Patents

Literature

151 results about "Beam axle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A beam axle, rigid axle or solid axle is a dependent suspension design, in which a set of wheels is connected laterally by a single beam or shaft. Beam axles were once commonly used at the rear wheels of a vehicle, but historically they have also been used as front axles in rear-wheel-drive vehicles. In most automobiles, beam axles have been replaced by front and rear independent suspensions.

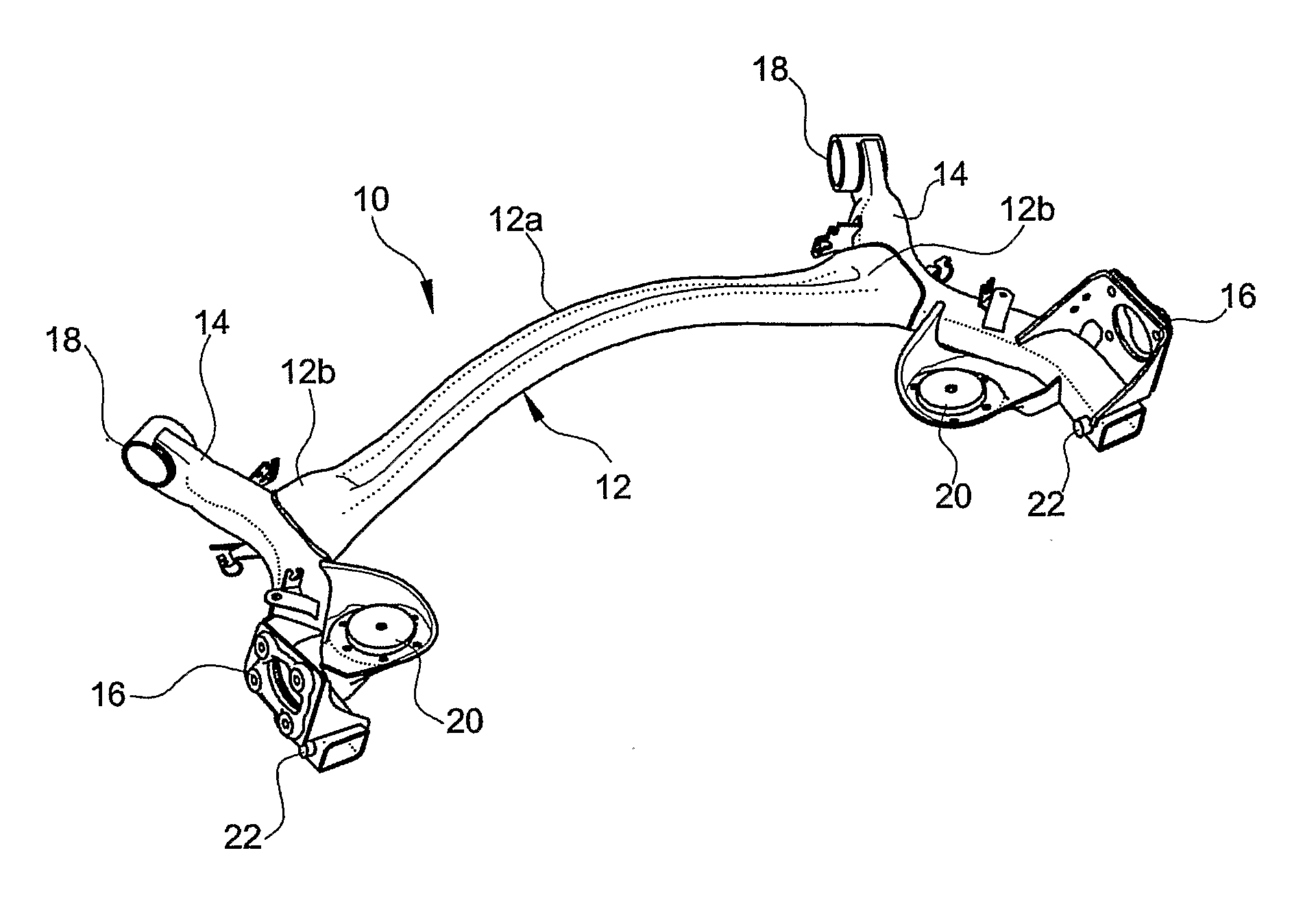

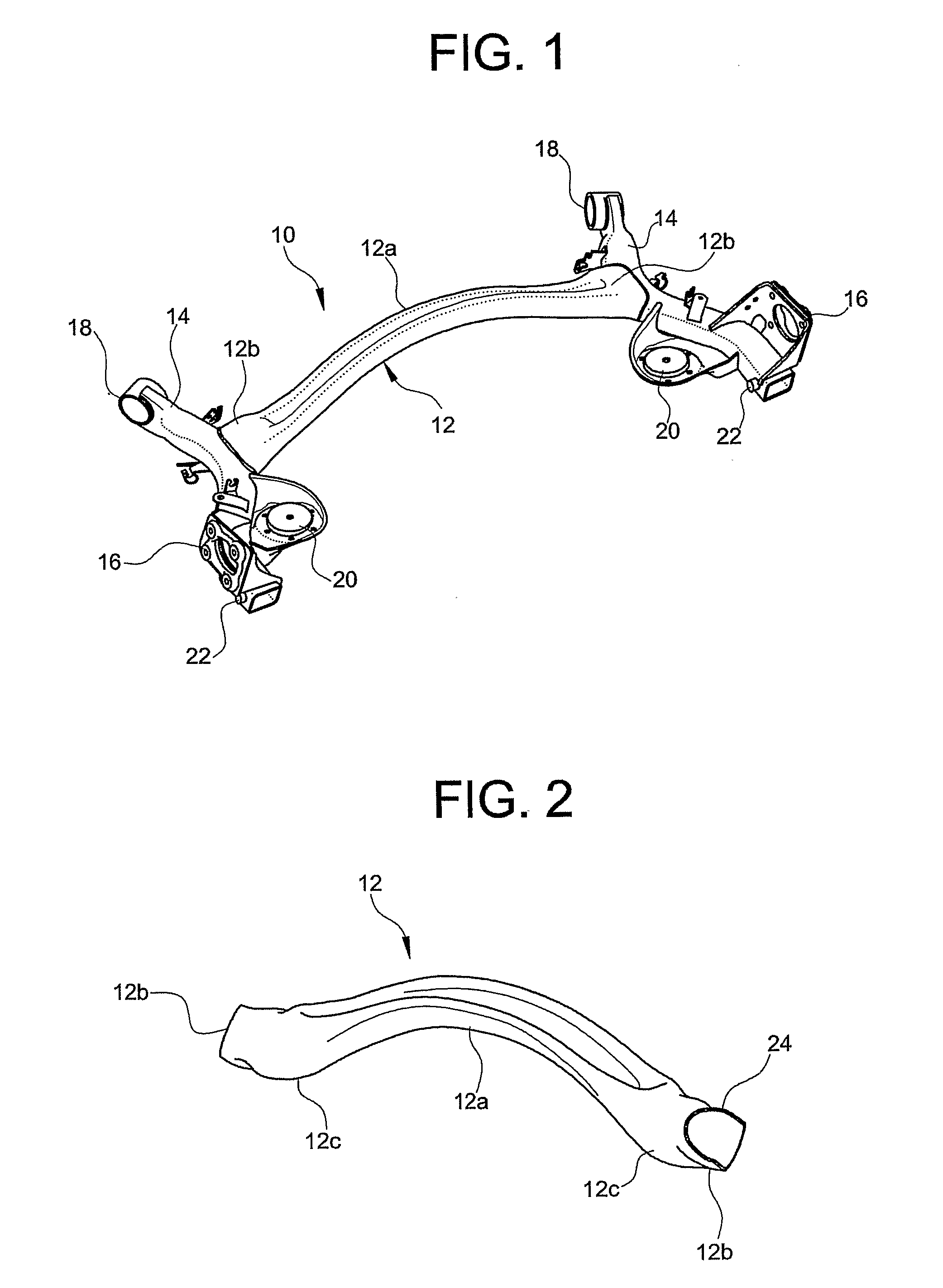

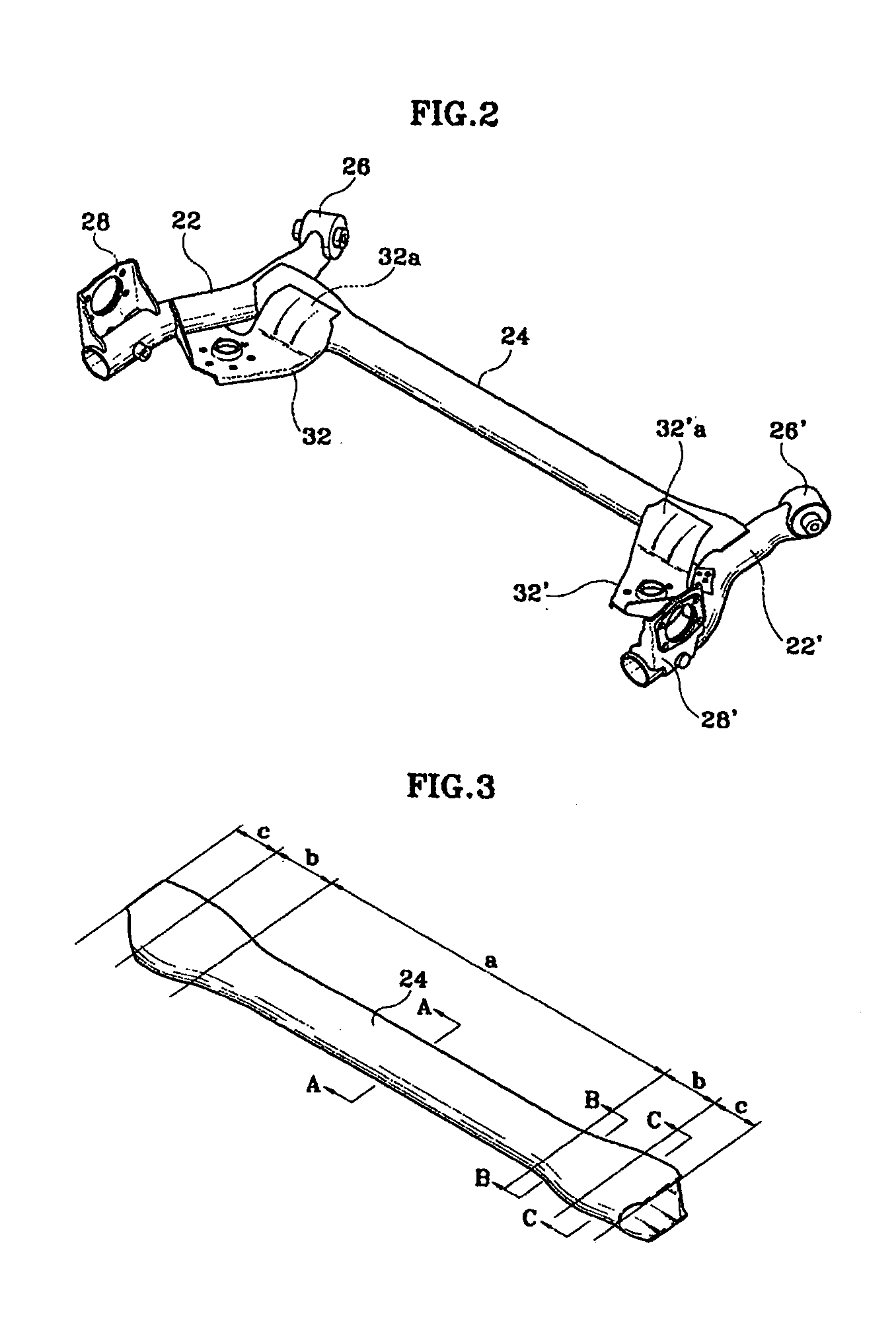

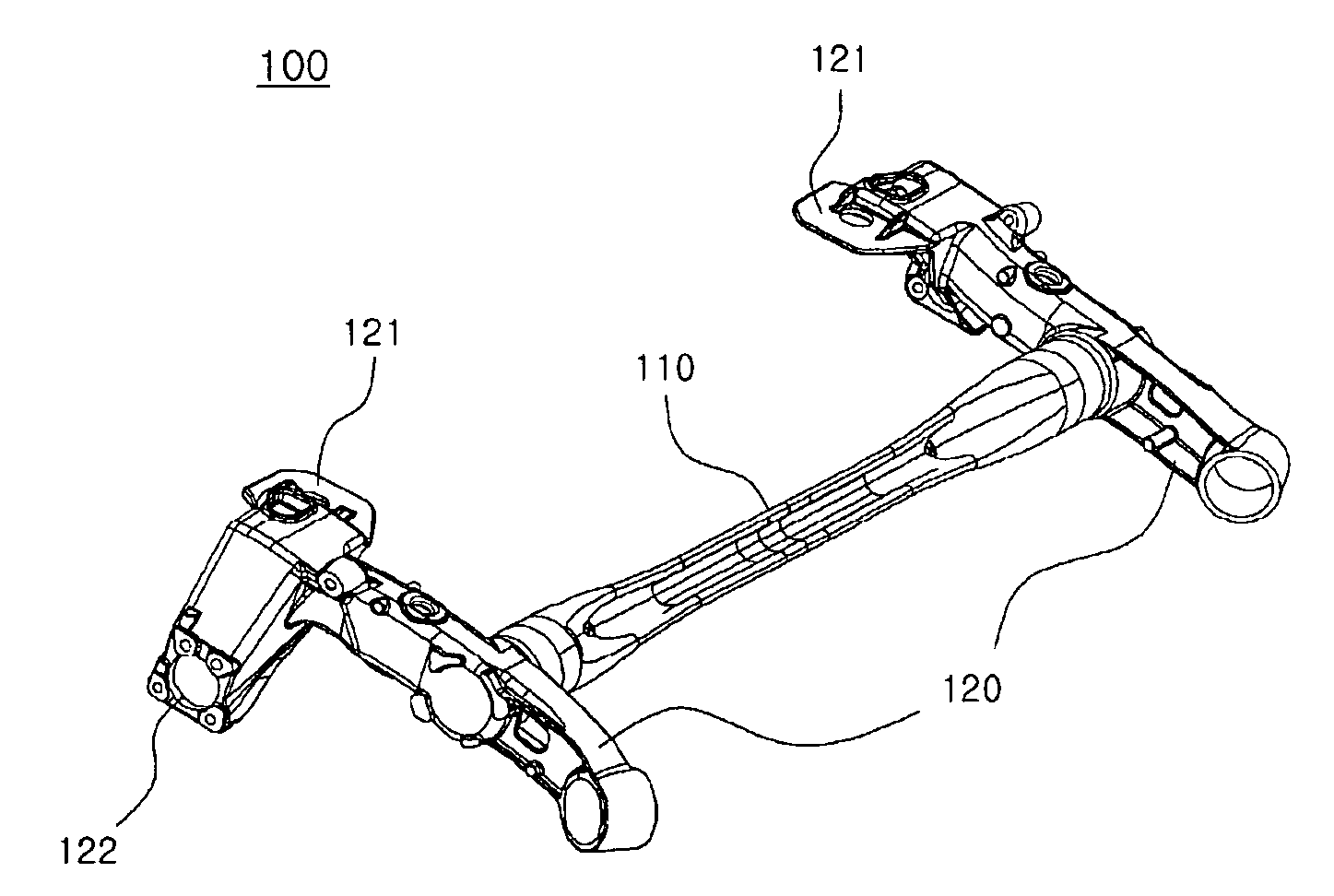

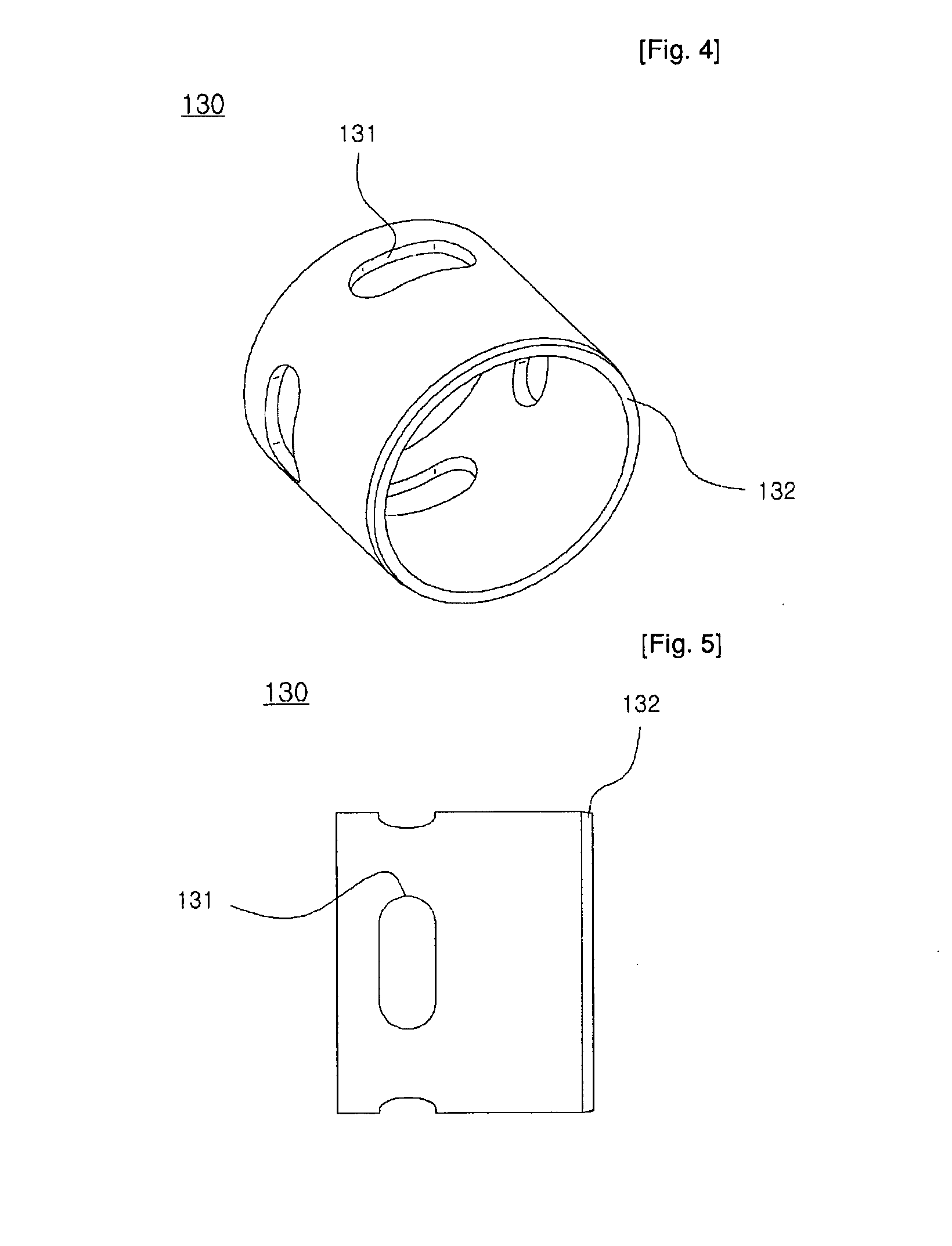

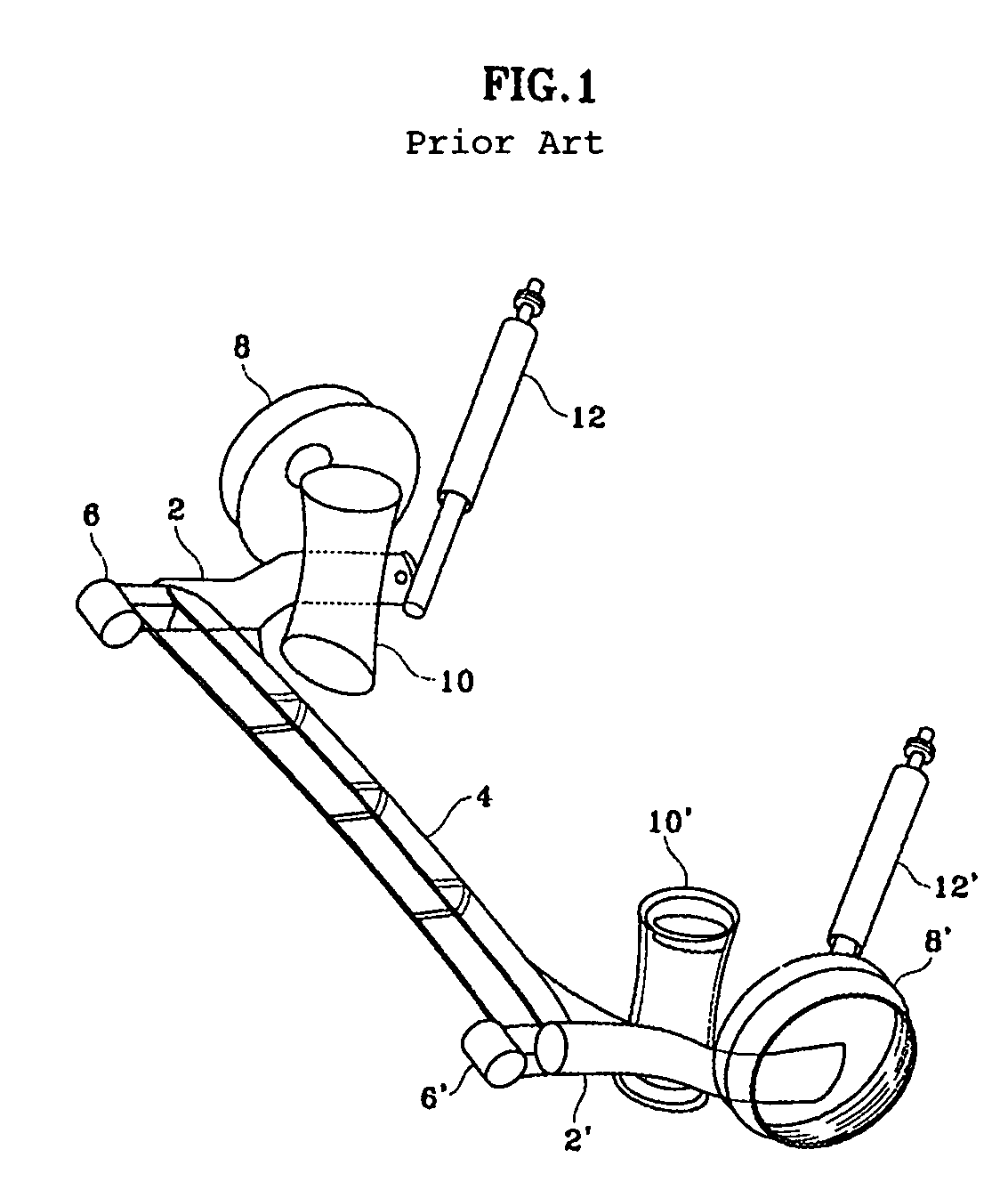

Cross-member for a rear twist-beam axle suspension for a motor-vehicle and method for its production

InactiveUS20110115183A1Increase valueAvailability problemMetal-working apparatusInterconnection systemsEngineeringMechanical engineering

A cross-member for a motor-vehicle twist-beam axle suspension includes a single piece of steel that defines a closed cross-section and integrally forms a middle section, a pair of end sections, and a pair of joining sections. The middle section has a center axis extending along a curvilinear path lying in a first plane and a squashed portion extending in a second plane inclined to the first plane. The end sections are adapted to be securely connected to respective trailing arms of the twist-beam axle suspension. Each of the joining sections is interposed between the middle section and the respective end section and defines an opposite concavity with respect to the middle section. A twist-beam axle suspension for a motor vehicle includes the cross-member and a pair of trailing arms. A method produces the cross-member for a motor-vehicle twist-beam axle suspension.

Owner:SISTEMI SOSPENSIONI SPA

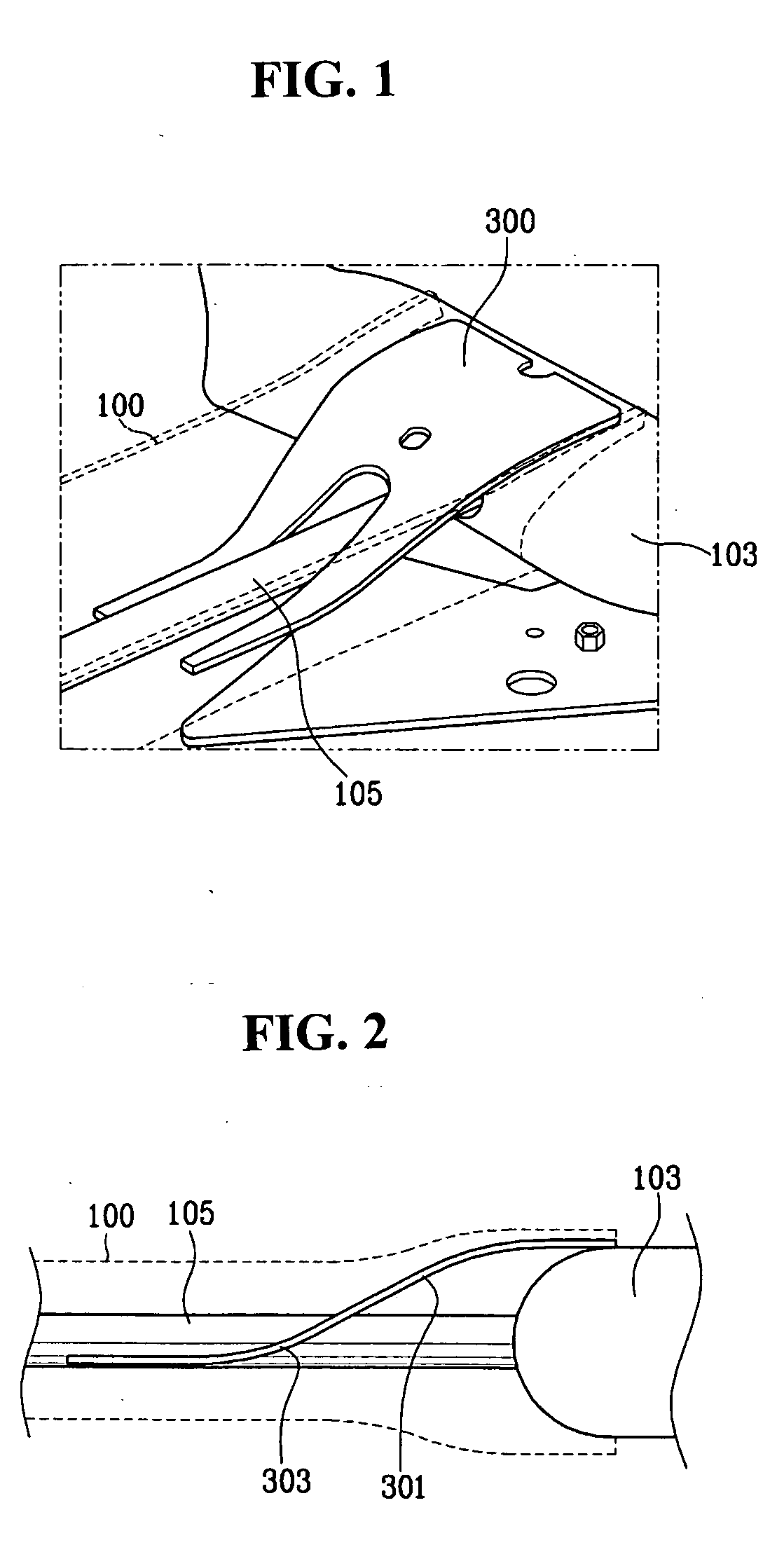

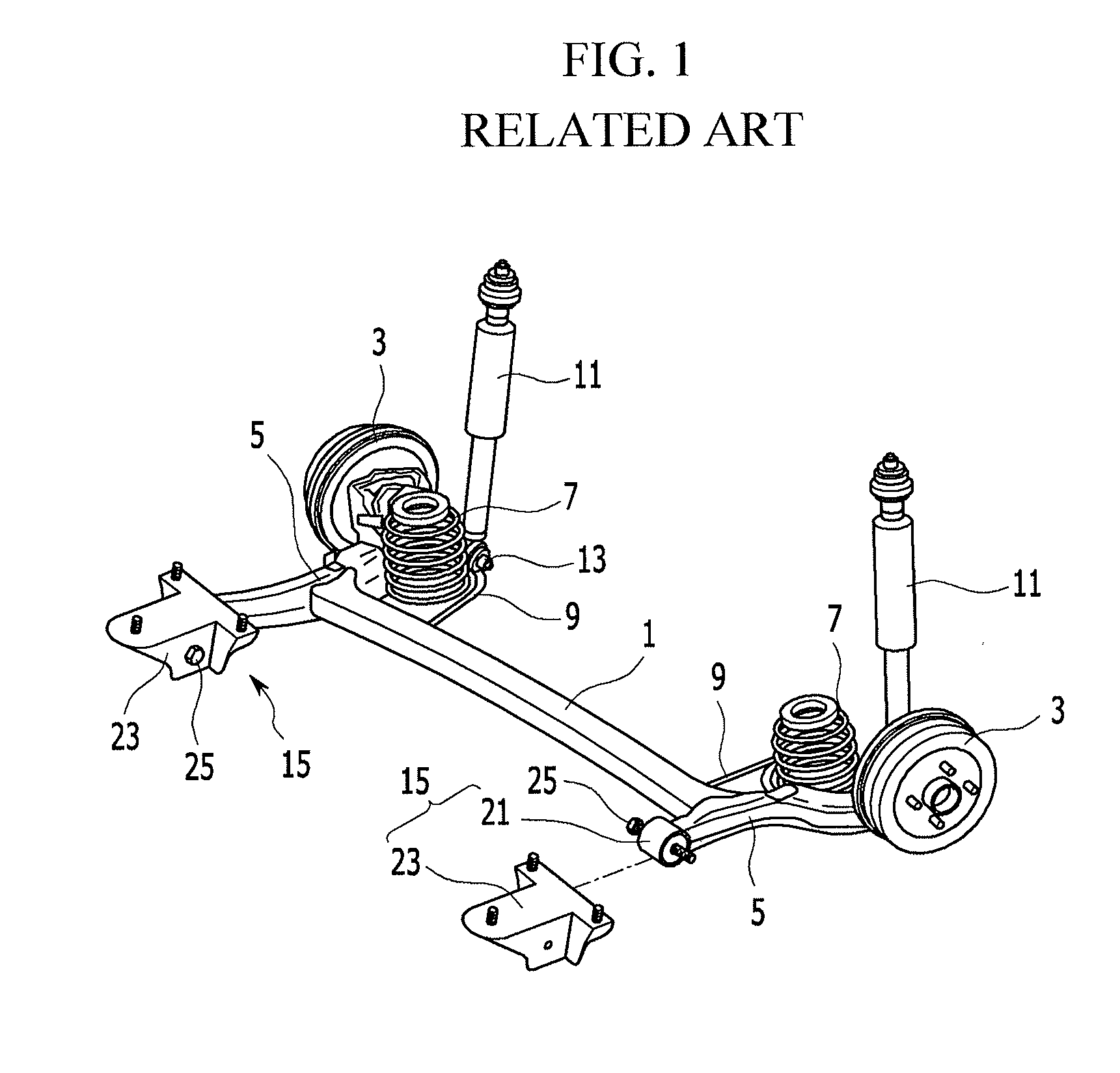

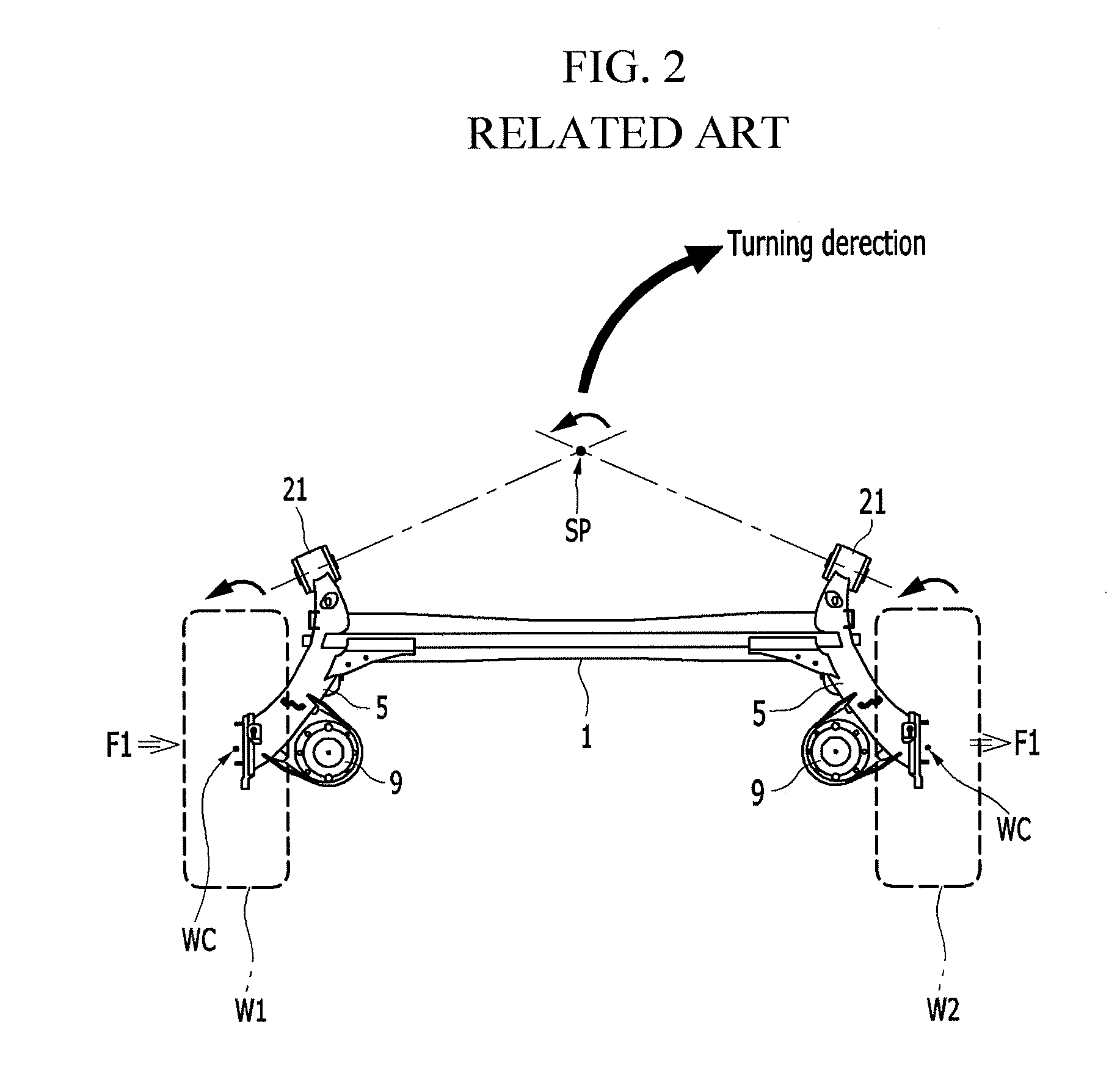

Rear suspension system

InactiveUS20070108714A1Increased durabilityInterconnection systemsResilient suspensionsMechanical engineeringBeam axle

A rear suspension system includes a plurality of trailing arms, a beam defining a space therein, and a plurality of reinforcing members, each with a first end connected to a respective one of the trailing arms and a second end contacting an interior surface of the beam. The second end of each reinforcing member is branched into two portions with a rod disposed between them. Each reinforcing member has at least one and preferably two curved portions, one near each end, both curved along the beam axis such that the second end of the reinforcing member is parallel with the rod.

