Online measurement device and measurement method thereof for pipeline flux instrument

A flow meter and verification device technology, applied in the field of online verification devices for pipeline flow meters, can solve the problems that image data cannot be transmitted and analyzed remotely, affects the analysis and judgment of the tested meter, and cannot track and monitor in real time, and achieves compact structure, Avoid misjudgment or time error, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (Embodiment 1, instrument online verification device)

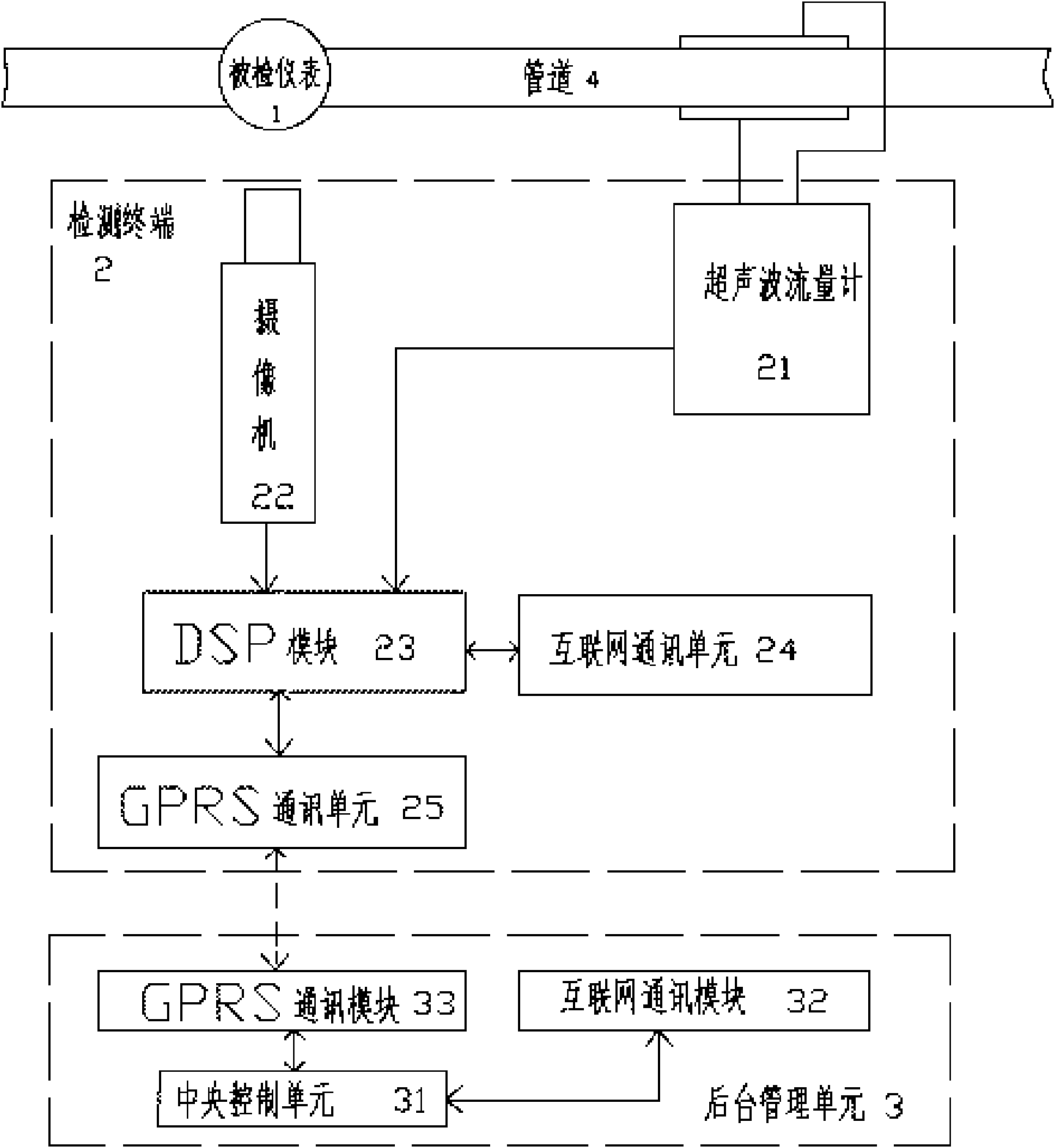

[0024] See figure 1 , the online verification device for pipeline flow meters in this embodiment includes: a detection terminal 2 and a background management unit 3, and the detection terminal 2 and the background management unit 3 are wirelessly connected through a GPRS wireless network.

[0025] The detection terminal 2 includes a flow meter 21 , a camera 22 , a DSP module 23 , an Internet communication unit 24 and a GPRS communication unit 25 connected to the DSP module 23 . The DSP module 23 includes an image processing unit and a control unit. The camera 22 of the detection terminal 2 is set facing the dial of the meter 1 under test. The flow meter 21 is fixed on the pipeline 4 . The output end of the camera 22 is electrically connected to the input end of the image processing unit. The output end of the flowmeter 21 is electrically connected with the input end of the control unit through the RS-232 serial...

