Patents

Literature

40results about How to "Strong thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

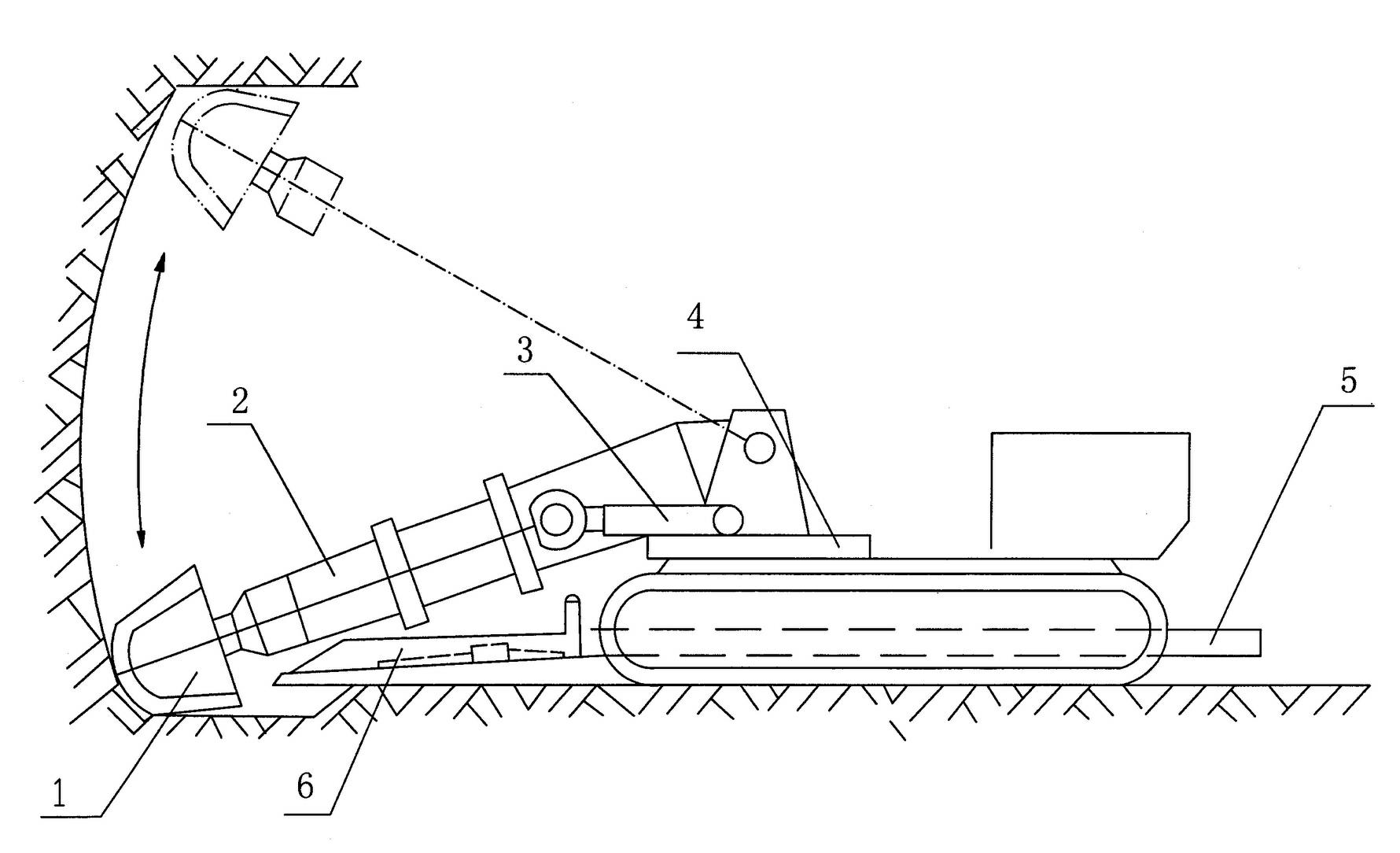

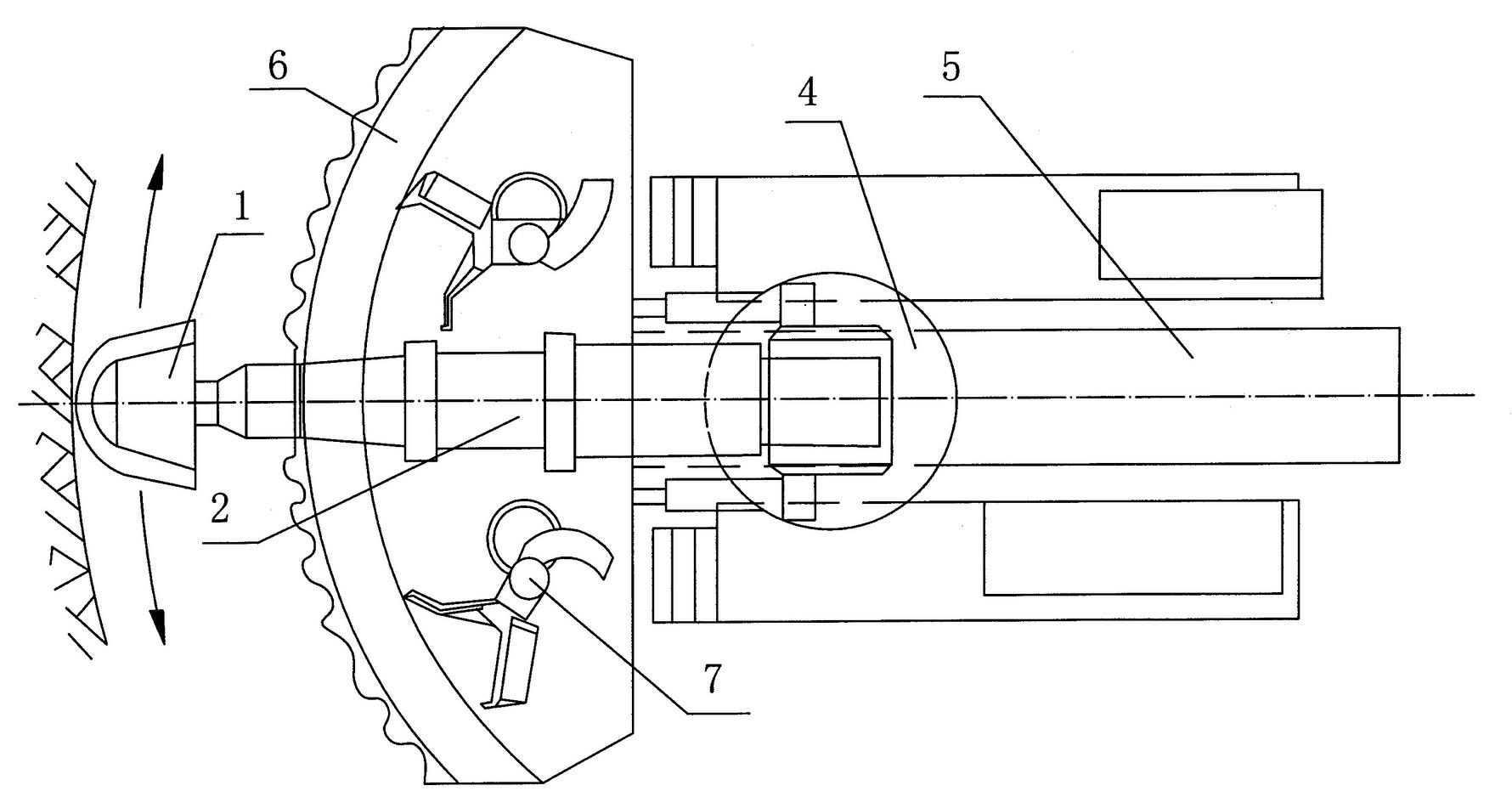

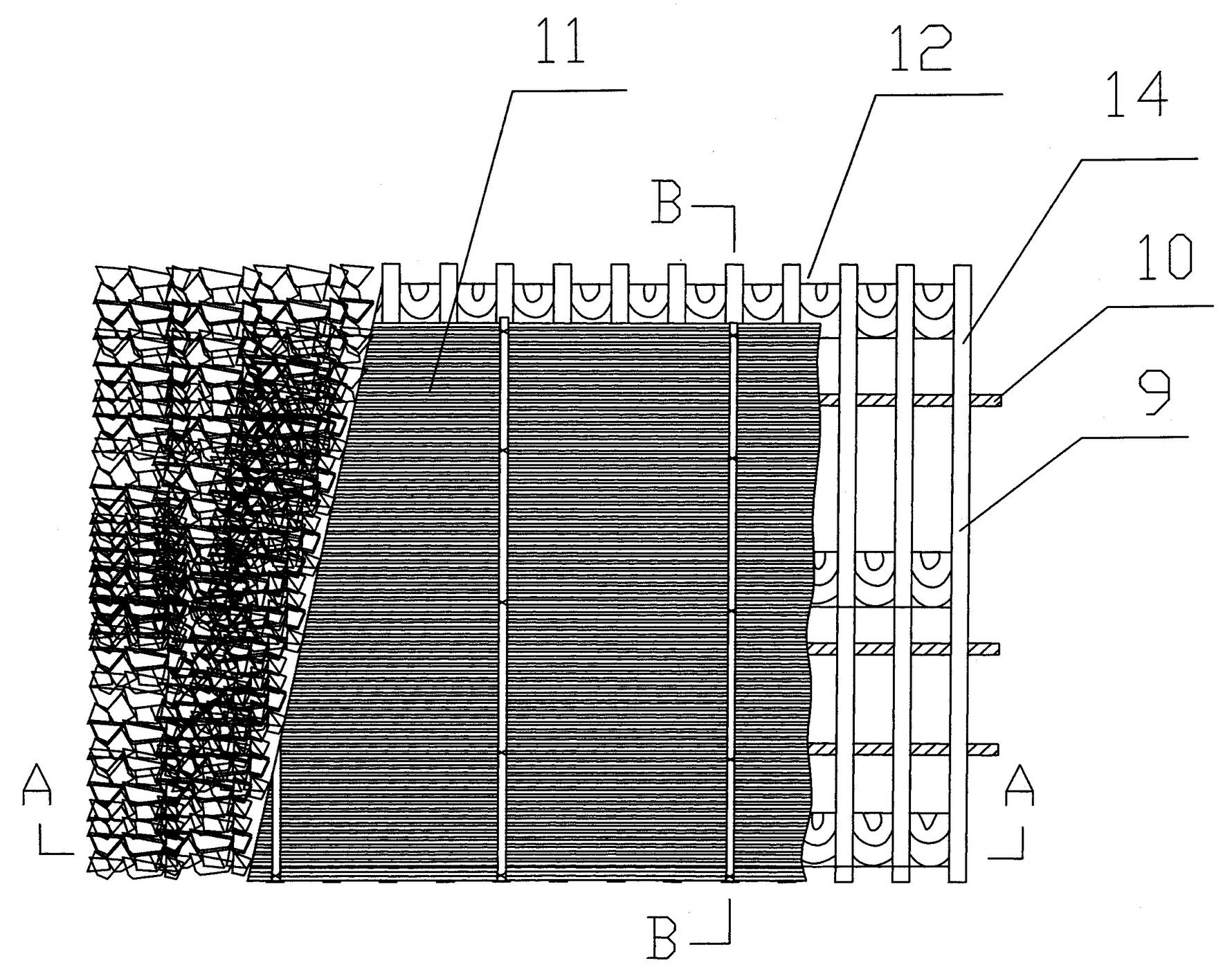

Method for mechanically mining coal by using steep seam pseudo inclination bracing type retractable flexible shield support

InactiveCN102562066ARealize mechanized miningStrong thicknessUnderground miningSlitting machinesHigh probabilityWorking environment

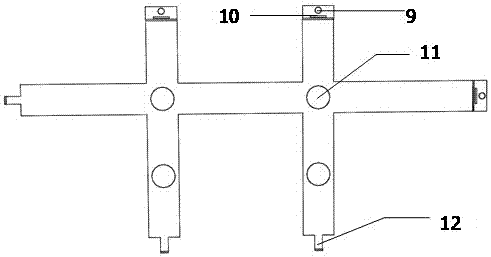

The invention discloses a method for mechanically mining coal by using a steep seam pseudo inclination bracing type retractable flexible shield support. By the method, a steep seam coal mining machine and a bracing type retractable flexible shield support are provided. The method comprises the following steps of: 1, mining, namely mining by arranging the coal mining machine on a pseudo inclination working surface; 2, loading and transporting the coal, namely raking a falling coal body to a conveying mechanism and conveying the falling coal body to the rear part of the coal mining machine by using left and right gathering arms of the coal mining machine, sliding the falling coal body to a coal sliding hole truck loading point through a sliding chute, loading and transporting; 3, supporting an operating area, namely arranging the bracing type retractable flexible shield support in the operating area; 4, ventilating the working surface; 5, atomizing for dust removal; 6, exploiting upper triangle coal; and 7, recycling lower triangle coal, namely dredging a finishing cut, lowering the shield support to a horizontal position gradually, disassembling and decomposing the coal mining machine, transporting to the next stoping working surface and completely recycling the shield support when the working surface is propelled to a place neara district rise hole. By the method, the problems of low recovery ratio, low mechanization degree, low single yield of the working surface, severe working environment, high probability of malignant accidents and the like in domestic and oversea steep seams can be radically solved.

Owner:袁野 +2

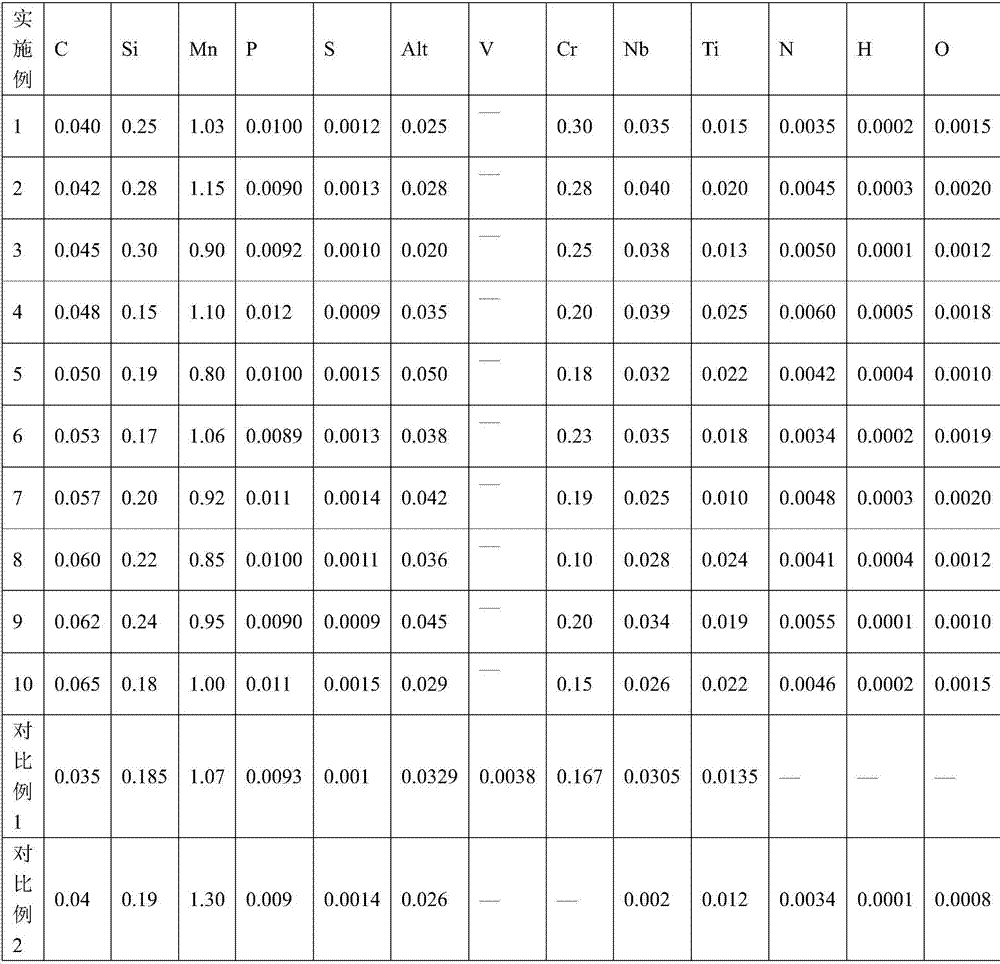

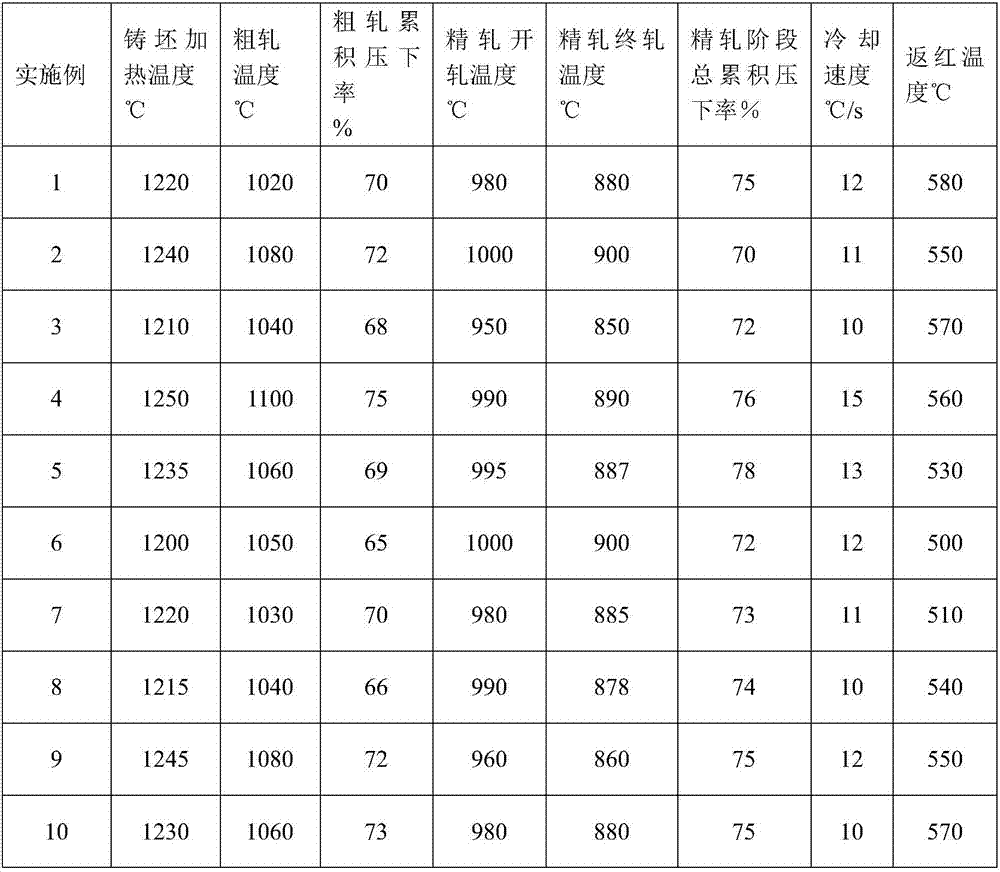

Low-yield-ratio thin-gauge high-strength and acid-resistant pipeline steel hot rolled coil plate and manufacturing method thereof

