Low temperature resistant prefabricated cable

A low temperature resistant and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of screw clamp lock structure sealing, inability to prevent condensation water, low temperature brittle performance and fast aging, etc., to eliminate the selection of wiring materials Improper, omit the cable stripping process, the effect of the welding point is firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

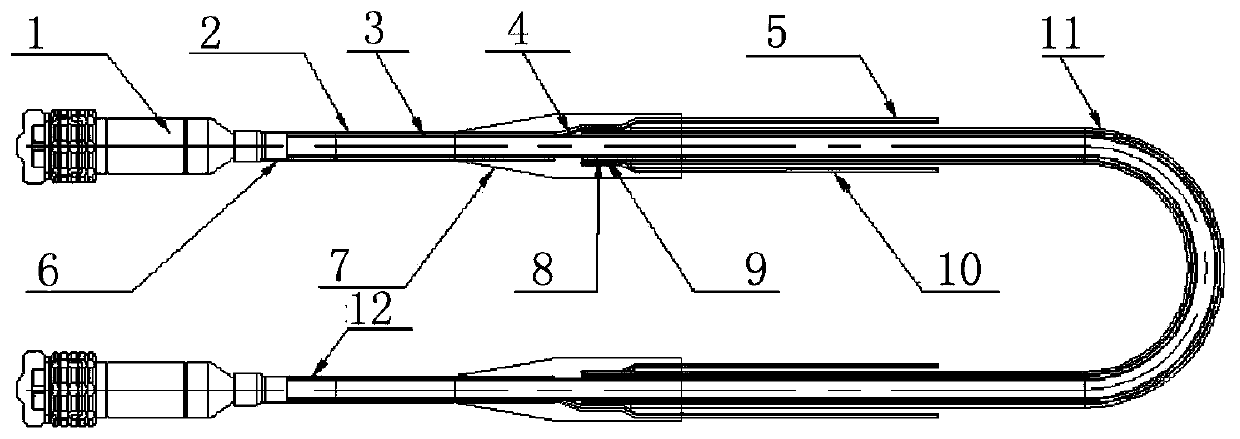

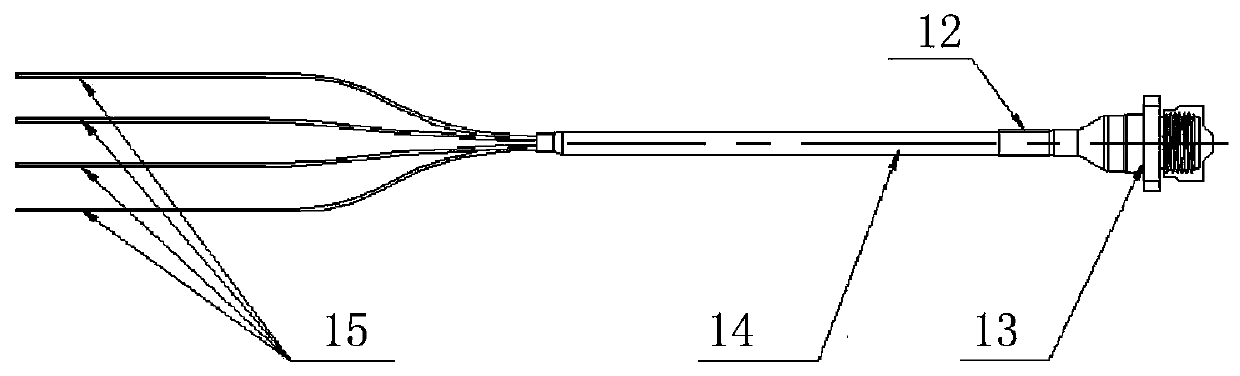

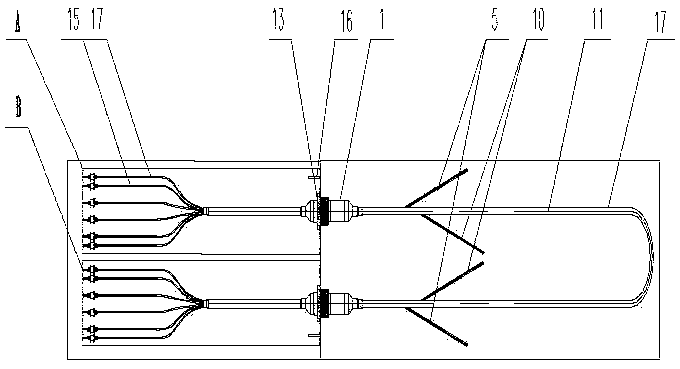

[0029] The invention is a low temperature resistant prefabricated cable, such as Figure 1-Figure 3 As shown, one end of the cable aviation plug 1 is crimped to the cable main cable 11 through the sealing crimping tube 6, and the cable aviation plug 1 integrates the cable and the gold-plated cable female ferrule inside. The prefabricated cable socket end 13 integrates cable branches and branch male ferrules inside, and is poured with insulating sealant. When in use, the cable aviation plug 1 is inserted into the prefabricated cable socket end 13, the cable connection installation is completed through the cable main cable 11 and the cable branch 15, and the external electrical equipment is connected through the prefabricated cable branch 15 to complete the current conduction. The shielding layer grounding wire 5 and the steel tape armor layer PE material sheathed grounding wire 10 welded to the shielding layer lead the induced current of the cable product into the earth.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com