Owner:KIA MOTORS CORP

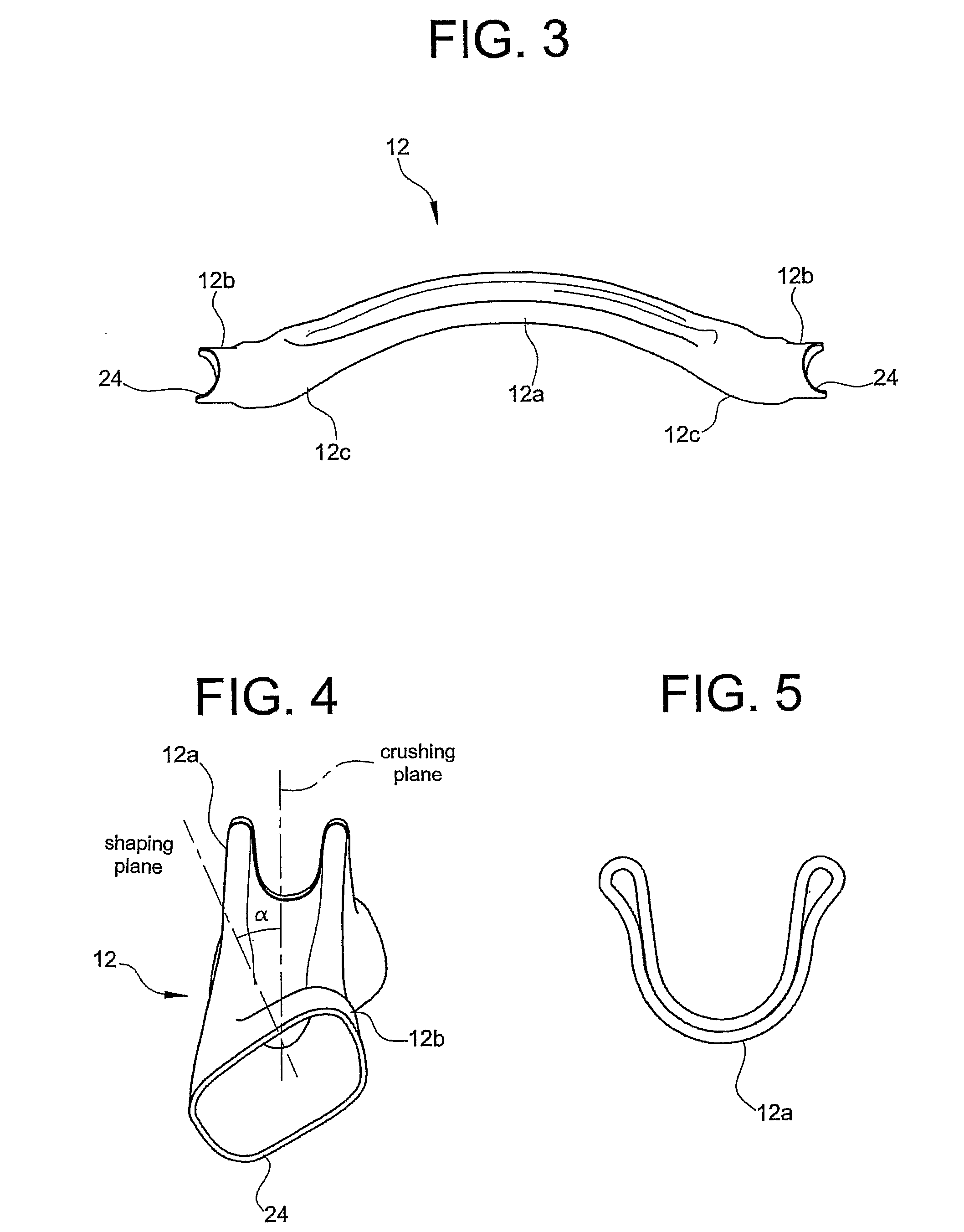

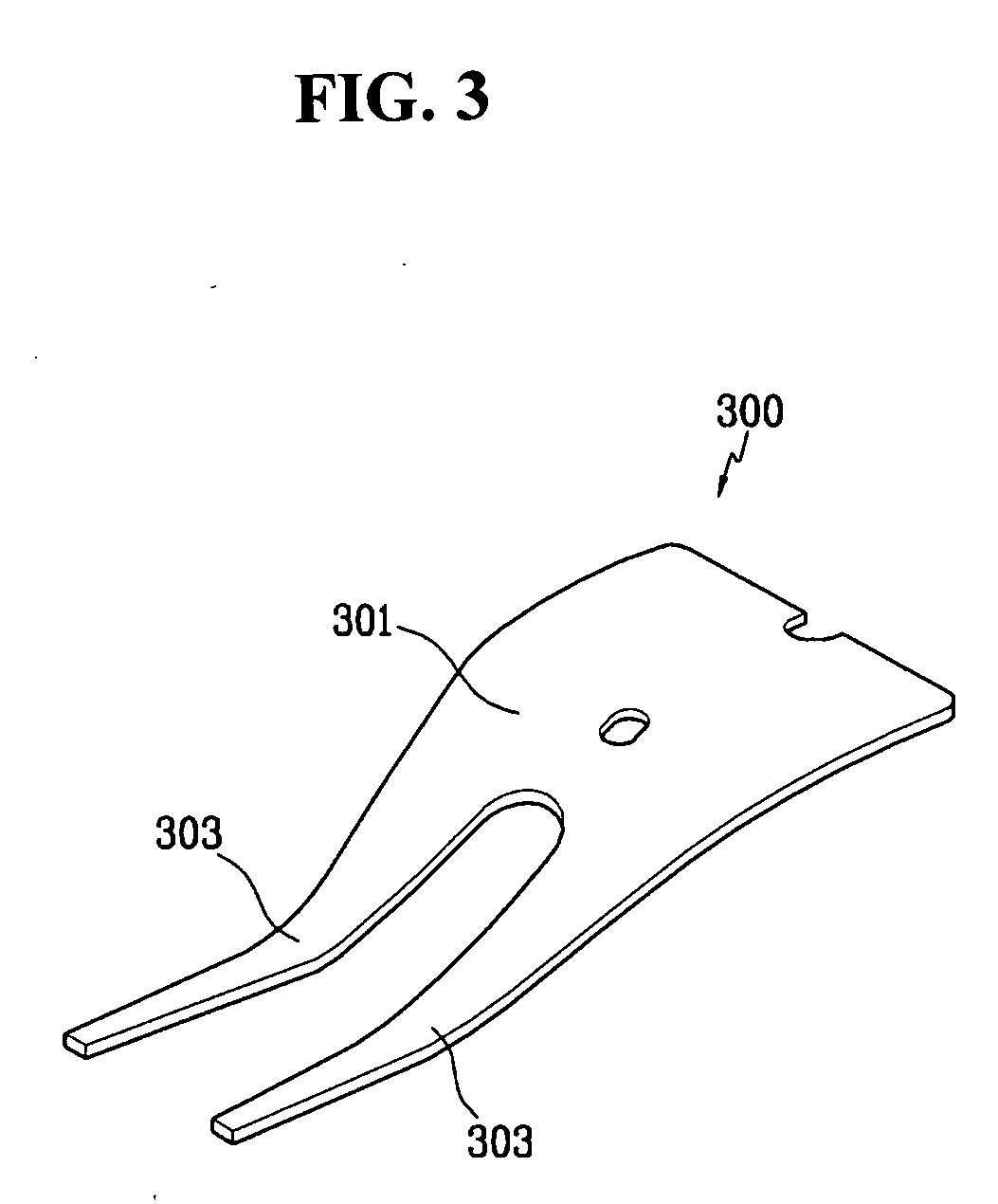

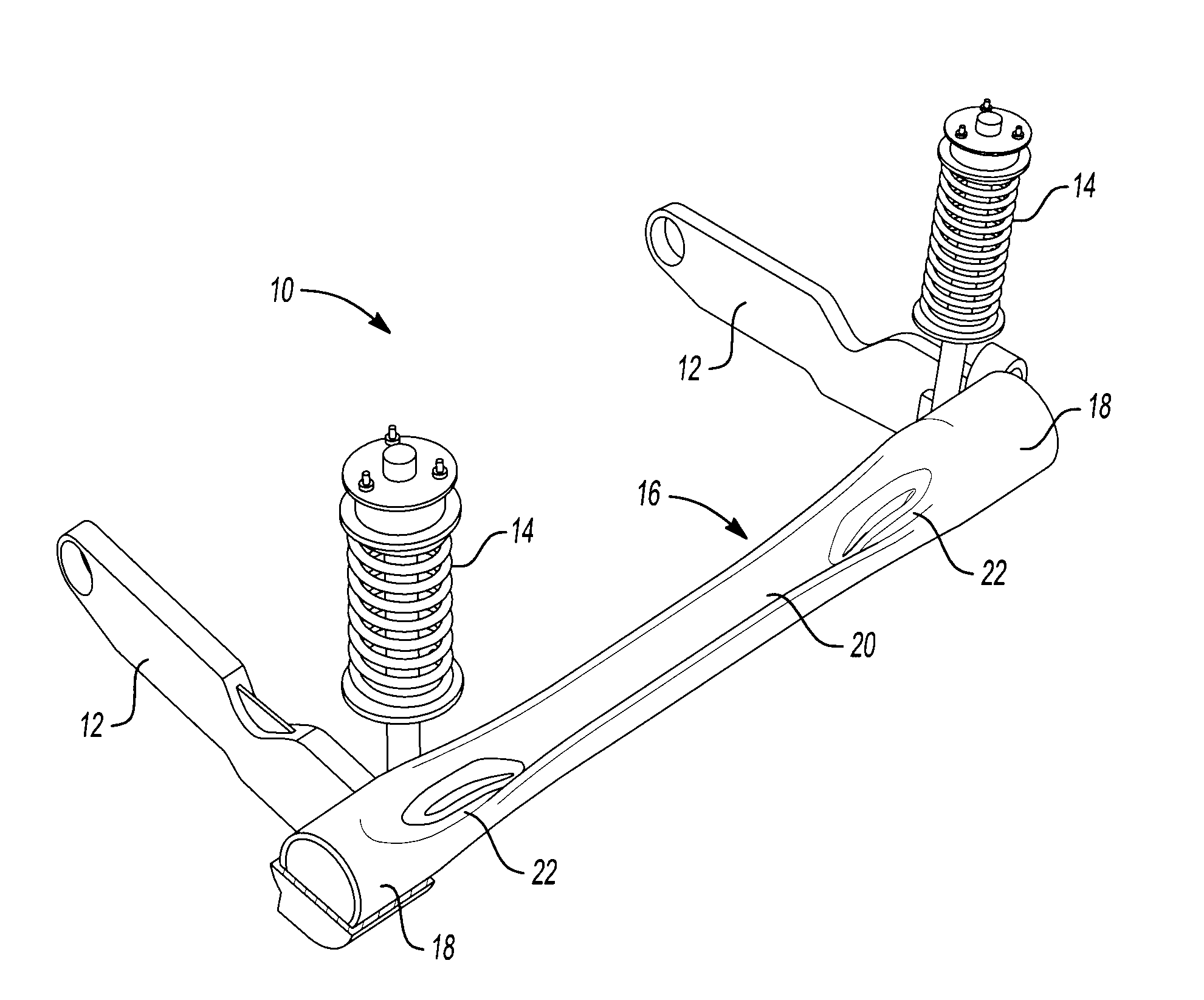

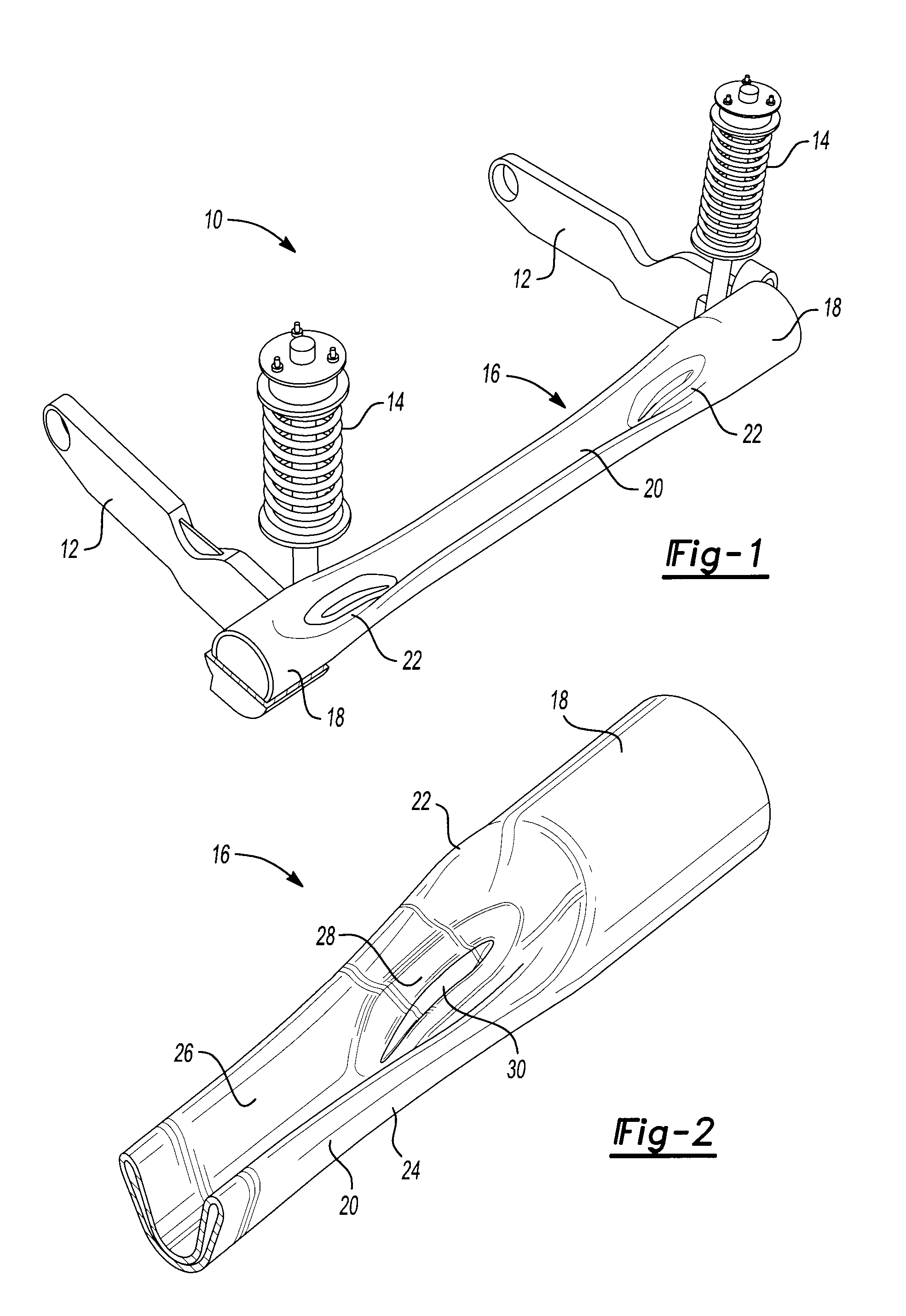

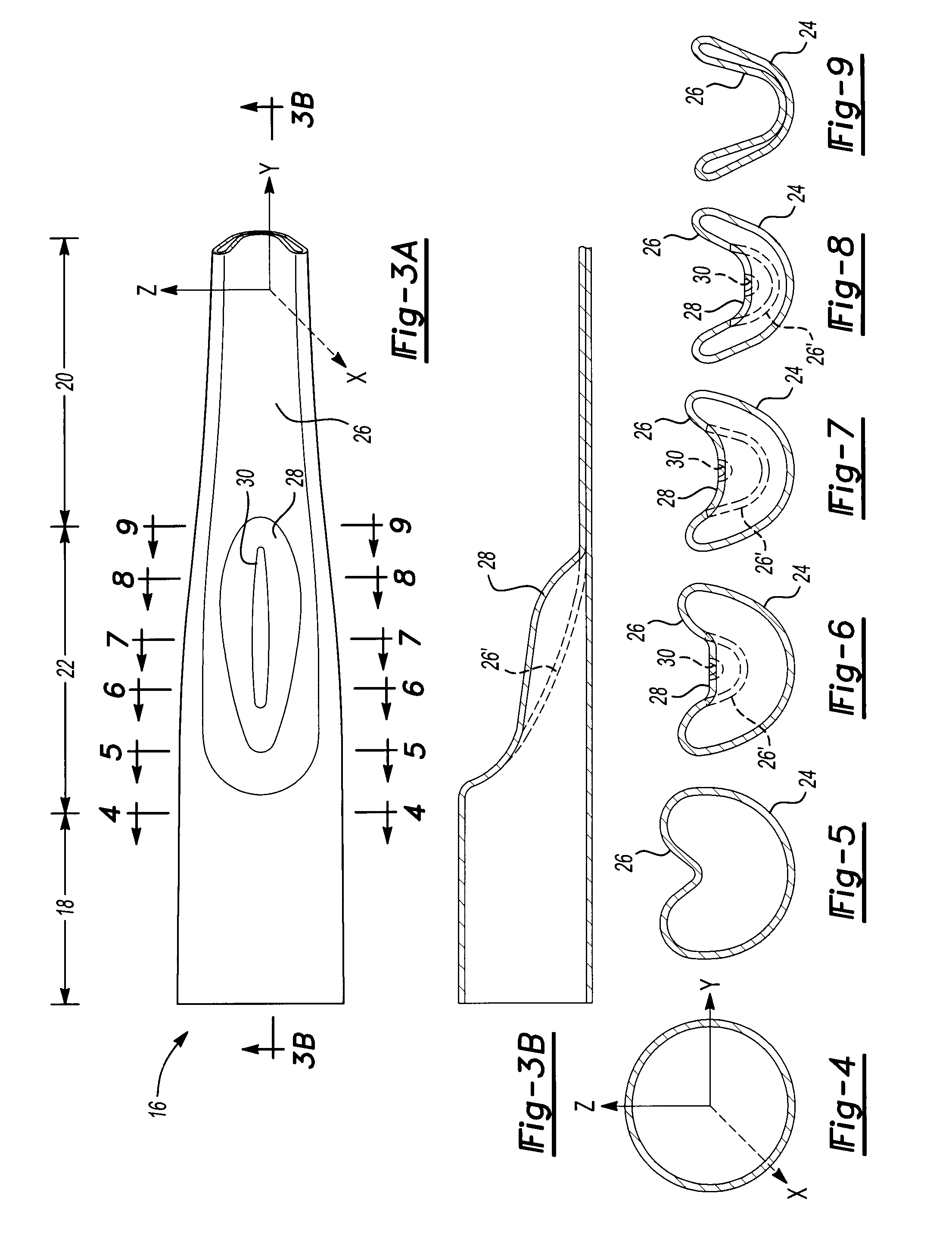

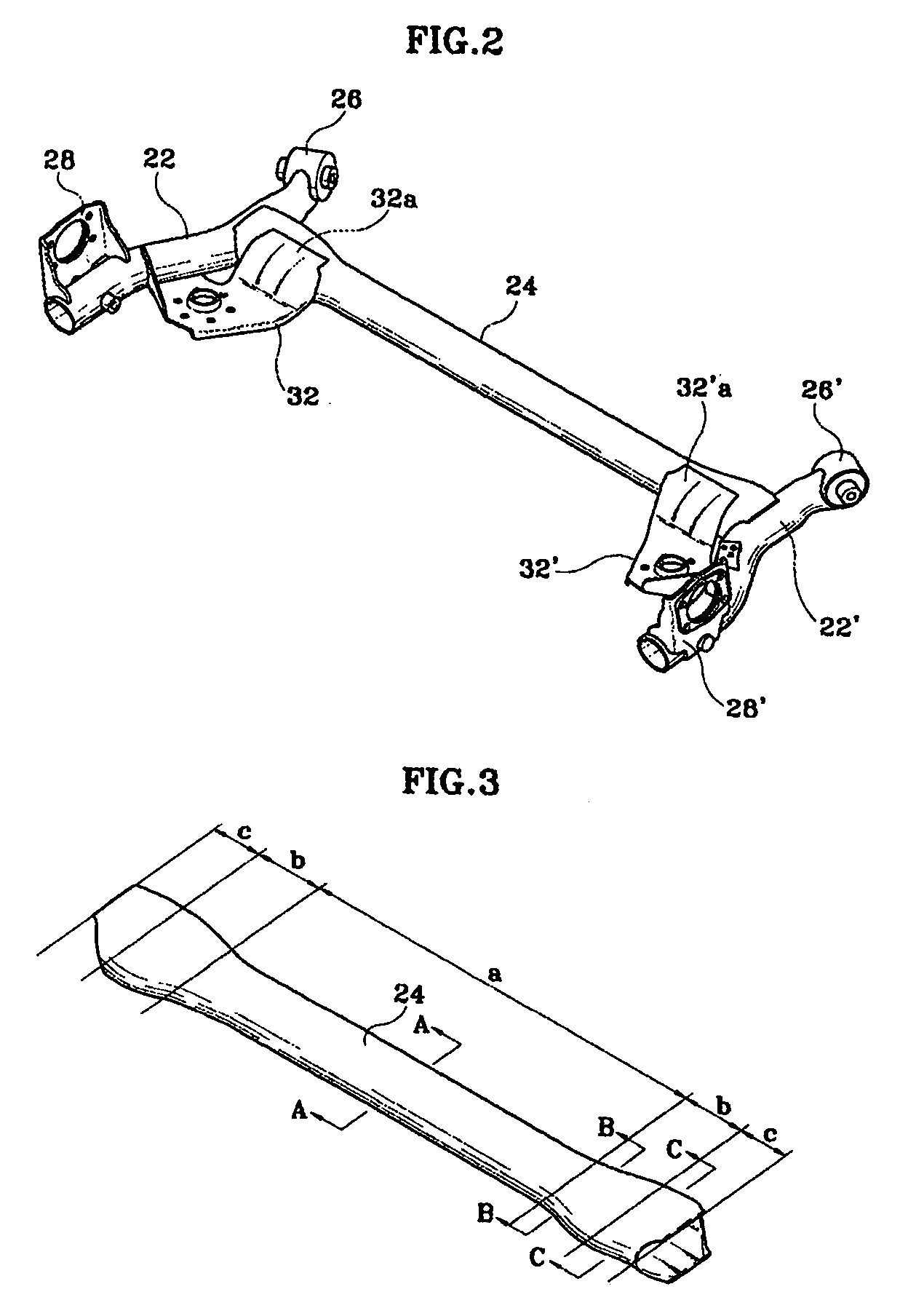

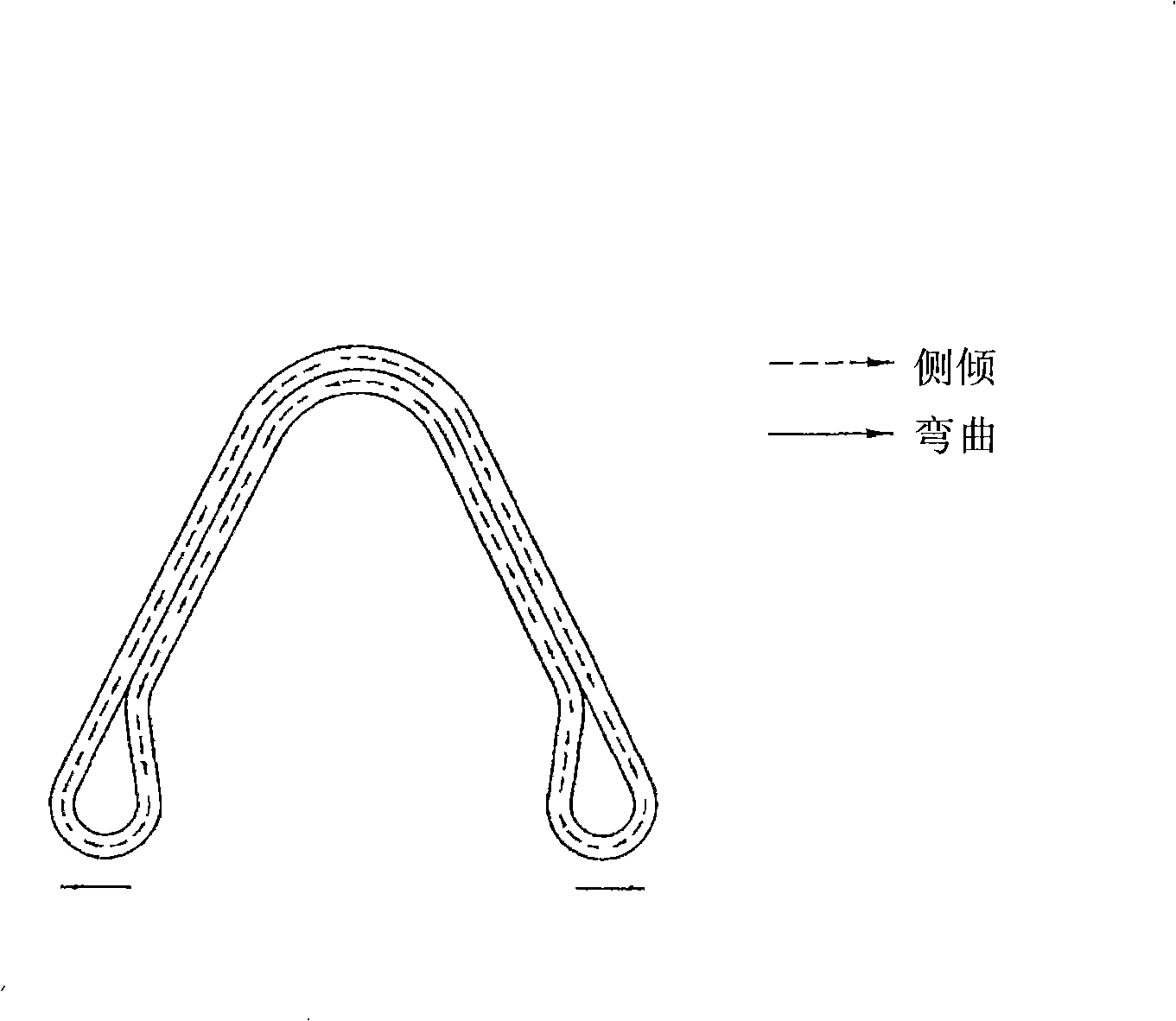

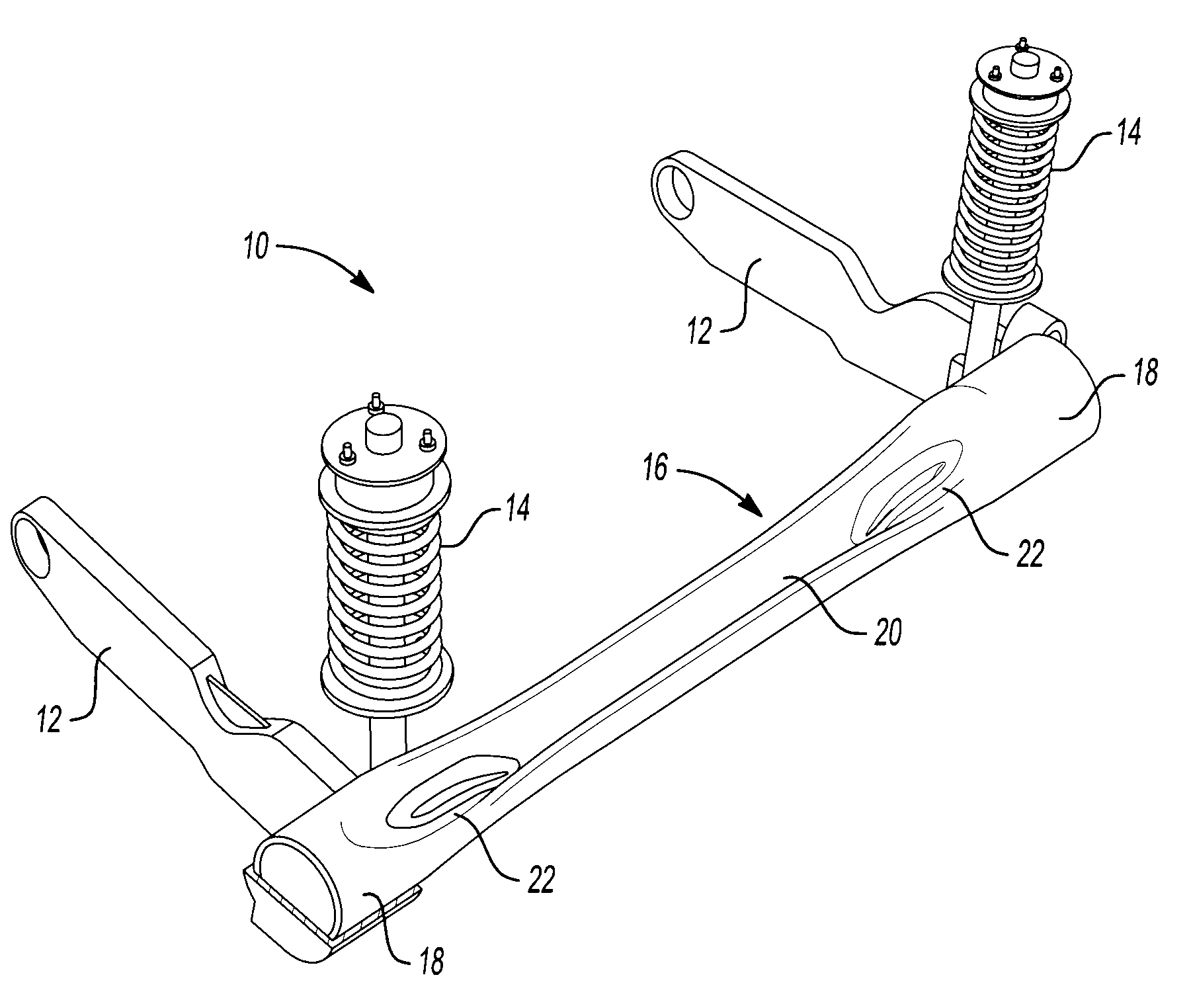

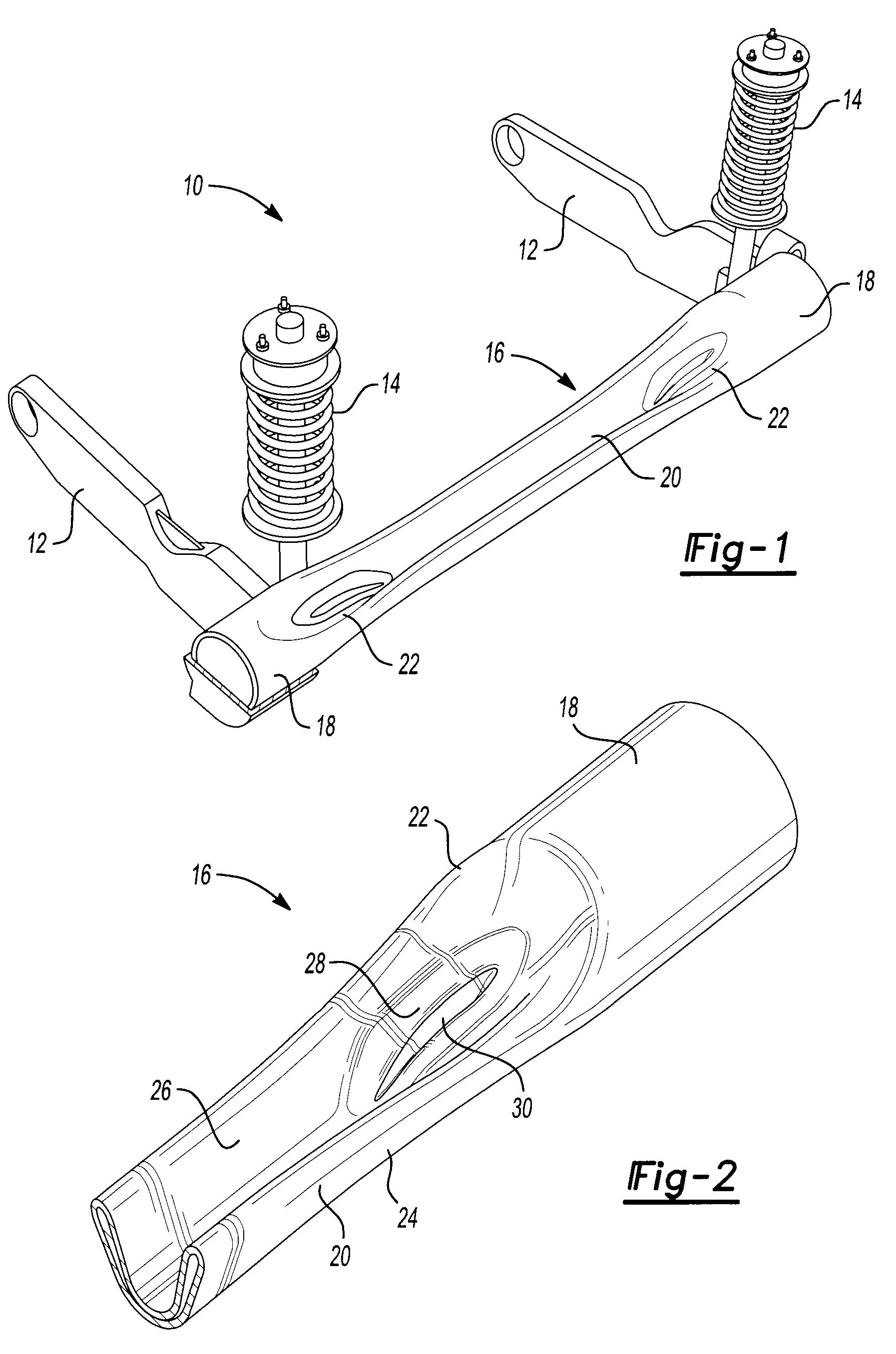

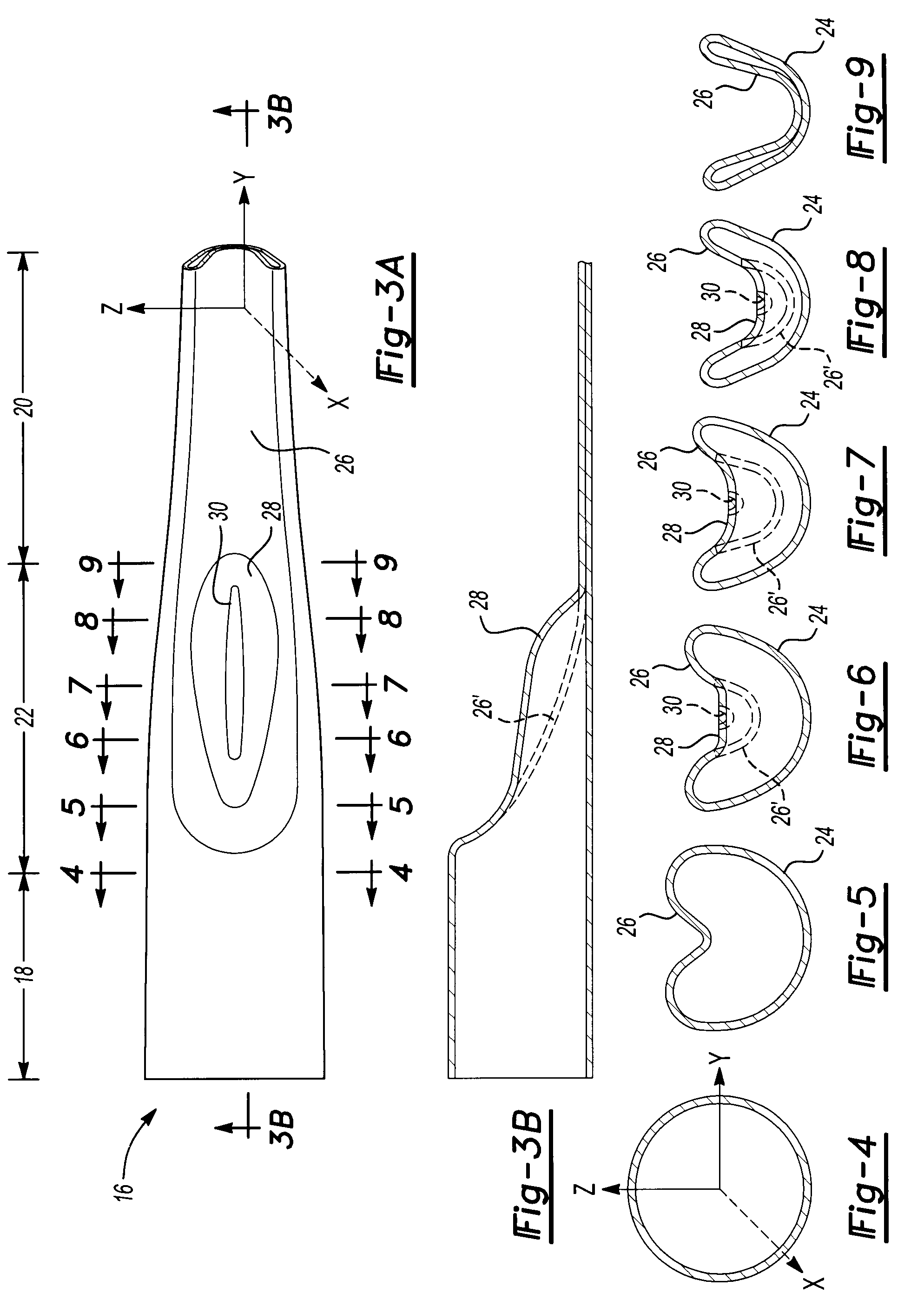

Twist Beam With Interlock

ActiveUS20100301577A1Increase flexibilityIncreased bending stiffnessInterconnection systemsWheel manufactureControl armFront-wheel drive

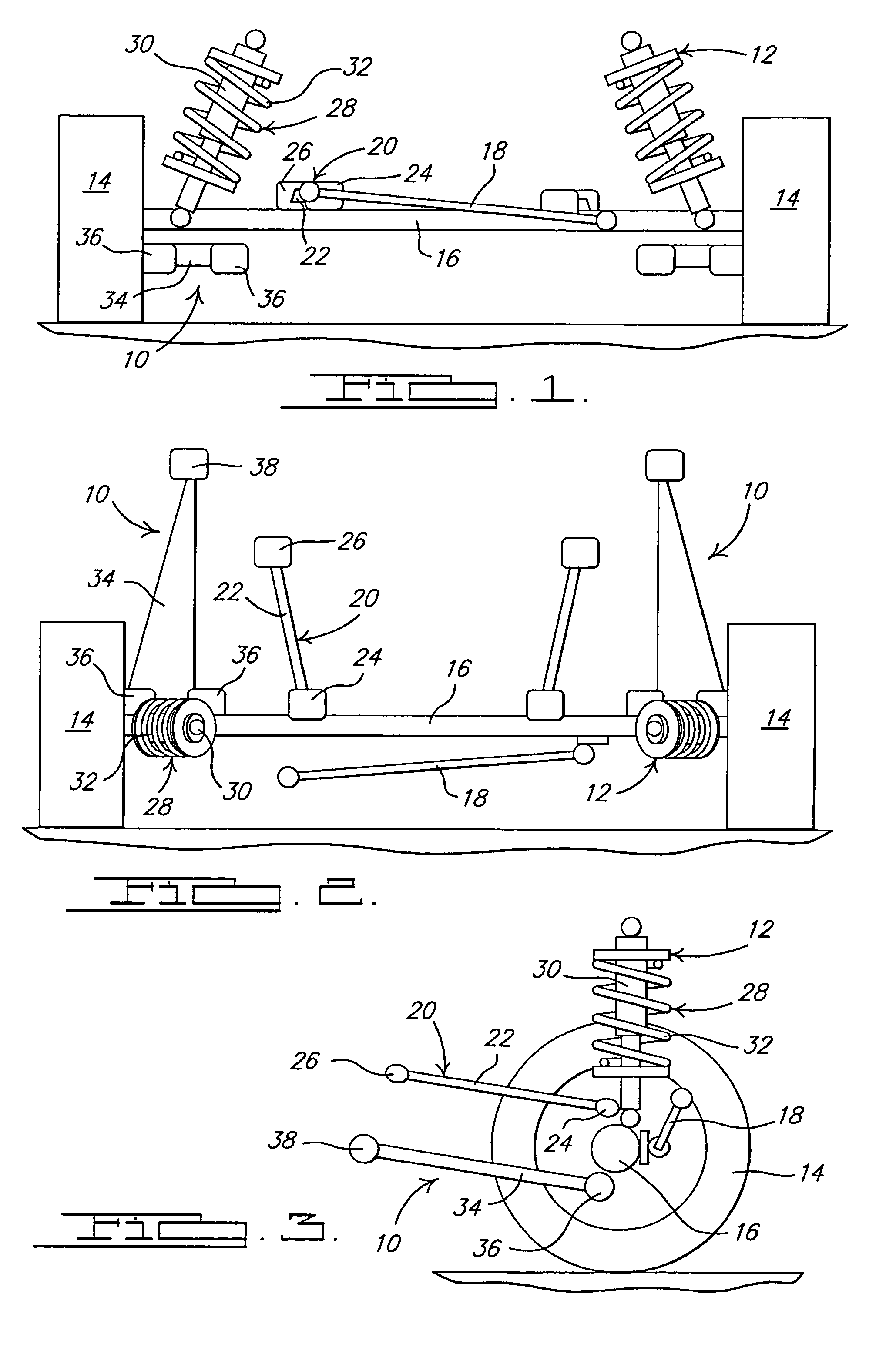

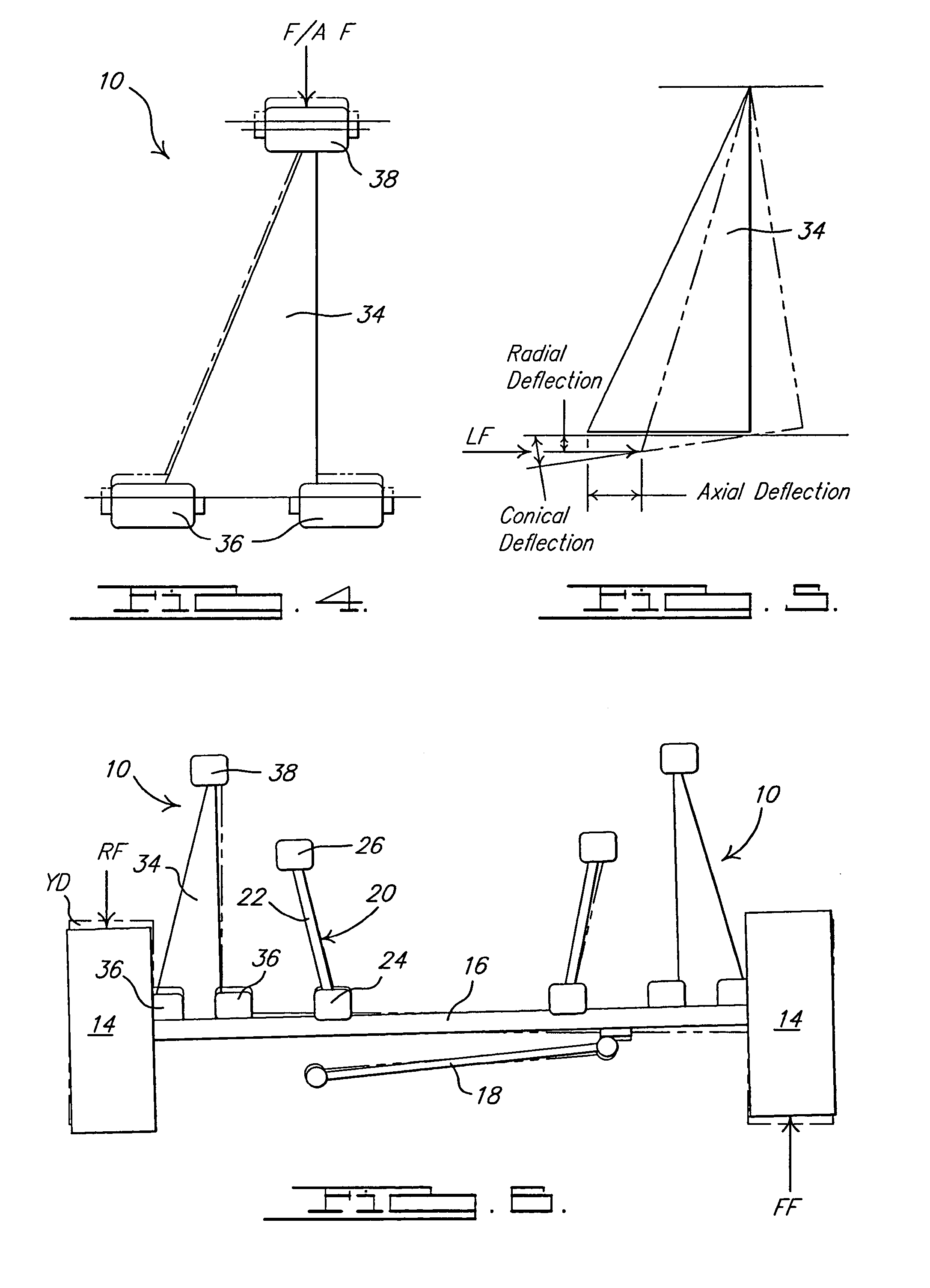

In a front wheel drive vehicle a traditional twist beam axle suffers from a short service life due to premature failures in intermediate areas between the end sections and the transitional section. A twist beam suspension is provided comprising a transverse strut (16) interconnecting longitudinal control arms (12). The transverse strut (16) may be formed from a tubular pipe. The tubular member may define a pair of tubular end sections (18), a deformed, U-shaped transitional section (20), and a pair of intermediate sections (22) between the end sections (18) and the transitional section (20). The intermediate section (22) may define a contour (28), known as a tongue. The tongue (28) enhances the flexibility in torsion and improves the stiffness in bending of the transverse strut (16). The tongue (28) may also include a concavity, to further aid in improving stiffness.