The invention provides a low-yield-ratio thin-gauge high-strength and acid-resistant pipeline steel hot rolled coil plate. The hot rolled coil plate comprises the chemical components, by mass, of 0.04%-0. 065% of C, 0.15%-0.30% of Si, 0.8%-1.15% of Mn, 0.012% of P or the less, 0.0015% of S or the less, 0.006% of N or the less, 0.025%-0.04% of Nb, 0.010%-0.025% of Ti, 0.1%-0.3% of Cr, 0.02%-0.05% of Als and the balance Fe and inevitable impurities. Through combination control over the components and the technique, the high strength, low yield ratio, excellent HIC resistance and excellent SSCC resistance of thin-gauge high-strength and acid-resistant pipeline steel can be achieved, the cost is lower, strength is higher, the thinner gauge can be achieved, control over the smelting and rolling processes is relatively simple, the production efficiency is greatly improved, and control over the process cost is greatly strengthened.

Owner:武汉钢铁有限公司

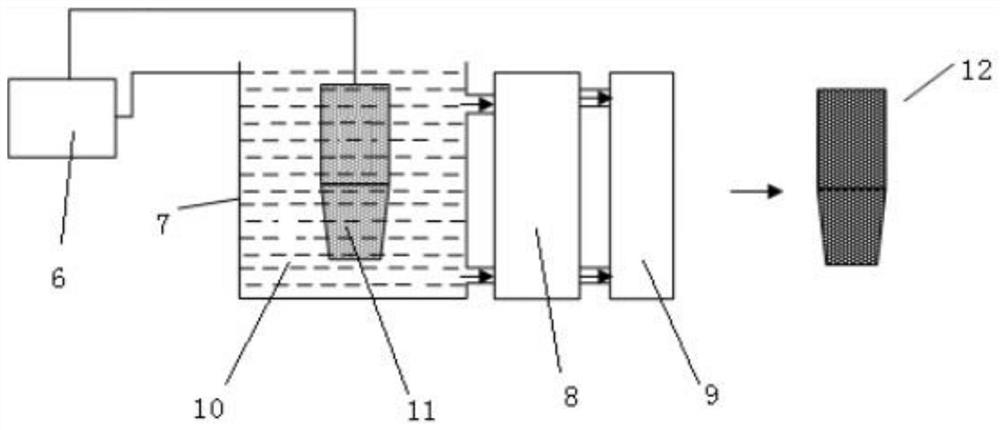

Preparation method of rare earth-iron intermediate alloy for low-oxygen rare earth steel

The invention discloses a preparation method of a rare earth-iron intermediate alloy for low-oxygen rare earth steel. The preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel comprises the steps that a vacuum smelting furnace is adopted, and rare earth metal and pure iron are placed in a crucible of the vacuum furnace at the mass ratio of 1-5:5-9; vacuumizing is conducted on the vacuum furnace until the pressure of the vacuum furnace is below 20 Pa, inert gas is fed for shielding, and the process of high-temperature melting-refining and electromagnetic stirring alloying is executed, wherein the high-temperature melting temperature is 1000-1500 DEG C, the temperature of the refining process is 1400-1500 DEG C, and the time is 5-15 minutes; molten metal is poured into an ingot mold, and then the rare earth-iron intermediate alloy is obtained. By the adoption of the preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel, the rare earth yield can be significantly improved, the content of the rare earth in the steel can be accurately controlled, the adding cost of the rare earth is reduced, and the plasticity, the low-temperature impact toughness, the thickness-direction property and the corrosion resistance of the steel are improved.

Owner:BAOTOU RES INST OF RARE EARTHS +1

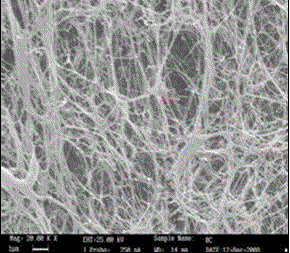

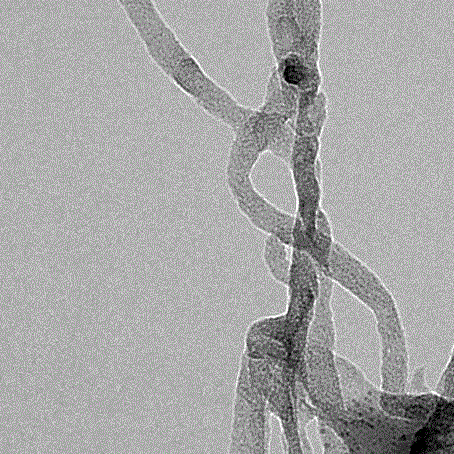

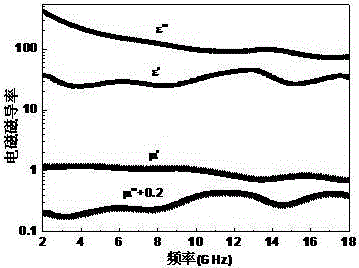

Composite electromagnetic shielding material and method for manufacturing same

InactiveCN102917577AHigh purityHigh crystallinityMagnetic/electric field screeningBacterial celluloseMetallic materials

The invention discloses a composite electromagnetic shielding material. The composite electromagnetic shielding material is characterized in that carbonized bacterial celluloses and a nanometer magnetic metal material are mixed to form the composite electromagnetic shielding material; or carbonized bacterial celluloses and a matrix material are mixed to form the composite electromagnetic shielding material; or carbonized bacterial celluloses and a nanometer magnetic metal material are mixed to form a mixture, and then the mixture and a matrix material are mixed to form the composite electromagnetic shielding material; the nanometer magnetic metal material is an optional one of Fe, Ni, Co, NiFe and CoFe; and the matrix material is an optional one of paraffin, epoxy resin and silicon dioxide. A method for manufacturing the composite electromagnetic shielding material includes steps of manufacturing bacterial celluloses; manufacturing the carbonized bacterial celluloses; and manufacturing the composite electromagnetic shielding material, and the like. The composite electromagnetic shielding material is thin, light, wide and strong, has the advantages of low cost, simplicity in manufacturing process, environmental protection and the like, and has wide application prospects in fields of electromagnetic pollution prevention, microwave dark chambers, high-frequency electronic products and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

