Patents

Literature

112results about How to "Shorten the on-site construction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

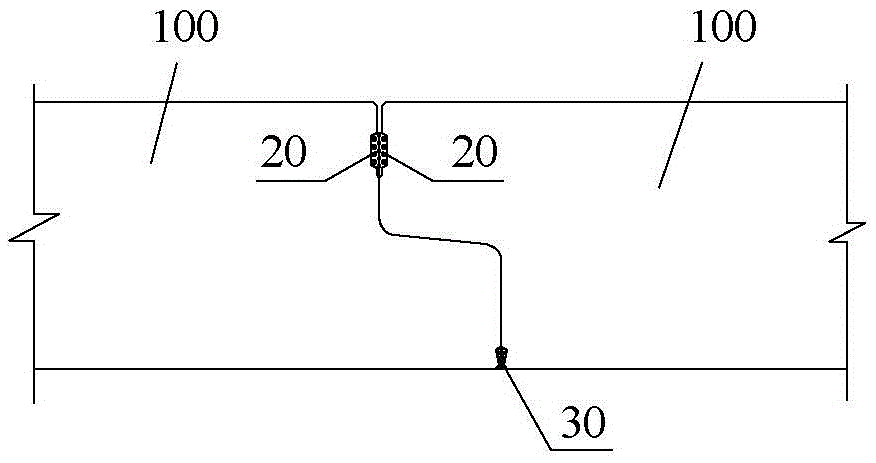

Pipe gallery prefabricated parts and assembly type rectangular comprehensive pipe gallery

ActiveCN105569076ASimple structureEasy installation and constructionArtificial islandsUnderwater structuresEngineeringButt joint

The invention provides pipe gallery prefabricated parts and an assembly type rectangular comprehensive pipe gallery. Each pipe gallery prefabricated part comprises a rectangular pipe section body. Each pipe section body comprises an insertion end and a socket end. The protruding portion of each insertion end is annularly arranged along an end opening and matched with an annular notch formed corresponding to the corresponding socket end. Circular-arc-shaped bolt connecting holes are correspondingly formed in all corners of each insertion end and the corresponding socket end. Nut operation hand holes are formed in the ends, located on the inner surface of each pipe section body, of all the bolt connecting holes. When two pipe gallery prefabricated parts are inserted, all corresponding bolt connecting holes in the inserting position are subjected to butt joint to form pipe gallery bolt connecting holes. The comprehensive pipe gallery comprises the pipe gallery prefabricated parts, circular-arc bolt mechanisms and sealing structures. Each circular-arc bolt mechanism comprises nuts and circular-arc-shaped bolts, and the bolts are matched with the bolt connecting holes. The pipe gallery prefabricated parts are sequentially inserted and matched end to end. The inserted pipe gallery prefabricated parts are connected to be a whole through the bolt connecting holes by the circular-arc bolt mechanisms. The sealing structures are circumferentially and annularly sealed on the inserting fitting surface along the pipe section bodies. According to the pipe gallery prefabricated parts and the assembly type rectangular comprehensive pipe gallery, the structure is simple, the spot construction site is small, the project amount is small, and efficient and rapid construction can be achieved.

Owner:SHENZHEN HUAHAN URBAN COMPREHENSIVE PIPE GALLERY TECH RES DEV CO LTD

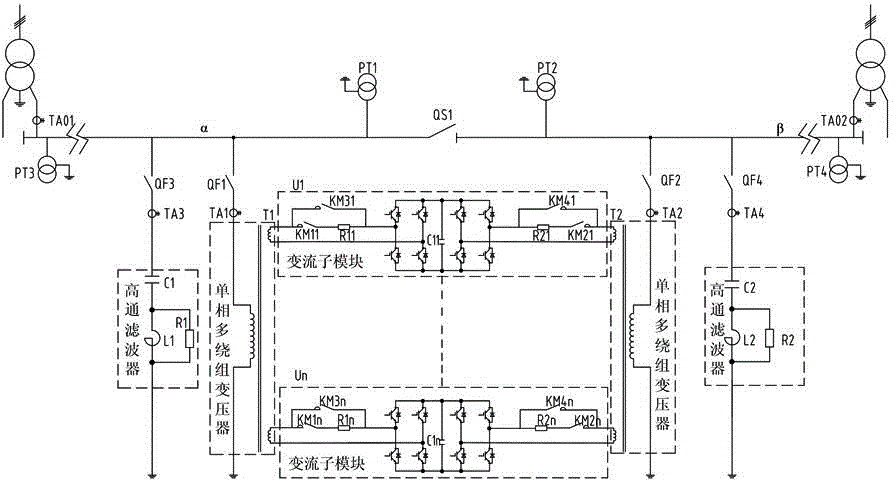

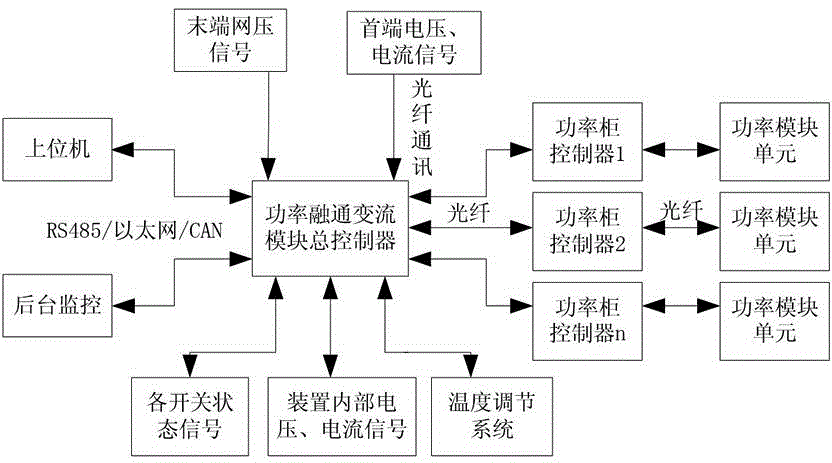

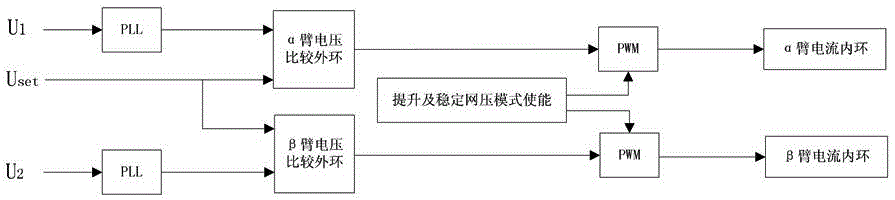

Traction power supply network tail end voltage boosting device with power fusing function and method of device

ActiveCN104901305ASuppress low harmonicsImprove capacity utilizationPower supply linesReactive power adjustment/elimination/compensationResonanceTransformer

The invention relates to a traction power supply network tail end voltage boosting device with a power fusing function and a method of the device. The device includes a multiple voltage reduction module and a power-fusing current-converting module; the multiple voltage reduction module is connected into two power supply arm power sources of the tail end of a traction power supply network and includes two single-phase multi-winding transformers of the same structure which are correspondingly connected into the two power supply arm power sources respectively through connection switches; the power-fusing current-converting module is used for performing energy conversion on the two power supply arm power sources and includes a plurality of current conversion sub modules; one set of voltage is connected into two input sides of each current conversion sub module through corresponding secondary windings of the two single-phase multi-winding transformers, so that energy conversion can be performed; and through controlling the switch-on of the current conversion sub modules, output voltage can be boosted, and power fusion of the two power supply arms can be performed. According to the method of the invention, the voltage of the tail end of the traction power supply network can be stabilized and boosted through controlling the power-fusing current-converting module. The device and the method of the invention have the advantages of simple structure, low cost, power fusion and train power network resonance suppression, and can boost the voltage of the tail end of the traction power supply network.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

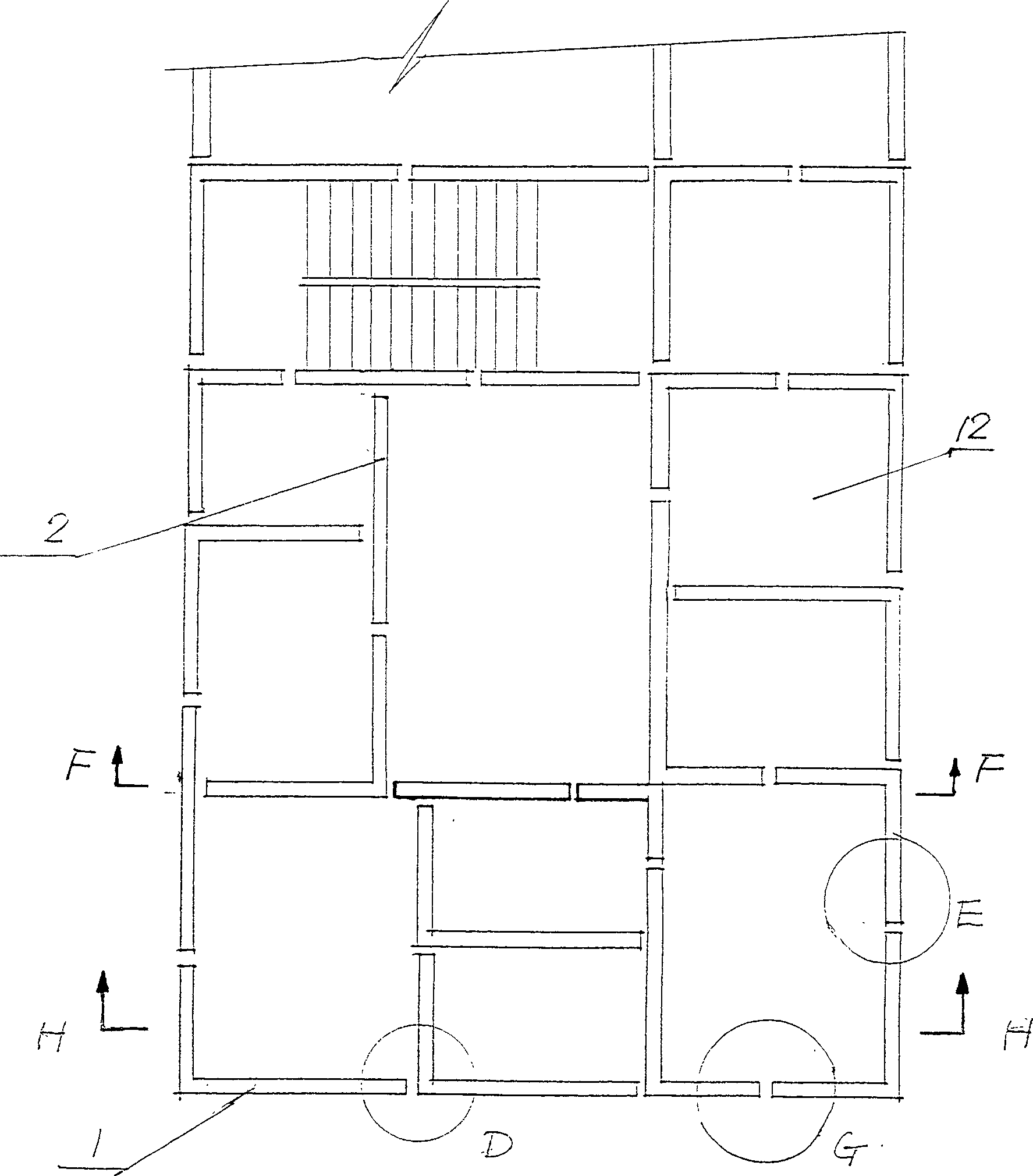

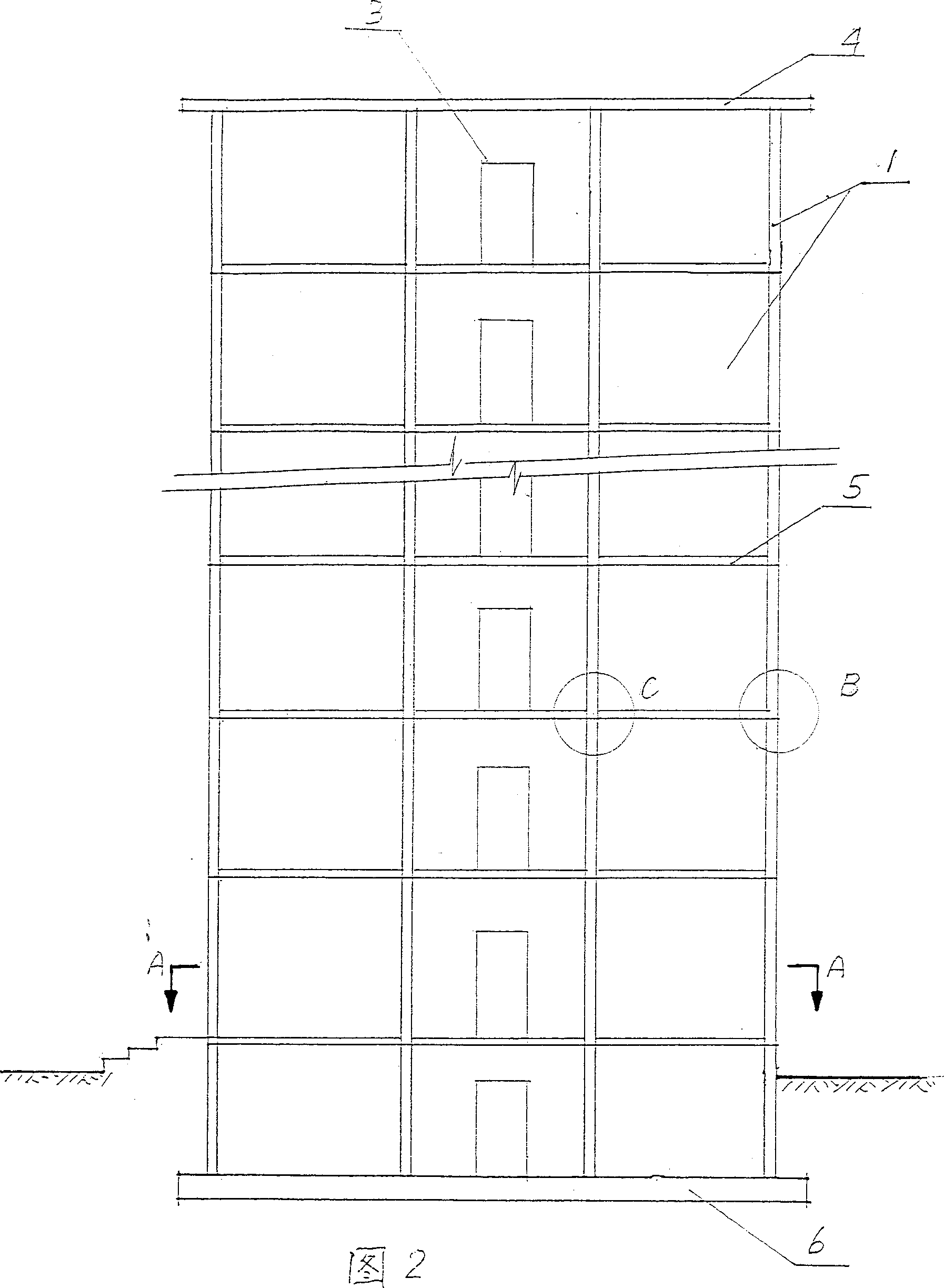

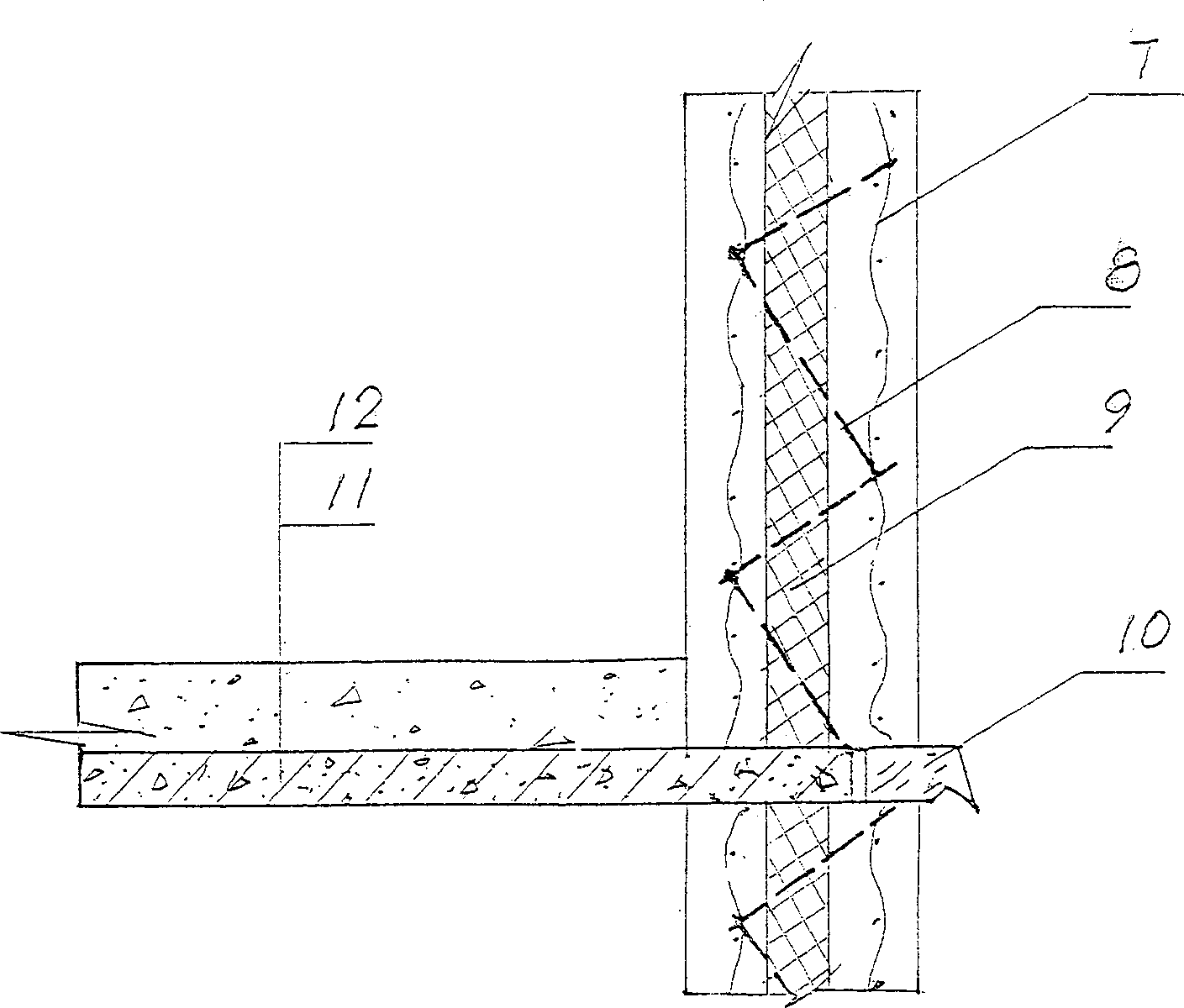

Prefabricated concrete shear wall building structure and its construction method

The present invention relates to building structure and construction method. It includes one wall structure comprising rigid net frame with shaped steel and steel wire member and planar sandwich layer with foamed glass; integrally cast floor board connected via steel wire net; combined construction process of assembling prefabricated members and site casting;a nd movable and easy-to-connect wall for variable bay and fitting setting. The present invention has high integral performance, short construction period and low building cost.

