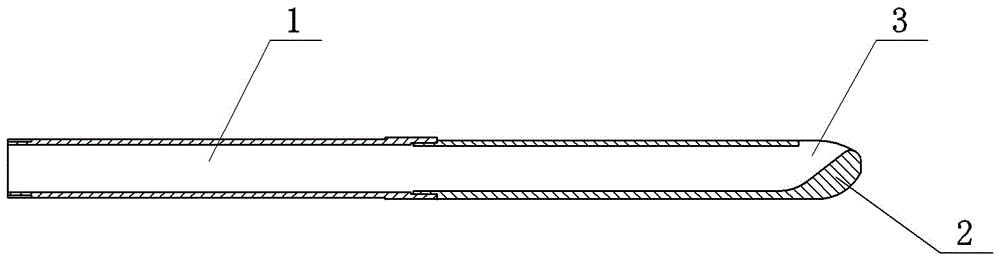

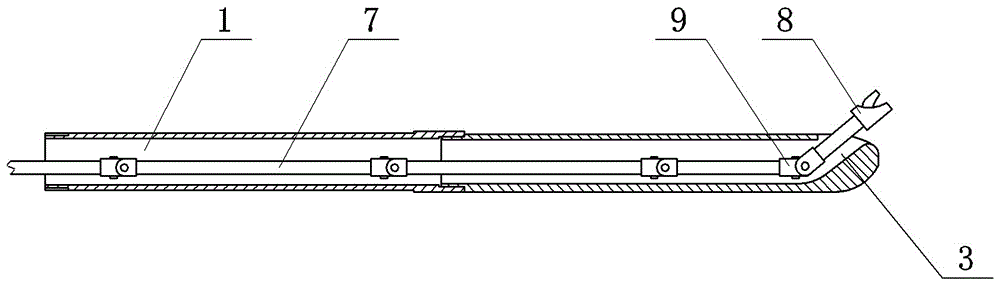

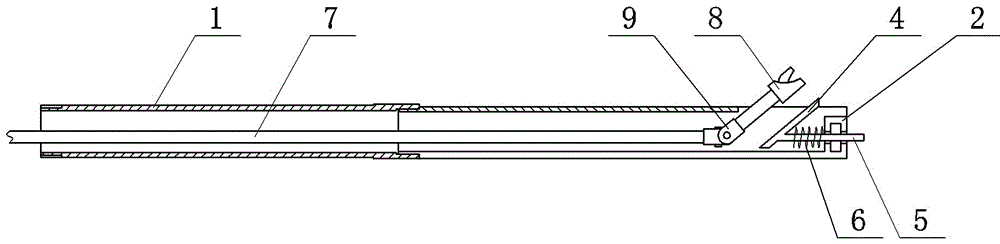

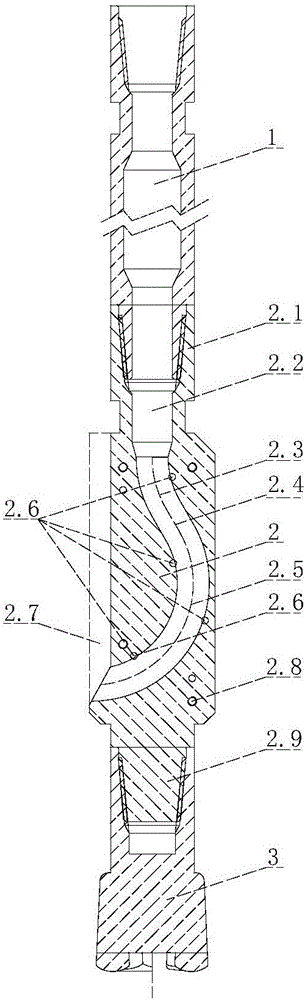

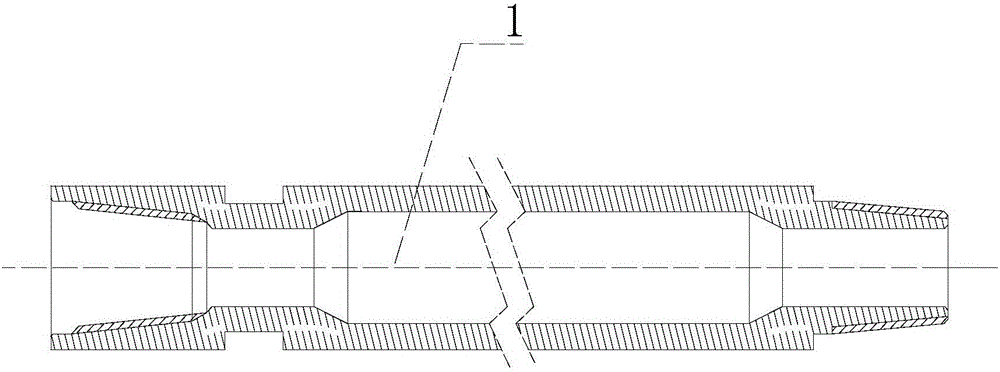

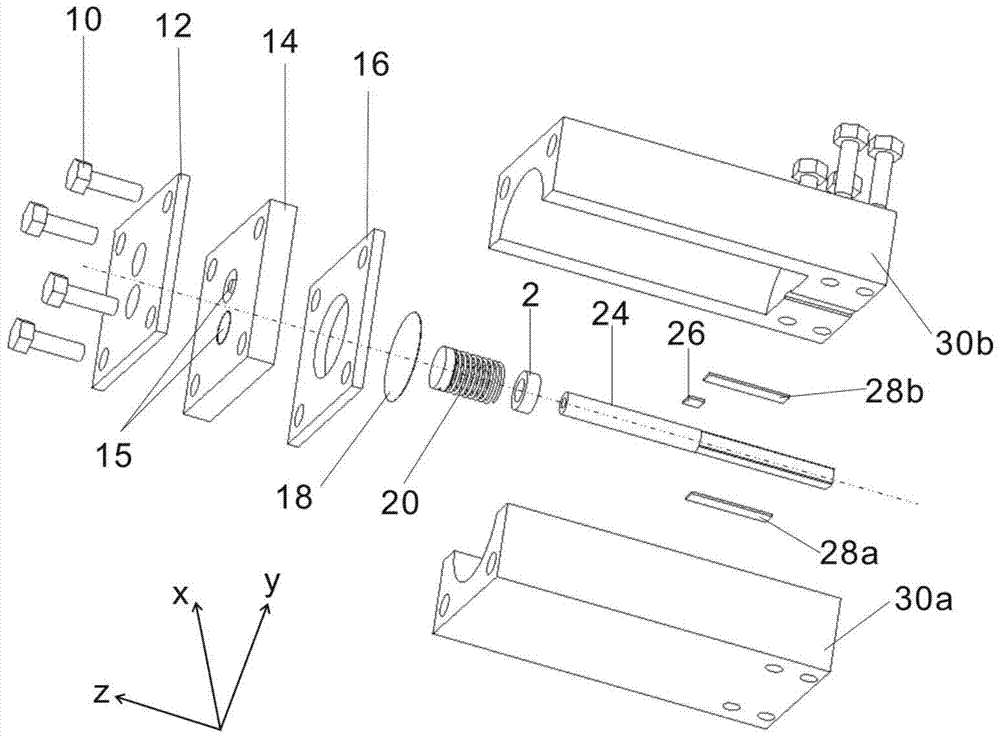

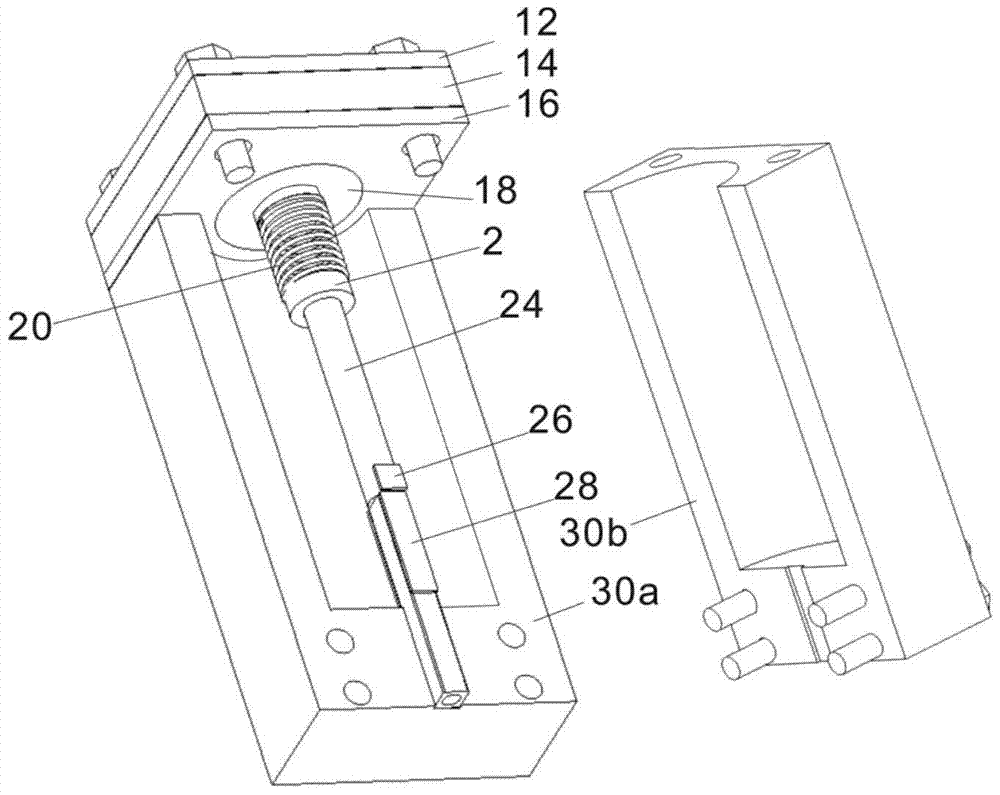

Track varying drilling method and device

InactiveCN106639877ALarge amount of extractionImprove the extraction effectDirectional drillingAnchoring boltsCoalPetroleum engineering

The invention discloses a track varying drilling method and device. Firstly drilling is conducted on a coal bed, then a track varying drilling pipe is inserted into a main drill hole, the front part of the track varying drilling pipe is provided with a tilting guide mechanism, an anchor cable drill of which a drill rod is capable of crooking is arranged in the track varying drilling pipe in a sleeved mode, and tilting drilling is conducted on the side wall of the main drill hole according to the various depths degree to which the track varying drilling pipe penetrates into the main drill hole.On the basis of the main drill hole and through reasonable redrilling by using a track varying drilling device, a drill hole area in which the main drill hole is regarded as a center, and a lateral drill hole is regarded as the radius is finally formed, in this way, a coal body can be loosened, the gas can be extracted, thus the extraction quantity of the gas in the drill hole is increased, and the gas extraction effect in the coal bed can be improved.

