Novel slipway beam for incremental launching construction

A technology of jacking construction and slideway beams, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as single structural form, inconvenient construction, and increased construction costs, so as to save construction costs and facilitate on-site construction. The effect of saving the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

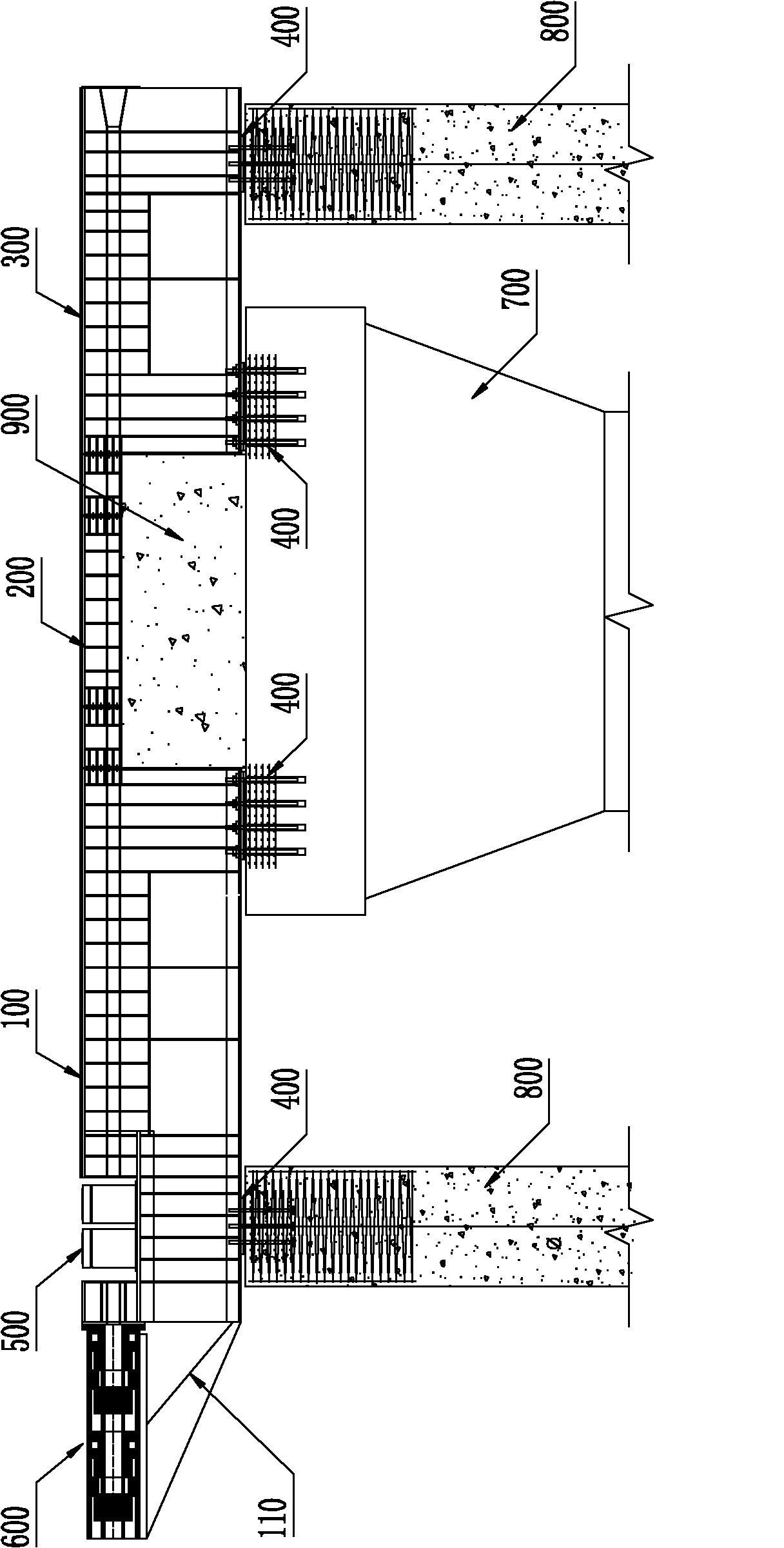

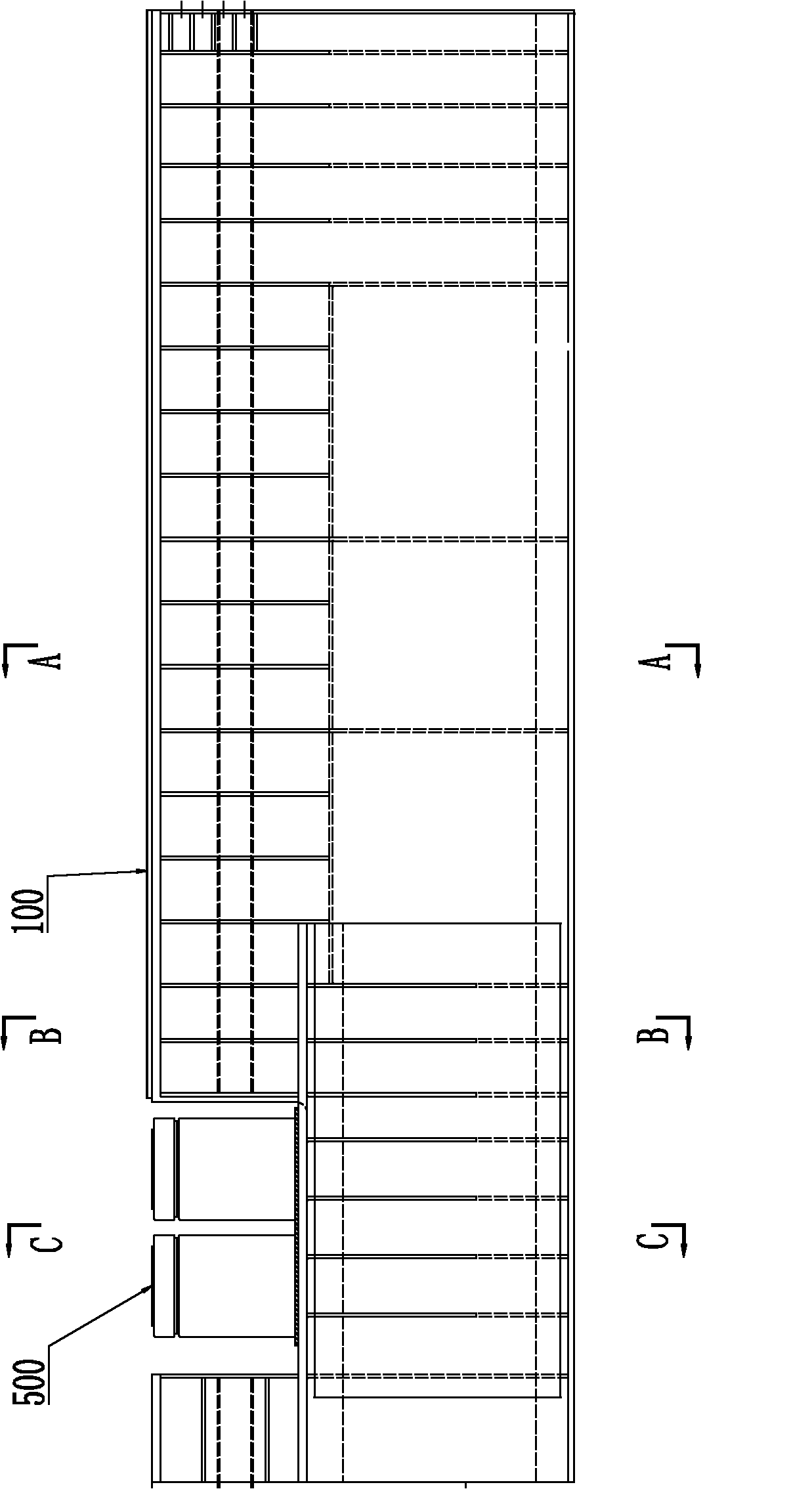