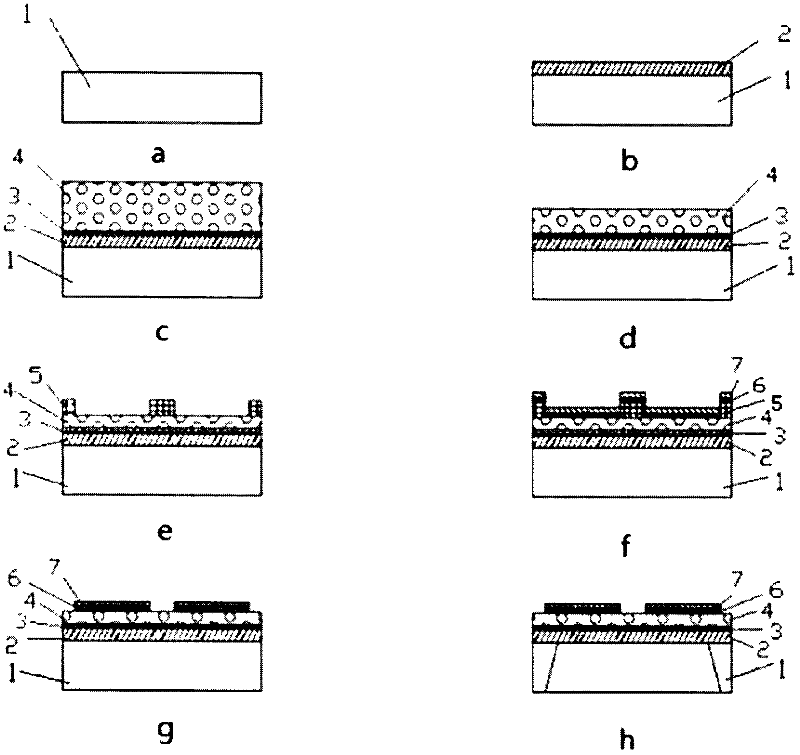

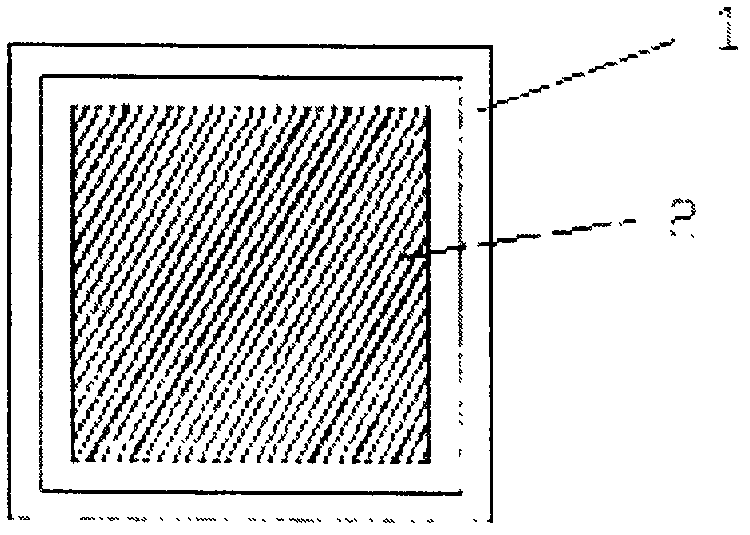

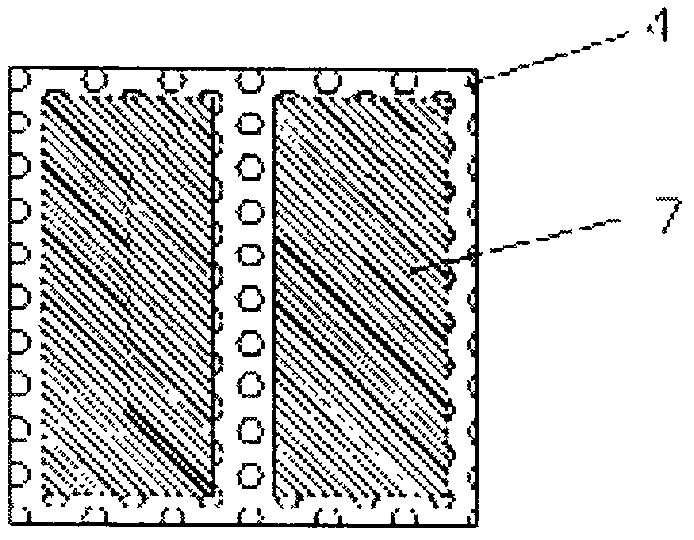

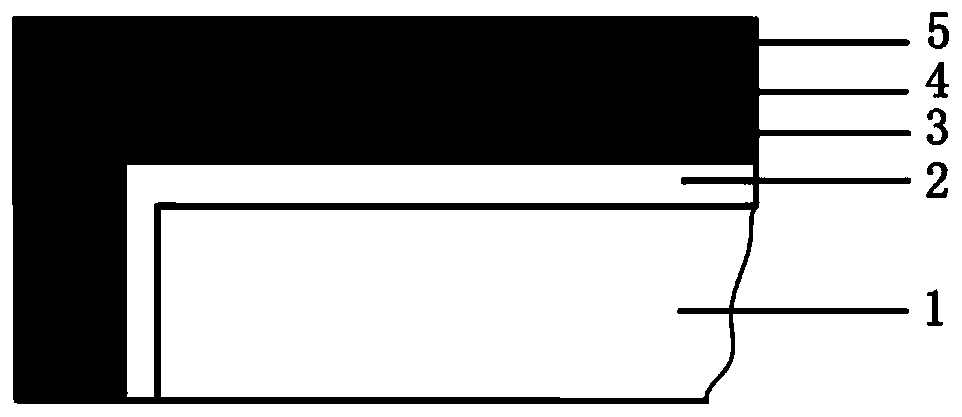

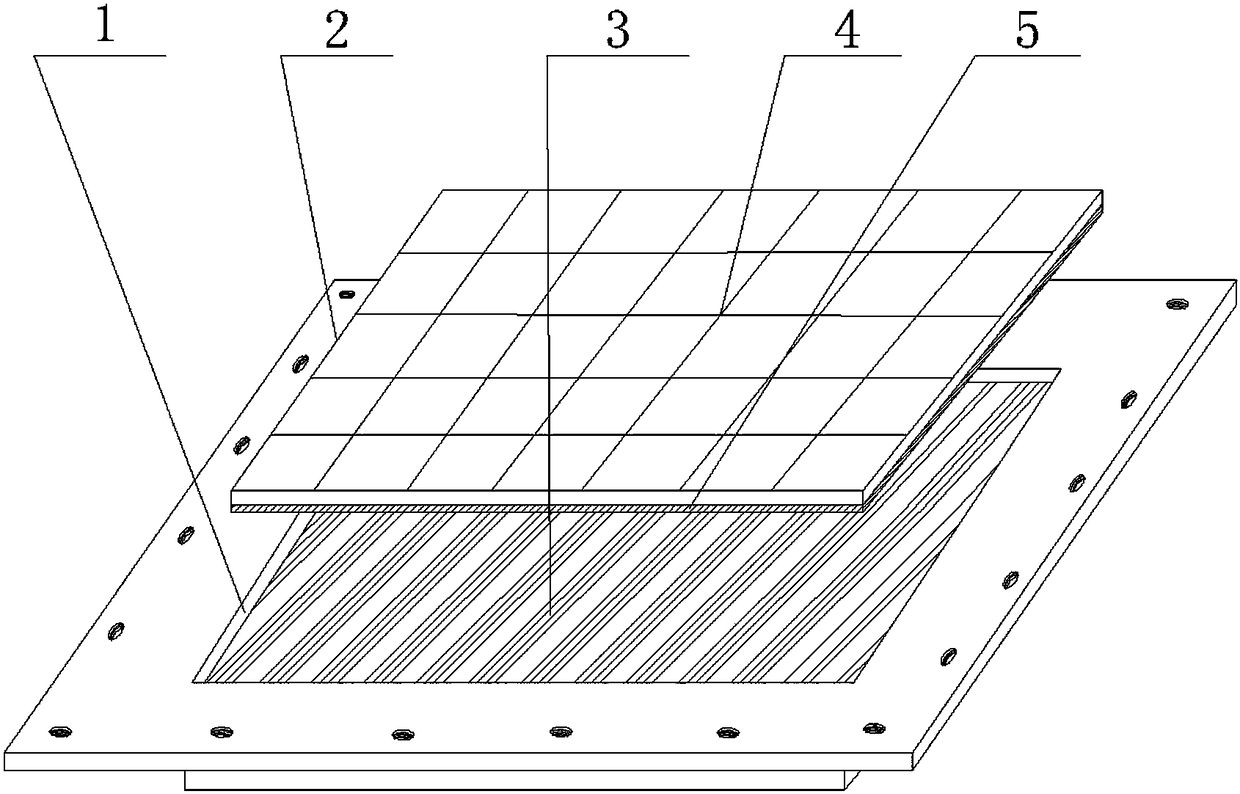

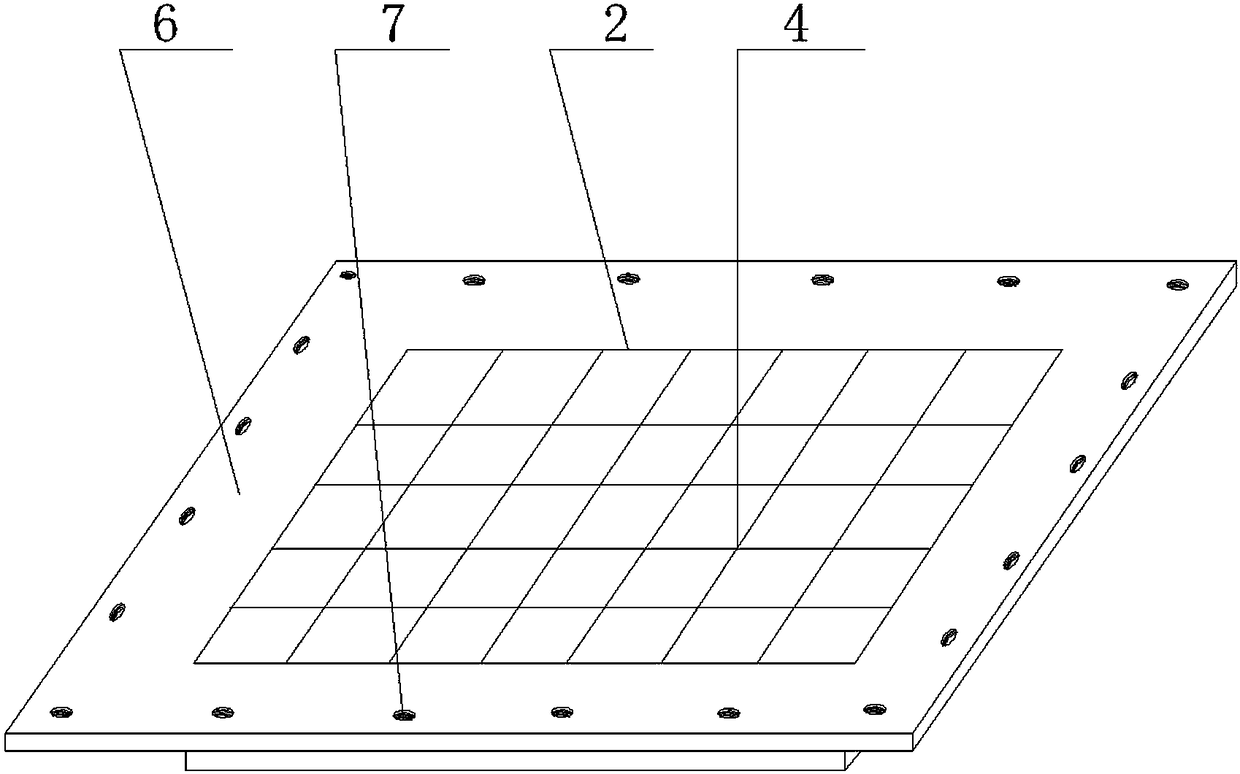

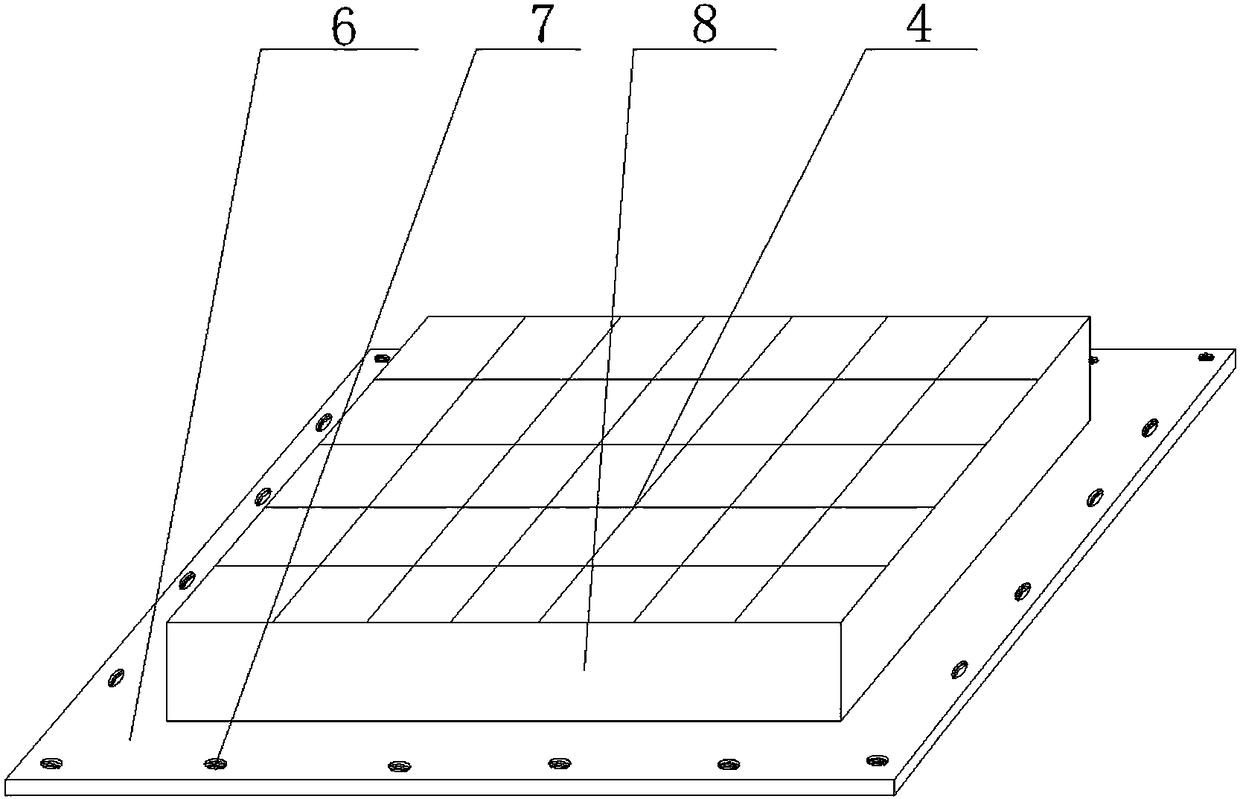

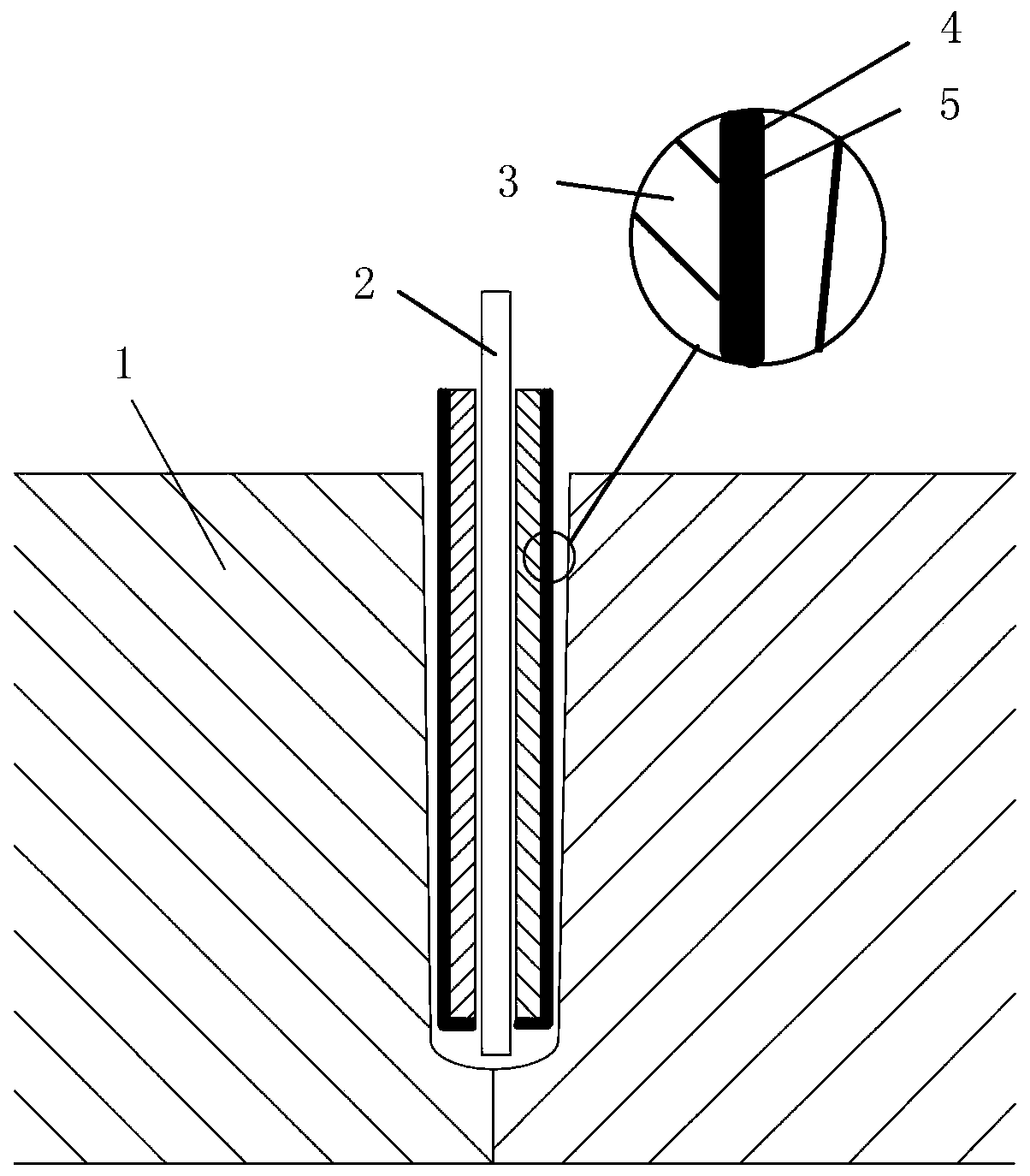

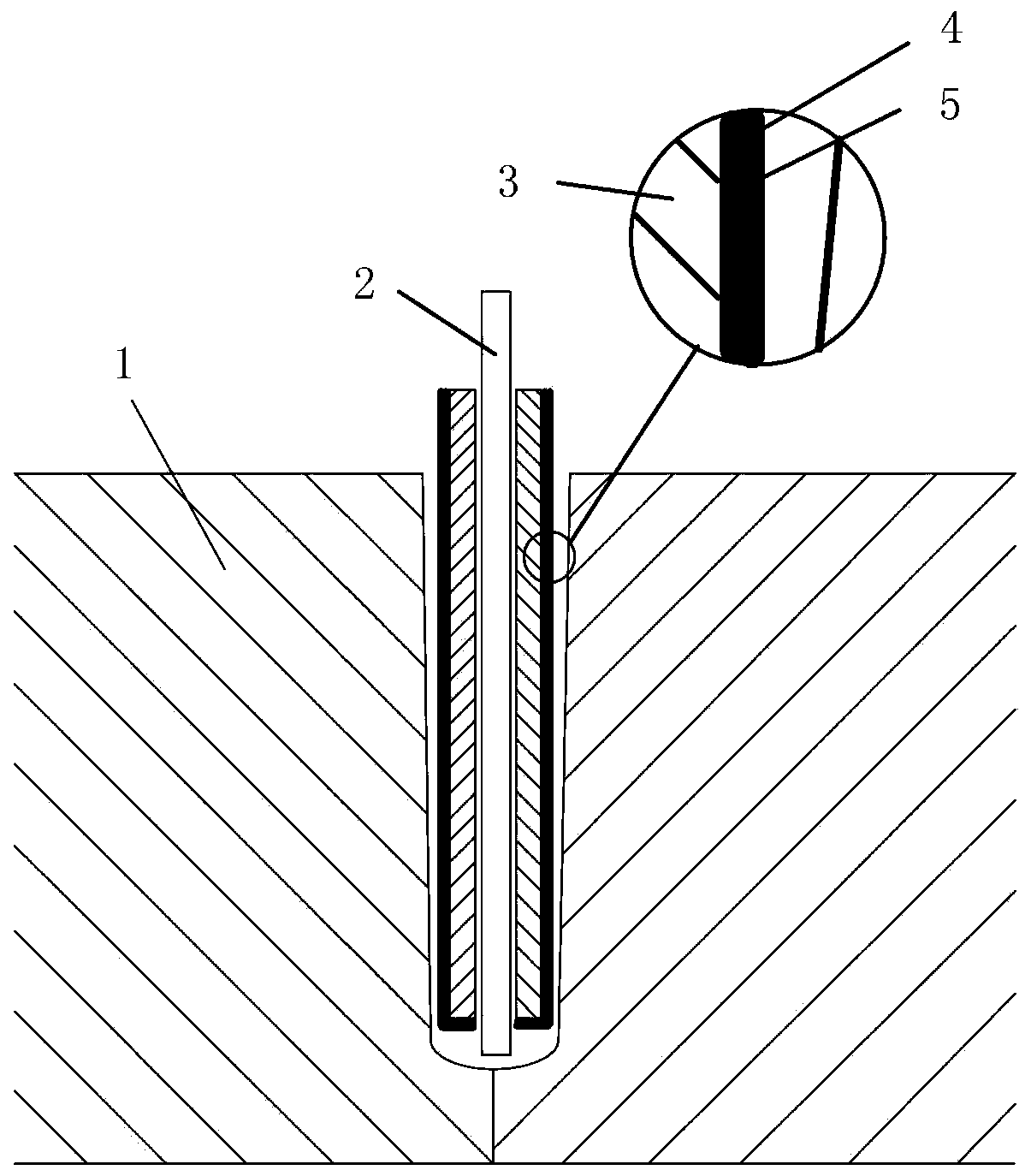

Pyroelectric infrared detector and preparation method thereof

InactiveCN102393249AEasy to processHigh material strengthPyrometry using electric radation detectorsPhysicsLarge capacity

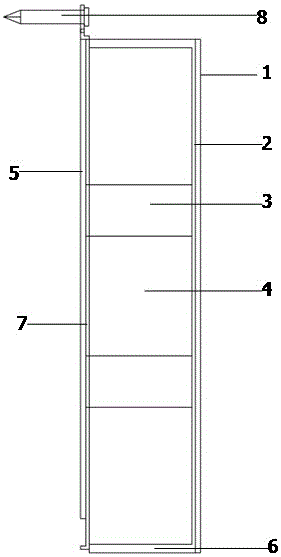

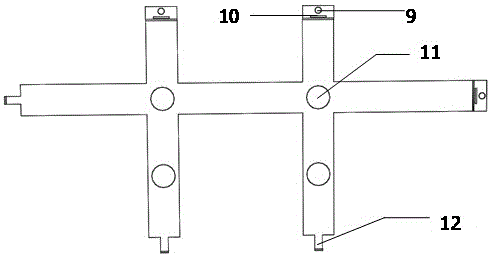

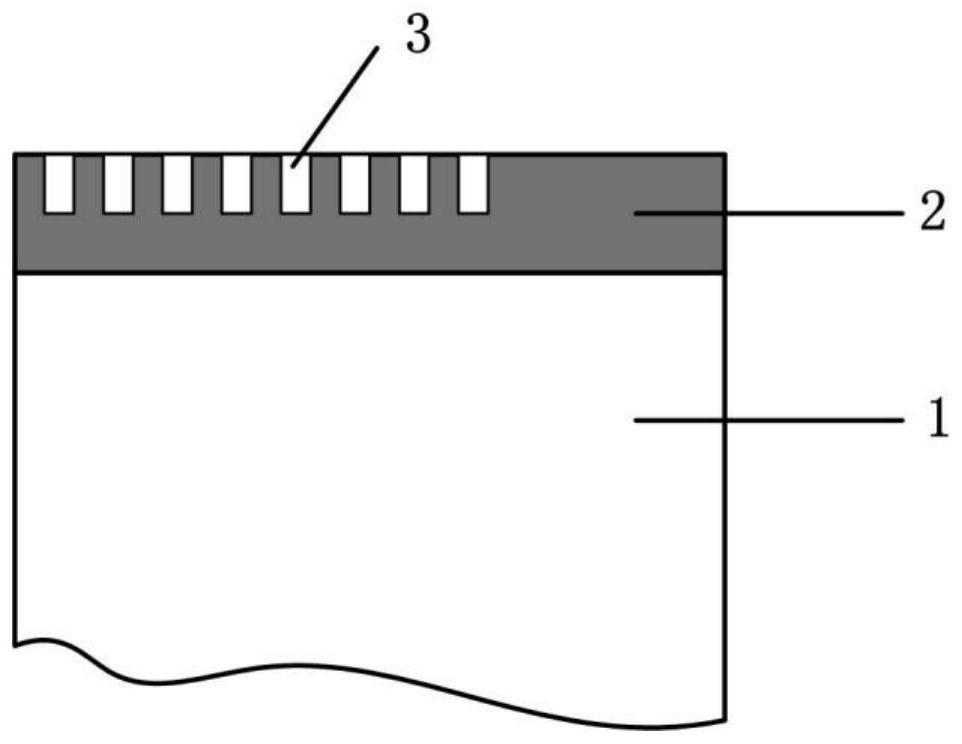

The invention discloses a pyroelectric infrared detector implemented by a wafer bonding technology, and a preparation method for the pyroelectric infrared detector. The pyroelectric infrared detector comprises a silicon substrate (1), and a thermal insulating layer (2), a bonding layer (3), a pyroelectric material sheet (4), an upper electrode layer and an infrared absorption layer (7) which are arranged on the surface of the silicon substrate (1), wherein the thermal insulating layer (2) and the pyroelectric material sheet (4) are bonded through the bonding layer (3) in the preparation method. A pyroelectric wafer and the silicon substrate are combined and the completeness of the original wafer is ensured; and compared with a thin-film pyroelectric detector made of the same pyroelectric material, the pyroelectric infrared detector has the advantages of high processability, high material strength, simple achievement of thickness, high capacity of resisting influence of external serious environment, low heat loss and the like.

