A method for prevention and control of stope rockburst pressure relief

A blasting pressure relief and rockburst technology, applied in the field of rockburst pressure relief prevention and control in stopes, can solve the problems of small diameter and hole depth of post rock drilling, limited pressure relief range, large amount of excavation engineering, etc. The effect of rock drilling tunnel engineering, large diameter and depth, and large pressure relief range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

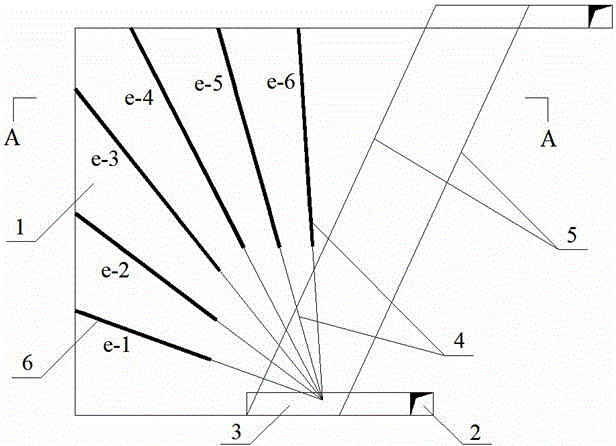

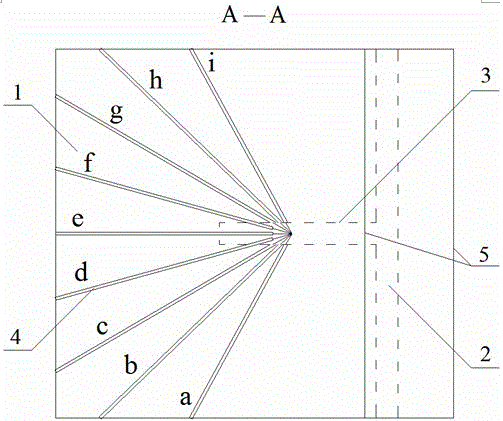

[0022] Implementation mode one: if figure 1 and 2 As shown, a deep ore body has an average horizontal thickness of 12 meters and an average inclination angle of 65o. In the figure 1 is the delineated rockburst dangerous area, 2 is the stage transportation roadway, 3 is the vein drilling roadway, and 4 is the beam blast hole. 5 is the boundary of the upper and lower plates of the ore body, and 6 is the charge section of the blast hole. The concrete steps of this implementation mode include:

[0023] (1) Delineate the high-stress area as the rockburst dangerous area, and carry out blasting and pressure relief; firstly, conduct rock mechanics experiments to analyze the rockburst tendency of the rock mass in the engineering area, and obtain the stress distribution law through the three-dimensional stress measurement method in the engineering area, and divide Out of the high stress area, predict the specific location where rockburst may occur in the project area, and use it as an...

Embodiment approach 2

[0028] Embodiment 2: The stope rockburst pressure relief prevention and control method of this embodiment is:

[0029] (1) Delineate the high-stress area as the rockburst dangerous area, and carry out blasting and pressure relief; firstly, conduct rock mechanics experiments to analyze the rockburst tendency of the rock mass in the engineering area, and obtain the stress distribution law by means of three-dimensional numerical simulation in the engineering area. In the high-stress area, predict the specific location where rockburst may occur in the project area, and use it as an area for rockburst pressure relief.

[0030] (2) At the stage where the blasting pressure relief area is located, the rock-drilling roadway is transported horizontally, and the rock-drilling roadway is a roadway that meets the working requirements of rock-drilling equipment, and the cross-sectional specification is 3×3.3 meters;

[0031] (3) Drill cluster blastholes with a diameter of 80mm and a depth o...

Embodiment approach 3

[0034] Embodiment 3: The stope rockburst pressure relief prevention and control method of this embodiment is:

[0035] (1) Delineate the high-stress area as the rockburst dangerous area, and carry out blasting and pressure relief;

[0036] First, rock mechanics experiments were carried out to analyze the tendency of rock mass rockburst in the project area. Through three-dimensional ground stress measurement in the project area, three-dimensional numerical simulation and other means, the stress distribution law was obtained, and high-stress areas were divided to predict the possibility of rockburst in the project area. The specific location is used as an area for rock burst pressure relief.

[0037] (2) At the stage where the blasting pressure relief area is located, the rock-drilling roadway is transported horizontally, and the rock-drilling roadway is a roadway that meets the working requirements of rock-drilling equipment, and the cross-sectional specification is 3.5×4 meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com