Embodiment 2

[0028] (Embodiment 2, instrument online verification method)

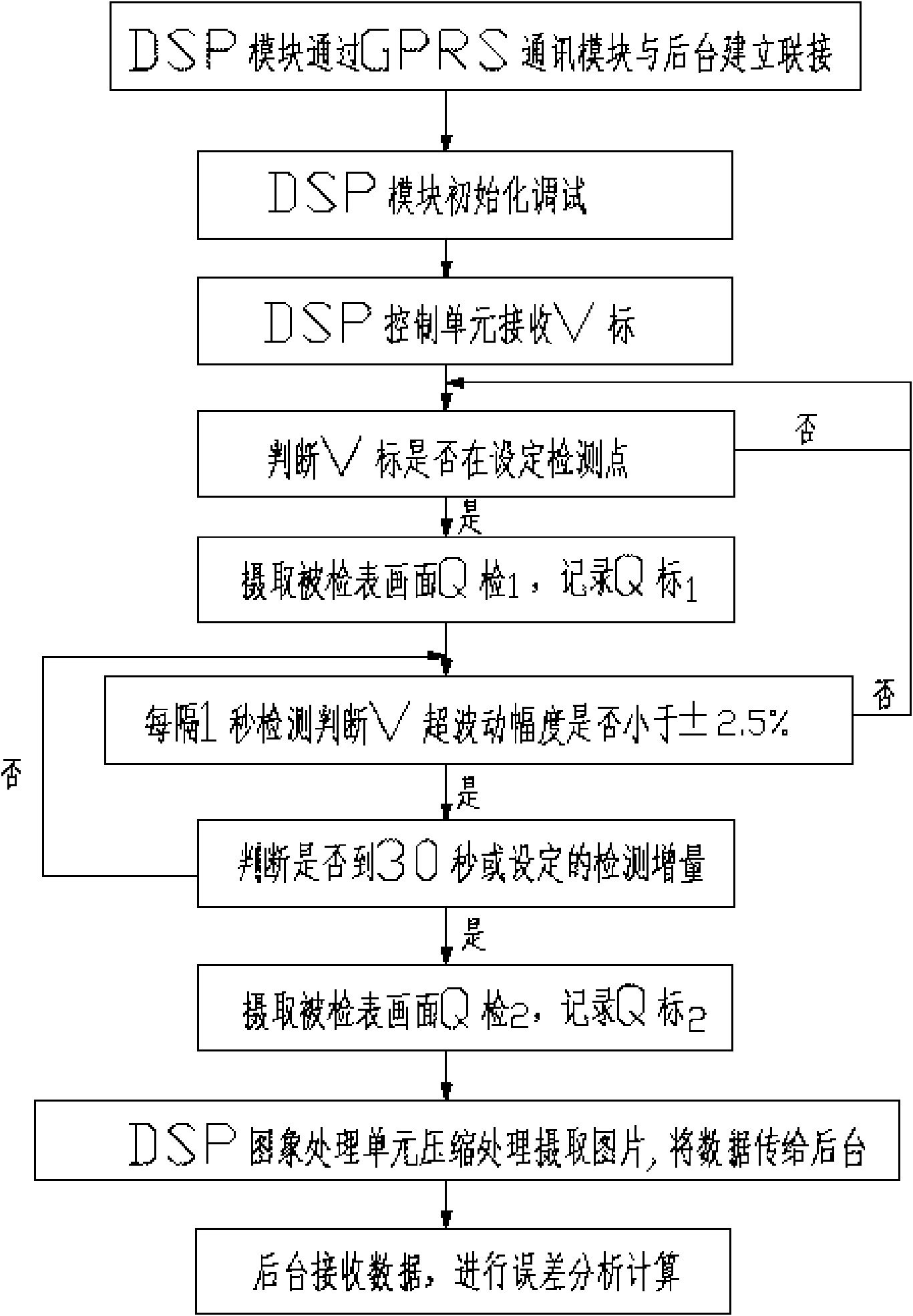

[0029] See figure 2 , The meter online verification method of this embodiment adopts the meter online verification device described in Embodiment 1.

[0030] The ultrasonic flowmeter is used as the standard flowmeter 21, which is directly installed on the outer wall of the pipeline 4, close to the instrument 1 under test. After obtaining the flow value flowing through the ultrasonic flowmeter and the flow value in the instrument under test on the pipeline 4, an error analysis is performed on the above two values to determine whether the accuracy of the instrument under test meets the requirements. Since the fluid in the pipeline 4 requires continuous flow without affecting normal operation, the readings of the tested instrument 1 and the flowmeter 21 are changing all the time, and the accuracy of online detection depends on capturing the readings of the flowmeter and the tested instrument at the same time.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com