Owner:朱维高

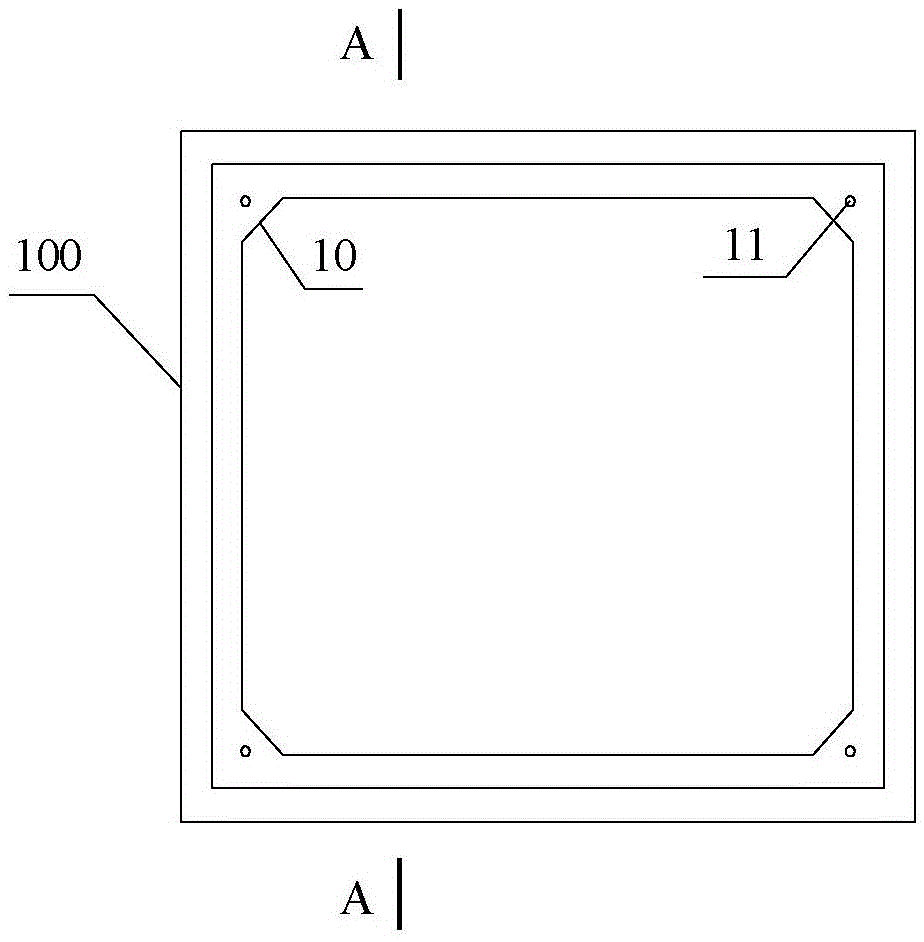

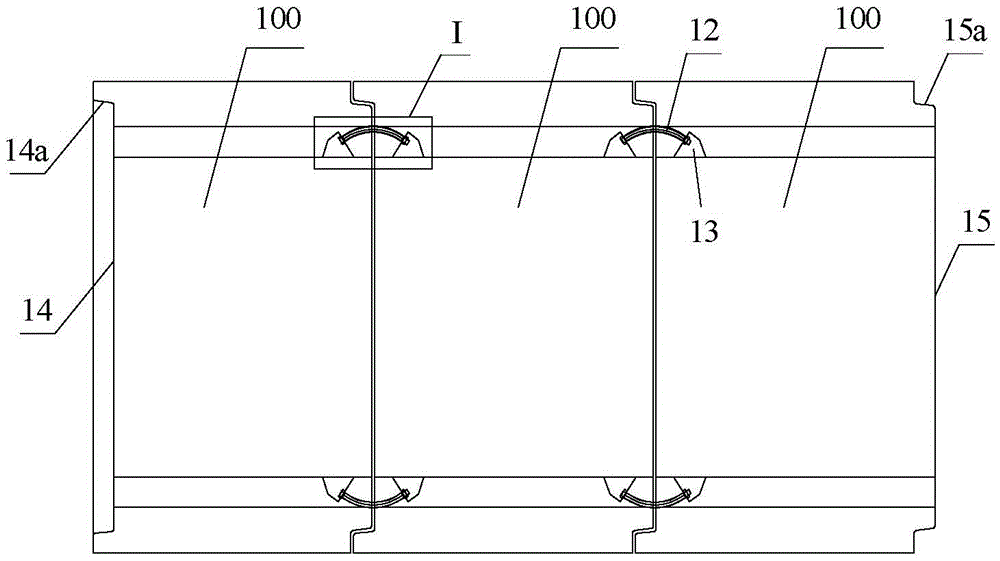

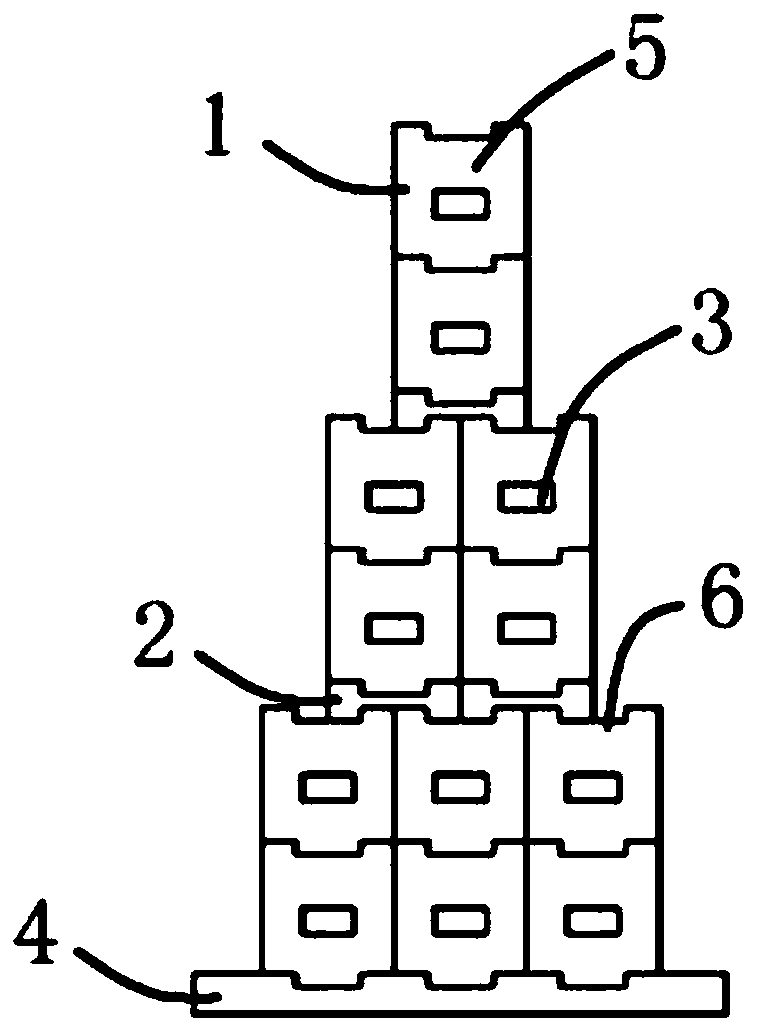

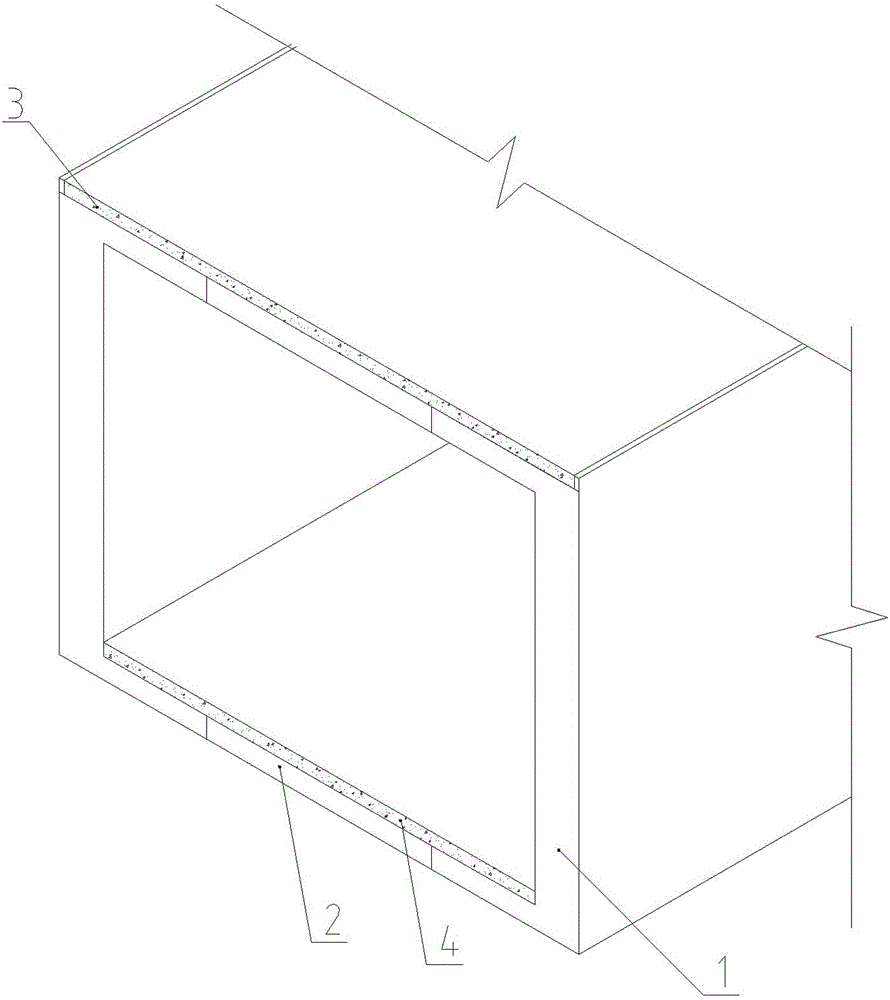

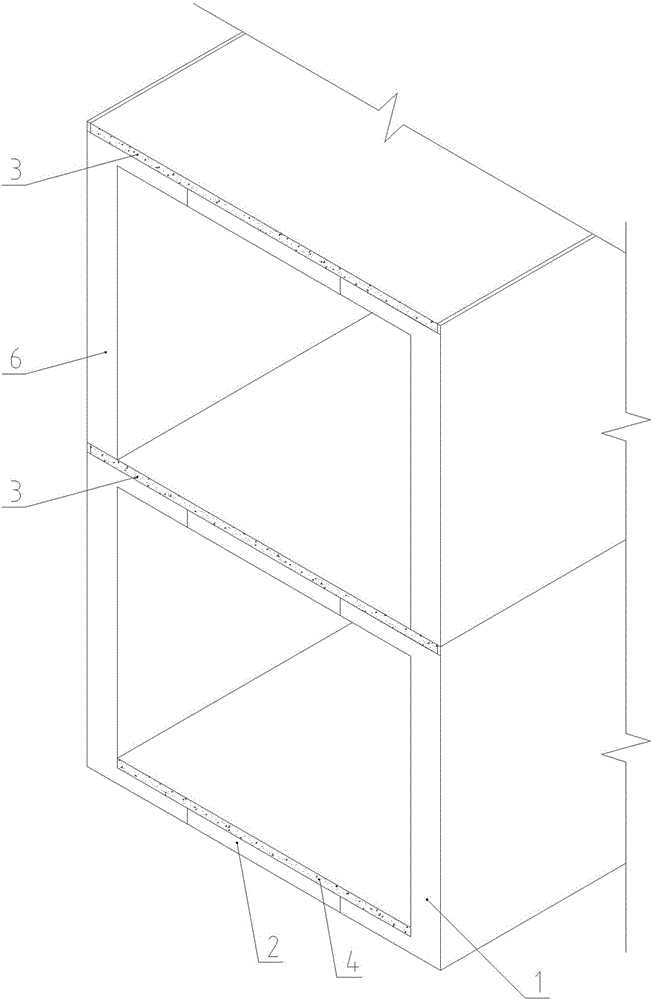

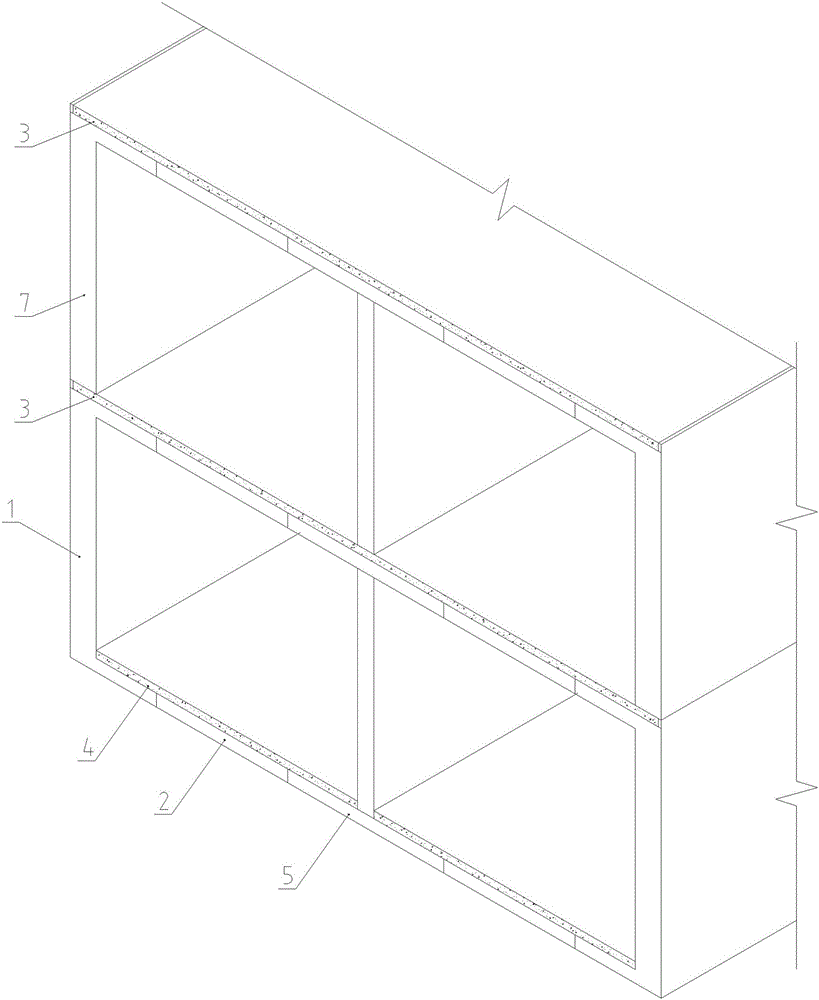

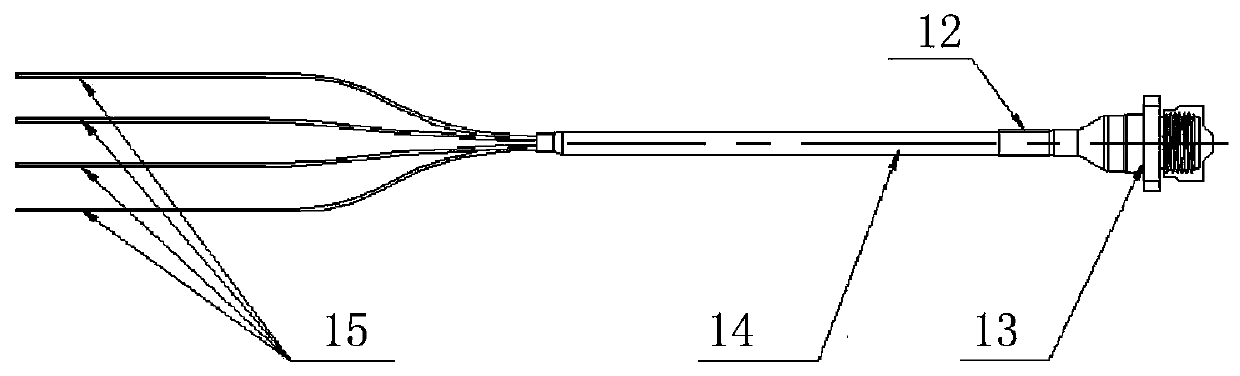

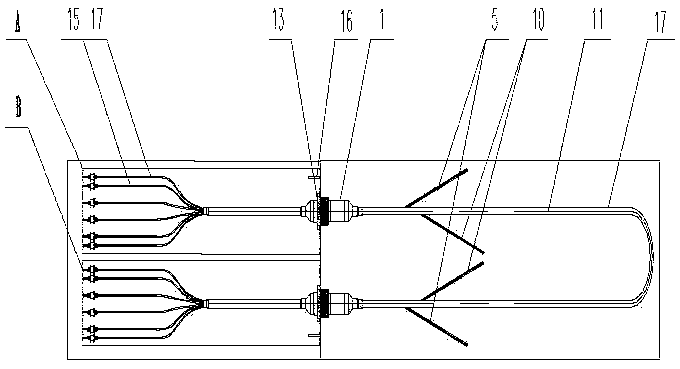

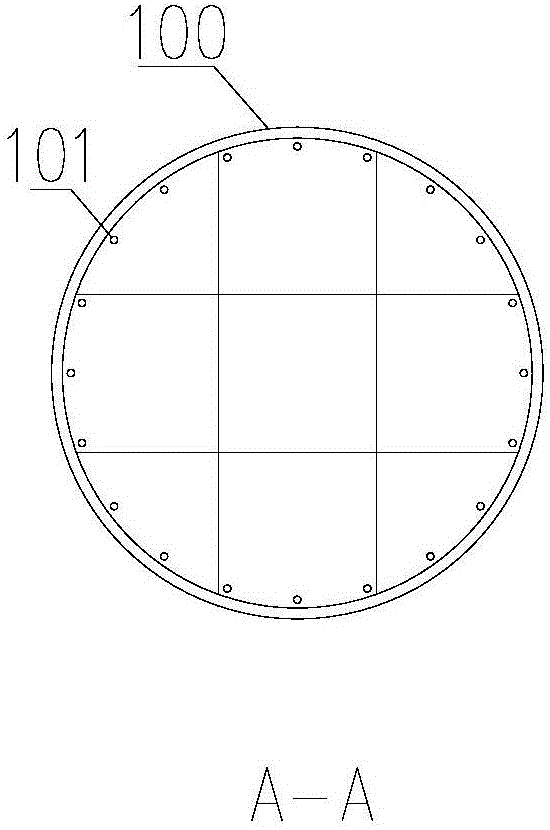

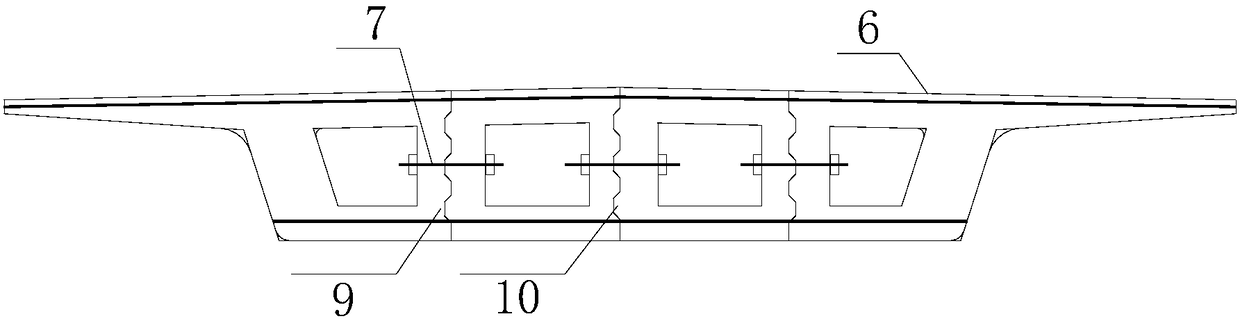

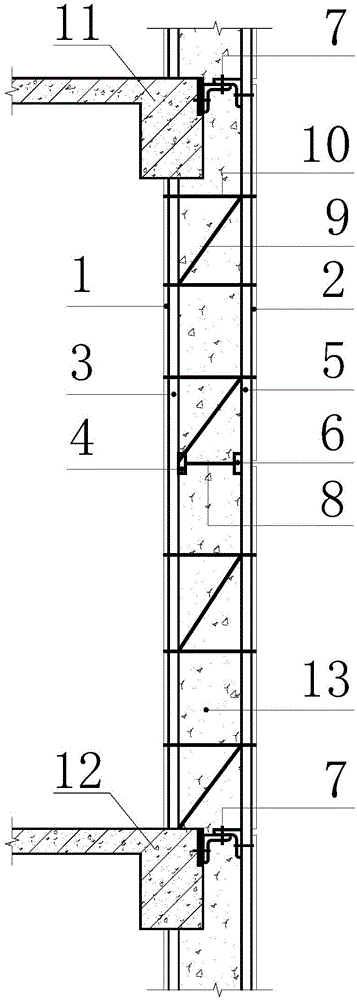

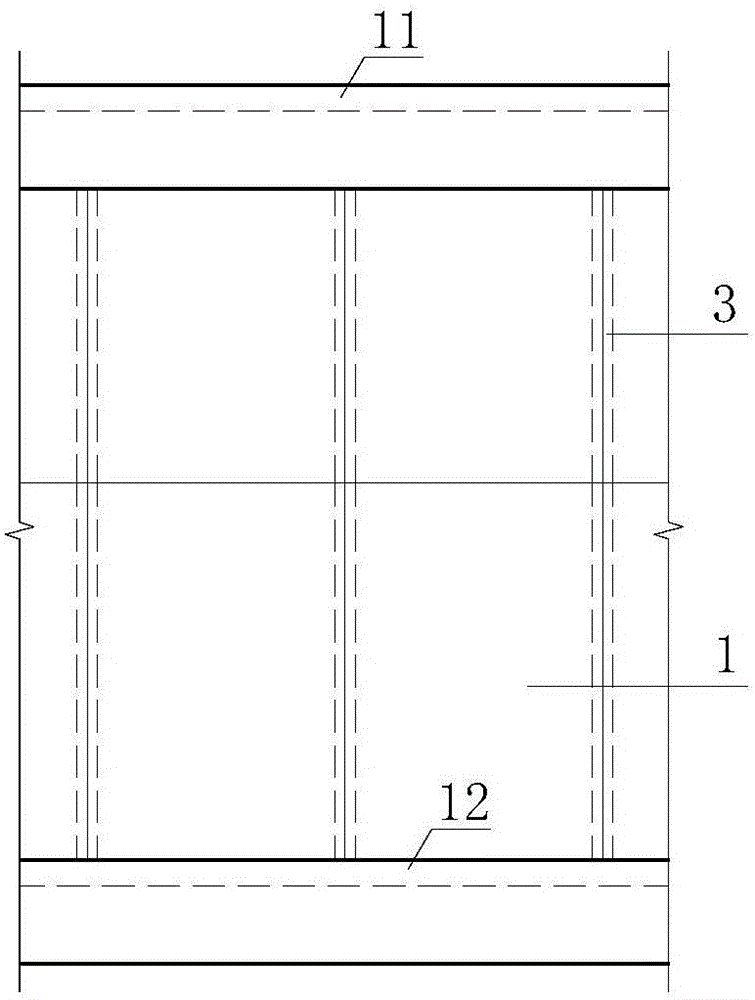

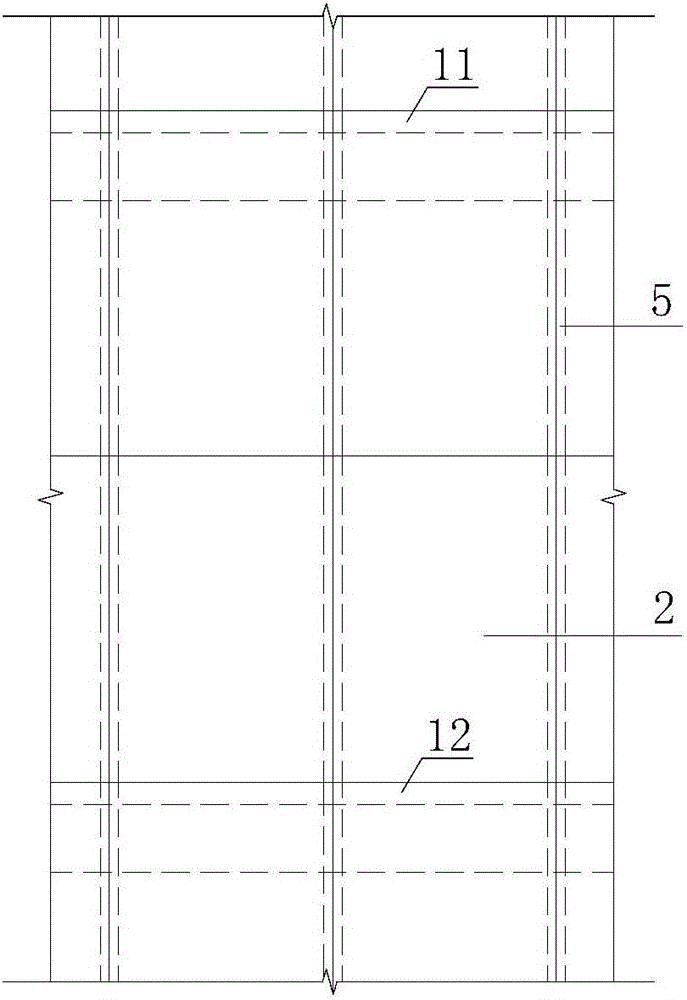

Pipe gallery prefabricated member and assembled comprehensive pipe gallery

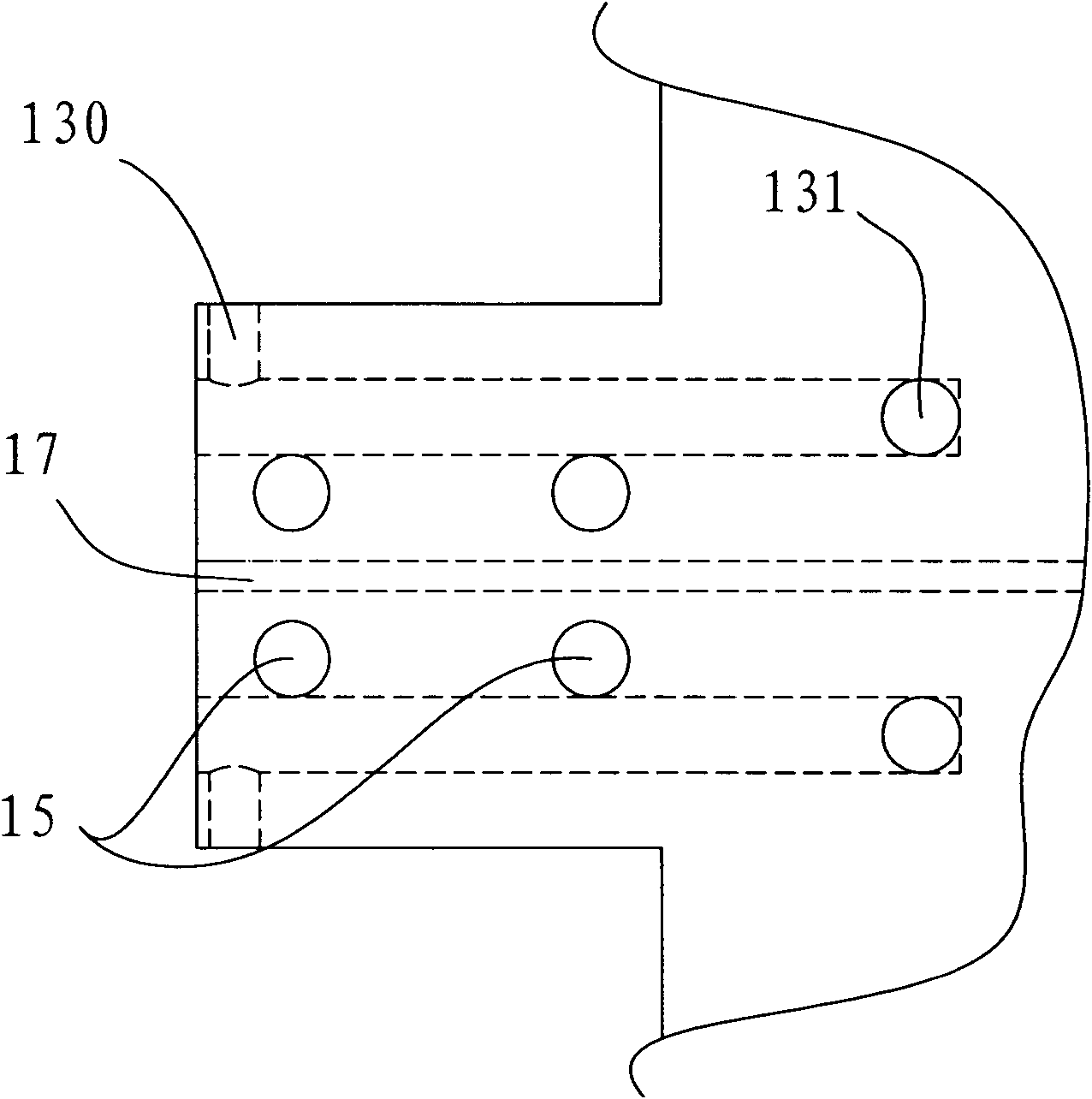

InactiveCN105256837AEasy to transportStable structural strengthArtificial islandsUnderwater structuresUtility tunnelEngineering

The invention provides a pipe gallery prefabricated member and an assembled comprehensive pipe gallery. The pipe gallery prefabricated member comprises a bottom frame prefabricated member and a cover board prefabricated member. The bottom frame prefabricated member comprises a bottom board, vertical boards, internal reinforcing pieces of the bottom board and the vertical boards and prestress steel cable holes formed in the inside corners connected with the bottom board and the vertical boards. A U-shaped bin groove is formed by every two adjacent vertical boards and the bottom board. The bottom frame prefabricated member at least comprises one U-shaped bin groove. Grooves A and protrusions A are arranged on the end faces of the portions, on the two sides of each U-shaped bin groove, of the bottom board and the end faces of the vertical boards respectively, wherein the protrusions A are inserted in the grooves A in a matched manner. Grooves B are formed in the upper end faces of the vertical boards of the U-shaped bin grooves. The cover board prefabricated member comprises protrusions B arranged on the bottom face and inserted in the grooves B in a matched manner, grooves C and protrusions C, wherein the two ends of the cover board prefabricated member are provided with the grooves C and the protrusions C, and the protrusions C are inserted in the grooves C in a matched manner. The pipe gallery comprises sealing pads, prestress steel cables, the bottom frame prefabricated member and the cover board prefabricated member. The needed pipe gallery is formed by assembling the bottom frame prefabricated member and the cover board prefabricated member. By the adoption of the pipe gallery prefabricated member and the assembled comprehensive pipe gallery, the site assembling construction load is low, transport and installation cost is low, assembling operation is flexible, and various use requirements are met.

Owner:SHENZHEN HUAHAN GUANLANG PROPERTY SERVICES CO LTD

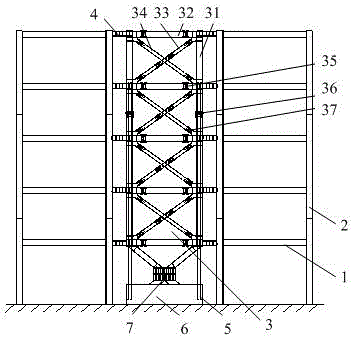

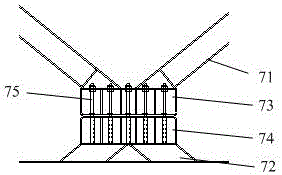

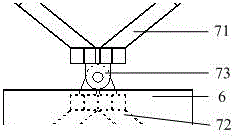

Assembling type swing self-resetting steel support structure system

ActiveCN106382041AIncrease lateral stiffnessShort construction periodProtective buildings/sheltersShock proofingShock resistanceSteel columns

The invention discloses an assembling type swing self-resetting steel support structure system. The system comprises structural columns and structural beams, which form a main structure, wherein the main structure and a steel support are connected through energy consumption elements; self-resetting stay ropes are arranged along steel columns of the steel support, the upper ends of the self-resetting stay ropes are tensioned at the tops of the steel columns of the steel support, and the lower ends of the self-resetting stay ropes are poured into a cast-in-situ foundation; and the steel support consists of slender steel components and is connected with the cast-in-situ foundation through a swing node. According to the assembling type swing self-resetting steel support structure system, the steel support serves as a whole to swing during the earthquake and does not generate relative deformation with the main structure, the energy consumption elements are deformed, and the energy is dissipated; after the earthquake, the structure is restored to an original state through the self-resetting stay ropes, so that the use functions of the structure is guaranteed; and the basic components are slender, and splicing parts are connected by virtue of bolts and can be produced in factories and spliced on site, so that the site project duration can be shortened. The assembling type swing self-resetting steel support structure system has the advantages of strong building adaptability and shock resistance, simplicity in construction, high construction quality, short project duration and the like.