Owner:HENAN POLYTECHNIC UNIV

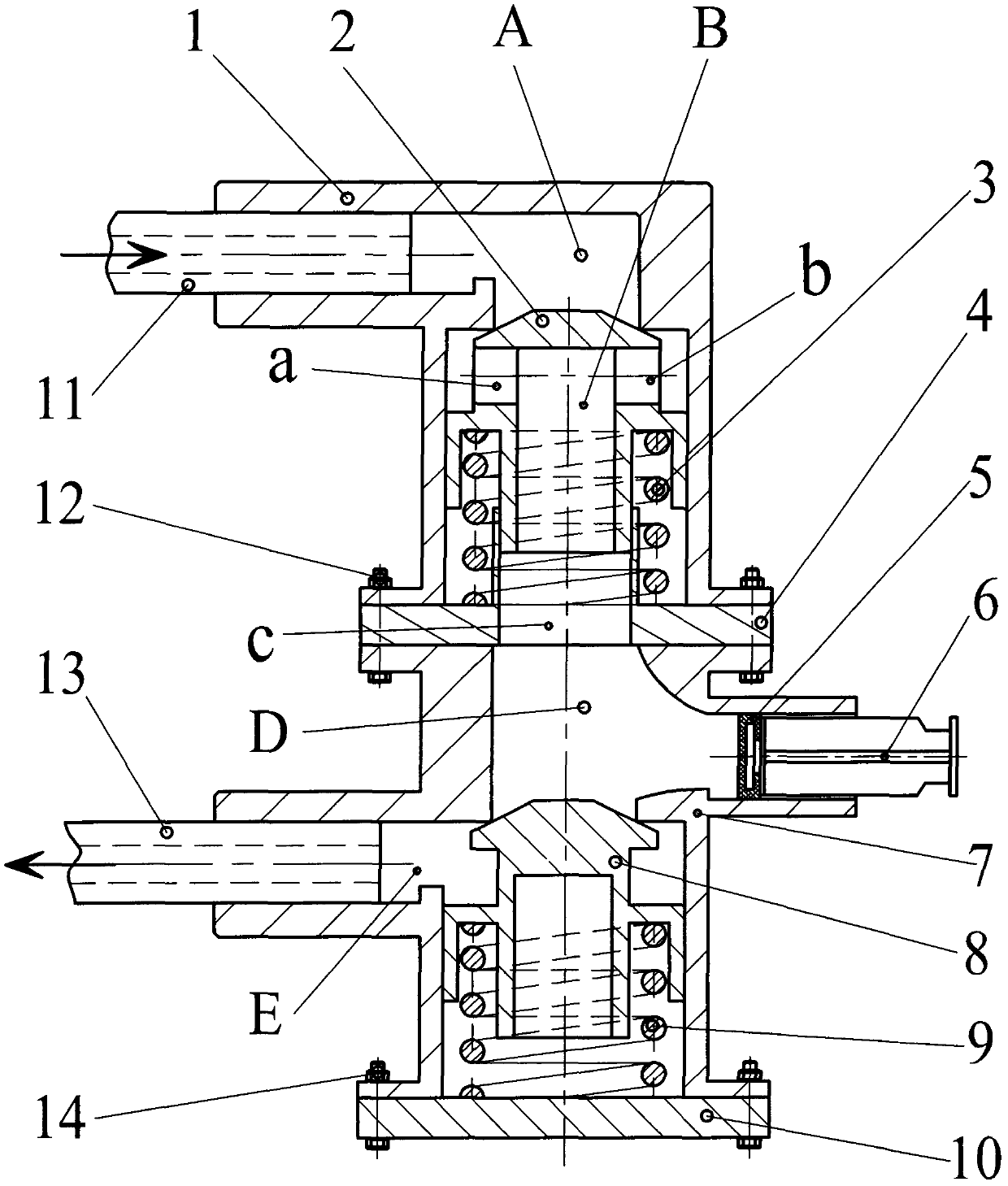

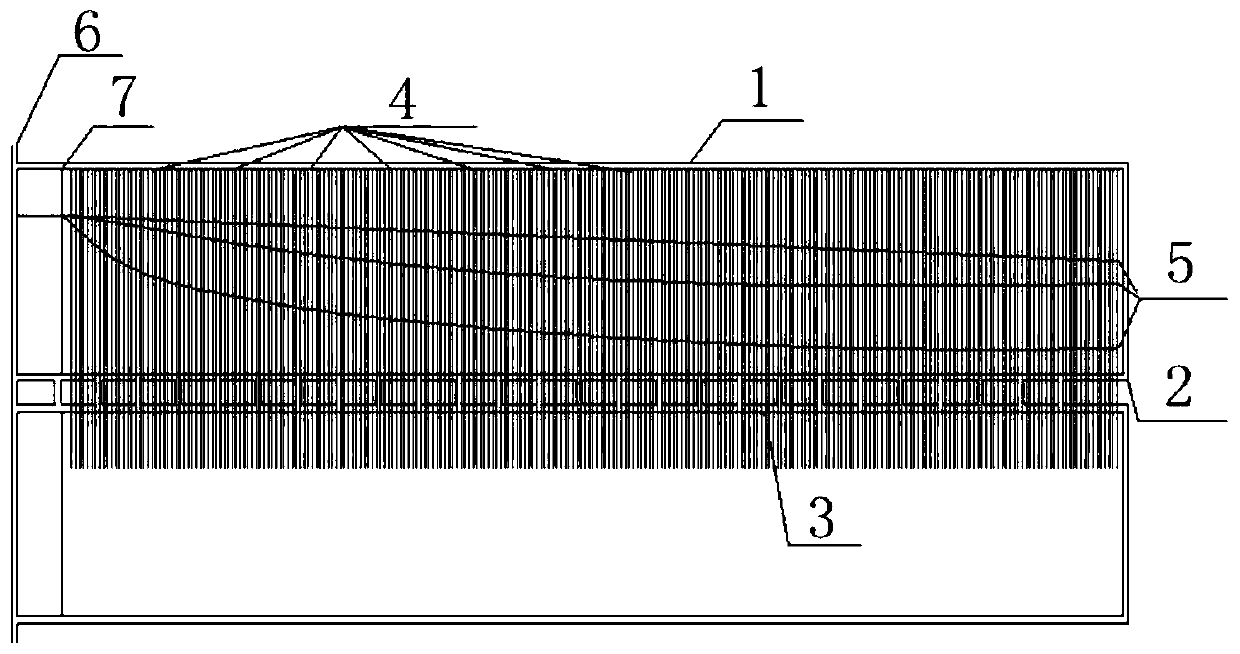

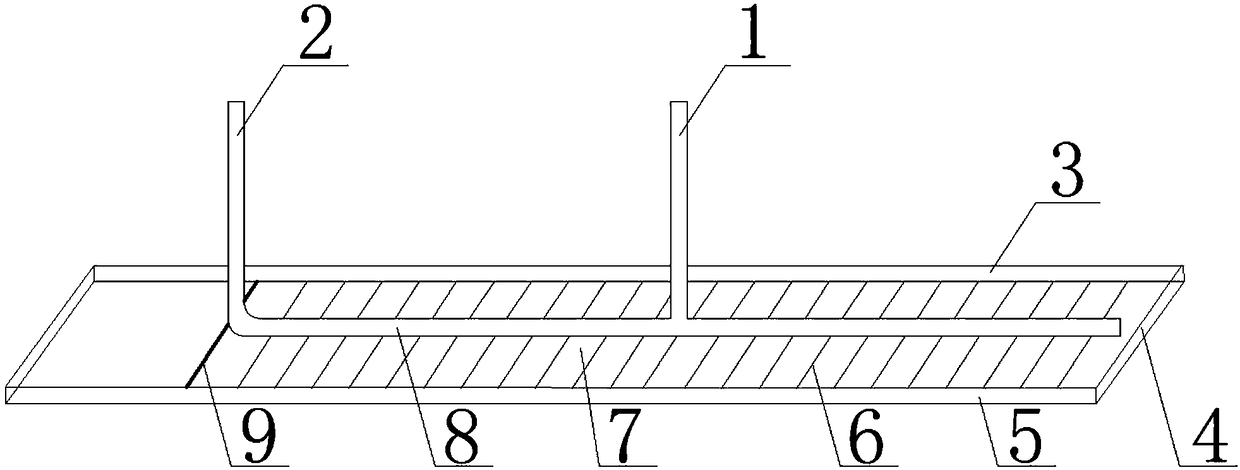

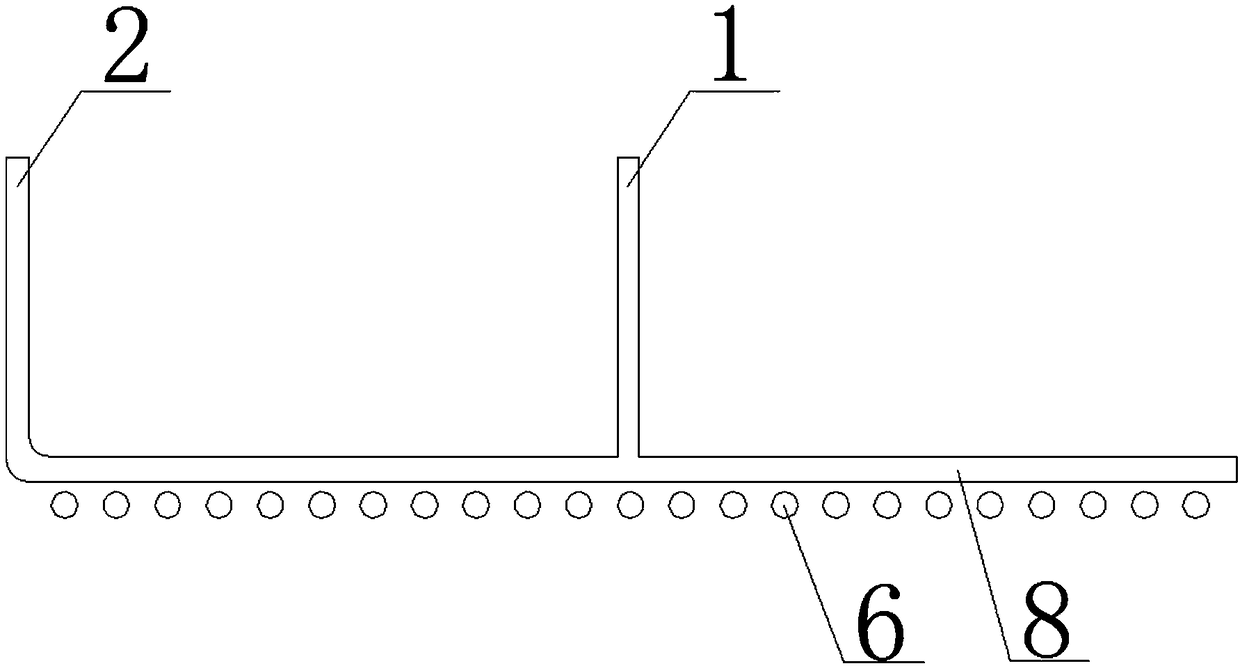

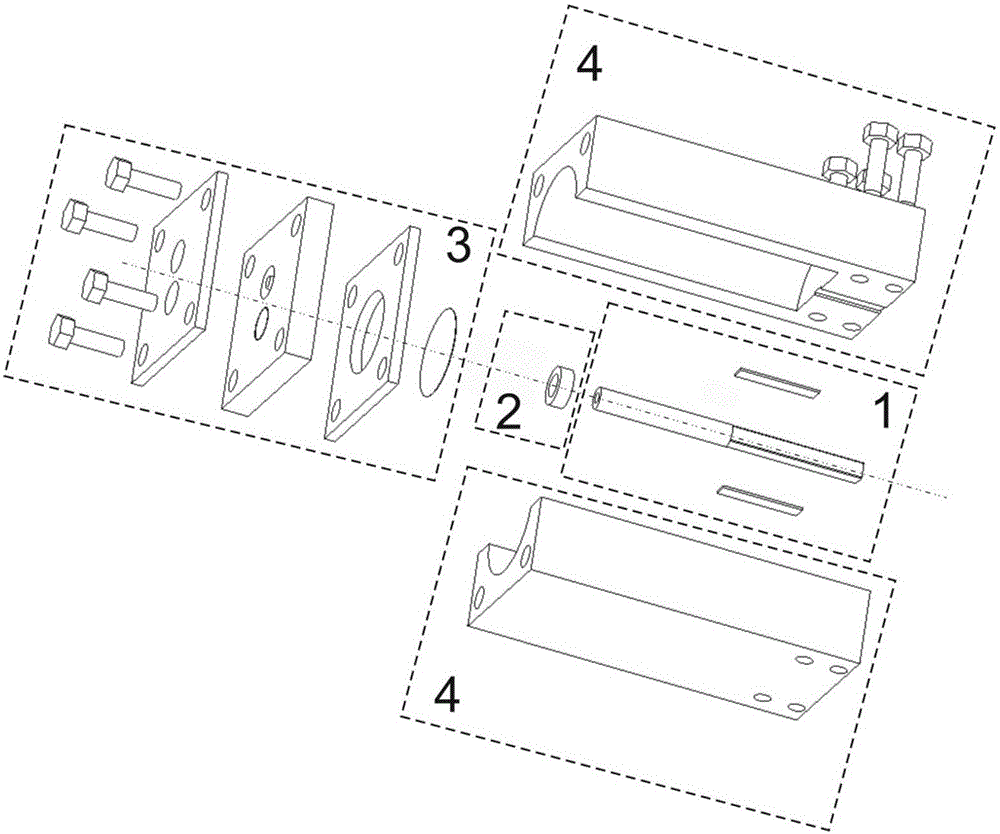

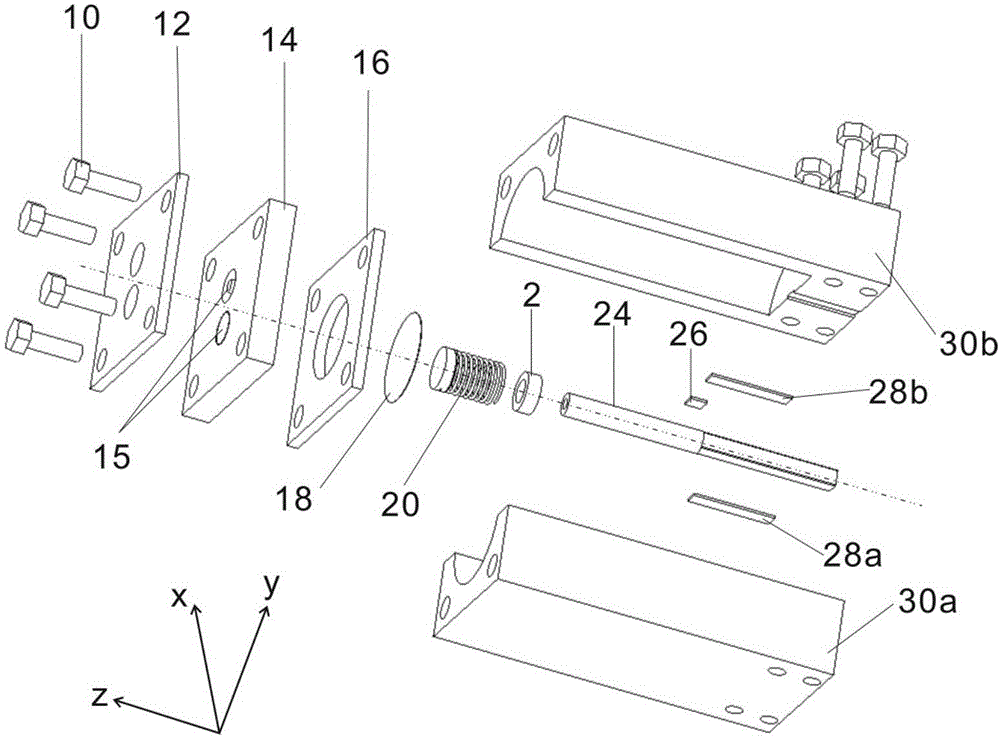

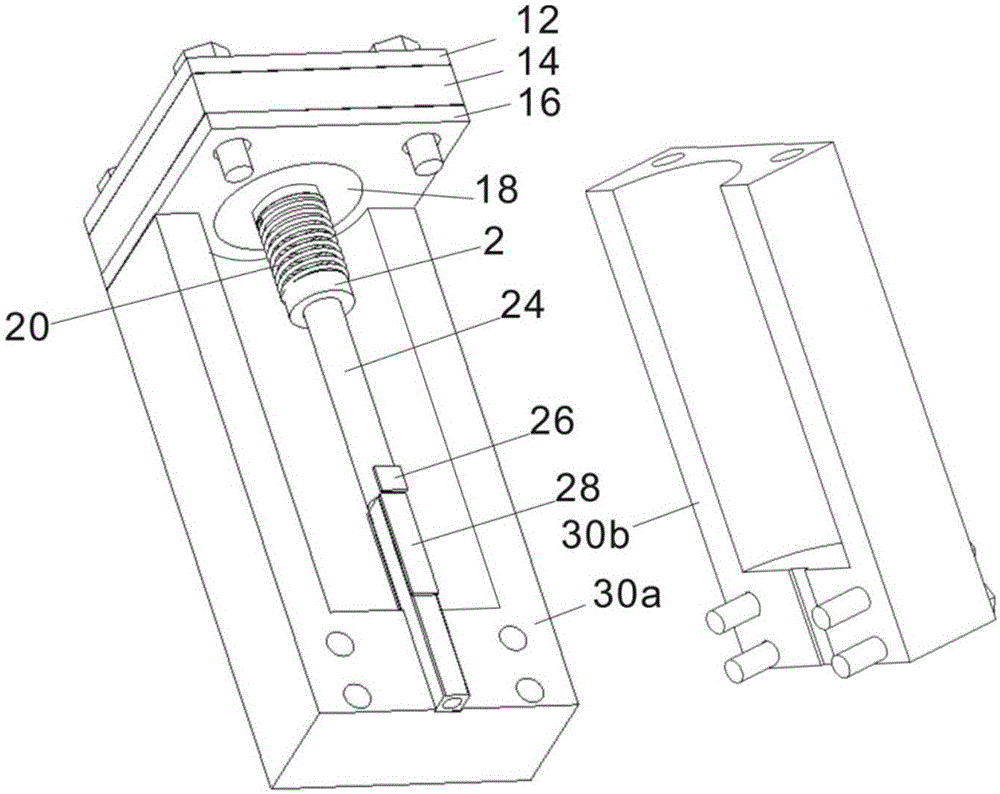

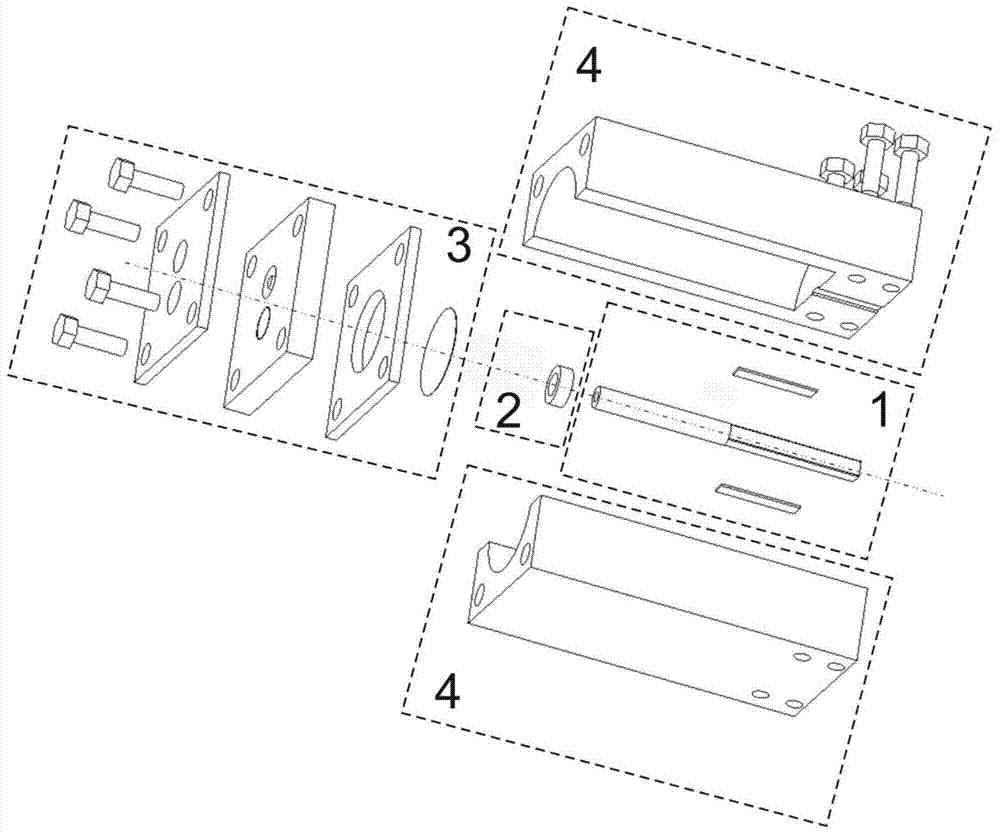

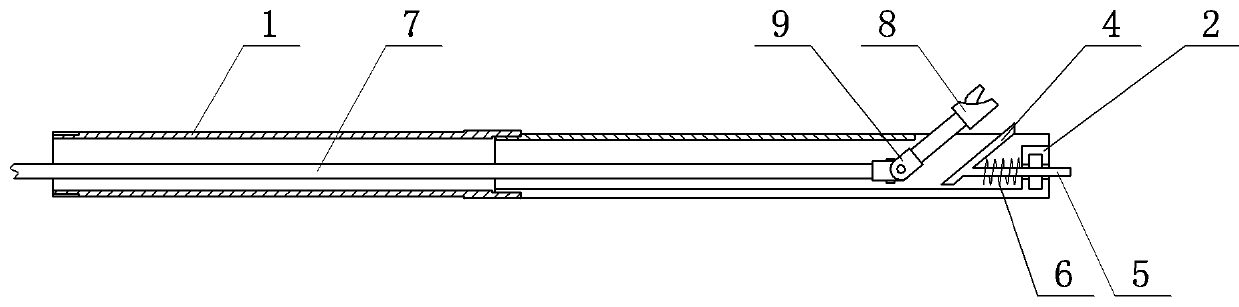

Backflow-prevention anti-blocking drainage device with large suction amount

ActiveCN103285432ASmooth drainageDrainage effect is goodSuction devicesEngineeringMechanical engineering

