Patents

Literature

69results about How to "Improve side resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

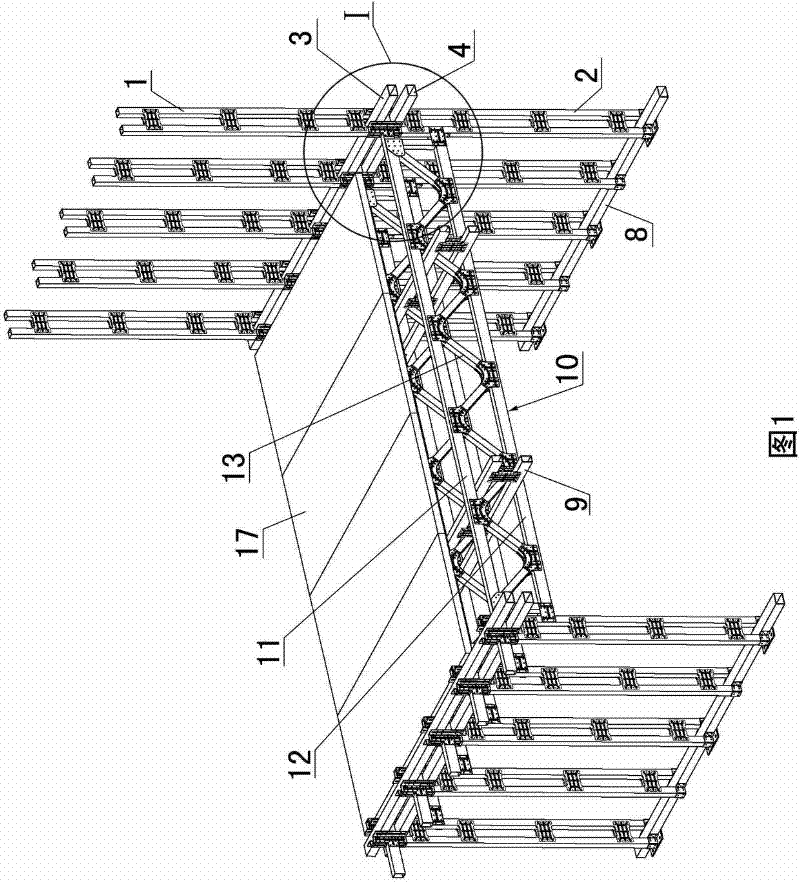

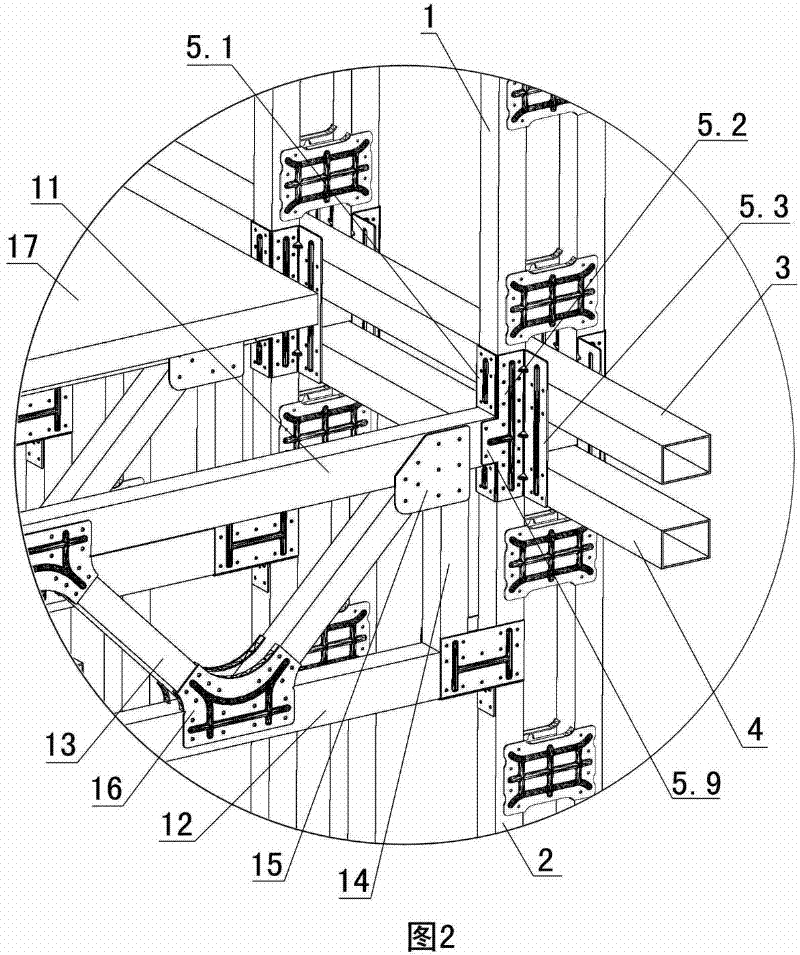

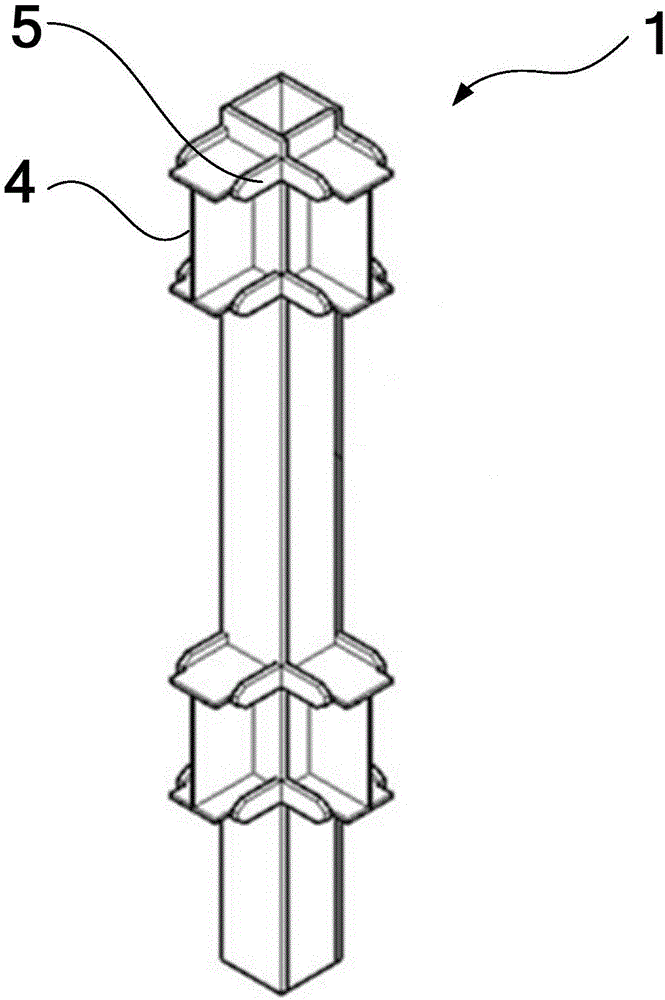

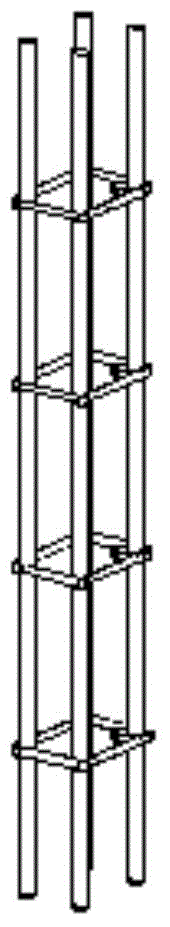

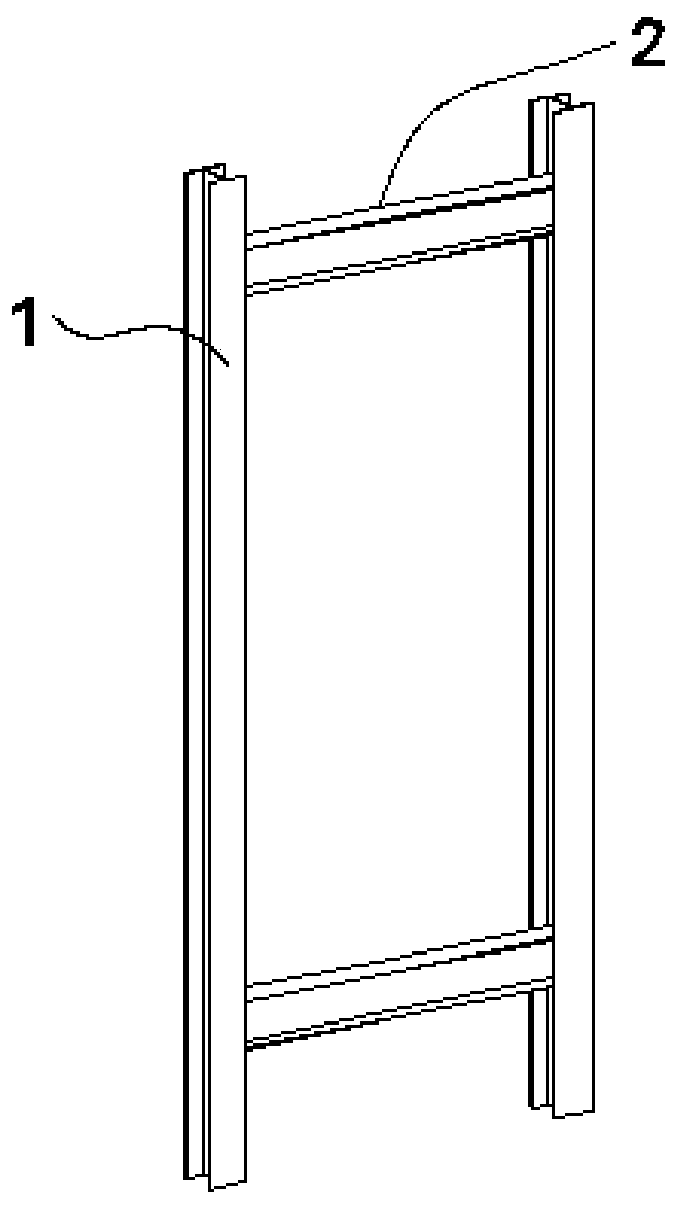

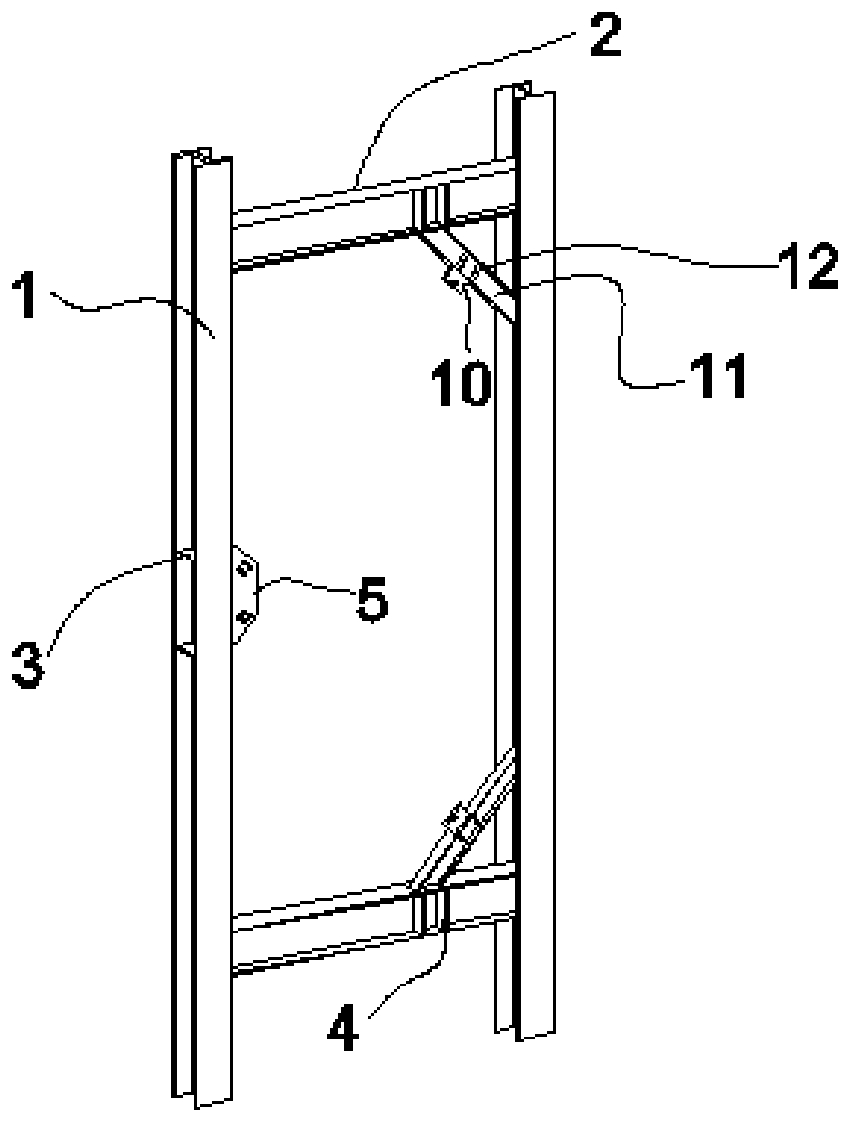

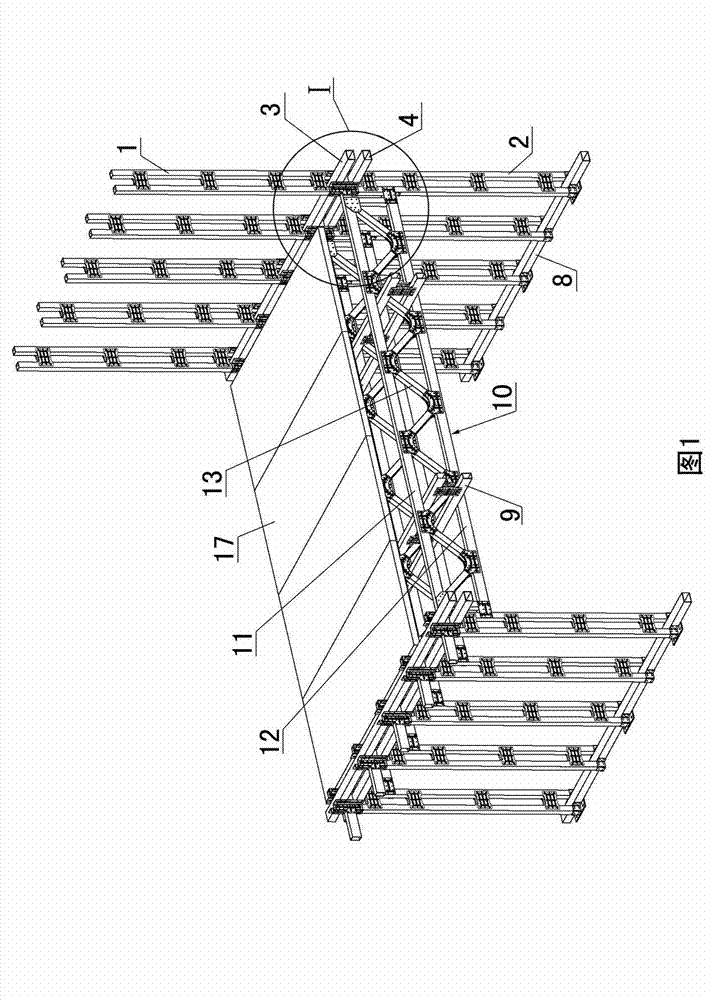

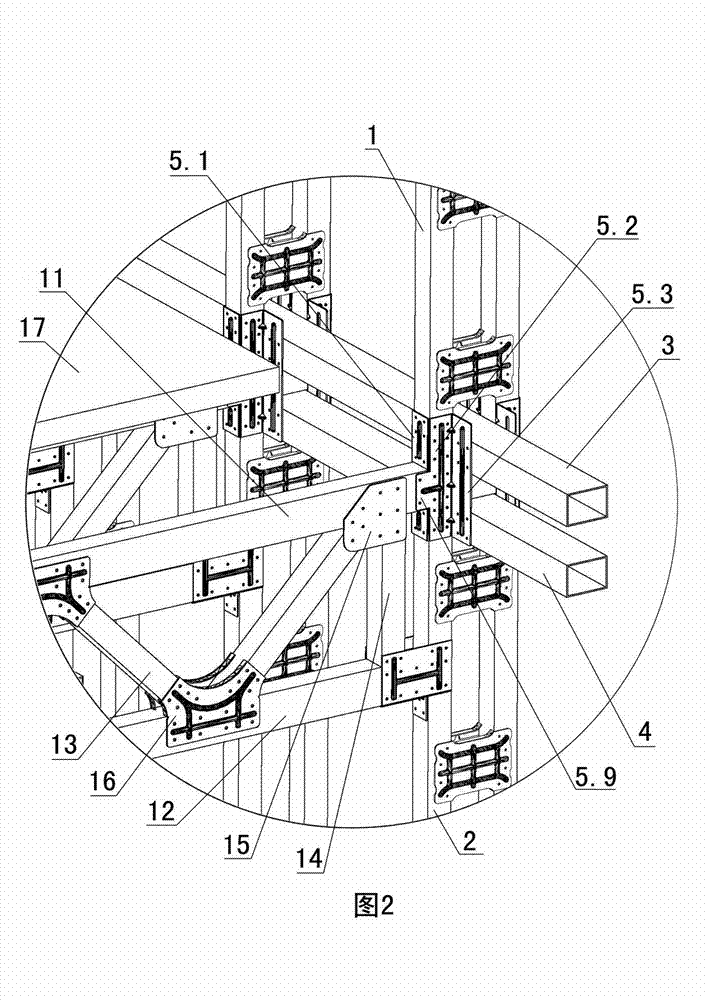

Truss combined beam and upper and layer connected light steel structure and construction method thereof

InactiveCN102359180ATroubleshoot simultaneous connectionsSolve the shortcomings that the pressure is not easy to meet the force requirementsGirdersJoistsRear quarterKeel

The invention discloses a truss combined beam and upper and layer connected light steel structure and a construction method thereof. The light steel structure comprises upper wall sheet columns distributed at intervals, lower wall sheet columns distributed at intervals, upper wall sheet column lower connecting pipes connected among the lower parts of the upper wall sheet columns, lower wall sheet column upper connecting pipes connected among the upper parts of the lower wall sheet columns, and truss combined beams connected between the upper wall sheet columns and the lower wall sheet columns through upper and lower connectors, wherein the upper and lower connectors are beam passing buckles, the web plates of the beam passing buckles consist of upper web plates and lower web plates, a square connecting port is formed between the upper web plates and the lower web plates, upper chord member connecting plates are extended from the left and right sides of the square connecting ports, and the upper chord member connecting plates and side plates of the beam passing buckles are positioned in the same plane. Through the light steel structure, the structural stability of a light steel keel house system is enhanced, and the floor surface beams, the connecting pipes and the floor panels do not easily vibrate.

