Patents

Literature

2091results about How to "Guaranteed synchronicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

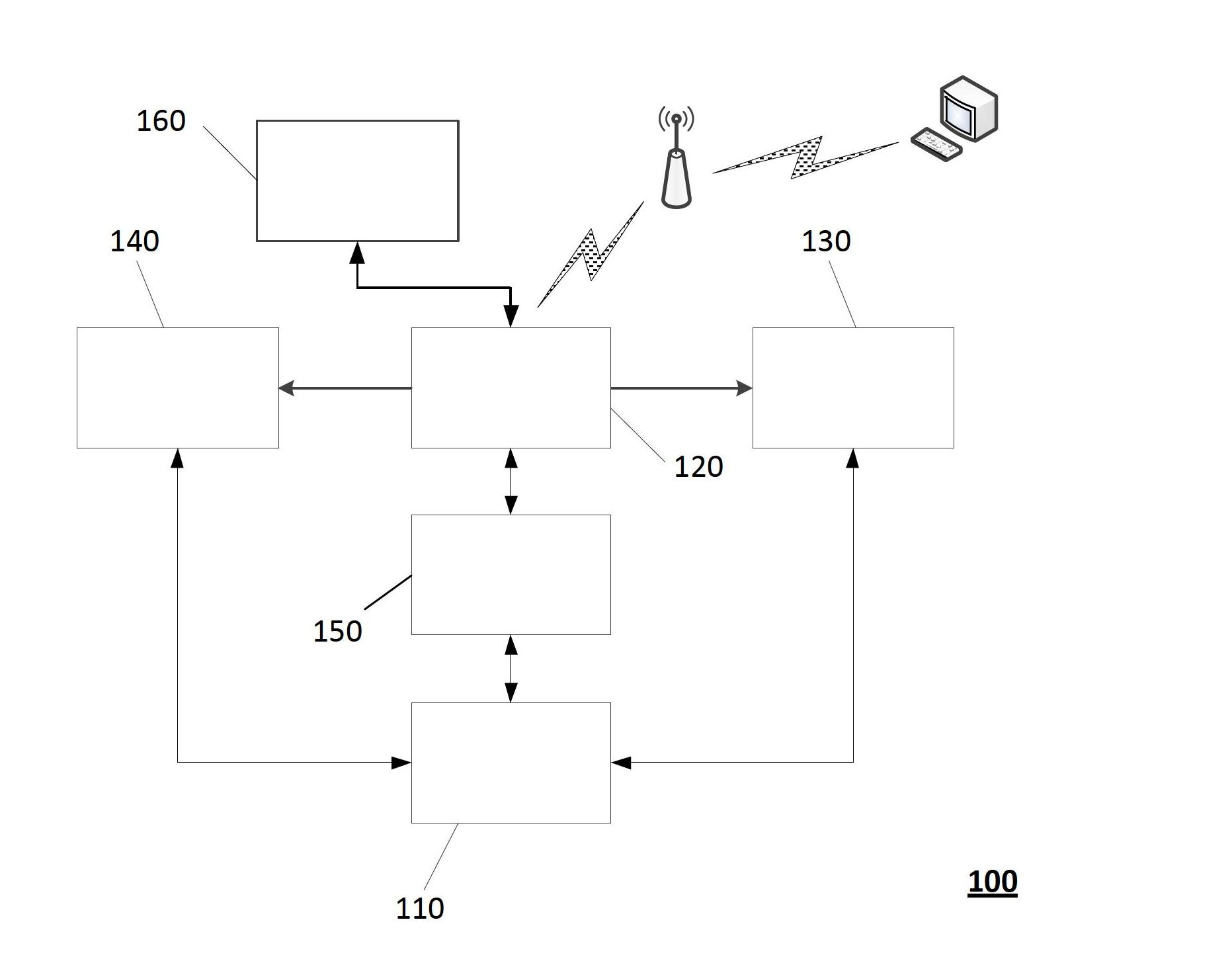

Video conference multi-party access method and equipment

InactiveCN106162040AGuaranteed synchronicityReduce processing timeTelevision conference systemsTwo-way working systemsAccess methodNetwork connection

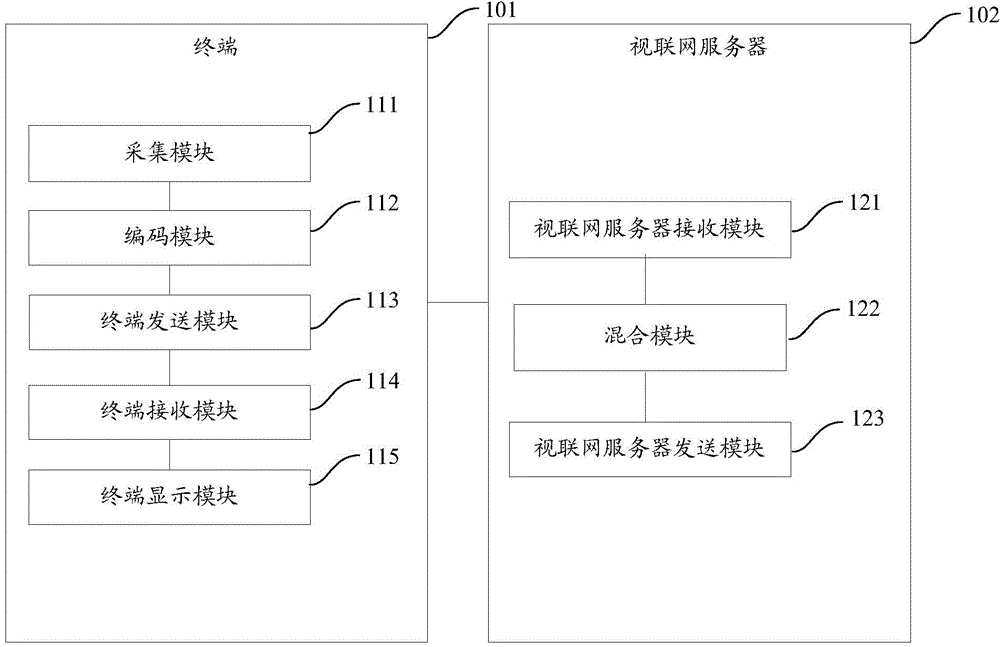

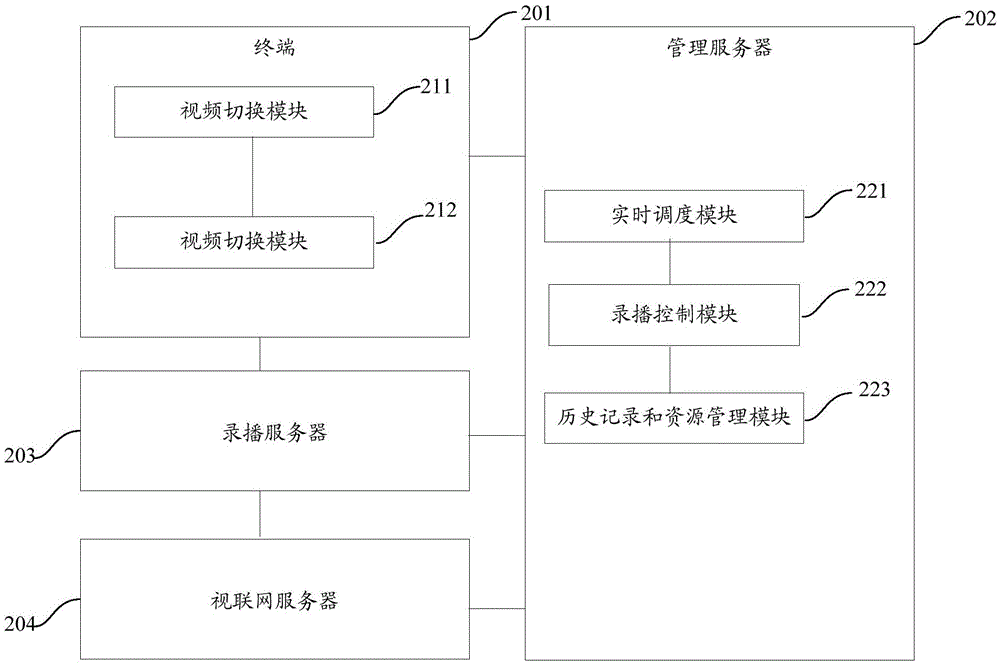

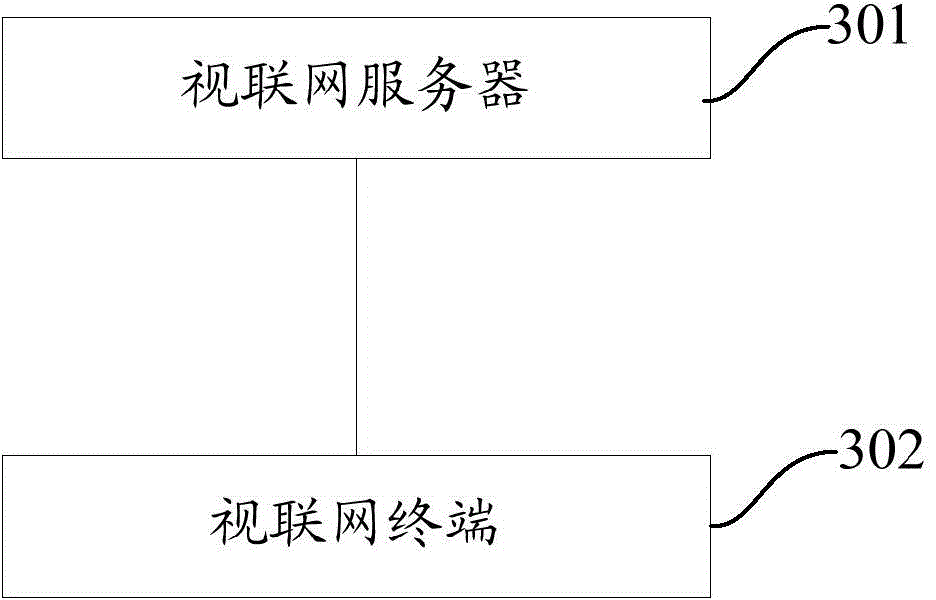

The invention provides a video conference multi-party access method and equipment. A terminal establishes network connection with an articulated naturality web server, and comprises an acquisition module, an encoding module, a terminal sending module, a terminal receiving module and a terminal display module, wherein the acquisition module is used for acquiring video signals and / or audio signals in a video conference process; the encoding module is used for encoding the acquired video signals and / or audio signals to obtain source signals which satisfy a unified code rate; the terminal sending module is used for sending the source signals to the articulated naturality web server; the terminal receiving module is used for receiving network flows sent by the articulated naturality web server; and the terminal display module is used for converting the received network flows to videos and / or audios and displaying the videos and / or audios on a screen. According to the video conference multi-party access method and equipment provided by the embodiment of the invention, the display real-time performance of multiple terminal sides which participate in a video conference can be guaranteed.

Owner:VISIONVERA INFORMATION TECH CO LTD

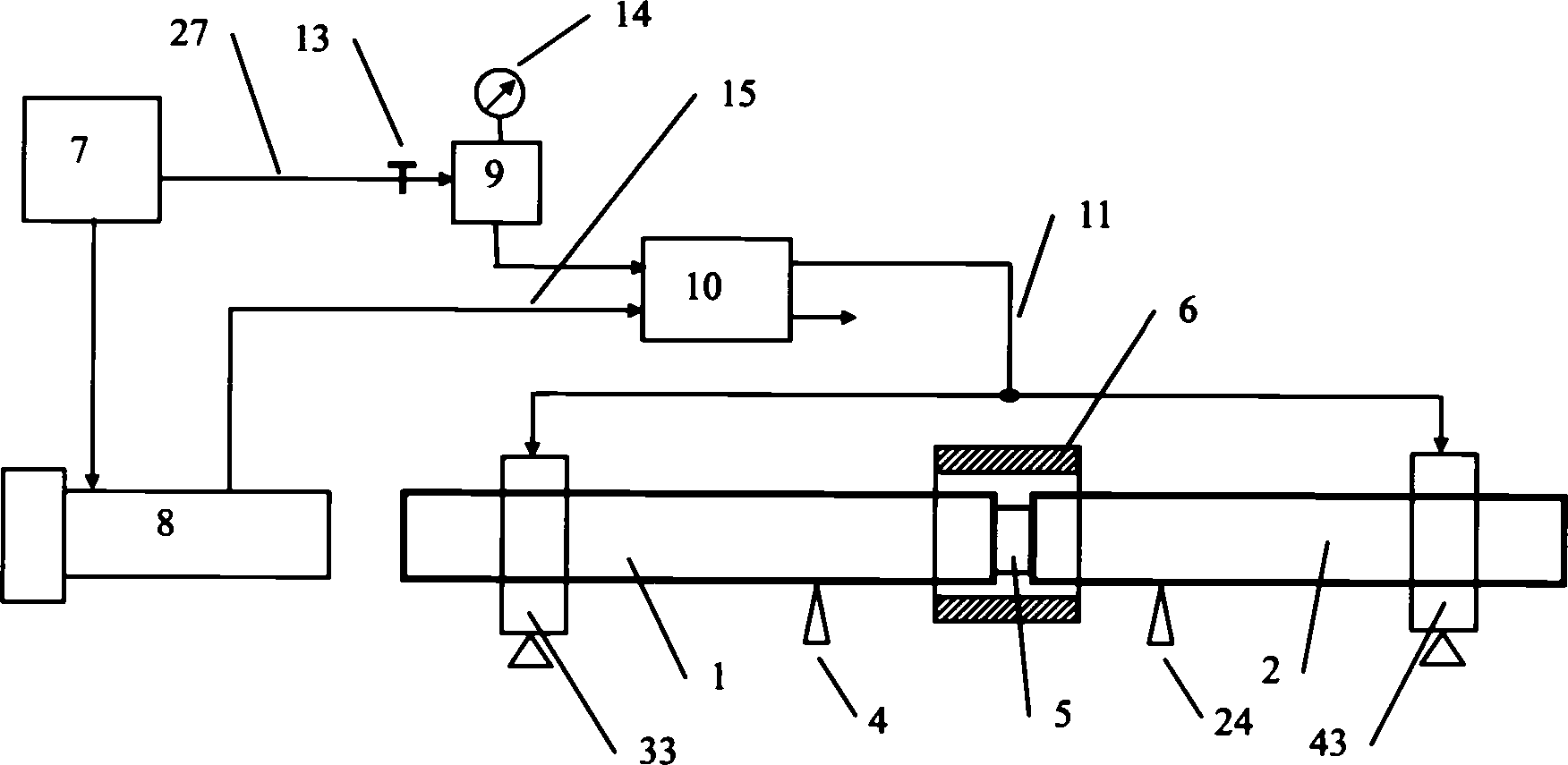

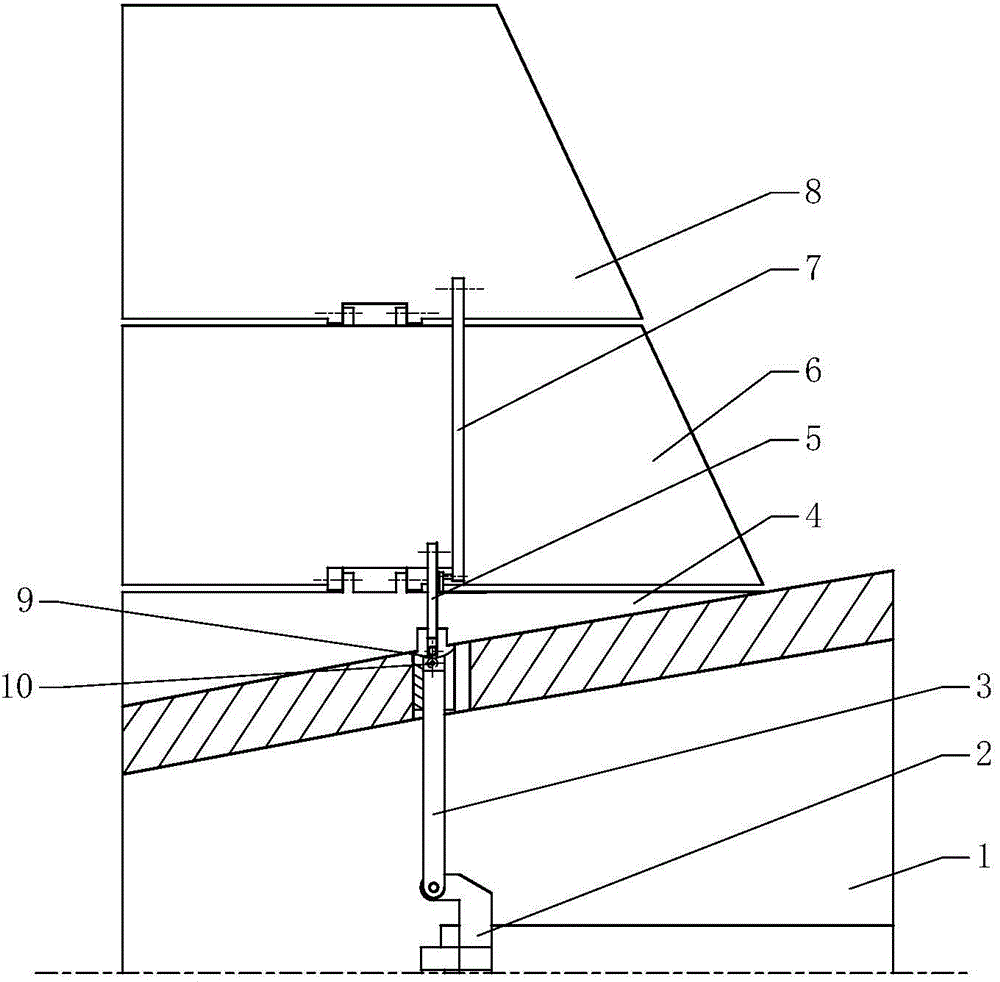

Center four-point leveling method and system of platform

ActiveCN102937813AGet rid of the danger of rolloverShed the loadControl using feedbackSimultaneous control of multiple variablesInductorEngineering

The invention provides a four-point leveling method of a platform. The method comprises the following steps that: legs extend out to touch a ground, rough regulation is performed in a large dip angle range, the legs stretch to a predetermined height, and fine regulation is carried out in a small dip angle range. The invention also provides a four-point leveling system of a platform, and the system comprises locking sleeve hydraulic legs (7)-(10), legs in-position inductors (19)-(22), a display and control combiner (30), a leveling controller (31), a hydraulic valve set (32), a pressure detection group (33) and a horizontal angle sensor (34). The system is simple in structure and control logic, the risk of side overturning in a control process is avoided, and the frequency of leveling is reduced.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

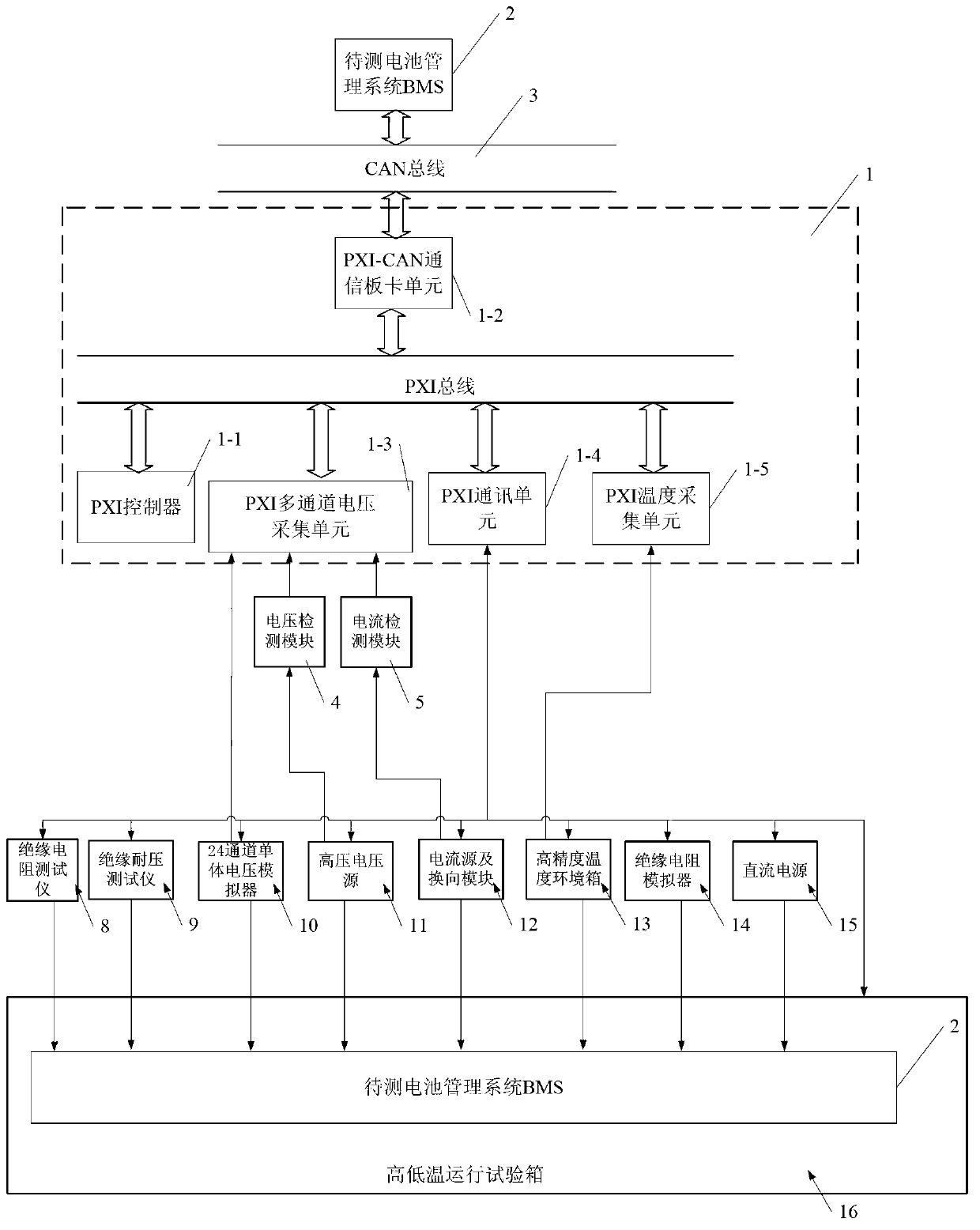

Battery management system performance test platform and testing method based on semi-physical simulation

InactiveCN103345163AGuaranteed validityDiversity guaranteedSimulator controlHeat managementEngineering

The invention relates to a battery management system performance test platform and a testing method based on semi-physical simulation and belongs to the field of systems. According to the battery management system performance test platform and the testing method based on semi-physical simulation, the problems existing in the aspects of effectiveness, practicality, accuracy, generality and comprehensiveness of an existing battery management system testing device and method are solved. A BMS to be tested and a simulation control and emulating unit of the test platform are connected with a CAN bus. A signal output end of an insulation resistance testing device, a signal output end of an insulation voltage resistant testing device, a signal output end of a 24-channel single-body voltage simulator, a signal output end of a high-voltage source, a signal output end of a current source and current reversing module, a signal output end of a high-accuracy temperature environment box, a signal output end of an insulation resistance simulator and a signal output end of a direct current power source are respectively connected with corresponding signal input ends of the BMS to be tested. The BMS to be tested is arranged in a high-low-temperature operational testing box. The testing method comprises the steps of safety testing and the comprehensive testing of state parameter measuring accuracy, SOC estimating accuracy, a battery fault diagnostic function, a heat management function and environment adapting performance and is used for testing the battery management system.

