Patents

Literature

61results about How to "Save engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Parking lot intelligent management system based on two-dimensional codes

InactiveCN105160928AImprove experienceSimple structureTicket-issuing apparatusIndication of parksing free spacesComputer moduleModularity

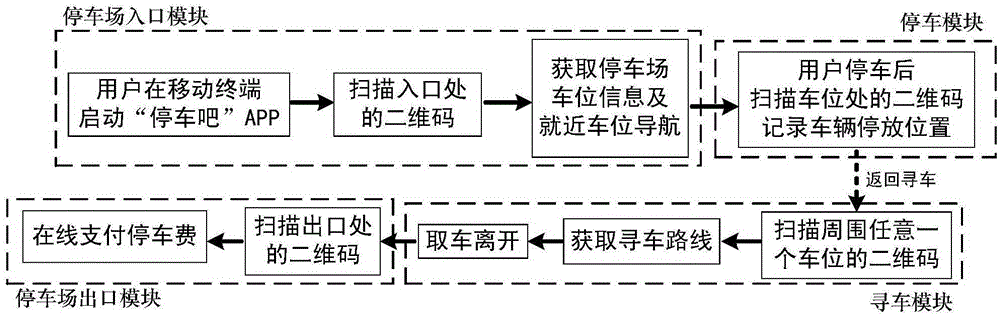

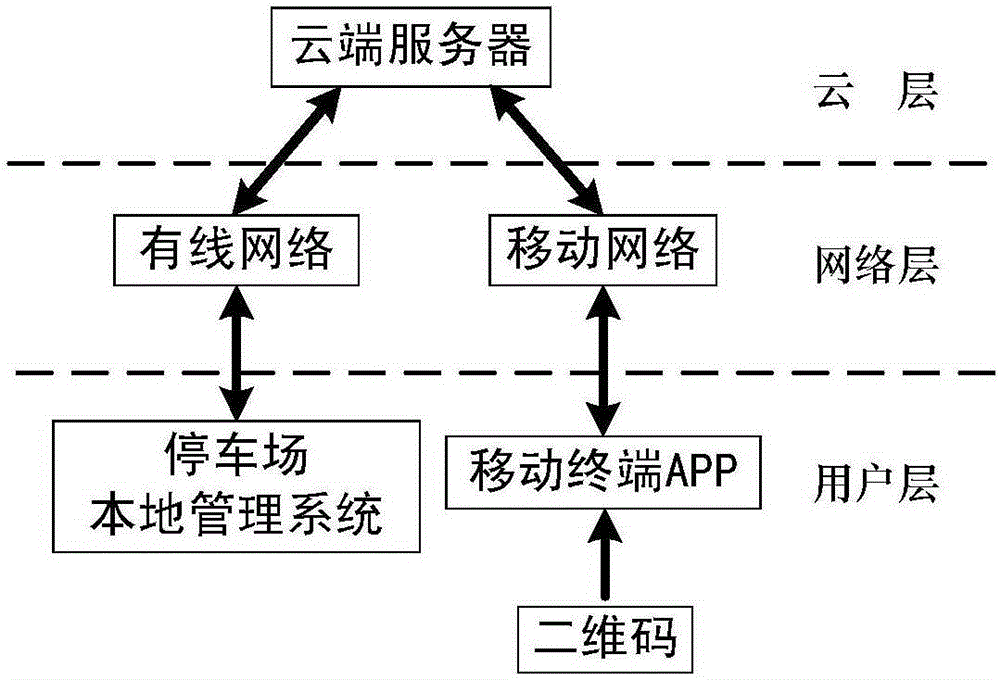

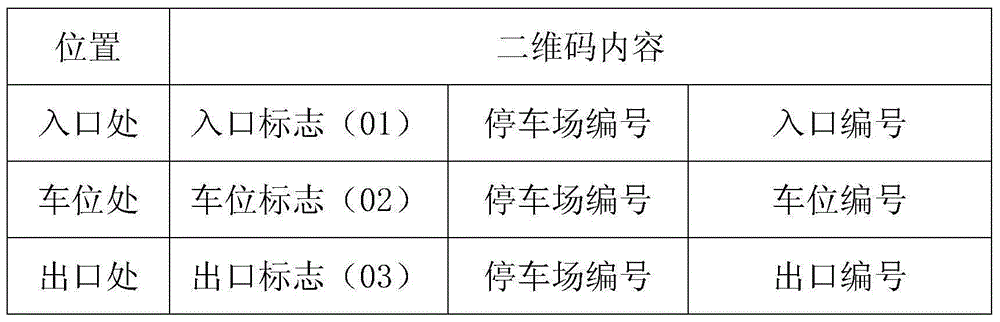

The invention discloses a parking lot intelligent management system based on two-dimensional codes. The system is characterized by comprising a mobile terminal APP, a background server, a parking lot PC terminal corresponding to each parking lot, a parking lot inlet module, a parking module, a vehicle searching module and a parking lot outlet module. The system achieves the following beneficial effects that (1) the mobile terminal APP replaces existing parking lot management equipment; (2) two-dimensional codes replace a conventional sensor identifying parking stall scheme; (3) two-dimensional codes are used for guiding a user when the user searches for a vehicle; (4) a modularized design is adopted for programs with different functions and each module function is relatively independent. Compared with conventional parking software requiring users to fully use all functions, the system allows users to conveniently select and use one or more service functions achieved through the parking lot inlet module, the parking module, the vehicle searching module and the parking lot outlet module according to their own demands.

Owner:HOHAI UNIV CHANGZHOU

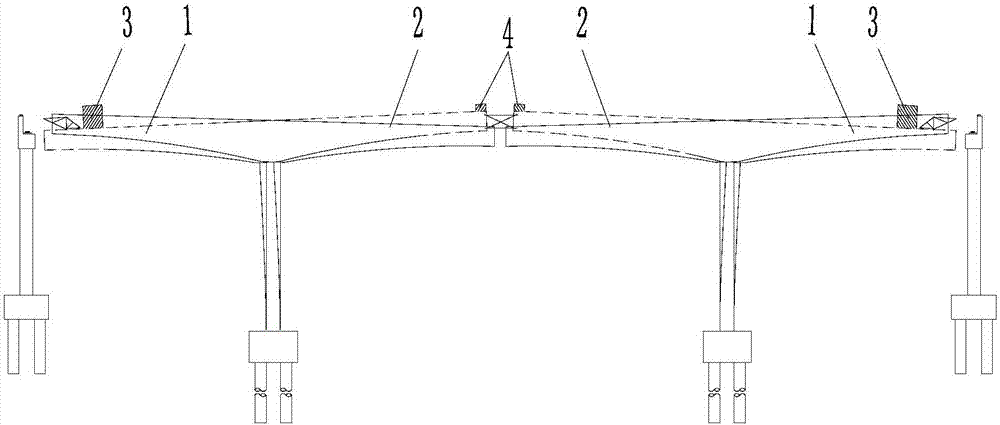

T structure closure pouring method for mountainous-area high-pier large-span continuous rigid-frame bridge

ActiveCN106948273ASave engineeringImprove securityBridge erection/assemblyHanging basketDeformation control

The invention discloses a T structure closure pouring method for a mountainous-area high-pier large-span continuous rigid-frame bridge. Before T structure closure pouring, weights are loaded at the cantilever ends of T structures to enable the cantilever ends of the two sides of T structure mid-span enclose sections to generate large longitudinal horizontal displacement towards to the two side-span directions so as to compensate shrinkage and creep and horizontal displacement generated due to later-period whole temperature reduction; the high-pier large-span characteristics are combined, adverse influence, on the continuous rigid-frame bridge internal force and deflection, of concrete shrinkage, creep and the temperature effect which are caused due to the effect of long-term load is reduced, and mid-span mid span bottom bending caused due to the influence of concrete shrinkage and creep is avoided; and weight bodies can obtain materials from local sources, pushing is not needed, simple and feasible effects are achieved, construction is convenient, safety is high, original side span cast-in-situ sections and enclose sections adopt hanging baskets for pouring till pouring is conducted to supporting seats, supporting engineering is reduced, after mid-span enclosure, in side span cast-in-situ, the whole rigidity is large, deformation control is good, and construction is easy.

Owner:CHONGQING JIAOTONG UNIVERSITY +2

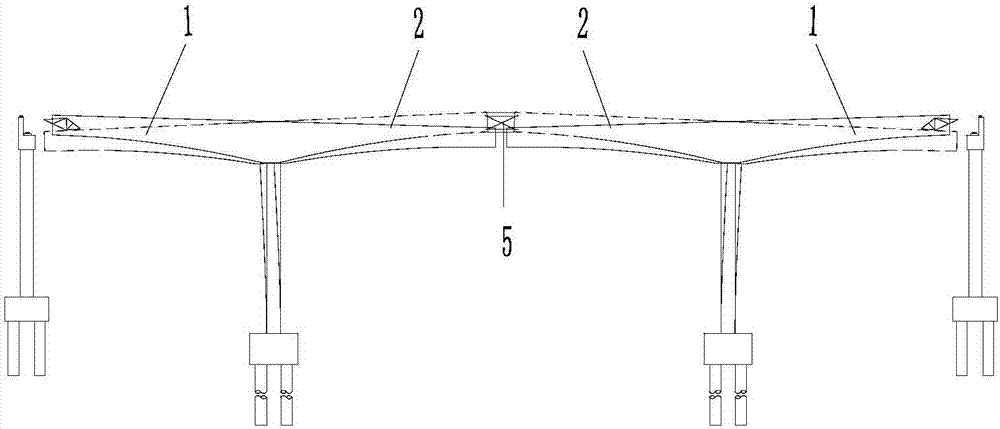

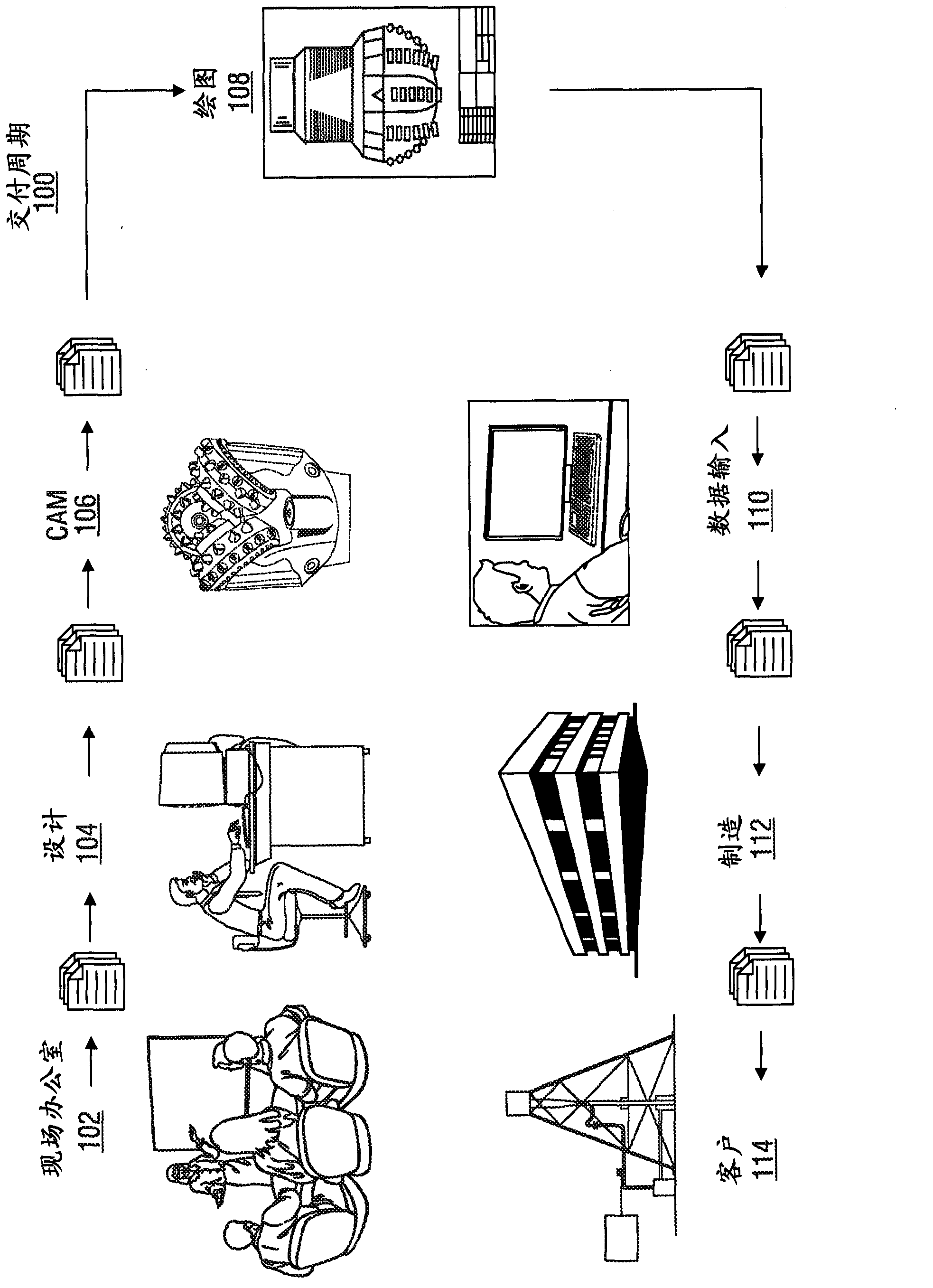

Method and apparatus for efficient implementation of design changes

InactiveCN103210390ASave engineeringShorten the timeDrill bitsCAD network environmentNetwork connectionGood practice

The disclosed embodiments allow a user to request new product designs and design changes remotely. The requested design or change is then submitted to a network-based automated process. The process may be remotely accessed by the user through a network connection. In one embodiment, the user may meet directly with a customer, pull up the specifications for the product in question, select a design or change desired by the customer, and submit the design or change. The process works in the background to validate the requested design according to one or more validation rules and / or best practices, and completes many of the necessary tasks to allow the requested design to proceed to manufacturing. Once the process has successfully completed the requested change, a notification is sent to the user containing information about the new or changed product, such as the new part number, order number, and the like.

Owner:BAKER HUGHES INC

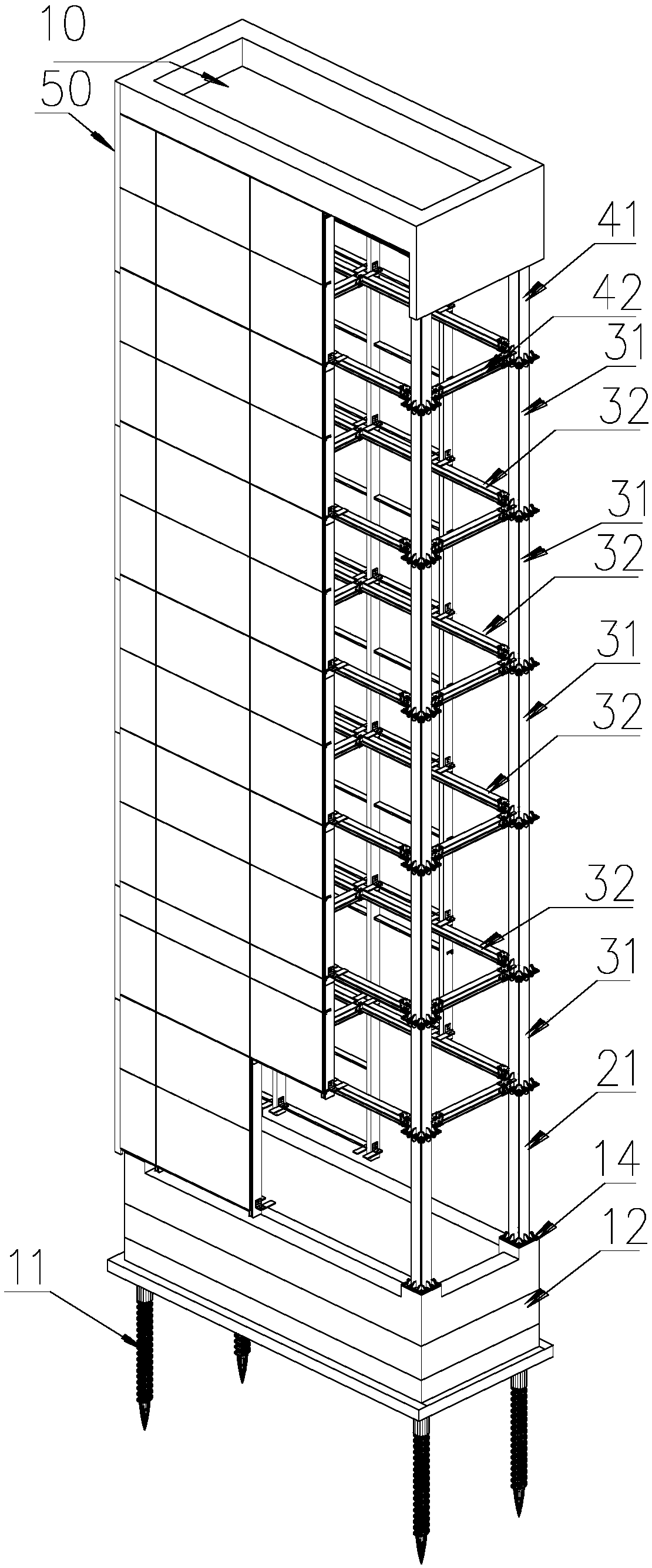

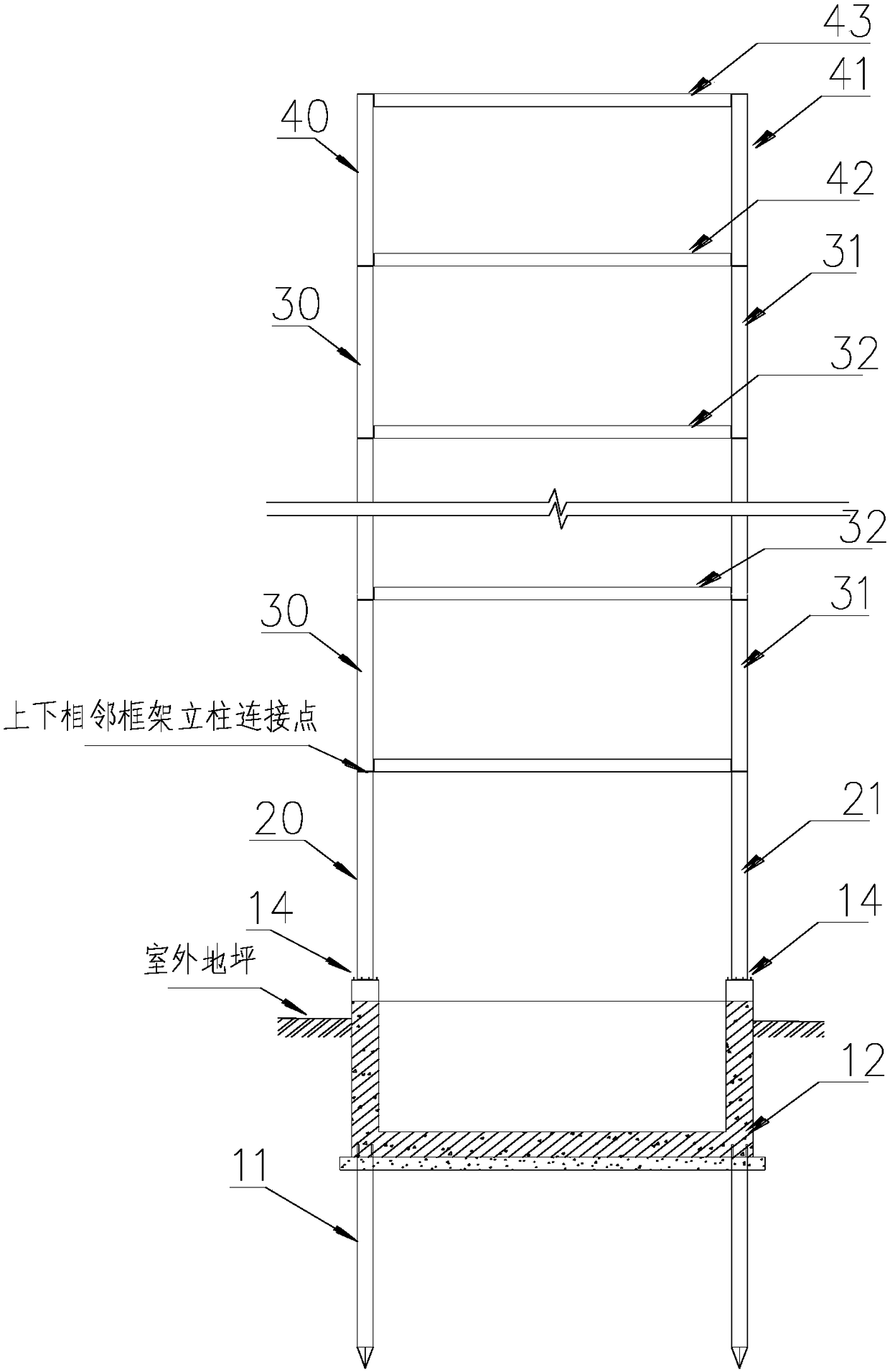

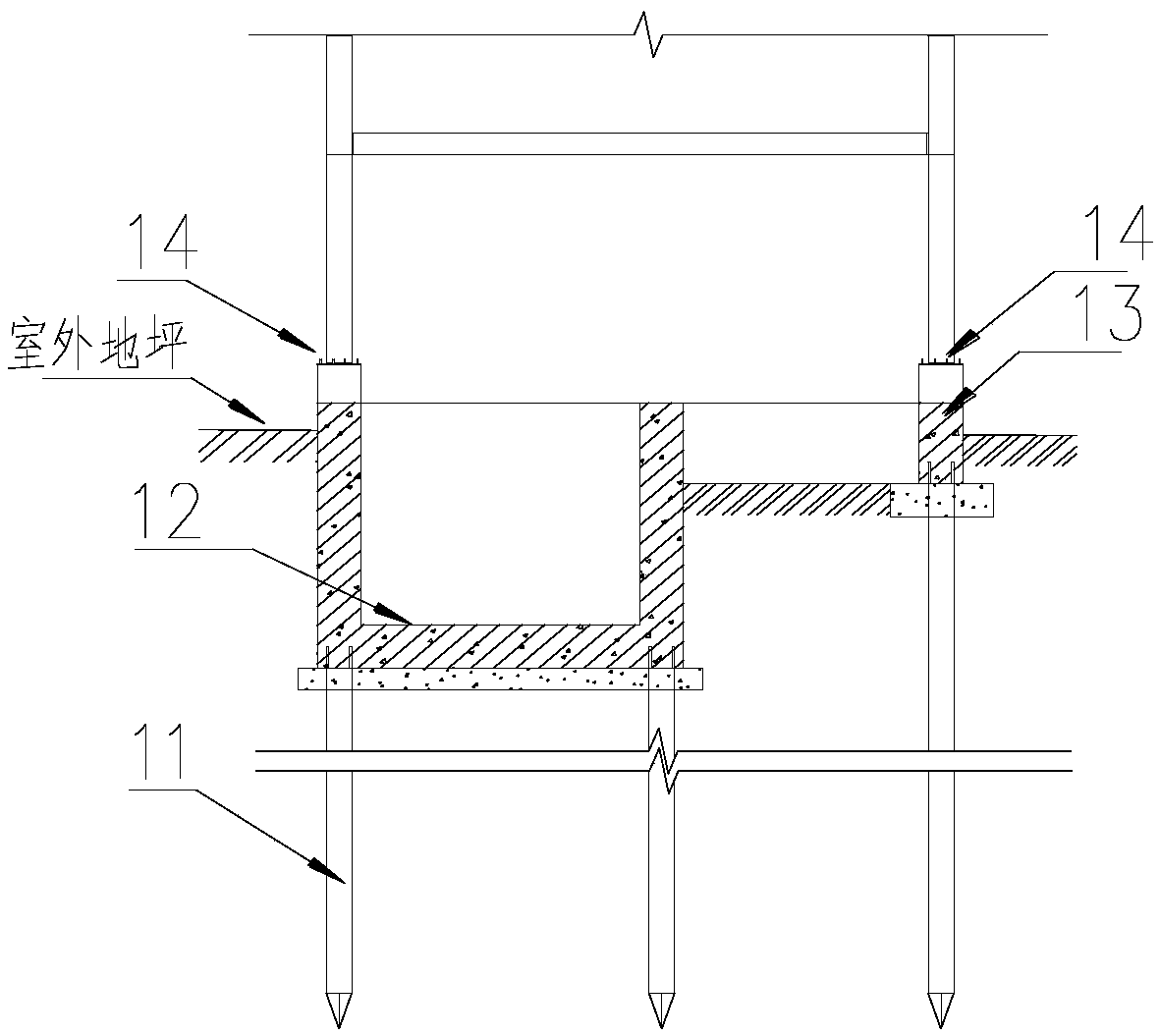

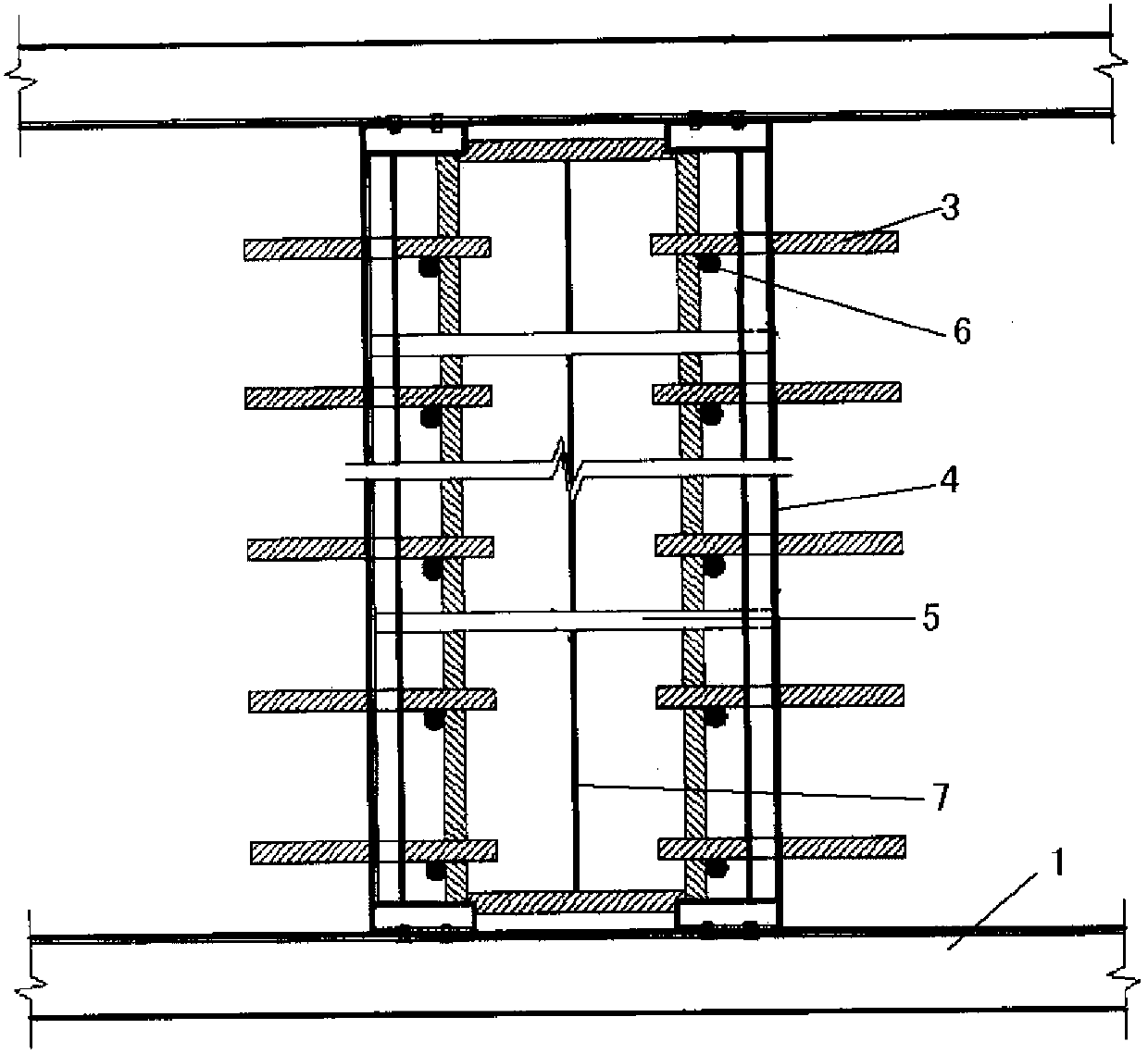

Jacking construction method for assembled-type external elevator shaftway structure

ActiveCN108532769ASmall space constraintsReduce the impactBuilding constructionsFalseworkReinforced concrete

The invention discloses a jacking construction method for an assembled-type external elevator shaftway structure. The jacking construction method comprises the steps that a foundation pit is excavated, and reinforced concrete foundations and pre-buried connecting components are made; a jacking guiding device is mounted on an existing building, and a jacking device is mounted at the bottom of the foundations; a jacking monitoring device is mounted on an assembled elevator shaftway top layer structure unit to conduct jacking operation of the top layer structure unit, the jacking operation stateis monitored in real time, and torsion or inclination of the structure is prevented cautiously; assembling and jacking of structure units of all standard layers are conducted in sequence, and a first-layer structure frame is mounted; equipment is dismounted, and an elevator shaftway and the existing building are connected through flexible connecting components layer by layer; construction of a roof, all layers of floors, partition plates and the first layer is conducted; and finally, an elevator is mounted. By adopting the jacking construction method, the occupied area is small, the period isshort, the efficiency is high, labor force is saved, heavy transportation vehicles and large lifting equipment are not needed, a scaffold does not need to be set up on site, and high-attitude operation and the influence on the daily life of residents can be reduced significantly.

