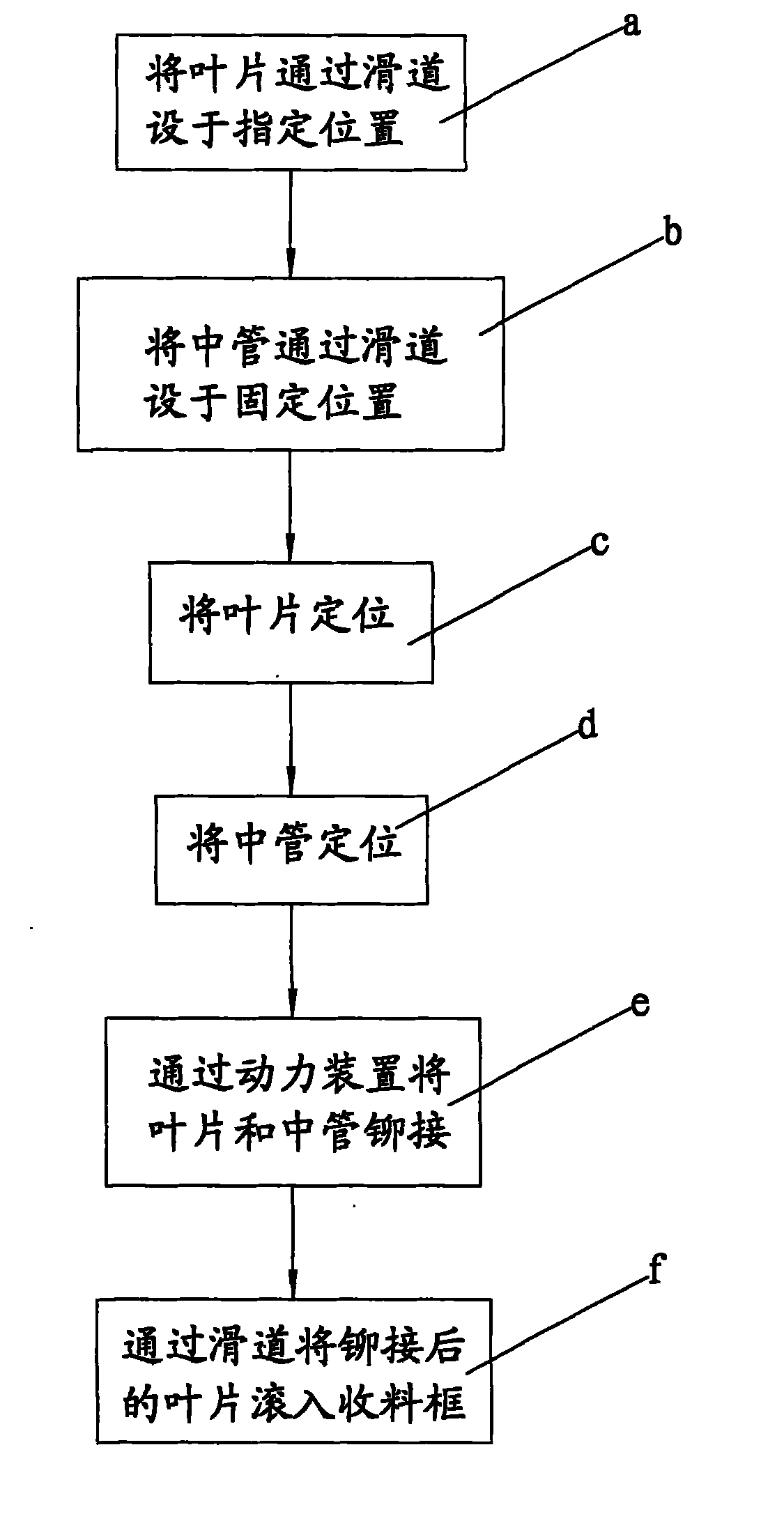

Hub blade automatic riveting machine and riveting method thereof

An automatic riveting and riveting machine technology, applied in the field of bicycle accessories, can solve problems such as unstable quality, numerous projects, and inability to automatically position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