Owner:MAGNA INTERNATIONAL INC

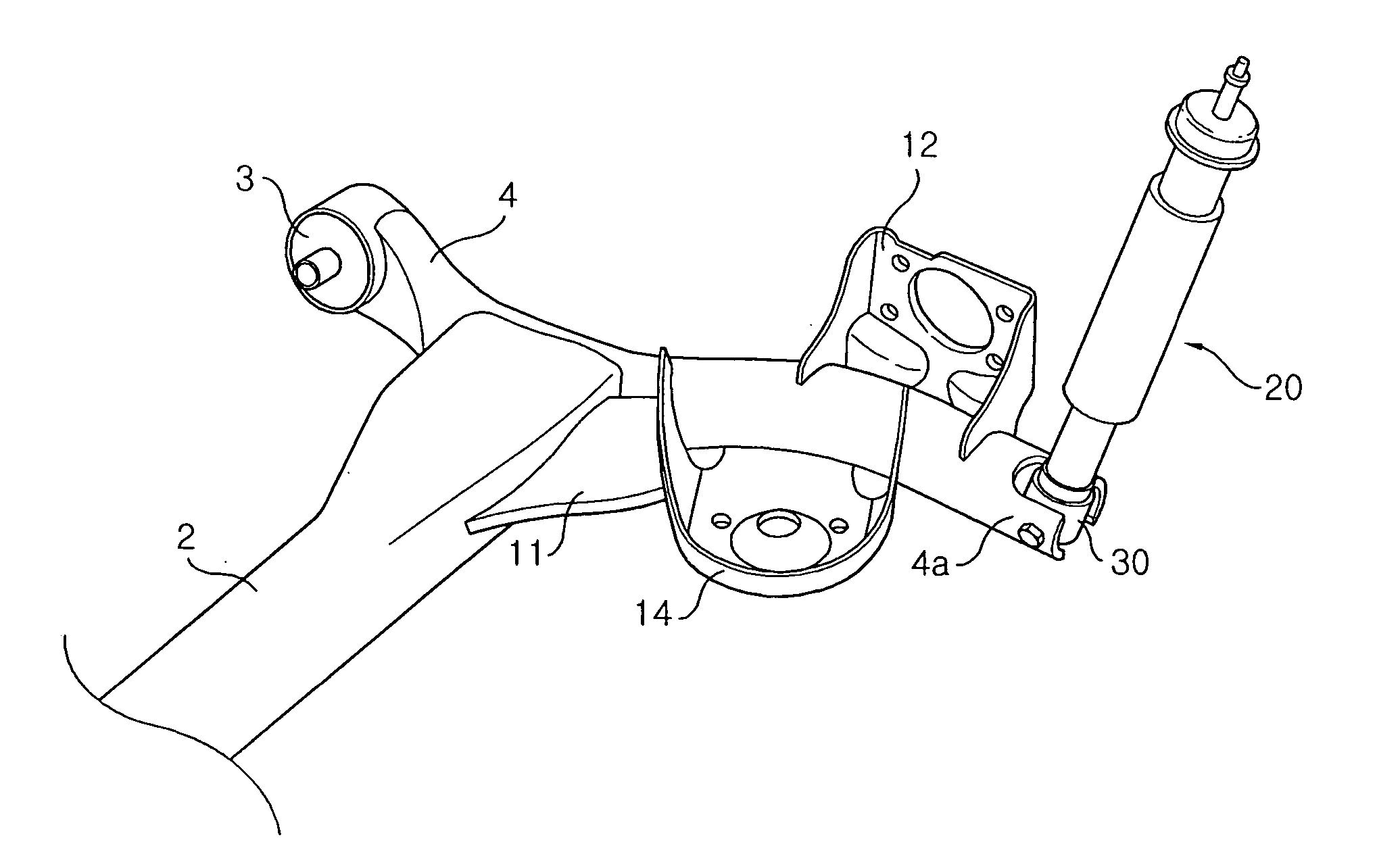

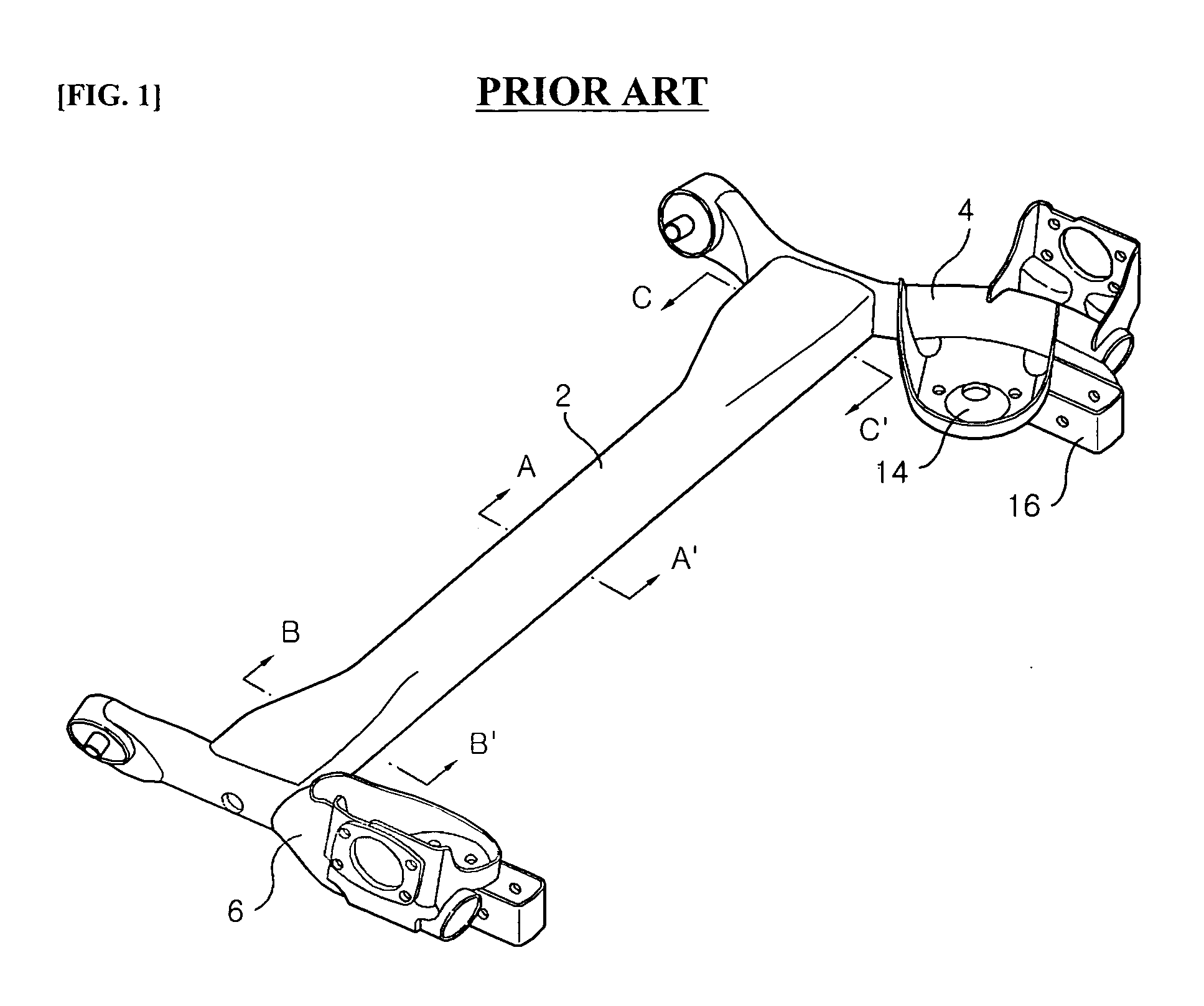

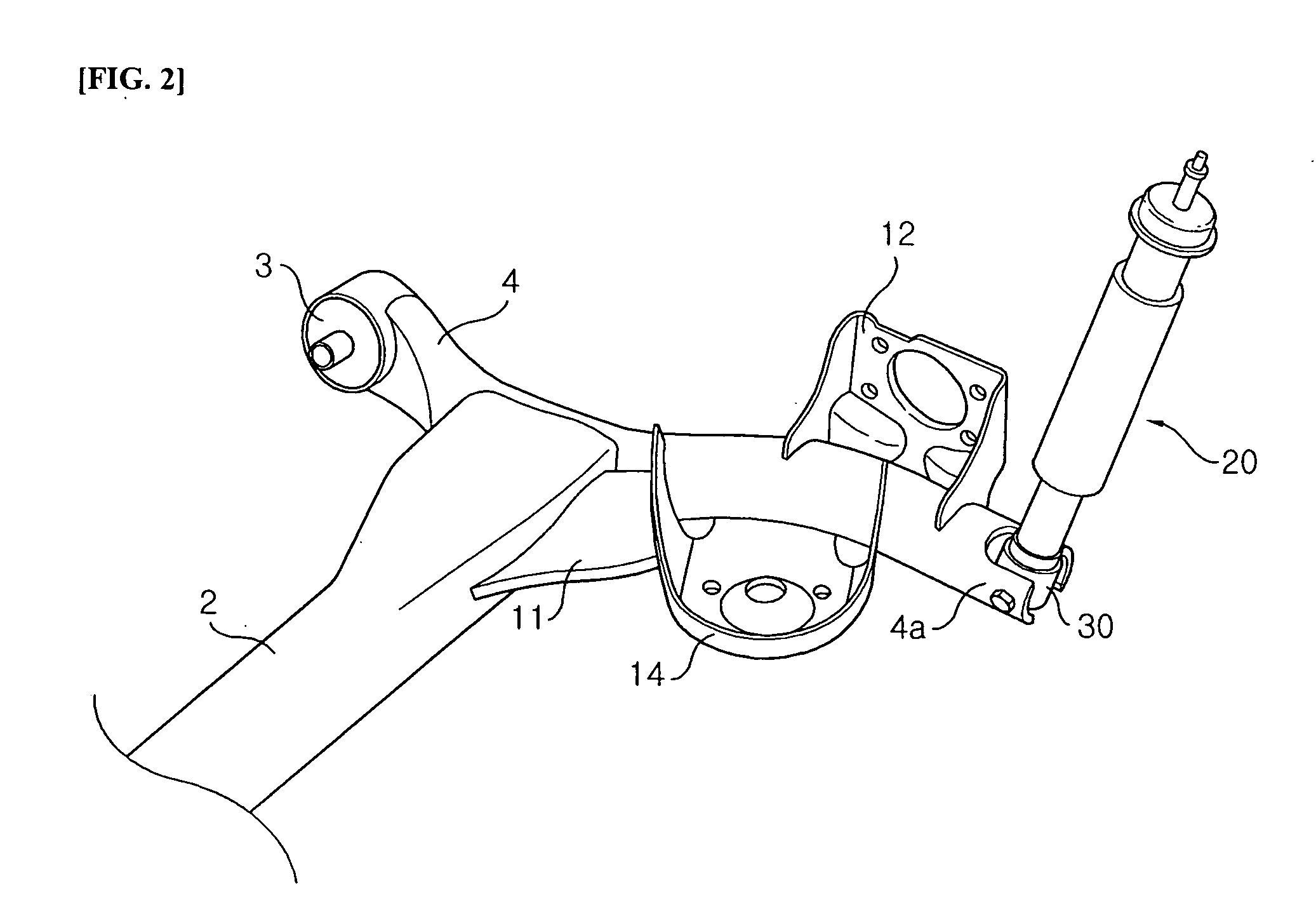

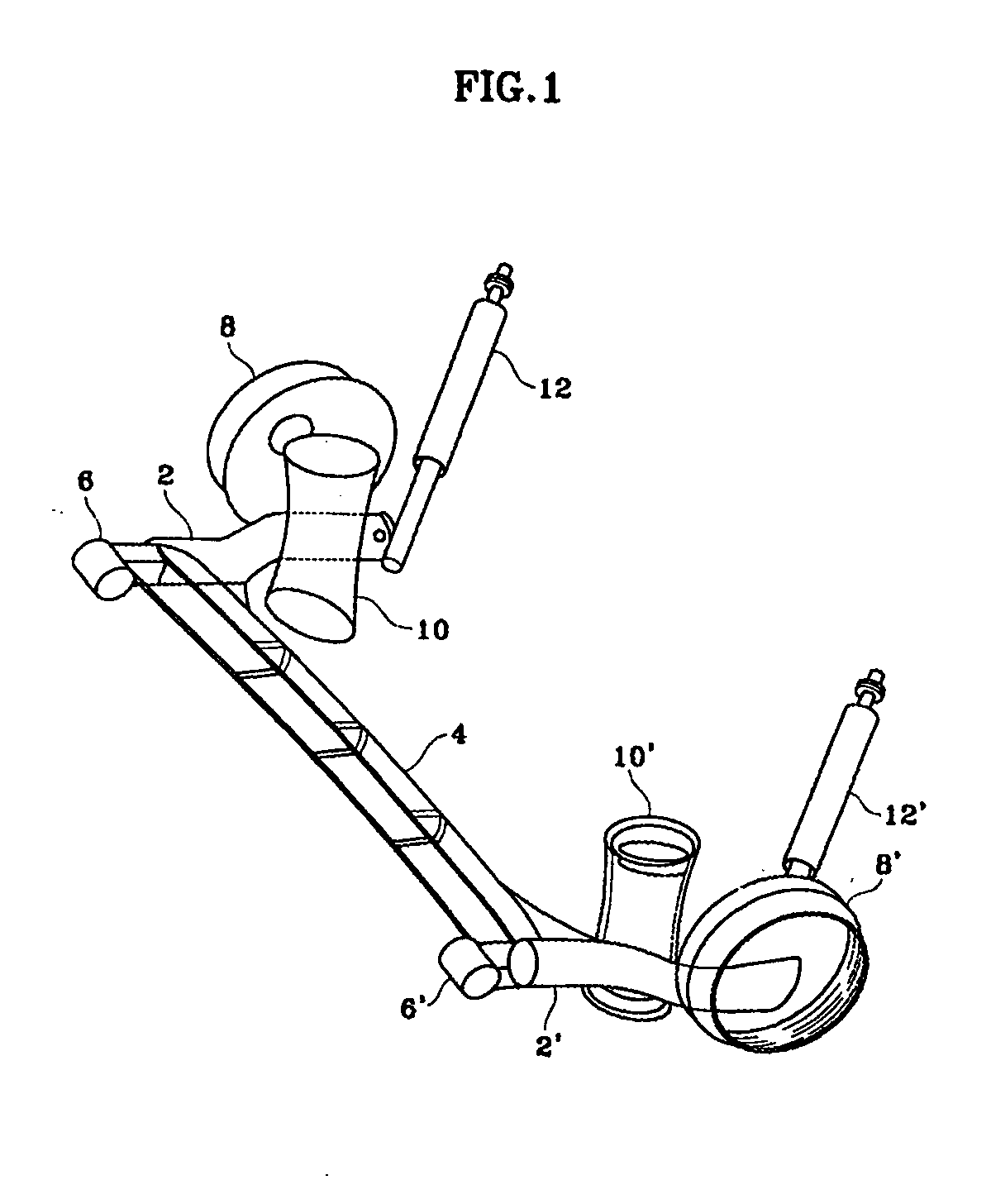

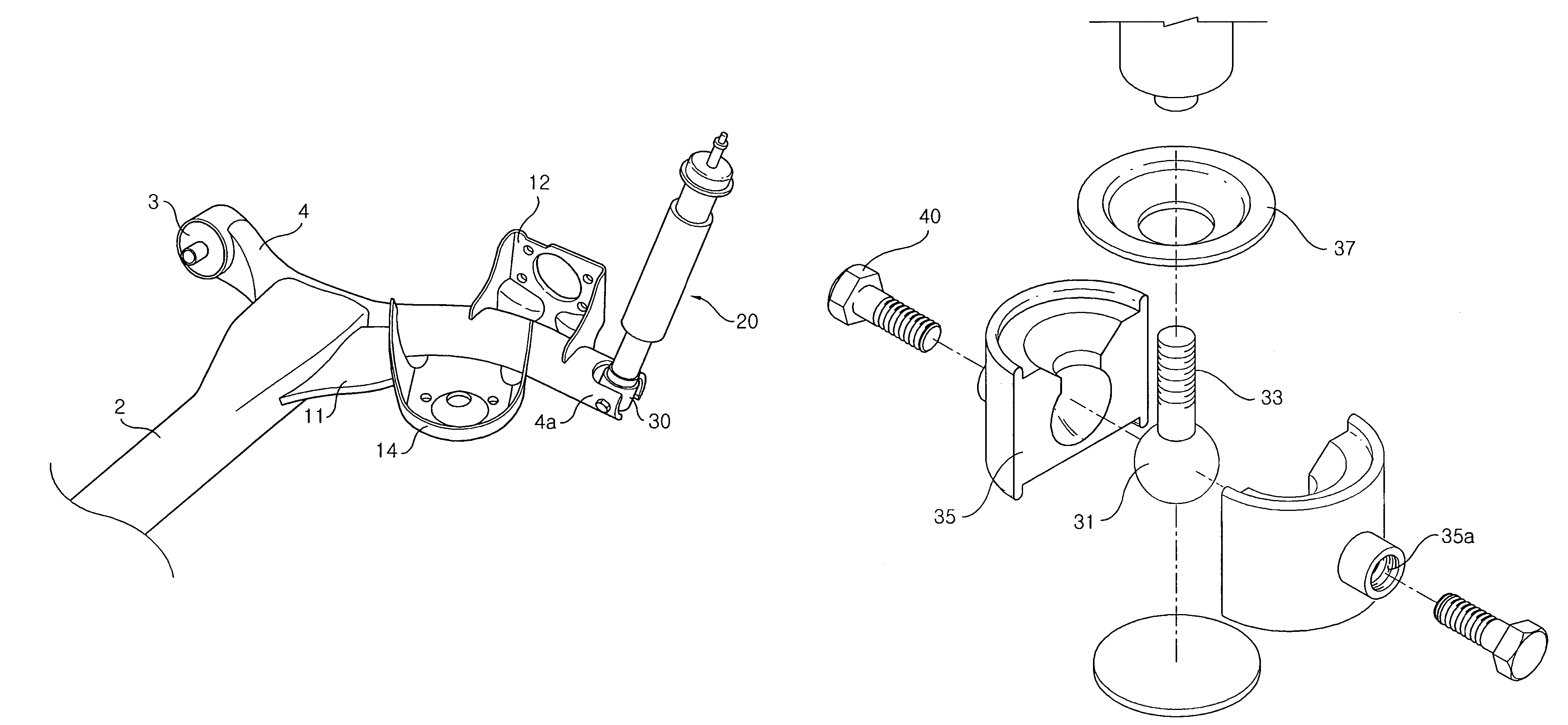

Torsion beam axle suspension

InactiveUS20050099060A1Reduce production expenseReduce weightCouplings for rigid shaftsInterconnection systemsEngineeringBall joint

A torsion beam axle suspension is provided, in which a shock absorber is directly mounted on right and left trailing arms and is further mounted to the mount by a ball joint. Thus, it is possible to reduce the weight and production expenses, thus to enhance productivity. Further, it is possible to considerably decrease a friction caused by movement of the shock absorber even though the transverse force is applied, thus to enhance the riding comfort.

Owner:HYUNDAI MOBIS CO LTD

Twist Beam Axle with Integral Torsion Bar

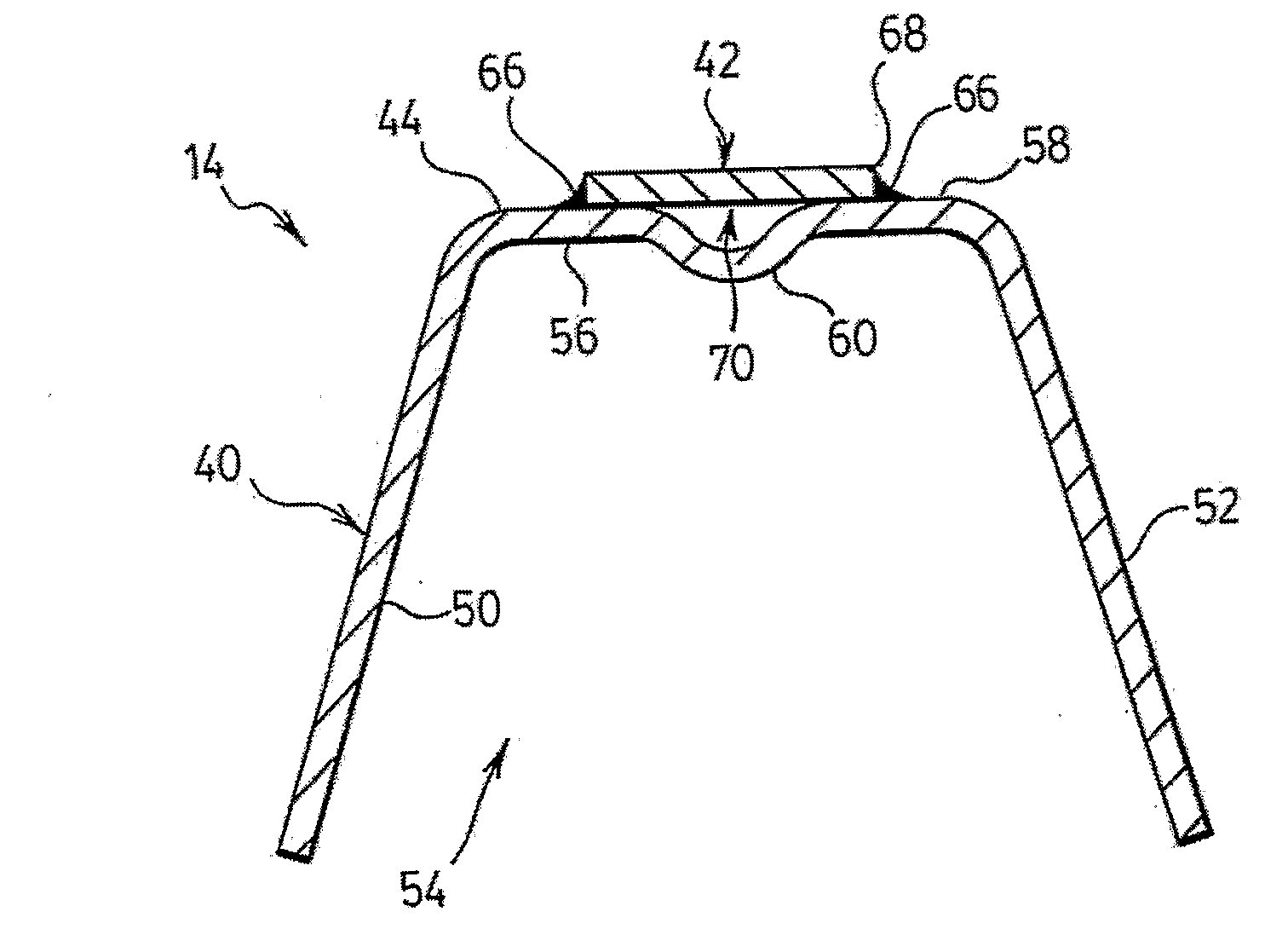

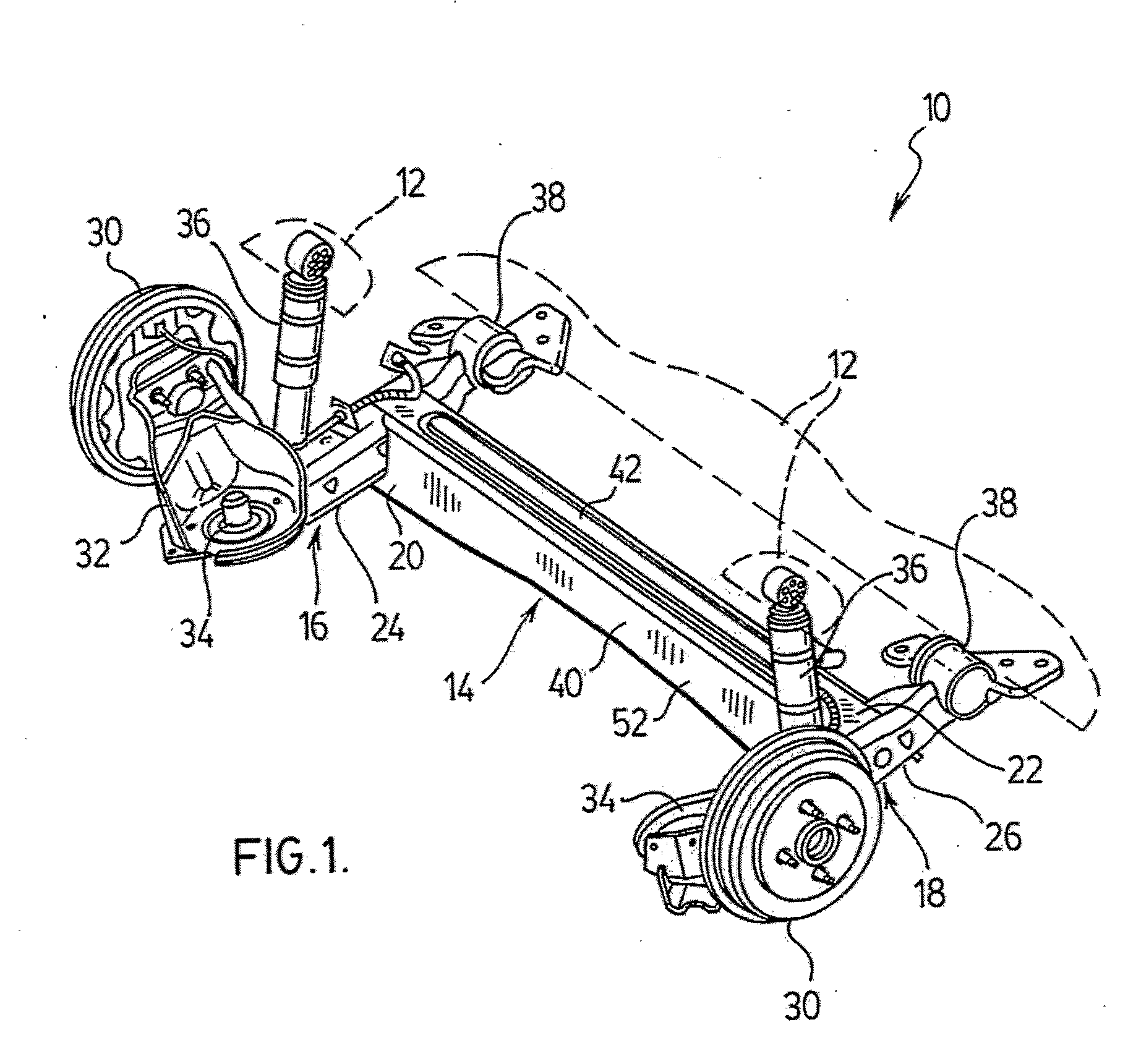

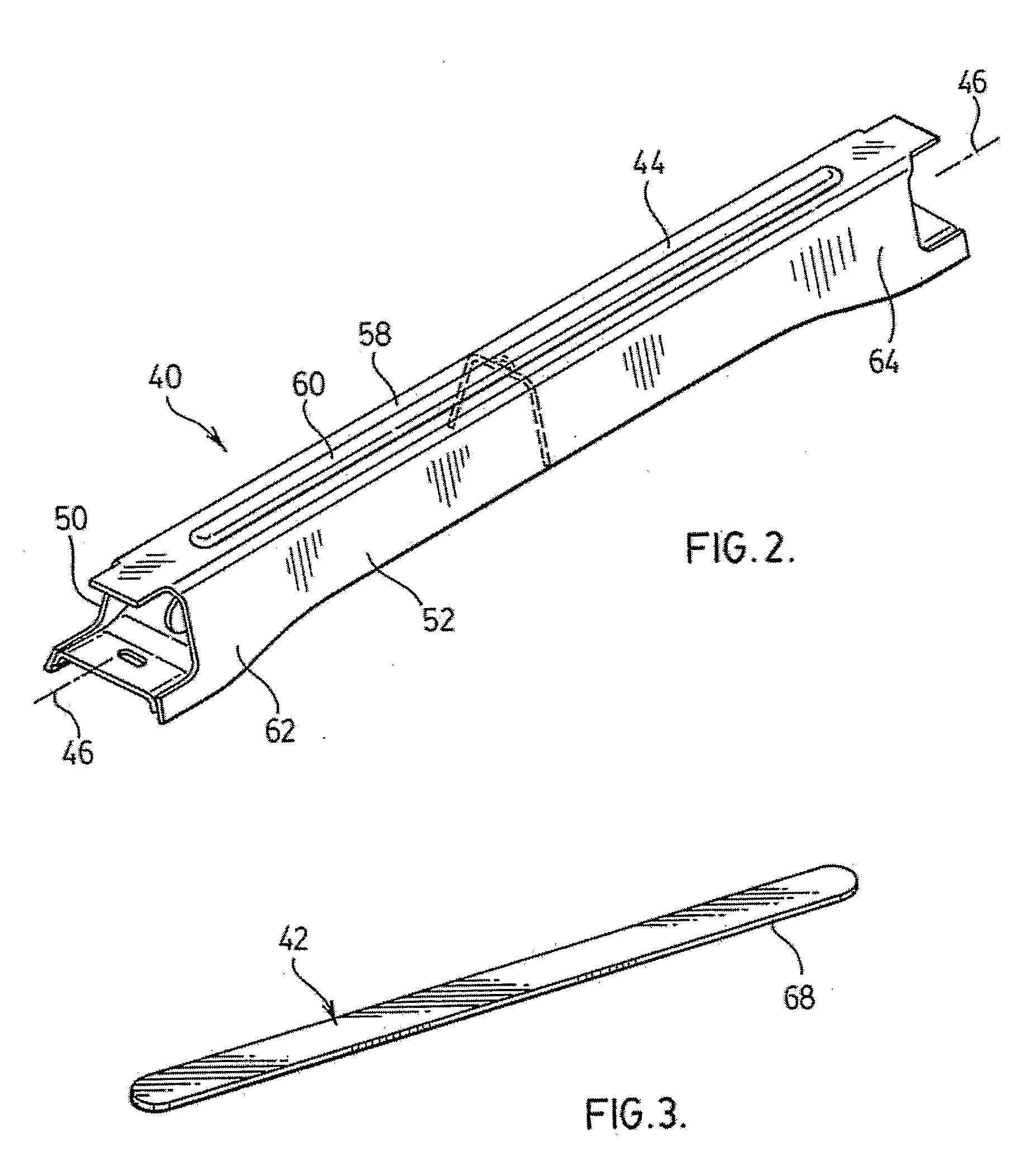

A traditional twist beam axle found in a vehicle includes a twist beam with a separate torsion beam or a hollow tube formed into an inverted U shape that acts as both the twist beam and the torsion beam. Both solutions are expensive to manufacture A twist beam axle (14) is provided wherein the torsion member (42) is rigidly secured to the twist beam (40) The twist beam (40) has a U-shaped cross-sectional configuration having a bight portion (44) with first (50) and second (52) projections extending therefrom Embodiments include the cross-sectional configuration having an open cavity and the bight portion (44) having an indentation into the open cavity and forming a depression that is covered by the torsion member (42) A method of forming the disclosed twist beam axle (14) is also provided, the method including the step of rigidly securing the torsion member (42) to the bight portion (44) of the twist beam (40)

Owner:MAGNA INTERNATIONAL INC

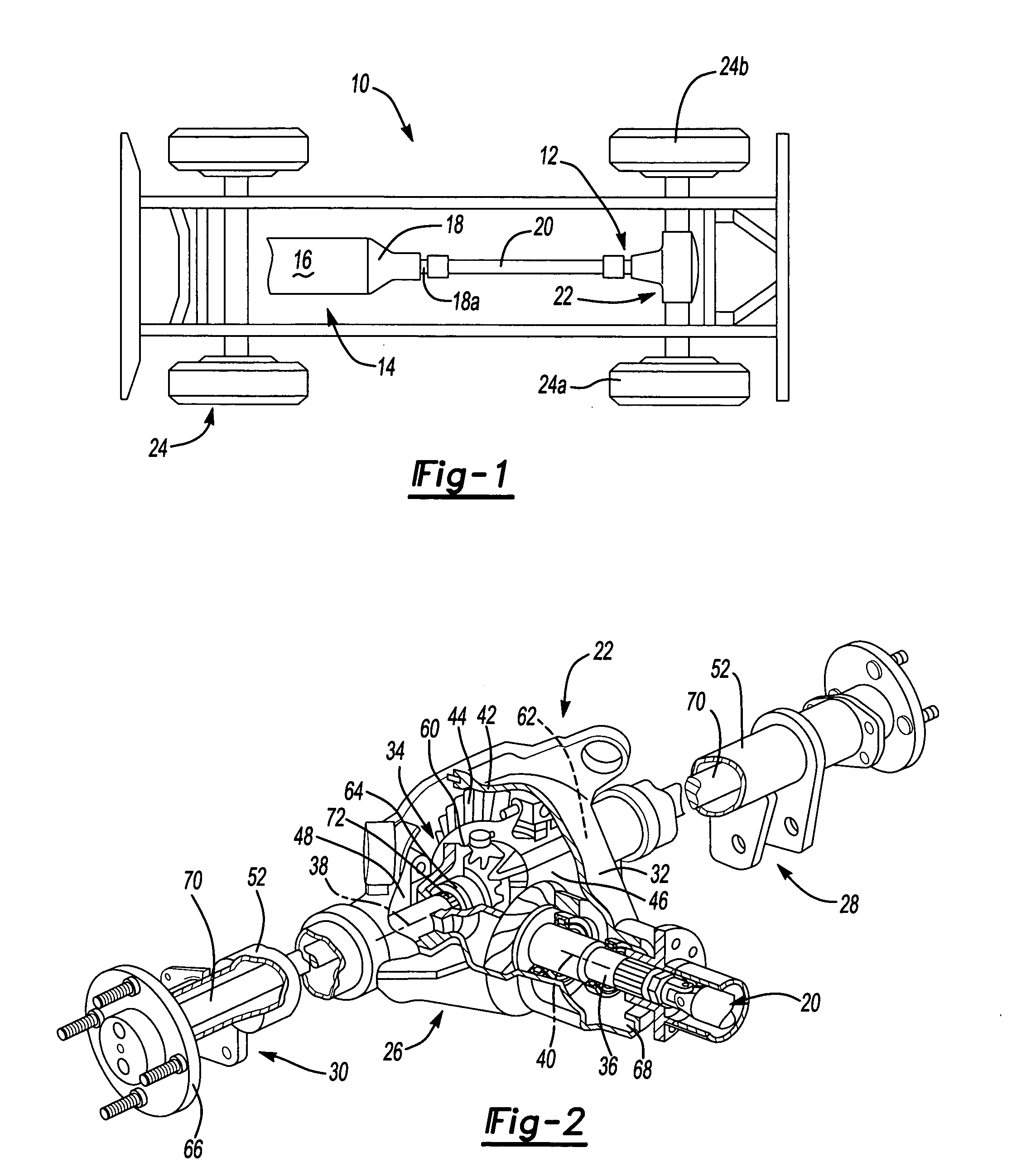

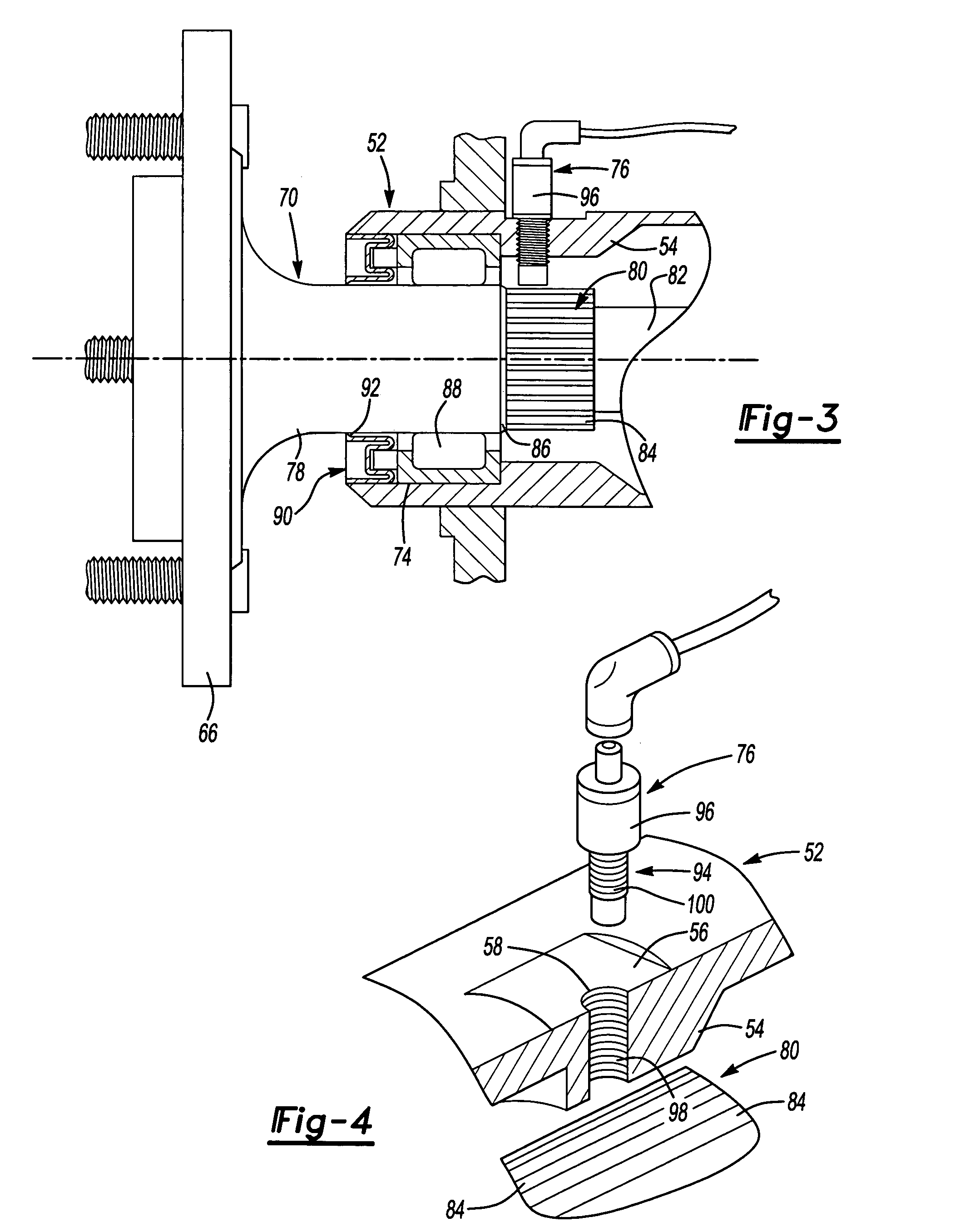

Beam axle with integral sensor mount and target

A vehicle axle assembly having an axle housing, an axle shaft and a sensor. The axle housing has a tubular portion. A flat is formed on an annular wall of the tubular portion proximate a distal end of the tubular portion. A hole, which intersects the flat, is formed through the tubular portion. The axle shaft can have an integrally formed target portion that includes a plurality of teeth. The sensor is mounted in the hole and abuts the flat to space a tip of the sensor apart from the teeth of the target portion by a predetermined distance.