Owner:华城(天津)建筑科技有限公司

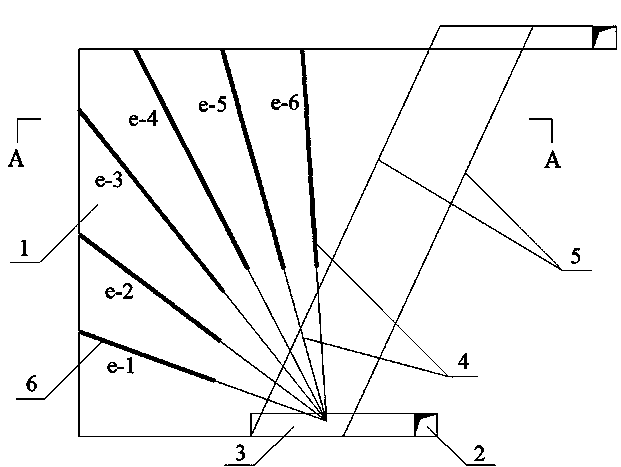

Stope rockburst pressure relief prevention method

InactiveCN103528444ASave engineeringChange the state of stress distributionBlasting cartridgesBurst pressureDrill hole

The invention relates to a stope rockburst pressure relief prevention method, and belongs to the technical field of underground mining. A high-stress rockburst dangerous area is firstly delineated as a burst pressure relief area, a horizontal construction rock drilling tunnel is then conveyed in the section where the burst pressure relief area is located, cluster-shaped blast holes with the diameter of 80-200mm and depth of 15-60m are drilled in rockburst rock mass, under the condition of uncompensated space, explosives are added to the blast holes to perform burst, and pressure relief in the rockburst dangerous area is completed. According to the method, drilling burst is directly performed on the rockburst dangerous area, high stress in the rock mass is relieved, and rockburst danger is eliminated.

Owner:KUNMING UNIV OF SCI & TECH

No-cutting-seam cement concrete pavement structure and construction method thereof

ActiveCN103276651AWith force transmission effectNo reduction in structural durabilityPaving detailsRoad surfaceRebar

The invention discloses a no-cutting-seam cement concrete pavement structure and a construction method thereof, belonging to the technical field of traffic road construction. The no-cutting-seam cement concrete pavement structure is characterized in that an aluminium plate is fixed on a foundation at a cutting seam of a traditional concrete pavement, an induced joint is reserved in the aluminium plate, and high-ductility fiber reinforced cement-based composite material is poured on the aluminium plate, so that an induced joint structure is formed between two concrete pavements; the construction method comprises the following steps of: fixing the aluminium plate on the foundation, wherein the induced joint is reserved in the aluminium plate; arranging two anchor steel bar brackets on the two sides of the aluminium plate along the center line of the joint; fixing a mould onto a side formwork, wherein a rabbet is reserved in the mould; and firstly pouring common concrete according to a traditional pavement construction technology, and then pouring and plastering the high-ductility fiber reinforced cement-based composite material in a preformed groove after the mould is disassembled. The no-cutting-seam cement concrete pavement structure guarantees the integrity of pavement, improves the road driving comfort, effectively reduces the engineering cost, reduces the maintenance cost and reduces the traffic jam caused by maintenance.

Owner:TSINGHUA UNIV +1

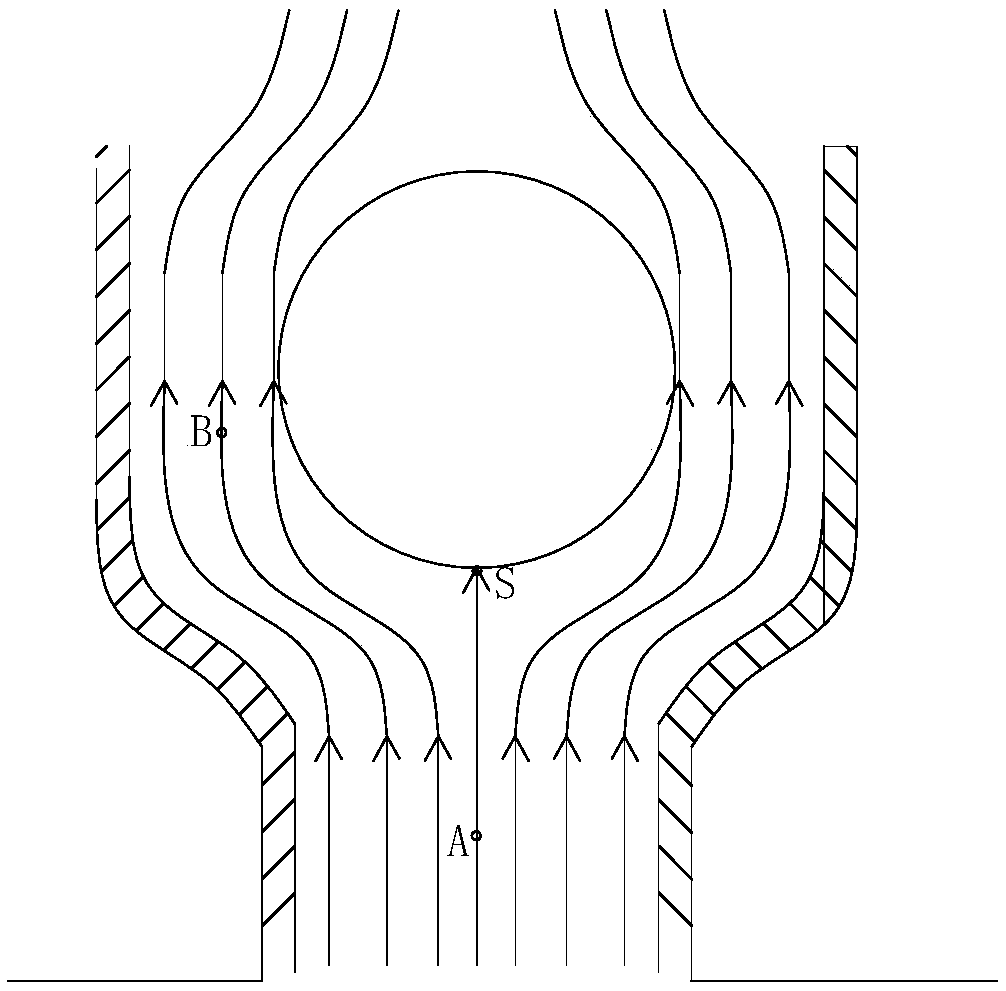

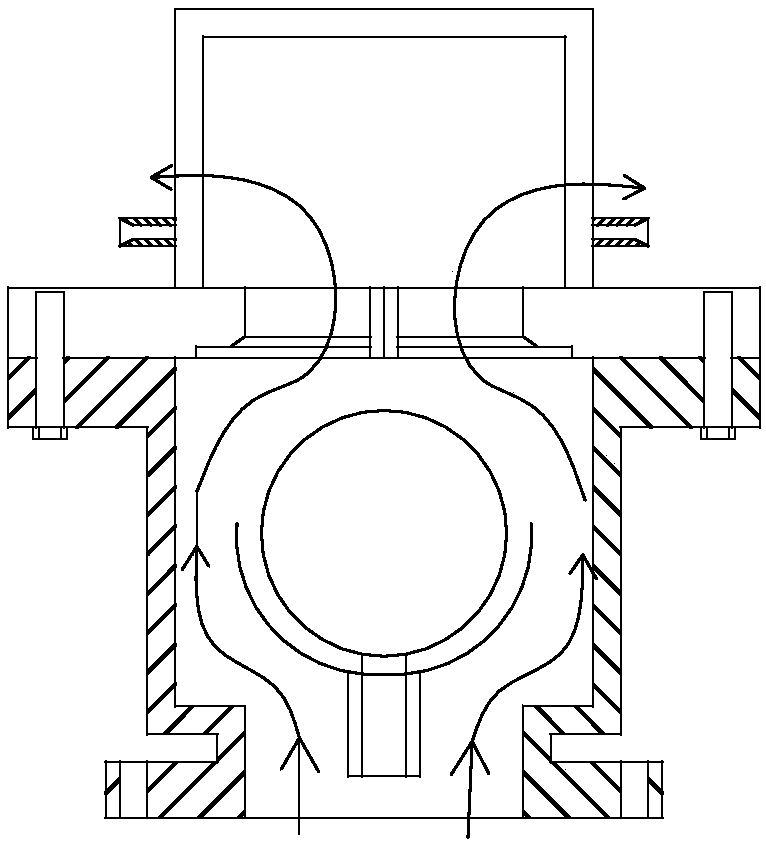

Realizing method for improving exhaust capacity of air inlet and exhaust valves

InactiveCN109163101AImprove intake and exhaust performanceExtended service lifeValve members for absorbing fluid energyDesign optimisation/simulationPipe burstingViewpoints

The invention discloses a realizing method for improving the exhaust capacity of air inlet and exhaust valves. On the basis of establishment of streamline mathematical models of the air inlet and exhaust valves, as for a water supplying system, the theoretical exhaust quantity is calculated, the types and specifications of the conventional air inlet and exhaust valves are determined, and the exhaust flow coefficients are calculated; and the same specification of the section-variable air inlet and exhaust valves with exhaust flow channels being in a streamline shape are designed, the actual exhaust quantity and the actual exhaust flow coefficients are tested, recorded and calculated on an exhaust performance test platform. Experiments prove that the exhaust capacity of the section-variableair inlet and exhaust valves is obviously improved, thus under the premise of meeting the exhaust requirements, the diameter and the number of the air inlet and exhaust valves can be decreased, investment is lowered, the anti-cavitation performance of inner components is improved, the service life is prolonged, and the pipe-bursting accident caused by improper type selection of the air inlet and exhaust valves is avoided; and the viewpoint that the internal and external pressure differences of the air inlet and exhaust valves are different, and thus the exhaust flow coefficients of the air inlet and exhaust valves are also different is put forward and verified for the first time, the basis is provided for improvement of type selection standards and formulation of production technical standards in the water supply industry in China, and the realizing method is of great significance to ensure safe operation of pipelines.

Owner:TAIYUAN UNIV OF TECH

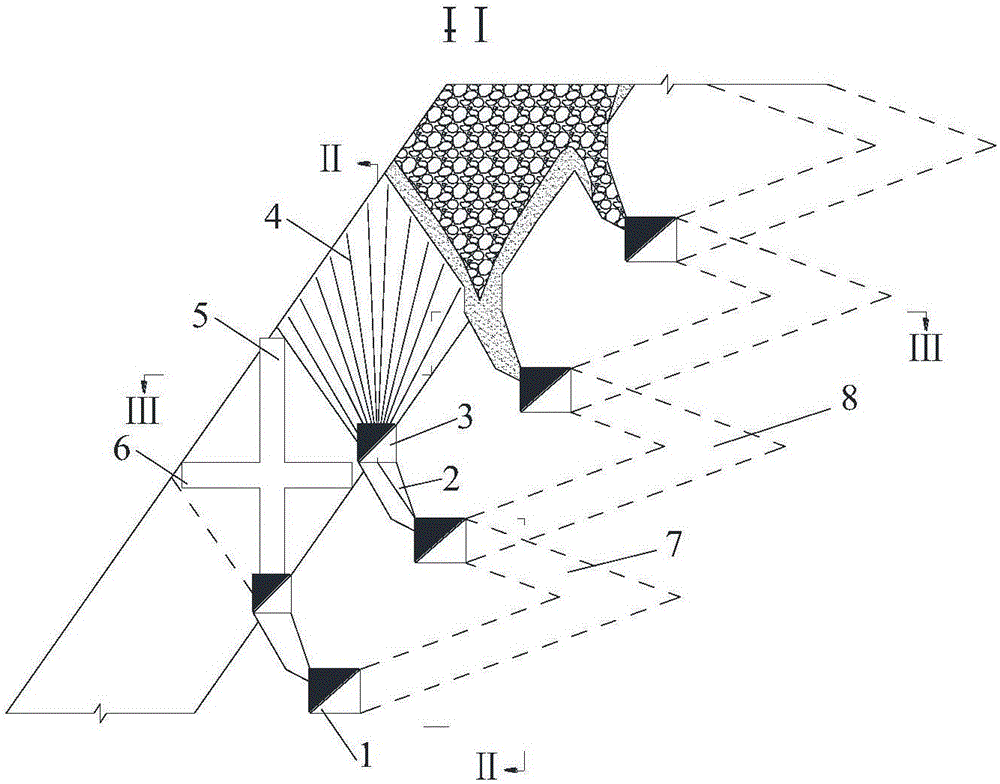

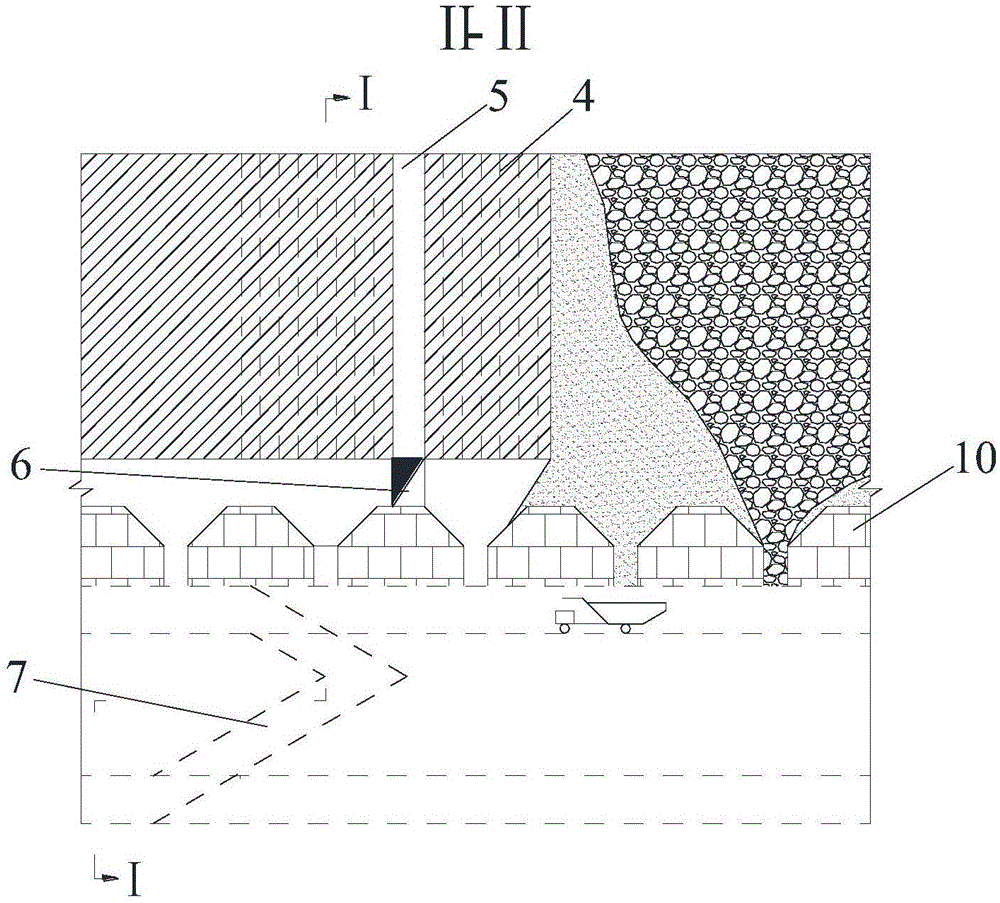

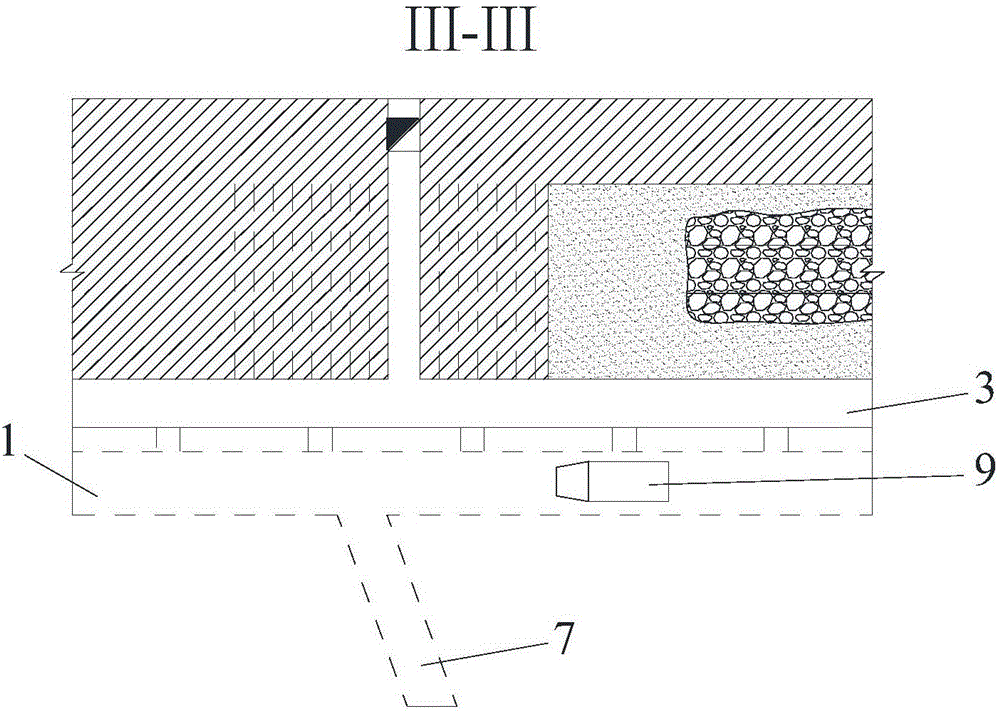

Truck collaborated ore removal type sublevel caving method with sill pillar

ActiveCN106837335AOvercome the shortcomings of low mining efficiencyHigh degree of mechanizationUnderground miningBlastingTransfer procedureEngineering

The invention discloses a truck collaborated ore removal type sublevel caving method with sill pillar. The method includes steps: dividing stages of inclined-steeply inclined thick ore bodies or arbitrary-inclination-angle extremely-thick ore bodies, in moderate steadiness or above, of footwall surrounding rock, and segmenting in the stages according to inclinations of the ore bodies; arranging footwall haulage ways and ramps for ore body footwall; tunneling short draw shafts and drilling drifts to the ore bodies through the footwall haulage ways; in stoping, adopting vertical fan-shaped medium-length hole caving; directly loading ores under overlying strata into trucks through the short draw shafts and ore discharging hoppers, and transporting to the ground through the ramps. A traditional vertical long hole caving type sublevel caving method with sill pillar is modified, the trucks are adopted for direct ore removal, and accordingly mechanization degree is raised, synergy of ore caving and ore removal is guaranteed, a bottom structure is simplified, ore transferring procedures are reduced, and mine production efficiency is improved.

