Directional hydraulic pressing penetration, permeability increase and outburst elimination method of guide groove

A guide groove and hydraulic fracturing technology, which is applied in directional drilling, earthwork drilling, gas discharge, etc., can solve problems such as abnormal high pressure, and achieve the effects of increasing pressure relief range, reducing pre-pumping time, and reducing measure drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

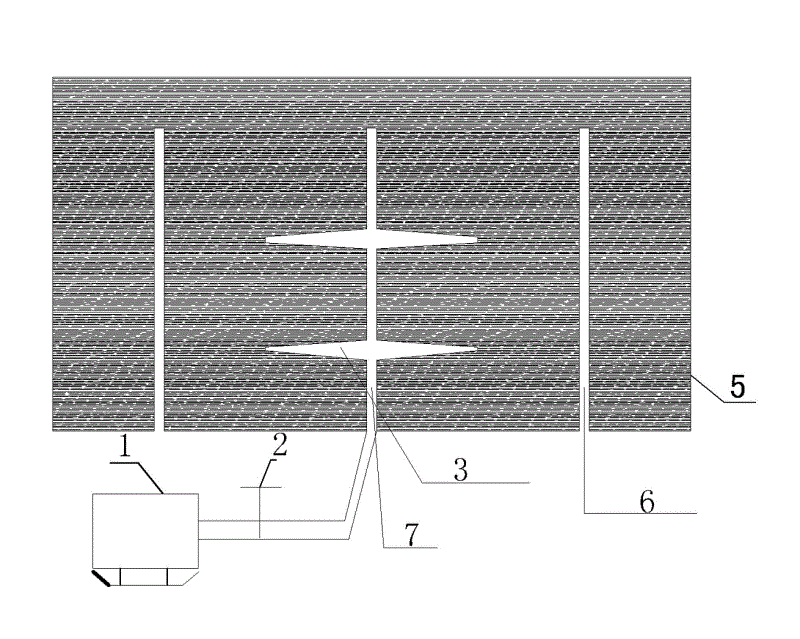

[0029] see figure 1 In the coal seam, construct the guide groove drilling 7 and several control drilling holes 6, and then form one or several guide grooves 3 in advance in the bedding boreholes, and then use the high-pressure hydraulic pump station 1 to inject high pressure into the guide groove drilling 7 Water, use the guide groove 3 and the control borehole 6 to carry out directional control on hydraulic fracturing, and press through the coal body between the guide groove borehole 7 and the surrounding preset control borehole 6, so that more holes are formed between the drill holes. Fissures, and a large amount of coal dust is carried out by high-pressure water. After the fracturing is completed, the guide groove borehole 7 and the control borehole 6 are both sealed and connected to the drainage system to start drainage.

[0030] Among them: the guide groove 3 is pre-formed in the coal body, which can be through jet deep penetration technology, or through hydraulic slitt...

Embodiment 2

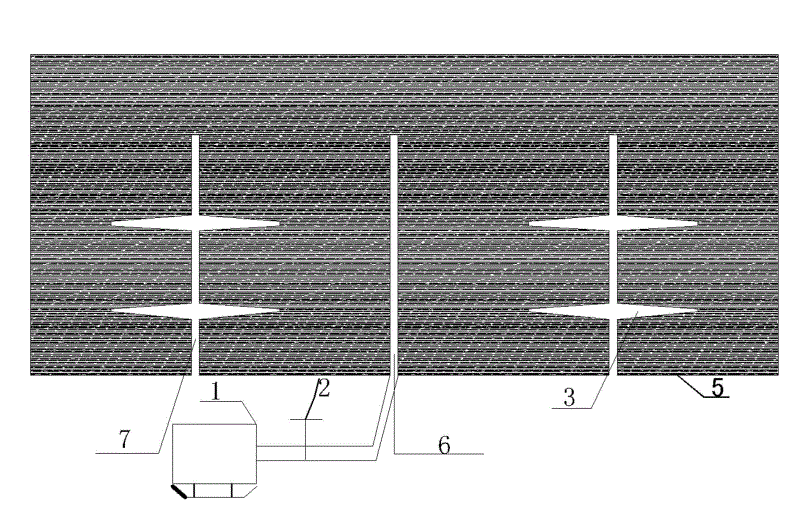

[0035] see figure 2 In the coal seam, a number of guide groove boreholes 7 and control boreholes 6 are constructed, and then one or several guide grooves 3 are pre-formed in the guide groove boreholes 7, and then the control boreholes 6 are hydraulically fractured, and the guide groove drill holes are used for hydraulic fracturing. The guide groove 3 and the control borehole 6 of the hole carry out directional control on hydraulic fracturing, and press through the coal mass between the control borehole 6 and the guide groove borehole 7, so that more cracks are formed between the boreholes, and through high pressure The water carried a large amount of coal dust. After the fracturing is completed, the guide groove borehole 7 and the control borehole 6 are both sealed and connected to the drainage system to start drainage.

[0036] Among them: the guide groove 3 is pre-formed in the coal body, which can be through jet deep penetration technology, or through hydraulic slitting, ...

Embodiment 3

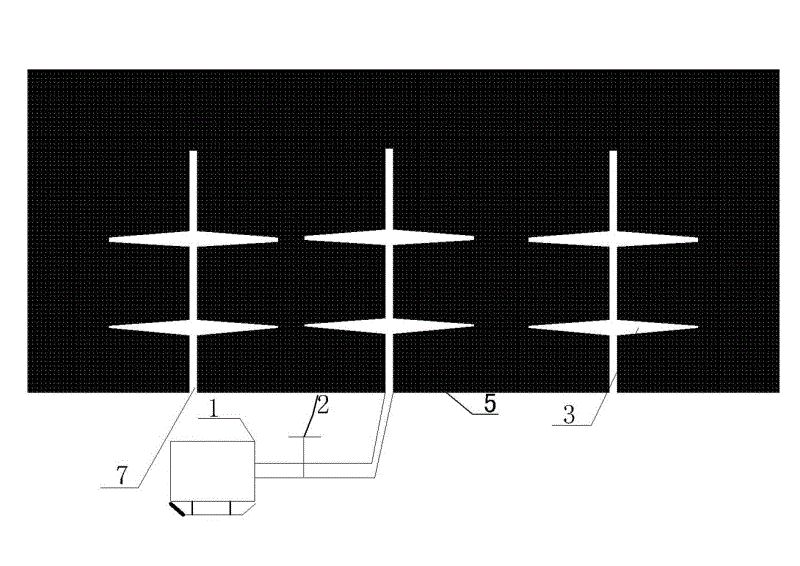

[0041] see image 3 , constructing several guide groove boreholes 7 in the coal seam, then pre-forming one or several guide grooves 3 in the guide groove boreholes 7, then carrying out hydraulic fracturing to the guide groove boreholes 7, and using the guide groove drilled by the guide groove boreholes 3 and the control borehole 6 carry out directional control on hydraulic fracturing, and press through the coal body between the guide groove boreholes 7, so that more cracks are formed between the boreholes, and a large amount of coal dust is carried out by high-pressure water. After the fracturing is completed, the guide groove boreholes 7 are all sealed and connected to the drainage system to start drainage.

[0042] Among them: the guide groove 3 is pre-formed in the coal body, which can be through jet deep penetration technology, or through hydraulic slitting, rotating water jet slit, hydraulic reaming technology, or through branch drilling and turning drilling. Hole techno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com