Owner:SUZHOU UNIV OF SCI & TECH

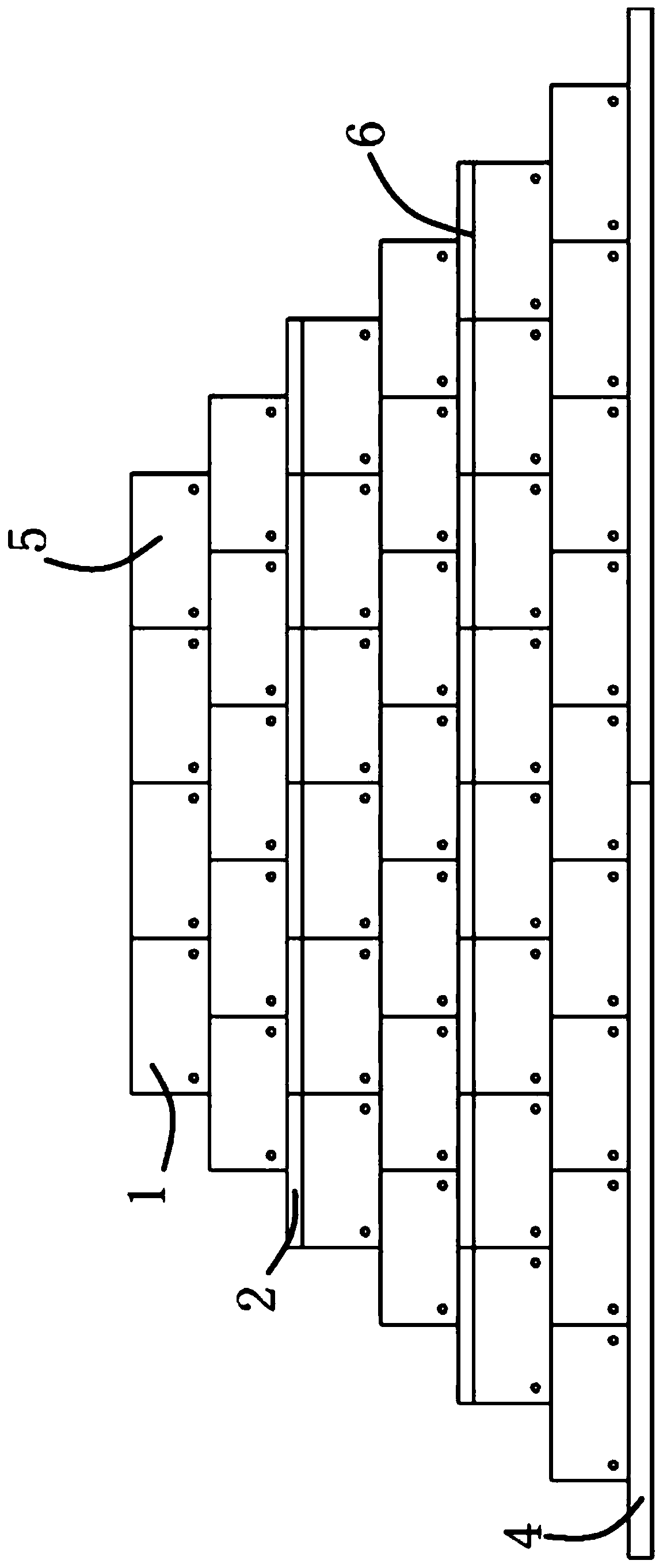

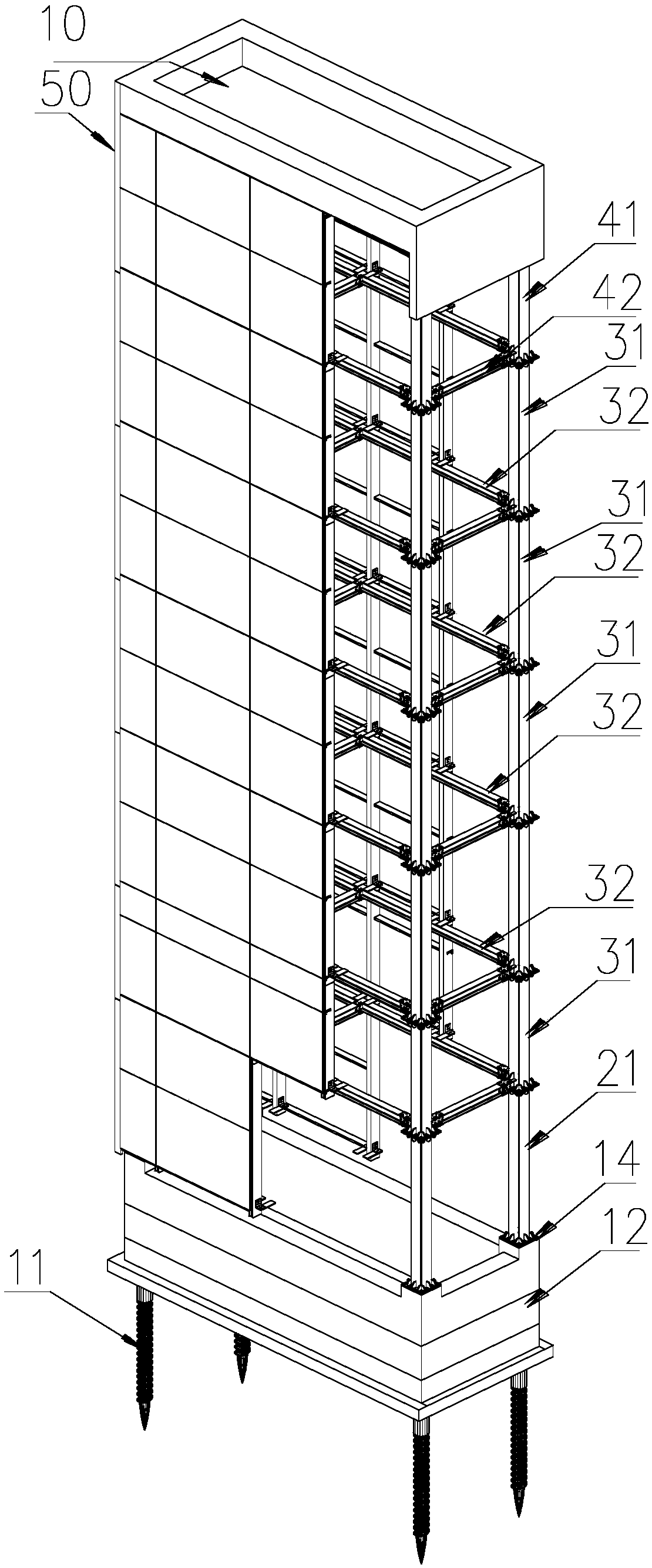

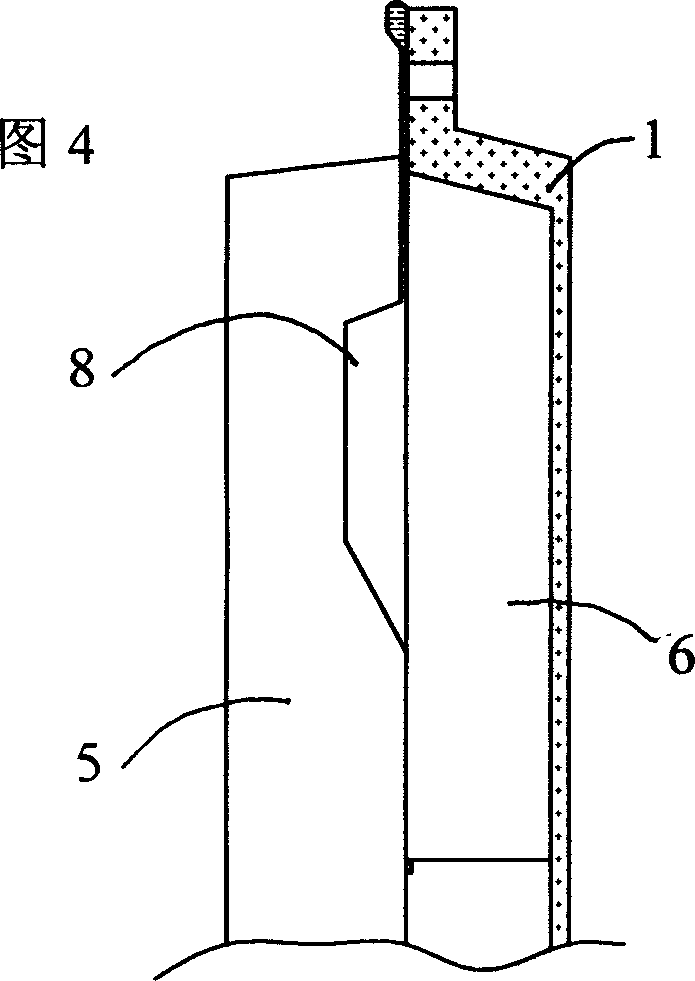

Jacking construction method for assembled-type external elevator shaftway structure

ActiveCN108532769ASmall space constraintsReduce the impactBuilding constructionsFalseworkReinforced concrete

The invention discloses a jacking construction method for an assembled-type external elevator shaftway structure. The jacking construction method comprises the steps that a foundation pit is excavated, and reinforced concrete foundations and pre-buried connecting components are made; a jacking guiding device is mounted on an existing building, and a jacking device is mounted at the bottom of the foundations; a jacking monitoring device is mounted on an assembled elevator shaftway top layer structure unit to conduct jacking operation of the top layer structure unit, the jacking operation stateis monitored in real time, and torsion or inclination of the structure is prevented cautiously; assembling and jacking of structure units of all standard layers are conducted in sequence, and a first-layer structure frame is mounted; equipment is dismounted, and an elevator shaftway and the existing building are connected through flexible connecting components layer by layer; construction of a roof, all layers of floors, partition plates and the first layer is conducted; and finally, an elevator is mounted. By adopting the jacking construction method, the occupied area is small, the period isshort, the efficiency is high, labor force is saved, heavy transportation vehicles and large lifting equipment are not needed, a scaffold does not need to be set up on site, and high-attitude operation and the influence on the daily life of residents can be reduced significantly.

Owner:华城(天津)建筑科技有限公司

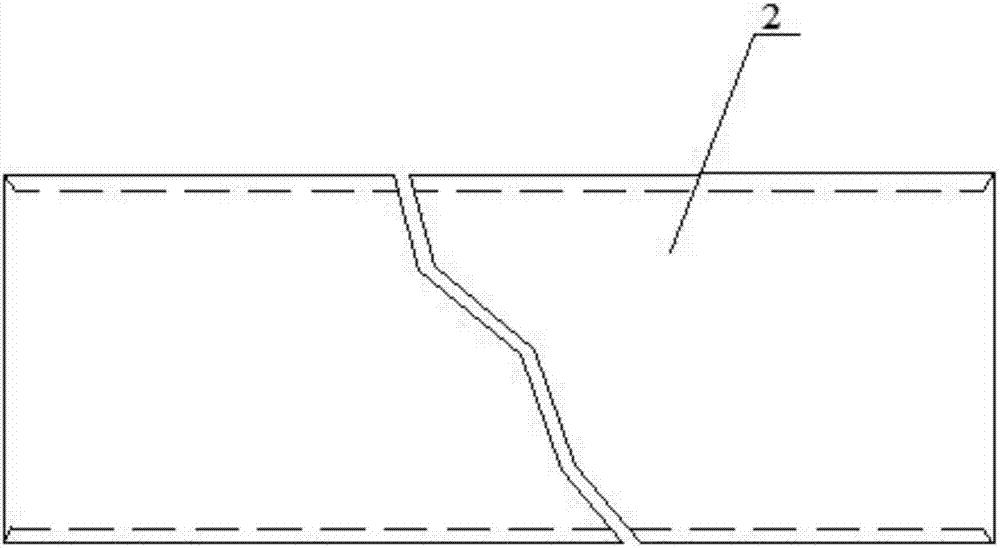

Fast building earthquake-resisting reinforcing method and device

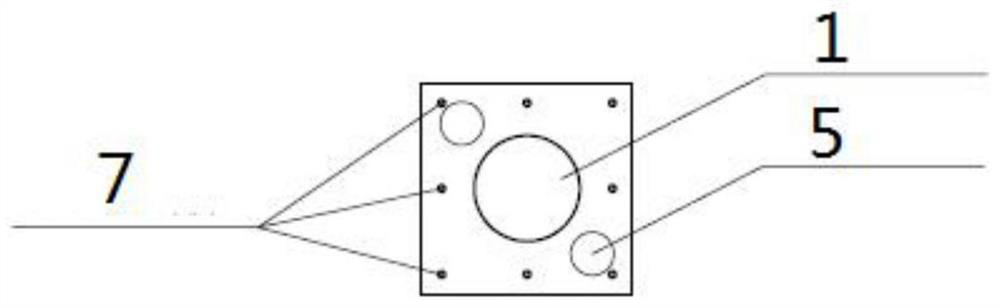

InactiveCN101936074AGuarantee product qualityShorten the on-site construction periodBuilding repairsShock proofingHalf fieldEngineering

The invention provides fast building earthquake-resisting reinforcing method and device. The fast building earthquake-resisting reinforcing device is a prefabricated part, the inner side of the prefabricated part is provided with a grout groove, and the grout groove is communicated with the outer side of the prefabricated part through more than one grout hole. The reinforcing method comprises the following steps of: removing the skin of the junction surface at the junction part between a wall of the reinforced building and the prefabricated part, and drilling anchoring holes in the wall, wherein the position of each anchoring hole is corresponding to the junction hole in the prefabricated part; installing the prefabricated part on the wall of the reinforced building through anchoring bolts, anchoring adjacent prefabricated parts, and fixedly bonding the prefabricated parts to the surface of the wall together. The technical scheme of field assembly of the prefabricated parts is adopted to reinforce the building, more than half field construction period can be shortened, the prefabricated parts can be produced in factories during school time, and enough time for ensuring production quality is guaranteed.

Owner:BEIJING TEXIDA TECH CO LTD

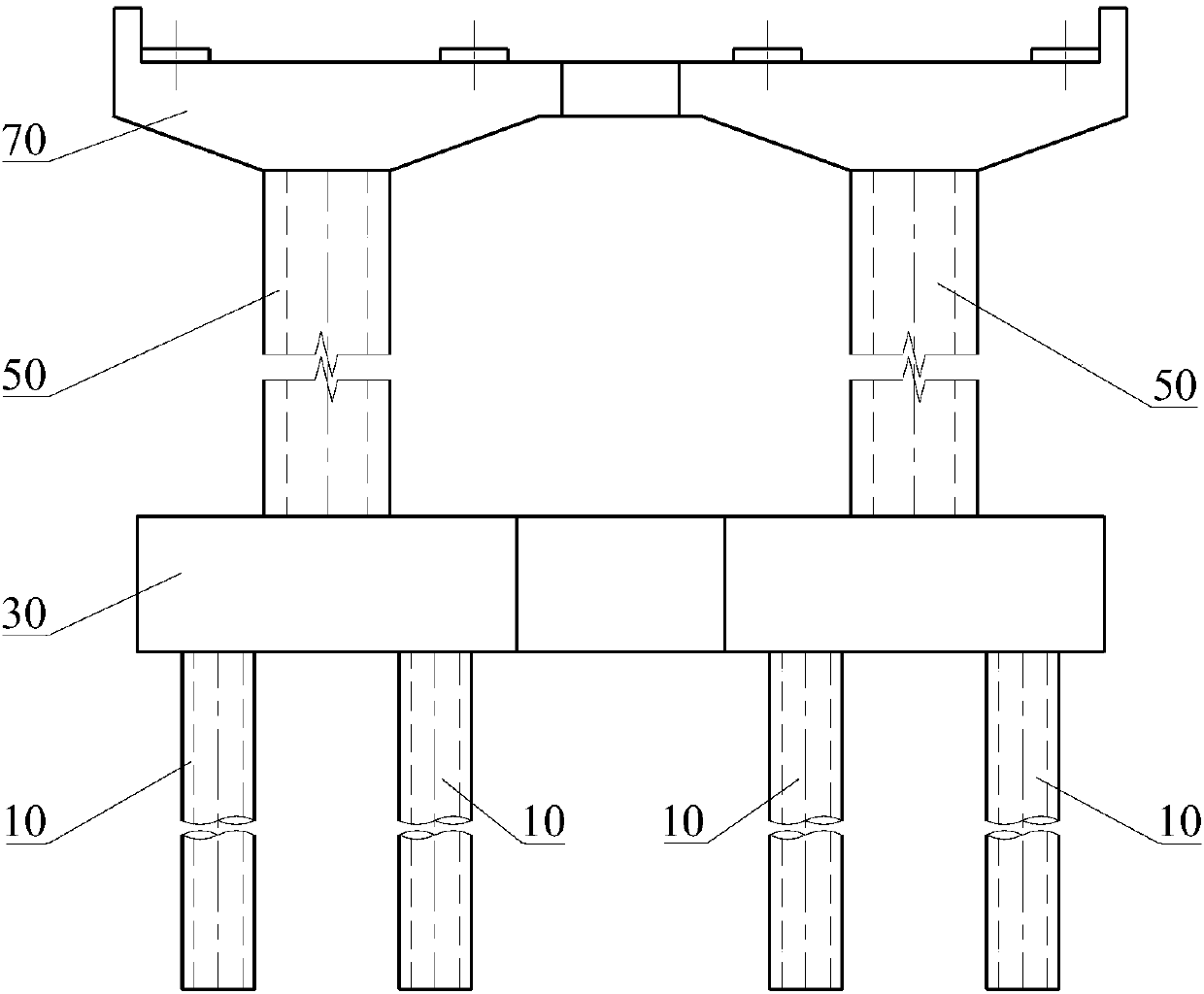

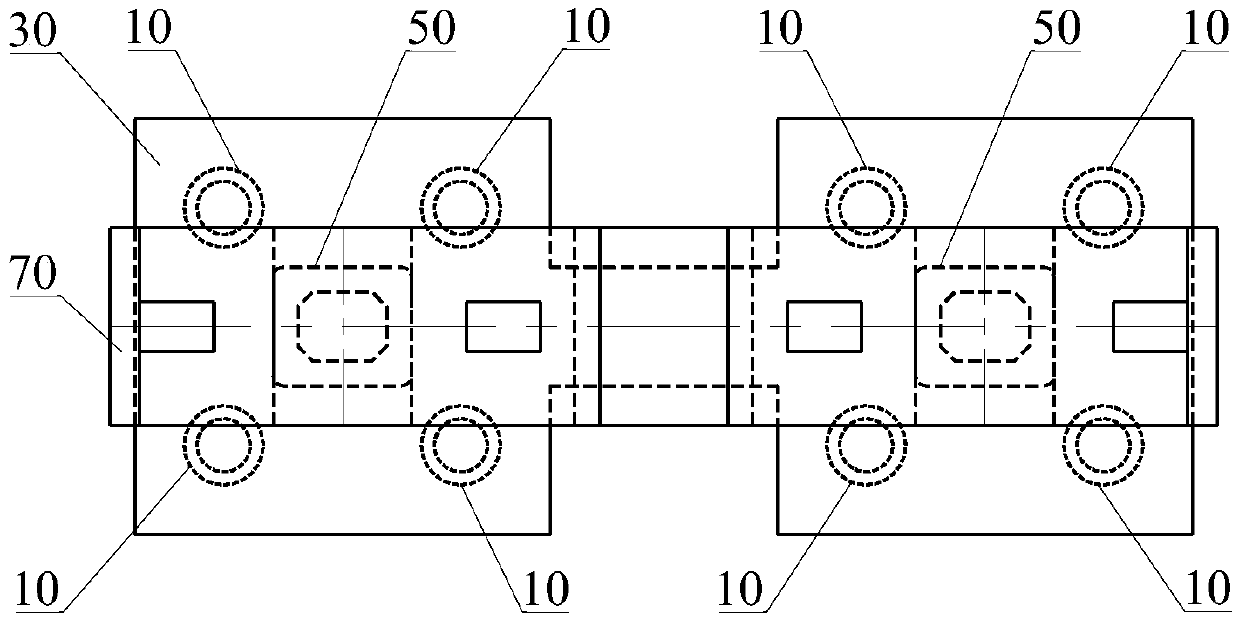

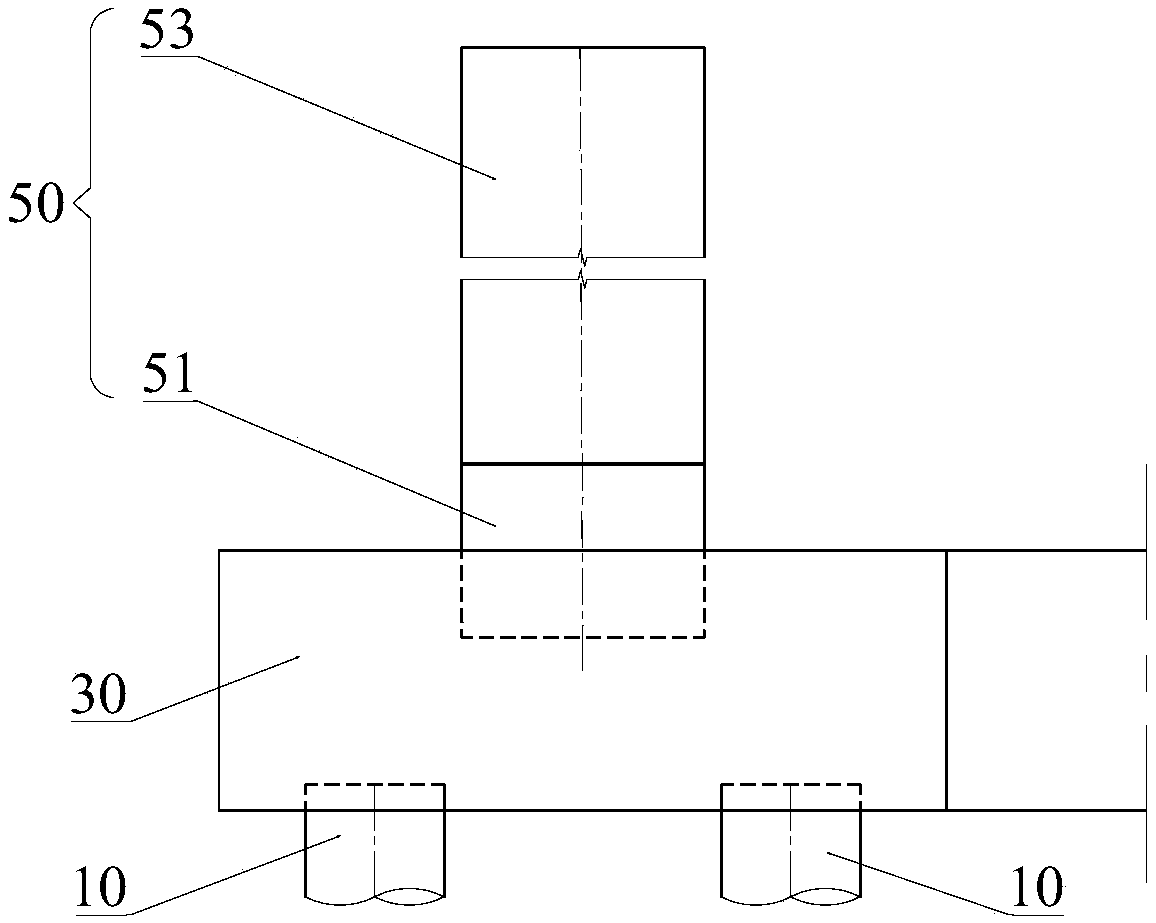

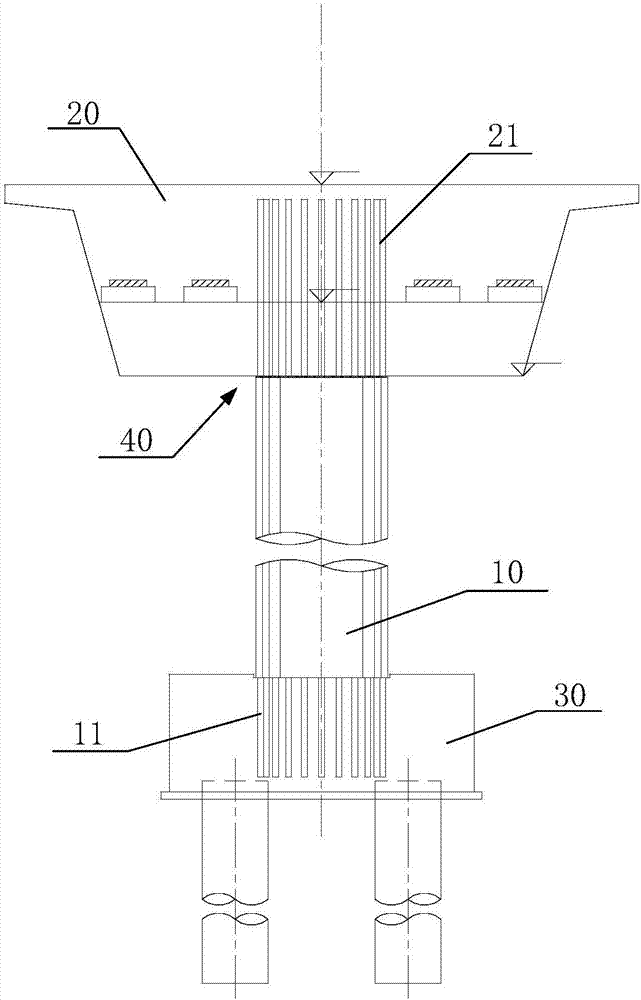

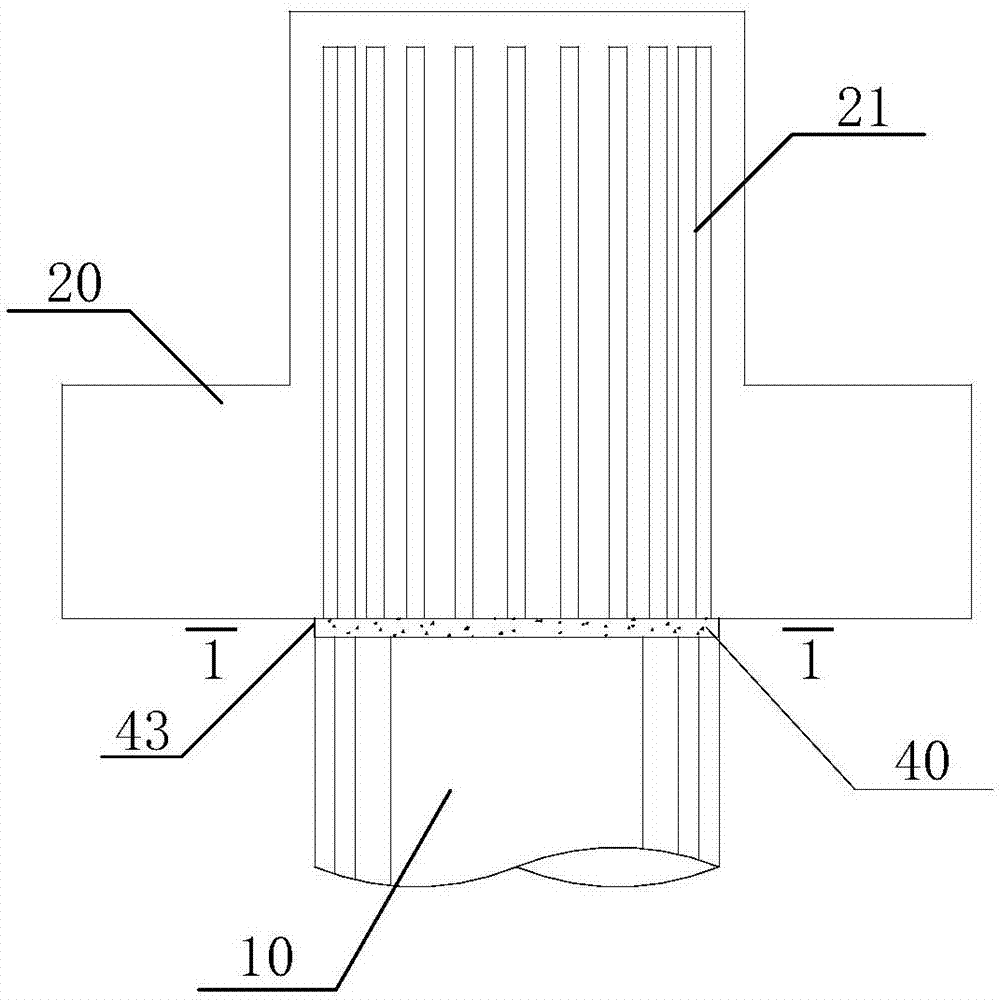

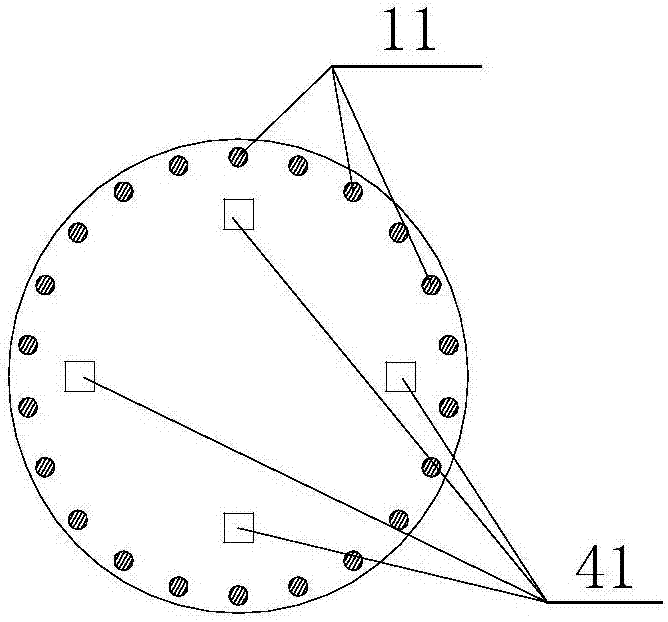

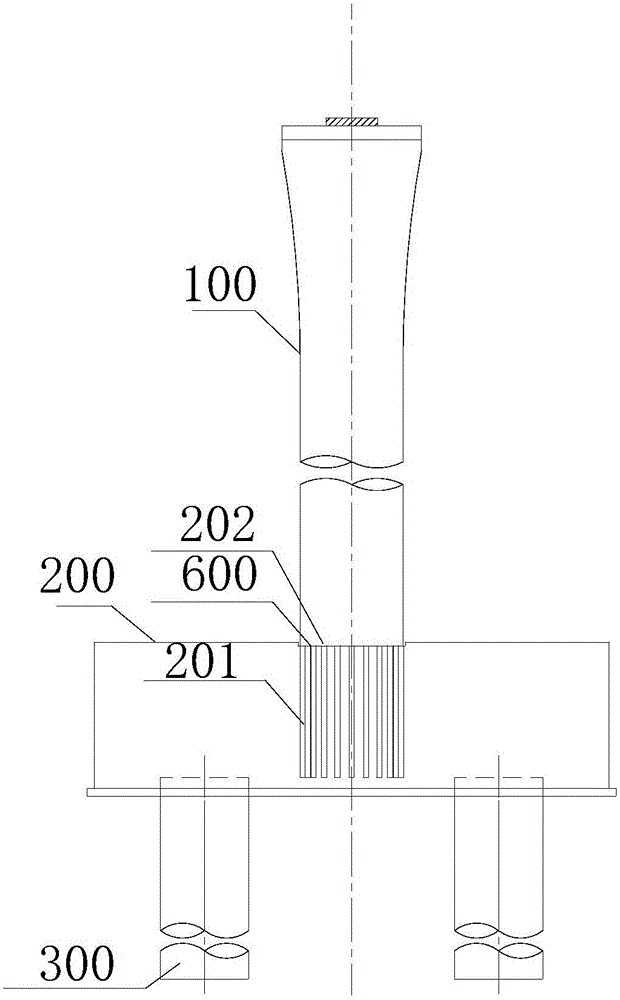

Assembled hollow pier based on end plate welding and construction method of assembled hollow pier