Owner:筑巢(北京)科技有限公司

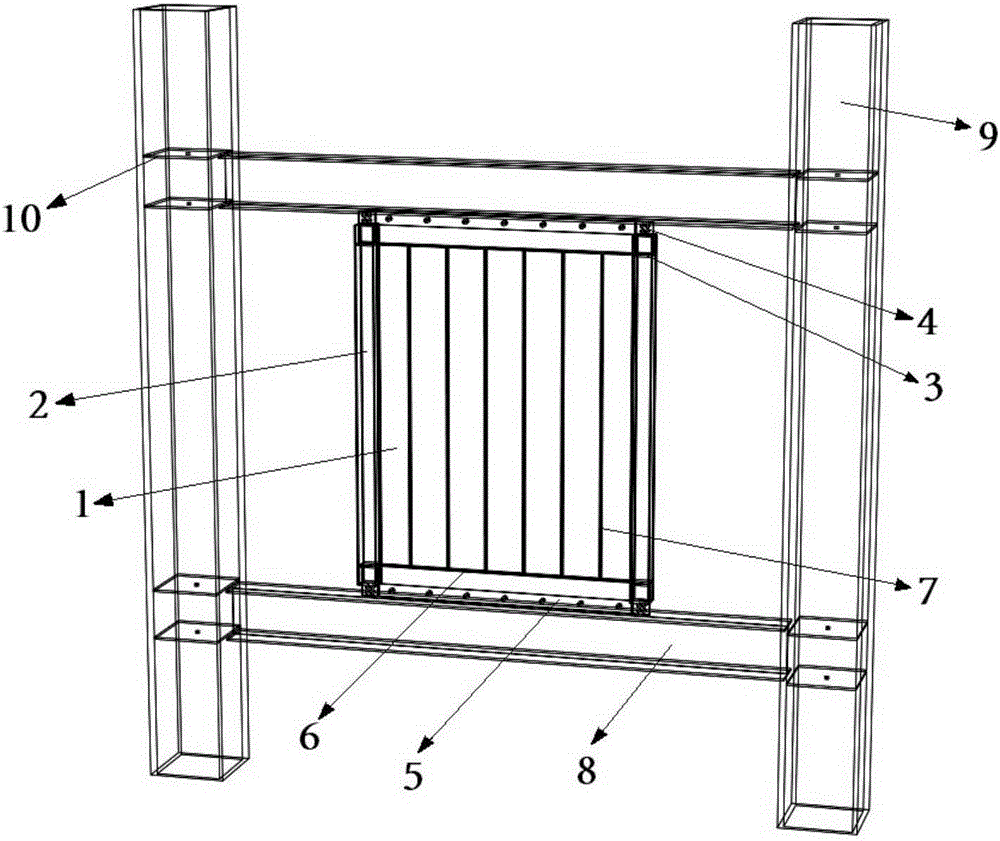

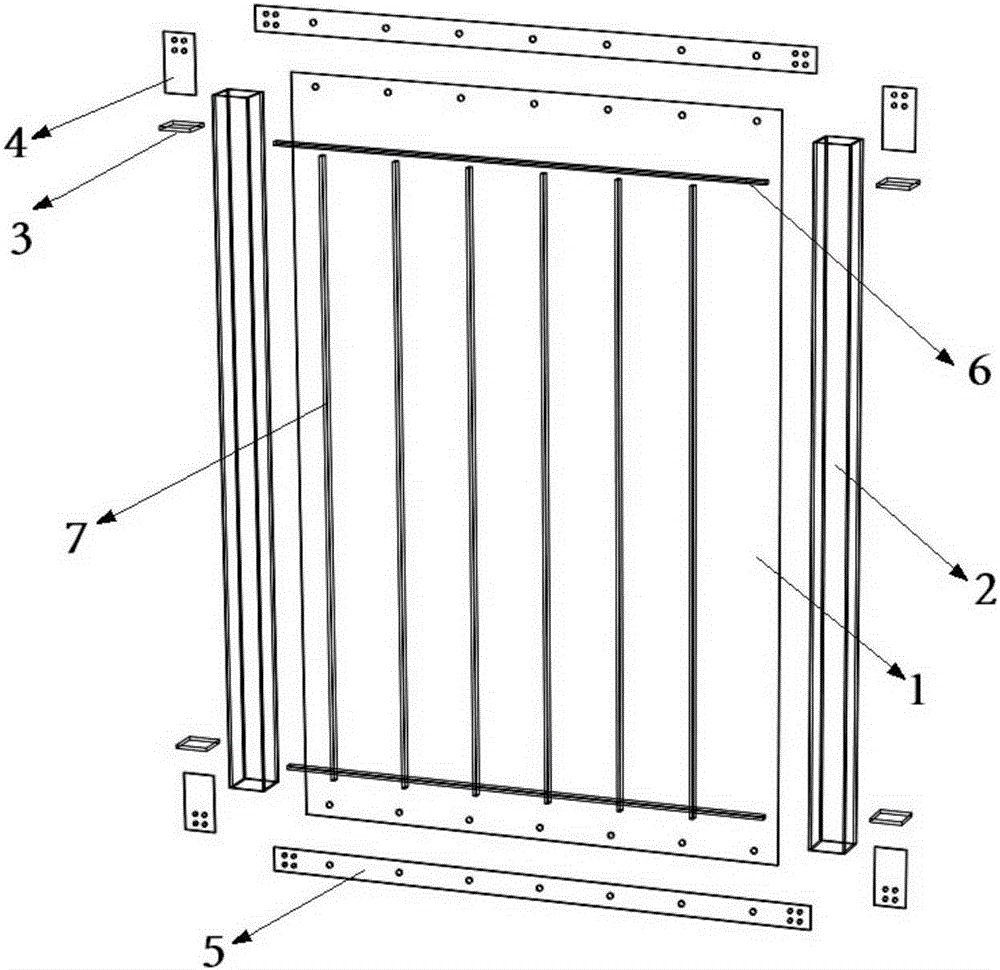

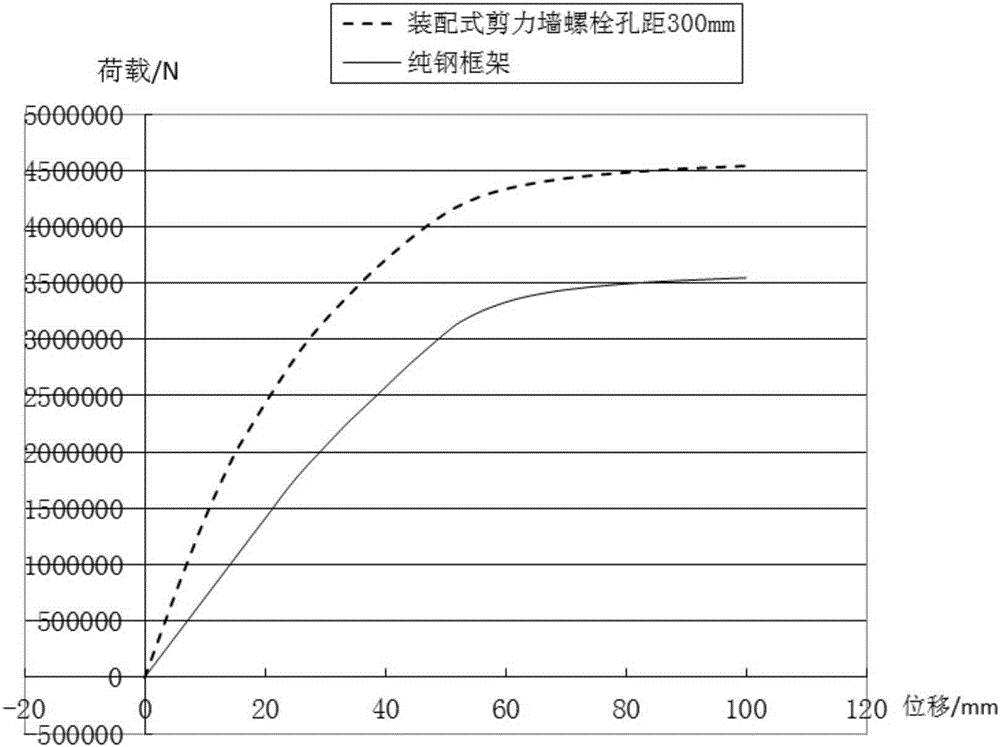

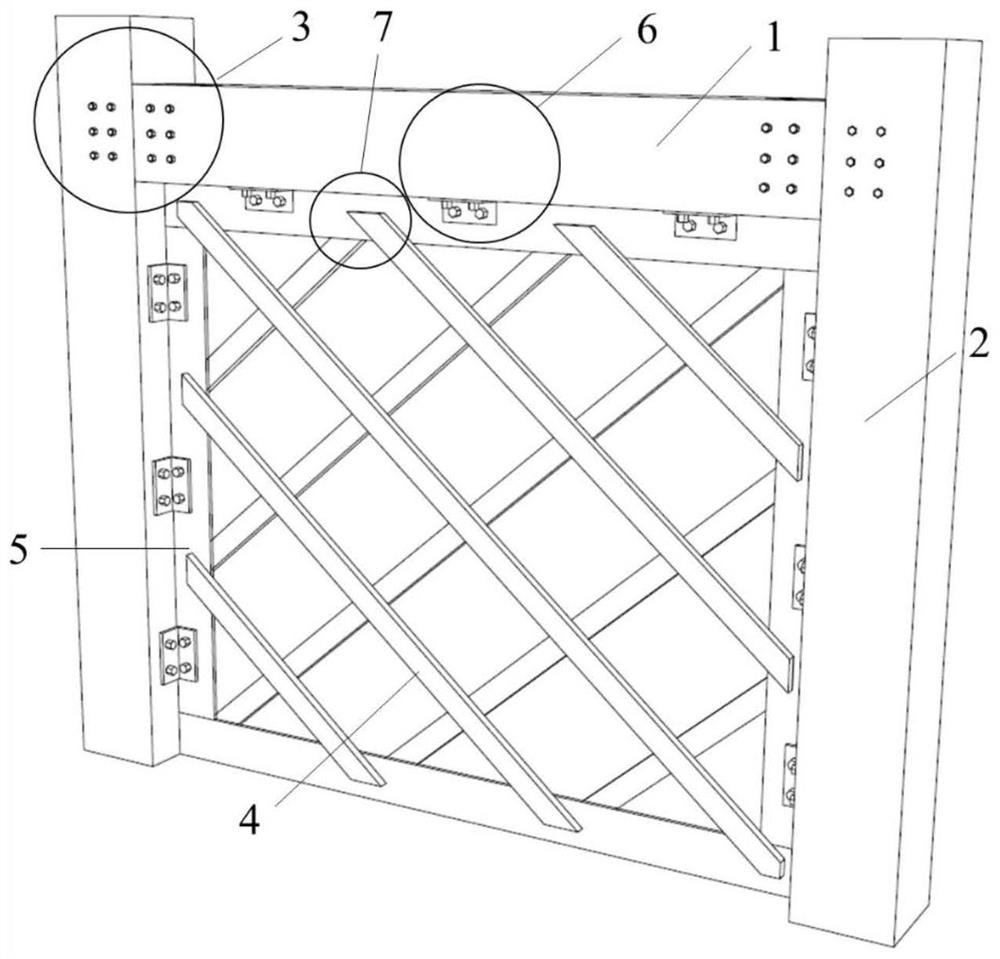

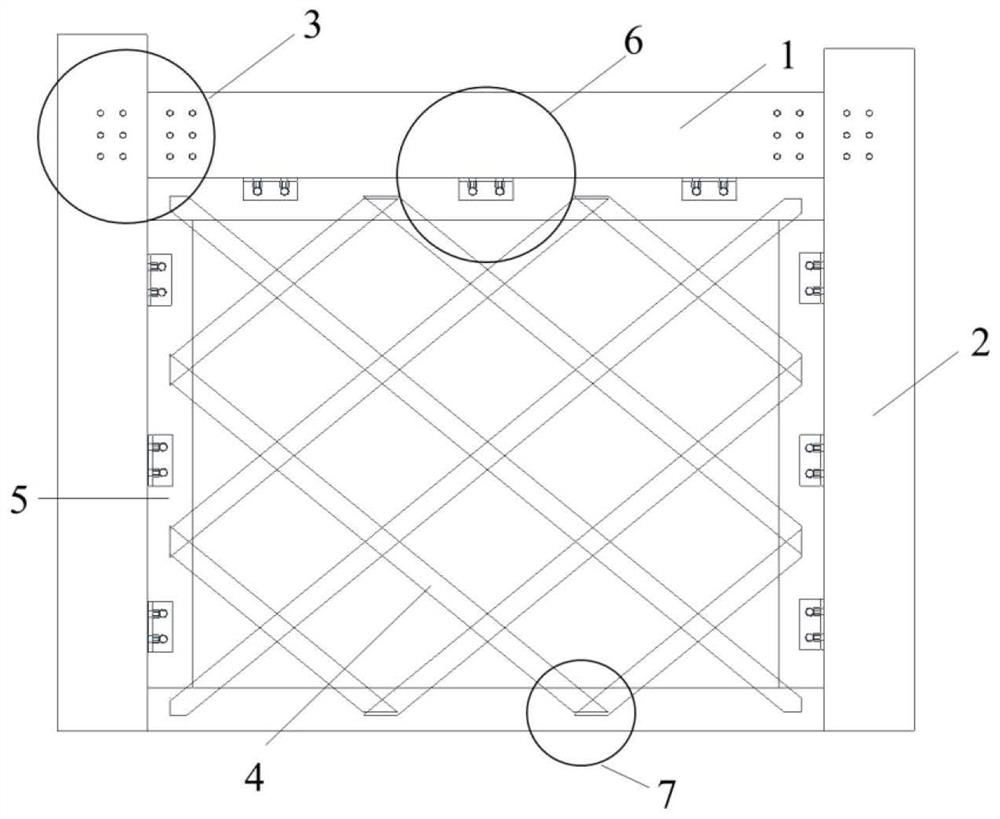

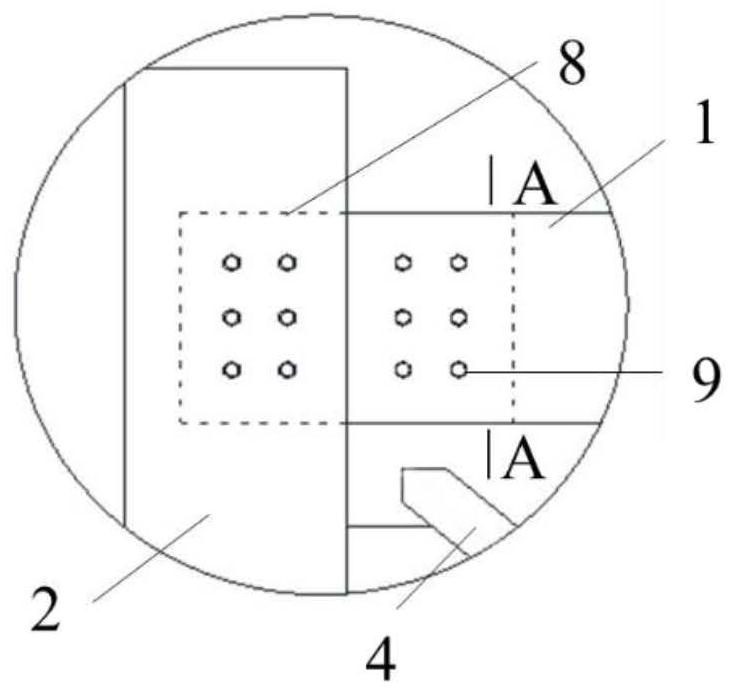

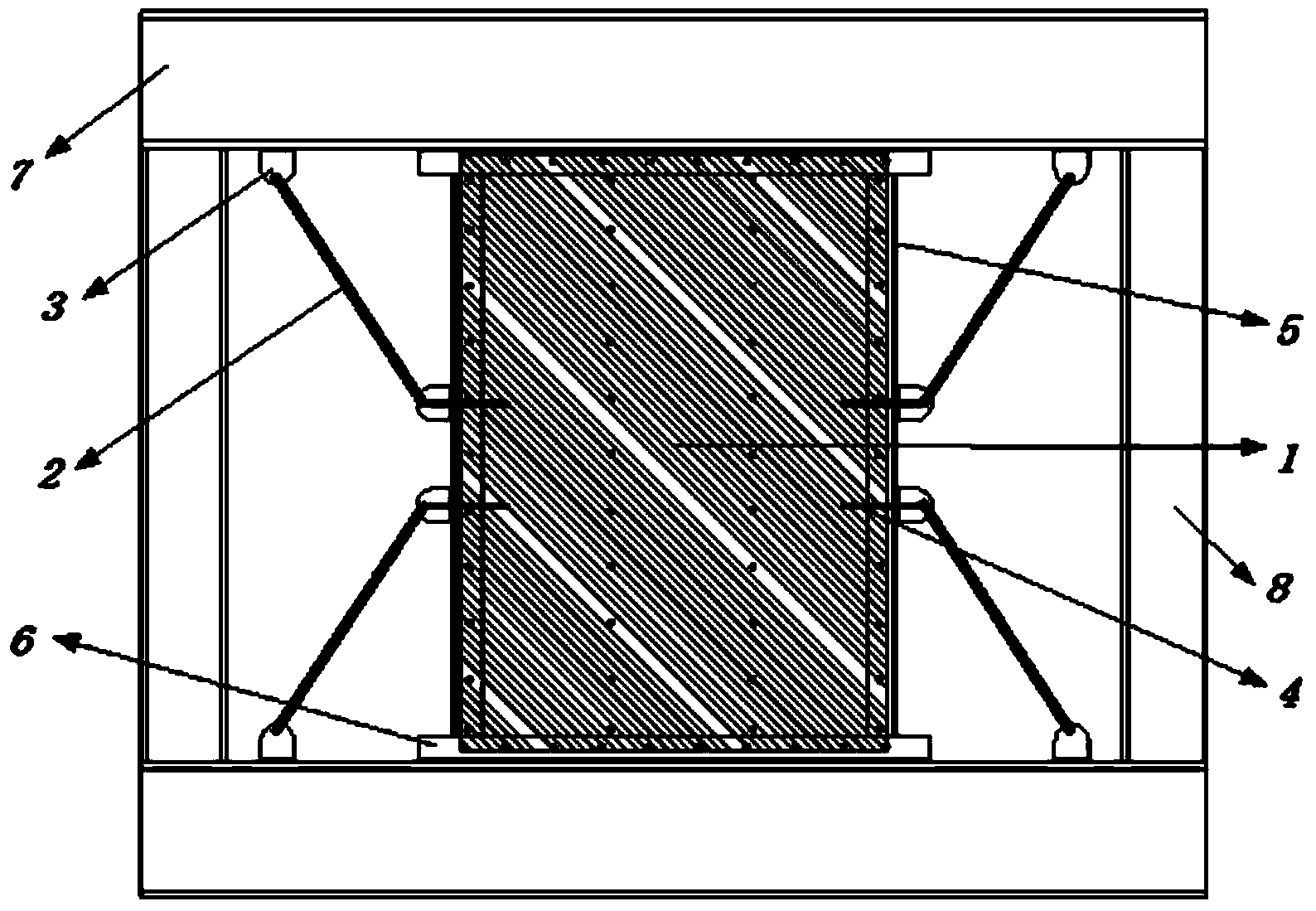

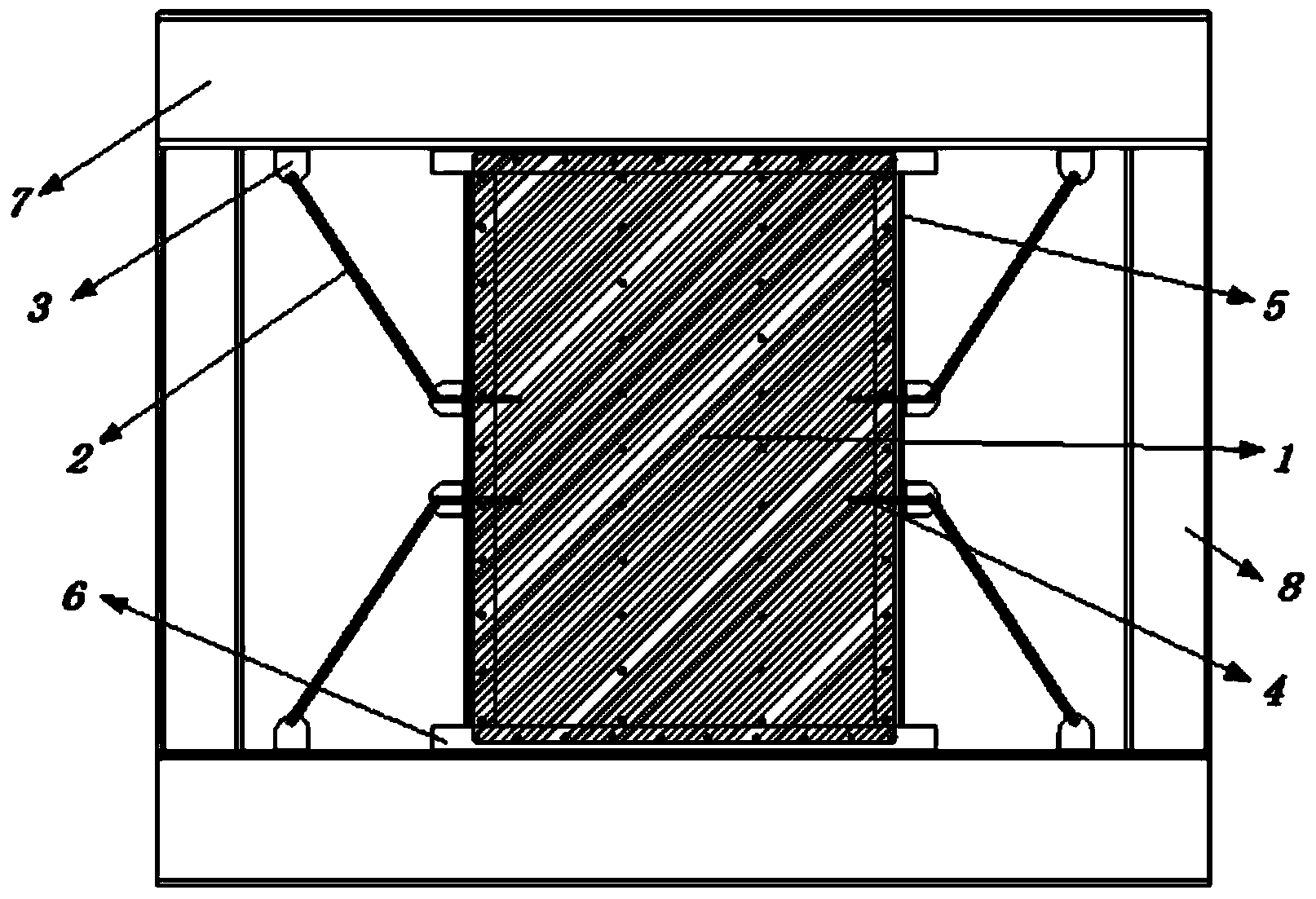

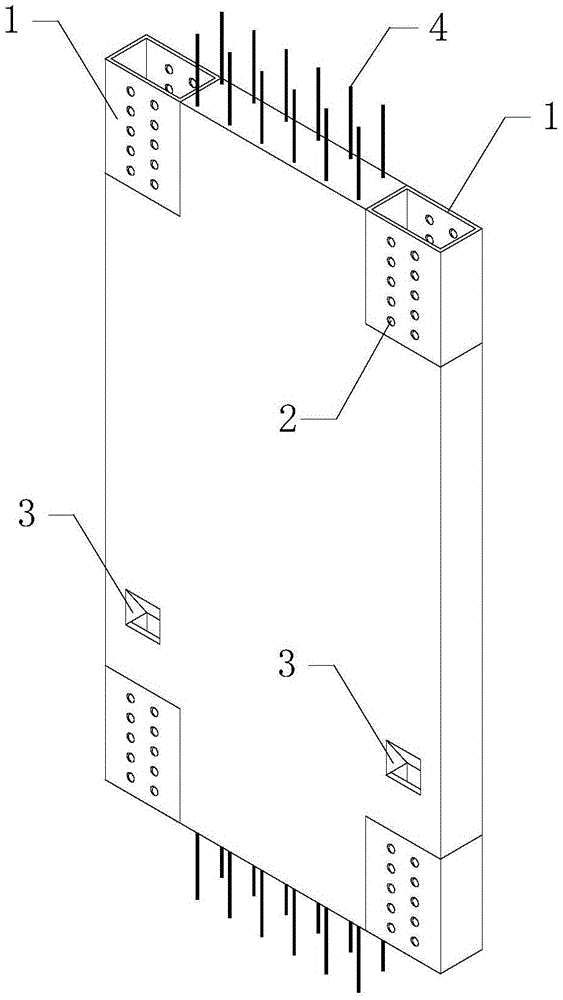

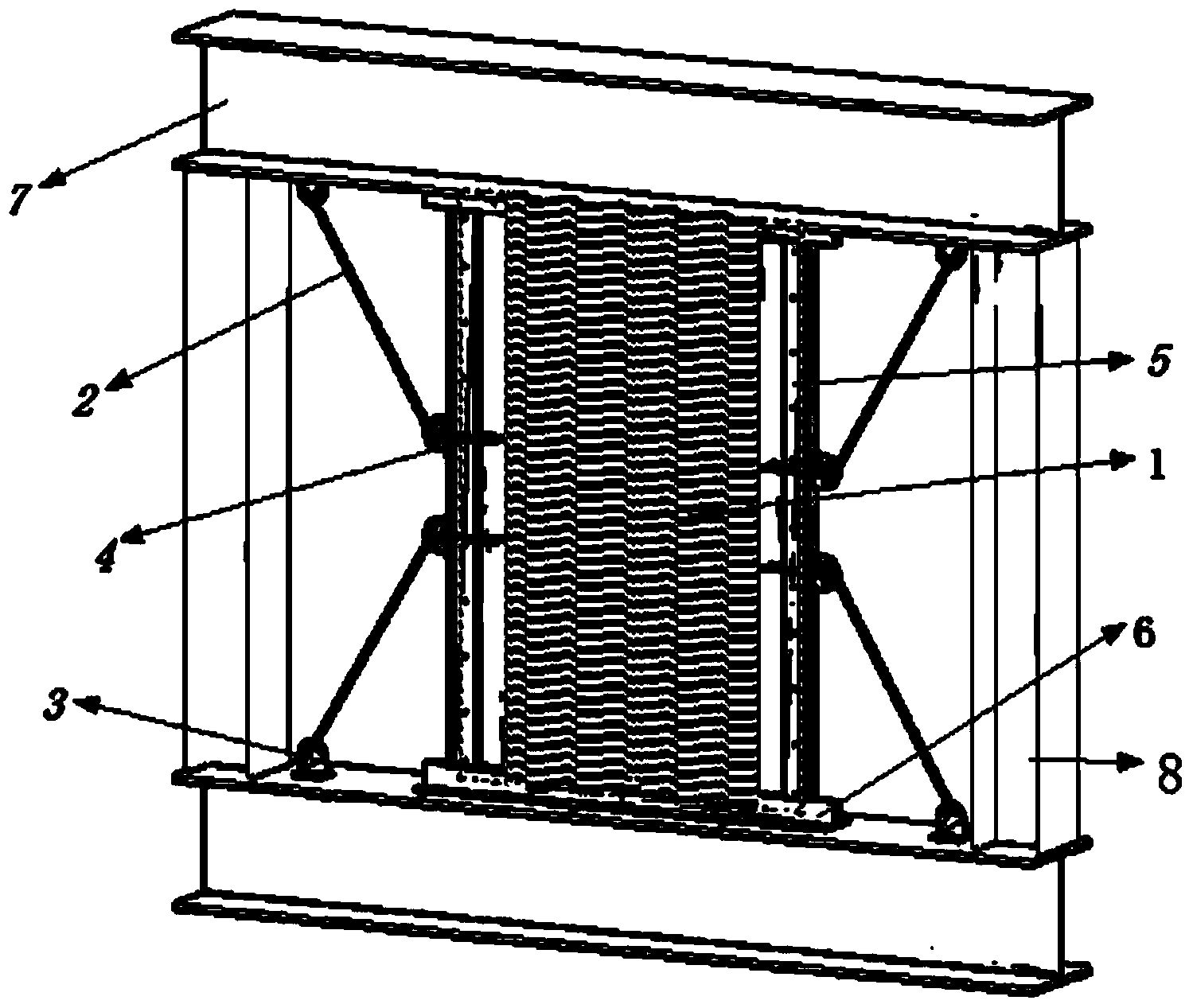

Assembly type ribbed steel plate shear wall with frame

InactiveCN105201103AImprove side resistanceEnsure safety and stabilityWallsLateral stiffnessSteel plate shear wall

The invention relates to an assembly type ribbed steel plate shear wall with a frame, and belongs to the technical field of structural engineering. The assembly type ribbed steel plate shear wall with the frame comprises an embedded steel plate, frame columns, frame column partition plates, frame column connecting plates, connecting plates, transverse rib plates, vertical rib plates, frame beams, frame columns and frame column partition plates. In the assembly type ribbed steel plate shear wall with the frame, the embedded steel plate, the frame columns, the frame column partition plates, the frame column connecting plates, the transverse rib plates and the vertical rib plates are welded into a whole shear wall module in a factory; the connecting plates and the frame beams are welded integrally in the factory; the connecting plates are connected with the whole shear wall module through high-strength bolts and are not connected with the frame columns; the frame columns and the frame column partition plates are welded, and the frame beams and the frame columns are welded or connected through bolts or connected in a bolt-welding mixed mode. The assembly type ribbed steel plate shear wall has the advantages of being high in lateral stiffness, bearing capacity and ductility, good in anti-seismic property and easy to construct, holes can be formed flexibly, the construction period is shortened, and construction cost is reduced.

Owner:BEIJING UNIV OF TECH

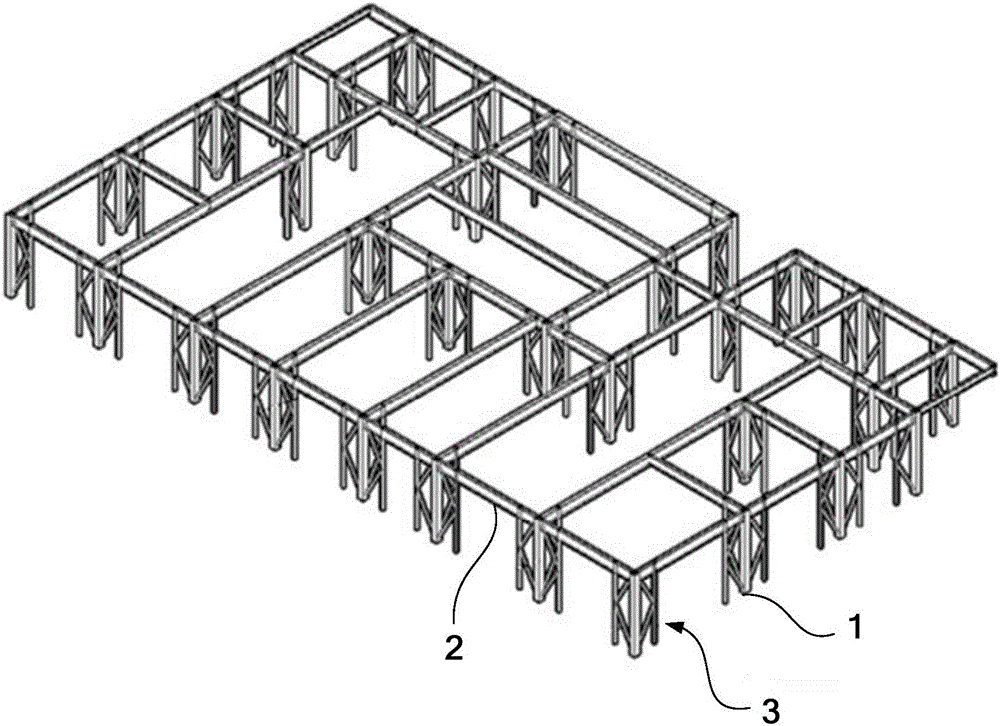

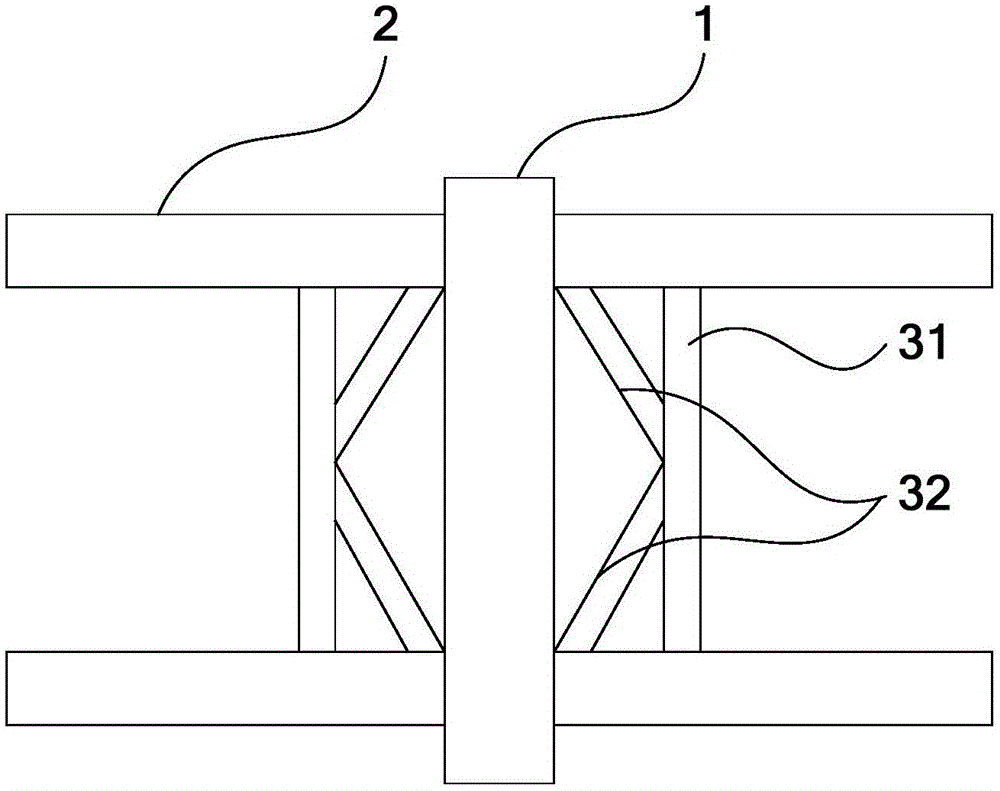

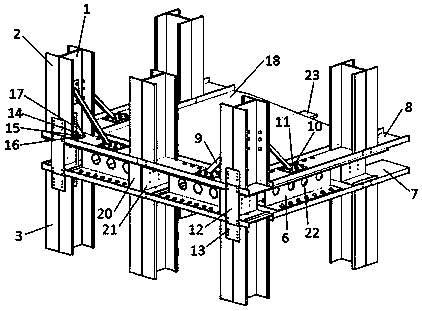

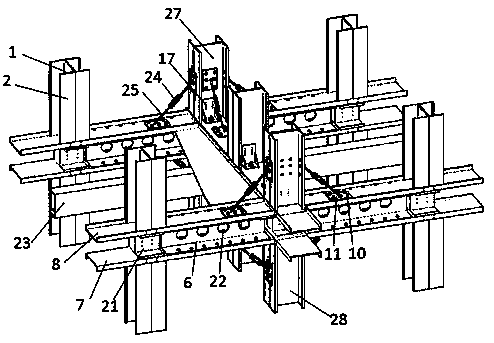

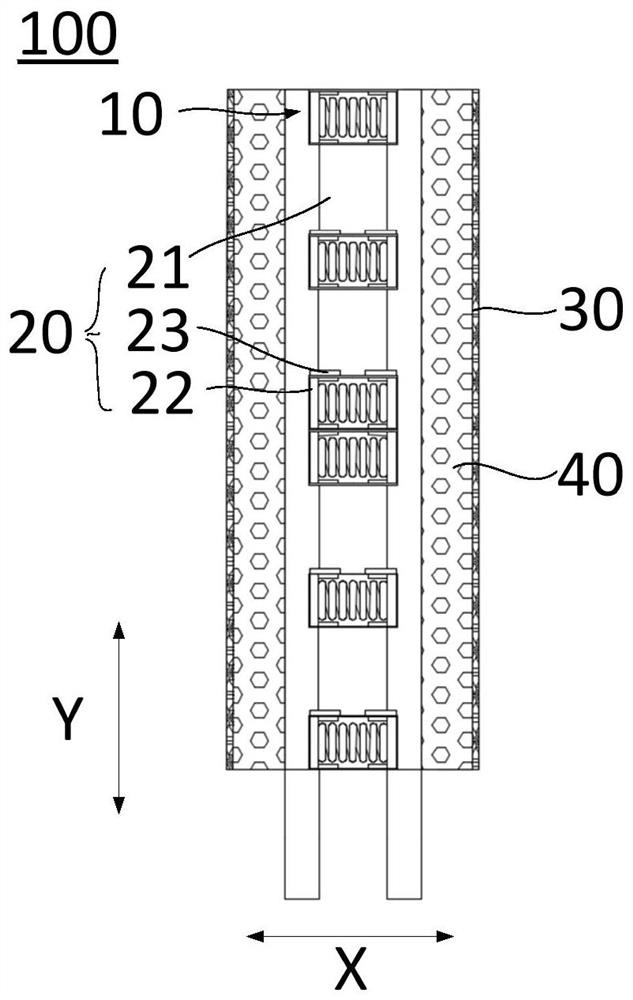

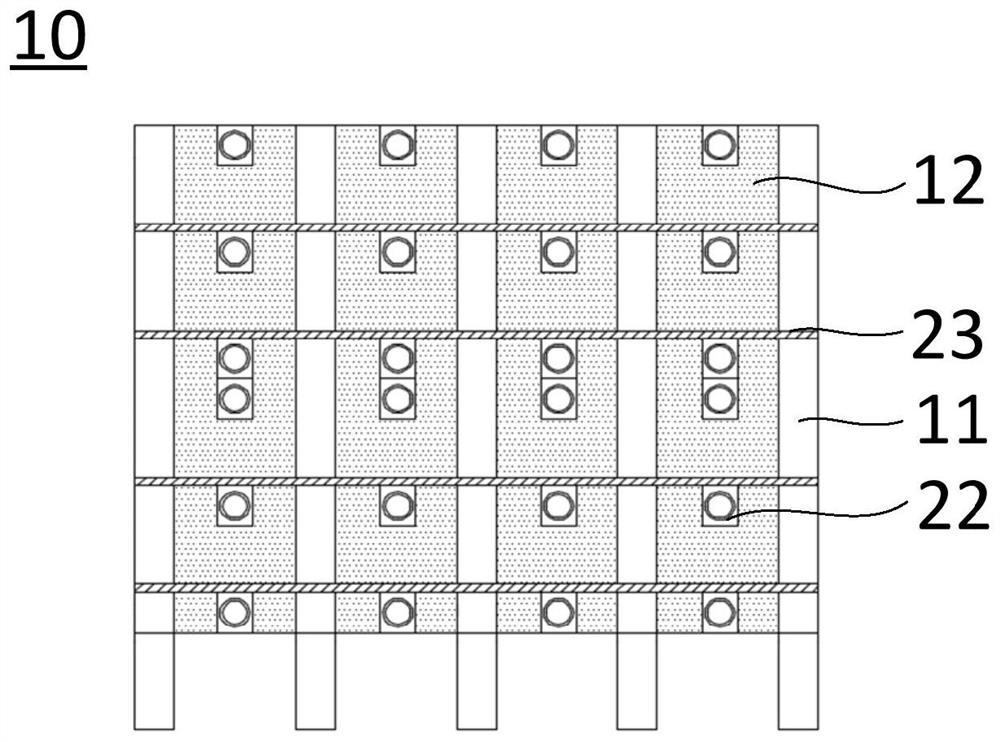

Assembled steel structure

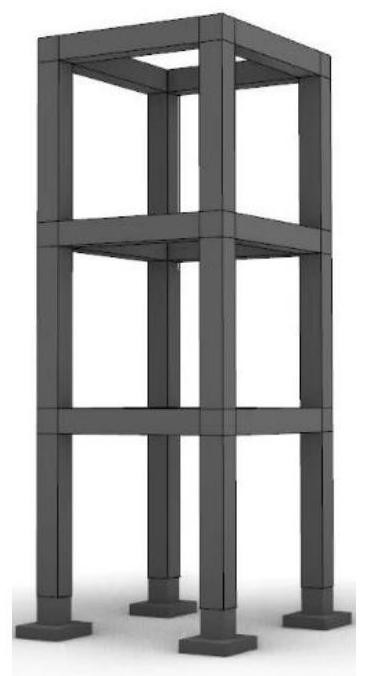

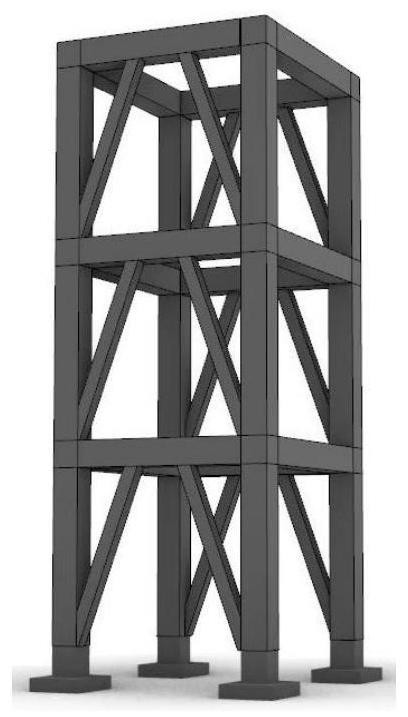

ActiveCN106759893AAvoid buckling collapseImprove side resistanceBuilding constructionsEngineeringBearing capacity

The invention relates to the technical field of building engineering, discloses an assembled steel structure and aims at improving lateral resistance to improve bearing capacity and stability of buildings. The assembled steel structure comprises multiple uprights which are erected parallelly, multiple cross beams which are horizontally arranged and connected with the uprights and K-shaped supporting frames arranged corresponding to joints of the uprights and the corresponding cross beams; each K-shaped supporting frame comprises a vertical stay bar and two oblique stay bars which are in K-shaped arrangement, each vertical stay bar is arranged vertically, two ends of each vertical stay bar are respectively connected with the corresponding crossbeam, and one end of each oblique stay bar is connected to the middle of the corresponding vertical stay bar while the other end of the same is connected with the corresponding upright.