The invention relates to a backflow-prevention anti-blocking drainage device with a large suction amount. The drainage device comprises a liquid inlet valve body (1), a liquid inlet valve core (2), a liquid inlet valve spring (3), an upper valve cover and a lower valve cover (4 and 10), a needle cylinder piston (5), a piston rod (6), a liquid discharging valve body (7), a liquid discharging valve core (8) and a liquid discharging spring (9), wherein the liquid inlet valve core (2) only allowing a liquid to flow downwards is arranged in the liquid inlet valve body (1), and an insertion hole for a liquid inlet pipe (11) is formed in the upper left part of the liquid inlet valve body (1); the liquid discharging valve core (8) only allowing the liquid to flow leftwards is arranged in the liquid discharging valve body (7); and an insertion hole of a liquid discharging pipe (13) and a duct allowing the needle cylinder piston (5) to move leftwards and rightwards are formed in the left side and in the upper right part of the liquid discharging valve body (7) respectively. The needle cylinder piston (5) moves leftwards and rightwards continuously, so that the liquid can be drained and discharged to a container. The backflow-prevention anti-blocking drainage device with a large suction amount has the advantages as follows: smooth drainage is realized, the drainage amount is large, retrograde infection of the liquid is prevented, blocking is avoided, and continuous drainage can be realized.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

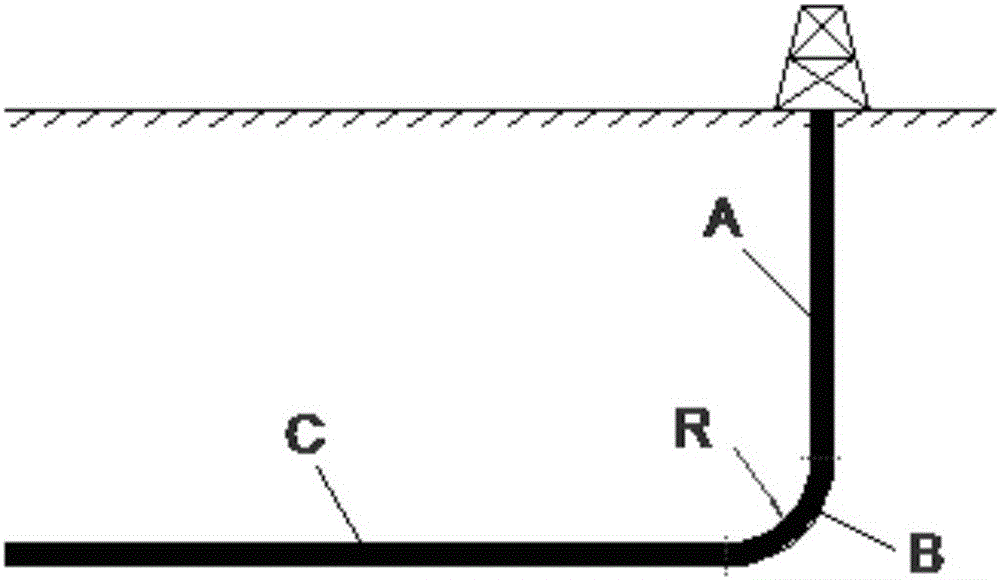

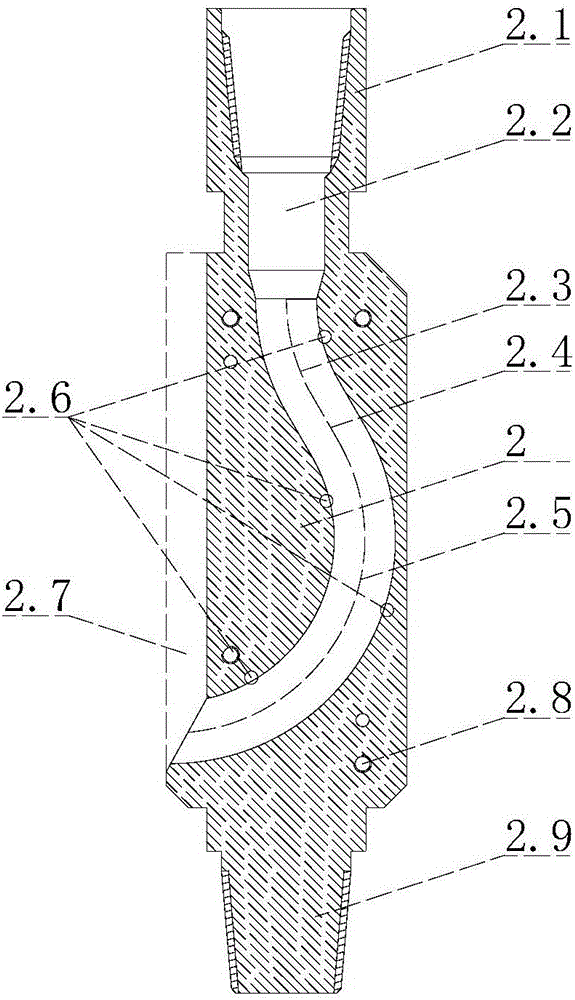

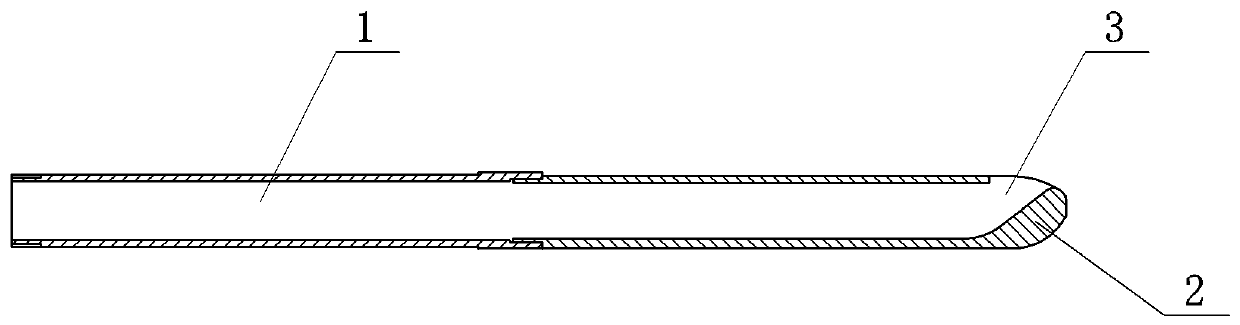

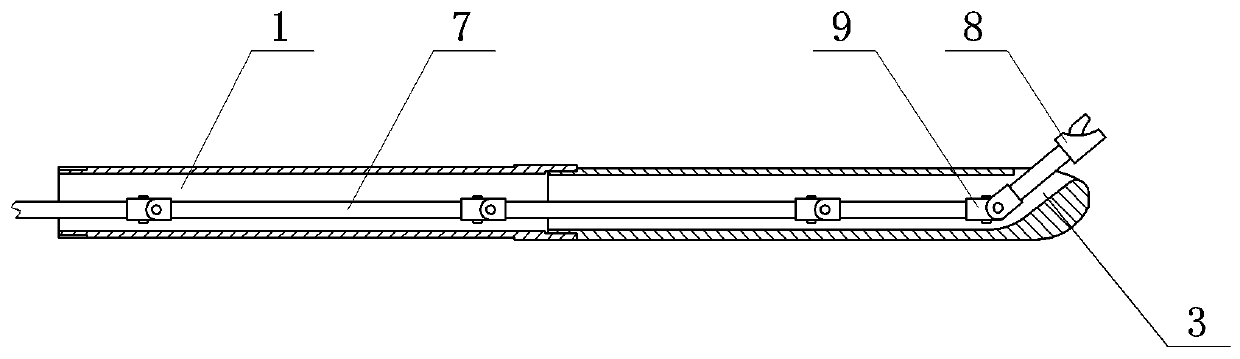

Coal mine downhole hydraulic jet tree-shaped drill hole guide device and method

ActiveCN105089499AEasy to feedEasy to processLiquid/gas jet drillingFluid removalHigh pressureTree shaped

The invention relates to a coal mine downhole self-propelled hydraulic jet tree-shaped drill hole guide device. The device comprises a drill rod, a guider, a drill bit and a dial. The drill rod is in threaded connection with the front end of the guider. The drill bit is in threaded connection with the tail end of the guider. A self-propelled drill bit connected with a high-pressure hose penetrates through the middle of the drill rod and then passes through the guider, the purpose of vertical guide to horizontal guide of the self-propelled drill bit is achieved, and finally self-propelled horizontal drilling is conducted on a coal seam. Horizontal steering of the guider is achieved by guider rotation driven by rotation of the drill rod, and the rotation angle is controlled by the dial. The dial is fixed to a chuck at the front end of the drill rod and the front end of a drilling rig. The device has the main effects that vertical guide to horizontal guide of the self-propelled drill bit along a guider track within a certain curvature radius is achieved, and then horizontal drilling of the self-propelled drill bit in the coal seam is achieved. The device is simple in structure, convenient to operate and mainly suitable for drilling tree-shaped drill holes in the gas extraction process of the low-air-permeability coal seam.

Owner:中国平煤神马控股集团有限公司 +1

Coal bed methane extraction method based on directional drilling and liquid nitrogen freezing heat cracking

ActiveCN110617047AImprove penetration propertiesIncrease extraction concentrationSurveyFluid removalLiquid nitrogenPermeation

The invention relates to a coal bed methane extraction method based on directional drilling and liquid nitrogen freezing heat cracking, and belongs to the technical field of methane treatment. An inclined drill hole is formed in the upper roadway of the extraction work face, and the inclined drilled hole is merged into an extraction pipe network to be subjected to methane extraction; after the work face methane extraction amount is attenuated, the inclined drill hole is detected, a drill hole with extraction failure is marked, meanwhile, a long-distance orientation drill hole is constructed ina retracement channel or air return main roadway of the extraction work face in the coal seam direction to serve as a liquid nitrogen injection hole, liquid nitrogen is injected into the long-distance orientation drill hole, through detection of the temperature in the drill hole marked as extraction failure, whether the drill hole is a liquid nitrogen influence hole or not is judged, if the holeis the liquid nitrogen influence hole, high-temperature air is injected into the drill hole, and the coal around the drill hole is cracked under the freezing heat condition, and the coal permeation characteristics are improved. The methane extraction amount is improved, the process is simple, and the work cost is low.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Heavy pressure slip-casting hole-sealing method for large-diameter extraction borehole

The invention relates to a method for large diameter borehole extracting and high-pressure grouting hole sealing, which is characterized in that the method comprises the following steps: at the coal seam top and in the floor roadway rock surface, an across-seam hole drilling and sealing section are constructed in the coal seam; a hole sealing pipe is positioned into the hole sealing stage; a grouting cavity is reserved between the hole sealing pipe and the hole wall of a borehole; a grouting pipe and a return pipe are respectively arranged in the two positions corresponding to the grouting cavity; the output pipe of a high pressure grouting pump communicates with the grouting pipe; grouting material is infused into the grouting cavity by the high pressure grouting pump through the grouting pipe, until the grouting material overflows out of the return pipe; the hole sealing section is formed through maintenance; across-seam hole drilling is constructed in the inner cavity of the hole sealing pipe. The method has the advantages that the hole sealing effect is good, the effective gas extraction time is long, and the construction method is simple.

Owner:HUAINAN MINING IND GRP

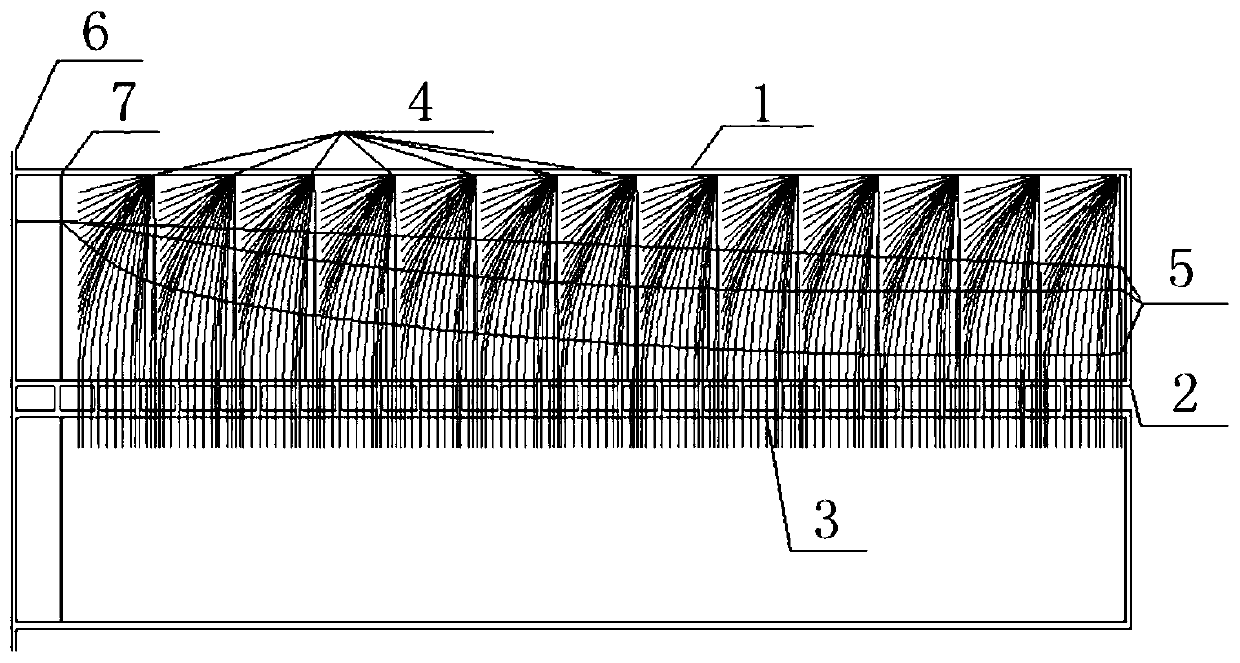

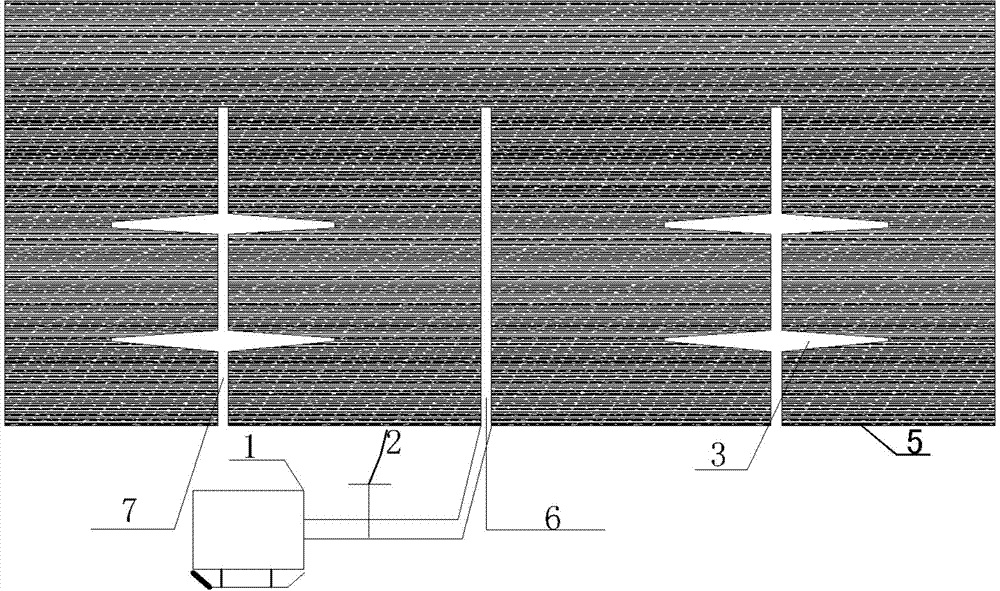

Joint gas extraction method combining two-way stereo interlaced hole drilling with collaborative directional long hole drilling

