Automatic detecting device of screw rod straightness and applications thereof

An automatic detection device and straightness technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor detection accuracy and slow detection speed, and achieve the effect of realizing automation, ensuring safety and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

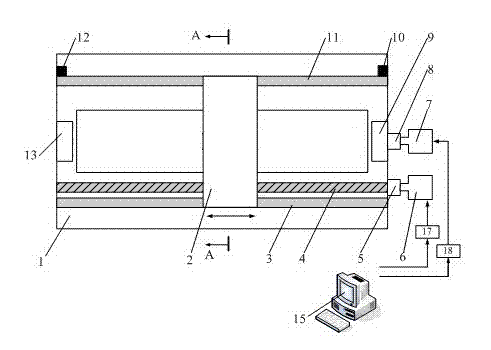

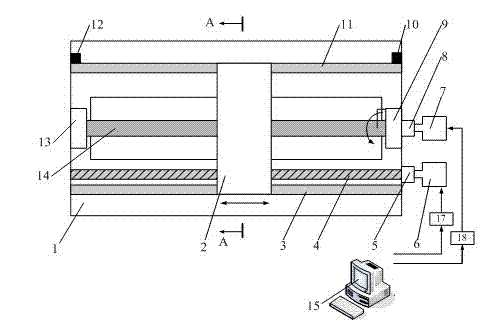

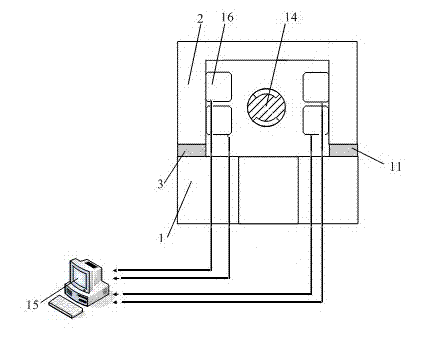

[0034] Such as figure 1 , figure 2 , image 3 As shown, a screw rod straightness automatic detection device includes a base 1 and a laser displacement sensor 16. There are 1-4 laser displacement sensors 16, and 4 are preferably selected in this embodiment, and also include a mobile measuring table 2, a measuring The table motion control system and the screw mandrel rotation system to be measured, the laser displacement sensor 16 is installed on the mobile measuring platform 2, and the laser displacement sensor 16 is connected with the industrial computer 15 through the data transmission line;

[0035] The motion control system of the measuring table comprises a first moving guide rail 3, a second moving guide rail 11, a ball screw 4, a first shaft coupling 5, a first servo motor 6 and a first servo controller 17; the first moving guide rail 3 and The second moving guide rail 11 is arranged on the base 1 in parallel; the ball screw 4 is parallel to the first moving guide ra...

Embodiment 2

[0042] Such as figure 1 , figure 2 , Figure 4 As shown, with embodiment 1, the difference is that there is one laser displacement sensor 16, then after a scanning measurement, the second servo motor 7 automatically controls the rotation of the measured screw mandrel 14, and is respectively positioned as figure 2 On the positions a, b, c, and d of the screw mandrel 14 to be tested according to the formula, scanning measurement is carried out respectively. After the data of the four positions are measured, the industrial computer 15 performs data processing and fits to obtain the straightness of the measured screw rod 14, and finally gives an evaluation conclusion on whether it is qualified or not.

Embodiment 3

[0044] Such as figure 1 , figure 2 , Figure 5 As shown, with embodiment 1, the difference is that there are two laser displacement sensors 16, then after a scanning measurement, the second servo motor 7 automatically controls the rotation of the measured screw mandrel 14, from the original as Figure 5 The a, b positions of the tested screw mandrel 14 are transferred to the c, d positions, and then scanning measurement is performed. After the data of the four positions are measured, the industrial computer 15 performs data processing and fits to obtain the straightness of the measured screw rod 14, and finally gives an evaluation conclusion on whether it is qualified or not.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com