ActiveCN108103926ARealize modularizationRealize industrial productionBridge structural detailsHeight differenceHollow core

The invention discloses an assembled hollow pier based on end plate welding and a construction method of the assembled hollow pier. The assembled hollow pier comprise pile foundations, cast-in-place bearing platform, prefabricated pier columns and prefabricated cap beams and is characterized in that the cast-in-place bearing platform is formed at the upper ends of the pile foundations in a cast-in-place manner and horizontally connected with the pile foundations; the prefabricated pile columns are vertically connected onto the cast-in-place bearing platform, each prefabricated pile column comprises an embedded pier column section partially embedded into the bearing platform and prefabricated pier column sections, and the prefabricated pier column sections are sequentially vertically weldedupwards to reach a set height and then connected with the lower end of the corresponding prefabricated cap beam. The assembled hollow pier has the advantages that the prefabricated pier column sections and the embedded pier column sections are prefabricated in a centralized manner, industrial production can be achieved, and construction quality can be increased; the embedded pier column sectionsare embedded by the aid of the cast-in-place bearing platform, pier column height differences in practical engineering are avoided by embedding depth change and modularizing prefabricated pier columnlengths, and modularized prefabricated pier column lengths are achieved.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

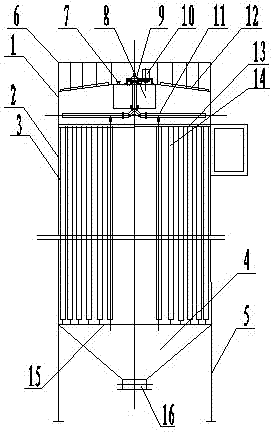

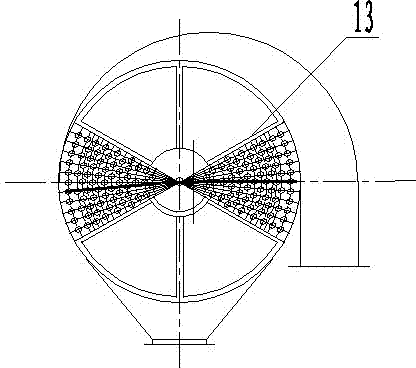

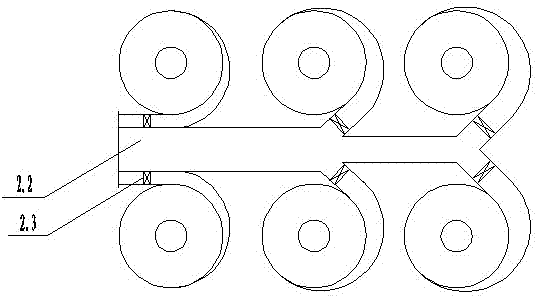

Large stepping type rotating pulse desuter

InactiveCN102755791ASolve the problem of unequal service lifeAccelerate the realization of localizationDispersed particle filtrationCycloneEngineering

A large stepping type rotating pulse desuter is composed of an upper barrel (with an air outlet), a volute, a middle barrel, an ash hopper, a support, a top guardrail, a compressed air inlet pipe, an air bag, a pulse valve, a stepping motor, a speed shifting mechanism, spray-blow pipes, a top cover, a tube nest, a filter bag assembly, a guide grid and an ash discharging valve. The large stepping type rotating pulse desuter is of a round structure and is simple in structure, convenient to construct and high in compression strength. A filter bag is a round special denting-preventing device. The tube nest is specially arranged. Filter area of one deduster reaches 2540 square meters, and one deduster is only provided with one pulse valve, two to three spray-blow pipes and one air bag arranged in an air purifying chamber and rotating to be balanced. An air inlet is arranged on the upper portion of the middle barrel and is a tangential cyclone inlet. A module type structure is adopted so that processing and transporting are facilitated. A plurality of large stepping type rotating pulse desuters can form a super large pulse desuter which has the advantages of being low in investment and operation expanse and wide in adaptive range.

Owner:ZUNYI CITY GUI KE TECH

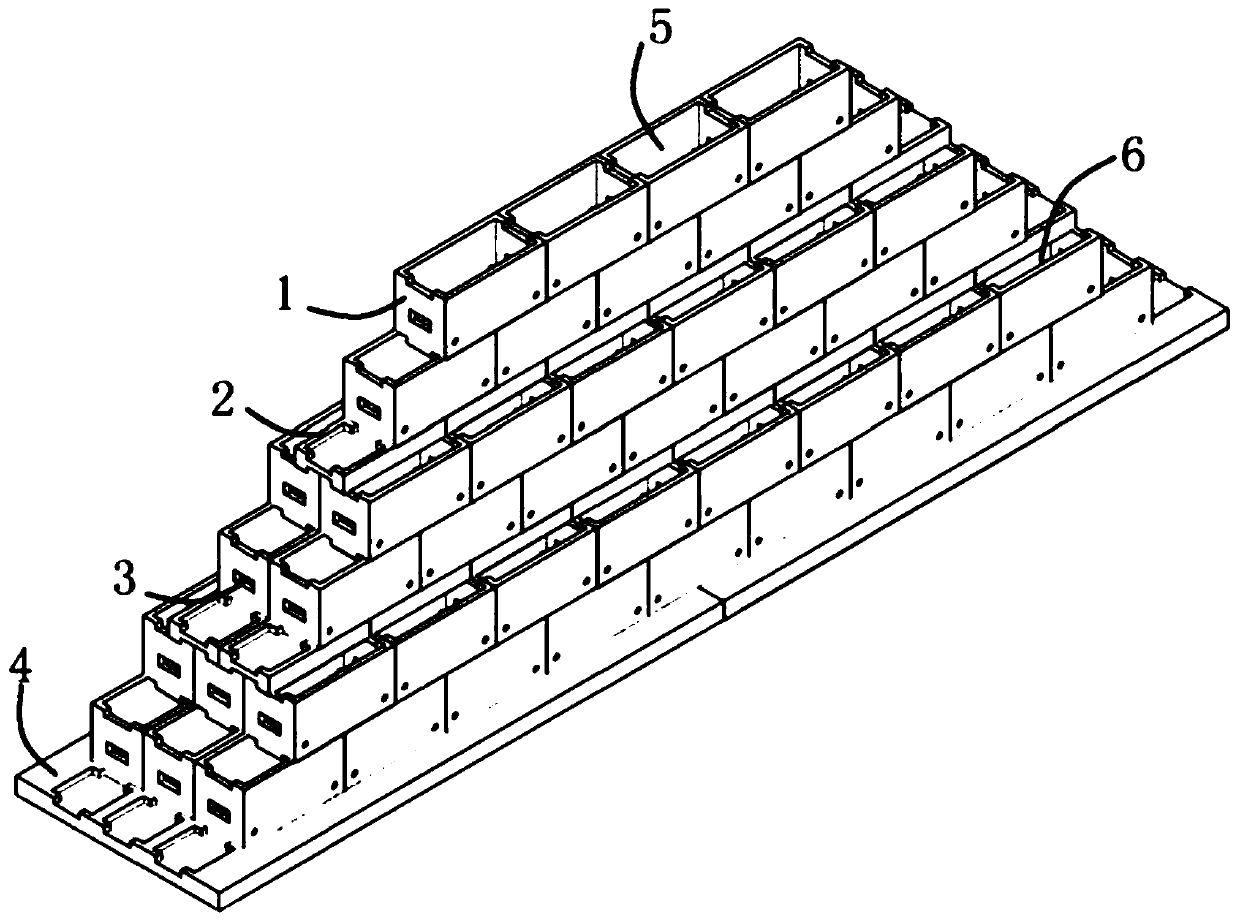

Fabricated concrete box retaining wall and construction method thereof

PendingCN110241849AReduce abandonmentLow costArtificial islandsUnderwater structuresRetaining wallMultiple layer

The invention discloses a fabricated concrete box retaining wall and construction method thereof. The fabricated concrete box retaining wall comprises a cast-in-situ foundation and a wall body arranged on the cast-in-situ foundation, concave string-shaped grooves are formed in the upper surface of the cast-in-situ foundation, the wall body is of a multiple-layer structure, each layer of the wall body comprises a plurality of prefabricated concrete box single bodies, the end parts of the two adjacent prefabricated concrete box single bodies in a single layer wall body are connected through side wall clamping blocks, compared with a traditional gravity retaining wall, according to the fabricated concrete box retaining wall, hollow concrete boxes are filled with waste soil stone materials, masonry or concrete cubic amount is reduced about 40 %, the cubic meter of earth and stone waste in engineering is utilized reasonably, the waste cubic of engineering is reduced, the engineering cost can be reduced over 15 %, the smallest assembling unit of the fabricated concrete box retaining wall is the prefabricated concrete box single bodies, all the prefabricated concrete box single bodies are the same in size, standardized production is facilitated, assembling construction is convenient, and the field construction period can be lowered over 30 %.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

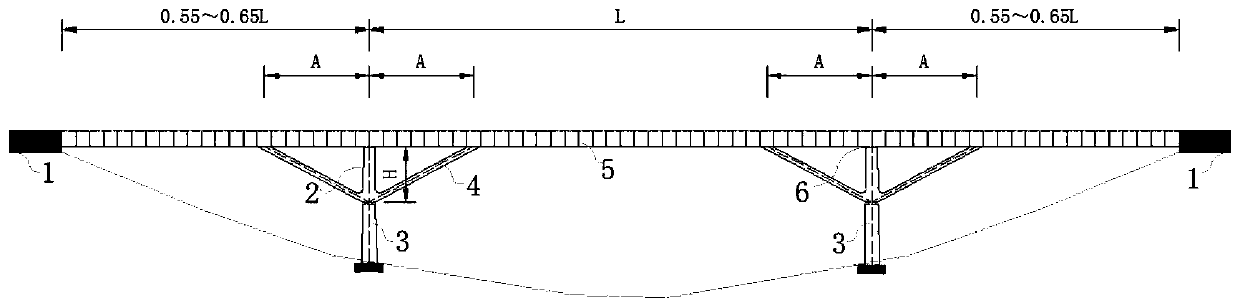

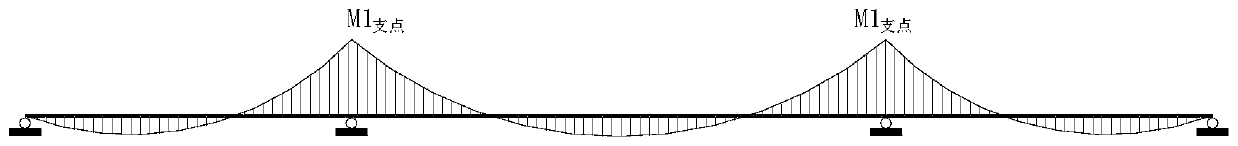

Long-span steel-concrete composite bridge structure and construction process thereof

PendingCN110344315AImprove support strengthRealize a large spanBridge structural detailsBridge erection/assemblyBridge deckPrefabrication

The invention discloses a long-span steel-concrete composite bridge structure and construction process thereof. Thus, the problems in the prior art of restricted bridge span and large integral steel using amount of bridges can be solved. The bridge structure and construction process can realize factory prefabrication and have beneficial effects of saving construction periods and steel using amount. The schemes include as follows: the bridge structure includes a steel main beam, a concrete bridge deck and bridge piers; the steel main beam includes multiple sections which can be assembled; the steel main beam adopts a box type section structure in a width direction; the two sides of the box type section structure are provided with outer longitudinal beams connected to the box type section structure; the concrete bridge deck is arranged on the top of the steel main beam and connected to the steel main beam; and steel diagonal bracings are arranged between the bridge piers and the steel main beam.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

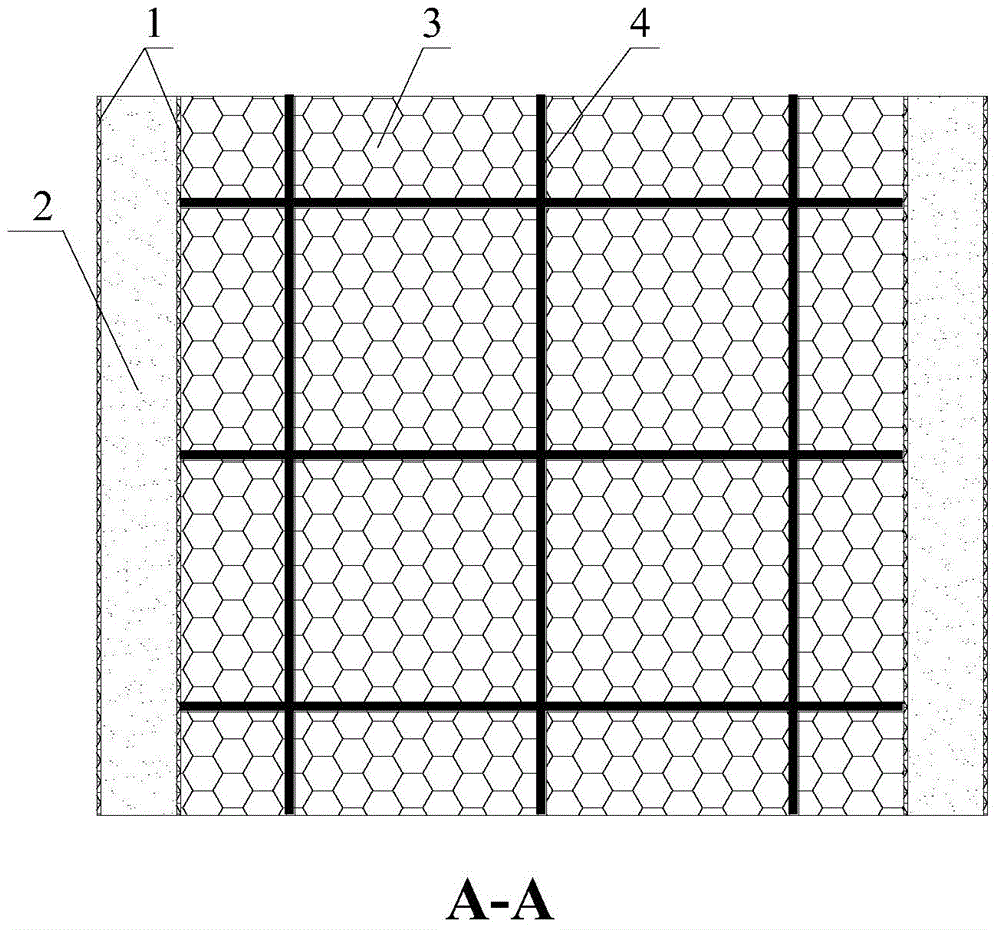

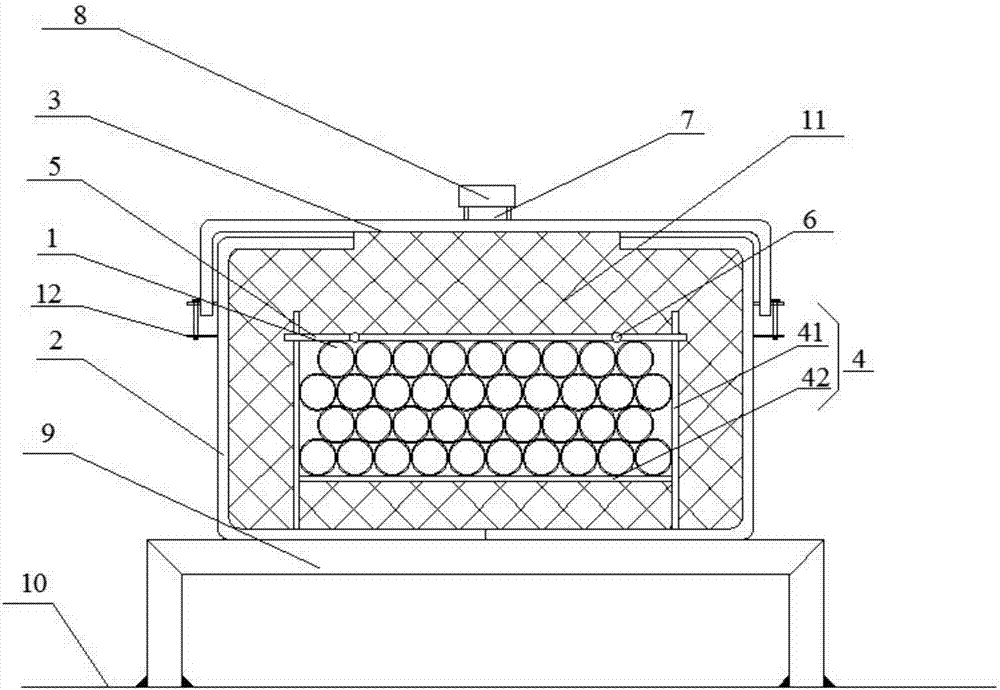

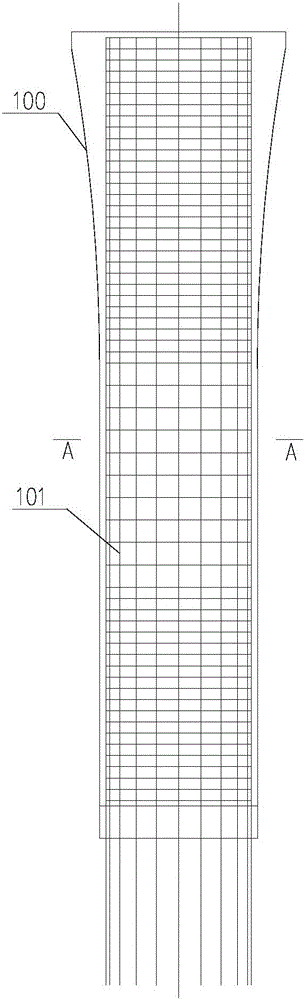

Prefabricated type reinforced concrete underground comprehensive pipe gallery and production mold thereof

InactiveCN105040732ALow costShorten the on-site construction periodArtificial islandsCeramic shaping apparatusReinforced concreteEngineering

The invention mainly discloses a prefabricated type reinforced concrete underground comprehensive pipe gallery. The prefabricated type reinforced concrete underground comprehensive pipe gallery is formed by sequentially arranging a plurality of integral type unit joints. The integral type unit joints comprise trough type prefabricated reinforced concrete plates and / or I-shaped, L-shaped and T-shaped prefabricated reinforced concrete plates and prefabricated reinforced concrete flat plates. All the plates are solid prefabricated plates, and upward-stretching connecting reinforcements are arranged on the top faces of the plates. The two trough type prefabricated reinforced concrete plates of each integral type unit joint are symmetrically spliced, or the trough type prefabricated reinforced concrete plates are combined with other prefabricated reinforced concrete plates or combined in a matched manner to form an integral type unit joint framework with a single channel or a left-and-right channel or an upper-and-lower channel or four upper-and-lower channels. Reinforced concrete overlapping layers are poured on the top face and the bottom face of the framework respectively to form the corresponding integral type unit joints. All the plates are prefabricated, then transported to the site and spliced according to process requirements, then reinforced concrete overlapping layers are poured, and therefore the integral type unit joints are manufactured and mounted. The manufacturing cost can be greatly lowered through workshop batch prefabrication, and the site construction period is greatly shortened through the treatment process of pouring the integral overlapping layers after site framework assembling and cooperation.

Owner:HUNAN DONGFANGHONG CONSTR GRP

Stand column and cover beam splicing structure

InactiveCN106906747AShorten the on-site construction periodSave construction siteBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention relates to a stand column and cover beam splicing structure used for splicing of a stand column and a cover beam. The bottom of the stand column is fixed to a bearing platform. A plurality of steel bars extend out of the top of the stand column. A plurality of metal corrugated pipes are embedded in the cover beam. The bottoms of the metal corrugated pipes are flush with the bottom face of the cover beam. The metal corrugated pipes correspond to the steel bars in position. A splicing joint between the stand column and the cover beam is filled with high-strength mortar or epoxy splicing glue. Grouting channels arranged in the cover beam. The two ends of each metal corrugated pipe communicate with a mortar inlet and a mortar outlet through the grouting channels correspondingly. According to the stand column and cover beam splicing structure, a traditional bridge building mode is changed, no bracket or formwork exists on a construction site, the site construction period is greatly shortened, the labor intensity of workers is relieved, and requirements for the construction site are reduced; the procedures of bracket foundation processing and bracket formwork erection on the site are omitted, and the economical efficiency is good; and meanwhile, adverse impact on the surroundings is reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

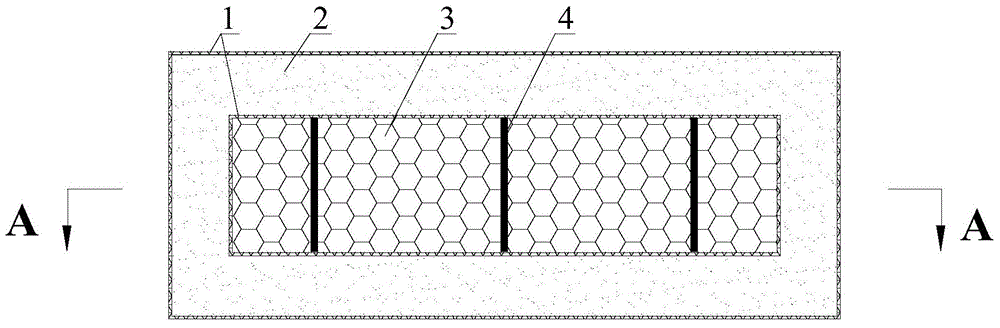

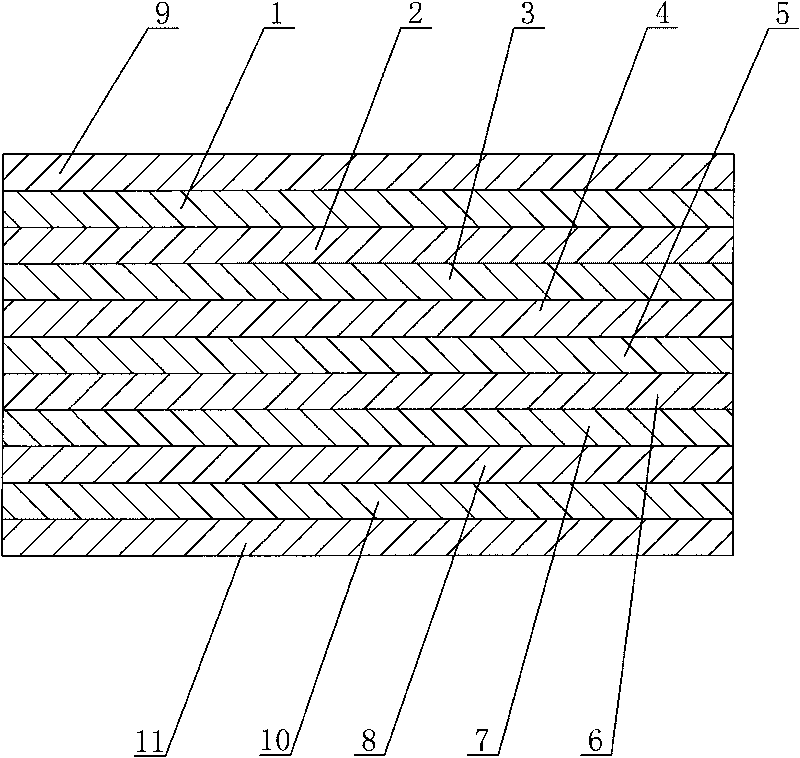

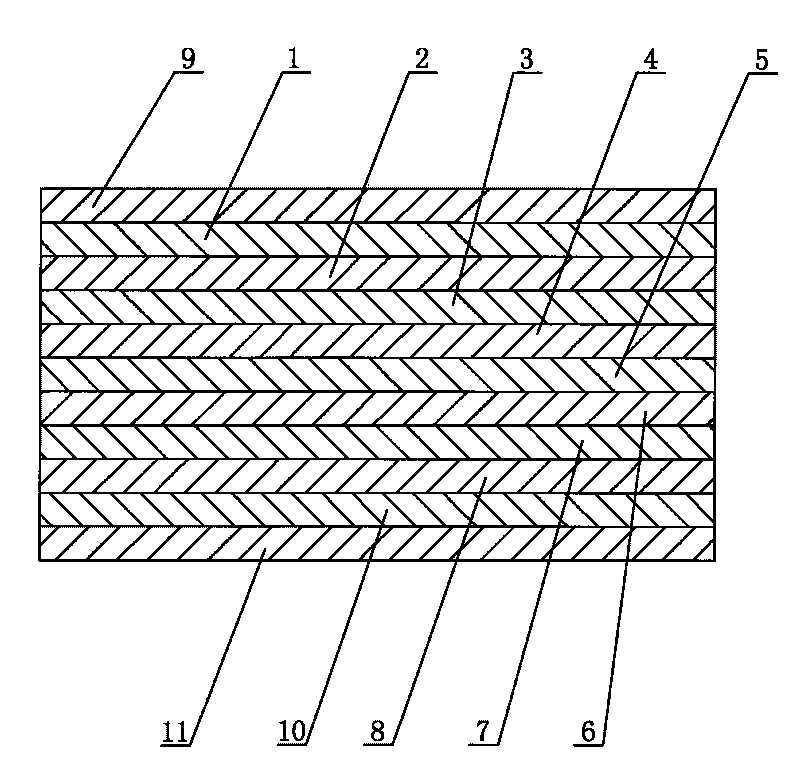

Novel building material of fiberglass composite structure, production device and production method

ActiveCN105089170AImprove carrying capacityReduce weightSynthetic resin layered productsHeat proofingThermal insulationBuilding material

The invention discloses a novel building material of a fiberglass composite structure, a production device and a production method. The novel building material comprises a heat insulation sandwich layer and a cement structural layer. The cement structural layer wraps the periphery of the heat insulation sandwich layer. The heat insulation sandwich layer comprises a reinforcing structural frame and a heat insulation foaming material. Gaps in the reinforcing structural frame are fully filled with the heat insulation forming material. The cement structural layer is made of cement. A fiberglass layer is arranged between the heat insulation sandwich layer and the cement structural layer in a partition mode, and the periphery of the outer side of the cement structural layer is wrapped with the fiberglass layer as well. The heat insulation layer is innovatively arranged in the cement structural layer, the structural performance and heat insulation performance are guaranteed while integrated design and manufacturing are achieved, modular prefabrication at a production base can be conducted, fast field spicing is achieved, and the field construction cycle can be greatly shortened.

