Submersible pump

A submersible pump and pump shaft technology, applied in general water supply saving, pump, pump control and other directions, can solve the problems of large noise and vibration, inconvenient operation, complex structure, etc., and achieve the effect of preventing blockage, convenient operation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

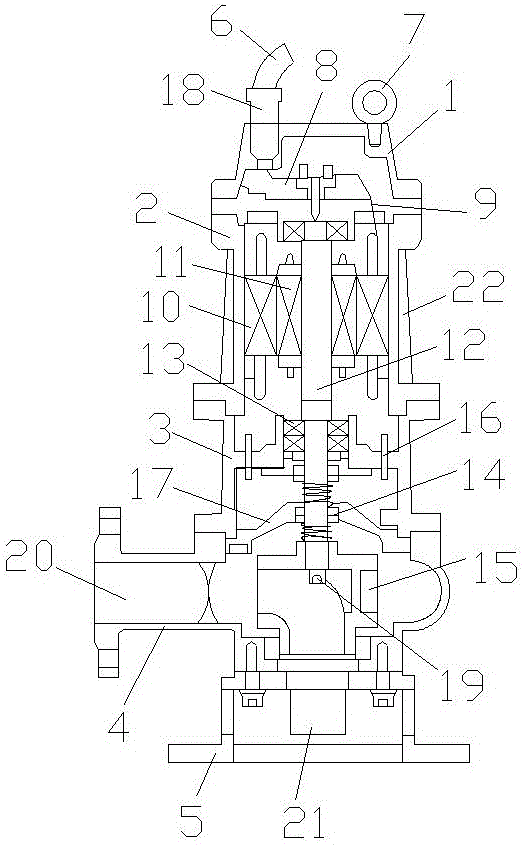

[0023] refer to figure 1 As shown, a submersible pump includes a motor cover 1, a motor casing 2, an oil tank 3, a pump body 4 and a base 5, and the motor cover 1, the motor casing 2, the oil tank 3, the pump body 4 and the base 5 sequentially from Arranged from top to bottom, the motor cover 1 is provided with a cable 6 and a hook 7, and the motor cover 1 is provided with a terminal board 8 and a water leakage detection probe-9, and the cable 6, the terminal board 8 and the water leakage detection probe -9 are electrically connected in turn, the motor housing 2 is provided with a stator 10, a rotor 11 and a pump shaft 12, the stator 10 is electrically connected to the wiring board 8, and the rotor 11 is connected to the pump shaft 12 in transmission, so The pump shaft 12 is provided with a bearing 13, a seal 14 and an impeller 15 in sequence, the bearing 13 is connected in rotation with the pump shaft 12, the bearing 12 is seamlessly connected with the motor casing 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com