Owner:鞍钢中电建筑科技股份有限公司

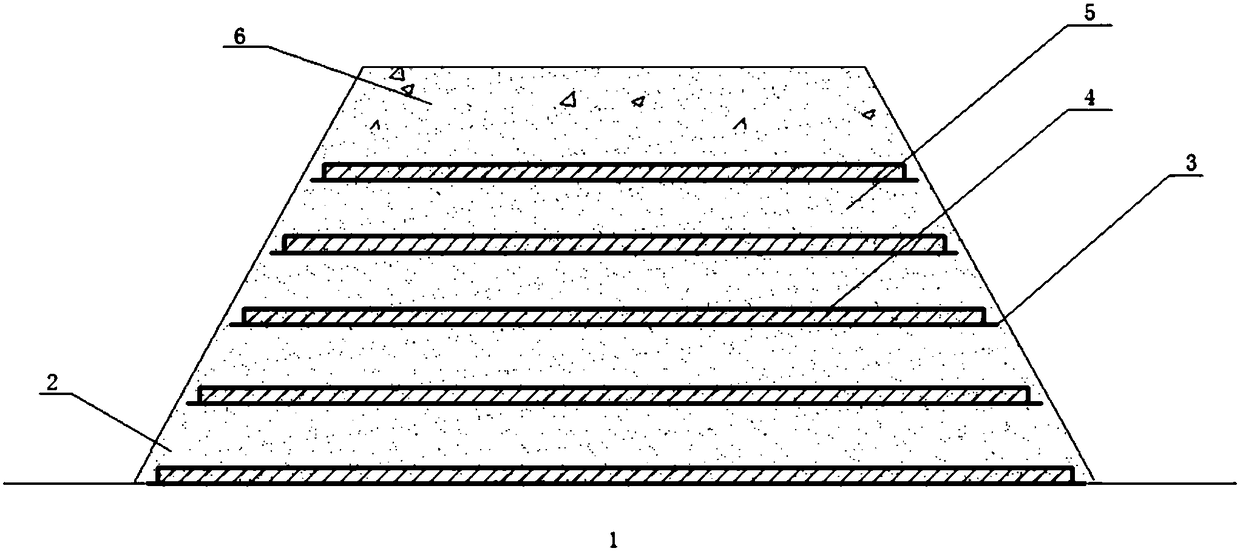

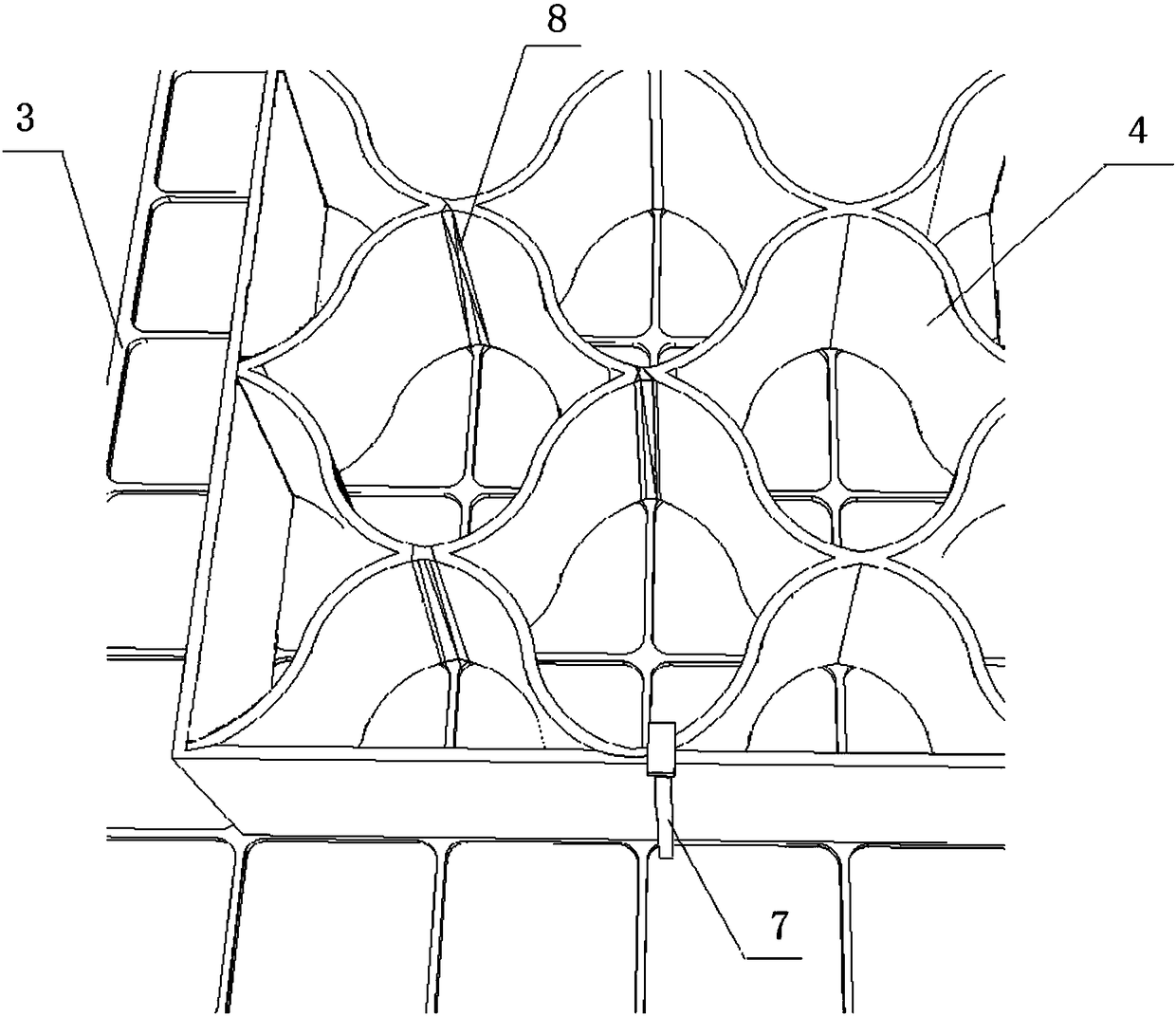

Domestic garbage incinerated ash and mixed soil composite reinforced subgrade and construction method thereof

ActiveCN108442200AImprove the bearing capacity of the foundationImprove stabilityRoadwaysGeocellsEngineering

The invention discloses a domestic garbage incinerated ash and mixed soil composite reinforced subgrade. The domestic garbage incinerated ash and mixed soil composite reinforced subgrade comprises a foundation layer, a subgrade layer paved on the top surface of the foundation layer and a road surface layer paved on the top surface of the subgrade layer, wherein the subgrade layer comprises a subgrade base body and a plurality of layers of reinforced structure layers; the subgrade base body is prepared from compacted filler and the filler is mainly prepared by mixing domestic garbage incinerated ash and clay; the reinforced structure layers are paved in the subgrade base body at intervals from bottom to top; the reinforced structure layer on the topmost layer is located on the bottom surface of the road surface layer; each reinforced structure layer is mainly composed of a geogrid and a geocell fixed at the top of the geogrid. According to the domestic garbage incinerated ash and mixedsoil composite reinforced subgrade disclosed by the invention, the urban domestic garbage incinerated ash is used as a filler component to be applied to subgrade construction, so that the environmentpollution is reduced, the land occupation problem caused by accumulation of garbage ash is alleviated and a novel way is provided for harmless and reclamation treatment on the ash; the domestic garbage incinerated ash and mixed soil composite reinforced subgrade disclosed by the invention has excellent strength and rigidity.

Owner:HUBEI UNIV OF TECH

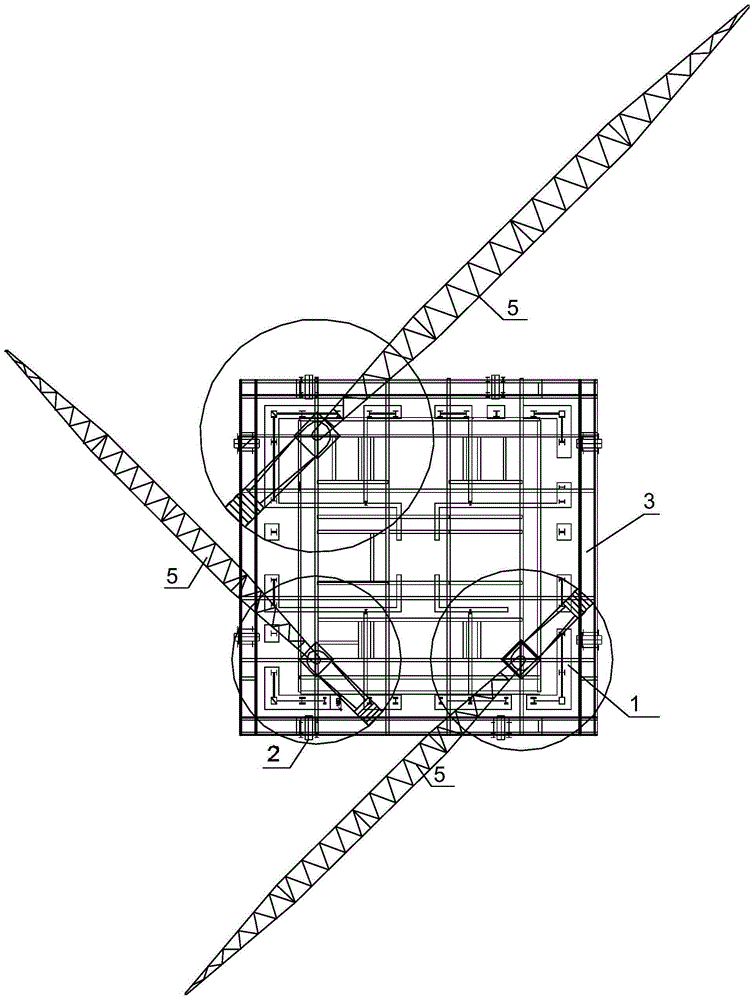

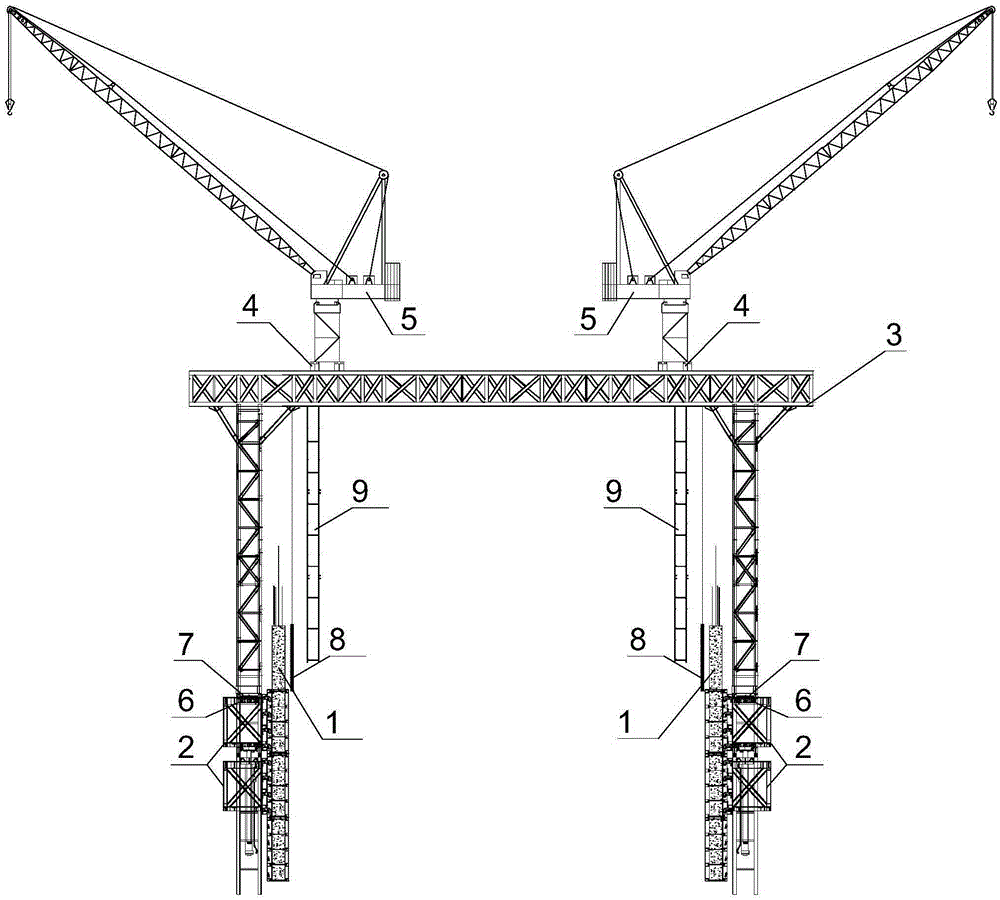

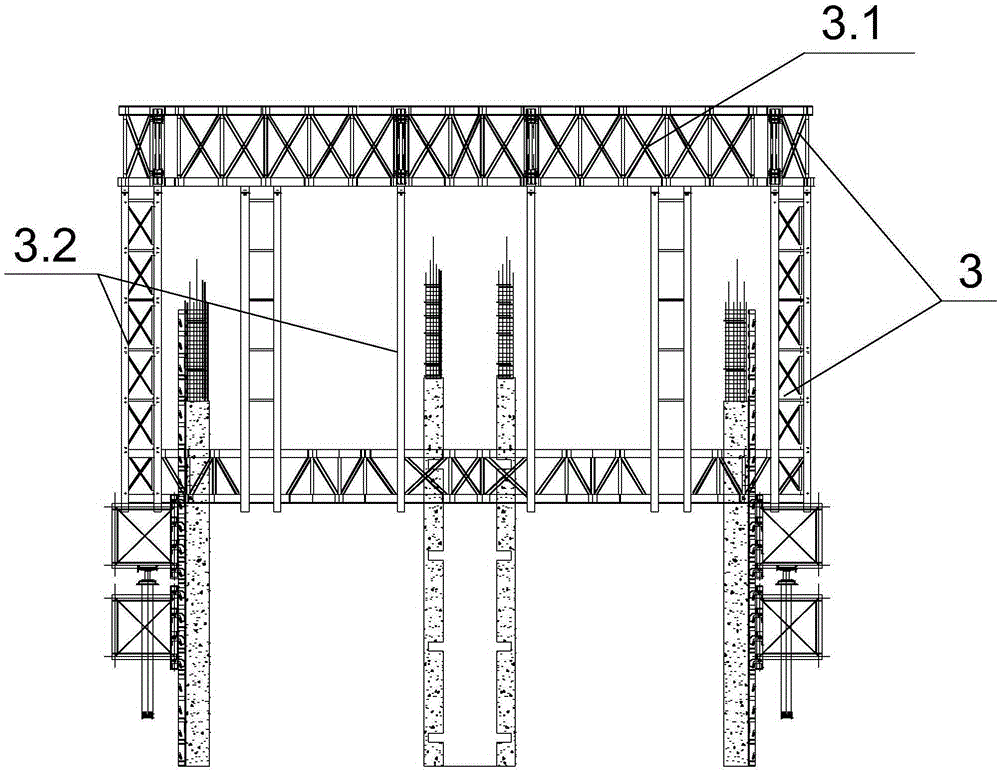

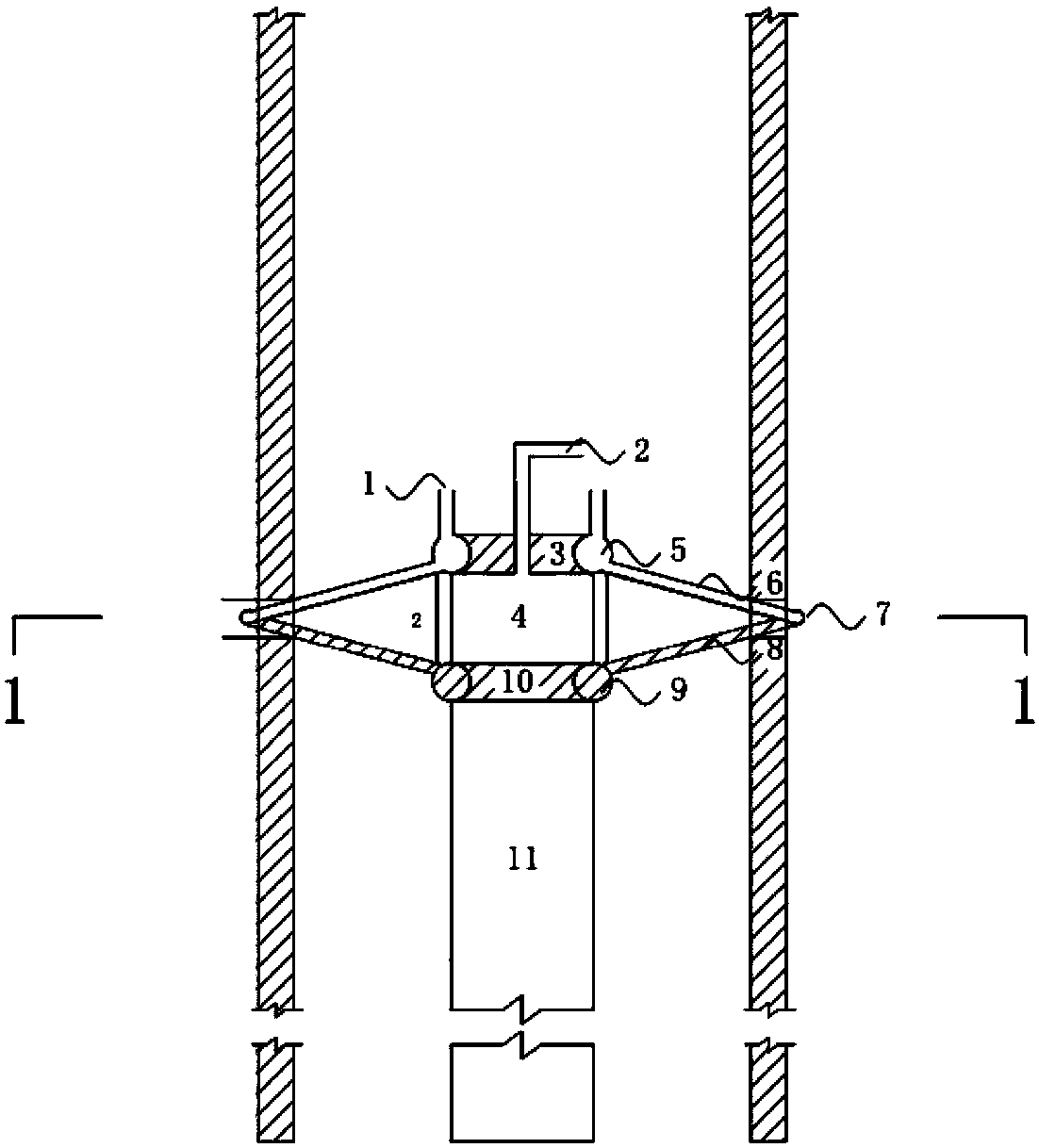

Self-standing tower crane and formwork integrated construction platform system

The invention discloses a self-standing tower crane and formwork integrated construction platform system. The self-standing tower crane and formwork integrated construction platform system comprises self-standing tower cranes, a steel frame device, supporting power devices, lateral resisting devices and leveling devices; the steel frame device comprises a frame platform and frame columns, and each frame column is installed on the wall body of the periphery of a core tube through the corresponding supporting power device; each supporting power device comprises a micro-convex fulcrum mechanism, an upper support frame, a lower support frame, a switchover stand column mechanism and a power mechanism, the micro-convex fulcrum devices are fixedly installed on the wall bodies of the peripheries of the core tubes, the upper support frames and the lower support frames are arranged on the upper portions and the lower portions of the micro-convex fulcrum devices in a hanging mode respectively, the switchover stand column mechanisms are put on the upper support frames, the upper portions of the power mechanisms are installed on the switchover stand column mechanisms, and the lower portions of the power mechanisms are fixedly connected with the lower support frames. According to the self-standing tower crane and formwork integrated construction platform system, a formwork and the tower cranes can be made to form an integrated structure, overall lifting is achieved, and the safety and the stability of the whole formwork during operation of the tower cranes are guaranteed.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +2