Owner:AMERICAN AXLE & MFG

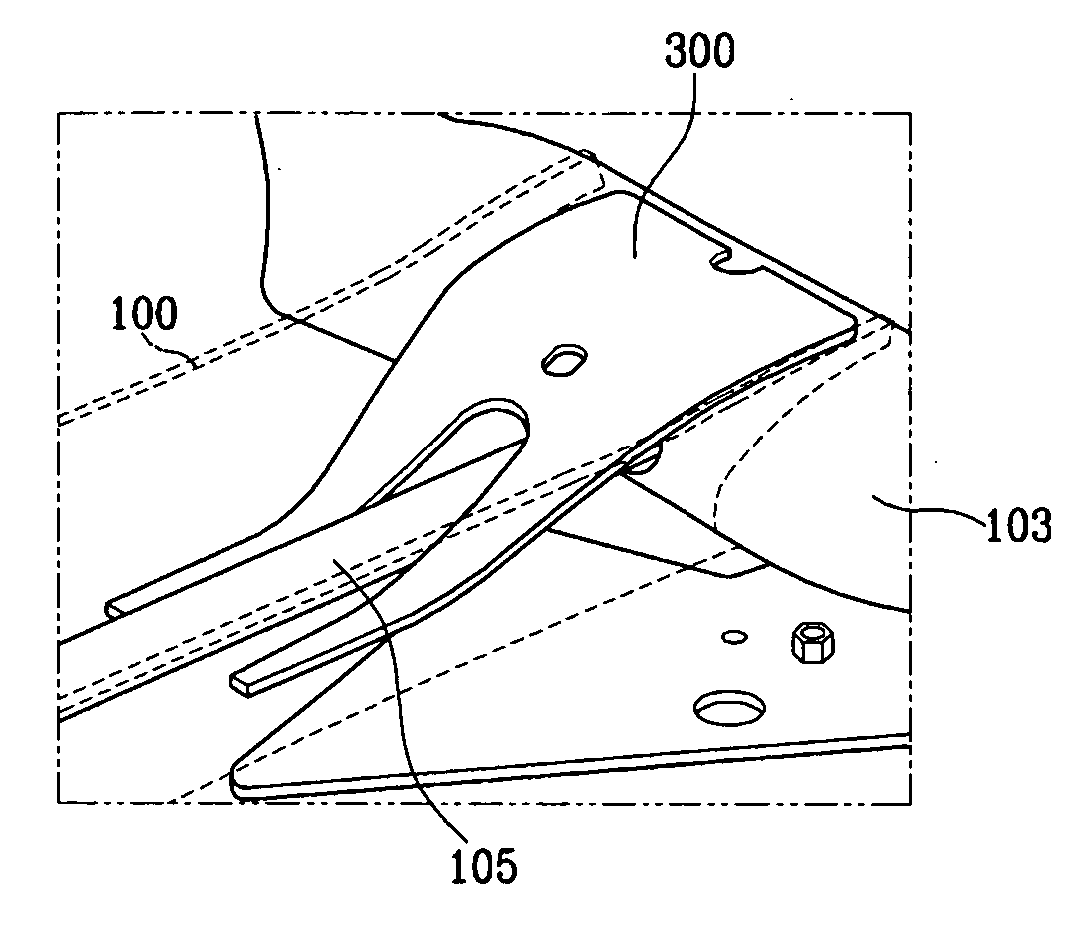

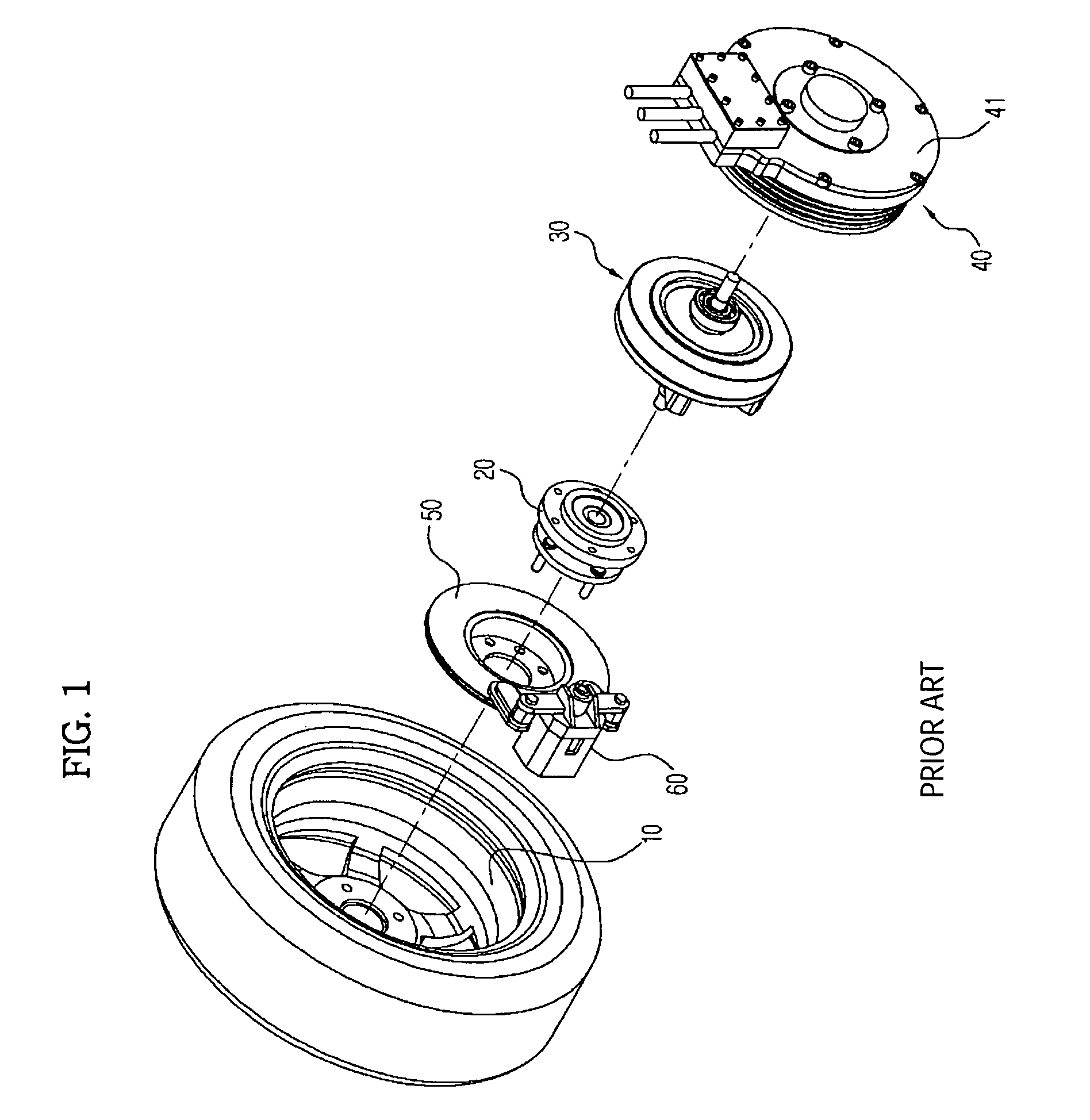

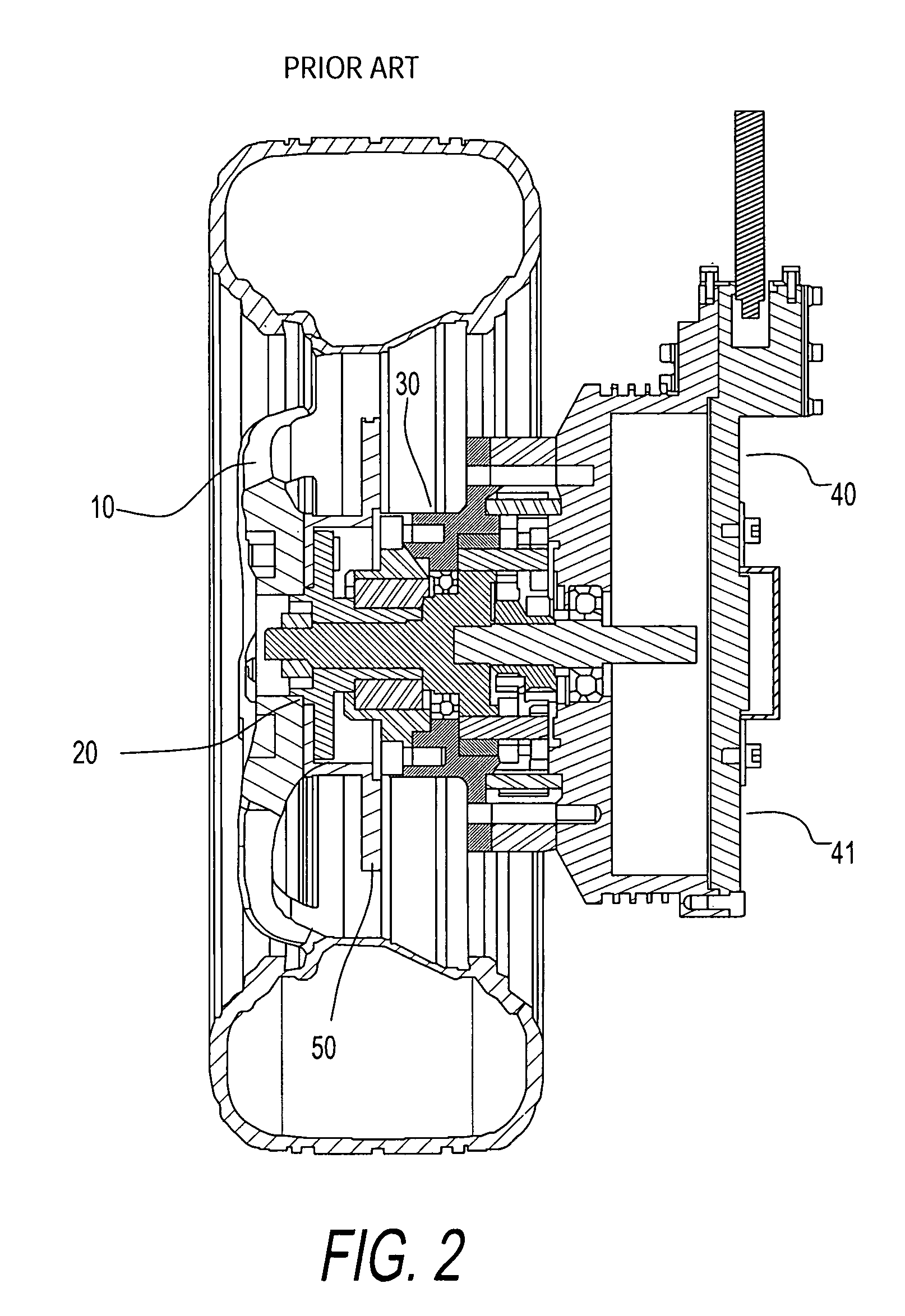

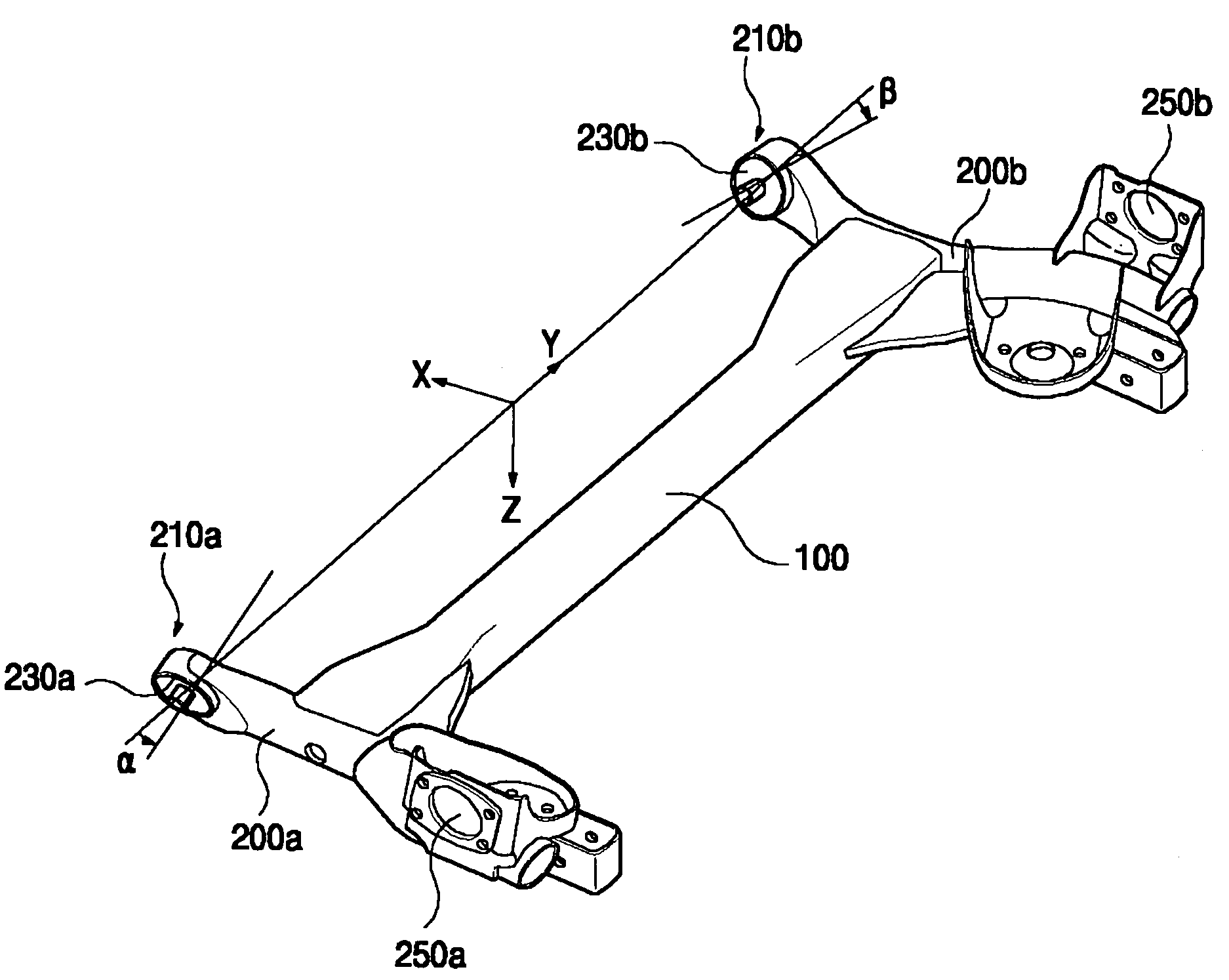

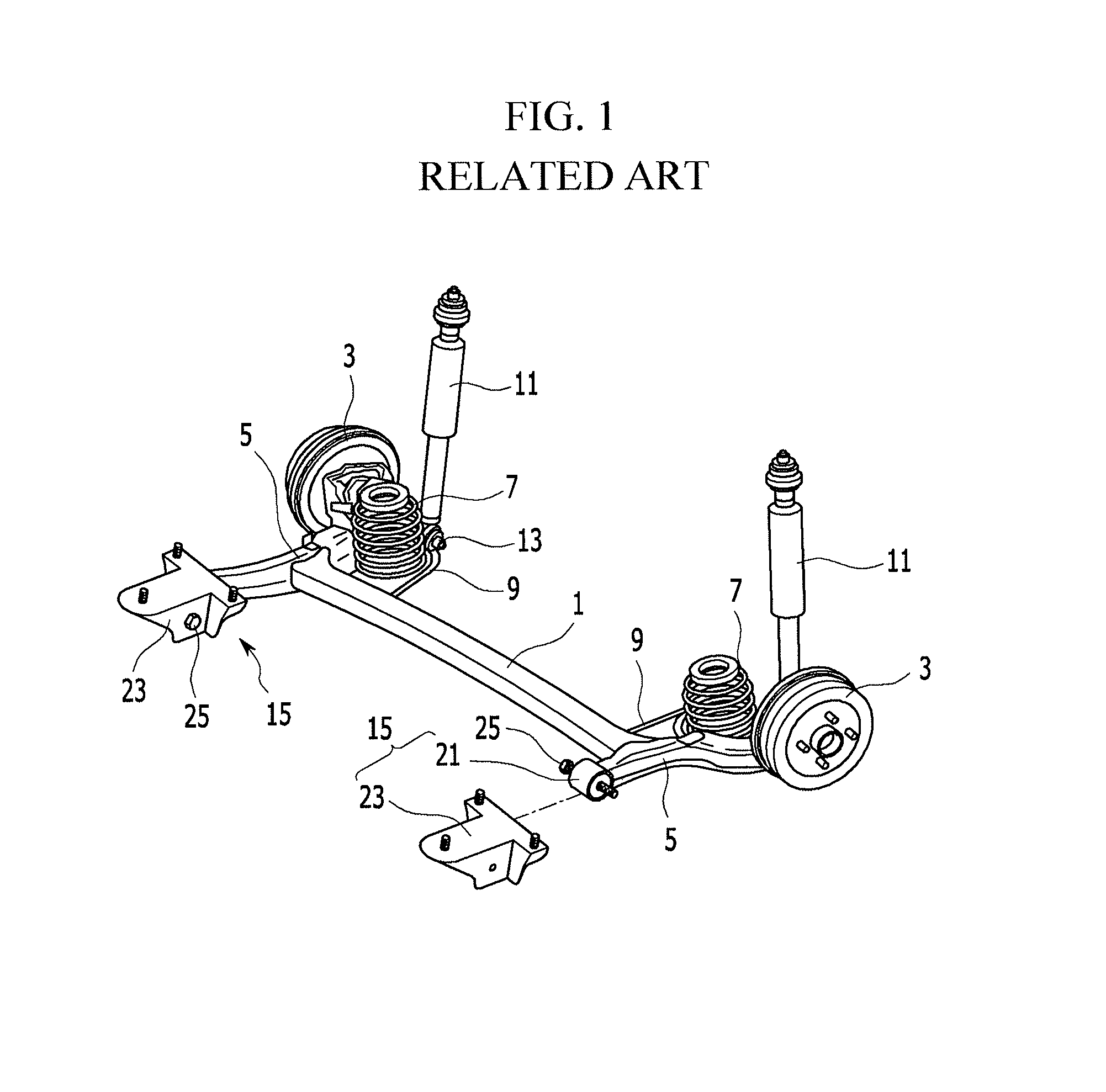

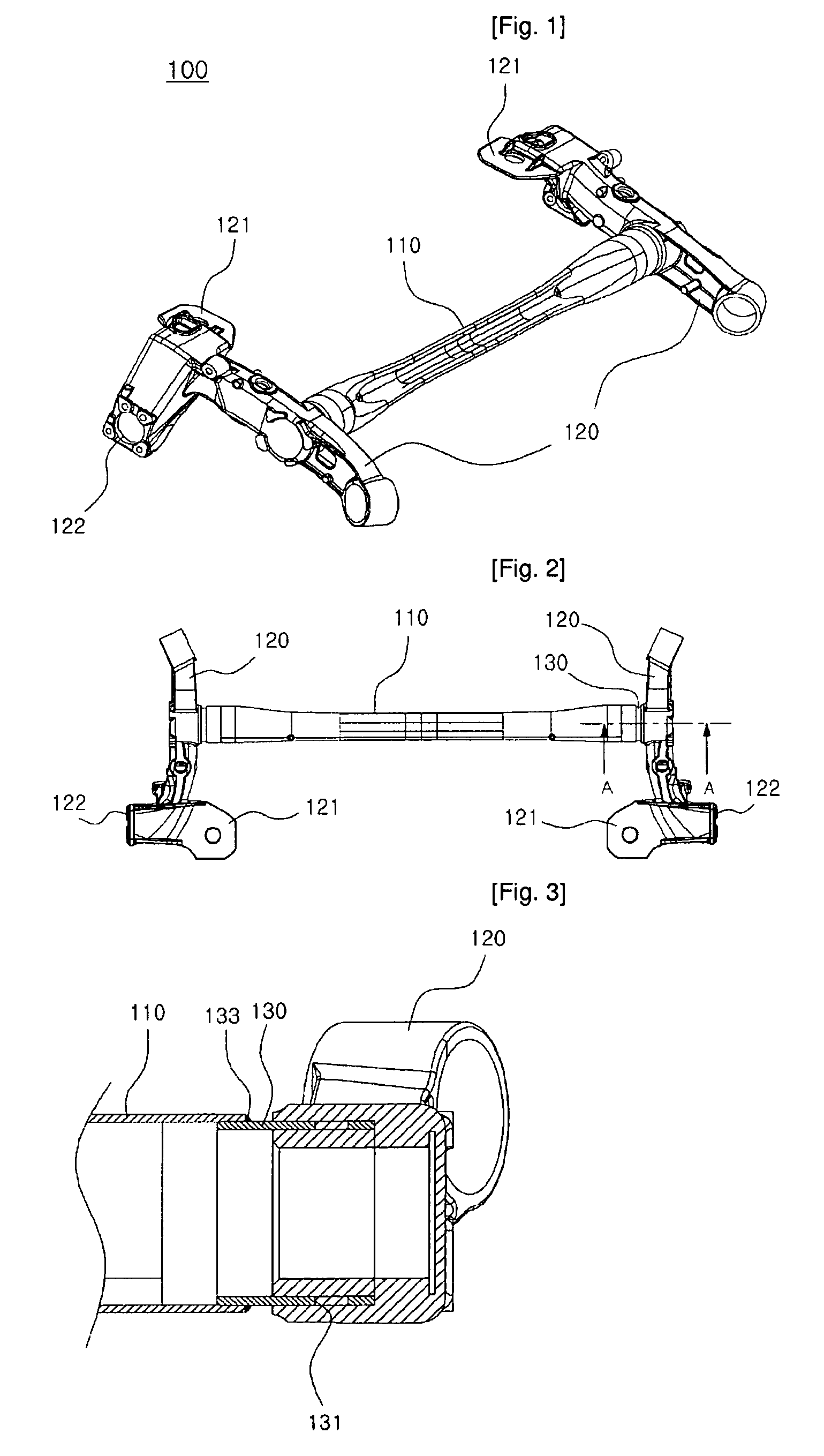

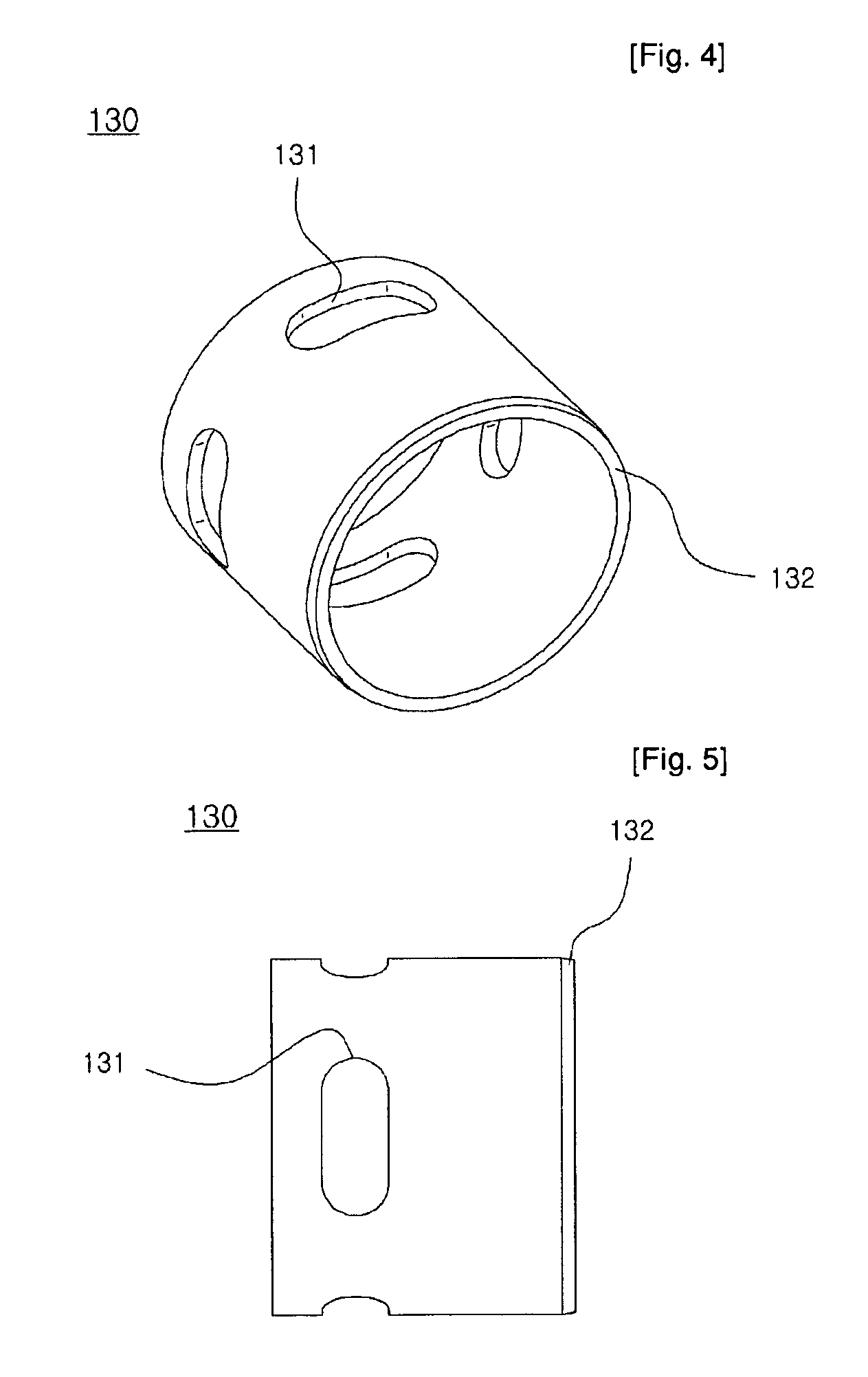

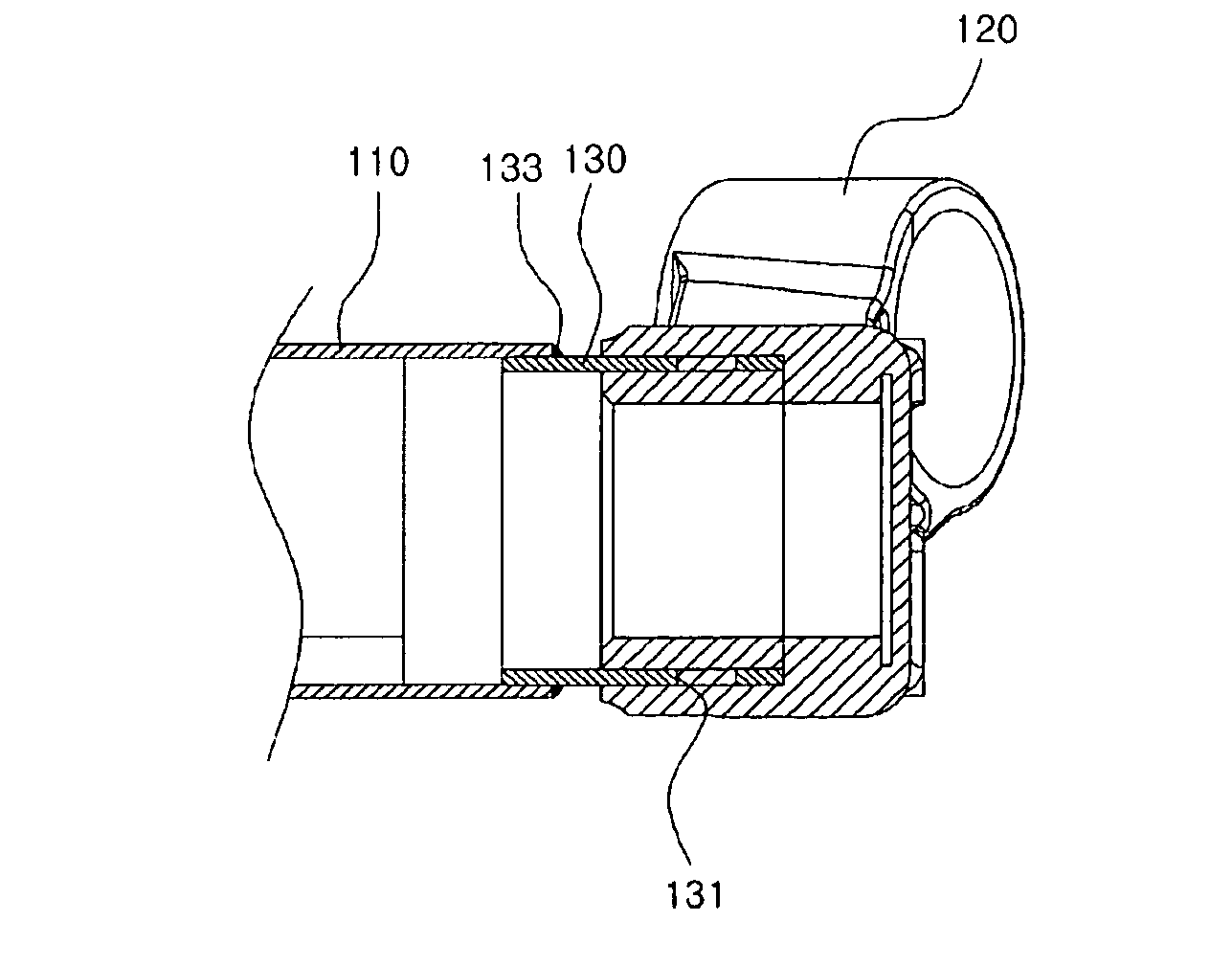

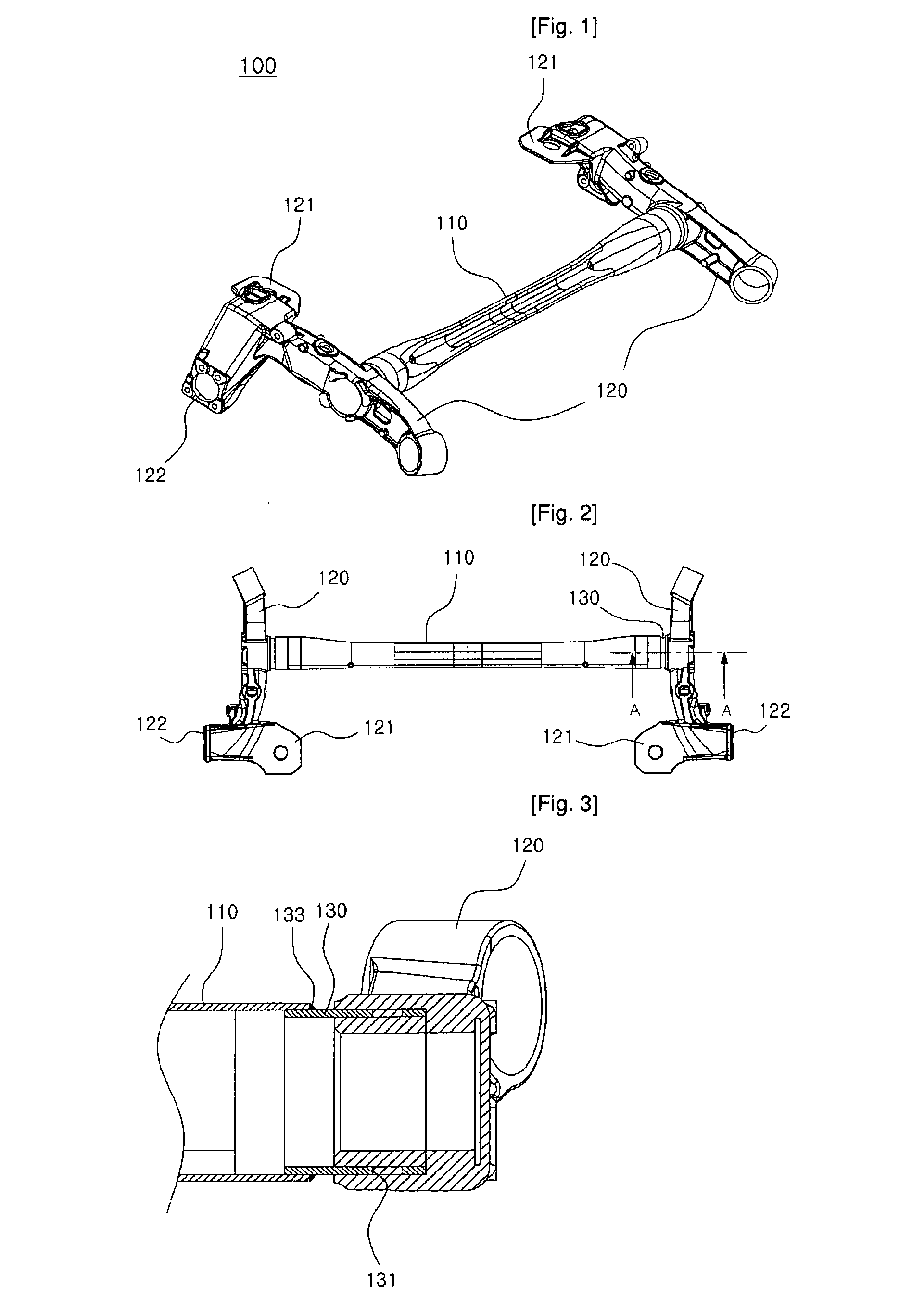

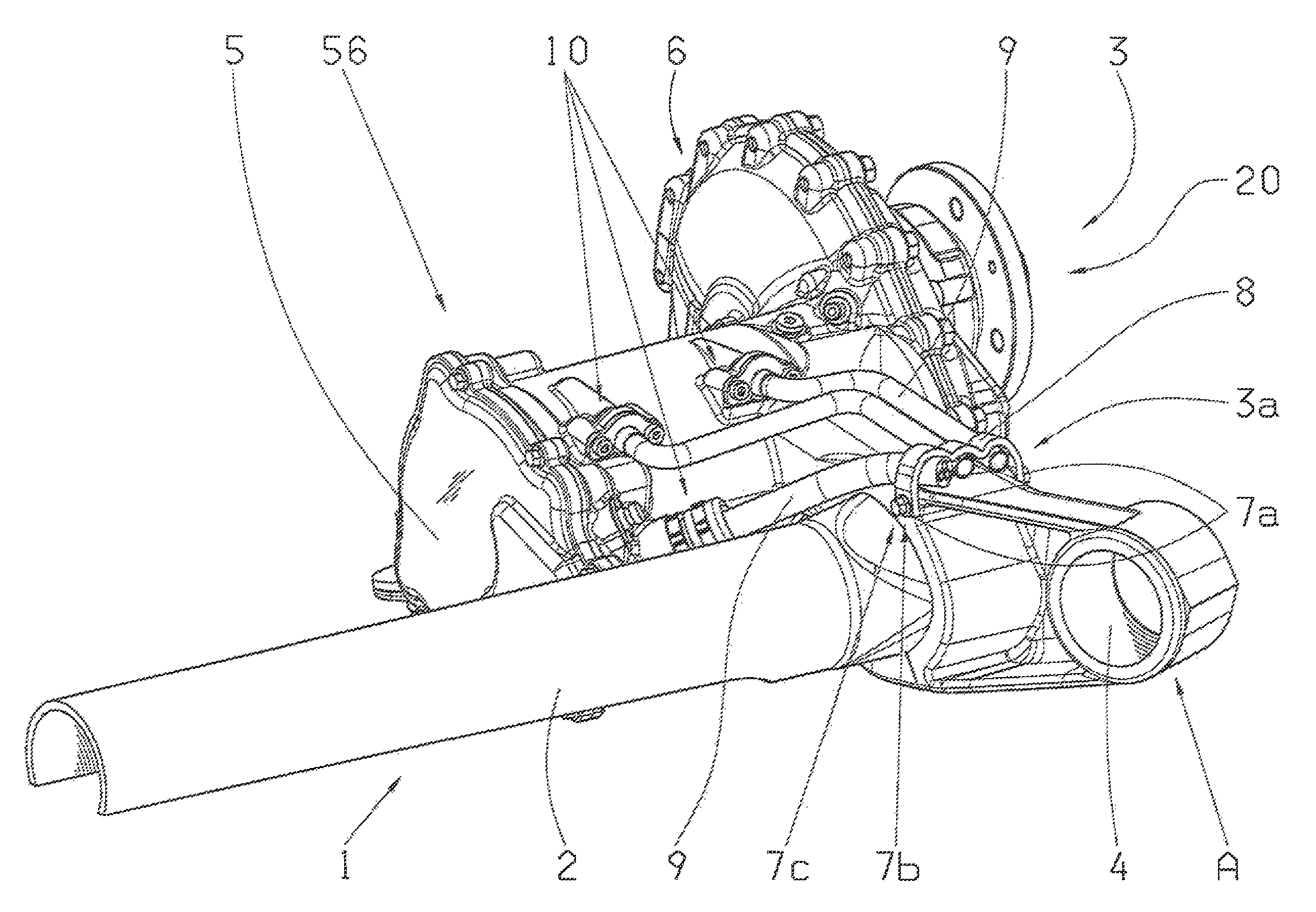

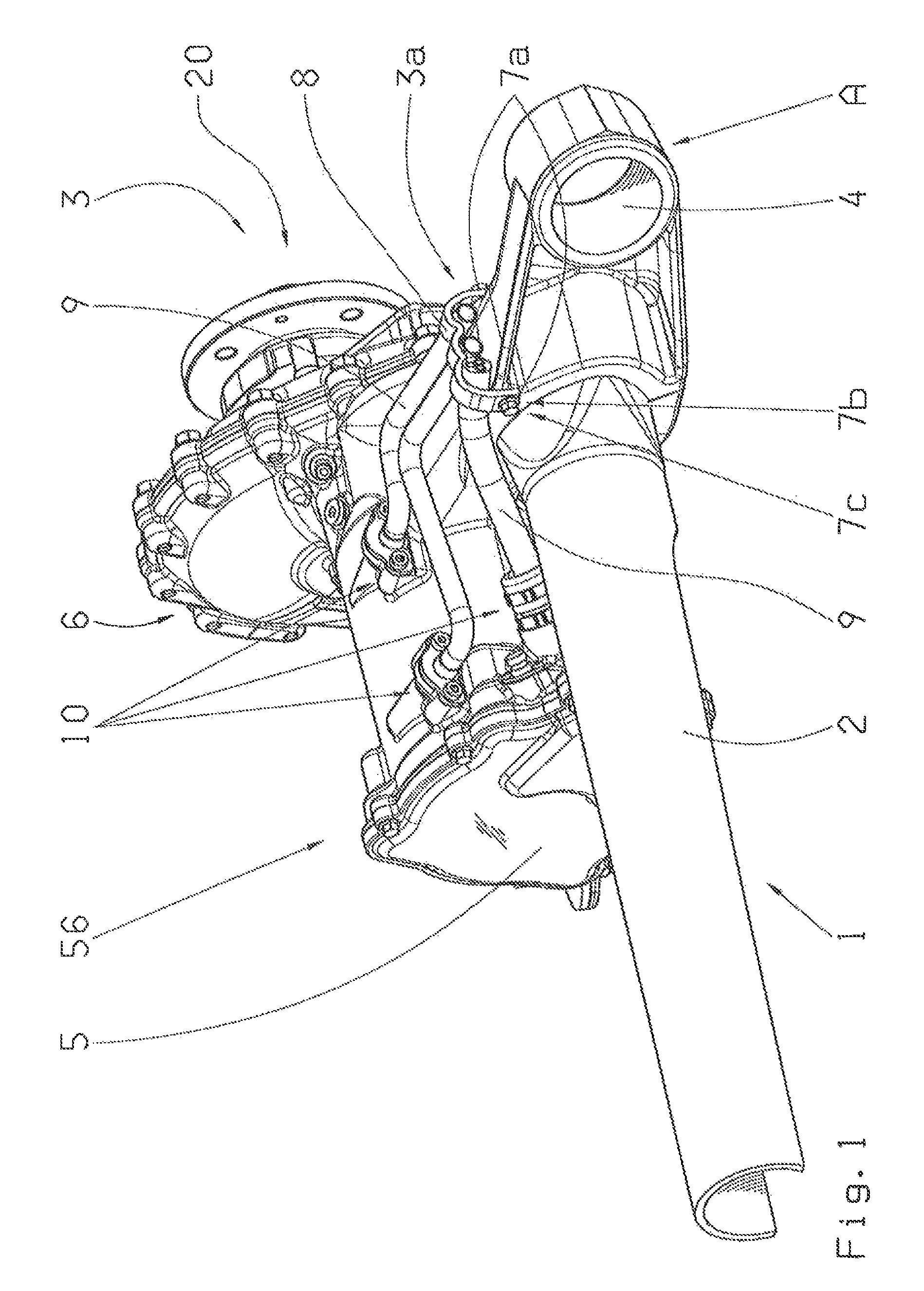

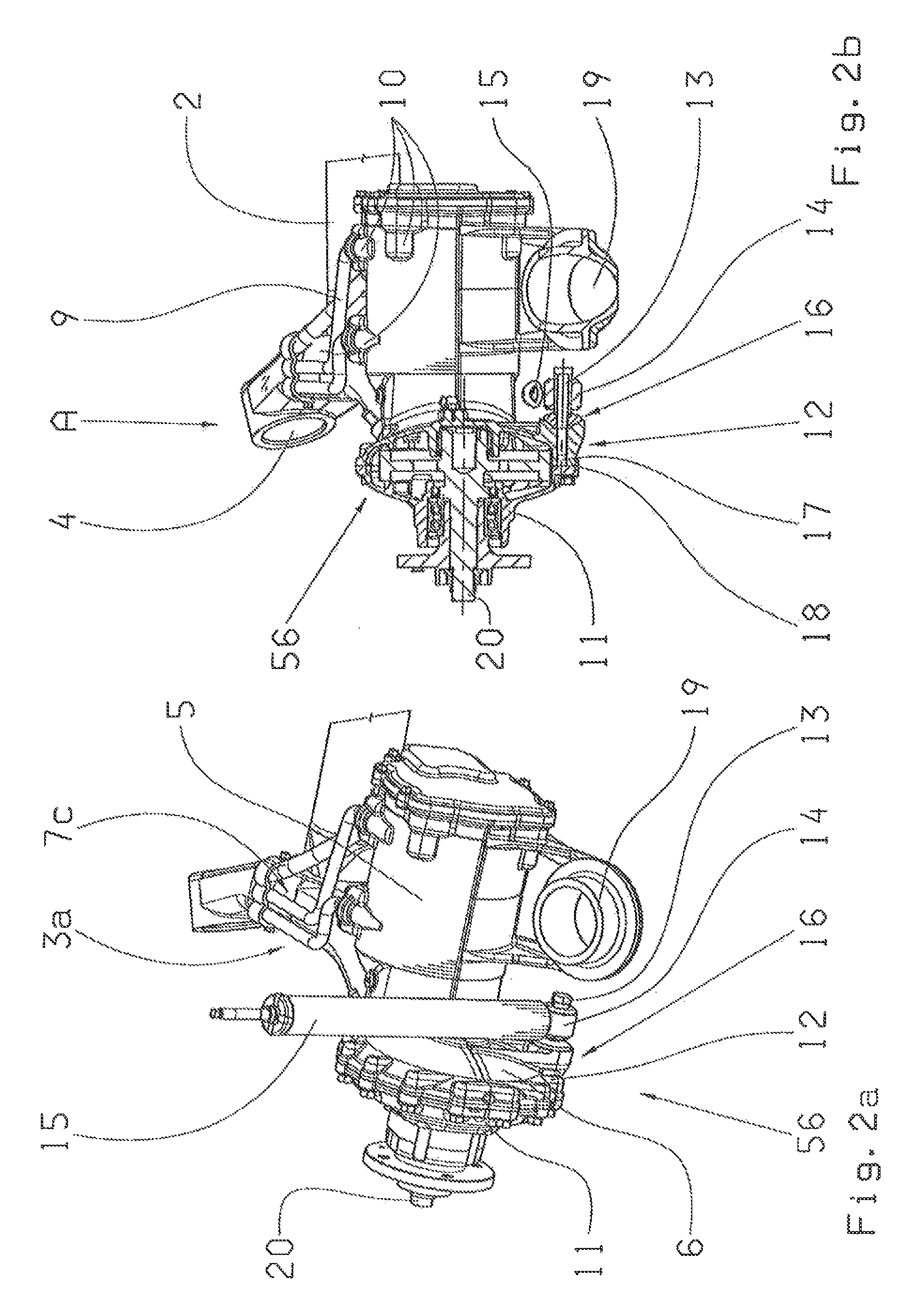

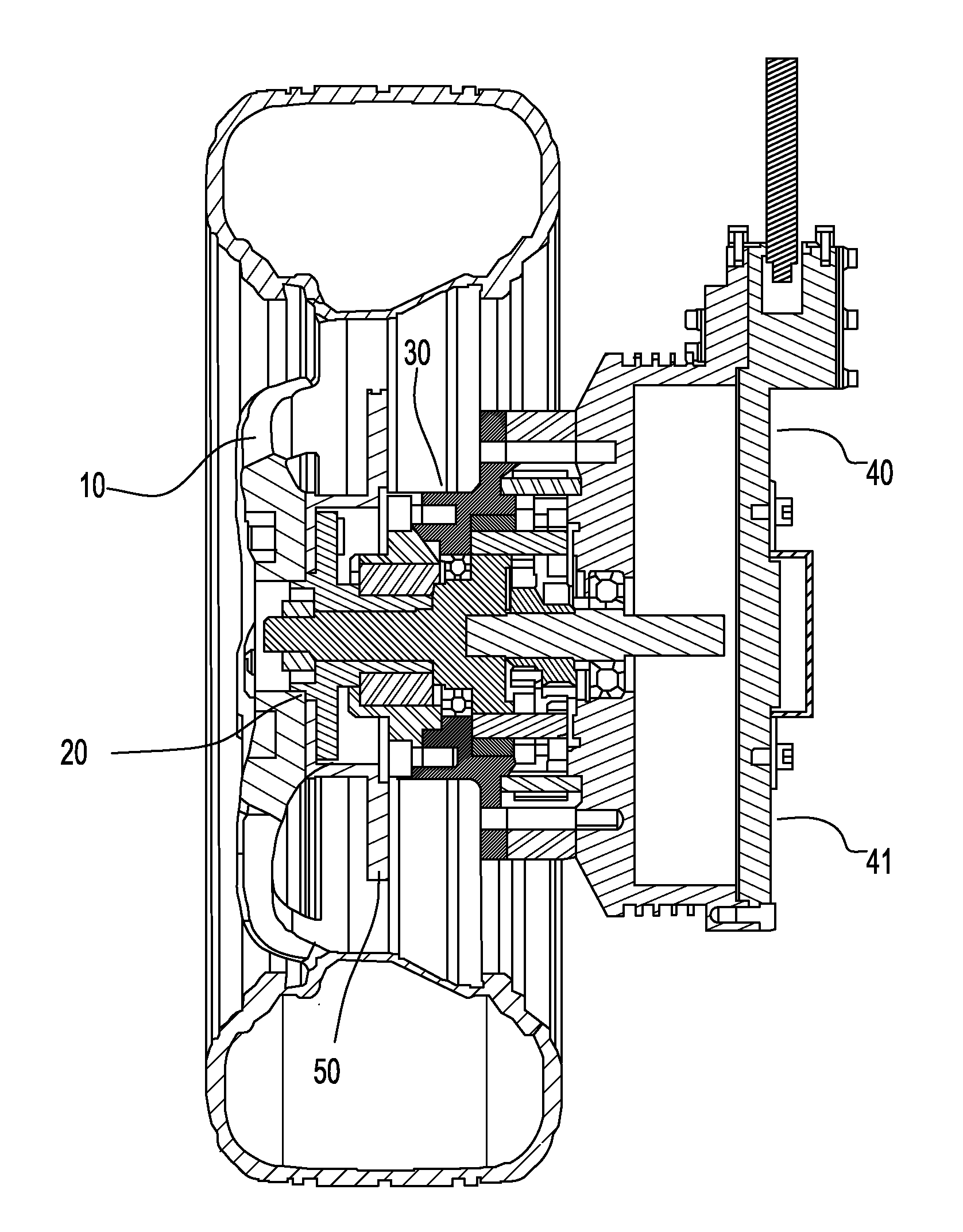

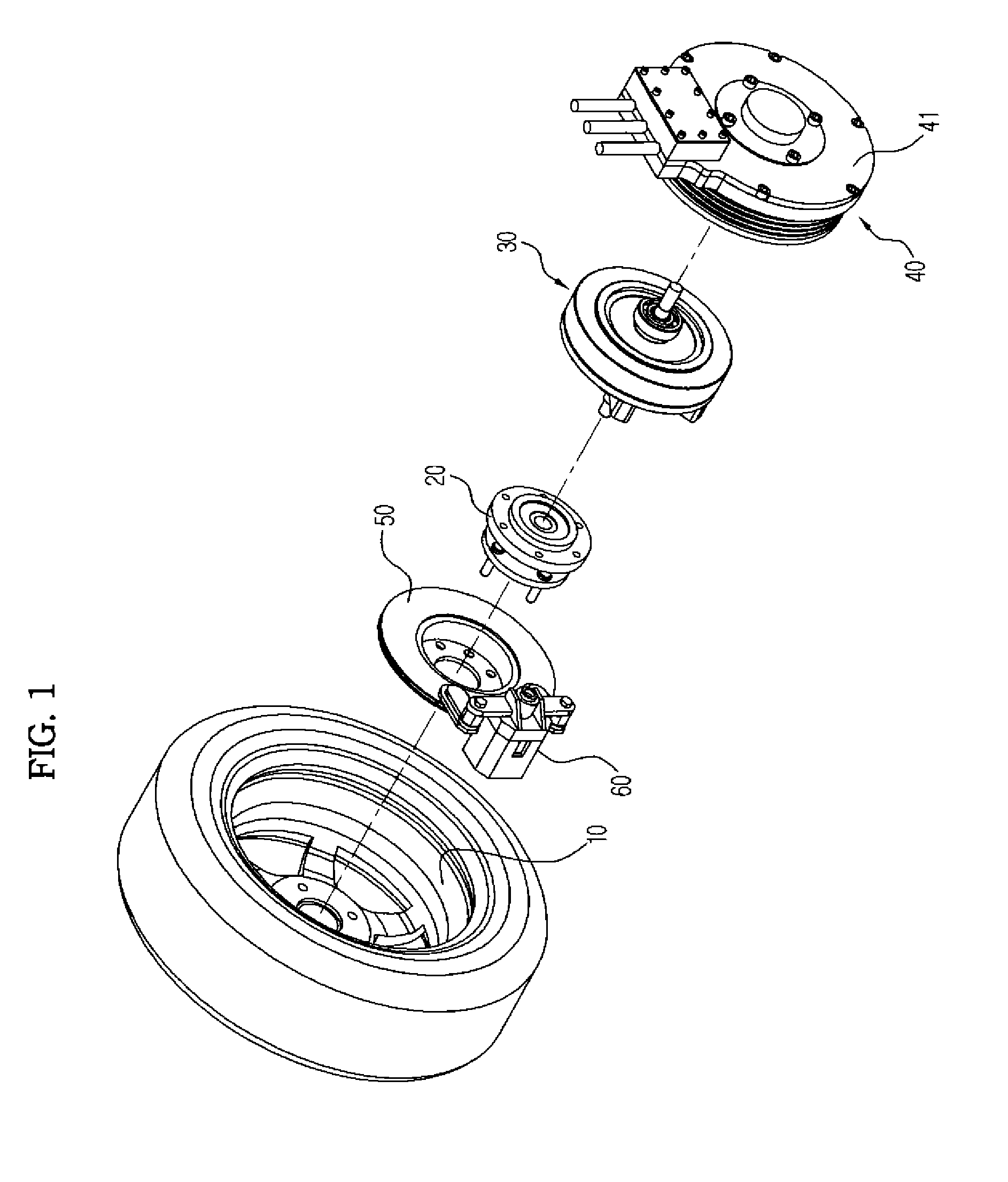

Mounting structure for in-wheel motor system

ActiveUS8863874B2Avoid damageFirmly connectedElectric propulsion mountingMotor depositionStileMotor system

A mounting structure for an in-wheel motor system is provided. The mounting structure includes the in-wheel motor system installed in a wheel of the vehicle, and a torsion beam axle (TBA) assembly to fix the in-wheel motor system to a vehicle body, wherein a rear portion of a motor housing includes a step portion formed in a stepped manner to have a decreased diameter, and a ring-shaped fastening face vertically arranged from the step portion, and the TBA assembly includes a trailing arm provided with a through hole to surround the step portion of the motor housing, a mount integrated with the trailing arm to fix the trailing arm to a vehicle body, and a plurality of fastening bolts to fix the motor housing to the trailing arm, wherein, when the step portion is fitted and coupled into the through hole, the fastening face closely contacts the trailing arm.

