Closed roof slab or wallboard and their uses

A roof panel and wall panel technology, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve the problems of poor thermal insulation, heat insulation, sound insulation, no other uses, and increased cost. Excellent thermal insulation performance, light weight and load-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

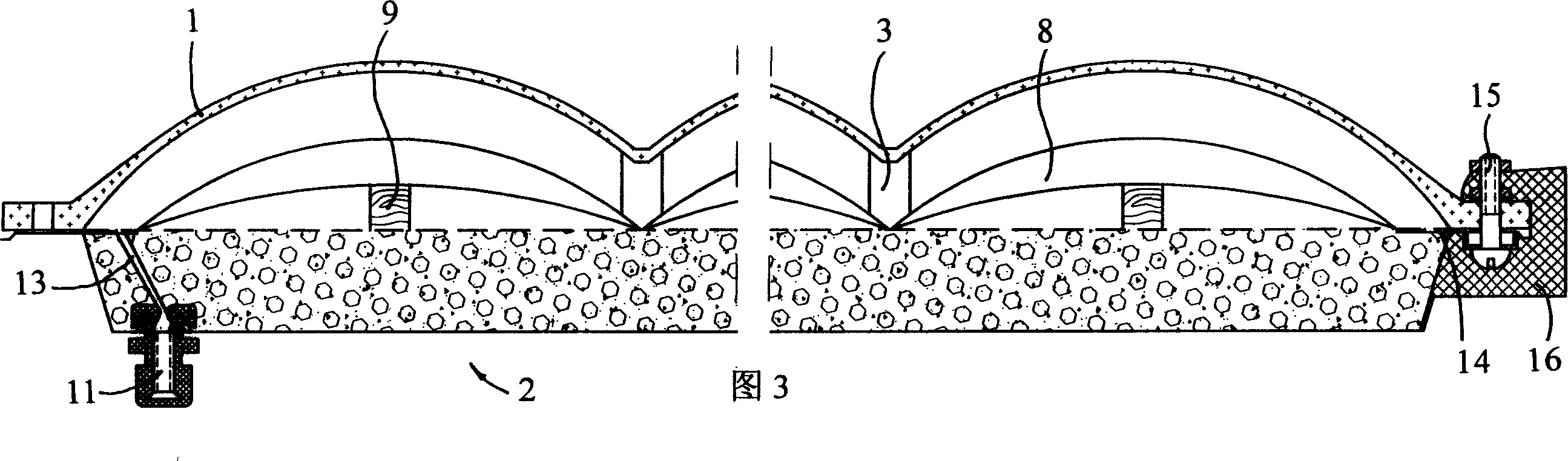

[0025] When the closed roof panel or wall panel of the present invention is in use, the side facing the outside, that is, the side on which the tempered glass plate 1 is installed is the outside, and the opposite side is the inside.