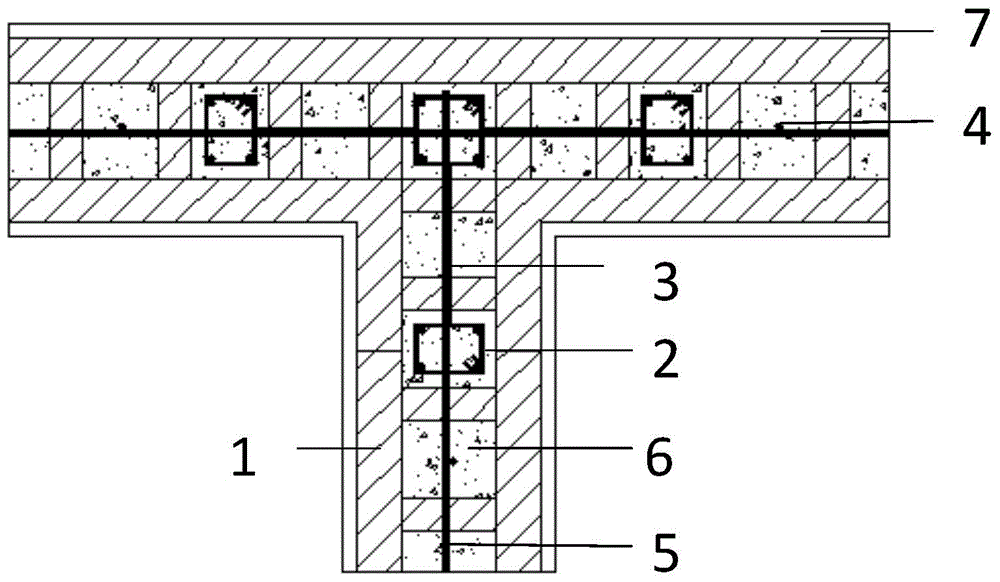

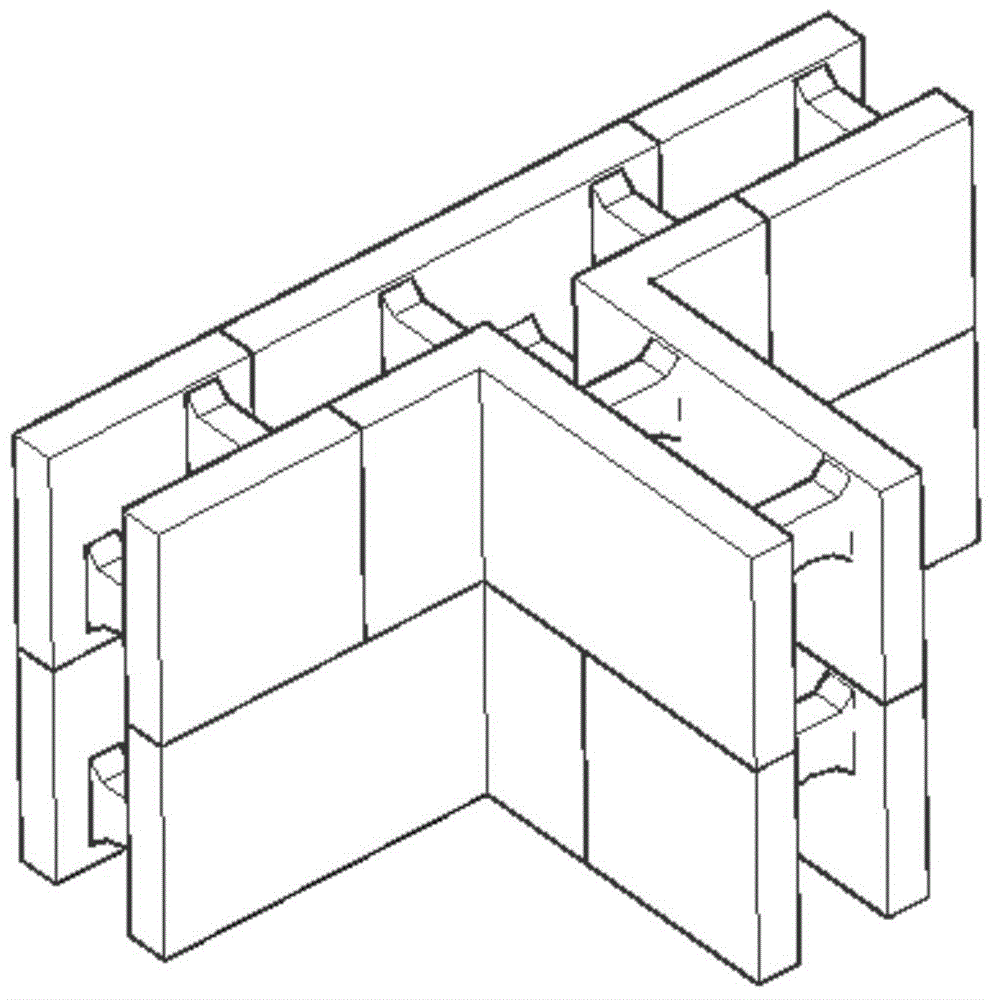

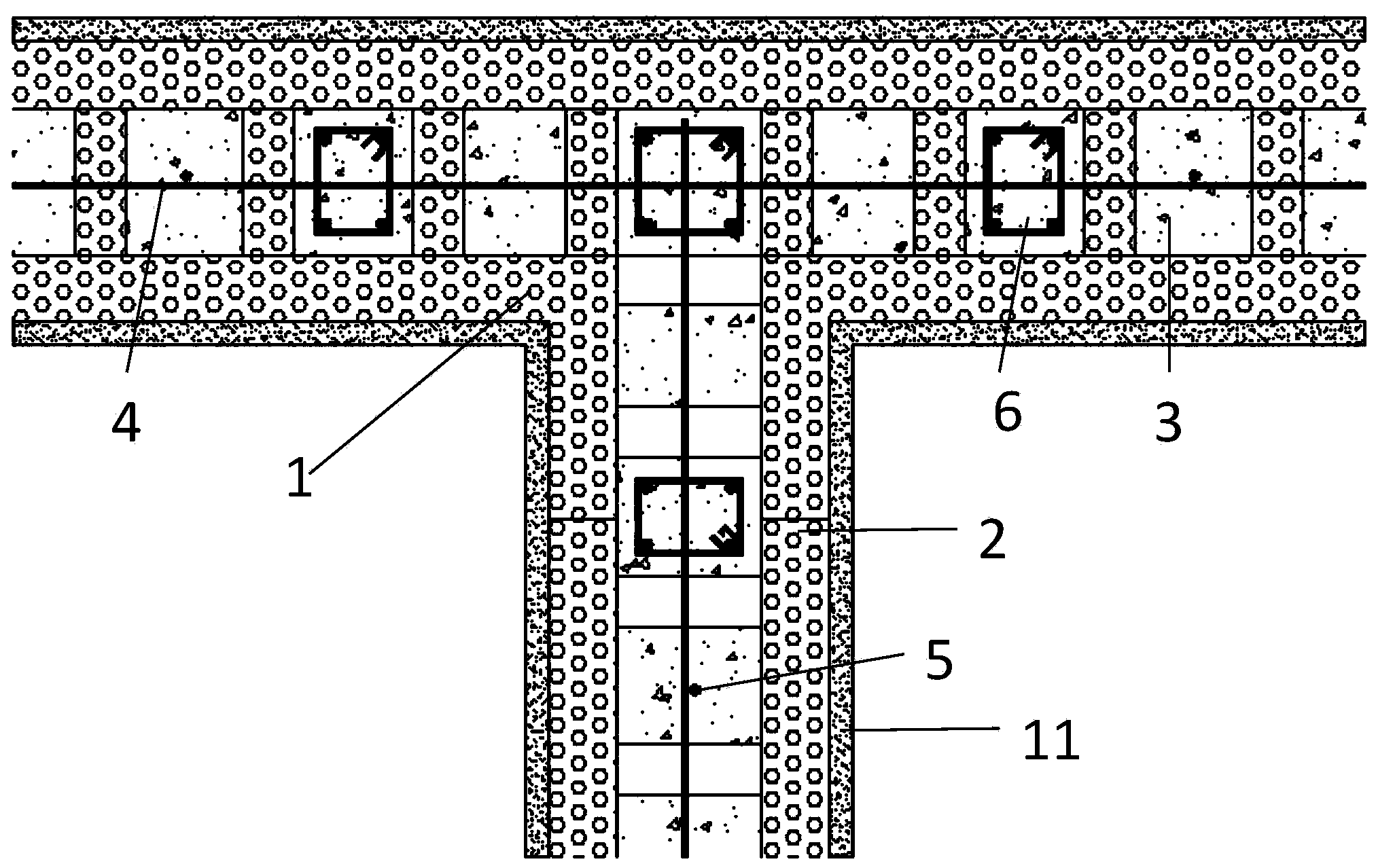

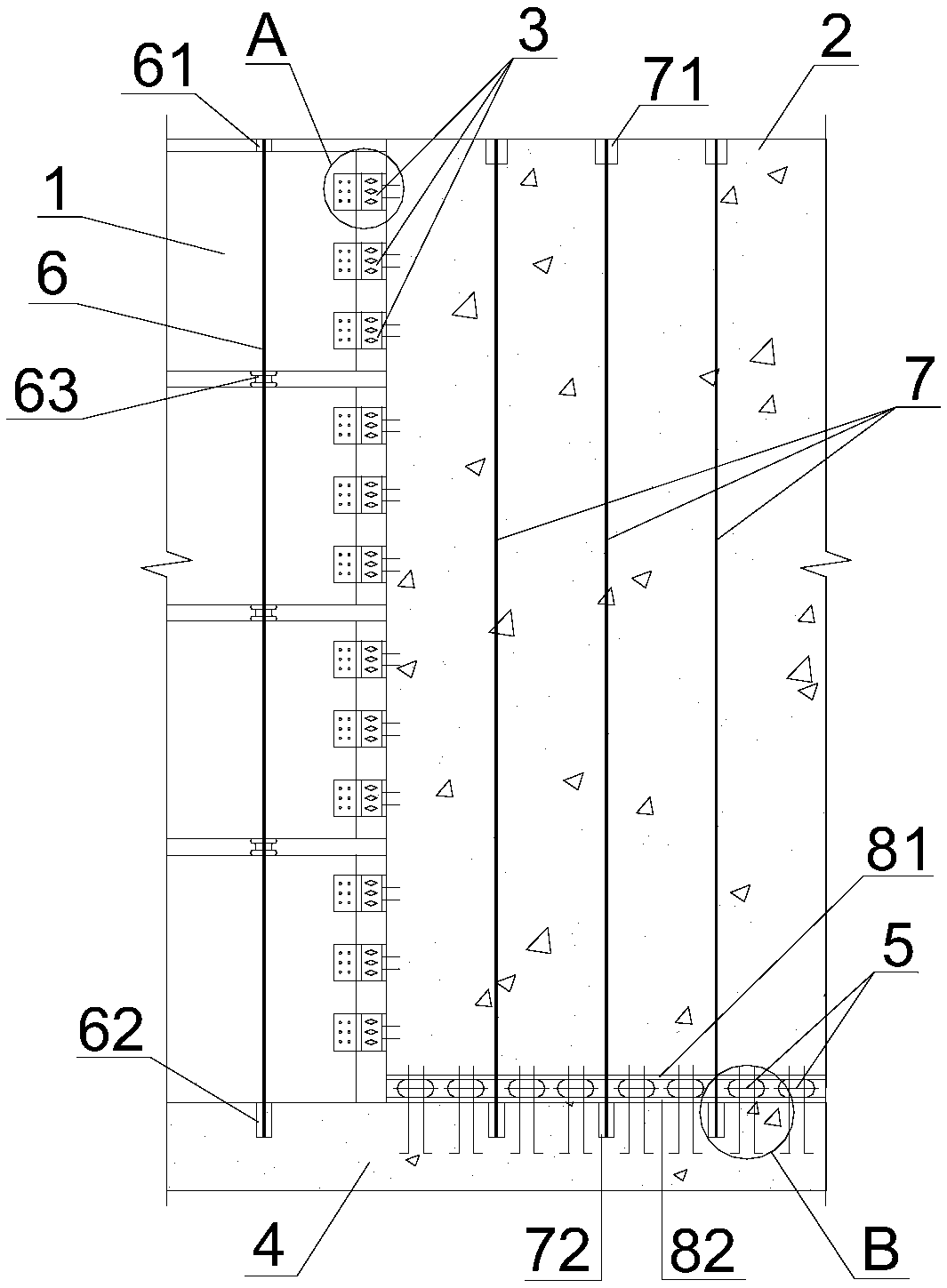

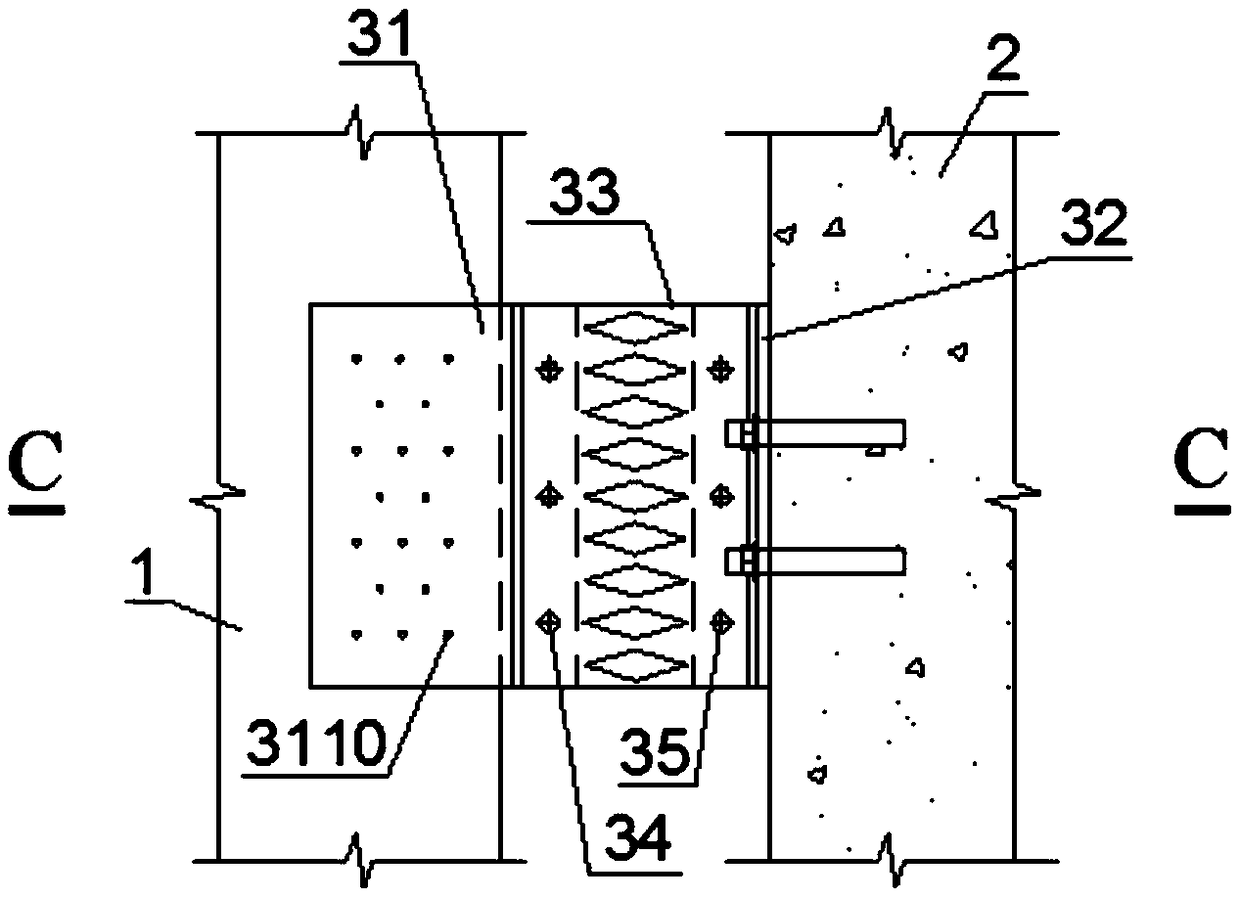

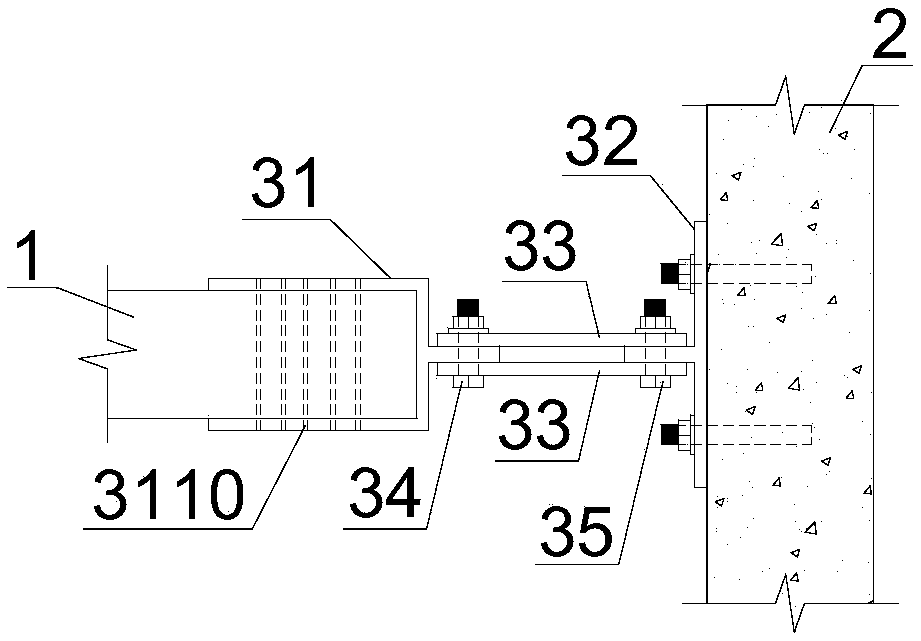

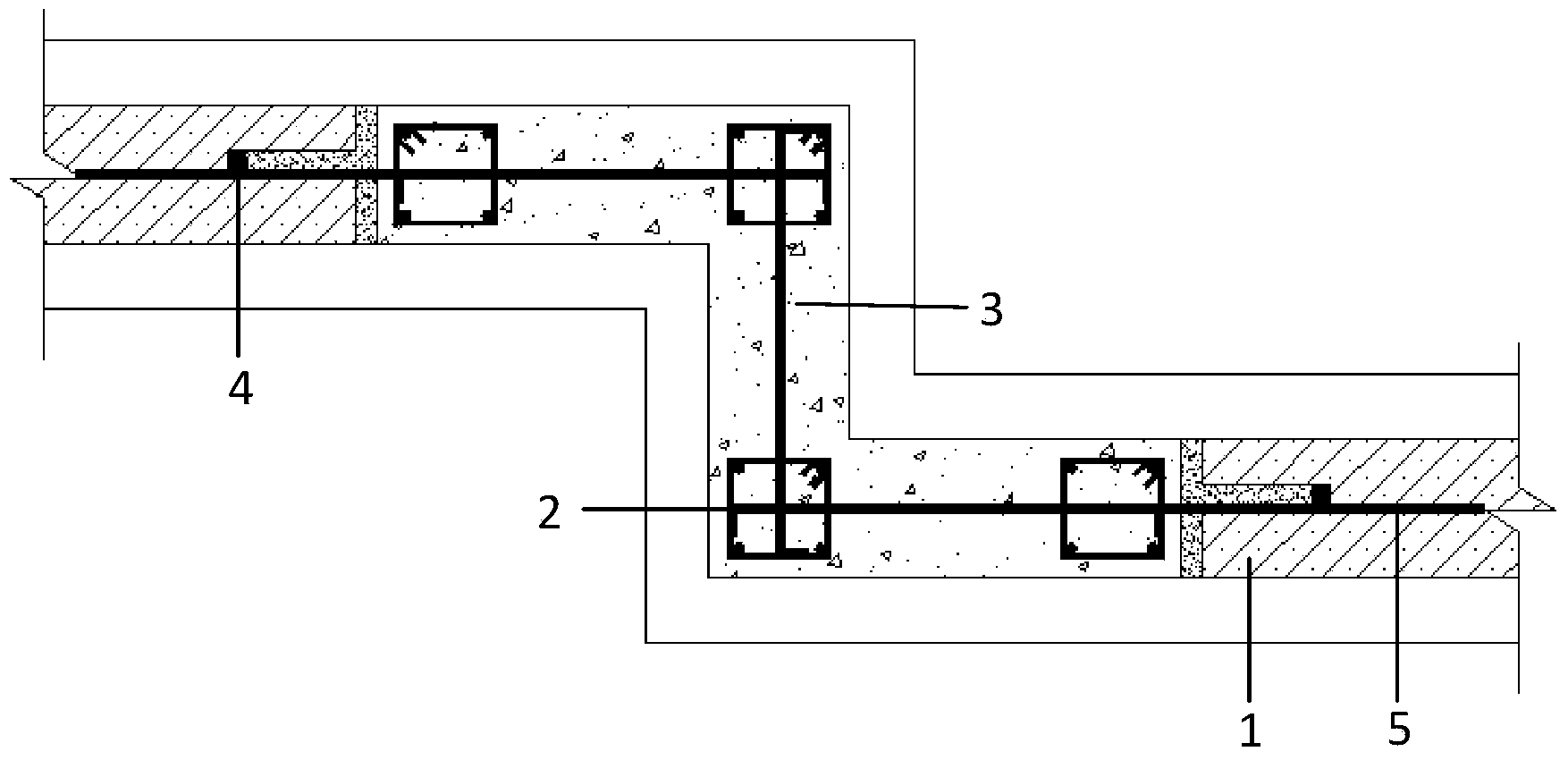

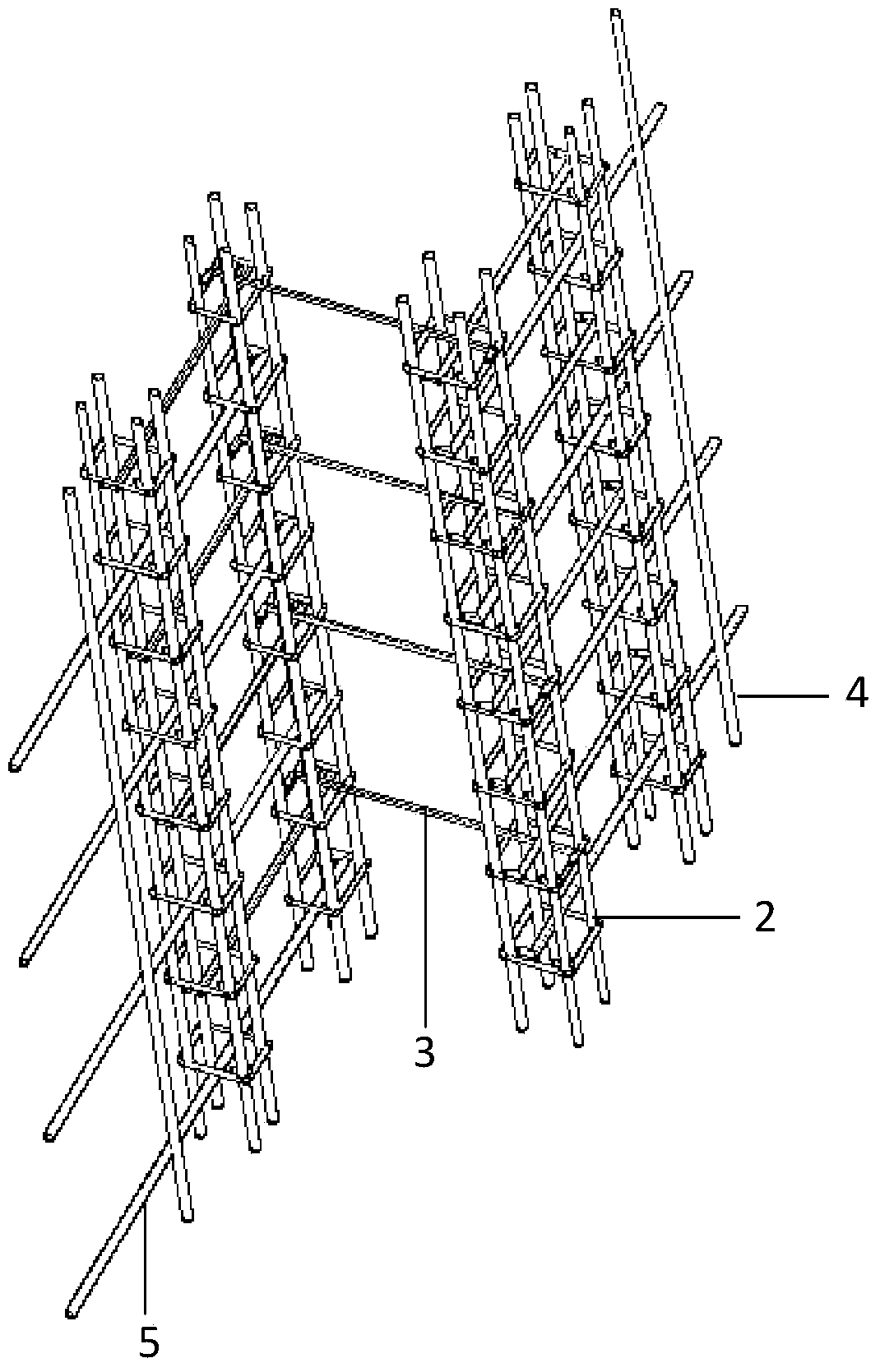

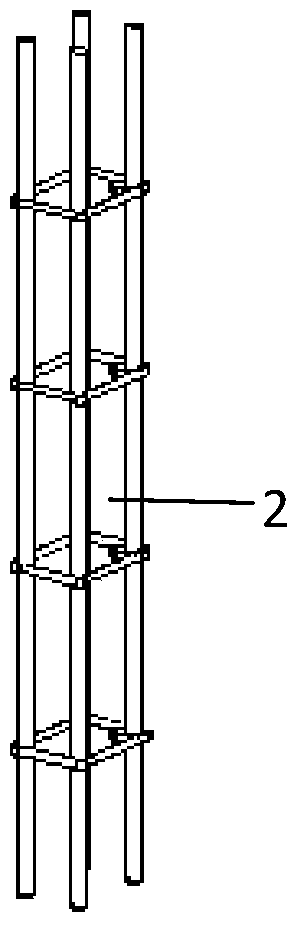

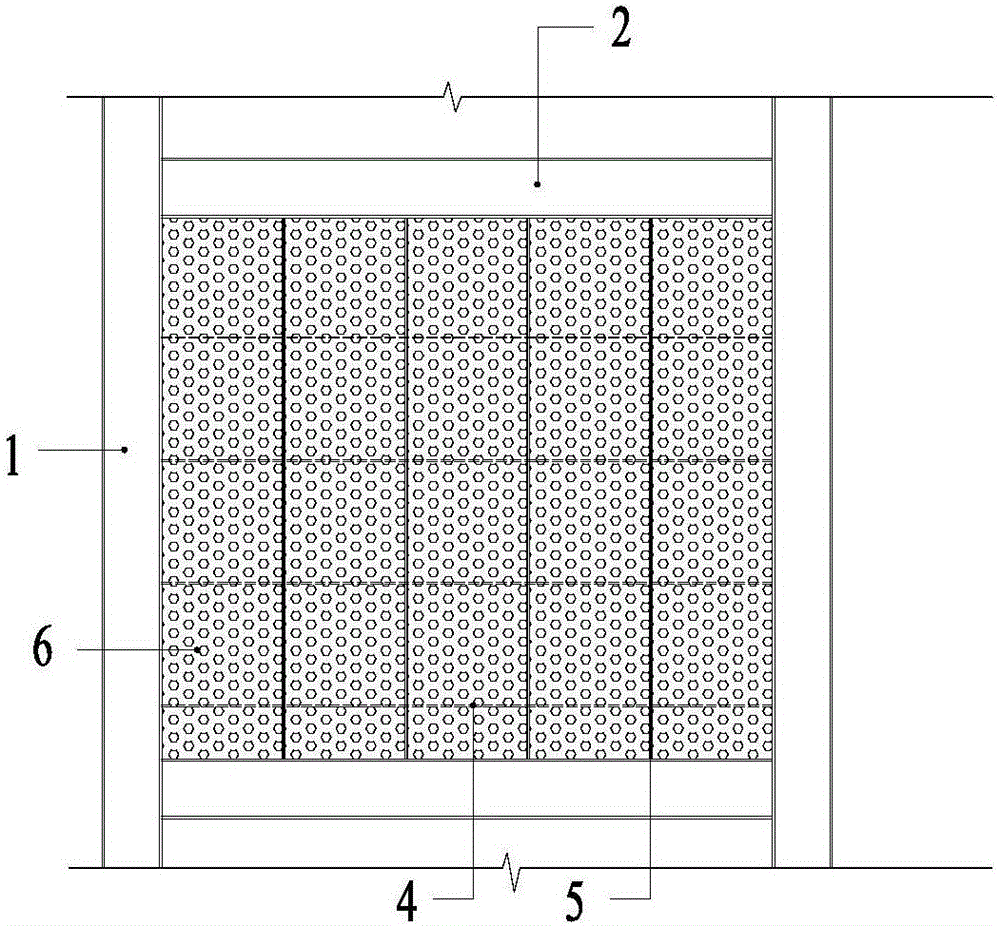

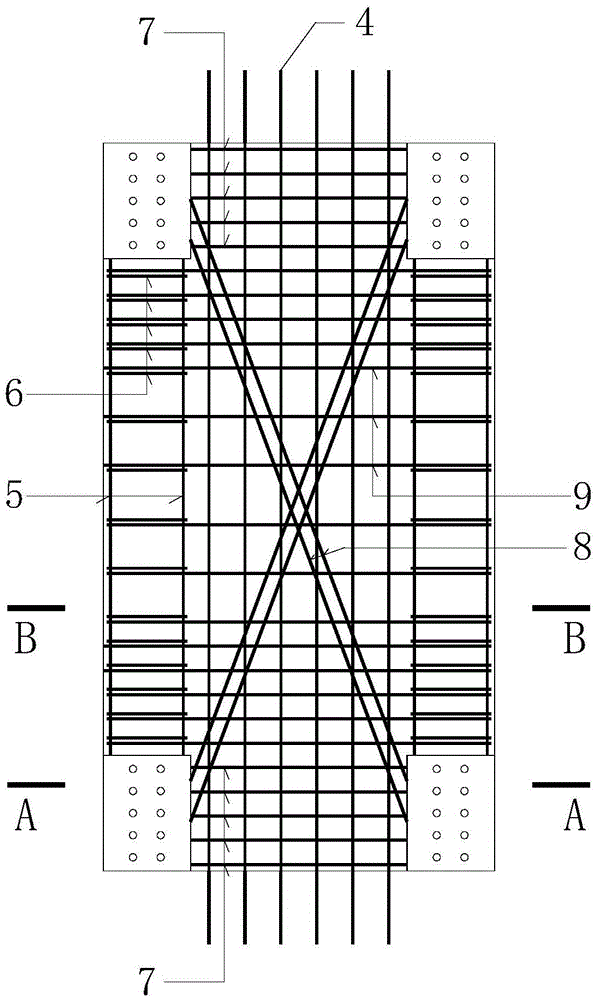

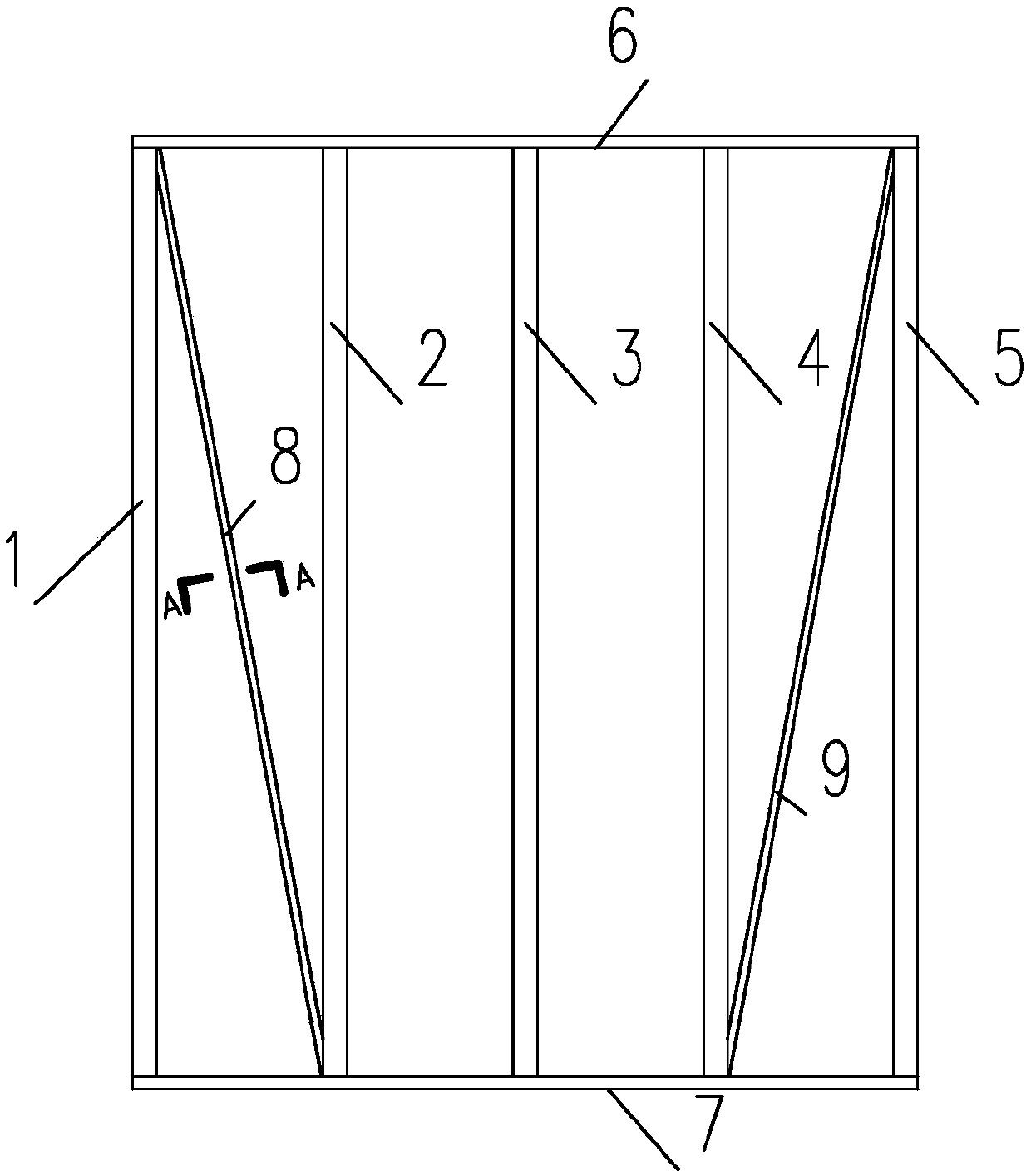

Single-line reinforcement thermal insulation bearing shear wall with T-shaped hidden posts at end parts and manufacturing method of shear wall

A single-line reinforcement thermal insulation bearing shear wall with T-shaped hidden posts at the end parts is an energy-saving wall body formed by thermal insulation building molds and concrete single-line reinforcement wall bodies and belongs to the technical field of earthquake-proofing of building structures. The shear wall comprises the thermal insulation building molds (1), the hidden posts (2); grid-structural reinforcing meshes (3), vertical wall body distributing steel bars (4), horizontal wall body distributing steel bars (5), concrete (6) and fiber anti-cracking mortar surface layers (7). The whole earthquake-proofing performance of the wall body is improved by the effective connecting among the hidden posts, the grid-structural reinforcing meshes, the horizontal wall body distributing steel bars and the vertical wall body distributing steel bars; the thermal insulation building molds are arranged at the inner and outer surfaces of the wall body, and the thermal insulation building molds adopt the insertion-seam splicing mode, so a house has a good thermal insulation performance. The wall body adopts the thermal insulation building molds as templates, so labor and materials of the templates are saved, and the construction period is shortened; holes are formed by ribs of the thermal insulation building molds when the wall body is poured, and the wall body actually adopts the shear wall with the holes, and all the holes become the single energy consumption units of the wall body, so the ductility and the energy consumption capability of the wall body are enhanced.

Owner:BEIJING UNIV OF TECH

T-frame insulation masonry single-row-reinforcement lightweight concrete wall and manufacturing method thereof

InactiveCN103758248AGood shear resistanceImprove side resistanceWallsBuilding material handlingRebarHazard reduction

The invention relates to a T-frame insulation masonry single-row-reinforcement lightweight concrete wall and a manufacturing method thereof and belongs to the technical field of building earthquake resistance and hazard reduction. The T-frame insulation masonry single-row-reinforcement lightweight concrete wall is applicable to rural multi-story buildings and is characterized in that hidden columns and tie bars are combined at wall corners, so that shear resistance is good, lateral rigidity of the wall is improved, and seismic performance of the wall is effectively enhanced; the hidden columns are as thick as the wall, so that building area is saved and column edging is avoided; the hidden columns, the tie bars, wall horizontal bars and wall vertical bars are effectively connected, so that overall seismic performance of the wall is improved.