Owner:HL MANDO CORP

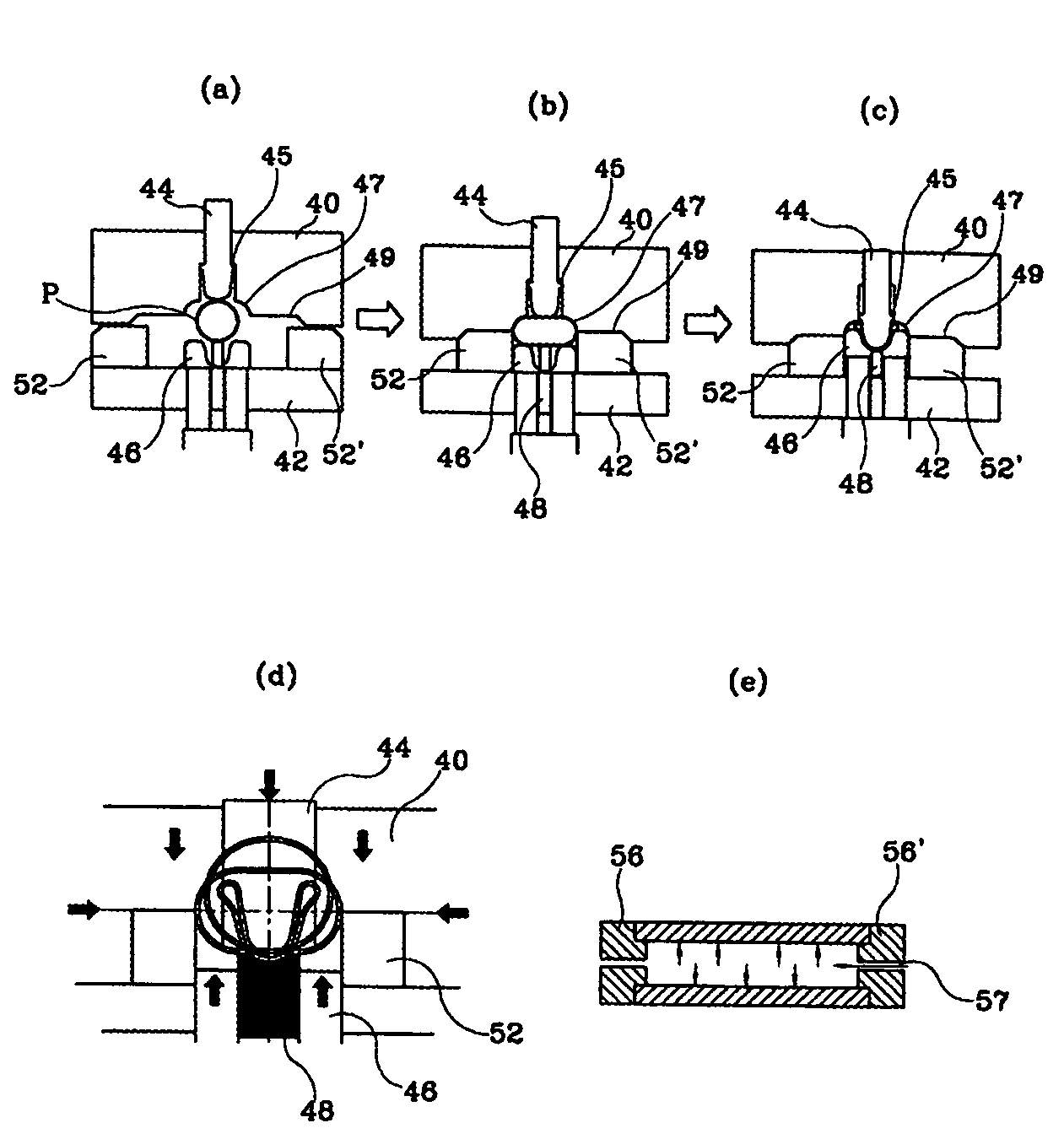

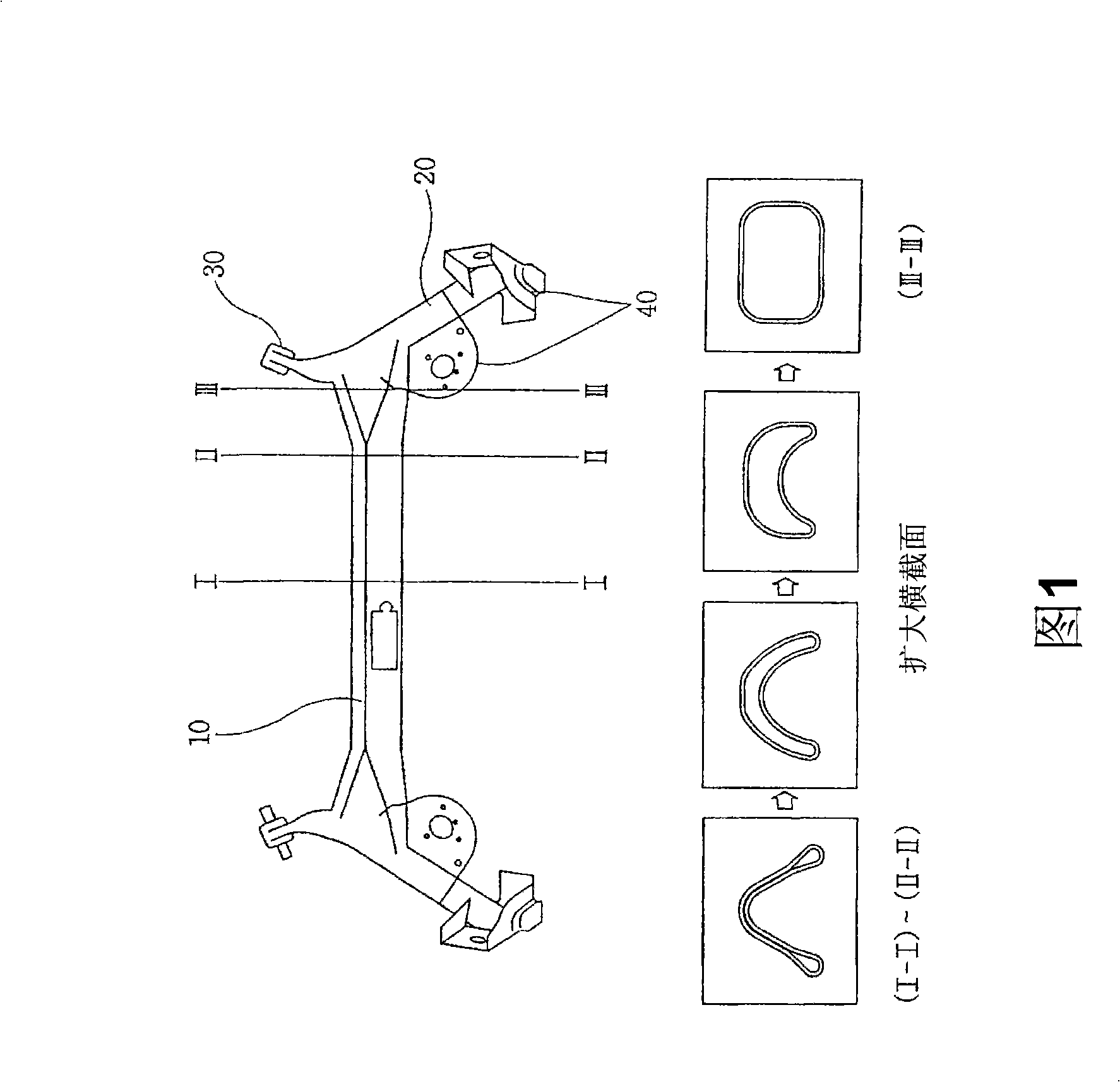

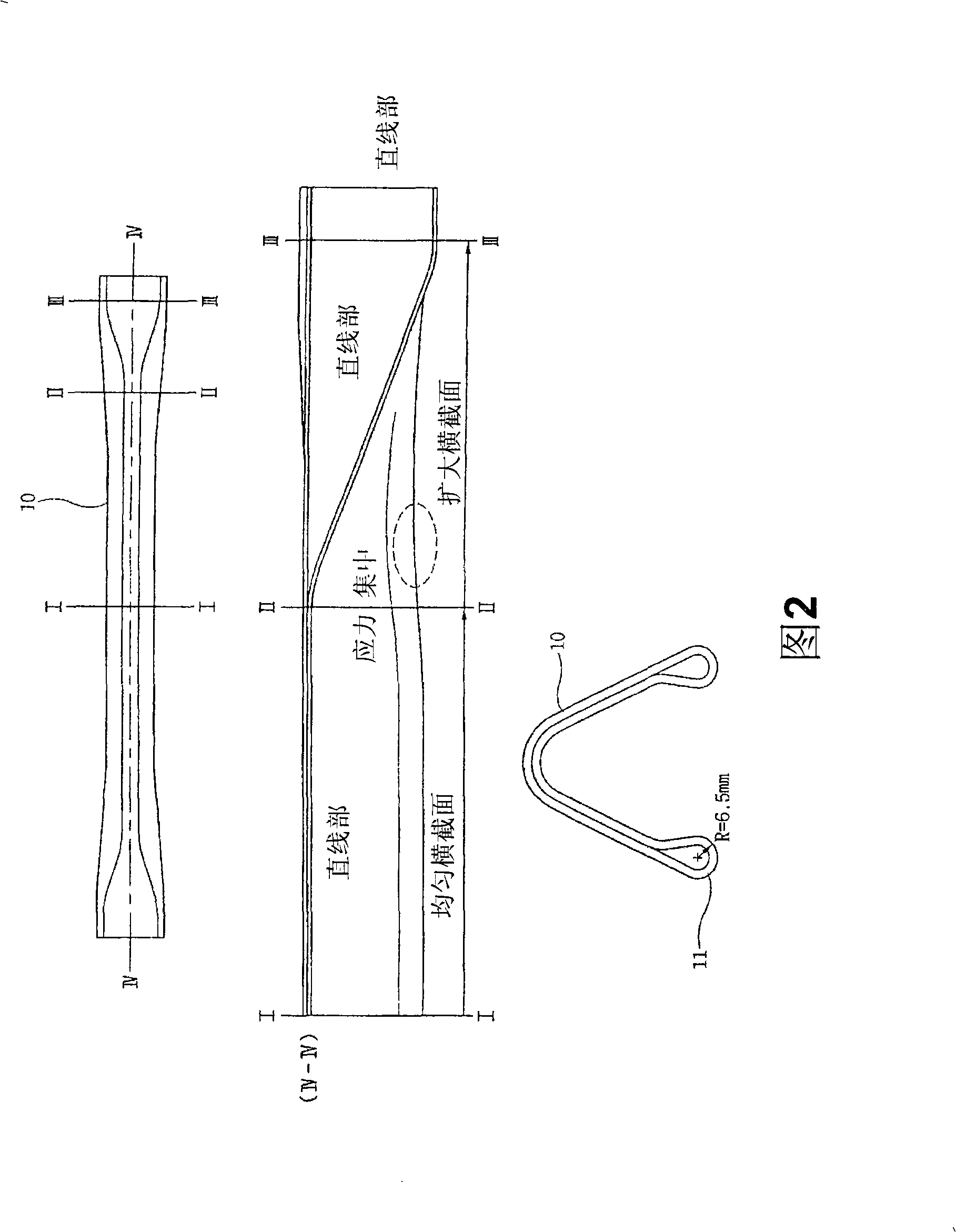

Torsion beam type suspension, method for forming torsion beam, and apparatus for forming torsion beam

ActiveUS20050035567A1Increased torsional stiffnessImprove rigidityMetal-working apparatusInterconnection systemsInterior spaceEngineering

A torsion beam type suspension and a forming method of a torsion beam are disclosed. In the torsion beam type suspension comprising a pair of left and right trailing arms connected to each other through a torsion beam, front ends of the trailing arms being used to mount a vehicle body by using joints, the torsion beam is obtained by forming an overall length of a pipe having a certain wall thickness by using a pressure forming process. In this case, end sections defined at both end portions of the torsion beam have a cross-sectional shape of a hollow oval, a center section defined at a center portion of the torsion beam has a cross-sectional shape of a hollow open loop, and middle sections defined between the center portion and both the end portions of the torsion beam have a cross-sectional shape of a hollow open loop. The loop of the middle sections defines an inner space larger than that defined by the loop of the center section. Further, since the torsion beam can be easily formed by adopting a hydro-forming process, it is possible to achieve high twisting rigidity, bending rigidity, and durability without requiring a torsion bar and reinforcement, which must be inevitably assembled to a conventional torsion beam axle, resulting in a reduction of the number of constitutive elements and the overall weight.

Owner:DONG HEE IND

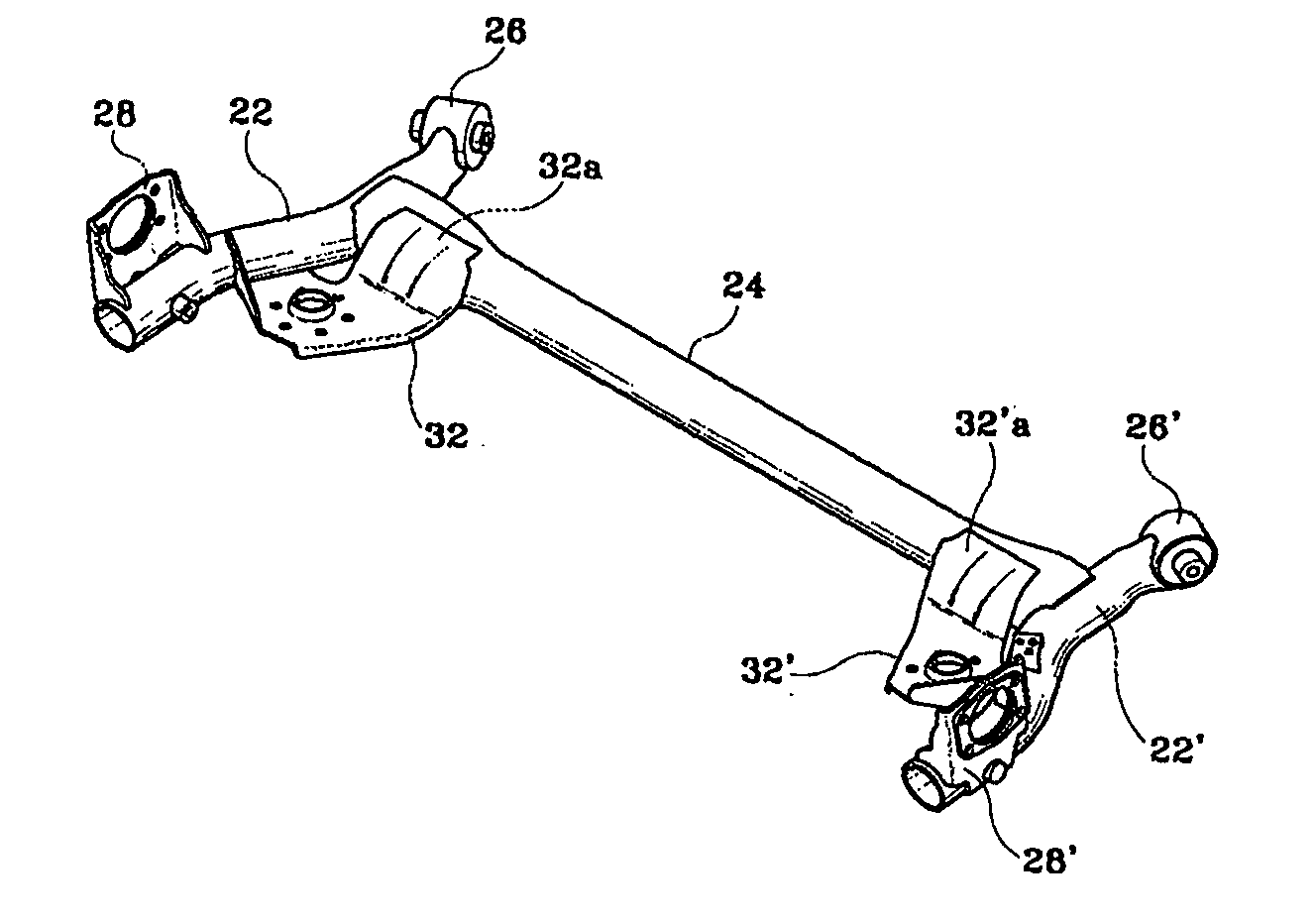

Coupled torsion beam axle type suspension system

ActiveUS20150123370A1Reduce amountSecuring drive stabilityInterconnection systemsResilient suspensionsBeam axleAutomotive engineering

A coupled torsion beam axle type suspension system (CTBA) may include trailing arms respectively coupled to opposite ends of a torsion beam, and a vehicle body-engaging unit provided in a front end portion of each of the trailing arm and engaging the each of the trailing arms to a vehicle body, wherein each vehicle body-engaging unit includes a trailing arm bush that may be coupled to a front end portion of the trailing arm, a rotation link disposed in front of the trailing arm bush and engaged thereto in a width direction of a vehicle, a slider rotatably connected to a front end portion of the rotation link, and slidable along a length direction of the vehicle body, and a connection link pivotally connecting an outer end portion of the rotation link and the vehicle body.

Owner:HYUNDAI MOTOR CO LTD

Torsion beam axle suspension

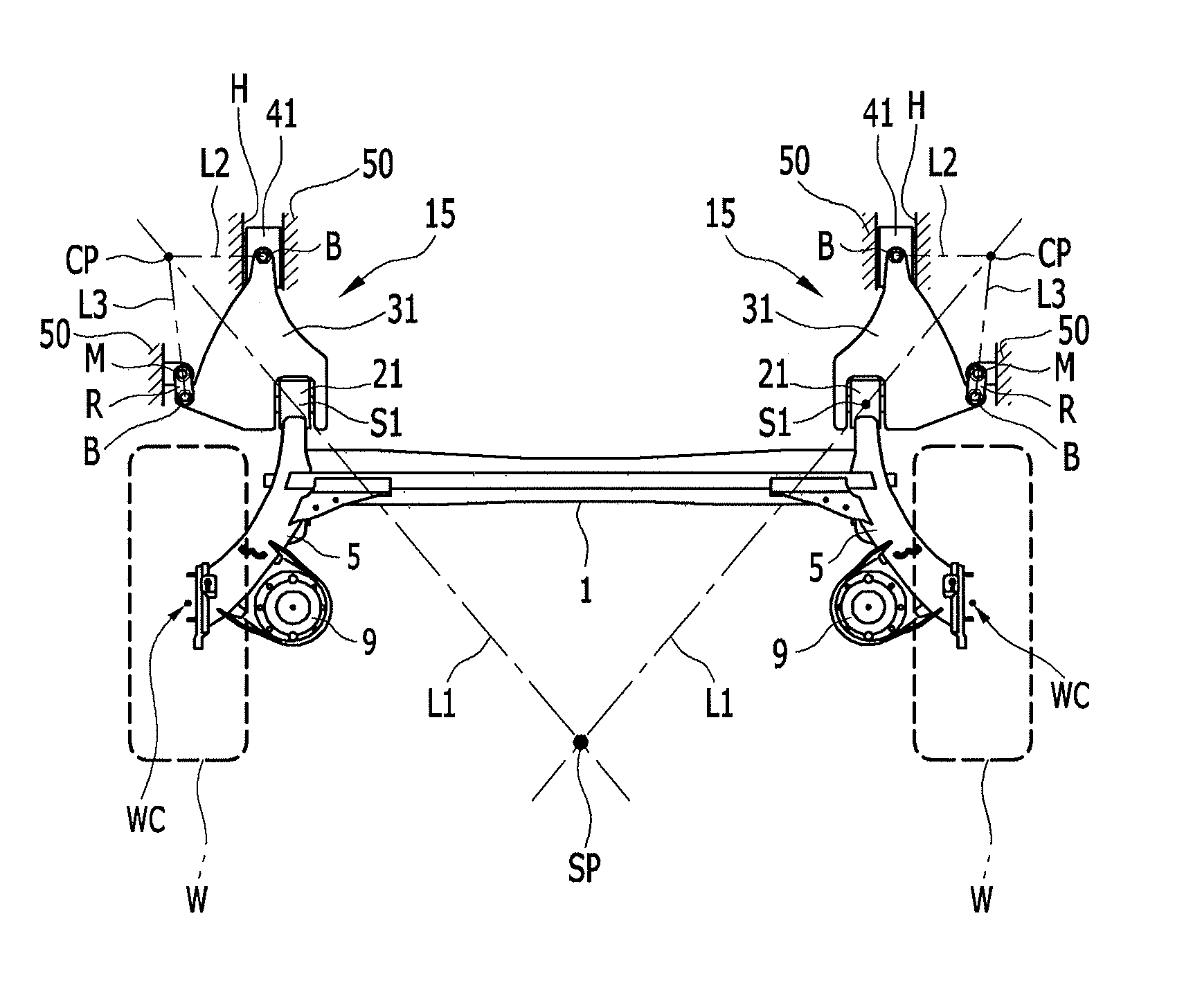

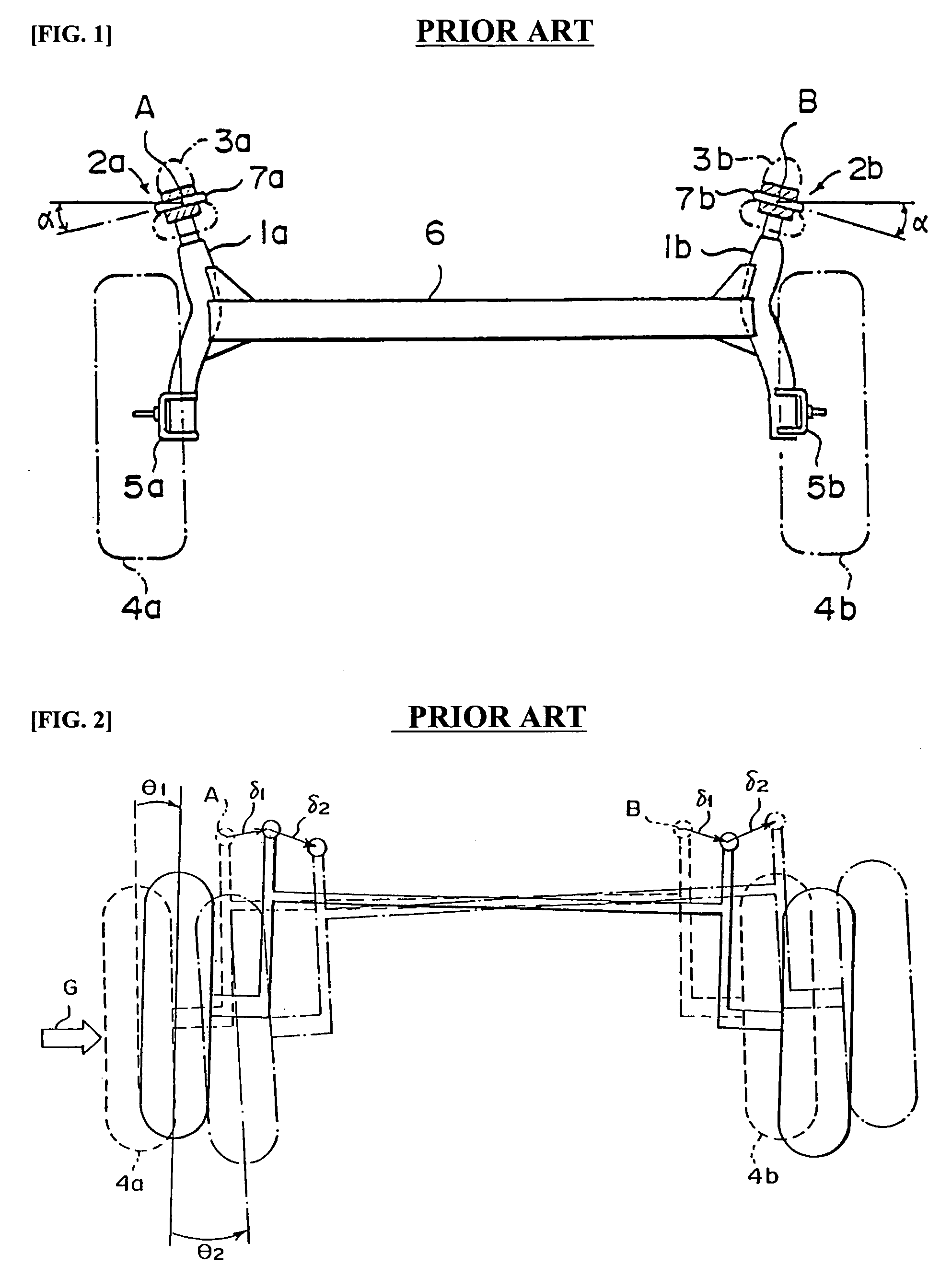

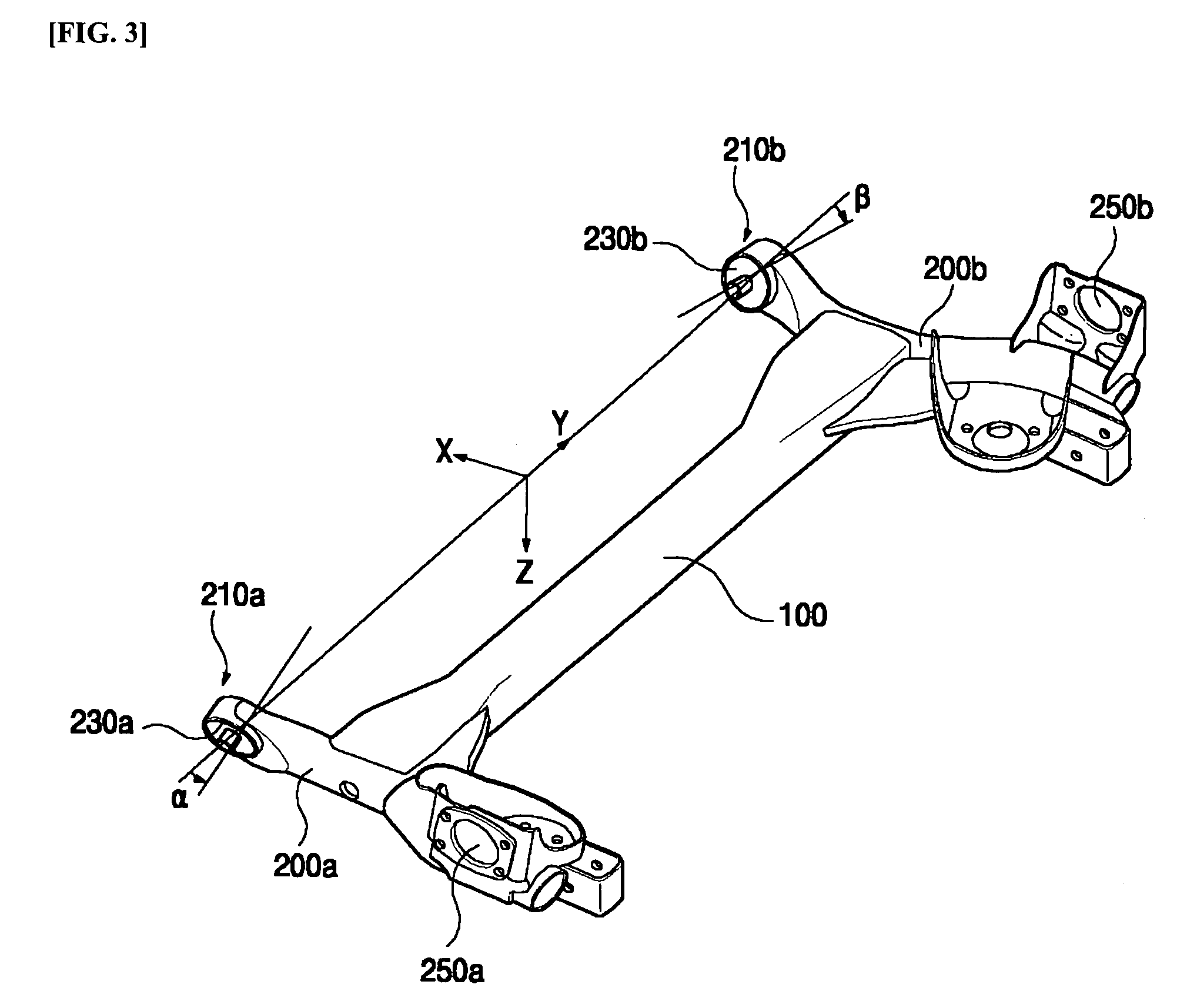

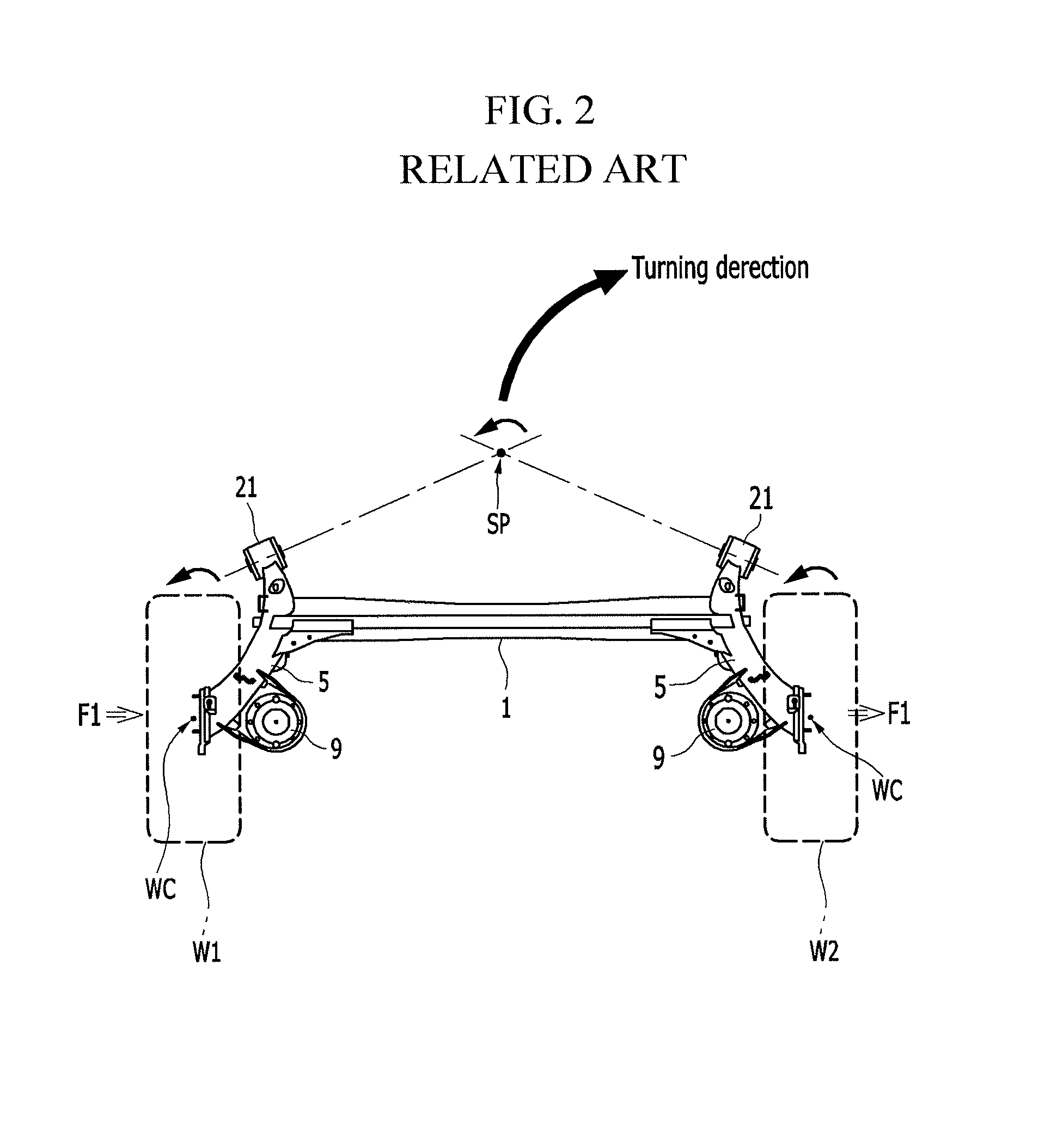

InactiveUS7044565B2Increase lateral stiffnessKeep it steadyInterconnection systemsResilient suspensionsTransverse forceSlant angle

In the torsion beam axle suspension of the present invention, by providing mounts formed on one end of each of trailing arms with a three-dimensional slant angle, when a transverse force is applied to a turning outer wheel at a rear suspension during cornering of a vehicle, toe-in characteristics are induced, and at the same time a transverse rigidity of the mounts can be increased.

Owner:HYUNDAI MOBIS CO LTD

Coupled torsion beam axle type suspension system

ActiveUS9079473B2Securing the turning stability thereofReduce amountInterconnection systemsResilient suspensionsBeam axleAutomotive engineering

A coupled torsion beam axle type suspension system (CTBA) may include trailing arms respectively coupled to opposite ends of a torsion beam, and a vehicle body-engaging unit provided in a front end portion of each of the trailing arm and engaging the each of the trailing arms to a vehicle body, wherein each vehicle body-engaging unit includes a trailing arm bush that may be coupled to a front end portion of the trailing arm, a rotation link disposed in front of the trailing arm bush and engaged thereto in a width direction of a vehicle, a slider rotatably connected to a front end portion of the rotation link, and slidable along a length direction of the vehicle body, and a connection link pivotally connecting an outer end portion of the rotation link and the vehicle body.

Owner:HYUNDAI MOTOR CO LTD

Ball and socket mount for shock absorber of torsion beam axle suspension

InactiveUS7427113B2Reduce productionReduce weightCouplings for rigid shaftsInterconnection systemsTransverse forceEngineering

A torsion beam axle suspension is provided, in which a shock absorber is directly mounted on right and left trailing arms and is further mounted to the mount by a ball joint. Thus, it is possible to reduce the weight and production expenses, thus to enhance productivity. Further, it is possible to considerably decrease a friction caused by movement of the shock absorber even though the transverse force is applied, thus to enhance the riding comfort.

Owner:HYUNDAI MOBIS CO LTD

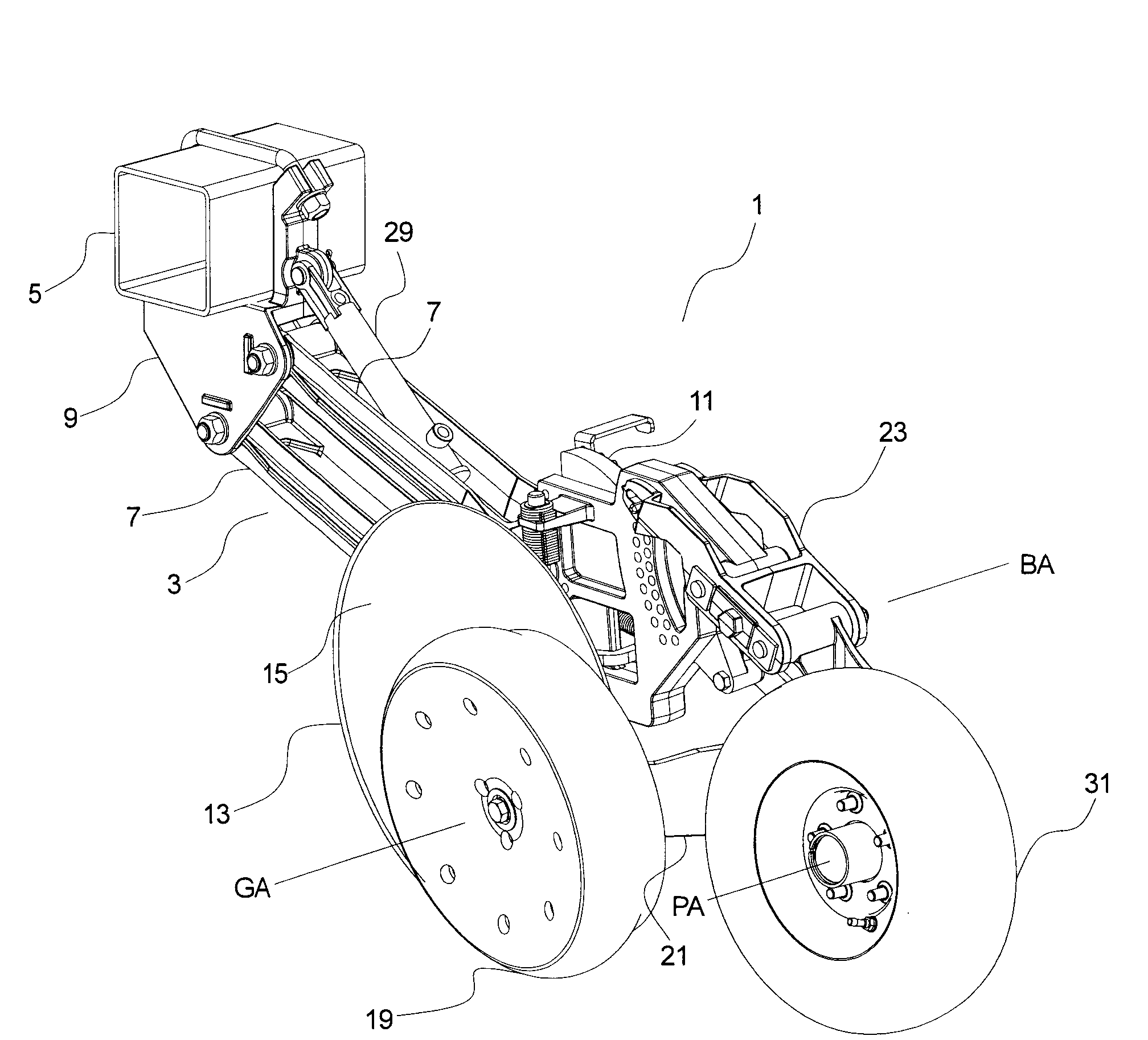

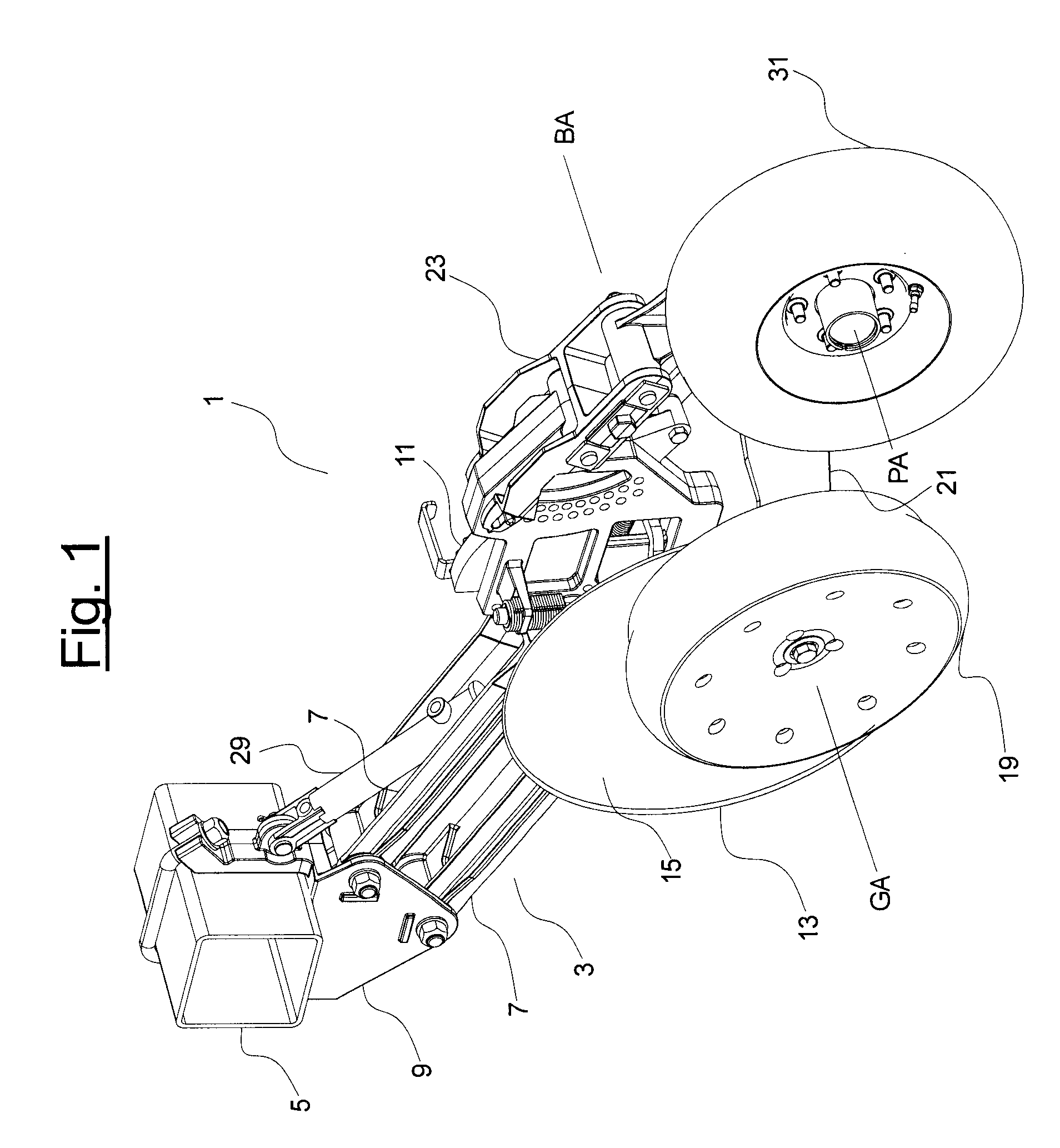

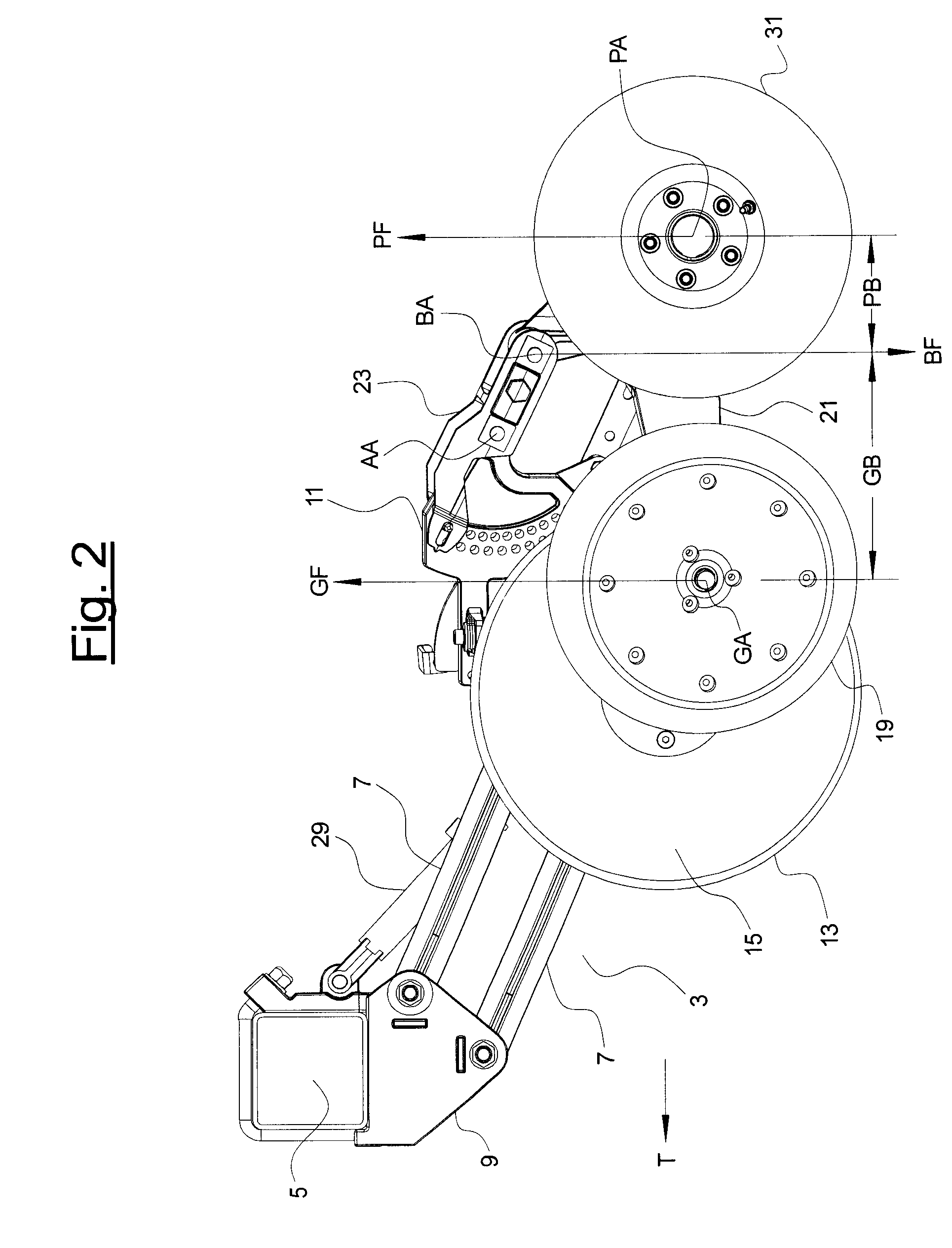

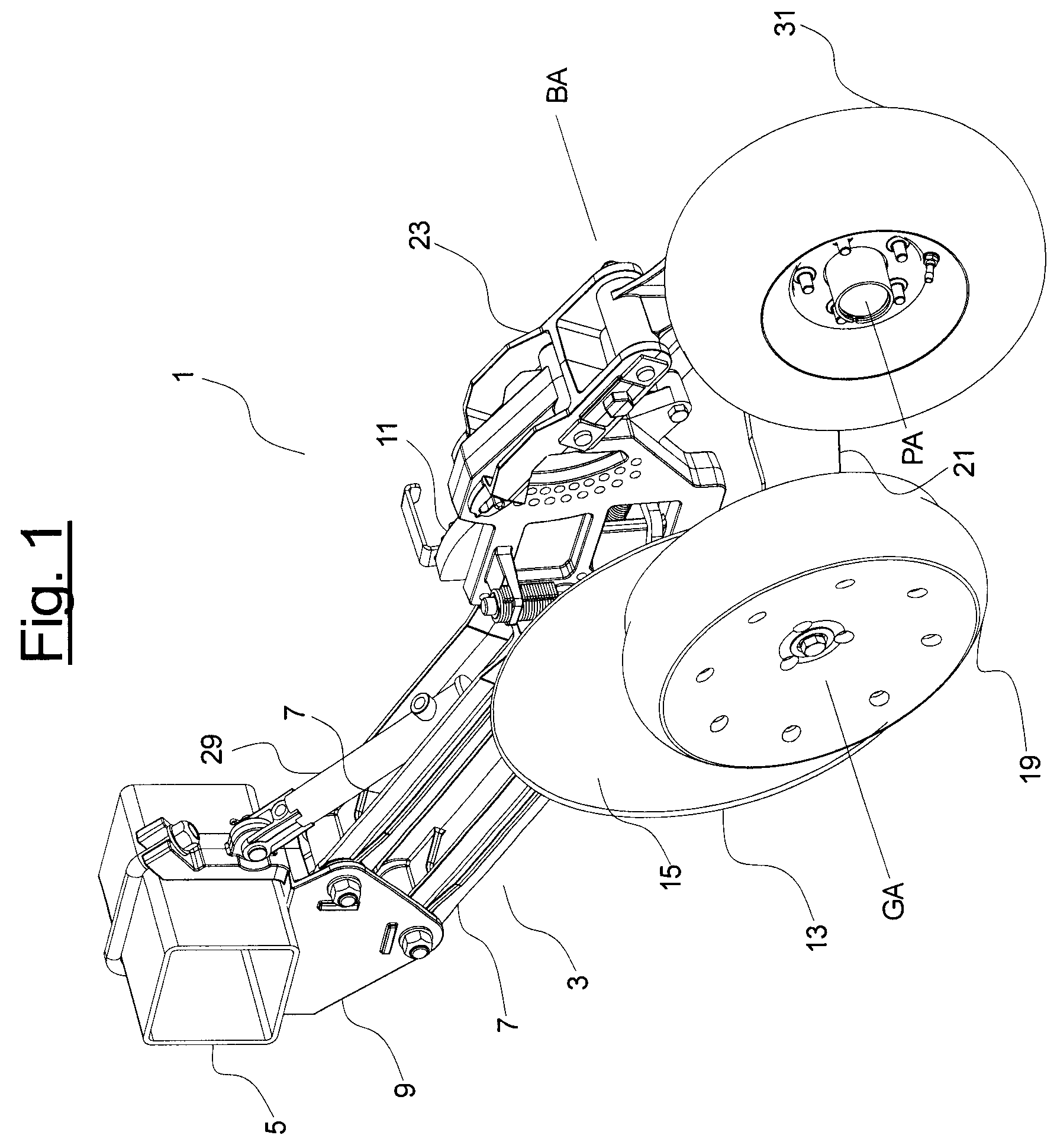

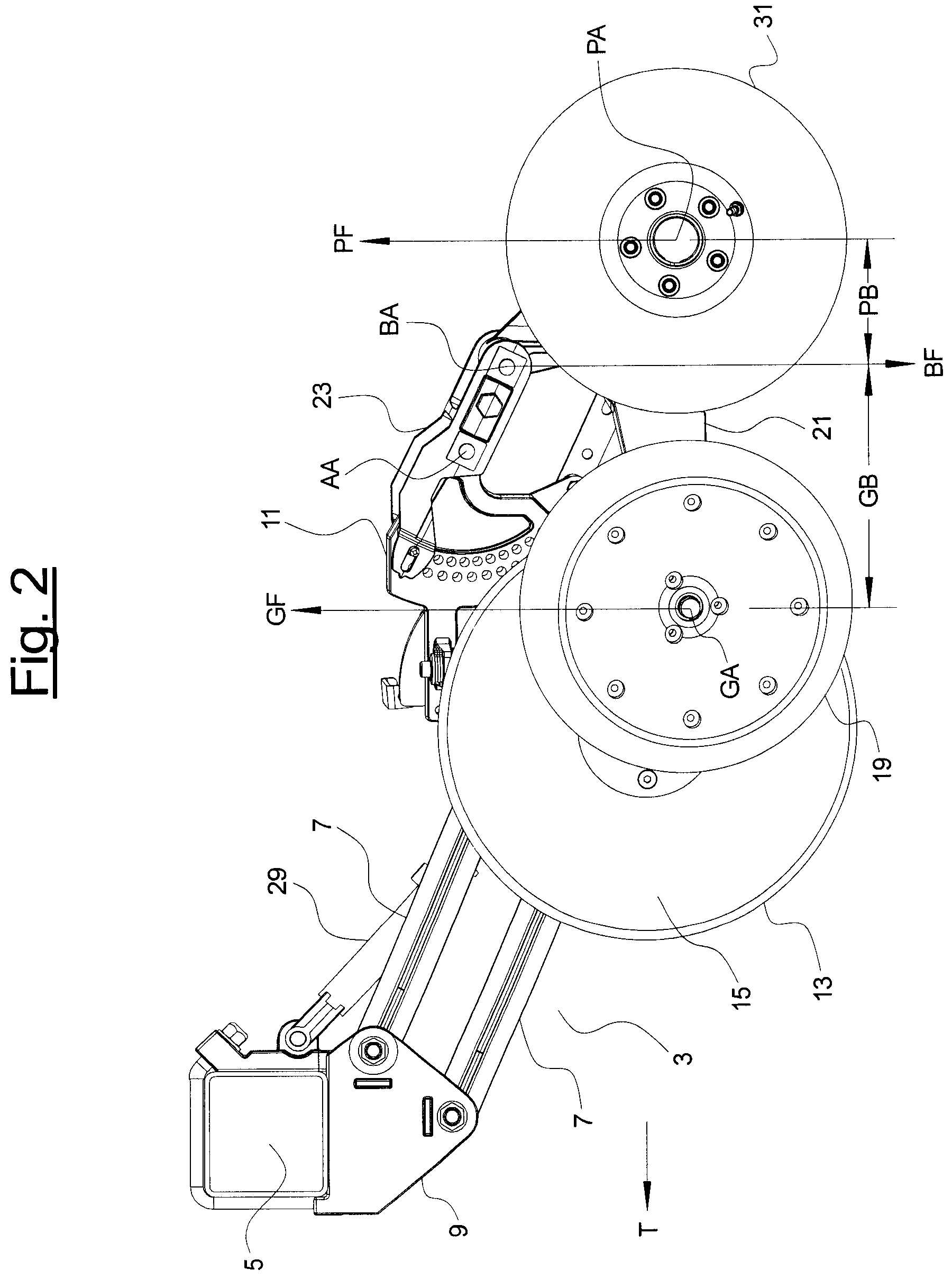

Single Disc Furrow Opener with Walking Beam

A furrow opener apparatus has an arm assembly adapted at a front end thereof for pivotal attachment to a seeder frame. A single disc is rotatably attached to the arm assembly about a disc axis at an angle to the travel. A walking beam is pivotally attached to the arm assembly rearward of the disc about a beam axis transverse to the travel direction. A bias element exerts a force on the arm assembly such that a downward bias force is exerted on the walking beam at the beam axis. A packer wheel is rotatably attached at a rear end of the walking beam, and a gauge wheel is rotatably attached at a front end of the walking beam. The gauge wheel is configured to roll along the ground adjacent to the leading face of the disc, and the packer wheel is configured to roll along the furrow.