Owner:HARBIN INST OF TECH +1

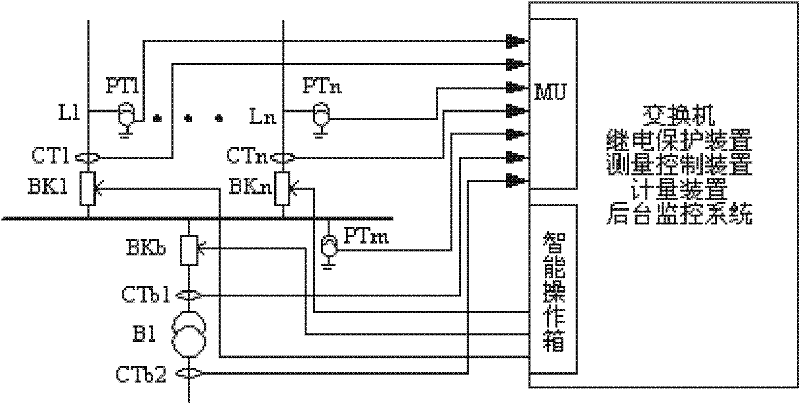

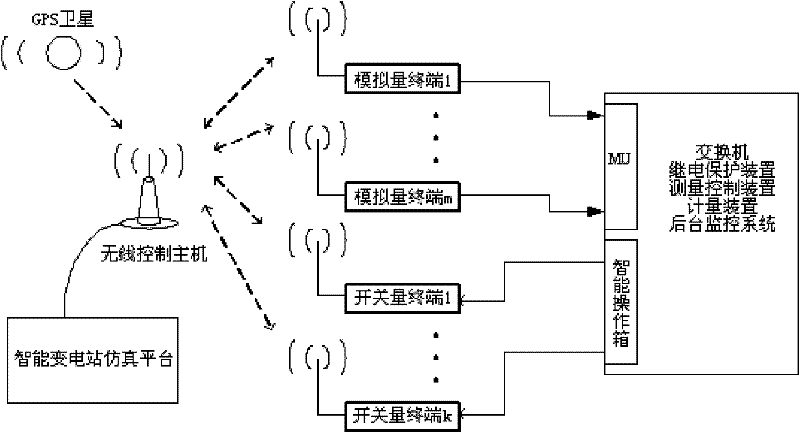

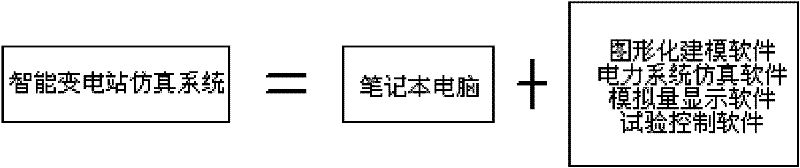

Method and device for testing overall performance of intelligent transformer substation

ActiveCN102510131AReal and trusted system environmentGuaranteed synchronicityCircuit arrangementsInformation technology support systemTime domainSmart substation

The invention discloses a method and a device for testing the overall performance of an intelligent transformer substation. The method comprises the following steps of: by taking a secondary system of the intelligent transformer substation as a check object, checking a combination unit and a network switch of the intelligent transformer substation; by taking a primary main connecting wire of the intelligent transformer substation, and a line and a power supply which are linearly connected with the primary main connecting wire as objects, establishing a transformer substation simulation model; according to configuration and test requirements of an electronic transformer and switching equipment of the intelligent transformer substation, arranging an acquirer simulator and a switch simulator; by using a numerical value simulation method, acquiring a time domain simulation result of an object system; and under the control of a test control system, synchronously inputting test signals of the acquirer simulator into the combination unit, and uploading an intelligent operation box command which is received by the switch simulator to the test control system, so that checking of the functional accuracy of the secondary system of the intelligent transformer substation is finished. Based on a numerical value simulation technology, a wireless transmission technology and a network exchange technology, the invention has a true and reliable test result by validation.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

Double-air path bidirectional automatic assembling device for high-temperature Hopkinson pressure bar experiment

InactiveCN1888851AGuaranteed synchronicityReduce temperature unevennessStrength propertiesEngineeringAtmospheric pressure

Two-way double steam paths self-motion assembled equipment for high temperature Hopkinson pressure-bar experiment belongs to material high temperature dynamic mechanics capability research field. Each gas driving rack set on incidence perch and transmission perch and push them towards specimen in assembling to form two-way assemble in order to keep specimen in the availability heating range. Push the driving gas path of rack and separate setting of air cannon startup gas path and set gas chief valve control the switch of driving gas path and air cannon startup gas path. It makes the driving rack and air cannon startup linkage without influence. Set small gas storage tin as driving gas source and control its air pressure to control the driving speed of the driving rack. It can keep the assembled stability of the equipment and enhance assembled success probability. It assures the synchronism of assembled equipment when the stress wave arrives to specimen to avoid the temperature of specimen rapidly drop for leaving heat fountain.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

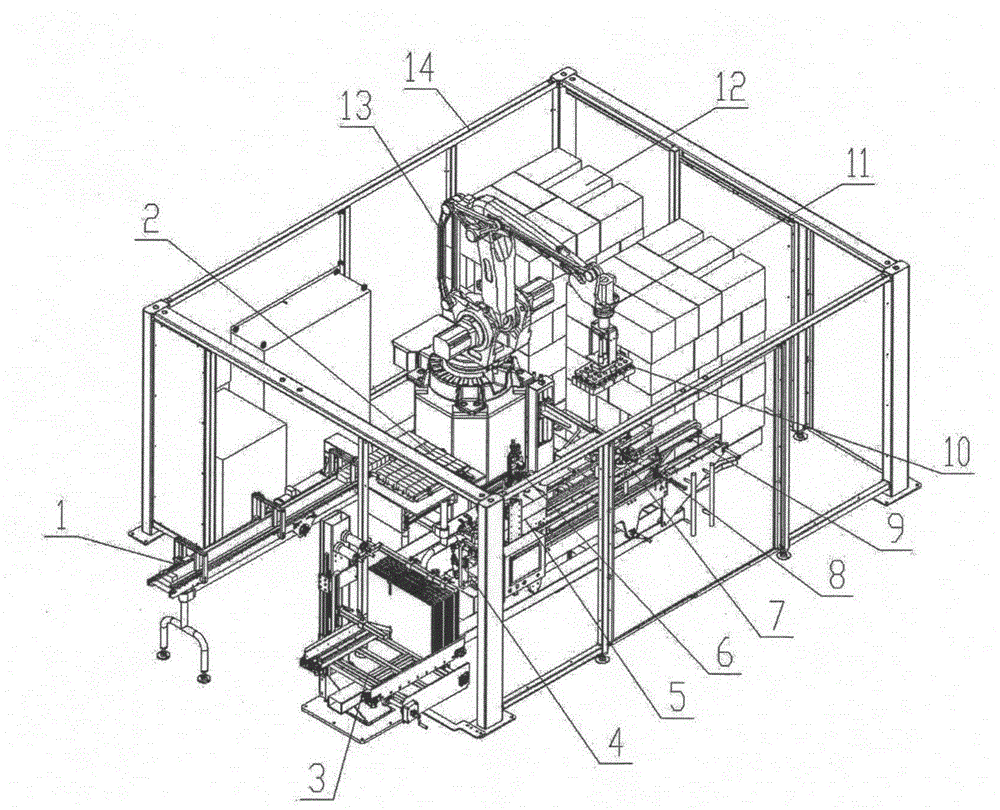

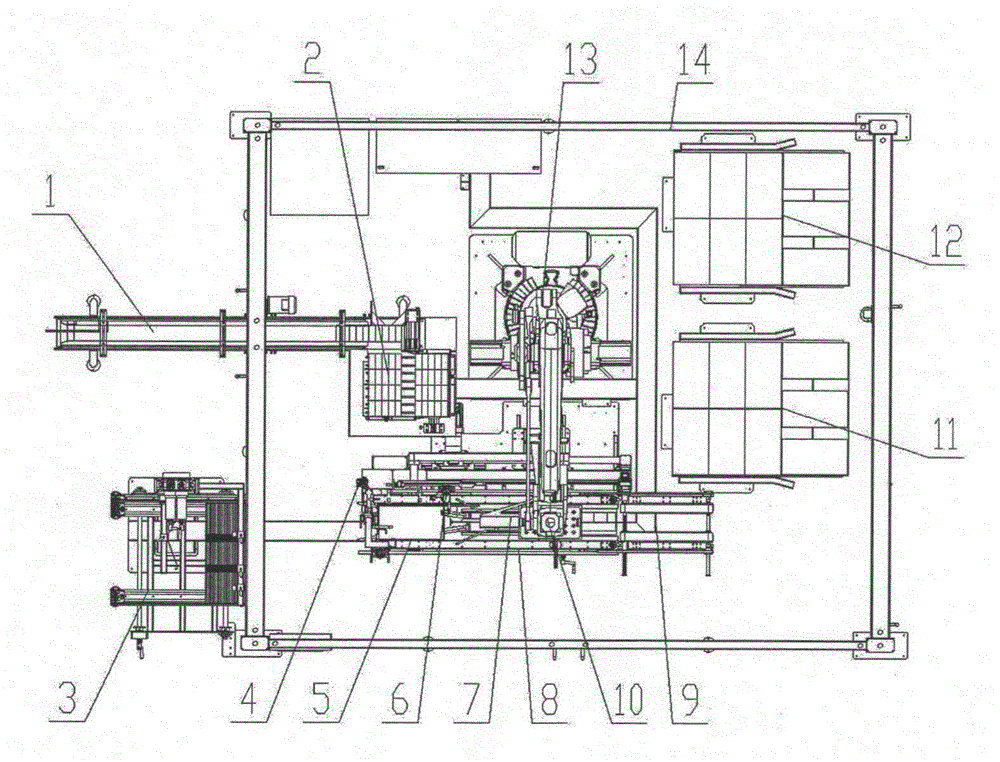

Carton filling and stacking all-in-one machine

ActiveCN104859894AReduce the difficulty of operationSmall footprintPackaging machinesCartonEngineering

The invention discloses a carton filling and stacking all-in-one machine. The carton filling and stacking all-in-one machine is characterized by comprising a carton conveying line and a storage device, wherein the head portion of the carton conveying line is connected with one side of a carton alignment device; the storage device is connected with one side of a carton filling station through an unpacking forming mechanism; the other side of the carton filling station is connected with one side of a carton strutting device; the other side of the carton alignment device is provided with a robot body; the robot body is provided with a carton filling and stacking grasp structure; a carton clamping and conveying device is arranged on the other side of the carton strutting device and connected with a carton sealing device; a carton labeling station is arranged on one side of the carton sealing device; a first tray and a second tray are arranged on one side of the carton labeling station. The functions of existing single machines are completely integrated on one machine, stations are linked tightly, the structure is compact, and operation is easy. The carton filling and stacking all-in-one machine is suitable for various specifications, stable in performance, high in efficiency and capable of greatly reducing labor cost.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

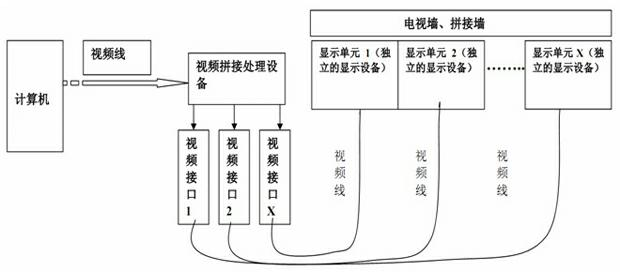

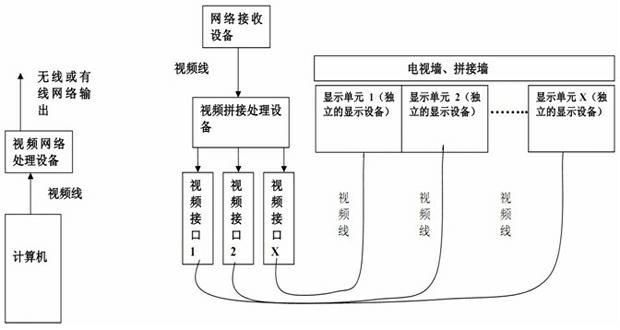

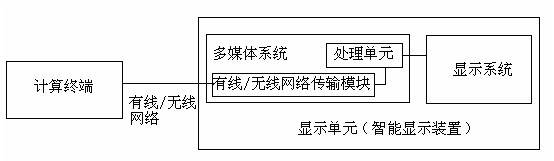

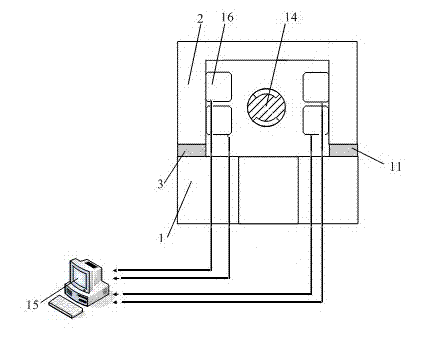

Splicing display wall, display method, system and intelligent display device

InactiveCN102609232ALow costFlexible Split PairingTelevision system detailsColor television detailsComputer moduleDisplay device

The invention discloses a splicing display wall, which is used for displaying a video signal provided by a computing terminal; the splicing display wall comprises a plurality of display units; each display unit comprises a multimedia system and a display system; the multimedia system comprises a processing module and a wired / wireless network transmission module connected with the processing module; the processing module is connected with the display system; the computing terminal is connected with the wired / wireless network transmission module of each display unit in a communication manner so as to form network; the computing terminal distributes independent IP or ID to each display unit; the processing module of each display unit respectively receives independent video picture information which is distributed to the corresponding IP or ID by the computing terminal; and the processing module of each display unit sends the independent video picture information to a display system of the corresponding display unit so as to process projection display.

Owner:刘尚俊

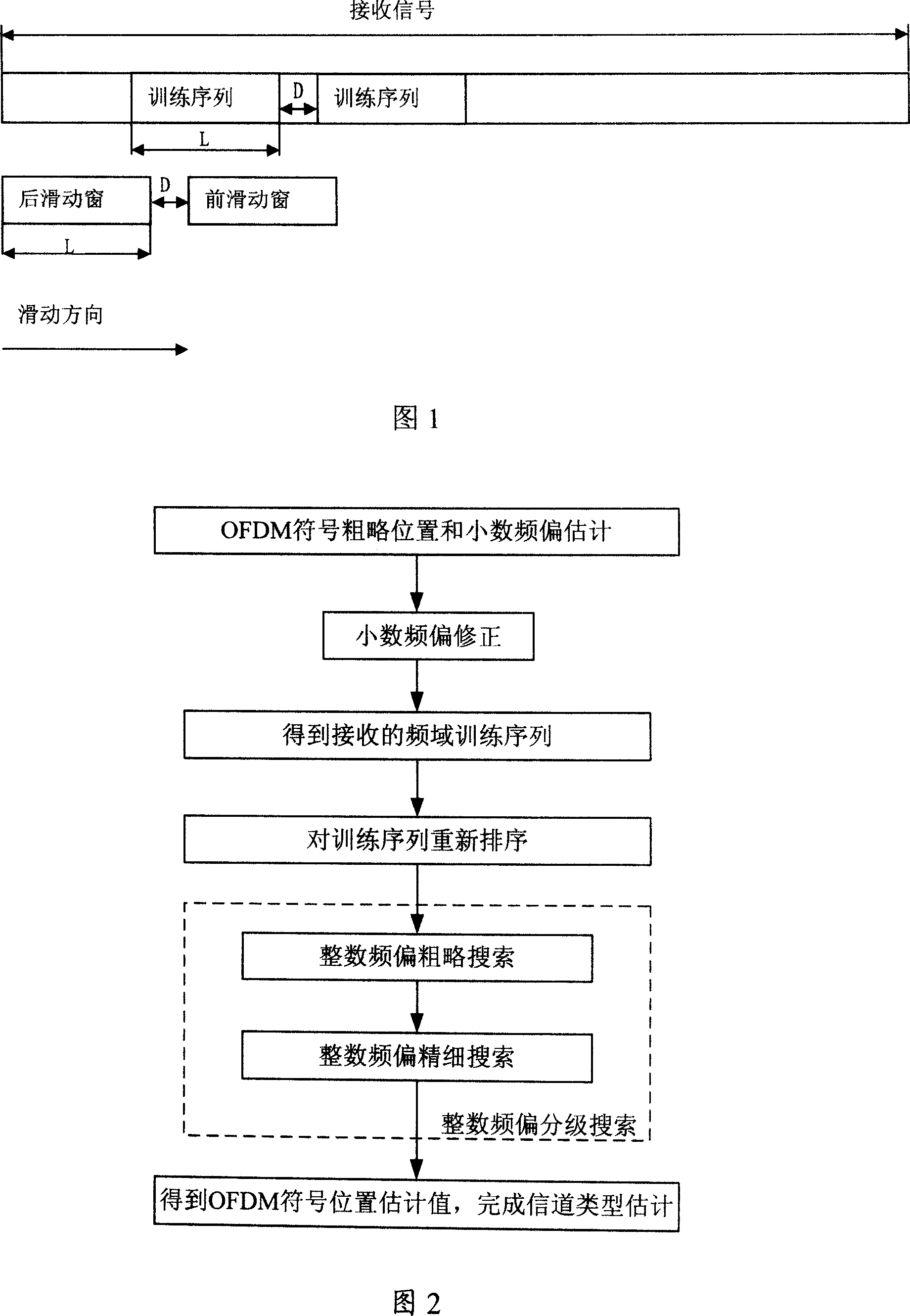

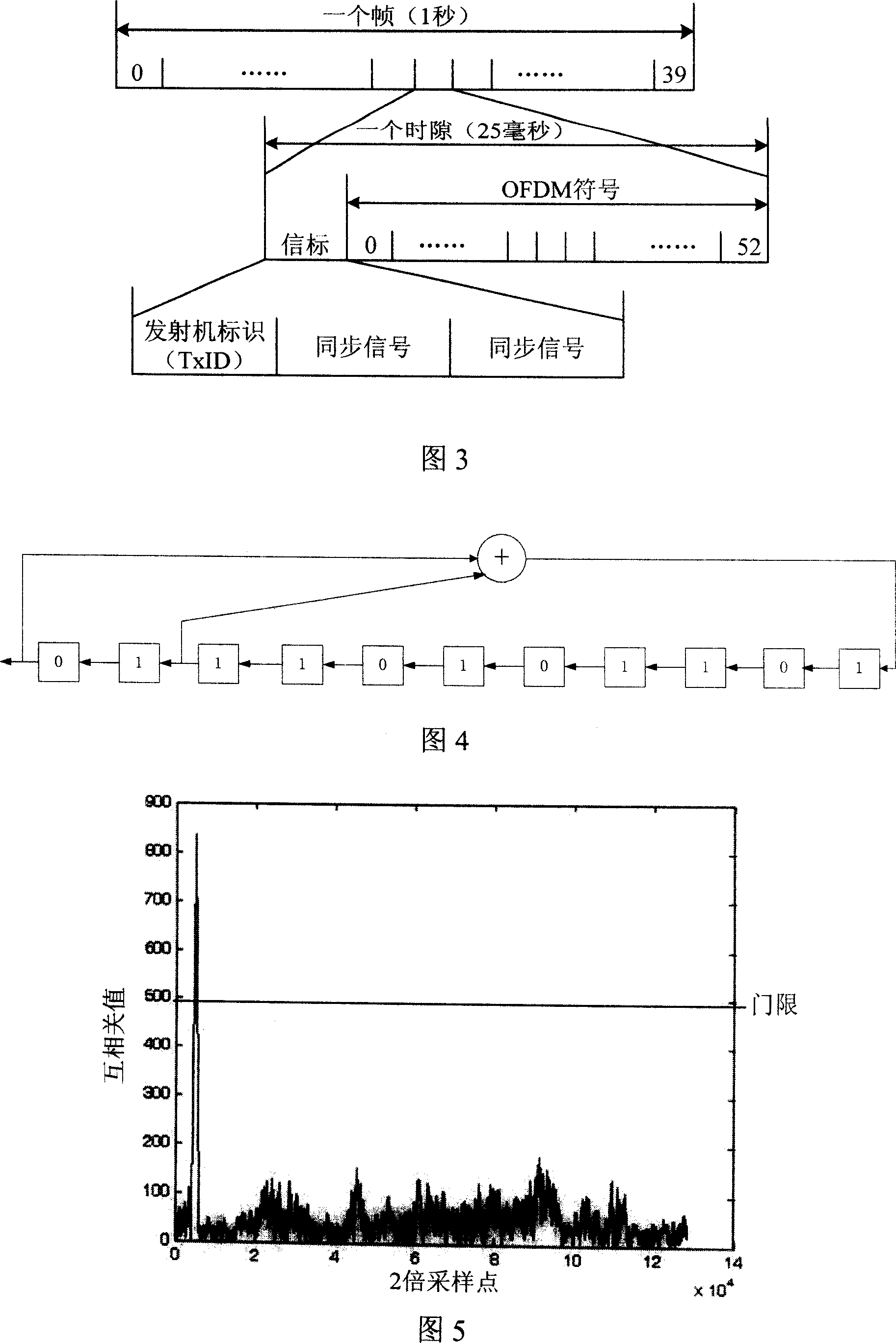

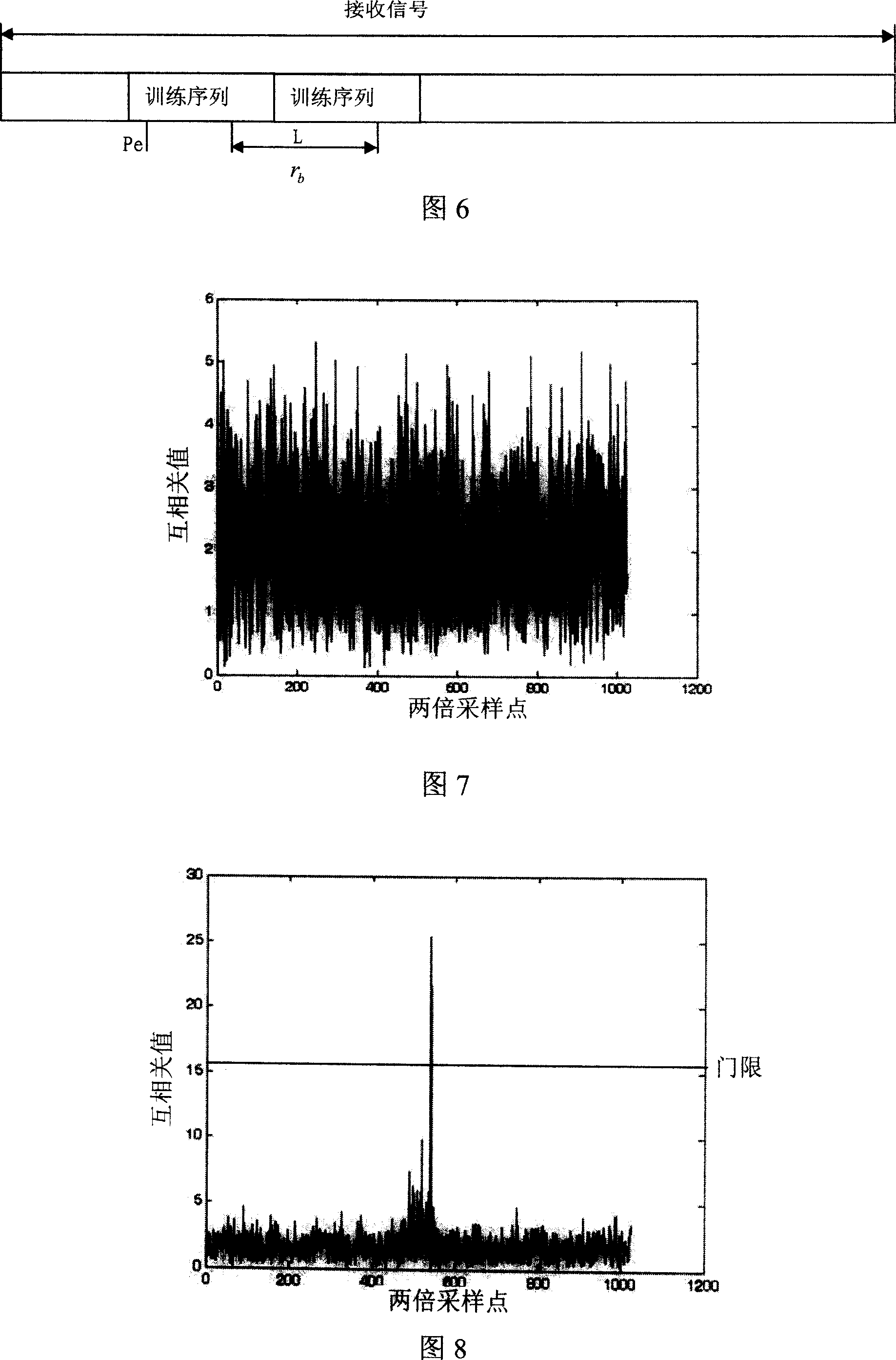

OFDM symbol and frequency synchronization and channel style estimating method

InactiveCN101018225AReduce the number of cross-correlation operationsImprove synchronization efficiencyBaseband system detailsMulti-frequency code systemsChannel typesInteger frequency offset

The disclosed method for synchronizing OFDM signal frequency and estimating channel type comprises: obtaining the coarse position and decimal frequency-offset estimation for OFDM signal; correcting the frequency-offset; reordering local or received frequency-domain training sequence; searching the coarse integer frequency-offset; fine searching the integer frequency- offset to obtain the integer frequency-offset estimation, OFDM signal position estimation, and the effective channel position. This invention reduces search operation time, and can ensure synchronization effect.

Owner:新奇点智能科技集团有限公司

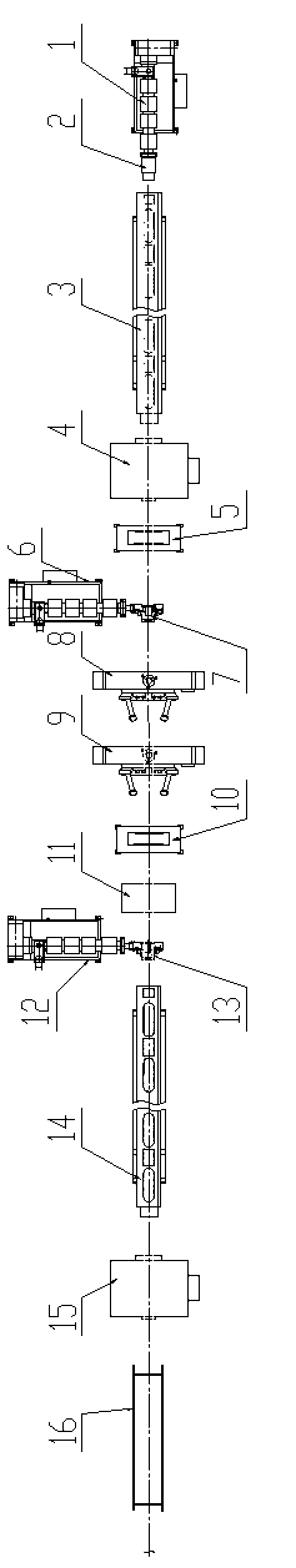

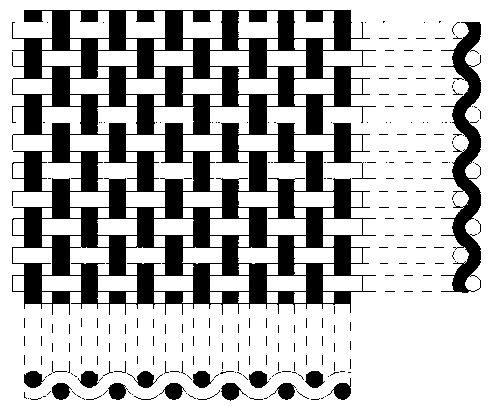

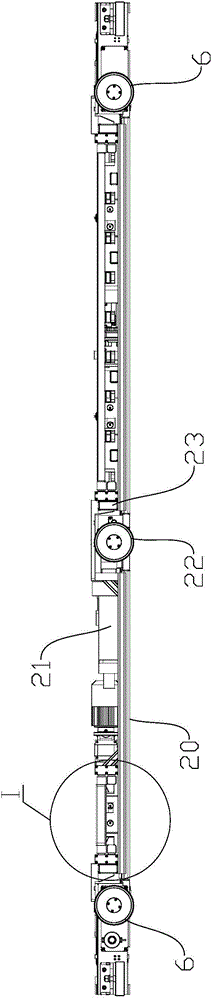

Fiber mesh tape-wound and reinforced composite pipe, preparation process and device

ActiveCN103016856AGuaranteed synchronicitySolve associativityRigid pipesMechanical propertyMaterials science

The invention relates to a fiber mesh tape-wound and reinforced composite pipe, a preparation process and a device, belonging to the technical field of forming processes of composite pipes. The composite pipe comprises an inner-layer core pipe and a post-coated layer, as well as a fiber mesh tape arranged between two layers, wherein the inner-layer core pipe is extruded by a core pipe extruding machine, the adhesive resin fiber mesh tape is heated through a post-heating box, and the composite pipe is finally obtained by traction through a post-traction machine, sizing through a vacuum spraying and sizing box and the like. According to the composite pipe disclosed by the invention, the technology is adopted, the preparation process is simple, the existing tape plastic covering treatment process and the composite pipe forming process are combined into a whole, the number of workers for production is reduced, and the degree of automation is improved; furthermore, the used device is a conventional device, and the cost is reduced; and in addition, adhesive resin is firstly coated on the outer surface of the core pipe, and the plain woven fiber mesh tape is further wounded, so that the interface problem in the pipe is effectively solved, the mechanical properties of the pipe are upgraded and the stability of the pipe during long-term use is also improved.