Owner:江苏溧阳建设集团有限公司

Bridge deck accessory component manufacturing mold and bridge deck accessory component manufacturing method

InactiveCN112497439AImprove entity qualityHigh degree of standardizationMouldsMould fastening meansAccessory structureArchitectural engineering

The invention discloses a bridge deck accessory component manufacturing mold. The bridge deck accessory component manufacturing mold comprises a bottom mold body, two end mold bodies and two side moldbodies, the end mold bodies and the side mold bodies are detachably connected with the bottom mold body, the two end mold bodies are connected to the two ends of the bottom mold body correspondingly,the two side mold bodies are connected to the two sides of the bottom mold body correspondingly, and the bottom mold body, the end mold bodies and the side mold bodies define a box-shaped structure with the upper end open. The bottom mold body is provided with a groove used for containing a bridge deck accessory component, the groove is formed by connecting continuously-bent bottom plates, the adjacent bottom plates are rotationally connected, a back arris gap is formed between the adjacent bottom plates, and an adjusting rod for adjusting the relative positions of the bottom plates is arranged below the bottom mold body. The bridge deck accessory component manufacturing mold effectively overcomes the defects that many installation procedures are needed for a traditional bridge deck system protection wall, a vertical wall, a side wall and other bridge deck accessory structures, the number of adopted formworks is large, concrete pouring is carried out multiple times, the formwork dismounting and mounting process is tedious, formwork dismounting needs to wait for the concrete strength, all the procedures are carried out in sequence, the construction period is long, the number of users is large, and time and labor are wasted when materials are transported, disassembled and assembled.