Owner:ZHONGBEI UNIV

Cubic boron nitride self-lubricating coated tool and preparation method thereof

ActiveCN108950537AImprove toughnessHigh surface hardnessMetallic material coating processesBoron nitrideAlloy

The invention discloses a cubic boron nitride self-lubricating coated tool and a preparation method thereof. A substrate material of the cutting tool is high speed steel or a hard alloy. The surface of the substrate is a cubic boron nitride coating including CsF, Mo and ZrO2. The coating is prepared by means of an electron beam cladding method. The preparation method comprises the following steps:(1) pre-treatment; (2) boron nitride layer presetting; (3) boron nitride layer cladding; and (4) post-treatment. The tool has integral good toughness, and the surface coating has relatively high hardness and wear resistance. In the cutting process, an in-situ reaction happens on CsF, Mo and ZrO2 under the action of high temperature to generate Cs2MoO4, so that a lubricating role can be played ata relatively high cutting temperature. Meanwhile, the cubic boron nitride self-lubricating coated tool is prepared by means of the electron beam method, so that the coating and the substrate have relatively high bonding strength, the preparation efficiency is high, and oxidization in the preparation process is avoided. The tool can be widely applied to dry cutting and cutting process of hardly processed materials.

Owner:SOUTHEAST UNIV

Method for preparing antifriction anti-fretting strengthening layer on surface of titanium alloy

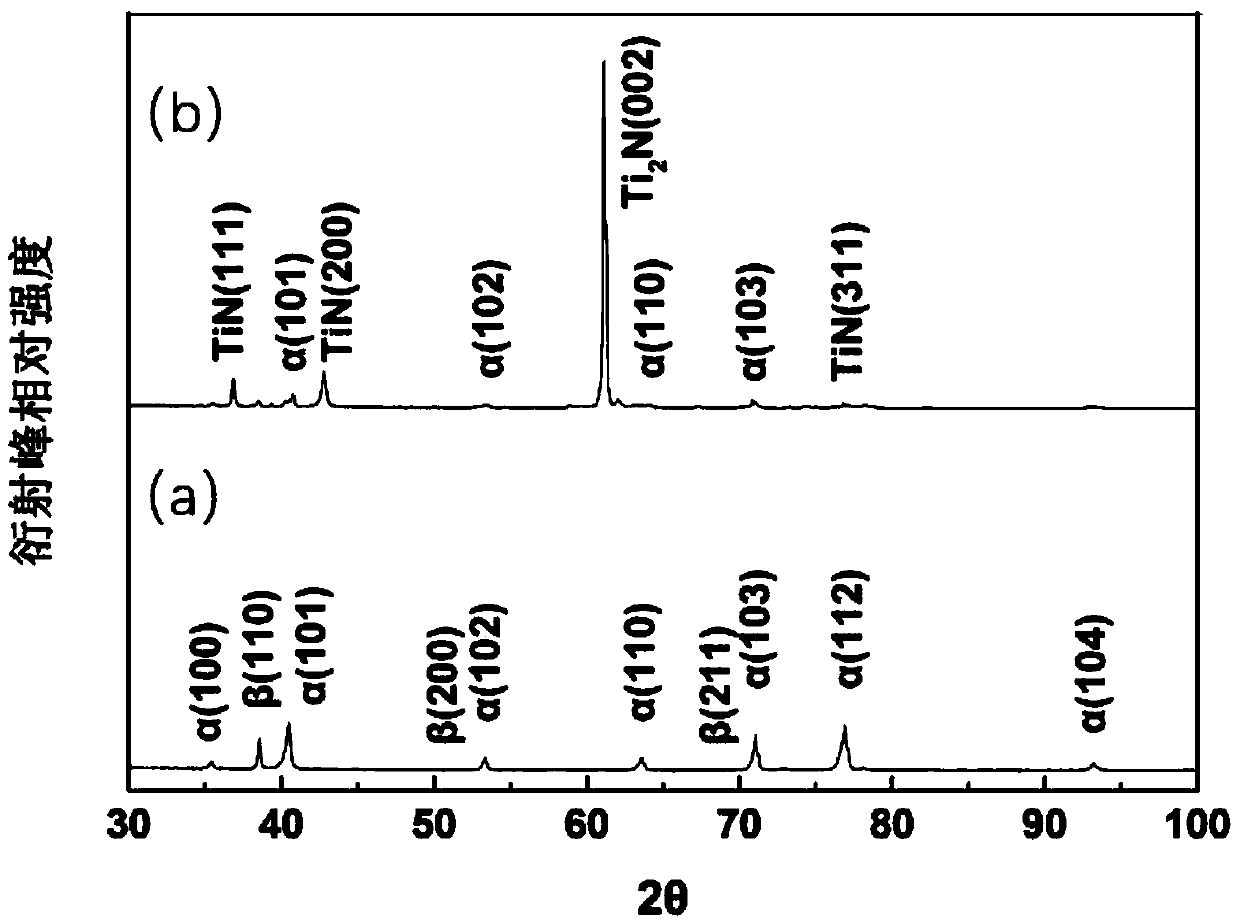

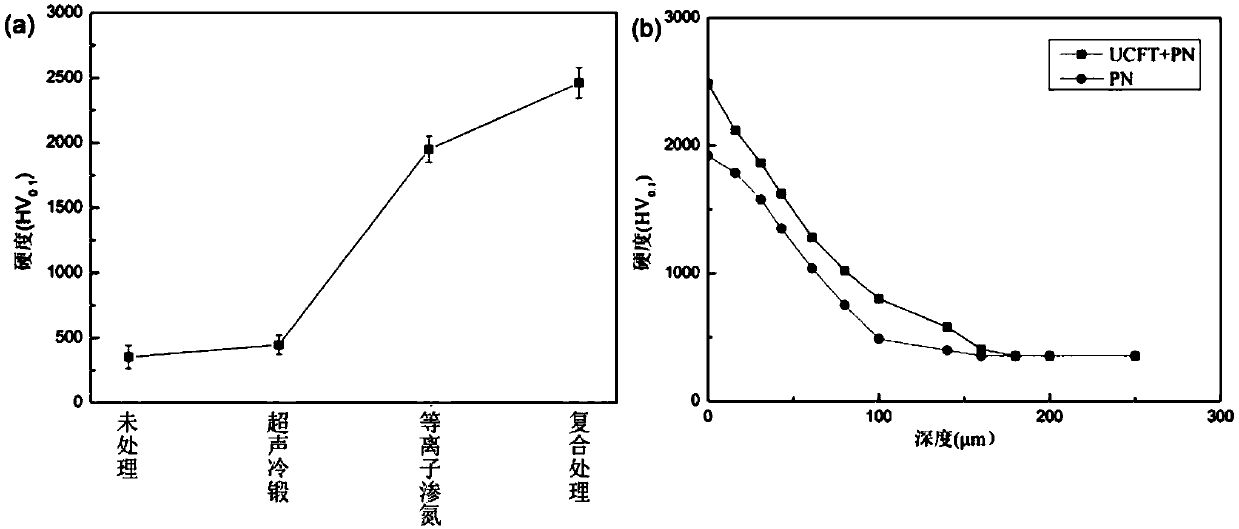

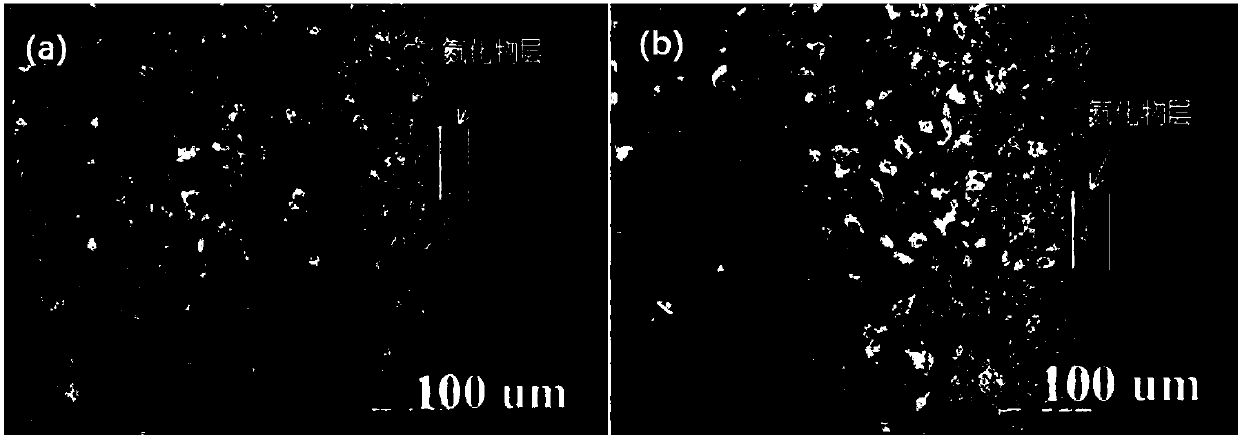

InactiveCN109837549ASimple technologyNoise and no pollutionSolid state diffusion coatingCrystallitePre treatment

The invention discloses a method for preparing an antifriction anti-fretting strengthening layer on the surface of a titanium alloy, and belongs to the technical field of aerospace material surface strengthening. Firstly, surface nanocrystallization pretreatment is performed on the titanium alloy to form a nano layer on the surface of the titanium alloy (the surface grain reaches nano level), simultaneously, ion nitridation treatment is performed on the basis of the pretreatment to solve the problems of low hardness and non-wear resistance of the titanium alloy and the problems of thin nitrided layer and weak bonding force of film base, and to improve the fretting resistance of different counter pairs in fretting wear process; and the surface nanocrystallization technology and the ion nitriding technology are combined and applied to TC4 titanium alloy, so that the problems of low hardness and poor wear resistance of the titanium alloy are solved, and the fretting performance problem ofthe titanium alloy under different working conditions (counter pairs) after composite treatment is solved as well. The TC4 aerospace titanium alloy with antifriction anti-fretting strengthening layeron the surface has higher anti-fretting performance and good reliability and stability when being applied to wear-resistant parts such as spacecraft fasteners.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

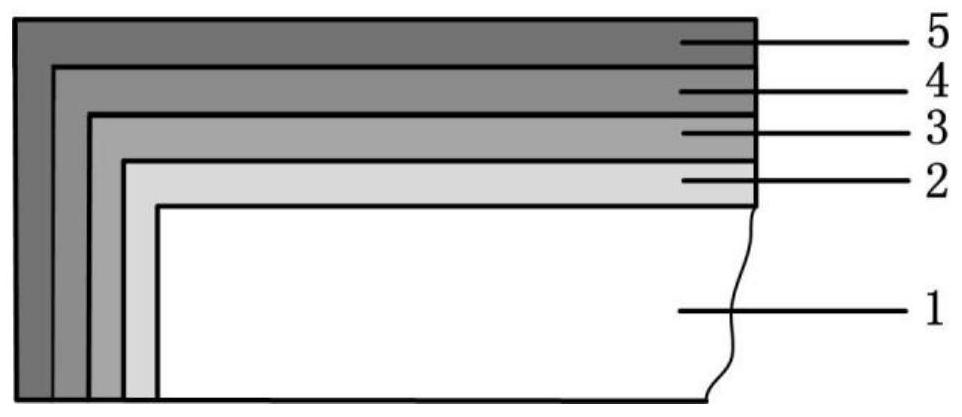

Wrapping paper and manufacturing method thereof, and wrapping plate with wrapping paper and manufacturing method thereof

InactiveCN102230306AStrong thicknessReduce thicknessFlexible coversWrappersFiberPulp and paper industry

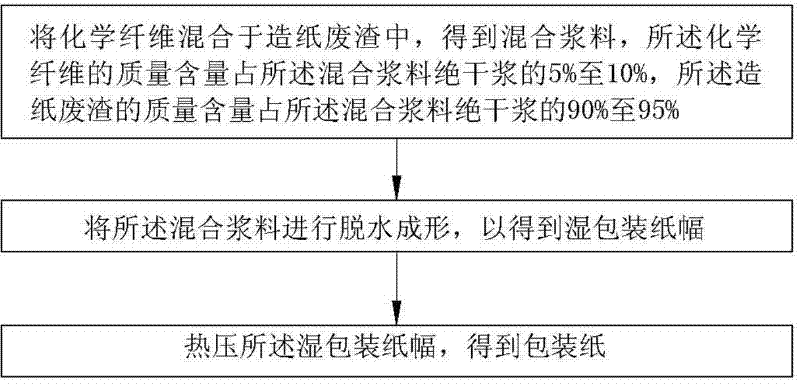

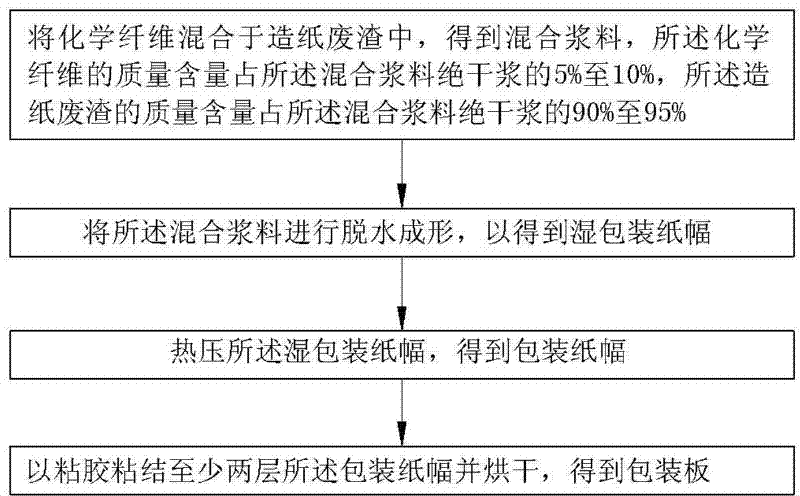

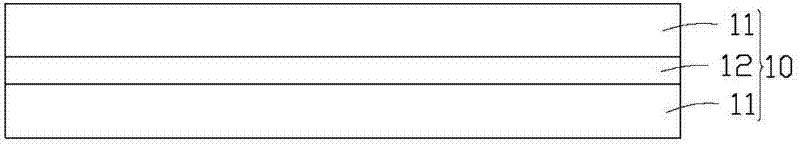

The invention relates to a manufacturing method of wrapping paper, which comprises the following steps: mixing chemical fiber into paper making waste residue to obtain a mixed pulp, wherein the chemical fiber accounts for 5-10% by mass of the absolute dry mixed pulp, and the paper making waste residue accounts for 90-95% by mass of the absolute dry mixed pulp; dewatering the mixed pulp to form, thereby obtaining a wet wrapping paper web; and carrying out hot compression on the wet wrapping paper web to obtain the wrapping paper. The invention also provides wrapping paper prepared by the manufacturing method of wrapping paper, and a wrapping plate with the wrapping paper and a manufacturing method thereof.

Owner:GOLD EAST PAPER JIANGSU

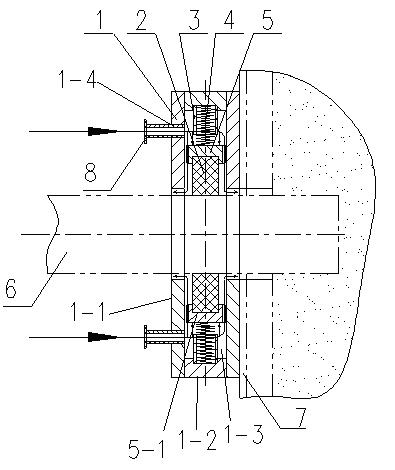

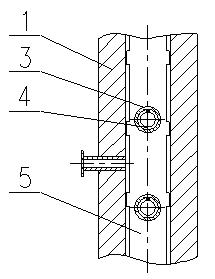

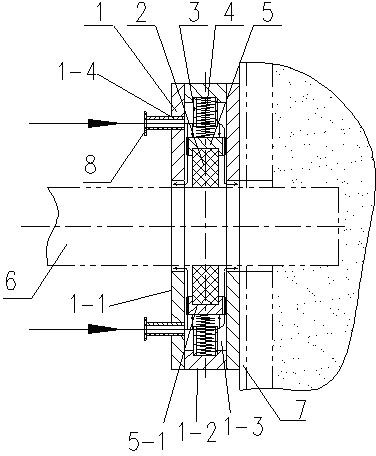

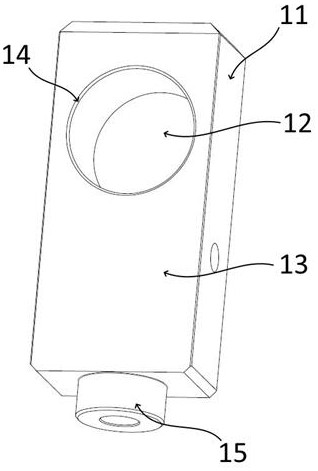

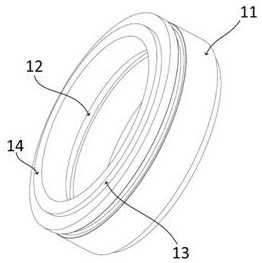

Novel high-temperature sealing device

InactiveCN102425669ACompact structureEasy to useEngine sealsHandling discharged materialMechanical engineeringHigh heat

The invention relates to a novel high-temperature sealing device. The novel high-temperature sealing device comprises sealing boxes (1), hard antifriction lubricating materials (2), spring guide pipes (3), springs (4) and pressing plates (5); each sealing box comprises a side wall (1-1) and a bottom wall (1-2) and the side wall and the bottom wall form a cavity (1-3); the hard antifriction lubricating materials, the spring guide pipes, the springs, and the pressing plates are all arranged in the cavity; the bottom wall is connected with the spring guide pipes, one end of each spring is fixed on the bottom wall and is positioned in the spring guide pipe, and the other end of each spring is contacted with the pressing plate; each pressing plate is provided with a groove (5-1), the hard antifriction lubricating materials are arranged on the groove, and are directly contacted with movement pieces (6); a gap is reserved between the pressing plate and the side wall; and the side wall is provided with an air port (1-4).