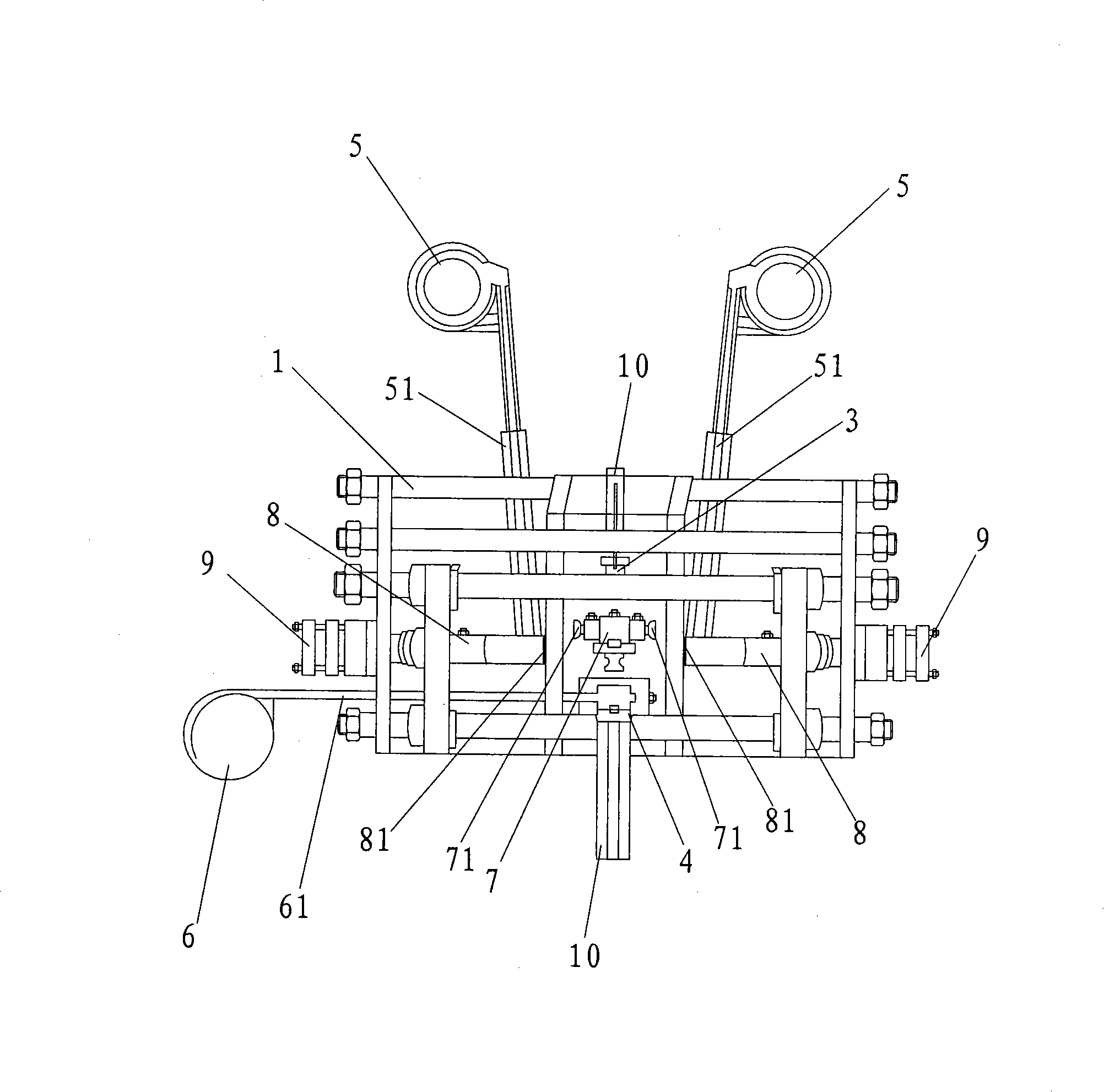

[0033] refer to figure 2 As shown, the present invention discloses an automatic riveting machine for hub blades, which includes a frame 1, upper and lower dies 3, 4 for pressing middle tubes, blade vibrating plate 5, middle tube vibrating plate 6, and blade jacking device 7, in:

