Structure and production process of building decoration heat preservation and sound insulation structure integrated plate

A technology of architectural decoration and production technology, which is applied in the direction of building structure, building components, thermal insulation, etc., and can solve problems such as increased construction costs, lack of decorative functions on the floor, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

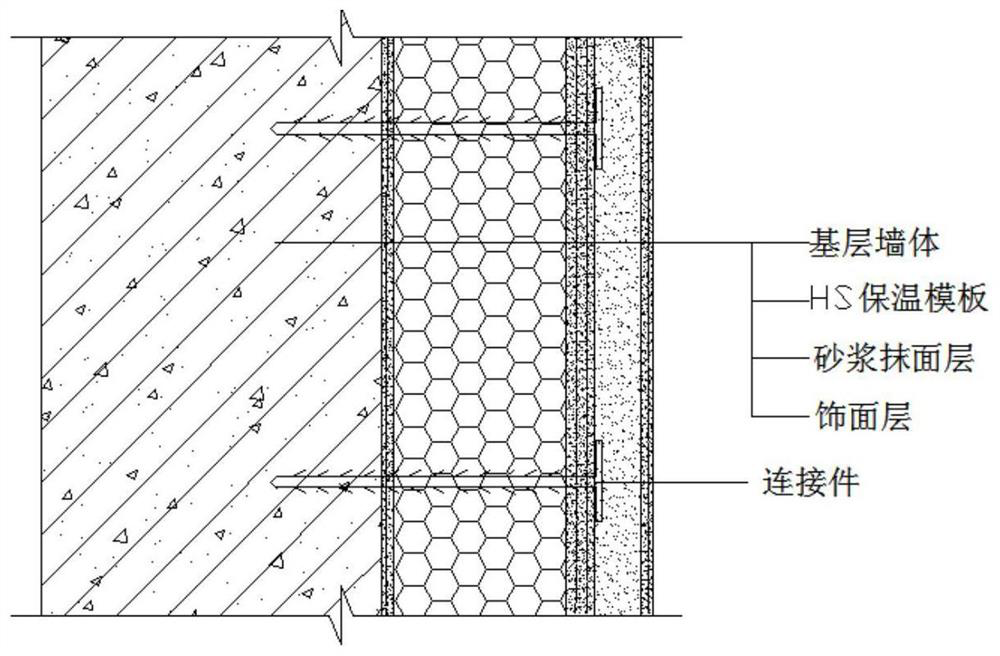

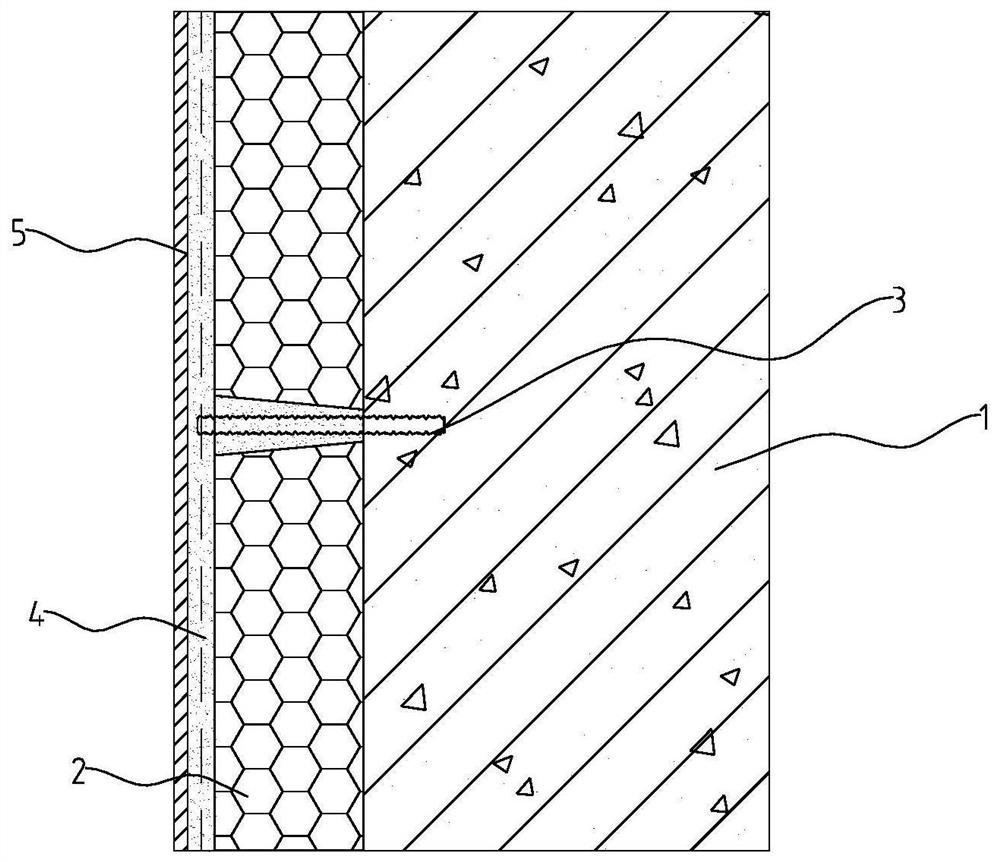

[0064] This embodiment provides a building decoration thermal insulation and sound insulation structure integrated board, its specific structure please refer to image 3 As shown, a protective layer 4 formed by anti-cracking mortar is laid on the lowermost layer, and a thermal insulation board is laid on the protective layer 4. The thermal insulation board can be a conventional foamed cement thermal insulation board or polystyrene foam board, polyurethane thermal insulation board, etc. There is a structural layer 1 on the insulation board, and the structural layer 1 is formed by pouring concrete. Of course, the structural layer 1 is the same as the general cast-in-place concrete structural layer 1, and the interior is equipped with steel bars. The pouring is integrated, and it can be directly transported to the construction site for installation in actual use. Among them, the setting method of the structural layer can be selected according to the scene of use, such as external ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com