A pressure relief method for rockburst prevention and control of surrounding rock on the side wall of shaft

A shaft and surrounding rock technology, which is applied to the prevention and control of rockburst pressure relief on the side wall of underground engineering shafts, underground mines, and the field of pressure relief prevention and control of rock bursts on the side walls of shafts. Advance pressure relief, limited range of pressure relief, etc., to achieve the effect of rockburst prevention, low cost and fast speed of pressure relief engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

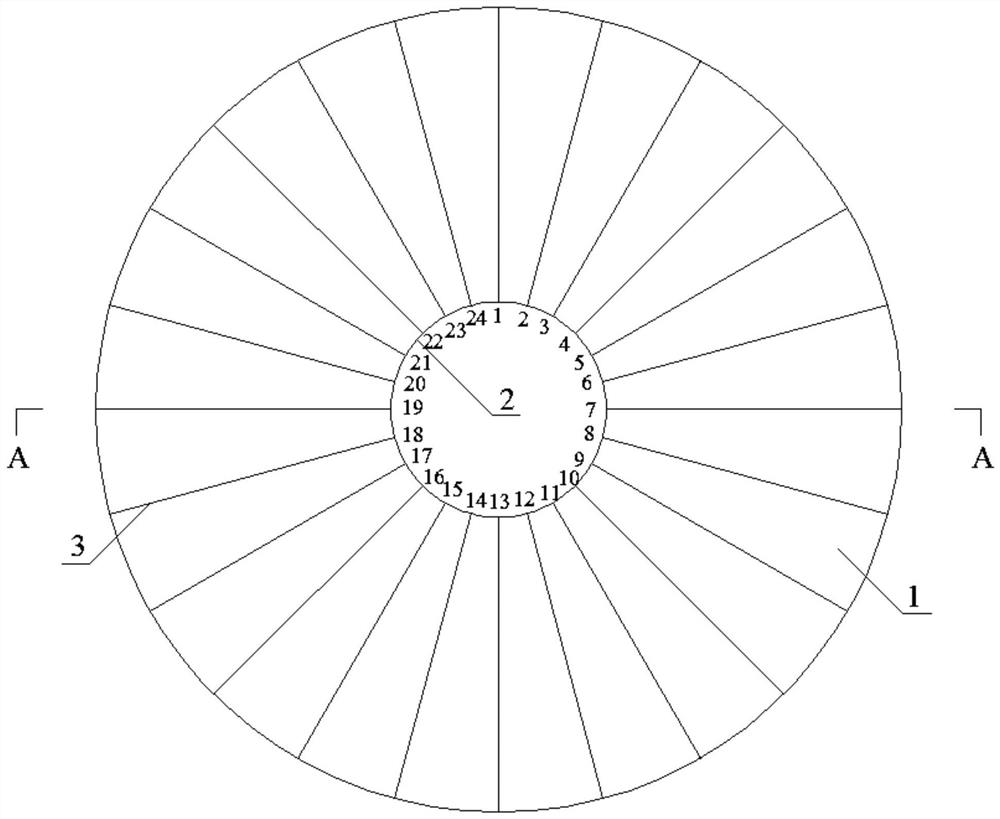

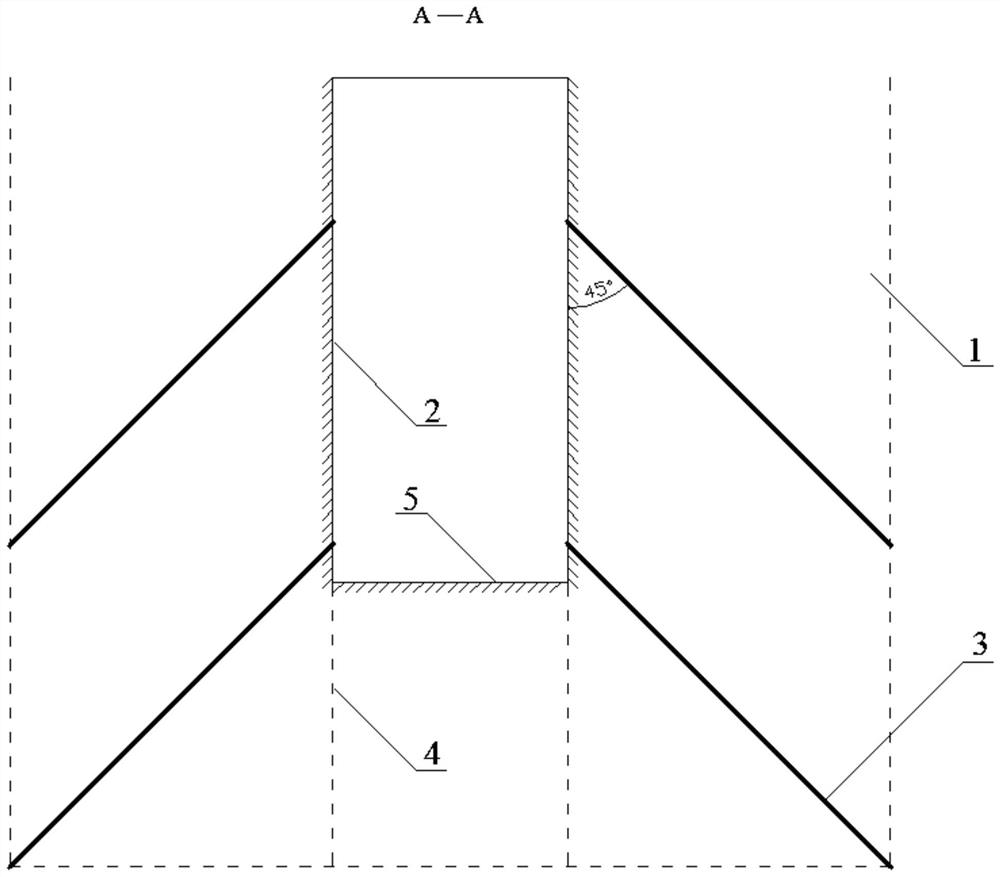

[0029] Example 1: Figure 1 ~ 2 A mine shaft, well depth L 526m, wellbocker digging section diameter 7.3m, 1 is a rocky area of the rock, 2 is the drilled hole, 3 is the pressure drill, 4 is the undefined wellbore, 5 is a well tutor Work face. The method of the present invention includes the following steps:

[0030] Step 1: Circle high stress area as a pressure relief drilling 3 to unload pressure, such as figure 1 As shown in the middle, the shaft side wall surrounding rock is a ring-burst hazard area 1. Select this ring-burst hazardous area 1 to blast-breaking the pressure-resistant pressure, performing the design and construction of pressure relief engineering;

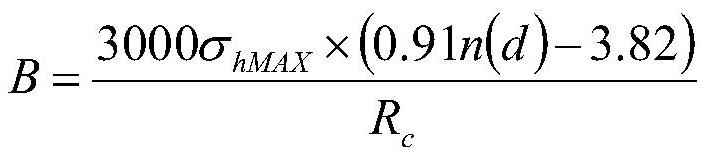

[0031] Step 2: According to the rupture zone formed by the large diameter pressure drilling 3 (i.e., the diameter of 80 to 300 mm), the plastic zone range determines the spacing of the pressure relief drilling hole 3; according to the standing rock high stress area The distance between the boundary and the well wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com