Advanced medium-length hole pressure relief and dust fall integrated method for working face of impact dangerous coal seam

A coal mining working face and working face technology, applied in drilling equipment and methods, dust prevention, ground mining, etc., can solve the problems of dense drilling arrangement, coal dust pollution, small effective range of pressure relief, etc., and achieve improved The effect of comprehensive dust reduction rate, reduction of engineering quantity and cost, and improvement of bolt support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

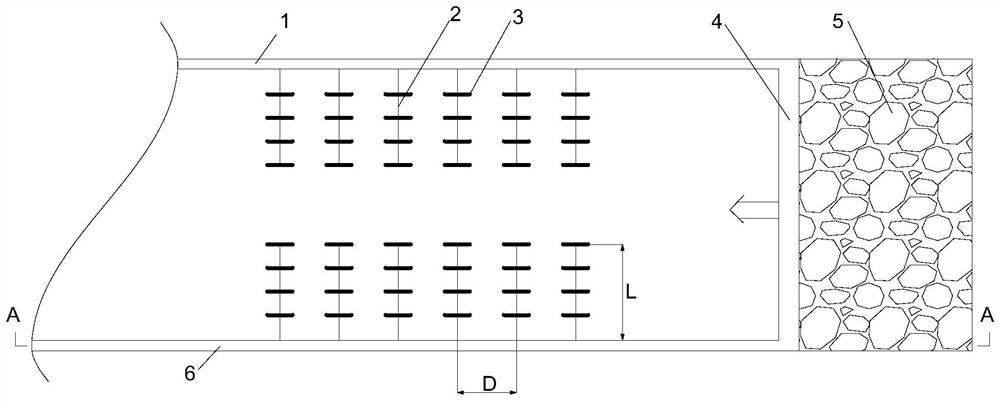

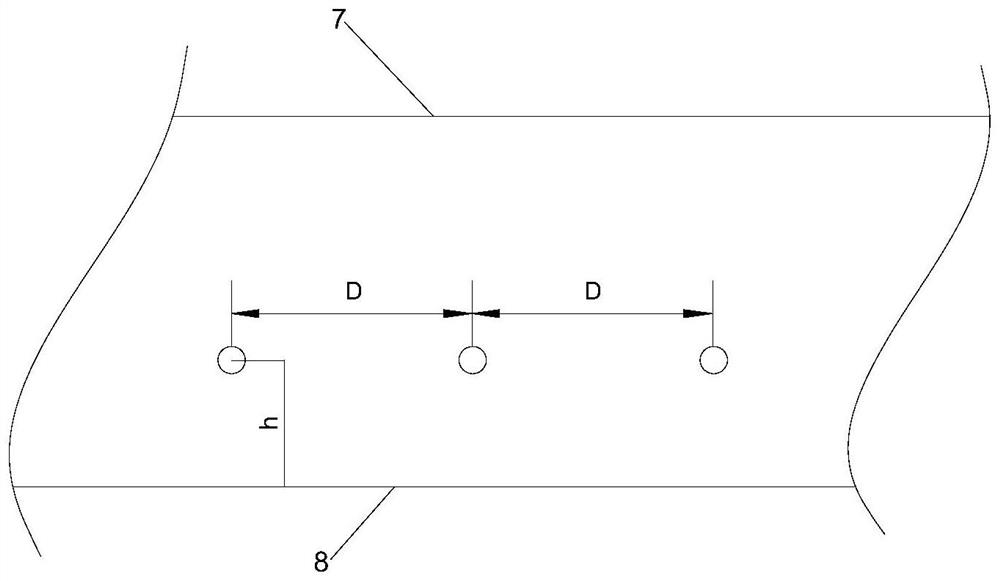

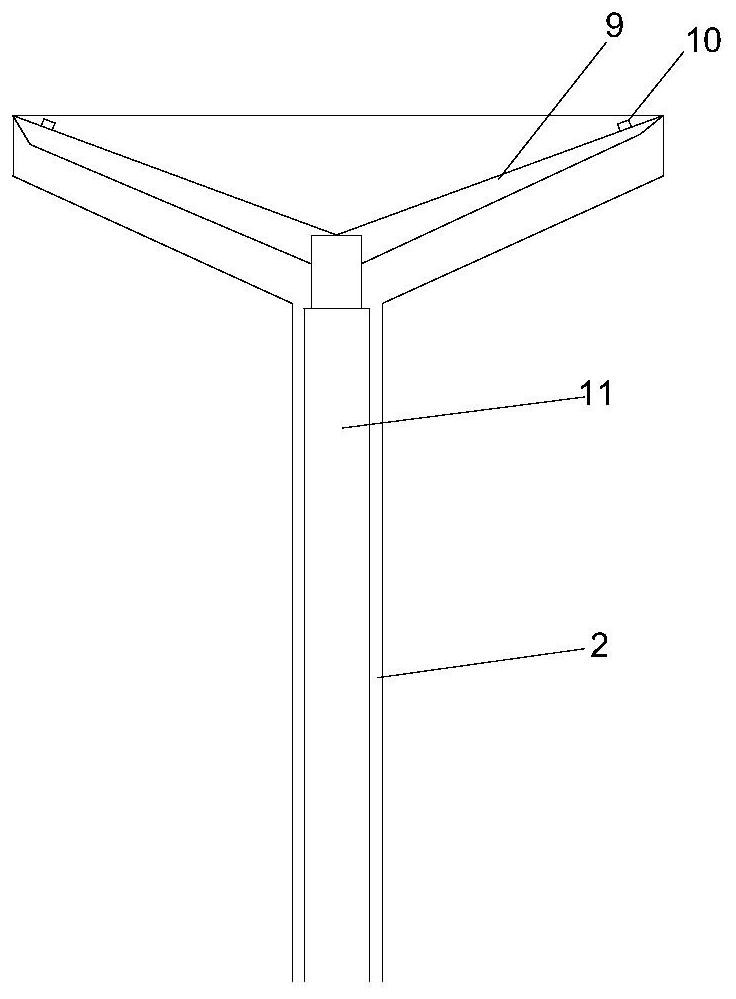

[0028] combine figure 1 and Figure 5 As shown, a specific implementation method of an integrated method for pressure relief and dust reduction in the advanced middle and deep holes of the impact dangerous coal seam working face provided by the present invention will be described.

[0029] In order to achieve the goal of high-efficiency and advanced pressure relief and coal seam dust reduction in the coal mining face, and ensure the safe and efficient production of the coal mining face, an integrated method of pressure relief and dust reduction in the advanced medium and deep holes of the impact dangerous coal seam working face is provided, and its specific steps include:

[0030] Step S1. By performing mine pressure monitoring and analysis in front of the adjacent working face along the trough, the adjacent working face along the trough includes working faces with similar geological conditions and mining conditions, and determine the influence range of the advanced bearing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com