One-dimensional nanometer electrode material, and preparation method and application thereof

A technology of nano-electrodes and silicon nano-wire arrays, which is applied in the direction of material analysis, nanotechnology, and material analysis through electromagnetic means, can solve problems such as excessive high voltage, and achieve the effect of reducing operating voltage and low breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

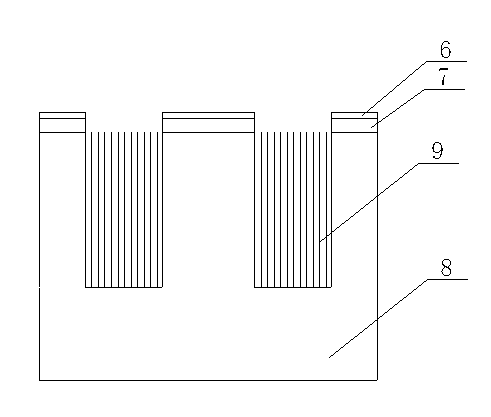

[0030] Such as figure 1 As shown, the one-dimensional nanometer electrode material of the present invention includes a silicon wafer substrate 8 , a silicon dioxide film 7 and a silicon nitride film 6 , and a silicon nanowire array 9 . The silicon dioxide film 7 and the silicon nitride film 6 are rectangular, and have the same size and shape (the silicon dioxide film 7 and the silicon nitride film 6 can be of various shapes, and the regular shape is preferable to facilitate mask preparation). The silicon dioxide film 7 is evenly distributed on the surface of the silicon wafer substrate 8 at intervals. The silicon nitride film 6 is deposited on the corresponding surface of the silicon dioxide film. The surface of the silicon wafer substrate between the silicon dioxide films 7 is etched to form a silicon nanowire array 9 . The silicon dioxide film 7 has a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com