Owner:GUANGXI UNIV

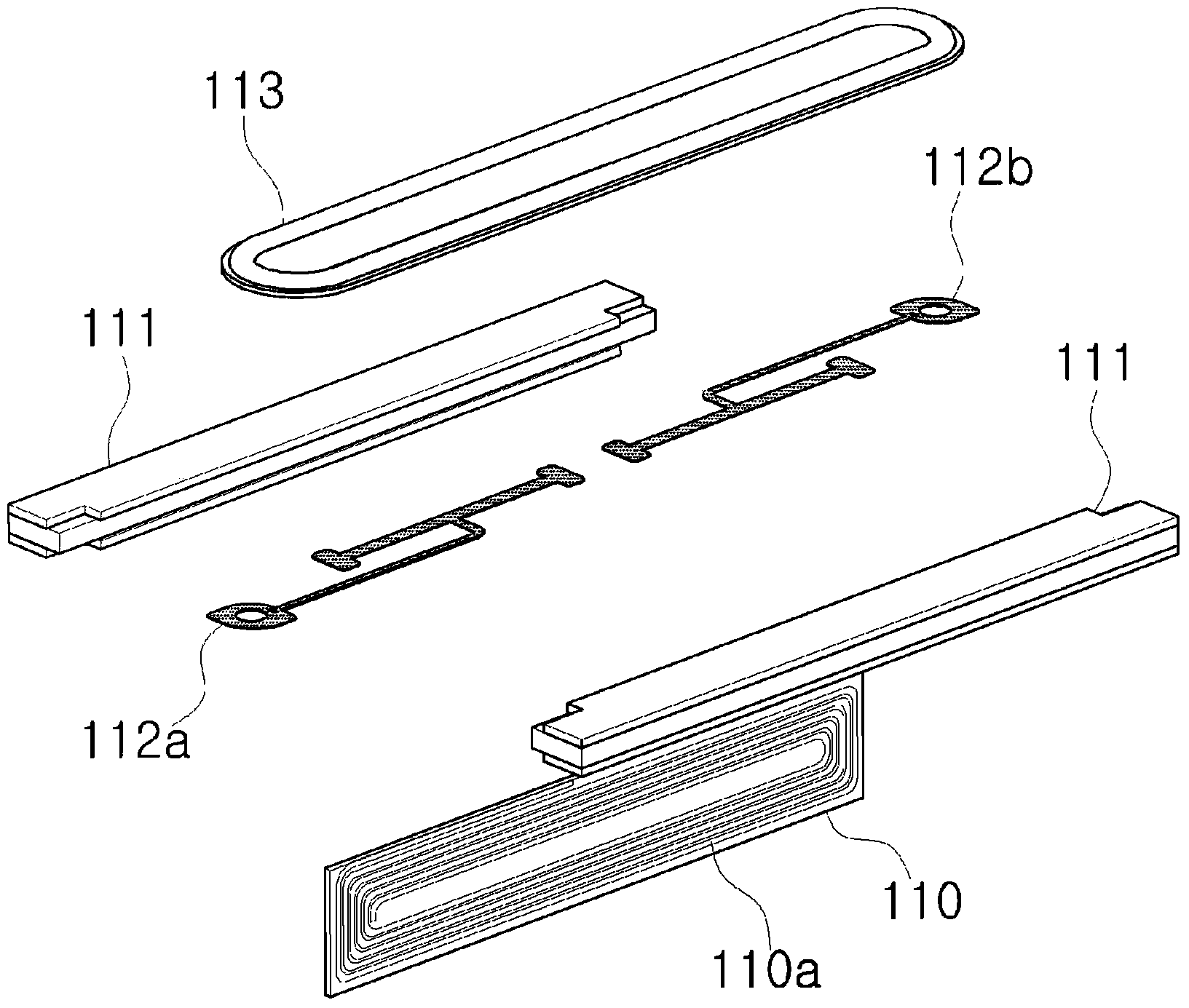

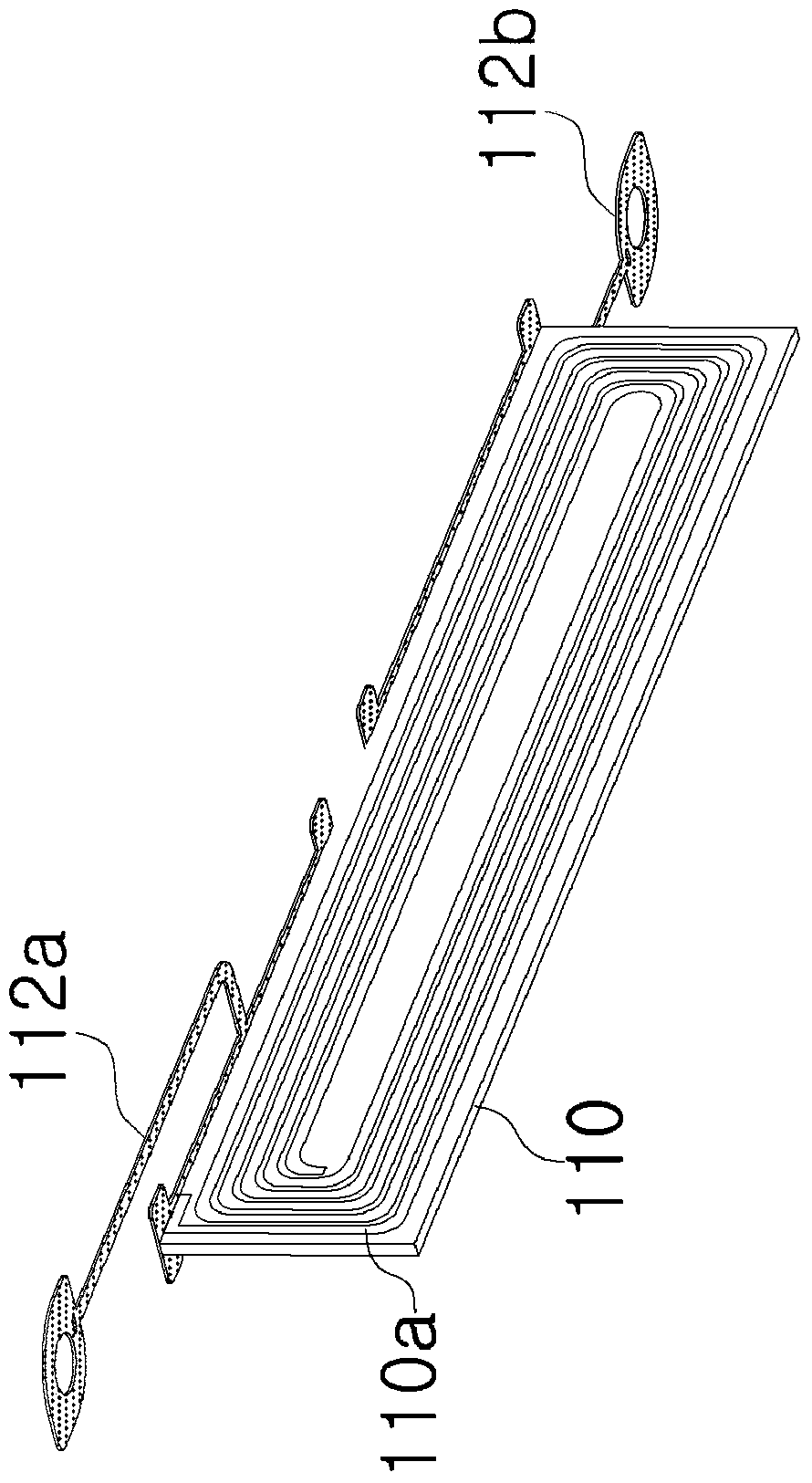

Flat type speaker having vibration-lead plate of PCB voice coil plates

InactiveCN103444204APolyphonic energySave engineeringElectrostatic transducer loudspeakersCircuit lead arrangements/reliefEngineeringLoudspeaker

The invention relates to a flat type speaker, and more particularly relates to a flat type speaker having a vibration-lead plate of PCB voice coil plates, wherein the flat type speaker having the vibration-lead plate of the PCB voice coil plates is installed above the voice coil plates, and is capable of shortening production processes and solving the quality deterioration problem due to disconnection of a lead wire by increasing the vibration efficiency and eliminating the lead wire connected to the voice coil. The flat type speaker is characterized by comprising a pair of magnetic bodies formed in parallel at a predetermined interval with a magnet and a yoke; the voice coil plate inserted in the space between the magnetic bodies to form a voice coil with a spiral pattern printed thereon; and the vibration-lead plates having a first vibration-lead plate and a second vibration-lead plate which are physically separated, each having +, - terminals formed on the front ends thereof. The first vibration-lead plate and the second vibration-lead plate are each provided with a coil plate sheet, at least one wing sheet and a vibration plate, wherein the coil plate sheet is adhered to the upper end of the voice coil plate, one end of the at least one wing sheet is connected to the coil plate sheet and the other end is connected to the + or - terminals, and the vibration plate is disposed the upper ends of the vibration-lead plates and vibrates from the vibration received from the voice coil plates.

Owner:DAHONG TECH CO LTD

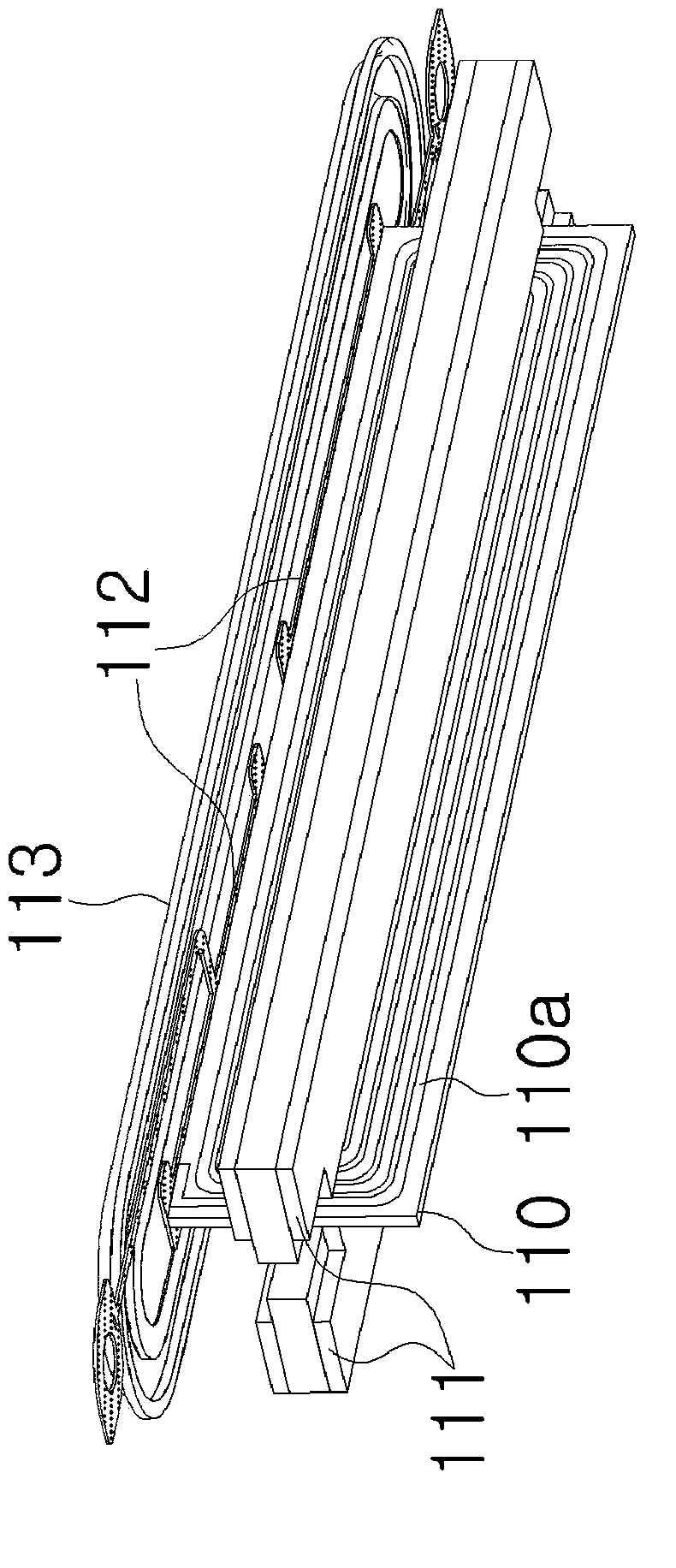

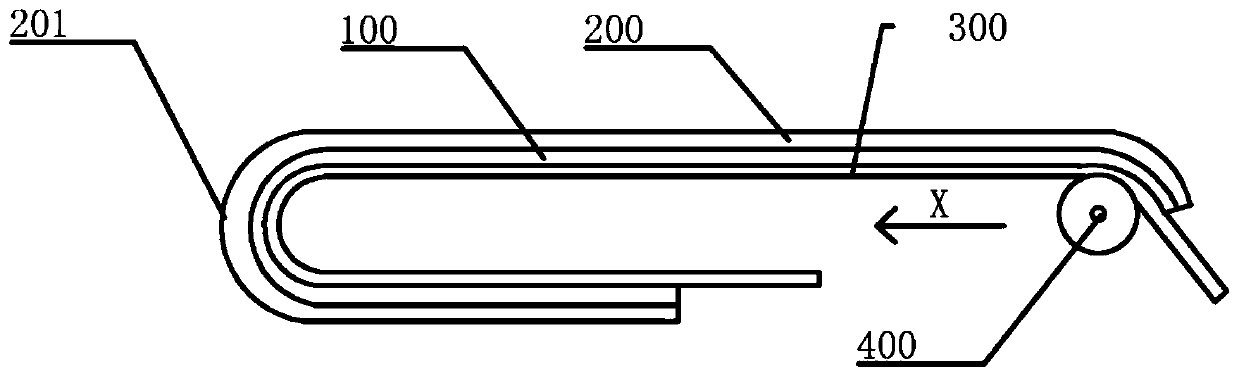

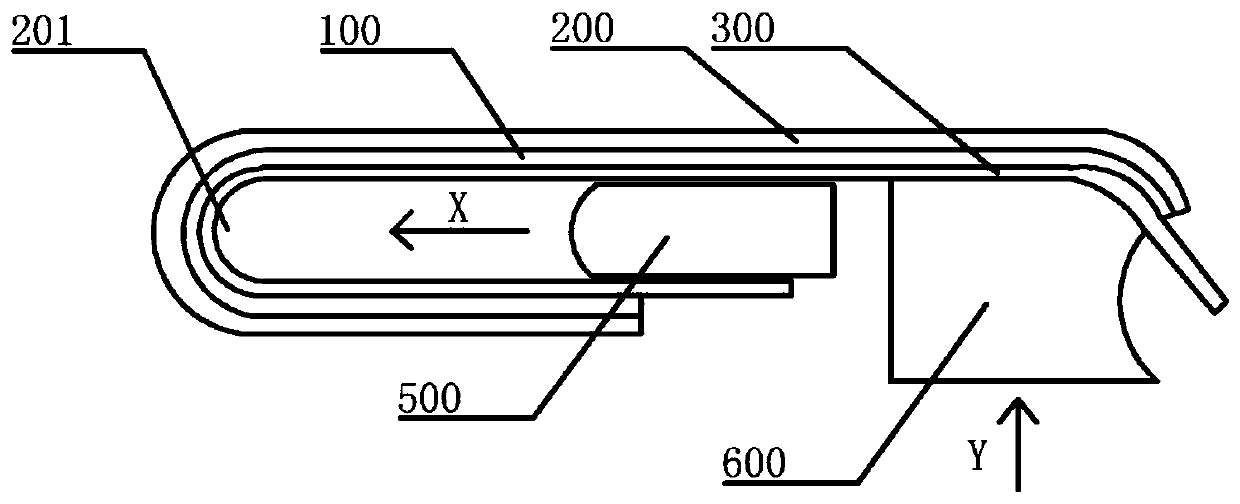

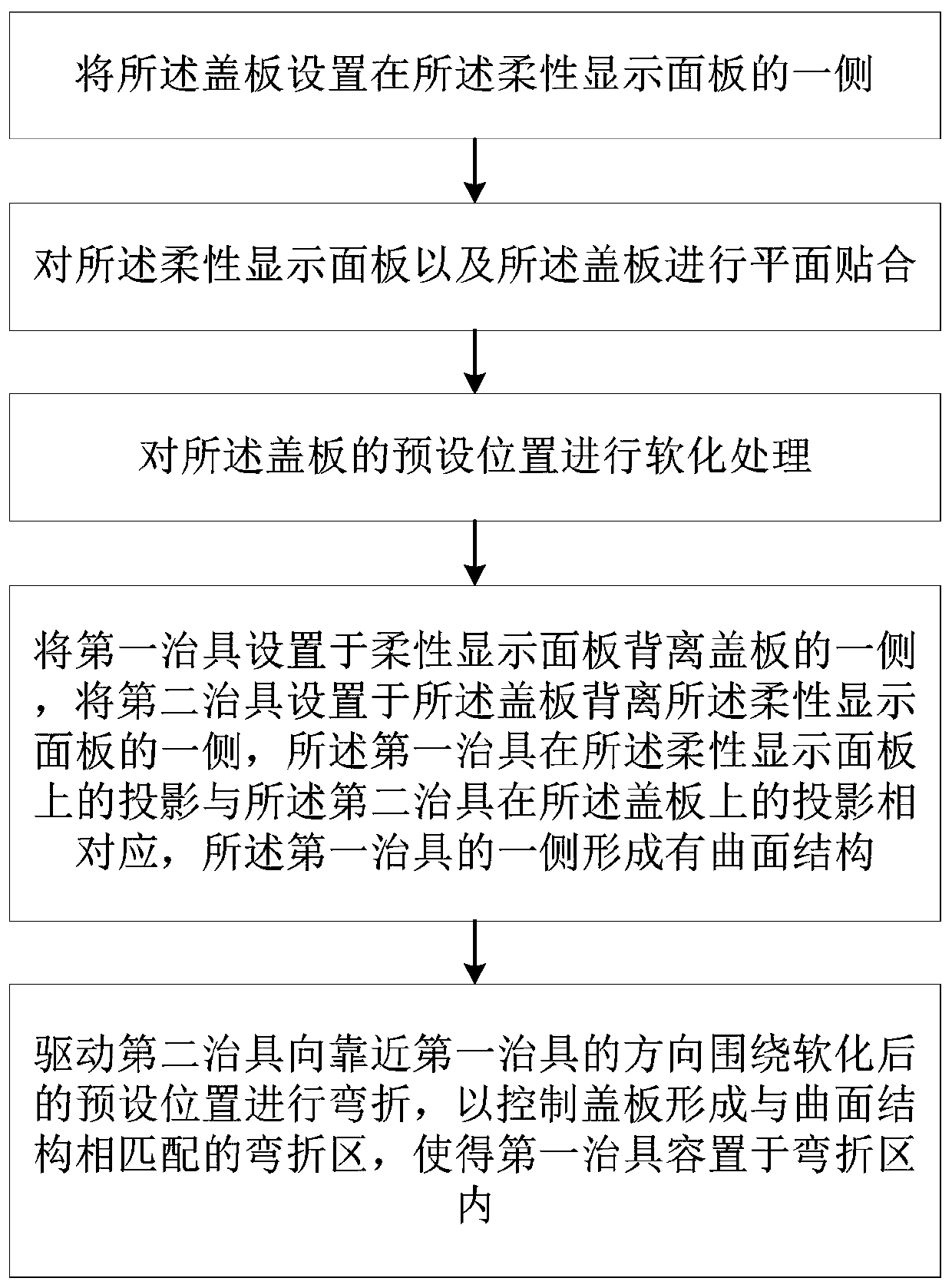

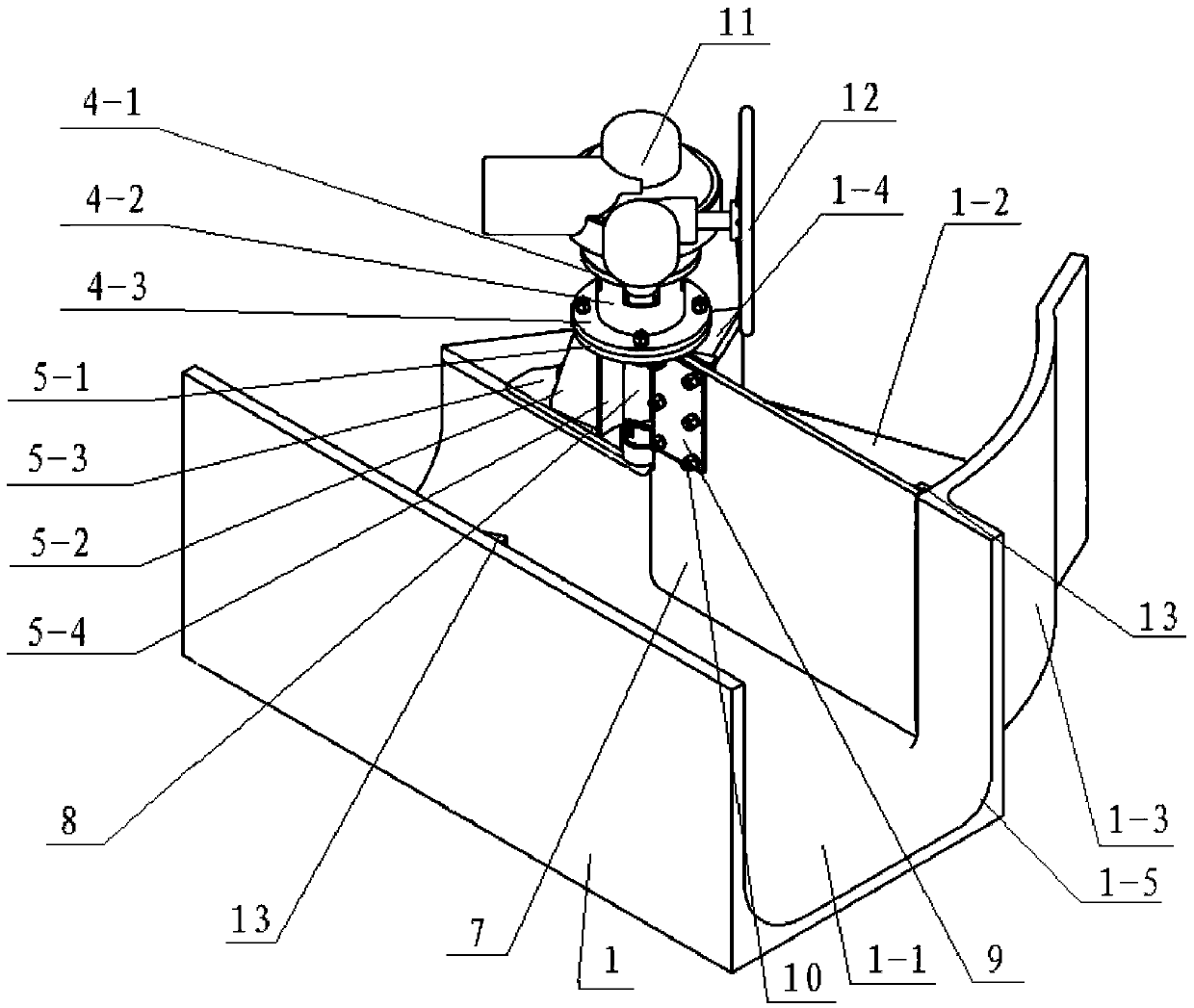

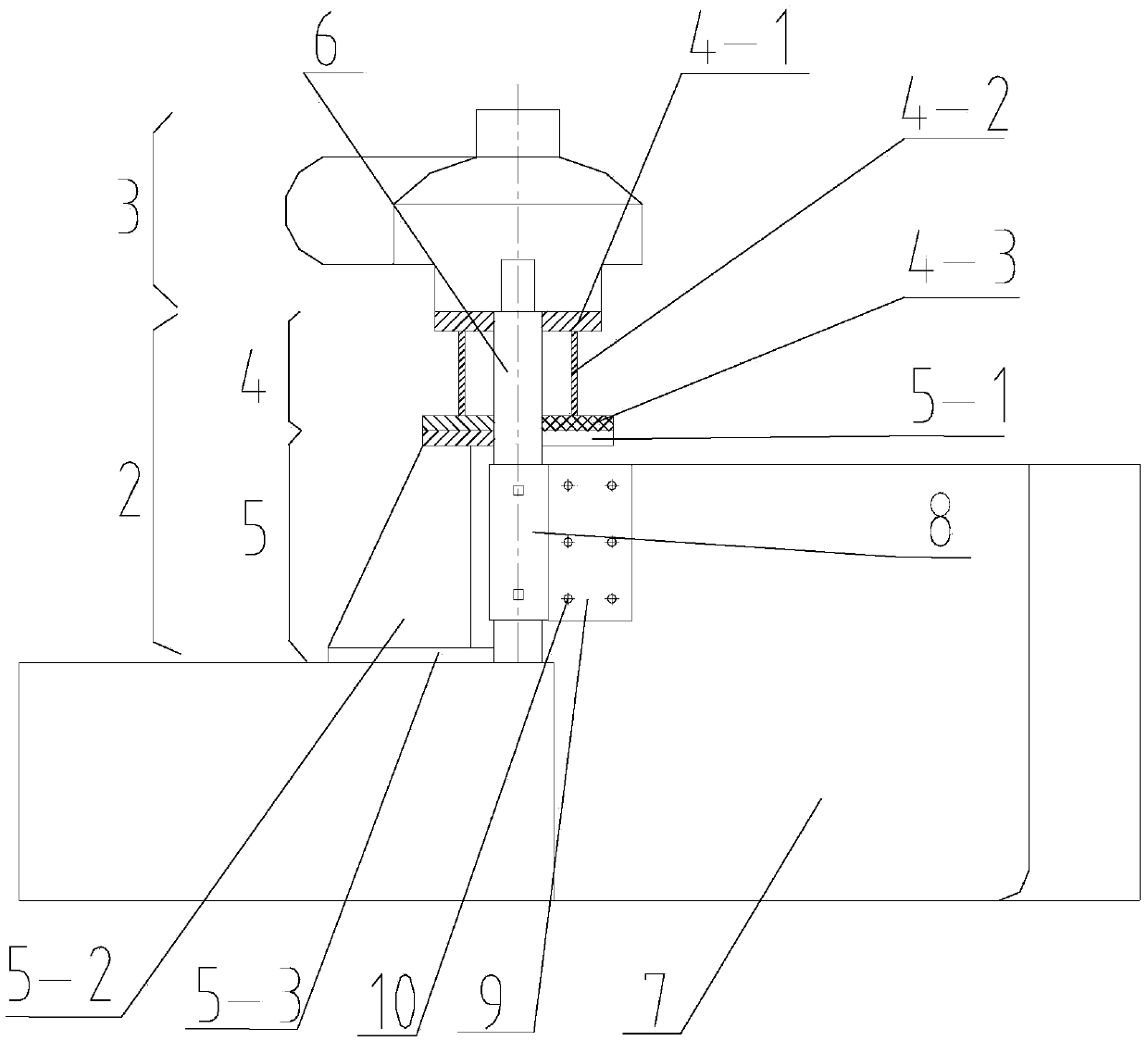

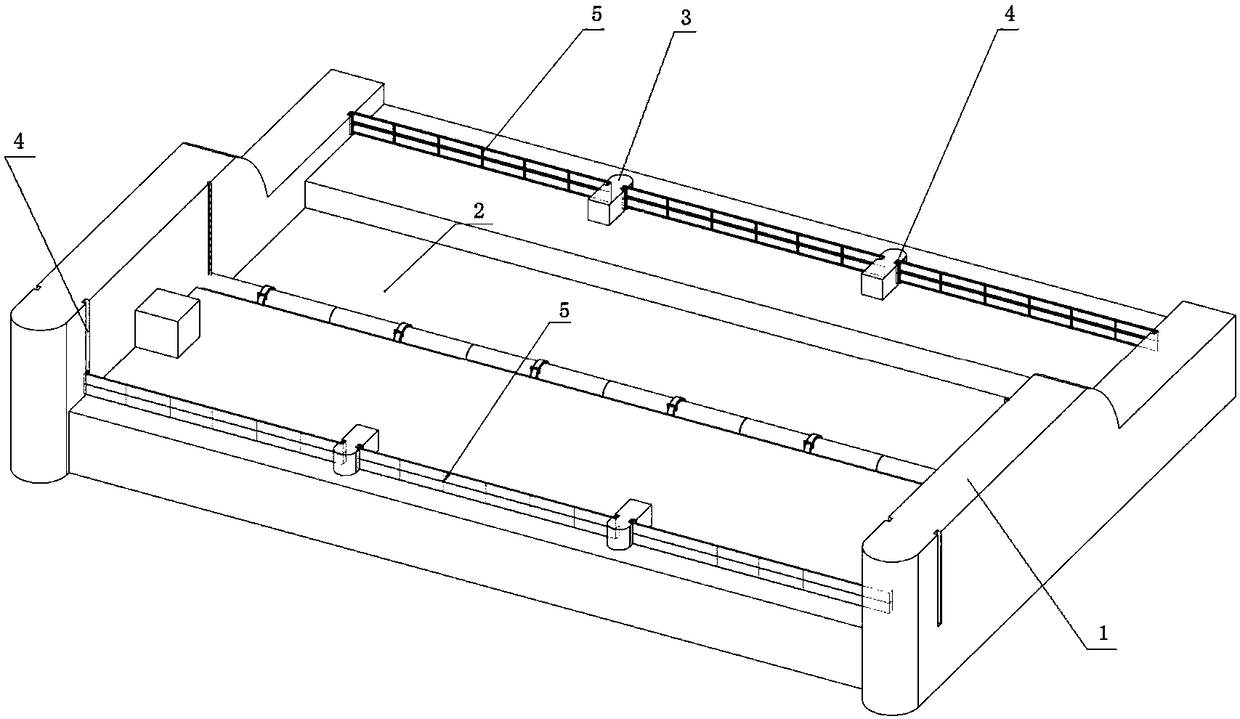

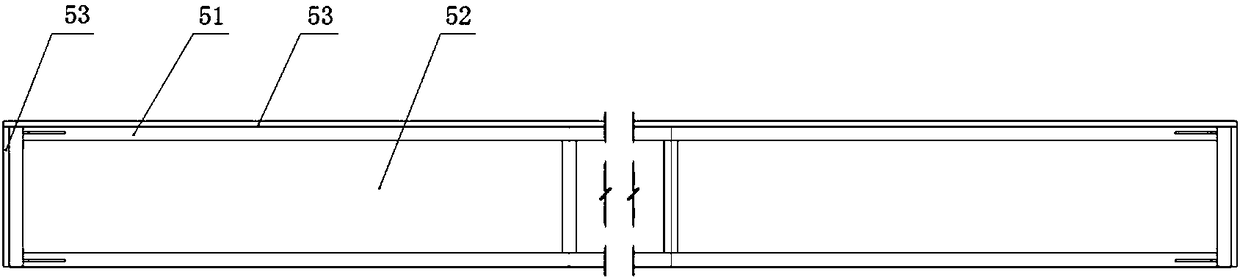

Laminating method and laminating device

ActiveCN111261046AEasy to controlSave engineeringIdentification meansStructural engineeringMechanical engineering

The invention discloses a laminating method, which is used for laminating a flexible display panel and a cover plate, and comprises the following steps of: arranging the cover plate on one side of theflexible display panel; carrying out plane fitting on the flexible display panel and the cover plate; softening the preset position of the cover plate; arranging a first jig on one side, deviating from the cover plate, of the flexible display panel, and arranging a second jig on the side, away from the flexible display panel, of the cover plate, wherein the projection of the first jig on the flexible display panel corresponds to the projection of the second jig on the cover plate, and a curved surface structure is formed on one side of the first jig; and driving the second jig to be bent around the softened preset position in the direction close to the first jig, so that the cover plate is controlled to form a bent area matched with the curved surface structure, and the first jig is contained in the bent area. According to the invention, the product yield and the display effect are improved.