Owner:ZHEJIANG WEIXING NEW BUILDING MATERIALS CO LTD

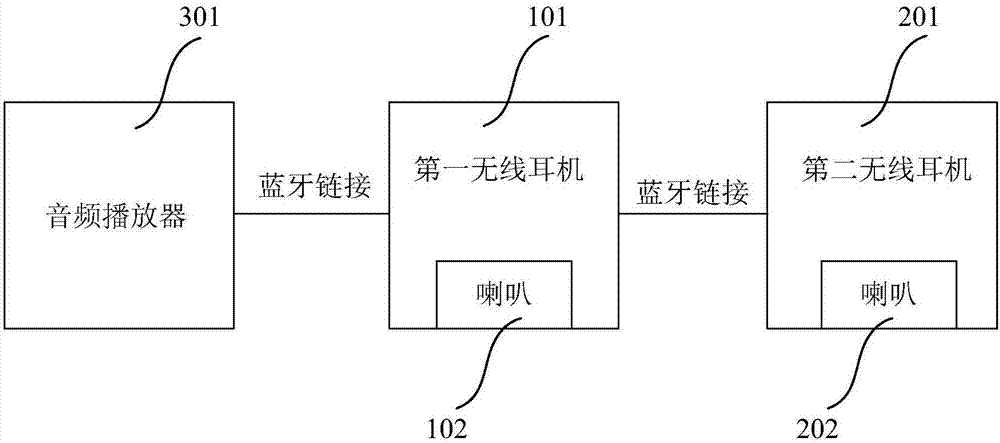

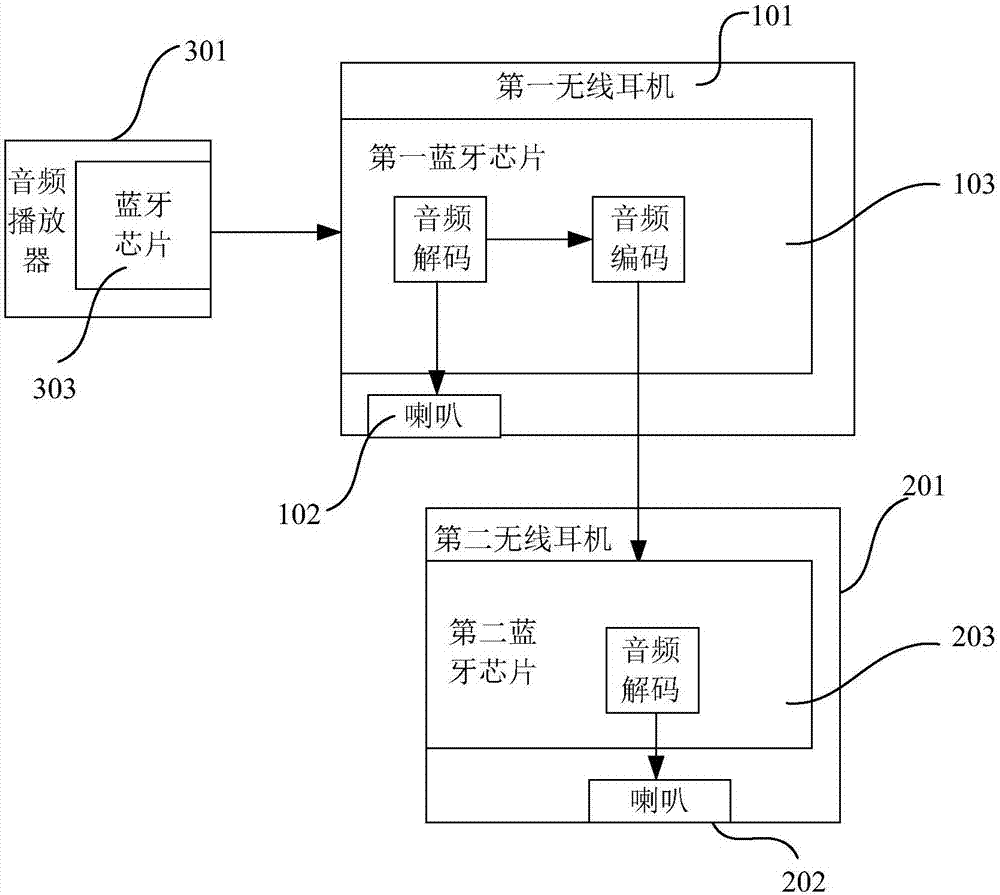

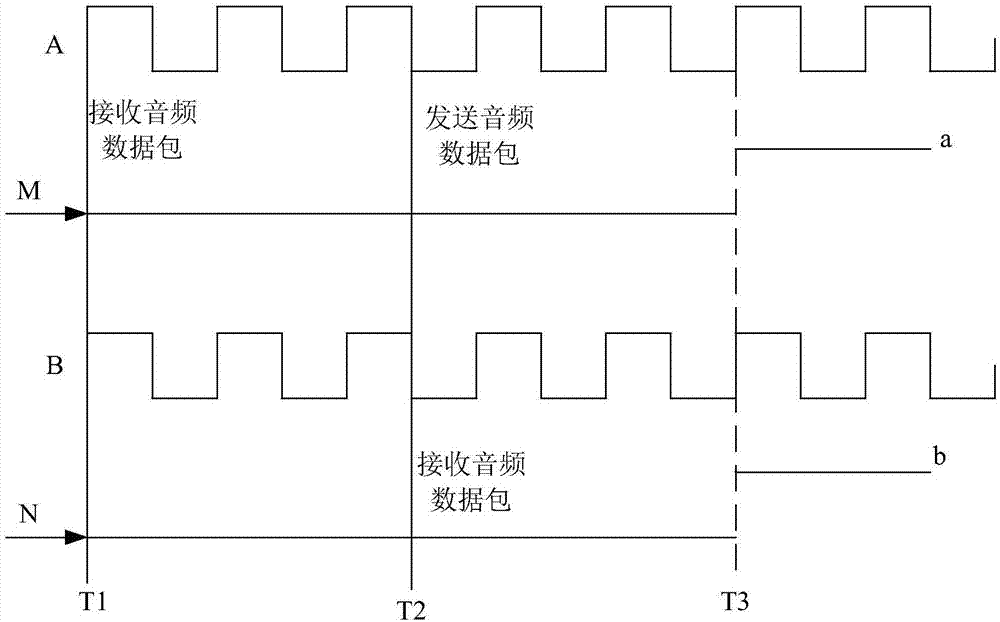

Audio data transmission method between double wireless earphones, and double wireless earphones

ActiveCN107333339ASave air bandwidthReduce the amount of data forwardingTime-division multiplexConnection managementData transmissionChannel data

The invention provides an audio data transmission method between double wireless earphones, and the double wireless earphones. The method comprises the following steps: a first wireless earphone performs data link with a wireless communication module of an audio player through a first wireless communication module to receive audio data; when the first wireless communication module receives first frame of audio data, the first wireless communication module inserts a playing starting time in an audio data packet; the audio data packet carrying the playing starting time is decoded and is divided into two paths of sound channel data, wherein one path of sound channel data outputs audio, and the other path of sound channel data is encoded; a second wireless communication module of the second wireless earphone receives the encoded audio data packet; the second wireless communication module of the second wireless earphone controls a playing starting time point according to the playing starting time in the encoded audio data packet. According to the audio data transmission method, the sound of the two earphones in wireless communication link reduces the blockage and generates no drift with time by means of wireless communication protocol extension and delay control.

Owner:BESTECHNIC SHANGHAI CO LTD

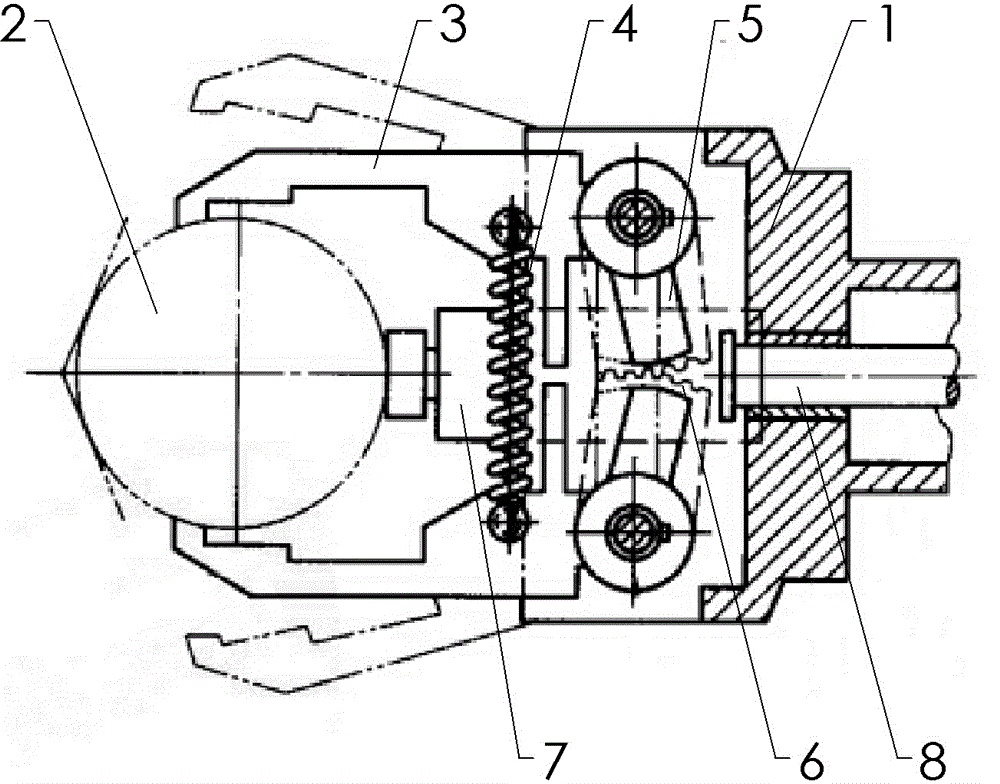

Mechanical arm for clamping cans

InactiveCN104528373AGuaranteed synchronicityProgramme-controlled manipulatorGripping headsManipulatorPiston rod

The invention discloses a mechanical arm for clamping cans. The mechanical arm for clamping cans is used for transferring cans efficiently and stably. The mechanical arm for clamping cans comprises an arm frame. Arm claws are symmetrically hinged to the arm frame and used for clamping the opposite sides of the cans. The arm frame is connected with a pressing rod located on the symmetrical line of the two arm claws in a sliding mode. A clamping portion of the pressing rod is located between the two arm claws so as to correspond to the side walls of the cans. The two sides of the pressing rod are provided with limiting grooves respectively. Rocking bars fixedly connected to the two arm claws are embedded into the limiting grooves to be driven to rotate. A telescopic air cylinder is arranged beside a drive portion, opposite to the clamping portion, on the pressing rod, and a piston rod of the telescopic air cylinder is located on the symmetrical line of the two arm claws. According to the mechanical arm for clamping cans, the two arm claws and the clamping portion of the pressing rod can conduct three-point clamping on the cans at the same time, and stable clamping can be achieved, clamping and loosening of the arm claws can be controlled automatically, and the mechanical arm for clamping cans is very convenient to operate.

Owner:CHONGQING QINFA FOOD

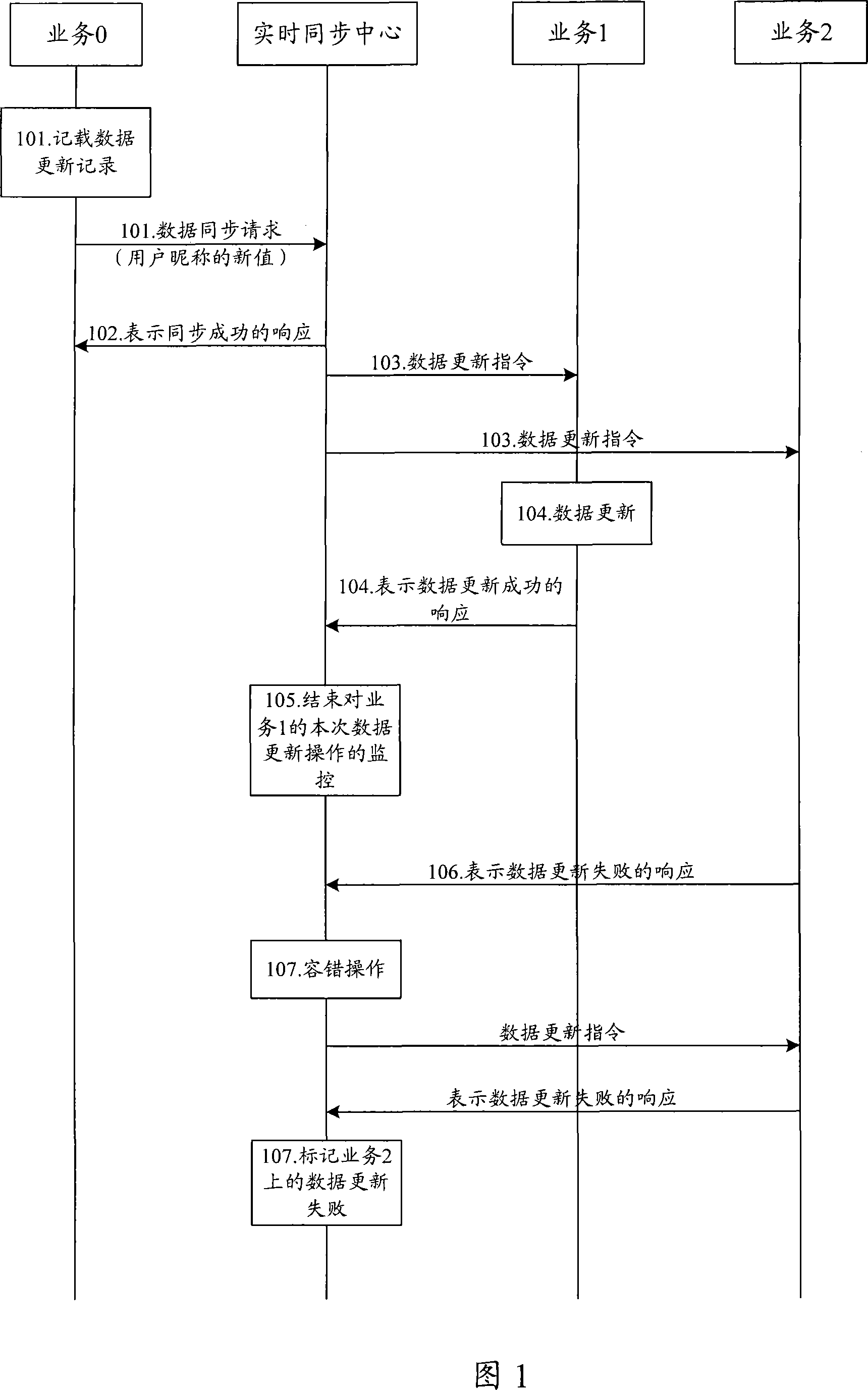

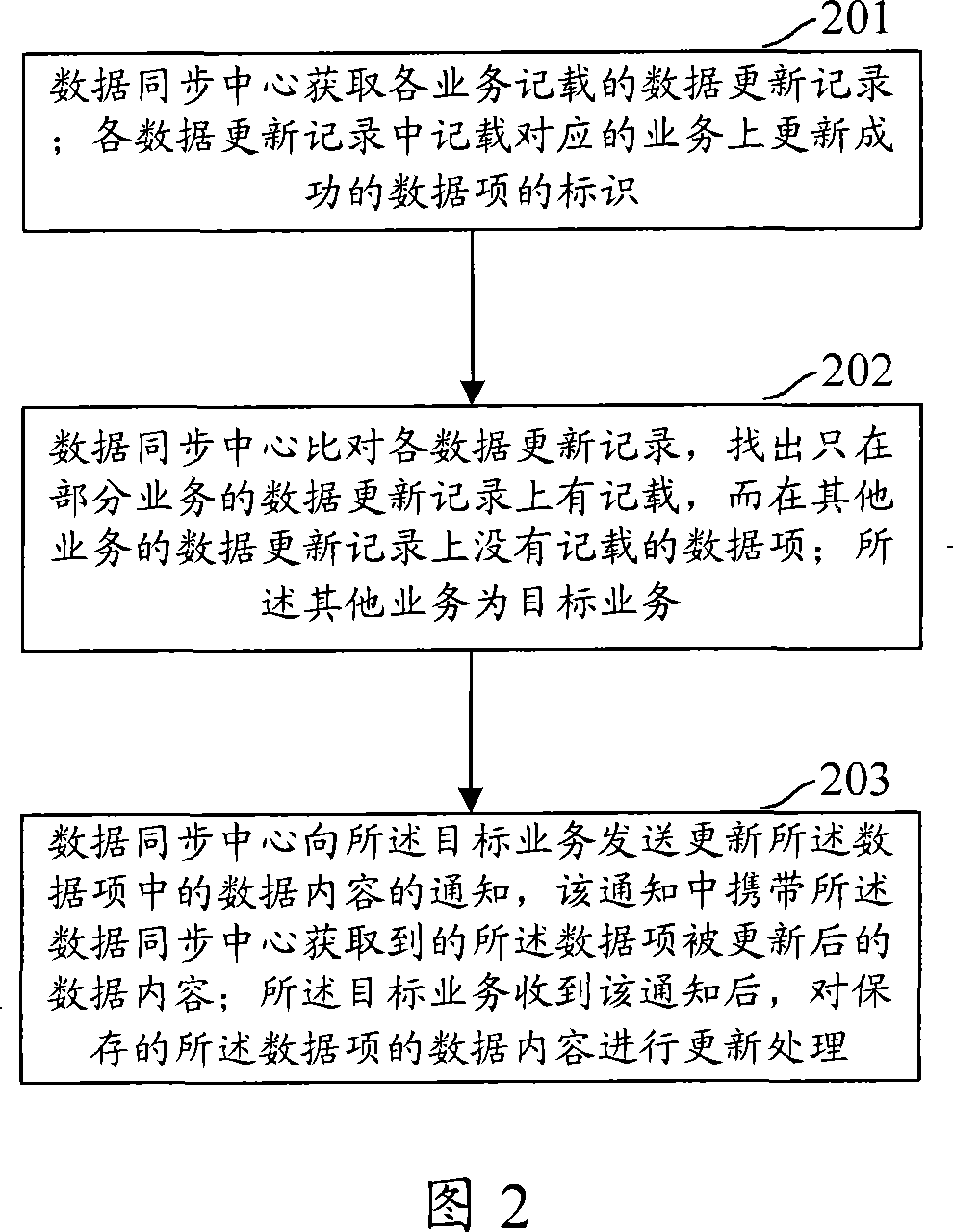

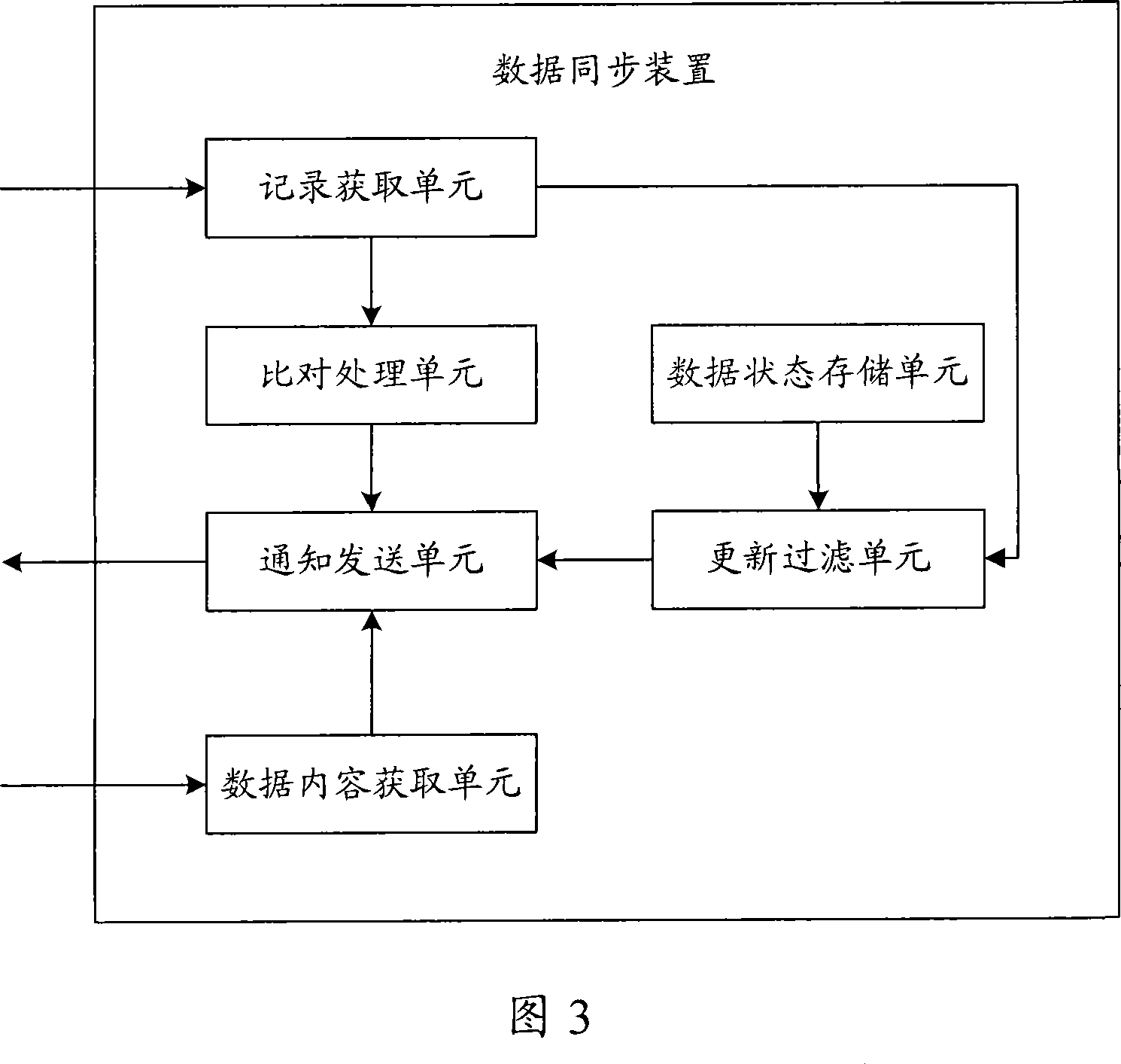

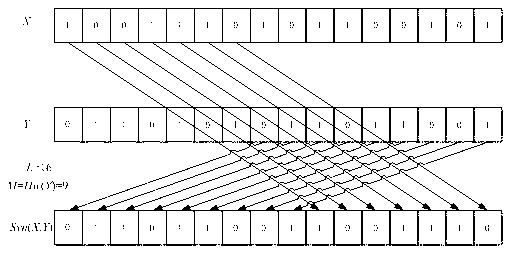

Data synchronization process and device

InactiveCN101216832AGuaranteed synchronicityMultiprogramming arrangementsSpecial data processing applicationsData contentData synchronization

The invention embodiment provides a data synchronization method which comprises data update records that the data synchronization center obtains from each operation and the corresponding marks for successful update of operational data items in each data update record. The method includes the following steps: the data synchronization center inter-compares each update record to find out the data item that only is contained by some operation data update records and not by other operations; the other operations are objective operations; the data synchronization center sends a notification of updating the content of the data item to the objective operations, wherein the notification carries the updated data content of the data item obtained by the data synchronization; the objective operations update the saved data content of the data item after receiving the notification. The invention embodiment further provides a synchronization device. The technical proposal of the invention embodiment can as far as possible guarantee the data content synchronization of the data item which needs to be maintained synchronization by each operation.

