Battery management system performance test platform and testing method based on semi-physical simulation

A technology of battery management system and hardware-in-the-loop simulation, which is applied in general control systems, control/regulation systems, instruments, etc., to achieve the effects of ensuring effectiveness and comprehensiveness, accuracy, and synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

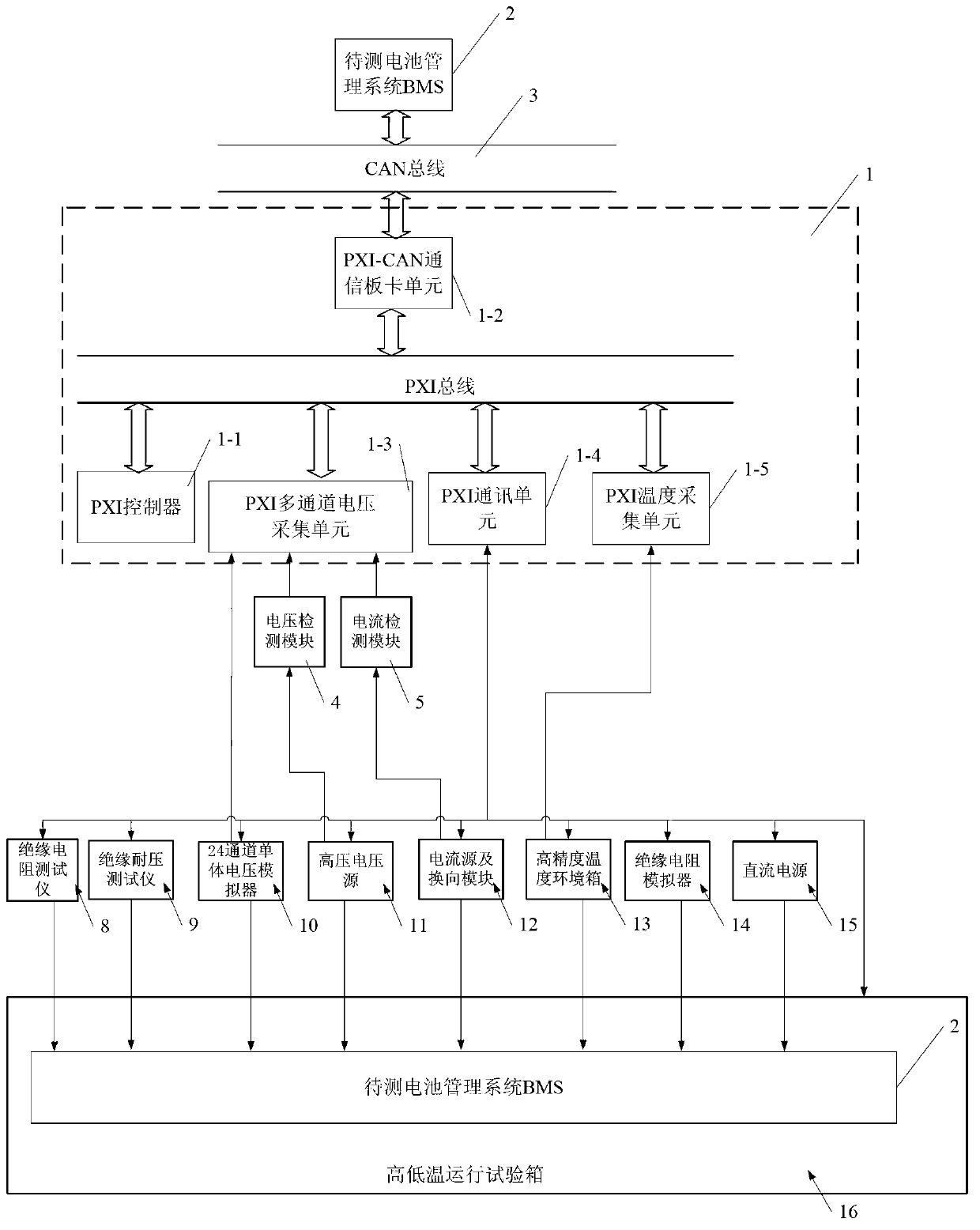

[0042] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the battery management system performance test platform based on hardware-in-the-loop simulation described in this embodiment, which includes a simulation control and simulation unit 1, a voltage detection module 4, a current detection module 5, an insulation resistance tester 8, an insulation withstand voltage Tester 9, 24-channel monomer voltage simulator 10, high-voltage voltage source 11, current source and current commutation module 12, high-precision temperature environment box 13, insulation resistance simulator 14, DC power supply 15 and high and low temperature operation test box 16 ;

[0043] The battery management system BMS2 to be tested realizes data interaction with the simulation control and simulation unit 1 through the CAN bus 3;

[0044] The high-voltage signal output terminal of the high-voltage voltage source 11 is connected to the high-voltage signal inpu...

specific Embodiment approach 2

[0058] Specific implementation mode two: the following combination figure 1 Describe this embodiment, this embodiment will further explain Embodiment 1, the battery management system performance test platform based on hardware-in-the-loop simulation described in this embodiment, the simulation control and simulation unit 1 includes a PXI controller 1-1, a PXI -CAN communication board unit 1-2, PXI multi-channel voltage acquisition unit 1-3, PXI communication unit 1-4 and PXI temperature acquisition unit 1-5;

[0059] Described PXI controller 1-1, PXI-CAN communication board unit 1-2, PXI multi-channel voltage acquisition unit 1-3, PXI communication unit 1-4 and PXI temperature acquisition unit 1-5 are all connected on the PXI bus ;

[0060] Described PXI communication unit 1-4 comprises the multiple communication interface of USB, GPIB, RS232, RS485, RS422, Ethernet, digital input / output, to adapt to the insulation resistance tester 8~high and low temperature operation test c...

specific Embodiment approach 3

[0063] Specific implementation mode three: the following combination figure 1 Describe this embodiment, the test method of the battery management system performance test platform based on hardware-in-the-loop simulation described in this embodiment, the test method includes: the safety of the insulation resistance test and the insulation withstand voltage performance test of the battery management system BMS2 to be tested sex test;

[0064] The process of described insulation resistance test is: PXI controller 1-1 sets insulation resistance test condition: comprise test time T, test voltage U, insulation resistance alarm lower limit value R and start and read the control signal of insulation resistance value, and Send the control signal to the PXI communication unit 1-4 through the PXI bus, and then send the control signal to the insulation resistance tester 8 by the PXI communication unit 1-4, start the insulation resistance tester 8, and make the insulation resistance tester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com