ActiveCN108223004ALarge amount of extractionIncrease extraction concentrationFluid removalGas removalCoal mine methaneCoal

The invention relates to a joint gas extraction method combining a two-way stereo interlaced hole drilling with collaborative directional long hole drilling. The method comprises the following steps that in the tunneling process of back production of the working face roadway in coal mine underground, long distance directional drilling is constructed along the inclination of a back production working face track crossheading, and coal bodies belonging to the back production working face transportation crossheading and a crossheading of the working face to be mined is pre-pumped. The gas extraction drill hole in the coal seam is constructed along the inclination of the back production working face along with the driving of the back production working face track crossheading. In the process ofdriving the back production working face transportation crossheading, and the exposed long distance directional drill hole is sealed by applying a hole sealing material, at the same time, a gas extraction drill hole of the coal seam is constructed along the inclination direction in the back production working face transportation crossheading, and the gas extraction drill hole of the coal seam inthe back production working face transportation crossheading and the gas extraction drill hole of the coal seam in the back production working face track crossheading can form a plane or a three-dimensional cross. The joint gas extraction method combining the two-way stereo interlaced hole drilling with the collaborative directional long hole drilling improves the efficiency of coal mine gas disaster control, reduces the construction quantity of gas control project in the coal mine underground, and has extremely high technicality and economical efficiency.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

Ultrasonic excitation-assisted hydraulic fracturing pressure relief method for improving permeability in underground coal mine

The invention discloses an ultrasonic excitation-assisted hydraulic fracturing pressure relief method for improving the permeability in an underground coal mine. The method takes the advantages of ultrasonic excitation and hydraulic fracturing technologies for permeability improvement; the hydraulic fracturing is implemented on the basis of ultrasonic excitation; and ultrasonic shock waves generated by an ultrasonic excitation device are used for changing the pore-fracture structure of a coal reservoir; and a large number of new uniformly distributed fractures are produced in advance, provideguiding fracture channels for high-pressure water splitting coal body expansion and fracturing in the hydraulic fracturing process and assist in achieving the relatively uniform hydraulic fracturing,thus, the controllability of the effective range of hydraulic fracturing is improved, and the permeability of a coal seam and the amount of gas extraction are greatly improved.