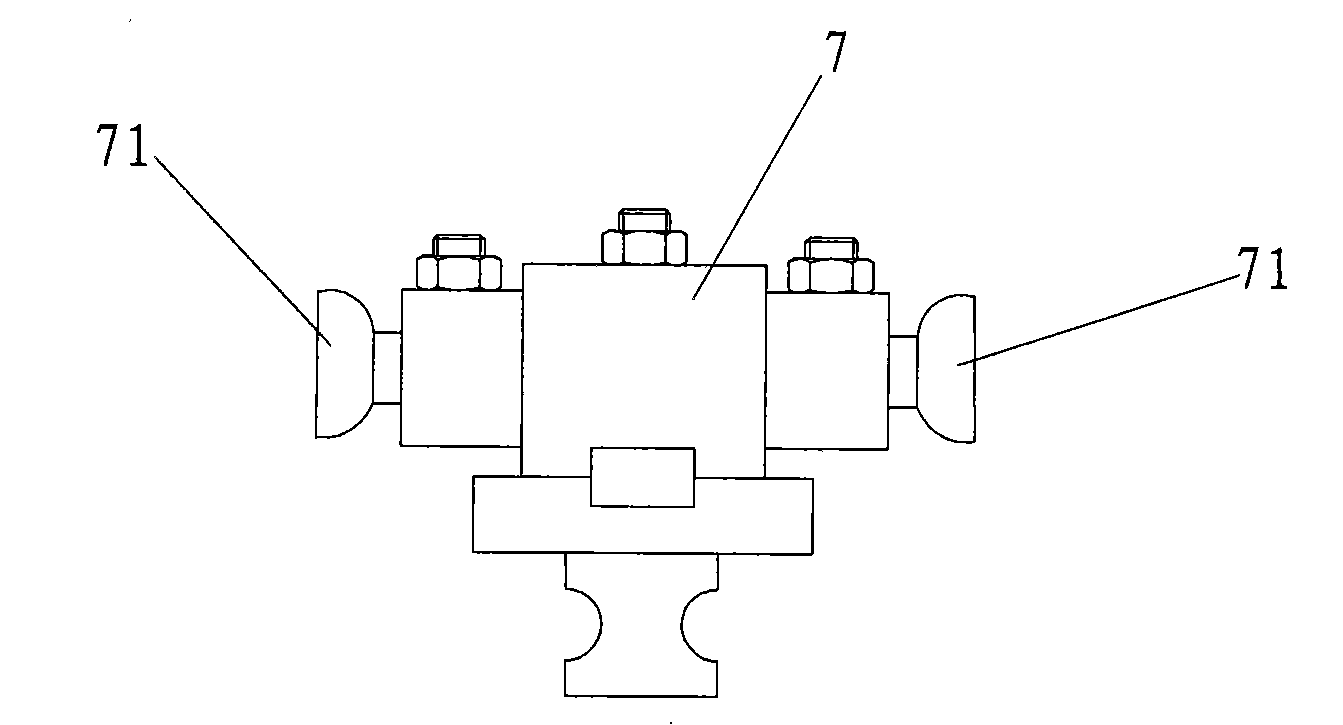

[0034] Cooperate Figure 4 , 5 As shown, the upper and lower molds 3 and 4 of the middle tube pressing are located on the upper and lower sides of the center of the frame 1, and cooperate with Figure 6 As shown, the blade vibrating disk 5 is symmetrically arranged on both sides of the frame, and it is connected to both sides of the blade ejector 7 of the frame 1 through the blade slideway 51. As shown in FIG. 8, the middle tube vibration plate 6 slides through the middle tube Road 61 links to each other with middle pipe pressing lower mold 4, and blade ejector 7 is also positioned on frame 1, and it can be controlled by inductor and solenoid valve (not shown in the figure), cooperates image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com