Owner:BOE TECH GRP CO LTD +1

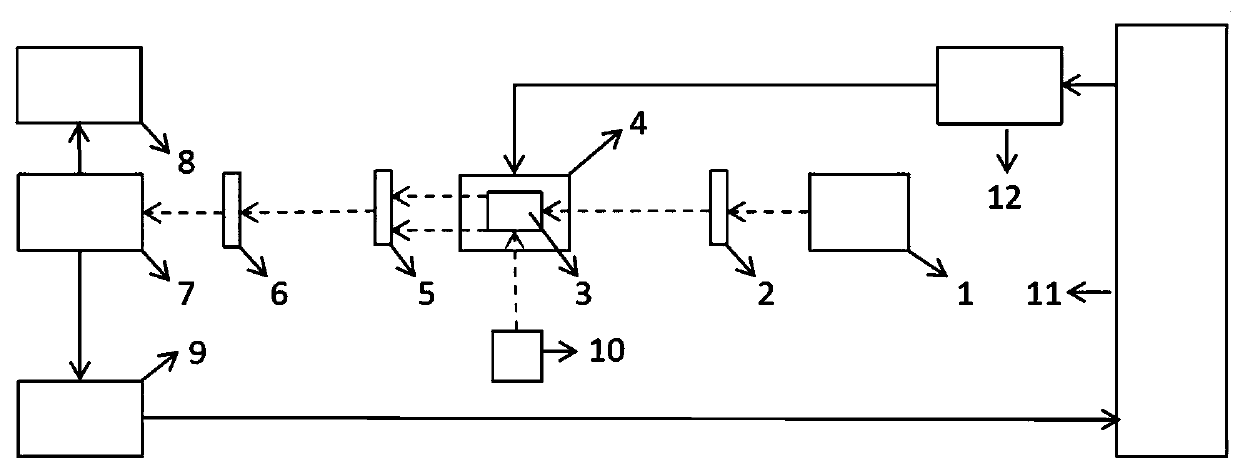

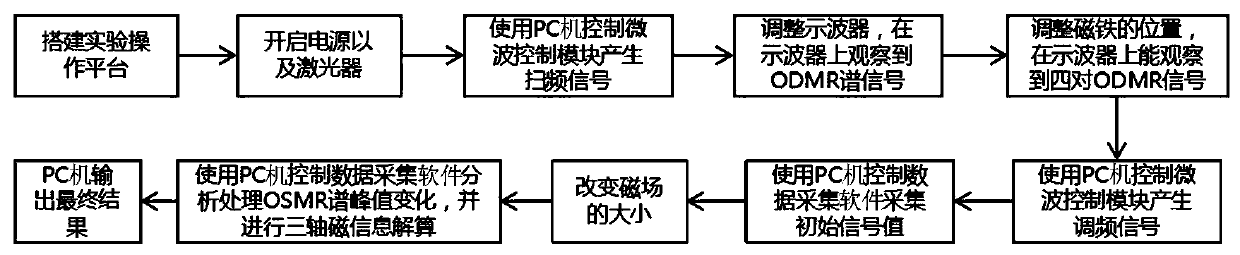

Single-path three-axis magnetic information detection method and system based on diamond NV color center

ActiveCN111521961AReasonable designSave engineeringMagnetic field measurement using magneto-optic devicesThree-component magnetometersMicrowave frequencyColour centre

The invention discloses a single-path three-axis magnetic information detection method and system based on a diamond NV color center. Under the action of laser and microwave swept-frequency signals, the diamond NV color center generates fluorescence, an optical signal acquired by a photoelectric detector is converted into an electric signal, and the ODMR spectrum of the diamond NV color center isobserved on an oscilloscope; the position of a magnet near the diamond is then adjusted; an ODMR spectrum for generating four pairs of peak values is obtained; frequency division regulation and control are performed on the microwave control module through the PC, four paths of microwave frequency signals of the single-side ODMR, which are output at equal frequency difference and equal time sequence, are generated; the data acquisition software acquires and records the signalas an initial value, changes the size of an external magnetic field, repeats the data acquisition step, compares the acquired new data with the initial value, performs electromagnetic information conversion and three-axis magnetic information calculation, and finally a final magnetic field change result is outputted bythe PC. The detection method is simple and convenient, large-scale experimental equipment and space are saved, and the experimental efficiency is improved.

Owner:ZHONGBEI UNIV

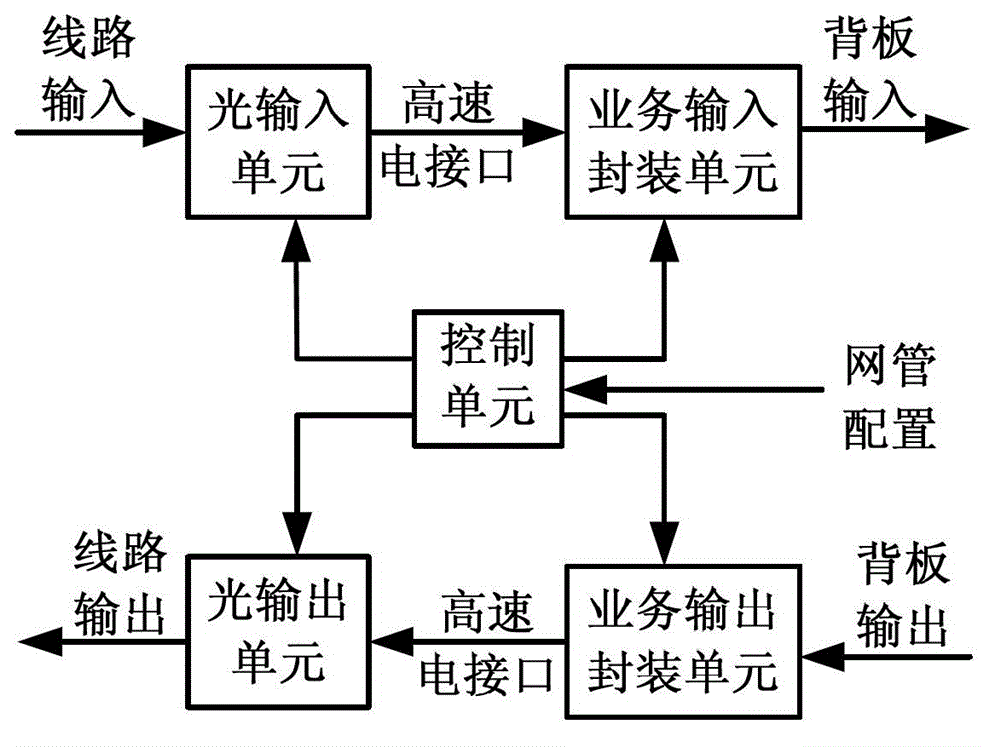

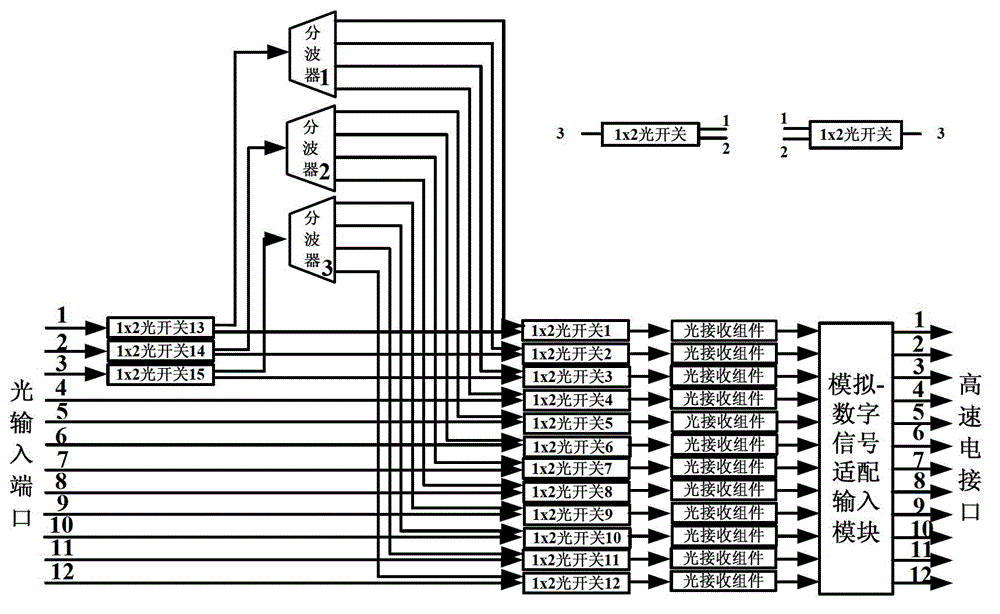

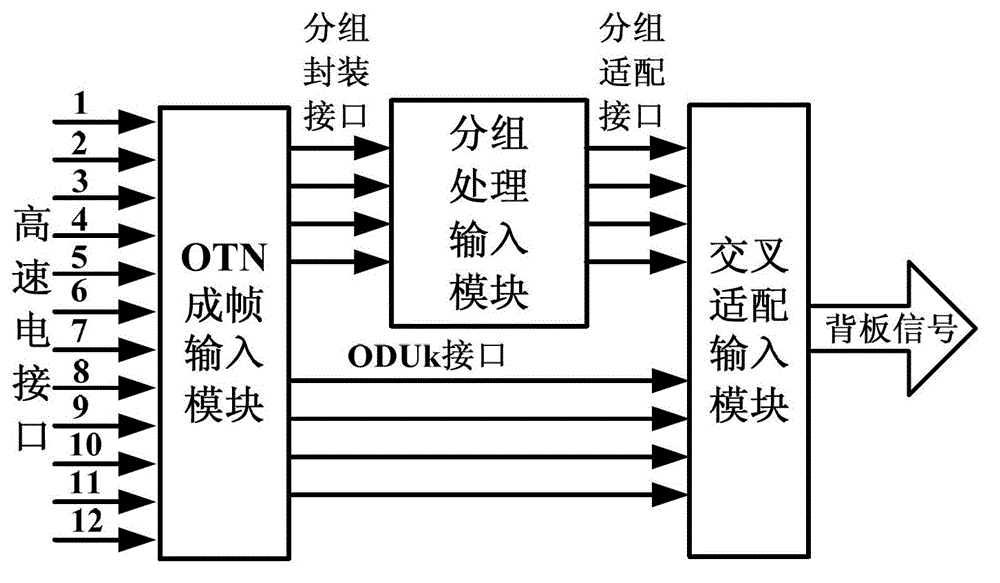

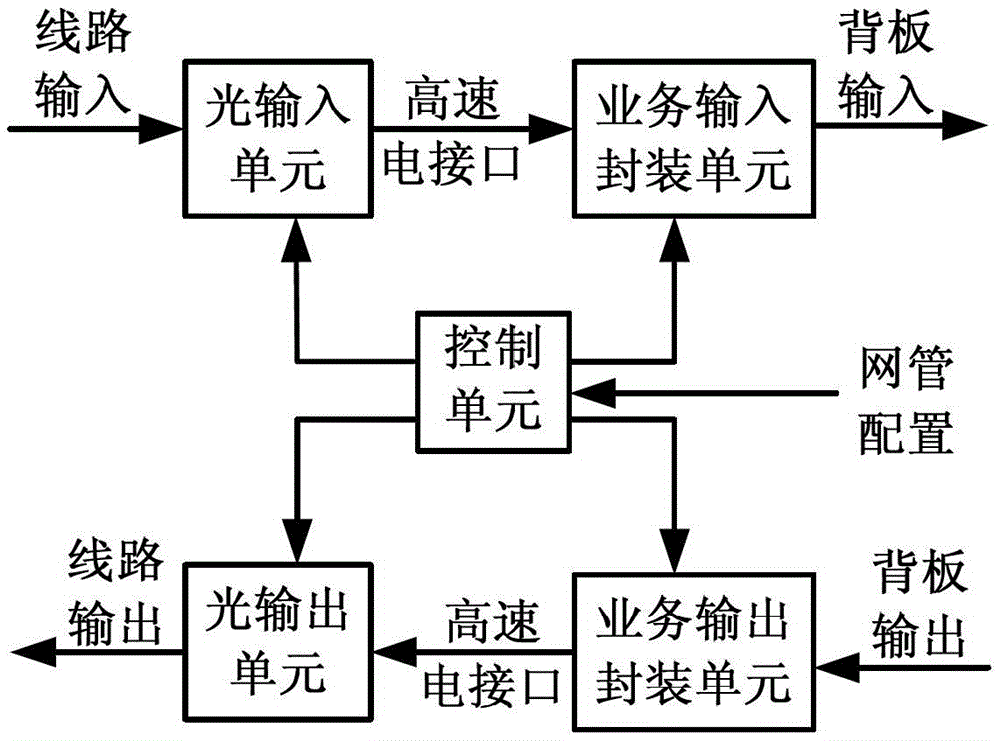

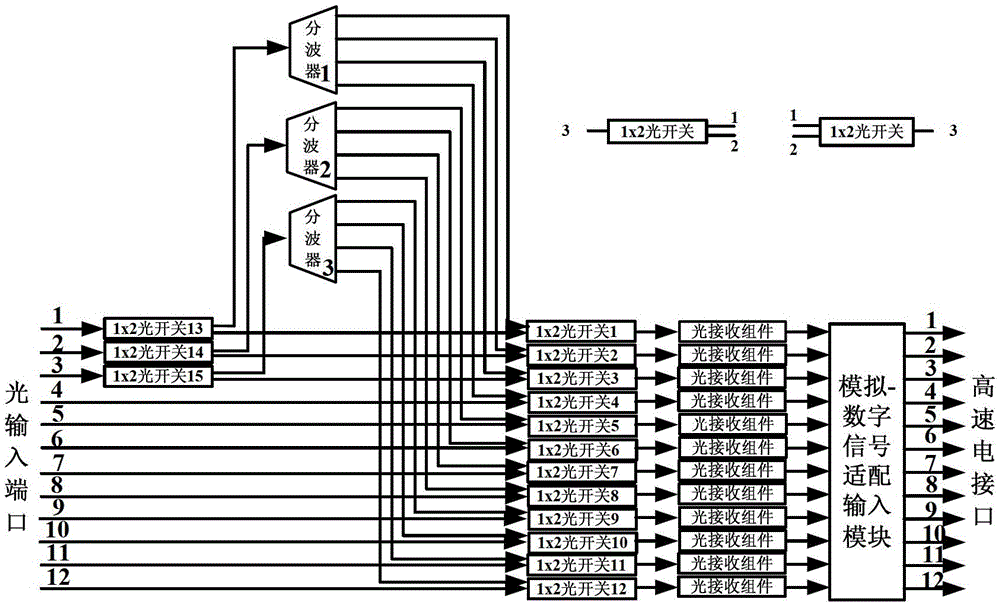

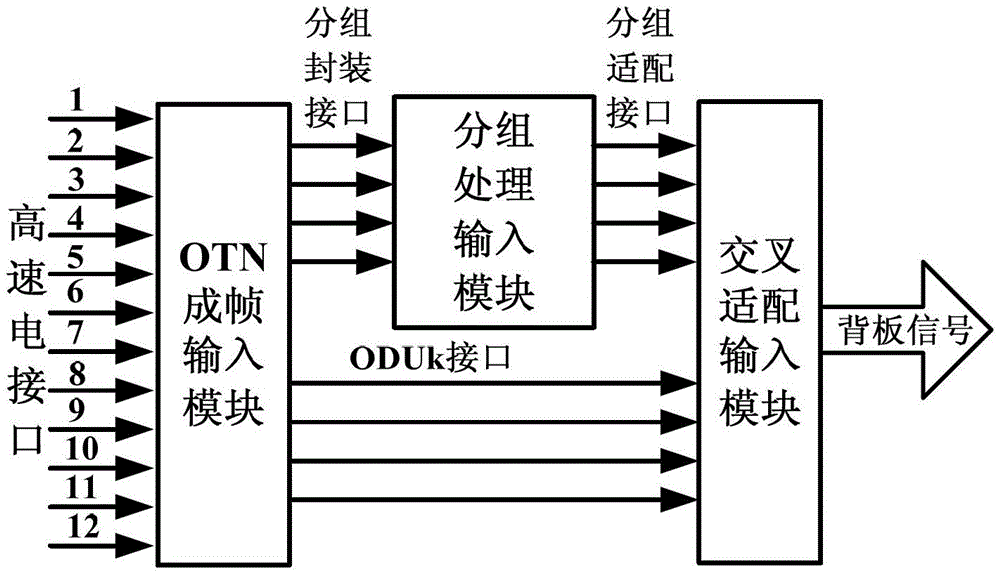

Common service access device and method adaptable to services of 1-11 Gbit/s, 40 Gbit/s and 100 Gbit/s

The invention discloses a common service access device and method adaptable to the services of 1-11 Gbit / s, 40 Gbit / s and 100 Gbit / s and relates to the field of optical fiber communications. The common service access device comprises a control unit, a light input unit, a light output unit, a service input encapsulation unit and a service output encapsulation unit, wherein the control unit is connected with the light input unit, the light output unit, the service input encapsulation unit and the service output encapsulation unit respectively; the light input unit comprises a plurality of light input ports, a plurality of wave separators and a plurality of high-speed electrical interfaces I; the light output unit comprises a plurality of light output ports, a plurality of wave combiners and a plurality of high-speed electrical interfaces II; the light input unit is connected with the service input encapsulation unit through the high-speed electrical interfaces I; the service output encapsulation unit is connected with the light output unit through the high-speed electrical interfaces II. The common service access device and method can be adaptable to the service access of rates and agreements of 1-11 Gbit / s, 40 Gbit / s and 100 Gbit / s, so that the types of the cards are reduced; a series of costs of the cards such as the design cost, the production cost and the engineering cost are lowered.

Owner:FENGHUO COMM SCI & TECH CO LTD

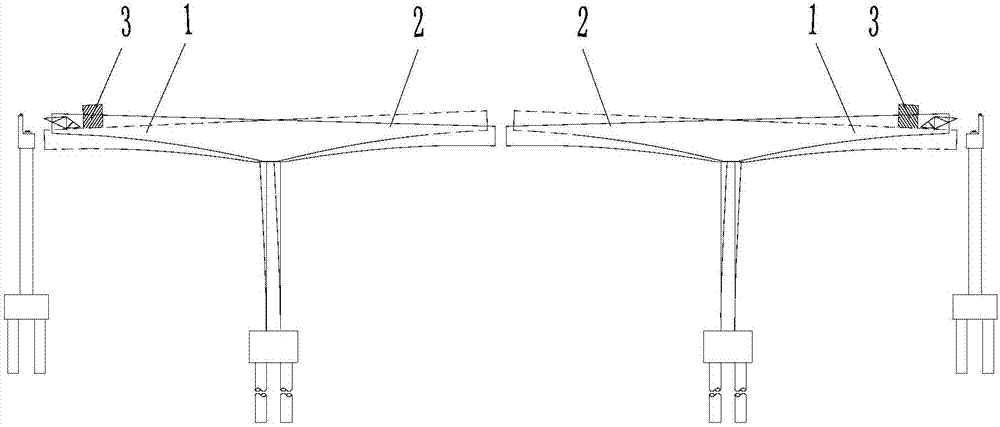

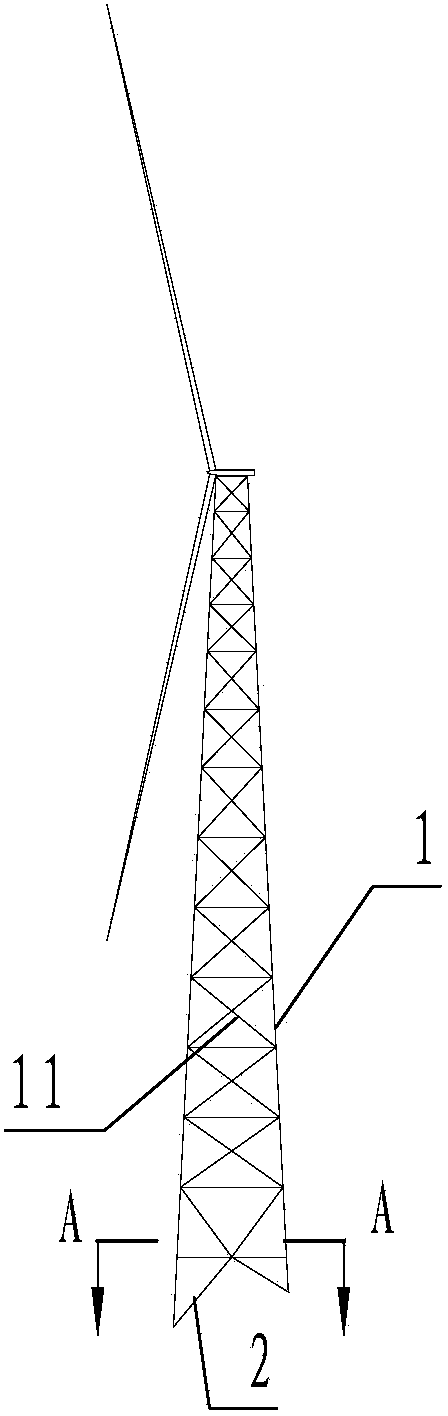

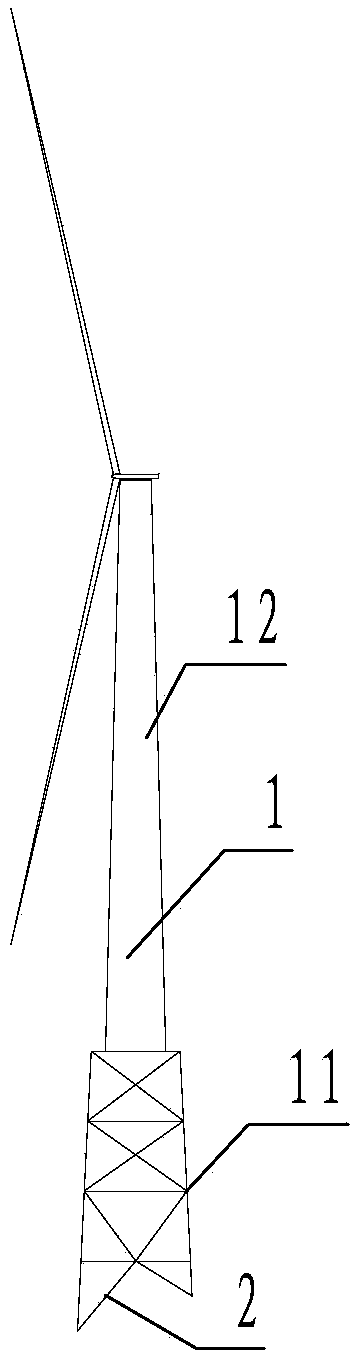

Wind power tower with long and short legs

The invention discloses a wind power tower with long and short legs. The wind power tower comprises three or more supporting legs, wherein the supporting legs are different in length and arranged at the bottom of the tower. The wind power tower with the long and short legs is composed of a tower body and the tower legs, wherein the tower body is further divided into an upper part and a lower part, the upper part is of a conical or latticed structure, and the lower part is of a latticed or conical structure. The wind power tower with the long and short legs has the advantages of being convenient to machine, transport and assemble and the like. Because the structure of the long and short legs is adopted for the tower, when the wind power tower is applied to gradient terrains in mountainous areas, earth rock excavation can be reduced, the construction period is greatly shortened, and meanwhile water and soil loss and damage to the biological environment are effectively reduced. Besides, the foundation manufacturing cost and the weight of the tower can be remarkably reduced due to the structure of the long and short legs, and thus the wind power tower with the long and short legs has significant social benefits and economic benefits.