Owner:SHAANXI COAL & CHEM TECH INST

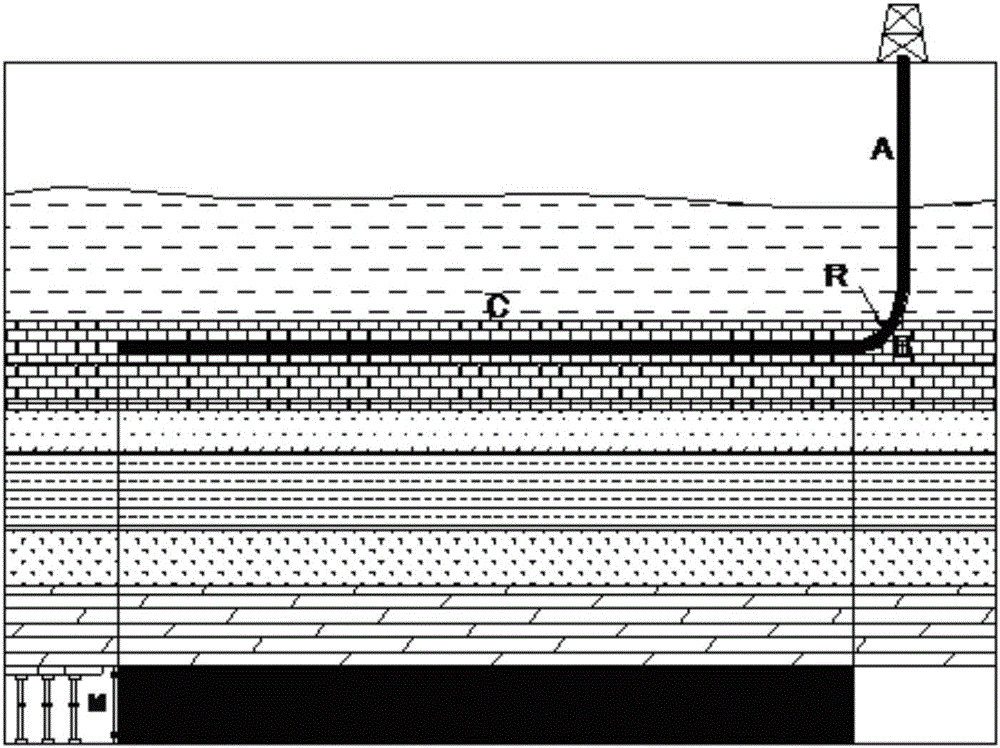

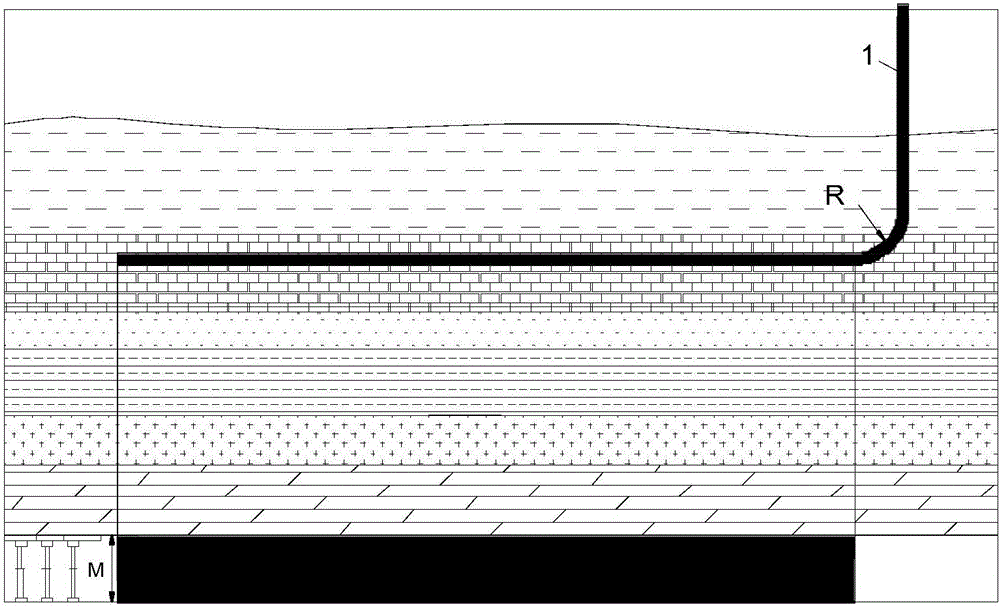

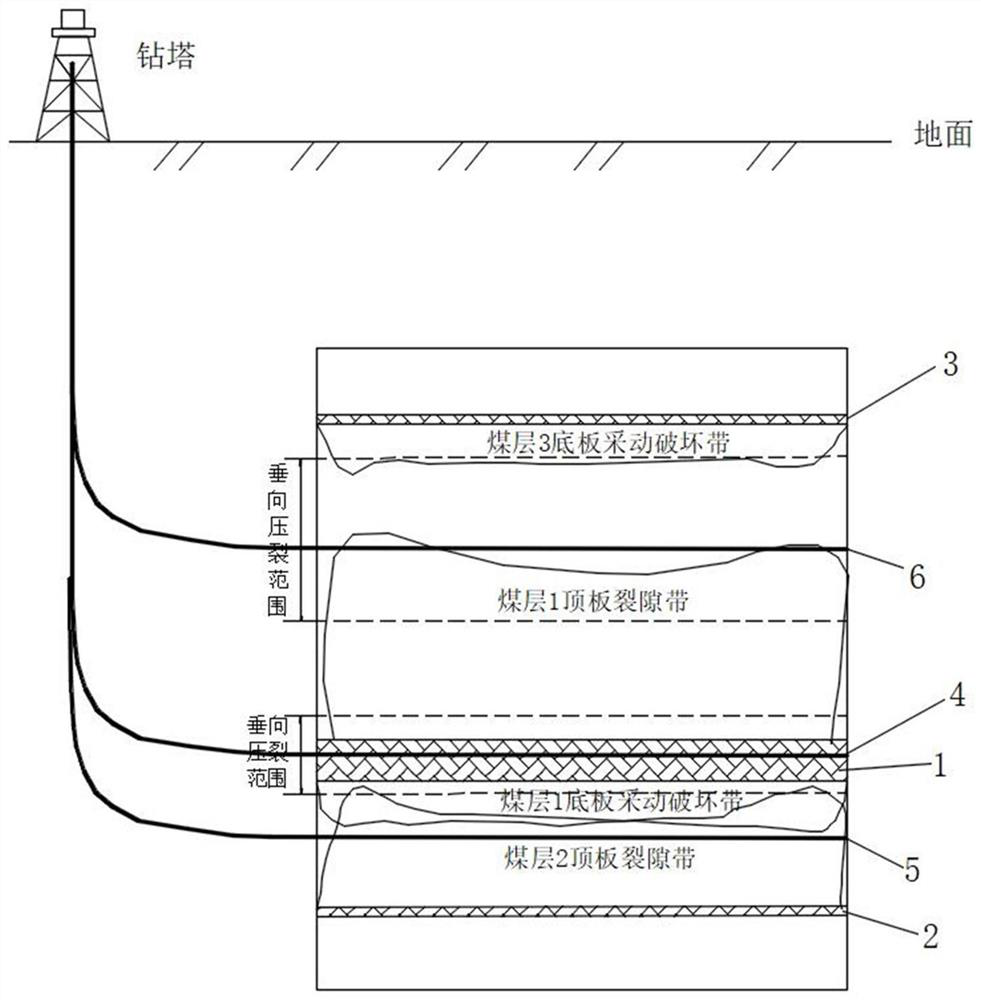

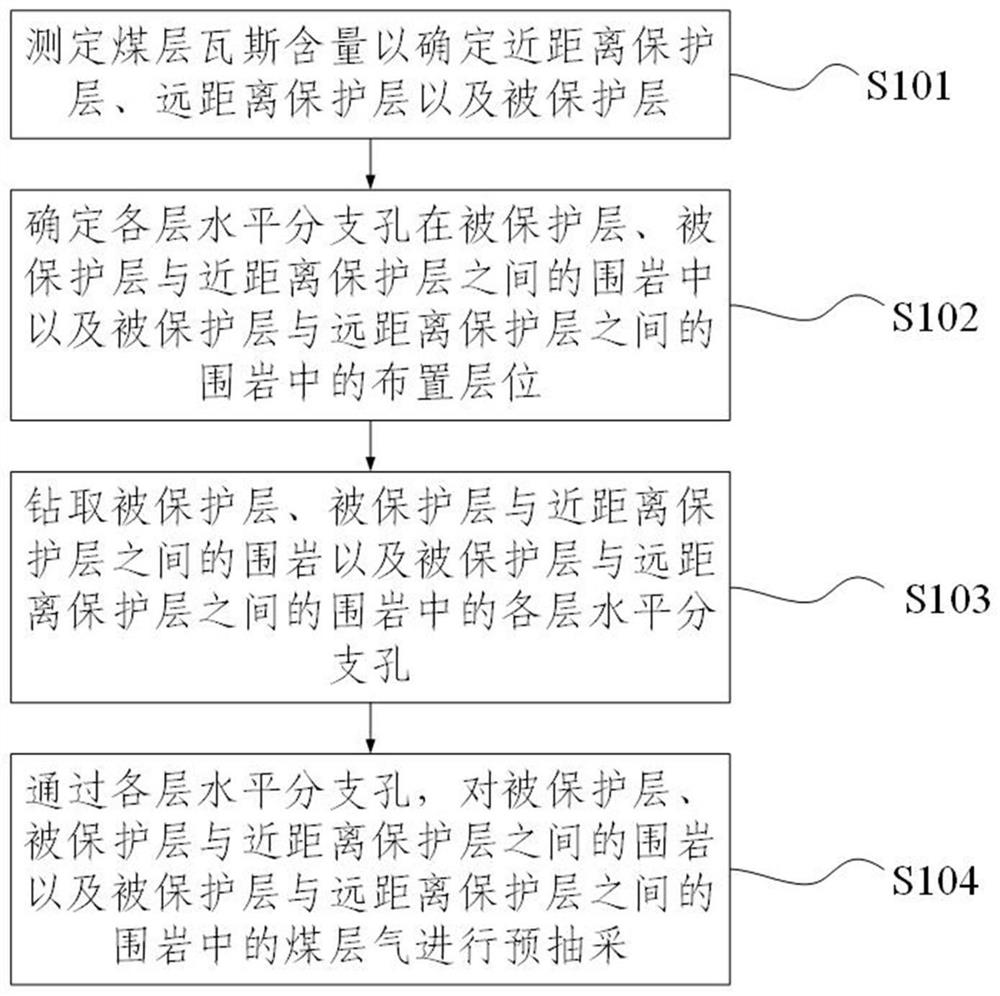

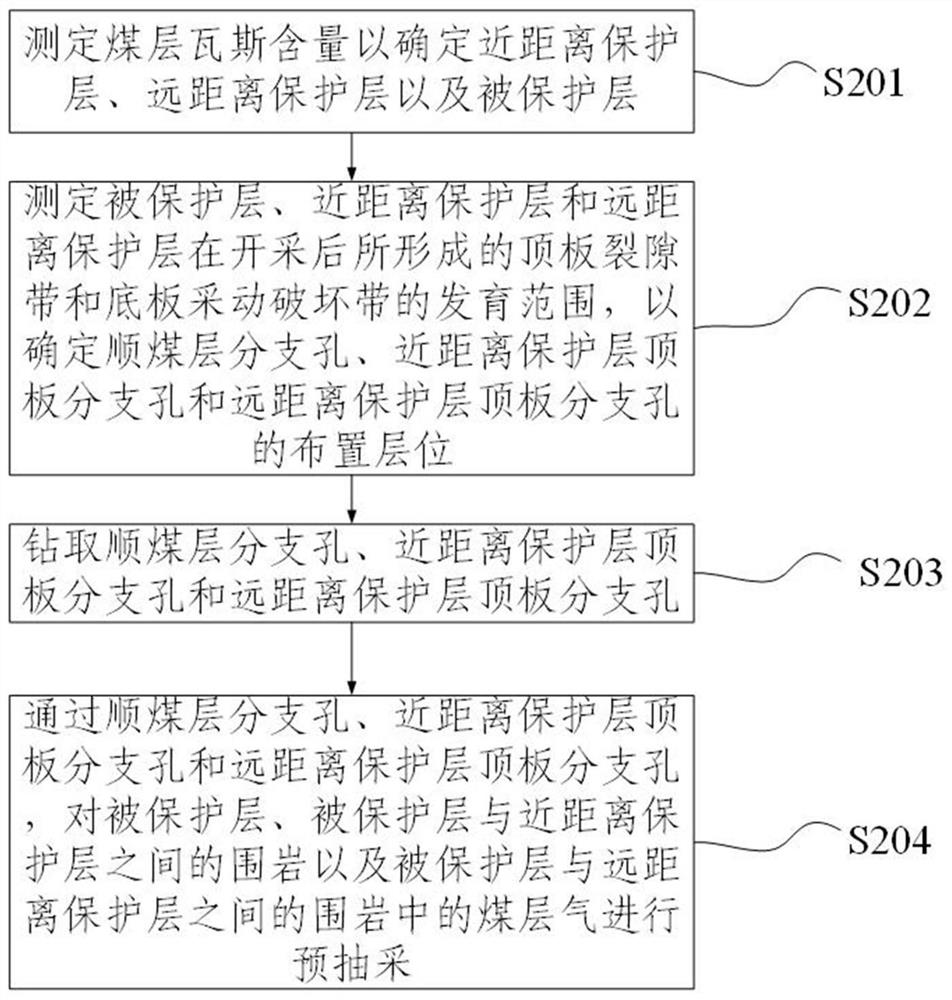

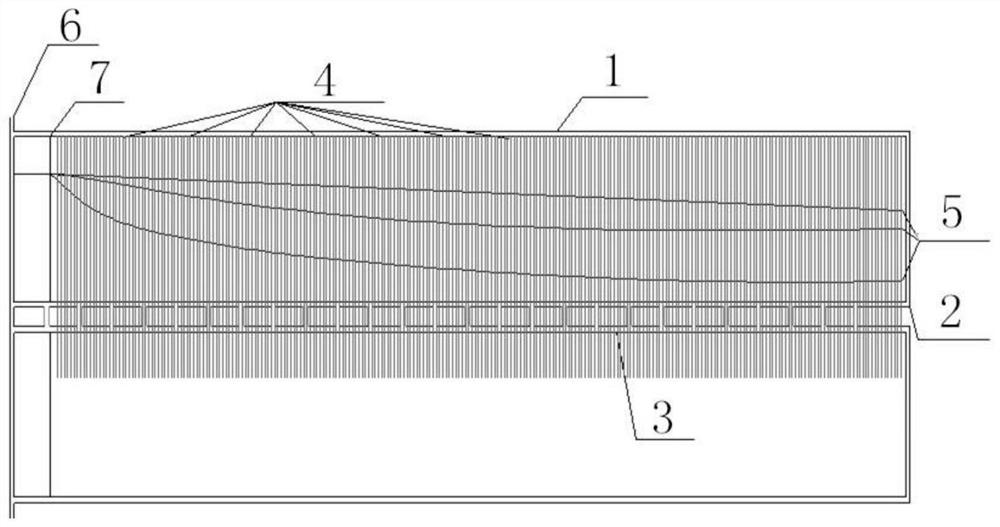

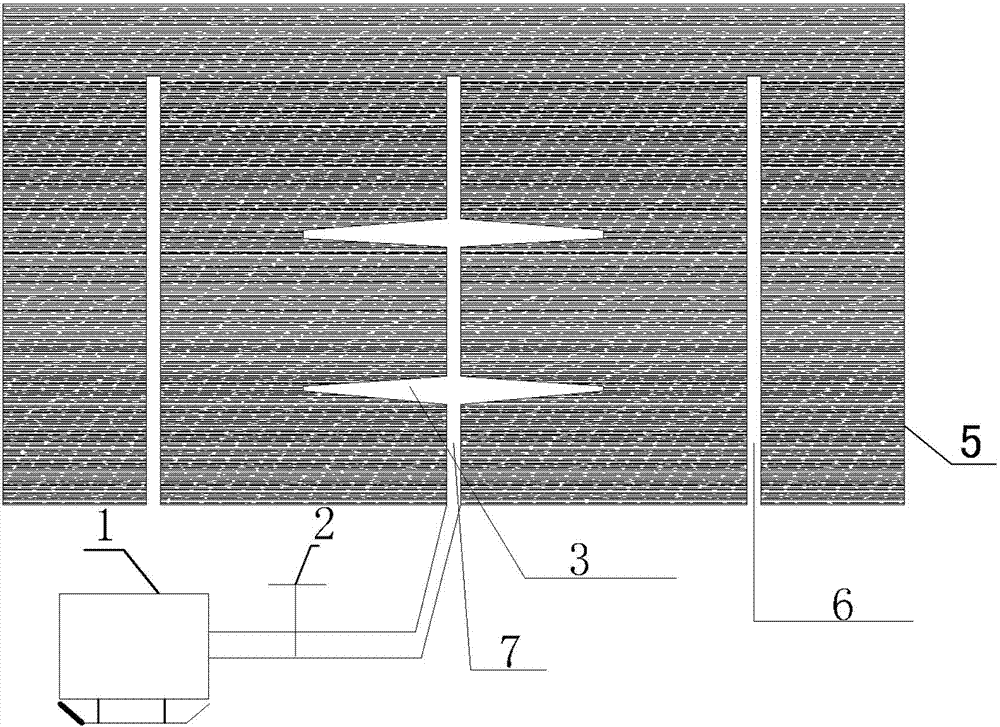

Coal and coal bed gas continuous development method based on ground directional horizontal holes

ActiveCN112879077AOvercome limitationsLarge amount of extractionFluid removalGas removalThermodynamicsEngineering

The embodiment of the invention provides a coal and coal bed gas continuous development method based on ground directional horizontal holes. The method comprises the steps that the coal bed gas content is measured to determine a close-range protection layer, a long-range protection layer and a protected layer; the arrangement layer positions of all layers of horizontal branch holes in the protected layer, surrounding rock between the protected layer and the close-range protection layer and surrounding rock between the protected layer and the long-range protection layer are determined; all layers of horizontal branch holes in the protected layer, the surrounding rock between the protected layer and the close-range protection layer and the surrounding rock between the protected layer and the long-range protection layer are drilled; and through all layers of horizontal branch holes, coal bed gas in the protected layer, the surrounding rock between the protected layer and the close-range protection layer and the surrounding rock between the protected layer and the long-range protection layer is pre-extracted. According to the method, the multi-layer-position and regional arrangement form is adopted for the directional horizontal holes, and the coal bed gas can be extracted in an all-around manner. Meanwhile, the extraction amount of the method is large, and the extraction efficiency is high.

Owner:CCTEG COAL MINING RES INST +1

Coal seam gas drainage method based on directional drilling and liquid nitrogen quick freezing and thermal fracturing

ActiveCN110617047BImprove penetration propertiesIncrease extraction concentrationSurveyFluid removalThermodynamicsCoal

The invention relates to a coal seam gas extraction method based on directional drilling and liquid nitrogen quick freezing and thermal cracking, belonging to the technical field of gas control. In this method, inclined boreholes are arranged along the trough on the recovery working face, and then the inclined boreholes are incorporated into the drainage pipe network for gas drainage; At the same time, long-distance directional drilling is constructed along the direction of the coal seam in the withdrawal channel or return air roadway of the mining face as the injection hole for liquid nitrogen, and then the liquid nitrogen is injected into the long-distance directional drilling. Determine whether the borehole is a borehole affected by liquid nitrogen by detecting the temperature in the borehole that indicates that the drainage fails. If it is a borehole affected by liquid nitrogen, inject high-temperature air into the borehole to make the coal around the borehole Crack occurs under the condition of rapid freezing and heat, which improves the permeability characteristics of coal body. The invention improves the gas extraction volume, has simple process and low operation cost.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Directional hydraulic pressing penetration, permeability increase and outburst elimination method of guide groove

ActiveCN102619552BLarge range of pressure reliefImprove breathabilityFluid removalDirectional drillingMining engineeringHigh pressure water

