Integrally cast demolding-free self-thermal insulation wall and construction method thereof

A form-removing, self-insulating technology, which is applied to walls, building components, buildings, etc., can solve problems such as unseen, unseen, and poor connectivity, so as to reduce the construction period, improve the comprehensive performance of green environmental protection, and improve Anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments provided with accompanying drawings.

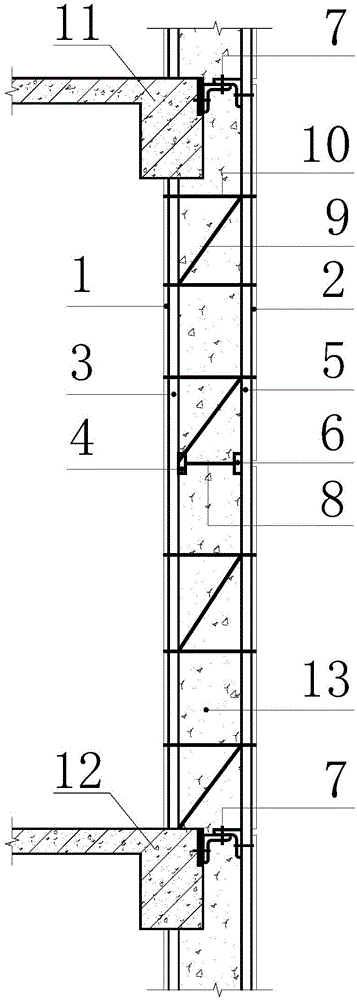

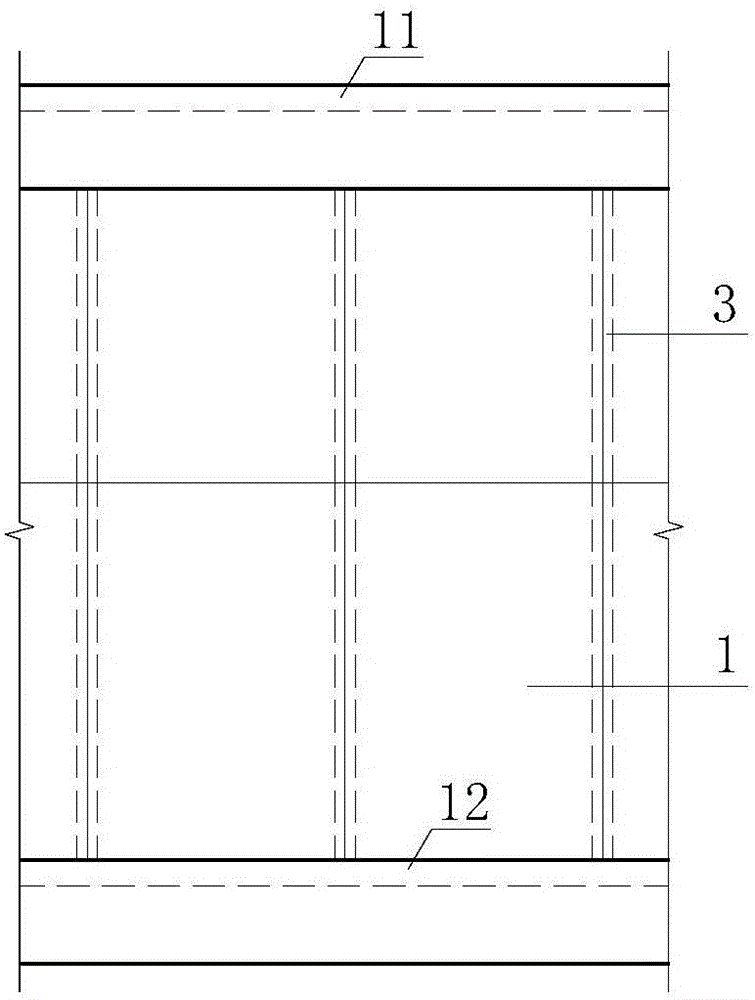

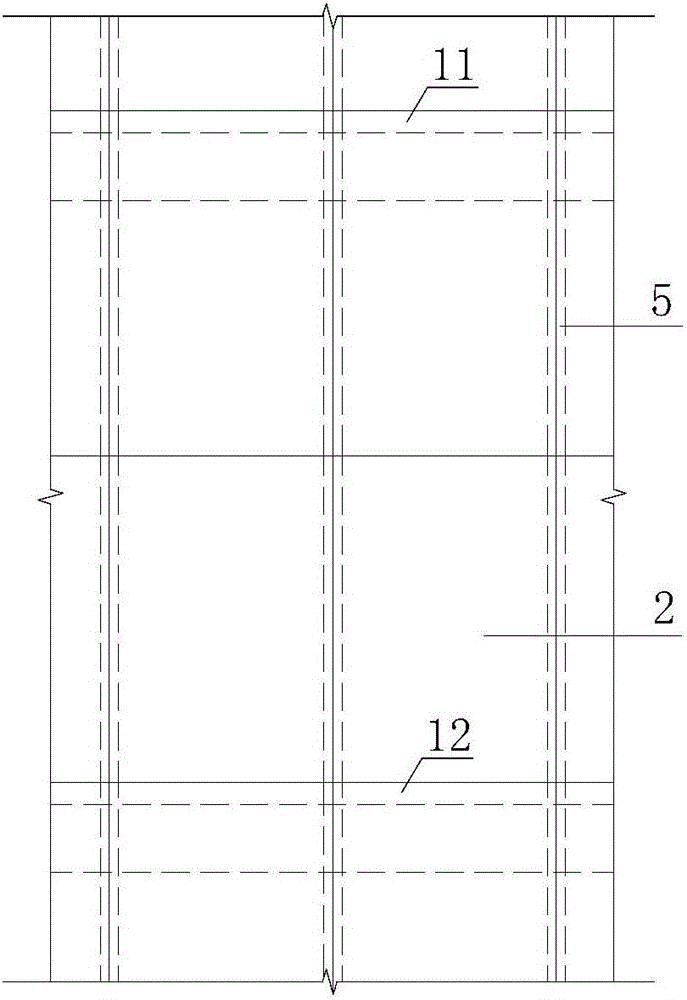

[0033] Such as figure 1 As shown, the self-insulation wall body of the present embodiment is composed of an outer wall, an inner wall, and a foam concrete insulation material 13 filled between the outer wall and the inner wall. Among them, the outer wall and the inner wall are respectively composed of multiple square (square or rectangular) non-demolition formwork splicing, and the non-demolition formwork is produced in a factory. Such as Figure 6 As shown, each free formwork is made of square steel frame 14 (square or rectangular), steel wire mesh 16 and inorganic hardened material 15, wherein the steel mesh is clamped in the inorganic hardened plate, and the periphery of the steel mesh is welded on the steel frame.

[0034] Such as figure 1 , image 3 and Figure 5As shown, the external wall free formwork 2 of the wall is welded on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com