Owner:NANJING KISEN INT ENG

Superhard self-lubricating coating tool and preparation method thereof

The invention discloses a superhard self-lubricating coating tool and a preparation method thereof, and can be widely applied to cutting machining of dry cutting and refractory materials. A tool base material is high-speed steel, and a laminated superhard coating composed of a hard alloy layer, an aluminum oxide ceramic layer, a silicon nitride ceramic layer and a cubic boron nitride layer is arranged on the surface of a base body in sequence, a laminated coating has the self-lubricating effect; the laminated coating has the function of self-lubrication, and is prepared by adopting a plasma spraying method. The tool integrates high-speed steel, hard alloy, alumina ceramic and silicon nitride ceramic, cubic boron nitride and the laminated coating, the adding of a carbon nano pipe (CNTs) and a boron nitride nanopipe (BNHTs) improves the hardness, the wear resistance and the toughness of the coating, the whole tool not only has good toughness, but also has very high hardness and wear resistance; and in the cutting process, when the temperature is low, the graphene can have a lubricating effect, when the temperature is high, PbO, Mo and TiB2 can generate in-situ reaction to generate PbMoO4, TiO2 and B2O3 with a lubricating effect, so that the friction and abrasion of the tool in the cutting process can be reduced, and the service life of the tool is prolonged.

Owner:SOUTHEAST UNIV

Processing method of solid wood door plate

The invention relates to a processing method of a solid wood door plate. The method comprises the following specific steps: laminating multiple single wood plates with a laminator; symmetrically paving the plates according to the tension surface by taking the grain direction as the length direction of the plates, and assembling; pressing the plates into laminated plates by using a hot press, wherein the thickness of each laminated plate is 5-14 mm, and the moisture content of each laminated plate is 2-10%; performing single-sided or double-sided lamination on 3-9 laminated plates or sandwiching double-sided laminated single plates among the laminated plates, and vertically superposing; and performing hot pressing or cold pressing to obtain the solid wood door plate. The method provided by the invention well solves the deformation problem of the door plate, controls the bending and buckling deformation of the door plate on the premise of not increasing the production cost, shortens the processing time, improves the production efficiency, prolongs the service life of the solid wood door, and improves the yield and quality of the solid wood door.

Owner:河北北方绿野居住环境发展有限公司

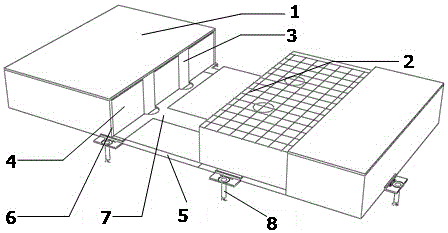

Sandwich heat-preserving decorative board with mixed hollow porous fiber reinforced heat-preserving mortar and manufacturing method

ActiveCN105735552AStrong impact resistanceSmall impact resistanceBuilding componentsEngineeringPorous fiber

The invention relates to a sandwich heat-preserving decorative board with mixed hollow porous fiber reinforced heat-preserving mortar and a manufacturing method.A heat-preserving core veneer of the heat-preserving decorative board is a formed veneer and provided with big and round through holes; a hanging part capable of being positioned is arranged at the inner side of a back plate and tightly attached to the back face of the heat-preserving core veneer, and the same big and round through holes are formed in the positions corresponding to the big and round holes in the heat-preserving core veneer; the ends of the hanging part capable of being positioned are provided with small and round holes, square holes and right-angled hooks used for connecting, installing and lapping the heat-preserving decorative board in a positioning mode; fiber grid cloth is arranged at the inner side of a panel and is spaced from the heat-preserving core veneer by 2 mm; the mixed hollow porous fiber reinforced heat-preserving mortar is poured into the periphery of the heat-preserving core veneer through sealed formworks, the panel, the back plate and sealed edges are formed after the mortar is hardened, and bridge-cutoff shear connectors are formed in the big and round holes; the decorative board has the advantages that a good integrated space stress structure is formed through overall pouring of the panel, the back plate, the bridge-cutoff shear connectors and the sealed edges, positioning and splicing are accurate, and the fireproof performance is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

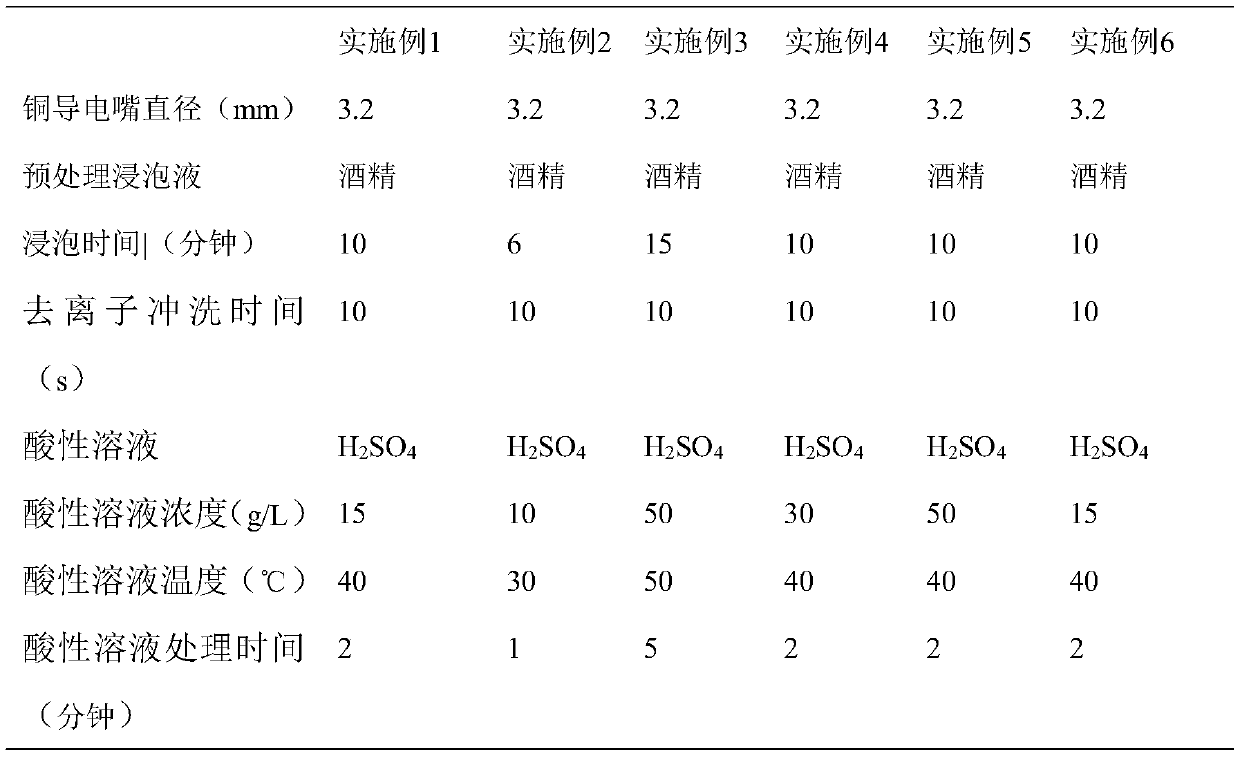

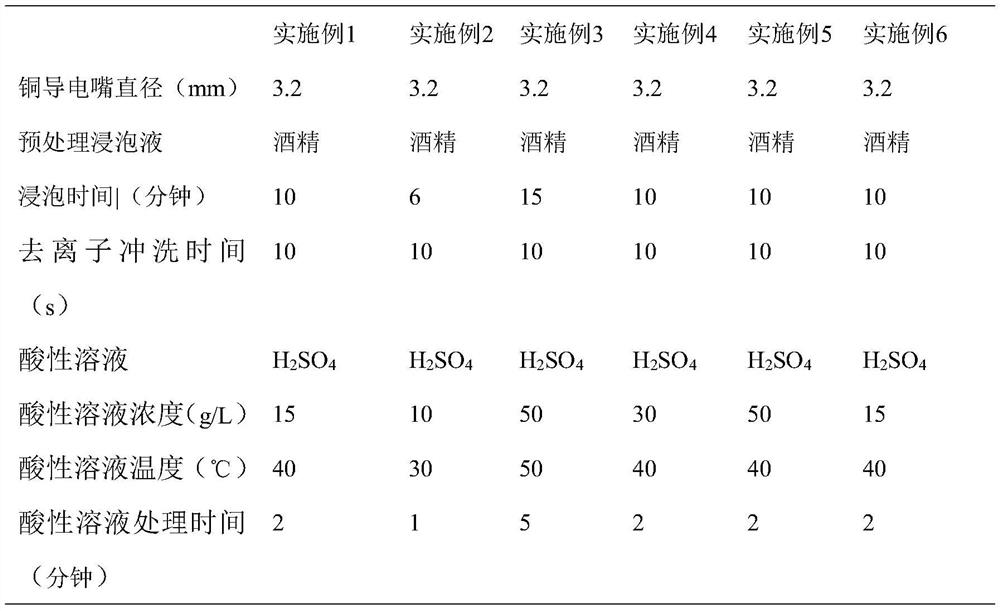

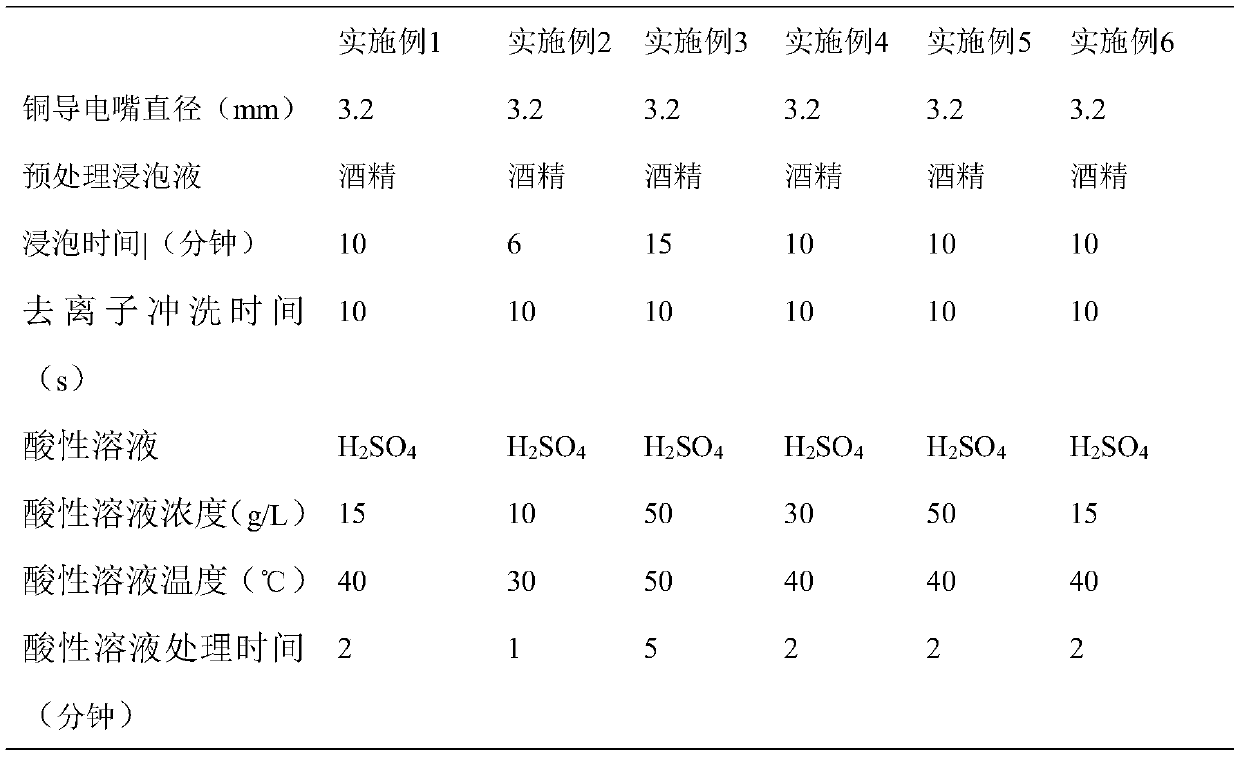

Method for preventing corrosion of high-manganese hot-formed steel after acid pickling

ActiveCN111659732AIncreased efficiency of iron or matrix iron actionReduce dosageMetal rolling arrangementsManganeseMetallic materials

The invention relates to the technical field of metal material processing, in particular to a method for preventing corrosion of high-manganese hot-formed steel after acid pickling. The method comprises the following steps that a plate blank of the high-manganese hot-formed steel is placed in a heating furnace and is heated to 1180-1210 DEG C, and heat preservation at the temperature is carried out for 25-40 minutes; rough rolling is conducted on the heated plate blank, the plate blank enters a finishing mill, the inlet temperature of the finishing mill is 1000-1010 DEG C, and coiling and uncoiling are conducted after finish rolling; the uncoiled plate blank enters a withdrawal and straightening machine, the insertion depth of a bending roller of the withdrawal and straightening machine iscontrolled to be 5-15 mm, and a hot-rolled coil obtained after withdrawal and straightening and descaling enters an acid pickling stage; and the hot-rolled coil is rinsed after taken out, wherein thechloride ion content of rinsing water is less than or equal to 10 mg / L, drying is carried out after rinsing, oiling is carried out, and then coiling is carried out to complete the method for preventing corrosion. According to the method for preventing corrosion of the high-manganese hot-formed steel after acid pickling, by controlling the components of the high-manganese hot-formed steel, the keytemperatures and processes of rough rolling and finish rolling, controlling the rolling rhythm, controlling the withdrawal and straightening parameter and operation in other aspects, occurrence of corrosion of the high-manganese hot-formed steel after acid pickling can be effectively prevented, and the method is simple, high in applicability and remarkable in effect.

Owner:SHOUGANG CORPORATION +1

Novel cold storage board

InactiveCN108316543AImprove fire performanceStrong thicknessBuilding componentsHigh densityFoaming agent

The invention discloses a novel cold storage board. The novel cold storage board comprises a box-shaped panel. An opening is formed in the upper portion of the box-shaped panel, the opening is coveredwith a sealing panel, and the size of the opening corresponds to the size of the sealing panel. The sealing panel is connected with the box-shaped panel in a sealed mode, and wing edges are arrangedon the periphery the box-shaped panel. A vacuum insulation board is arranged on the lower surface of the sealing panel, and a vacuum insulation board is arranged on the inner bottom surface of the box-shaped panel. A filler layer is arranged between the two vacuum insulation boards in the box-shaped panel, and the filler layer is a rock wool insulating layer. The lower surface of the sealing paneland the vacuum insulation board are bonded by a flame-retardant polyurethane foaming agent, and the bottom surface of the box-shaped panel and the vacuum insulation board are bonded by the flame-retardant polyurethane foaming agent. Concave-convex reinforcing ribs are separately arranged on the outer bottom surface of the box-shaped panel and the upper surface of the sealing panel. The novel coldstorage board has good thickness of the thermal insulating layer and excellent heat preservation and thermal insulation effects; high density, strong endurance, good heat preservation and fireproof effects and strong overall tensile strength are achieved; and the novel cold storage board can be used in the field of cold storages, board rooms and the like.

Owner:SUZHOU BUDE MECHANICAL & ELECTRICAL EQUIP CO LTD

Electrostatic powder spraying method for valve casting

InactiveCN105457858AImprove adhesionStrong adhesionPretreated surfacesCoatingsEnvironmental resistanceSpray coating

The invention discloses an electrostatic powder spraying method for valve casting. Valve casting is processed by surface treatment, electrostatic spraying and workpiece curing, the surface, subjected to spraying treatment, of the valve casting is greatly improved in degree of finish, so that sealing reliability of a sealing surface, matched with an encapsulated gate plate, of a valve body is improved, and friction force, in a starting process, of the gate valve is further reduced, and therefore, operation torque is reduced; compared with a conventional spray coating, the valve casting is environmentally-friendly, is great in thickness of a spraying layer, is strong in adhesive force, is not liable to drop, and is relatively improved in abrasion resistance and water erosion resistance.

