Air flotation gathering and distributing drying and degreasing integrated liquid-gas separation equipment

A liquid-gas separation, gathering and dispersing technology, applied in liquid separation, dispersed particle separation, gas fuel, etc., can solve problems such as high production costs, natural gas leakage, safety issues, etc., to ensure accuracy and timeliness, and realize remote control , The effect of reducing on-site operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

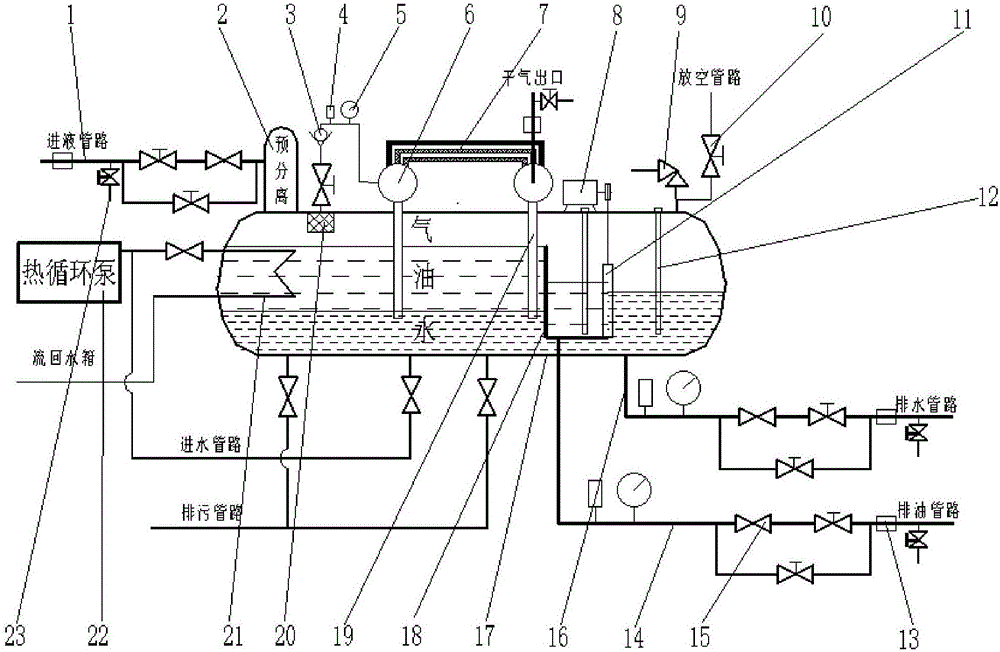

[0015] Referring to each figure, the integrated liquid-gas separation equipment of air flotation gathering and distributing drying and degreasing includes a tank body 17, a drier, a heat circulation pump 22 and a control cabinet, and is characterized in that the drier is arranged in the middle of the top of the tank body 17, A pre-separation chamber 2 and an electronically controlled water weir height control mechanism 8 are arranged above the tank body 17. The pre-separation chamber 2 communicated with the inside of the tank body 17 is arranged on one side of the dryer, and the liquid inlet pipeline 1 is connected to it, and the electric control The water weir height control mechanism 8 is arranged on the other side of the dryer, and the outside of the tank body 17 is connected with an exhaust pipeline, a drainage pipeline 16, an oil discharge pipeline 14, a heating pipeline, a cleaning pipeline and an emptying pipeline, wherein The oil discharge pipeline 14 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com