Ignition devices for igniting gas mixtures in gas-operated internal combustion engines

A technology of gas mixture and ignition device, which is applied in the direction of engine ignition, internal combustion piston engine, combustion engine, etc., can solve the problems of loss and rising maintenance cost of internal combustion engine, and achieve the effect of prolonging service life and reducing throttling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

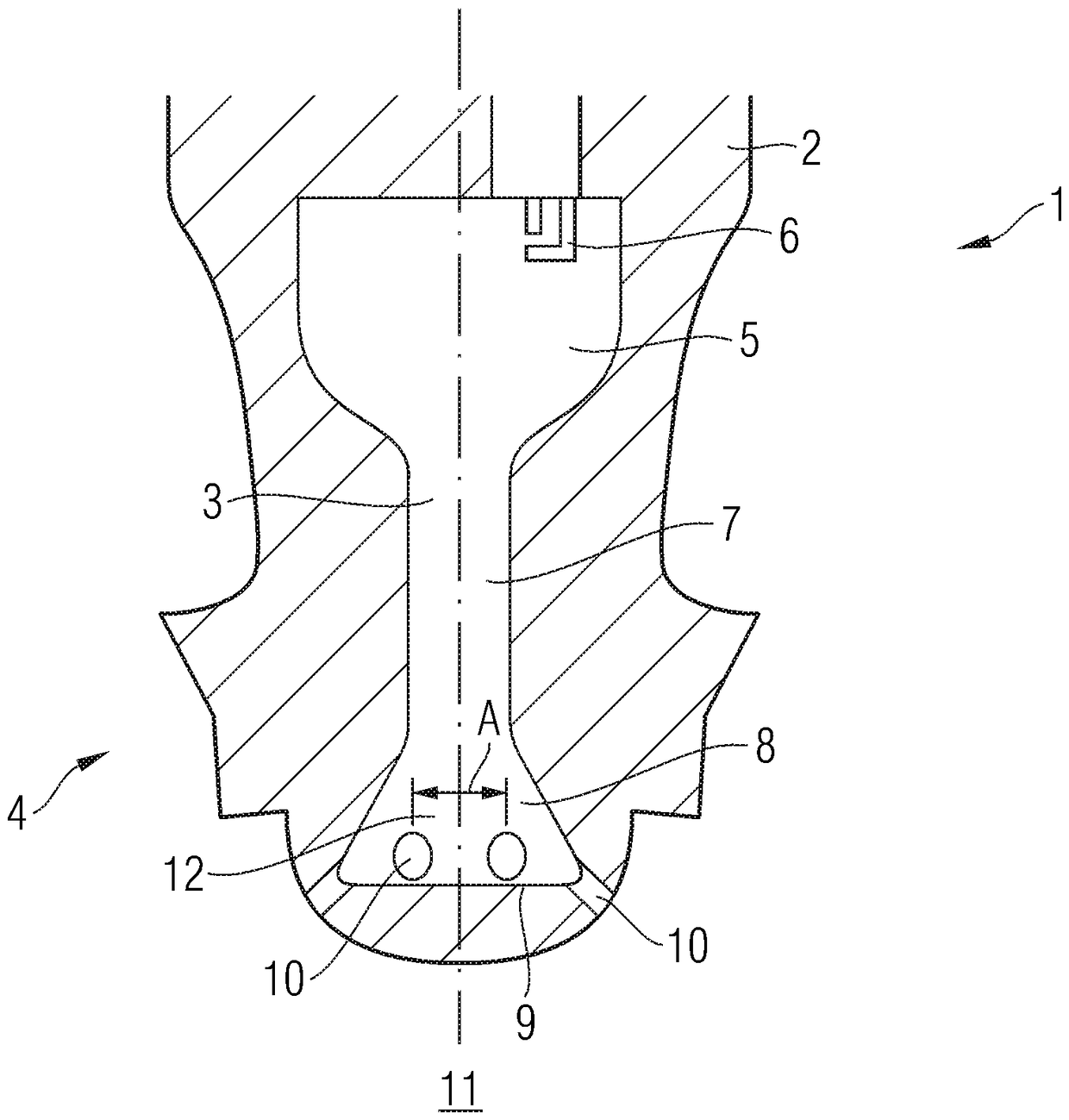

[0040]The ignition device 1 has a schematically shown housing 2 , which, due to the section-varying outer diameter of the housing 2 , has a section-changing outer contour along the longitudinal extension of the housing 2 . This makes it possible to provide a housing shape that takes into account the thermal and mechanical loads acting on the housing during operation of the ignition device 1 , which lead to corresponding component stresses. In this case, the housing quite generally has a longitudinal extension which is larger than the transverse extension in the region of the largest housing diameter.

[0041] The housing has an inner recess 3 which has three sections of different arrangement and is designed as a pre-chamber 4 . The prechamber 4 has a prechamber belly 5 in which a spark plug 6 is arranged for igniting the gas mixture in the prechamber 4 .

[0042] The prechamber 4 is flushed with gas during the intake stroke of the main combustion chamber of the gas motor (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com