Owner:福建永福铁塔技术开发有限公司 +1

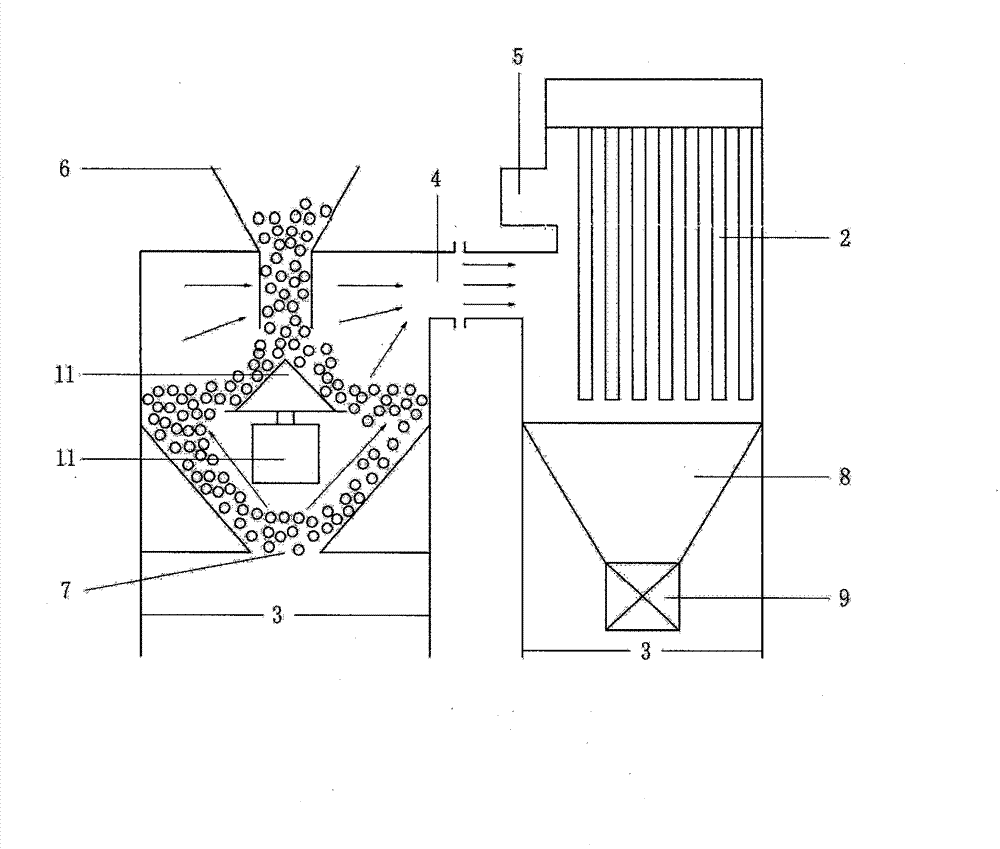

Centrifugal dedusting equipment for mine stones

InactiveCN102772970AEfficient purificationImprove build qualityCombination devicesBaghouseEngineering

The invention provides centrifugal dedusting equipment for mine stones, comprising a support, a centrifugal machine and a pulsed bag filter, wherein the centrifugal machine and the pulsed bag filter are arranged on the support side by side and are communicated with each other by a pipeline, and the upper part of the pulsed bag filter is provided with a draught fan. According to the centrifugal dedusting equipment, in the crushing and producing process of the mine stones, the centrifugal dedusting equipment is added between a crusher and a screening device, so that due to the synergistic effect of the mechanical centrifugal force and the reversed air charging, the stones in the process of producing can be further purified, the dust pollution of the mine production site can be thoroughly eliminated, the quality of the building stones can be effectively improved, and the quality of a building can be guaranteed. The product has the advantages that the dedusting effect is good, the dead angle of a dedusting device in the crushing and producing process of the mine stones can be eliminated, the equipment is safe and reliable to use and is beneficial for the environment protection of the mine production, etc.

Owner:哈尔滨市阿城区昌利矿山除尘设备厂

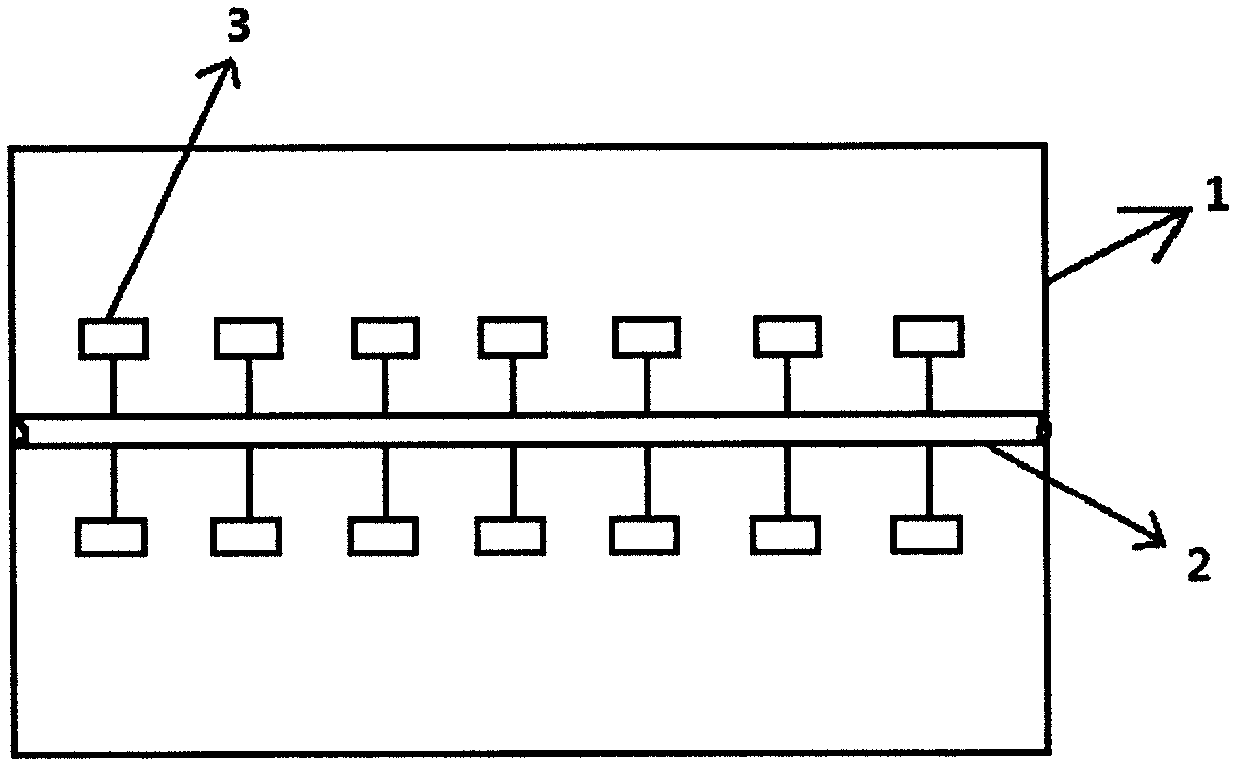

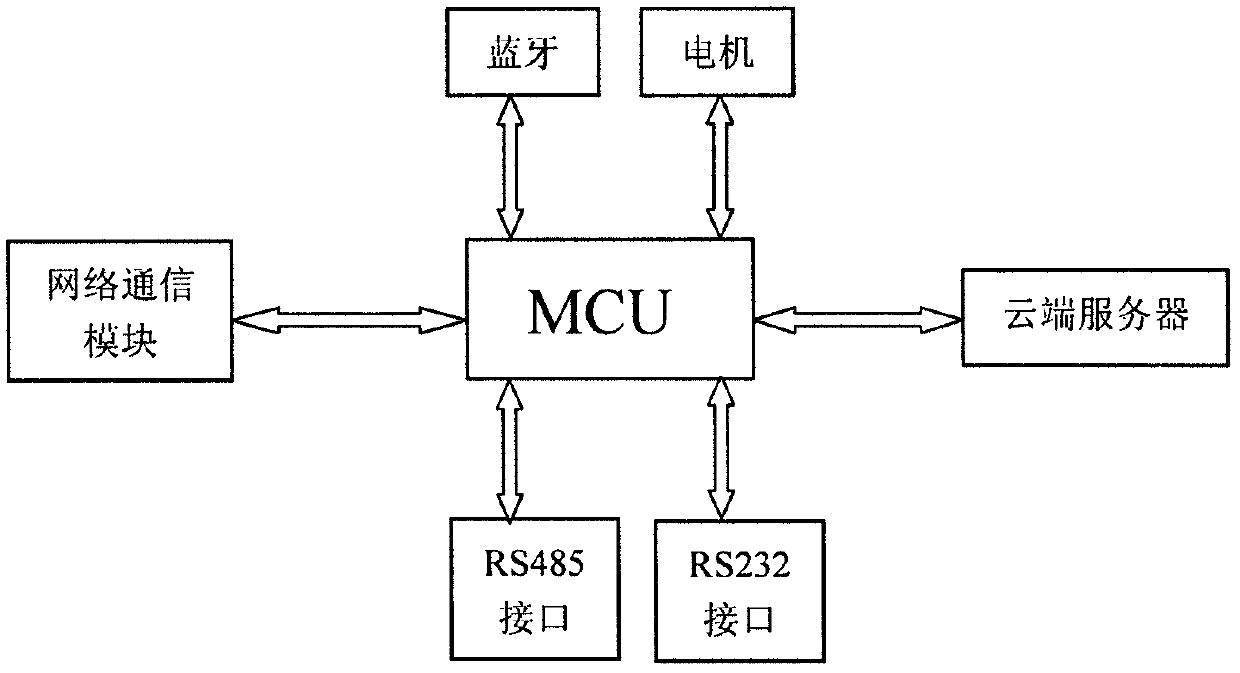

Standardized parking system for shared bicycles

InactiveCN109671261ADoes not affect experienceReduce loss rateRoad vehicles traffic controlMicrocontrollerParking area

The invention relates to the field of shared bicycles, in particular to a standardized parking system for shared bicycles. The standardized parking system comprises a parking pile used for parking theshared bicycles, two USB-to-RS485 interfaces or two USB-to-RS232 interfaces are formed in the parking pile at each interval of 0.5 m, and the interfaces are used for being connected with microcontrollers on shared bicycle locks; all the shared bicycles are provided with the corresponding interfaces; and after the shared bicycles enter a standardized parking area, the USB-to-RS485 interfaces or the USB-to-RS232 interfaces are connected with interfaces reserved in the shared bicycle locks, a unique ID certificate of a bicycle is identified, and thus standardized parking is completed. By adopting the standardized parking system, under the situation of ensuring that user experience and the management mode of a bicycle operator are not affected as much as possible, standardized parking is realized to the maximum extent, convenience is provided for traffic management of cities, and thus development of sharing economy is greatly promoted.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

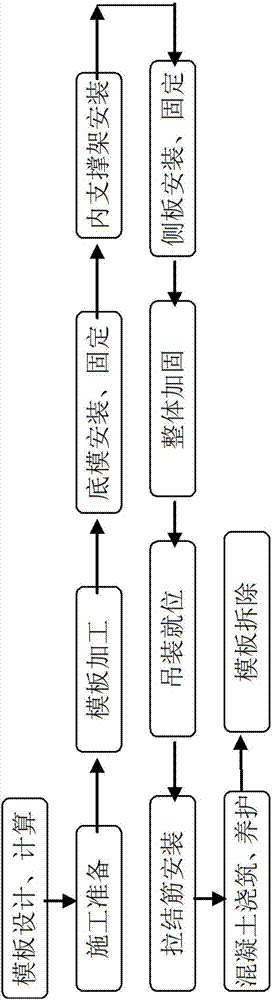

Installation and construction method of high formwork of super high-rise elevator shaft

ActiveCN107503365AFast constructionShorten the construction periodFoundation engineeringEngineeringRebar

The invention discloses an installation and construction method of a high formwork of a super high-rise elevator shaft. The installation and construction method comprises two stages including a construction preparation stage and a construction operation procedure, wherein the construction operation procedure comprises the steps of (1) processing the formwork, (2) installing and fixing a bottom die, (3) installing an inner support frame, (4) installing and fixing a side die, (5) integrally reinforcing, (6) hoisting a box body in place, (7) installing a connecting reinforcement, (8) pouring concrete, and monitoring, and (9) removing the formwork. According to the reinforcement and construction method of the high formwork of the super high-rise elevator shaft, traditional formworks, battens and steel pipes are used as raw materials, the formworks are used as face plates, the battens are used as inner ridges, the steel pipes are used as outer ridges so as to manufacture the box body, a lifting machine is installed in the elevator shaft, steel pipe supports are arranged in the box body so as to solve the problem of side pressure of concrete to the box body, the box body is locked by adopting the steel pipes so as to solve the problem of floating resistance of the box body to the concrete, and the steel pipes are connected with bottom reinforcements of a raft by utilizing round steel.

Owner:SHANGHAI BAOYE GRP CORP

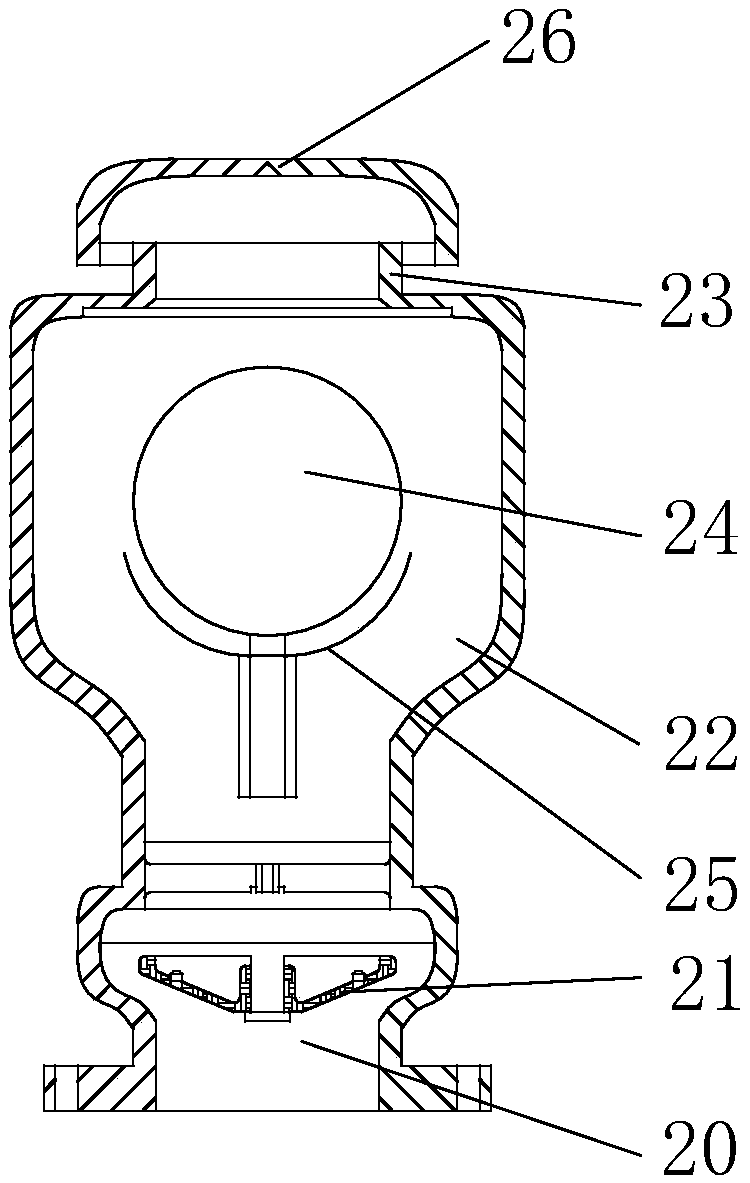

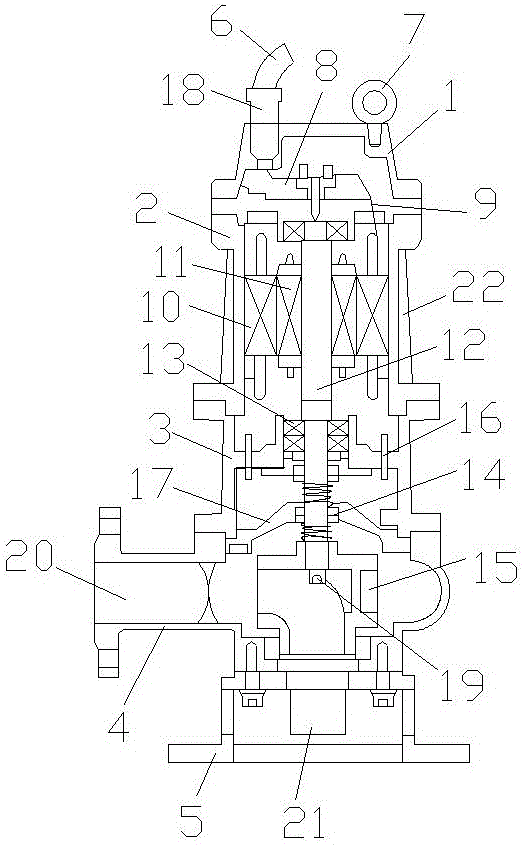

Submersible pump

InactiveCN105090056ACompact structureReduce volumeGeneral water supply conservationPump componentsImpellerWater leakage

The invention discloses a submersible pump. The submersible pump comprises a motor cover, a motor shell, an oil tank, a pump body and a base, wherein the motor cover, the motor shell, the oil tank, the pump body and the base are arranged from top to bottom in sequence; a cable and a hanging hook are arranged on the motor cover; a wire connecting plate and a first water leakage detecting probe are arranged in the motor cover; the cable, the wire connecting plate and the first water leakage detecting probe are electrically connected in sequence; a stator, a rotor and a pump shaft are arranged in the motor shell; the stator is electrically connected with the wire connecting plate; the rotor is in transmission connection with the pump shaft; and a bearing, a sealing piece and an impeller are arranged on the pump shaft in sequence. The submersible pump greatly improves the dirt passing capacity, is compact in structure, small in size, low in noise, prominent in energy saving effect and convenient for maintenance, largely reduces the construction cost, and is convenient and reliable in use.

Owner:WUHU HUANQIU AUTO PARTS

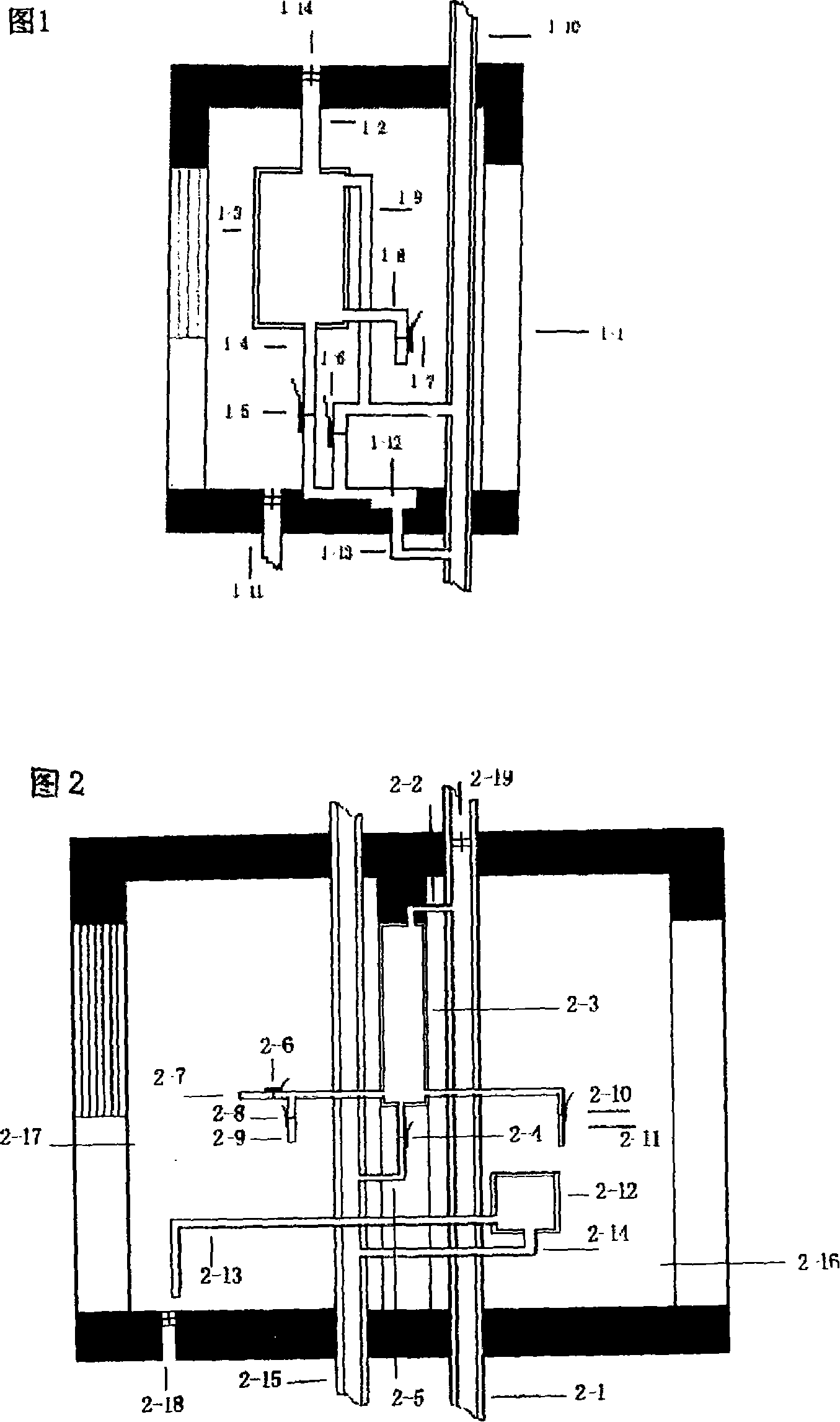

Swing type flow divider valve for sluiceway

The invention discloses a swing type flow divider valve for a sluiceway. The swing type flow divider valve comprises a groove body, a valve body and a transmission device. The groove body is of a three-way structure, a main groove of the three-way groove body is in butt joint with a main sluiceway body and fixed in a welding mode, a branch groove of the three-way groove body is in butt joint with a branch sluiceway body and fixed in a welding mode, the lower portion of a valve frame of the valve body is connected with a main groove and branch groove included angle connecting plate of the groove body through a bolt, a valve plate connected with a main shaft of the valve body is arranged in the groove body, the transmission device is connected with the upper portion of the valve frame of the valve body through a bolt, the upper end of the main shaft of the valve body is in transmission connection with the transmission device, the transmission device drives the main shaft of the valve body to rotate to drive the valve plate of the valve body to swing, and thus closure transformation of the flow divider valve is achieved. Compared with the prior art, the swing type flow divider valve has the advantages that due to the adoption of the swing type flow divider valve, the sealing performance between the valve plate and the sluiceway is improved, the labor intensity of workers is relieved, the equipment maintenance amount is reduced, and near half investment can be reduced in a project compared with a wedge disc used in the past.