Owner:QINGDAO HEDELONG MACHINERY

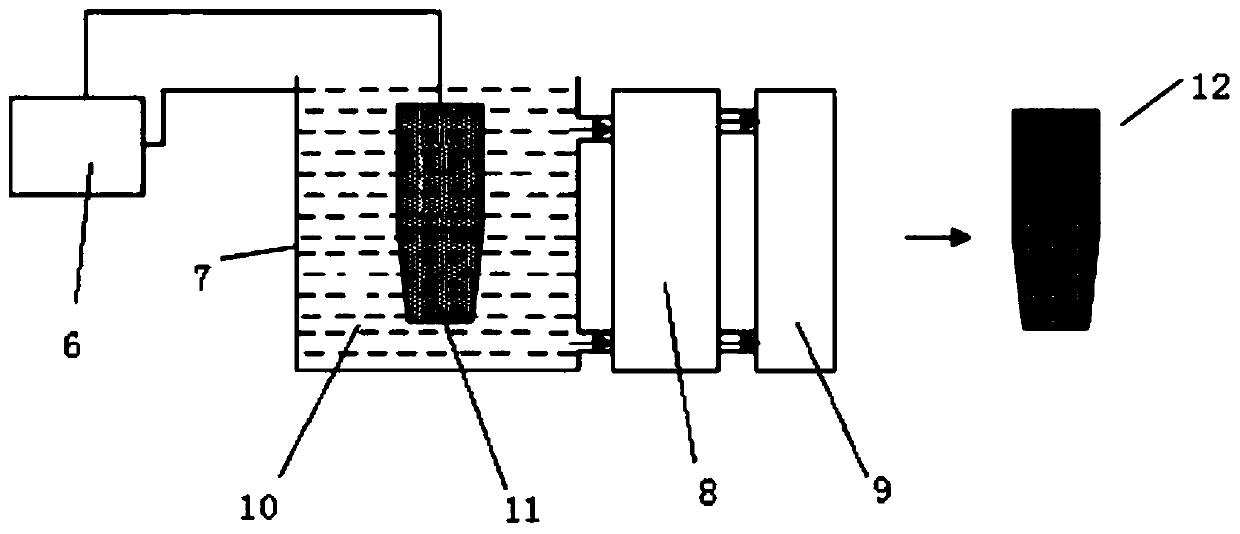

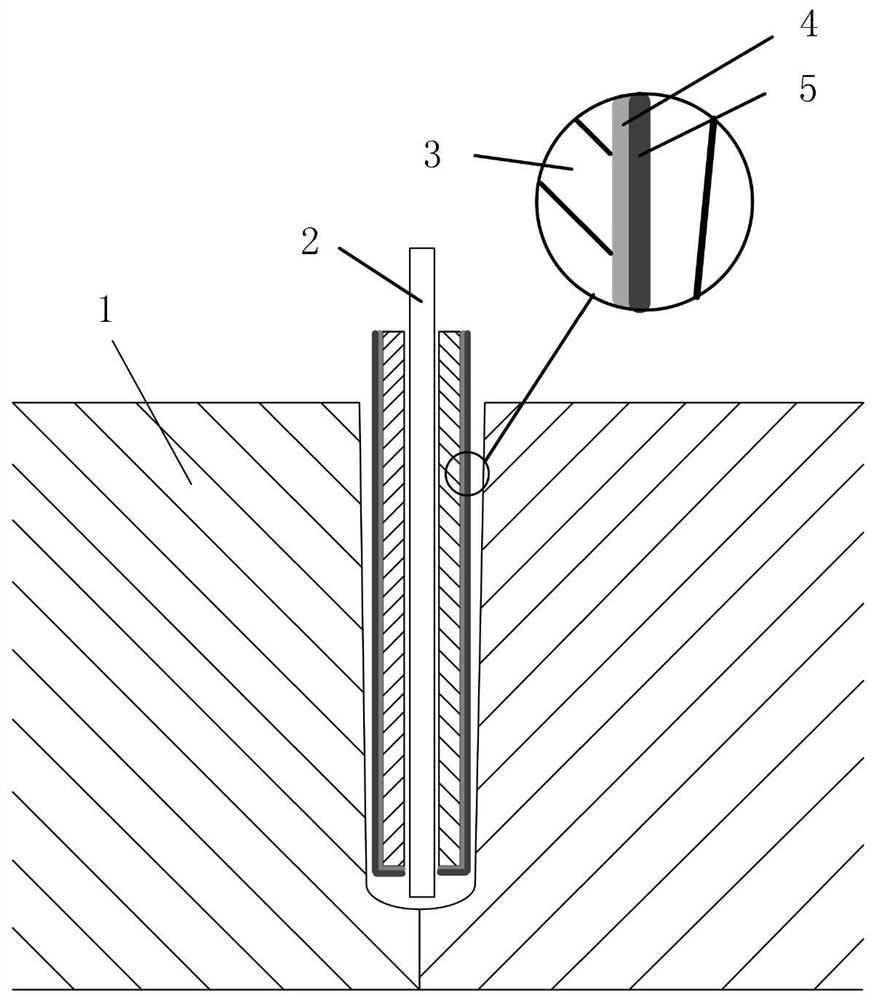

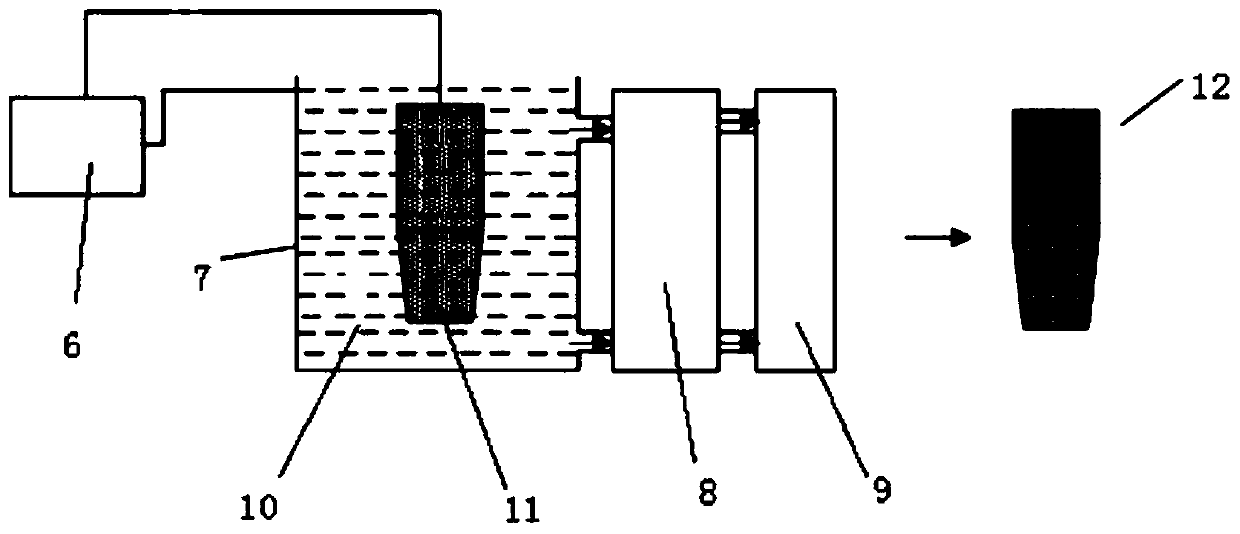

Preparation method of deep and narrow gap gas metal arc welding contact tube

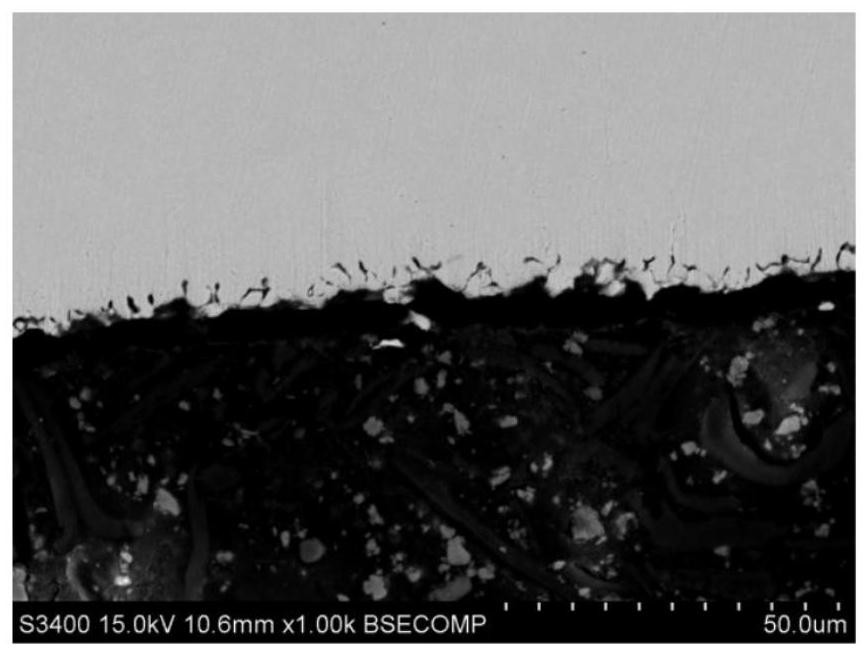

ActiveCN110952104AExcellent friction and wear resistanceImprove high temperature resistanceHot-dipping/immersion processesAnodisationElectrolytic agentMicro arc oxidation

The invention discloses a preparation method of a deep and narrow gap gas metal arc welding contact tube. A copper contact tube is used as a substrate; the copper contact tube is subjected to hot-dipaluminum plating treatment by adopting a solvent method to plate an aluminum layer on the surface of the copper contact tube; and then, in the electrolyte, the aluminum layer of the copper contact tube is subjected to micro-arc oxidation, and the welding contact tube with the outer layer provided with the high-temperature-resistant and insulating ceramic coating is obtained. The contact tube has the advantages of being small in film layer thickness, high in resistivity, good in abrasion resistance and resistant to high temperature, breaks through the size limitation of insulation treatment ofa traditional narrow-gap gas metal arc welding contact tube, can be applied to welding of a deep and narrow gap groove connector, and improves the welding efficiency.

Owner:SOUTHWEST JIAOTONG UNIV

Reinforced degradable intravascular stent material and preparation method thereof

InactiveCN106139245ALow hemolysis rateStrong thicknessProsthesisGlycidyl methacrylateDisodium glycerophosphate

The invention discloses a reinforced degradable intravascular stent material and a preparation method thereof. The reinforced degradable intravascular stent material comprises the following components: L-polylactide, polyglycolic acid, chitosan oligosaccharide, glycidyl methacrylate, aliskiren hemifumarate, nizofenone fumarate, D-threitol, erythritol, glycodeoxycholic acid sodium, silk fibroin, L-eucine ethyl ester hydrochloride, sodium acryloyldimethyl taurate, disodium beta-glycerophosphate, itaconyl chitosan, nano zirconium dioxide, acetic acid, dichloromethane and hexafluoroisopropanol. The stent material provided by the invention reaches degradation time of 65 to 79 days, has a hemolytic rate of lower than 3.5%, is excellent in blood compatibility, and can reduce adverse effects which cause thrombus; moreover, a stent made of the reinforced degradable intravascular stent material is high in supporting force and strong in anti-fracture strain capacity, a thickness of the stent can be further reduced, and the reinforced degradable intravascular stent material is beneficial to blood circulation and application of small molecule vessels. The stent material provided by the invention is safer, more reliable and more effective to use and has an excellent application prospect.

Owner:林春梅

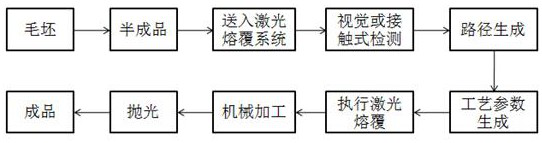

Laser cladding method for valve plate and valve seat in valve

InactiveCN111945149AStrong hardness and wear resistanceIncrease the amount addedMetallic material coating processesCorrosion resistantStructural engineering

The invention discloses a laser cladding method for a valve plate and a valve seat in a valve, and belongs to the technical field of laser processing and manufacturing. The method comprises the stepsthat step 1, a semi-finished product is prepared; step 2, visual detection or contact detection is performed; step 3, a path is generated; step 4, laser cladding is performed; and step 5, machining isconducted. Sealing surfaces of the valve plate and the valve seat are subjected to surface treatment through a laser coating technology, and sealing coating which is compact in structure, resistant to abrasion and corrosion and high in thickness is obtained. Through compounding and optimization, an optimal proportion of Cr, Ni and Fe is obtained, a Cr-Fe alloy phase is formed, and the surface ofthe Cr-Fe alloy phase has higher hardness and abrasion resistance. Walking pause time is set at a chamfer, so that an addition amount of cladding powder is increased, and the problems of melting and collapsing of a base material under a high-temperature condition in the cladding process are avoided.

Owner:南京派纳克激光科技有限公司

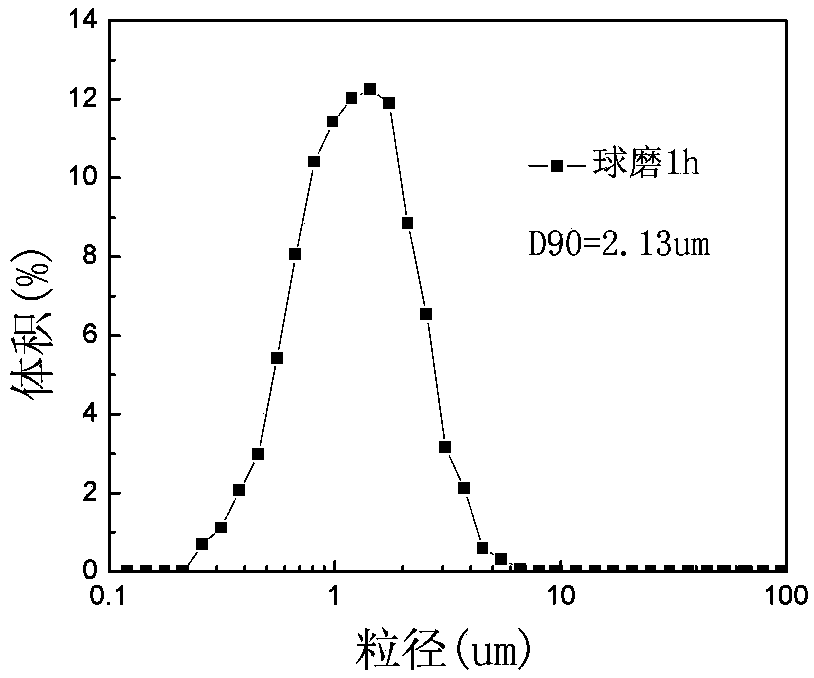

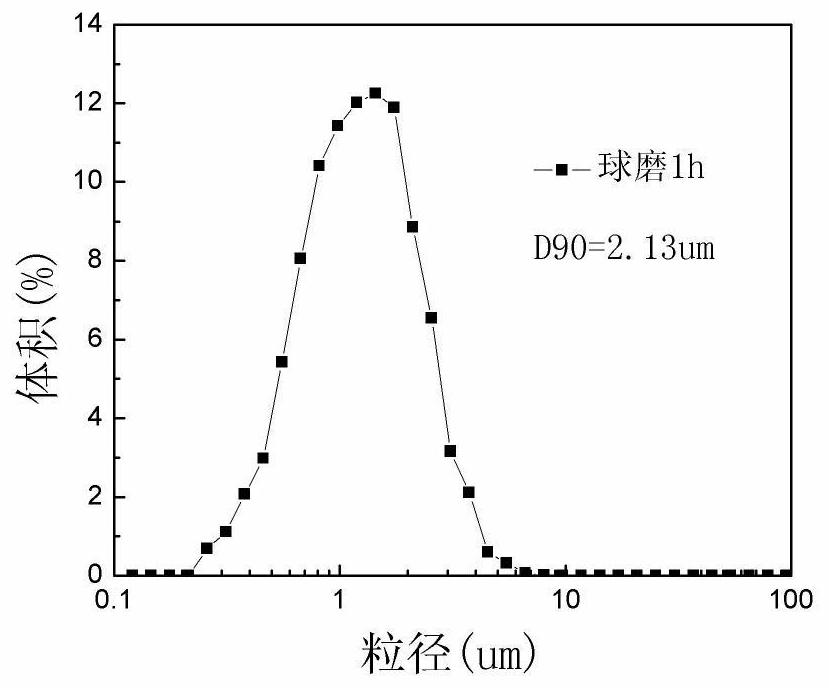

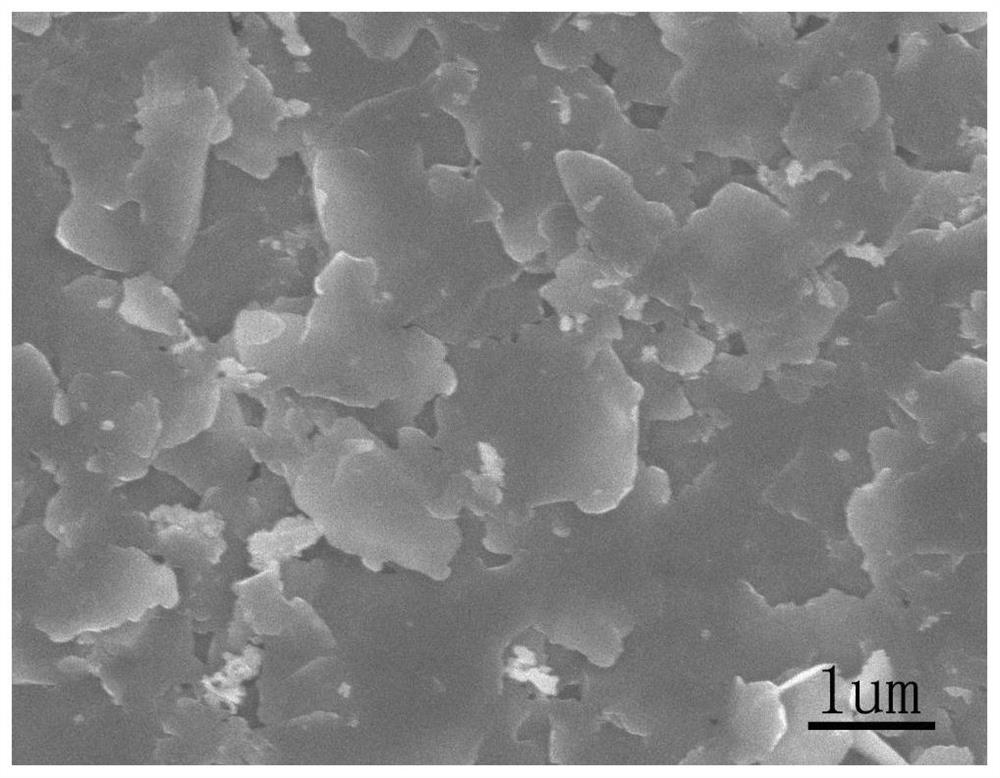

Illite mineral based waterborne anti-ultraviolet finishing liquid preparation method

ActiveCN107620207AGood film formingSmall particle sizeFibre treatmentCoatingsLight reflectionUltraviolet protection

The invention relates to an illite mineral based waterborne anti-ultraviolet finishing liquid preparation method and application of waterborne anti-ultraviolet finishing liquid to high polymer material ultraviolet shielding and protection. High-purity illite is subjected to superfine treatment according to a wet milling method by making full use of lamellar structural characteristics and light reflection effects of illite, and consequently lamellar illite can be completely stripped into micro-lamellar illite thinner and smaller in particle size to enhance ultraviolet reflection and refractioneffects to shield ultraviolet to greater extent. Due to a high-purity superfine state of the lamellar illite, prepared illite-based finishing liquid is great in coating performance, aqueous, nontoxicand free of influences on textile hand feel. The method is simple in production process, low in cost, high in yield and efficiency and suitable for industrial production. The obtained superfine illitefinishing liquid has a great ultraviolet shielding performance and can be applied to anti-ultraviolet finishing of textiles and ultraviolet protection of outdoor products, and a novel idea is provided for high-added-value development and utilization of illite.

