Assembling type swing self-resetting steel support structure system

A steel support and self-resetting technology, which is applied to building components, protective buildings/shelters, building types, etc., can solve the problems of no wall fully swinging, no swinging wall shock absorption form, etc., to shorten the site The effect of strong construction period, strong earthquake resistance and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

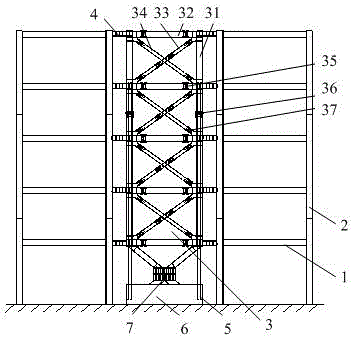

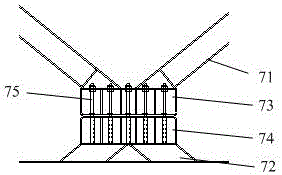

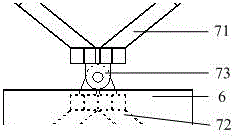

[0028] refer to Figure 1-5 As shown, an assembled swing self-resetting steel support structure system includes a structural column 1 and a structural beam 2, the structural column 1 and the structural beam 2 constitute the main structure, and the main structure and the steel support 3 pass through energy dissipation The elements 4 are connected, the self-resetting cable 5 is set along the steel column 31 of the steel support 3, the upper end is stretched on the top of the steel column 31 of the steel support 3, and the lower end is poured in the cast-in-place foundation 6, and the steel support 3. Connect with the cast-in-place foundation 6 through a swing node 7;

[0029] The steel support 3 includes a steel column 31, a steel beam 32, a short steel support section 33 and a long steel support section 34, and the steel column 31, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com