Owner:鞍钢集团工程技术有限公司

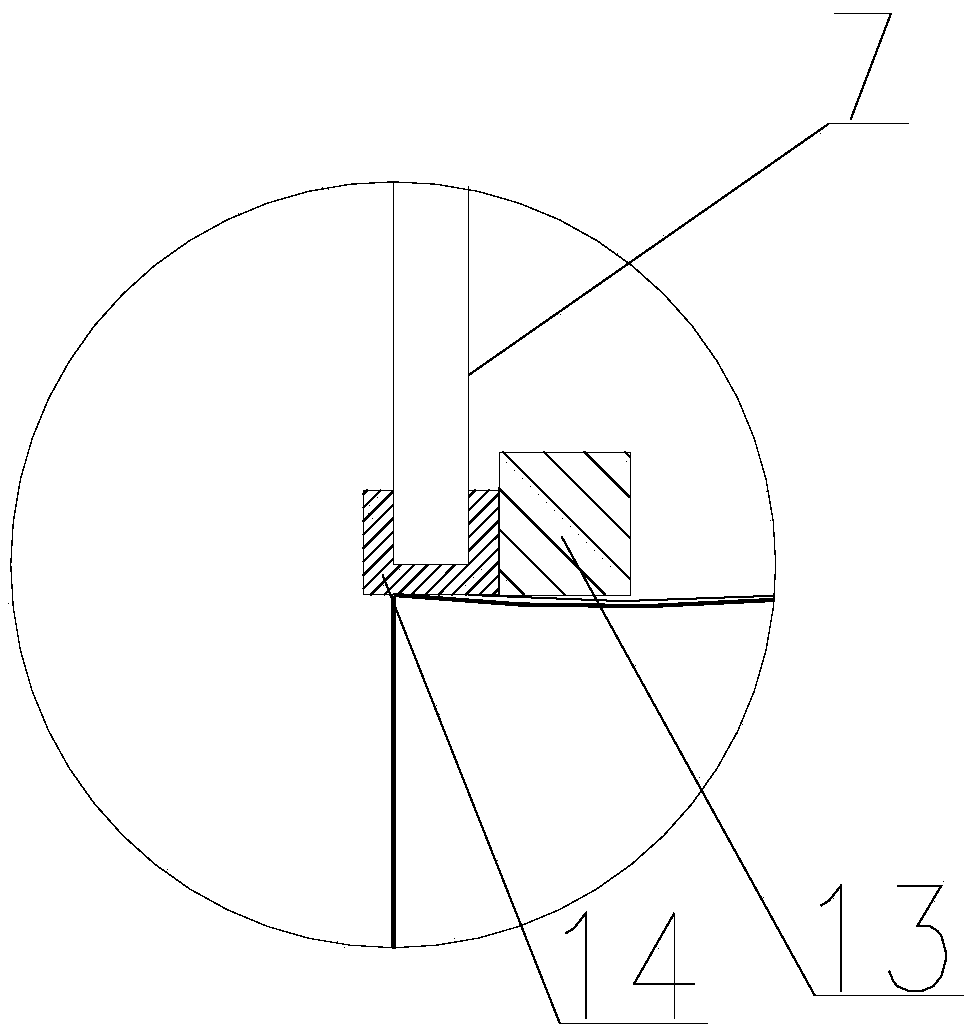

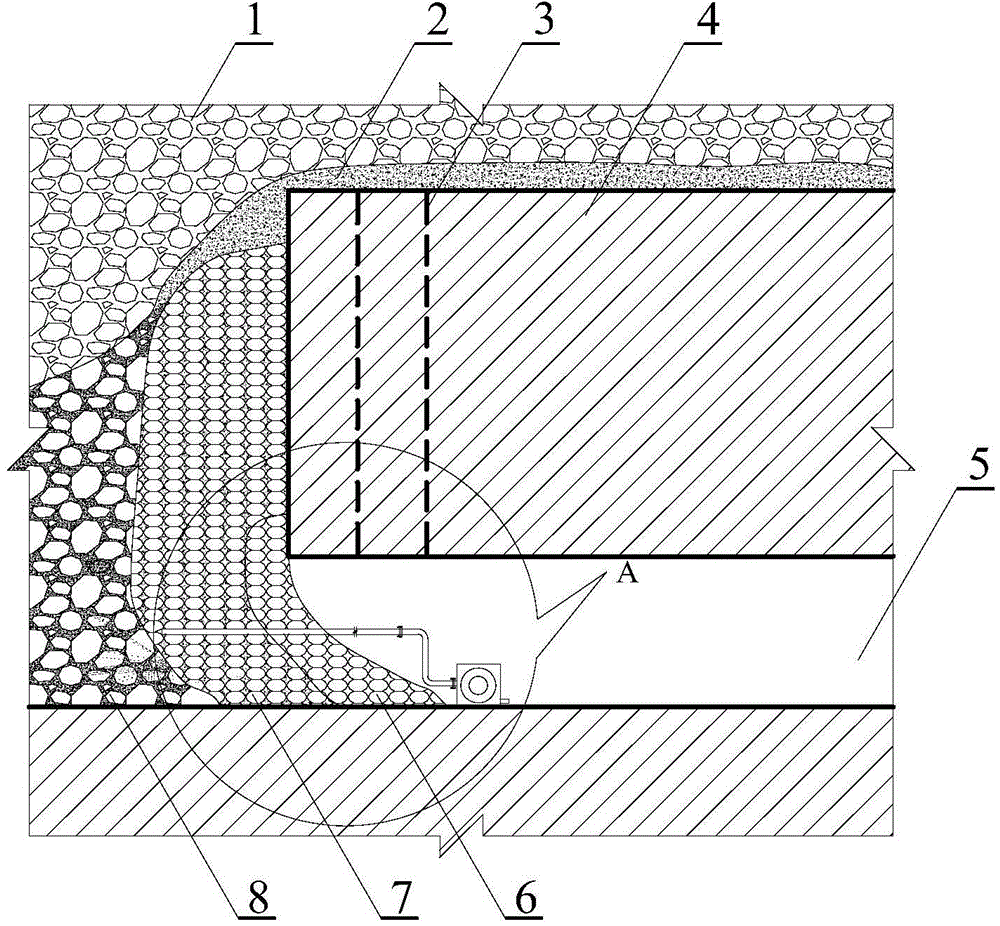

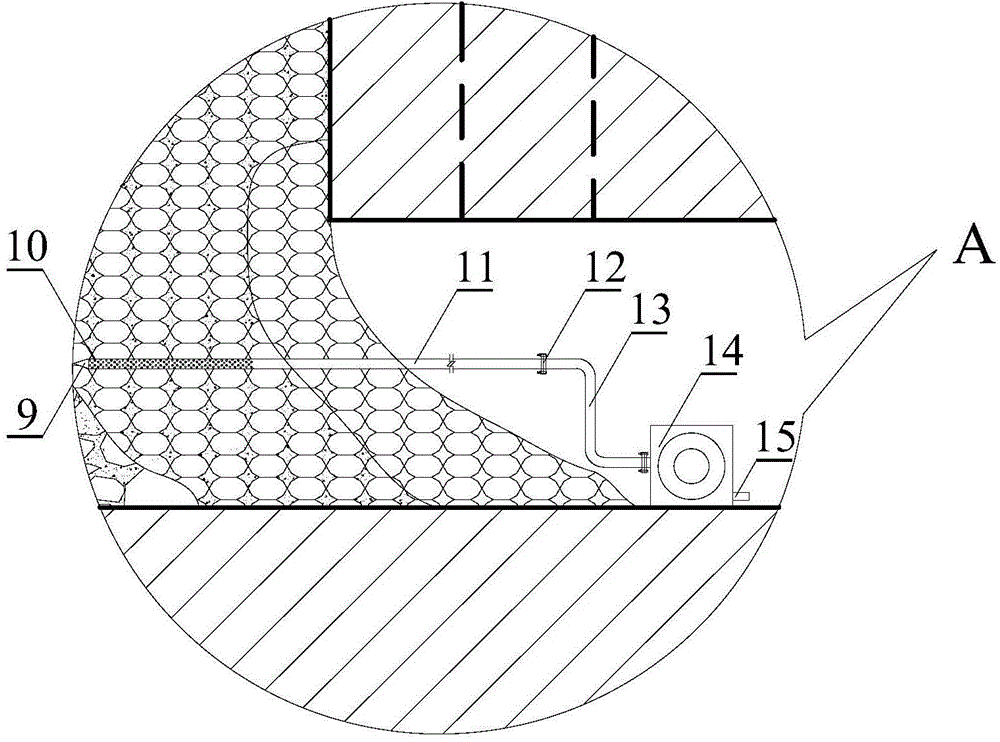

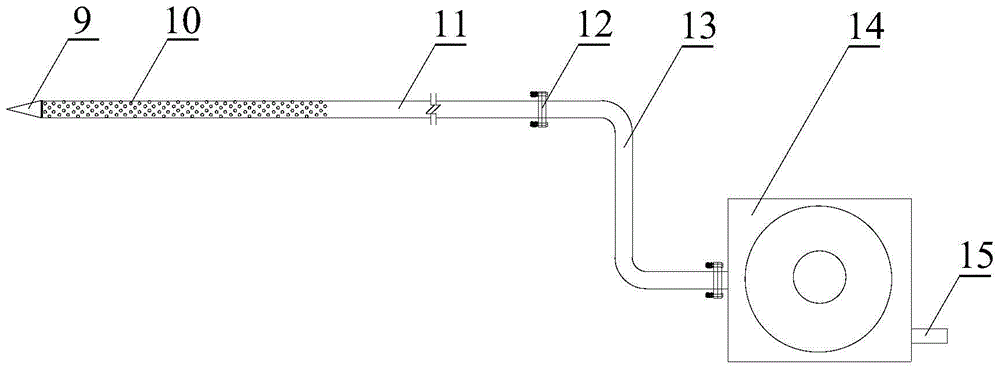

Stope debris flow treatment method in caving mining method and device thereof

ActiveCN104879129ASimple technologyEasy constructionUnderground miningSurface miningWater dischargeWater filter

Owner:CENT SOUTH UNIV

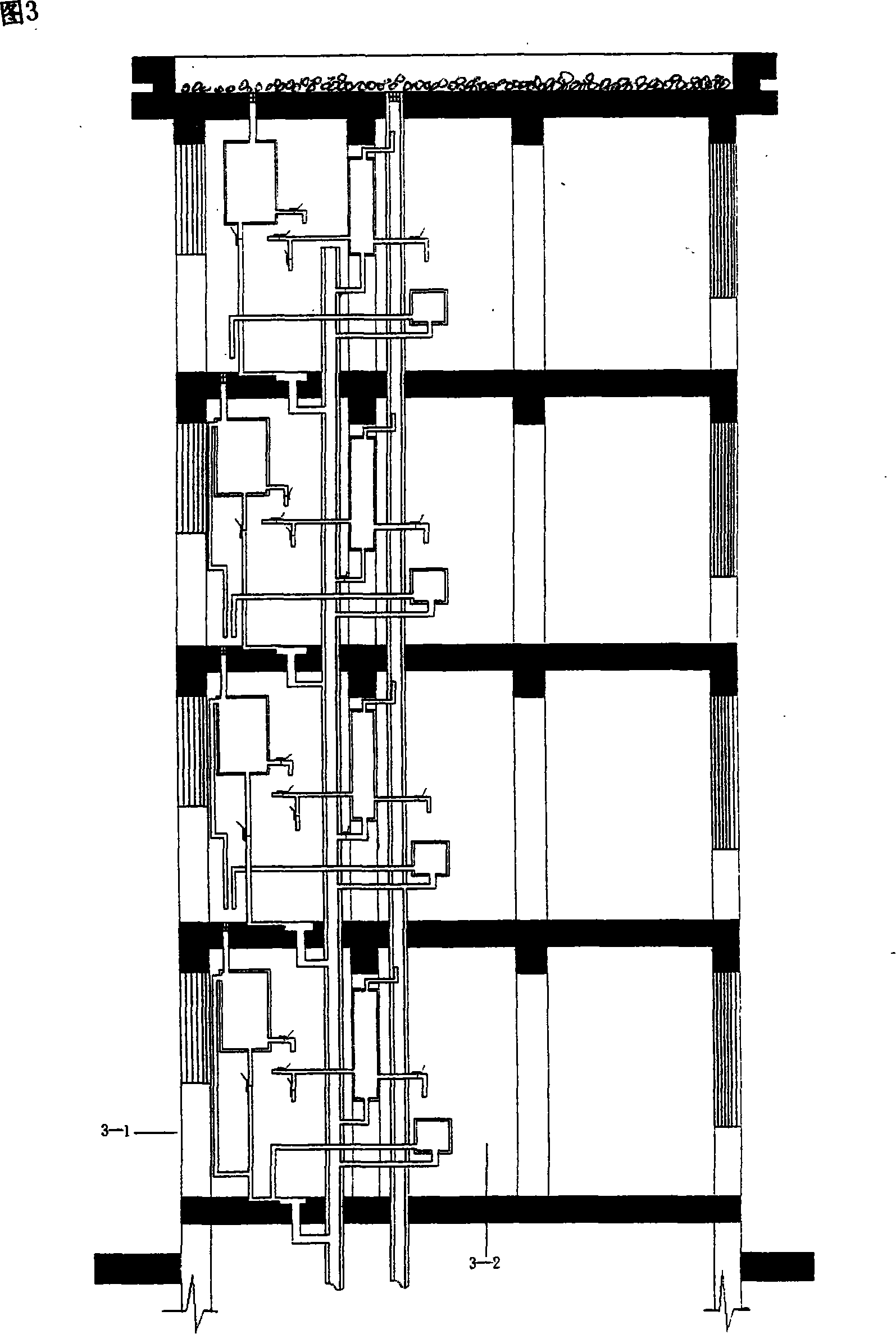

Large watercourse dam bulkhead gate

The invention discloses a large watercourse dam bulkhead gate. The large watercourse dam bulkhead gate comprises earth banks already constructed on the two sides; working areas for constructing a maingate dam are arranged in the earth banks; detection gate piles are correspondingly arranged on the upstream and the downstream places of the two outer sides of the working areas; corresponding gate slots are formed in the two sides of the detection gate piles and the inner side walls of the earth banks 1 on the two sides; and closed type bulkhead gates are inserted into the corresponding gate slots from top to bottom. Watercourse overcurrent in non-working areas are utilized effectively, and the working areas can be protected effectively during heavy rain or floods; the difficulties of a steel dam / hydraulic dam in later curing and maintenance are overcome, the curing danger and cost under raw water are reduced, and multiple projects which can not be maintained originally are optimized tobe maintainable projects; and the bulkhead gates of the large watercourse dam bulkhead gate are simple in structure, light in weight and convenient to operate and the cost is saved.

Owner:GAOYOU HENGLI HYDRAULIC WHOLE SET EQUIP

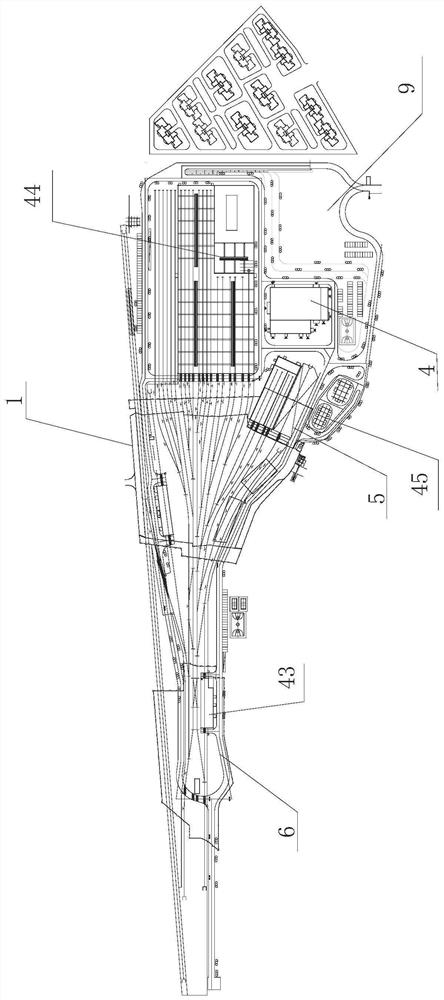

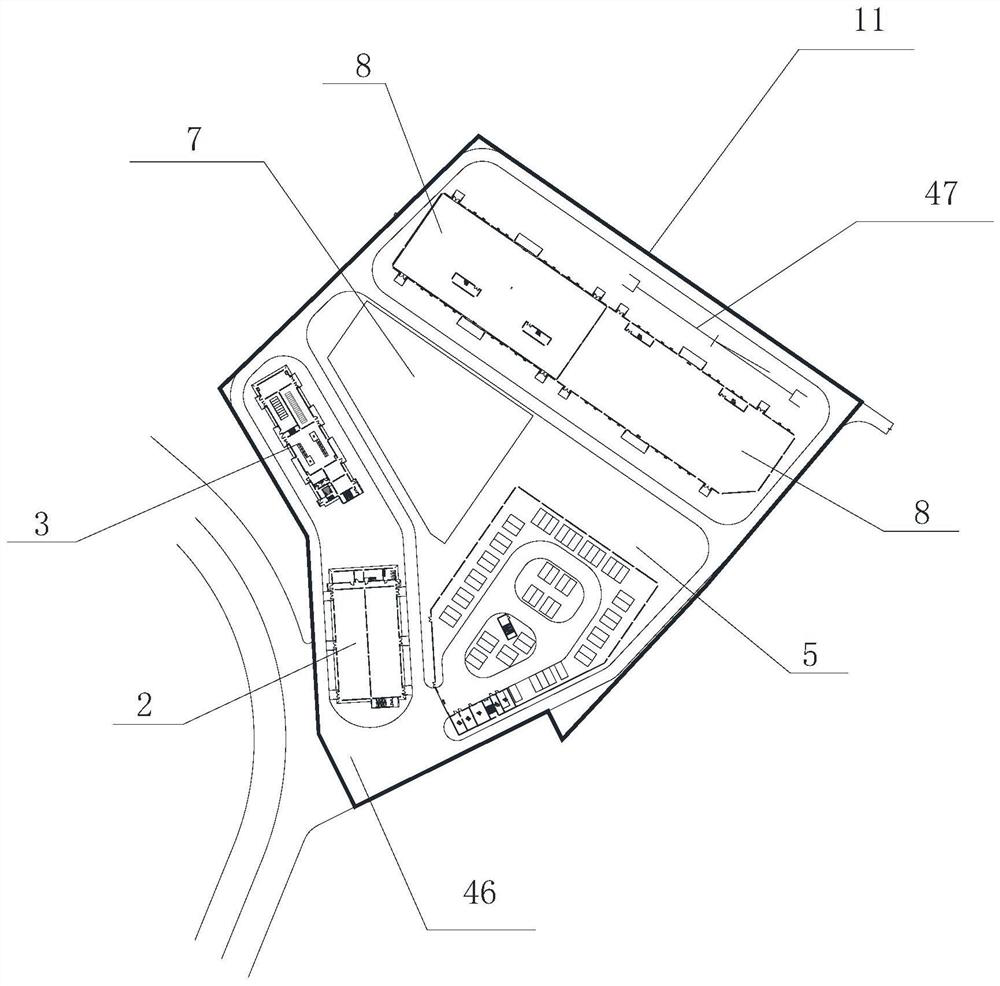

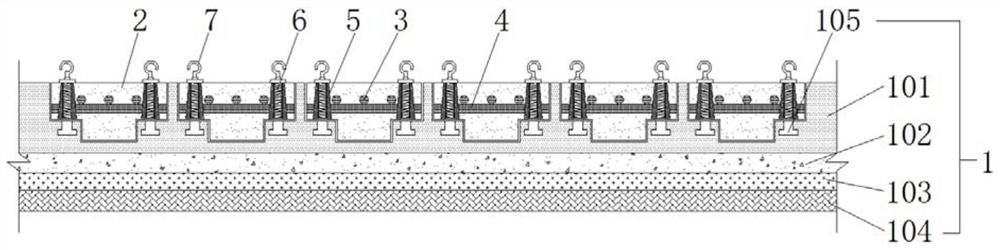

Rail transit vehicle base in area needing high fill

PendingCN113833345AReduce construction difficultyImprove construction progressBuilding insulationsSewage drainingRock engineeringArchitectural engineering

The invention provides a rail transit vehicle base in an area needing high fill. The rail transit vehicle base comprises an overhead plate, and the overhead plate is of a multi-layer concrete frame structure and comprises a top plate, a sandwich plate and a base layer which are arranged from top to bottom; the rail-mounted area structure of the rail transit vehicle base is arranged on the top plate and comprises a rail and a storeroom with the rail. The pre-yard area structure of the rail transit vehicle base is based on the natural ground elevation of a mountainous area and is arranged in a staggered mode relative to the rail-mounted area structure. The sandwich plate is provided with a functional room, a car parking lot and a connecting channel; a flood discharging channel is formed between the sandwich plate and the base layer. According to the technical scheme, the rail transit vehicle base is designed through an overhead plate structure, earth-rock engineering can be effectively reduced, the engineering investment and construction difficulty can be reduced, the overall structural stability is enhanced, post-construction settlement is effectively controlled, and the land utilization rate is increased.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

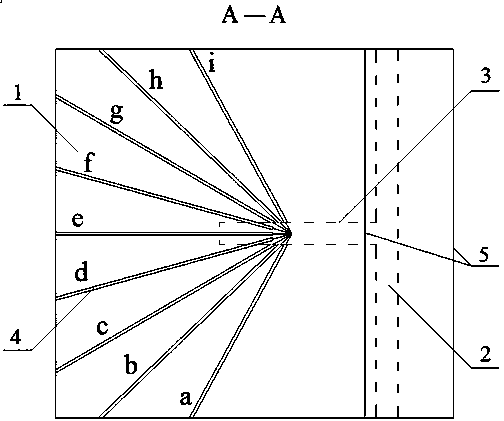

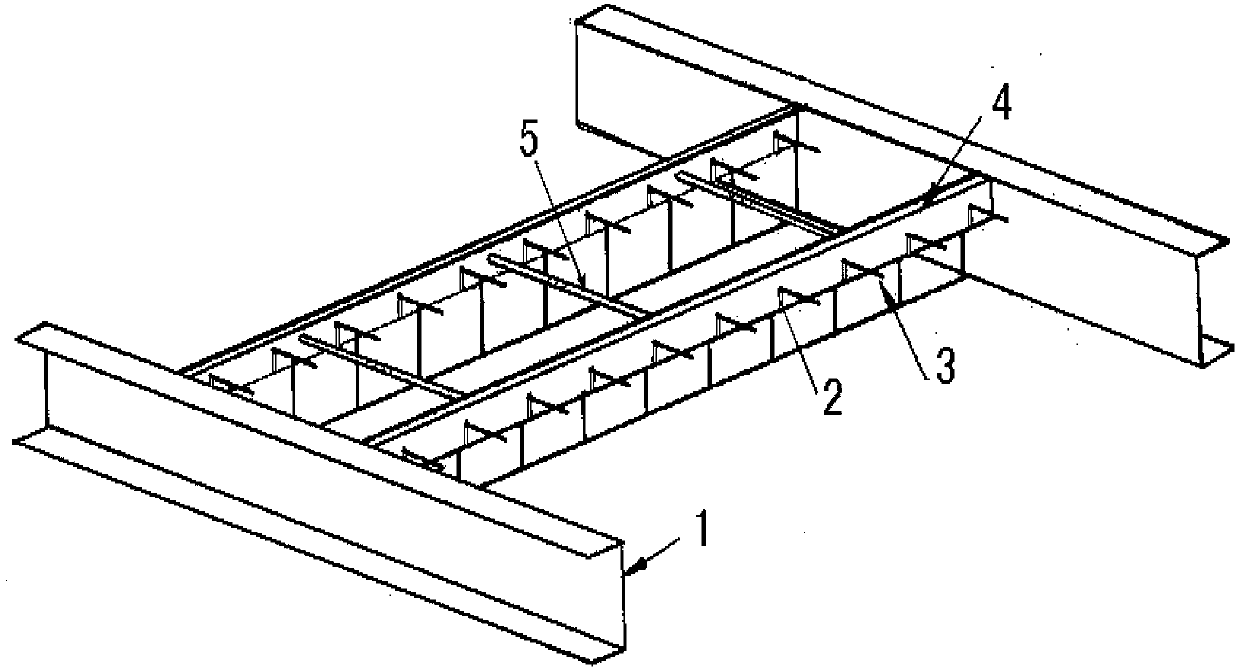

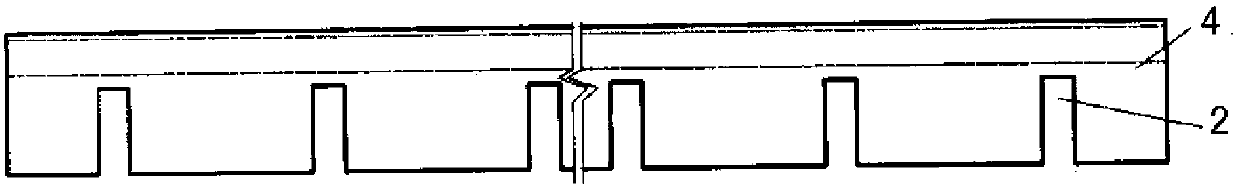

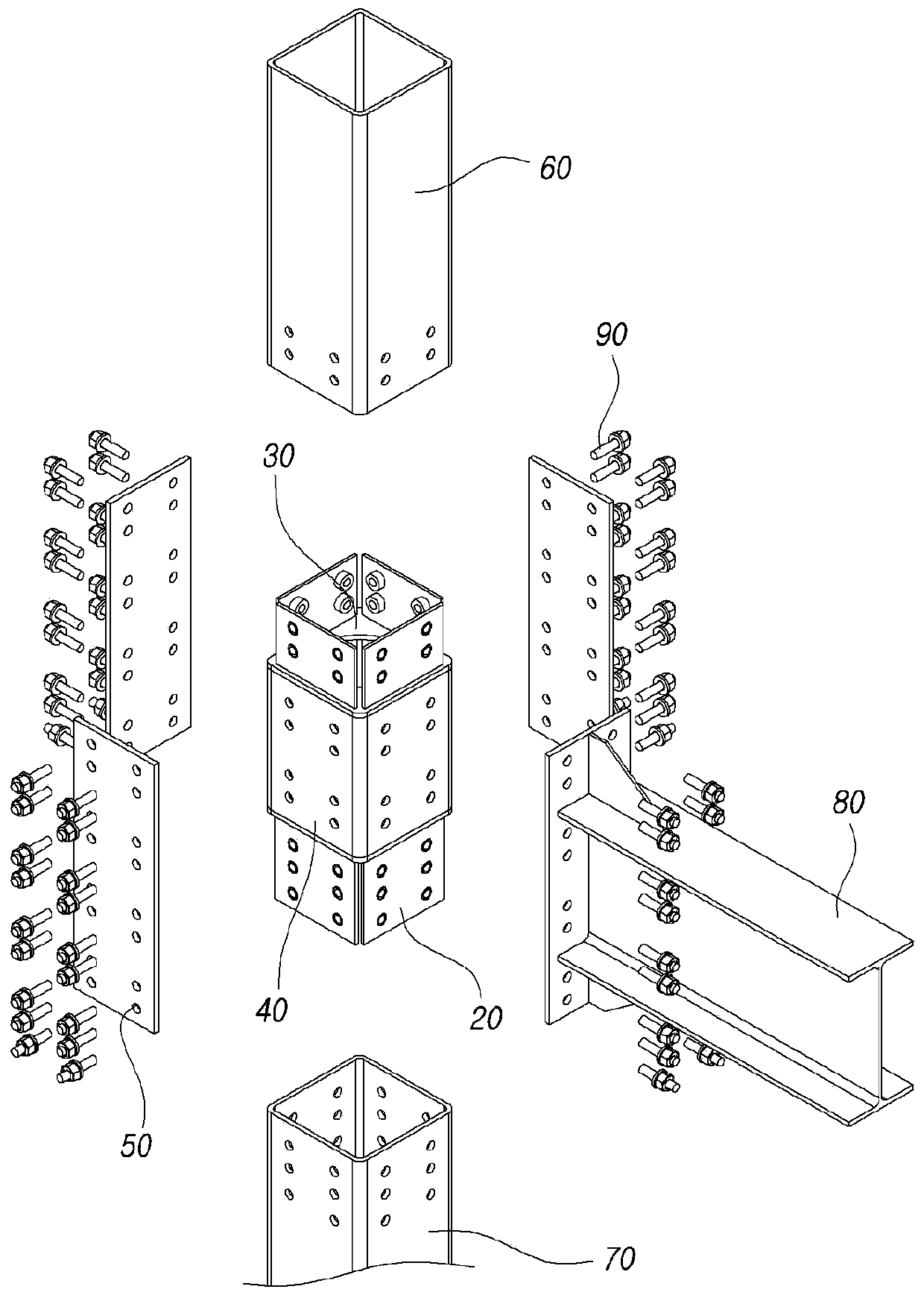

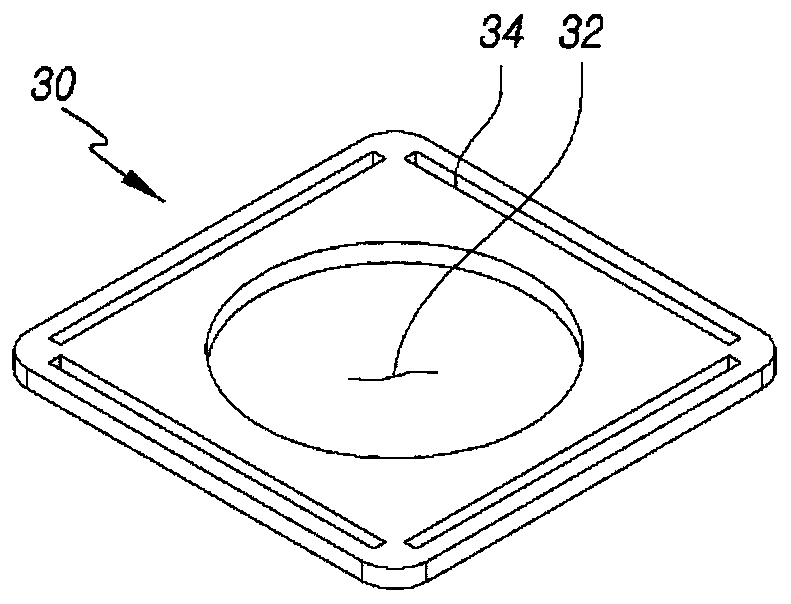

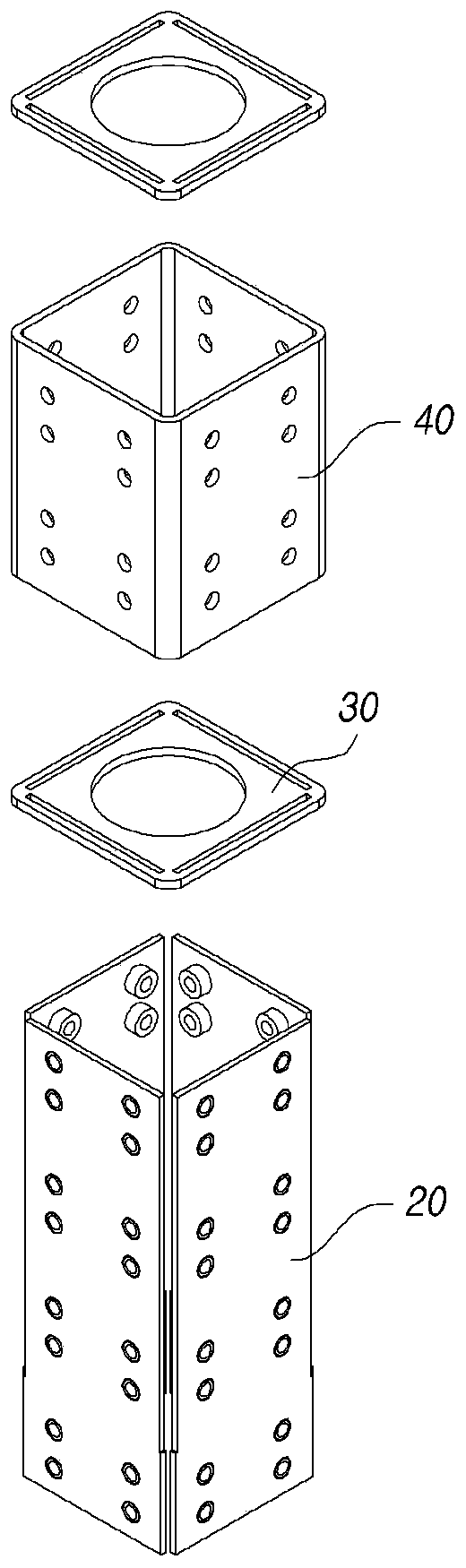

Joint core for joining column and beam, and method for joining column and beam using same