Owner:TENCENT TECH (SHENZHEN) CO LTD

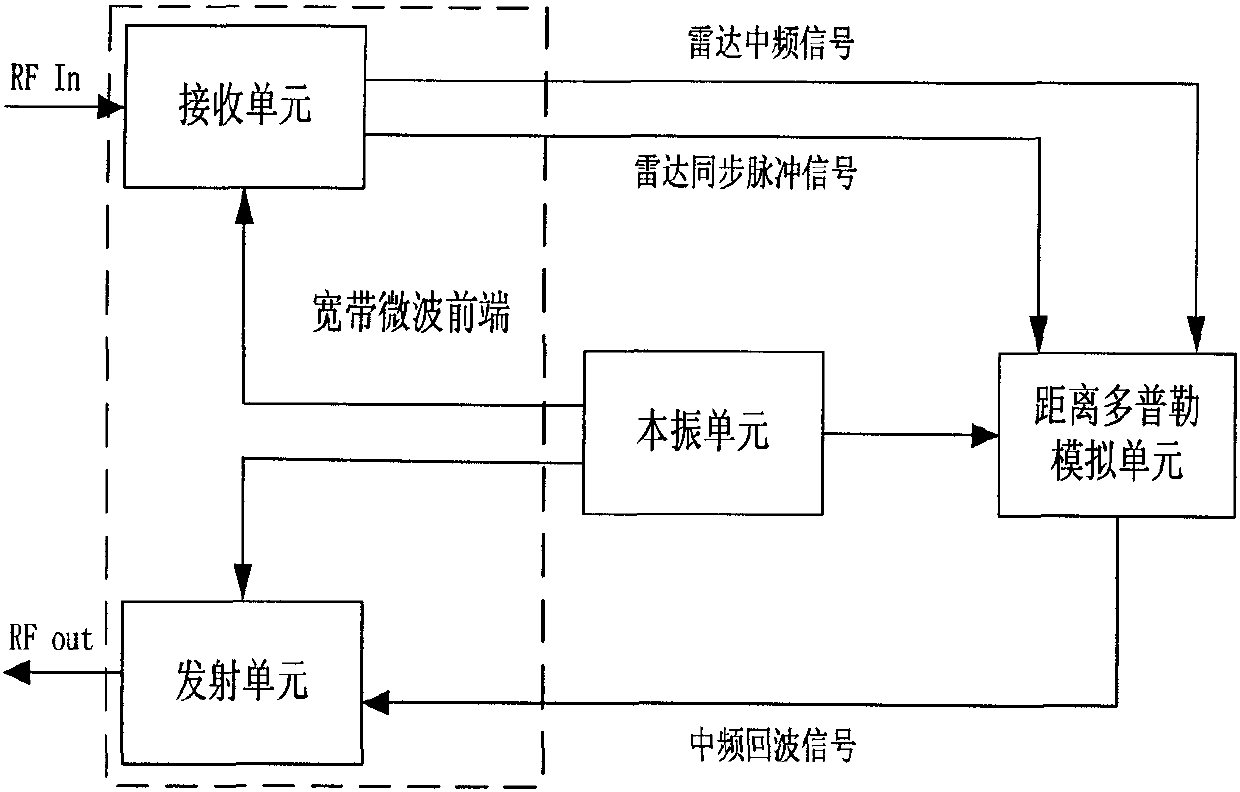

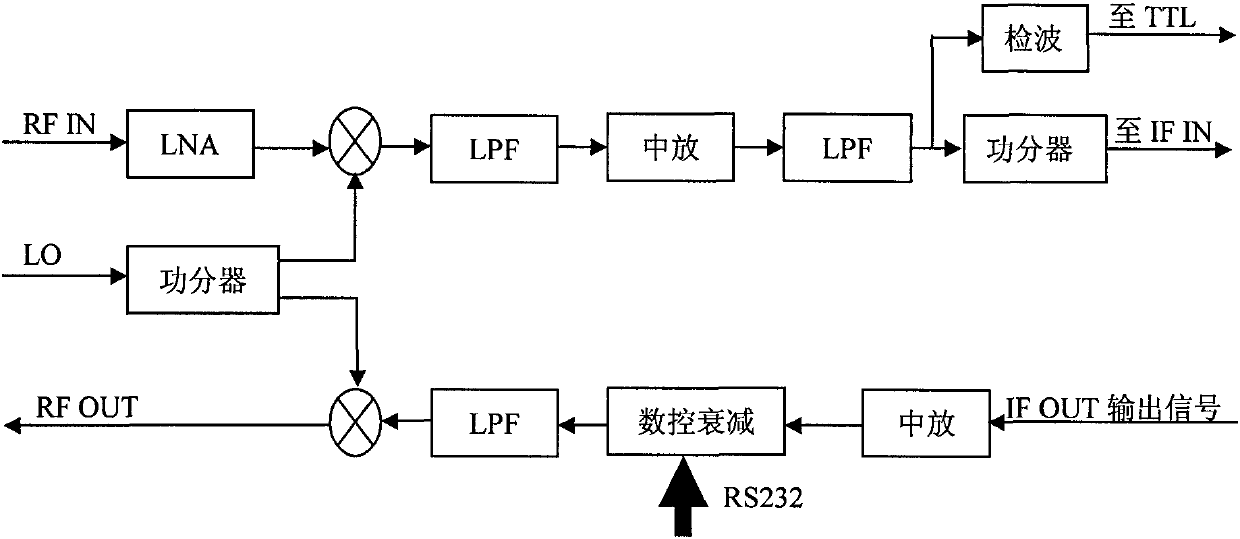

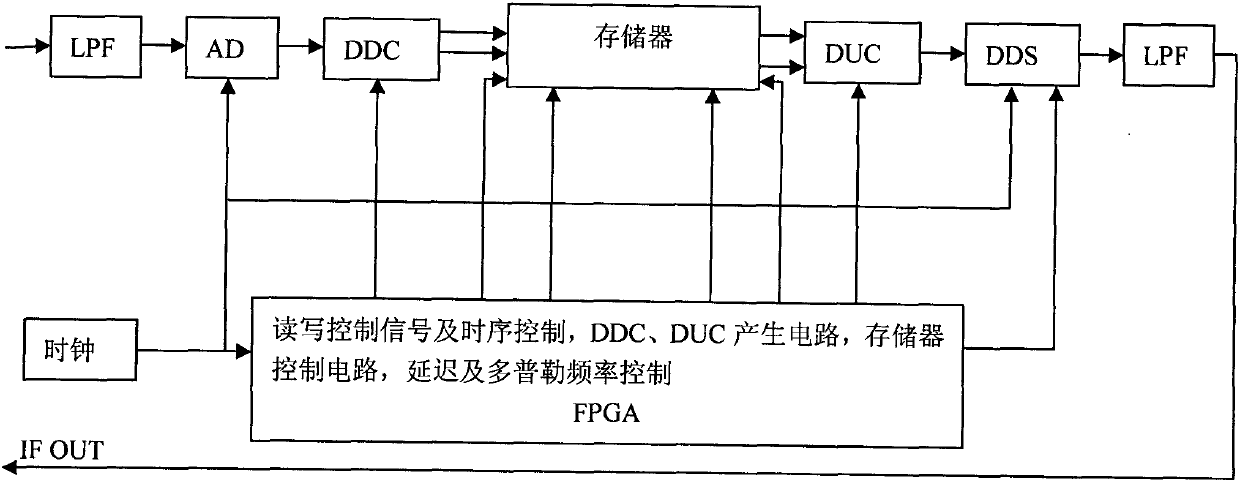

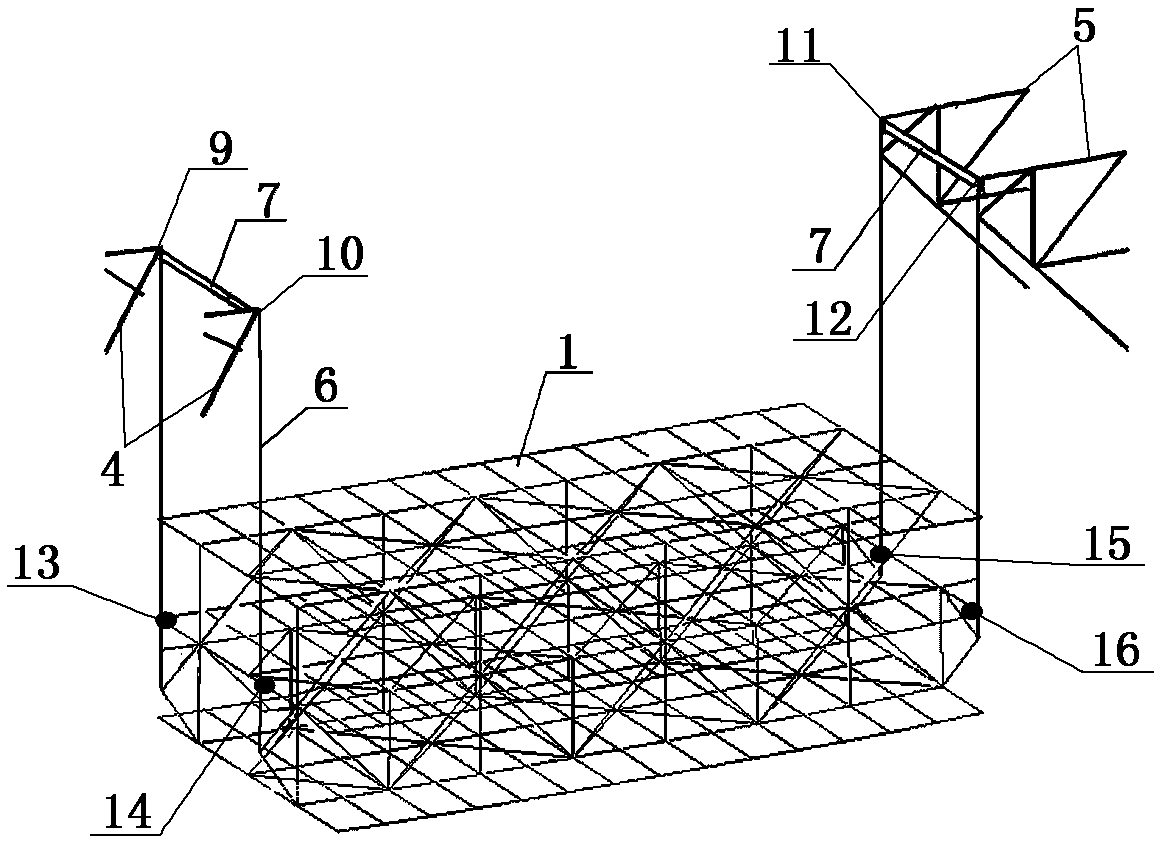

Broadband radar target simulation method and system

InactiveCN111183741BMeet the requirements of far-field testingImplement full functional testingWave based measurement systemsDigital dataWideband radar

The present invention relates to a broadband radar target simulation method and system, characterized in that: the received radar radiation signal enters the broadband down-converter of the simulation system through an attenuator and a low-noise amplifier to perform conversion from radio frequency to intermediate frequency, and the down-conversion output IF 70MHz band-pass signal, 70MHz IF modulation signal is low-pass filtered and then band-pass samples the input analog modulation signal, and the output digital data is digitally down-converted in the FPGA, demodulated to the digital baseband signal and delayed; the delayed The data is output to the IQ data processing circuit of the FPGA, and finally the target simulation in the microwave frequency band is radiated to the radar through the signal output by the DAC. The invention adopts space coherent reception, which can fully meet the requirements of radar far-field testing.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

Hoisting system and hoisting construction method for large steel corridor trusses

InactiveCN105507600AImproves strength and stabilityImprove structural strengthBuilding material handlingJackscrewDead weight

The invention discloses a hoisting system and a hoisting construction method for large steel corridor trusses. The hoisting system comprises lifting points, hanging points and jack lifting equipment. The jack lifting equipment is mounted between the lifting points and the hanging points, the lifting points comprise first lifting frames and second lifting frames, the first lifting frames are connected with first main structures, the second lifting frames are connected with second main structures, four embedded steel beams which have equal heights and are parallelly arranged are arranged in the two lifting frames of each lifting point, the lifting points are arranged at the ends of the embedded steel beams, two box-shaped brackets are respectively welded on two sides of each beam body of each lifting point, a jack is mounted on each box-shaped bracket, and each torsion-resistant steel beam is welded between the two corresponding box-shaped brackets on the inner sides of the beam bodies of the corresponding lifting points; the four corresponding hanging points which vertically correspond to the lifting points on a frame are arranged on each steel corridor truss, and steel strands penetrate the box-shaped brackets from top to bottom and are fixed by the aid of anchors after descending and penetrating the hanging points. Each large steel corridor truss can be synchronously lifted by the aid of the four corresponding hanging points during construction. The hoisting system and the hoisting construction method have the advantages that the hoisting system is reasonable in design and easy to operate, and problems of large occupied land areas, heavy dead weights and poor balance in existing large steel corridor truss hoisting procedures can be effectively solved by the aid of the hoisting system and the hoisting construction method.