Owner:JILIN UNIV

A superhard self-lubricating coating tool and its preparation method

ActiveCN110241347BHigh hardnessImprove wear resistanceMolten spray coatingOxide ceramicBoron nitride

Owner:SOUTHEAST UNIV

A preparation method of a deep narrow gap melting electrode gas shielded welding contact tip

ActiveCN110952104BExcellent friction and wear resistanceImprove high temperature resistanceAnodisationHot-dipping/immersion processesElectrolytic agentMicro arc oxidation

Owner:SOUTHWEST JIAOTONG UNIV

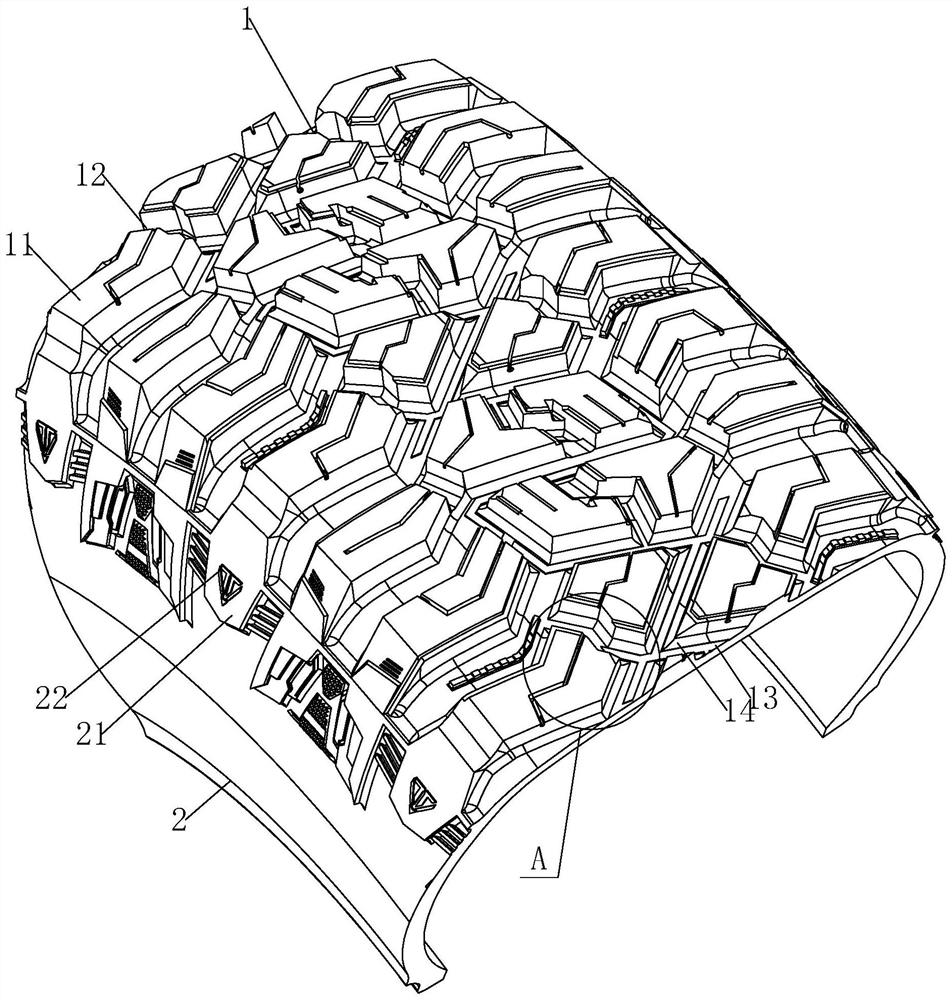

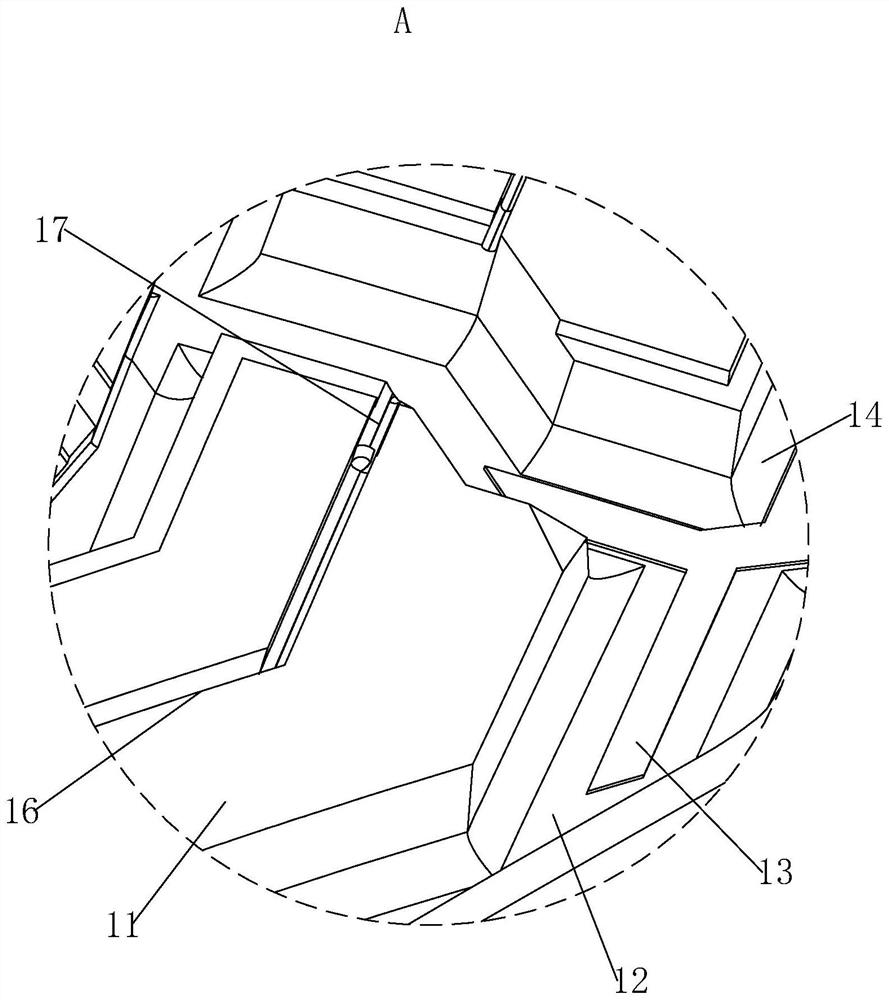

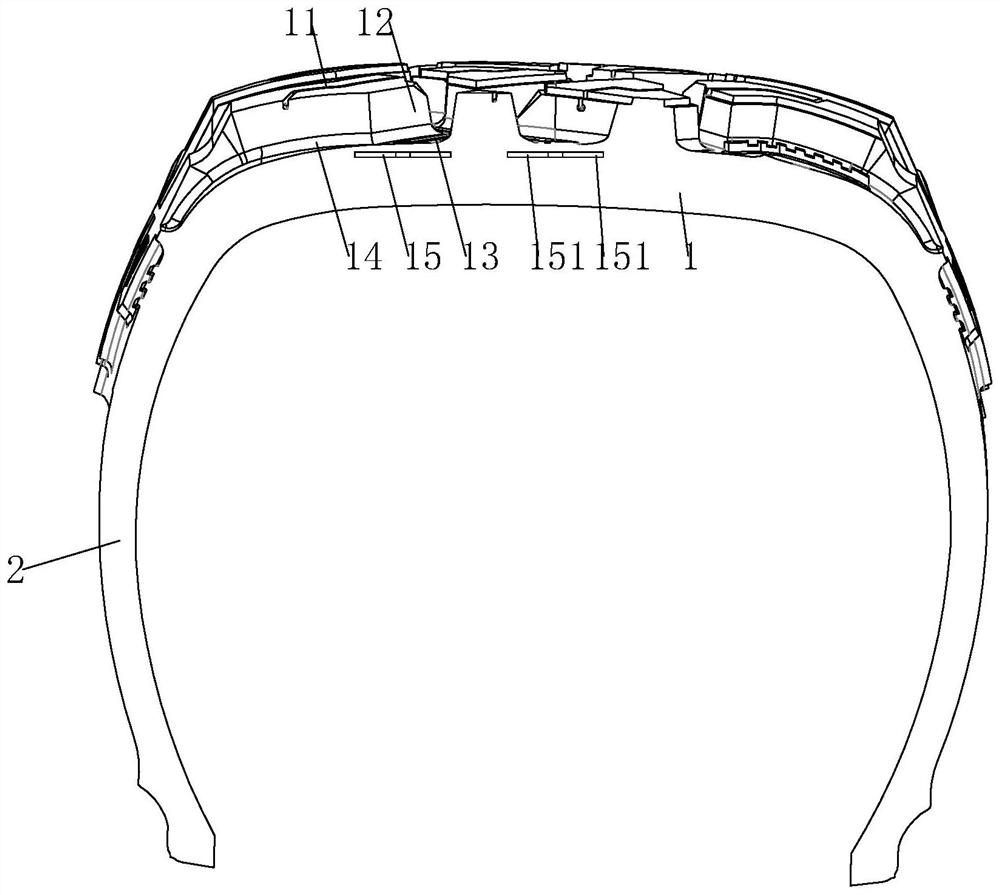

Semi-steel UTV tire

PendingCN114872497AImprove stab resistanceImprove overall securityTyre tread bands/patternsTyre sidewallsPuncture resistanceAll terrain vehicle

The invention relates to a semi-steel UTV tire, and relates to the technical field of tires, the semi-steel UTV tire comprises a tread and a sidewall, pattern blocks are arranged on the tread at intervals, grooves are formed between the pattern blocks, anti-puncture strips are arranged at the bottoms of the grooves in the groove trend, the width of the anti-puncture strips is smaller than that of the grooves, the thickness of the anti-puncture strips is set to be 1-3 mm, and the width of the anti-puncture strips is set to be 1-3 mm. The tread structure layer is provided with a stab-resistant strip, transition slopes are connected between the bottoms of the grooves on two sides of the stab-resistant strip and the pattern blocks, a metal reinforcing frame is arranged in the tread structure layer below the stab-resistant strip, the metal reinforcing frame is arranged along the trend of the grooves, and the width of the metal reinforcing frame is greater than that of the stab-resistant strip. The semi-steel UTV tire disclosed by the invention has better puncture resistance, and the running safety of an all-terrain vehicle can be improved.