Owner:CCTEG SHENYANG RES INST

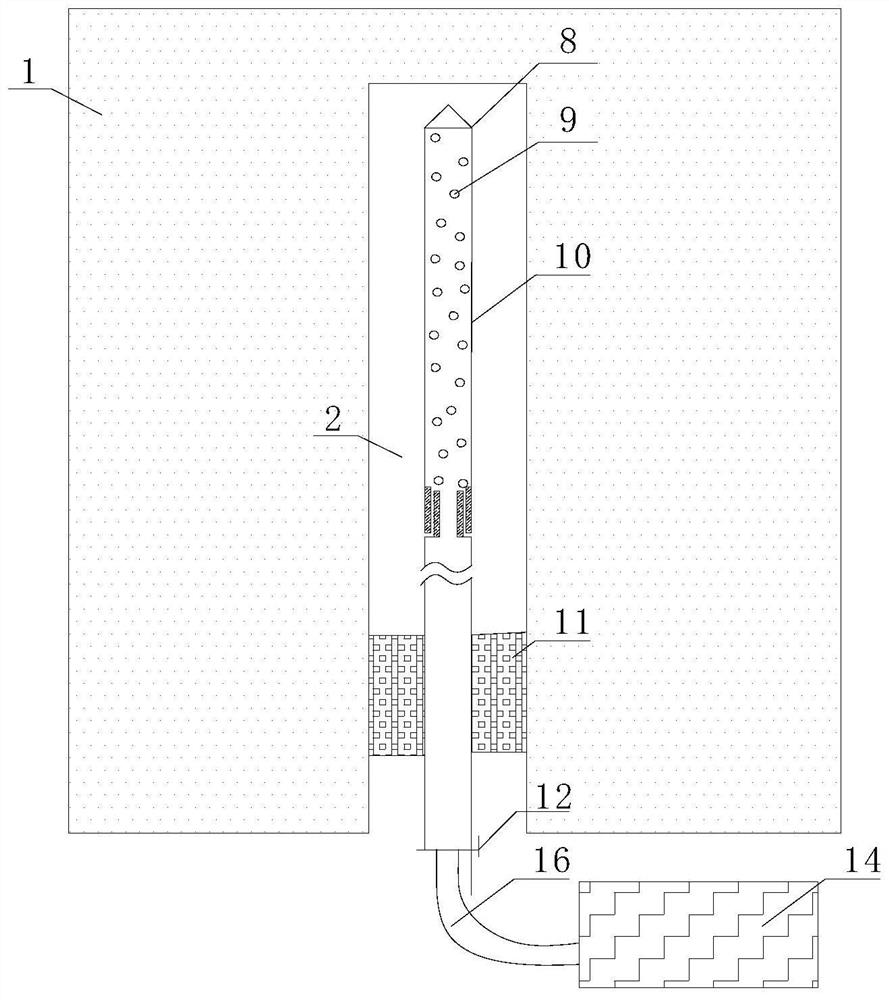

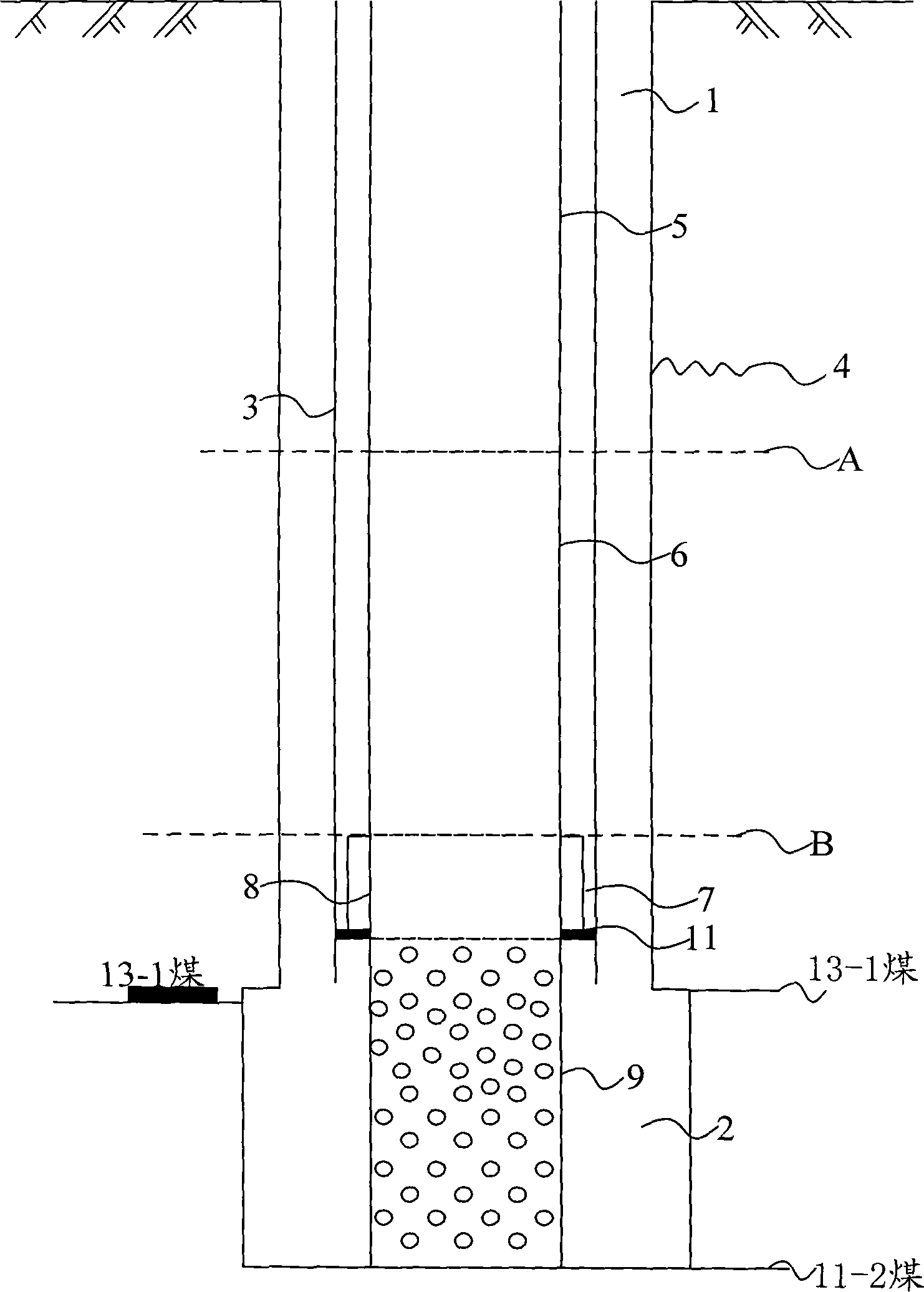

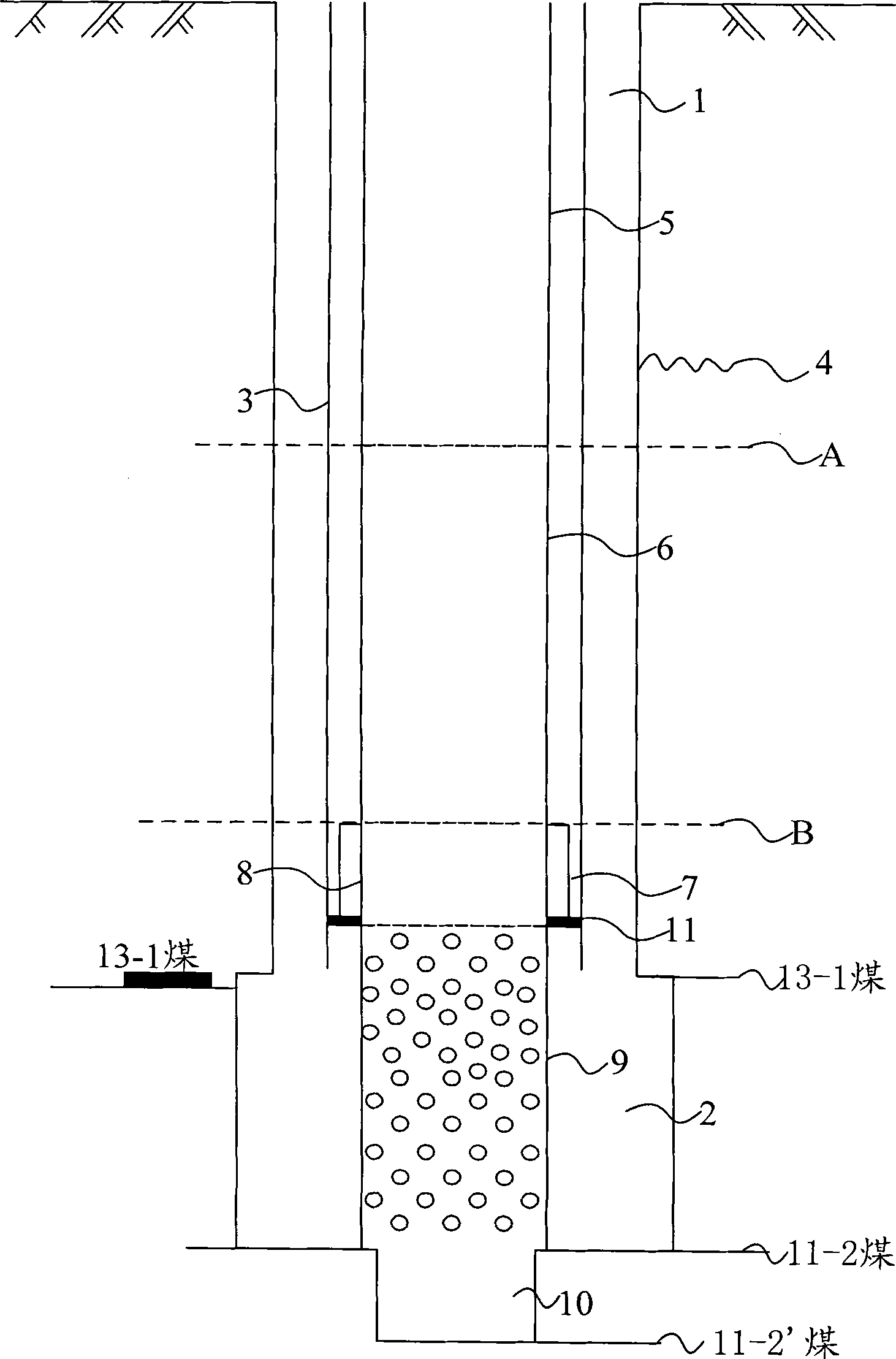

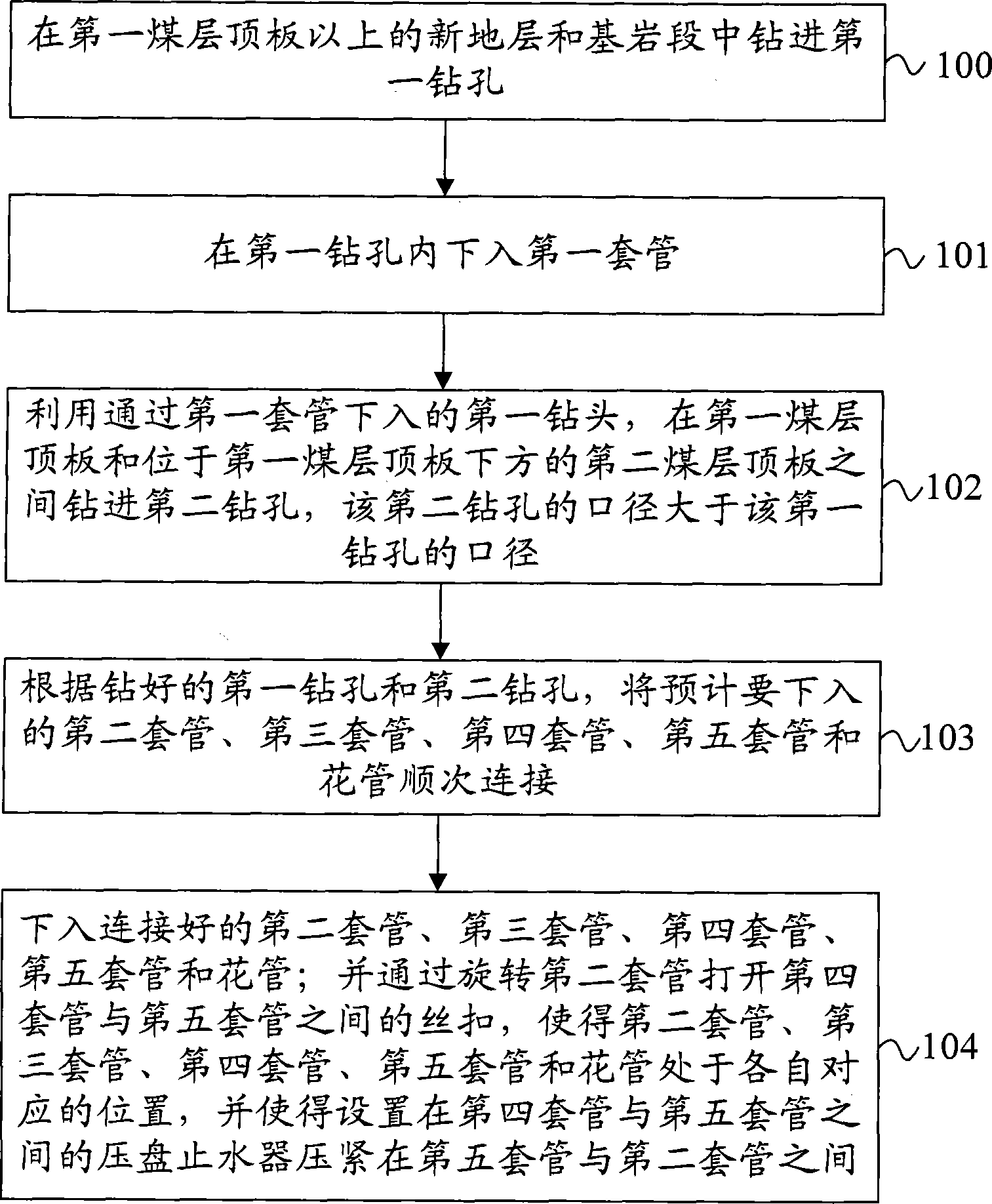

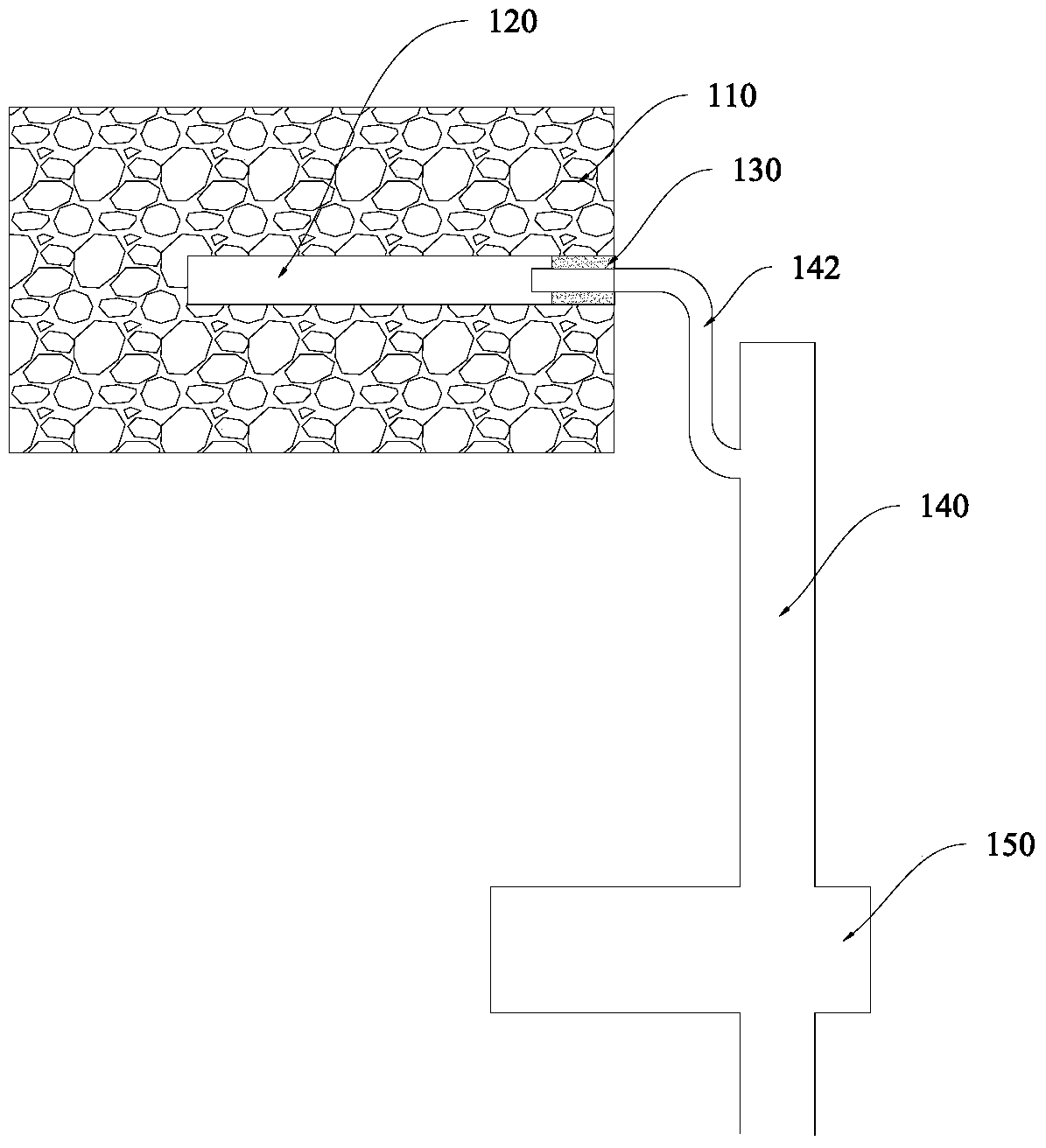

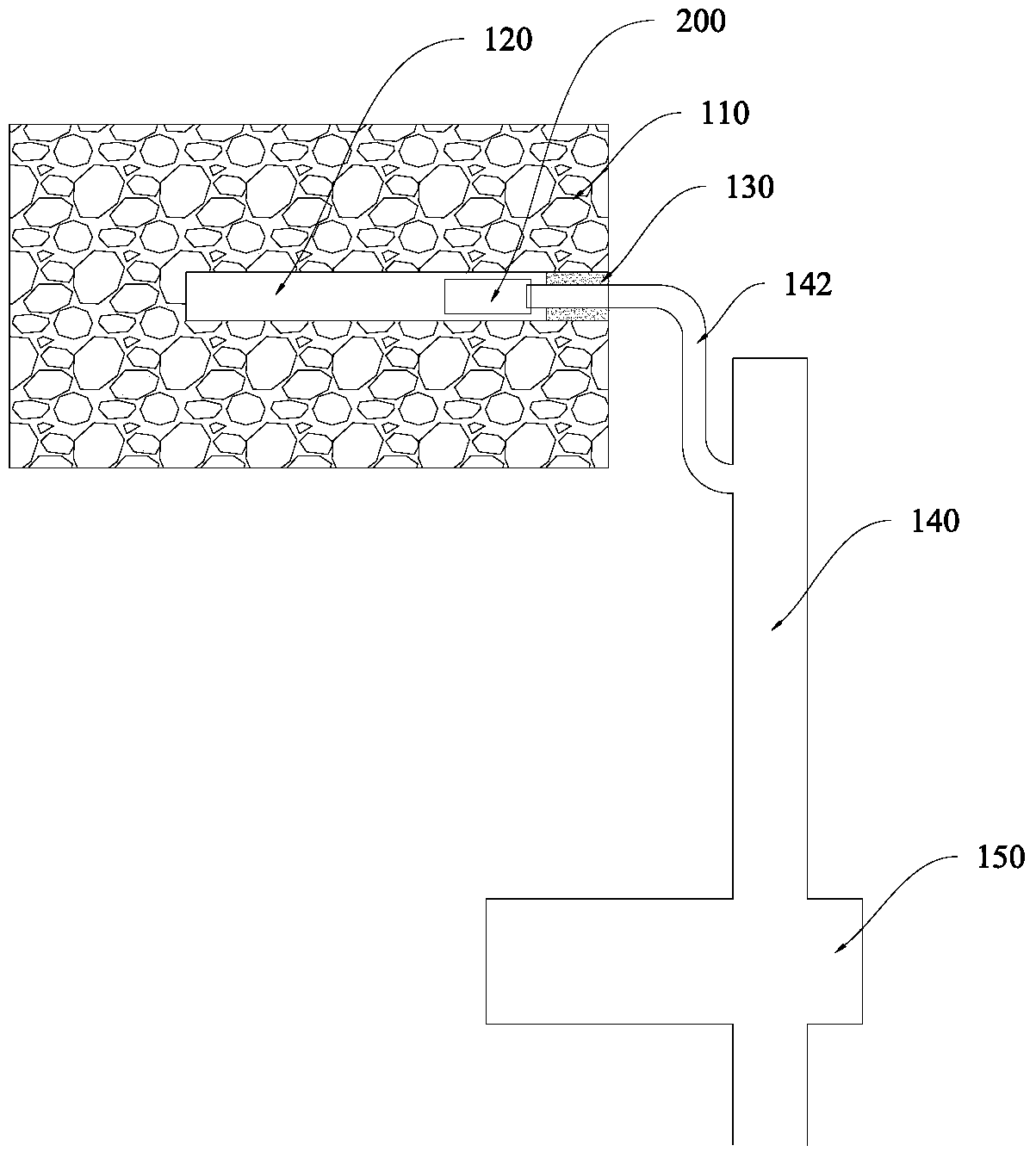

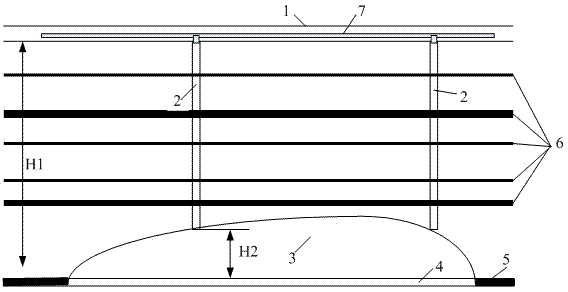

Gas drainage borehole and construction method thereof

ActiveCN102536115BBuffer or avoid damageEffective protectionDrilling machines and methodsBedrockCoal

The invention provides a gas drainage borehole and a construction method thereof. The gas drainage borehole comprises a first borehole and a second borehole. The first borehole is bored in a new stratum above a first coal seam roof and a bedrock section. The second borehole is bored between the first coal seam roof and a second coal seam roof below the first coal seam roof, and the diameter of the second borehole is larger than that of the first borehole. A first sleeve is disposed in the first borehole. A second sleeve is disposed in the first sleeve and above a first position above a bedrock face, a third sleeve is disposed in the first sleeve and between the lower side of the first position and a second position above the first coal seam roof, a fourth sleeve is connectedly arranged below the third sleeve, a fifth sleeve equal to the third sleeve in diameter and wall thickness is further disposed in the fourth sleeve, and a perforated pipe is connectedly arranged below the fifth sleeve and inside the second borehole. According to the technical scheme, the quality of the gas drainage borehole can be improved effectively, and gas yield is increased.

