Hybrid hollow porous fiber reinforced thermal insulation mortar sandwich thermal insulation decorative board and manufacturing method

The technology of thermal insulation decorative board and thermal insulation mortar is applied in the field of thermal insulation board for building construction, which can solve the problems of small thickness, etc., and achieve the effects of stable weather resistance, clear force, and improved fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments do not limit the present invention in any form.

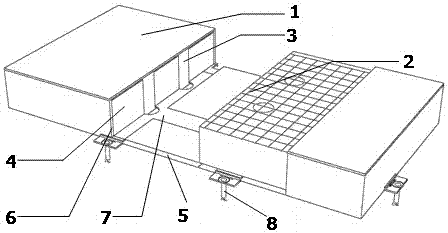

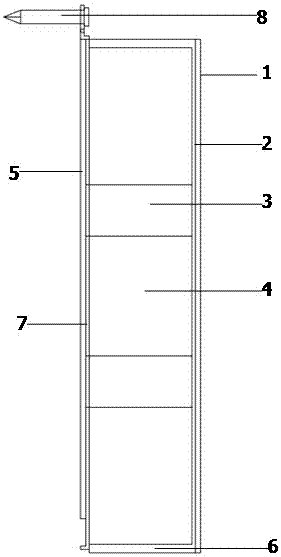

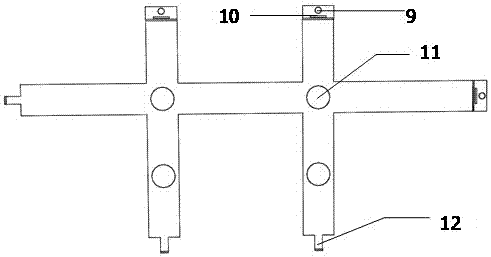

[0036] see Figure 1 to Figure 4 , the hybrid hollow porous fiber reinforced thermal insulation mortar sandwich thermal insulation decorative panel given in this example, its structural composition includes hybrid hollow porous fiber, inorganic thermal insulation mortar, thermal insulation core board 4, fiber mesh cloth 2, and positionable pendant 7 and finishes, where:

[0037] The hybrid hollow porous fiber adopts inorganic hollow fiber, which is a mixture of chopped glass hollow fiber and basalt fiber, and the volume ratio of the hybrid fiber accounts for 0.5%-0.8% of the volume of the thermal insulation mortar;

[0038] Inorganic thermal insulation mortar is one of vitrified microbead fireproof thermal insulation mortar, composite aluminum silicate thermal insulation mortar, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com