Prestress waveform section steel plate shear wall

A steel plate shear wall, corrugated steel plate technology, applied in the direction of walls, building components, buildings, etc., can solve the problem of not being able to give full play to the strength and ductility of steel, save manpower and material resources, improve shear performance, energy consumption hysteresis loop full Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

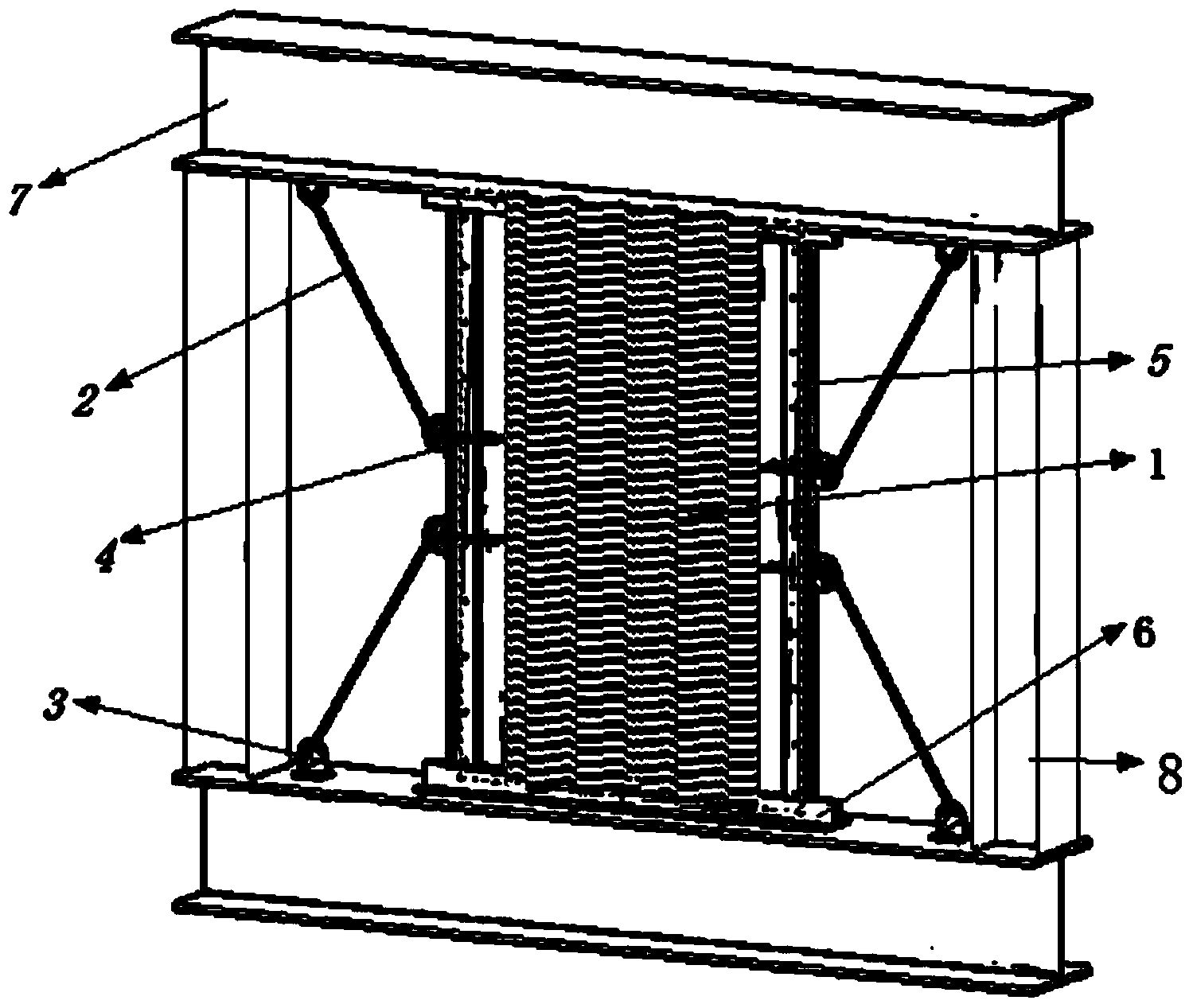

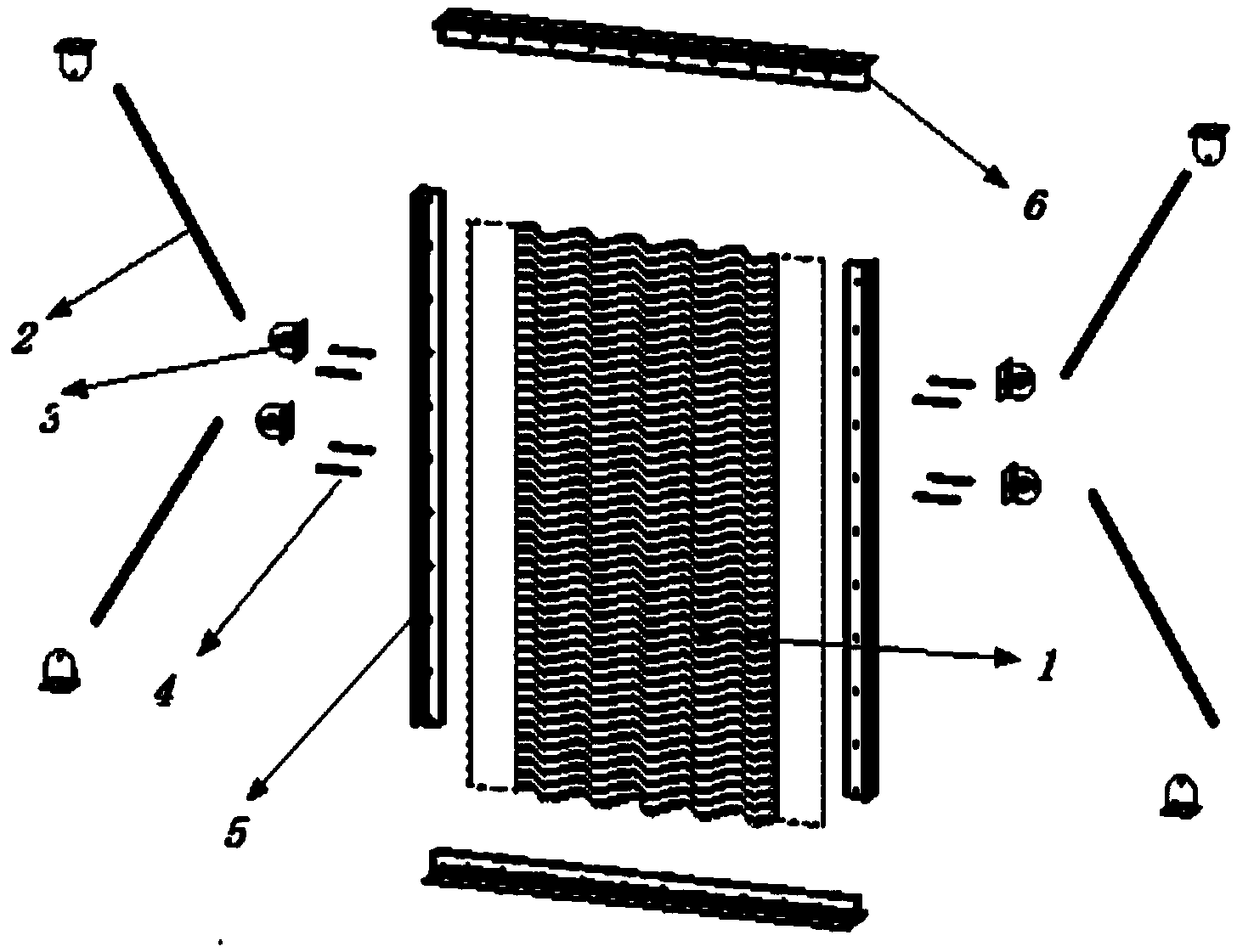

[0024] Such as figure 1 , 2 As shown, 1—embedded corrugated steel plate, 2—prestressed rod, 3—connecting ear plate, 4—bracket, 5—vertical edge member, 6—horizontal edge member, 7—frame beam, 8—frame column.

[0025] The prestressed corrugated section steel plate shear wall includes an embedded corrugated steel plate 1 , prestressed rods 2 , connecting lugs 3 , brackets 4 , edge members, frame beams 7 and frame columns 8 . The embedded corrugated steel plate 1 adopts a thin steel plate with a thickness of 5-10 mm; the prestressed rod 2 adopts a prestressed cable or a prestressed tie rod; the connecting lug 3 is an end lug for fixing the prestressed cable ; The edge member is a vertical edge member 5 and a horizontal edge member 6, the vertical edge member 5 is a double-leg T-shaped steel, and the horizontal edge member 6 is a double angle steel placed in parallel, and two ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com