Owner:HUAINAN MINING IND GRP

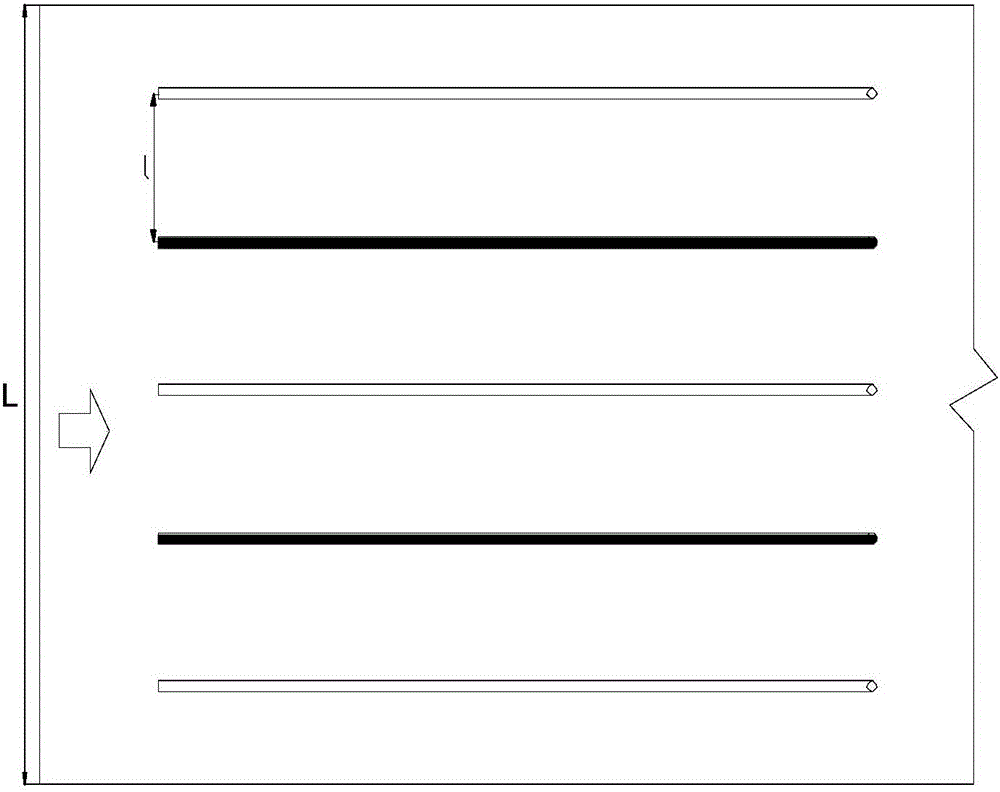

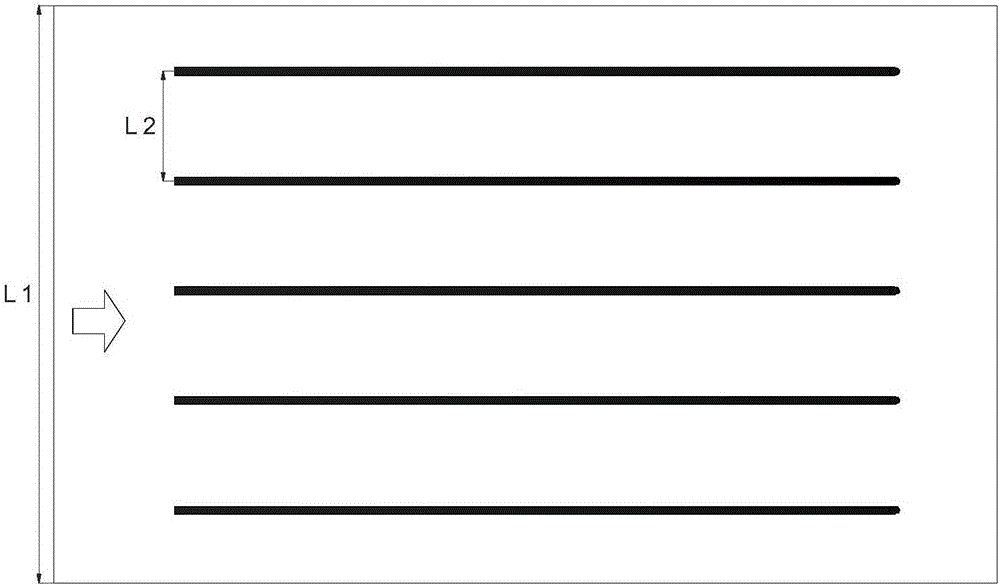

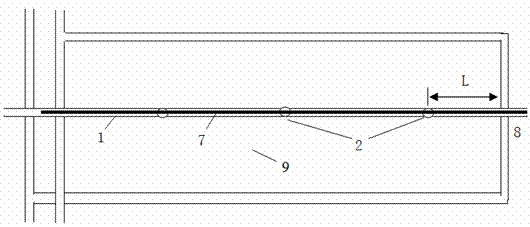

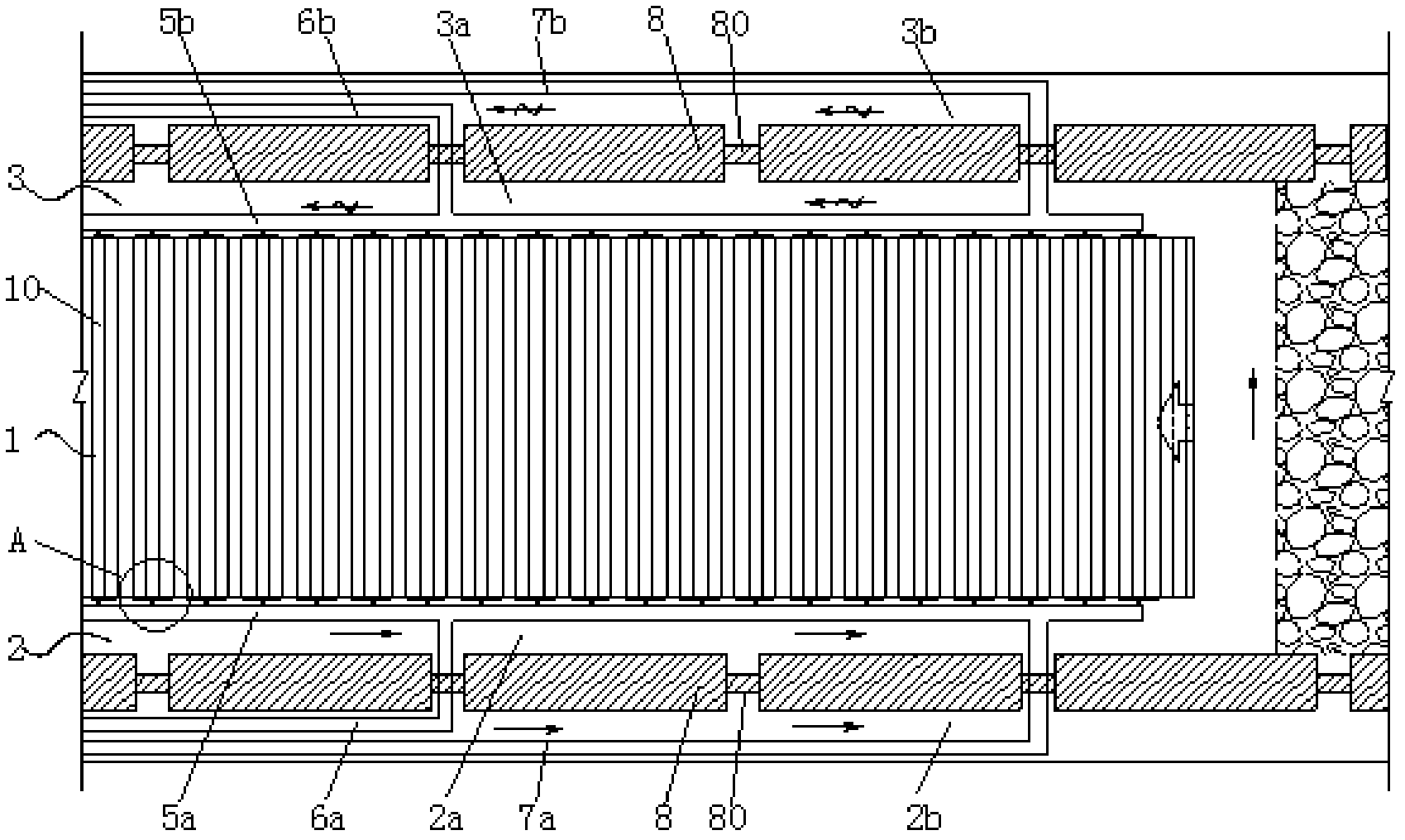

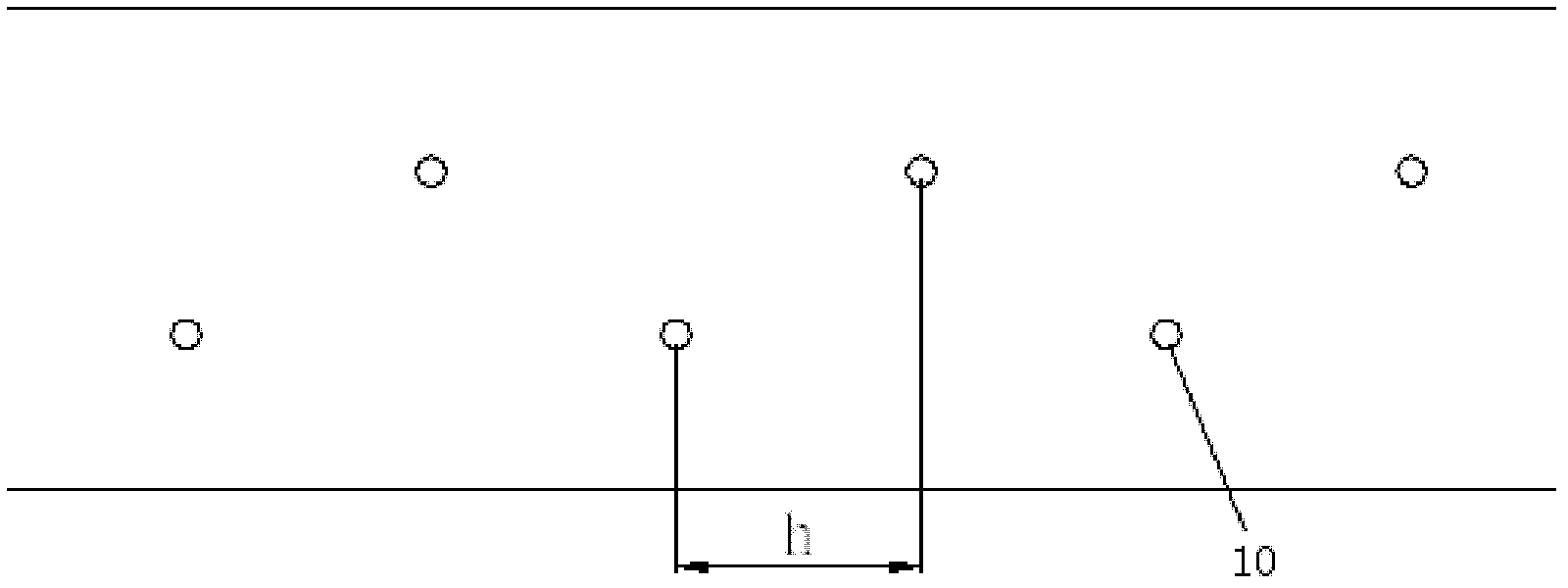

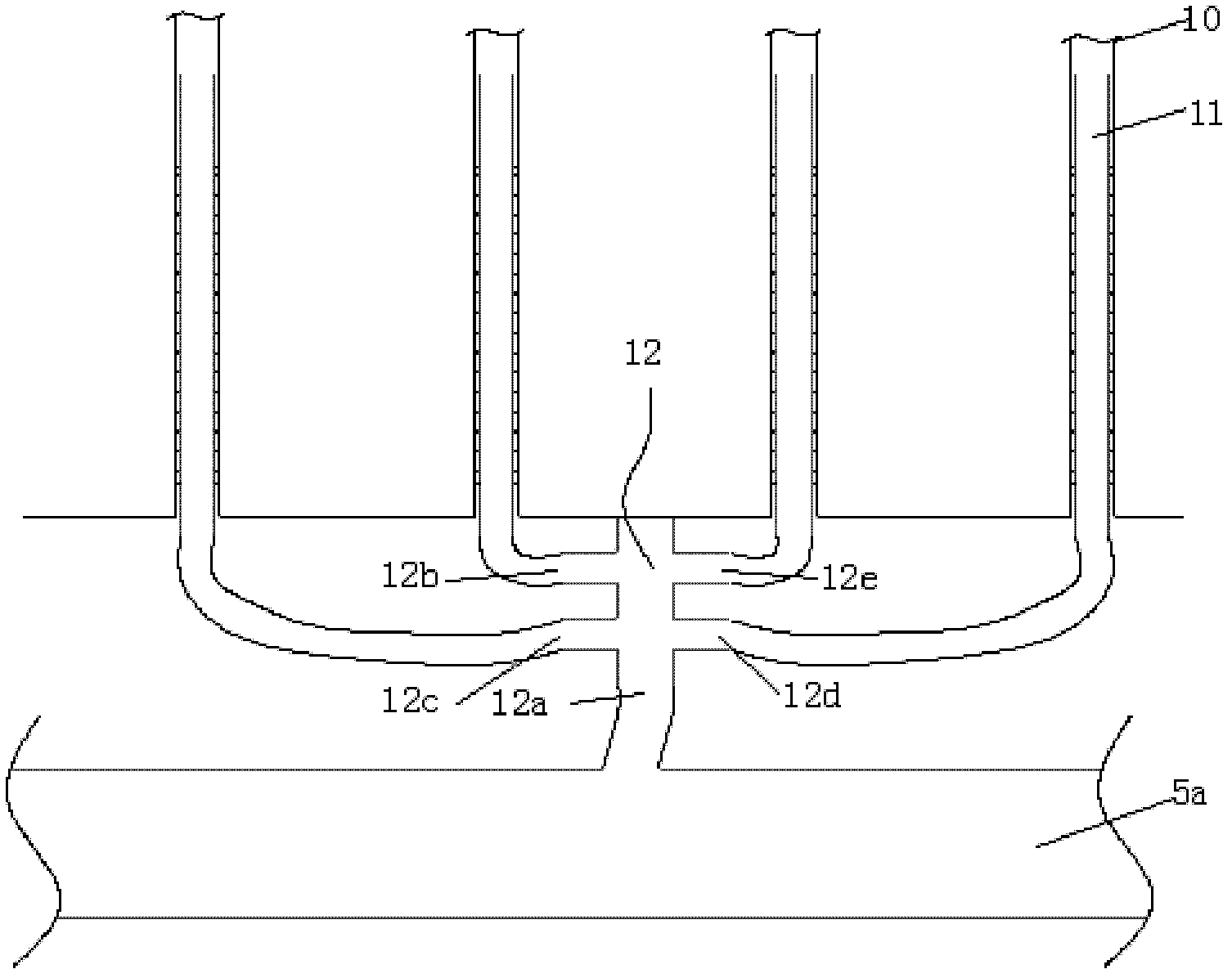

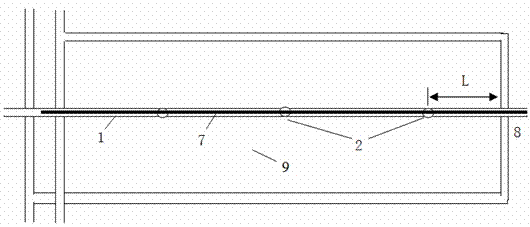

Low permeability coal seam gas pre-drainage method though intensive drilling holes and pipe pressure-up

InactiveCN103046946BSolve the problem of small effective extraction radiusAchieve large-scale anti-reflectionGas removalEngineeringCoal

The invention discloses a low permeability coal seam gas pre-drainage method though intensive drilling holes and pipe pressure-up. The method includes the following steps: a plurality of through drilling holes are arranged on a pre-drainage coal seam; a first drainage pipe is laid on one side of an air inlet roadway close to the pre-drainage coal seam, and one ends of the plurality of through drilling holes are connected with the first drainage pipe; a second drainage pipe is laid on one side of an air return roadway close to the pre-drainage coal seam, the other ends of the plurality of through drilling holes are connected with the second drainage pipe so as to enable the plurality of through drilling holes to be communicated with the first drainage pipe and the second drainage pipe respectively to form a gas pre-drainage system, and a first negative pressure boosting pipe system is laid in the air inlet roadway and communicated with the first drainage pipe so as to boost negative pressure of the first drainage pipe; and a second negative pressure boosting pipe system is laid in the air return roadway and communicated with the second drainage pipe so as to boot negative pressure of the second drainage pipe.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Novel device capable of increasing coal seam cracks

InactiveCN109268061AImprove fracturing effectLarge amount of extractionMining devicesDisloding machinesEngineeringHigh pressure

The invention overcomes the shortcomings in the prior art and provides a novel device capable of increasing coal seam cracks, guiding the existing high pressure gas, greatly reducing the loss of the target pressure, improving the fracturing efficiency and greatly increasing gas efficiency. The novel device capable of increasing the coal seam cracks comprises an energy release valve body, a deflector is disposed at the top of a chamber of the energy release valve body, the deflector is of a rotary body structure with the parabolic section, the deflector is disposed upside down on the top of theenergy release valve body, and a gas pressure relief vent is disposed in the side wall of the energy release valve body corresponding to the upper portion of a pressure concentrating device, so thathigh pressure gas entering the chamber of the energy release valve body can be ejected out from the gas pressure relief vent. The novel device can be widely applied to the fields of coal bed gas and underground coal mine gas extraction and fracturing.