Owner:CHINA RAILWAY BEIJING ENG GRP CO LTD +1

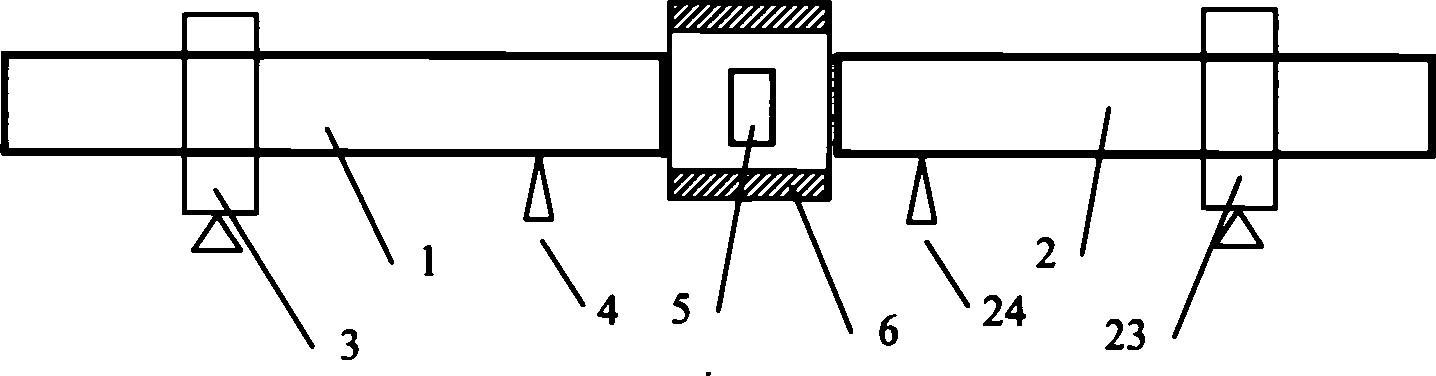

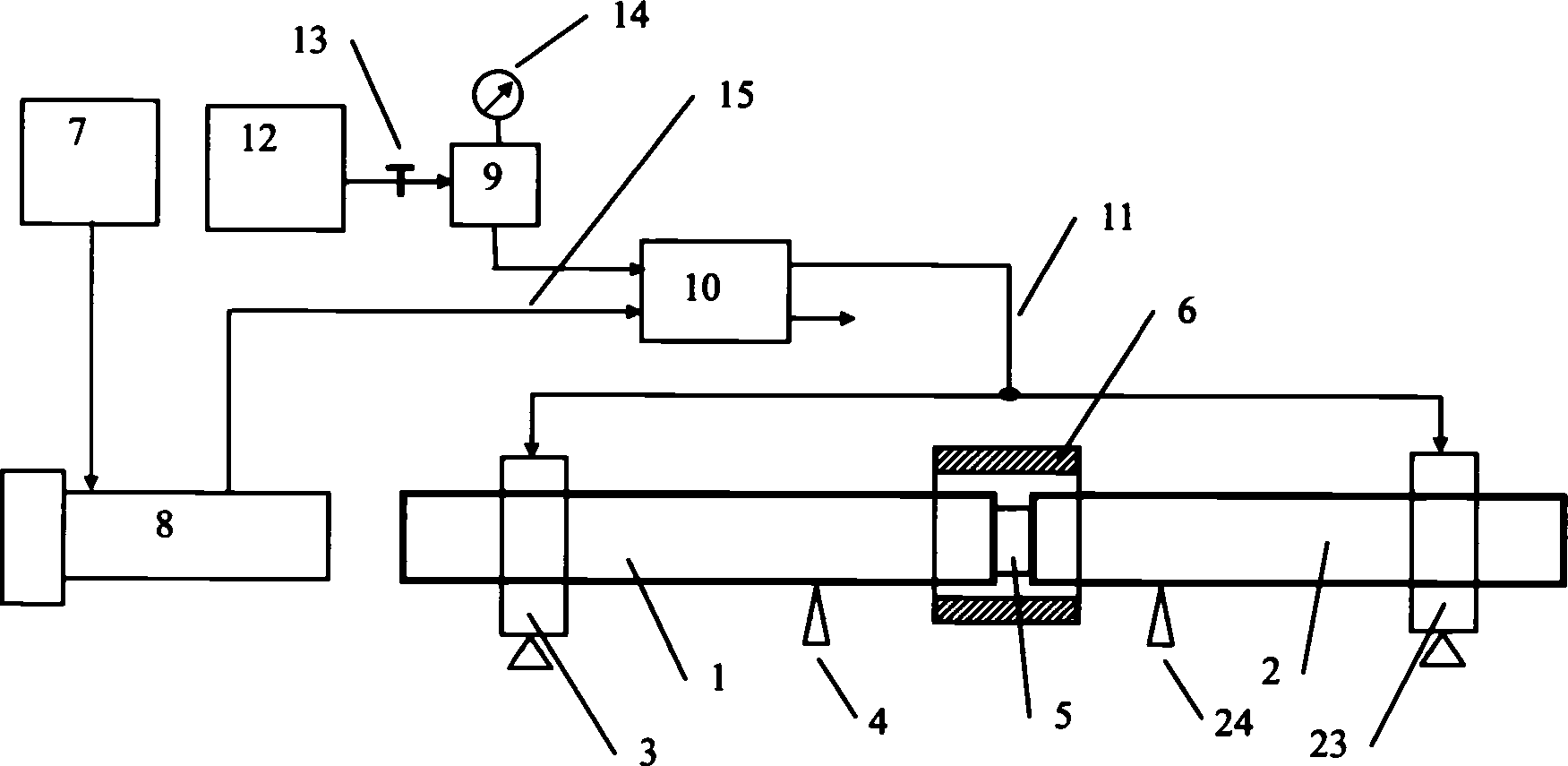

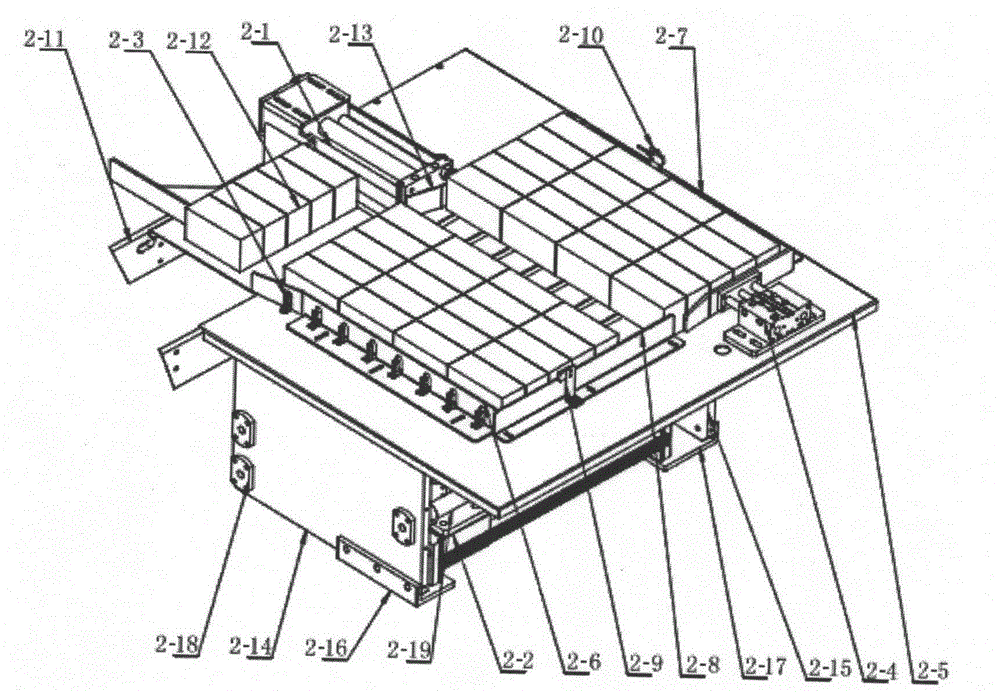

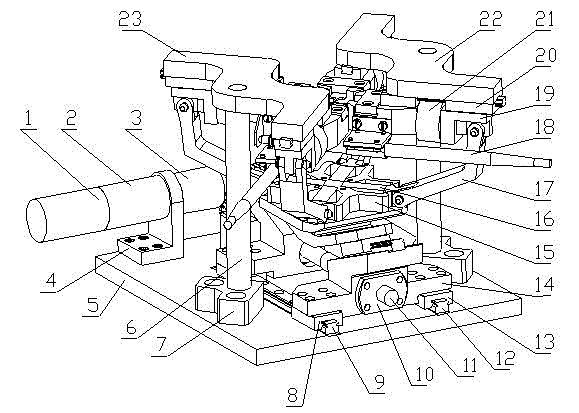

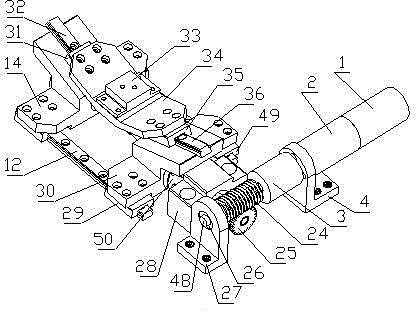

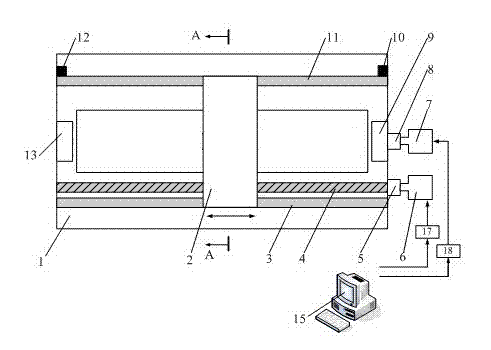

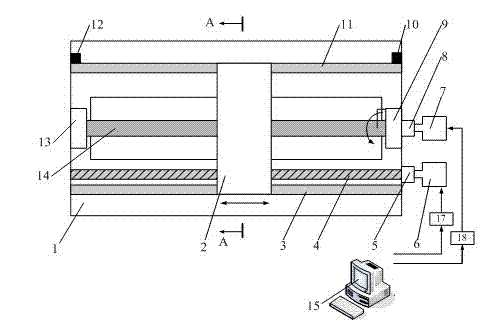

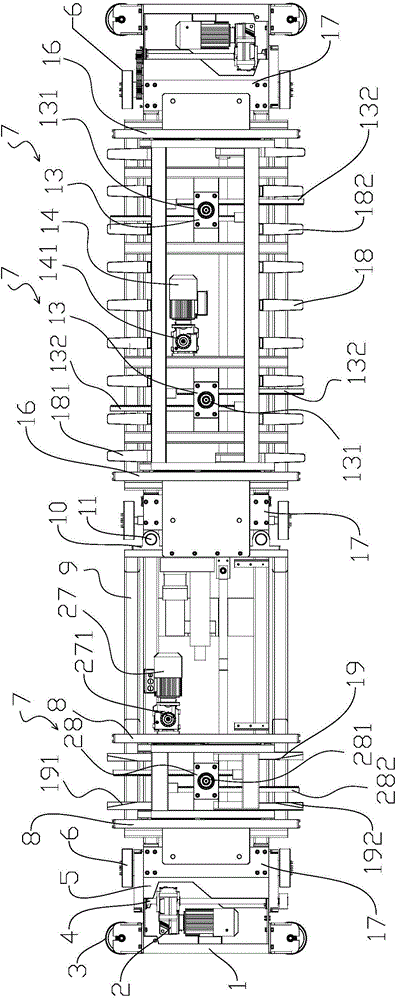

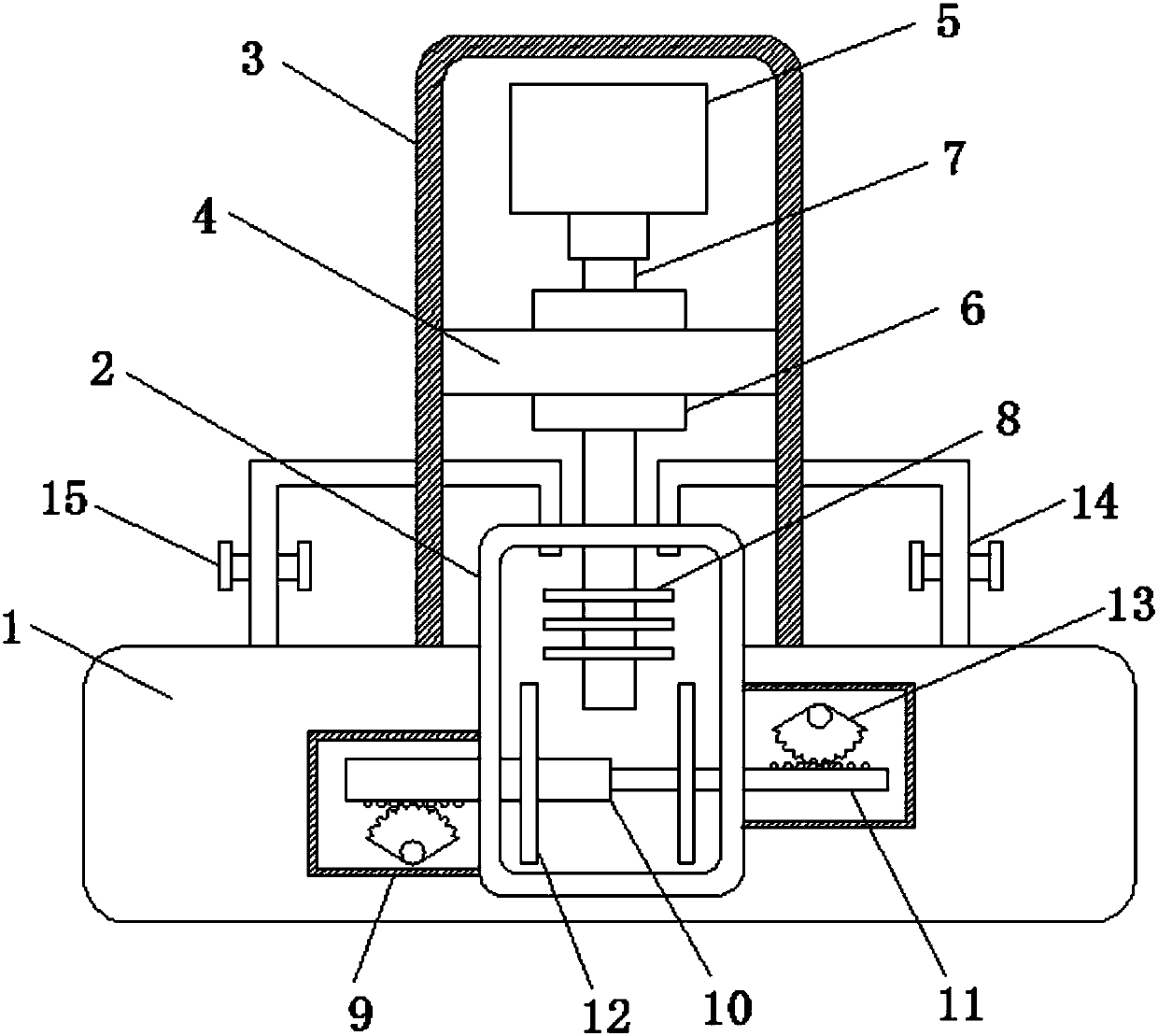

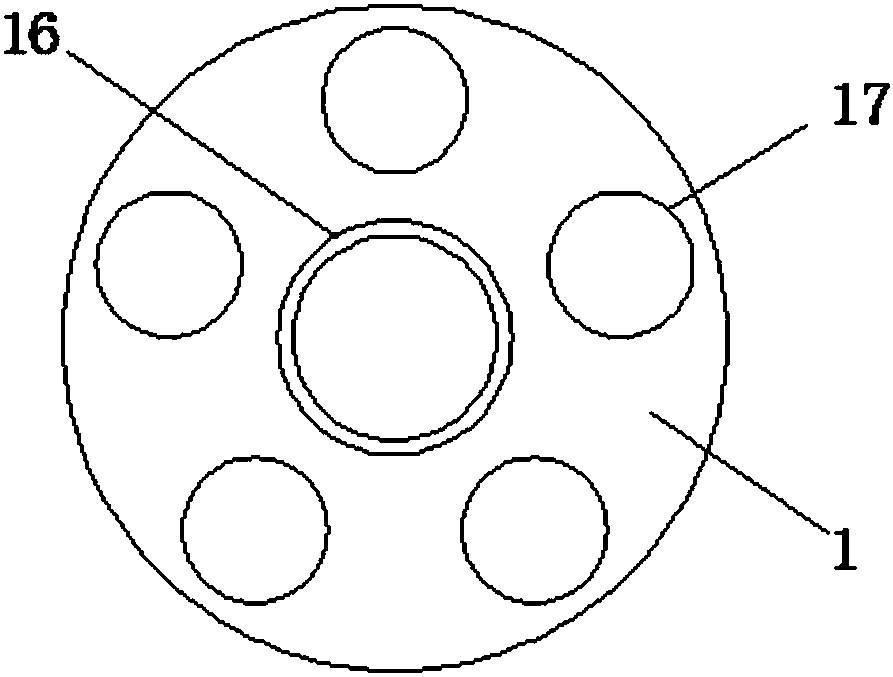

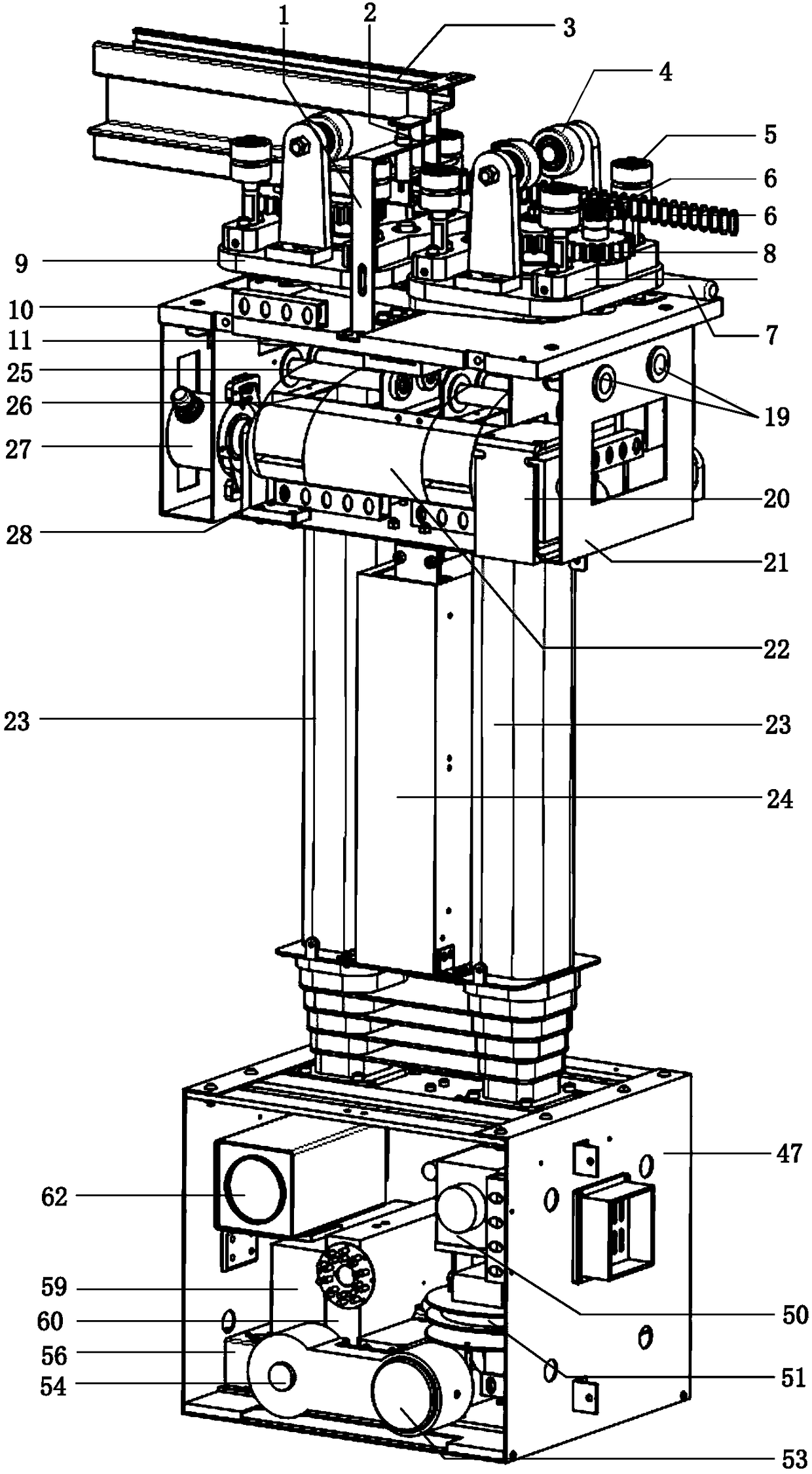

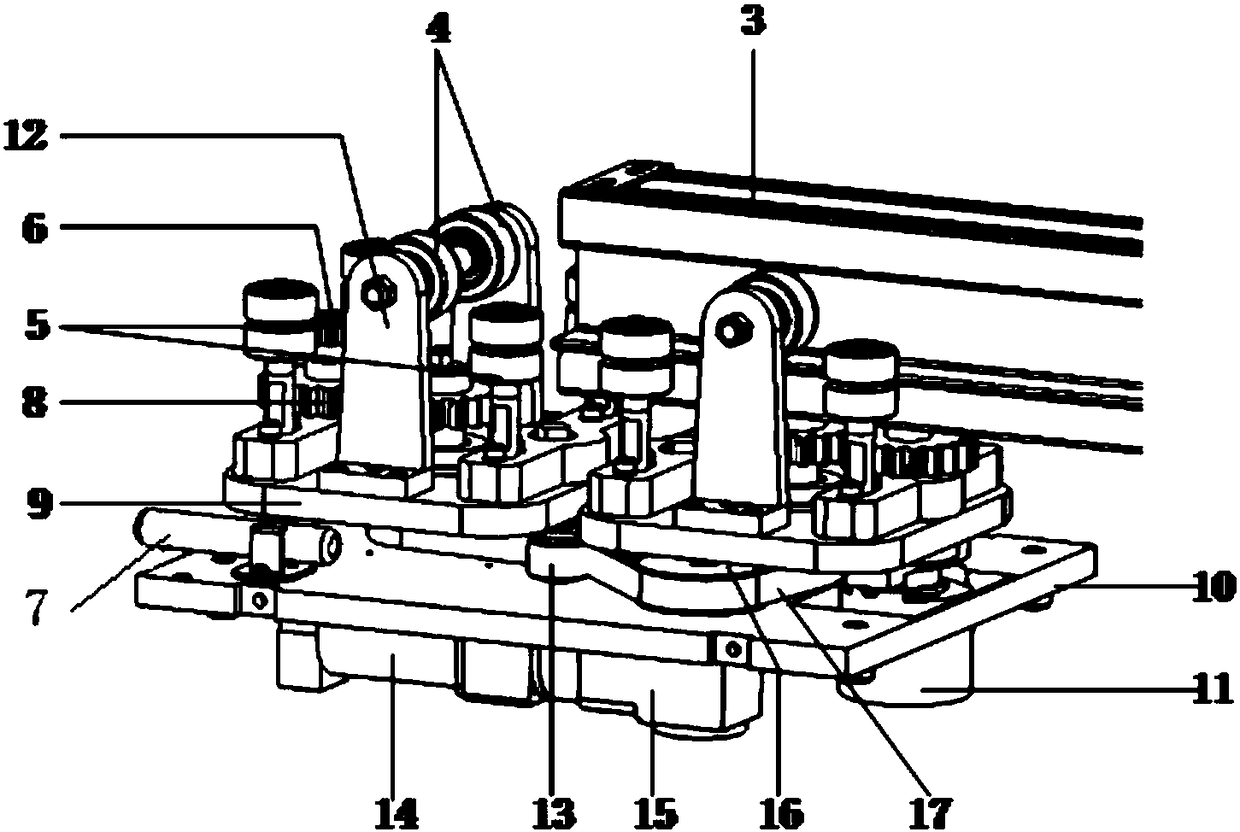

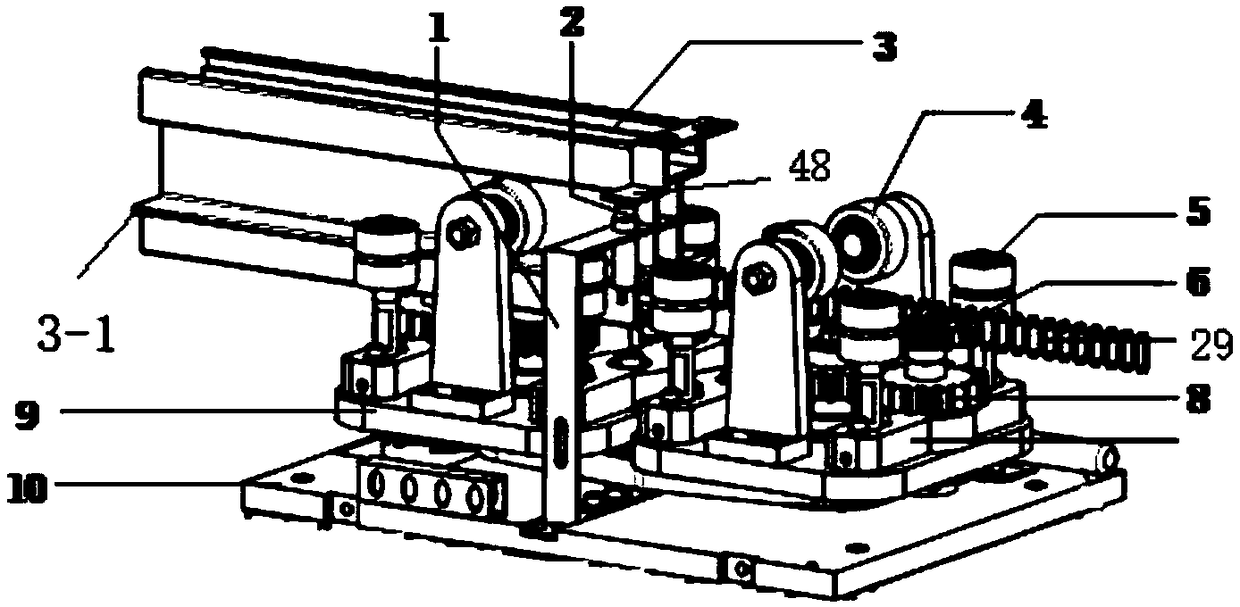

Material micro-mechanical property biaxial tension-fatigue test system and test method thereof

ActiveCN104913974ANovel structureCompact structureMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesFatigue loadingScientific instrument

The invention relates to a material micro-mechanical property biaxial tension-fatigue test system and a test method thereof, and belongs to the field of precise scientific instruments. The test method is characterized in that orthogonal tensile load is applied to a test piece to make two mutually vertical tensions exist in one plane, and fatigue load can also be applied to the test piece on the basis of the tensile load in order to research the micro-mechanical properties of a material under different load forms and load sizes. The system is composed of a precise loading-transmitting unit, a fatigue unit, a mechanics and deformation signal detection unit, and a test piece clamping unit. The test system has the advantages of novel and compact structure, respective realization of uniaxial tension test, biaxial tension test, uniaxial tension-fatigue test and biaxial tension-fatigue test, good compatibility with an optical microscope, and dynamic research of the relationship between the microstructure of the material and the deformation damage mechanism under tension-fatigue load conditions.

Owner:JILIN UNIV

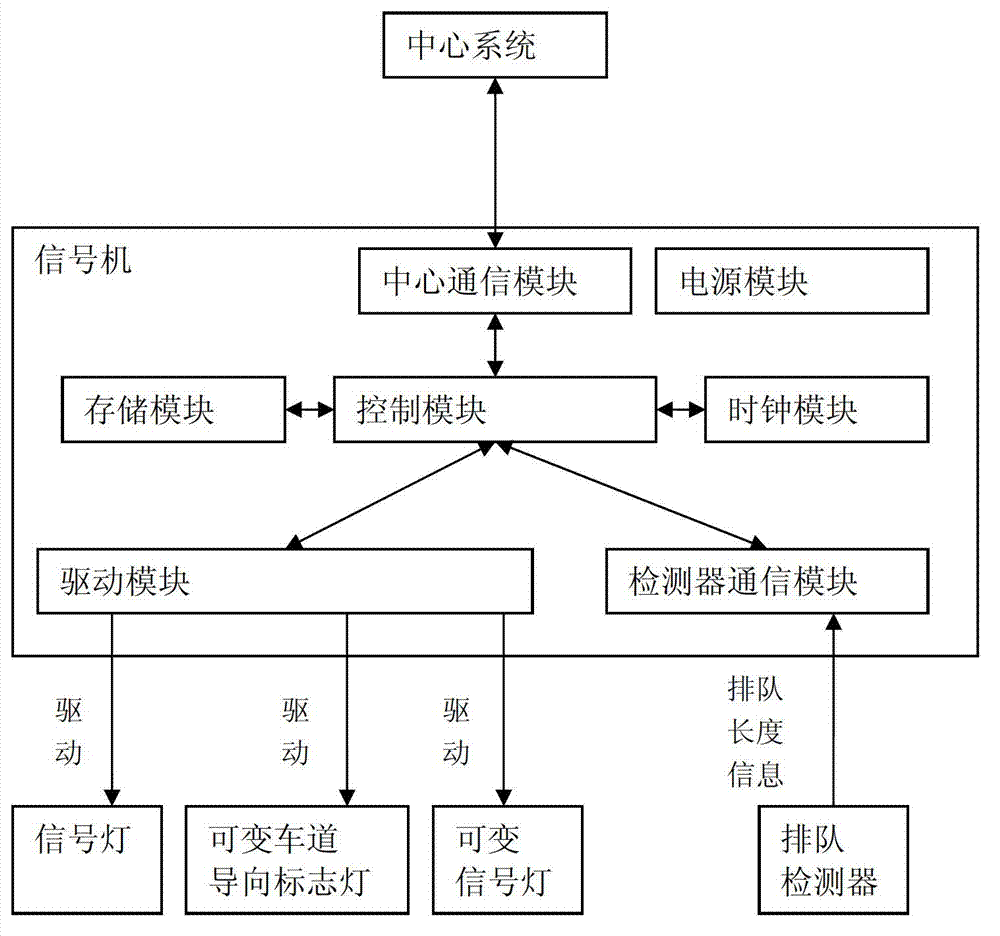

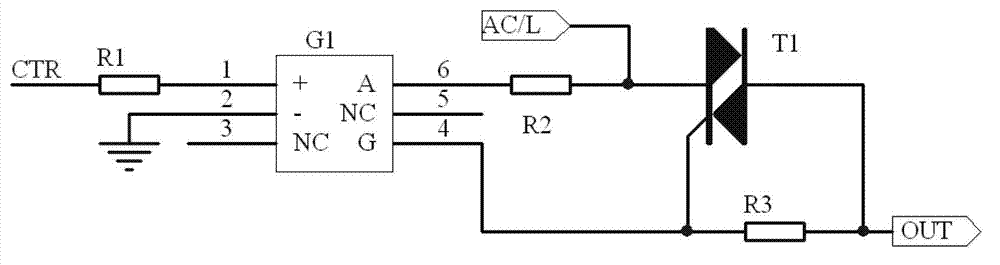

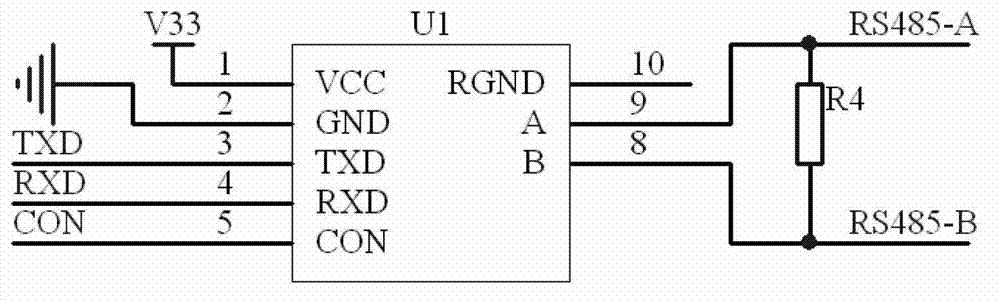

Road traffic signal control system for reversible lane of adaptive intersection

InactiveCN102968905AGuaranteed synchronicityImprove traffic efficiencyControlling traffic signalsTraffic signalControl system

The invention relates to a road traffic signal control system for a reversible lane of an adaptive intersection. The road traffic signal control system comprises a road traffic signal control machine, a reversible lane guide marker lamp and a variable signal lamp, wherein the road traffic signal control machine comprises a micro controller; the micro controller is connected with a driving module and a detector communication module; the driving module is respectively connected with the reversible lane guide marker lamp and the variable signal lamp; and the detector communication module is connected with a queuing detector. The road traffic signal control system has the advantages that a signal machine, the reversible lane guide marker lamp, the variable signal lamp and the queuing detector are organically combined with one another; the signal machine synchronously controls the reversible lane guide marker lamp and the variable signal lamp, so that the synchronism of the variable signal lamp and the reversible lane guide marker lamp is guaranteed during switching; and due to rational switching, an intersection police does not need to command on the spot, so that resources, such as police strength, can be saved.

Owner:JIANGSU AEROSPACE DAWEI TECH CO LTD

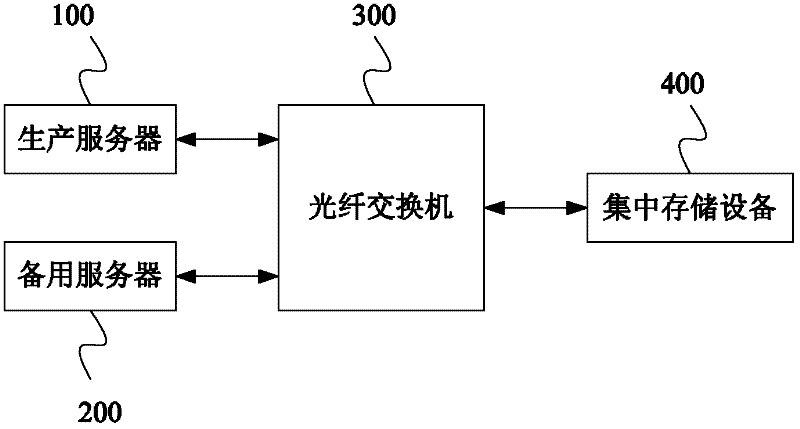

Redundancy backup method and system of production server

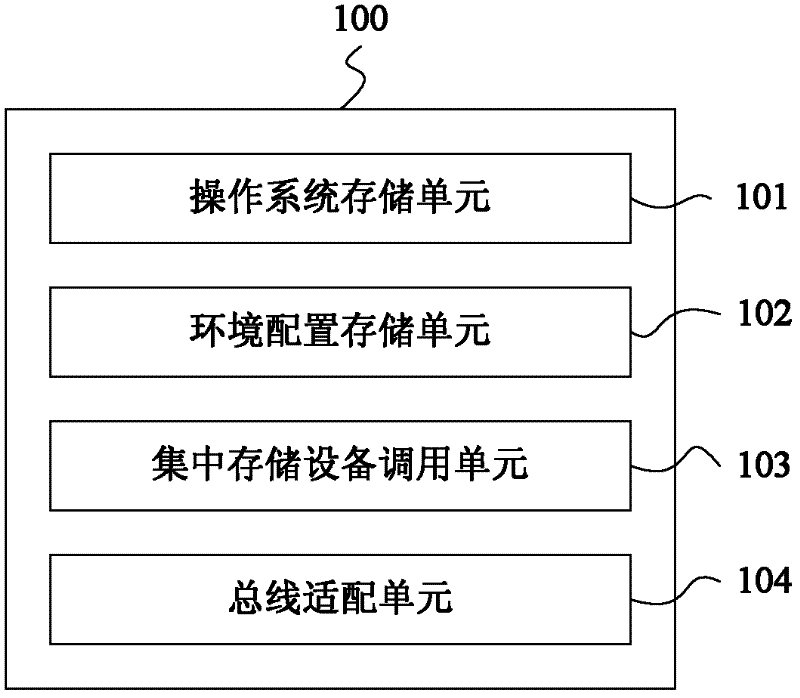

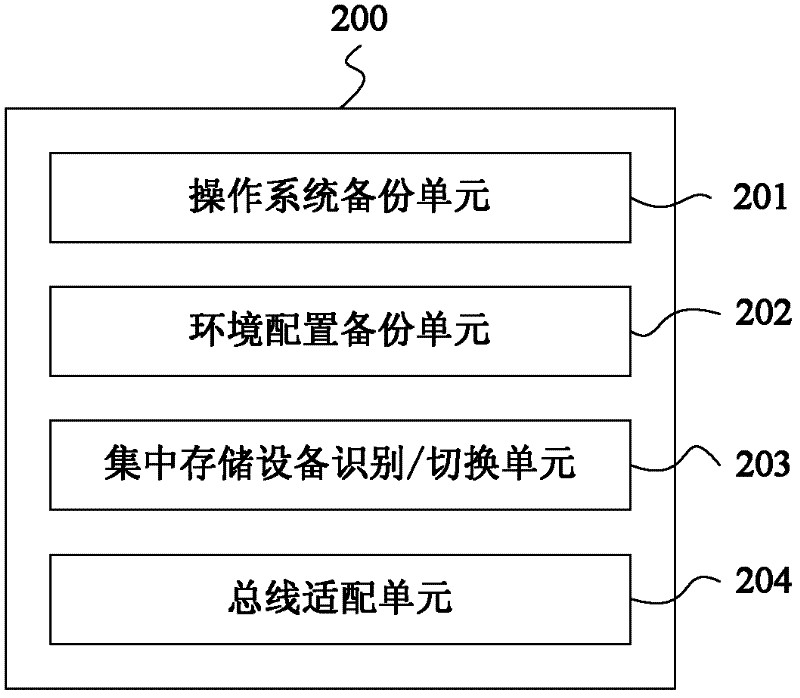

ActiveCN102655460AGuaranteed synchronicityGuaranteed continuityData switching networksOperational systemApplication software

The invention provides a redundancy backup method and system of a production server. The redundancy backup system comprises a production server, a standby server, an optical fiber switchboard and a concentrated storage device, wherein the production server is connected with the concentrated storage device through the optical fiber switchboard, the standby server is connected with the concentrated storage device through the optical fiber switchboard; the production server comprises an operating system storage unit, an environment configuration storage unit, a concentrated storage device scheduling unit and a bus adapter unit; the standby server comprises an operating system backup unit, an environment configuration backup unit, a concentrated storage unit identifying / switching unit and a bus adapter unit; the optical fiber switchboard comprises a mapping relationship storage unit and a concentrated storage device access unit; and the concentrated storage device comprises a database storage unit, a middleware storage unit, an application software storage unit and a service data storage unit. According to the invention, the problem of rapid adaption of the standby server to the failed production server is solved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Automatic detecting device of screw rod straightness and applications thereof

ActiveCN102889863AGuaranteed parallelGuaranteed accuracyUsing optical meansBall screwControl engineering

The invention discloses an automatic detecting device of screw rod straightness and applications thereof, and belongs to the field of automatic straightness detecting devices. The automatic detecting device of screw rod straightness comprises a base platform, a laser displacement sensor, a moving measuring platform, a measuring platform control system and a to-be-measured screw rod rotary system, wherein the laser displacement sensor is installed on the moving measuring platform and is connected with an industrial computer through a data transmission line; the measuring platform moving control system comprises a first moving guide rail, a second moving guide rail, a rolling ball screw rod, a first coupling, a first servo motor and a first servo controller. According to the invention, straightness of a screw rod with spiral groove characteristics can be detected automatically, and the automatic detecting device has the advantages of rapid detection process, accurate results and low product detection cost.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL +1

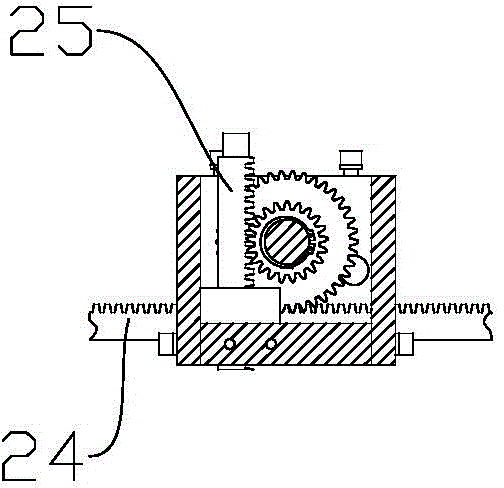

Transfer robot for warehousing stereoscopic garage

The invention discloses a transfer robot for a warehousing stereoscopic garage. The transfer robot is characterized by comprising traveling wheels for moving in the front-back directions, moving driving mechanisms, a supporting trolley underframe, a lifting mechanism and retractable forked type automatic centering mechanisms. The moving driving mechanisms include a front moving driving mechanism and a rear moving driving mechanism and are respectively fixedly connected with two ends of the supporting trolley underframe, and the traveling wheels for moving in the front-back directions can be driven to rotate, so that the transfer robot can move in the front-back directions; the lifting mechanism comprises lifting frames, an electric push rod, gear cases, transmission racks and lifting guide columns, the electric push rod is fixedly connected with the transmission racks, gears in the three gear cases can be driven, and lifting racks further can be driven, so that the lifting frames can ascend and descend; front comb frames and rear comb frames of the automatic centering mechanisms can be driven by driving motors, chain transmission mechanisms, gear transmissions and retractable racks to be stretched out and drawn back, so that parking spaces can be centered, and centering combs can be stretched out and drawn back. The transfer robot has the advantages that the transfer robot is in a retractable forked type transfer structural design, accordingly, the utilization rate of clear spaces of the stereoscopic garage can be increased, the quantity of equipment can be reduced, and the service cost can be lowered.