Owner:THE SECOND CONSTR OF CTCE GROUP +1

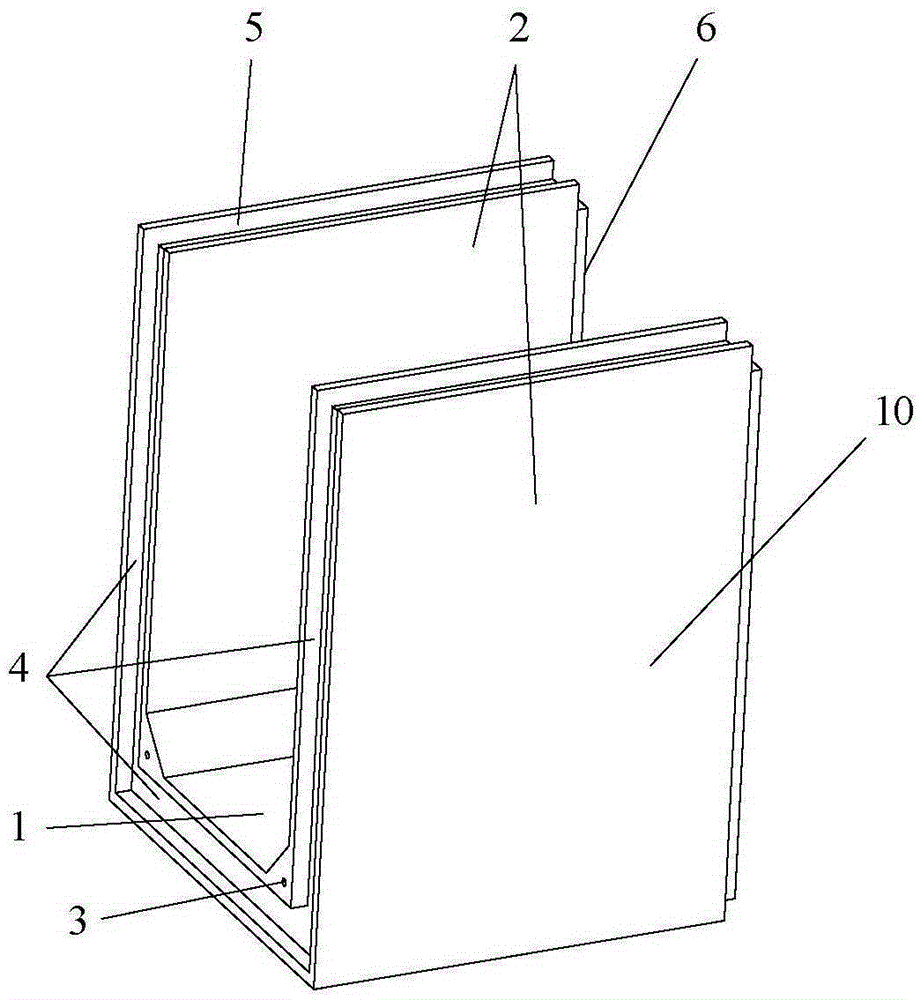

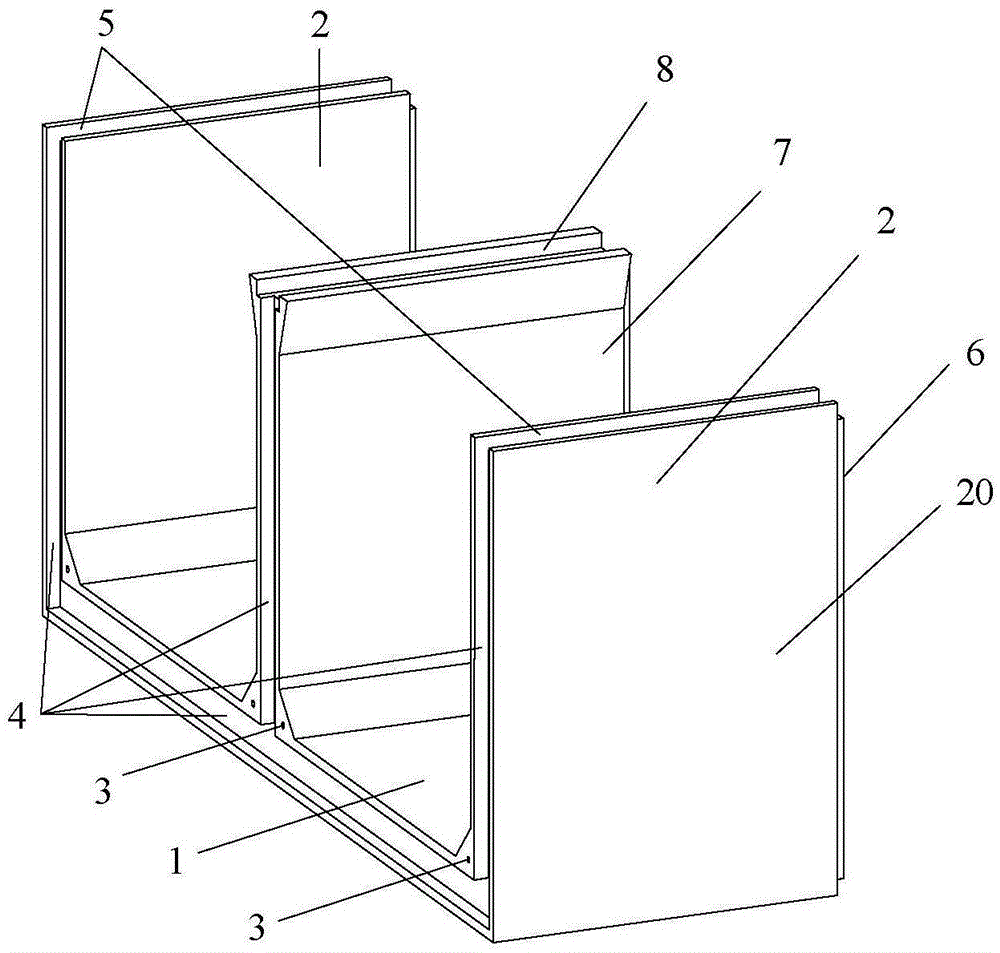

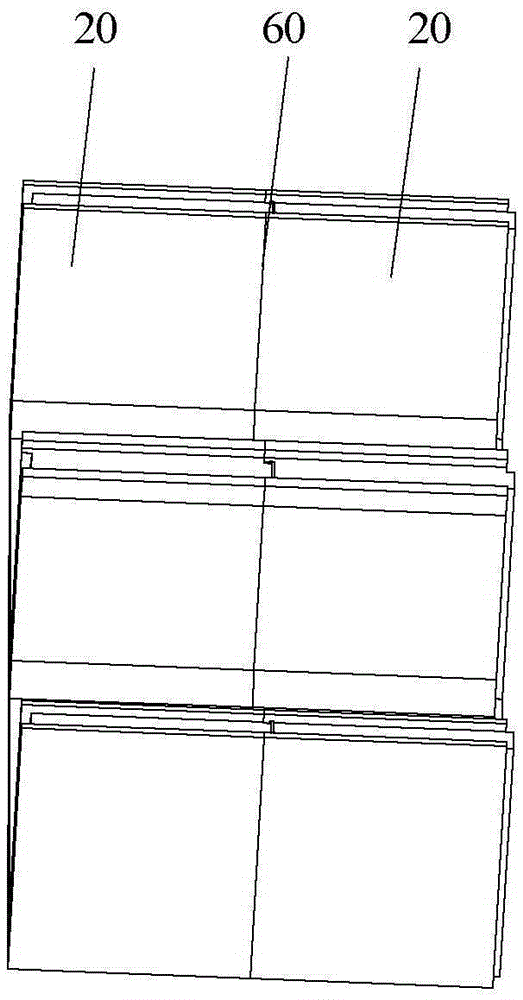

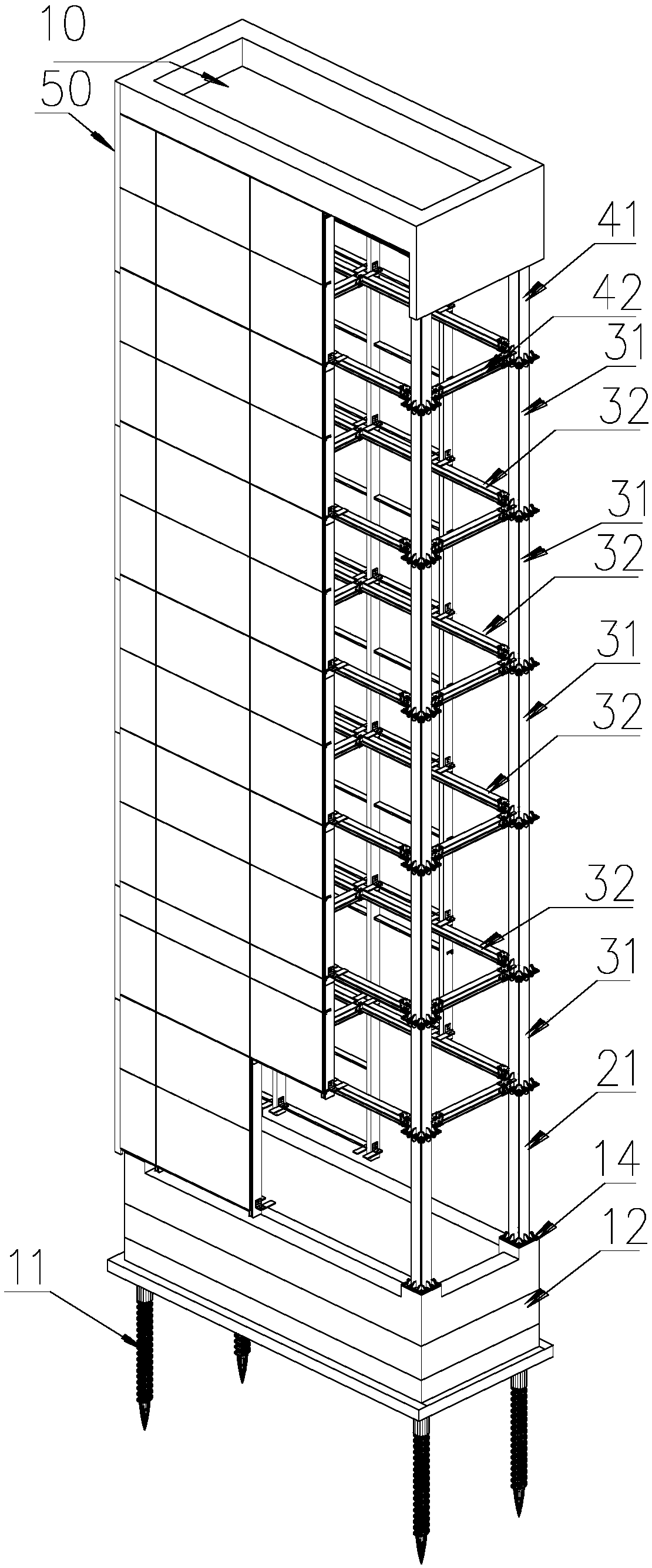

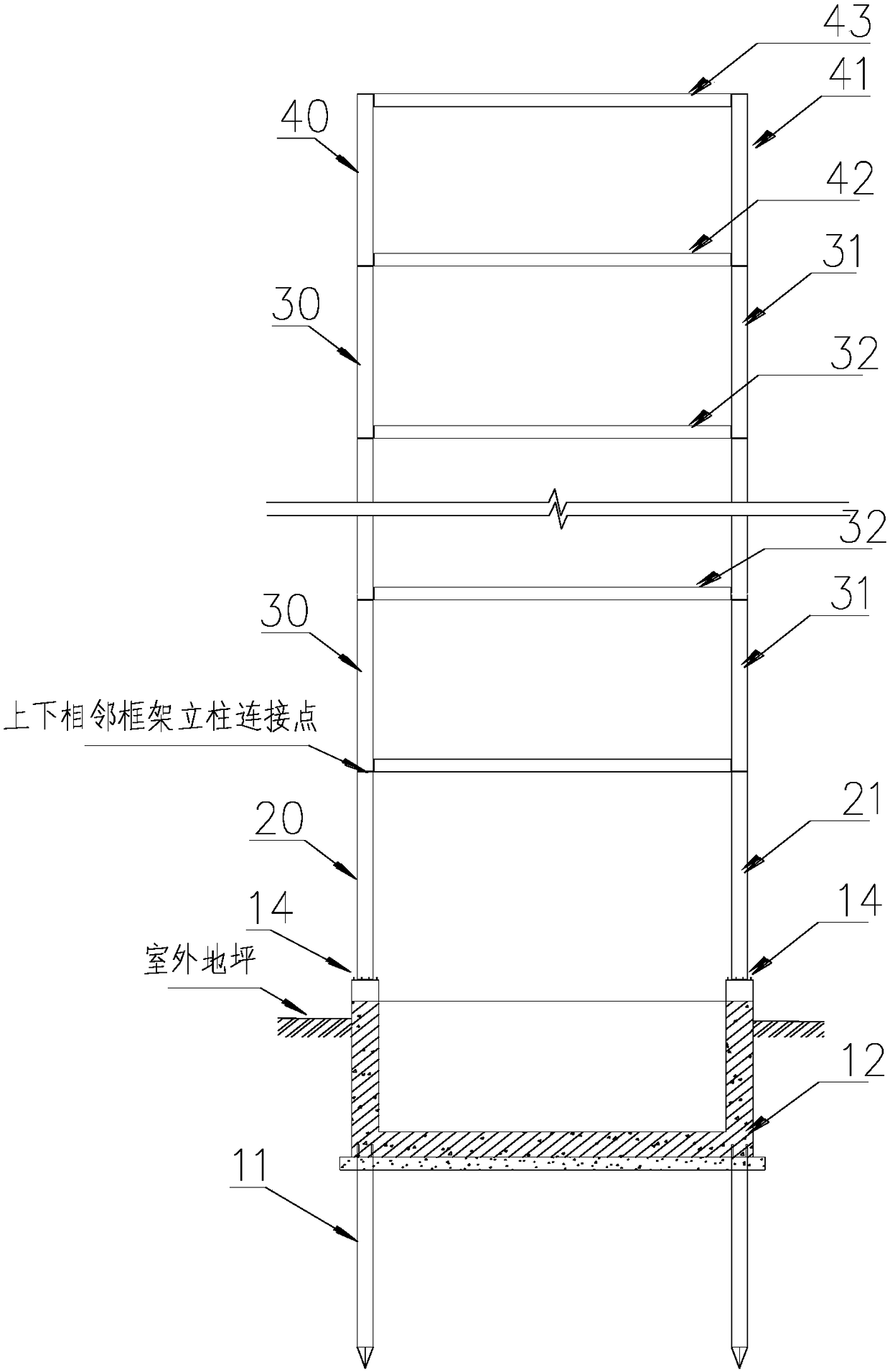

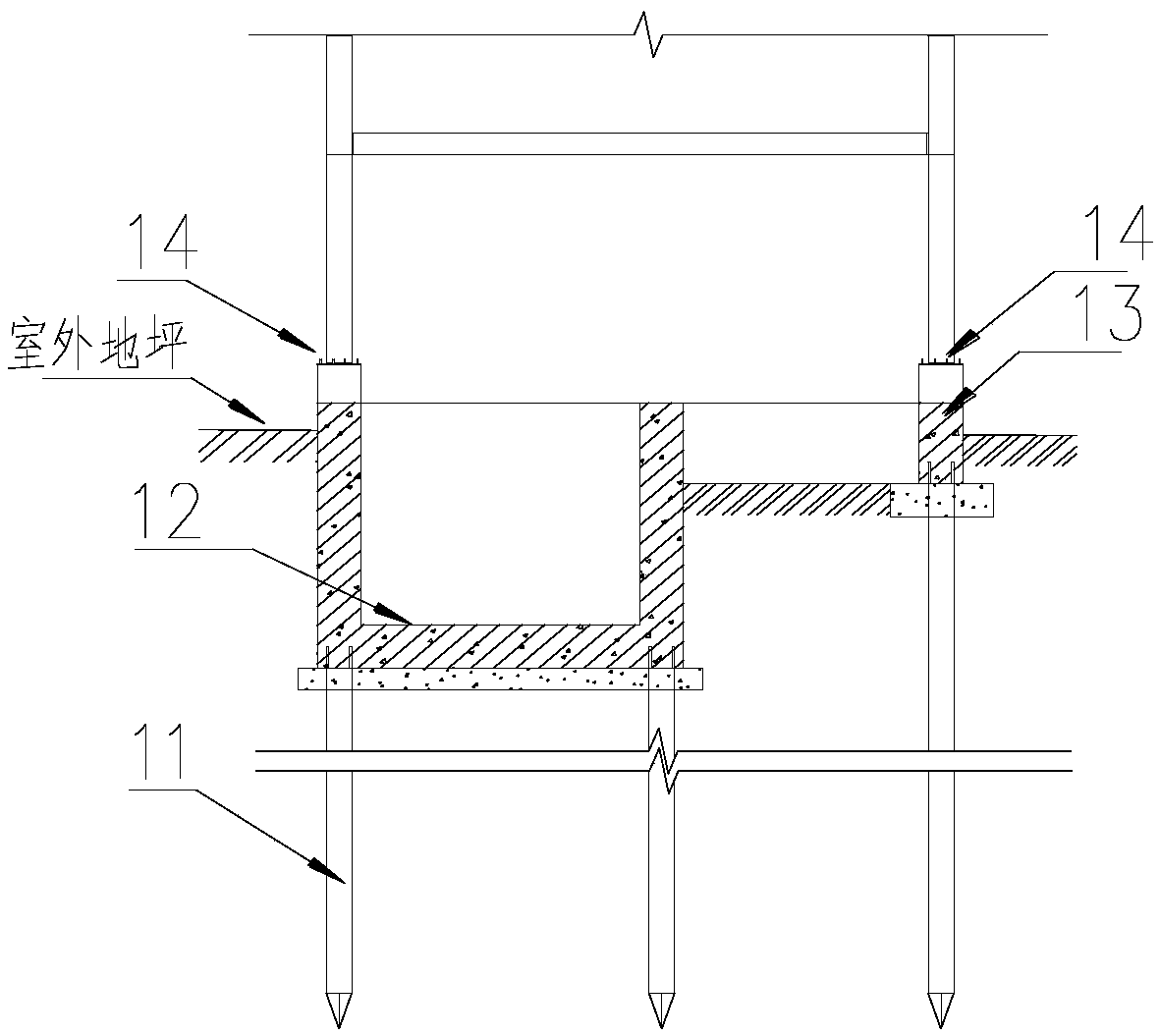

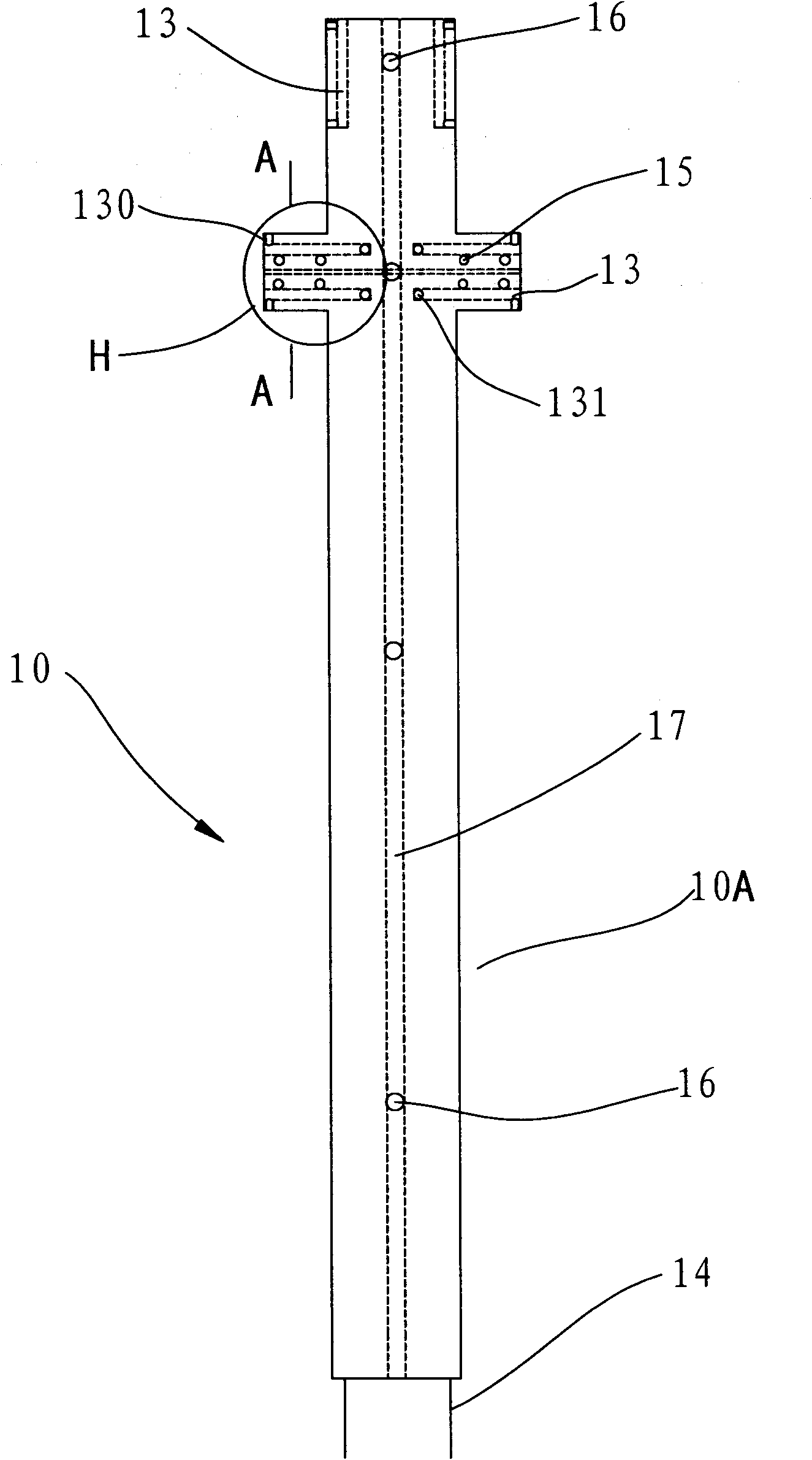

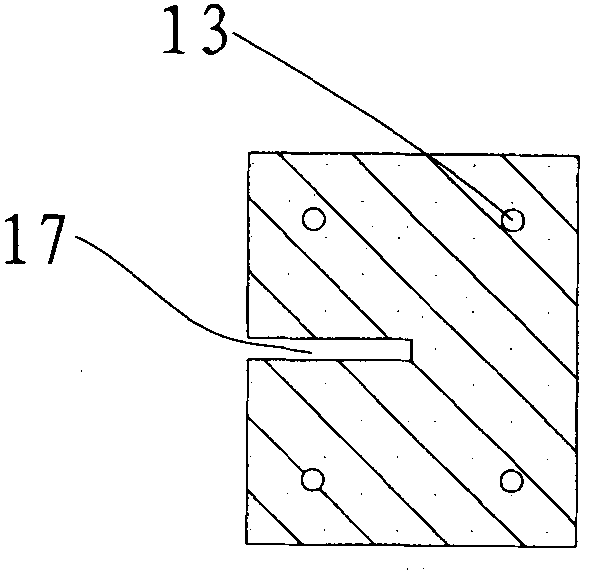

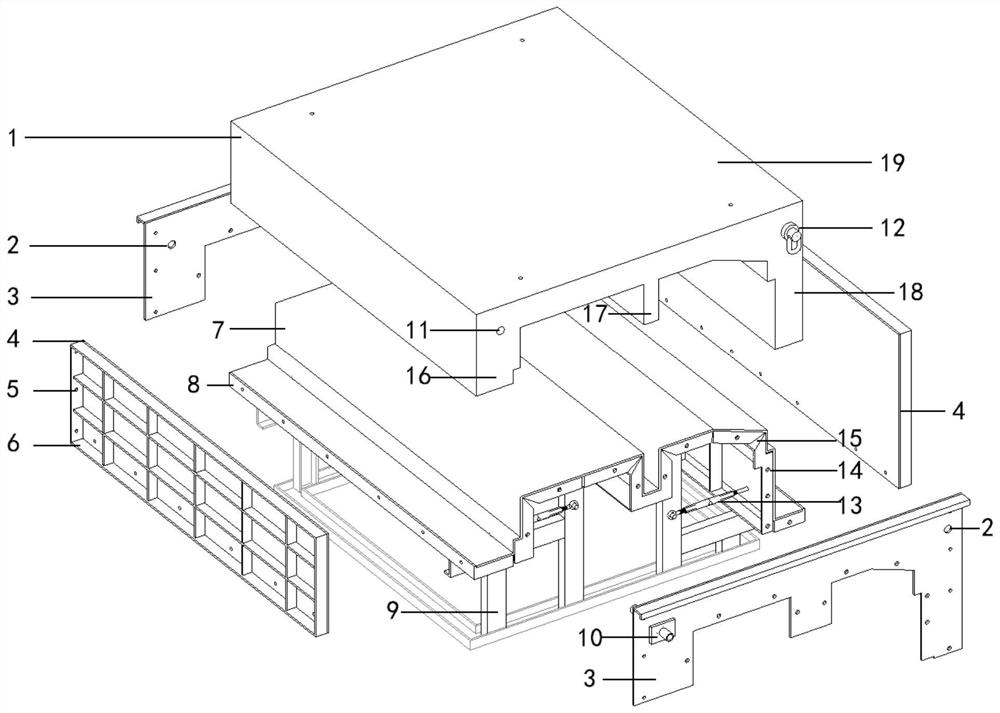

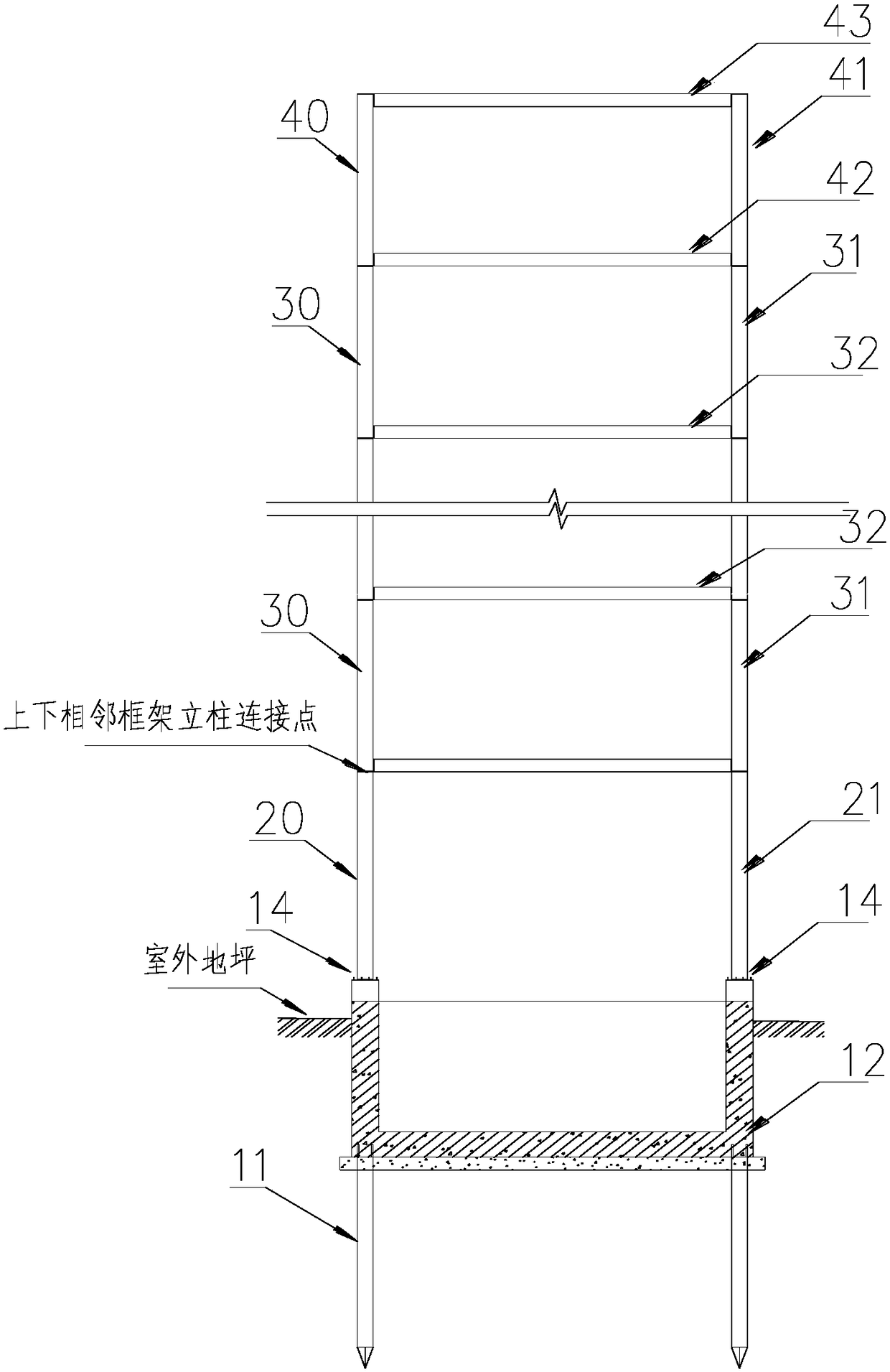

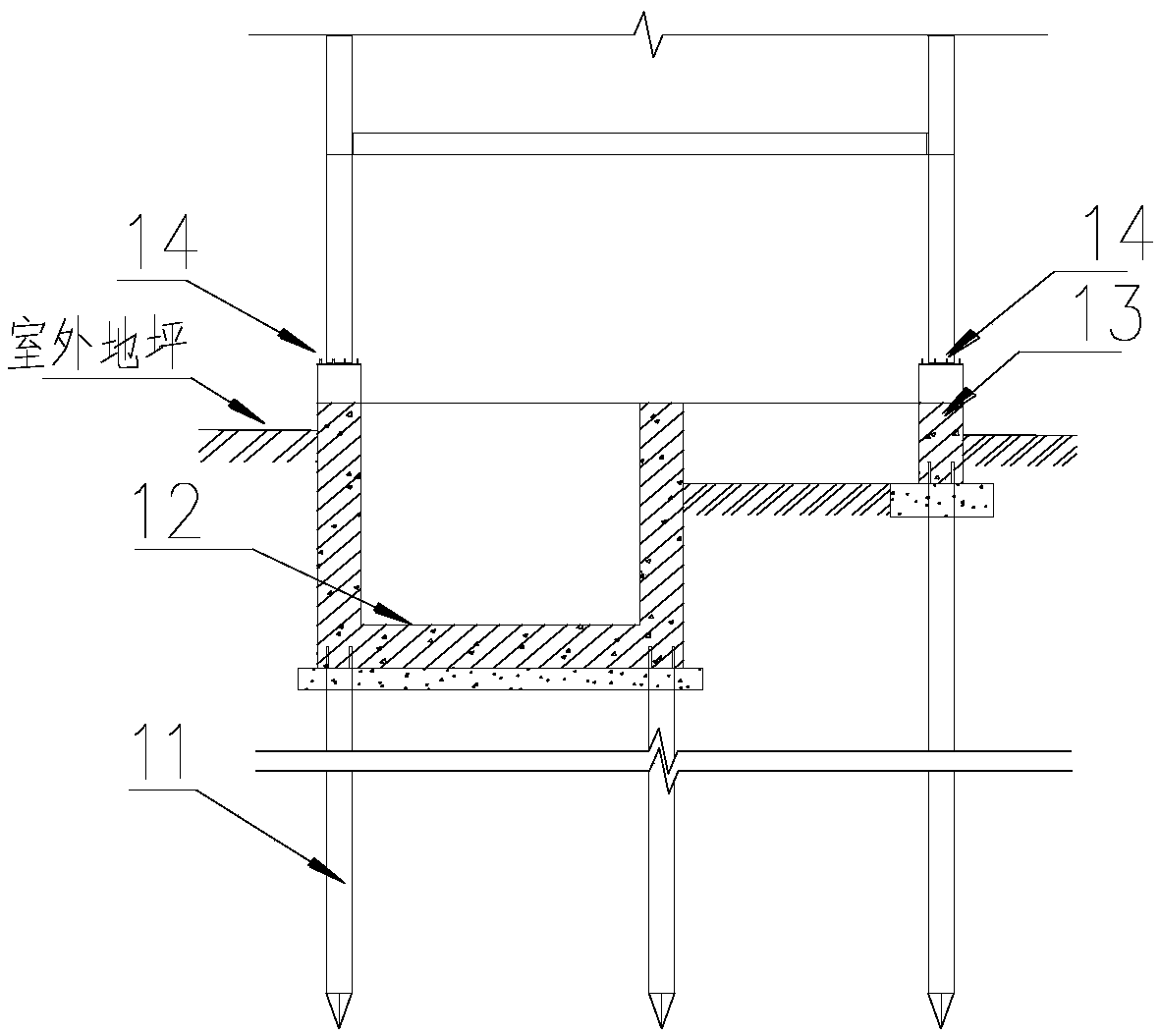

Assembly type additional lift shaft structure adapting to jacking construction

The invention discloses an assembly type additional lift shaft structure adapting to jacking construction. The assembly type additional lift shaft structure adapting to jacking construction comprisesa foundation, a prefabricated steel frame supporting structure, a light curtain wall envelop structure and a roof. The prefabricated steel frame supporting structure comprises a first layer frame, a plurality of standard layer frames and a top layer frame. Each layer frame comprises four or more stand columns, wherein the positions of the stand columns are set in a face-to-face mode. The bottom ends of the first layer stand columns are connected with embedded parts of the foundation, and the stand columns of the layer frames are connected in sequence in an end-to-end mode. A transverse beam isconnected between the bottoms of every two adjacent stand columns of the same standard layer frame so that a U-shaped structure can be formed. Transverse beams are arranged between the tops of everytwo adjacent stand columns of the top layer frame and between the bottoms of every two adjacent stand columns of the top layer frame. The exterior of each layer frame supporting structure and the corresponding portion of the light curtain wall envelop structure are combined to form an independent shaft structure unit, and jacking is accomplished by the layer structure units. A plurality of flexible connecting components are arranged between the prefabricated steel frame supporting structure and an existing building. The assembly type additional lift shaft structure adapting to jacking construction is high in degree of standardization, light in weight of each single component and low in component specification, and coincides with the development trend of building industrialization, standardization and assembly.

Owner:华城(天津)建筑科技有限公司

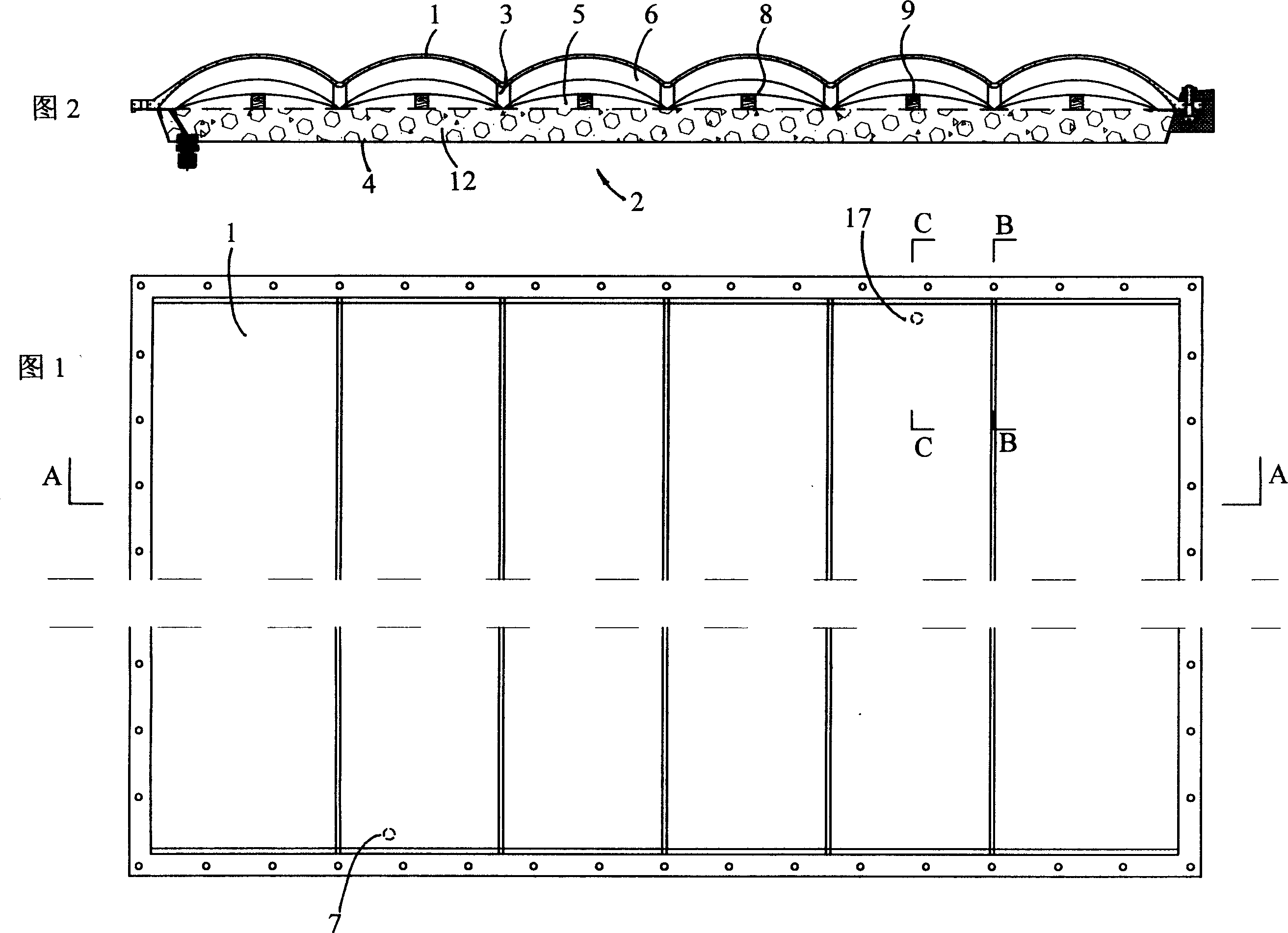

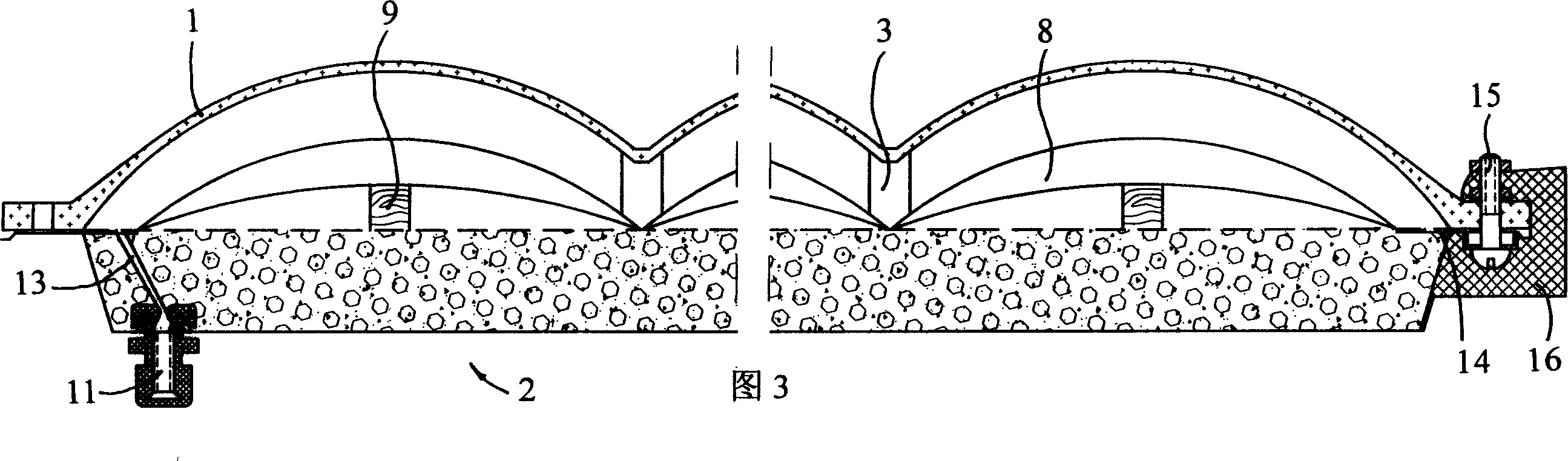

Closed roof slab or wallboard and their uses

InactiveCN1566585AGood insulation performanceGood energy saving effectRoof covering using slabs/sheetsSolar heating energySolar waterWall plate

An enclosed roof board or wall board, comprises a filled pressured formed board and a glass plate enclosed and connected onto it, the shape of the glass plate cross-section is at-least one arc; a vacuum layer is arranged between the filled pressured formed plate and the glass plate, a vacuum emptying nozzle which is connected to the vacuum layer is set on the filled pressure formed plate. The invention has advantages as sound insulation, heat insulation, energy saving, small sized and light weight, and also can be used as solar water heater.

Owner:李洪久

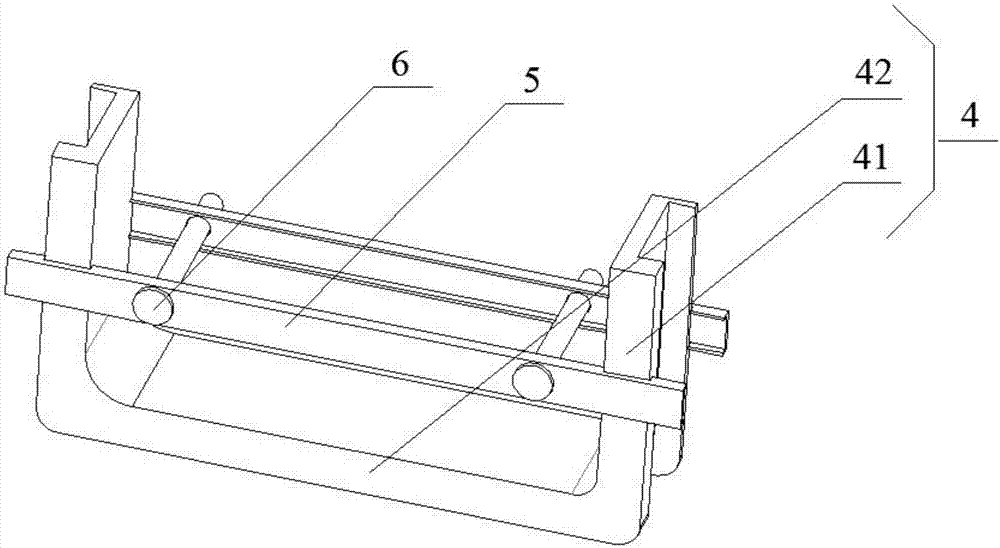

Degaussing cable trough, laying device for ship cable and cable laying method

ActiveCN107425488AEasy laying workReduced Scratch DamageApparatus for laying cablesVertical barEngineering

The invention provides a degaussing cable trough, a laying device for a ship cable and a cable laying method and relates to the technical field of cable laying. The degaussing cable trough comprises a cable trough body, a cover board and a cable fastening hook for fixing the cable, wherein the section of the cable trough body is rectangular and an opening is formed in the top; the cover board covers the opening in the top of the cable trough body; the cable fastening hook is internally arranged in the cable trough body and comprises a U-shaped bracket and two opposite and parallel lifting rods; the U-shaped bracket is formed by two vertical bars and a bottom bar; two grooves are formed in the inner side of each lifting rod and are correspondingly limited in the outer ends of the two vertical bars; and the two lifting rods are connected through a fastener. The laying device for the ship cable is formed by connecting a plurality of degaussing cable troughs and two adjacent degaussing cable troughs are connected through one sleeve. The cable laying method is implemented by adopting the laying device for the ship cable. The cable laying work of a constructor can be greatly facilitated through laying the cable in each cable trough body, and a scratched injury to the cable is reduced.

Owner:宝应帆洋船舶电器配件制造有限公司

Application of modular construction to roll hole construction of furnace wall of annealing furnace

The invention relates to modular construction, in particular to an application of modular construction to roll hole construction of a furnace wall of an annealing furnace. The application modular construction to roll hole construction of the furnace wall of the annealing furnace comprises the steps of: 1, analyzing and optimizing a drawing, decomposing the design and installation characteristics of roll holes of the furnace wall, and drawing a part decomposition drawing of structural deployment of various roll holes; 2, off-line processing an insulating layer backer board and a masonry working layer prefabricating module in a factory, and processing the roll holes or pouring prefabricating modules according to the part drawing; and 3, calculating the modulus of the brick courses of the furnace wall on site according to level of the roll holes, setting a level from the masonry furnace wall to the roll holes, and pairing the prefabricating modules. According to the application modular construction to roll hole construction of the furnace wall of the annealing furnace provided by the invention, the masonry quality of the furnace wall can be improved and the online construction period can be shortened, and the purpose of energy conservation and emission reduction can be realized to control environmental pollution.

Owner:CHINA MCC20 GRP CORP

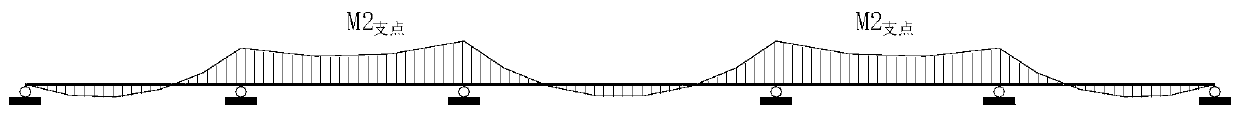

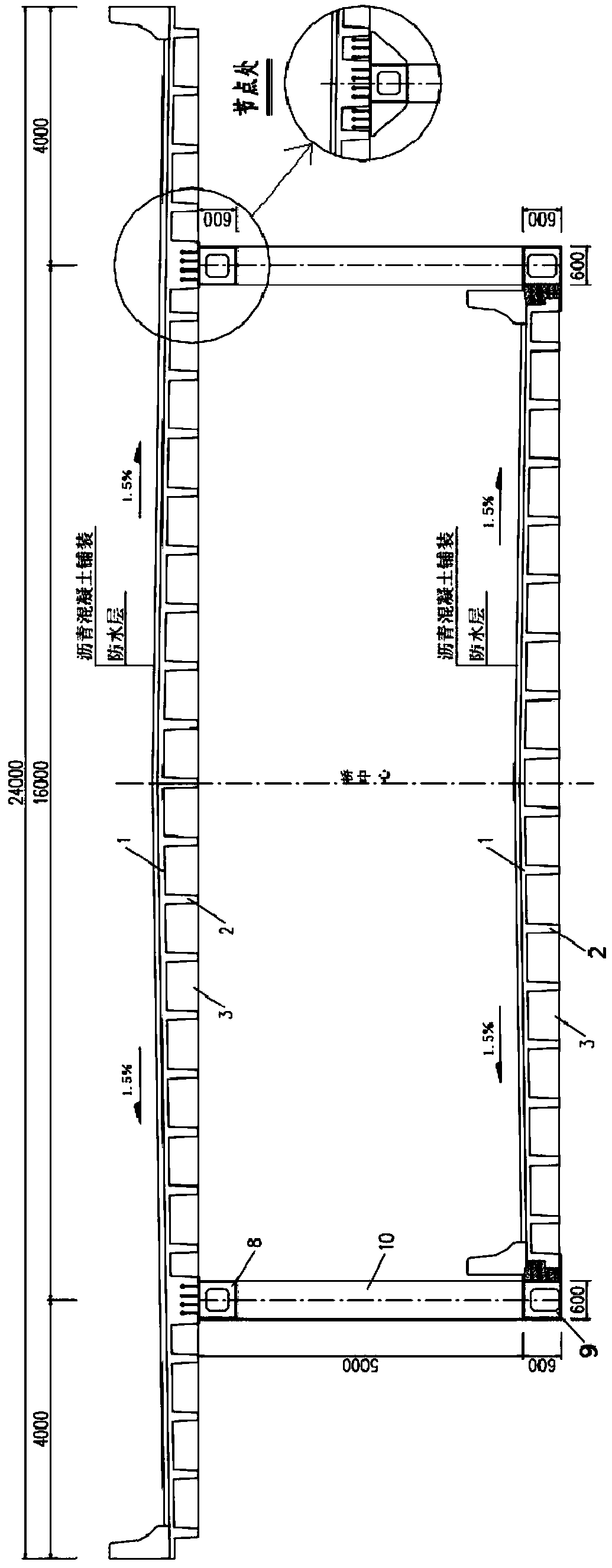

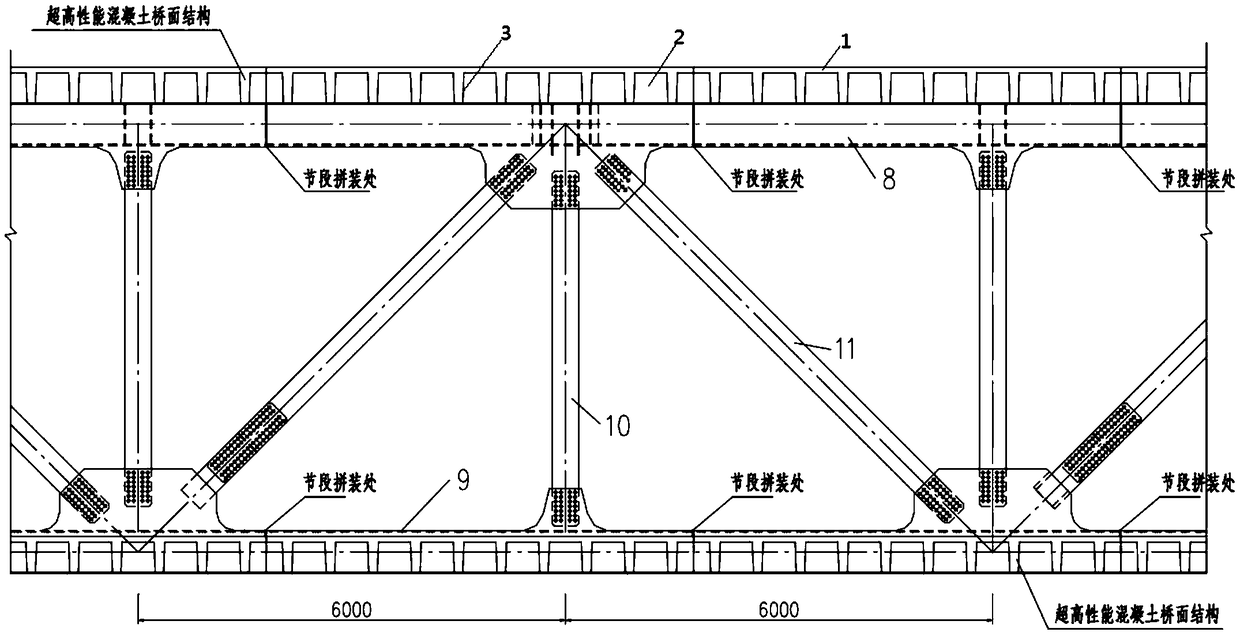

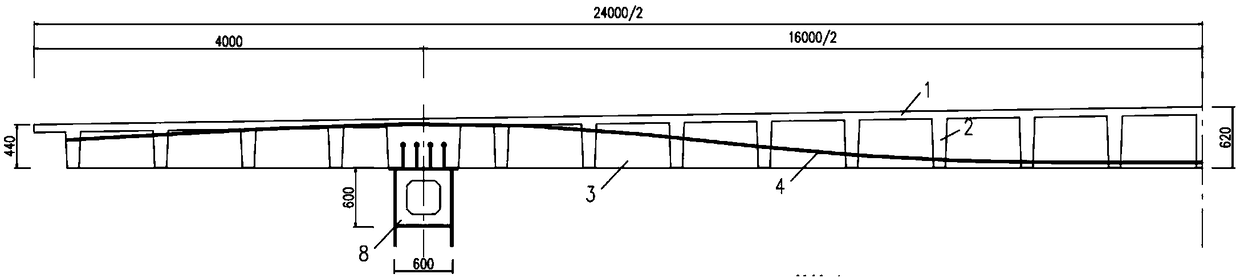

Ultra-thin bridge deck structure, truss bridge and construction method of truss bridge

ActiveCN109112961AReduce on-site assembly construction timeShorten the on-site construction periodTruss-type bridgeBridge structural detailsBridge deckRebar

The invention relates to an ultra-thin bridge deck structure, truss bridge and construction method of truss bridge. The bridge deck structure comprises a bridge deck, a plurality of transverse ribs arranged on the bottom surface of the bridge deck and parallel to the width direction of the bridge deck, and a plurality of longitudinal ribs arranged on the bottom surface of the bridge deck and parallel to the length direction of the bridge deck, wherein the plurality of transverse ribs are uniformly distributed along the length direction of the bridge deck, and the plurality of longitudinal ribsare uniformly distributed along the width direction of the bridge deck; the transverse rib is provided with a first prestressed reinforcement hole channel and at least two transverse reinforcement bars, the first prestressed reinforcement hole channel is gradually away from the bridge deck from the outside to the inside, and the transverse reinforcement bars are positioned below the first prestressed reinforcement hole channel. The bridge deck structure of the invention is in the form of dense grid formed by interweaving longitudinal and transverse ribs, and then forms an integral bridge deckstructure with the bridge deck. Compared with conventional steel-concrete composite bridge deck structure and ordinary concrete bridge deck structure, its overall stiffness is large and its weight islight, and its superior performance is prominent, thus realizing the function of ultra-thin bridge deck and lightening dead weight.