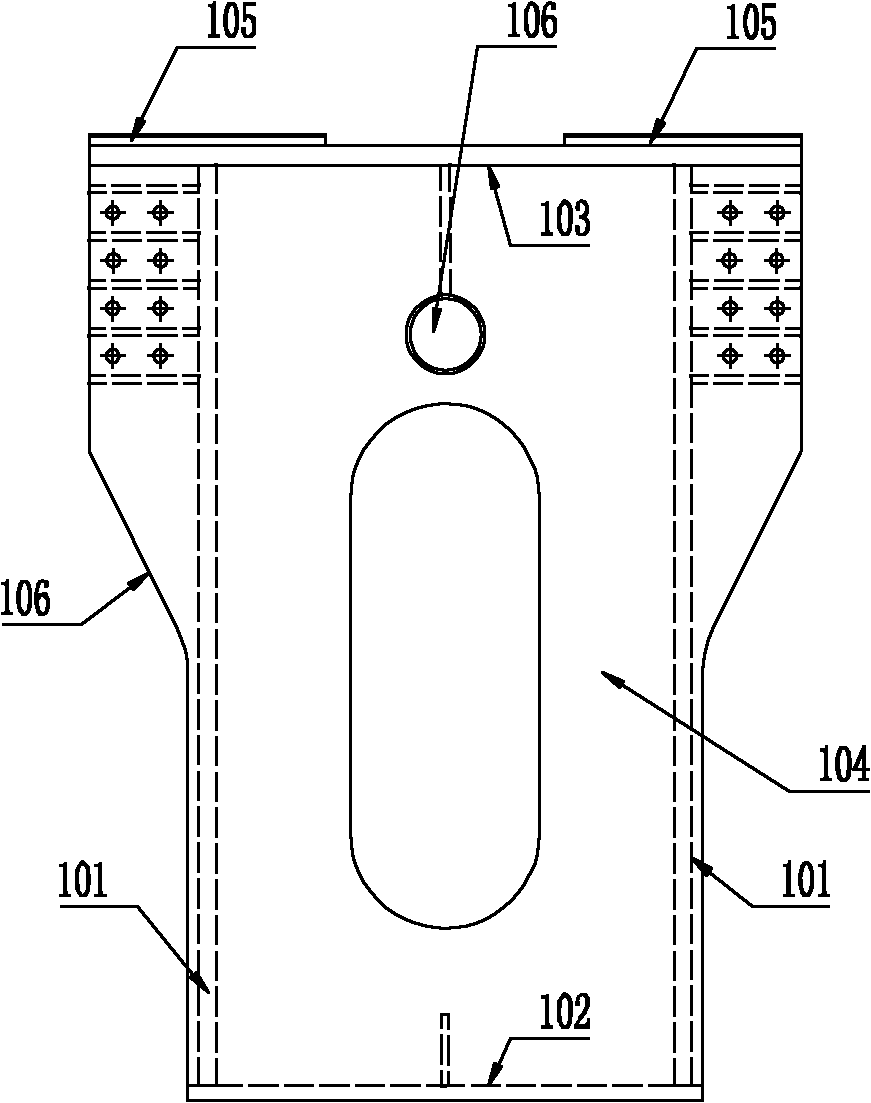

[0018] like figure 1 As shown, the present invention includes the front and rear slideway beams 300, 100 and the middle slideway beam 200 of a box-shaped structure, and the heights of the front and rear slideway beams 300, 100 are consistent and higher than the height of the middle slideway beam 200, thereby Realize that the slideway beam keeps the continuity of the top surface of the slideway beam when crossing the pier top pad stone, and can save steel materials. The rear slideway beam 100 and the front slideway beam 300 pass through the embedded parts 400, the main pier 700 and the side of the pier respectively. The bracket 800 is fixedly connected, the middle slideway beam 200 is supported on the upper surface of the main pier 700 through the support pad 900, and the two ends of the middle slideway beam 200 are respectively connected with the front and rear slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com