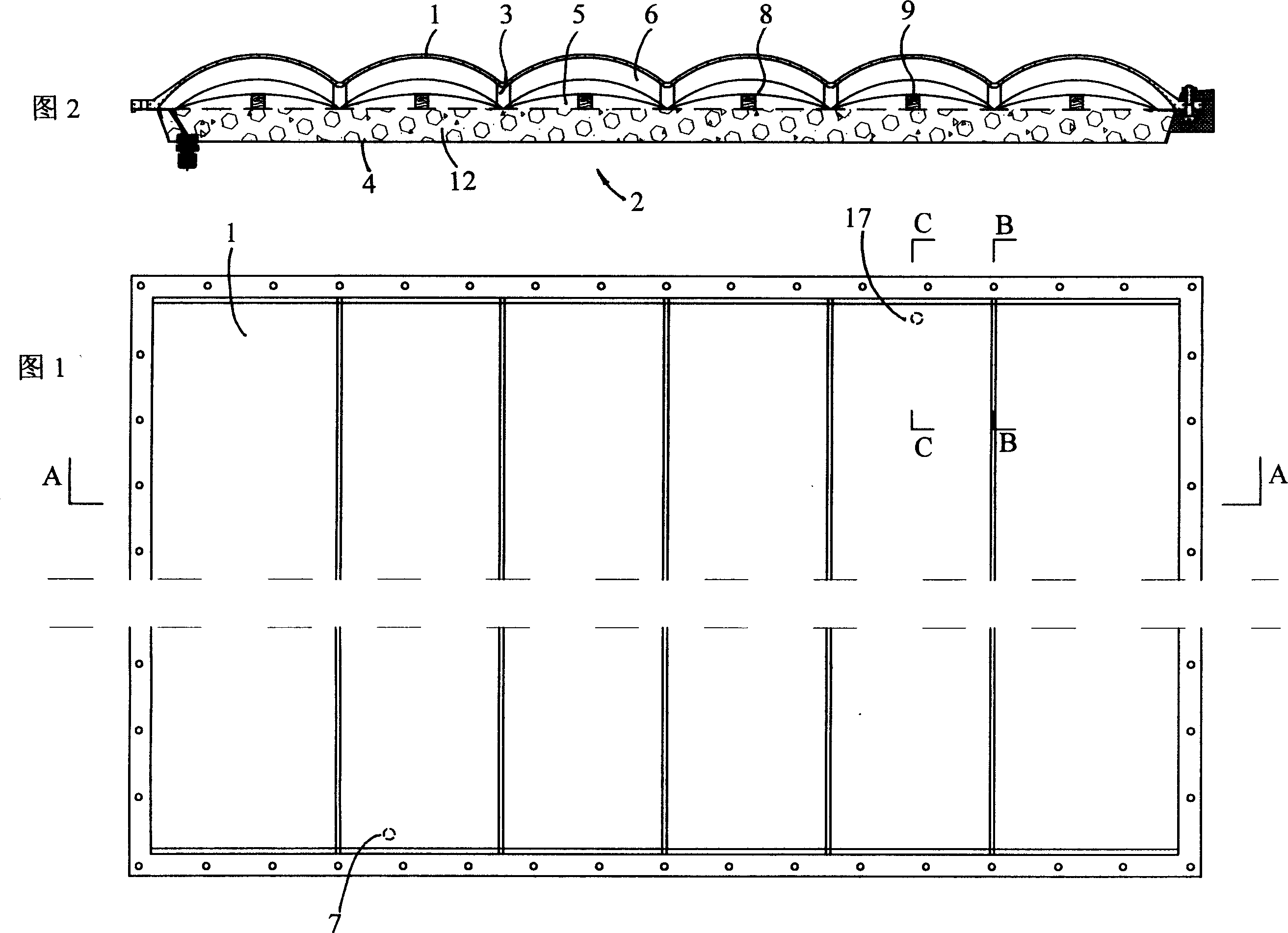

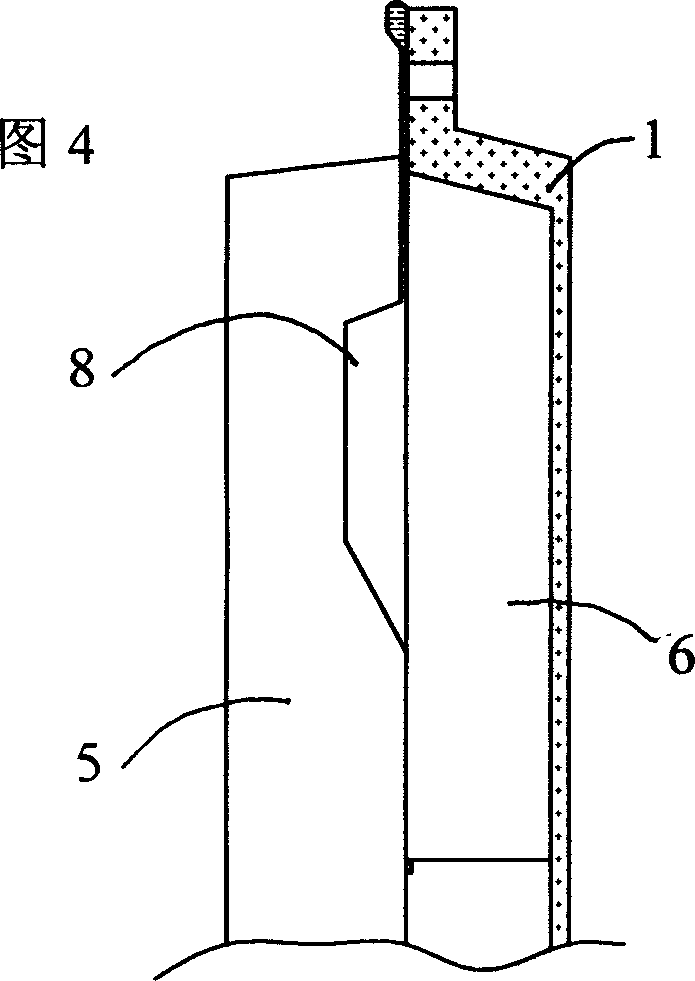

[0026] See Figure 1 to Figure 5 . The closed roof panel or wall panel of the present invention comprises a filling profiled plate 2 and a tempered glass plate 1 sealingly connected to the filling profiled plate 2, and a water jacket arranged between the filling profiled plate 2 and the tempered glass plate 1 . An inner vacuum layer 5 is formed between the water jacket and the filling and pressing plate 2 , and an outer vacuum layer 6 is formed between the water jacket and the toughened glass plate 1 .

[0027] The cross-sectional shape of the tempered glass plate 1 is six arches connected in sequence, the four arches at the middle part are the same, the two arches at both ends are the same, and the curvature is smaller than the curvature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com