Owner:BEIJING UNIV OF TECH

Orthogonal plywood shear wall-concrete core tube mixed lateral-load-resistance system

ActiveCN108708479AImprove side resistanceEliminate residual deformationWallsProtective buildings/sheltersLoad resistancePre stress

The invention relates to an orthogonal plywood shear wall-concrete core tube mixed lateral-load-resistance system. The system includes an orthogonal plywood shear wall, a concrete core tube, replaceable energy-dissipation connectors, a concrete foundation, prestressing swing supports, a first post-tensioned unbonded prestressing bar, a second post-tensioned unbonded prestressing bar, a first steelshim and a second steel shim. The orthogonal plywood shear wall is connected with the concrete core tube through the several replaceable energy-dissipation connectors, the concrete core tube is connected with the concrete foundation through the first steel shim, the second steel shim and the several prestressing swing support, the first post-tensioned unbonded prestressing bar runs through the concrete core tube longitudinally and is fixed by an anchorage device, and the first post-tensioned unbonded prestressing bar runs through the orthogonal plywood shear wall longitudinally and is fixed by an anchorage device and the second post-tensioned unbonded prestressing bar runs through the concrete core tube longitudinally and is fixed by an anchorage device. Compared with the prior art, the system can effectively reduce the damage of orthogonal plywood wallboards and concrete shear walls in an earthquake, energy-dissipation components are easily replaced, and the difficulty and cost of post-earthquake repair can be reduced.

Owner:TONGJI UNIV

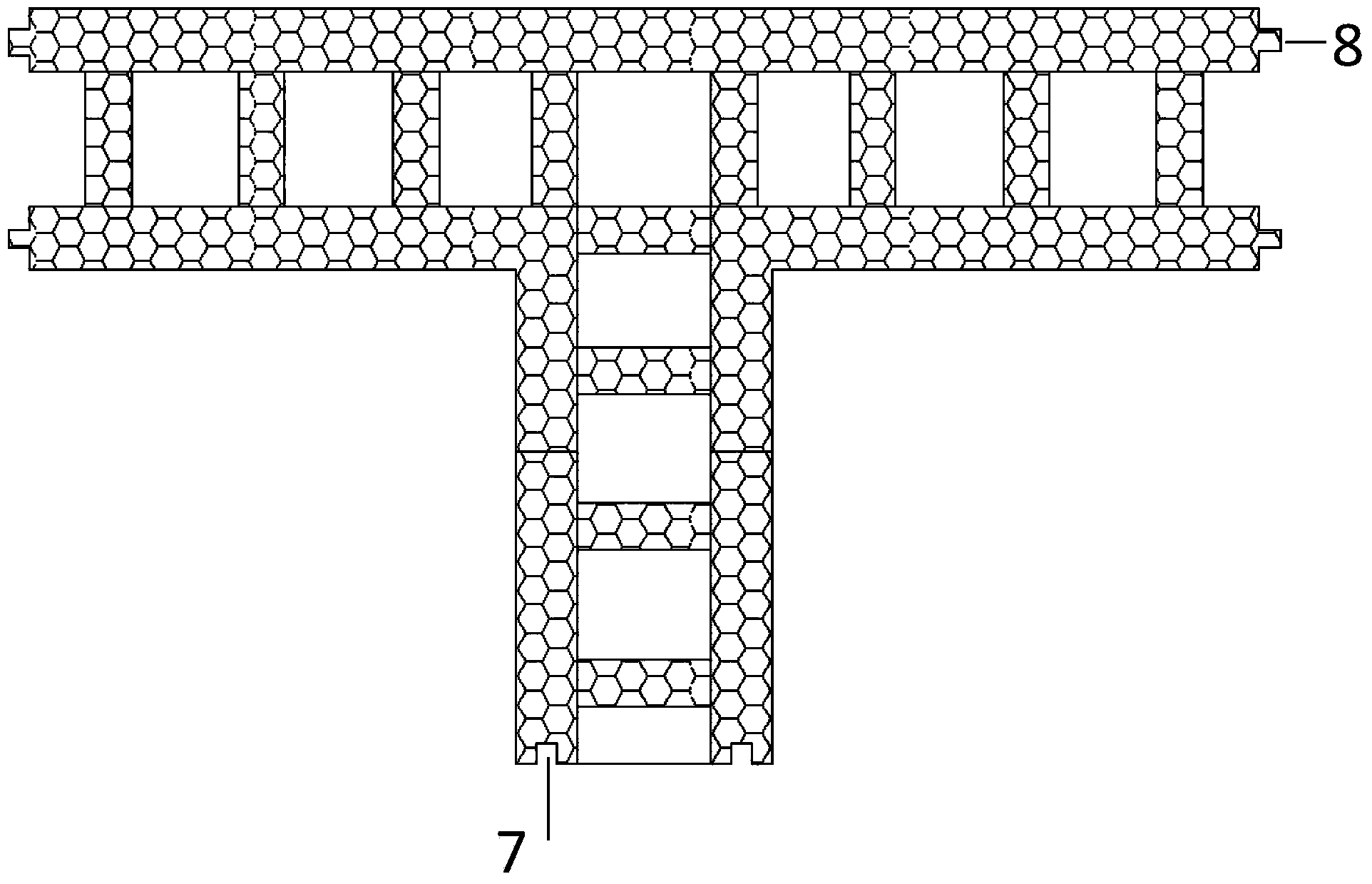

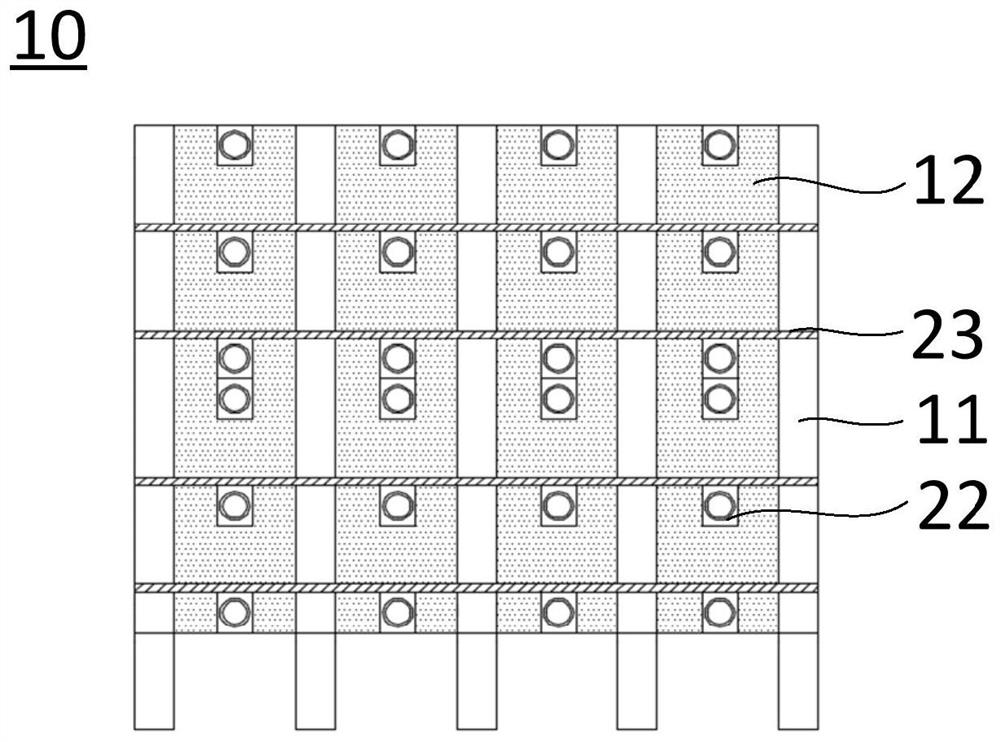

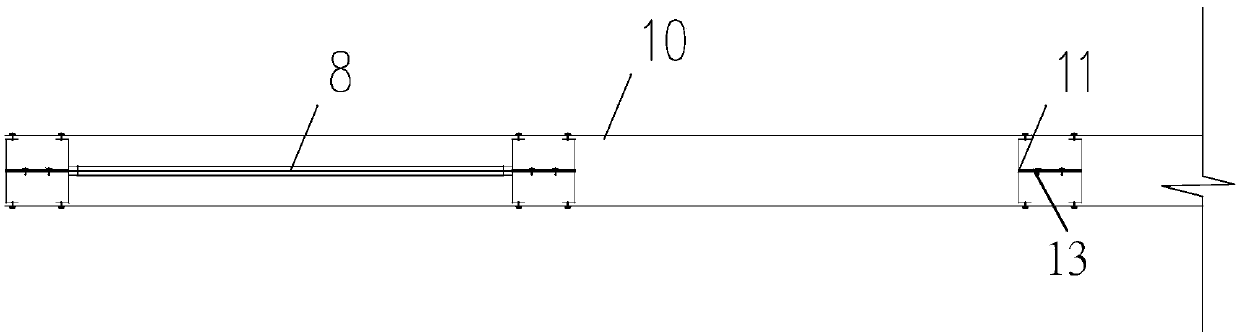

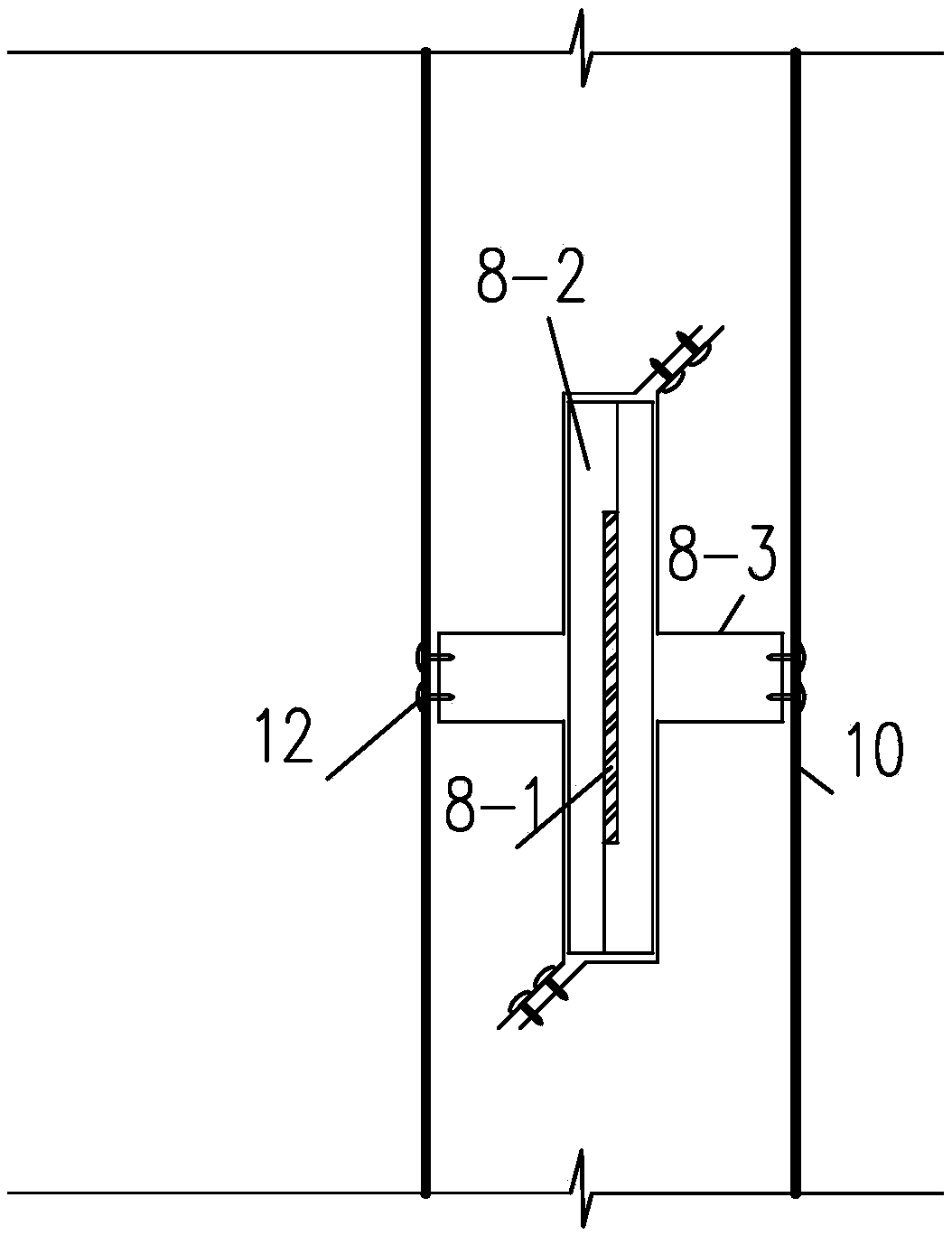

Reinforcing structure between longitudinal and transverse walls of cold-formed thin-walled section steel house

InactiveCN108755955ANo significant increase in costDoes not add significant weightBuilding constructionsCold formedEngineering

The invention discloses a reinforcing structure between longitudinal and transverse walls of a cold-formed thin-walled section steel house. The reinforcing structure comprises beams and wall frame columns, wherein the beams and the wall frame columns are mutually matched. The wall frame columns comprise lower-layer columns and upper-layer columns; the beams comprise floor beams (23), lower-layer house U-shaped beams (7) and upper-layer house U-shaped beams (8); the tops of the lower-layer columns are inlaid in openings of the U-shaped steel top beams (7) and fixed; the bottoms of the upper-layer columns are inlaid in openings of the U-shaped steel bottom beams (8) and fixed; the lower-layer columns and the upper-layer columns are connected through connecting pieces (12); anti-pulling pieces (17) are connected between the lower-layer columns and the U-shaped steel top beams (7), and anti-pulling pieces (17) are connected between the upper-layer columns and the U-shaped steel bottom beams (8); and H-shaped reinforcing components (6) between steel layers are connected between the U-shaped steel top beams (7) and the U-shaped steel bottom beams (8). The reinforcing structure is characterized in that oblique supporting pieces are connected between parts of the upper-layer columns and the U-shaped steel bottom beams (8) and / or oblique supporting pieces are connected between parts ofthe lower-layer columns and the U-shaped steel top beams (7).

Owner:SOUTHWEAT UNIV OF SCI & TECH

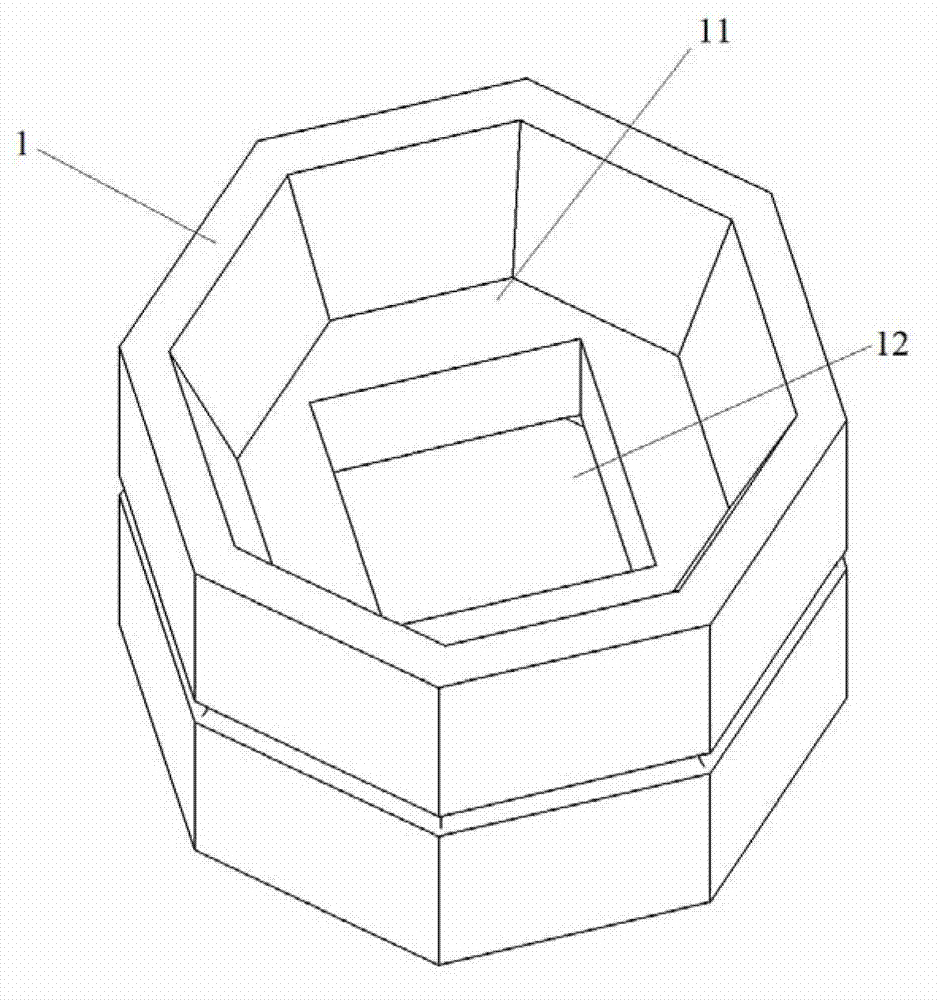

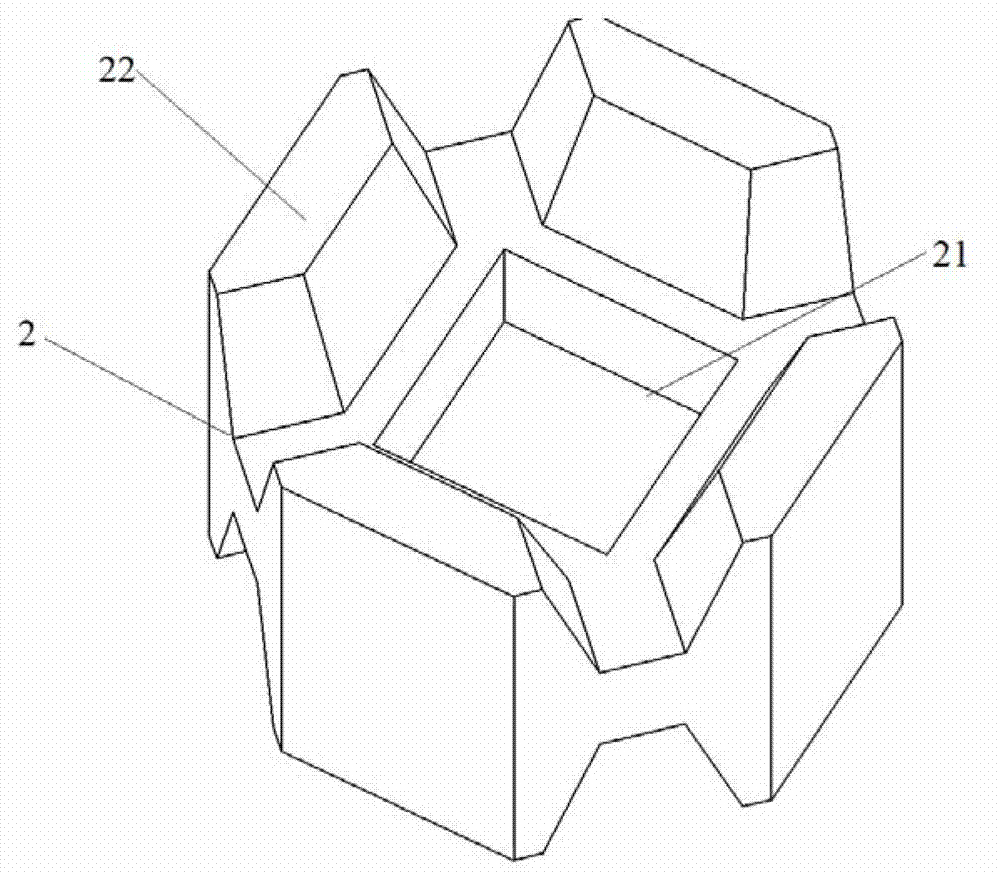

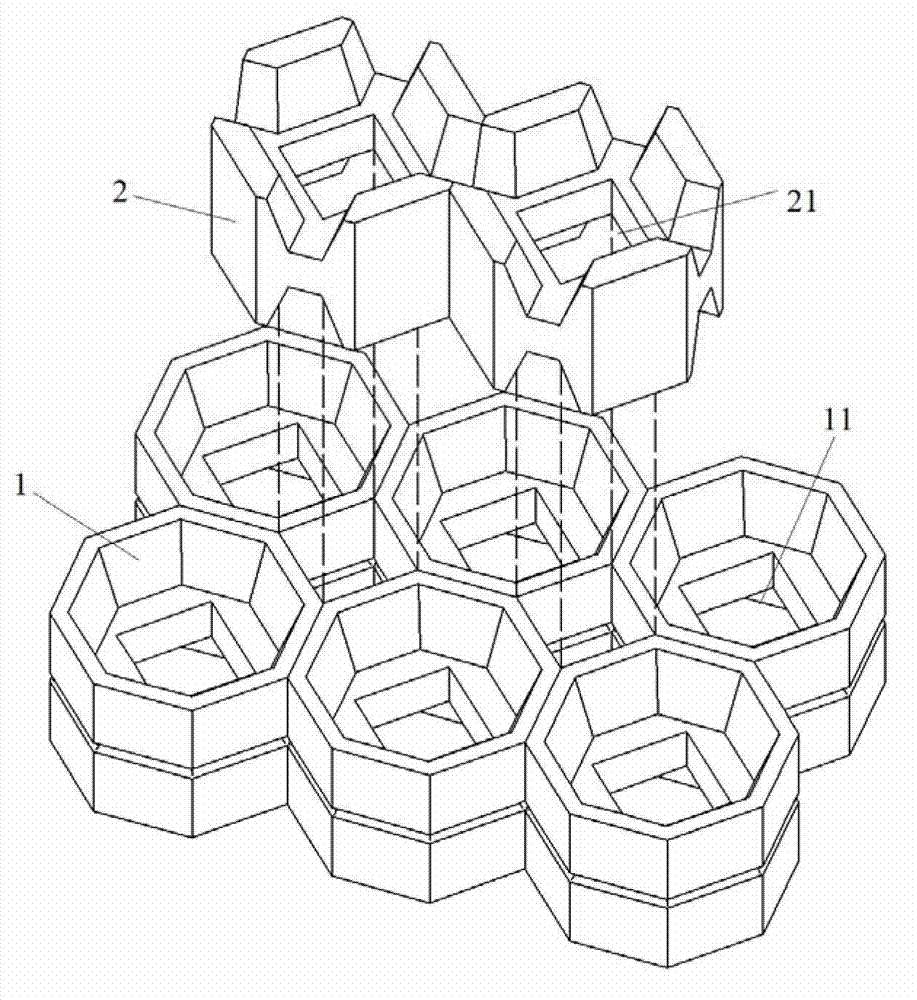

Novel octagonal retaining wall building block with interlocking pourable holes arrayed on each other layer in staggered manner

ActiveCN103046512AImprove shear resistanceImprove integrityArtificial islandsCoastlines protectionRetaining wallShear strength

The invention relates to a novel octagonal retaining wall building block with interlocking pourable holes arrayed on each other layer in a staggered manner. The building block comprises a concave building block and a convex building block in a shape of an octagonal cylinder, symmetric octagonal grooves are arranged on the top face and the bottom face of the concave building block, four hexagonal protrusions are symmetrically arranged on the top face and the bottom face of the convex building block, the concave building block and the convex building block are in upper-lower layer arrangement, the four hexagonal protrusions of the bottom face of each convex building block on an upper layer are inserted into octagonal grooves of adjacent four concave building blocks on a lower layer for interlocking, and a square hole is arranged at the center of each of concave building blocks and the convex building blocks respectively. Compared with the prior art, the novel octagonal retaining wall building block with the interlocking pourable holes arrayed on each other layer in a staggered manner is high in shearing strength, simple in operation, safe, reliable, high in feasibility and the like.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Light block wall with Z-shaped column frames and built-in single-row reinforcing bars and manufacturing method thereof

InactiveCN103726592AImprove side resistanceImprove seismic performanceWallsBuilding material handlingSteel barSingle row

Owner:BEIJING UNIV OF TECH

Assembly type wood-bamboo frame-grid wall structure system suitable for village and town residences

PendingCN112922191AImprove protectionReduce pollutionWallsProtective buildings/sheltersAgricultural engineeringBiology

The invention discloses a low multi-layer assembly type wood-bamboo frame-grid wall structure suitable for village and town residences. The system comprises an external wood frame and an internal grid shear wall made of standard wood or raw bamboo, and wood beams and wood columns of the external wood frame are connected through slotted-in steel plates; an internal wood grid component and an external wood frame of the wood frame-wood grid shear wall structure are connected through a joint bar, and the joint bar serving as a middle component is in bolt connection with the wood grid component and is in angle steel connection with the external wood frame; and an internal bamboo grid component and an external wood frame of the wood frame-bamboo grid shear wall structure are hinged through lug plates at the ends of the internal bamboo grid component and the external wood frame, and the slotted-in steel plates penetrate through the wood beams or the wood columns and are fixed with the wood beams or the wood columns through split bolts. The assembly type wood-bamboo frame-grid wall structure system has good anti-seismic performance and high environmental protection benefits, and is convenient to construct and low in manufacturing cost.

Owner:TIANJIN UNIV

Prestress oblique double-layer folded steel plate shear wall

The invention relates to a prestress oblique double-layer folded steel plate shear wall and belongs to the technical field of structural engineering. The prestress oblique double-layer folded steel plate shear wall comprises an embedded oblique double-layer folded steel plate, prestress rods, connecting lug plates, brackets, edge components, frame beams and frame columns, wherein the embedded oblique double-layer folded steel plate is in bolt connection with the edge components, the prestress rods and the connecting lug plates are connected and symmetrically disposed on two sides of the embedded oblique double-layer folded steel plate, the vertical edge components are welded with the horizontal edge components, the connecting lug plates are symmetrically arranged at beam flange parts of the frame beams and welded with the frame beams, the horizontal edge components are welded with or in bolt connection with the frame beams, the brackets are welded with the vertical edge components and the embedded oblique double-layer folded steel plate, and the frame beams are connected with the frame columns. The prestress oblique double-layer folded steel plate shear wall as a lateral-load-resistant component for high-rise building structures or other structures has the advantages of good anti-seismic performance, high ductility, saturated energy dissipation hysteretic loop, and the like.