Owner:BOURGAULT INDS

Torsion beam axle having connecting tube between torsion beam and trailing arm

InactiveUS7862059B2Coupling forceEnhanced couplingInterconnection systemsResilient suspensionsEngineeringBeam axle

A torsion beam axle includes a torsion beam, a plurality of trailing arms made of a material different from that of the torsion beam, and connecting tubes made of a material better than that of the trailing arms with respect to weldability with the torsion beam, and integrally coupled to the trailing arms at one end part thereof, and welded to the torsion beam at the other end part thereof. Thereby, the coupling force between the trailing arms and the torsion beam made of different materials can be improved.

Owner:AUSTEM CO LTD

Torsion beam axle having connecting tube between torsion beam and trailing arm

InactiveUS20100127470A1Coupling forceEnhanced couplingInterconnection systemsResilient suspensionsEngineeringBeam axle

A torsion beam axle includes a torsion beam, a plurality of trailing arms made of a material different from that of the torsion beam, and connecting tubes made of a material better than that of the trailing arms with respect to weldability with the torsion beam, and integrally coupled to the trailing arms at one end part thereof, and welded to the torsion beam at the other end part thereof. Thereby, the coupling force between the trailing arms and the torsion beam made of different materials can be improved.

Owner:AUSTEM CO LTD

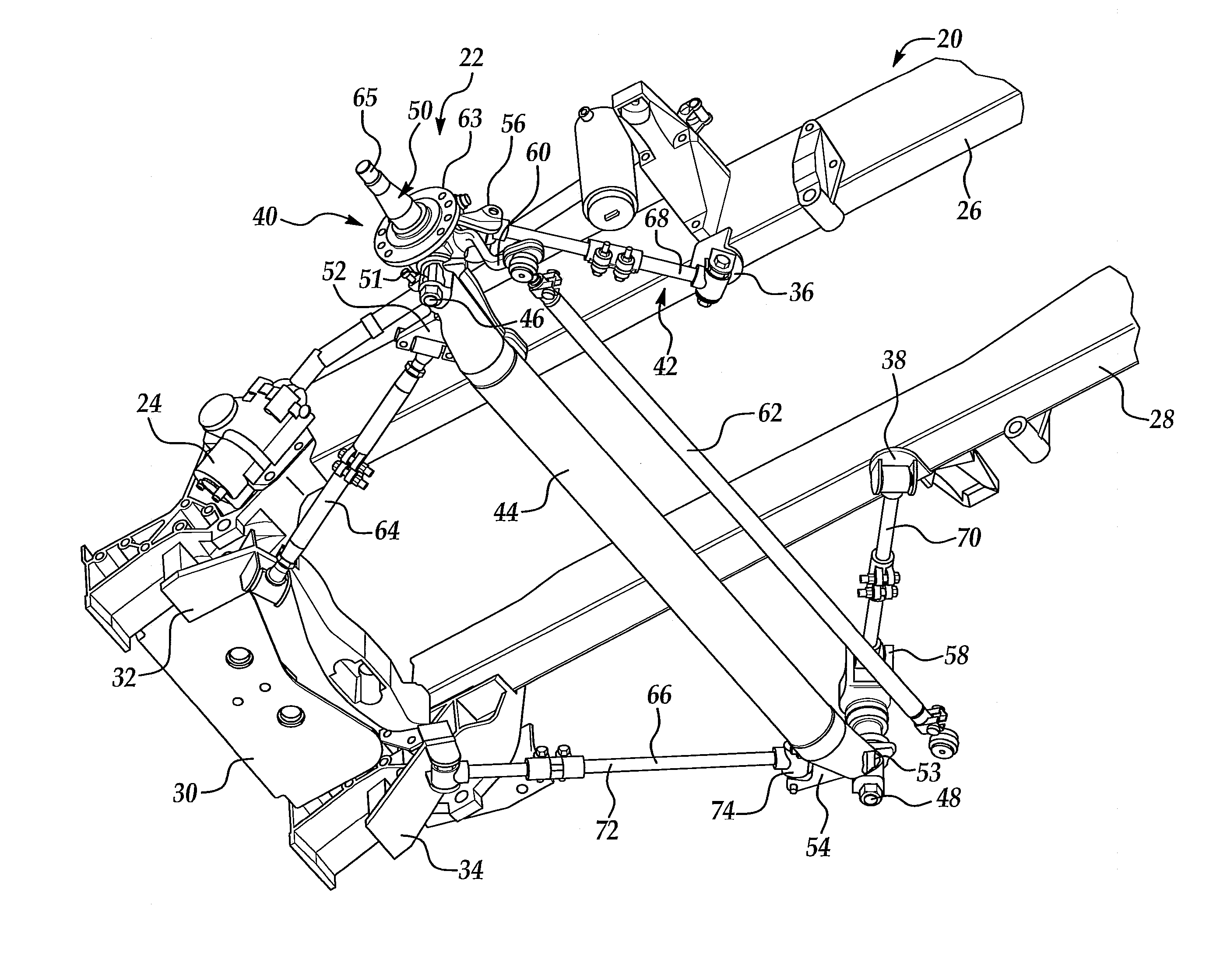

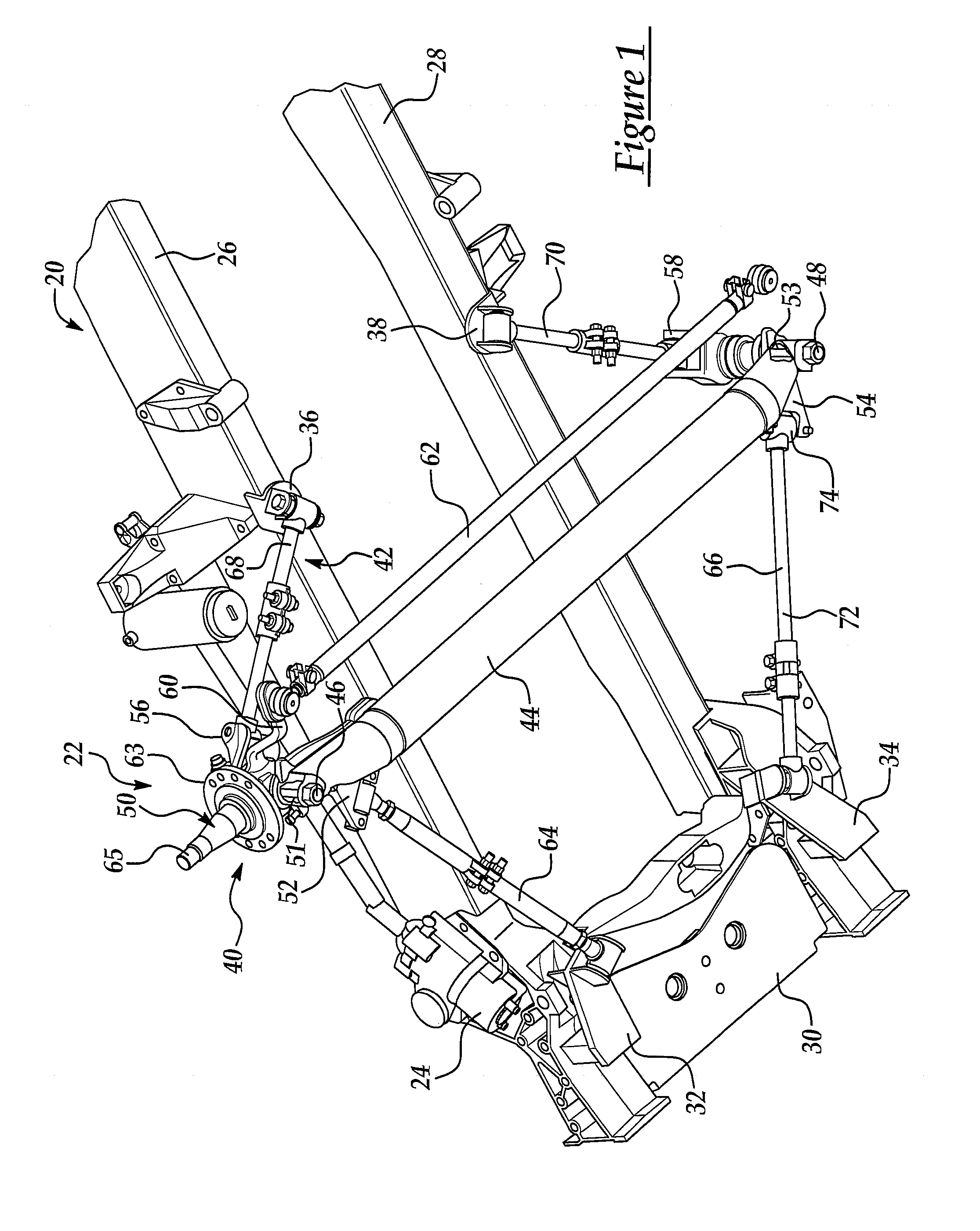

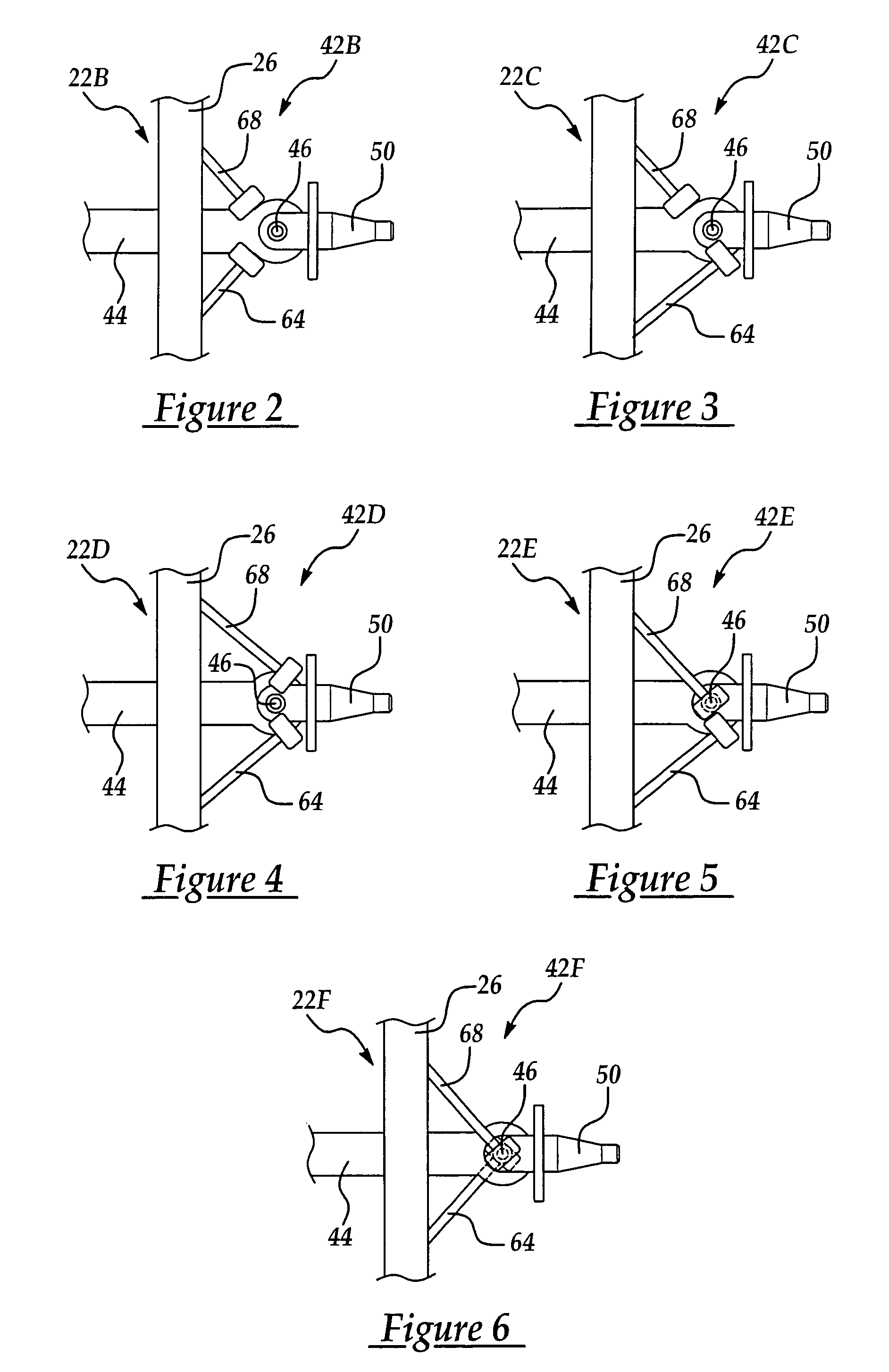

Beam axle suspension with diagonal link

A steer axle and suspension assembly are provided that produce lateral stability in the vehicle without the use of a transverse rod and without generating undue loads on the steer axle beam. The assembly includes at least one suspension arm that is connected to the frame and to a component of the steer axle assembly such as the axle beam, kingpin, or steering knuckle. The suspension arm is connected to the steer axle assembly at a location outboard of the longitudinal frame rails of the vehicle and extends longitudinally at an angle to the frame rails. The suspension arm arrangement can be used with a variety of suspensions including leaf spring and multi-link suspensions.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

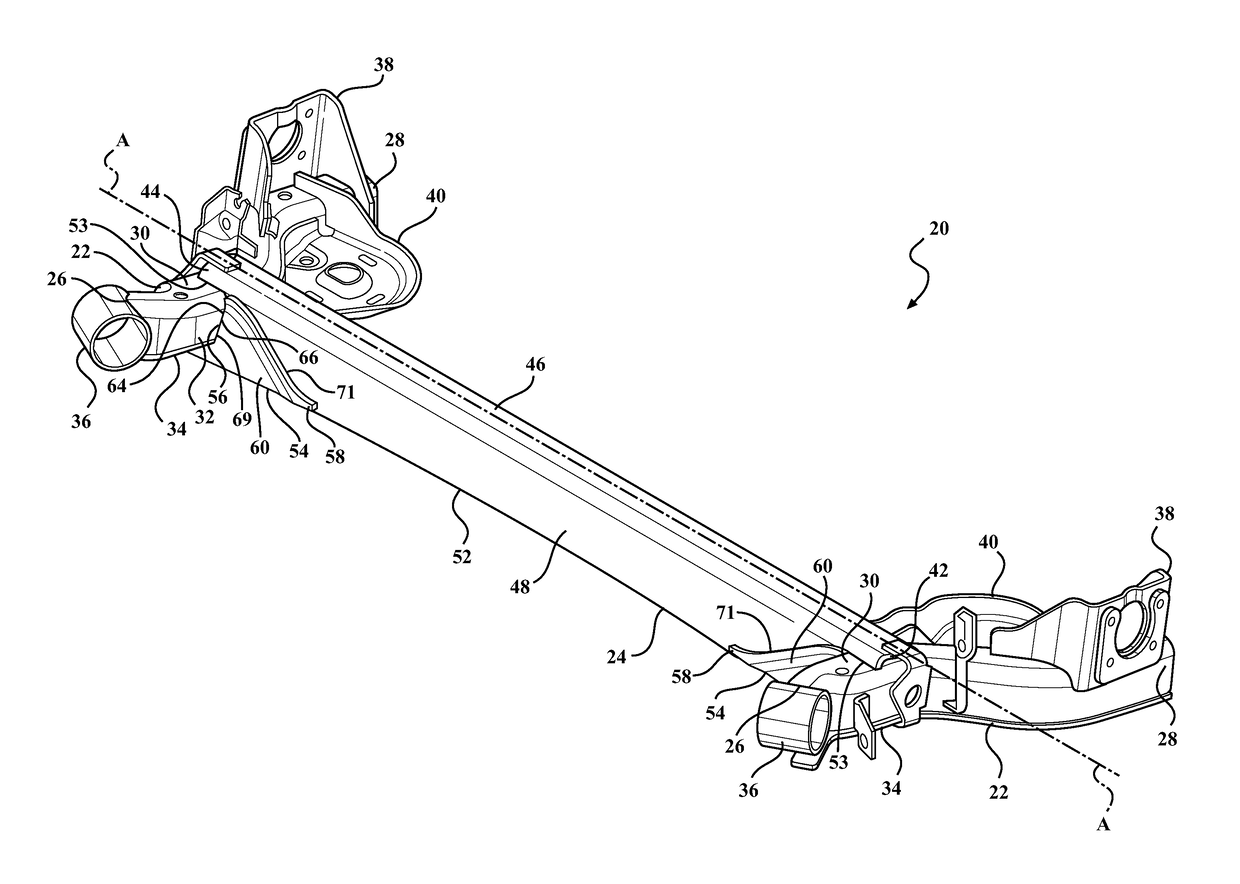

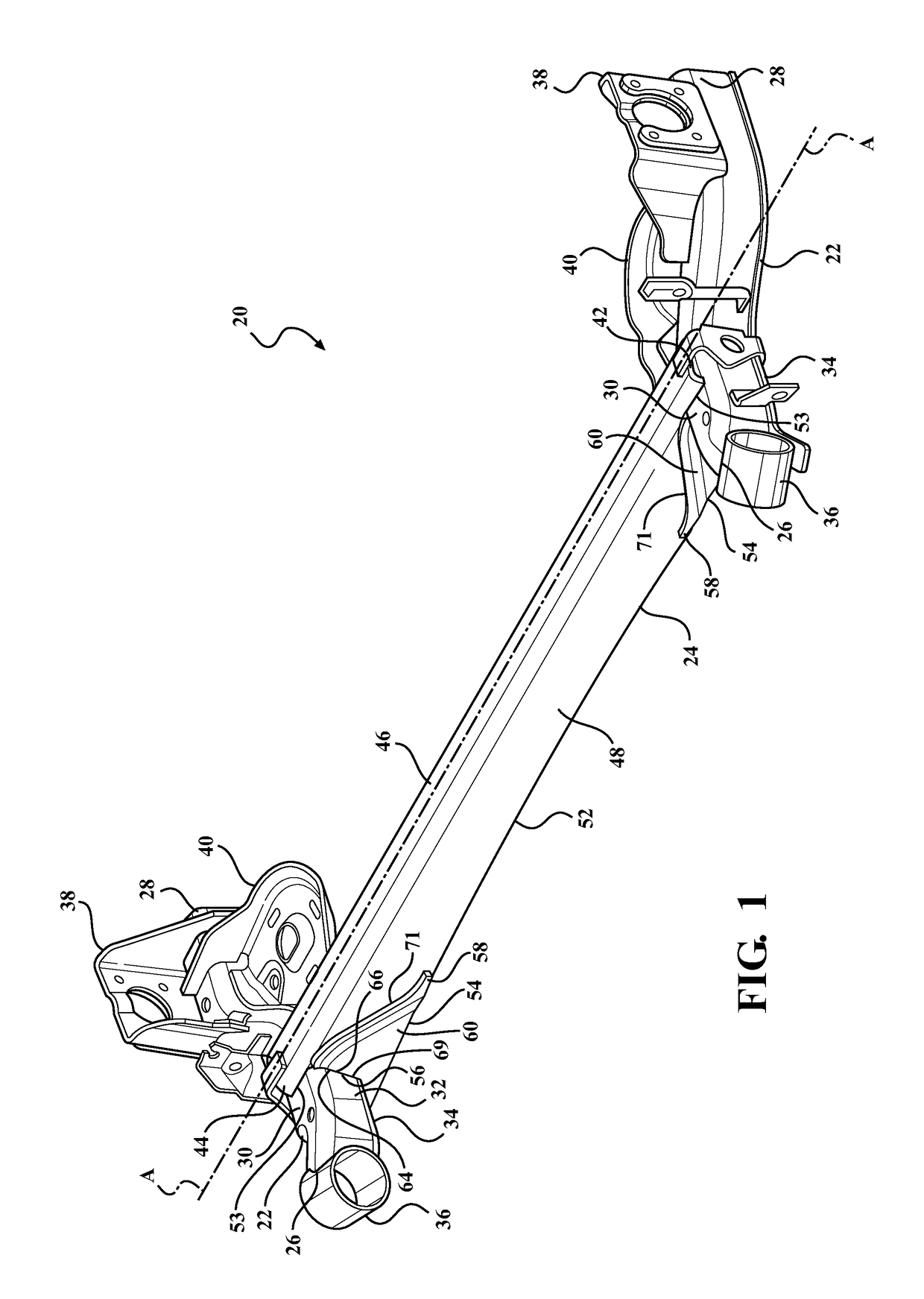

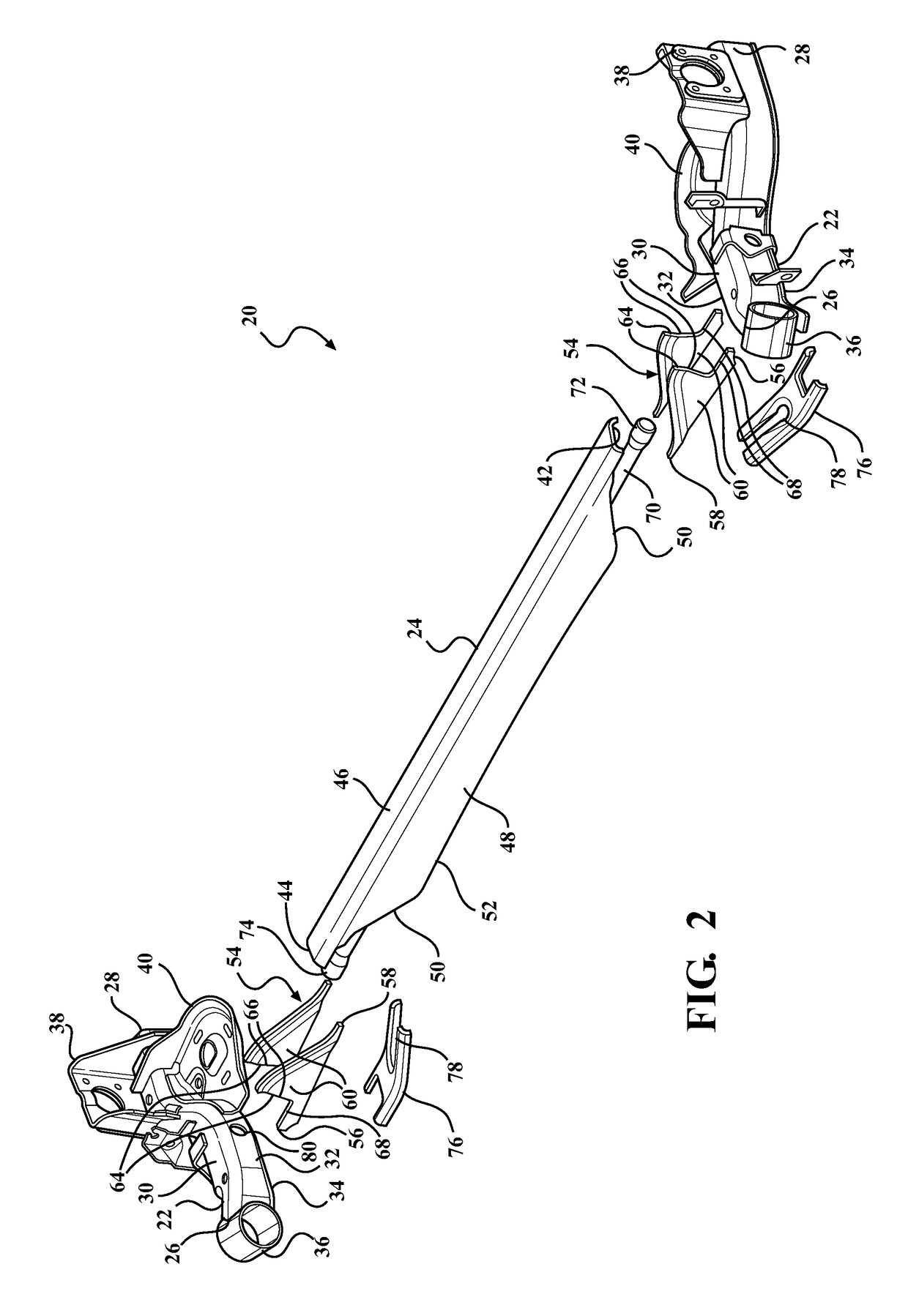

Twist Beam Axle Assembly With Lateral Adjustability

ActiveUS20170197487A1Increased manufacturing flexibilityInterconnection systemsAxle unitsMechanical engineeringBeam axle

A twist axle assembly (20) of a vehicle includes a pair of trailing arms (22) and a twist beam (24) having a base portion (46) extending along an axis (A) between first and second twist beam ends (42, 44). The twist beam (24) includes a pair of side walls (48) extending downwardly from the base portion (46) and each disposed in spaced relationship with the trailing arms (22). At least one mounting bracket (54) extends from a first mounting bracket end (56) disposed in abutting relationship with a respective trailing arm (22) to a second mounting bracket end (58) disposed in overlaying relationship the side walls (48) of the twist beam (24) for allowing the mounting bracket to axially slip or slide along the side walls (48) of the twist beam (24) and provide for lateral or axial adjustment of the twist axle assembly (20) during the manufacturing process.

Owner:MAGNA INTERNATIONAL INC

Single disc furrow opener with walking beam

A furrow opener apparatus has an arm assembly adapted at a front end thereof for pivotal attachment to a seeder frame. A single disc is rotatably attached to the arm assembly about a disc axis at an angle to the travel. A walking beam is pivotally attached to the arm assembly rearward of the disc about a beam axis transverse to the travel direction. A bias element exerts a force on the arm assembly such that a downward bias force is exerted on the walking beam at the beam axis. A packer wheel is rotatably attached at a rear end of the walking beam, and a gauge wheel is rotatably attached at a front end of the walking beam. The gauge wheel is configured to roll along the ground adjacent to the leading face of the disc, and the packer wheel is configured to roll along the furrow.

Owner:BOURGAULT INDS

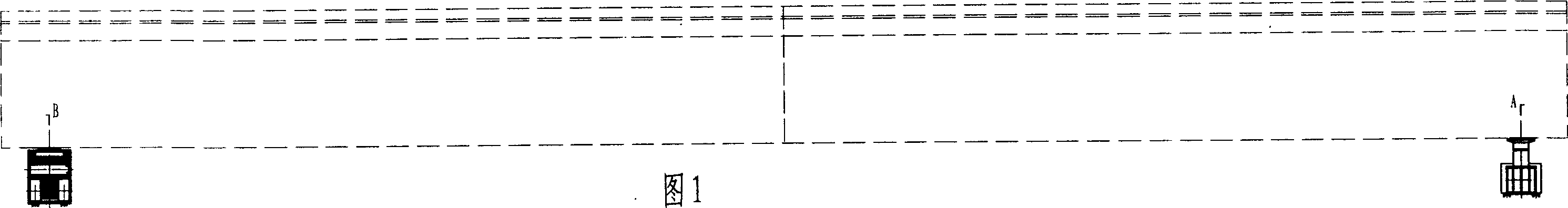

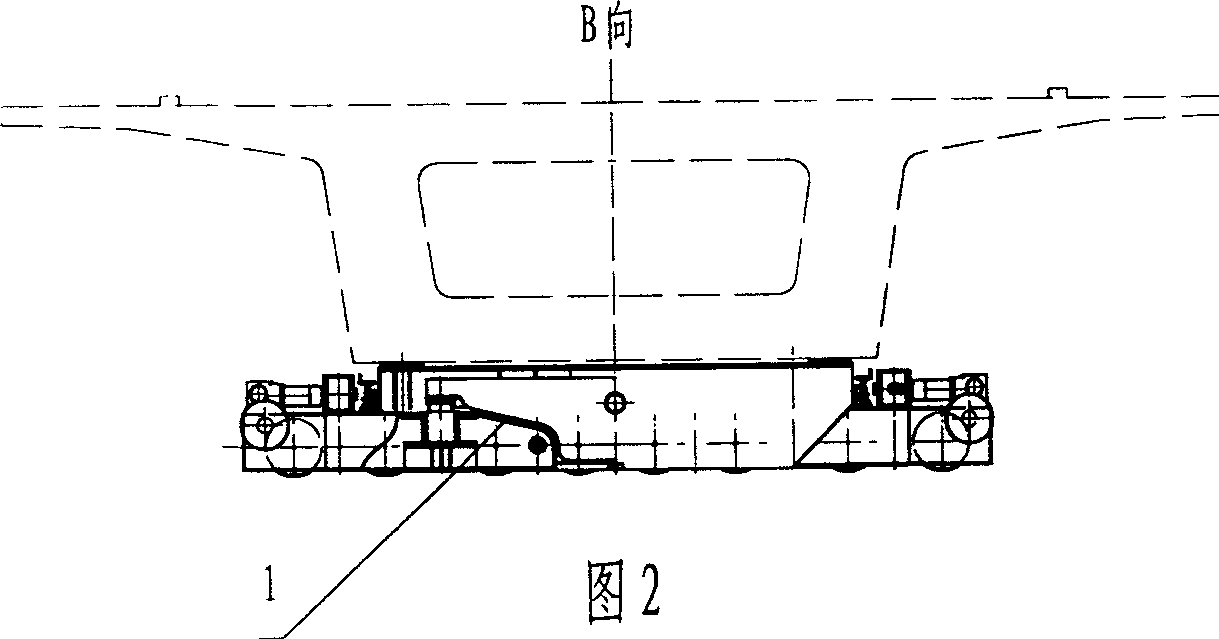

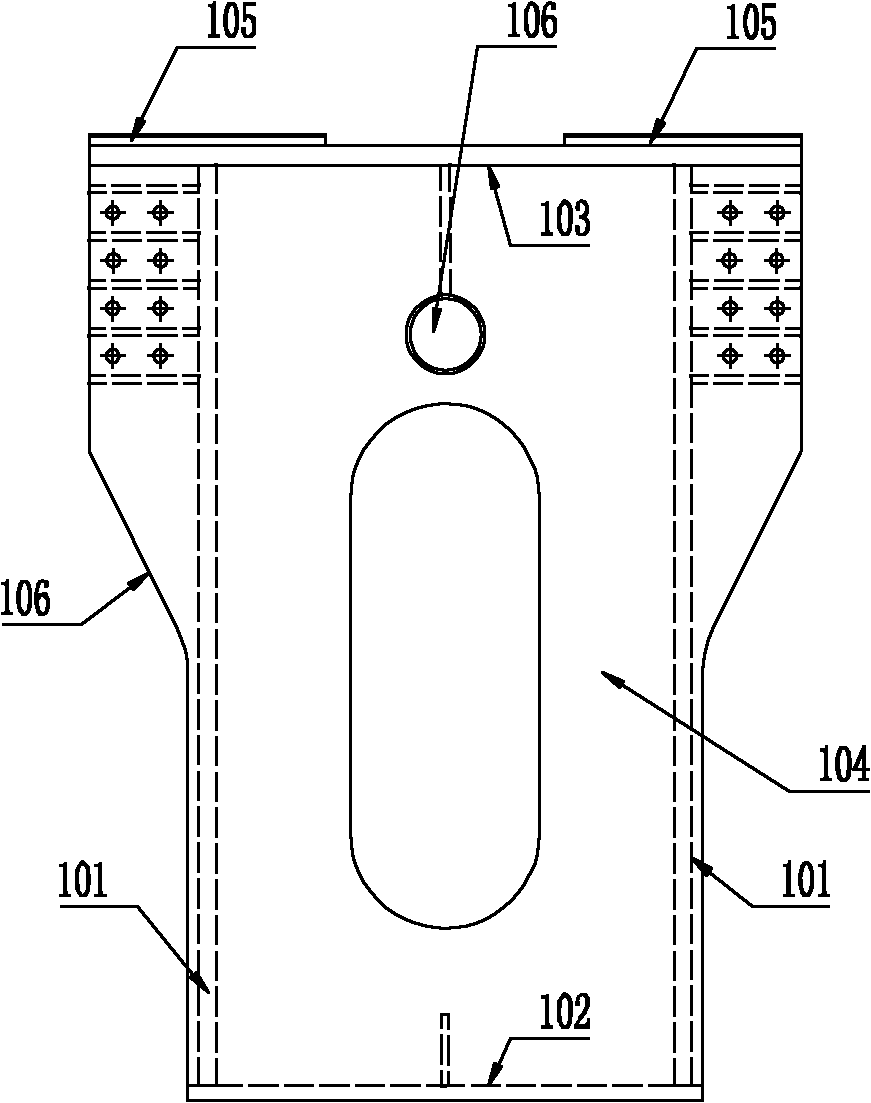

Box girder-moving trolley

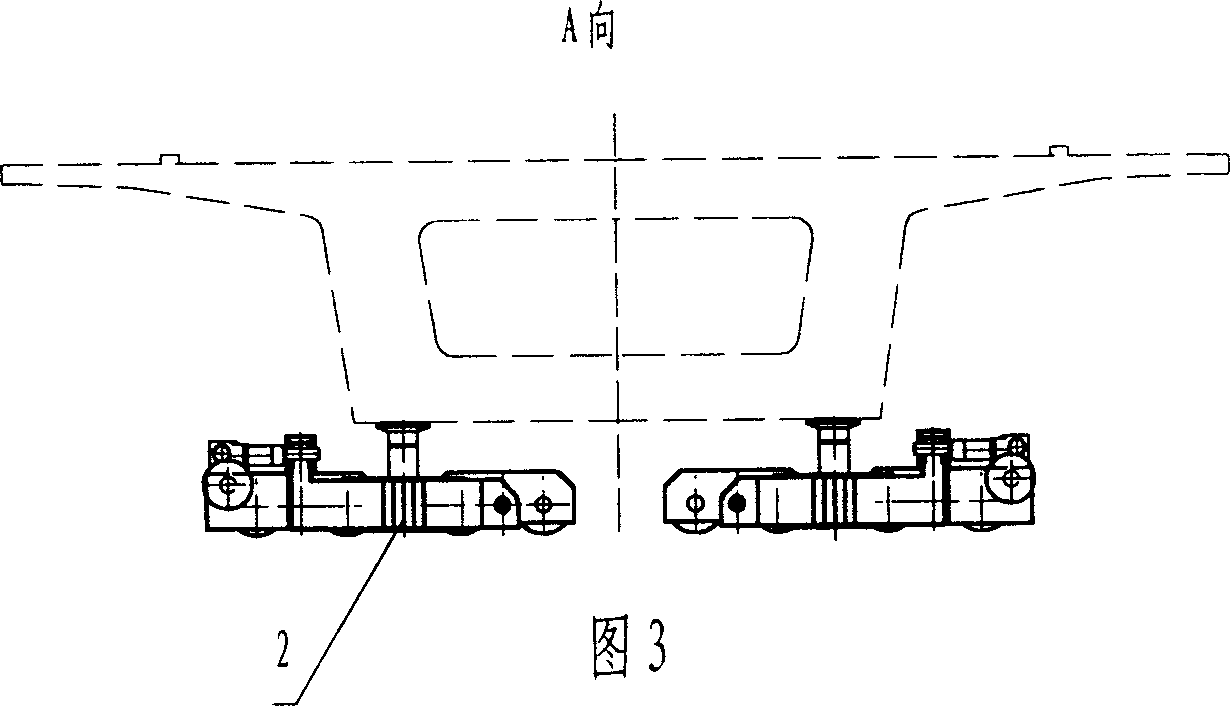

InactiveCN1843891AGuaranteed synchronicityImprove carrying capacityLifting devicesBridge structural detailsMotor speedDrive wheel

The invention discloses a construction technique, that the motion of prefabricated beam on the base and the track, which can be used in box-beam moving vehicle of passenger transport special railway line. It is characterized in that: it comprises a flexible support vehicle, and two steel support vehicles, which are independently arranged on four tracks at two sides of beam producing field; and it also comprises a speed detector, a force detector, an alarm device, a hydraulic controller and an electric appliance controller. Wherein, the flexible support vehicle is formed by four driving single vehicles, four driven single vehicles, a hydraulic mechanical lock, a hydraulic support, a solid beam axle, a solid beam and a outer frame beam; the rigid support vehicle is formed by two driving single vehicles, two driven single vehicles, a small balance beam, a speed sensor, and a hydraulic support; the power transmission is completed by the transmission device of motor speed reducer via gear wheel to drive wheels; the walking of driven single vehicle is transmitted via small balance beam; the speed detector detects the synchronous property of walking; the force detector detects if the force is over the preset value; the whole support capacity can reach 900t. The invention has stable working and easy operation with beam lifting-moving functions.