ActiveCN110291261ASave engineeringFirmly connectedBuilding constructionsProtective buildings/sheltersEngineering

The present invention relates to a joint core for joining a column and a beam that may secure excellent rigidity by a simple process and not require welding. To this end, provided is a joint core for joining a column and a beam, comprising: a closed-section intermediate column; a diaphragm; and an internal reinforcement, wherein the diaphragm is formed with a slit to insert the internal reinforcement thereinside, and the internal reinforcement inserted in the diaphragm is engaged with the intermediate column. According to the present invention, high rigidity is secured when a closed-section column and a beam are joined together as compared to that of the conventional art. In addition, assembly without welding is possible when the closed-section column and the beam are joined together, such that the process may be shortened, the joining may be easily performed, and quality becomes uniform.

Owner:高立安

Water-fetching water-saving device for preventing and curing acid rain

InactiveCN101122139ADoes not occupy an areaDoes not take up spaceGeneral water supply conservationWater/sewage treatmentWater dischargeHuman waste

An ''acid rain control water intaking and saving device'' is a facility and a method of first treating and purifying with an acid rain control facility when collecting acid rain, then collecting the rain water and household waste water, making full and reasonable use of the water resource, and saving valuable water. With the technology, as initially estimated, our country can intake water about 10 billion cubic meters each year, save water 10 billion cubic meters, save power 12 billion kilowatt-hour, reduce household waste water discharge 10 billion cubic meters, and save about 40 billion yuan. The ''acid rain control water intaking and saving device'' has functions of acid rain purification, water intaking, water saving, power (electricity) saving, waste water discharge reduction, drinking water supply, shower water supply, supply of water for household cleaning and hygiene and temperature regulation, and can save engineering and construction materials. Using the ''acid rain control water intaking and saving device'' does not take up building area and space, does not change the building drawings, does not affect the house structure and shape. Rainwater intaken on the top floor does not contact the ground, without chemical pollution, without pollution from feces (stool and urine, spit) of people (healthy people and patients) and animals, without sewage, sludge and sludge pollution, and is the cleanest and best drinking water on earth.

Owner:秦川

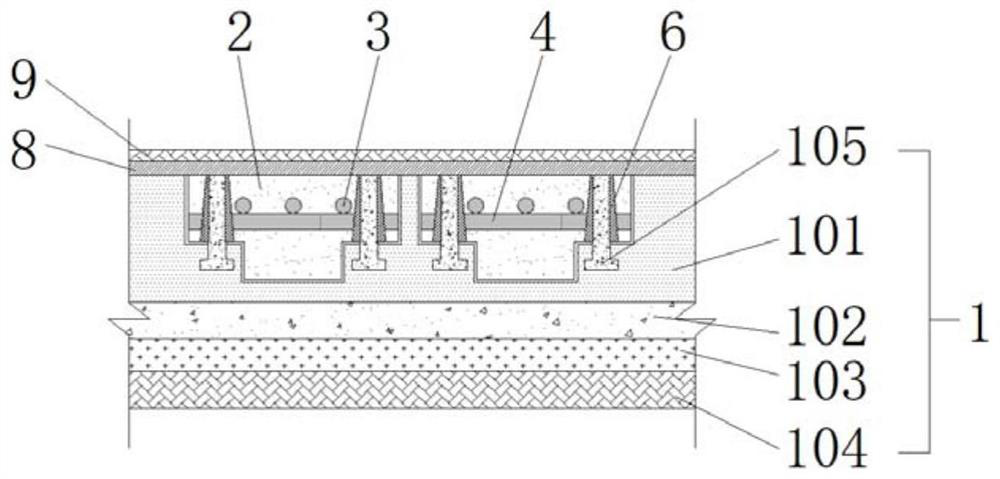

Roadbed construction method of highway reinforced concrete pavement

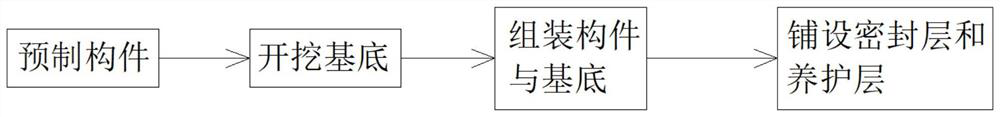

ActiveCN112227125AEase of partial repairExtended service lifeRoadwaysSolid waste managementSealcoatArchitectural engineering

The invention discloses a roadbed construction method of a highway reinforced concrete pavement. The roadbed construction method comprises the following steps: 1, prefabricating reinforced concrete pavement components; 2, excavating and laying a base; 3, assembling the reinforced concrete pavement component and the base; 4, laying a sealing layer and a maintenance layer, wherein the reinforced concrete pavement component in the step 1 comprises a concrete block, a longitudinal steel bar, a transverse steel bar, a fixing piece, a limiting piece and a lifting hook, the longitudinal steel bar andthe transverse steel bar are embedded in the concrete block, and the longitudinal steel bar and the transverse steel bar are connected in a bundling mode; fixed pieces are embedded in the left end and the right end in the concrete block correspondingly, the fixed pieces and the limiting pieces are arranged in a one-to-one correspondence mode, and the limiting pieces are welded to the lifting hooks. According to the roadbed construction method of the highway reinforced concrete pavement, the roadbed formed after construction is long in service life, large-area breakage is prevented, and partial repair of the pavement is facilitated.

Owner:温州展业建设工程有限公司

Universal service access device and method adapted to 1-11gbit/s, 40gbit/s and 100gbit/s services

The invention discloses a common service access device and method adaptable to the services of 1-11 Gbit / s, 40 Gbit / s and 100 Gbit / s and relates to the field of optical fiber communications. The common service access device comprises a control unit, a light input unit, a light output unit, a service input encapsulation unit and a service output encapsulation unit, wherein the control unit is connected with the light input unit, the light output unit, the service input encapsulation unit and the service output encapsulation unit respectively; the light input unit comprises a plurality of light input ports, a plurality of wave separators and a plurality of high-speed electrical interfaces I; the light output unit comprises a plurality of light output ports, a plurality of wave combiners and a plurality of high-speed electrical interfaces II; the light input unit is connected with the service input encapsulation unit through the high-speed electrical interfaces I; the service output encapsulation unit is connected with the light output unit through the high-speed electrical interfaces II. The common service access device and method can be adaptable to the service access of rates and agreements of 1-11 Gbit / s, 40 Gbit / s and 100 Gbit / s, so that the types of the cards are reduced; a series of costs of the cards such as the design cost, the production cost and the engineering cost are lowered.

Owner:FENGHUO COMM SCI & TECH CO LTD

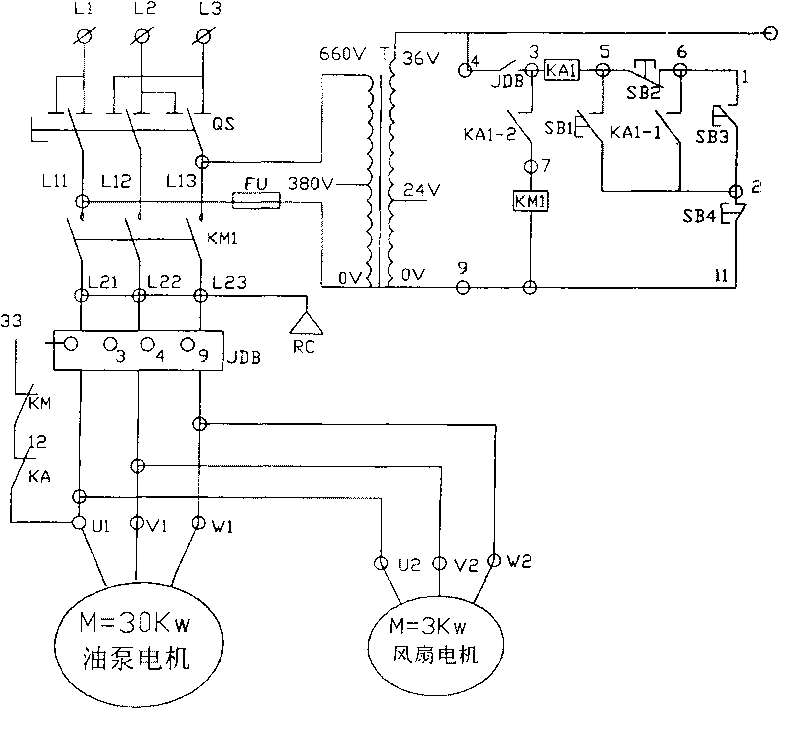

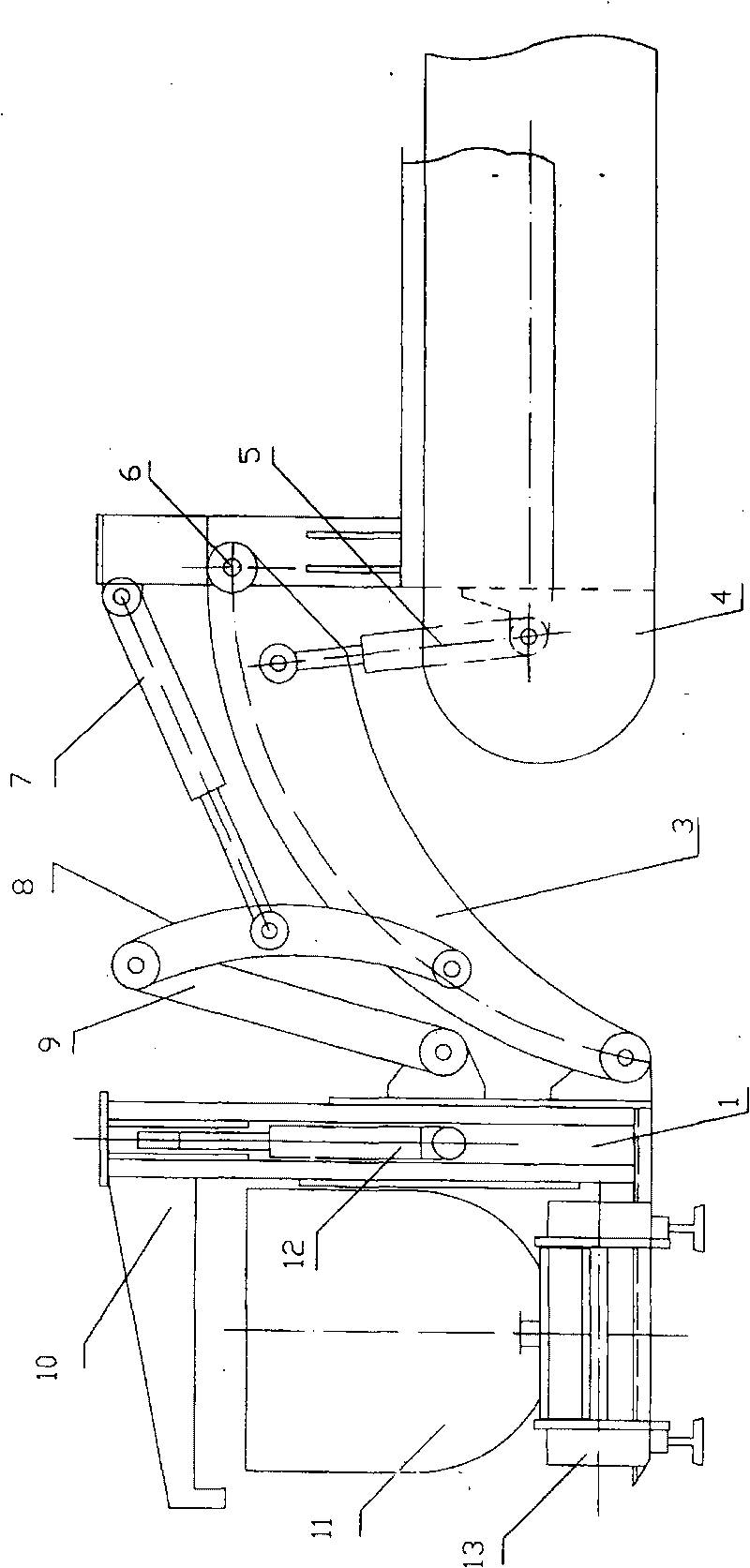

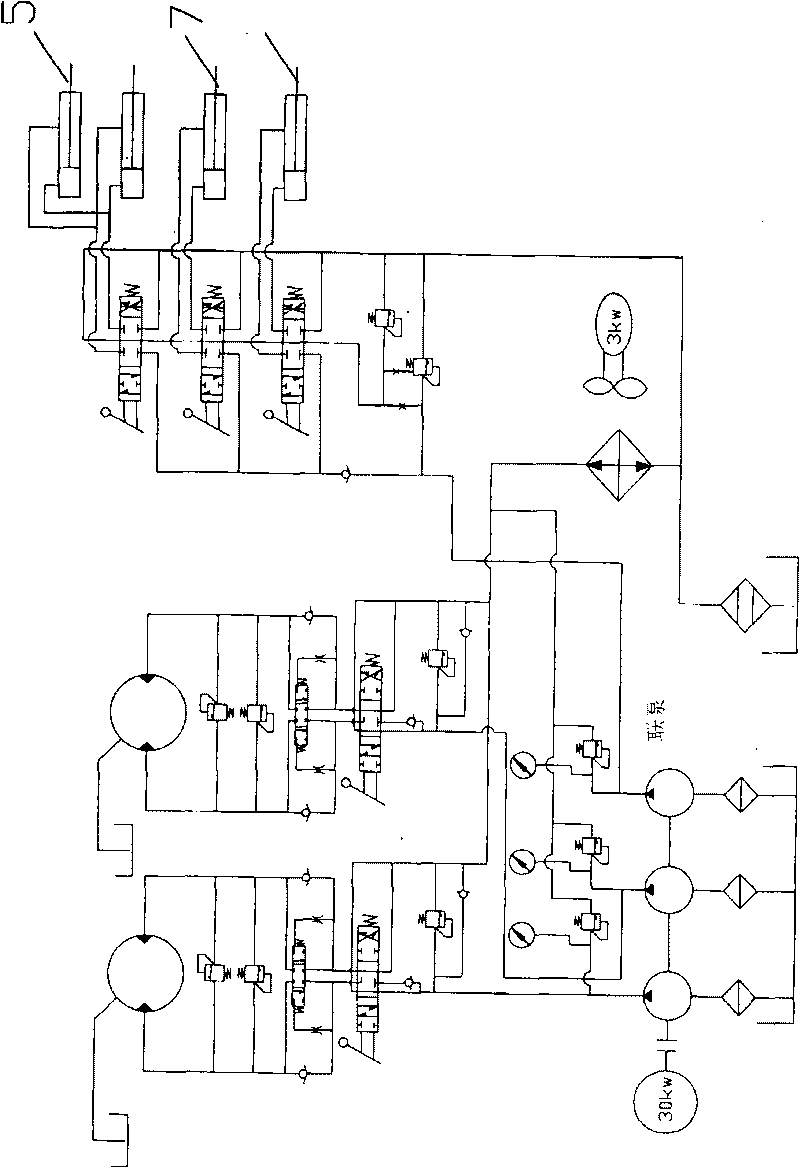

Mine mobile ladle tumbler

InactiveCN101761357ASave engineeringObvious benefitsMaterial fill-upSocial benefitsElectric power system

The invention discloses a mine mobile ladle tumbler, composed of a travelling device, a ladle tumbling device as well as a hydraulic system and a power system which provides power and instruction for the travelling device and the ladle tumbling device. By adopting the invention, waste filling system is greatly simplified, hundreds of meters of sinking and driving engineering is reduced, and dozens of equipment are reduced, and direct economic benefit and social benefit are significant.

Owner:冀中能源峰峰集团有限公司大淑村矿

Novel HS white gravure ink

The invention discloses novel HS white gravure ink. The novel HS white gravure ink relates to the field of printing ink. The novel HS white gravure ink comprises: 18 to 23% of synthetic wax, 7 to 12% of a black pigment, 1 to 2% of an additive, 1 to 2% of alcohol, 3 to 8% of vinyl acetate, 25 to 30% of methyl vinyl ketone and 33 to 38% of toluene. The novel HS white gravure ink can be prepared into sticky ink after being attached with a heat-sealing material, saves processes, reduces the number of product layers, has a downy tactility and broadens a use range.

