Polycrystalline diamond compact with functional gradient structure and preparation method of polycrystalline diamond compact

A technology of polycrystalline diamond and functional gradient, applied in metal processing equipment, additive manufacturing, earthwork drilling and mining, etc., to achieve the effects of relieving residual thermal stress, improving production efficiency, and changing the state of stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

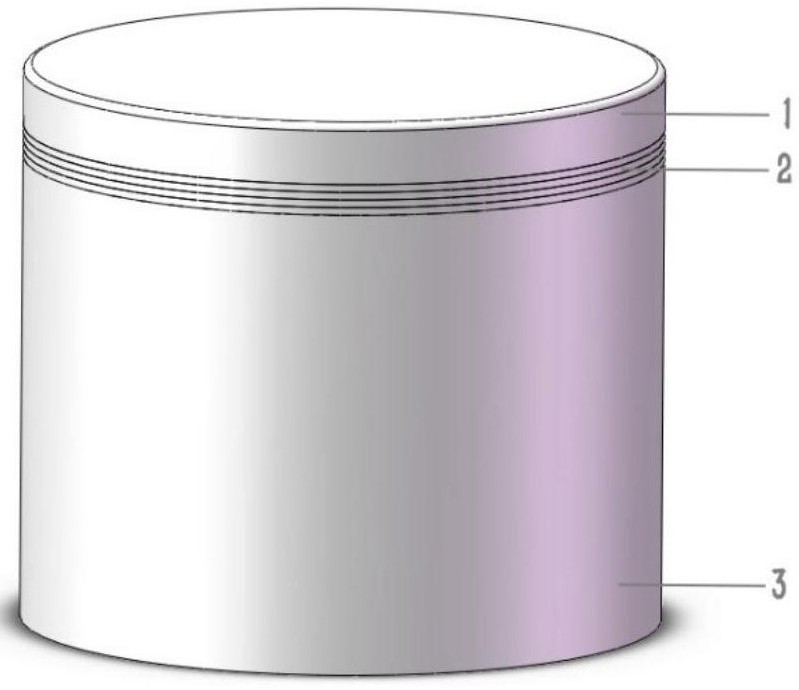

[0032] Such as figure 1 As shown, the polycrystalline diamond compact with functionally graded structure includes three parts: a polycrystalline diamond layer, an n-layer PCD / tungsten carbide composite gradient layer, and a cemented carbide substrate. The diameter × height of the polycrystalline diamond composite sheet of the design model 1913 is 19.05mm × 13.20mm. The volume fraction of diamond in the polycrystalline diamond layer is 100%. In the cemented carbide matrix layer, WC-13wt%Co is used (YG13) alloy powder, its composition ratio is WC87%, Co13%, set 4 intermediate gradient layers, the volume content of YG13 in each gradient layer is 15%, 35%, 55%, 75%, and the corresponding gradient layers The volume content of diamond in the medium is 85%, 65%, 45%, and 25%, respectively. The particle size of the pre-alloyed powder is 0.038-0.044 mm, and the particle size of the diamond powder is 0.12-0.15 mm.

[0033] Its production process is as follows:

[0034] (1) Select an ap...

Embodiment 2

[0040] Such as figure 1 As shown, the functionally graded polycrystalline diamond compact structure includes three parts: a polycrystalline diamond layer, an n-layer PCD / tungsten carbide composite gradient layer, and a cemented carbide substrate. The diameter × height of the polycrystalline diamond composite sheet of the design model 1613 is 15.88mm × 13.20mm. The volume fraction of diamond in the polycrystalline diamond layer is 100%. In the cemented carbide matrix layer, WC-15wt%Co is used (YG15) alloy powder, its composition ratio is WC85%, Co15%, set 5 intermediate gradient layers, the volume content of YG15 in each gradient layer is 15%, 25%, 35%, 55%, 75%, corresponding The volume content of diamond in each gradient layer is 85%, 75%, 65%, 45%, and 25%, respectively. The particle size of the pre-alloyed powder is 0.061-0.074 mm, and the particle size of the diamond powder is 0.250-0.297 mm.

[0041] Its production process is as follows:

[0042] (1) Select an appropri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com