Owner:江苏绿艺杭萧钢结构工程有限公司

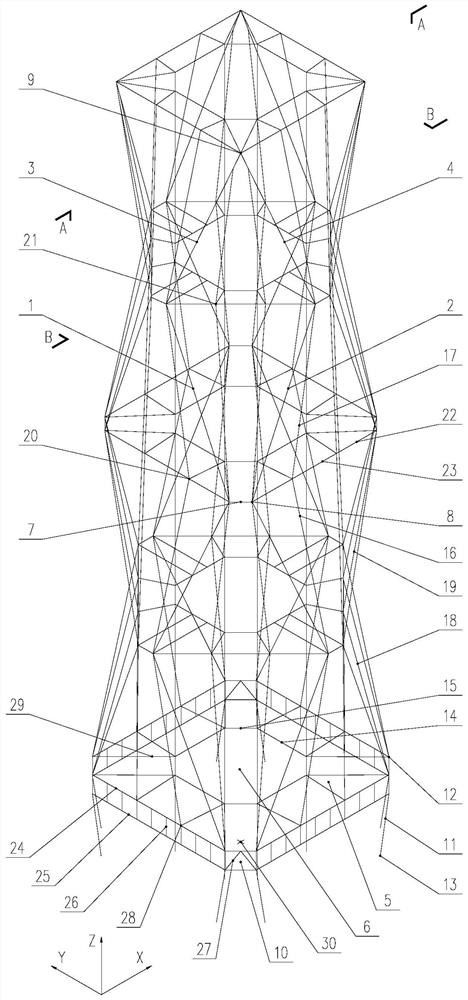

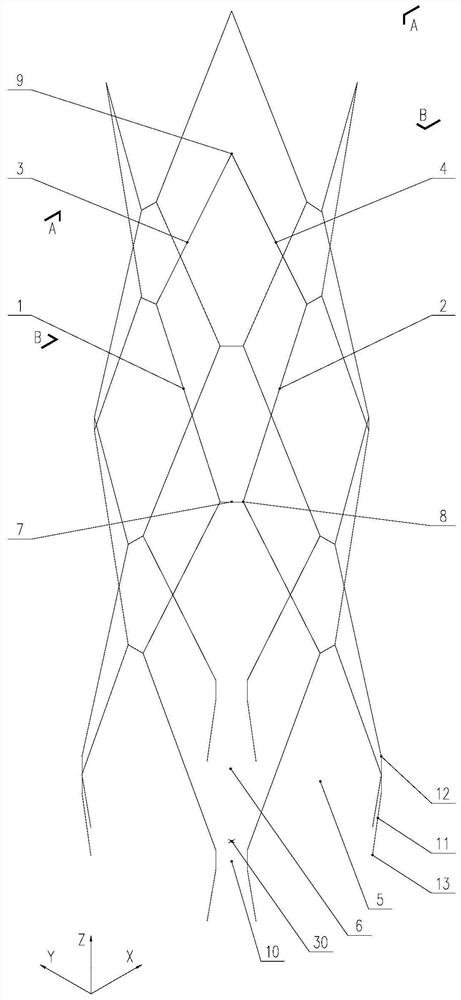

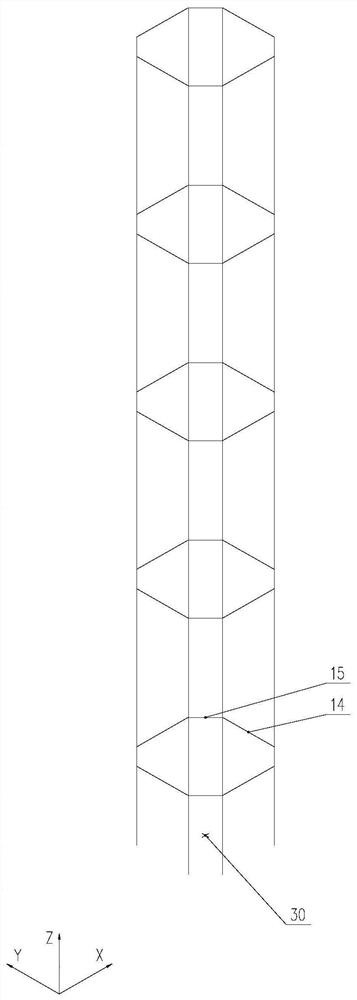

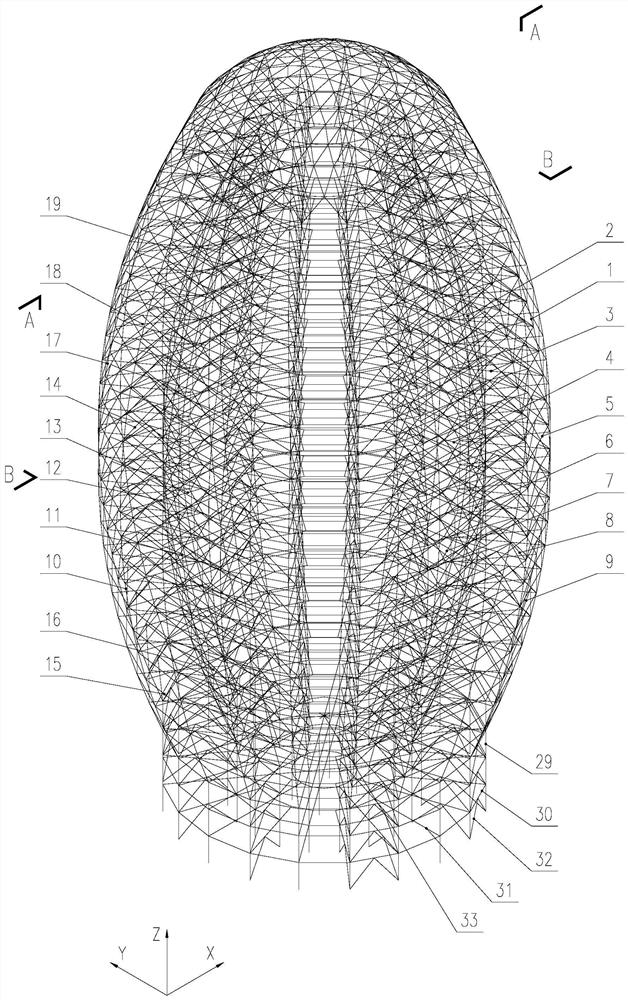

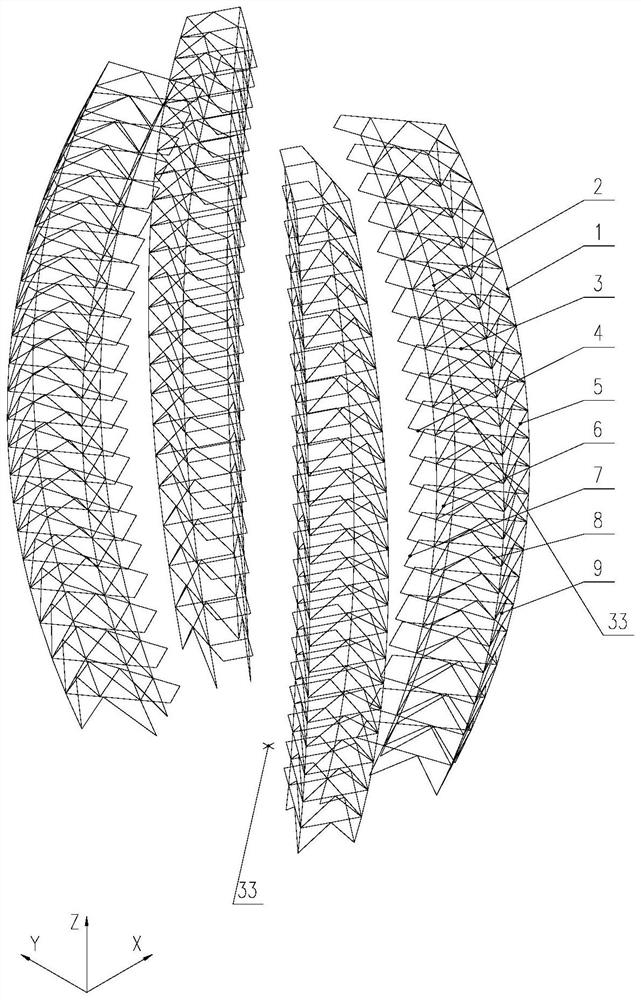

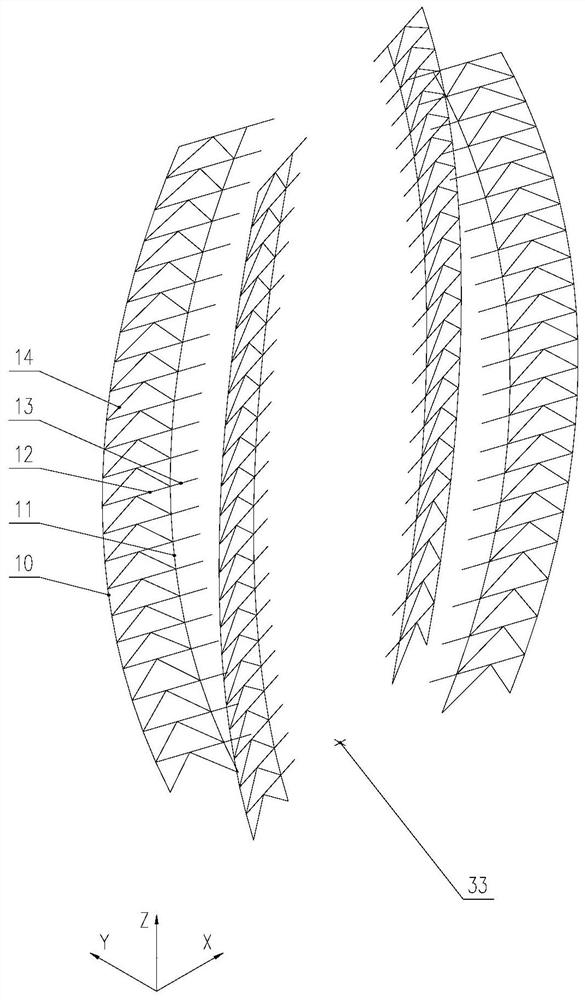

Bottom-converted vertical-face large-rhombus-grid giant-inclined-column super-high-rise structure and forming method

ActiveCN113006281AReasonable structureImprove side resistanceExtraordinary structuresBuilding material handlingCross connectionMechanical engineering

The invention relates to a bottom-converted vertical-face large-rhombus-grid giant-inclined-column super-high-rise structure. The bottom-converted vertical-face large-rhombus-grid giant-inclined-column super-high-rise structure comprises large-rhombus-grid giant inclined columns, an inner core cylinder, grid-face inner secondary inclined columns, node-layer circumferential steel beams, a bottom conversion truss and other floor steel beams; and the large-rhombus-grid giant inclined columns are connected in a crossed mode through bidirectional giant inclined column components and arranged in a high-altitude landing mode, and a vertical-face space large-rhombus-grid oblique-crossing outer cylinder with the plane being a four-corner trimming combination is formed. The bottom-converted vertical-face large-rhombus-grid giant-inclined-column super-high-rise structure has the advantages that the advantages of bottom large-space conversion and high lateral stiffness resistance of the combined double-cylinder oblique-crossing grid super-high-rise structure and the advantages of the four-corner trimming combination double-cylinder building modeling function of vertical-face large rhombus grids are brought into full play; the structure is conveniently controlled through indexes such as the bearing capacity, the overall lateral stiffness resistance and the torsion resistance, and the reasonability and effectiveness of the overall structure system are further guaranteed; and component forming modules of the bottom-converted vertical-face large-rhombus-grid giant-inclined-column super-high-rise structure are clear, and the wide application prospect is achieved.

Owner:ZHEJIANG UNIV CITY COLLEGE

Steel plate shear wall structure and construction method

InactiveCN106677379AWork lessImprove construction efficiencyConstruction materialWallsReinforced concrete columnSheet steel

The invention relates to a steel plate shear wall structure, and belongs to the field of structural engineering. The structure comprises steel reinforced concrete columns, steel reinforced concrete beams, a steel web and lightweight wallboards; the steel reinforced concrete columns and the steel reinforced concrete beams are welded, the left side and the right side of the steel web and the steel reinforced concrete columns are welded, the upper side and the lower side of the steel web and the steel reinforced concrete beams are welded, stiffening ribs are arranged on the front side face and the back side face of the steel web, and the stiffening ribs and the steel web are welded; the lightweight wallboards adopt autoclaved lightweight concrete panels, and the lightweight wallboards are arranged in blocks formed by adjacent stiffening ribs on the steel web and connected with the steel reinforced concrete columns and the steel reinforced concrete beams through pipe clamps. The steel plate shear wall structure has the advantages of being convenient and rapid to construct, good in heat insulation effect, good in shear strength and bending resistance, low in dead weight and the like.

Owner:HANGZHOU ZETONG ARCHITECTURE ENERGY SAVING NEW MATERIALS CO LTD

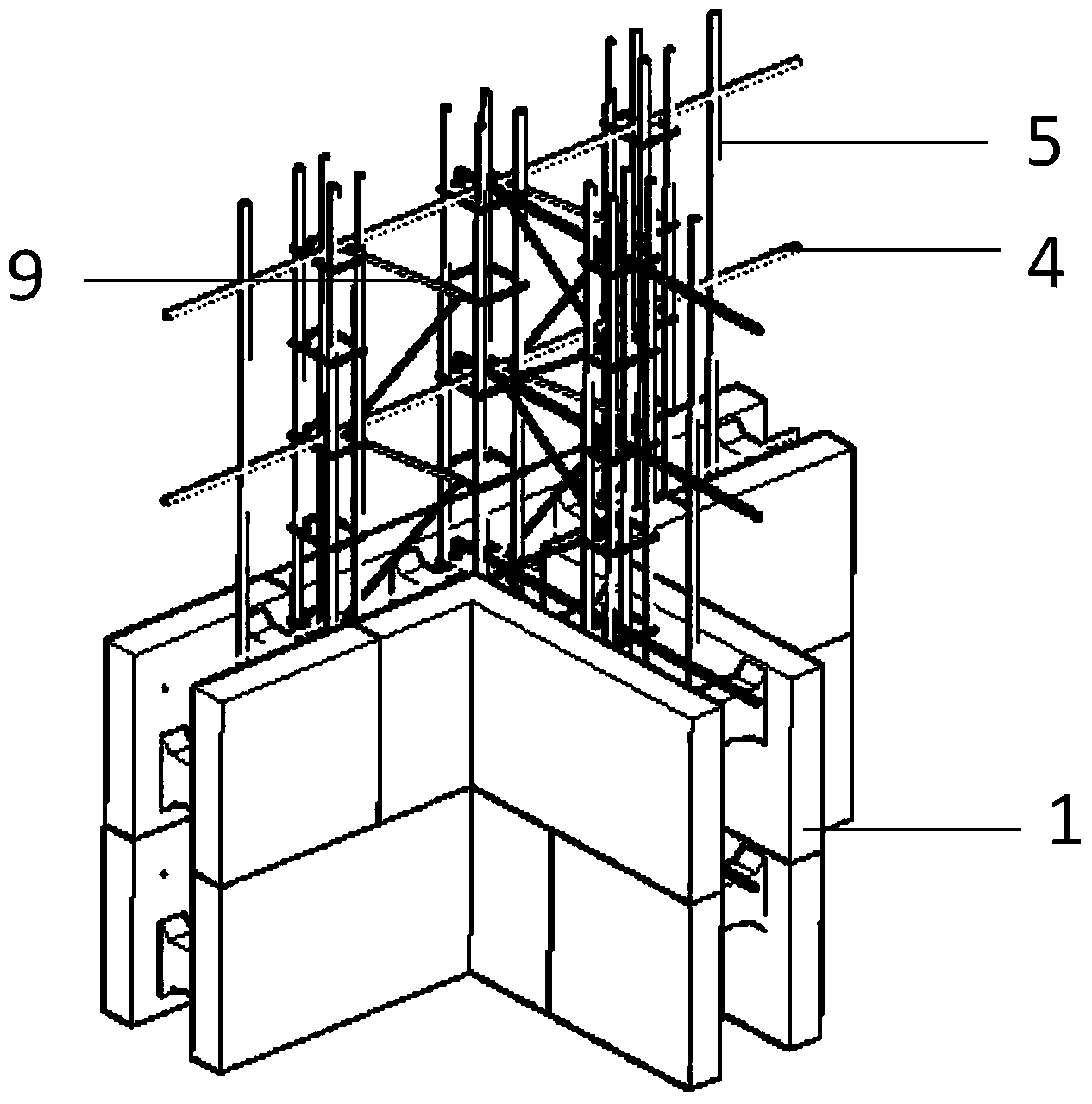

A prefabricated shear wall and wall-beam connection structure with edge restraint components

ActiveCN103883034BImprove seismic energy dissipation characteristicsFirmly connectedWallsHigh energyClassical mechanics

The invention discloses an assembled shear wall and a wall-beam connection structure with edge constraining components. The structure includes a shear wall and a beam prefabricated by concrete. The four corners of the shear wall are preset with rectangular steel pipes, the upper and lower sides are preset with steel bars, and the bottom of the shear wall is provided with a feed inlet. Both sides of the shear wall are provided with concealed columns, and the longitudinal bars of the concealed columns are welded on the inner side of the rectangular steel pipe; the described shear wall is provided with cross reinforcement, and the two ends of the cross reinforcement are welded on the outside of the rectangular steel pipe. A steel plate and a grouting sleeve are pre-embedded on the beam. The upper and lower walls are initially connected by connecting steel plates, tension bolts, longitudinal reinforcement protruding from the wall, and embedded sleeves in beams, etc., and then the final connection is realized by post-cast concrete. The invention has the advantages of high energy consumption during earthquakes, convenient hoisting and docking, fast installation and the like. It can be widely used in the assembled monolithic frame-shear wall structure, and has broad engineering application prospects.

Owner:SOUTHEAST UNIV

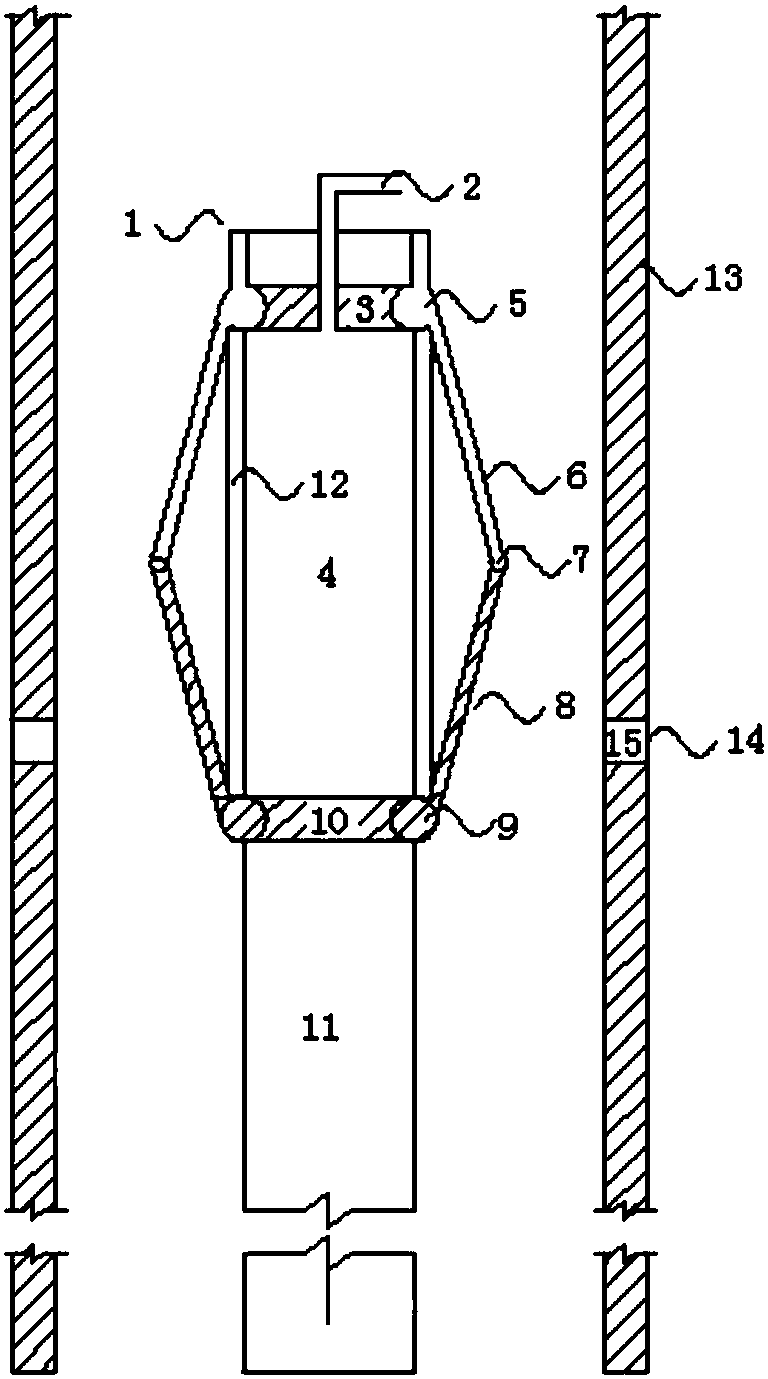

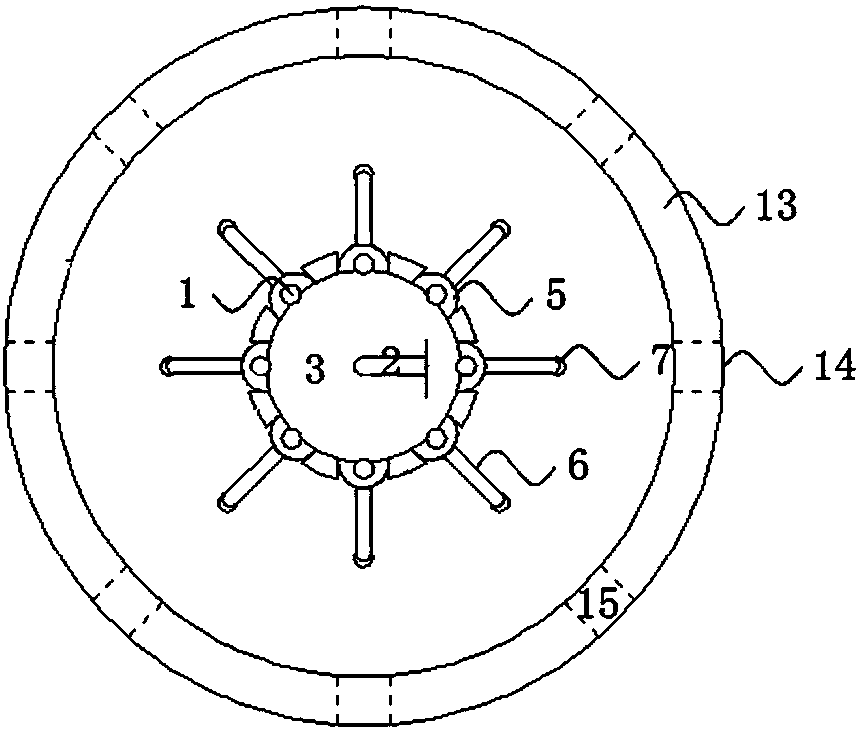

Construction device and method for multifunctional pipe pile for drainage of land reclamation and island building

ActiveCN108396728AReduce dosageSave the cost of fillingBulkheads/pilesSoil preservationOcean bottomSpray nozzle

The invention discloses a construction device and method for a multifunctional pipe pile for drainage of land reclamation and island building. Holes are formed in the side surfaces of pile bodies of aprefabricated pipe pile, the pipe pile is wrapped with geotextile, an upper piston is driven by expansion and shrinkage of a hydraulic liner to lift and drop vertically along guide columns, and hingeassemblies are driven to bend; the guide columns and the hinge assemblies are arranged between the upper piston and a lower piston, and the hinge assemblies are mounted on the guide columns; slurry enters upper spherical hinges through grouting ports, passes through upper linkage pipes, enters middle spherical hinges and is sprayed out by spray nozzles; the prefabricated pipe pile is partially embedded into submarine soil mass, layered placement for drainage is performed repeatedly in a sandy soil and soft soil layered alternate manner, grouting is performed after solidification, and different outwards grouting angles of a grouting fluid from the side wall holes of the pile correspond to different functions. The construction device and method have the advantages that bearing capacity, pull resistance and lateral resistance of a pile foundation are improved, and the bearing capacity of the pile foundation is improved effectively; expenditures are reduced, construction efficiency is increased, the requirement for fast island forming is met, and differential settlement of filled soil layers is controlled effectively.

Owner:ZHEJIANG UNIV

Underground diaphragm wall and construction method thereof

ActiveCN113123325AGood shock and vibration damping performanceStrong shear resistanceProtective foundationBulkheads/pilesSlurry wallArchitectural engineering

The invention relates to the technical field of building wallboards, and discloses an underground diaphragm wall and a construction method thereof. The underground diaphragm wall comprises a concrete layer and a shock absorption layer, wherein the concrete layer and the shock absorption layer are distributed in the horizontal direction and are arranged adjacently; the concrete layer comprises a structural column, a reinforcement cage and filling concrete; and the shock absorption layer comprises a plurality of groups of rubber damping pads and a plurality of groups of spring assemblies which are distributed at intervals, and each group of rubber damping pads are filled between at least two groups of spring assemblies. The underground diaphragm wall provided by the invention is buried in the ground, has soil retaining, anti-seepage and support functions and has good anti-seismic and vibration reduction performance.

Owner:SHENZHEN UNIV

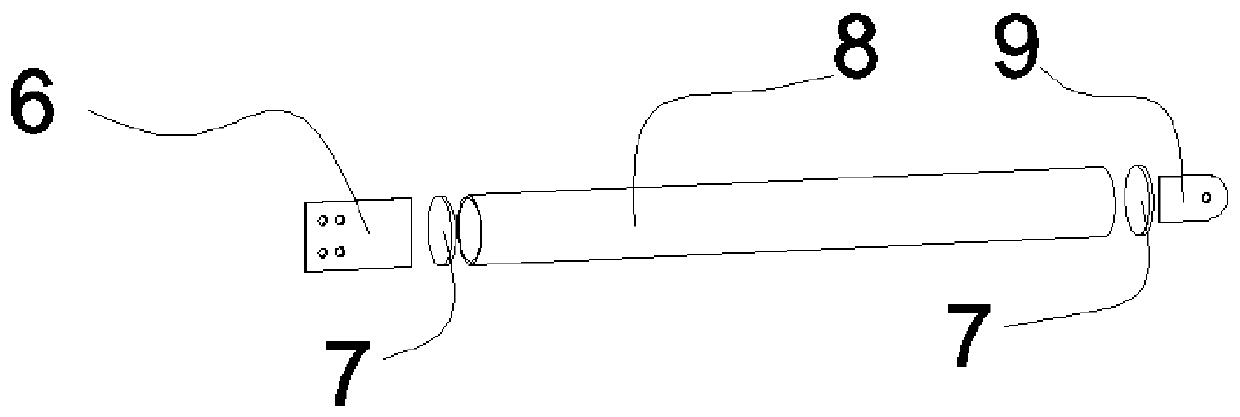

Cold-formed steel composite wall sandwiched with light-weight fabricated anti-buckling supports

PendingCN109555243APrevent slippingHave the effect of re-constrainingWallsProtective buildings/sheltersKeelSeismic resistance

The invention belongs to the field of building engineering, and particularly relates to a cold-formed steel composite wall sandwiched with anti-buckling supports, and wall surface plate material layers and cold-formed steel are used as constraining parts for the anti-buckling supports. The cold-formed steel composite wall includes upper and lower guide rails transversely arranged and vertically-and-oppositely-arranged keel columns, and the anti-buckling supports and outer cover wall panels are sandwiched between the vertically-and-oppositely-arranged keel columns. Steel strips are used as corematerials in the sandwiched supports, a wrap-around cross-section body composed of wall surface plate materials such as OSB plates and the cold-formed steel is used as a constraining member, and thewrap-around cross-section body in the constraining member are connected with the outer cover wall panels correspondingly by self-tapping screws. According to the cold-formed steel composite wall sandwiched with the anti-buckling supports, the side resistant ability of the cold-formed steel composite wall can be improved, the steel strips can be brought into full play under compression and tension,and the seismic resistance of the wall can be improved. The cold-formed steel composite wall includes the anti-buckling supports, wherein the anti-buckling supports are fabricated, no wet work exists, construction is simple, less labor is applied, and the requirements of green buildings and fabricated buildings are met.

Owner:SHENYANG JIANZHU UNIVERSITY

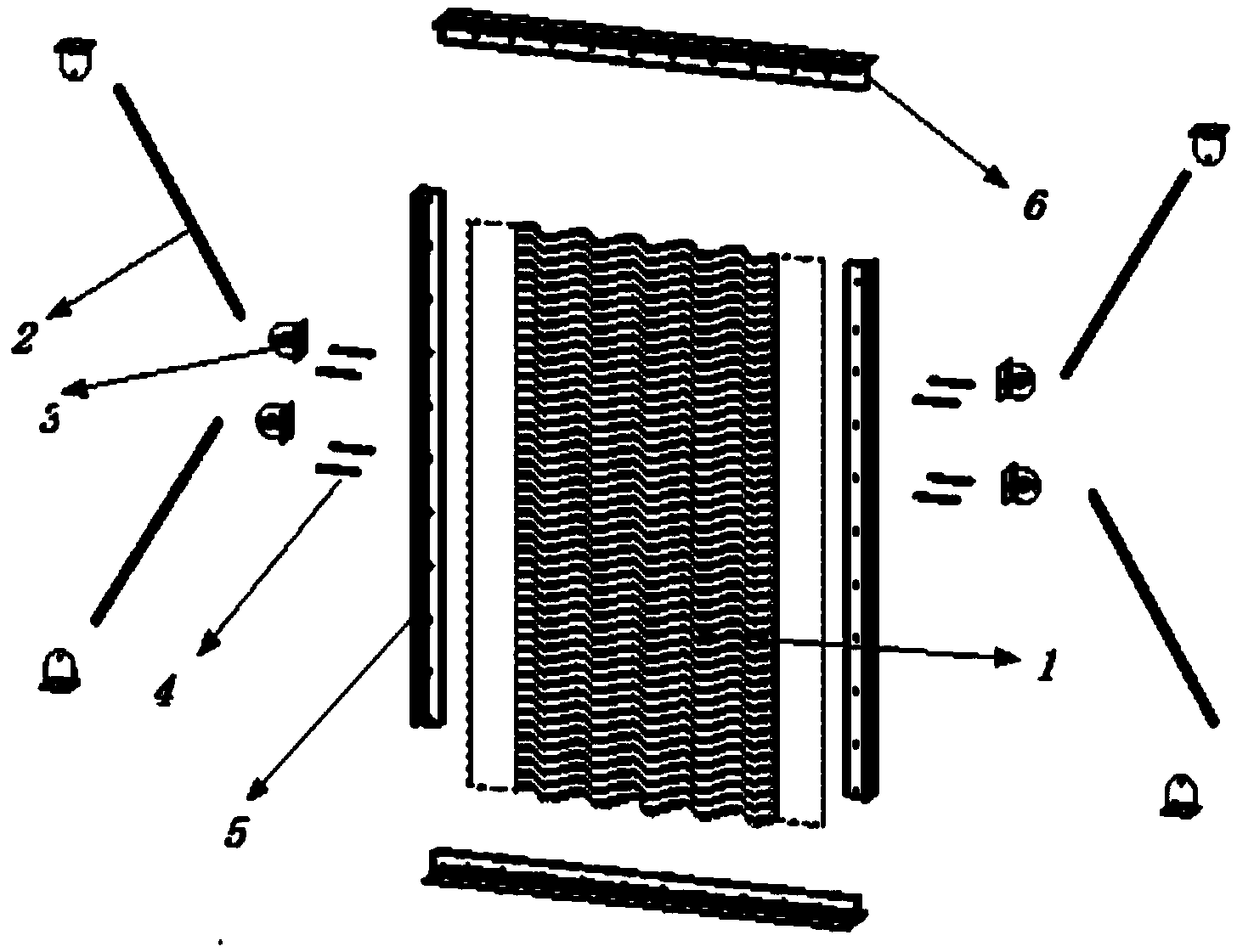

Prestress waveform section steel plate shear wall

The invention relates to a prestress waveform section steel plate shear wall and belongs to the technical field of structural engineering. The prestress waveform section steel plate shear wall comprises an embedded waveform steel plate, prestress rods, connecting lug plates, brackets, edge components, frame beams and frame columns, wherein the embedded waveform steel plate is in bolt connection with the edge components, the prestress rods and the connecting lug plates are symmetrically disposed on two sides of the embedded waveform steel plate, the vertical edge components are welded with the horizontal edge components, the connecting lug plates are symmetrically arranged at beam flange parts of the beam frames and welded with the frame beams, the horizontal edge components are welded with or in bolt connection with the frame beams, the brackets are welded with the vertical edge components and the embedded waveform steel plate, and the frame beams are welded with, in bolt connection, or in welded and bolt hybrid connection with the frame columns. The prestress waveform section steel plate shear wall has the advantages of good anti-seismic performance, high ductility, saturated energy dissipation hysteretic loop, and the like, and is an excellent anti-seismic energy dissipation component.