Owner:TIANJIN WANDA TYRE CO LTD

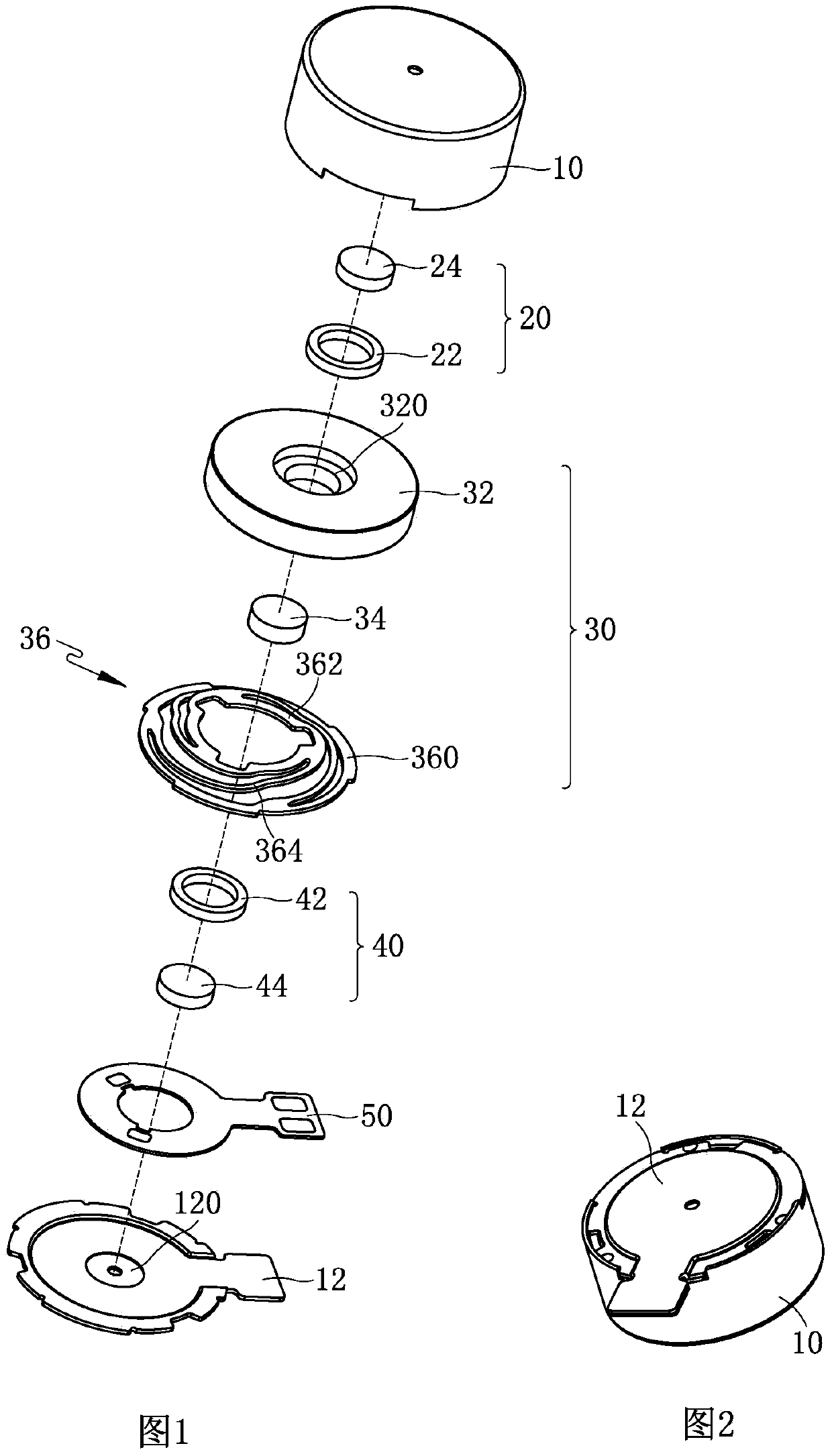

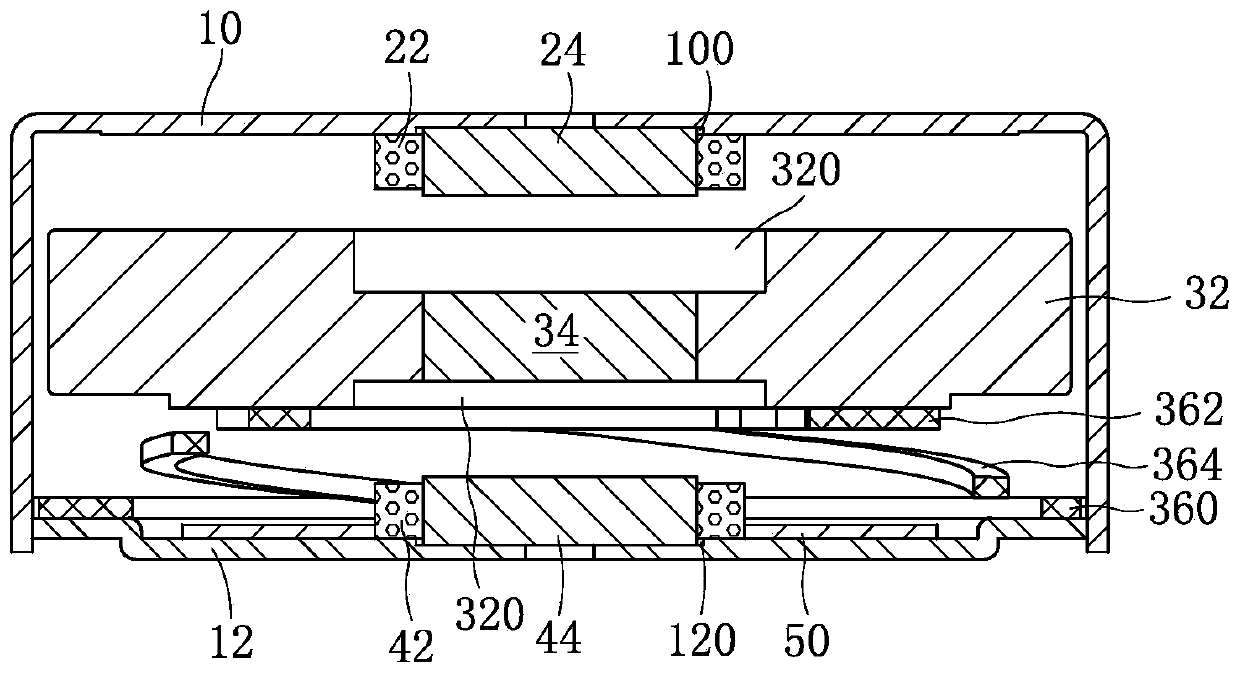

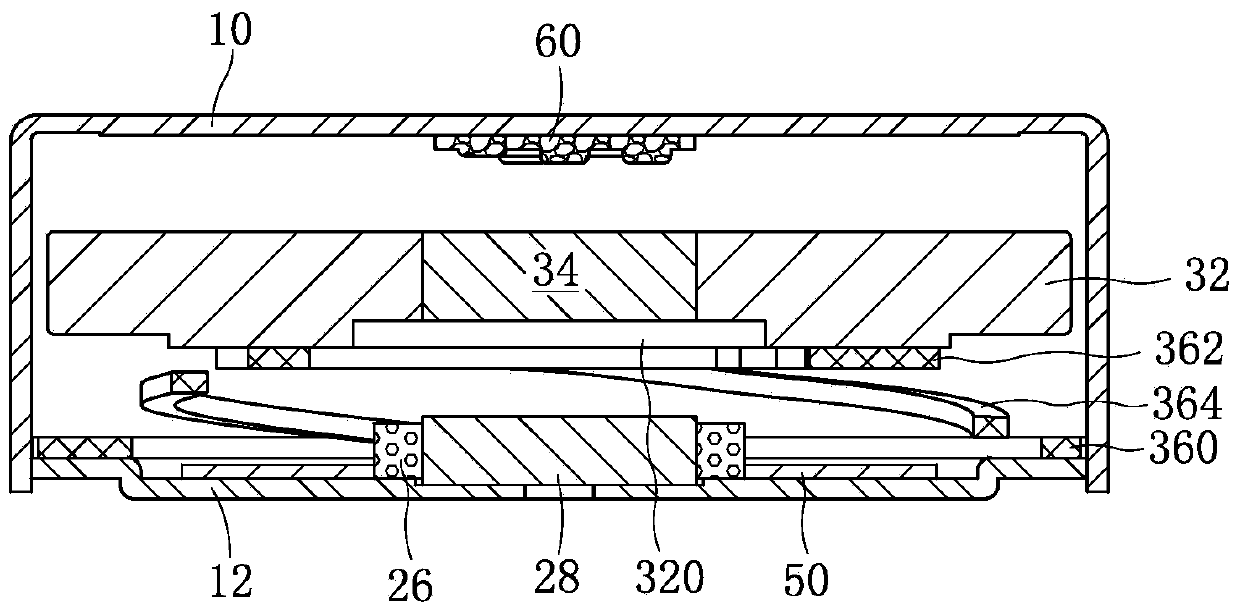

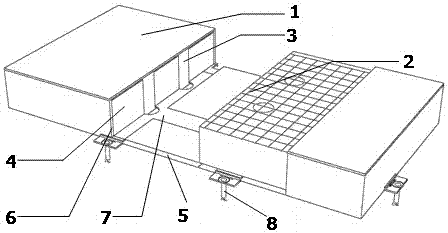

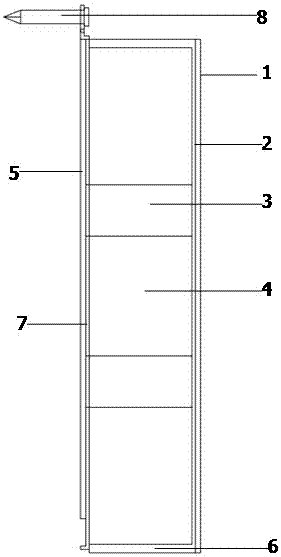

vibration motor

The invention discloses a vibrating motor relating to the micro-motor technical field. The vibrating motor comprises a shell body, a stator and a vibrator; the vibrator is suspended in the shell body through an elastic supporting element; the vibrator comprises a quality block and a permanent magnet embedded on the quality block; the stator comprises a coil; the coil is a disc coil, is horizontally fixed on the shell body and corresponds to the permanent magnet in the vertical direction; the magnetizing direction of the permanent magnet is parallel to the magnetic field direction generated by the coil; and a vibrating space is reserved between the vibrator and the stator on in a vibration direction. According to the vibrating motor of the invention, the technical problems that the vibrating motor in the prior art is large in thickness and small in vibrating sense are solved; the vibrating motor of the invention is featured by strong vibrating sense, small thickness, high reliability and long service life and can satisfy the design demands of a portable charging device for high performance and thin type of the vibrating motor.

Owner:GOERTEK INC

Hybrid hollow porous fiber reinforced thermal insulation mortar sandwich thermal insulation decorative board and manufacturing method

ActiveCN105735552BStrong impact resistanceSmall impact resistanceBuilding componentsThermal insulationEngineering

The invention relates to a sandwich heat-preserving decorative board with mixed hollow porous fiber reinforced heat-preserving mortar and a manufacturing method.A heat-preserving core veneer of the heat-preserving decorative board is a formed veneer and provided with big and round through holes; a hanging part capable of being positioned is arranged at the inner side of a back plate and tightly attached to the back face of the heat-preserving core veneer, and the same big and round through holes are formed in the positions corresponding to the big and round holes in the heat-preserving core veneer; the ends of the hanging part capable of being positioned are provided with small and round holes, square holes and right-angled hooks used for connecting, installing and lapping the heat-preserving decorative board in a positioning mode; fiber grid cloth is arranged at the inner side of a panel and is spaced from the heat-preserving core veneer by 2 mm; the mixed hollow porous fiber reinforced heat-preserving mortar is poured into the periphery of the heat-preserving core veneer through sealed formworks, the panel, the back plate and sealed edges are formed after the mortar is hardened, and bridge-cutoff shear connectors are formed in the big and round holes; the decorative board has the advantages that a good integrated space stress structure is formed through overall pouring of the panel, the back plate, the bridge-cutoff shear connectors and the sealed edges, positioning and splicing are accurate, and the fireproof performance is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A toughened and reinforced in-situ reactive micro-textured self-lubricating coating tool and its preparation method

ActiveCN110257822BGood self-lubricating performanceReduce friction and wearMetallic material coating processesLaser beam welding apparatusBoron nitrideAlloy

The invention discloses a toughening and reinforcing in-situ reaction micro-texture self-lubricating coating cutter and a preparation method thereof. The base material of the tool is high-speed steel or hard alloy, and the surface of the base is made of PbO, Mo, TiB 2 A cubic boron nitride coating of , BNNTs, CNTs and graphene, the coating surface has a micro-texture; the coating is prepared by a plasma vacuum spraying method. The tool has good toughness as a whole, and the addition of BNNTs and CNTs makes the cubic boron nitride coating on the surface of the tool have good toughness, high surface hardness and wear resistance; during the cutting process, when the temperature is low, graphene can play a role Lubrication effect, PbO, Mo and TiB at high temperature 2 In situ reaction will occur to generate PbMoO with lubricating effect 4 、TiO 2 , B 2 o 3 Synergistically with the micro-texture, it can reduce the friction and wear of the tool during the cutting process and improve the tool life. The tool can be widely used in dry cutting and cutting of difficult-to-machine materials.

Owner:SOUTHEAST UNIV

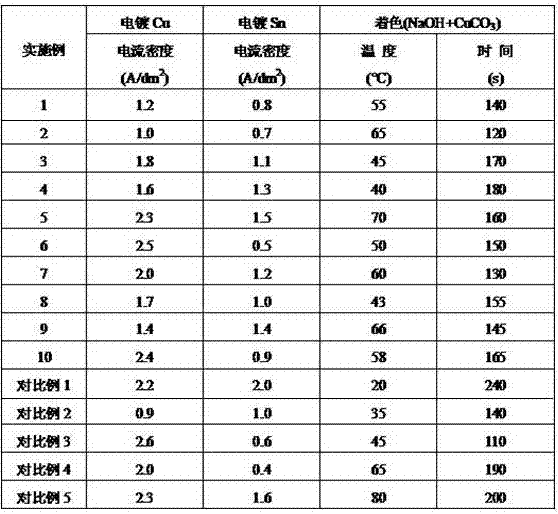

A kind of production method of composite coating strapping for gold and silver jewelry packaging

InactiveCN104789963BLow costGuaranteed stabilitySuperimposed coating processStrappingComposite plate

A production method of a composite plated tie for packaging gold and silver jewelries comprises the following steps: carrying out cold rolling, carrying out routine degreasing, and annealing; making a belt: uncoiling, cutting to form strips, and burring; electroplating Cu at normal temperature; carrying out first time water washing, and drying; electroplating Sn or Zn at normal temperature; carrying out second time water washing, and drying; coloring; carrying out third time water washing, and drying; and routinely reeling. The thickness, the tensile strength and the elongation percentage of the above produced product are 0.1mm, 800-830MPa and 8-9% respectively. A uniform and compact Cu-Sn or Cu-Zn composite plated layer with strong adhesion and with the thickness of 3-5[mu]m is formed on the surface of the product; and the colored product has brilliant orange red or blue black appearance, and the gloss loss rate of the composite plated layer 540d later does not exceed 5%, so binding and packaging needs of gold finger rings, necklaces, bracelets, ruby, sapphire and other gold and silver jewelries are met.

Owner:武汉钢铁有限公司

A kind of preparation method of water-based anti-ultraviolet finishing liquid based on illite mineral

ActiveCN107620207BGood film formingSmall particle sizeFibre treatmentCoatingsPhysical chemistryLight reflection

The invention relates to an illite mineral based waterborne anti-ultraviolet finishing liquid preparation method and application of waterborne anti-ultraviolet finishing liquid to high polymer material ultraviolet shielding and protection. High-purity illite is subjected to superfine treatment according to a wet milling method by making full use of lamellar structural characteristics and light reflection effects of illite, and consequently lamellar illite can be completely stripped into micro-lamellar illite thinner and smaller in particle size to enhance ultraviolet reflection and refractioneffects to shield ultraviolet to greater extent. Due to a high-purity superfine state of the lamellar illite, prepared illite-based finishing liquid is great in coating performance, aqueous, nontoxicand free of influences on textile hand feel. The method is simple in production process, low in cost, high in yield and efficiency and suitable for industrial production. The obtained superfine illitefinishing liquid has a great ultraviolet shielding performance and can be applied to anti-ultraviolet finishing of textiles and ultraviolet protection of outdoor products, and a novel idea is provided for high-added-value development and utilization of illite.

Owner:JILIN UNIV

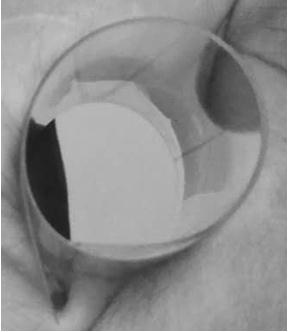

A kind of preparation method of ultra-thin glass

The invention relates to the technical field of glass, in particular to a preparation method of ultra-thin glass, comprising the following steps: (1) taking glass, soaking the glass in a thinning etchant, and performing the first thinning treatment on the glass; (2) The thinned glass is double-sided grinding and polishing; (3) The double-sided grinding and polishing glass is attached to the carrier glass, and then soaked in the thinning etchant, and the glass is subjected to the second thinning treatment to make Get ultra-thin glass. The ultra-thin glass preparation method of the present invention can prepare ultra-thin glass with thin thickness, strong light transmission, good softness, and high touch sensitivity. It is used to prepare ultra-thin glass with a thickness of 0.03mm.

Owner:东莞市嘉逸光电有限公司

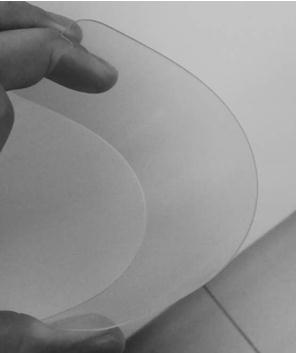

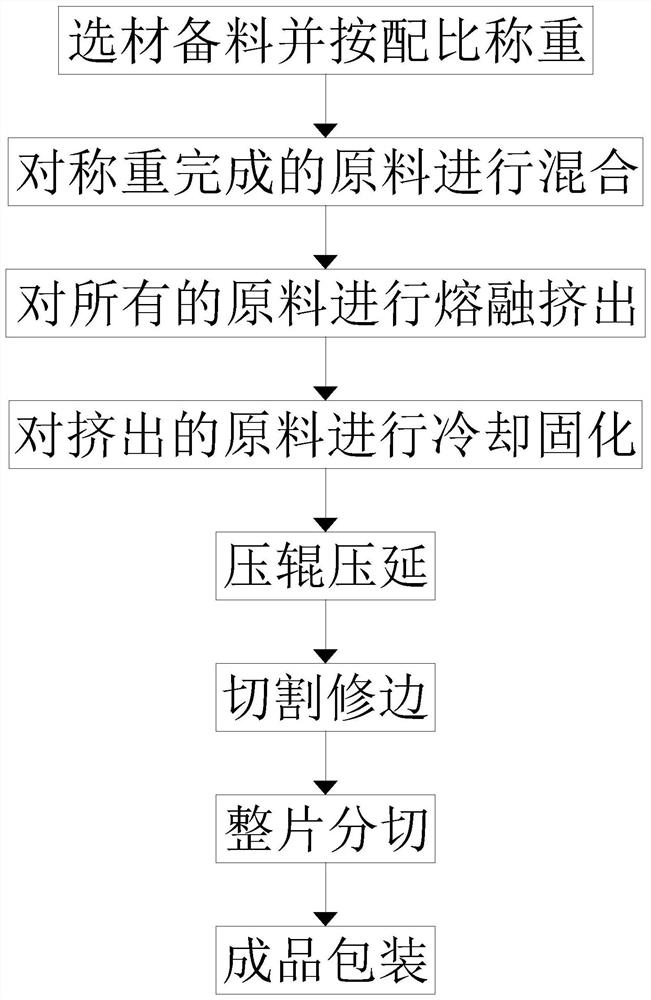

Preparation method of anti-ultraviolet card protecting film

The invention provides a preparation method of an anti-ultraviolet card protecting film, and belongs to the technical field of anti-ultraviolet mechanisms. The preparation method of the anti-ultraviolet protective card film comprises the following steps: S1, preparing raw materials for preparing the anti-ultraviolet protective card film; S2, mixing the raw materials subjected to load bearing together; S3, carrying out melt extrusion on the raw materials; S4, rapidly cooling the extruded raw materials; s7, the tidy thin film is cut; and S8, the cut sheet-shaped thin film is packaged. When the card protecting film is used, the film is cut into the sheet-shaped film in a specified shape through the cutting machine, the sheet-shaped film is moved into the packaging machine through the grabbing mechanism, packaging of the sheet-shaped film is achieved, the card protecting film is higher in ultraviolet resistance, meanwhile, the card protecting film has the advantages of being resistant to tension, waterproof, fireproof, insulated, resistant to corrosion and the like, and the service life of the card protecting film is prolonged.

Owner:YIXING YULONG PLASTIC PACKAGE PROD

Preparation method of deep narrow gap consumable electrode gas protection welding current contact nozzle

InactiveCN110453228AHigh resistivityImprove wear resistanceHot-dipping/immersion processesAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a preparation method of a deep narrow gap consumable electrode gas protection welding current contact nozzle. A copper current contact nozzle is used as a substrate; the coppercurrent contact nozzle is treated through hot dip aluminum plating by means of a solvent method, an aluminum layer is plated on the surface of the copper current contact nozzle; and then in an electrolyte, the aluminum layer of the copper current contact nozzle is subjected to micro-arc oxidation, and the welding current contact nozzle with a high-temperature-resistant and insulated ceramic coating on the outer layer is obtained. The film layer of the current contact nozzle has the advantages of being thin, high in electrical resistivity, good in abrasion resistance and resistant to high temperature, the size limit of the insulation treatment of traditional narrow gap consumable electrode gas protection welding current contact nozzles is broken, application to welding of deep narrow gap groove joints can be achieved, and the welding efficiency is improved.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com