Owner:湖南三匠工程科技有限公司

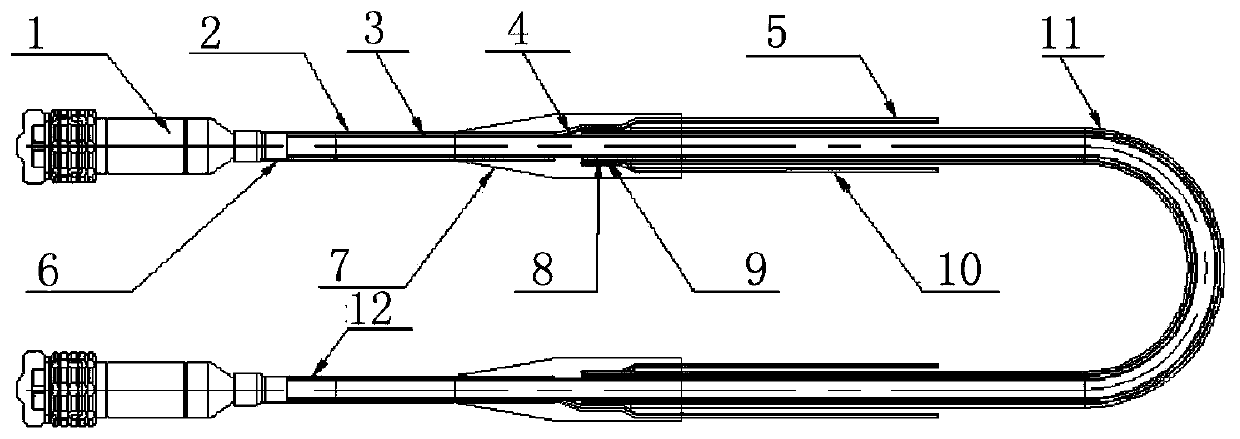

Low temperature resistant prefabricated cable

PendingCN110311265ASimple structureReasonable designLine/current collector detailsElectrically conductive connectionsAviationPlug and produce

The invention belongs to the technical field of substation equipment and particularly relates to a low temperature resistant prefabricated cable. The low temperature resistant prefabricated cable is characterized in that a main cable is crimped by one end of a cable aviation plug through a sealing crimping tube, and the cable aviation plug is internally integrated with a cable and a gold-plated cable female insertion core; a prefabricated cable socket end is internally integrated with a cable branch and a branch male insertion core and is filled with insulating sealant; the cable aviation plugis plugged into the prefabricated cable socket end, cable connection is completed through the main cable and the cable branch, and external electrical equipment is connected through the prefabricatedcable branch. The low temperature resistant prefabricated cable has advantages of simple structure, reasonable design, plug and play and convenient and quick properties. Tensile strength of the cablebranch and the socket end and sealing performance of the branch and the socket end can be improved; condensation in the socket is avoided, and a ground wire sheath is prevented from freezing and cracking; a ground wire is secure and is not easy to shed, sealing performance and insulation property are stronger, cables are easy to distinguish and find out, difficulty of on-site construction is reduced, the process of stripping is eliminated, and the on-site construction cycle is shortened.

Owner:国网内蒙古东部电力有限公司经济技术研究院 +3

Bendable coated composite veneer

InactiveCN101716784AReduce use costFireproof and moistureproofWood veneer joiningMetal layered productsCement boardEngineering

The invention discloses a bendable coated composite veneer with functions of fire resistance and moisture resistance, and a paint layer, a dyed veneer layer, a first glue layer, an outer paper layer, a second glue layer, an aluminum foil layer, a third glue layer and an inner paper layer are sequentially arranged from outside to inside. The bendable coated composite veneer has the advantages that the bendable coated composite veneer with the structure has low using cost and can shorten the field construction period, be bonded on gypsum boards, cement boards, magnesium boards, glass, plastic boards, metal boards and other similar materials and products thereof, play the roles of protection, decoration and beautifying, have the functions of fire resistance, moisture resistance and the like, be bent by 90 degrees or more than 90 degrees, be used for special-shaped wrap-adhering and be produced into a variety of types of packaging boxes, and marks of pattern, name of manufacturer, address, telephone and the like can be printed on the inner side of the inner paper layer.

Owner:张家港市博腾新型材料有限公司

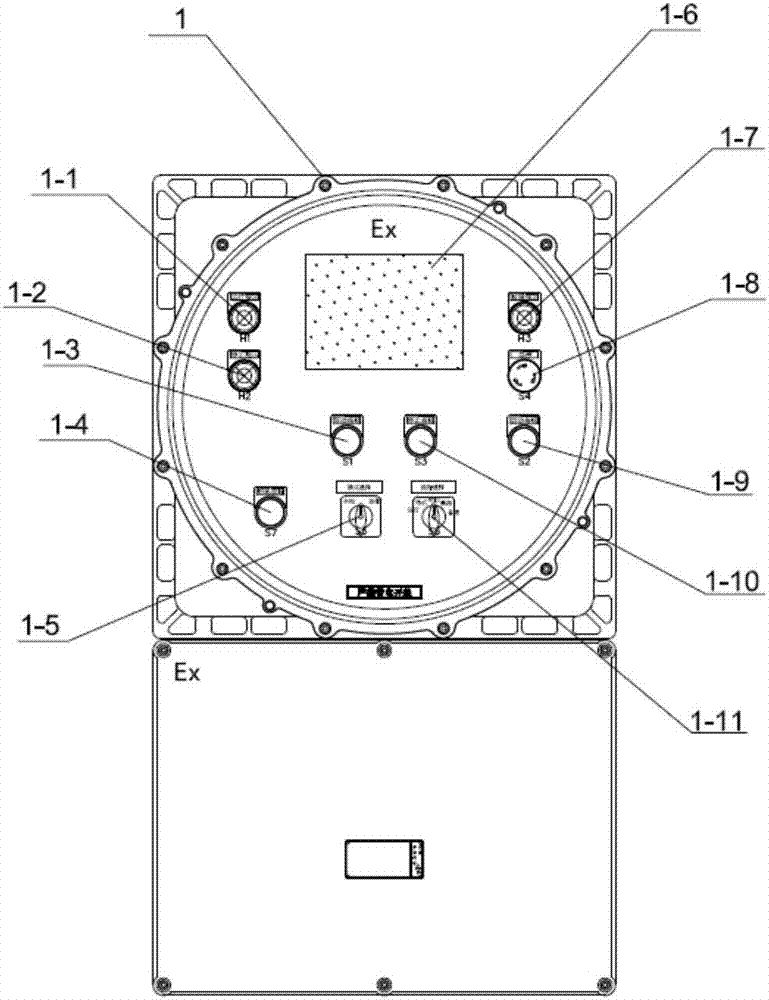

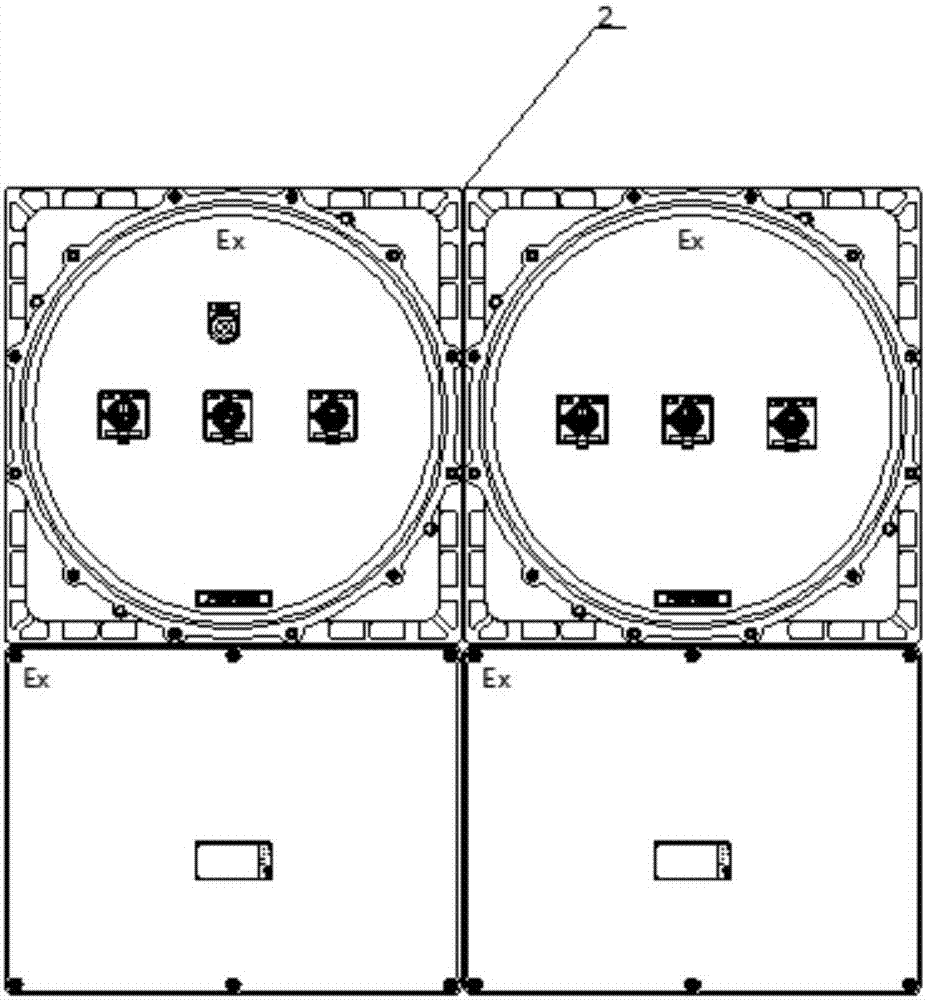

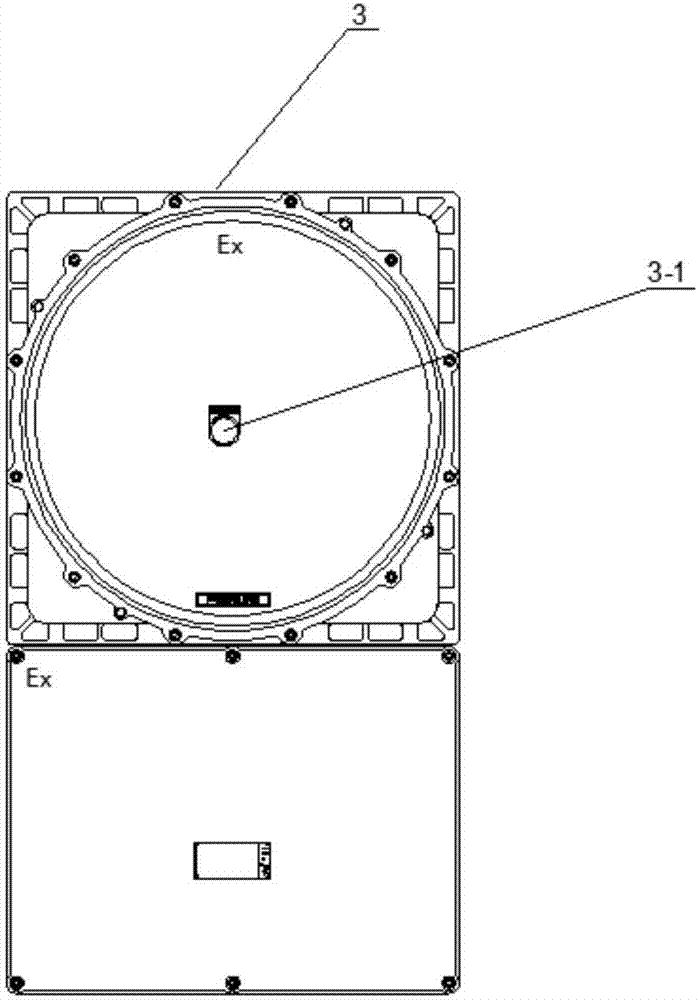

Control system and method for skid-mounted type hydrogen injection device

PendingCN107044585AReduce cable costsShorten the on-site construction periodContainer filling methodsGas handling applicationsAcousto-opticsPressure sensor

The invention discloses a control system and method for a skid-mounted type hydrogen injection device. The control system comprises a process controller and a safety controller. The process controller is connected to a starting button, a pressure sensor and a temperature sensor, receives signals of the starting button, the pressure sensor and the temperature sensor and is connected to a compressor, a cooling fan, a circulation water pump and a valve to control the compressor, the cooling fan, the circulation water pump and the valve to work. The safety controller is connected to an emergency stop signal detecting module, a hydrogen leaking detecting module and a fire detecting module, receives signals of the emergency stop signal detecting module, the hydrogen leaking detecting module and the fire detecting module and is connected to the process controller, the compressor, the valve, an acousto-optic alarming device and a display device to transmit control signals. The control system is provided with the two controllers responsible for process control and safety control correspondingly, and the priority of the safety controller is higher than that of the process controller, so that safety operation of the hydrogen injection device is guaranteed.

Owner:ZHANGJIAGANG FURUI HYDROGEN ENERGY EQUIP CO LTD

Device for assembling stand column with bearing platform of bridge

PendingCN106436554AEnsure quality accuracyEnsure dimensional accuracyBridge structural detailsBridge erection/assemblyRebarBuilding construction

The invention discloses a device for assembling a stand column with a bearing platform of a bridge. The device is used for assembling the stand column with the bearing platform of the bridge, and comprises a plurality of stand column steel bars extending out of the bottom of the stand column of the bridge, and a plurality of metal bellows embedded in the bearing platform, wherein the length direction of the metal bellows is parallel to the vertical direction of the bearing platform; the position of the metal bellows corresponds to that of the stand column steel bars, and the number of the metal bellows corresponds to that of the stand column steel bars; and when the stand column of the bridge is assembled with the bearing platform, each of the stand column steel bars is correspondingly inserted into the corresponding metal bellow, and then high-strength mortar or seam abutting glue is arranged at the abutted seam between the stand column and the bearing platform. According to the device disclosed by the invention, the construction period can be shortened, the influence on the surrounding environment can also be reduced, the quality of concrete pouring can be better controlled, and the project cost is low.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

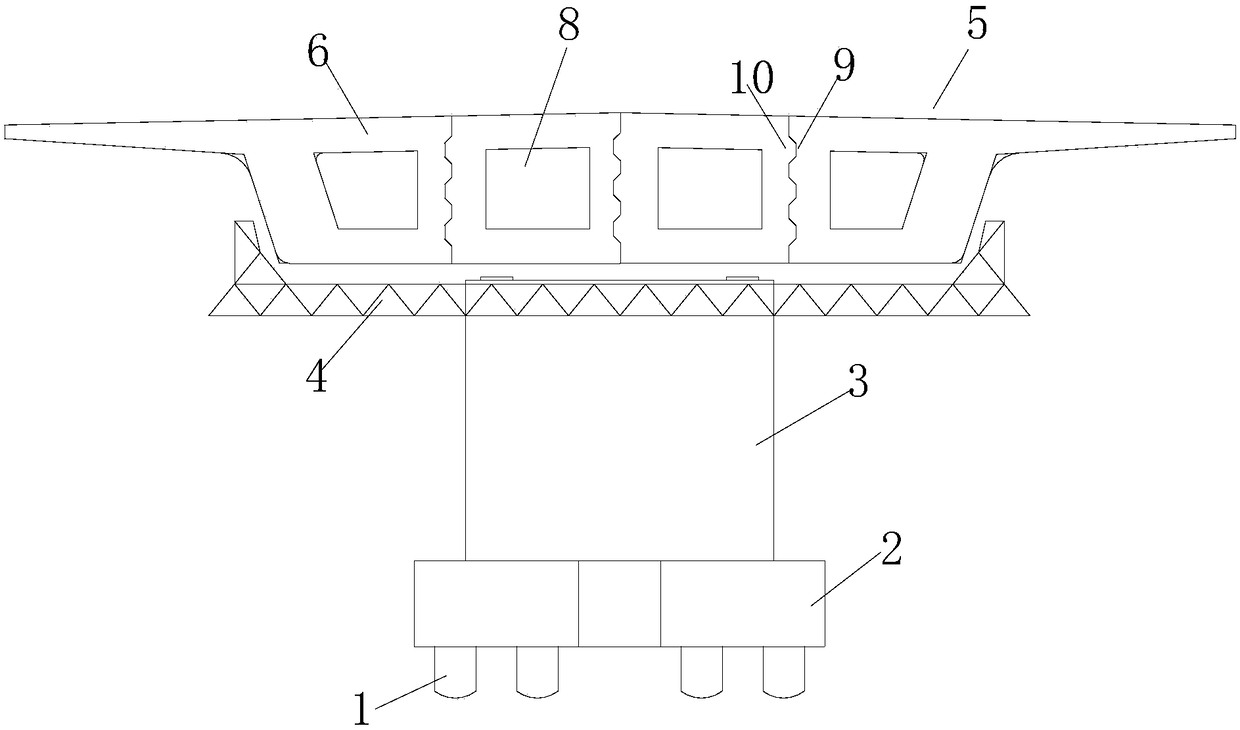

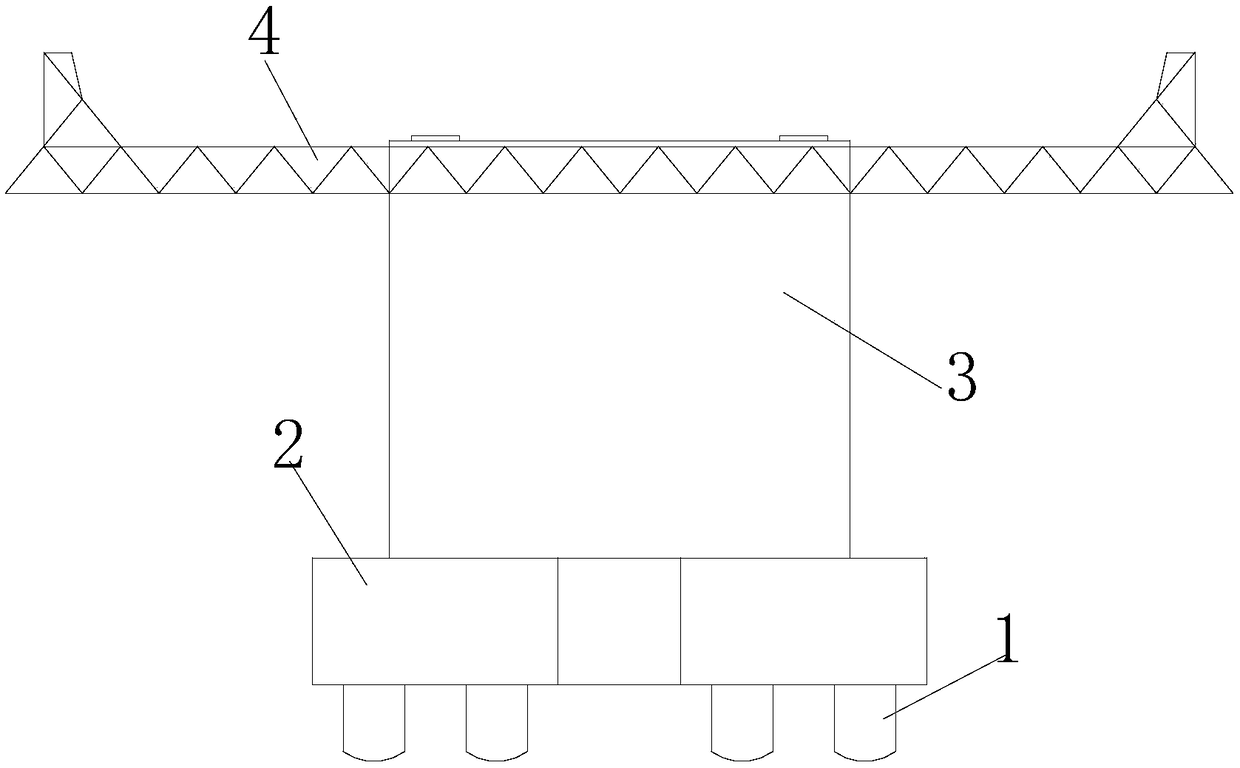

Prefabricated concrete large box girder structure connected in transverse bridge direction through dry connecting method

PendingCN108411759AImprove the landscape effectReduce the impactFoundation engineeringBridgesBox girderPrecast concrete

The invention discloses a prefabricated concrete large box girder structure connected in the transverse bridge direction through a dry connecting method. The structure comprises construction pile foundations, a bearing platform, an upright, a construction support and a prefabricated foundation component. The bearing platform is installed at the upper end of the construction pile foundations, the upright is installed at the upper end of the bearing platform, the construction support is installed at the upper end of the upright, the prefabricated foundation component is placed at the upper end of the construction support, reinforcement cages are arranged in the prefabricated foundation component and provided with multiple prefabricated sections, and every two adjacent prefabricated sectionsare connected through a fixing piece. The structure has the beneficial effects that a concrete large box girder is built through a prefabrication assembling method, compared with a cast-in-place structure, a field construction period is shortened, the influence of construction on the environment is reduced, a field construction method is flexible, devices such as a crawler crane convenient to transfer can be used for lifting construction, multi-point construction can be achieved, large box girder dry connecting method prefabrication assembly can be achieved, construction procedures are few, and a large box girder landscape effect is good.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

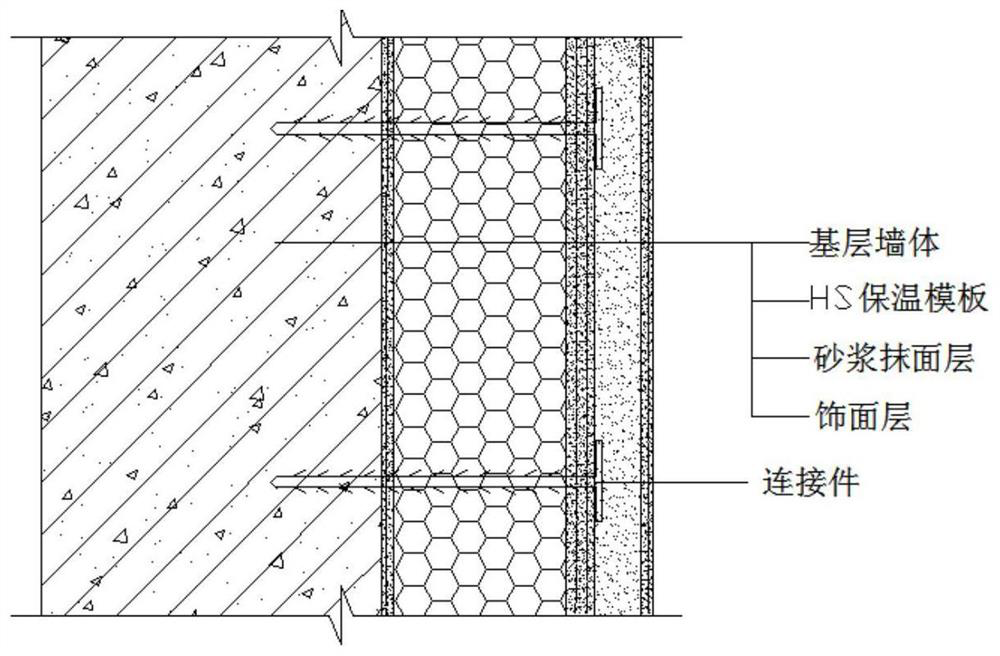

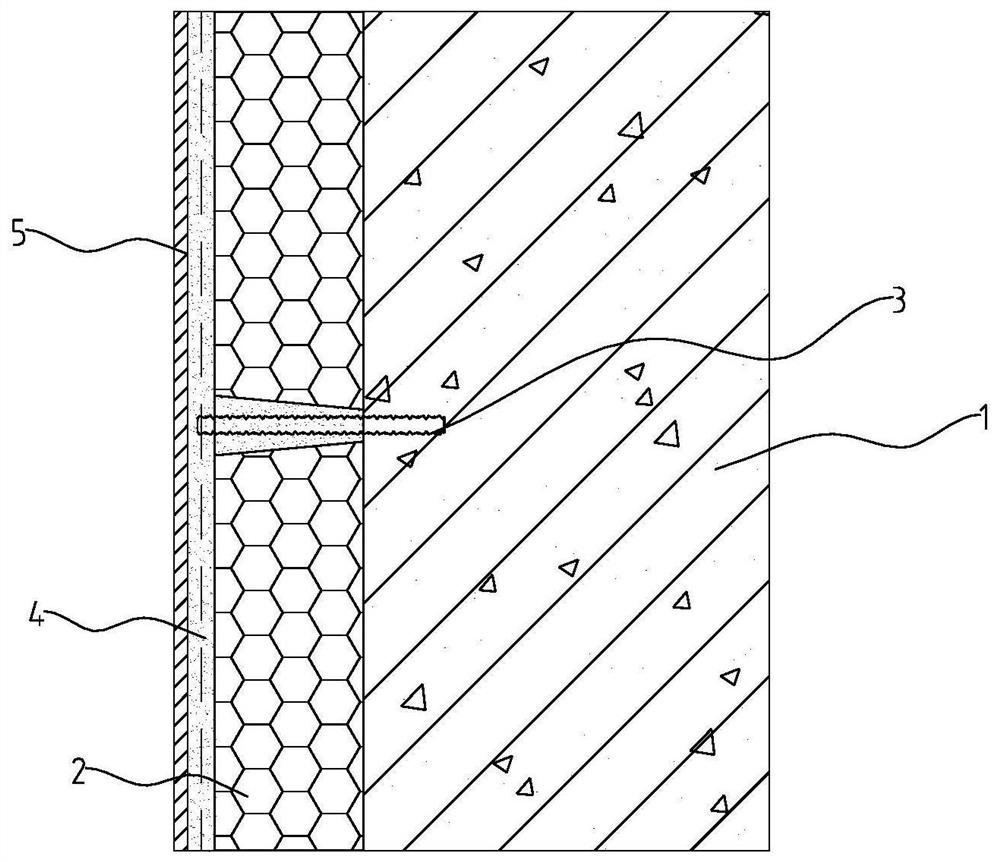

Integrally cast demolding-free self-thermal insulation wall and construction method thereof

InactiveCN106592814AImprove construction efficiencyReduce time spentWallsWire gauzeThermal insulation

An integrally cast demolding-free self-thermal insulation wall is composed of an outer wall body, an inner wall body and bead concrete filler. The outer wall body and the inner wall body are each formed by covering a steel wire gauze welded to a square steel frame with an inorganic hardening board. An outer wall body non-dismantling formwork is fixedly connected to outer wall body vertical keels, the upper portion and the lower portion of each vertical keel are of the identical length, and the vertical keels are transversely distributed at intervals. An inner wall body non-dismantling formwork is fixedly connected to inner wall body vertical keels between an upper slab and a lower slab of each floor. Horizontal connecting pieces and oblique connecting pieces are arranged between the inner wall body vertical keels and the outer wall body vertical keels. A non-dismantling formwork connecting piece is arranged between the outer wall body non-dismantling formwork and the inner wall body non-dismantling formwork. The thermal insulation wall can be integrally divided into the outer wall body and the inner wall body for construction, the outer wall body can be constructed together with a building body structure synchronously by the aid of a construction scaffold of a major structure, the inner wall body can be constructed indoors at any time after construction of the outer wall body is completed, construction is flexible and convenient, the occupied space of the scaffold is small, the construction efficiency is high, and the construction cost is low.