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

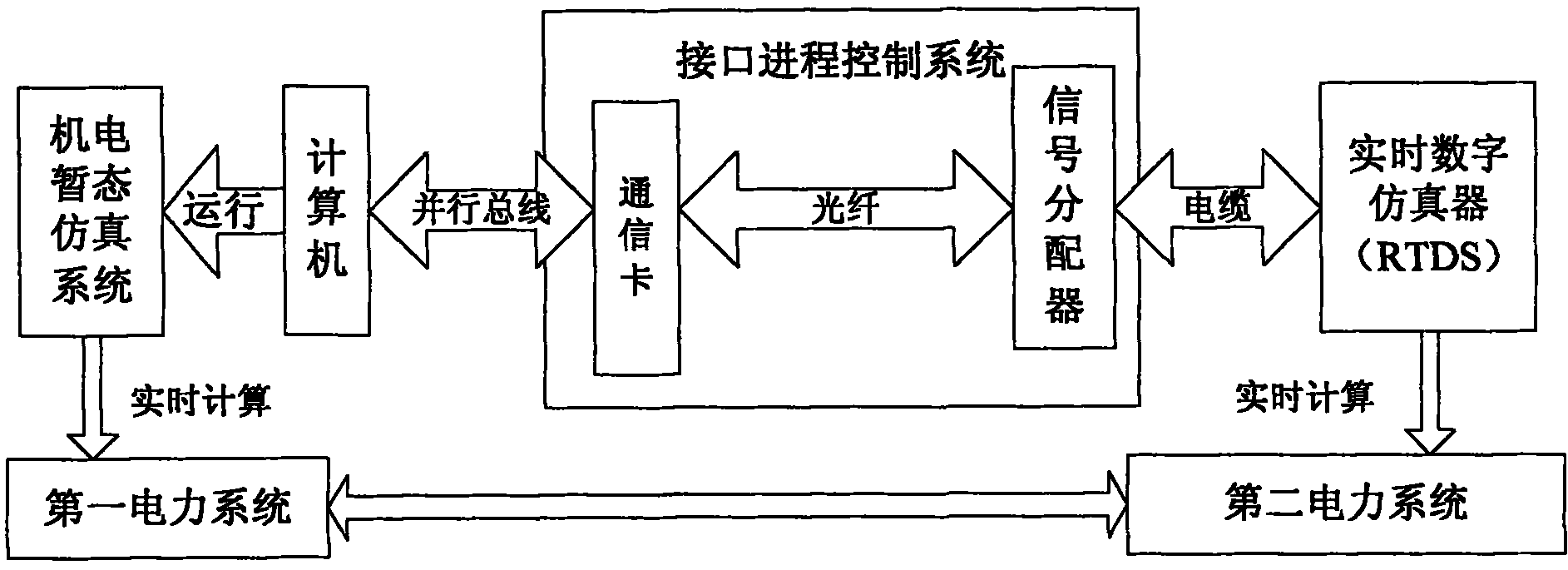

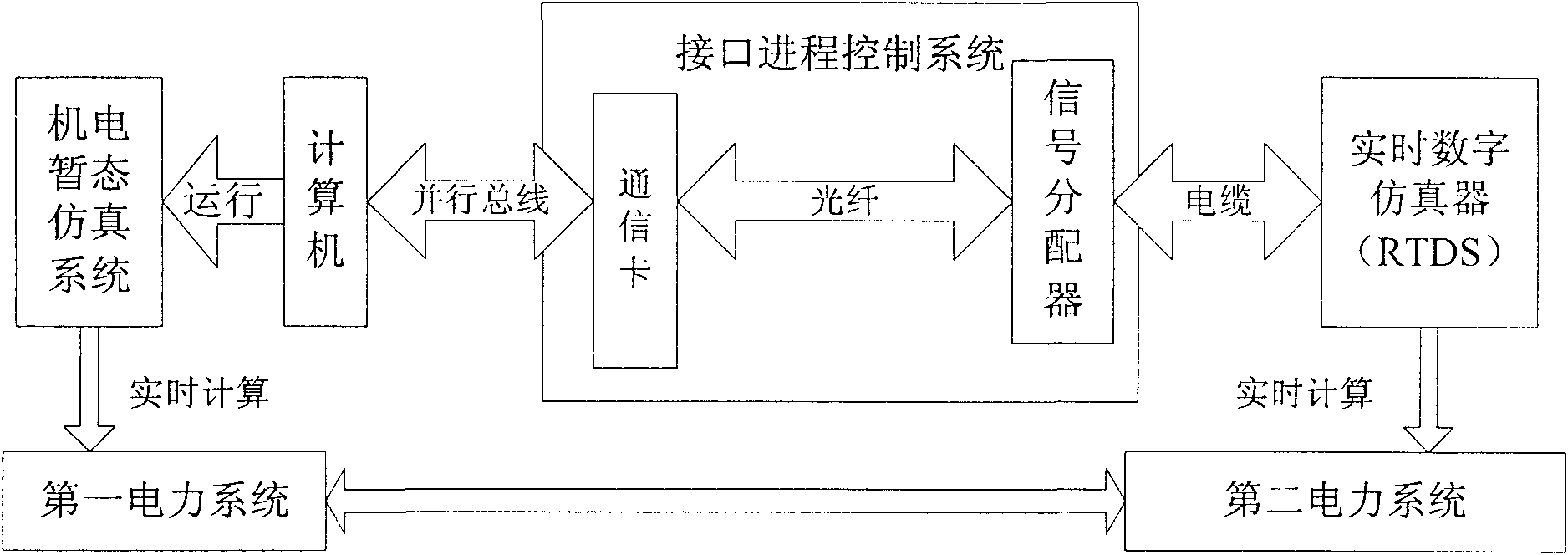

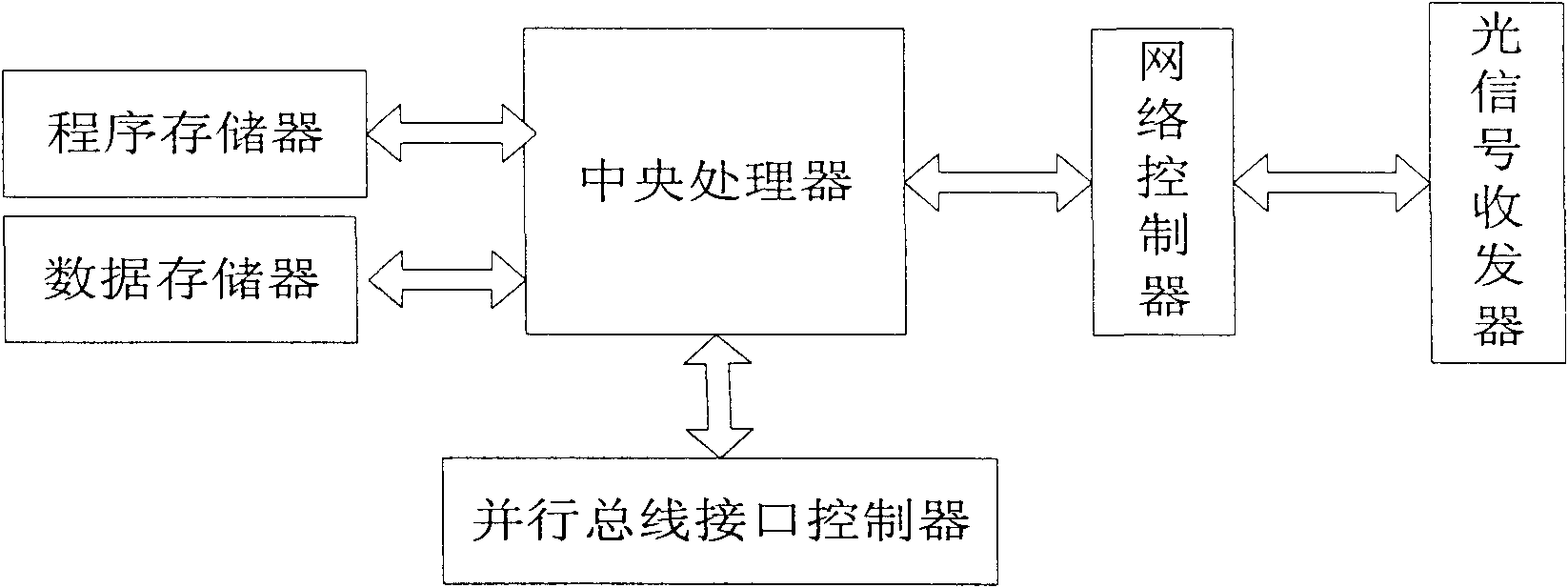

Electromagnetic transient-state and electromechanical transient-state mixed real-time simulation interface process control system

InactiveCN101814733AGuaranteed synchronicityAccurate Timing MechanismSpecial data processing applicationsAc network circuit arrangementsTransient stateReal-time simulation

The invention relates to an electromagnetic transient-state and electromechanical transient-state mixed real-time simulation interface process control system which belongs to the technical field of the transient-state simulation of an electric power system. The electromagnetic transient-state and electromechanical transient-state mixed real-time simulation interface process control system comprises a communication card and a signal distributor, wherein the communication card is used for receiving the electromechanical transient-state simulation calculation result of an electromechanical transient-state simulation system to a first electric power system by a parallel bus on a computer, transmitting the electromechanical transient-state simulation calculation result to the signal distributor, also receiving the electromagnetic transient-state simulation calculation result of a real-time digital simulator of the signal distributor to a second electric power system and transmitting the electromagnetic transient-state simulation calculation result to the computer; the signal distributor transmits the received simulation calculation result of the first electric power system to the real-time digital simulator, receives the electromagnetic transient-state simulation calculation result of the second electric power system and transmits the electromagnetic transient-state simulation calculation result to the communication card; and the communication card and the signal distributor are connected by an optical fiber. The control system ensures the synchronism of the two simulation systems which are the electromagnetic transient-state system and the electromechanical transient-state system, the real-time property of the interface process control system and the communication accuracy and the communication distance of the interface process control system.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

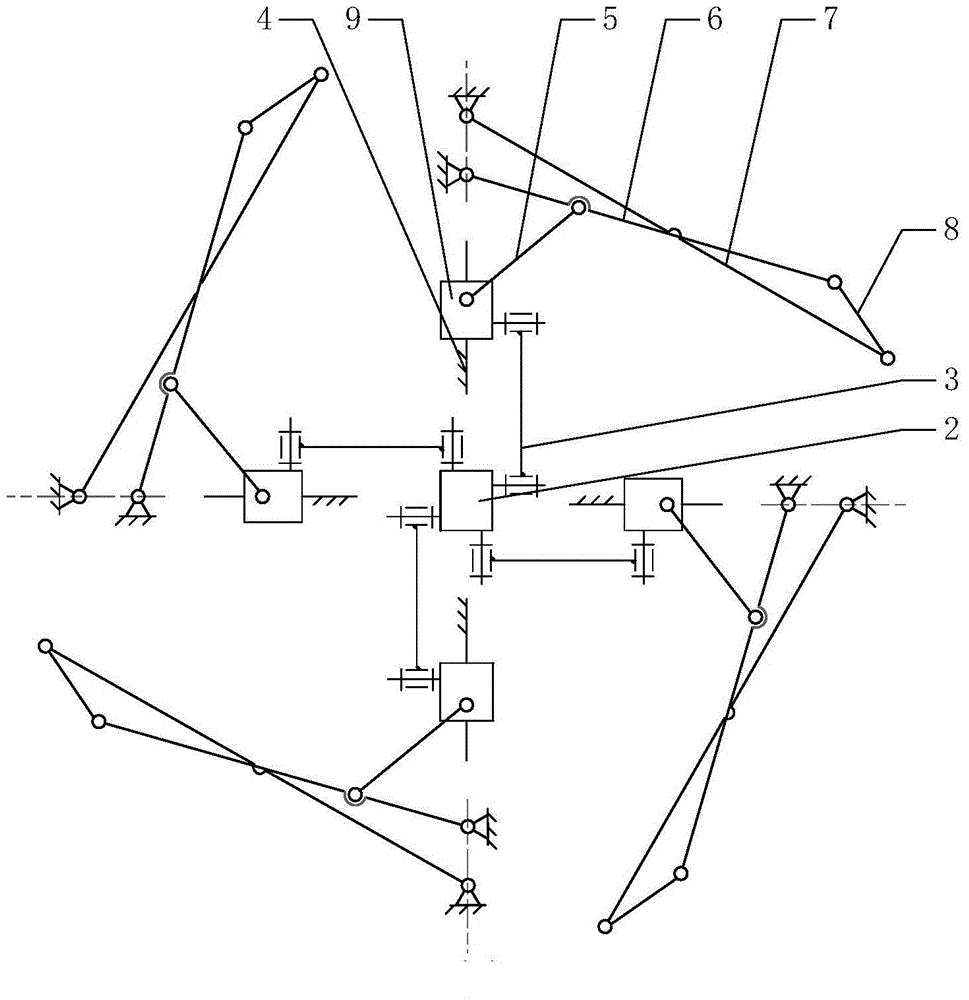

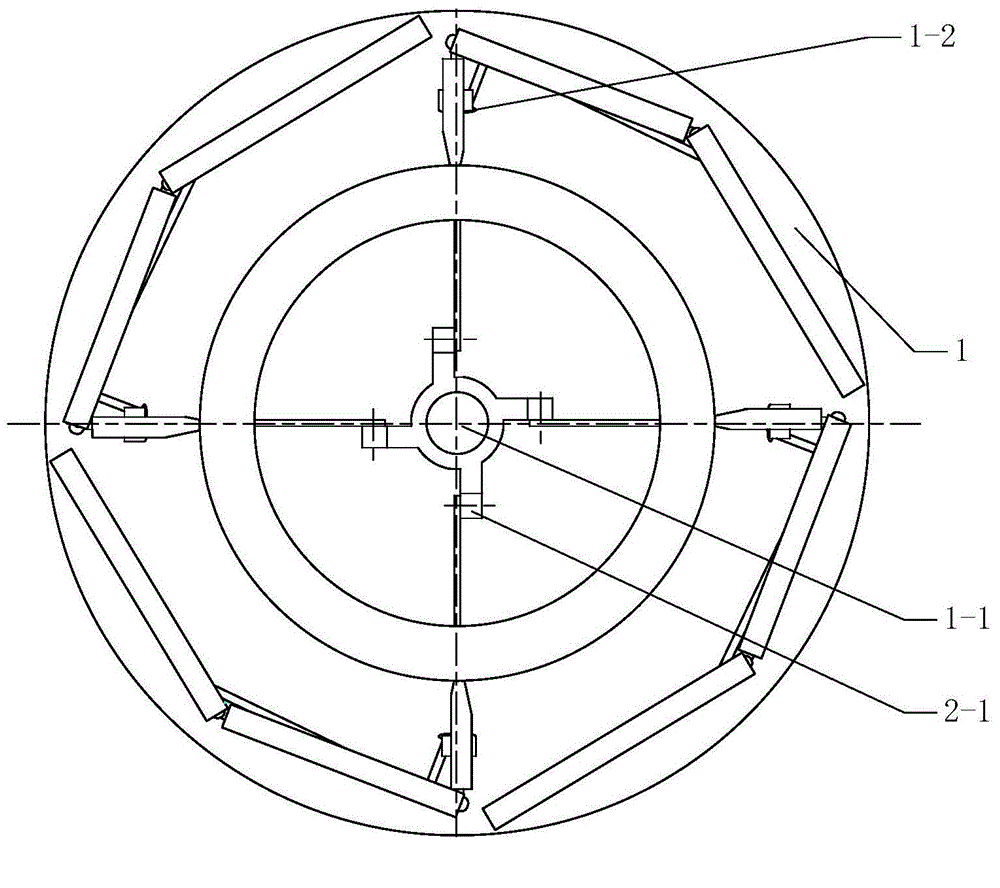

Single-drive synchronous unfolding mechanism provided with multiple folding control planes

The invention discloses a single-drive synchronous unfolding mechanism provided with multiple folding control planes. Each control plane of a traditional small guided missile is independently driven by a torsion spring to be unfolded, synchronism is difficultly ensured, and the adopted unfolding mechanism enable the radial size of the guided missile to be large during folding. The single-drive synchronous unfolding mechanism comprises a cabin body, an actuator cylinder, a connecting rod and four unfolding mechanisms, wherein an actuator cylinder installing seat is fixed to the cabin, the actuator cylinder is connected with an actuator cylinder installing seat sliding pair, four actuator cylinder convex lugs are evenly distributed on the actuator cylinder, each actuator cylinder convex lug is hinged to the inner end of one connecting rod, and the outer ends of the four connecting rods extend out of installing holes formed in the unfolding mechanism respectively and are hinged to slide blocks of the corresponding unfolding mechanism. The unfolding mechanism comprises a rudder stick, the slide blocks, lug pieces, a middle rudder, a rudder tip, connecting rods and a spring locking mechanism, wherein the spring locking mechanism is used for locking the slide blocks and a rudder shaft. The transverse size of a missile body is effectively decreased during control plane folding. The controllability and synchronism in the unfolding process of the four control planes are ensured through driving of the single actuator cylinder.

Owner:ZHEJIANG SCI-TECH UNIV

Novel energy source water mixing and stirring device

InactiveCN107649044AGuaranteed synchronicityImprove the mixing effectShaking/oscillating/vibrating mixersRotary stirring mixersNew energyWater production

The invention discloses a novel energy source water mixing and stirring device, which comprises a base, wherein the upper side wall of the base is provided with a stirring box in an inserted manner; the upper side wall of the base is provided with a placing box; the placing box is sleeved on the outer side of the stirring box; a fixing plate is arranged between the inner walls of the placing box;a fixing block is inserted on the fixing plate; a threaded opening is formed in the fixing block; a threaded rod is inserted in the threaded opening; the outer wall of the threaded rod is provided with external screw threads matched with the inner wall of the threaded opening; a servo motor is arranged in the placing box; a driving motor of the servo motor is fixedly connected with the upper end of the threaded rod; the lower end of the threaded rod penetrates through the upper side wall of the stirring box and extends to the inside of the stirring box; one end, positioned inside the stirringbox, of the threaded rod is provided with a plurality of stirring blades in a sleeved manner. Through the vertical movement of the stirring blades and the left and right pushing of a push plate, the stirring effect during the novel energy source water production can be improved; the structure is simple; convenience and practicability are realized.

Owner:CHENGDU LEYE TECH CO LTD

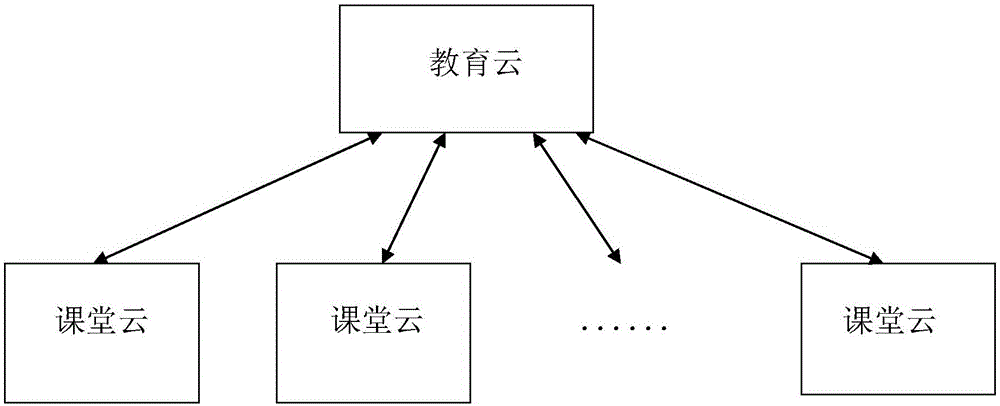

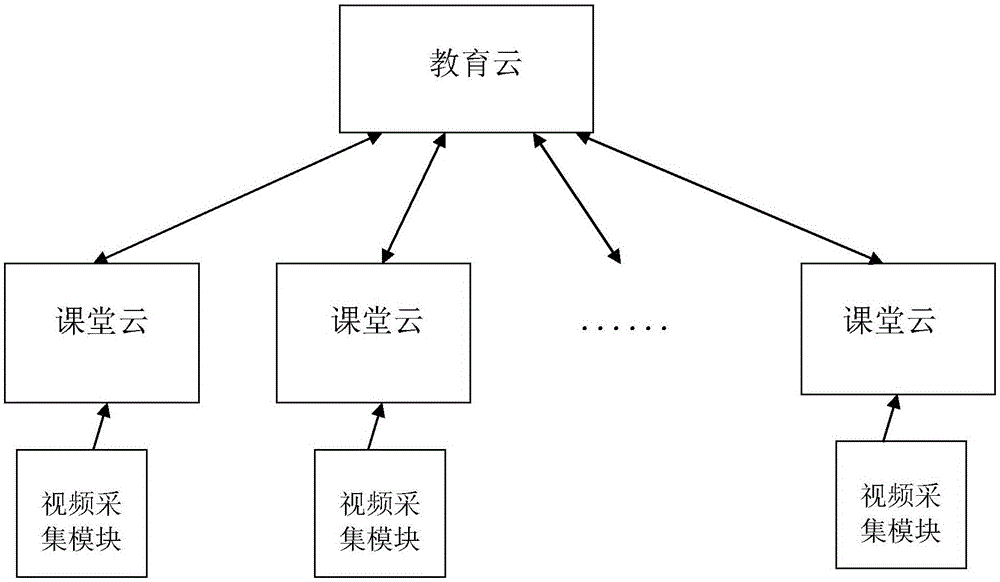

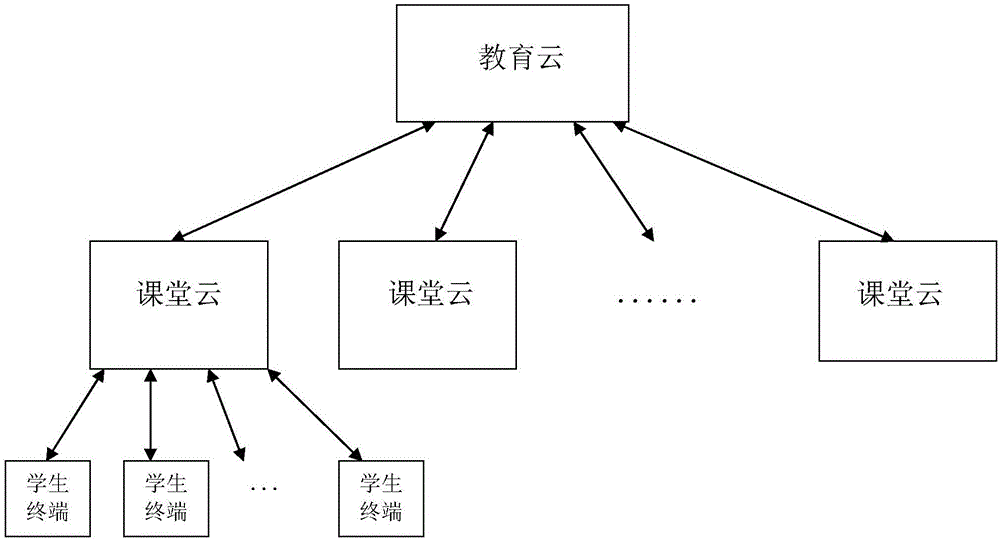

Classroom cloud and education cloud collaborative teaching interaction system and method

InactiveCN105047033AAvoid problems that cannot reach the local area and affect teachingImprove experienceElectrical appliancesInteraction systemsMultimedia

The invention discloses a classroom cloud and education cloud collaborative teaching interaction system comprising an education cloud platform and multiple classroom cloud platforms. The education cloud platform is used for receiving and storing teaching resources and pushing the resources to the classroom cloud platforms according to the preset push rules, and the target classroom cloud to which the resources are pushed and the time requirement at which the resources are pushed are set in the push rules. The classroom cloud platforms are used for receiving the teaching resources pushed by the education cloud platform to be used by local teaching and collecting local resources to be uploaded to the education cloud platform. With application of the classroom cloud and education cloud collaborative teaching interaction system, the education cloud can actively push the resources to the classroom clouds when the network is idle, and teachers can use the teaching resources already pushed to the local for teaching even the network is disconnected or the network is congested in teaching so that effectiveness of classroom teaching under the condition of no network or network delay and congestion can be guaranteed.

