Mine mobile ladle tumbler

A technology for turning tanks and mines, applied in mining equipment, fillings, safety devices, etc., can solve the problems of large amount of engineering and poor adaptability, reduce equipment, simplify the gangue filling system, and achieve obvious direct economic and social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

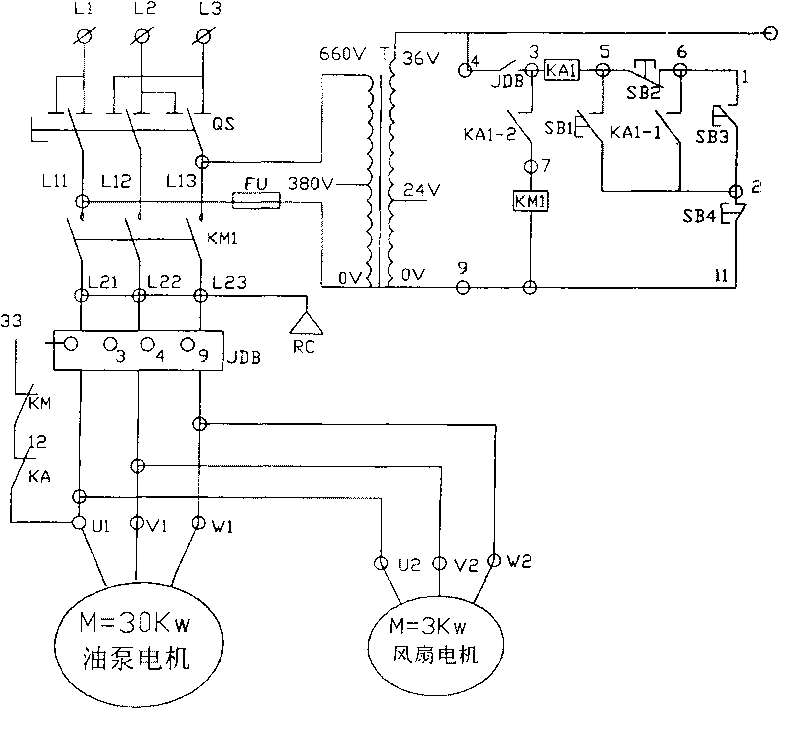

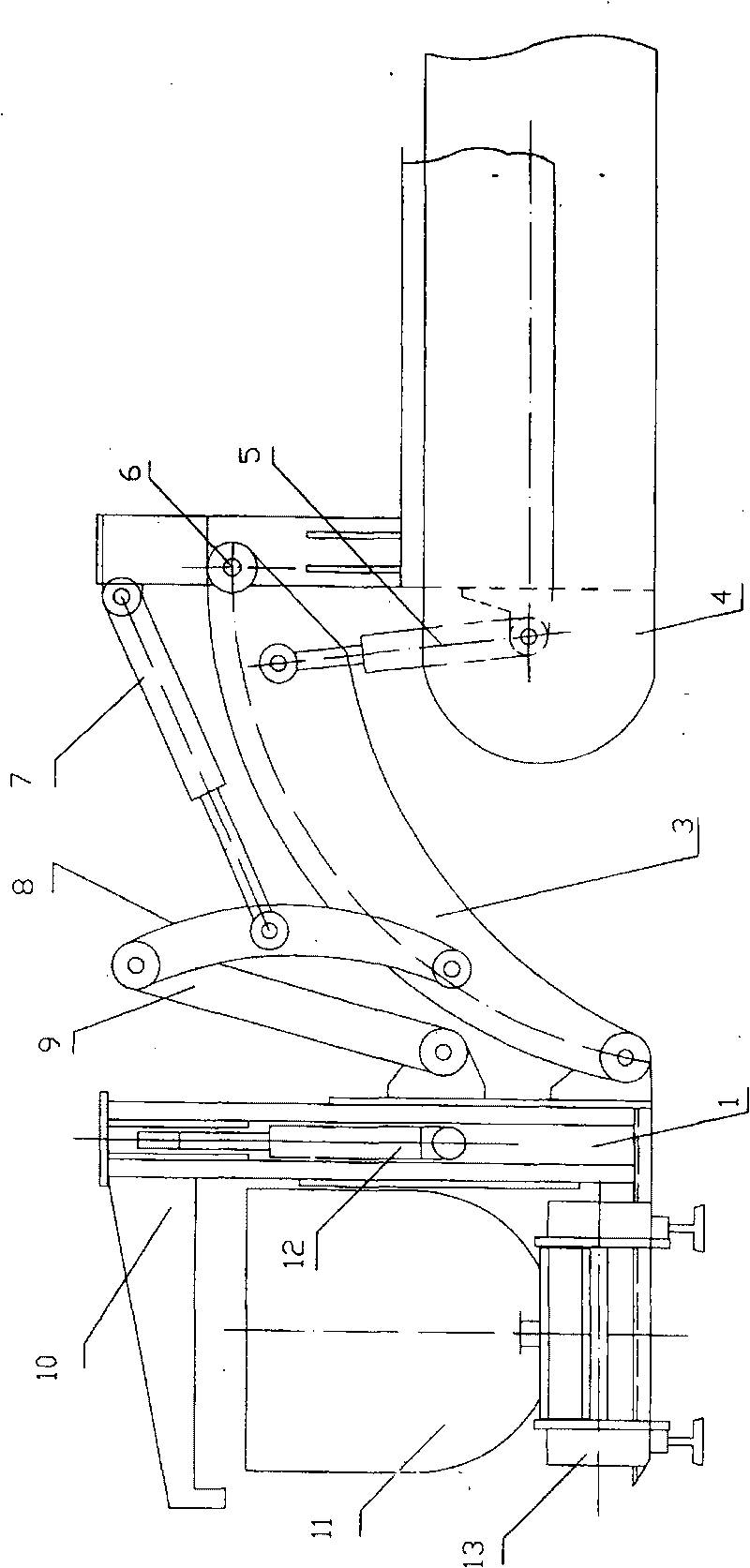

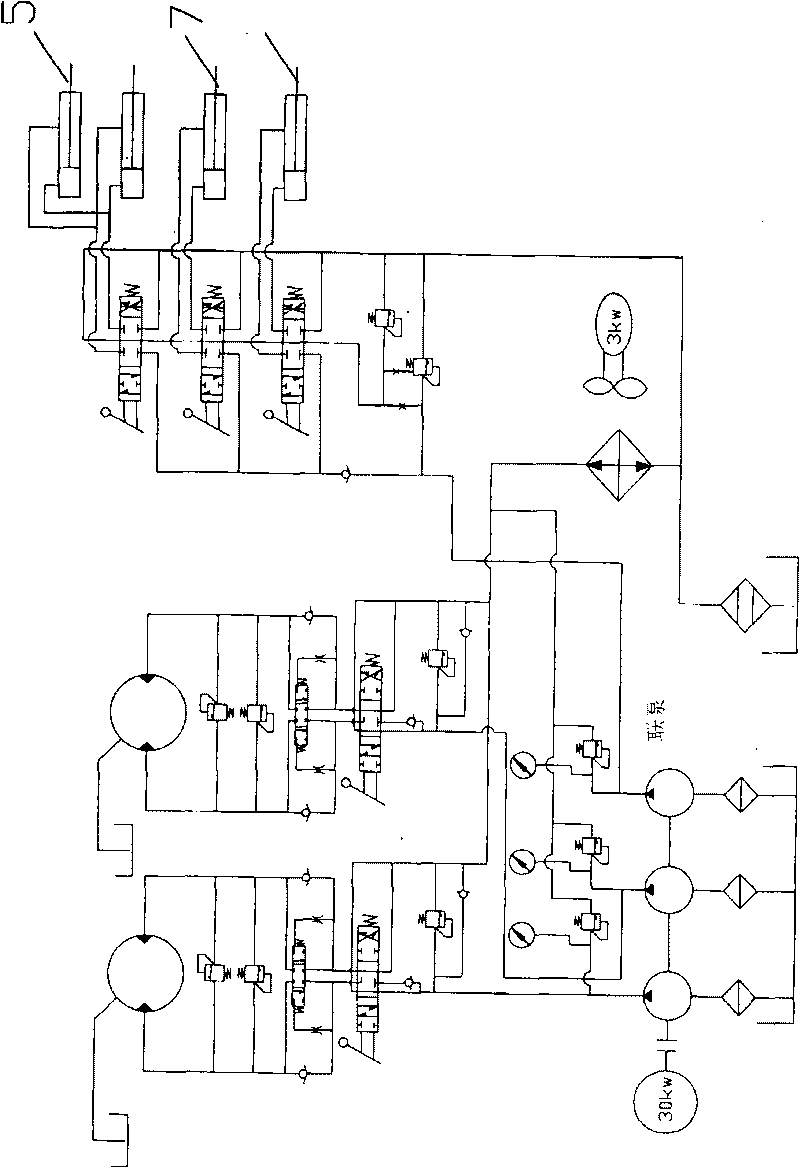

[0018] Such as figure 1 As shown, the mining mobile can turning machine is composed of a traveling device 4, a tank car turning device, and a hydraulic system and an electric system that provide power and instructions for the walking device 4 and the tank car turning device. The tank car turning device is composed of a trailer frame 1 , locking arm 10, locking cylinder 12, lifting arm 3, lifting cylinder 5, overturning arm I8, overturning arm II9 and overturning cylinder 7, and the carriage frame 1 is composed of a vertical arm and a cross arm of an "H" type structure The cross arm is perpendicular to the vertical arm, and the cross arm and the vertical arm form an "L" shaped shovel. The lock cylinder 12 is vertically arranged in the middle of the vertical arm, and the lock arm 10 is fixed on the lock cylinder 12. The top of the piston rod, the locking arm 10 and the carriage frame 1 form a side "U"-shaped jaw, which can clamp and turn the tank car 13 and the tank 11 together....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com