Owner:WENZHOU HELI CONSTR MACHINERY

Torsion beam type suspension, method for forming torsion beam, and apparatus for forming torsion beam

ActiveUS7377041B2Improve rigidityWell formedMetal-working apparatusInterconnection systemsInterior spaceEngineering

Owner:DONG HEE IND

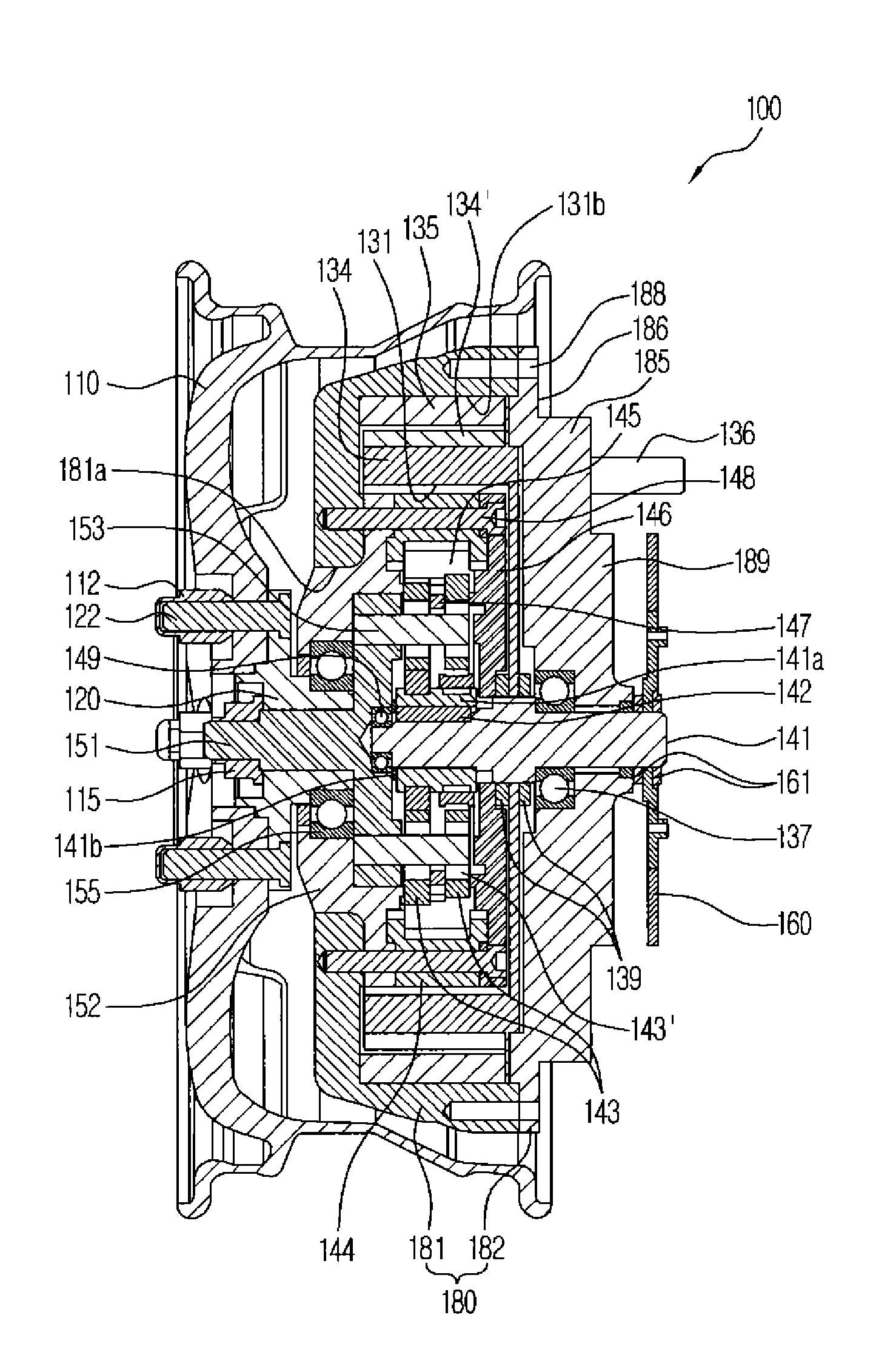

Axle for a motor vehicle

InactiveUS9045029B2Increase dampingExtended service lifeElectric devicesElectric propulsion mountingElectric machineElectric vehicle

A vehicle axle, in particular a torsion beam axle for an electric vehicle, with at least one trailing arm on which is arranged a drive unit located close to a wheel, and the drive unit comprises an electric machine and a transmission unit. The drive unit, close to the wheel, has at least one supply line and at least one damper such that the drive unit, close to the wheel, is formed at least partially as a trailing arm and the damper is connected, on at least one side, to the drive unit at least in a single-shear manner and can be connected, on at least the other side, to a body of the electric vehicle. The at least one vehicle axle is utilized on a motor vehicle.

Owner:ZF FRIEDRICHSHAFEN AG

Tubular beam of torsion beam axle type suspension

The present invention relates to a tubular beam of a torsion beam axle type suspension, which includes a uniform cross-sectional portion with the smallest tail radius and cross-sectional width throughout the tubular beam, a variable cross-sectional area that extends from the uniform cross-sectional portion and gradually increases in the tail radius and cross-sectional width, and an enlarging cross-sectional portion that extends from the variable cross-sectional portion. Therefore, it is possible to minimize reduction of roll rigidity and improve durability of a tubular beam. Further, it is possible to add understeer characteristics to a tubular beam with an oversteer tendency by minimizing the reduction in transverse rigidity and making a shear center higher.

Owner:HYUNDAI MOTOR CO LTD

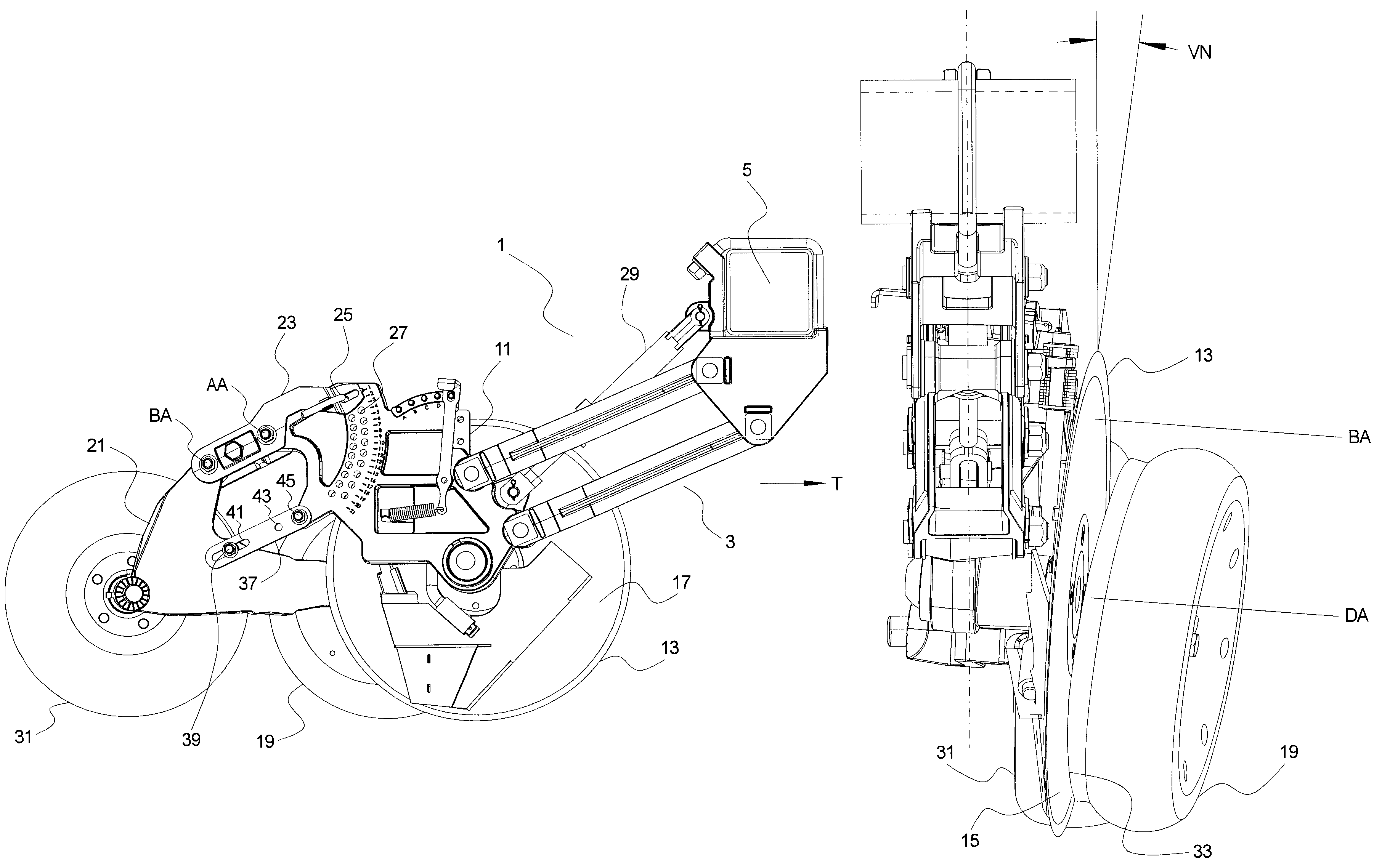

Mounting structure for in-wheel motor system

ActiveUS20140020966A1Avoid damageFirmly connectedElectric propulsion mountingMotor depositionElectric machineEngineering

Disclosed herein is a mounting structure for an in-wheel motor system. The mounting structure includes the in-wheel motor system installed in a wheel of the vehicle, and a torsion beam axle (TBA) assembly to fix the in-wheel motor system to a vehicle body, wherein a rear portion of a motor housing includes a step portion formed in a stepped manner to have a decreased diameter, and a ring-shaped fastening face vertically arranged from the step portion, and the TBA assembly includes a trailing arm provided with a through hole to surround the step portion of the motor housing, a mount integrated with the trailing arm to fix the trailing arm to a vehicle body, and a plurality of fastening bolts to fix the motor housing to the trailing arm, wherein, when the step portion is fitted and coupled into the through hole, the fastening face closely contacts the trailing arm.

Owner:HL MANDO CORP

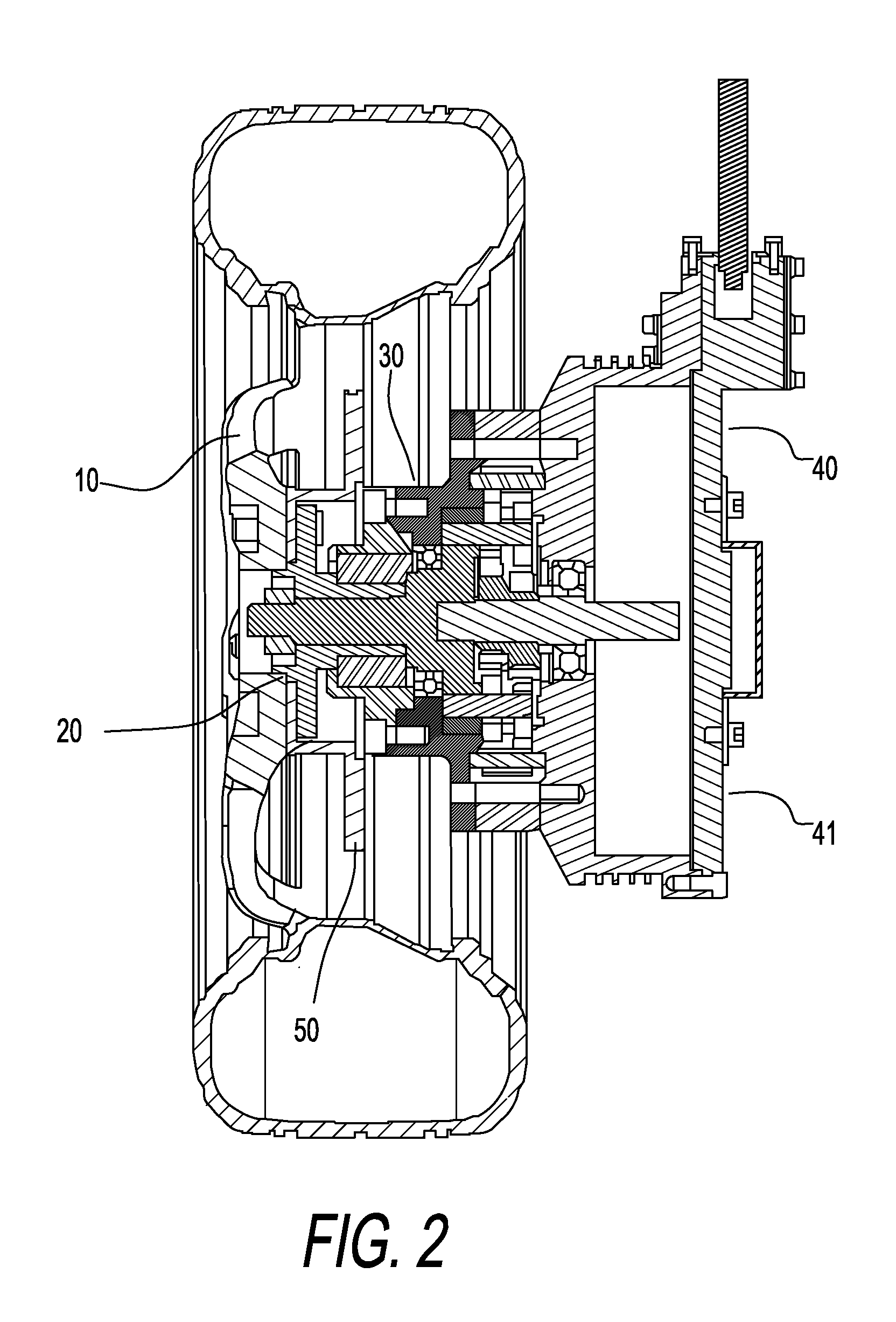

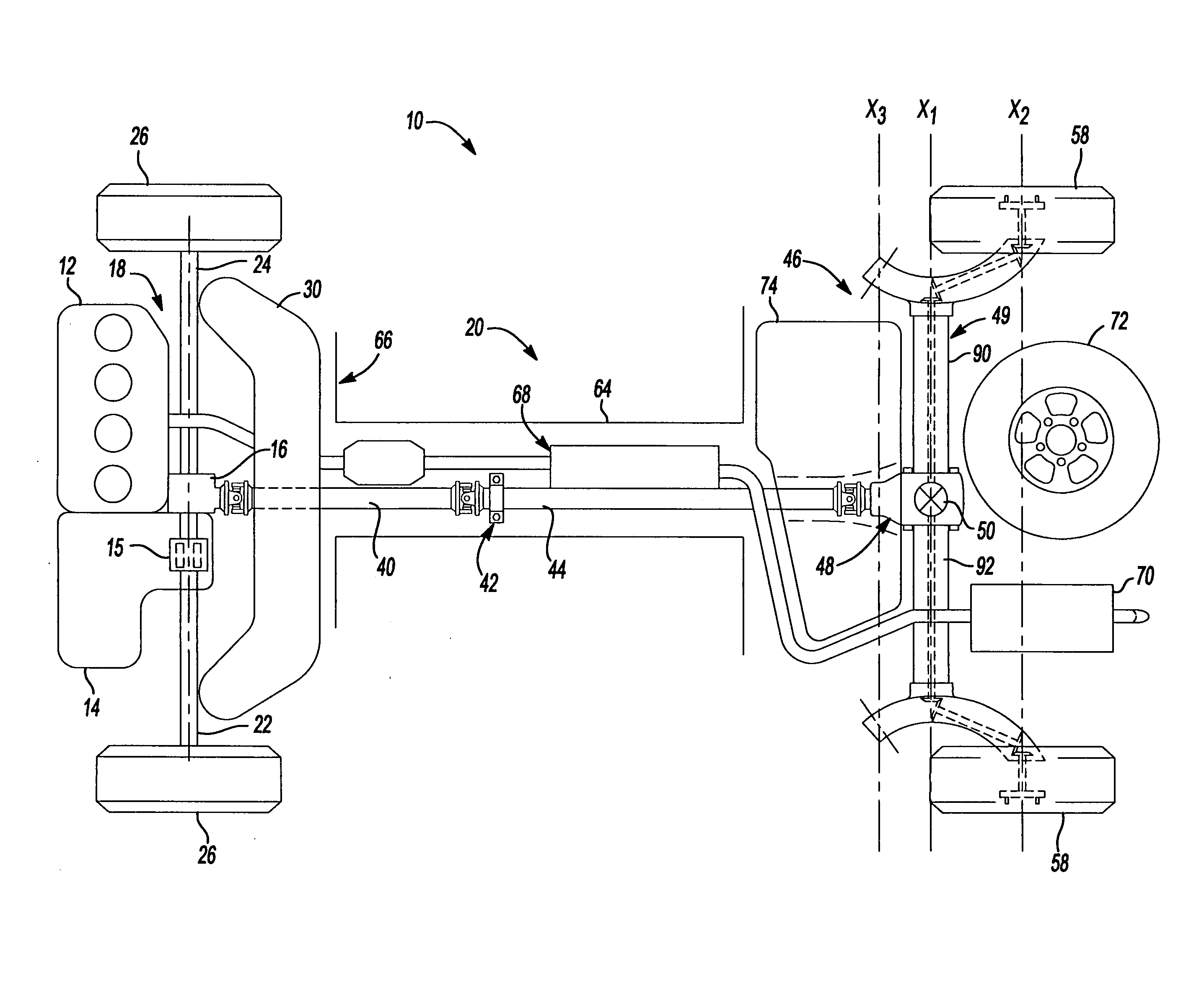

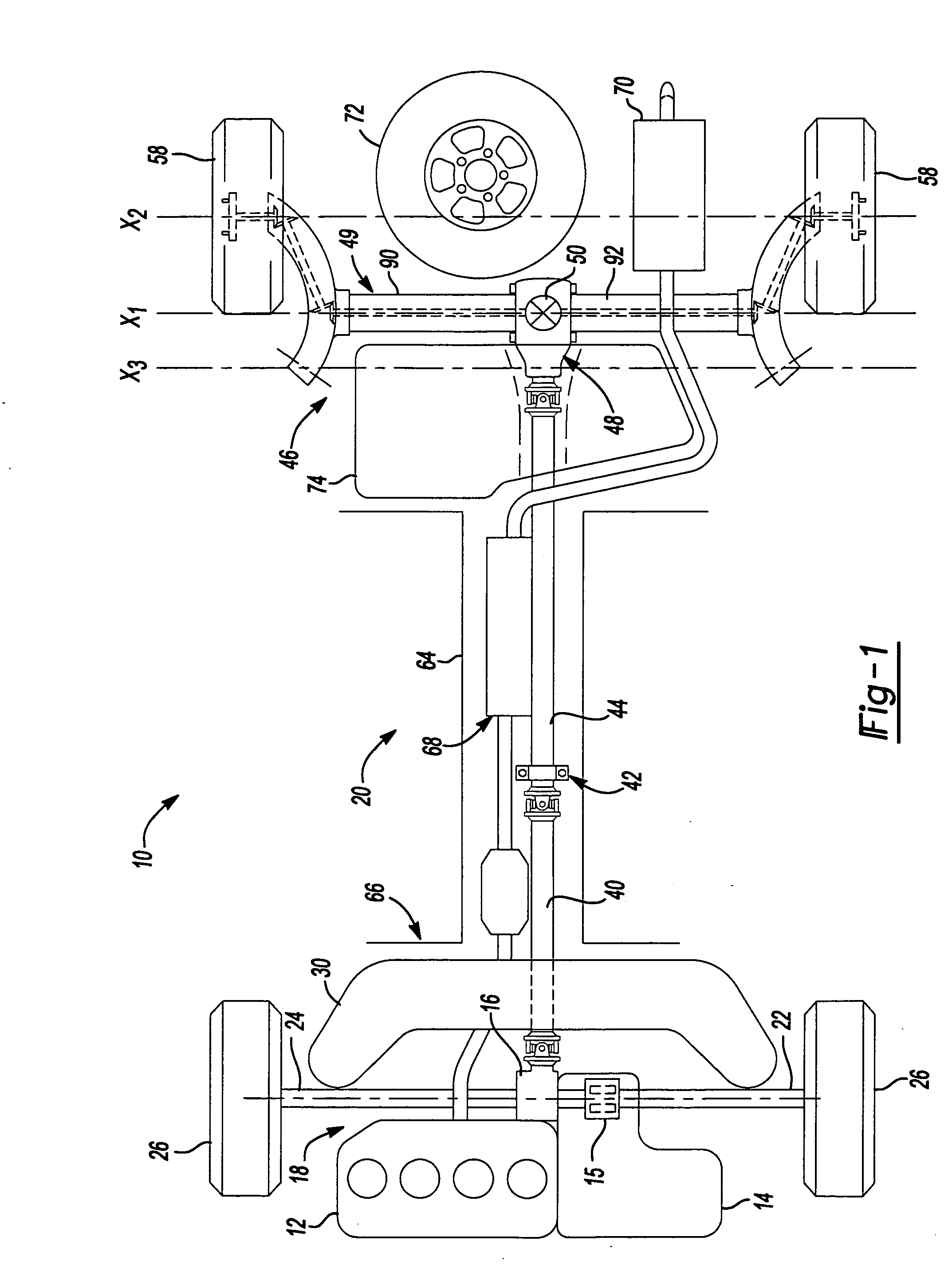

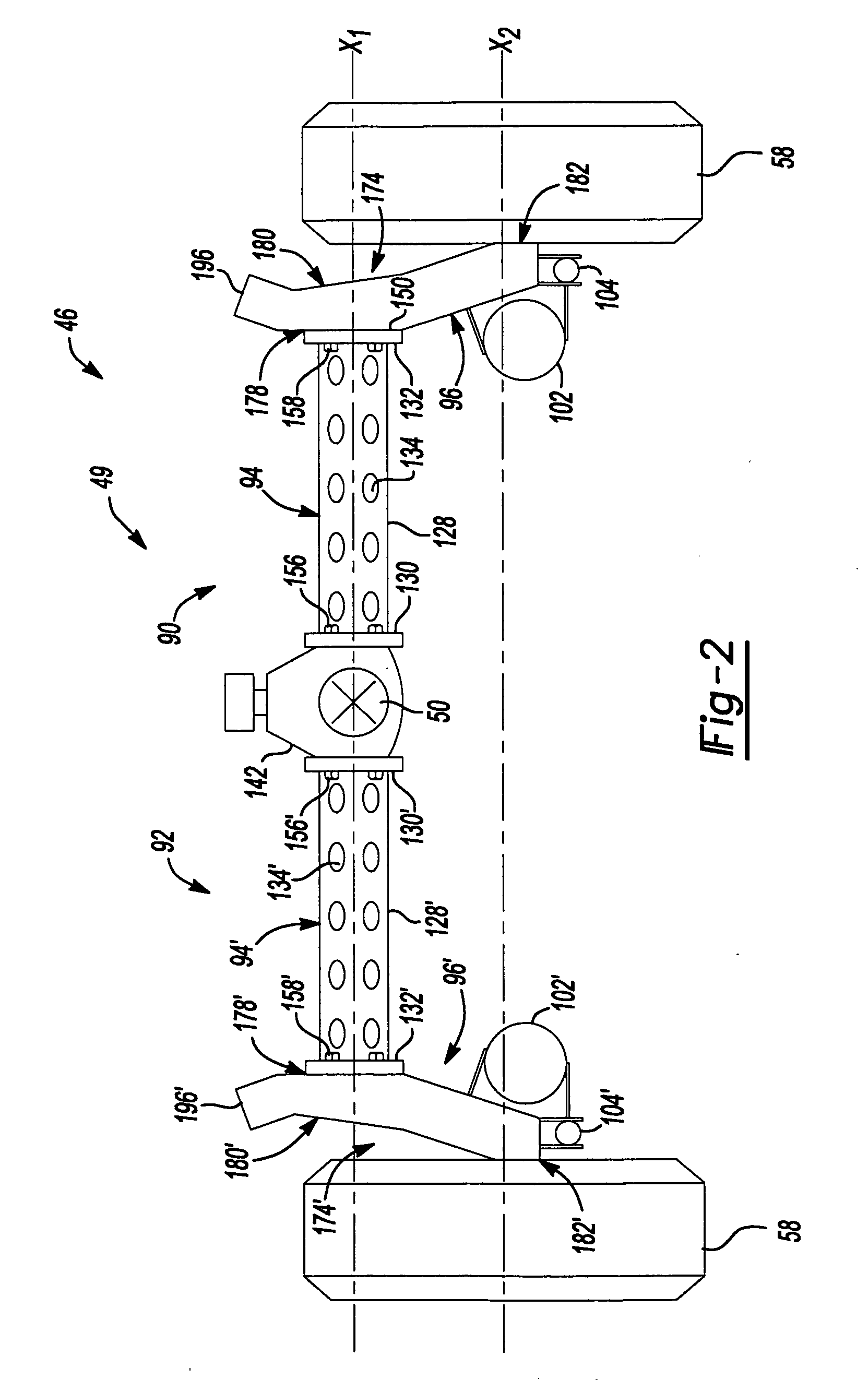

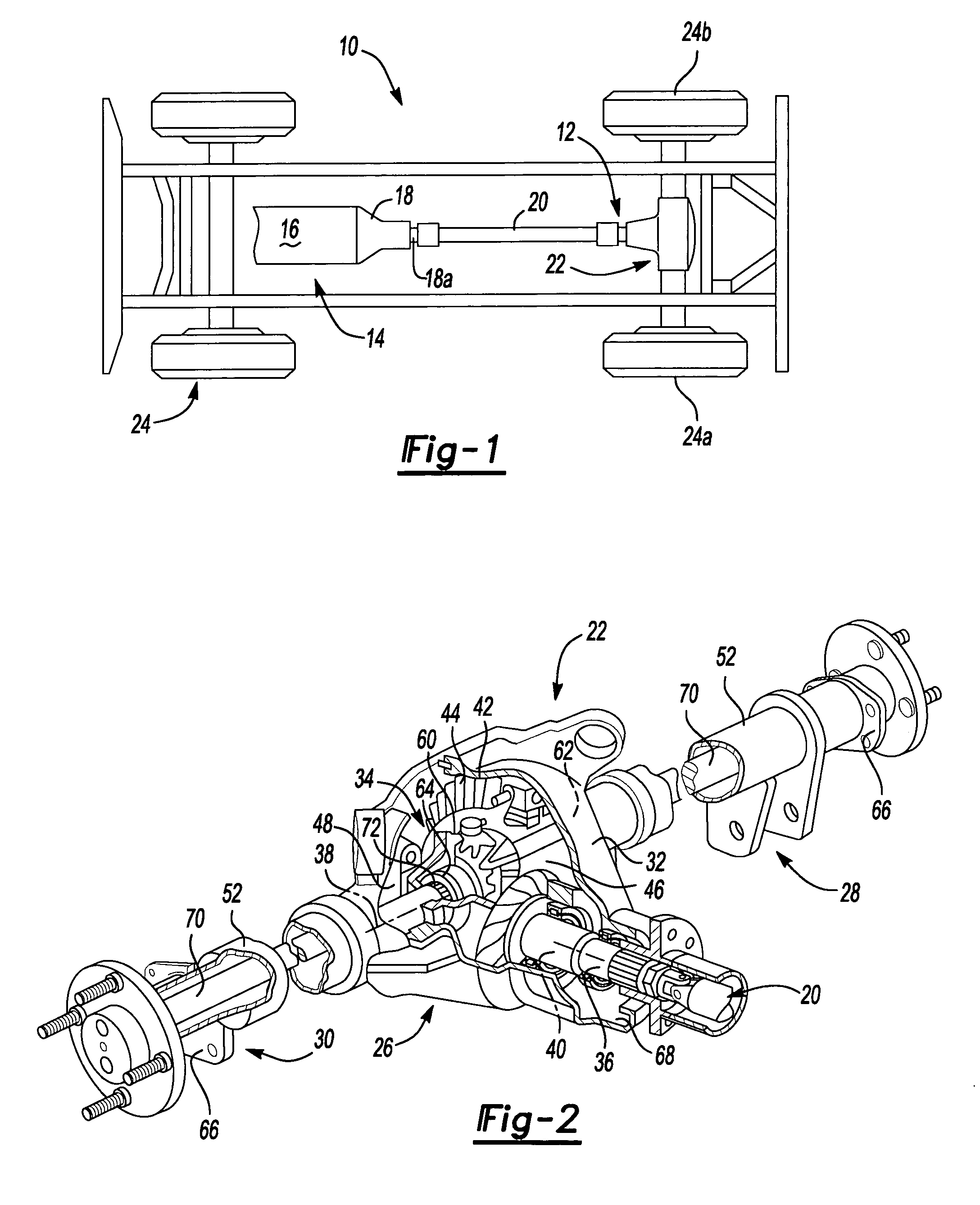

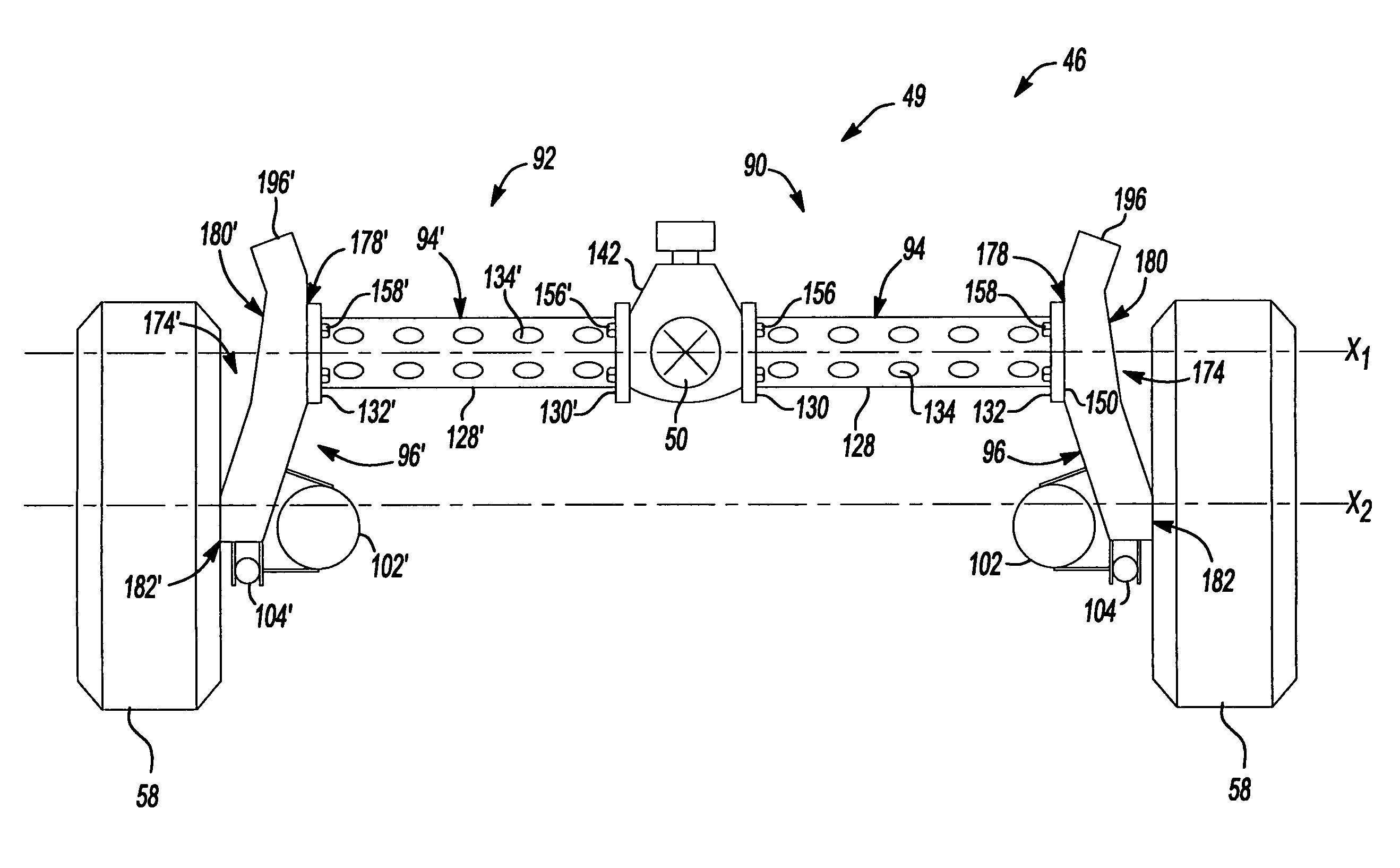

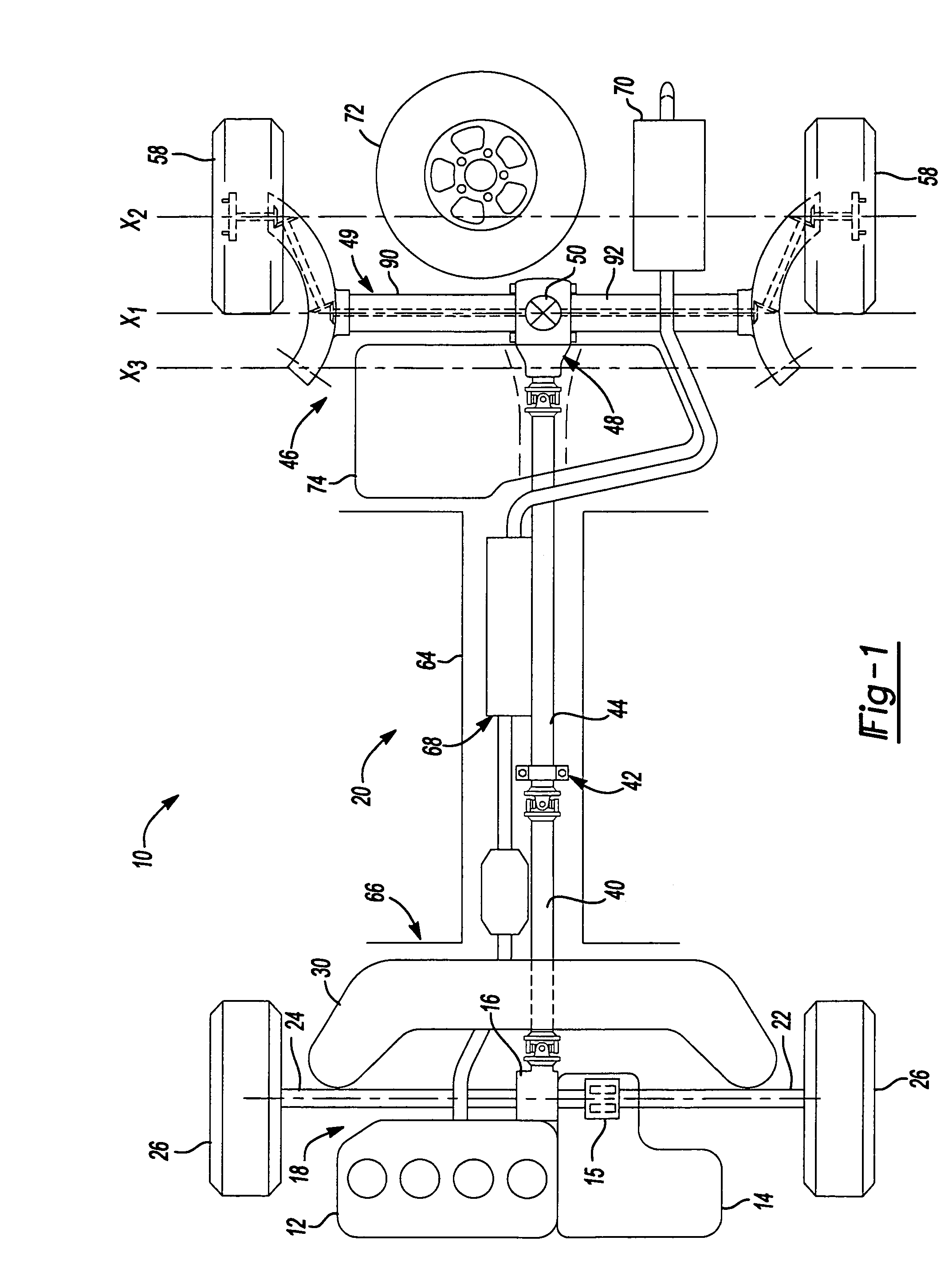

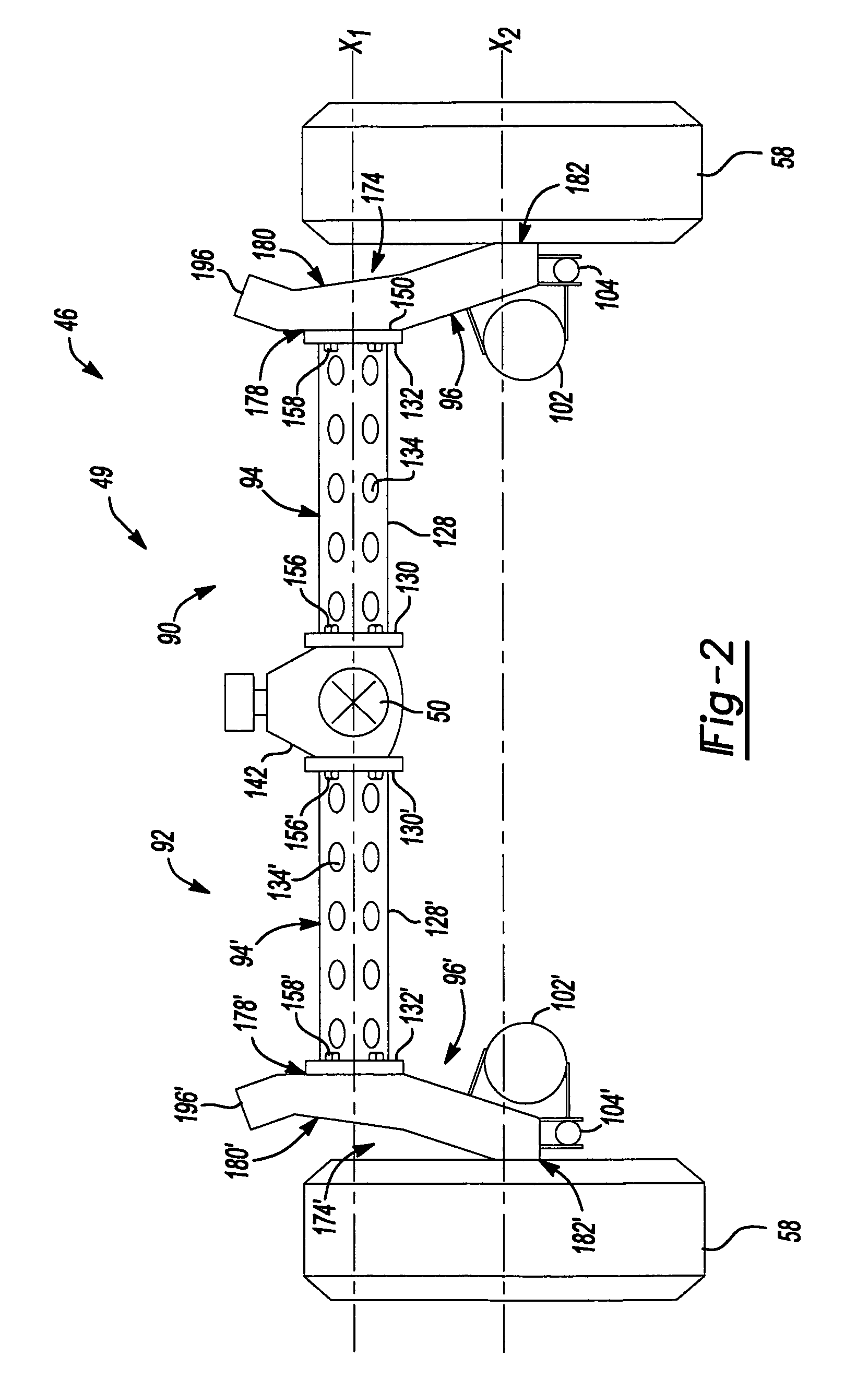

Live twist beam axle assembly

A drive axle and suspension assembly for a vehicle having a power source and wheels including a torsionally compliant twist beam suspension and a driveline assembly. The twist beam includes a twist element defining a first lateral axis and arm portions adapted to rotatably support the wheels of the vehicle along a second axis extending substantially parallel to the first axis. The driveline assembly is adapted to receive torque from the power source and drive the wheels. The driveline assembly includes a plurality of power transmission rotatably supported by arm portions.

Owner:AMERICAN AXLE & MFG

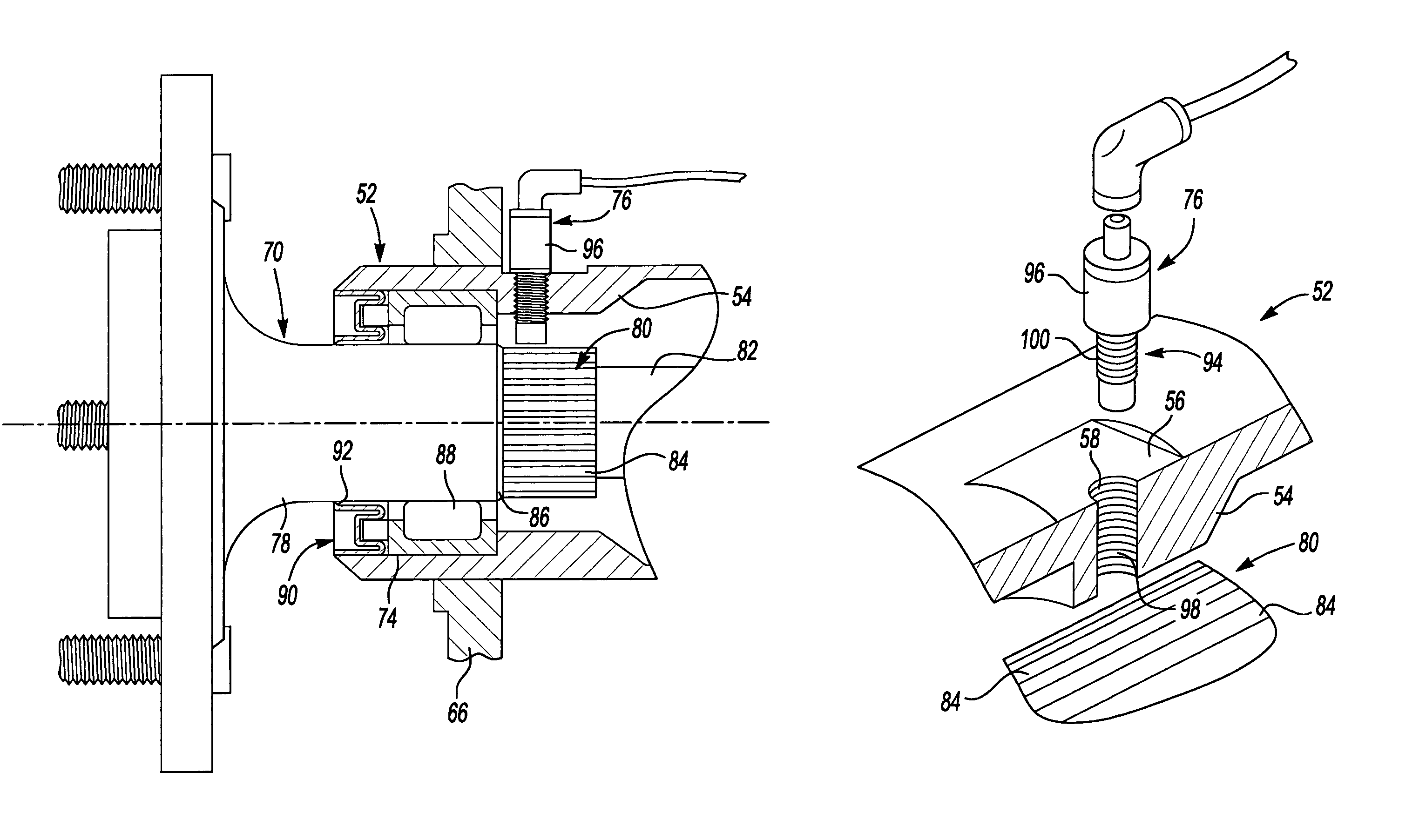

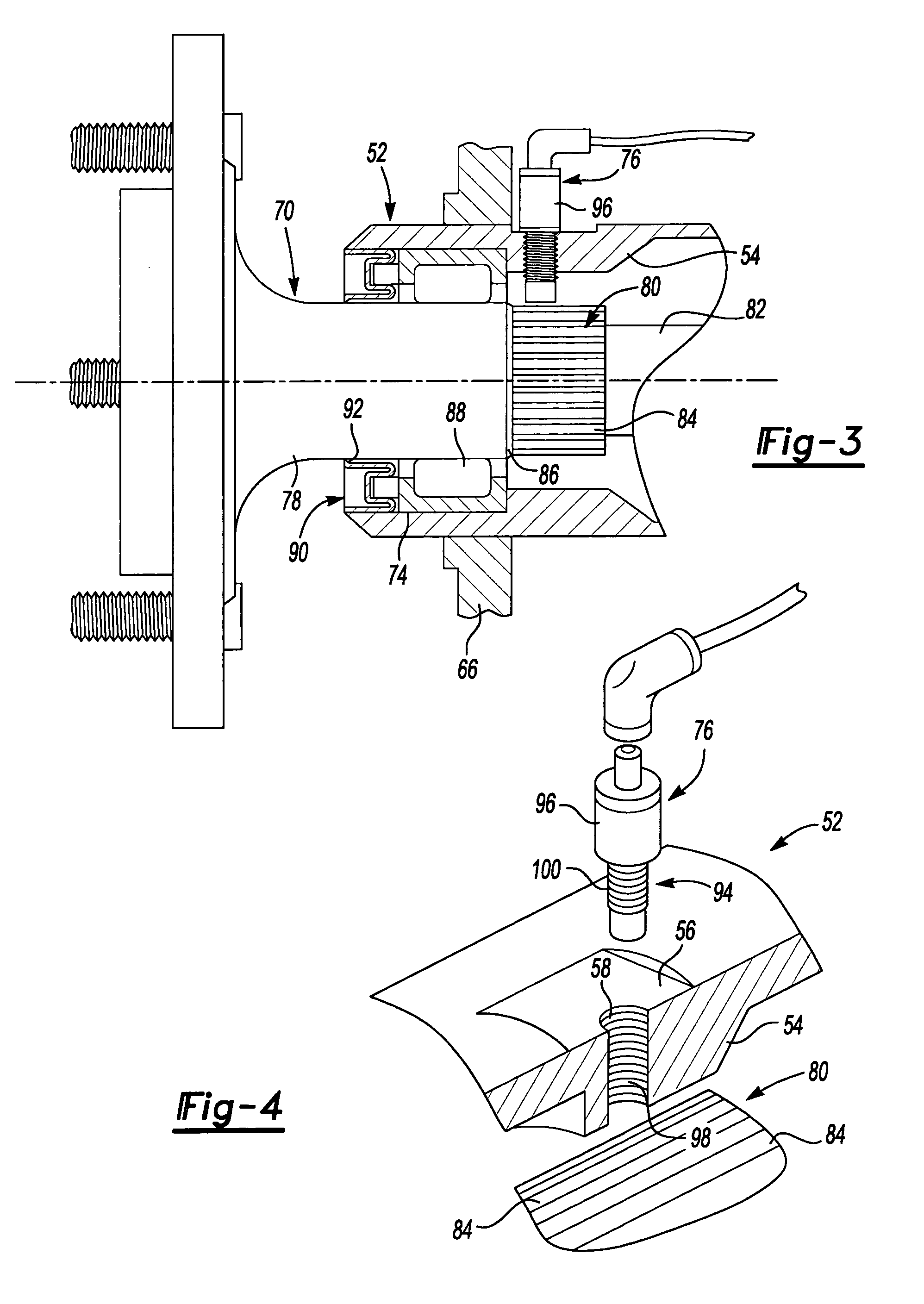

Beam axle with integral sensor mount and target

A vehicle axle assembly having an axle housing, an axle shaft and a sensor. The axle housing has a tubular portion. A flat is formed on an annular wall of the tubular portion proximate a distal end of the tubular portion. A hole, which intersects the flat, is formed through the tubular portion. The axle shaft can have an integrally formed target portion that includes a plurality of teeth. The sensor is mounted in the hole and abuts the flat to space a tip of the sensor apart from the teeth of the target portion by a predetermined distance.

