Mechanical arm for clamping cans

A technology for manipulators and cans, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

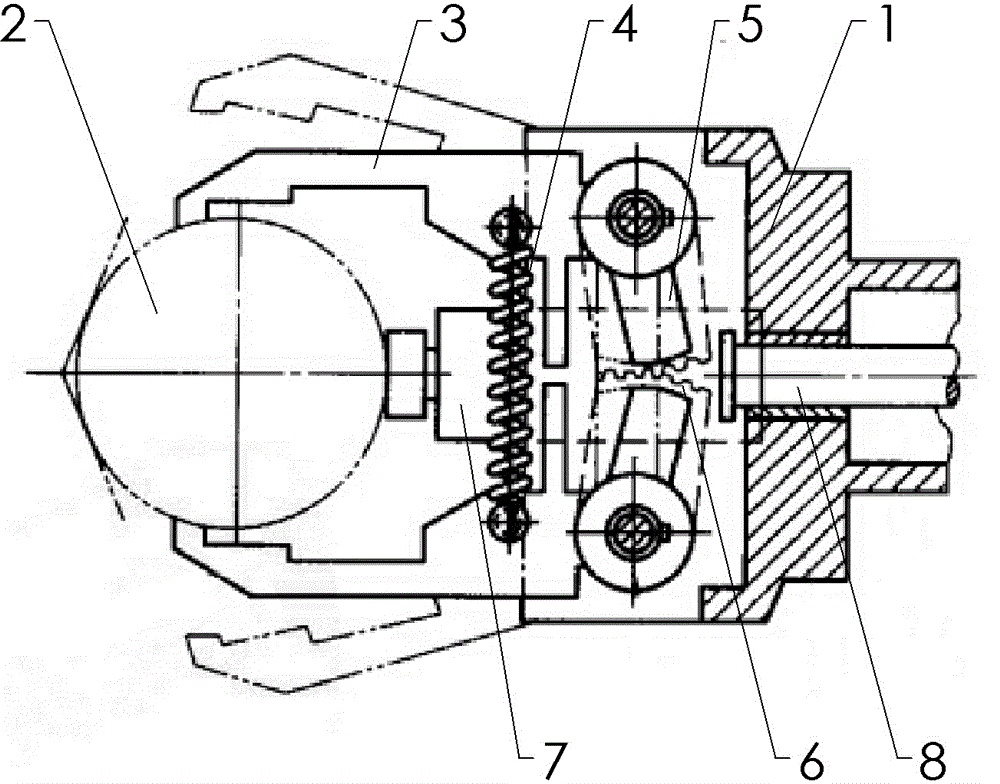

[0012] The reference numerals in the drawings of the description include: boom 1, can 2, arm claw 3, extension spring 4, rocking bar 5, sector gear 6, pressure rod 7, piston rod 8 of telescopic cylinder.

[0013] The embodiment is basically as attached figure 1 As shown: the arm frame is installed on the movable equipment, and the left and right sides of the arm frame are symmetrically hinged with arm claws for clamping the opposite side of the can, and a tension spring is connected between the two arm claws. The claws of the two arms mesh with each other through sector gears. The synchronization of rotation is better.

[0014] Through the dovetail groove, the arm frame is slidably connected with a pressure rod located in the middle of the symmetrical line of the two arm claws. The clamping part of the pressure rod is located between the two arm claws to correspond to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com