Owner:SHANGHAI SHENYUE INK

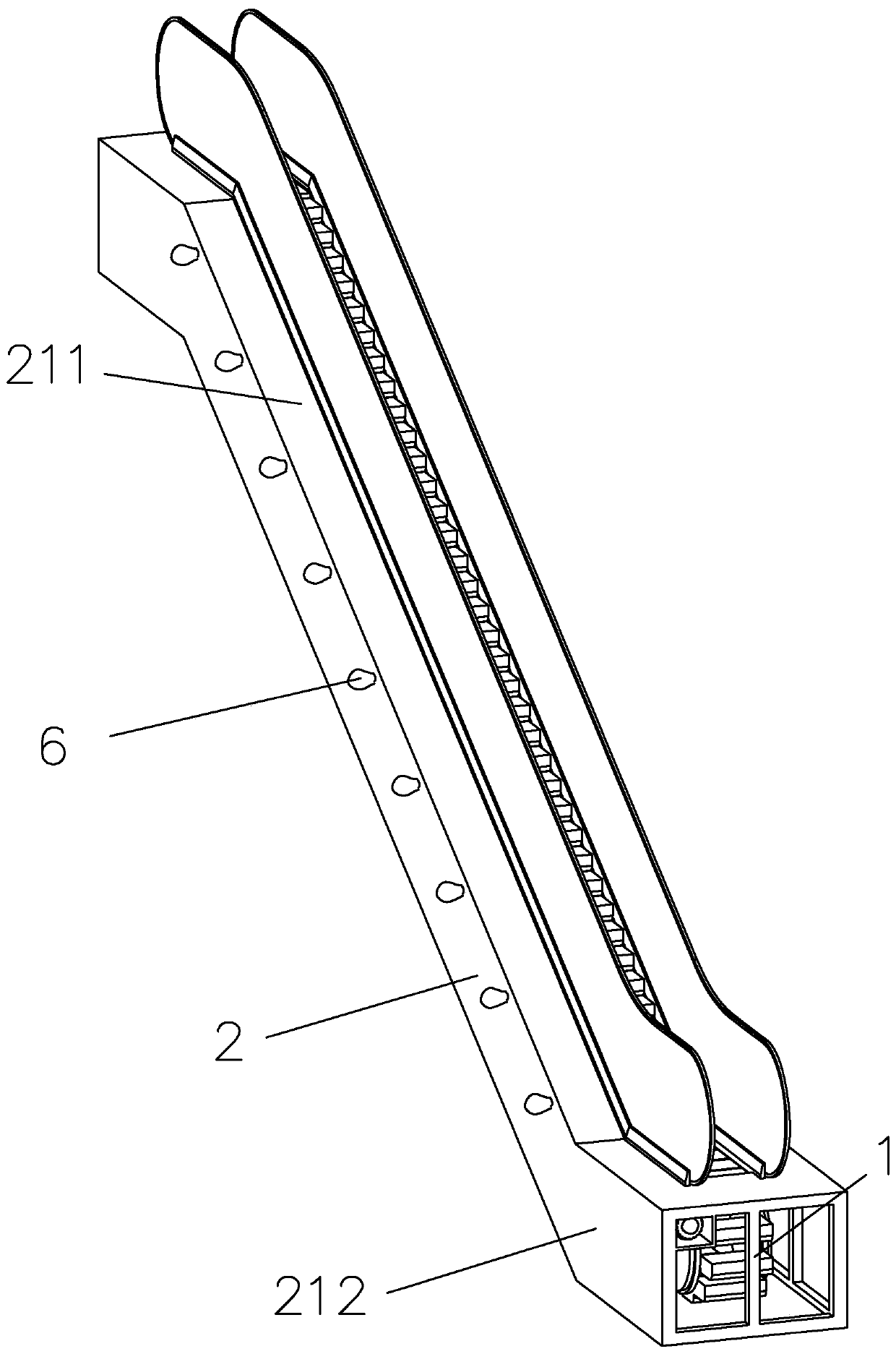

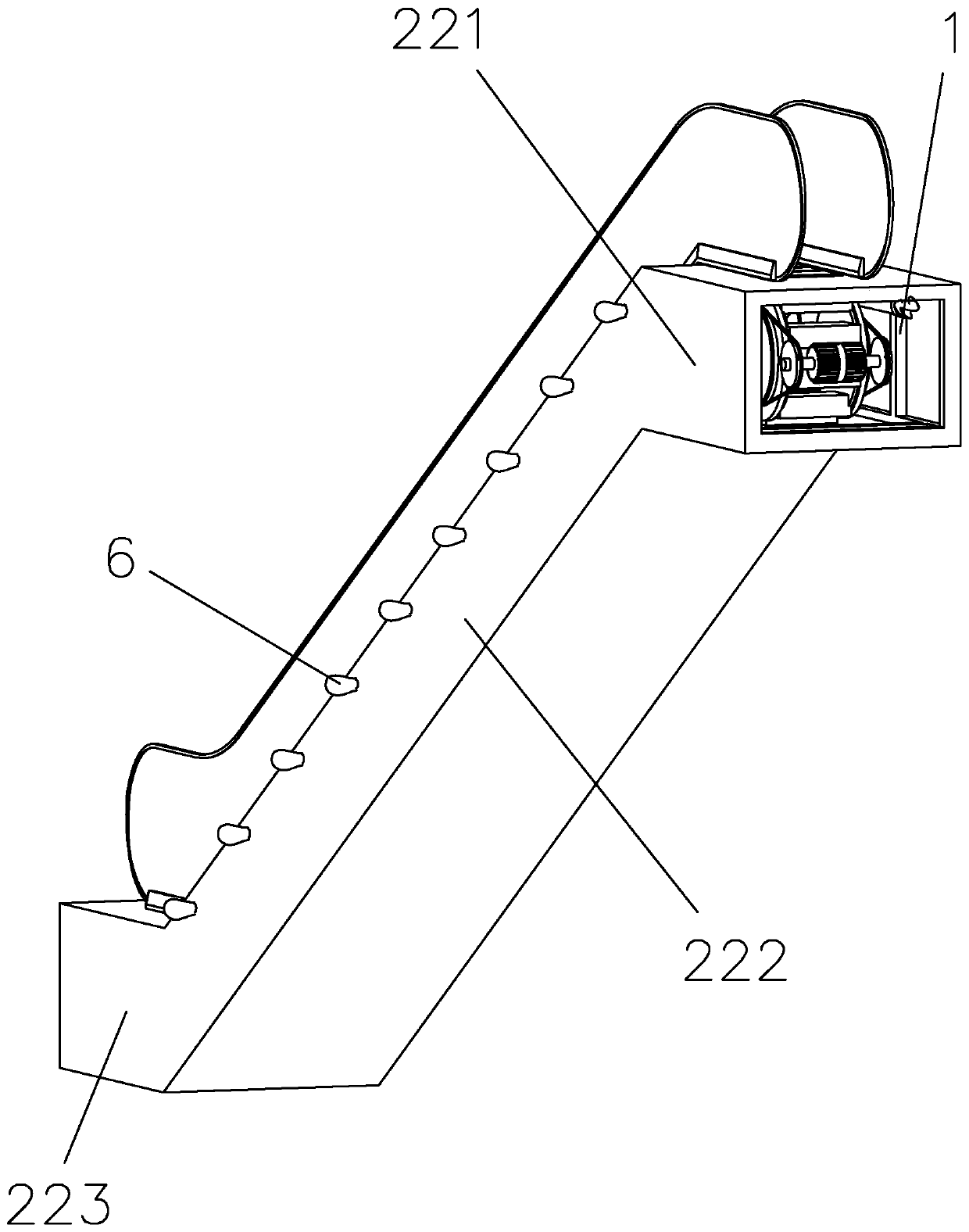

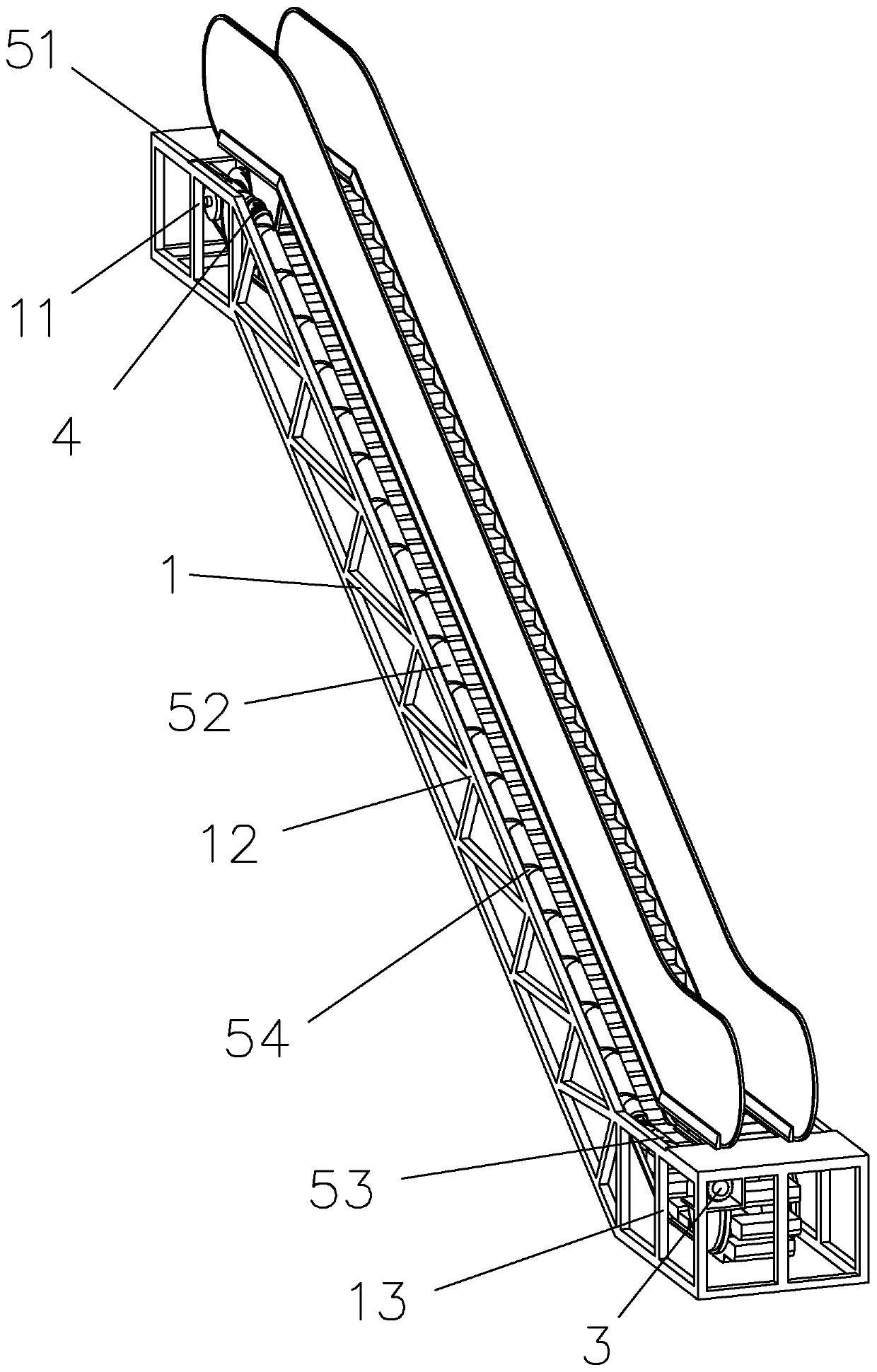

Escalator and installation method thereof

ActiveCN109823951AImprove installation efficiencySave engineeringEscalatorsEngineeringMechanical engineering

The invention discloses an escalator, which comprises a truss, wherein an outer decorative plate is arranged on the outer surface of the truss; the outer decorative plate is a leather body, and the leather body comprises a bottom sealing part for sealing the lower surface of the truss, a side sealing part for sealing the side surface of the truss and two upper sealing parts for sealing the upper surface of the truss. The leather body is connected to the two upper surfaces of the truss through screws. The truss is divided into an upper horizontal section, an inclined horizontal section and a lower horizontal section which are sequentially connected, and the leather body matching truss is divided into an upper horizontal leather body covering the upper horizontal section, an inclined leatherbody covering the inclined section and a lower horizontal leather body covering the lower horizontal section. The invention relates to an escalator and an installation method thereof, which can realize one-time covering of the upper surface, the side surface and the lower surface of the truss, without performing covering operations to the upper surface, the side surface and the lower surface of the truss respectively; a construction frame is not needed, so the engineering of constructing and dismantling the construction frame is omitted, and the installation efficiency of the outer decorativeplate is improved.

Owner:QUANZHOU LICHENG YUNLI PROTECTION EQUIP CO LTD

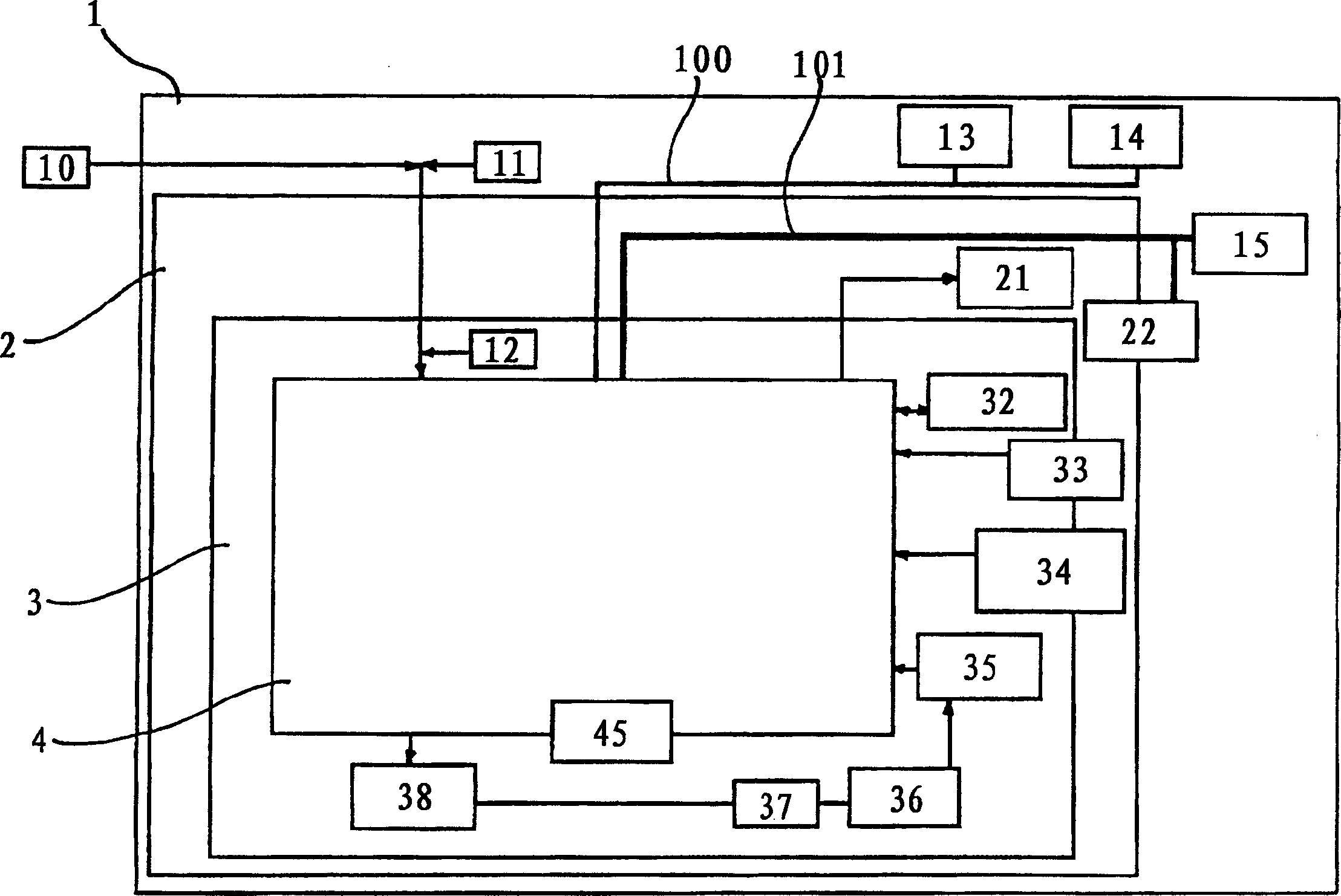

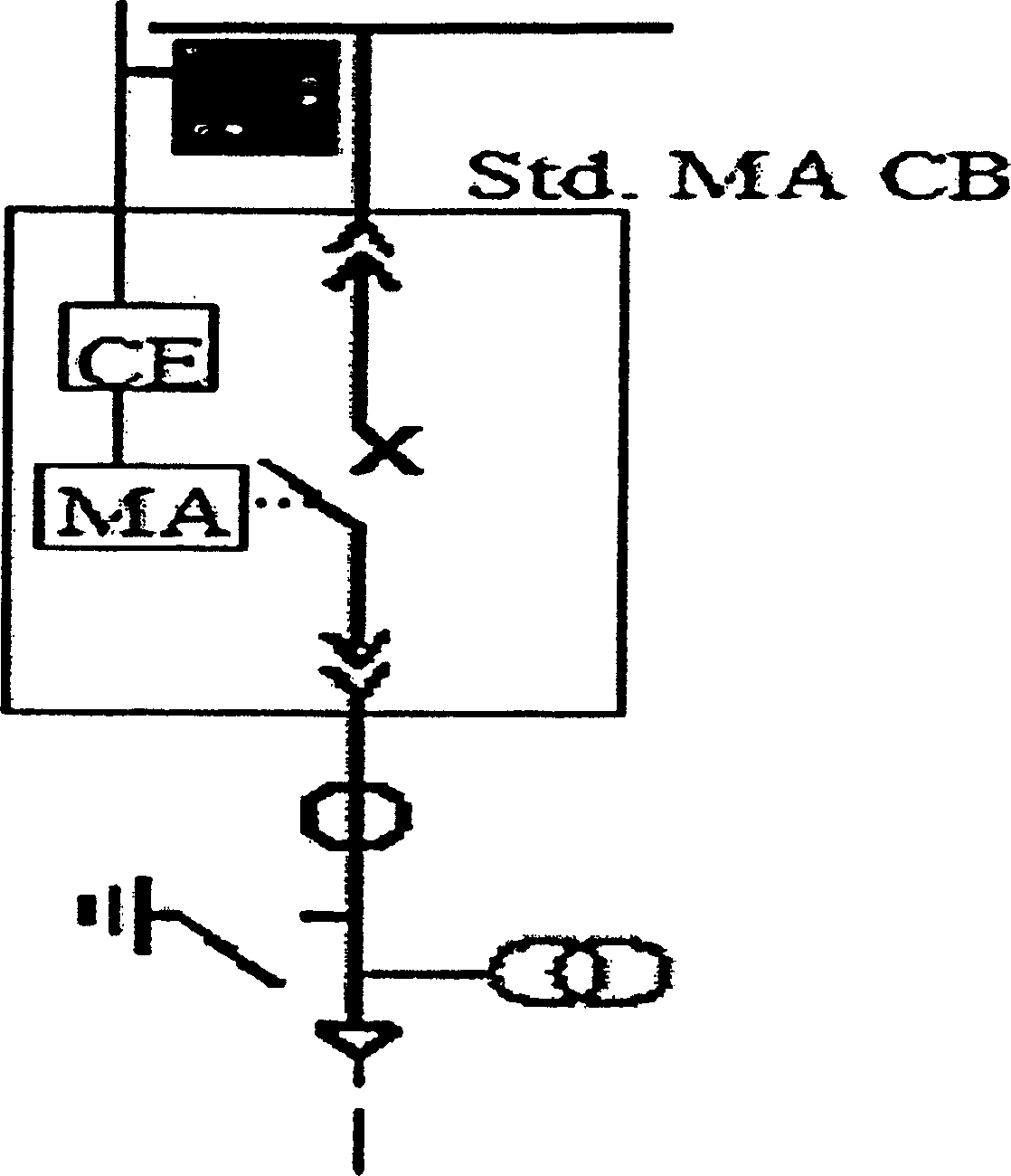

A medium voltage integrated switchgear

InactiveCN1610998AIncreased complexityAvoid coordinationBoards/switchyards circuit arrangementsEmergency protection data processing meansHuman–machine interfaceCommunications system

An electric power distribution switchboard (1) in which one or more functional units are equipped with a switching device compartment (3) that integrates primary and secondary functions. Within the switching device compartment (3) are included, together with the switching device (37), the current and voltage sensors(36), the position sensors for interlocking, a human machine interface (HMI) and an Intelligent Electronic Device (IED) (4) and the related local configuration point (32) to configure the IED (4). The IED (4) realizes functional unit supervision, control, protection, communication and monitoring and acts as a concentrating point of functional unit information and decisions. The switchboard (1) of the invention further comprises power supply section, an I / O section and a communication system.

Owner:ABB (SCHWEIZ) AG

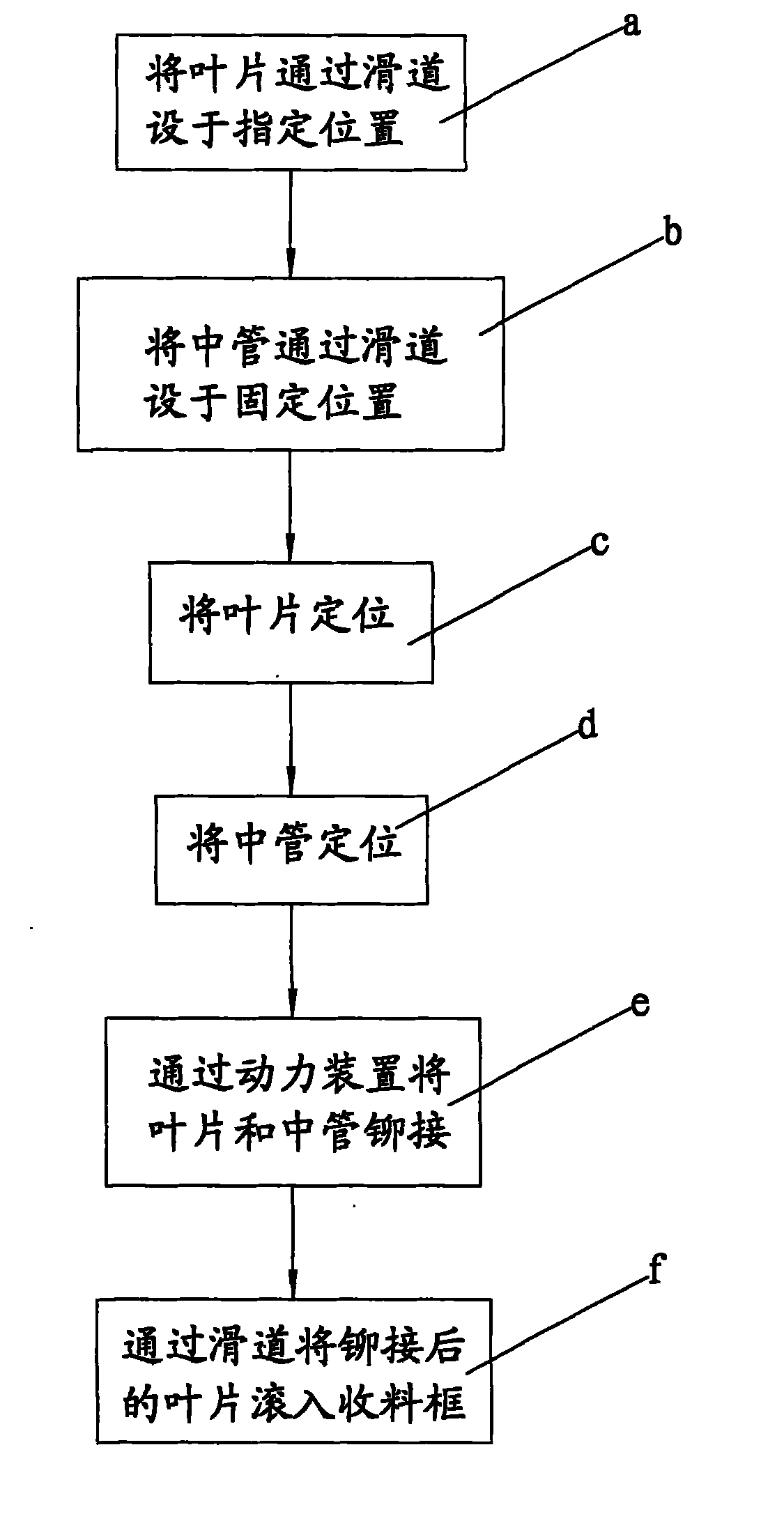

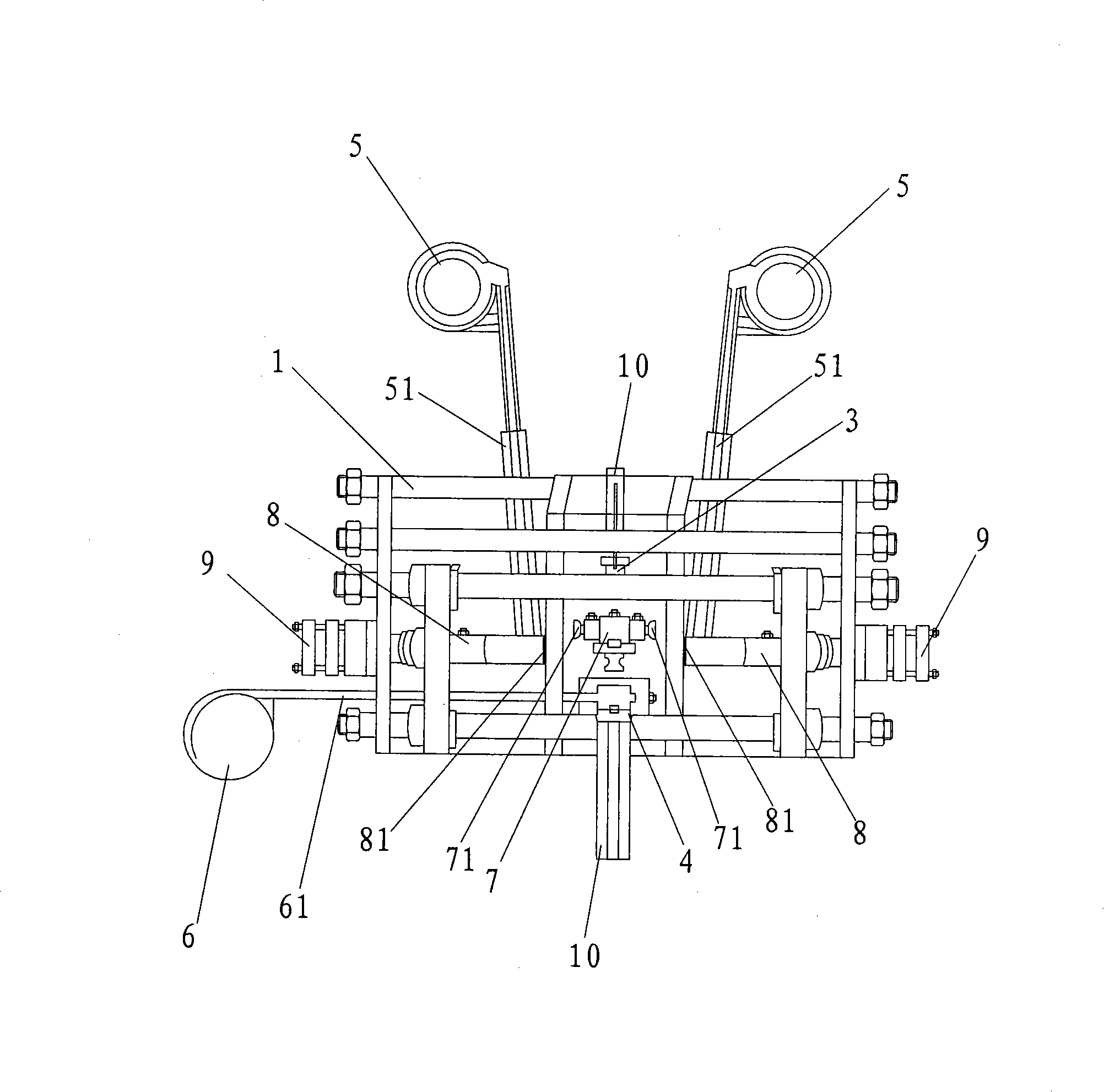

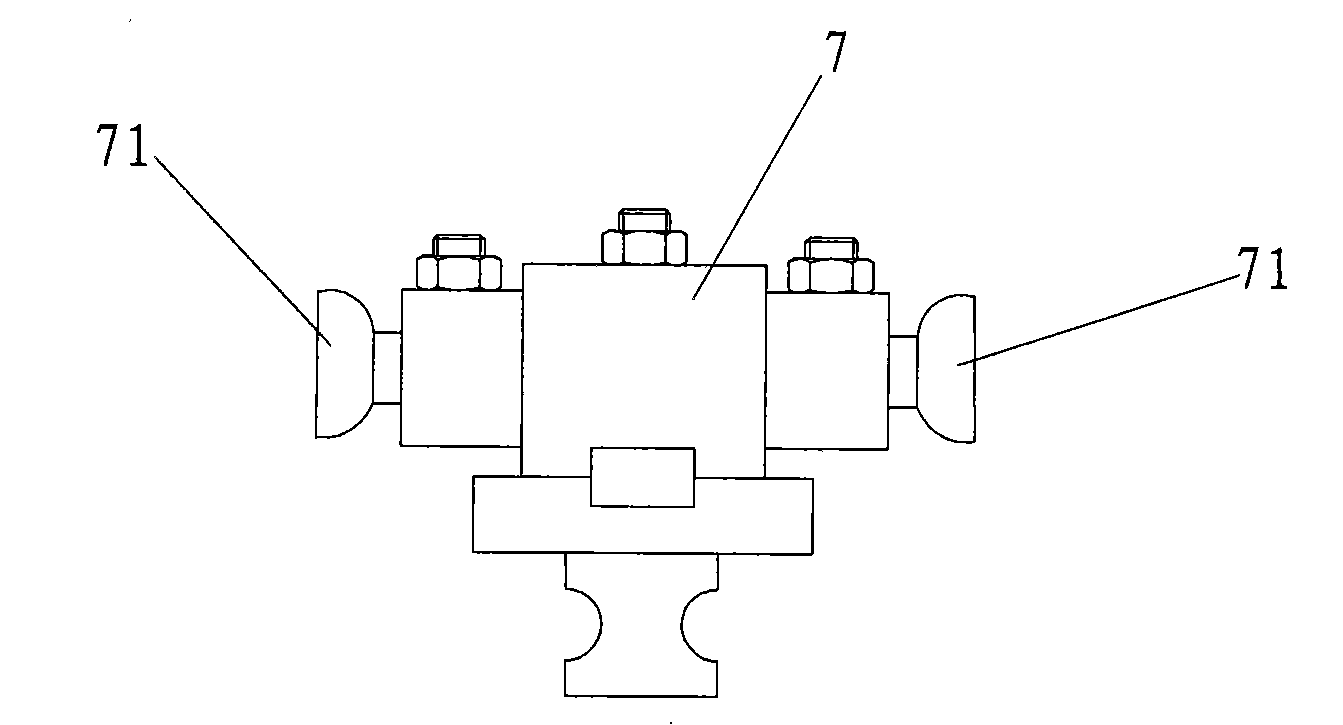

Hub blade automatic riveting machine and riveting method thereof

The invention discloses a hub blade automatic riveting machine comprising a stand, a medium tube, a medium tube pressing upper die, a middle tube pressing lower die, a blade vibrating disk, a middle tube vibrating disk and a blade ejector. The blade vibrating disk is connected with the stand through a blade slideway; the medium tube vibrating disk is connected with the medium tube pressing lower die through a medium slideway; the blade ejector fixes the blades on a blade positioning die on the stand; the medium tube pressing upper die and the medium tube pressing lower die are controlled through an air pressure cylinder; two blade positioning dies are externally provided with an oil cylinder respectively; and both sides of the blade ejector are provided with small roller cones. When the hub blade automatic riveting machine is used, the blades and the medium tube are respectively arranged in the blade vibrating disk and the medium tube vibrating disk; the blades enter into both sides ofthe blade ejector through the blade slideway; the medium tube enters into the medium tube pressing lower die through the medium tube slideway; the blades are positioned through the blade ejector, andthen the medium tube is positioned; and the oil cylinder moves towards the middle for riveting. The invention patent adopts the automatic operation, thereby reducing the work, lowering the cost, reducing the labor, and improving the quality and the stability of products.

Owner:久钰车料(昆山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com