Owner:BEIJING UNIV OF TECH

Angle brace type energy-consuming K-brace modular side-resistant unit structure

InactiveCN111042326AReduce adverse effectsImprove side resistanceProtective buildings/sheltersShock proofingEngineeringStructural engineering

An angle brake type energy-consuming K-brace modular side-resistant unit structure comprises vertical supporting rods, horizontal supporting rods, inclined supporting pieces and angle brace rods. Thetwo vertical supporting rods are in parallel, and the two horizontal supporting rods are perpendicularly arranged between the two vertical supporting rods, so that a rectangular frame structure is formed. The joints between one vertical supporting rod and the two horizontal supporting rods are provided with the angle brace rods correspondingly. One ends of the two inclined supporting pieces are both hinged to the middle of the other vertical supporting rod, and the other ends of the two inclined supporting pieces are hinged to the middles of the angle brace rods correspondingly. Each inclinedsupporting piece comprises an inclined supporting rod connecting plate, end plates, an inclined supporting rod and a lug plate, wherein the end plates are welded to the two ends of the inclined supporting rod correspondingly, the inclined supporting rod connecting plate is perpendicularly fixedly arranged on one end plate, and the lug plate is perpendicularly fixedly arranged on the other end plate. According to the angle brace type energy-consuming K-brace modular side-resistant unit structure, the angle brace rods and the inclined supporting pieces are arranged in the frame structure, the bending deformation of the angle brace rods serves as the energy-consuming part of a side-resistant unit, and therefore the adverse effects of the earthquake action on the body structure are reduced.

Owner:鞍钢中电建筑科技股份有限公司 +1

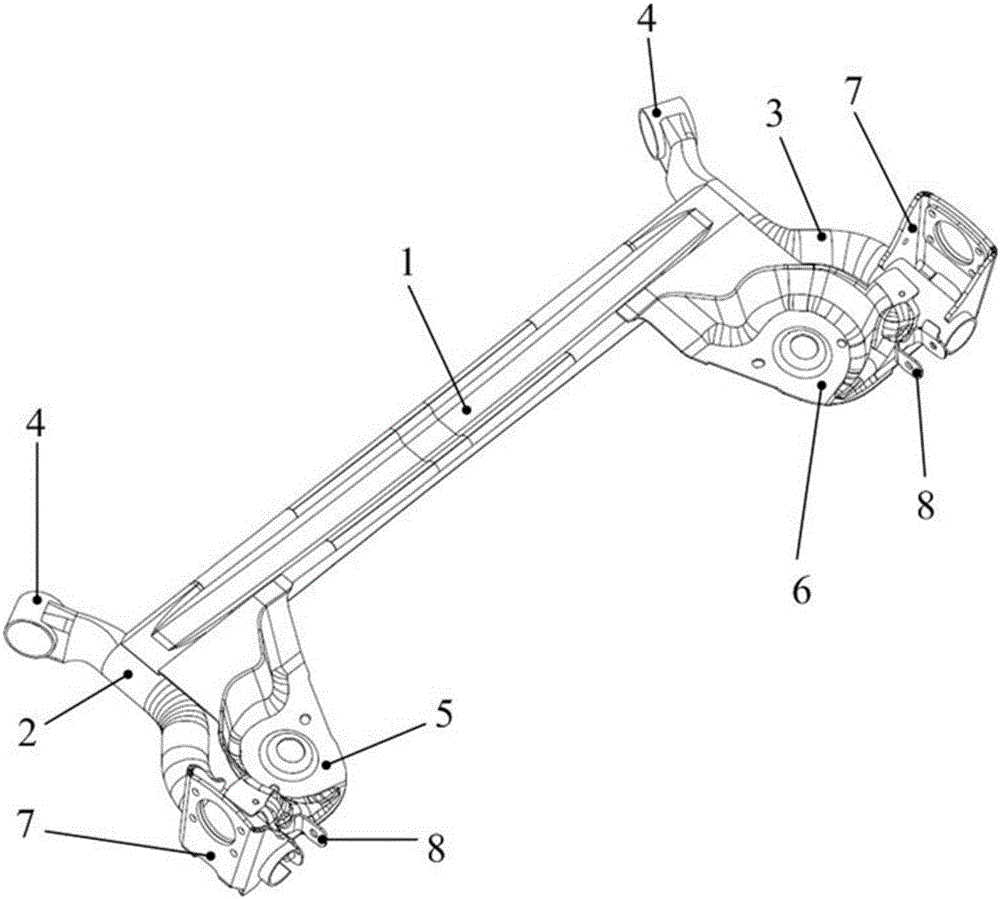

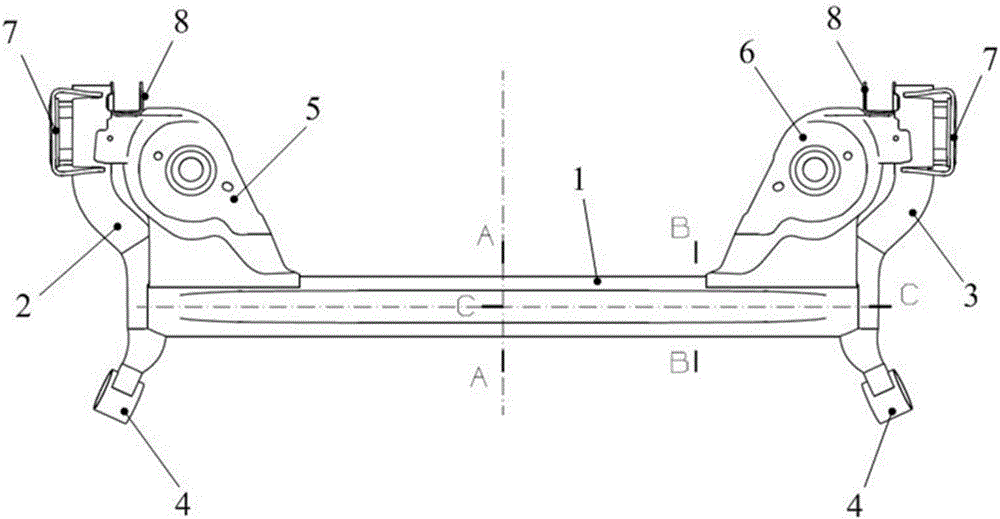

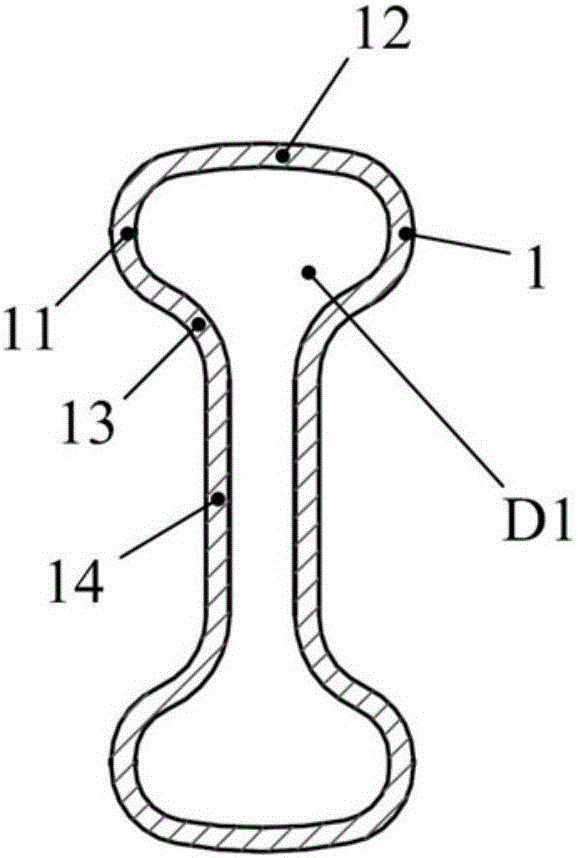

Torsion beam automobile axle and automobile

InactiveCN106347053ASimple structureImprove deformationResilient suspensionsEngineeringIndependent suspension

The present invention provides a torsion beam axle and an automobile, including a torsion beam, wherein the radial section of the torsion beam is a first variable-size section, and the middle part of the first variable-size section is narrower than both ends; and the The axial section of the torsion beam is a second variable size section, and the middle part of the second variable size section is narrower than the two ends. The torsion beam axle and the automobile provided by the invention change the structure of the torsion beam without affecting the overall performance of the suspension and the positioning of the wheels. By reducing the section coefficient of the middle part, the deformation of the torsion beam is improved, so that the torsion beam has The characteristics of the lower swing arm make the present invention have the characteristics of an independent suspension; the cross-sectional shape of the torsion beam is changed, and the torsional rigidity of the torsion beam axle is improved, thereby improving the lateral resistance of the vehicle; without using cross bars and stabilizer bars, The structure is simplified and the cost is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Double-ring combined super high-rise structure based on vertical face arc-shaped steel frame-support and forming method

ActiveCN113006280AReasonable structureLight weightExtraordinary structuresBuilding material handlingHigh level structureEngineering

The invention relates to a double-ring combined super high-rise structure based on a vertical face arc-shaped steel frame-support. The double-ring combined super high-rise structure comprises steel support small frame cylinders, steel support plane frames, inner and outer ring circumferential steel beams, support-free steel beam columns, a roof conversion truss, a single-layer dome net shell and a bottom base structure; the steel support small frame cylinders are located at the positions of building elevator shafts in the four corners of a plane; and the steel support plane frames are located on the two sides of the plane, and the steel support plane frames and the steel support small frame cylinders are arranged in a spaced mode. The double-ring combined super high-rise structure has the beneficial effects that the advantages of high bearing capacity, high lateral resistance and arc-shaped vertical face double-ring combined building modeling function of the double-ring combined super high-rise structure are brought into full play; modeling and functions of a double-ring combined super high-rise building with high bearing capacity, high lateral resistance and an arc-shaped vertical face can be achieved while the self weight is reduced and the bearing performance is guaranteed; the reasonability and effectiveness of the whole structure system are further guaranteed conveniently through control over the bearing capacity, the overall rigidity, the torsional property and other indexes; and wide application prospects are achieved.

Owner:ZHEJIANG UNIV CITY COLLEGE

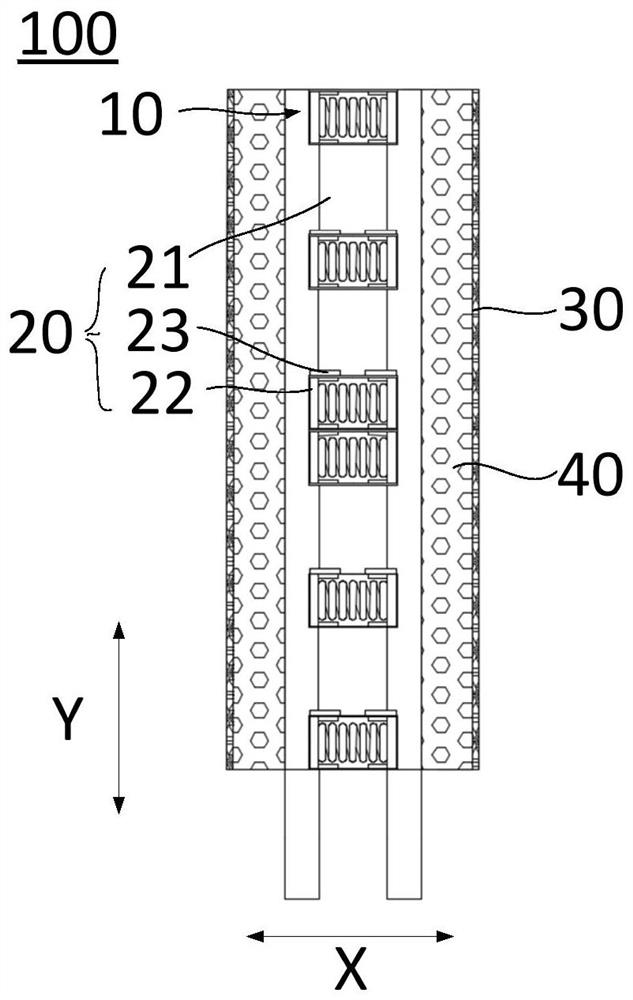

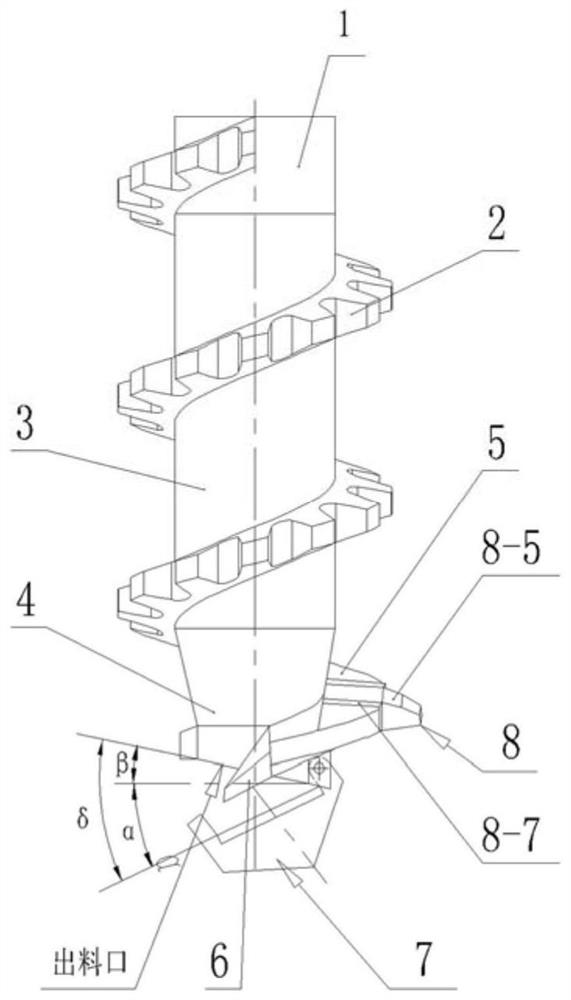

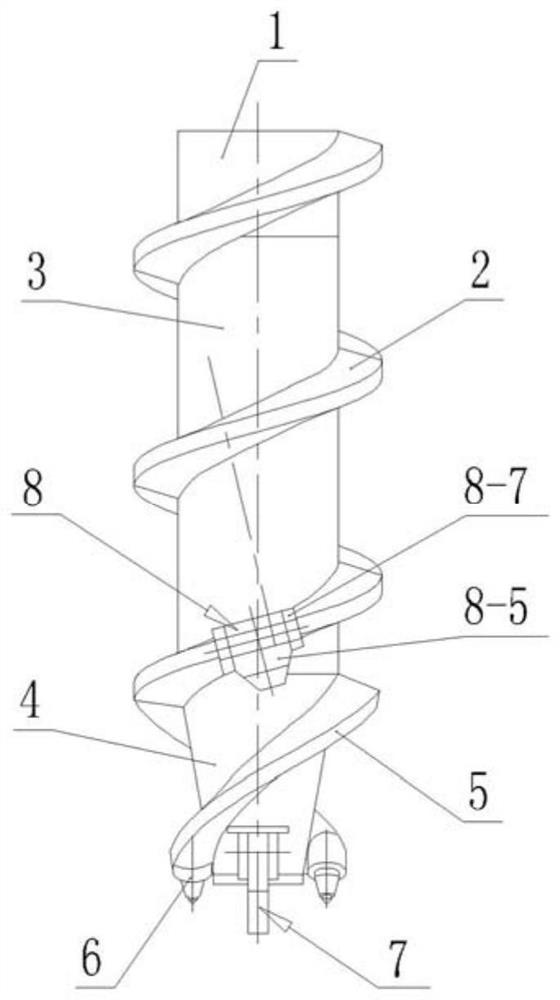

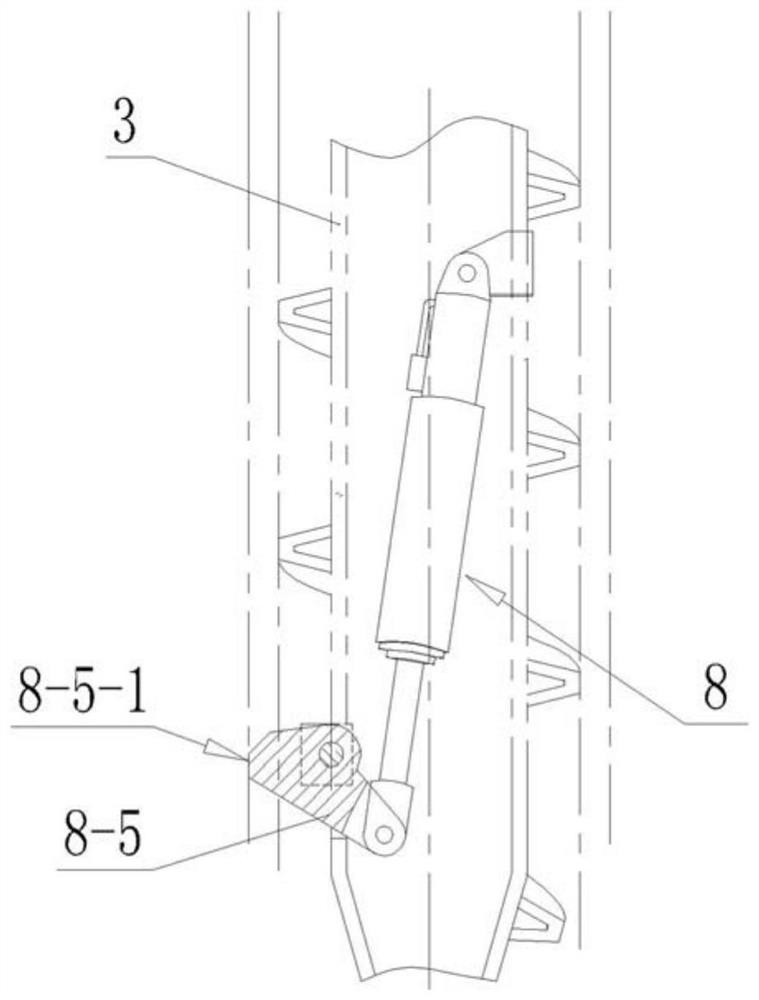

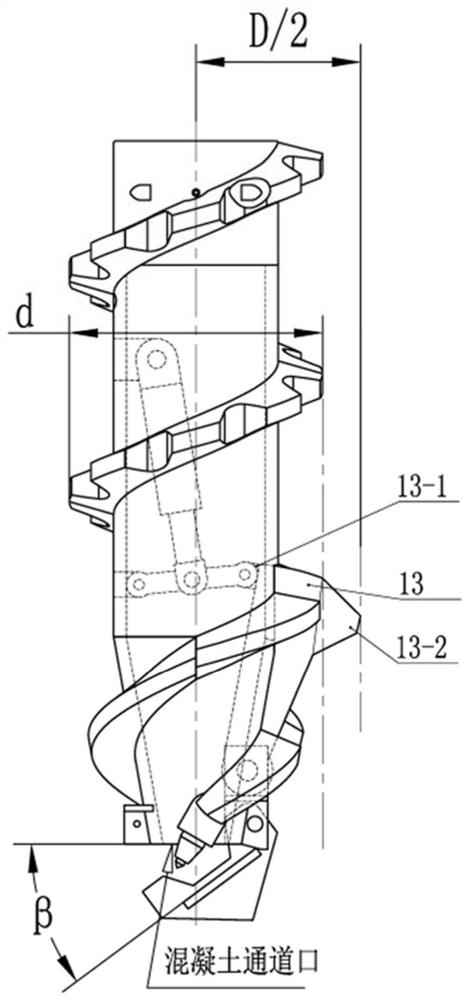

Cast-in-place concrete pile with expanded-diameter threaded pile section, drill bit device for pile forming and pile forming method

PendingCN112252308AStrong pull-out resistanceMeet the requirements of the maximum carrying capacityDrill bitsBulkheads/pilesStructural engineeringSandcrete

The invention relates to a cast-in-place concrete pile with an expanded-diameter thread pile section, a drill bit device for pile forming and a pile forming method. The cast-in-place concrete pile with the expanded-diameter threaded pile section comprises a concrete main body pile, and the concrete main body pile is composed of a pile bottom, a pile body and a pile top; the shape of the pile bottom is an expanded head structure formed by extending the concrete main body pile to the periphery through re-compacted concrete; the cast-in-place concrete pile is provided with a thread pile section and at least one expanded-diameter thread pile section, and the thread pile section is formed by spirally coiling threads which are of an integrated structure and protrude outwards on the outer edge ofthe concrete main body pile; the expanded-diameter threaded pile section is formed by extending part of the threaded pile section to the periphery through re-compacted concrete, and the outer diameter of the outer edge of the expanded-diameter threaded pile section is larger than that of the outer edge of the threaded pile section; and the thread pile section and the expanded-diameter thread pilesection are arranged on the pile body and / or the pile top. The cast-in-place concrete pile is suitable for soil layers such as filled soil, cohesive soil, silt and sandy soil, one-time pile forming is achieved, and the high bearing capacity is achieved.

Owner:刘守进 +1

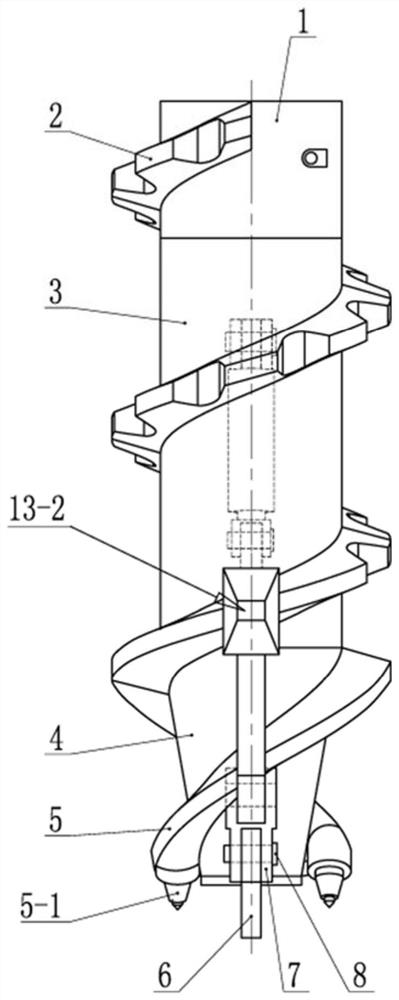

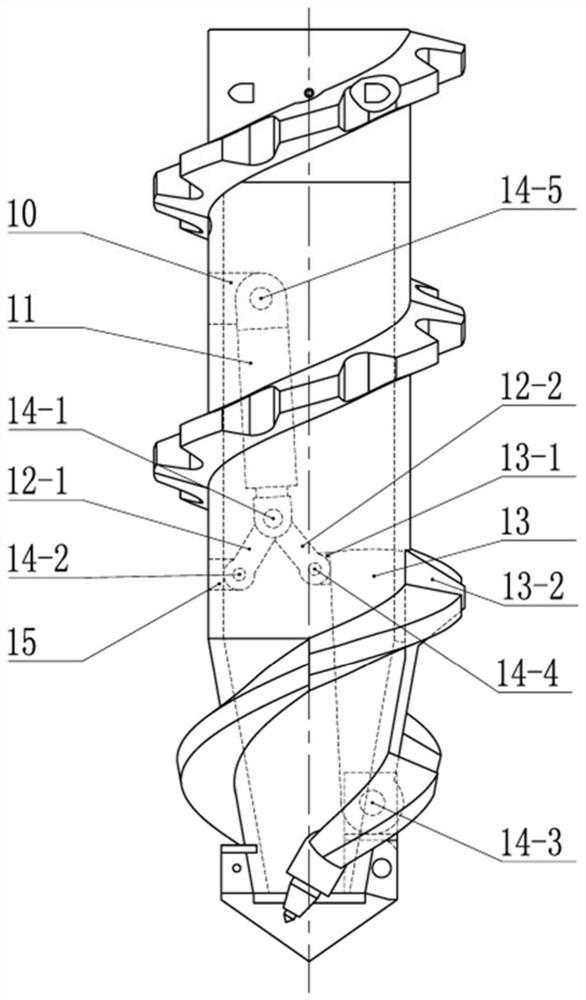

Cast-in-place concrete pile with mixing layer wrapped pile section, drill bit for pile forming and construction method

PendingCN112900424AImprove bearing capacityImprove carrying capacityDrill bitsSealing/packingResidual soilsDrill bit

The invention relates to a cast-in-place concrete pile with a mixing layer wrapped pile section, a drill bit for pile forming and a construction method. The cast-in-place concrete pile with the mixing layer wrapped pile section is composed of a pile body section and a pile bottom section; the pile body section at least comprises one mixing layer wrapped pile section; and the mixing layer wrapped pile section is arranged at the bottom end and / or the middle portion and / or the top end of the pile body section. According to the mixing layer wrapped pile section, the periphery of a pile body of a foundation pile section is wrapped by a mixing layer which has a certain thickness and is formed by a mixture formed by stirring and mixing pile side soil and concrete through an extruding and expanding protruding block of the drill bit, and the mixing layer wrapped pile section and the pile body of the foundation pile section are fixedly connected into the integrated pile section; the bearing capacity of the created pile is high, the controllability of the outer diameter of the mixing layer is good, the extruding and expanding protruding block in an expanding sliding block in the drill bit has the soil extruding effect during work, and threaded pile sections with different expanding diameters can be formed; and the drill bit for pile forming is simple in structure, has the soil extruding and hole forming functions, and is small in residual soil emission, easy to operate during pile forming construction, good in pile forming quality controllability, high in work efficiency and free of vibration and mud during construction.

Owner:刘守进 +1

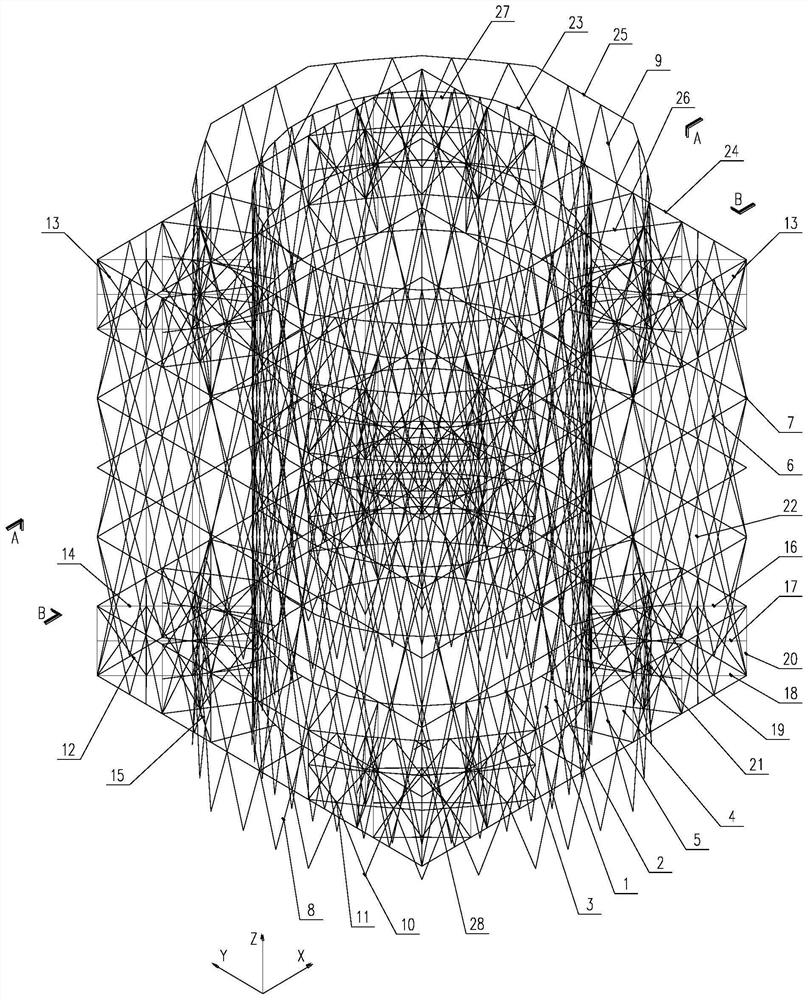

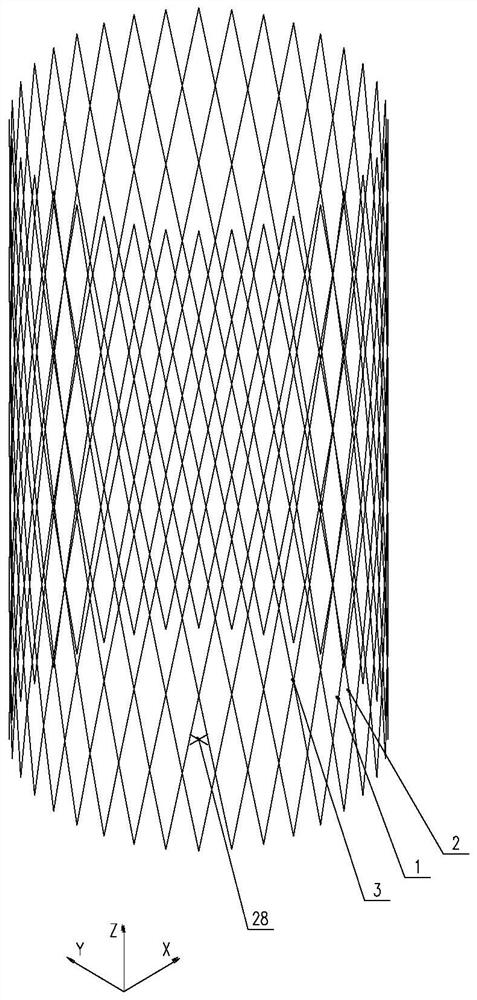

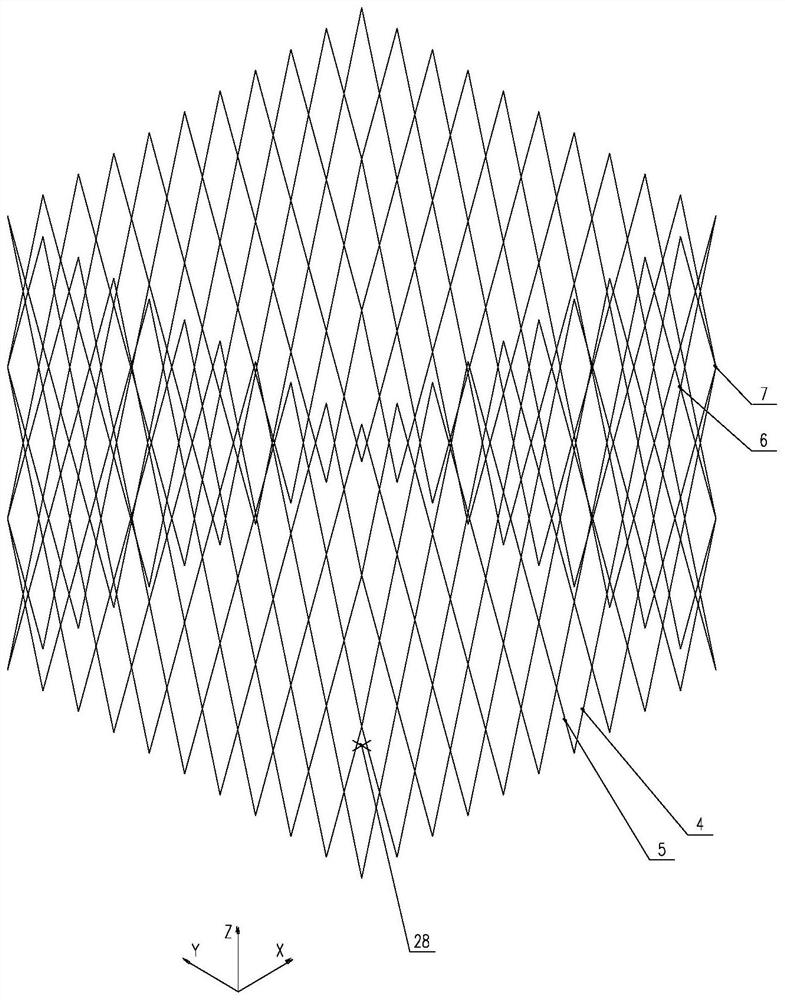

Bottom-indented double-cylinder oblique-crossing grid super high-rise structure with circular inside and square outside and forming method

ActiveCN113107093AGive full play to the high anti-side performanceReasonable structureClimate change adaptationExtraordinary structuresCross connectionCantilever

The invention relates to a bottom-indented double-cylinder oblique-crossing grid super high-rise structure with circular inside and square outside. The bottom-indented double-cylinder oblique-crossing grid super high-rise structure comprises an inner-circle through-height oblique-crossing cylinder, an outer-square non-landing oblique-crossing cylinder, an outer-ring indented oblique column, a corner multi-layer cantilever truss, a non-landing frame column and a floor steel beam; the inner-circle through-height oblique-crossing cylinder is located in the center of the whole structure and is formed by connecting two-way oblique column components in a crossed mode and arranged in a through-height mode, and a plane-circle-shaped vertical oblique-crossing grid inner cylinder is formed; and the outer-square non-landing oblique-crossing cylinder is located on the outer side of the inner-circle through-height oblique-crossing cylinder. The super high-rise structure has the beneficial effects that the structure system is reasonable in structure, and the design and bearing of the inner-circle and outer-square double-cylinder building modeling super high-rise structure system with the large-cantilever-indented bottom and the interior through-height atrium can be achieved; and component composition modules of the bottom-indented double-cylinder oblique-crossing grid super high-rise structural system with the round inside and the square outside are clear, and the bottom-indented double-cylinder oblique-crossing grid super high-rise structural system with the circular inside and the square outside has wide application prospects in the bottom-large-cantilever-indented double-cylinder building modeling super high-rise structural system with the large-cantilever-indented bottom and the interior through-height atrium.