Owner:山西鸿海科瑞技术有限公司

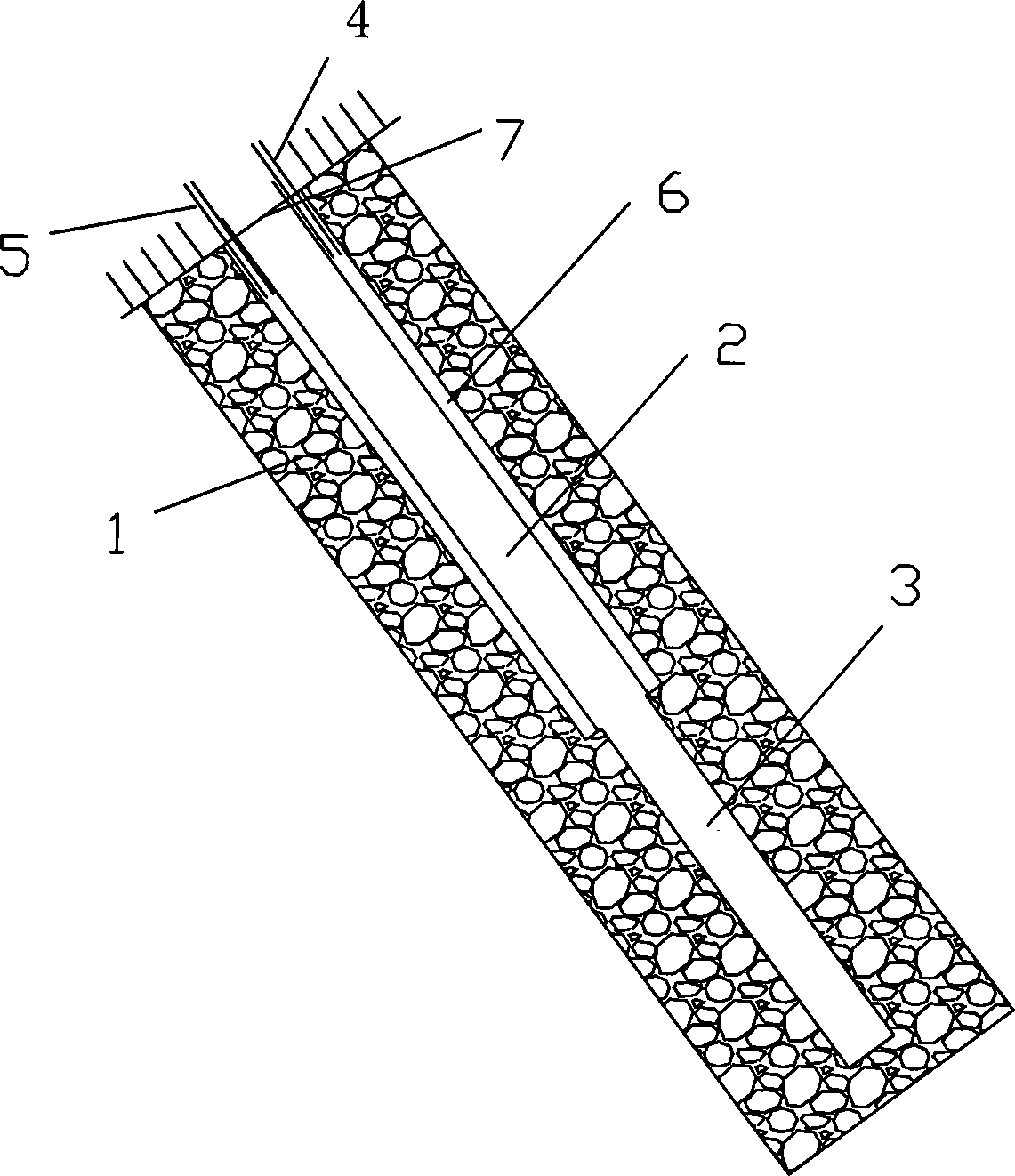

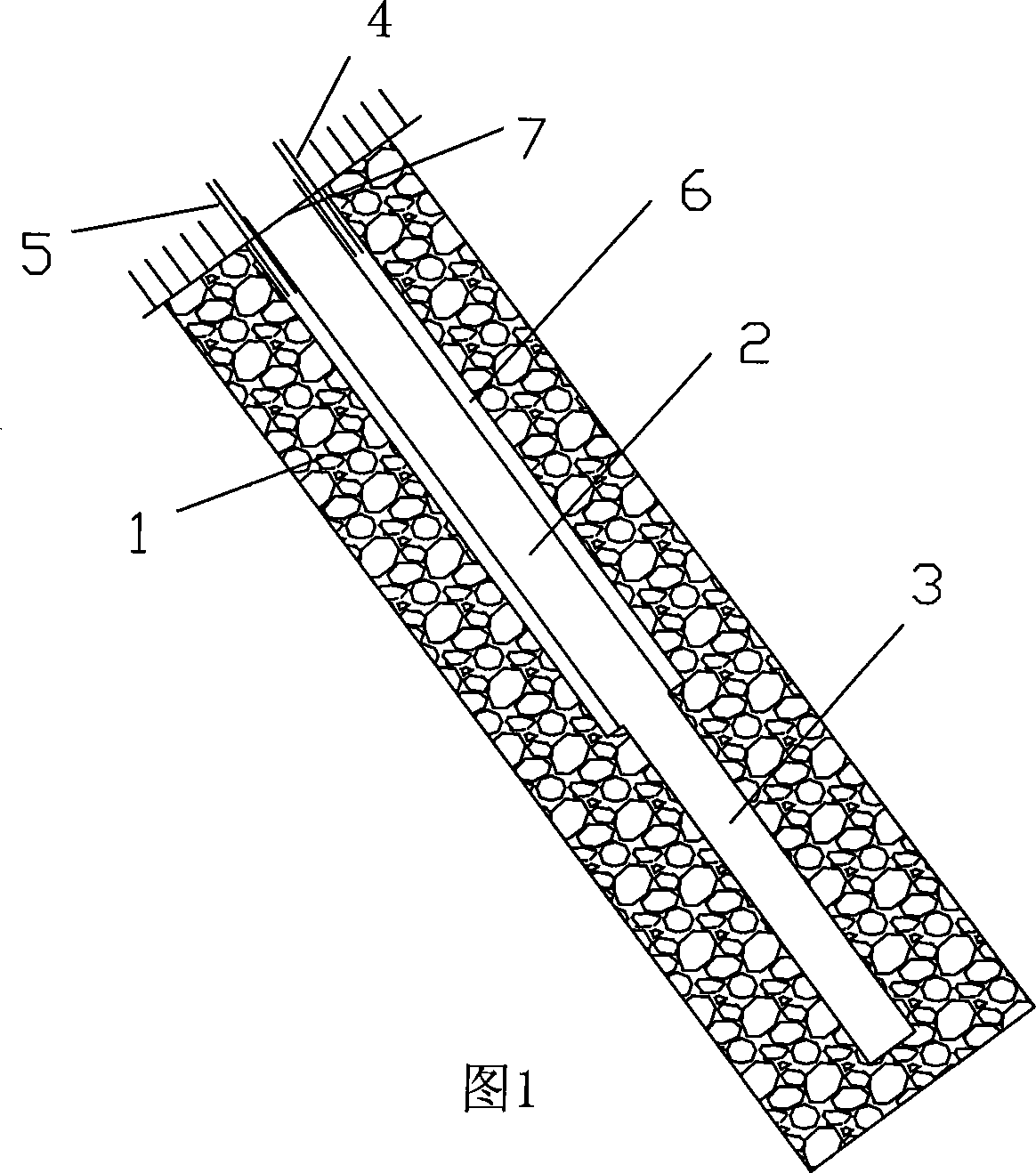

Coal seam gas extraction method based on U-shaped well and directional drilling

ActiveCN106948860BIncrease extraction concentrationLarge amount of extractionFluid removalGas removalWell drillingCoal mine methane

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Gas collector

InactiveCN105401975BIncrease extraction concentrationLarge amount of extractionGas removalInlet valveEngineering

The invention provides a gas collector comprising an inlet valve, a negative pressure valve and a bottle body. The inlet valve and the negative pressure valve are arranged on the bottle body. The bottle body is provided with a movable component opposite to the negative pressure valve. The movable component and the bottle body are connected together via the flexible seal material. The negative pressure valve and a gas main collecting pipeline are in communication with each other and the negative pressure valve is composed of a negative pressure bulkhead. The movable component is provided with a connecting piece and the connecting piece connects the movable component with the negative pressure bulkhead. The gas enters the bottle body via the inlet valve so as to drive the movable component to move towards one side that is far away from the negative pressure valve. The movable component drives the negative pressure bulkhead to move so as to turn on the negative pressure valve through the connecting piece. In this way, the gas in the bottle body enters the gas main collecting pipeline via the negative pressure valve. The concentration of the gas extracted by the above gas collector is high.

Owner:李昆

Underground dark mining drilling well gas extraction method

ActiveCN102226412BLarge amount of extractionIncrease extraction concentrationFluid removalGas removalWell drillingCoal

The invention discloses an underground dark mining drilling well gas extraction method, comprising the following steps: firstly constructing a gas extraction lane in a hard rock layer below an upper-group coal seam worked out area or above an unmined coal seam of the vertical distance of a firstly mined coal seam; carrying out middle construction on the gas extraction lane along the pushing direction of the firstly mined working face; starting the construction from a dark mining well of an open-off cut side and the part of the open-off cut in the gas extraction lane after construction; constructing the dark mining well the bottom of which is vertical to the top plate of the firstly mined working face at intervals; arranging an extraction pipe connected with the gas extraction pipeline; and connecting the extraction pipelines in the dark mining well into a mine gas extraction system through the gas extraction pipeline for gas predraining before mining, gas extraction in mining and gas extraction after mining. The method has the advantages of a ground drilling well extraction coal seam group, namely large extraction amount, high extraction concentration and good extraction effect, is good in stability and small in work amount, has low possibility to break and is easy to drain.

Owner:CHINA UNIV OF MINING & TECH

Anti-reflux and anti-clogging drainage device with large suction volume

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Low gas permeability coal seam liquid phase co 2 Phase change fracturing anti-reflection mesh gas drainage method

ActiveCN106194244BLarge amount of extractionEnsure safe productionFluid removalGas removalProcess engineeringPhase change

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

Method and device for dredging pores and cracks of coal seam gas extraction drill hole

ActiveCN111749644ALarge amount of extractionImprove extraction efficiencySurveyGeothermal energy generationPipeVALVE PORT

The invention relates to the technical field of gas extraction, in particular to a method and device for dredging pores and cracks of coal seam gas extraction drill holes. The device comprises a negative pressure pipe and a positive pressure pipe which communicating with drill holes, the negative pressure pipe is connected with the drill holes through a first connecting pipe, a metering unit and afirst valve are installed on the first connecting pipe, the metering unit is used for detecting gas flow and pressure, the positive pressure pipe is connected with the drill holes through a second connecting pipe, a second valve is installed on the second connecting pipe, and the drill holes communicate with one another; the method comprises the following steps that S1, installation is conducted;S2, initialization is conducted; S3, negative pressure dredging is conducted; and S4, when dredging cannot be conducted by adopting the negative pressure dredging in the step S3 and the gas flow Q detected by the metering unit is smaller than or equal to a first set value, positive pressure dredging is adopted. Holes and crack channels in a coal gas migration process are dredged, the extraction efficiency of the drill holes is improved, and the gas extraction amount is increased.

Owner:SHANDONG ANYI MINING EQUIP CO LTD

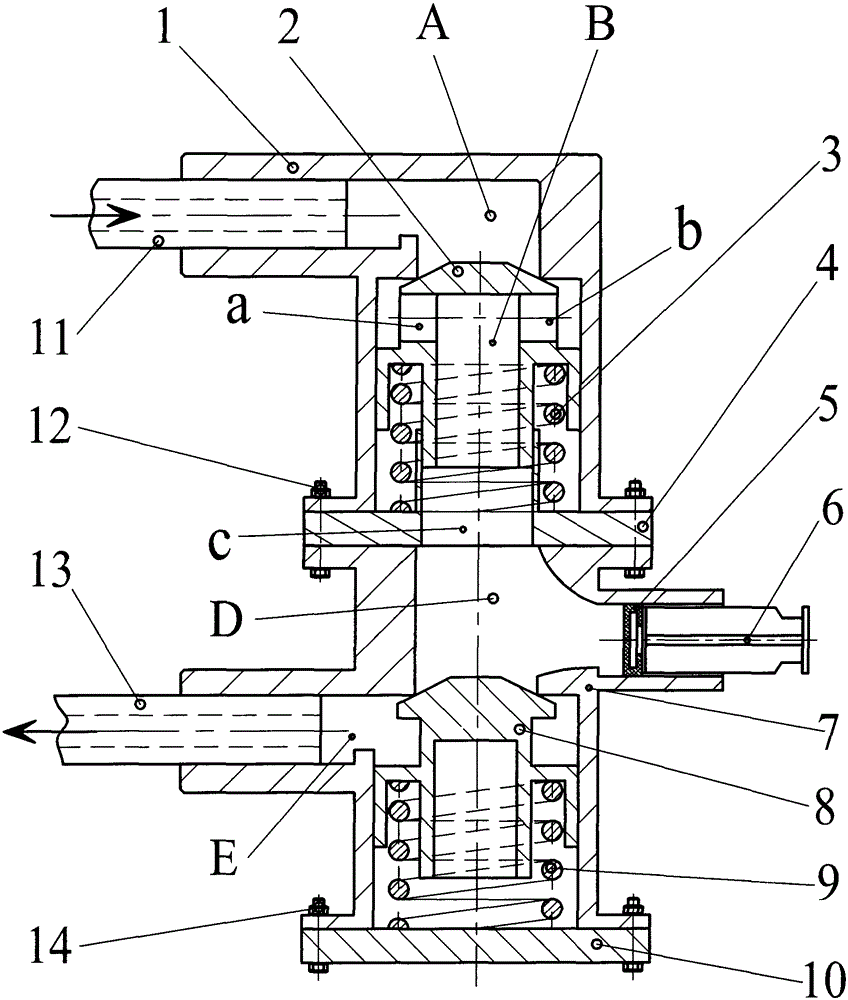

Piezoelectric pump based on secondary resonance

ActiveCN105089993ASolve high-frequency characteristicsFix workFlexible member pumpsPositive-displacement liquid enginesElectricityVena contracta diameter

The invention discloses a piezoelectric pump based on secondary resonance. The piezoelectric pump comprises a first vibrating body, a second vibrating body, a pump cavity and a base, wherein the outer wall of the bottom end of a vibrating pipe is connected with a piezoelectric element to form the first vibrating body; the pump cavity consists of a film, a pump cavity plate, a valve plate, a one-way valve and an inlet and outlet flow orifice plate; the bottom end of the first vibrating body is fixed by the base, and the other end thereof is sleeved and connected with the second vibrating body; the second vibrating body, the film and the pump cavity plate are sequentially connected; the pump cavity plate, the valve plate and the inlet and outlet flow orifice plate are fixedly connected with the base; and an inlet one-way valve part and an outlet one-way valve part are mounted on the valve plate. With the adoption of the technical scheme, the problem that the high frequency characteristic of a piezoelectric sheet and the low frequency characteristic of the one-way valve in the piezoelectric pump are not compatible is solved. In addition, the piezoelectric pump has a recyclable driving structure and a replaceable pump cavity body, so that the cost is reduced, and liquid cross contamination is avoided.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Piezoelectric Pump Based on Second Resonance

ActiveCN105089993BSolve high-frequency characteristicsSolve the problem that it can only work at low frequencyFlexible member pumpsPositive-displacement liquid enginesVena contracta diameterResonance

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Variable trajectory drilling method and device

InactiveCN106639877BLarge amount of extractionImprove the extraction effectDirectional drillingAnchoring boltsCoalPetroleum engineering

The invention discloses a track varying drilling method and device. Firstly drilling is conducted on a coal bed, then a track varying drilling pipe is inserted into a main drill hole, the front part of the track varying drilling pipe is provided with a tilting guide mechanism, an anchor cable drill of which a drill rod is capable of crooking is arranged in the track varying drilling pipe in a sleeved mode, and tilting drilling is conducted on the side wall of the main drill hole according to the various depths degree to which the track varying drilling pipe penetrates into the main drill hole.On the basis of the main drill hole and through reasonable redrilling by using a track varying drilling device, a drill hole area in which the main drill hole is regarded as a center, and a lateral drill hole is regarded as the radius is finally formed, in this way, a coal body can be loosened, the gas can be extracted, thus the extraction quantity of the gas in the drill hole is increased, and the gas extraction effect in the coal bed can be improved.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com