Owner:HUAZHONG NORMAL UNIV

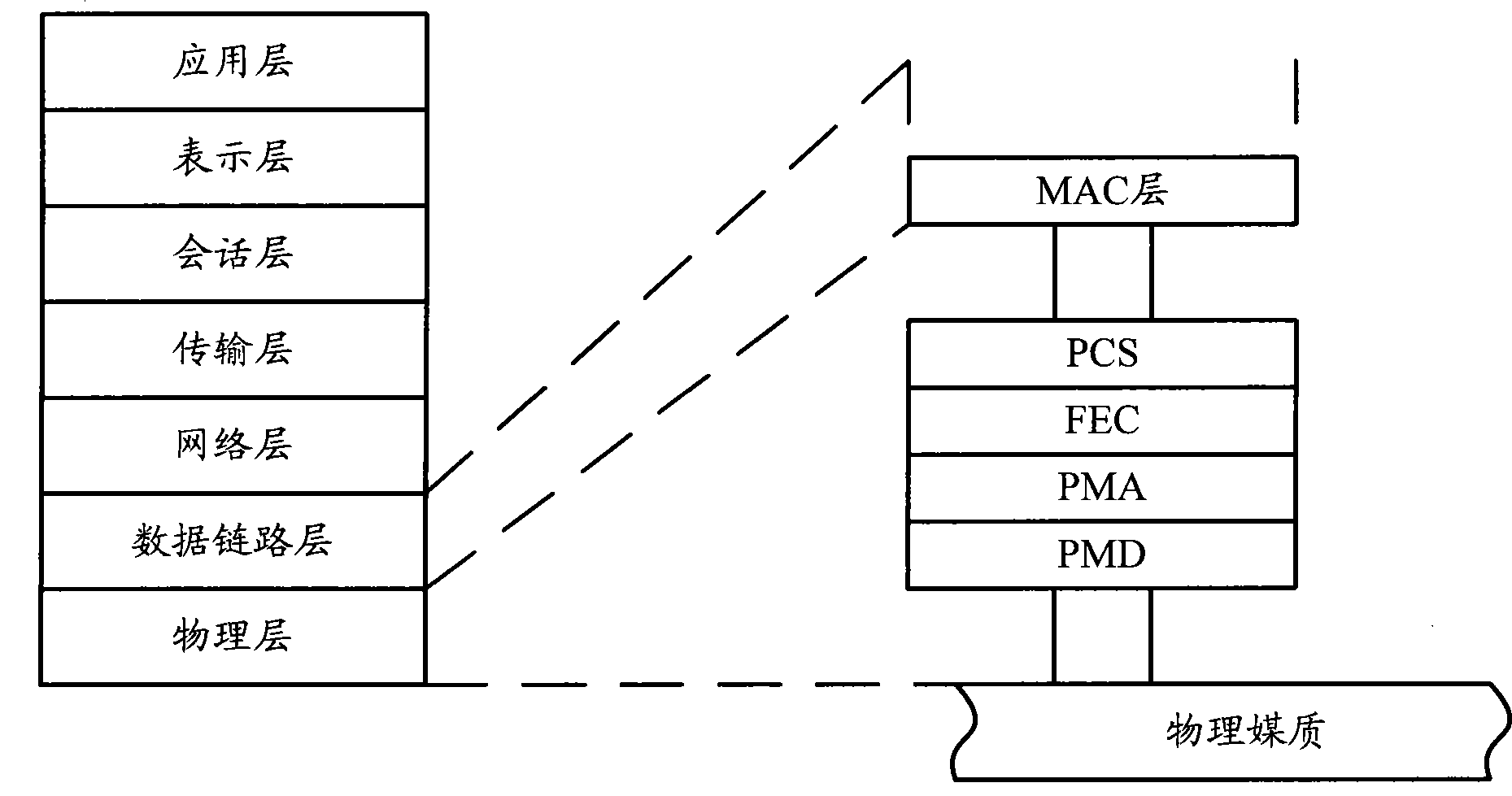

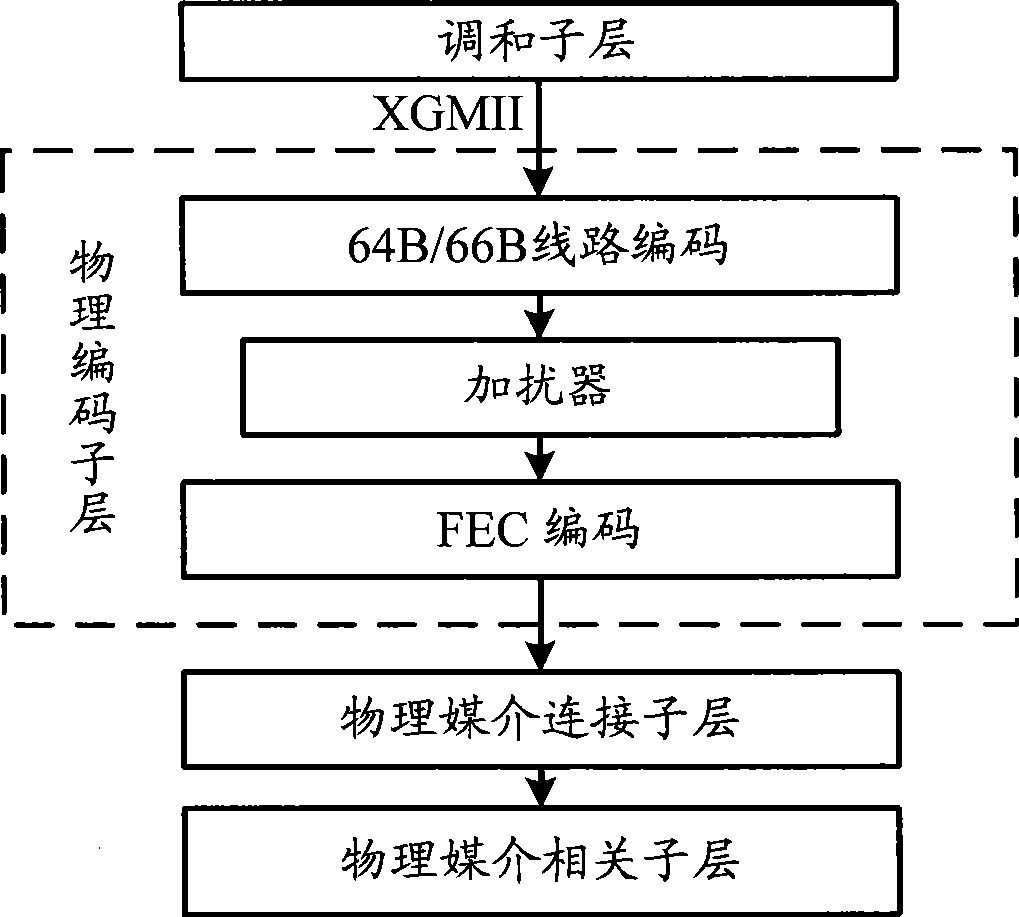

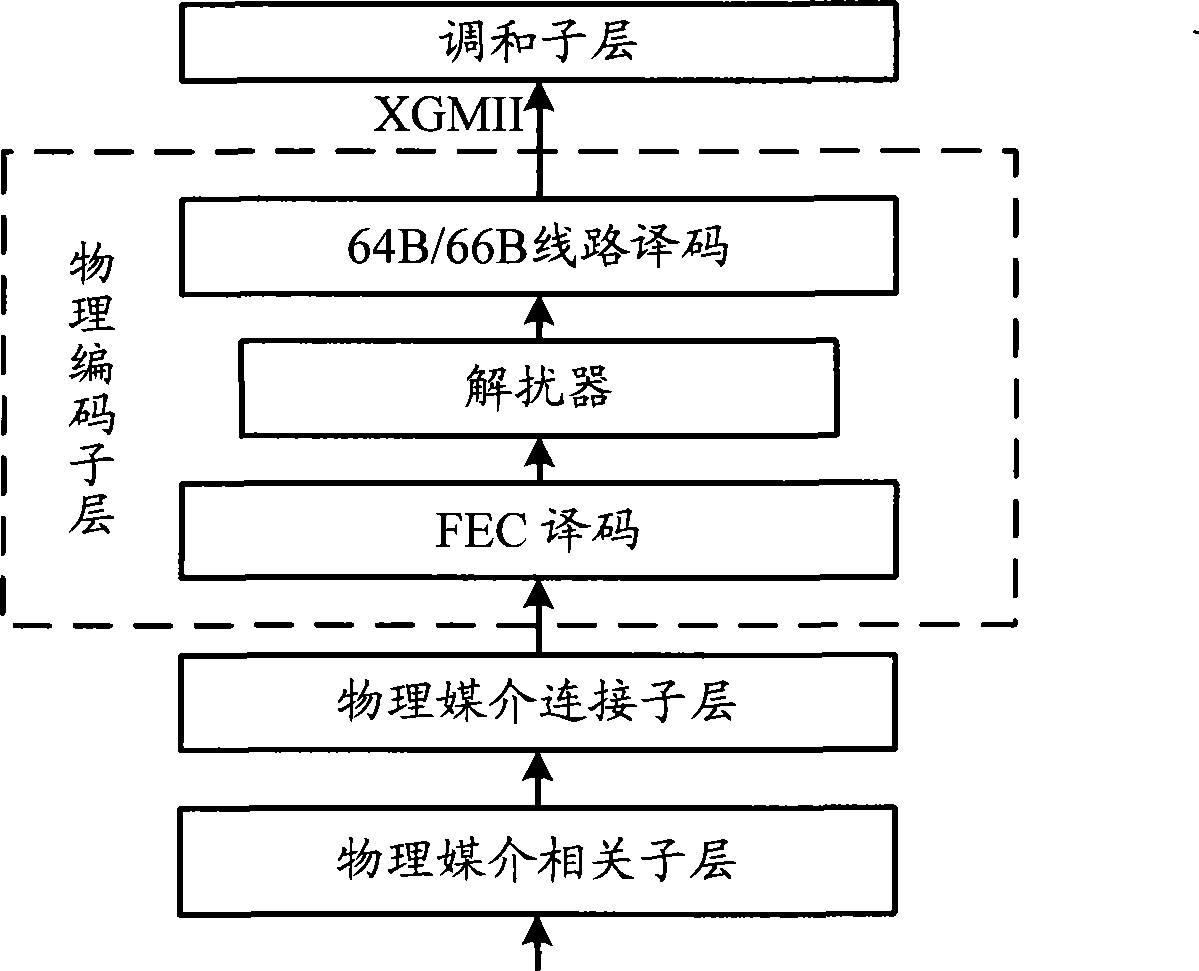

Method and apparatus for encoding and decoding data

ActiveCN101436917ACoding gain is not affectedGuaranteed synchronicityData representation error detection/correctionError preventionData encodingLine code

The execution mode of the invention discloses a method for coding data, which is to add additional synchronous heads to data subjected to line coding and FEC coding and then send the data through framing. The execution mode of the invention also provides a corresponding method for decoding the data, a data coder and a data decoder. With the addition of redundant information used for synchronization, the execution mode of the invention can also ensure the synchronous performance of a transmission system under the condition that the line coding selects an algorithm with smaller redundancy; besides, the additionally added synchronous heads do not take part in the FEC coding computation to ensure that the coding gain of the FEC is not affected.

Owner:XFUSION DIGITAL TECH CO LTD

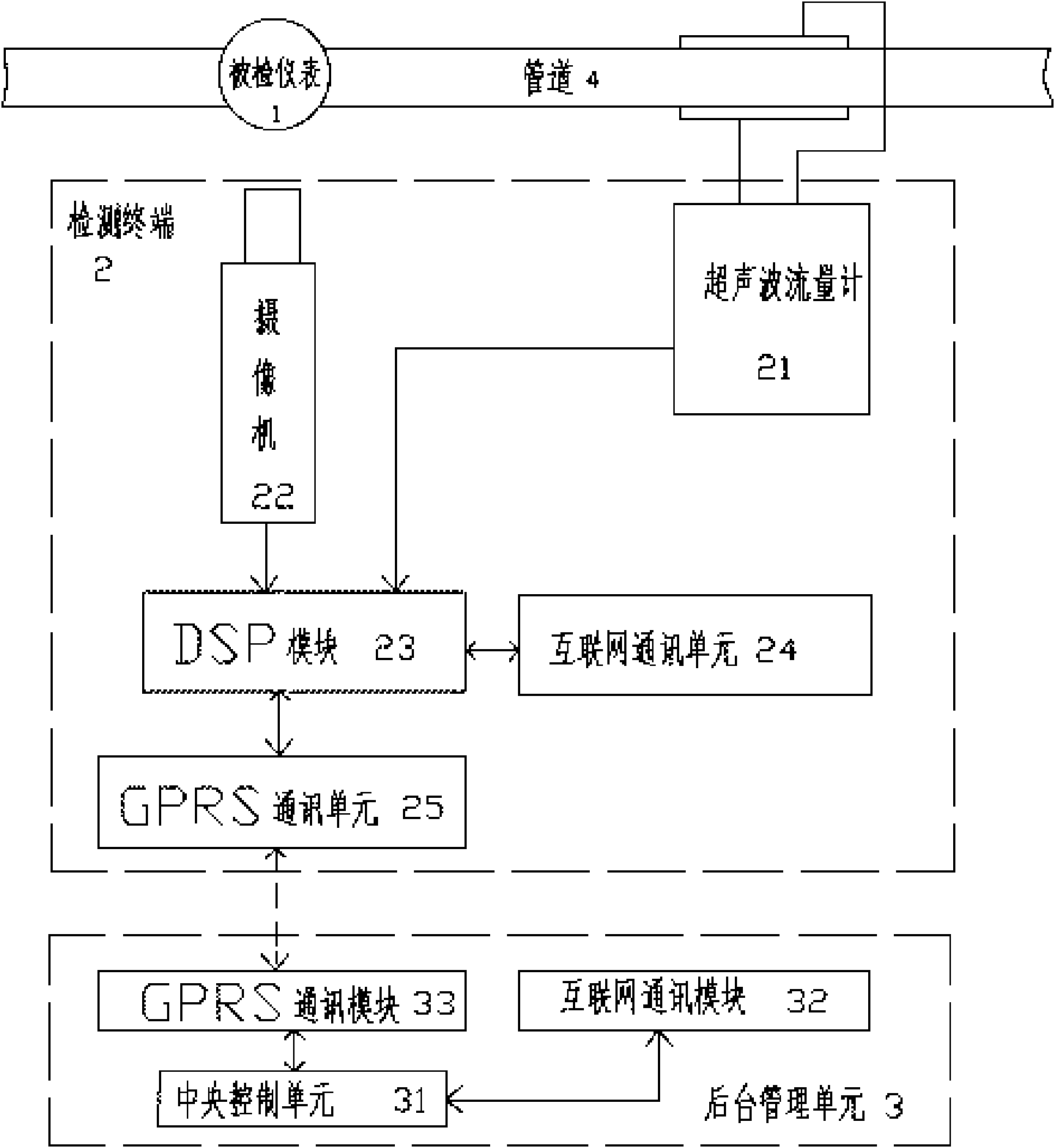

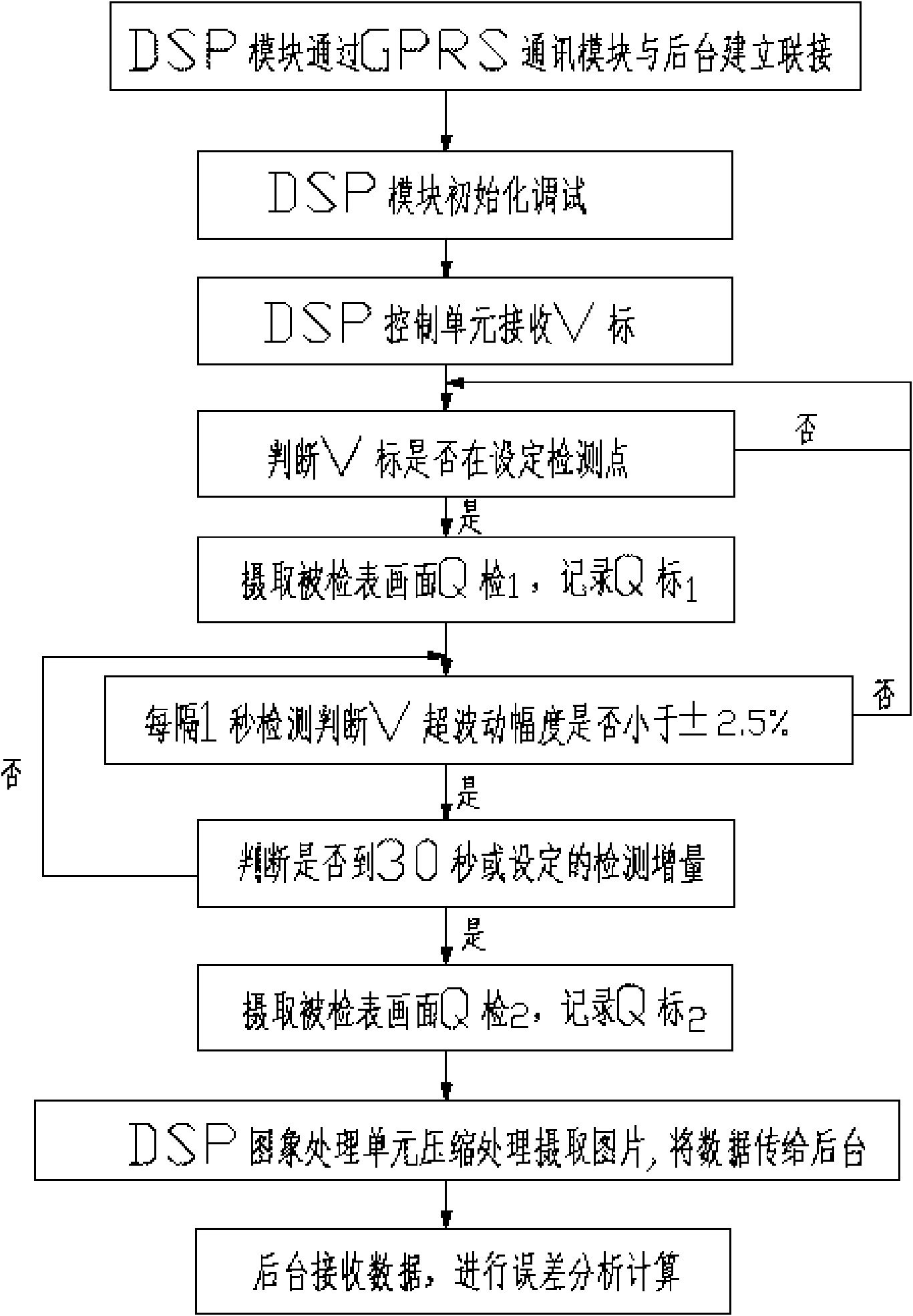

Online measurement device and measurement method thereof for pipeline flux instrument

InactiveCN101561309AReduce on-site operationsWide range of workTesting/calibration apparatusComputer hardwareCommunication unit

The invention discloses an online measurement device and a measurement method thereof for a pipeline flux instrument, comprising a detection terminal and a background management unit; the detection terminal comprises a flowmeter, a camera, a DSP module and a communication unit connected with the DSP module; the background management unit comprises a central control unit and a communication module connected with the central control unit; the detection terminal and the background unit carry out data communication by a GPRS wireless network and / or an Internet; the output terminals of the camera and the flowmeter are respectively connected with the image signal input terminal and the flux value signal input terminal of the DSP module; the camera of the detection terminal right faces to the dial plate of the instrument to be measured; the flowmeter is arranged on the pipeline; and the background management unit respectively obtains the accumulated flux in the pipeline within unit time by the camera and the flowmeter in the detection terminal so as to calculate the measurement error of the instrument to be measured.

Owner:CHANGZHOU INST OF MEASUREMENT & TESTING TECH +1

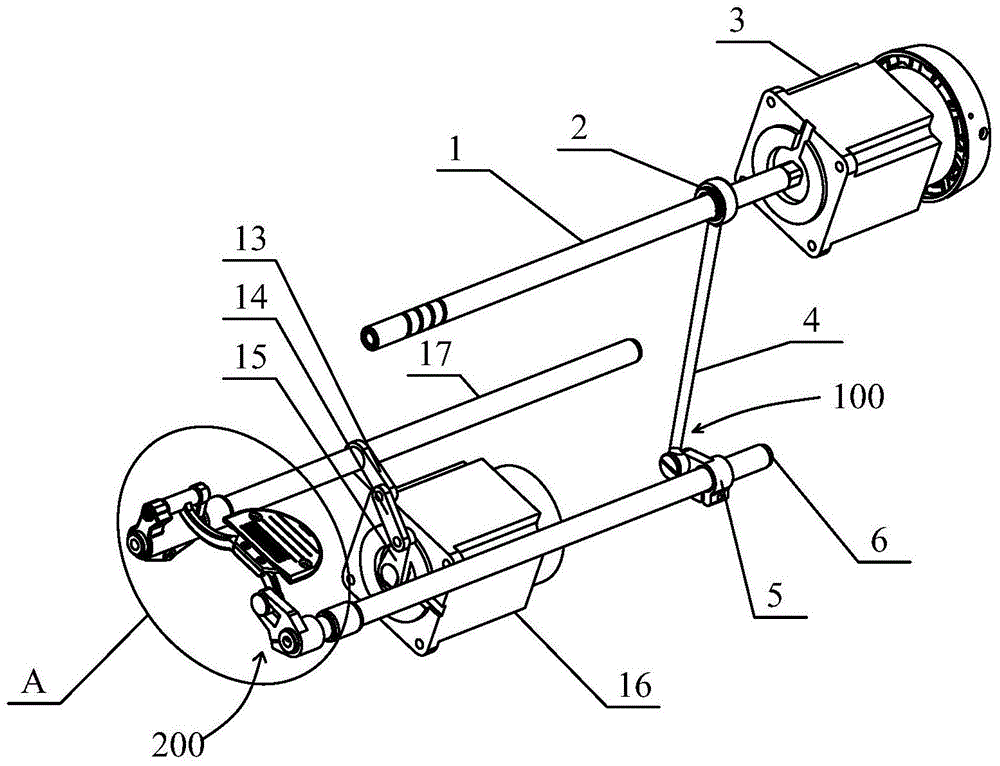

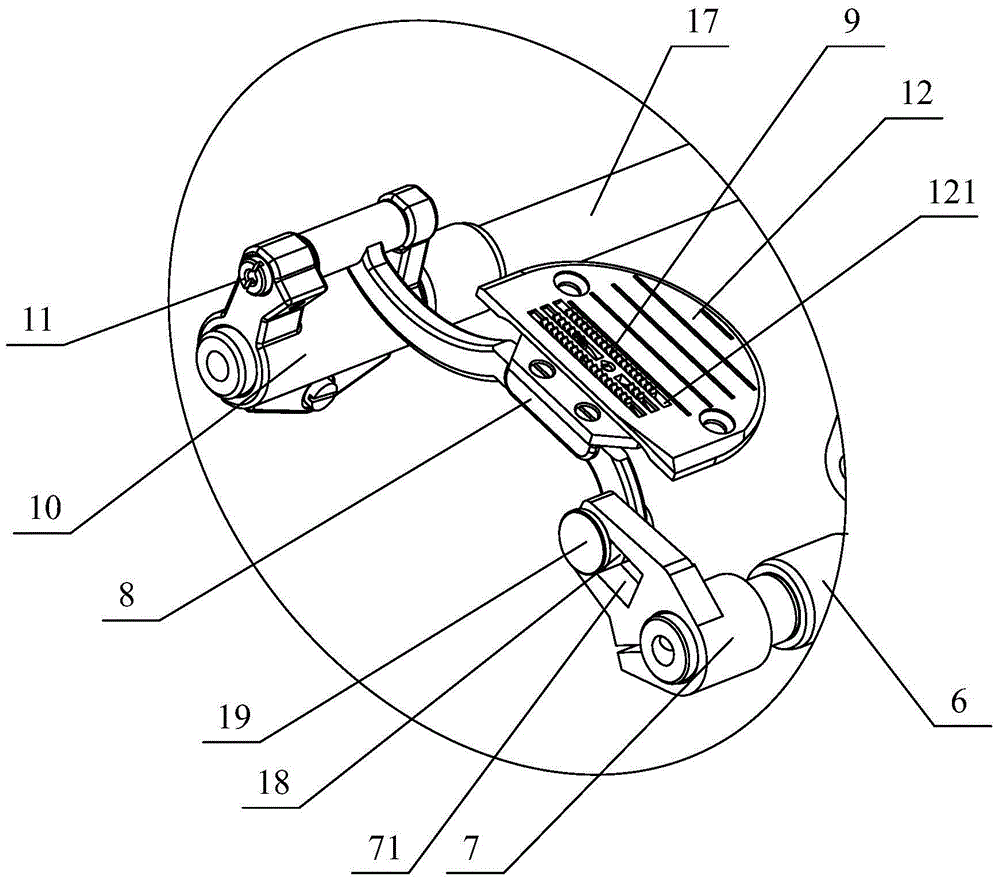

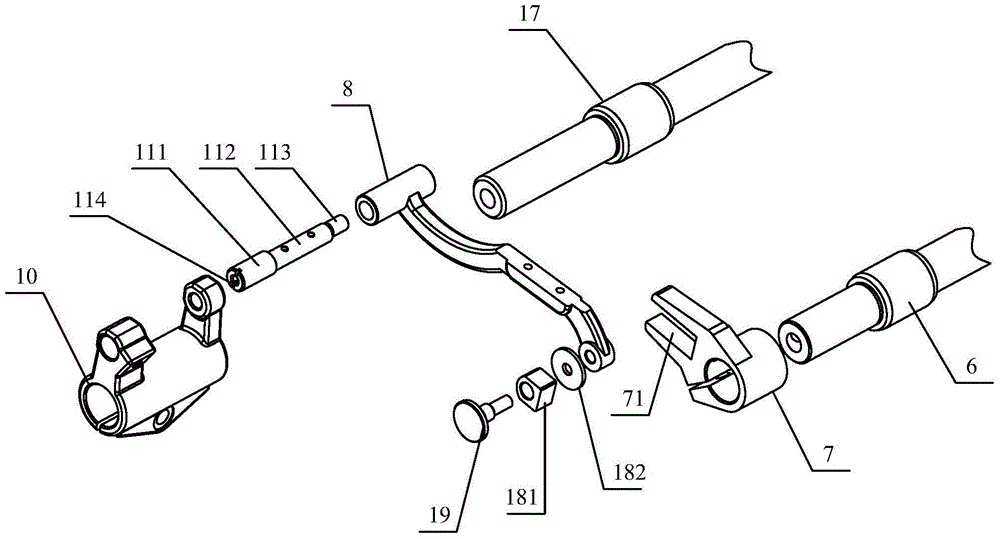

Dog lifting feeding mechanism of sewing machine and sewing machine

The invention provides a dog lifting feeding mechanism of a sewing machine. The mechanism comprises a first motor, a second motor, a dog rack and feed dogs fixed on the upper end surface of the dog rack, wherein the first motor is connected with the dog rack through a dog lifting mechanism; the second motor is connected with the dog rack through a cloth feeding mechanism; the dog lifting mechanism comprises an upper shaft and a dog lifting shaft which are arranged in parallel; the upper shaft is connected with the dog lifting shaft through a first transmission unit and drives the dog lifting shaft to swing back and forth with own axis as a center line; the dog lifting shaft is connected with the dog rack through a second transmission unit and drives the dog rack to reciprocate up and down. According to the dog lifting feeding mechanism of the sewing machine and the sewing machine, synchronism between rotation of the first motor and vertical movement of the dog rack can be guaranteed, deviation of a feeding time point is effectively avoided, and the noise is greatly reduced. According to the dog lifting feeding mechanism of the sewing machine and the sewing machine, synchronism between rotation of the first motor and vertical movement of the dog rack can be guaranteed, and deviation of a feeding time point is effectively avoided.