Owner:AMERICAN AXLE & MFG

Suspension control arm assembly for vehicles

InactiveUS7588260B2Deflection characteristics that are tunableEliminates complianceRigid suspensionsInterconnection systemsControl armBeam axle

Owner:GM GLOBAL TECH OPERATIONS LLC

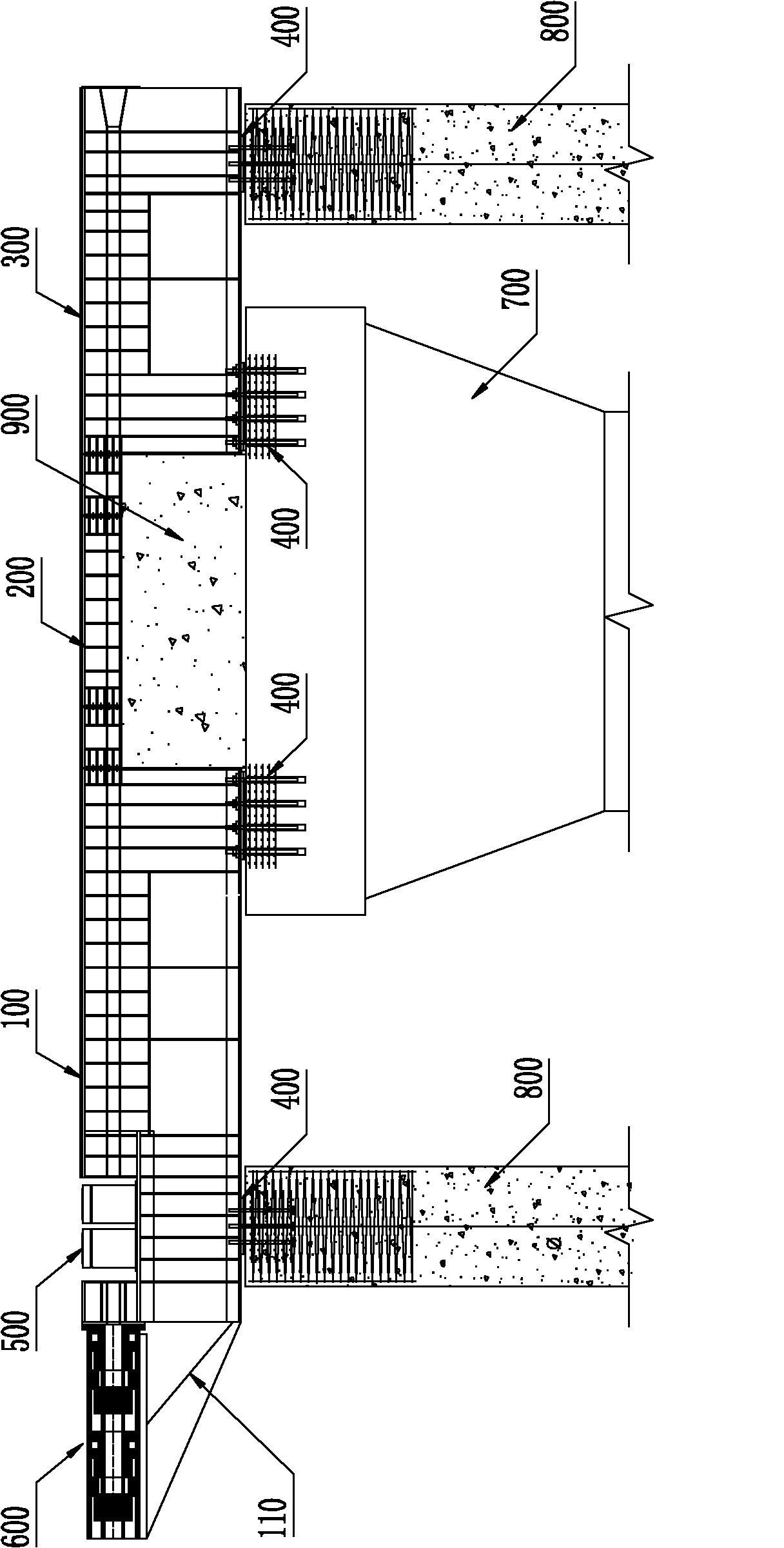

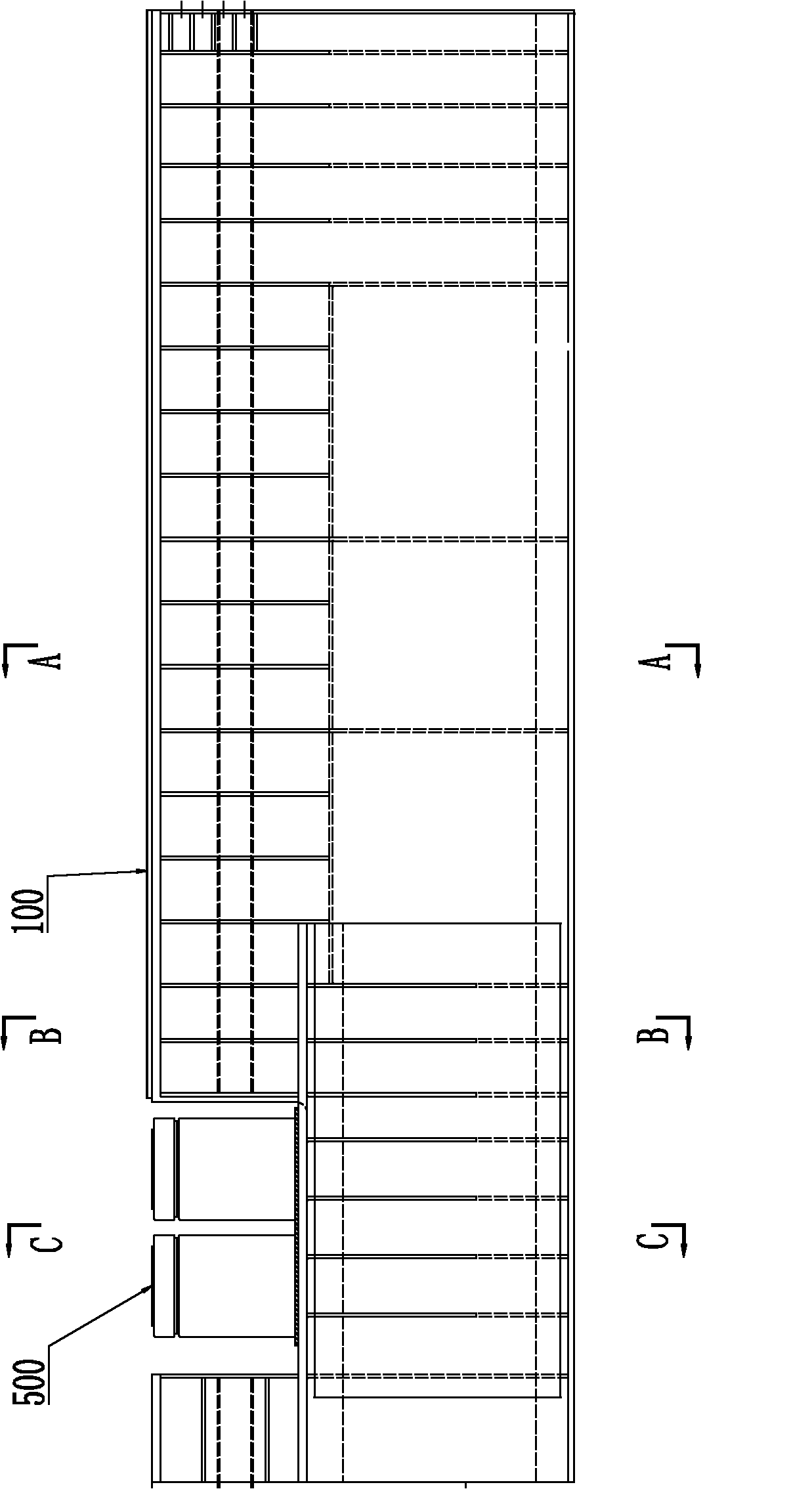

Novel slipway beam for incremental launching construction

InactiveCN101929129AGuaranteed continuityConvenient on-site constructionBridge erection/assemblyBeam axleBuilding construction

The invention discloses a novel slipway beam for incremental launching construction. The beam comprises a front slipway beam, a back slipway beam and a middle slipway beam which have box-shaped structures and are connected into a whole through bolts, wherein an upper surface on the back part of the back slipway beam is provided with a concave pit; four vertical lifting jacks are vertically arranged in the concave pit and arranged in an array form along the axial central cross section of the back slipway beam; the back end face of the beam slipway beam is provided with a support platform; a horizontal continuous lifting jack is arranged on the support platform; the left and right sides of the upper surfaces of the front, back and middle slipway beams are provided with stainless steel plates respectively; and traction rope insertion pipes are arranged inside the front, back and middle slipway beams along the length directions of the front, back and middle slipway beams. The slipway beam has the advantages of ensuring the continuity of horizontal lifting, projecting and longitudinal movement in a steel beam pier-passing process well, bringing convenience to field construction, saving construction period, avoiding additional arrangement of temporary individual projecting and horizontal lifting structures and saving construction cost.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

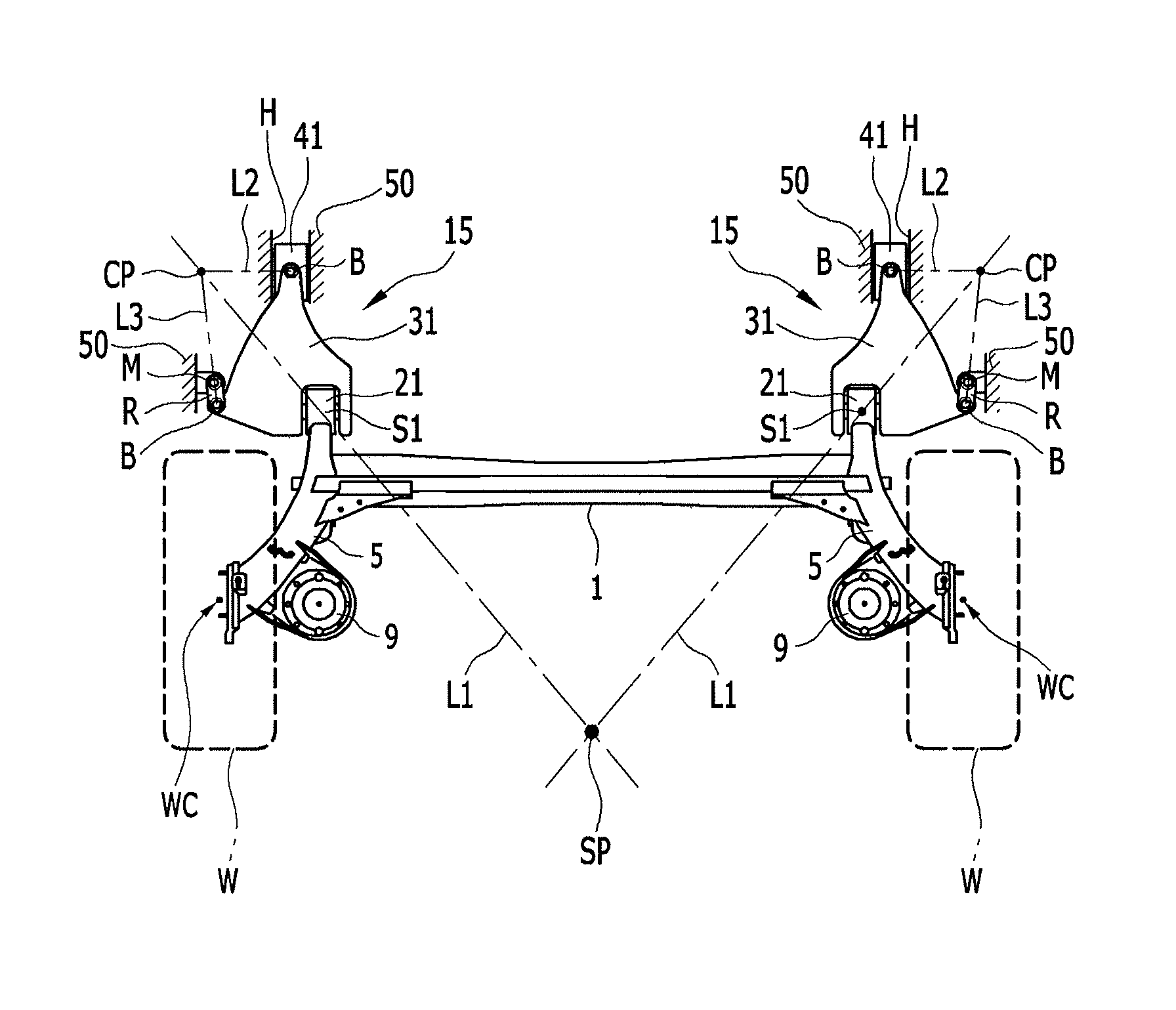

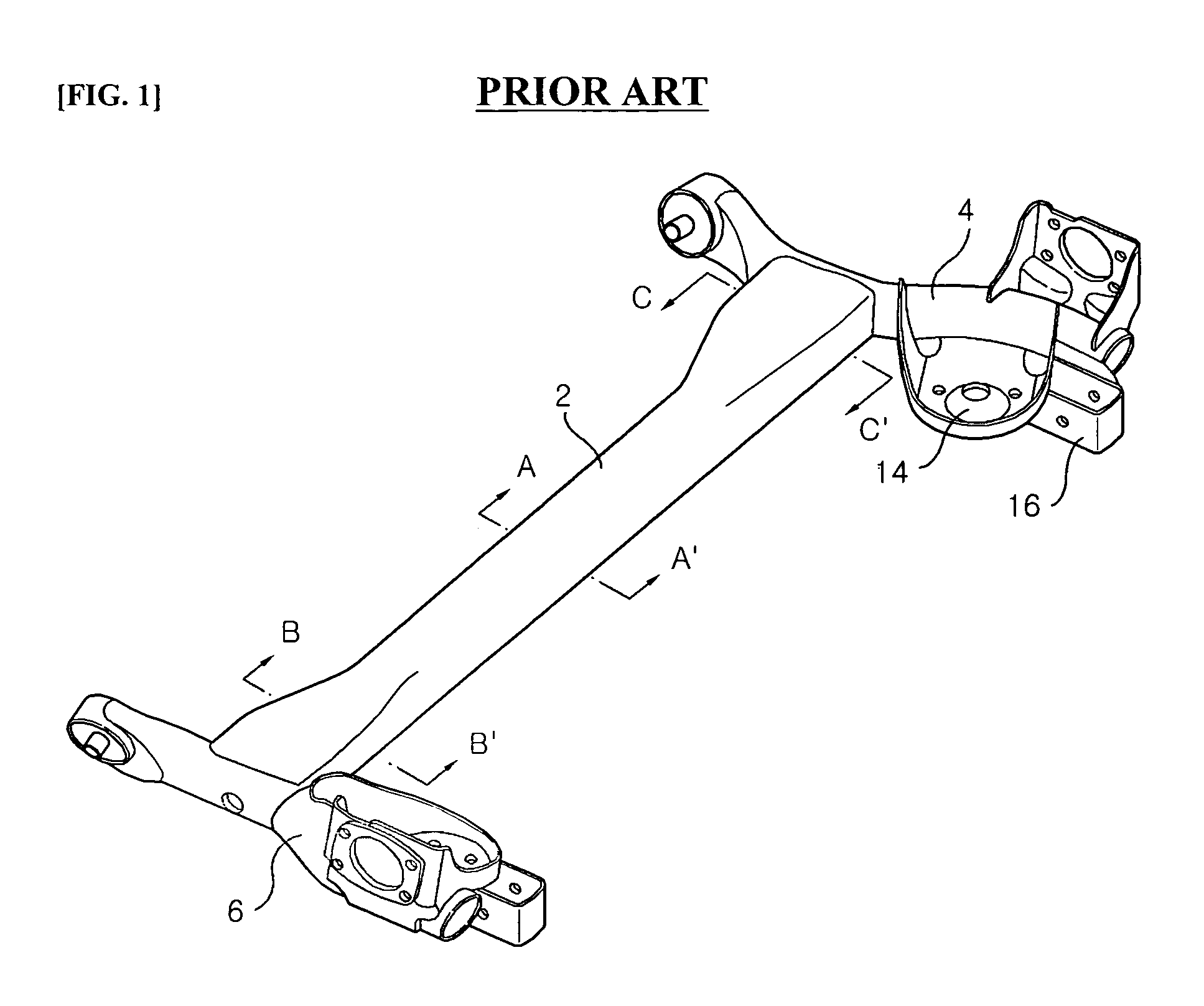

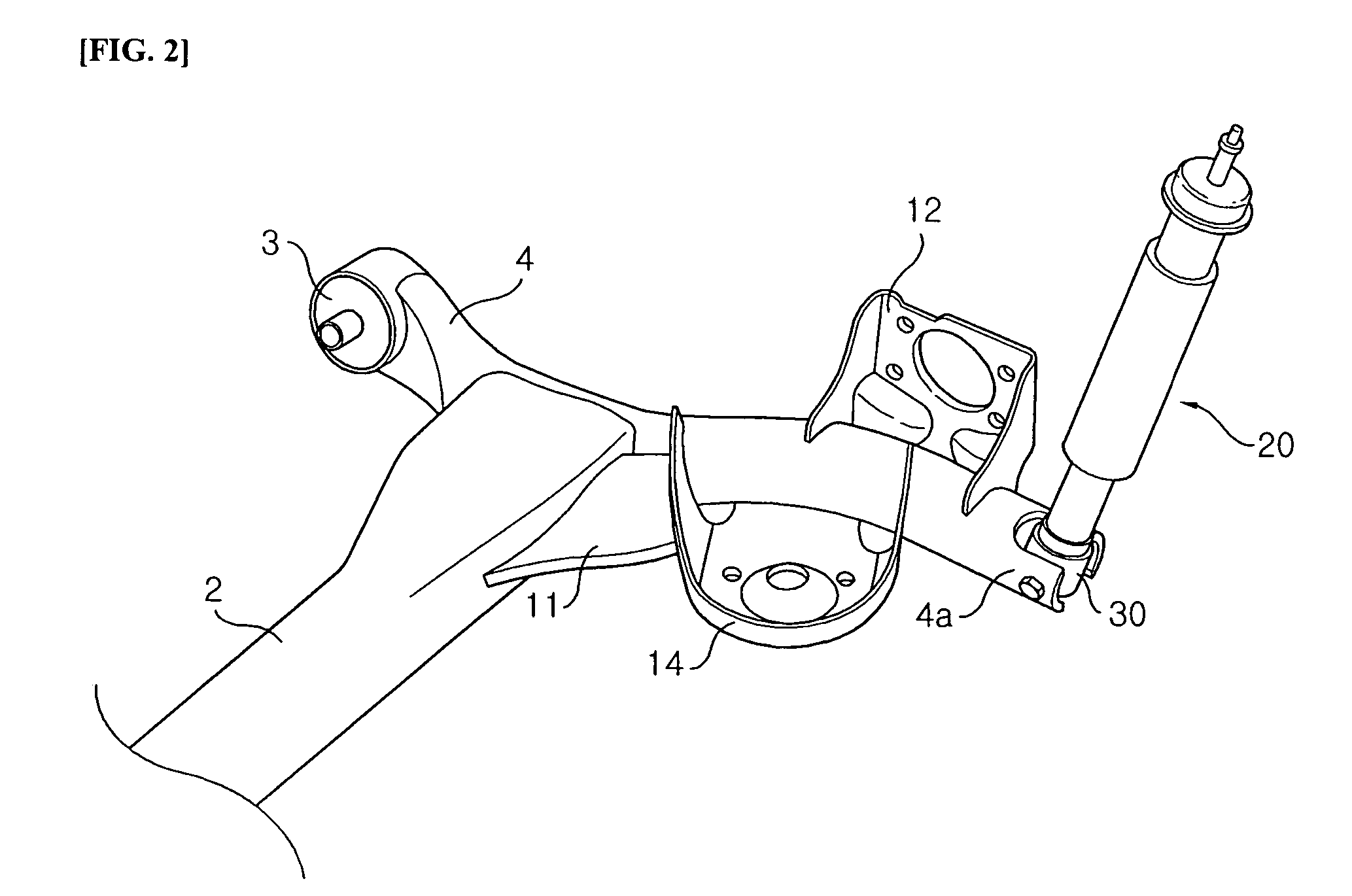

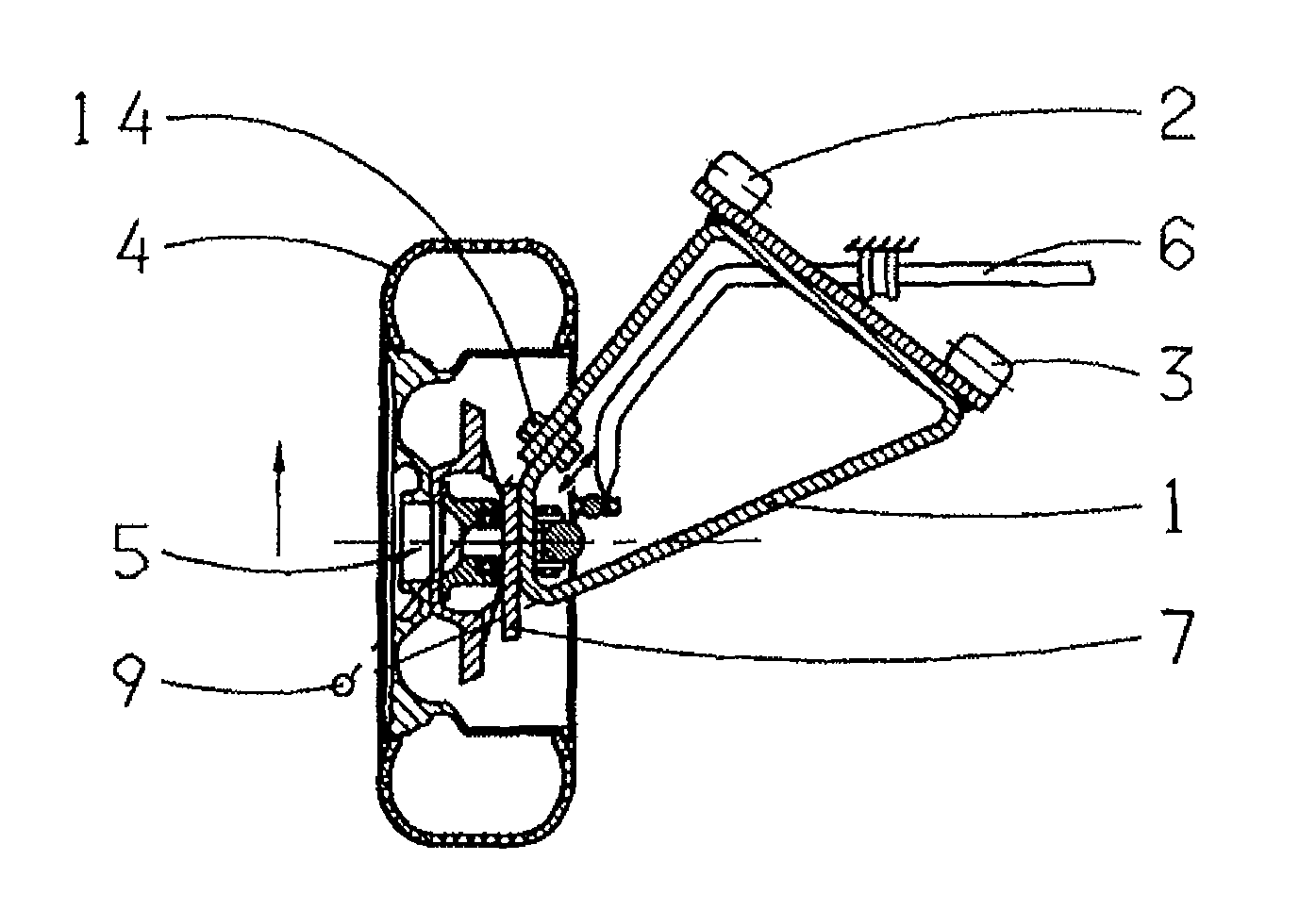

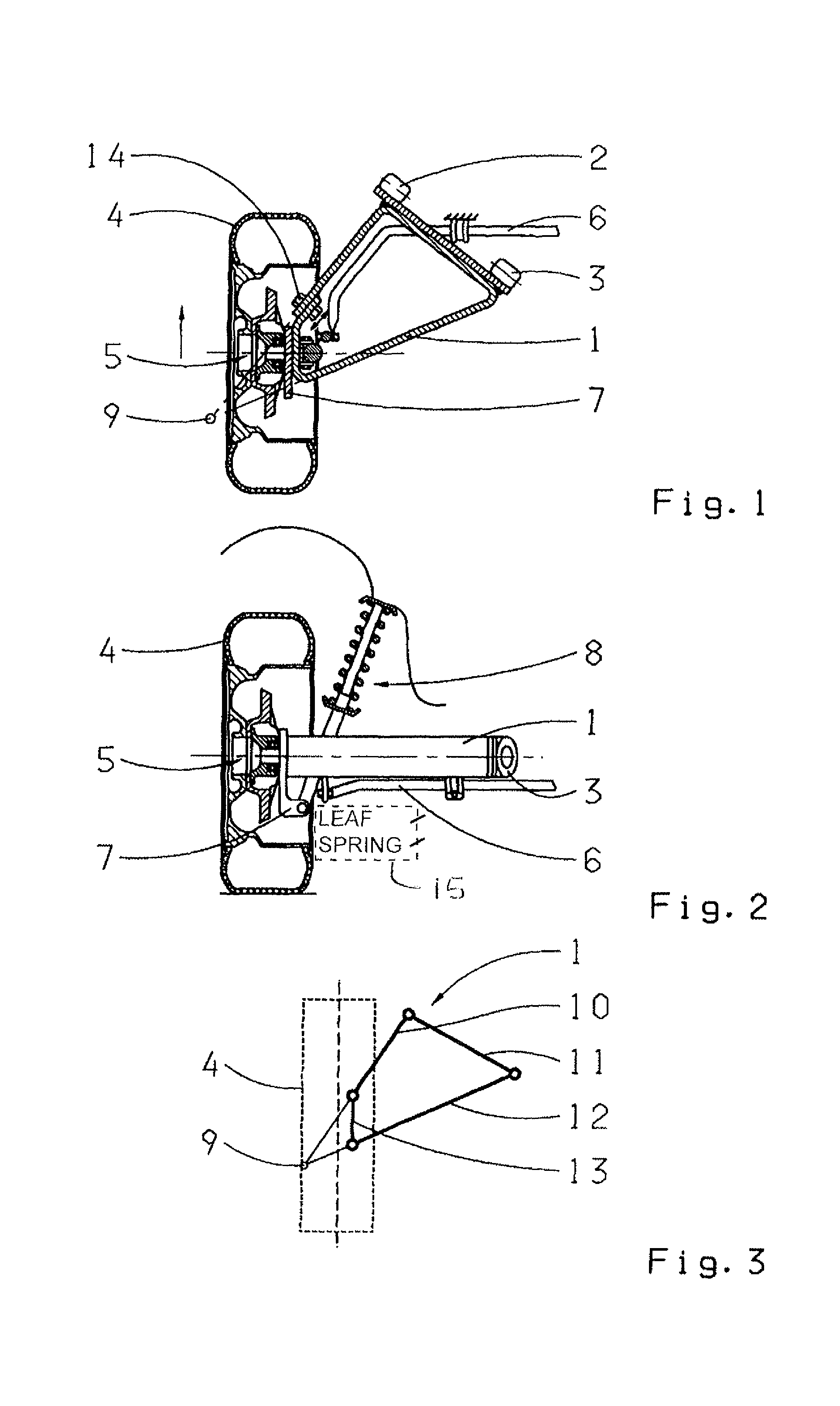

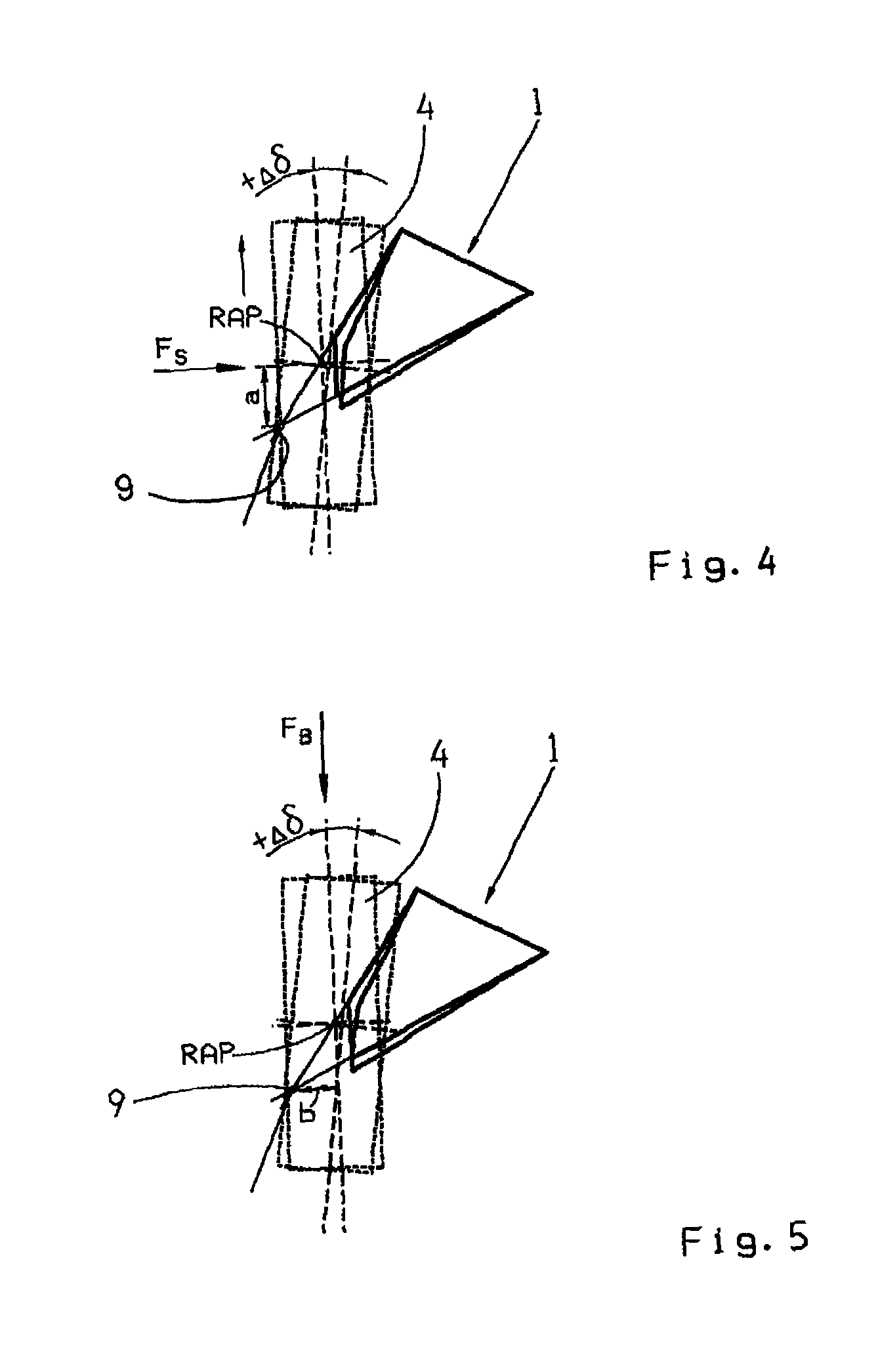

Semi-trailing arm axle for a motor vehicle

InactiveUS8523209B2Avoid oversteerSteering partsInterconnection systemsMobile vehicleMotor vehicle part

A semi-trailing arm axle for a motor vehicle which comprises a semi-trailing arm (1) for each wheel (4) of the axle. Each semi-trailing arm (1) is flexible about the vertical axis and is mounted to the body or on a support frame by at least one mounting (2, 3). Each wheel (4) of the axle is connected to its respective flexible semi-trailing arm (1) by way of at least one wheel bearing (5), and the flexible semi-trailing arm (1) is the sole wheel-guiding element.

Owner:ZF FRIEDRICHSHAFEN AG

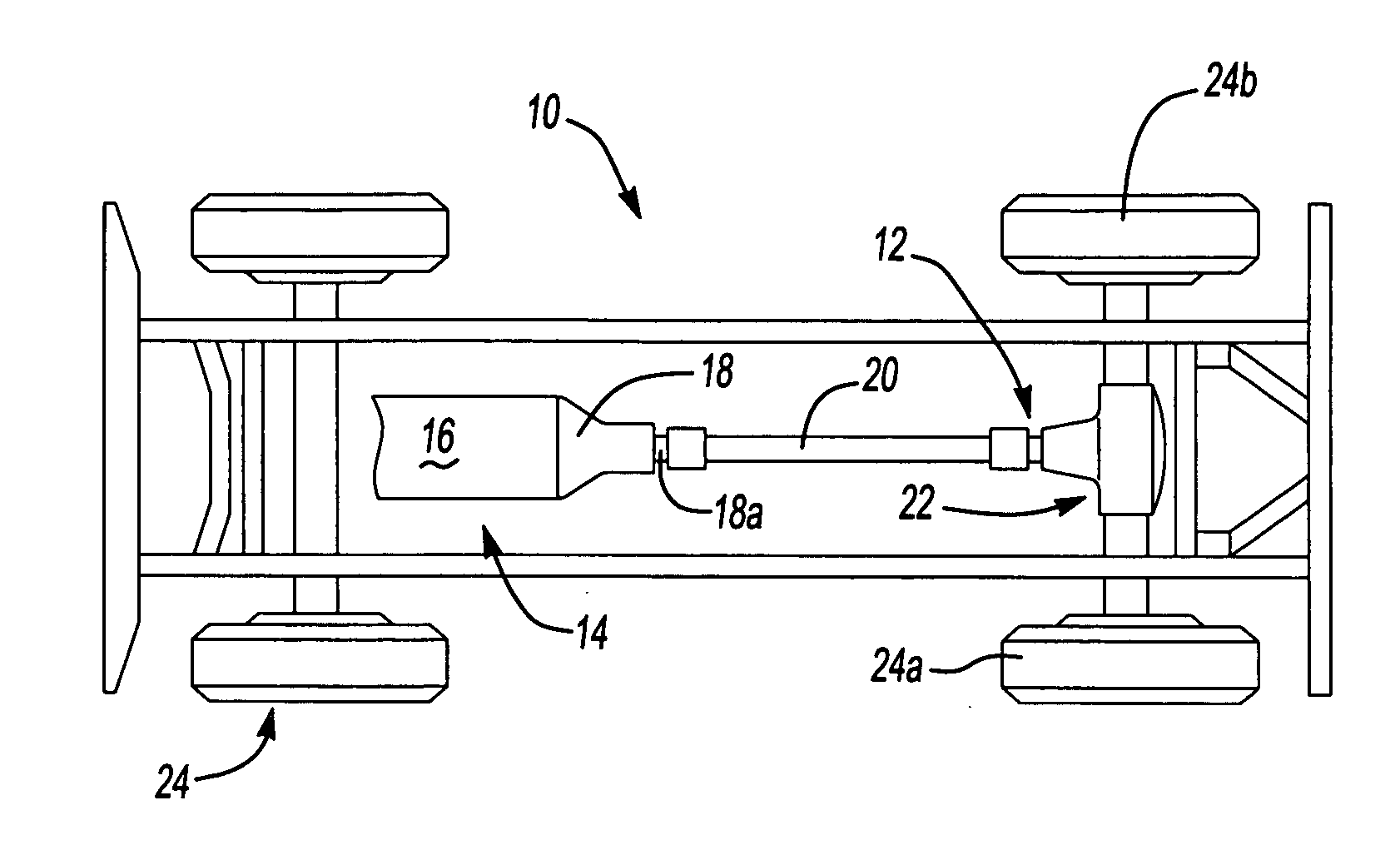

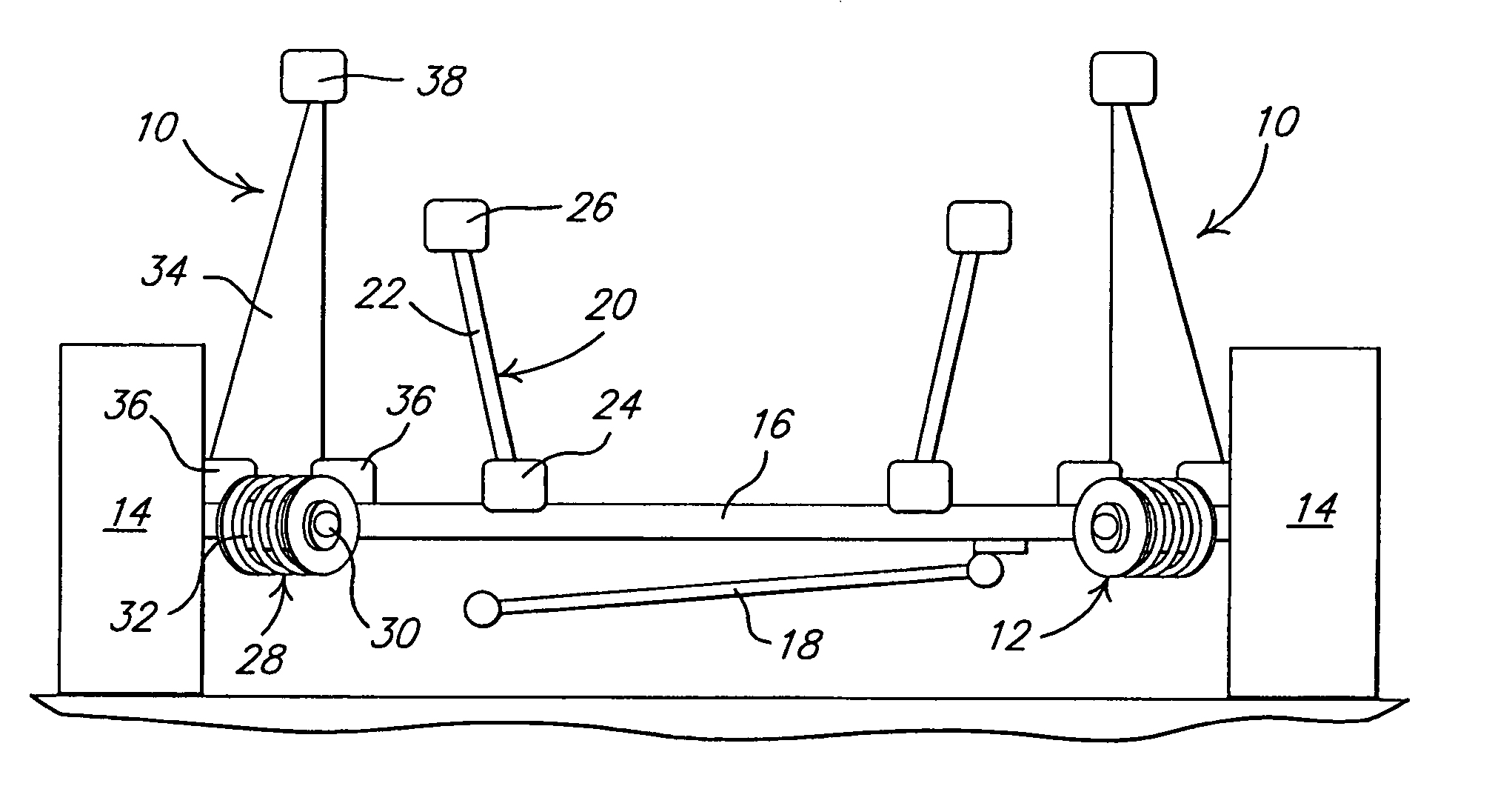

Twist beam with interlock

ActiveUS8205898B2Increased bending stiffnessIncrease flexibilityInterconnection systemsWheel manufactureControl armFront-wheel drive

In a front wheel drive vehicle a traditional twist beam axle suffers from a short service life due to premature failures in intermediate areas between the end sections and the transitional section. A twist beam suspension is provided comprising a transverse strut (16) interconnecting longitudinal control arms (12). The transverse strut (16) may be formed from a tubular pipe. The tubular member may define a pair of tubular end sections (18), a deformed, U-shaped transitional section (20), and a pair of intermediate sections (22) between the end sections (18) and the transitional section (20). The intermediate section (22) may define a contour (28), known as a tongue. The tongue (28) enhances the flexibility in torsion and improves the stiffness in bending of the transverse strut (16). The tongue (28) may also include a concavity, to further aid in improving stiffness.

Owner:MAGNA INTERNATIONAL INC

Live twist beam axle assembly

A drive axle and suspension assembly for a vehicle having a power source and wheels including a torsionally compliant twist beam suspension and a driveline assembly. The twist beam includes a twist element defining a first lateral axis and arm portions adapted to rotatably support the wheels of the vehicle along a second axis extending substantially parallel to the first axis. The driveline assembly is adapted to receive torque from the power source and drive the wheels. The driveline assembly includes a plurality of power transmission rotatably supported by arm portions.

Owner:AMERICAN AXLE & MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com