Owner:辽宁金帝建筑设计有限公司

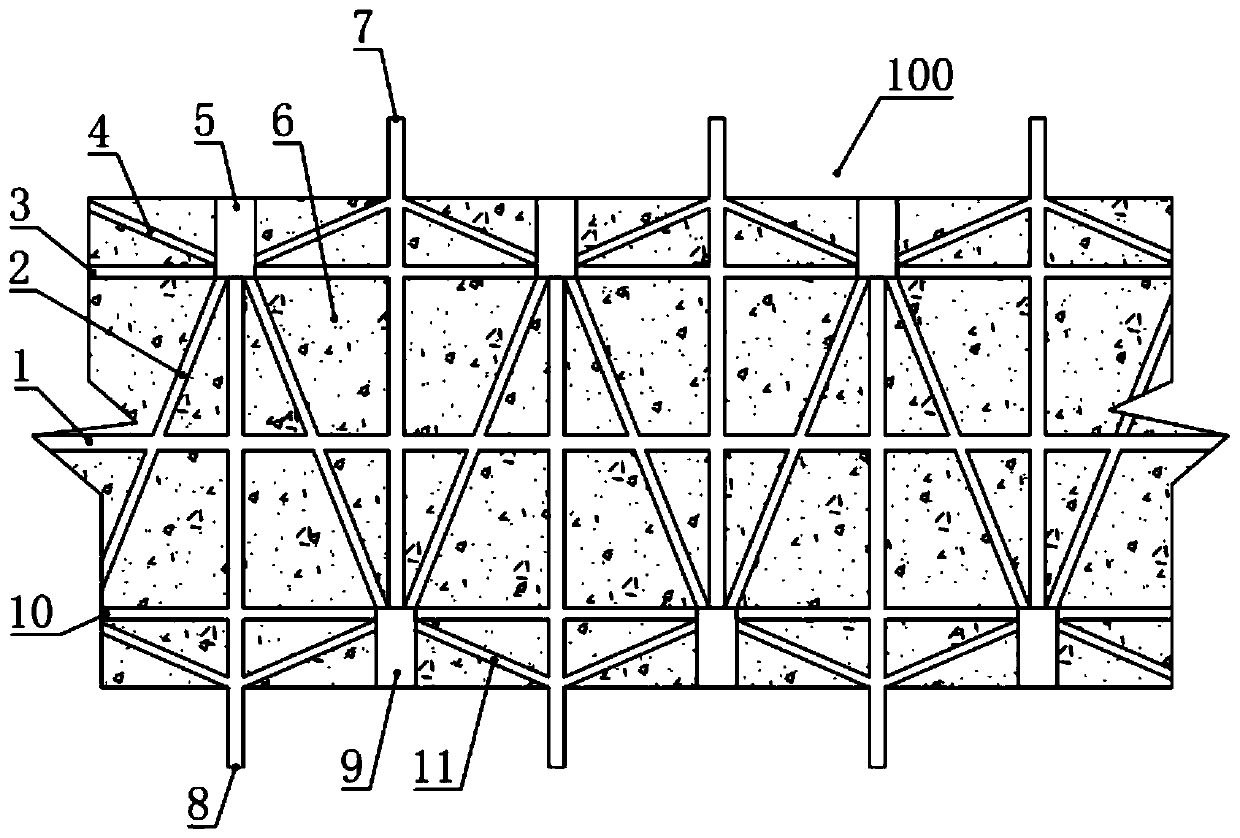

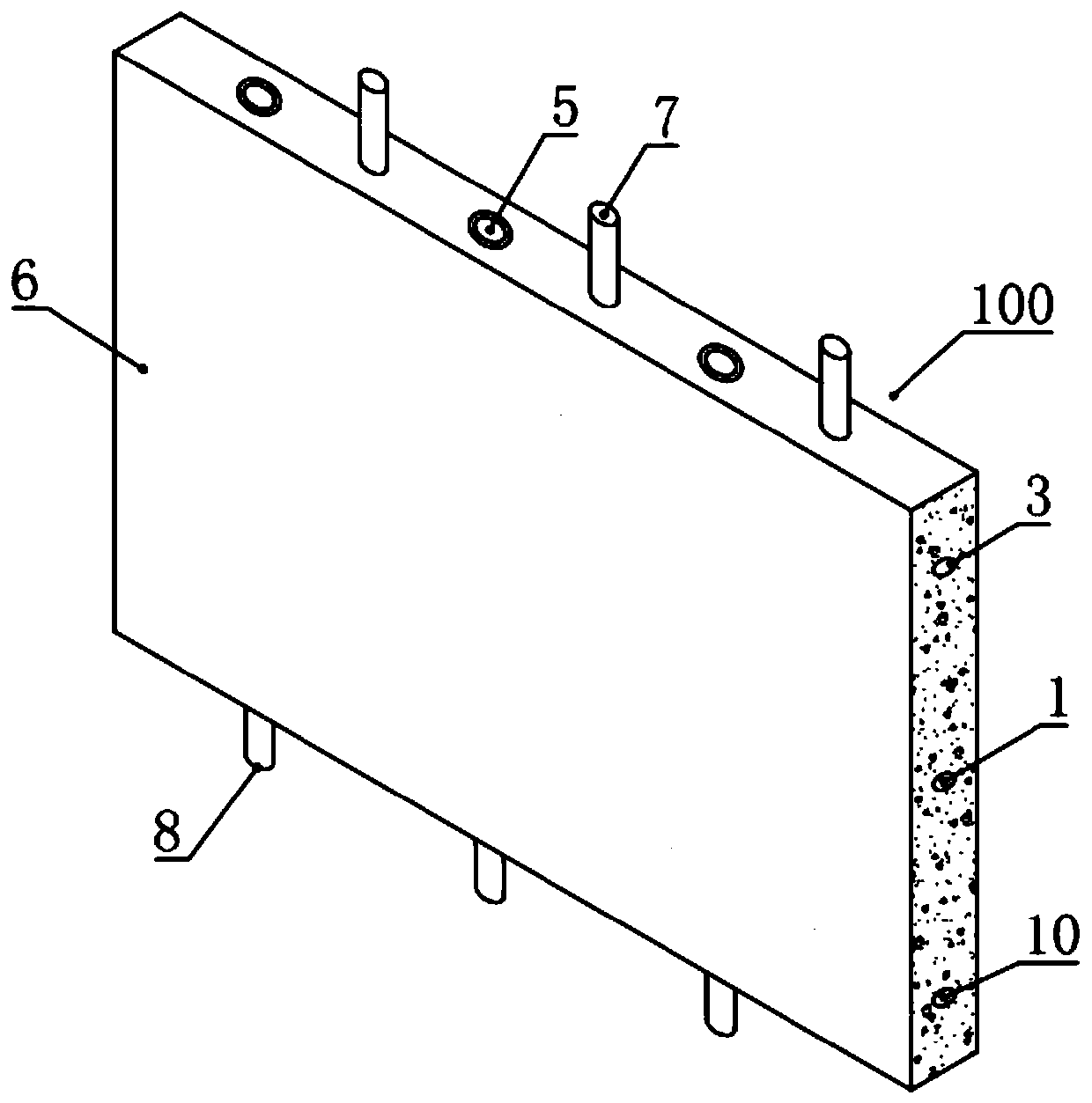

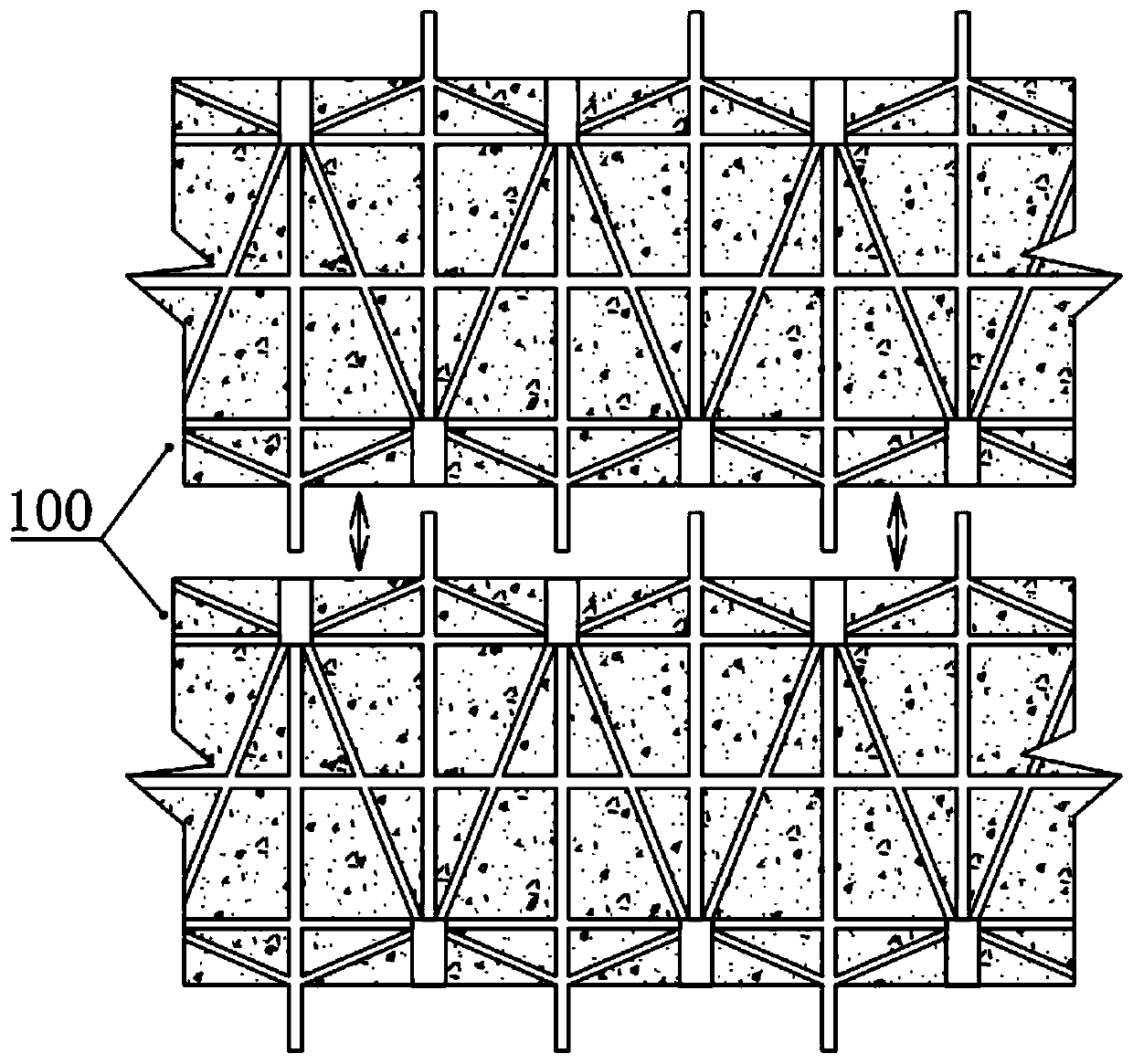

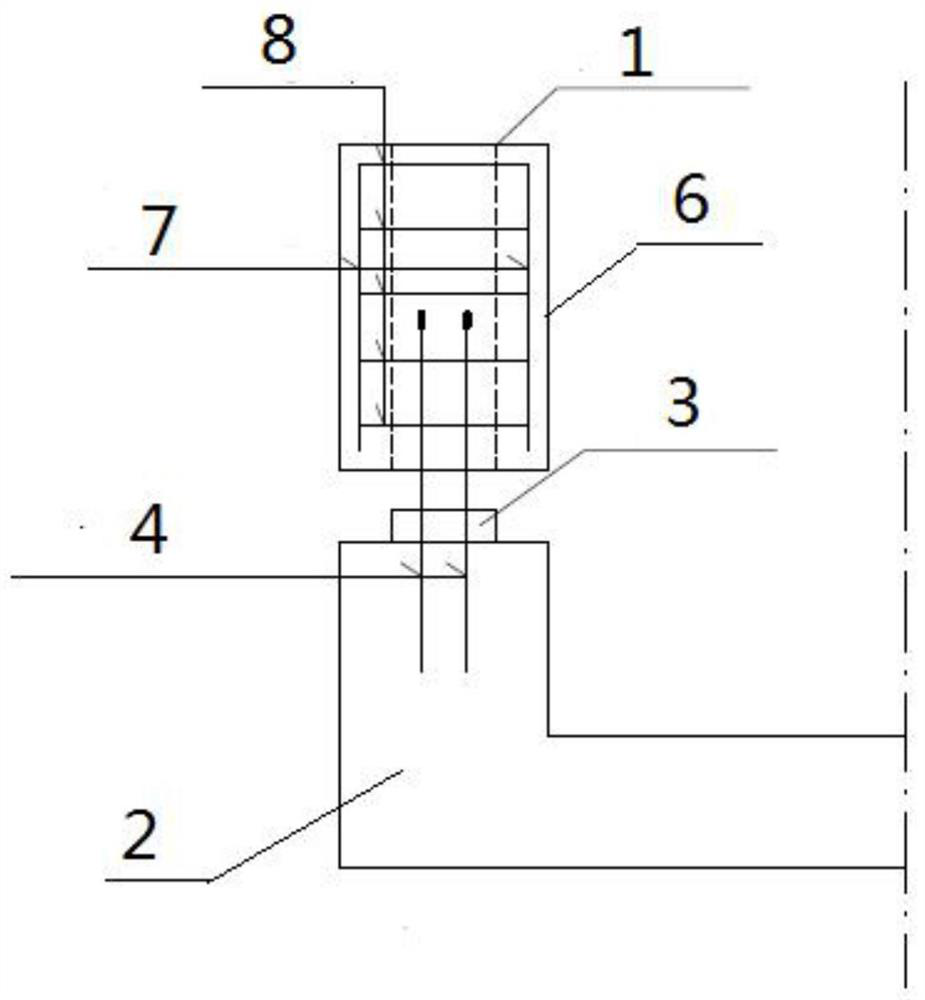

Fabricated shear wall structure vertical connecting structure

ActiveCN111021583AGood oblique support effectStable supportWallsBuilding reinforcementsArchitectural engineeringHorizontal bar

The invention relates to the technical field of building construction, in particular to a fabricated shear wall structure vertical connecting structure which comprises a precast shear wall module. Theprecast shear wall module comprises a plurality of first plug-in components and second plug-in components which are horizontally arranged in a staggered way; upper horizontal bars, middle horizontalbars and lower horizontal bars are sequentially and horizontally installed and fixed onto the first plug-in components and the second plug-in components from top to bottom; an upper diagonal bracing bar is further arranged between each two adjacent upper connecting cylinders; a lower diagonal bracing bar is further arranged between each two adjacent lower connecting cylinders; a middle diagonal bracing bar is further arranged between each two adjacent upper connecting cylinder and lower connecting cylinder; casting spaces are formed on the lower sides of the upper end surfaces of the upper connecting cylinders and the upper sides of the lower end surfaces of the lower connecting cylinders; and concrete is casted in the casting spaces. According to the fabricated shear wall structure vertical connecting structure provided by the invention, the site construction period is shortened, the construction speed of a fabricated industrialized residence can be improved, and the construction requirement of the site operation is reduced.

Owner:JILIN JIANZHU UNIVERSITY

Prefabricated inspection pit stand column and construction method thereof

InactiveCN111706128AShorten the on-site construction periodAvoid changeStrutsPillarsArchitectural engineeringRebar

The invention discloses a prefabricated inspection pit stand column and a construction method thereof, and relates to the technical field of rail traffic inspection pits. The prefabricated inspectionpit stand column comprises a prefabricated column body, wherein the middle of the prefabricated column body is provided with a central through hole which penetrates through two ends of the prefabricated column body; the bottom end of the prefabricated column body is supported on a ground beam; the ground beam is provided with a spacing boss by corresponding to the position of the central through hole; the central through hole is clamped to the spacing boss; the reserved reinforcing steel bar of the ground beam extends into the central through hole from the bottom end of the central through hole; and in addition, the central through hole is filled with concrete mortar to enable the prefabricated column body to be fixedly connected with the ground beam. The prefabricated inspection pit standcolumn does not require on-site pouring, has a short on-site construction period and high construction accuracy.

Owner:SHANGHAI JIANKE ENG CONSULTING

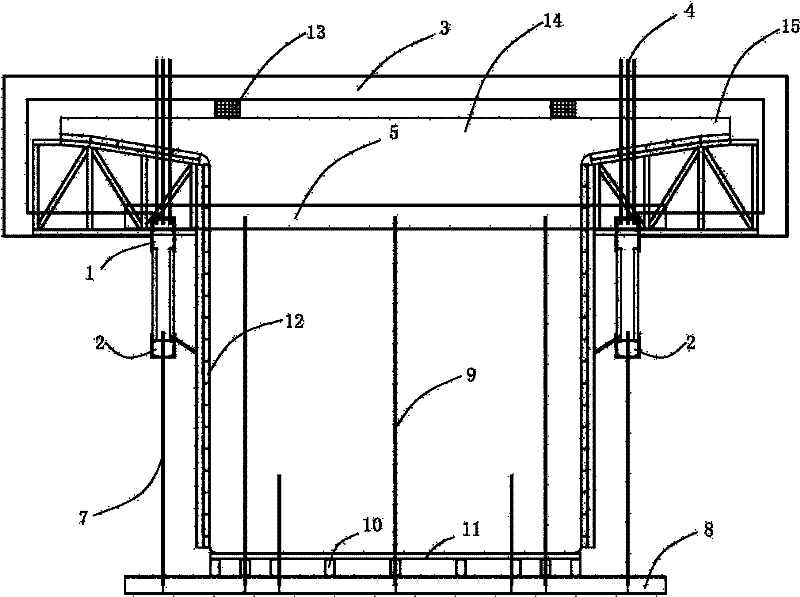

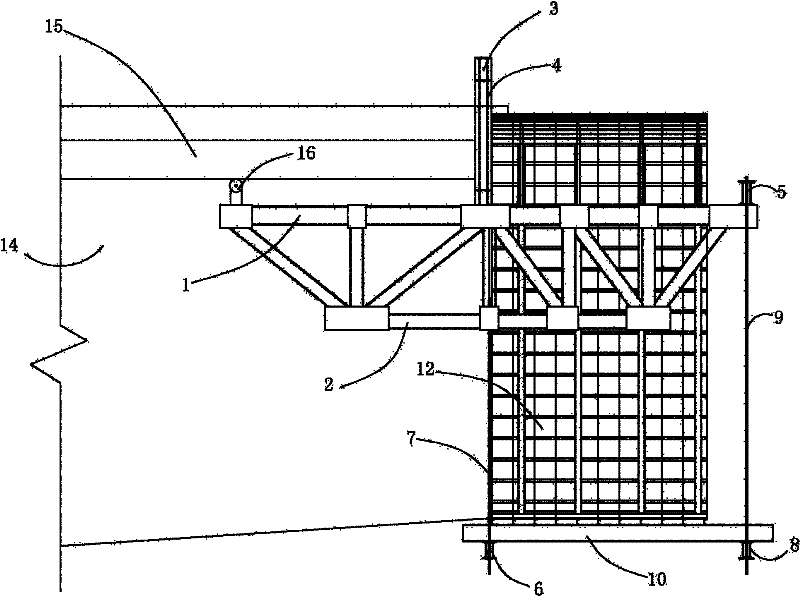

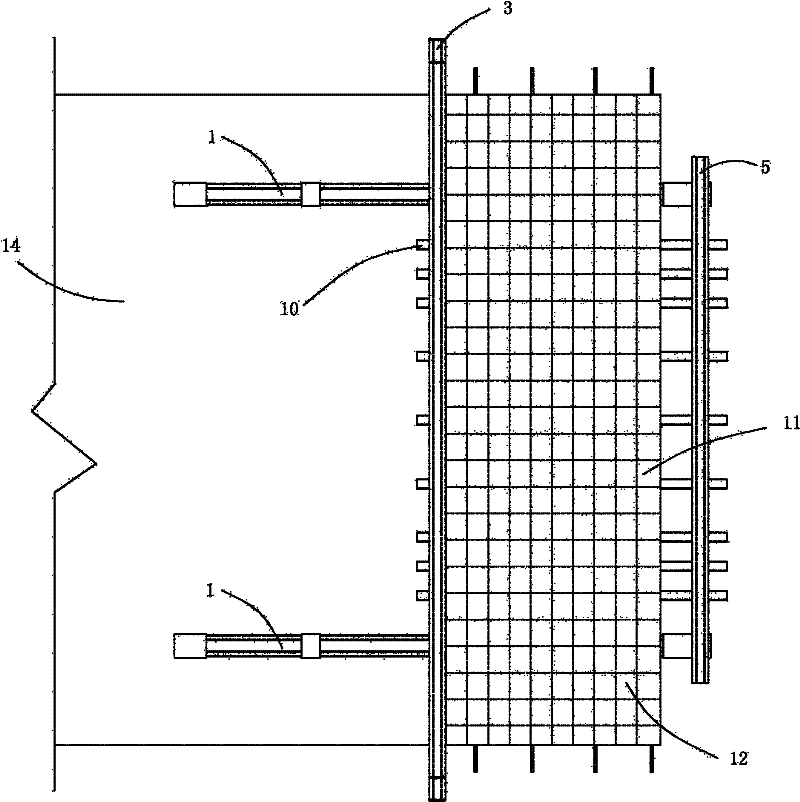

Lower supported hanging basket in bridge construction and application thereof

ActiveCN102094392BShorten the on-site construction periodClear forceBridge erection/assemblyTravel modeArchitectural engineering

The invention discloses a lower supported hanging basket in bridge construction and application thereof. The invention is characterized in that: the lower supported hanging basket is provided with two primary trusses having inverted trapezoidal structures, and an upper chord shoring jack is arranged between the tail of an upper chord and the bottom surface of a box girder edge board; an upper rear suspender is arranged between the middle of the upper chord and an upper rear crossbeam; the front end of the upper chord is connected with an upper front crossbeam; a lower rear suspender is arranged between the middle of a lower chord and a lower rear crossbeam; the upper front crossbeam is connected with a lower front crossbeam through a front suspender; parallelly arranged bottom basket longitudinal beams are fixedly connected between the lower front crossbeam and the lower rear crossbeam; and a hanging basket bottom die is fixedly arranged on the bottom basket longitudinal beams, and hanging basket side dies are positioned on the inner side of the two primary trusses. The hanging basket travelling mode is improved, a bound framework of steel reinforcement can be integrally hoisted into a bottom die platform space and directly subjected to concreting operation, and the construction period is shortened.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

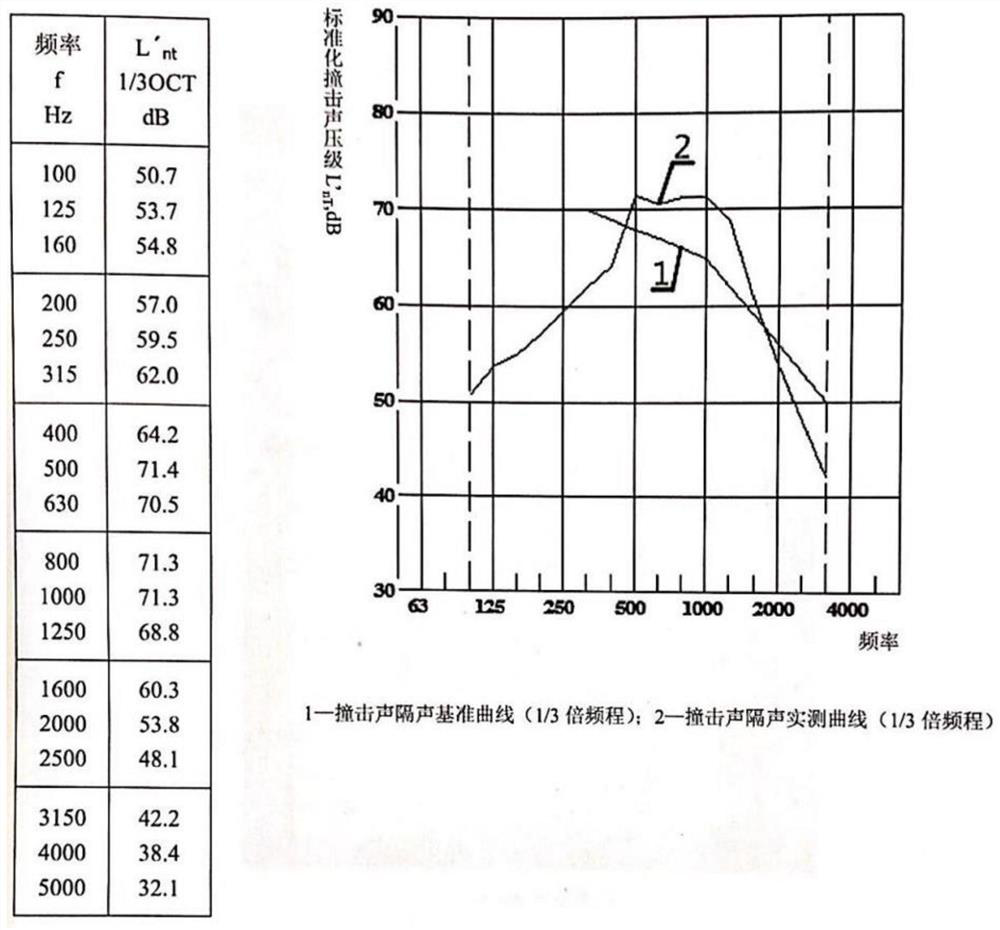

Structure and production process of building decoration heat preservation and sound insulation structure integrated plate

PendingCN113386255ARealize industrial productionDecorative realizationRoof covering using slabs/sheetsWallsInsulation layerConstruction engineering

The invention discloses a structure and a production process of a building decoration heat preservation and sound insulation structure integrated plate. The integrated plate comprises a structural layer, a heat preservation and sound insulation layer and a protective layer which are sequentially arranged from top to bottom, wherein a reinforcing material is embedded in the protective layer. The integrated plate can be produced in advance in a factory by using the special production process, the integrated plate is formed through one-time pouring, compared with existing production using a non-dismantling form, the integrated plate is simple in process, raw materials can be saved, the integrated plate can be directly conveyed to a construction site to be used after production is completed, on-site wet operation is reduced, pollution to the construction site is effectively reduced, construction procedures are reduced, meanwhile, exposed plastic ground anchors and other objects are not arranged on the integrated plate, plastering decoration is not needed, and on-site construction procedures can be further reduced.

Owner:四川省欧威新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com