Owner:ZHEJIANG UNIV CITY COLLEGE

Cross-laminated timber shear wall-concrete core tube hybrid lateral force system

ActiveCN108708479BAvoid damageImprove side resistanceWallsProtective buildings/sheltersLoad resistancePre stress

Owner:TONGJI UNIV

An underground continuous wall and its construction method

ActiveCN113123325BGood shock and vibration damping performanceStrong shear resistanceProtective foundationBulkheads/pilesSlurry wallArchitectural engineering

Owner:SHENZHEN UNIV

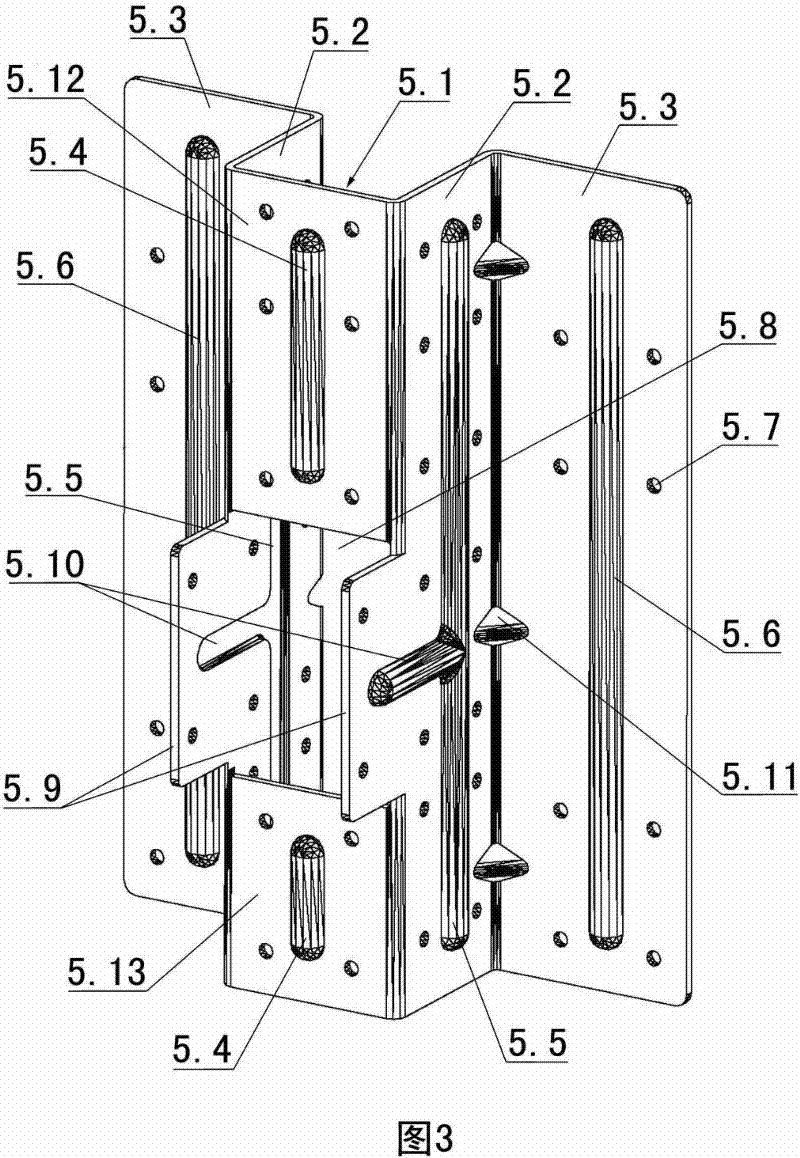

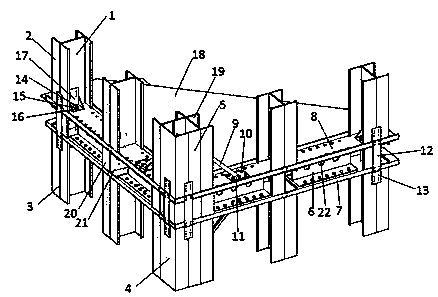

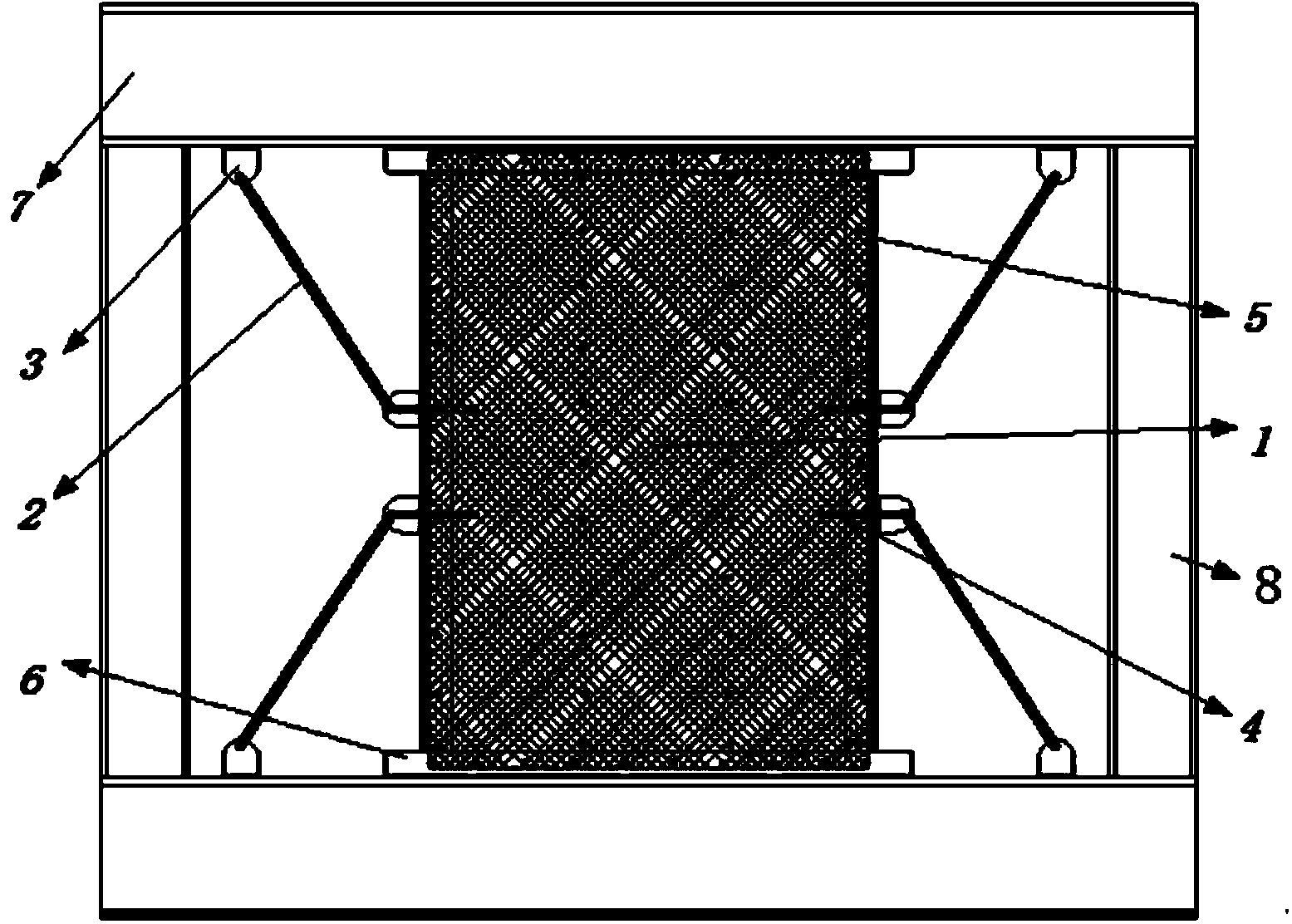

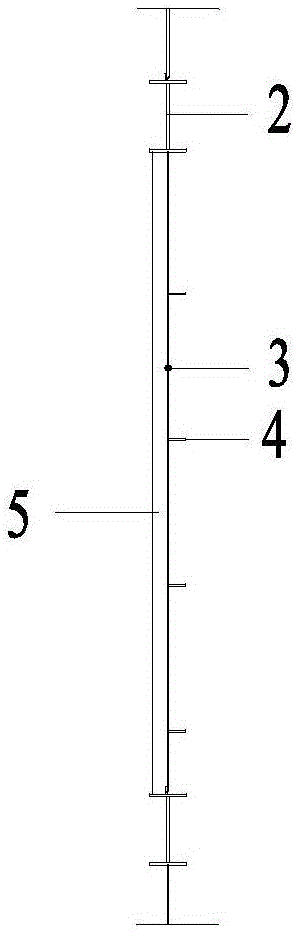

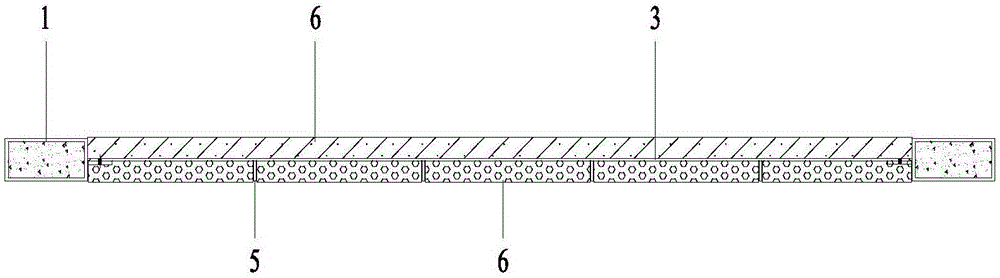

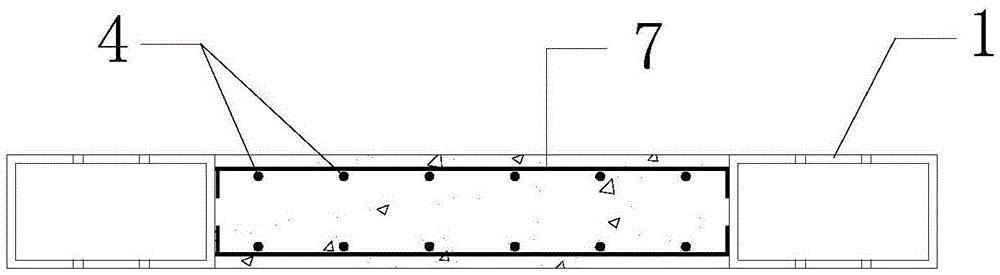

Truss combined beam and upper and layer connected light steel structure and construction method thereof

InactiveCN102359180BImprove manufacturing precisionReduce construction costsGirdersJoistsRear quarterStructural stability

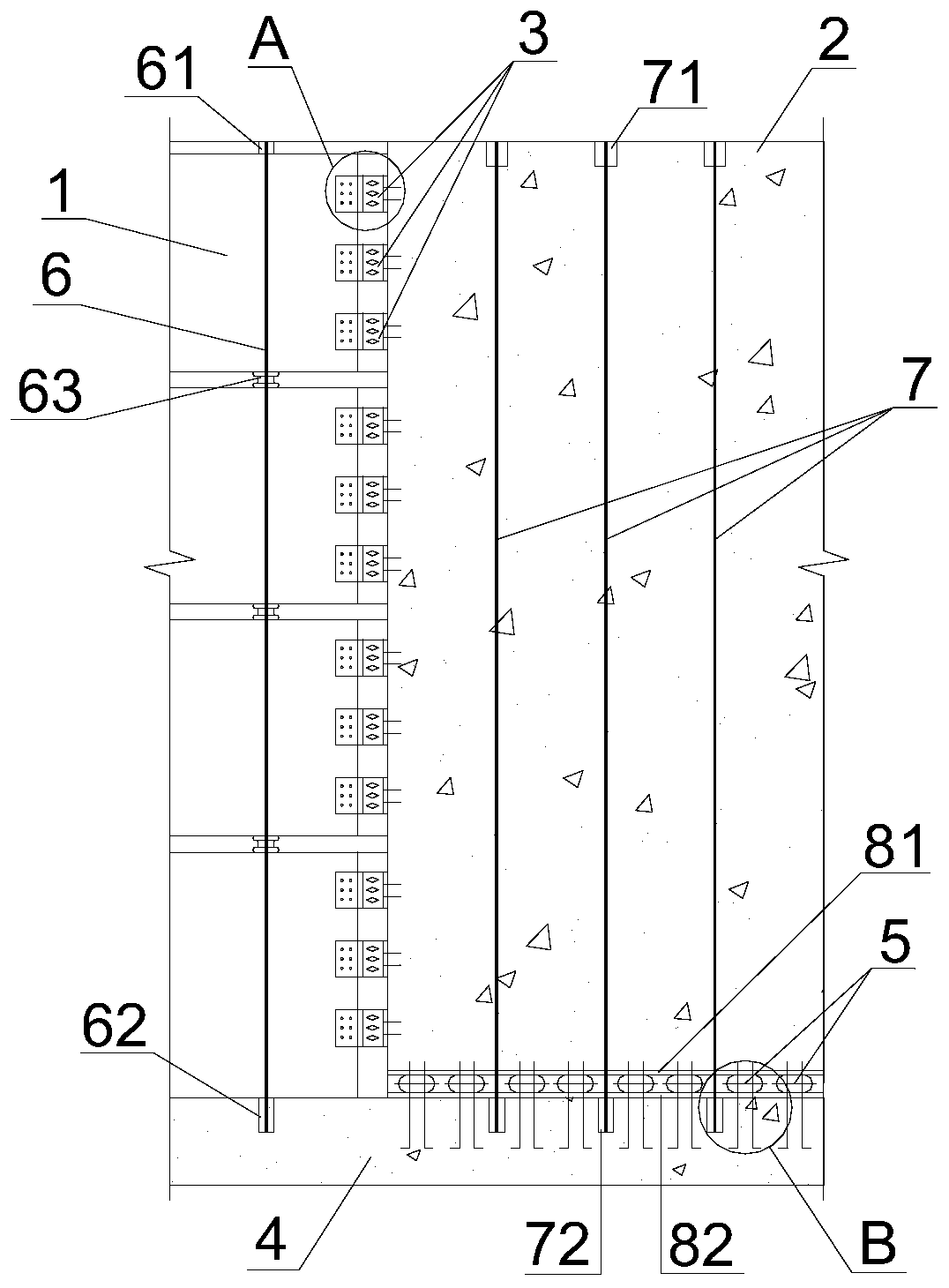

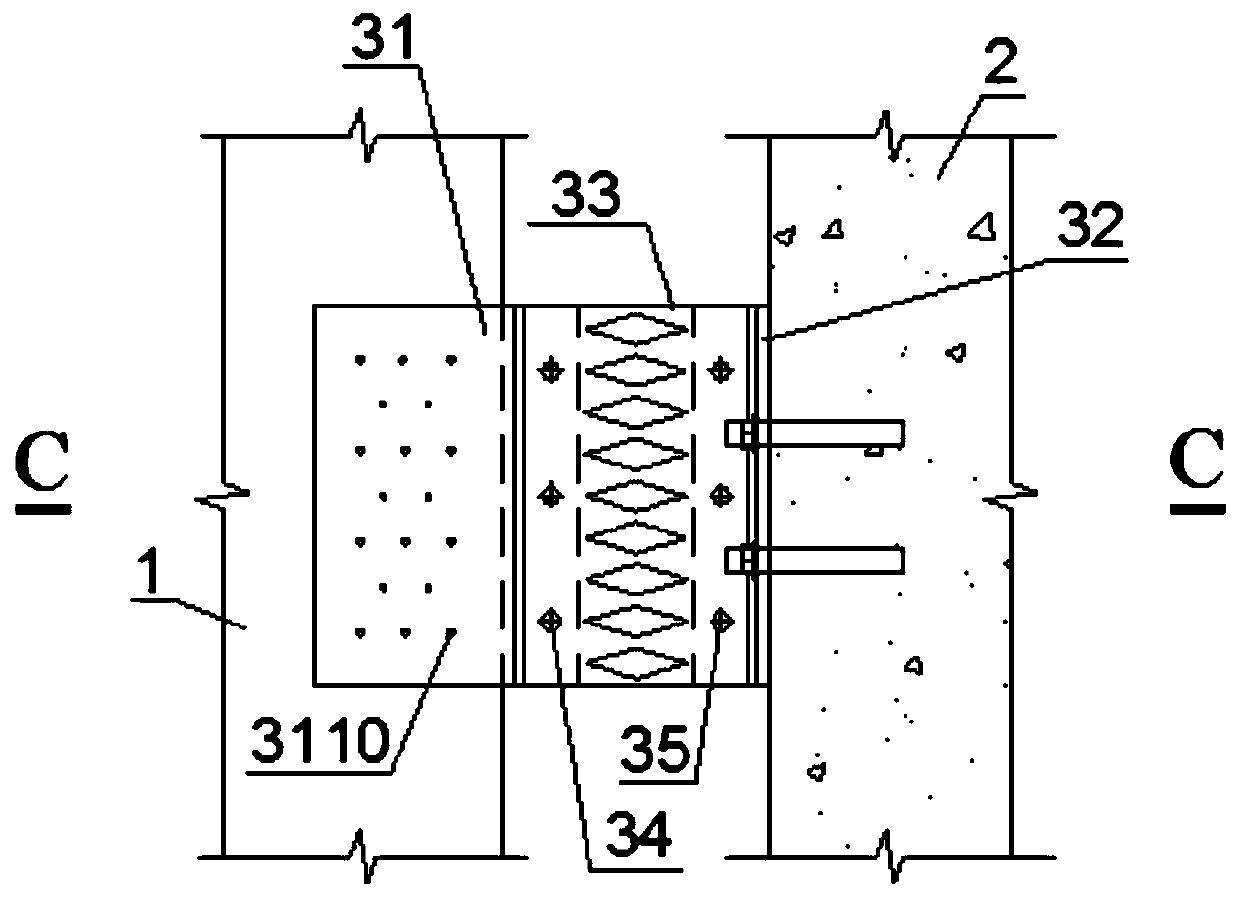

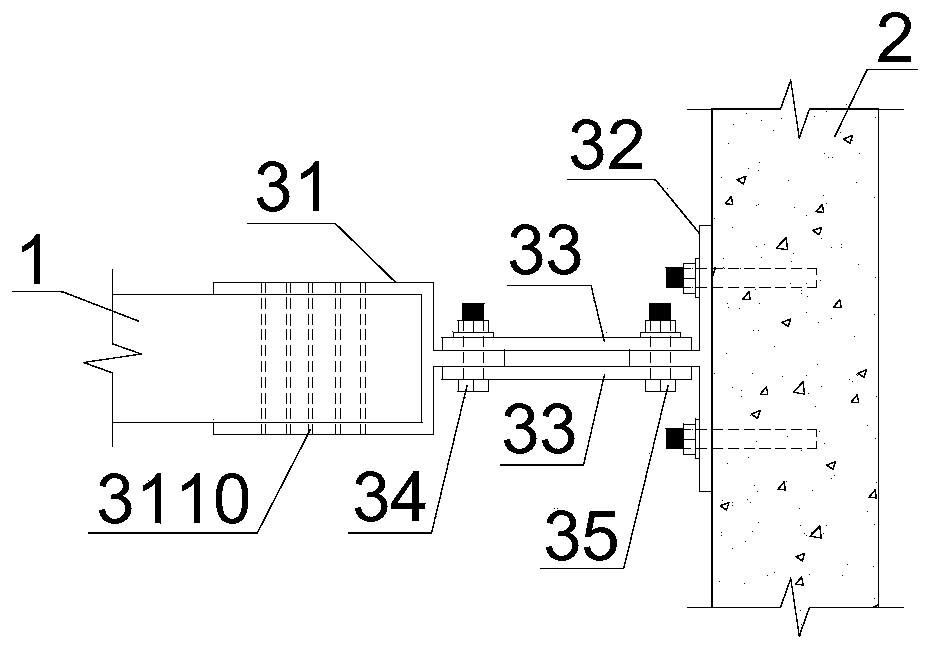

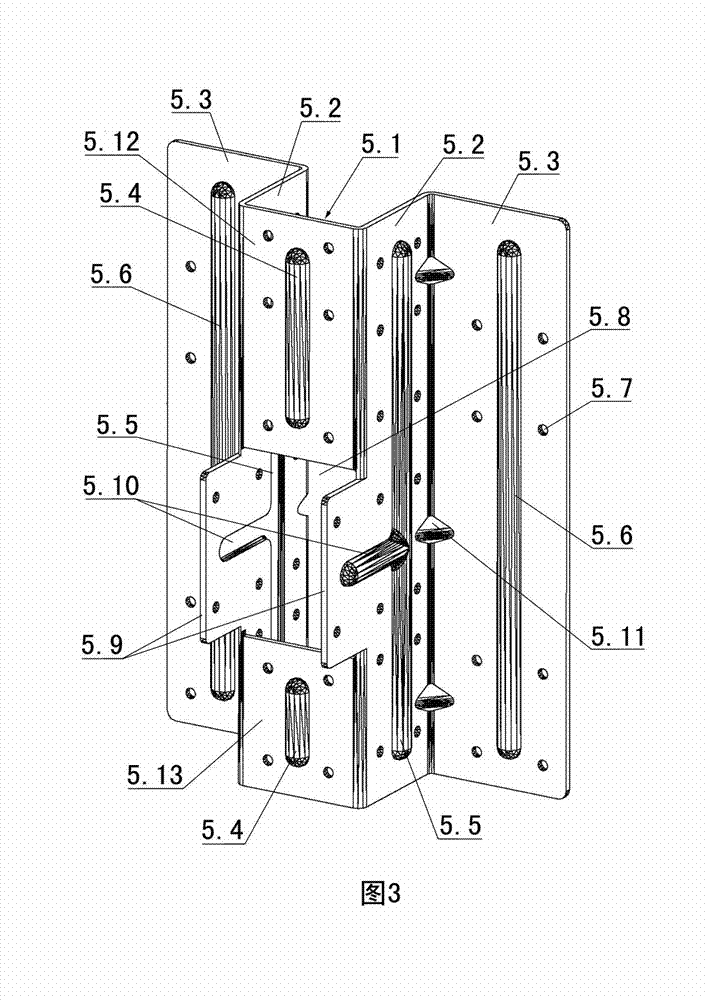

A light-weight steel structure for connecting truss composite beam to upper and lower layers and a construction method therefor, comprising upper layer wall panel posts (1) distributed at intervals, lower layer wall panel posts (2) distributed at intervals, a lower connecting tube for the upper layer wall panel posts (3) connected between the lower parts of the upper layer wall panel posts (1), an upper connecting tube for the lower layer wall panel posts (4) connected between the upper parts of the lower layer wall panel posts (2), and a truss composite beam connected between the upper layer wall panel posts (1) and the lower layer wall panel posts (2) by means of an upper and lower layer connector, the upper and lower layer connector being a cross-beam fastening (5), wherein a cross-beam fastening web (5.1) is composed of an upper web (5.12) and a lower web (5.13); a square connecting part (5.8) is provided between the upper web (5.12) and the lower web (5.13); an upper chord connecting plate (5.9) extends from the left and right side edges of the square connecting part (5.8); and the upper chord connecting plate (5.9) and a cross-beam fastening side plate (5.2) are located in the same plane.

Owner:筑巢(北京)科技有限公司

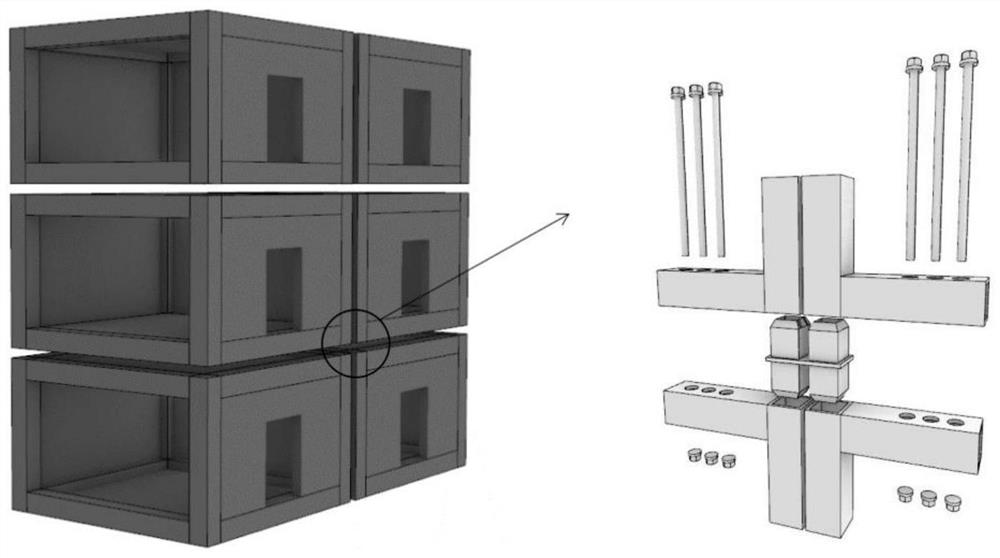

Mixed assembly type steel structure building and construction method thereof

PendingCN114753501AImprove assembly rateImprove productivityFloorsArchitectural engineeringSteel frame

The invention discloses a mixed fabricated steel structure building and a construction method thereof, the whole building is divided into odd-numbered layers and even-numbered layers, main components of the odd-numbered layers comprise columns and walls, and module units of a module fabricated building are used in the even-numbered layers. And after the foundation (7) is completed, first-layer columns (6) are firstly constructed, then module units (4) of the module assembly type building are hoisted on a second layer, and then odd-number floors and even-number floors are sequentially and alternately constructed. The connection nodes (1, 2 and 3) between the odd-layer columns and the even-layer module unit column extension sections (5) are arranged in the odd-layer areas and can be exposed outside, enough construction space is provided, connection construction is facilitated, and the construction quality can be ensured. Compared with a module assembly type building, the hybrid building has higher lateral stiffness, and compared with a traditional steel frame and steel frame-supporting building, the hybrid building has higher assembly rate and production rate.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com