Owner:JACK SEWING MASCH CO LTD

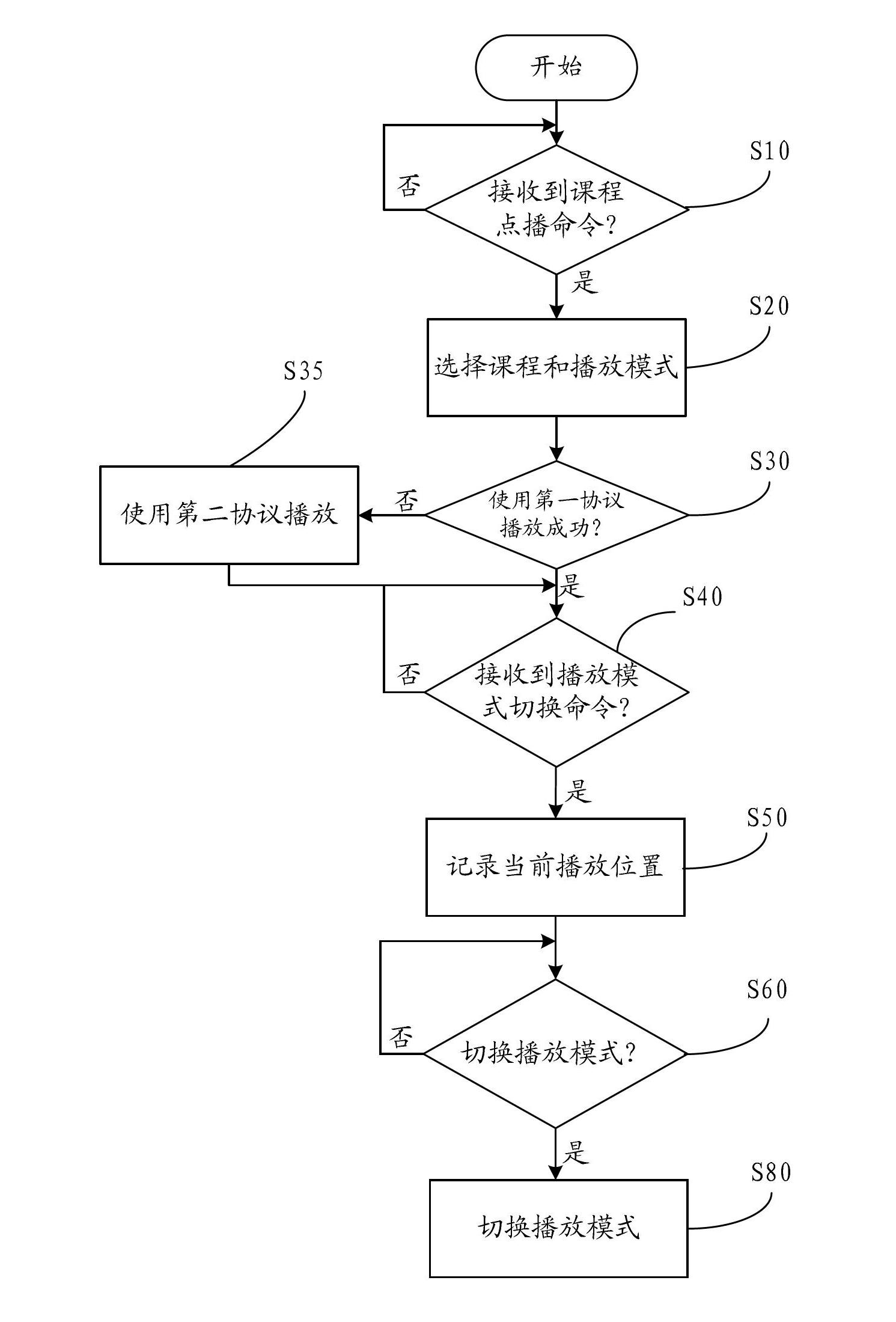

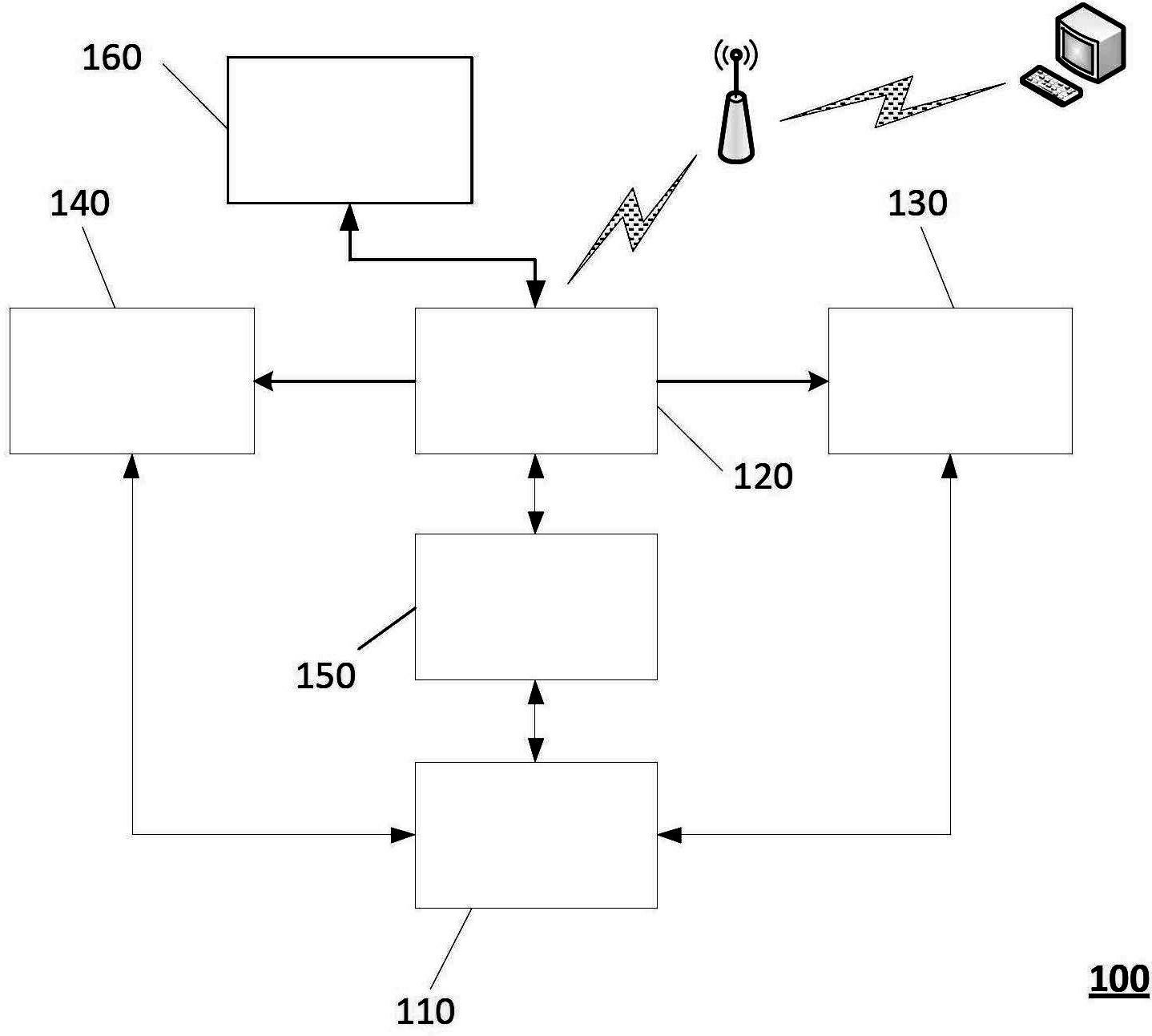

Mobile video playing system and method for remote instruction

ActiveCN102646346AGood playback reliabilityImprove compatibilityElectrical appliancesComputer terminalMode switch

The invention relates to a mobile video playing method for remote instruction, which based on the mobile video playing system. The mobile video playing system comprises a storage module, a user communication module, a video switching module, a video synchronization module and a video protocol switching module, wherein the storage module stores course video, the user communication module is connected with a user terminal, when the user communication module receives a playing mode switching command from the user terminal, the video switching module switches the current course video into target course video according to information related to the target playing mode, the video synchronization module synchronizes the playing position of the target course video with the current playing position of the current course video according to information of the current playing position, which is related to the current course video, and the video protocol switching module switches a protocol used by playing the current video according to the condition that the current video is played successfully. According to the invention, more course seeing mode options can be provided for a user, and further better use experiences are provided.

Owner:北京中熙正保远程教育技术有限公司

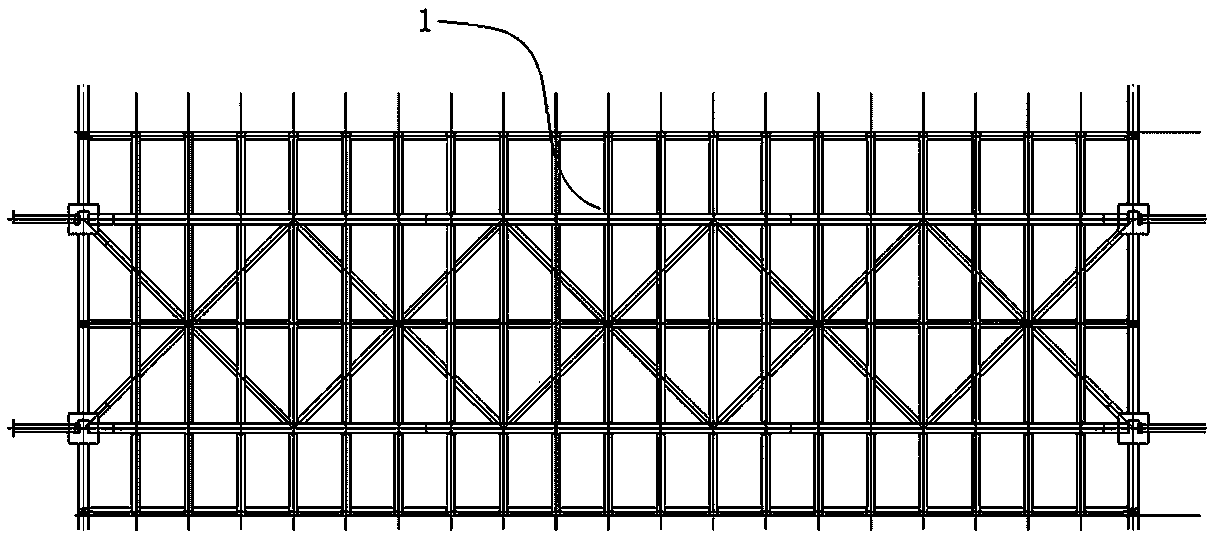

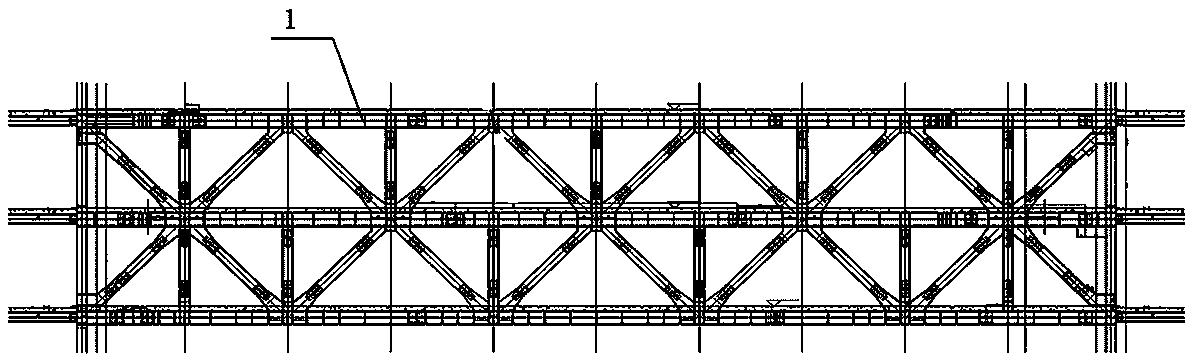

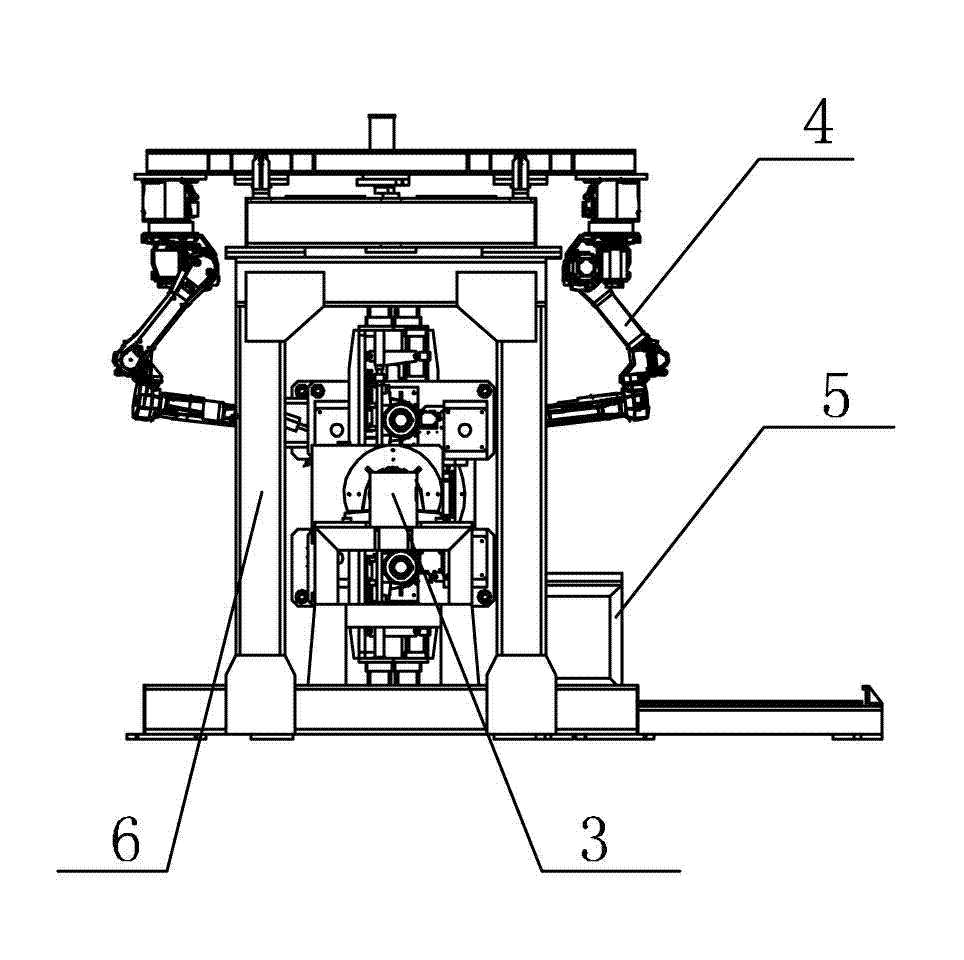

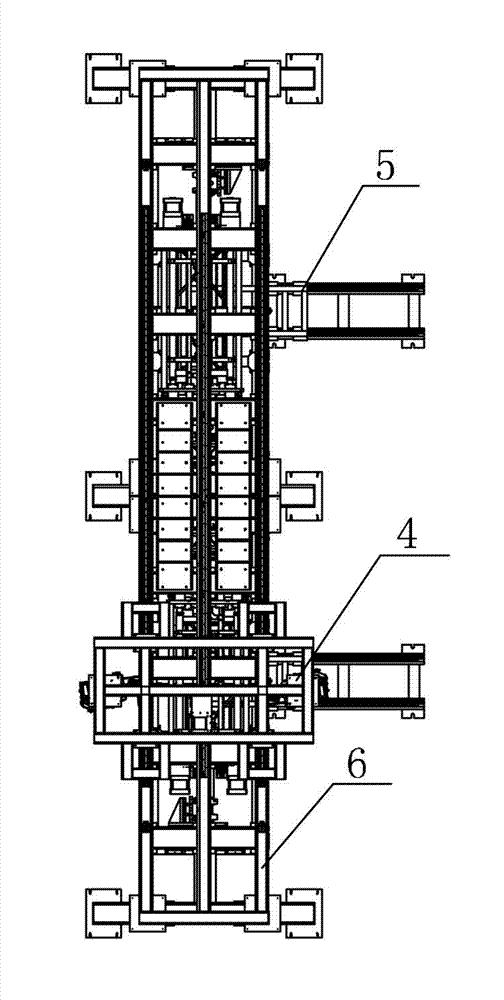

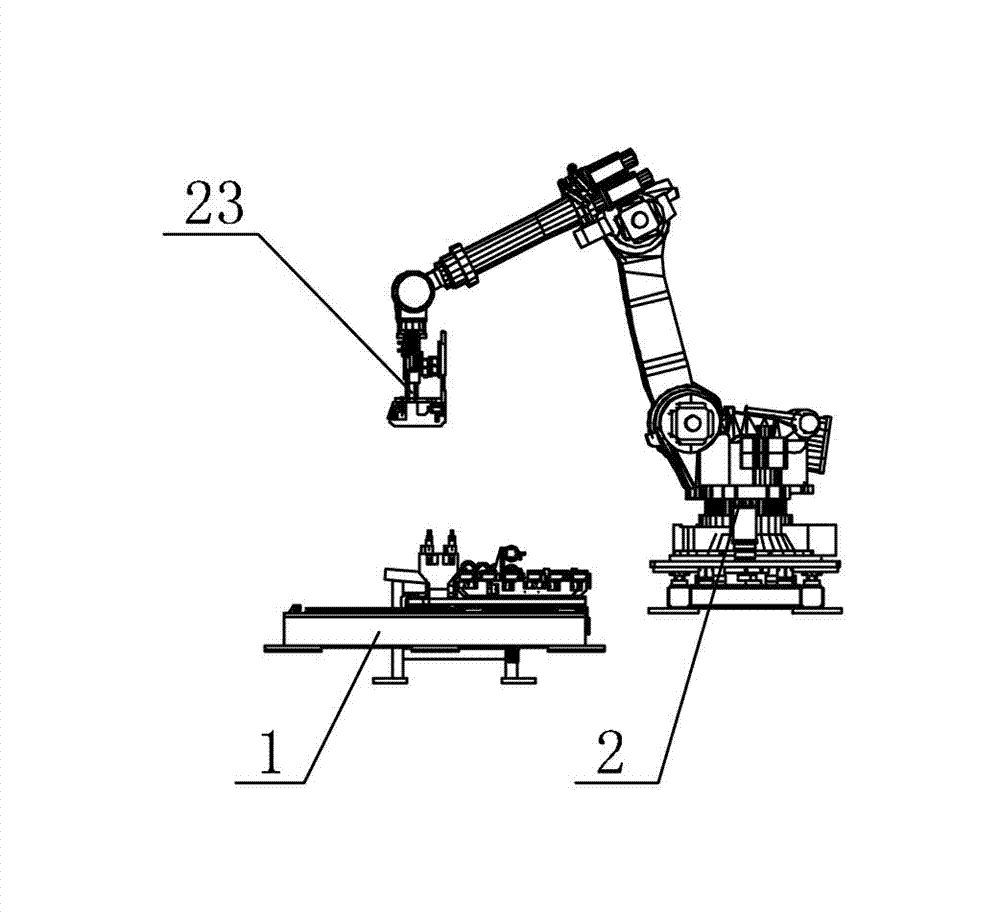

Integrated equipment of automatic robot welding system of standard knots

ActiveCN102896445AGuaranteed synchronicityImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesManipulatorRobot welding

The invention discloses integrated equipment of an automatic robot welding system of standard knots. The integrated equipment comprises a feeding sliding table tooling, a transporting manipulator, a standard knot deflection tooling, a welding manipulator and a discharging mechanism, wherein a three-dimensional coordinate detection device of the standard knot tooling is arranged on the standard knot deflection tooling; an electromagnetic clamp is arranged on the transporting manipulator; a welding gun guide track is arranged on the arm of the transporting manipulator; a welding gun sliding mechanism is connected with two sides of the welding gun guide track; a welding gun is fixed on the welding gun sliding mechanism; the rotary disc of the standard knot deflection tooling is integrally connected with a standard knot positioning bracket; the rotary disc is driven by a speed change motor; the welding manipulator is hung on a truss; and the standard knot deflection tooling is arranged below the truss. Compared with the traditional manual welding method, the consistency in welding quality, the welding efficiency and the safety reliability can all meet the requirements on the quality and the number in manufacturing modern high-tech products.

Owner:重庆立诚重工科技集团有限公司

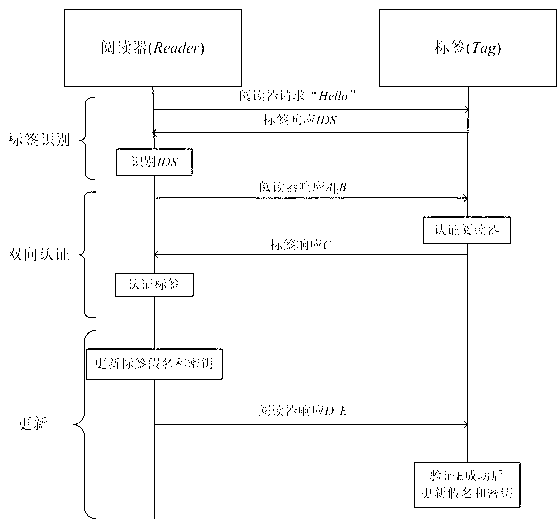

RFID (radio frequency identification) mutual authentication protocol method

ActiveCN103078741AReduce computing needsReduce storage requirementsUser identity/authority verificationCo-operative working arrangementsThree stageExclusive or

The invention relates to an RFID (radio frequency identification) mutual authentication protocol method, which comprises the following three stages: a tag identification stage, a mutual authentication stage and an update stage, wherein at the tag identification stage, a reader sends a request to a tag, and the tag returns an identification section (IDS) to the reader after receiving the request; at the mutual authentication stage, after the IDS is identified by the reader, an exclusive-or operation related to a digital synthetic operation is conducted to obtain A and B, A and B are sent to the tag, after the reader is identified by the tag through received A||B, related calculation is conducted to obtain C, C is sent to the reader, and the tag is identified by the reader; and at the update stage, after C is successfully identified by the reader, IDS and secret keys (K1 and K2) in C are updated, then D and E are calculated and sent to the tag, and after E is successfully identified by the tag, IDS and secret keys of E are updated. Only the simple digital synthetic or exclusive-or operation exists in the RFID mutual authentication protocol method. Therefore, the RFID mutual authentication protocol method has the beneficial effects that the calculation amount and storage space of the tag can be effectively reduced, various attacks such as impersonation, retransmission, tracking and denial of service can be resisted, and forward security is provided.

Owner:上海诚扬信息科技有限公司

Multi-degree-of-freedom modular inspection robot

InactiveCN108381564ASuitable for narrow space environmentGuaranteed positioning accuracyMonorailsBogiesModularitySimulation

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com